Cutting equipment special for reed papermaking

A cutting device and reed technology, applied in the field of reed paper cutting equipment, can solve the problems of poor quality of manual cutting work, reduce the production efficiency of reed paper making, and high labor intensity, so as to improve cutting efficiency and processing quality, improve cutting processing efficiency and Quality, avoid labor-intensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

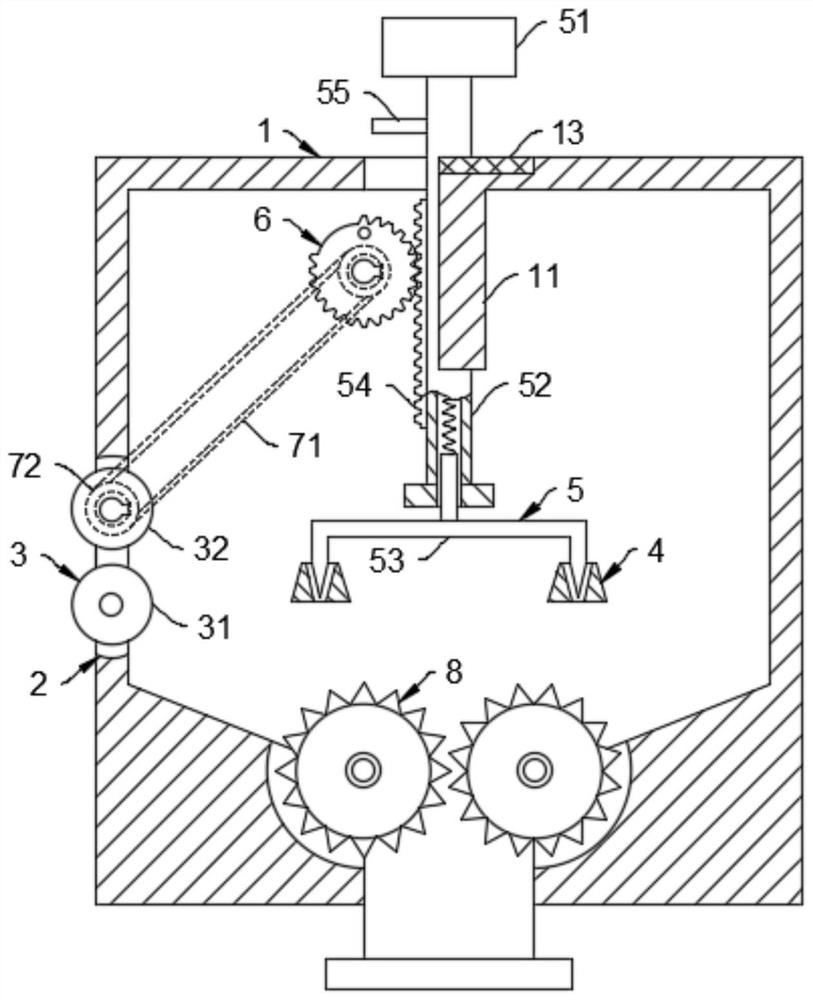

[0028] Such as Figure 1-4 As shown, a kind of cutting equipment specially used for reed papermaking includes a box body 1, and the box body 1 is provided with a feed port 2, and one end of the box body 1 close to the feed port 2 is rotatably connected with a guide roller 3. It should be noted that the feed The feed port 2 is used for cutting and feeding the dried reeds, and the guide roller 3 includes a support roller 31 and a pressure roller 32, and the reeds are flattened by rolling to facilitate the subsequent cutting work.

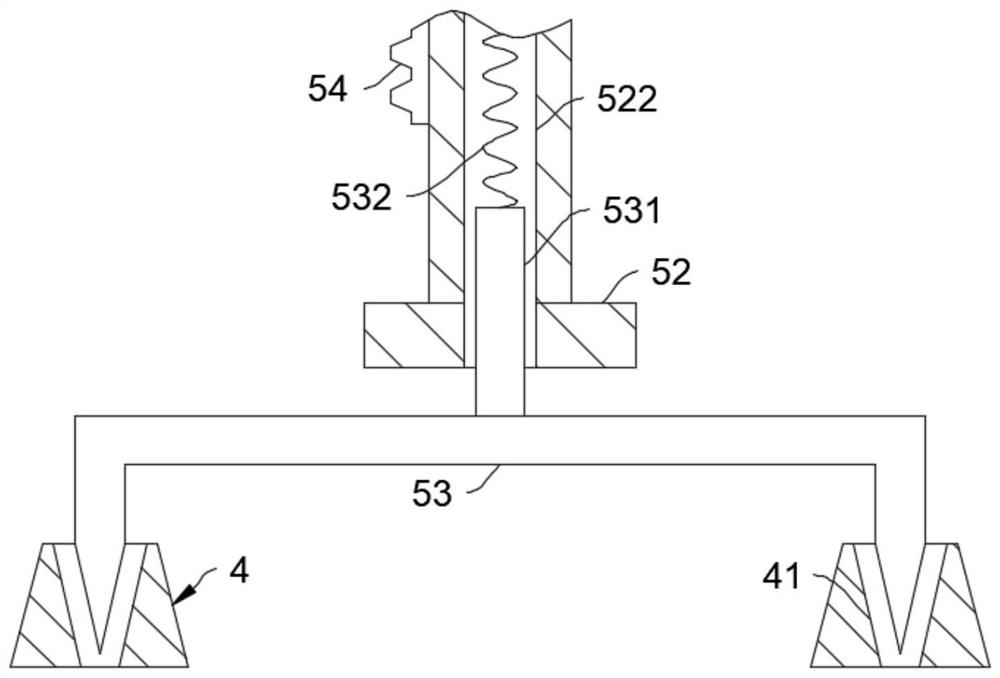

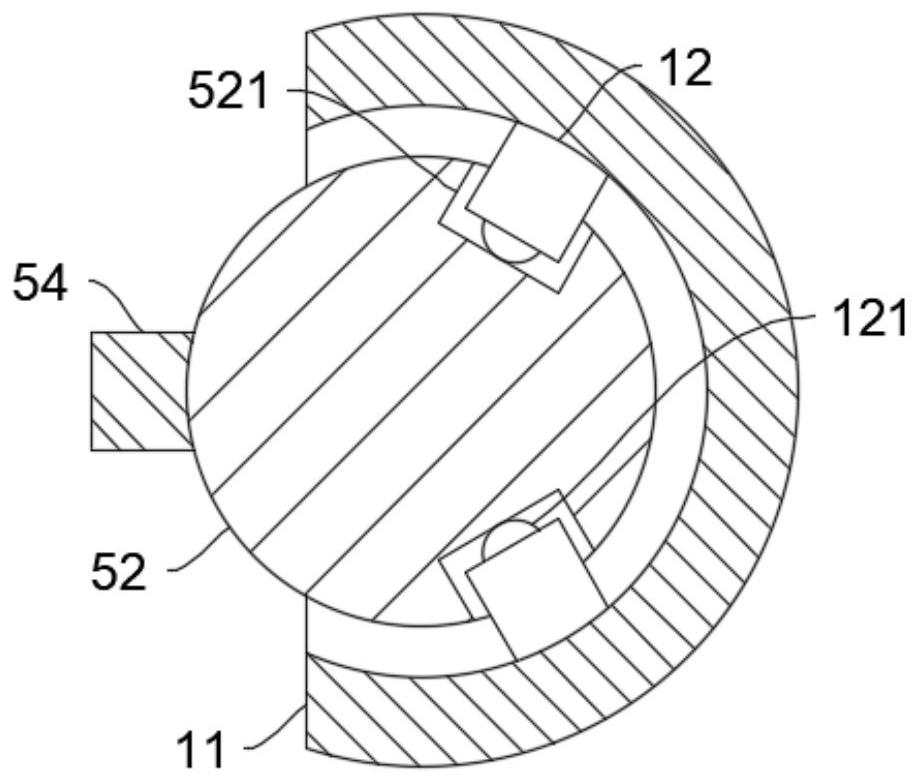

[0029] The horizontal position of the box body 1 close to the guide roller 3 is symmetrically provided with a cutting table 4, and the cutting table 4 is movably connected with a cutting device 5 to realize the pre-cutting work of reeds. The cutting device 5 is slidingly connected with the box body 1. It should be noted that , the cutting device 5 includes a counterweight 51, a slide bar 52 and a slitting frame 53, the slide bar 52 is slidably connect...

Embodiment 2

[0042] Such as Figure 5 Shown, the difference between this embodiment and embodiment 1 is:

[0043] The end of the sliding sleeve 11 far away from the counterweight 51 is provided with a ceramic electric sheet 14, and the box body 1 is provided with an arc-shaped groove 15, and the arc-shaped groove 15 is fixedly connected with an electromagnetic block 16, and the electromagnetic block 16 and the ceramic electric sheet 14 are electrically connected. The electromagnetic block 16 is slidably connected to the push plate 18 through the return spring 17. The push plate 18 is made of ferromagnetic material. The ceramic electric sheet 14 makes the ceramic electric sheet 14 generate an instantaneous current, and then the electromagnetic block 16 is energized through the electrical connection, and the electromagnetic block 16 is energized to magnetically attract the push plate 18 of the ferromagnetic material, so that the push plate 18 and the arc groove 15 slides and rises, when the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com