Explosion device of filling pile head and construction method thereof

A construction method and cast-in-place pile technology, which are applied in sheet pile walls, infrastructure engineering, construction, etc., can solve the problems of large dust, large amount of work and slow construction in the removal process, and reduce the difficulty of removal and construction cost. , the effect of high turnover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0027] There are two structural forms of the breaking device:

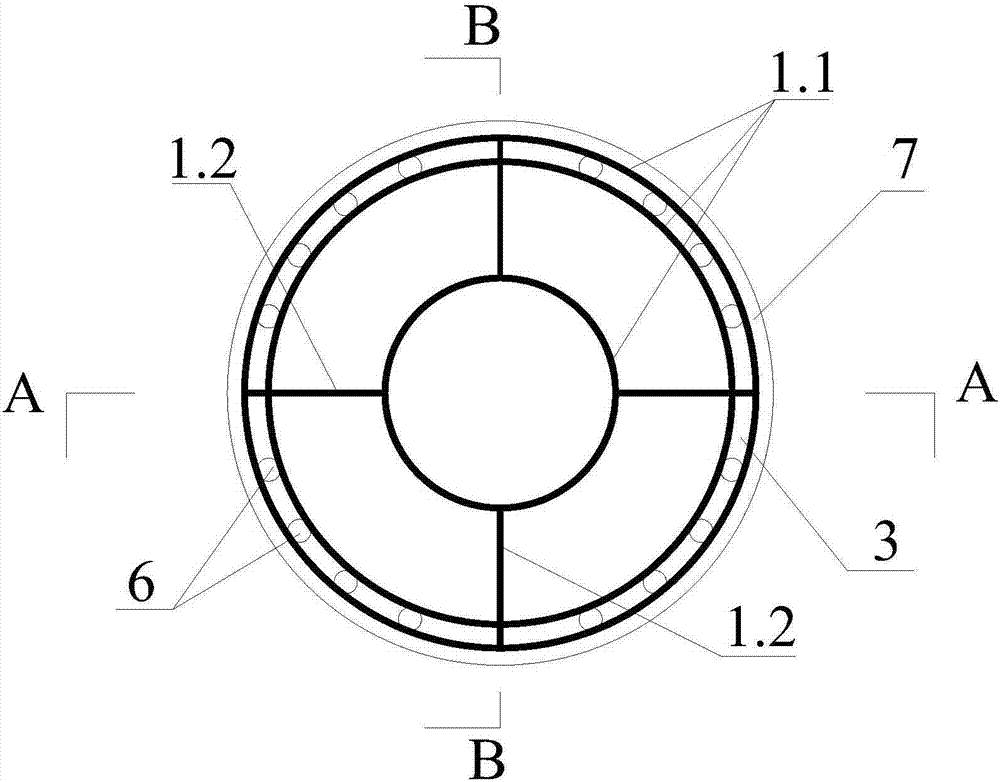

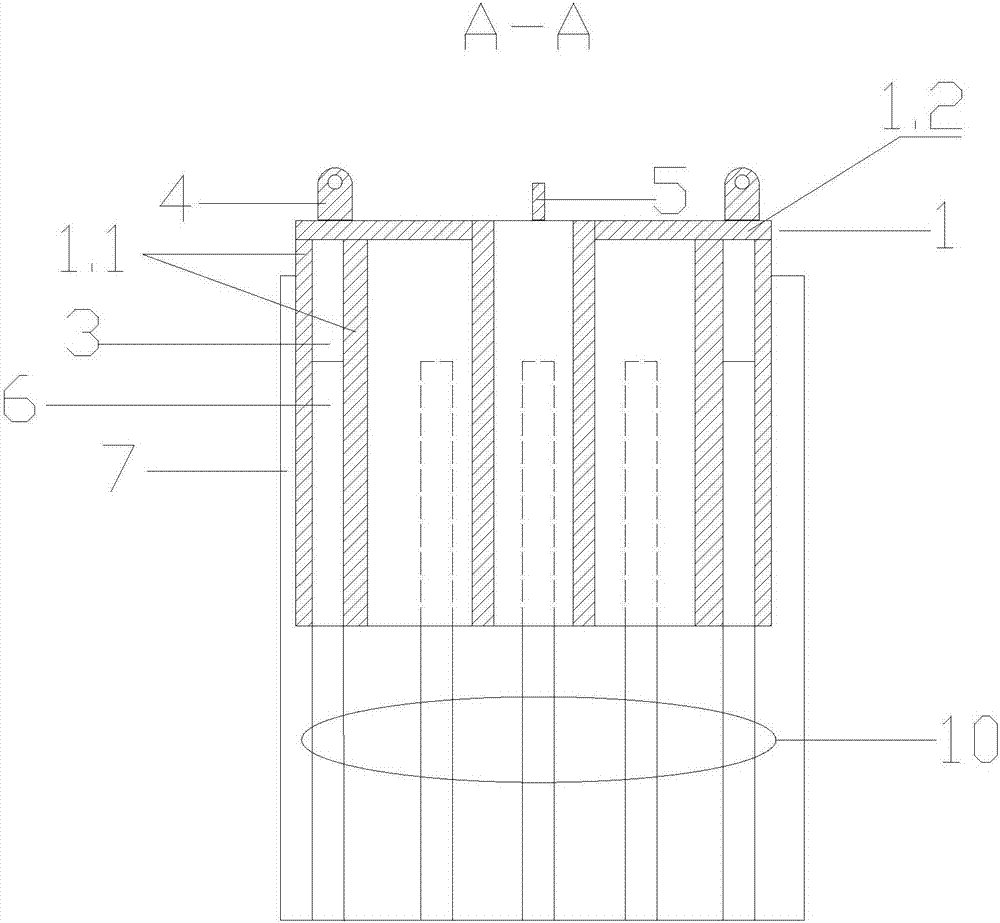

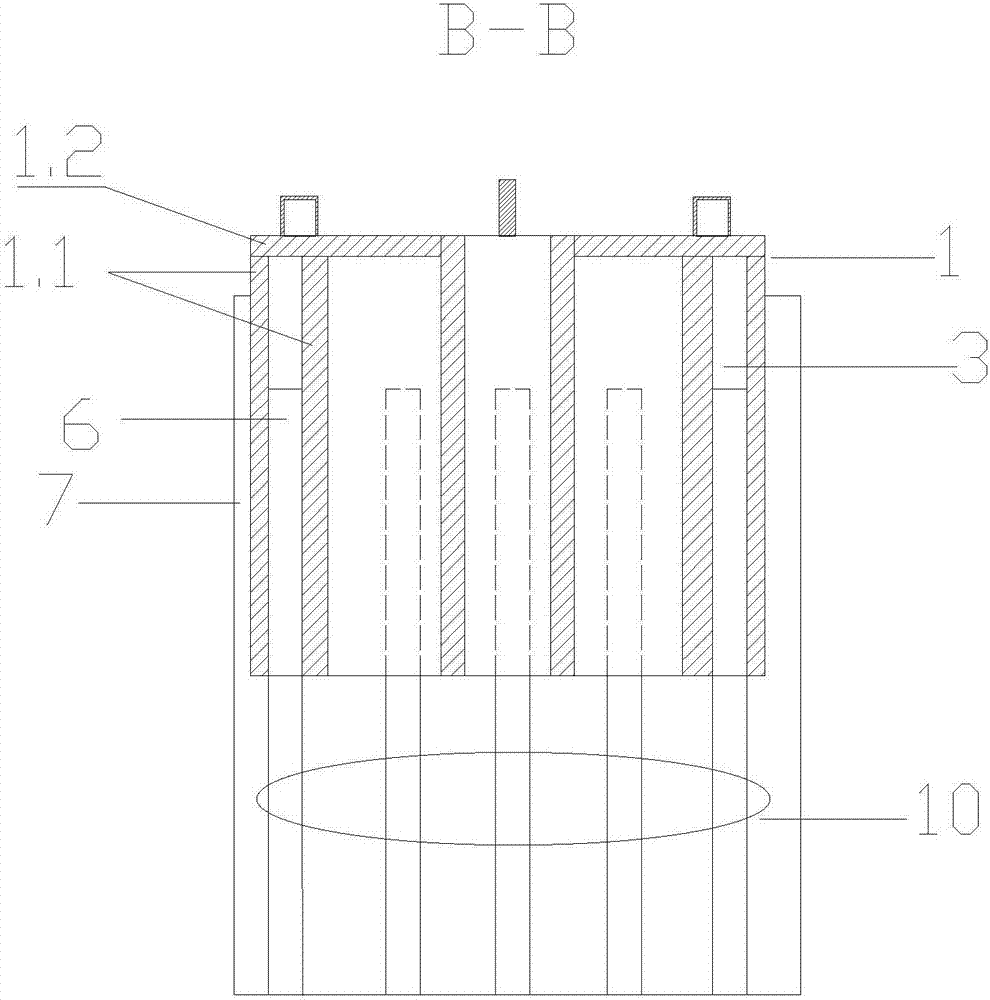

[0028] Such as figure 1 The breaking device of cast-in-place pile head shown in -3 includes three coaxial annular casings 1.1, and the tops of the annular casings 1.1 are fixedly connected by connecting stiffeners 1.2 to form a device body 1 of an integral structure. The gap between the outermost annular casing of the device body 1 and its adjacent annular casing is the main reinforcement positioning interlayer 3, between the inner wall of the outermost annular casing of the device body 1 and the outer wall of the adjacent annular casing The distance is less than the diameter of the main rib 6.

[0029] Such as Figure 4 As shown in -6, it includes two coaxial annular casings 1.1, and the tops of the annular casings 1.1 are fixedly connected to the device body 1 of an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com