Patents

Literature

1134results about How to "Meet construction requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

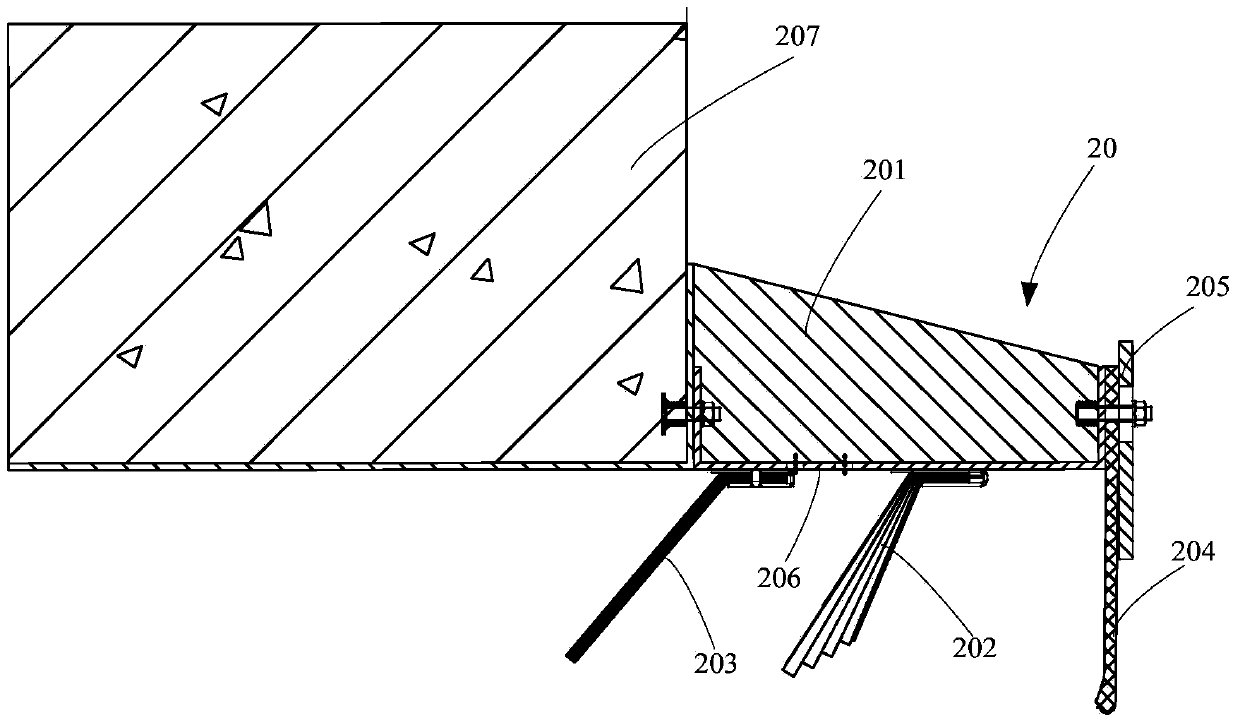

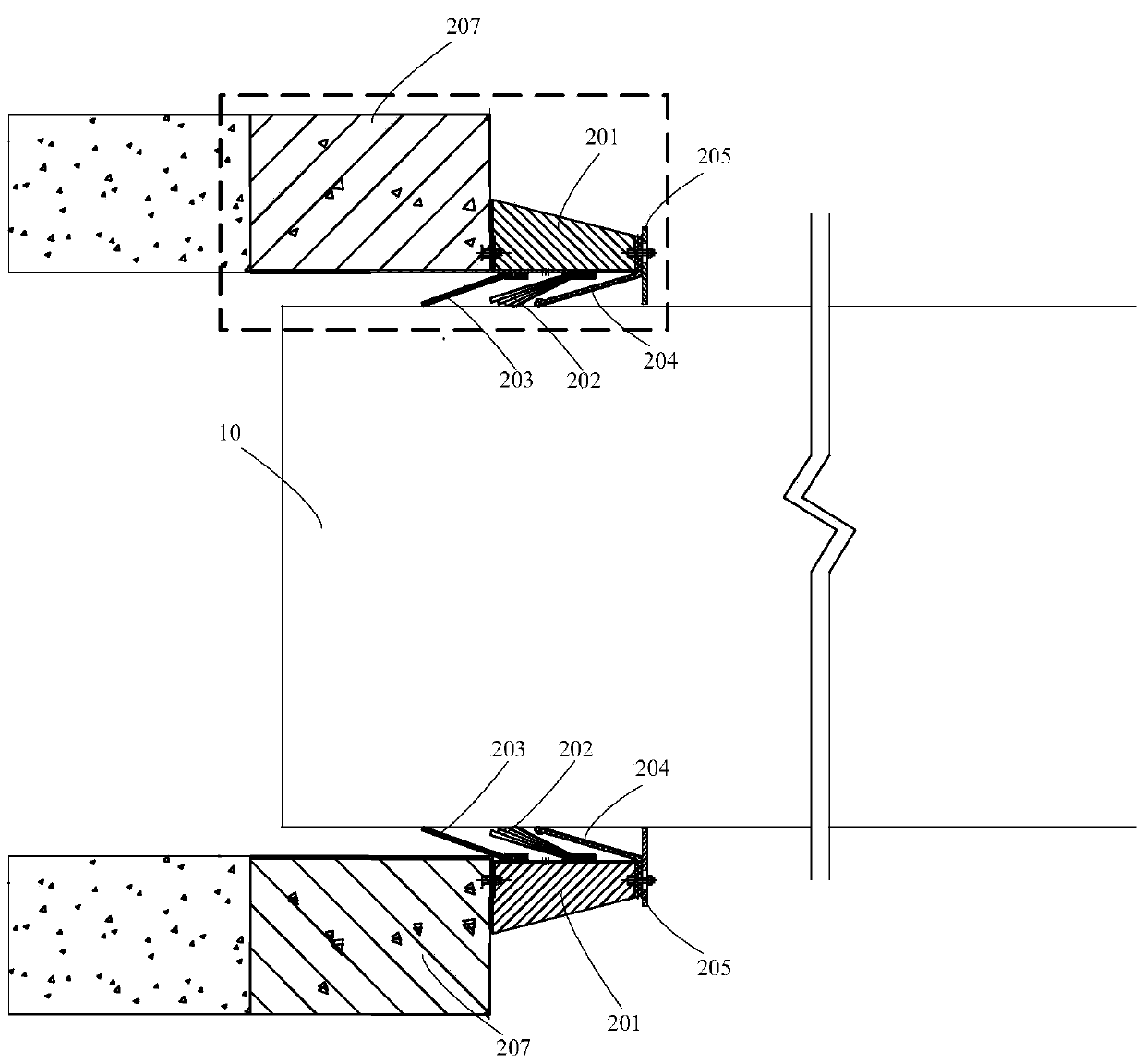

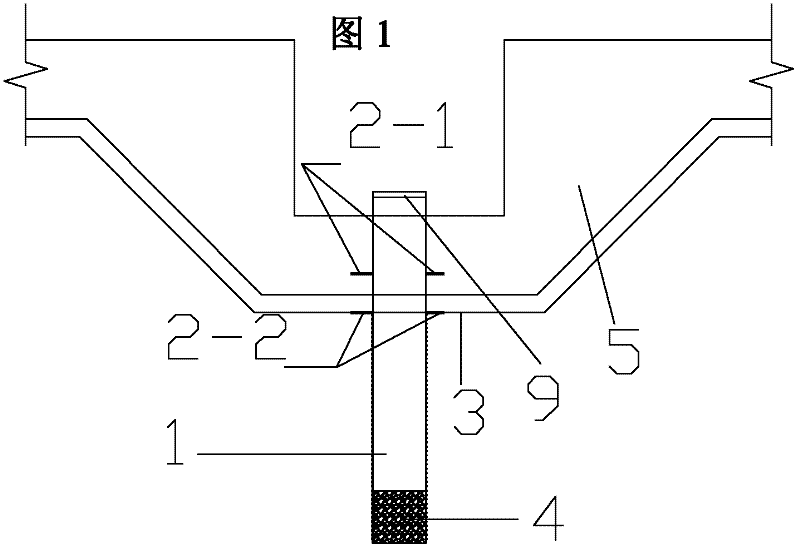

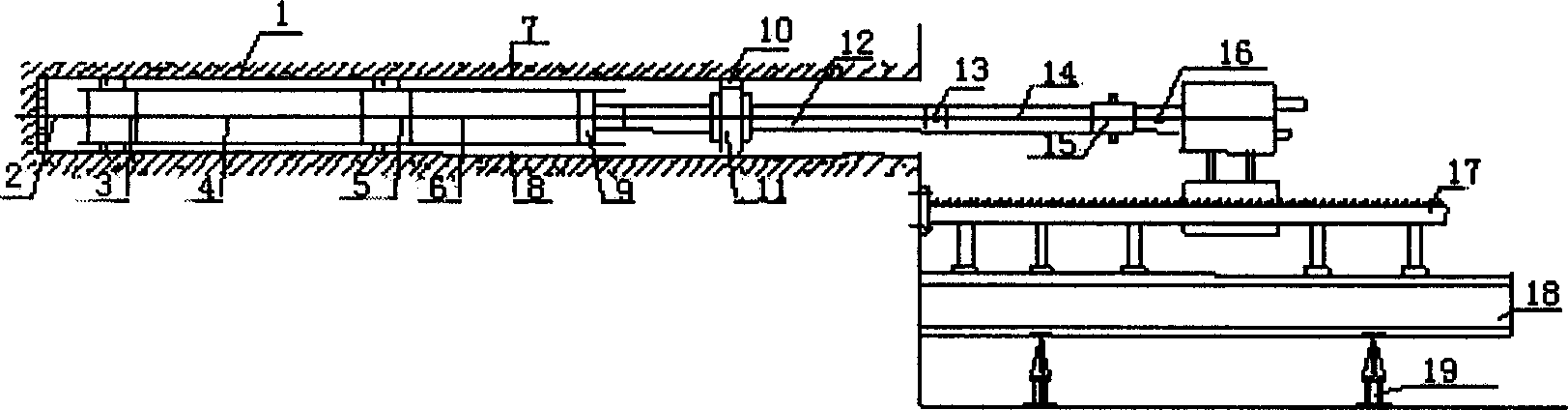

Ultra-large full-face rectangular pipe jacking tunneling construction method

ActiveCN104265321AExcavation construction realizationSolve large sectionsUnderground chambersTunnel liningSlurryBuilding construction

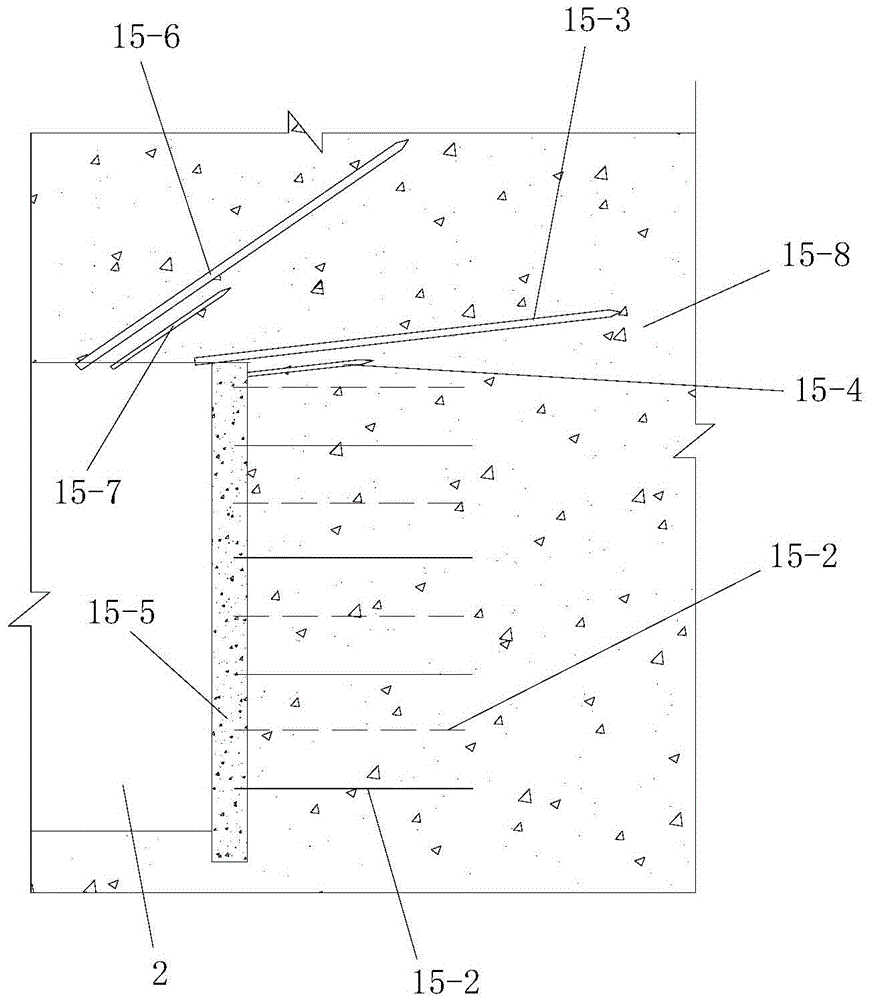

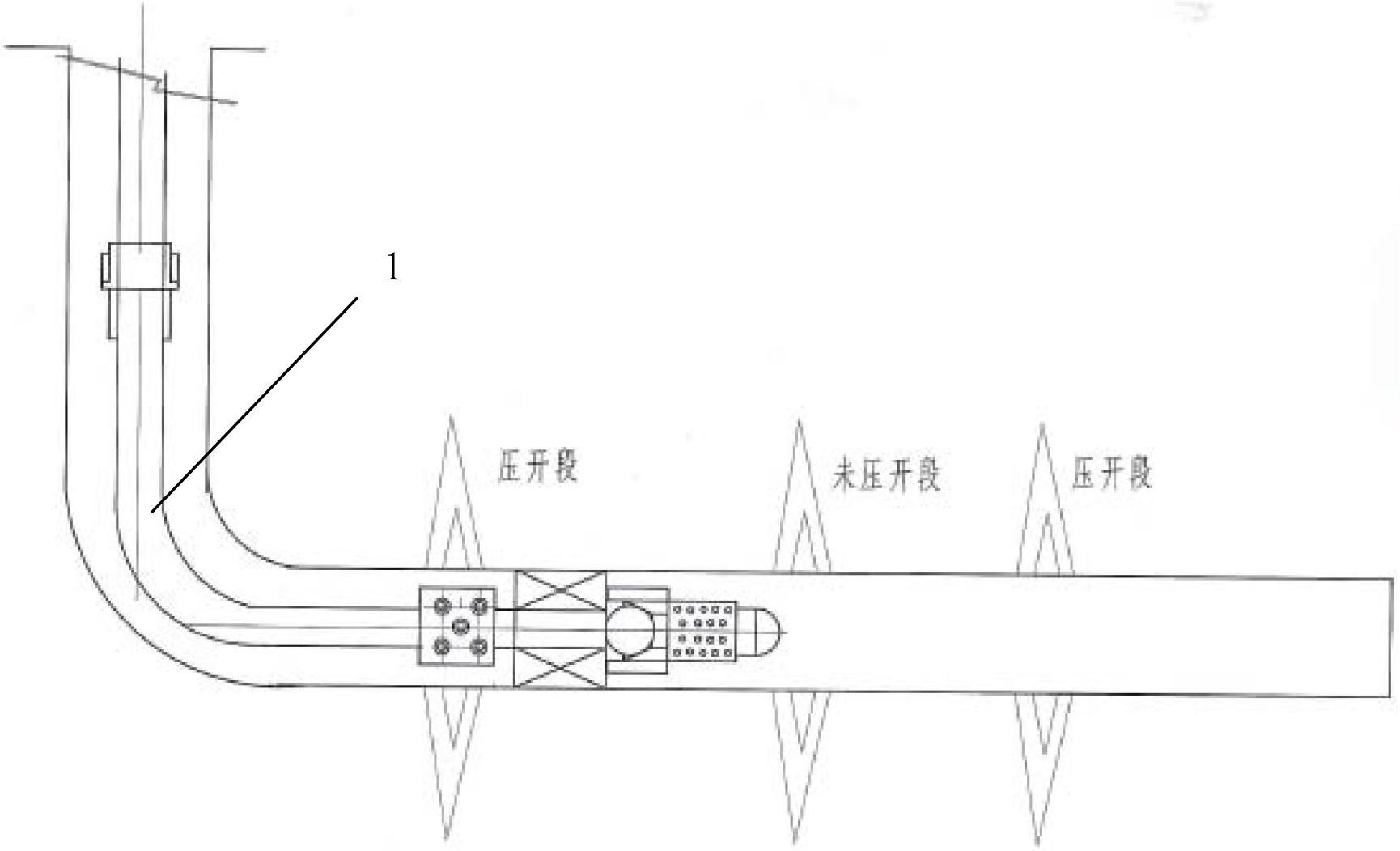

The invention relates to an ultra-large full-face rectangular pipe jacking tunneling construction method, which comprises the following steps that: a tunnel line axial line is determined, and a launching shaft and a receiving shaft are set; a pipe jacking machine is arranged on a guide rail arranged in the launching shaft to be debugged; the pipe jacking machine performs tunneling along the tunnel line axial line, and pipe joints are spliced in the launching shaft; when the pipe jacking machine reaches the receiving shaft, the pipe joints are separated from the pipe jacking machine, and the tunnel breakthrough is realized; curing slurry is injected to pipe joint peripheries through slurry injecting holes formed in the pipe joints, and soil bodies around the tunnel are reinforced; and shaft joints are cast in connecting positions of structure lined walls and the pipe joints in the positions of the receiving shaft and the launching shaft. The ultra-large full-face rectangular pipe jacking tunneling construction method has the advantages that the hole entering and exiting and non-excavation tunneling construction of the pipe jacking machine is realized; the ultra-large full-face rectangular tunneling construction is realized; and the problems in a long-face long-distance and curve tunneling process in the conventional ultra-large full-face rectangular pipe jacking tunneling construction are solved.

Owner:SHANGHAI TUNNEL ENG CO LTD +1

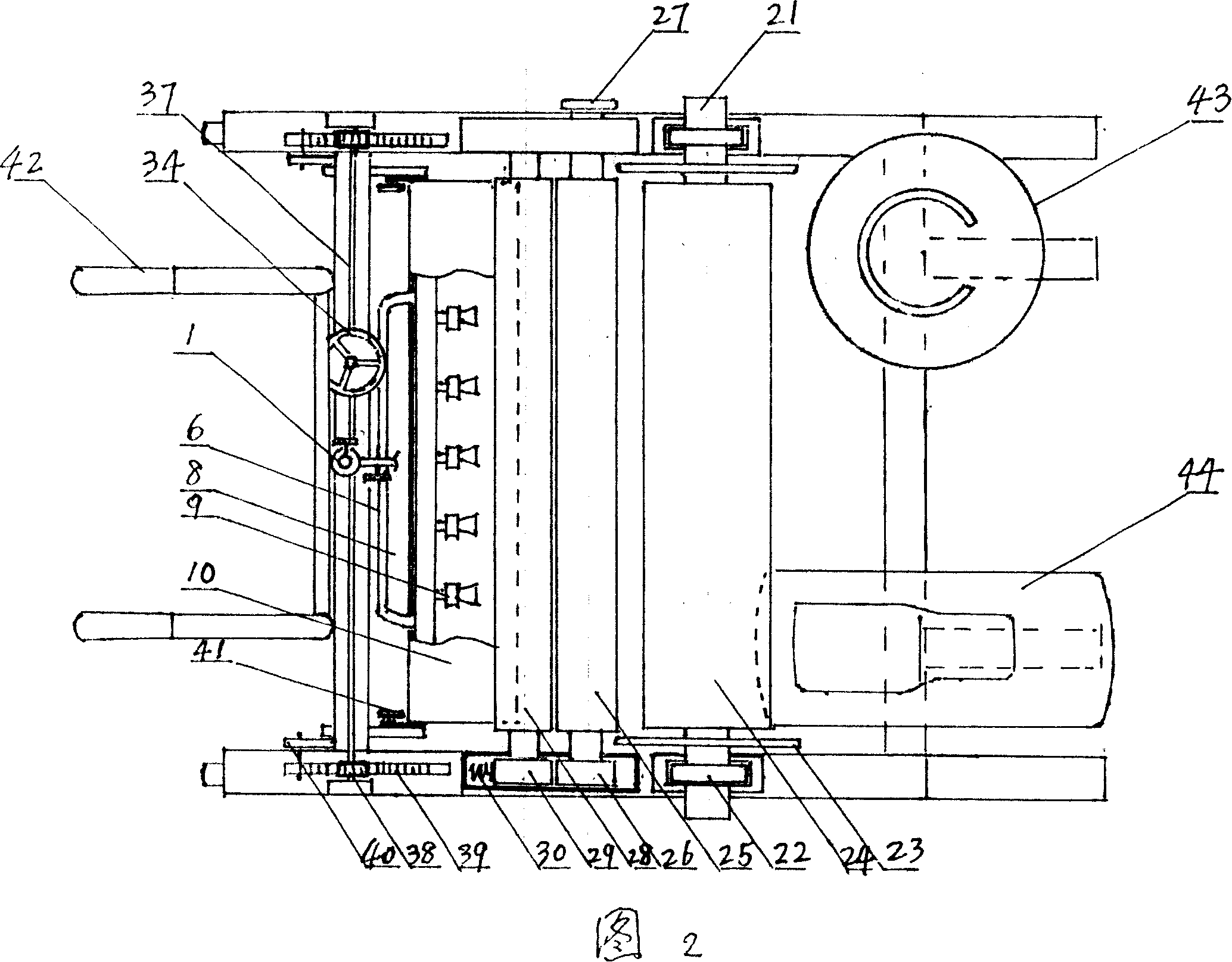

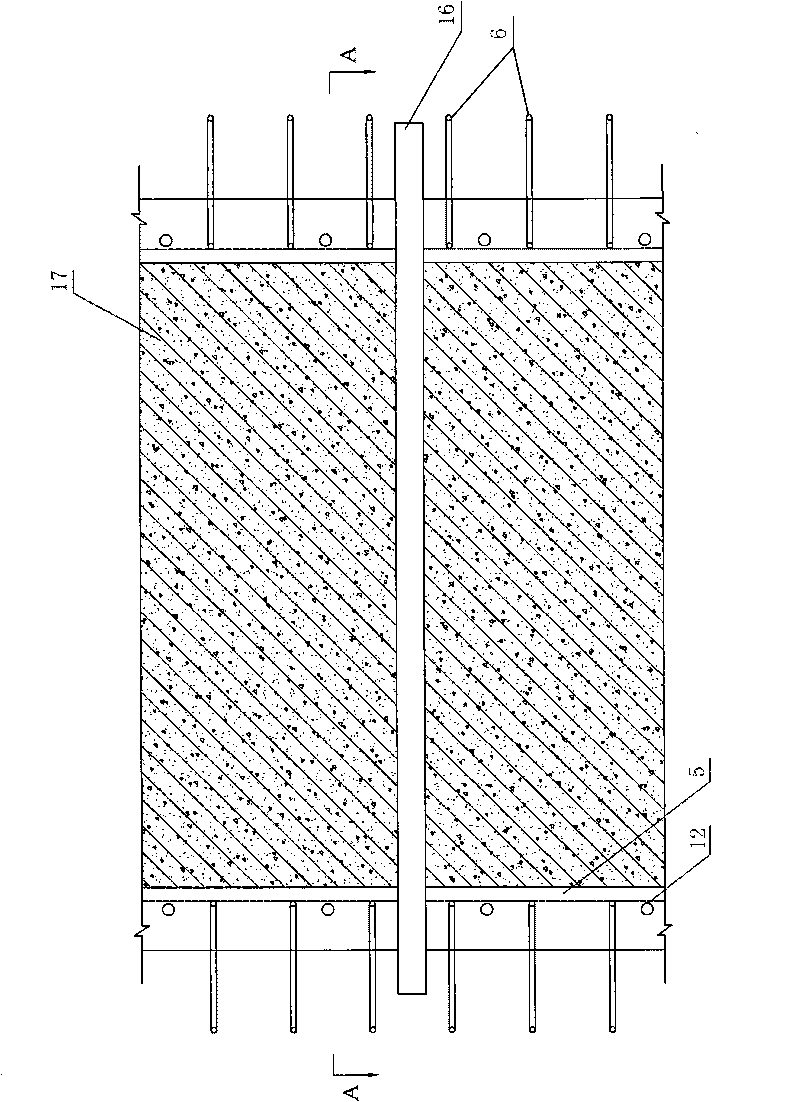

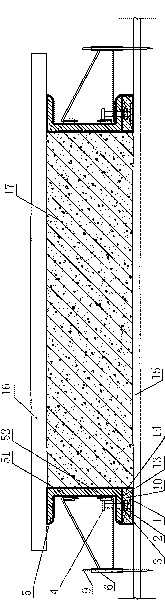

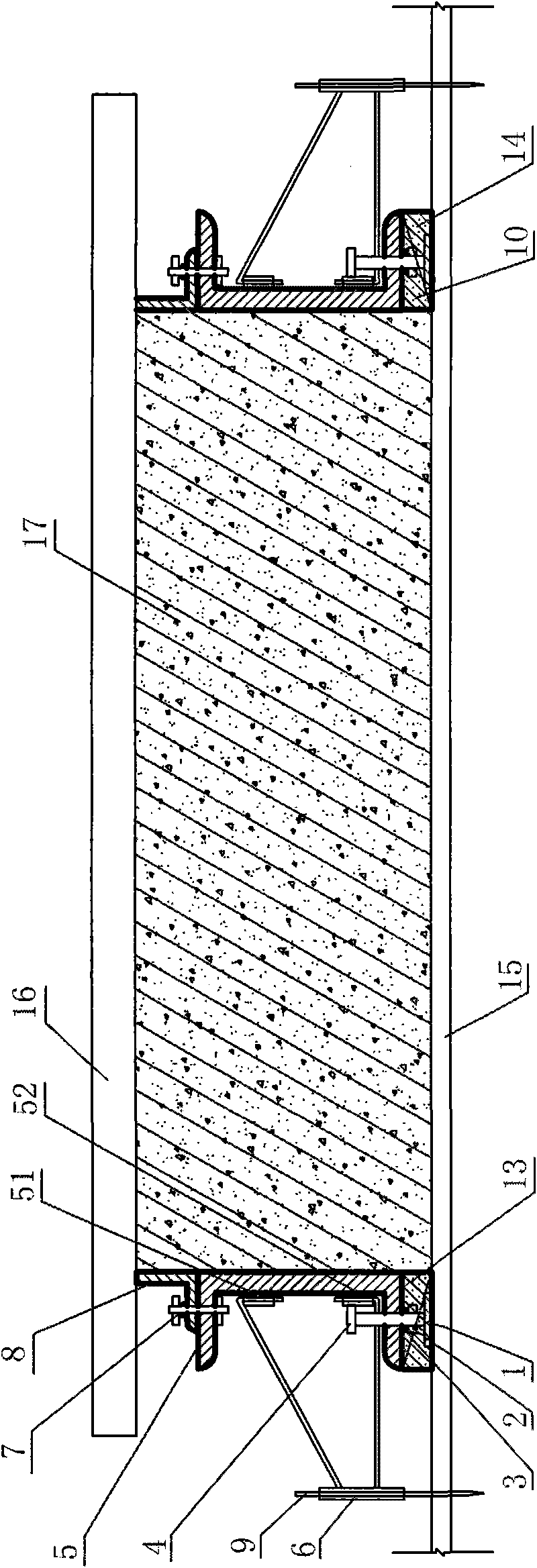

Water-proof coiled material layer

InactiveCN101109210AImprove construction efficiencyReduce labor intensityRoof toolsEngineeringGasoline

A waterproof coil laying machine is provided, which pertains to the laying equipment for waterproof coil for waterproof tech in roofs of buildings, and comprises a frame, a laying mechanism and a heater. The laying mechanism comprises a coil shaft 21, guide roll 25 and 28, a tension roll 32, and a pressing roll 33; the heater comprises a mixture gas distribution valve 1, a mixed air conveying pipe 6, and a burner 7. The mixture gas distribution valve 1 is in form of 3 pipe sets. The burner comprises a burner gas pipe 8, a row of flame nozzles 9 mounted on the gas pipe and flame covers 10. The invention realizes mechanization in laying of waterproof coil, is of high construction efficiency, lightens greatly labor intensity; the invention employs LPG, especially compressed air for supporting combustion, the fire is strong, the temperature is high, can enable the surface of the waterproof coil to melt rapidly; and in addition, as the inner course has a low temperature rise, the structure and waterproof property of the whole material will not be damaged, the construction quality is good; as using LPG, the cost is reduced comparing with using gasoline.

Owner:王新格

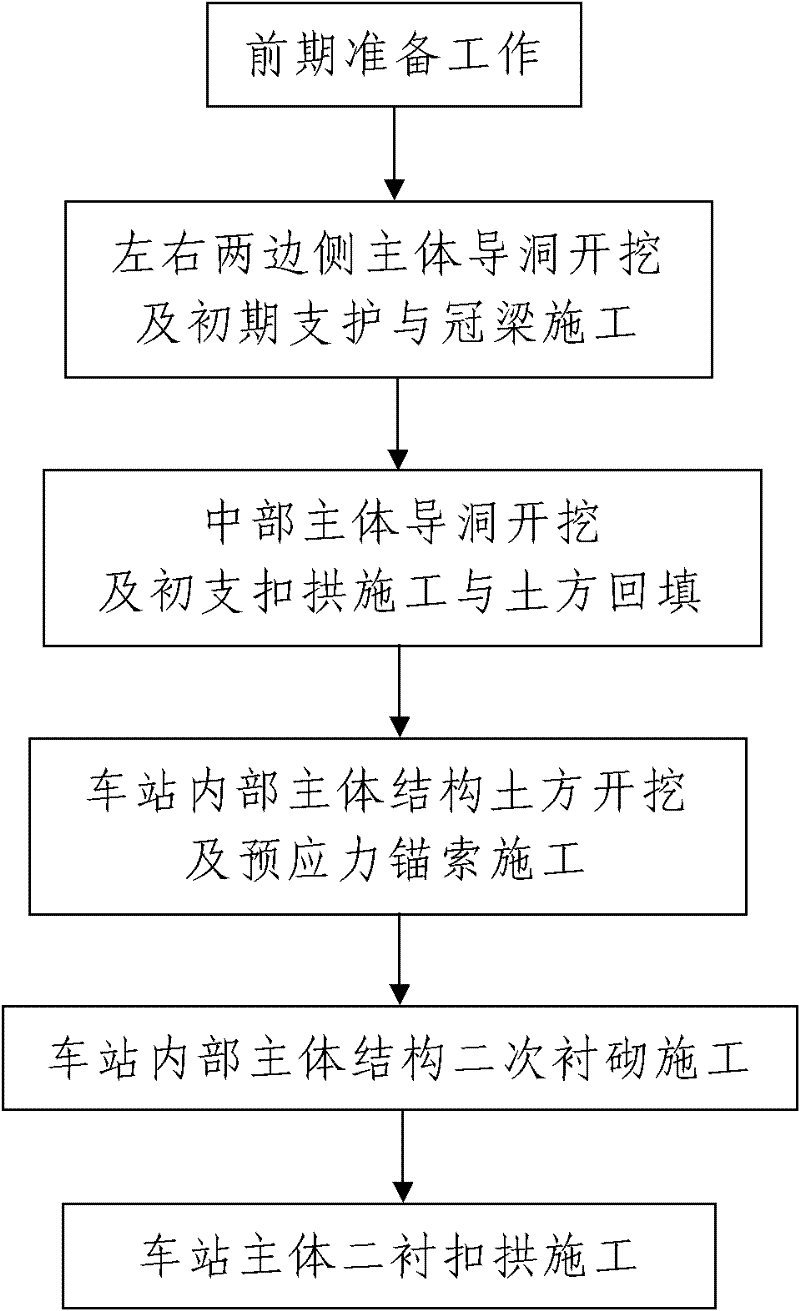

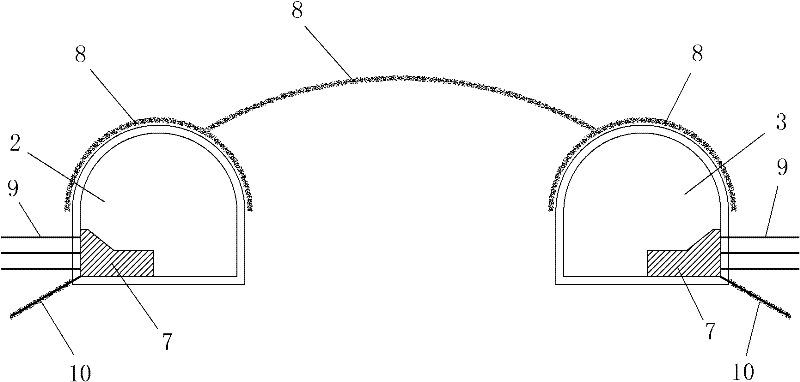

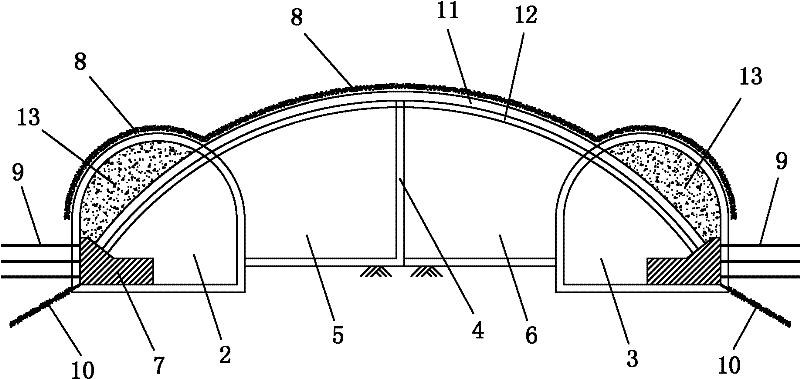

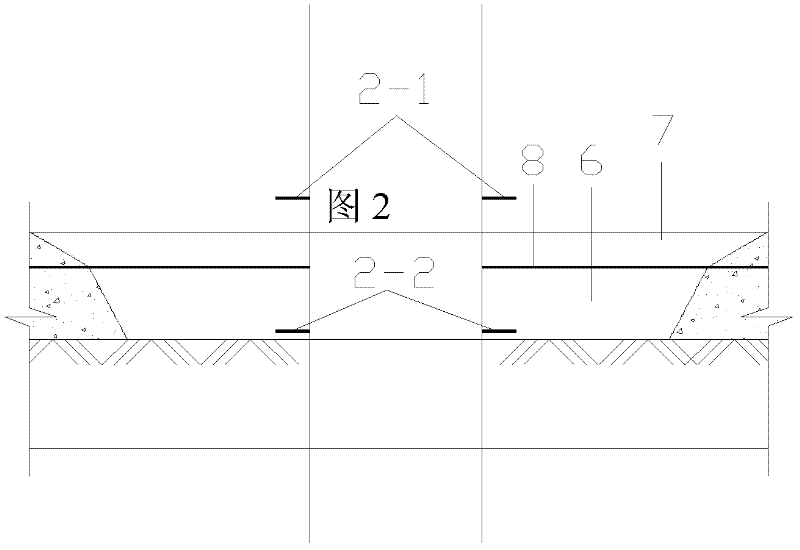

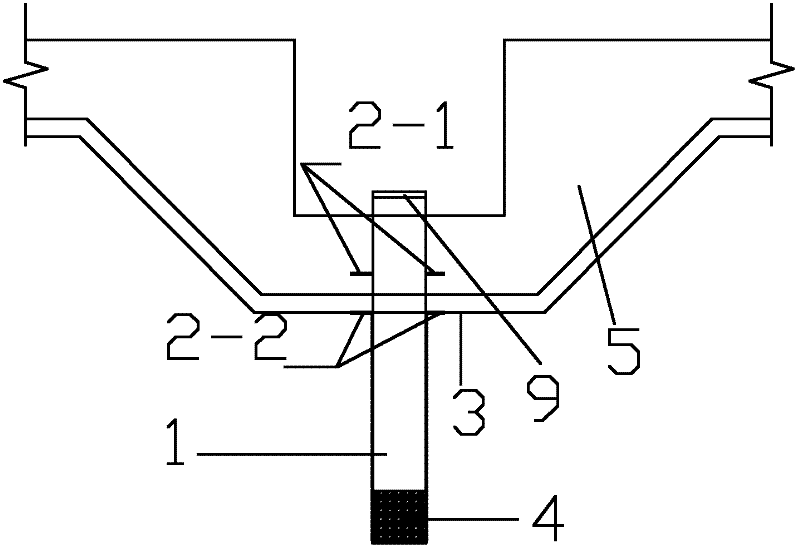

Construction method of large-span subway station main body by using arched cover method and station main body structure

ActiveCN102226403ASimplify construction stepsEasy constructionUnderground chambersSupporting systemArchitectural engineering

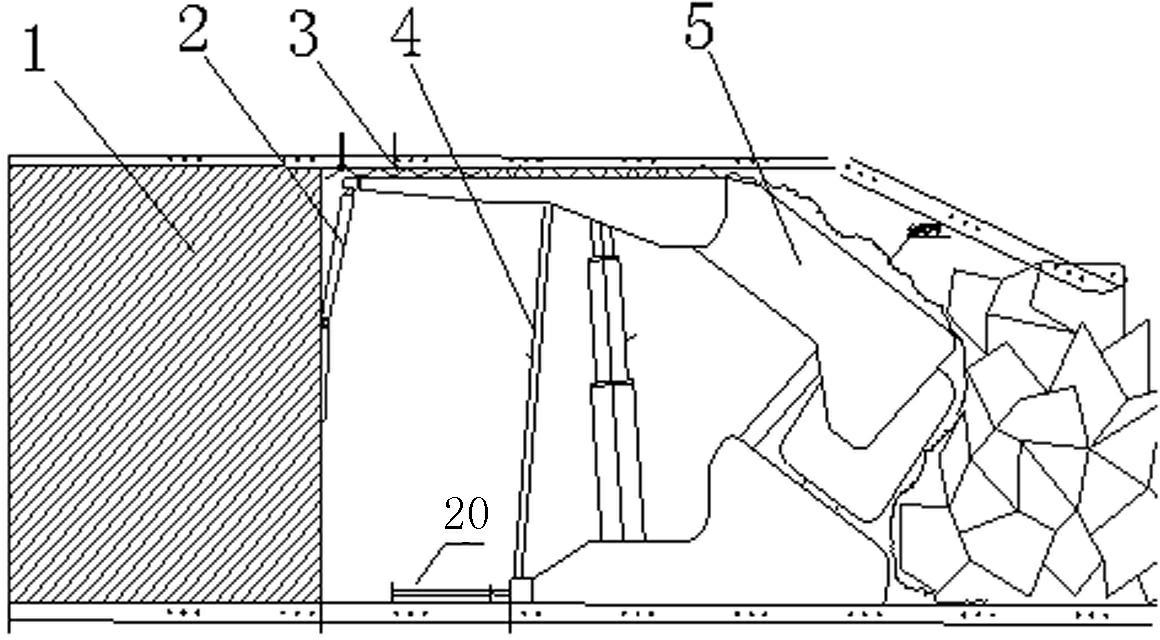

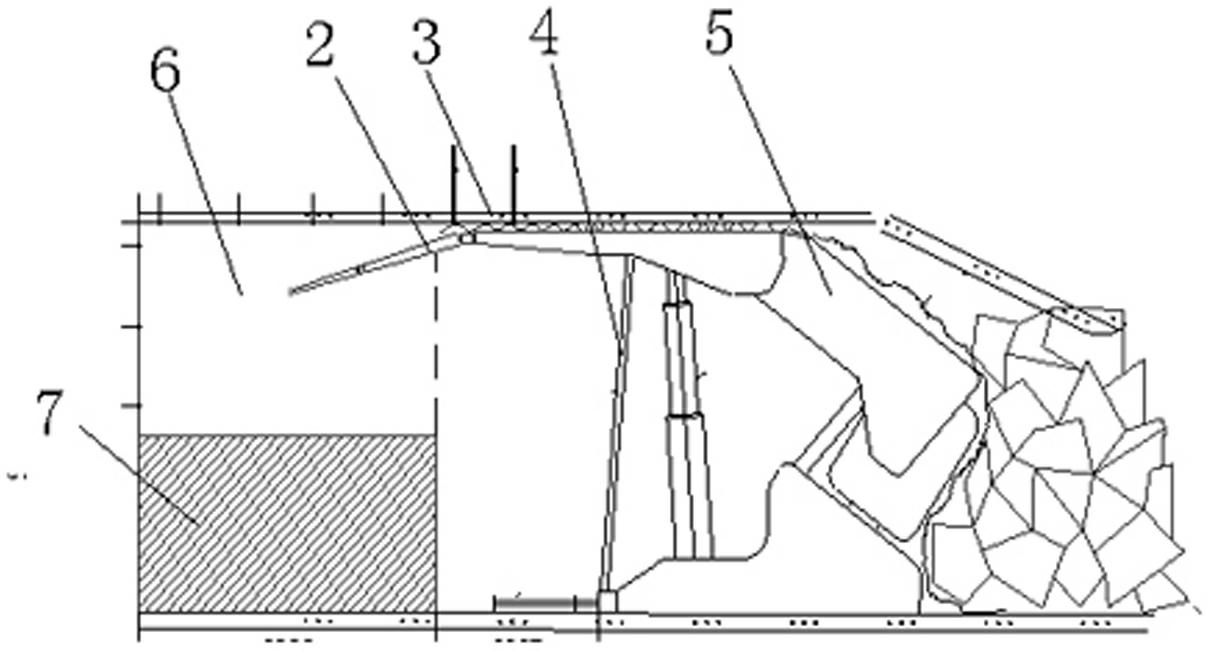

The invention discloses a construction method of a large-span subway station main body by using an arched cover method and a station main body structure. The construction method comprises the following steps: 1. making first-phase preparations; 2. excavating main body pilot tunnels at the left side and the right side, and carrying out primary support and top beam construction; 3. excavating a middle-part main body pilot tunnel, carrying out primary support and arch buckling construction, and refilling the earthwork; 4. carrying out earthwork excavation on a main body structure in the station, and prestressing force anchor cable construction; 5. carrying out secondary lining construction on the main body structure in the station; and 6. carrying out secondary lining and arch buckling construction on the station main body. The station main body structure comprises the main body structure in the station, a central post, a central plate and a main body arch part, wherein, the main body arch part comprises a middle arch fragment and two side arch fragments respectively arranged in the two side main body pilot tunnels formed by excavation in advance; and the main body arch part comprises a primary support system and a station main body arch buckling secondary lining structure from the outside to the inside. The station main body structure provided by the invention has reasonable design, simple construction steps, convenience in realization, small construction difficulty and rapid construction speed; the subway station formed by the construction method has a stable structure and a good use effect.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

Anticorrossion antiwear ceramic paint

InactiveCN1325931AHigh hardnessImprove wear resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyGlass fiber

An anticorrosion and antiwear ceramic paint is prepared from epoxy resin (28.5-35 wt.portions), dibutyl phthalate (3.75-6), mixed solvent of xyrene and n-butyl ester (20-24), gas-phase SiO2 (0.5-1) and ceramic powder (38-45) which contains TiO2 (3-6.3), Al2O3 (11.7-20) and Si3N4 (16-20.45). The weight ratio of main component to slidifying agent is (14.5-17):1. It can be directly applied to the surfaces of metal, glass fibre, plastic, or concrete with the advantages of high antiwear performance and adhesion, and thin and compact coated layer.

Owner:BEIJING UNIV OF CHEM TECH

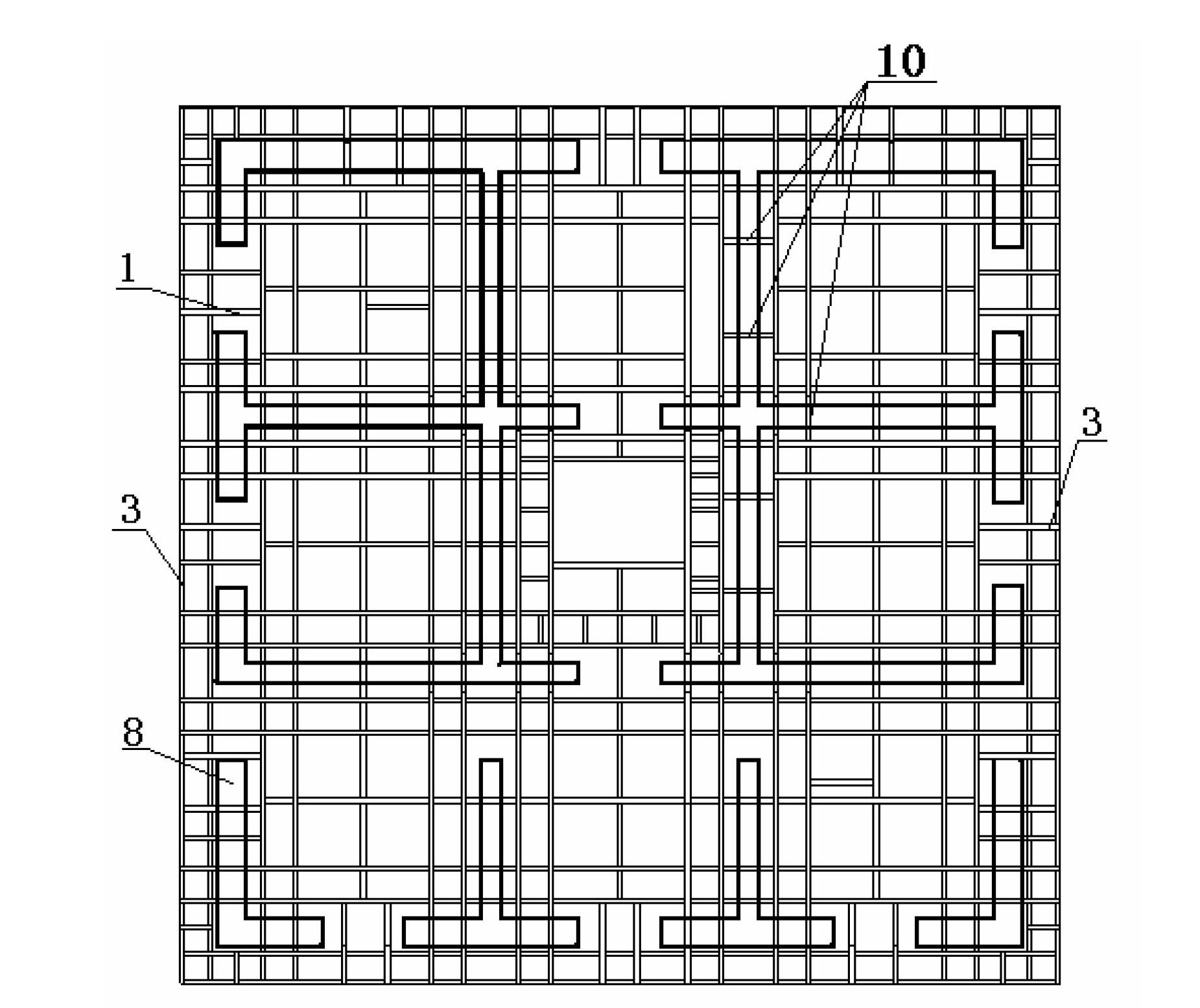

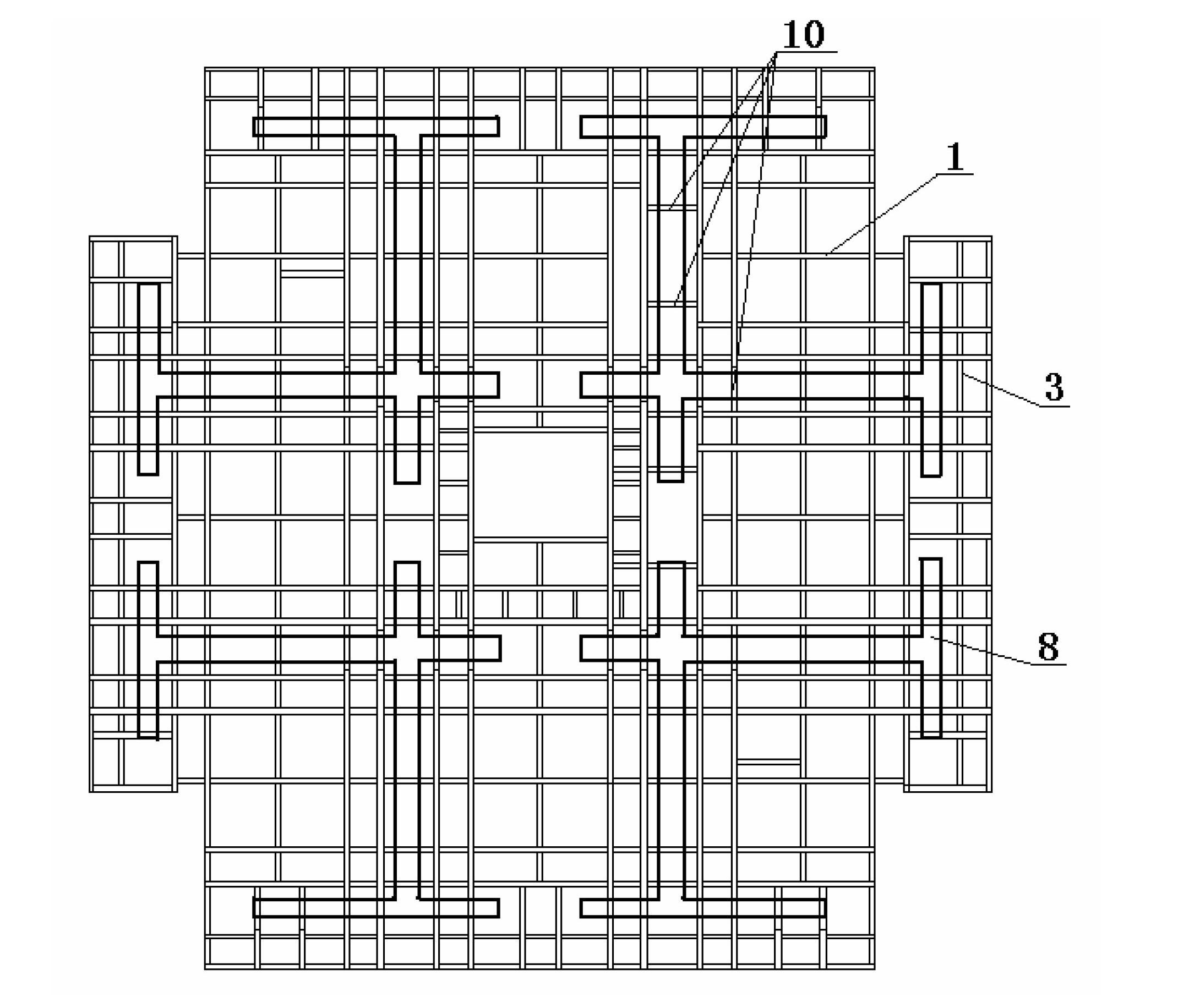

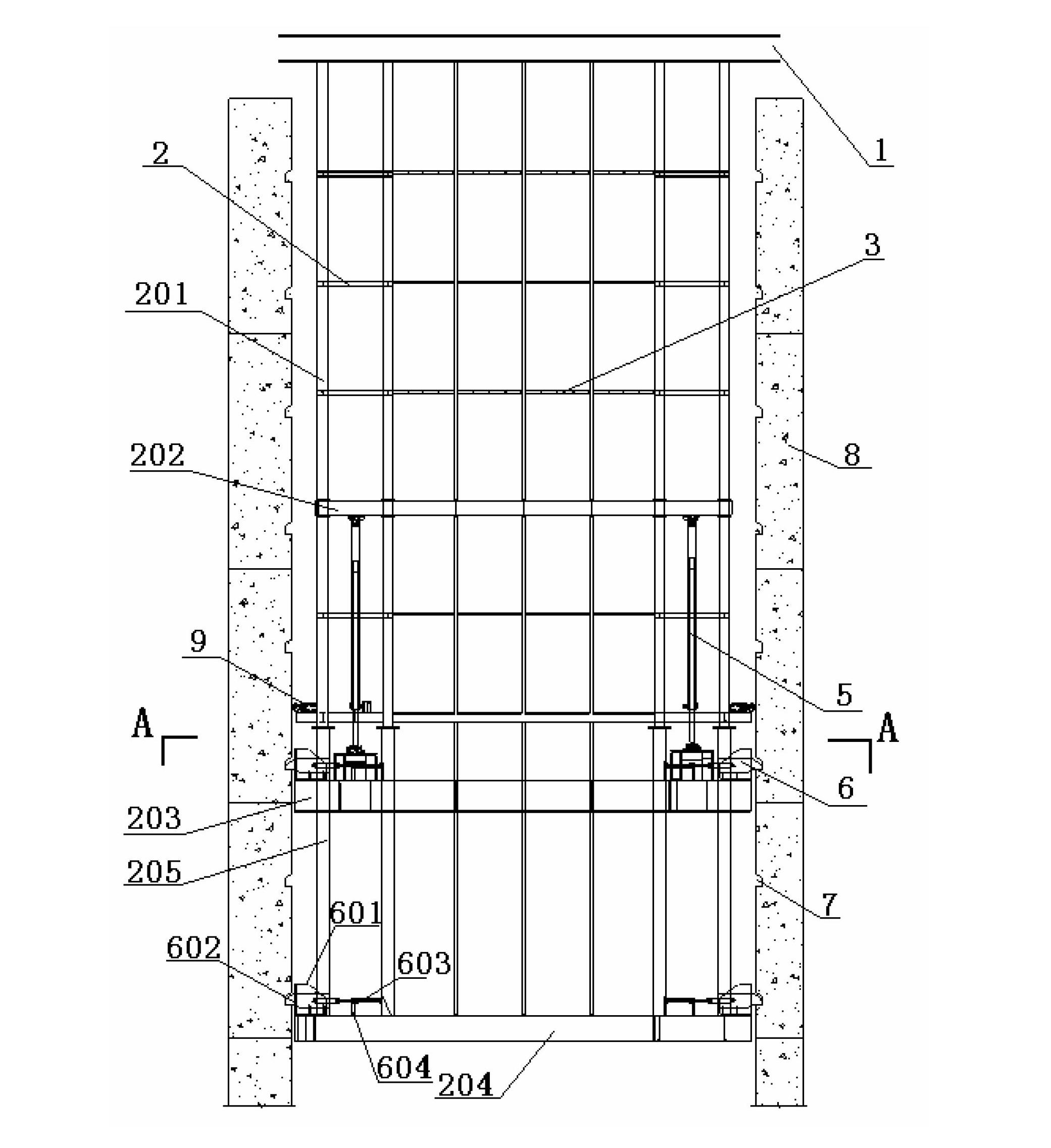

Drum frame supporting power built-in integrated jacking steel platform formwork system and construction method

ActiveCN102661039AEasy maintenanceAvoid the risk of falling objectsForms/shuttering/falseworksBuilding material handlingSteel columnsShear wall

The invention discloses a drum frame supporting power built-in integrated jacking steel platform formwork system, comprising a steel platform, a support system, a suspended scaffold, a template system and a hydraulic jacking power system; the support system comprises a drum frame support and an internal framework support; the drum frame support is located under the steel platform, and comprises a steel platform support, an oil cylinder counter-force beam, a guide roller, a support steel column and a drum frame support beam; the internal framework support is arranged inside the drum frame support and located between the drum frame support beam and the oil cylinder counter-force beam; the hydraulic jacking power system comprises a hydraulic jacking oil cylinder and a power control system thereof; the hydraulic jacking oil cylinder is inverted between the oil cylinder counter-force beam and the internal framework support; telescopic brackets are arranged at the end portions of the internal framework support and the drum frame support beam, respectively; and the telescopic brackets are supported in a preformed hole in a shear wall. The drum frame supporting power built-in integrated jacking steel platform formwork system is capable of realizing the construction operation of a complex core drum, shortening the construction period and ensuring high altitude construction safety, and also capable of improving the green construction level.

Owner:SHANGHAI CONSTRUCTION GROUP +1

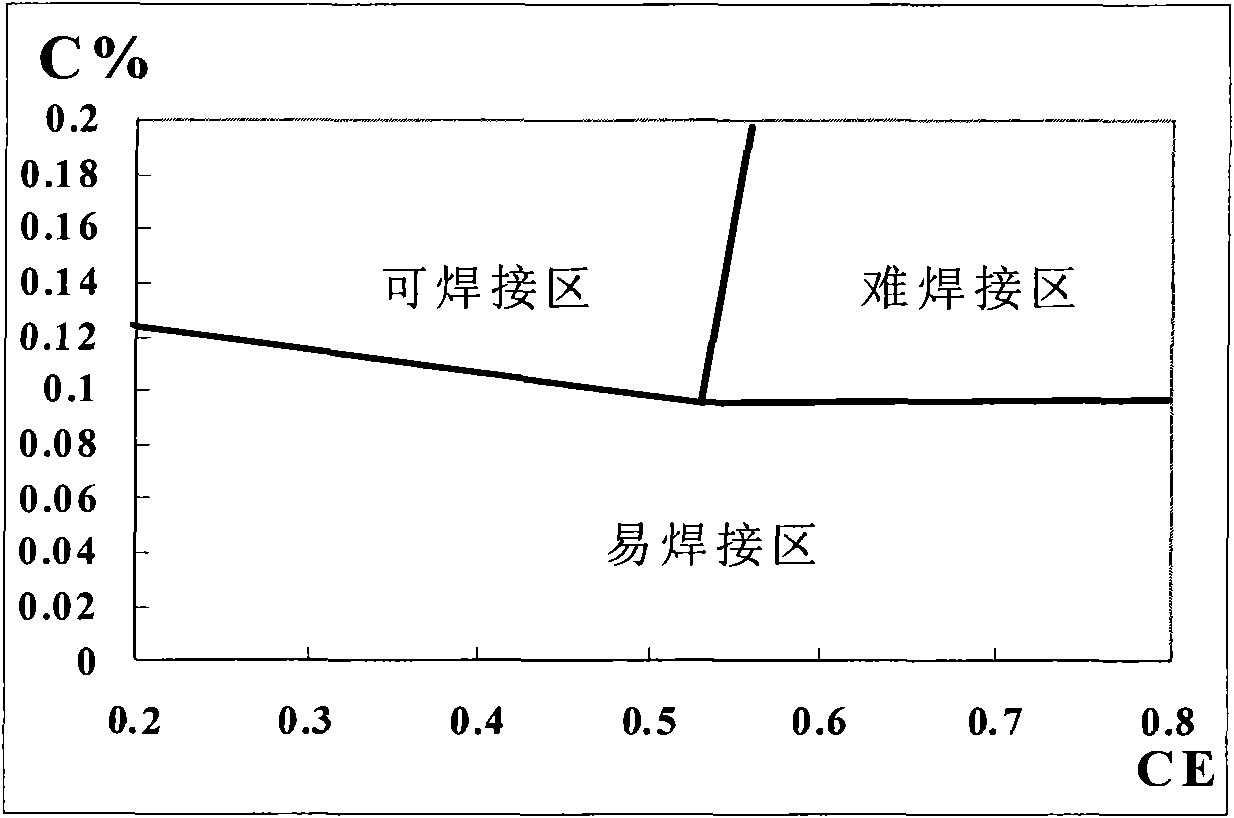

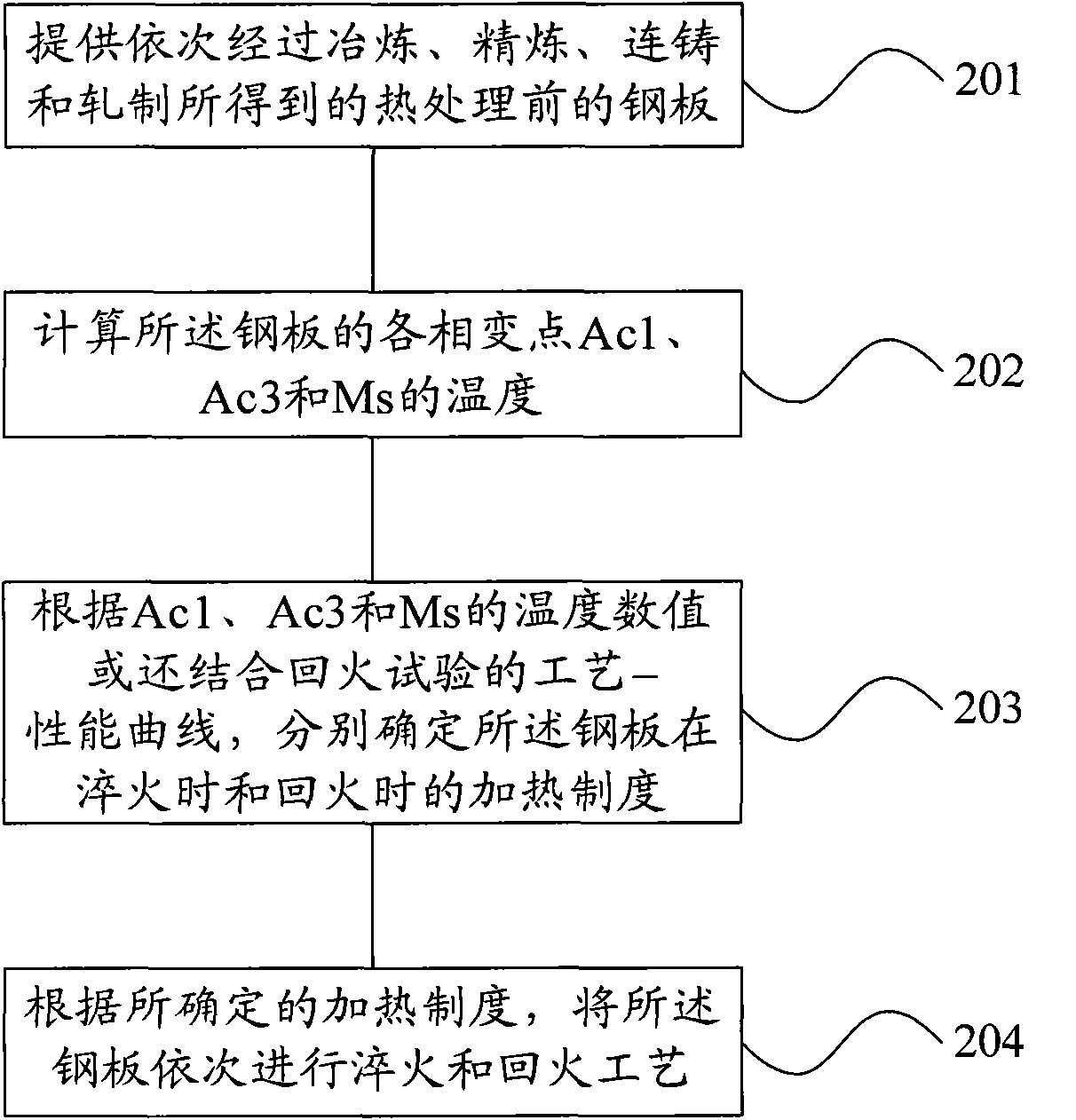

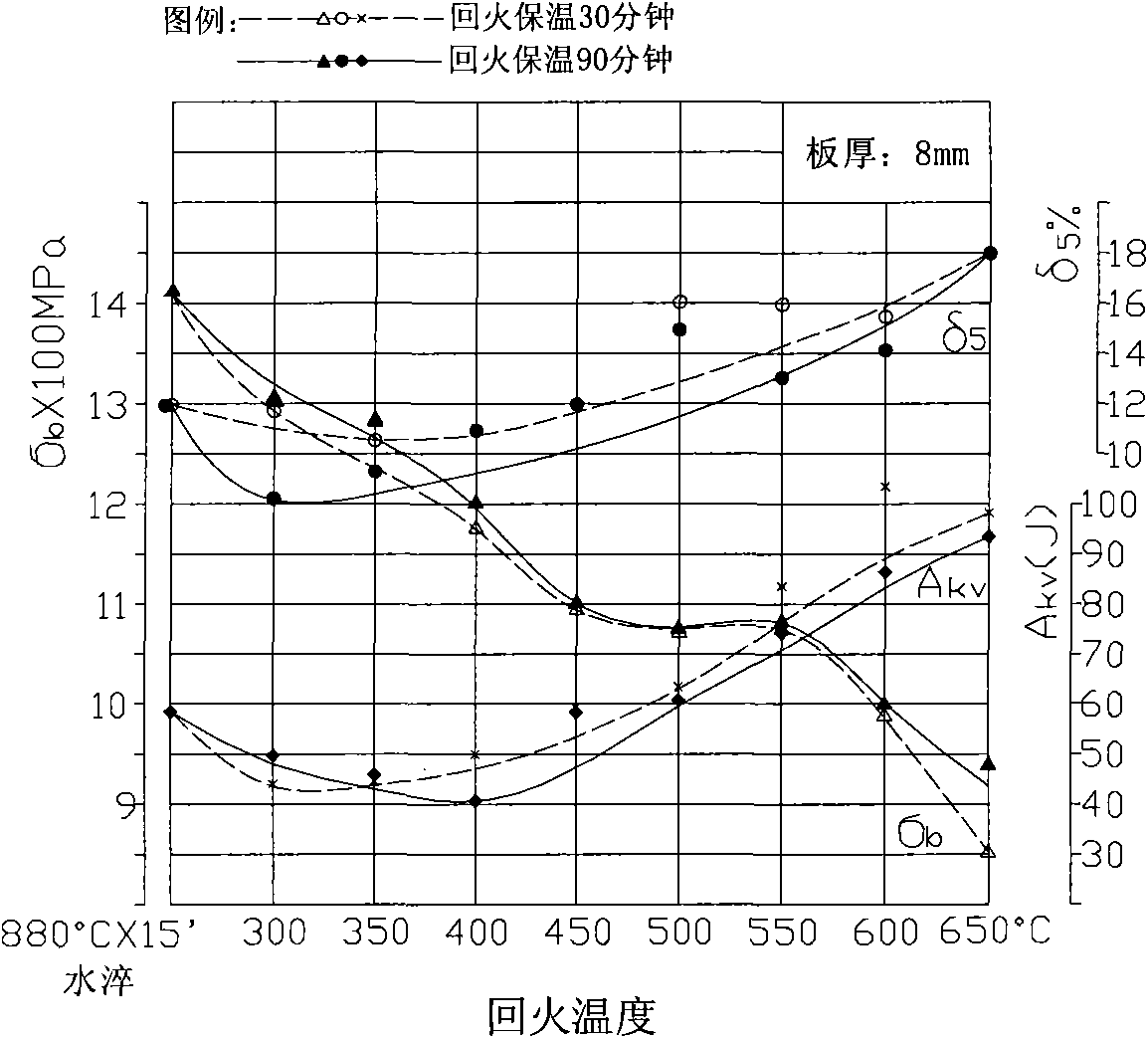

Quenching steel plate for engineering machinery with 900MPa-grade yield strength and production method thereof

InactiveCN101899630AHigh strengthImprove toughnessRoll force/gap control deviceTemperature control deviceSheet steelHigh intensity

The invention provides a quenching steel plate for engineering machinery with 900MPa-grade yield strength, comprising the following components in percentage by mass: 0.13 to 0.18 percent of C, 1.20 to 1.60 percent of Mn, not more than 0.010 percent of S, not more than 0.020 percent of P, not more than 0.50 percent of Si, not more than 0.50 percent of Cr, not more than 0.50 percent of Ni, 0.30 to 0.60 percent of Mo, not more than 0.003 percent of B, not more than 0.05 percent of V, not more than 0.03 percent of Ti, not more than 0.03 percent of Nb, not less than 0.018 percent of Al and the balance of Fe and other unavoidable impurities; and the mass percentages of all the components in the steel plate also need to satisfy the condition that the value of the carbon equivalent is not more than 0.56 percent. The invention also provides a production method of the quenching steel plate for engineering machinery with 900MPa-grade yield strength. The steel plate has favorably-matched strength and tenacity, and the welding performance of the steel plate can satisfy the construction requirements on steels for manufacturing high-strength welding structures of the engineering machinery; meanwhile, the strength, the tenacity and the plasticity of the provided steel plate are all superior to similar WELDOX900-standard products in foreign countries.

Owner:BAOSHAN IRON & STEEL CO LTD

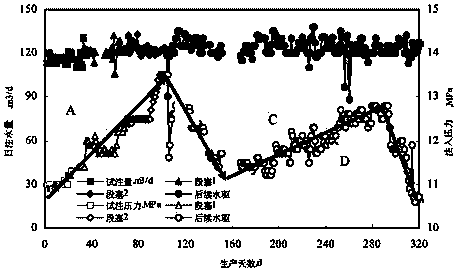

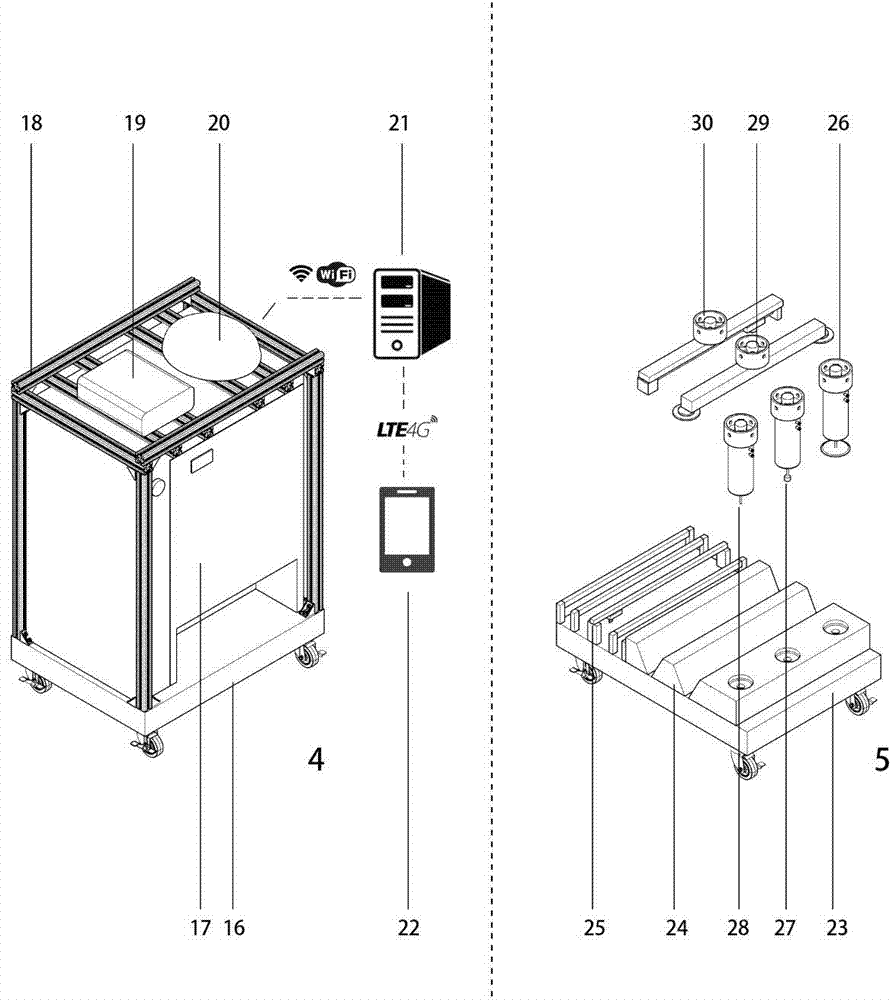

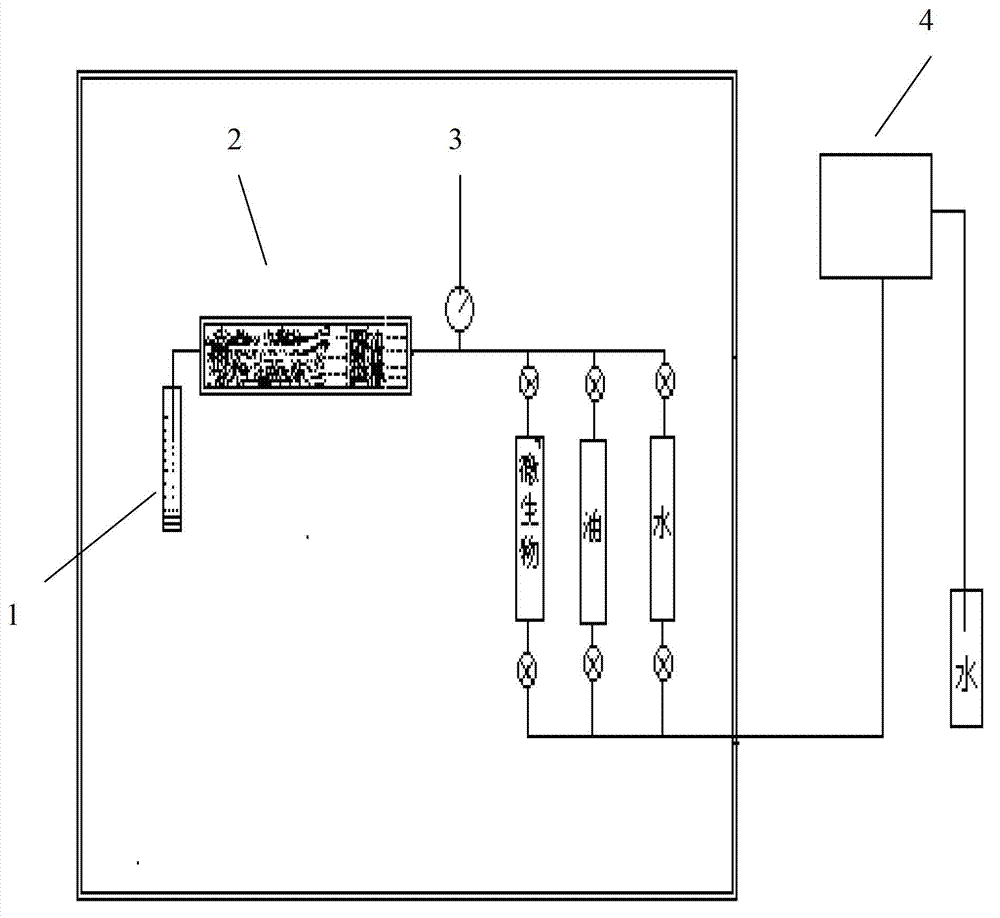

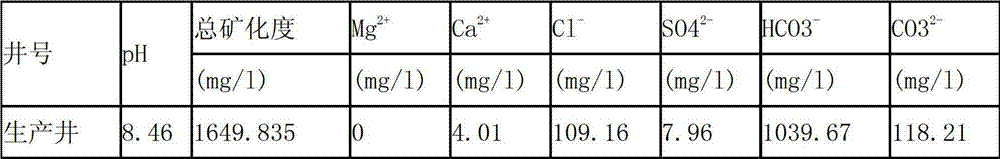

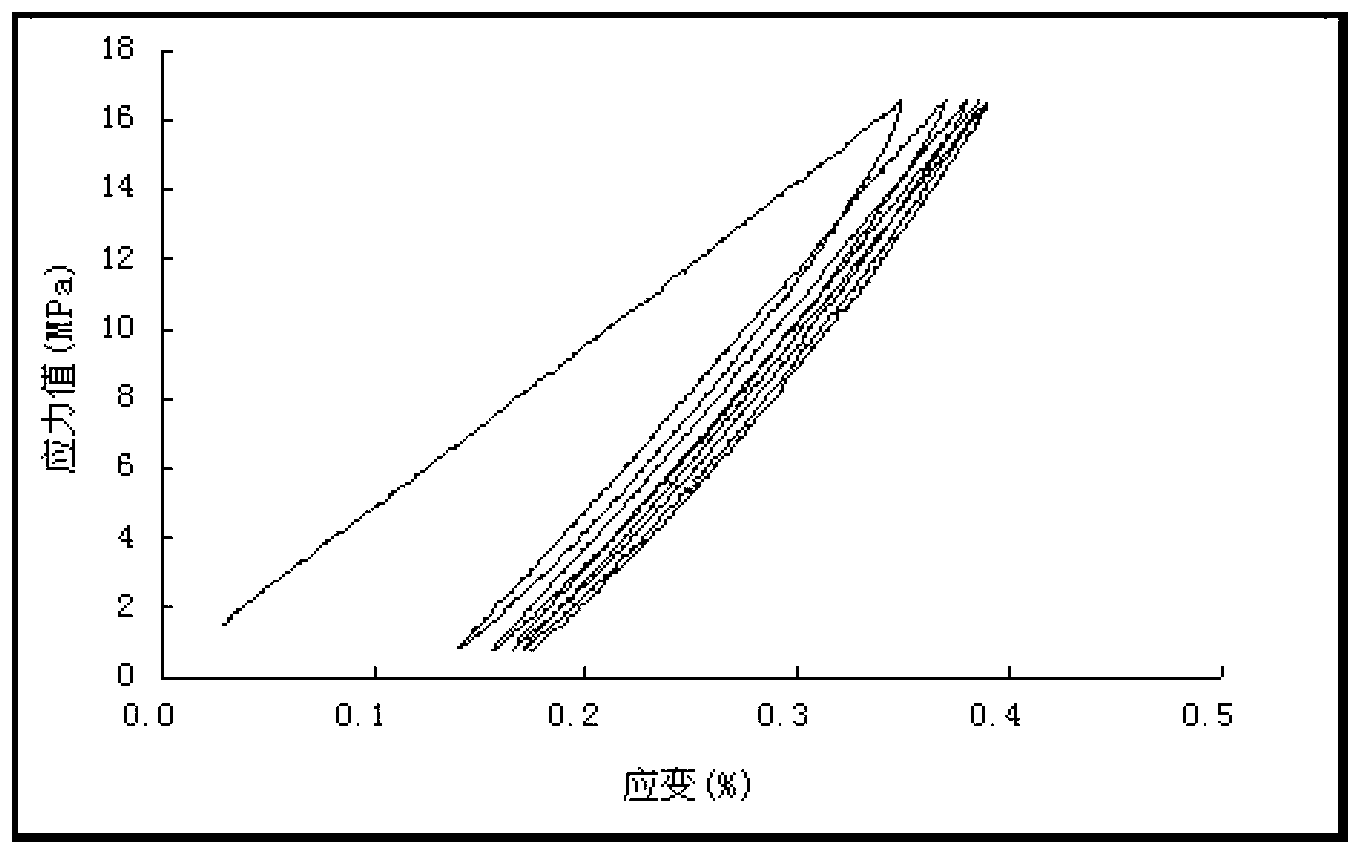

Method for activating indigenous microorganisms of oil reservoir for oil displacement after polymer flooding

ActiveCN104234675AIncrease the number ofExpand the affected volumeFluid removalInjection wellPolymer flooding

The invention discloses a method for activating indigenous microorganisms of an oil reservoir for oil displacement after polymer flooding. The method is characterized in that an oil displacement slug capable of activating indigenous microorganisms of the oil reservoir is injected into a target oil reservoir of the oil displacement through an injection well; the oil displacement slug comprises an activating agent slug and an activating agent protection slug; during an injection process, the activating agent slug and the activating agent protection slug are alternately injected for at least more than 2 times; the total volume of the activating agent slug is two times or more bigger than that of the activating agent protection slug (the most suitable range is controlled to be 2-5 times). According to the method disclosed by the invention, the number of the functional microorganisms of the oil reservoir is increased by injecting an exogenous activating agent; the recovery efficiency can be improved by 3-5 percent after the polymer flooding, and the applicability is good.

Owner:PETROCHINA CO LTD +1

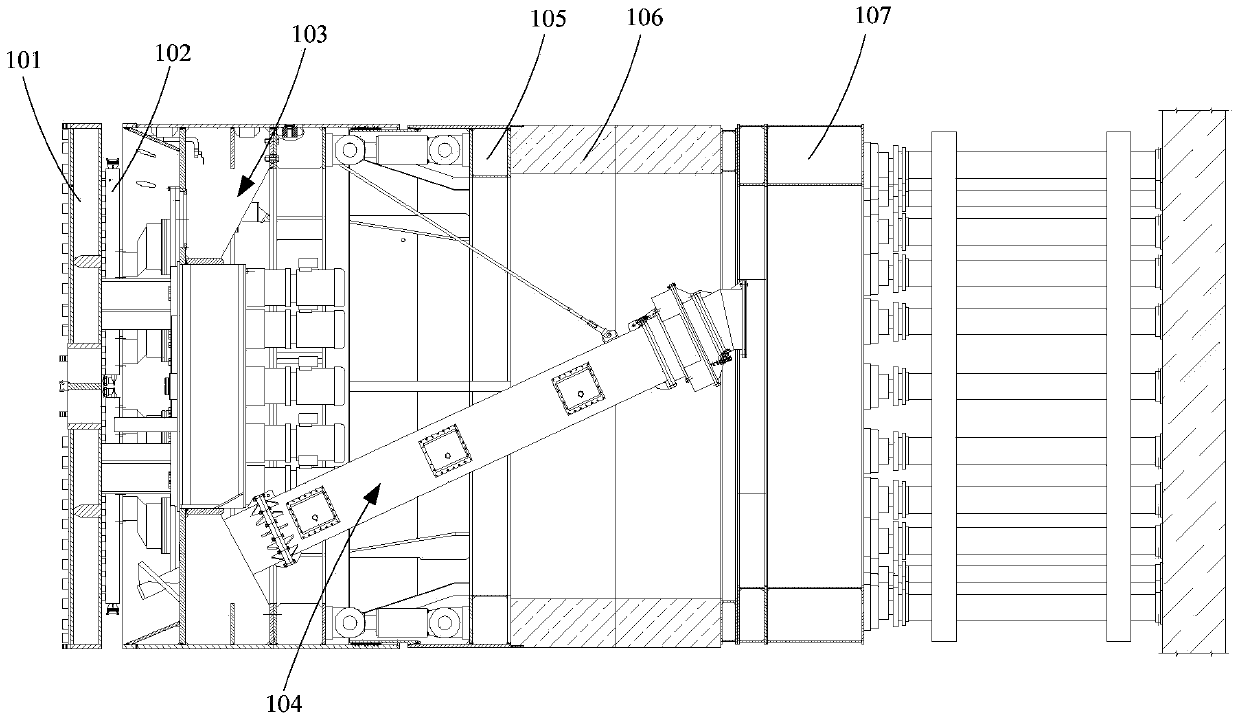

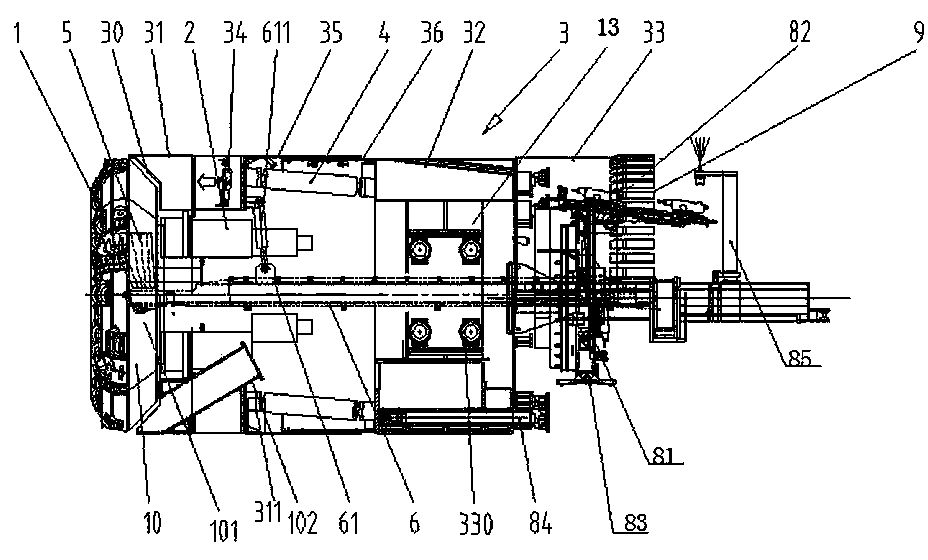

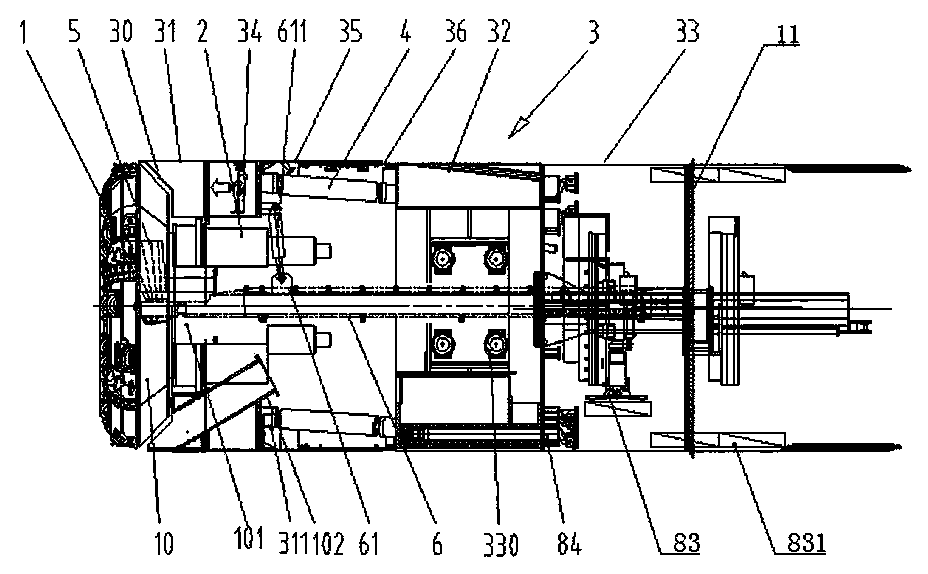

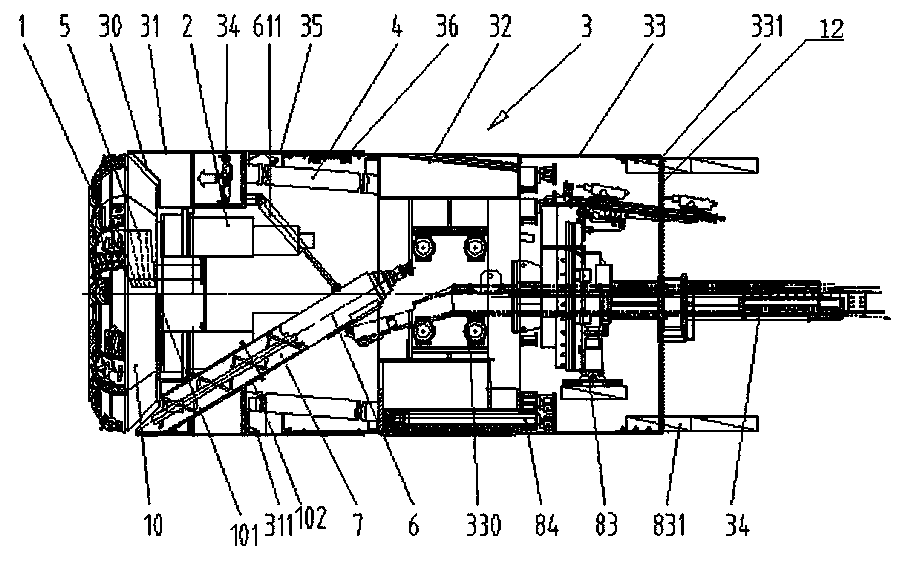

Combined type double-shield tunneling machine

ActiveCN104196538AIncrease the lengthShorten the lengthUnderground chambersTunnel liningSupporting systemDual mode

The invention discloses a combined type double-shield tunneling machine which comprises a cutter, an anterior shield, a cab, a main driving device, an inside-and-outside stretching shield, a V-shaped arrangement main propelling system, a hinge system, a supporting shield, a boot supporting system, a tail shield, an auxiliary propelling system, a dual-mode deslagging system, an integration supporting system and the like. Four working modes including of the double shielding modes including the support boot and segmental lining mode and the support boot and anchor-plate timbering mode, the single shielding mode and the ERB mode can be achieved, and efficient tunneling, efficient deslagging and efficient timbering are achieved under the hard rock, sandy soil and soft soil geological conditions. The combined type double-shield tunneling machine has the outstanding advantages that one device can meet various complex-geology tunneling construction requirements, the geology applicability of the tunneling machine is greatly improved, the frequency of tunneling machine replacement in tunnel construction is decreased, and production efficiency is greatly improved.

Owner:中船(青岛)轨道交通装备有限公司

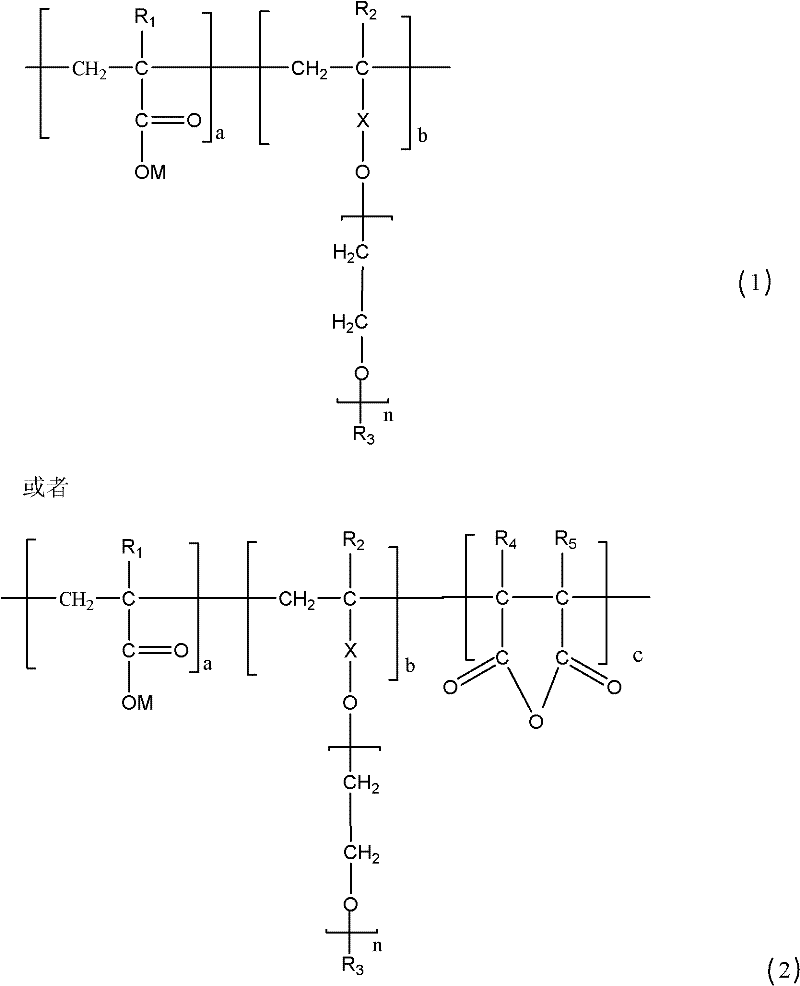

A polycarboxylate water reducer with high water reducing rate and high slump retention, its synthesis method and its use

The invention belongs to the technical field of building materials, and specifically relates to a polycarboxylic acid water reducer with a high water-reducing rate and high slump constant holding capacity, and its synthetic method and use method. The polycarboxylic acid water reducer comprises 2-methallyl polyoxyethylene ether (TPEG), 2-acrylamido-2-methylpropanesulfonic acid (AMPS), methacrylic acid (MAA), ammonium persulfate (APS), sodium hydroxide and water. The synthetic method comprises the following steps that 1, TPEG, AMPS and MAA are prepared respectively into mixed solutions with concentrations in a range of 20 to 50%; 2, simultaneously, APS is added with a proper amount of water and is dissolved in the water; 3, the TPEG and AMPS monomer mixed solutions prepared by the step 1 are added into a reactor; nitrogen is fed into the mixture in the reactor; a condenser tube is mounted; the mixture is heated to a temperature of 60 to 100 DEG C with stirring; the MAA monomer solution prepared by the step 1 and the APS solution prepared by the step 2 are respectively added dropwisely into the heated mixture, wherein dropwise addition time of the MAA monomer solution is in a range of 1 to 5 hours and dropwise addition time of the APS solution is in a range of 1.5 to 5.5 hours; and after the dropwise addition is finished, the mixture with the MAA monomer solution and the APS solution undergoes a reaction at a constant temperature for 1 to 2 hours; 4, reaction products obtained by the step 3 are cooled and are neutralized by a NaOH solution to form desired products. The synthetic method of the polycarboxylic acid water reducer is a one-step synthetic method and has simple processes. Products prepared through the synthetic method have the advantages of stable performances, low doping quantity, high water-reducing rate, high slump constant holding capacity and good market prospects.

Owner:KZJ NEW MATERIALS GROUP CO LTD

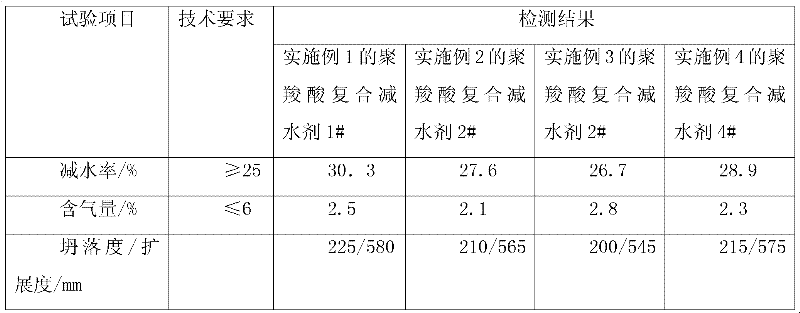

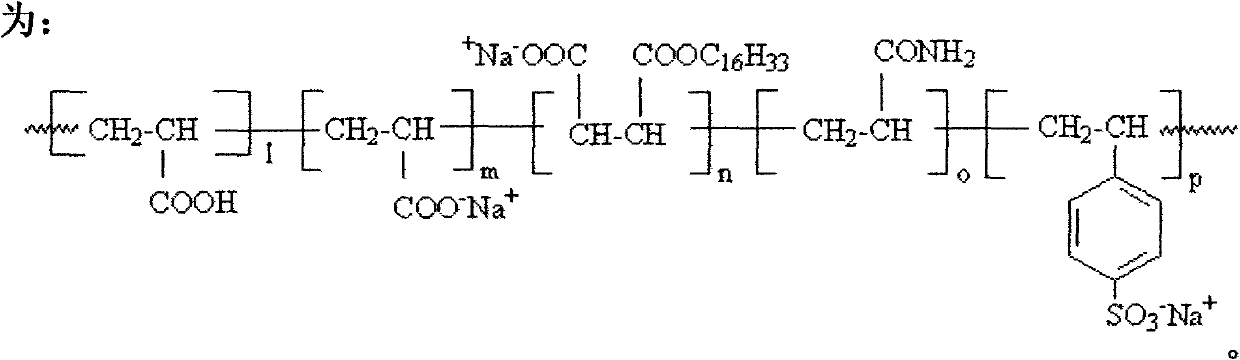

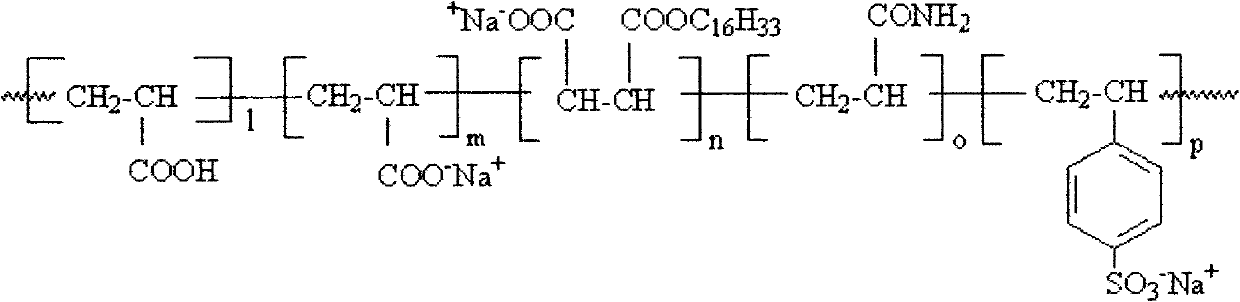

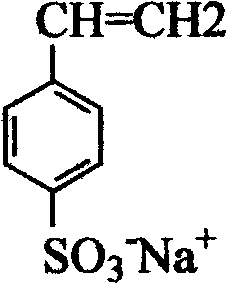

Composite polycarboxylic acid water reducing agent

The invention belongs to the technical field of concrete additives, in particular relates to a water reducing agent, and more particularly a composite polycarboxylic acid water reducing agent. The composite polycarboxylic acid water reducing agent is characterized by being prepared from the following components in percentage by mass: 8-28.6 percent of polycarboxylic acid high-performance water reducing agent, 0.5-7.36 percent of inhibiting agent, 0.001-0.15 percent of functional aid, 0.01-0.65 percent of preservative and the balance of water, wherein the total mass percentage of the components is 100 percent. The composite polycarboxylic acid water reducing agent is applied to freshly mixed concrete. After a template coated with waste engine oil or rosinate soap is dismantled, the surface of hardened concrete is smooth, air bubbles are reduced remarkably, and the construction requirement is fully met. By adopting the composite polycarboxylic acid water reducing agent, the problem of a large quantity of air bubbles on the surface of concrete, produced after the use of demolding agents such as waste engine oil or rosinate soap and the like is solved.

Owner:CHINA STATE CONSTR ENG CORP TIANJIN +1

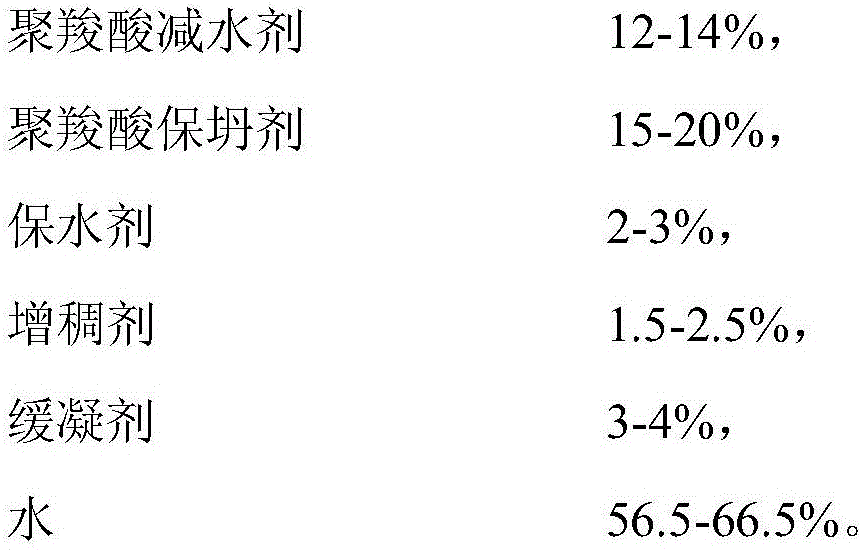

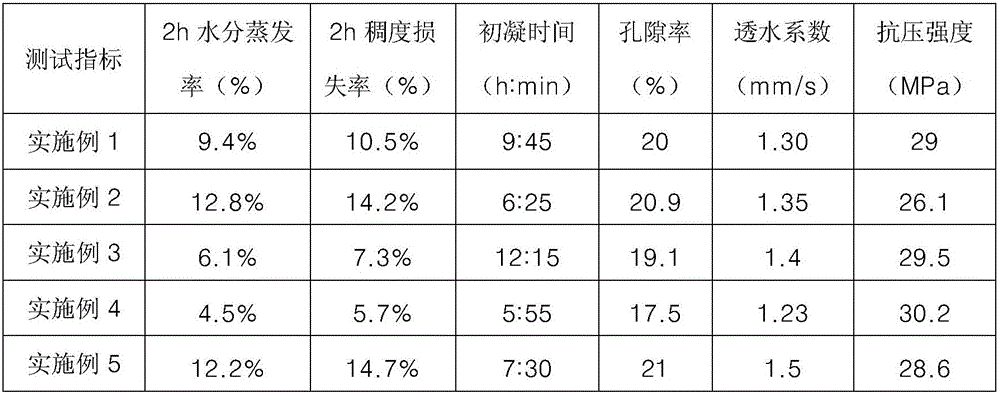

Pervious concrete special-purpose additive and use thereof

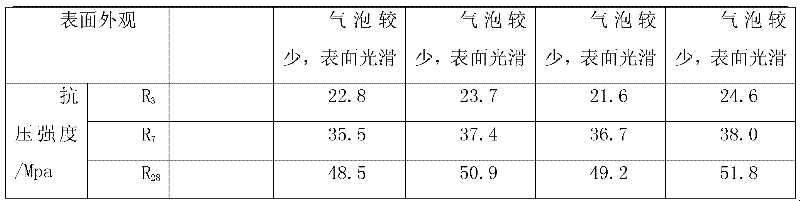

The invention discloses a pervious concrete special-purpose additive and a use thereof. The pervious concrete special-purpose additive comprises, by mass, 10-20% of a polycarboxylic acid water reducer, 5-25% of a polycarboxylic acid slump retaining agent, 0.5-3% of a water-retaining agent, 0.5-5% of a thickening agent, 1-5% of a delayed coagulant and 52-75% of water. A mass ratio of the additive to the gelling material in the pervious concrete is 1-2%. Ingredients of the pervious concrete special-purpose additive produce good synergism. The pervious concrete special-purpose additive guarantees water permeability, well keeps pervious concrete workability for 2h or more, improves strength after aging and realizes pervious concrete premixing production.

Owner:JIANGSU SOBUTE NEW MATERIALS

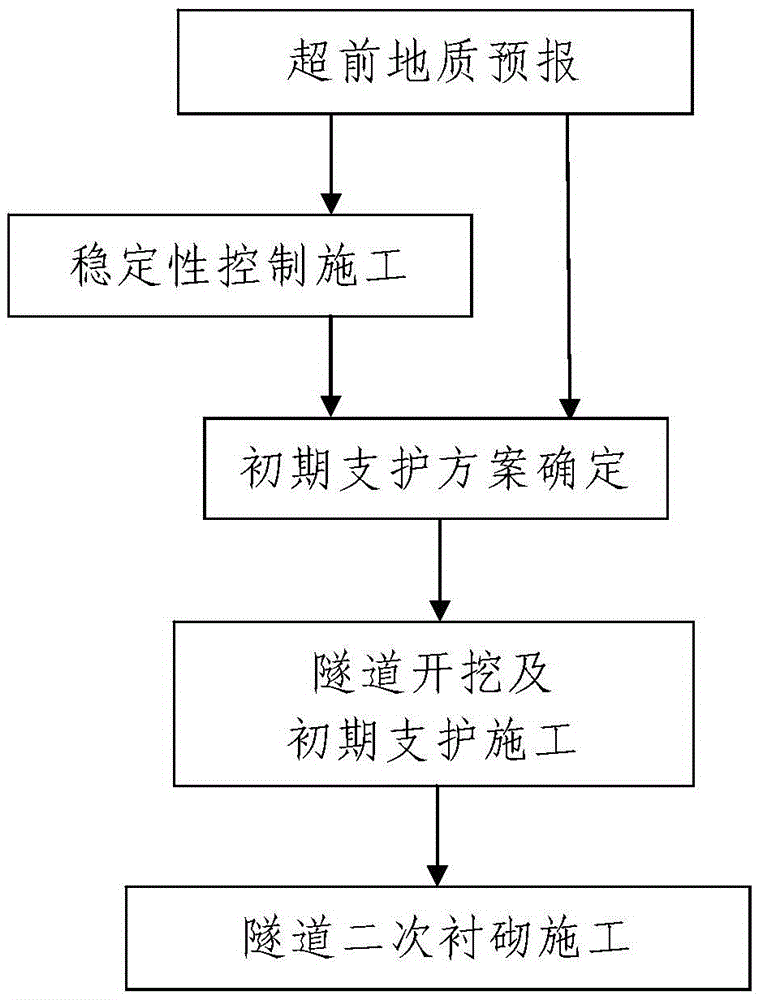

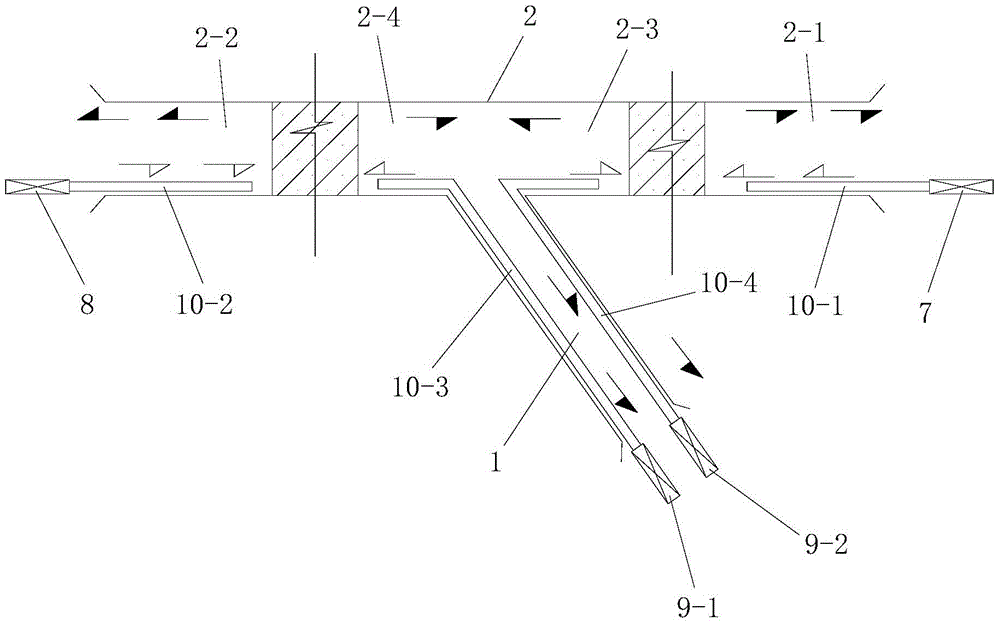

Water-rich weak surrounding rock long-and-big tunnel construction method

The invention discloses a water-rich weak surrounding rock long-and-big tunnel construction method. The method includes that a tunnel inclined shaft is arranged on one side of a main tunnel of a tunnel to be constructed, the main tunnel is divided into a tunnel entry section, a tunnel exit section and a middle connecting section connected between the tunnel entry section and the tunnel exit section, the middle connecting section is divided into an inclined shaft assisting construction entry section and an inclined shaft assisting construction exit section, and each of the tunnel entry section, the tunnel exit section, the inclined shaft assisting construction entry section and the inclined shaft assisting construction exit section is divided into multiple sections for construction. A construction method of each section includes: step 1, performing geological forecasting in advance, and when a debris flow formation exists ahead, entering a step 2, or else, entering a step 3; step 2, performing stability control construction; step 3, determining a primary supporting scheme; step 4, excavating the tunnel, and performing primary supporting construction; step 5, performing secondary lining construction on the tunnel. The water-rich weak surrounding rock long-big tunnel construction method is simple in step, reasonable in design, simple and convenient to construct, good in using effect, capable of meeting construction requirements of water-rich weak surrounding rock long-and-big tunnels, short in construction period and safe in construction process.

Owner:CHINA RAILWAY 20 BUREAU GRP

Rotary type viscous fluid damper

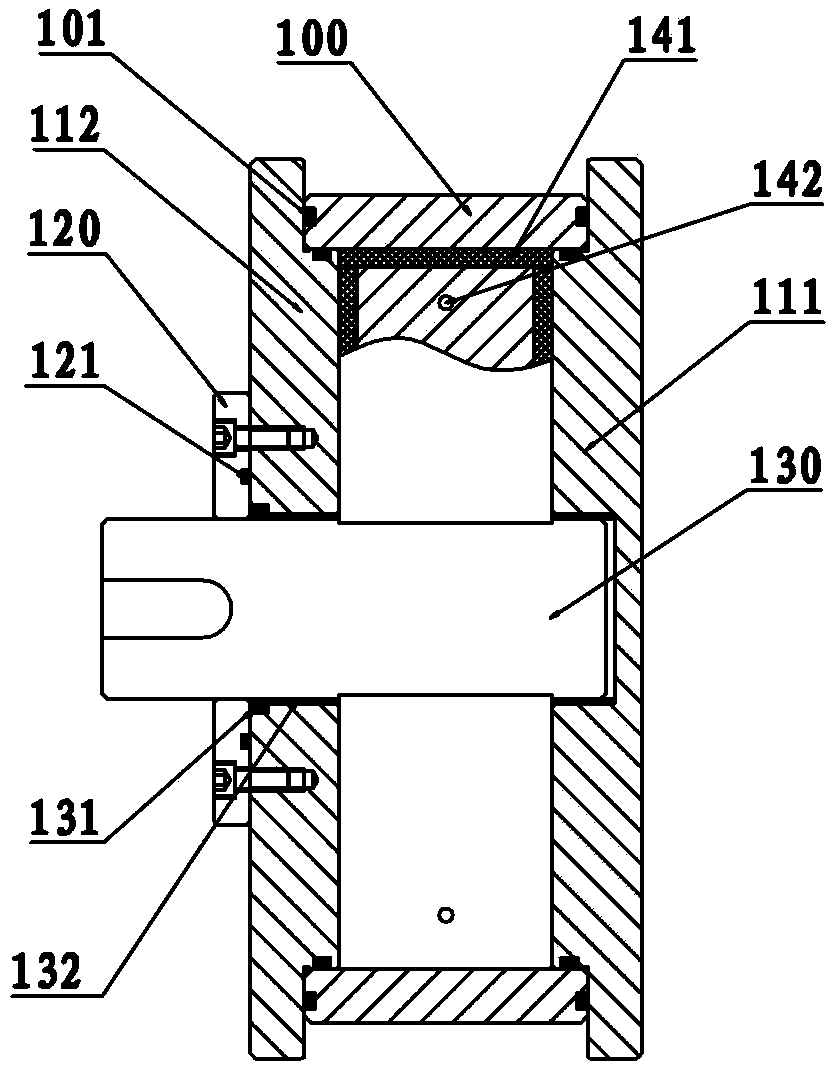

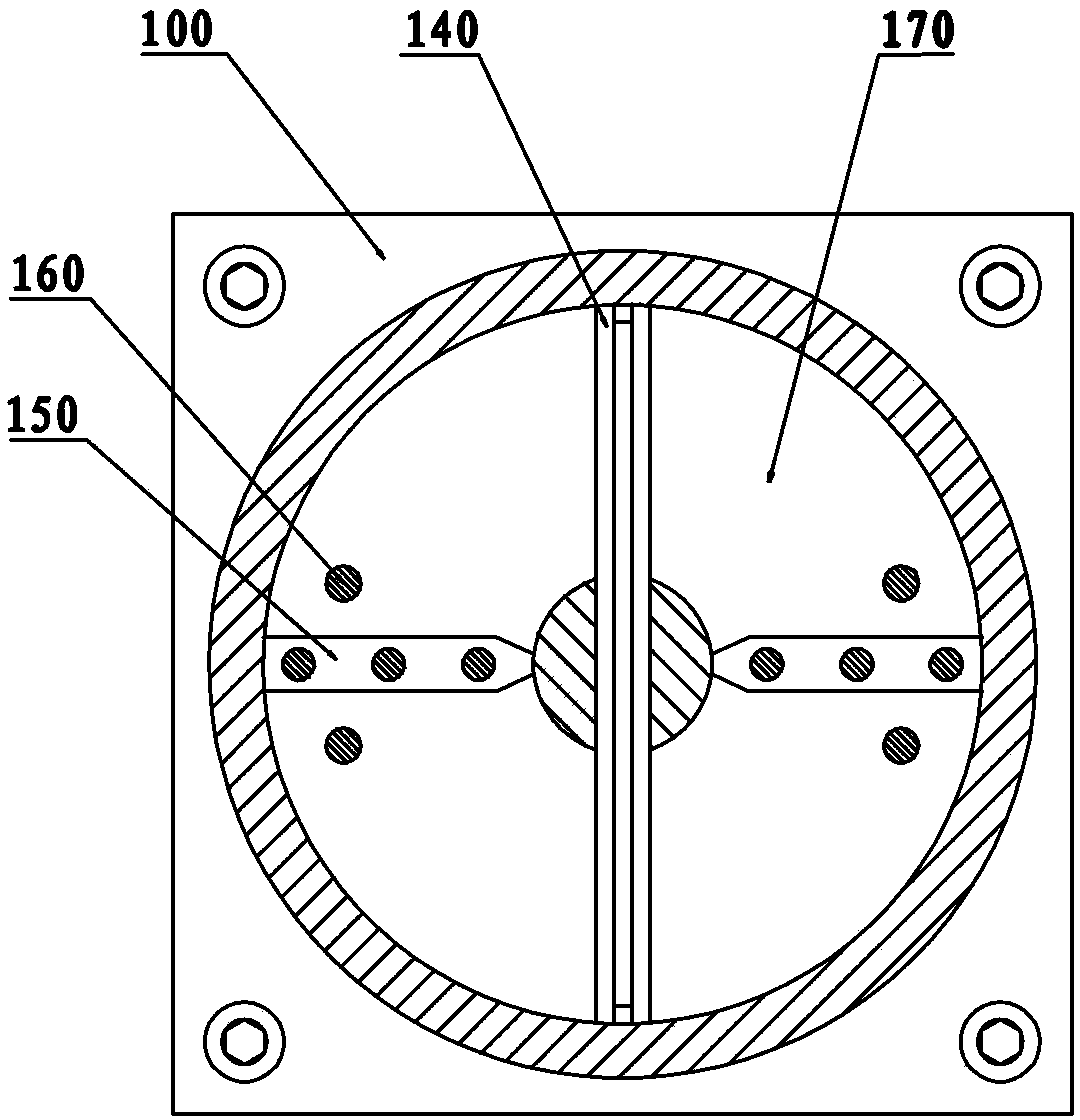

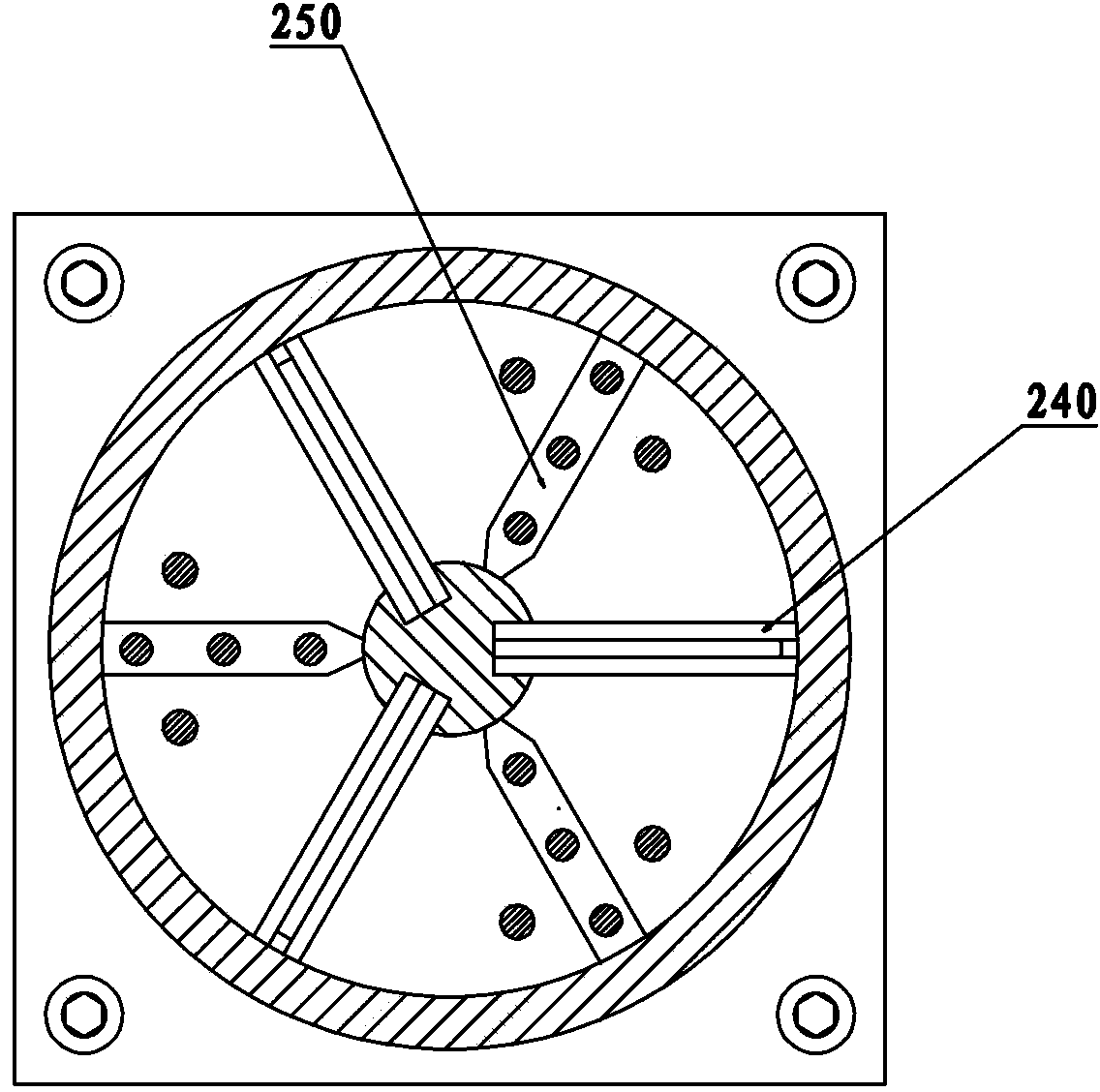

InactiveCN103388360AGood resistance to torsional vibrationMeet construction requirementsShock proofingEngineeringFront and back ends

The invention relates to the design field of dampers, in particular to a rotary type viscous fluid damper, which comprises a cylinder body, a front guide sleeve, a rear guide sleeve, a cavity dividing block, a rotary blade and a rotary shaft, wherein the front guide sleeve and the rear guide sleeve are respectively arranged on front and back ends of the cylinder body so as to form a closed space; the rotary blade, the rotary shaft and the cavity dividing block are simultaneously arranged in the closed space; one end of the rotary shaft penetrates through a central point of the front guide sleeve; the other end of the rotary shaft is movably connected with a central point of the rear guide sleeve; the rotary blade is arranged on the side face of the rotary shaft; the cavity dividing block is simultaneously connected with the front guide sleeve and the rear guide sleeve, and divides the closed space into spaces with equal volume; damping holes are arranged on the rotary blade; and damping medium are filled in the closed space. Through applying the technical scheme, the damping effect is better, and the size is smaller.

Owner:刘康安

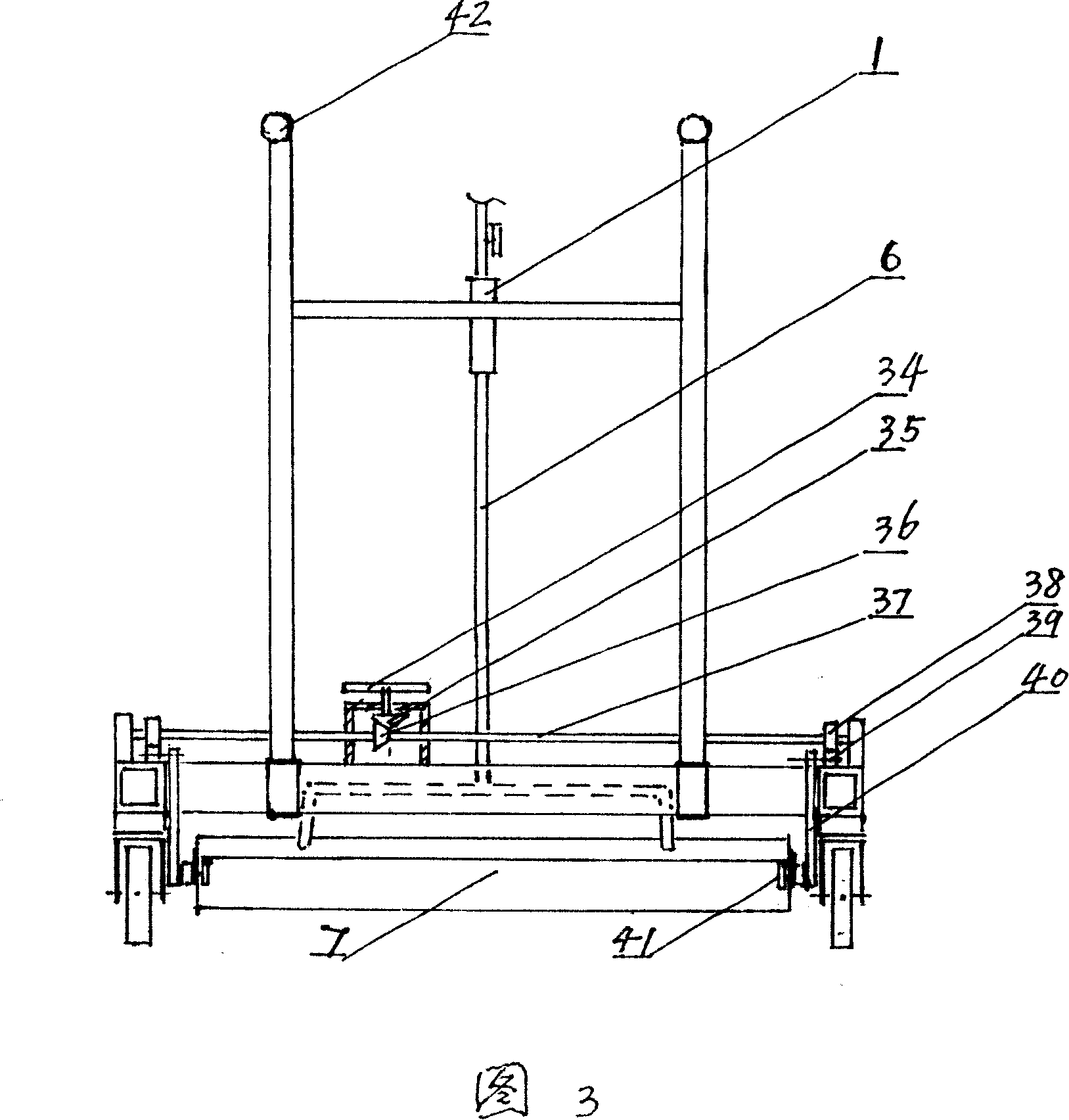

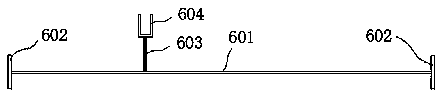

Control device of flatness and elevation of cast-in-place concrete ground surface and method for construction

InactiveCN101748896AEffective control of flatnessMeet construction requirementsRoads maintainenceBuilding material handlingEngineeringCushion

The invention relates to a control device of the flatness and the elevation of a cast-in-place concrete ground surface, which comprises a master groove steel mould, a mater groove steel bracket for fixing the master groove steel mould, and a bracket fixing piece, wherein the master groove steel mould is provided with n groups of module elevation adjusting mechanisms; each group of the module elevation adjusting mechanism comprises a support cushion plate and a set of adjusting bolt which consists of a support screw rod, a fastening cushion ring and an adjusting screw cap; and the support cushion plate is put into a gap between the master groove steel mould and the foundation. The method for controlling the flatness and the elevation of the cast-in-place concrete ground surface with the control device comprises the following steps: installing n groups of the module elevation adjusting mechanisms on the master groove steel mould; measuring the elevation of the top of a supporting and baffling concrete mould, and adjusting the elevation of the supporting and baffling concrete mould with the module elevation adjusting mechanisms; and locking the master groove steel mould to guarantee the flatness and the elevation of the cast-in-place concrete ground surface. The control device has simple structure, convenient construction method, and can effectively control the precision of the flatness and the elevation of the cast-in-place concrete ground surface, wherein n equals to 2-150.

Owner:广西建工第五建筑工程集团有限公司

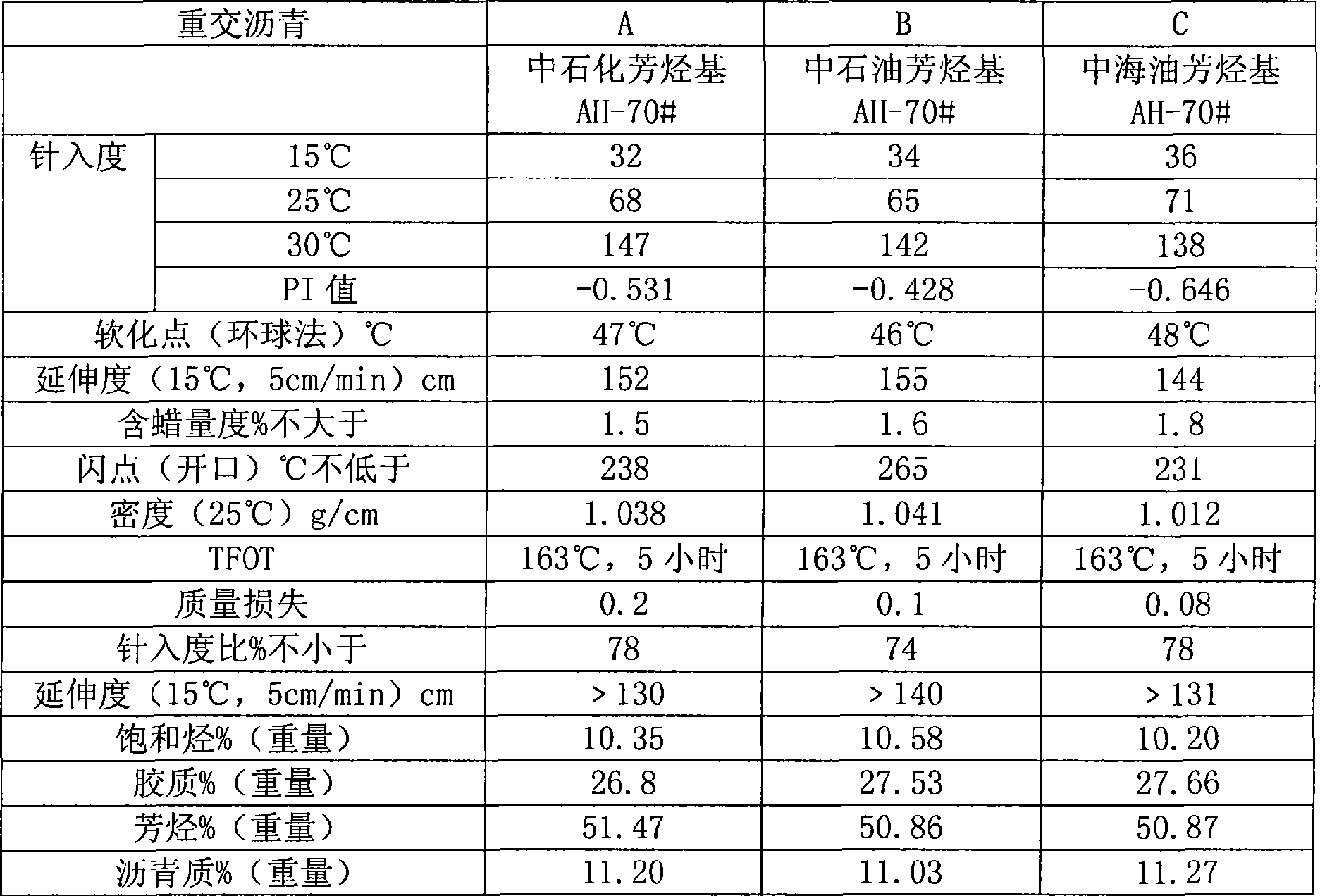

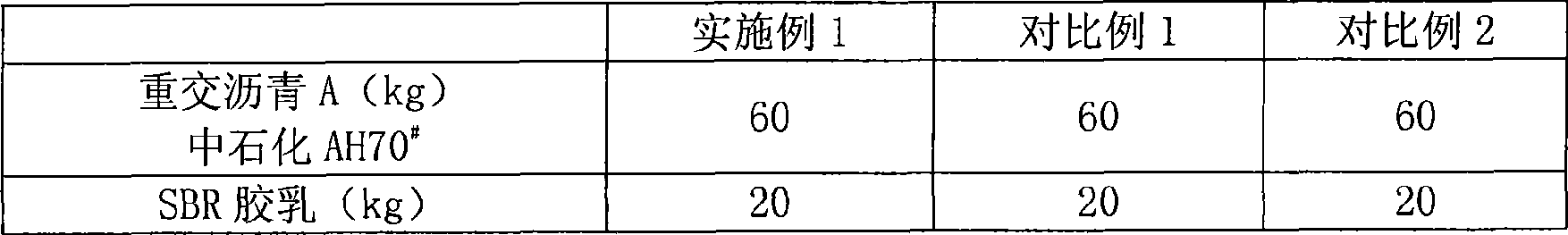

High strength cold state asphalt fissure cementation water-proof glue and preparation thereof

ActiveCN101475748AGood anti-aging performanceImprove high temperature performanceOther chemical processesBuilding insulationsTO-18Adhesive

The invention relates to high-strength cold asphalt crack-pouring waterproof adhesive and a preparation method thereof. The waterproof adhesive comprises the following components in portion by weight: 15 to 20 portions of modifier polymer, 2.0 to 3 portions of dispersant, 0.5 to 2.0 portions of stabilizing agent, 50 to 60 portions of heavy rubber asphalt, 1.5 to 2.0 portions of emulsifying agent, 15 to 18 portions of purified water, and 4 to 16 portions of curing agent. The waterproof adhesive has the advantages of simple preparation, reliability and excellent properties, can be widely applied to crack pouring for large traffics in cities and countryside, heavy loading high-grade roads, stress absorbing structural layers, waterproof and mist sealing layers or layer sealing mat coats and the like, and remarkably improves water proofing, skid resistance, flatness and abrasion resistances of the roads.

Owner:钦兰成

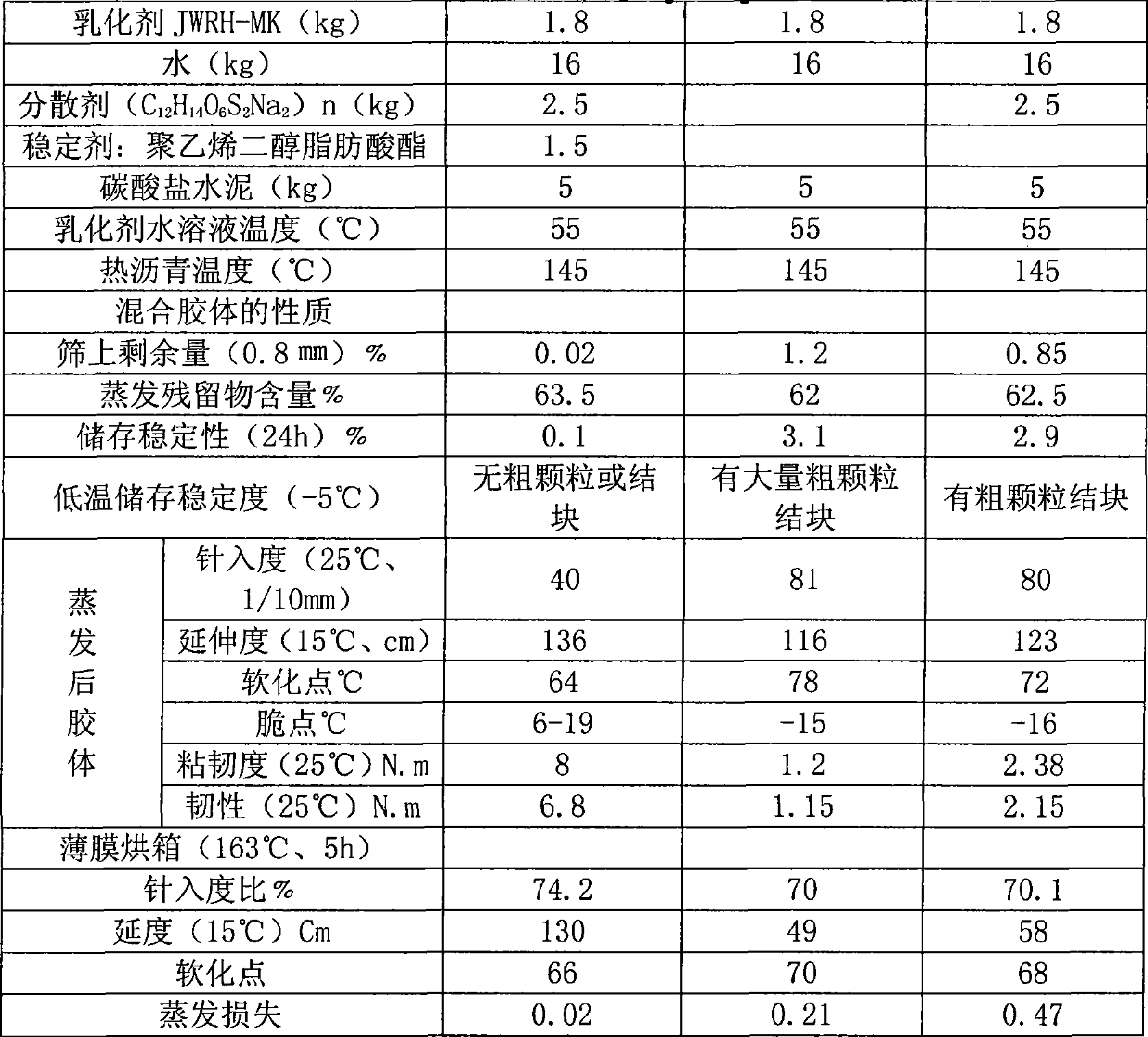

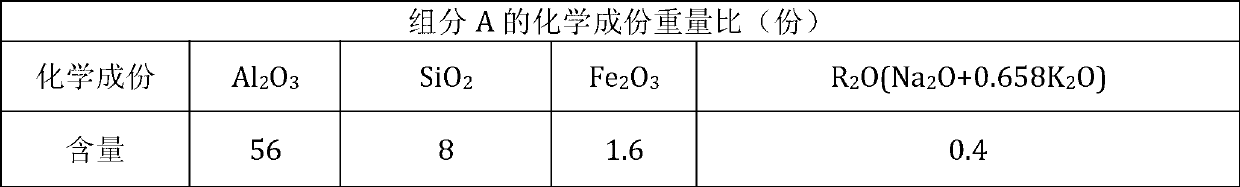

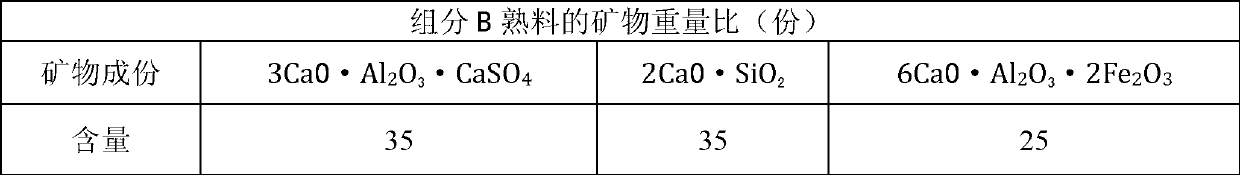

High-temperature-resistant non-silicate cement paste system for cementing thermal production well of thickened oil

ActiveCN102994058AAdjustable density and thickening timeGood liquidityDrilling compositionSilicate CementHeat regulation

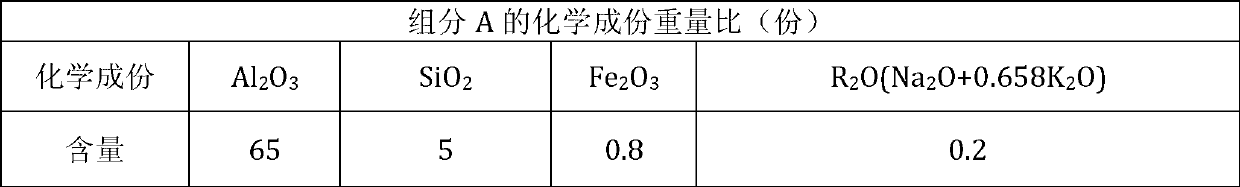

The invention relates to a high-temperature-resistant non-silicate cement paste system for cementing a thermal production well for thickened oil. The high-temperature-resistant non-silicate cement paste system is composed of the following components in parts by weight: 100 parts of high-temperature-resistant cement, 1.0-4.0 part(s) of fluid loss agent, 1.0-4.0 part(s) of dispersant, 0.5-3.0 part(s) of thickening time control agent, 60-120 parts of water and 15-80 parts of heat regulators, wherein the high-temperature-resistant cement is formed by mixing components A and B, the component A comprises 50-77 parts of Al2O3, 0.5-8.0 part(s) of SiO2, 0.5-2.5 part(s) of Fe2O3 and 0-0.4 part of R2O(Na2O+0.658K2O), and the component B comprises 33-63 parts of 3CaO.Al2O3.CaSO4, 14-37 parts of 2CaO.SiO2 and 15-35 parts of 6CaO.Al2O3.2Fe2O3. The high-temperature-resistant non-silicate cement paste system disclosed by the invention has great significance to enhancement of safe and efficient development of the thickened oil and has broad market prospect.

Owner:SOUTHWEST PETROLEUM UNIV

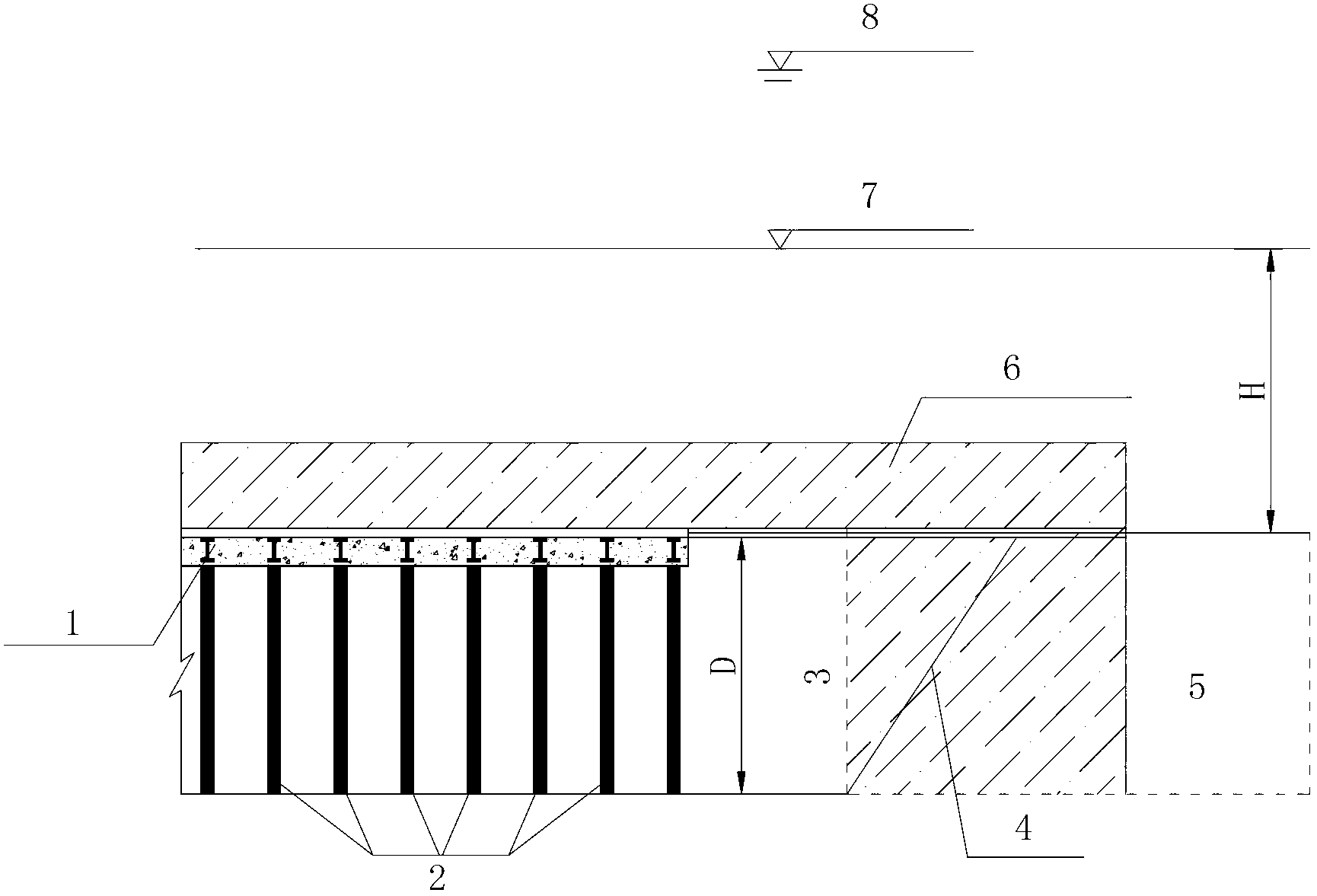

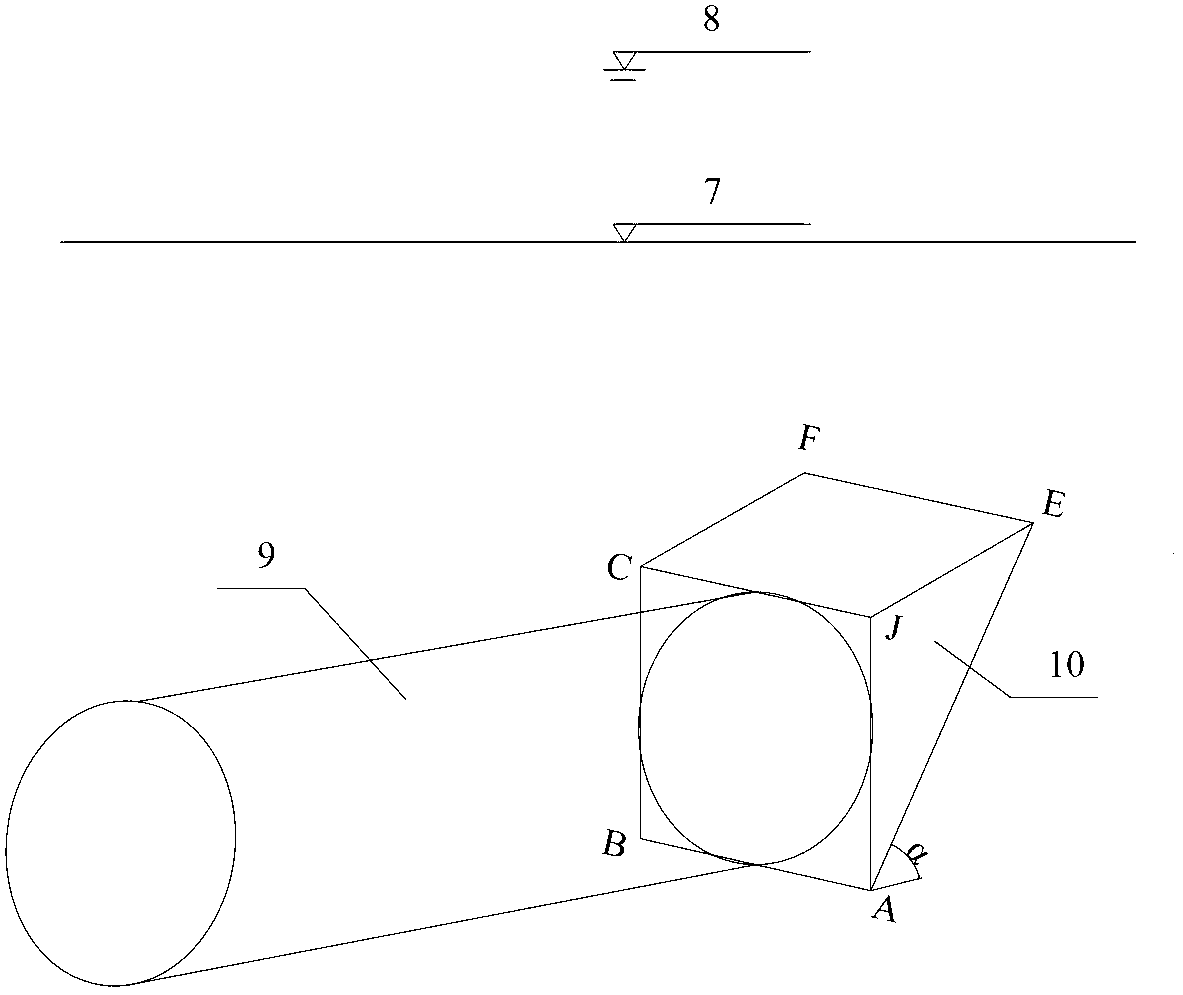

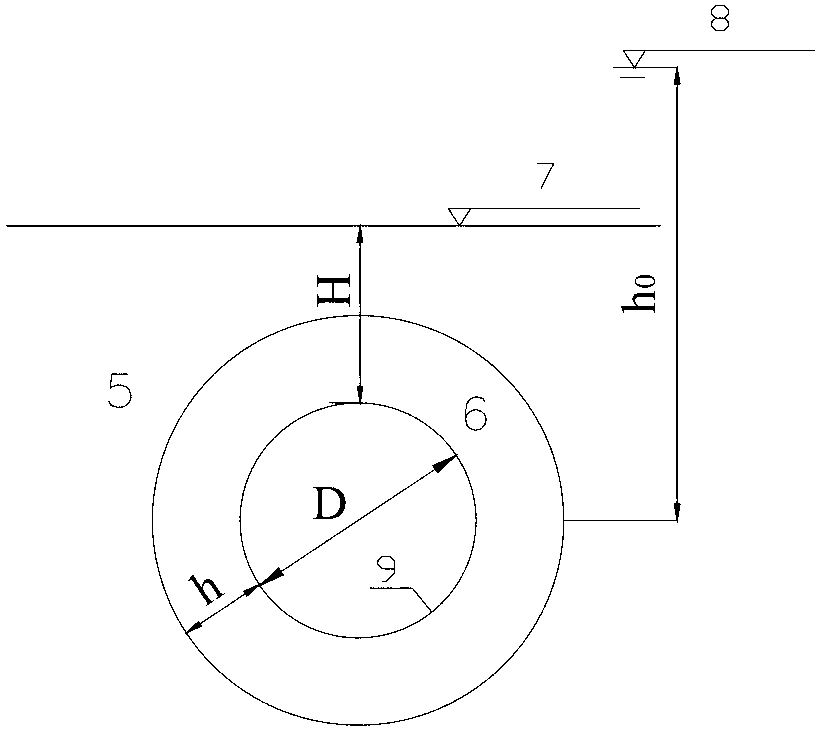

Method for designing thickness of underwater tunnel subsurface excavated construction grouting reinforcement ring

InactiveCN102704947AEnsure construction safetyLow costUnderground chambersTunnel liningLeast squaresStability factor

The invention discloses a method for designing the thickness of an underwater tunnel subsurface excavated construction grouting reinforcement ring. The method is characterized by comprising the following steps of: 1, selecting a group of reinforcement ring thickness parameters, and calculating the stability factors of a tunnel construction working surface under different reinforcement ring thickness conditions; 2, obtaining a reinforcement ring thickness-stability factor regression curve according to a least squares method based on different reinforcement ring thicknesses and corresponding stability factors; and 3, obtaining a reinforcement ring thickness required by a tunnel under a certain designed stability factor condition according to the reinforcement ring thickness-stability factor regression curve. A reinforcement ring thickness is obtained with the method for designing the thickness of the underwater tunnel subsurface excavated construction grouting reinforcement ring, so the field engineering construction requirements can be met, the construction safety of the tunnel can be ensured, and the engineering cost can be reduced.

Owner:CENT SOUTH UNIV

Modularized and integrative disassembling and installing methods for blast furnace

InactiveCN102146488ASatisfy construction safetyMeet construction requirementsBlast furnace componentsBlast furnace detailsCast houseBuilding construction

The invention relates to the installation method field of smelting equipment of iron, in particular relates to modularized and integrative disassembling and installing methods for a blast furnace. The modularized and integrative disassembling method for the blast furnace comprises: disassembling a furnace top system, disassembling a hot wind surrounding pipe, disassembling a layer beam and casting house platform and disassembling a furnace body. The modularized and integrative disassembling method is characterized in that when the furnace top system, the hot wind surrounding pipe, the layer beam and casting house platform and the furnace body are dissembled, the modularized and integrative disassembling method is adopted. The modularized and integrative insulating method for the blast furnace comprises: installing the furnace top system, installing the hot wind surrounding pipe, carrying out furnace body construction, carrying out layer beam and casting house platform construction and carrying out finished product groove construction and is characterized in that when the furnace top system, the hot wind surrounding pipe, the furnace body, the layer beam and casting house platform and the finished product groove are installed, the modularized and integrative installing method is adopted. According to the invention, construction efficiency is high, safety is high, and production cost is reduced.

Owner:SHANGHAI BAOYE CONSTR INDAL FURNACE ENG TECH

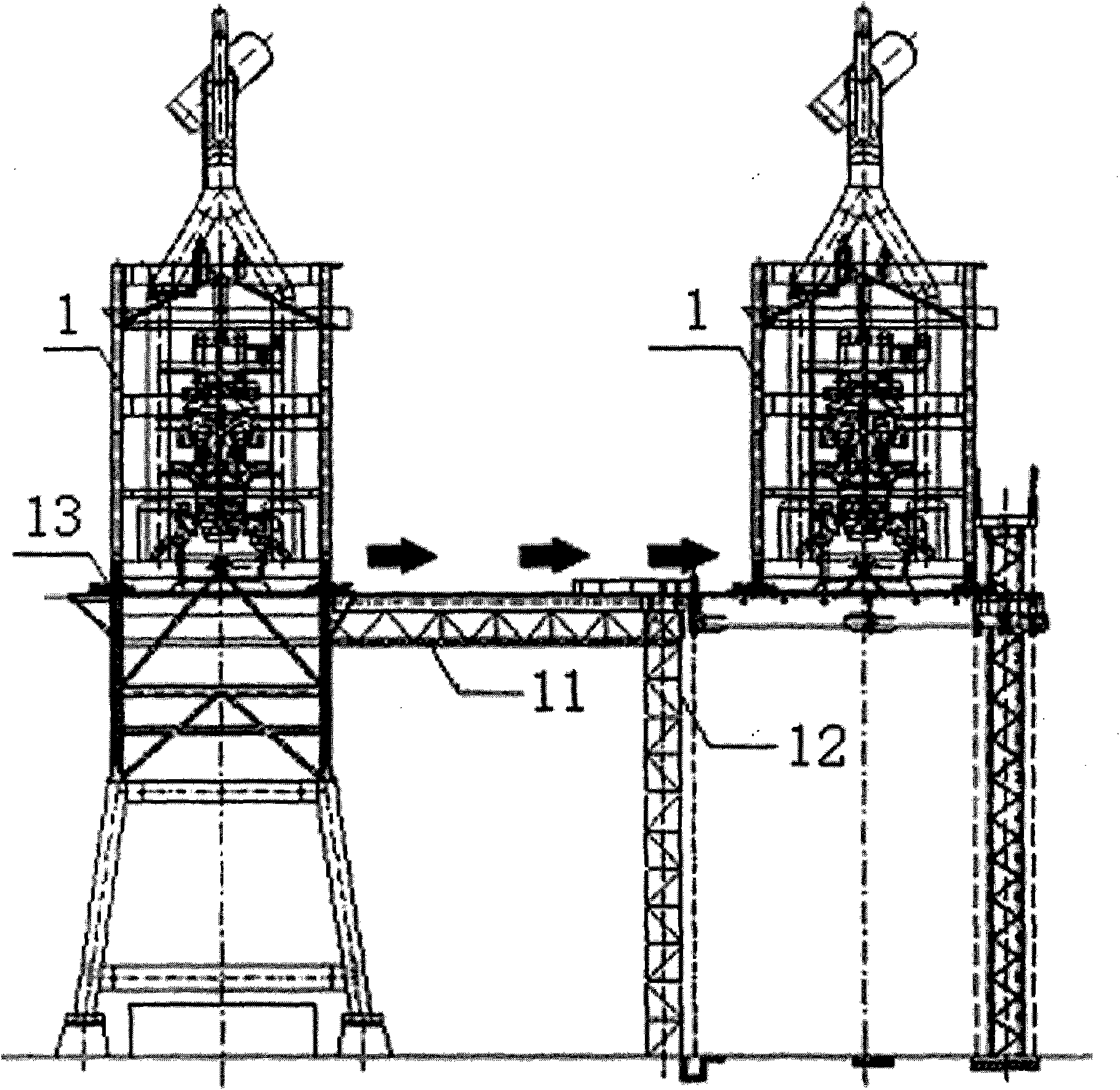

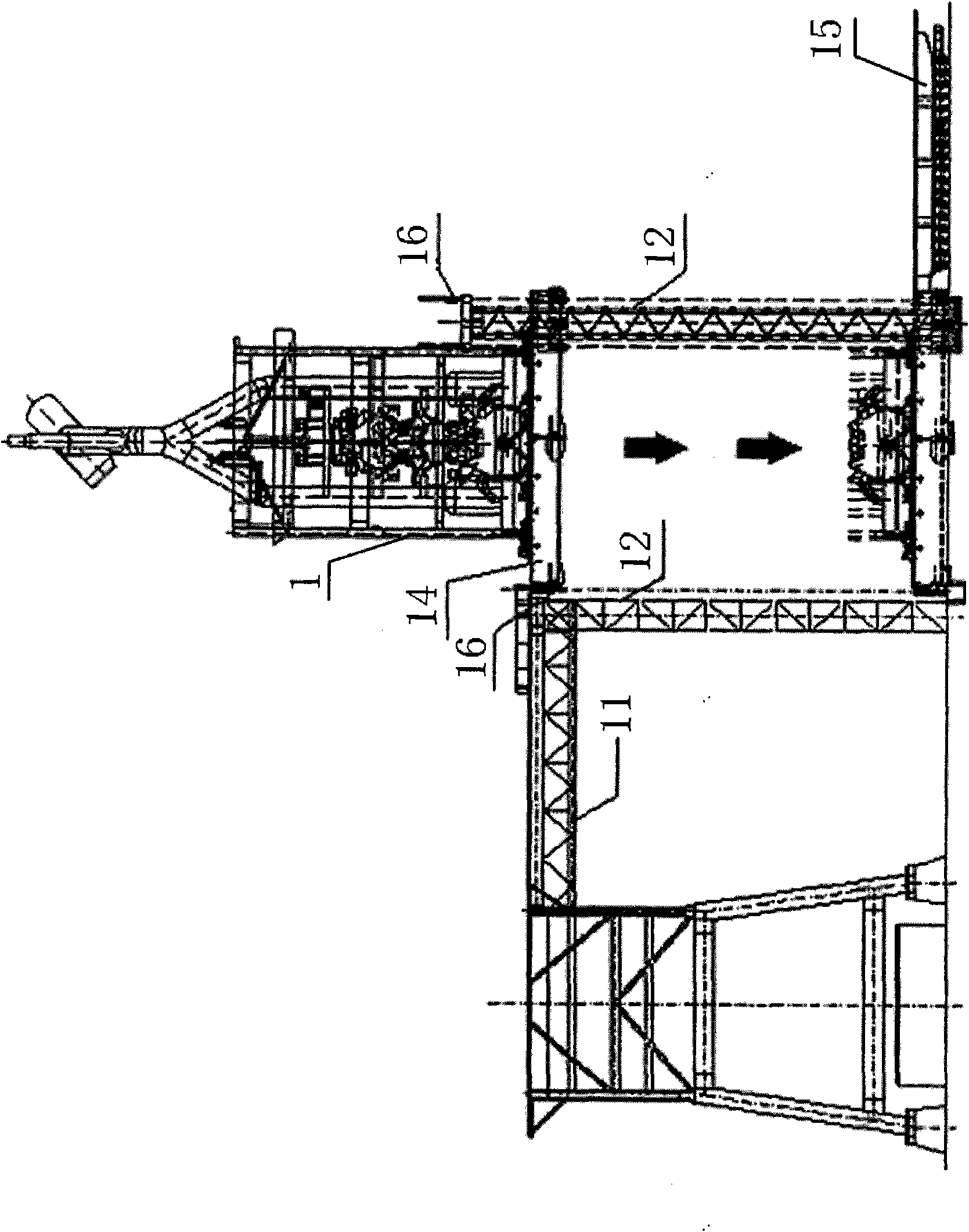

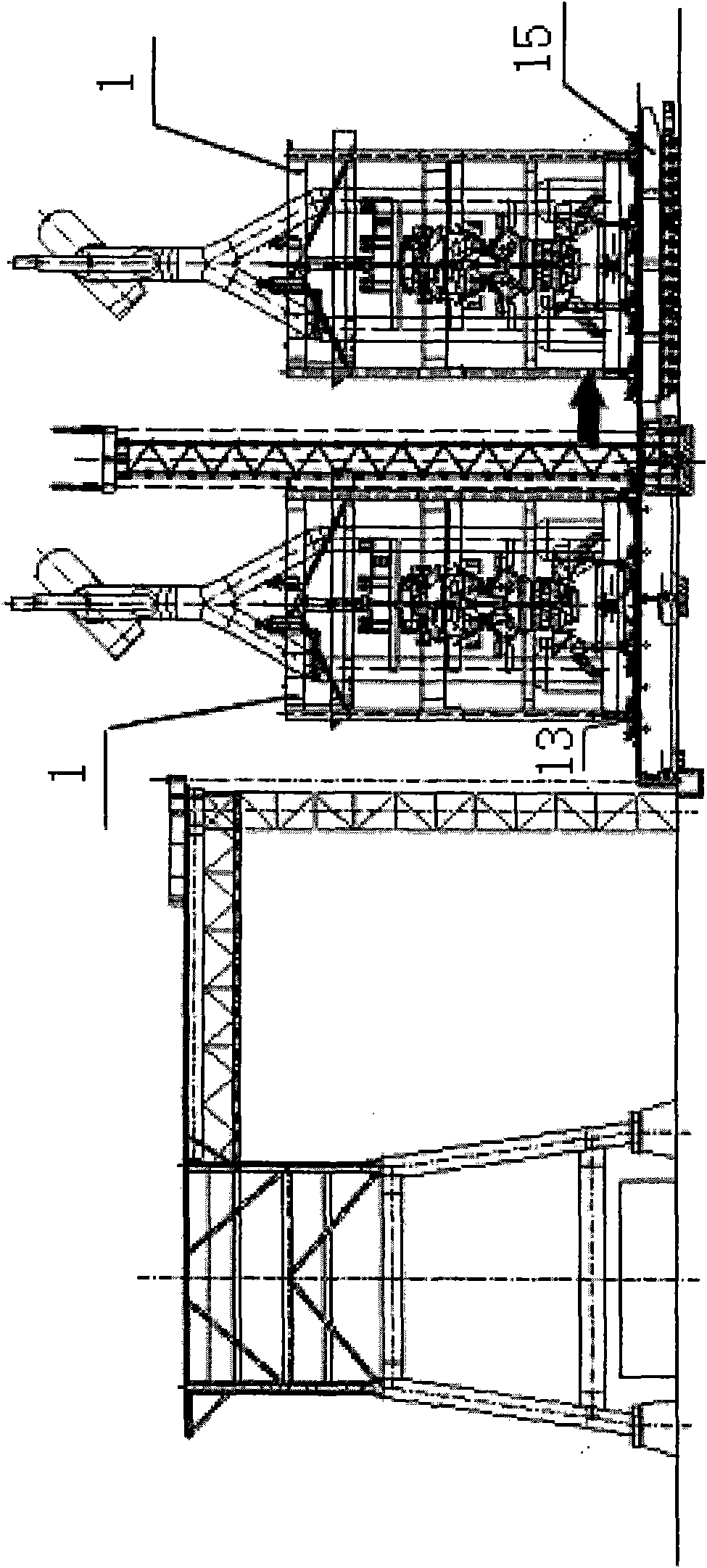

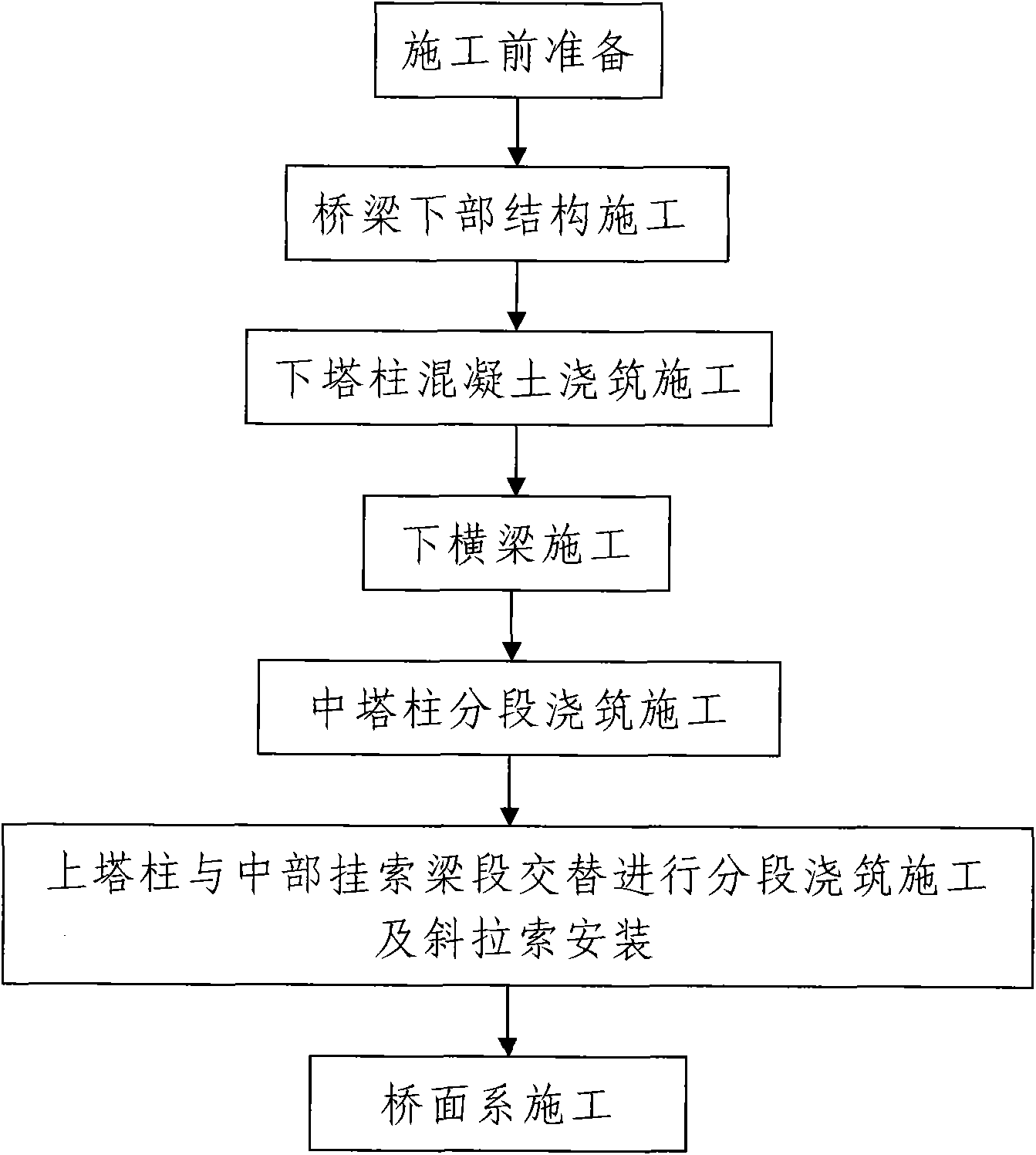

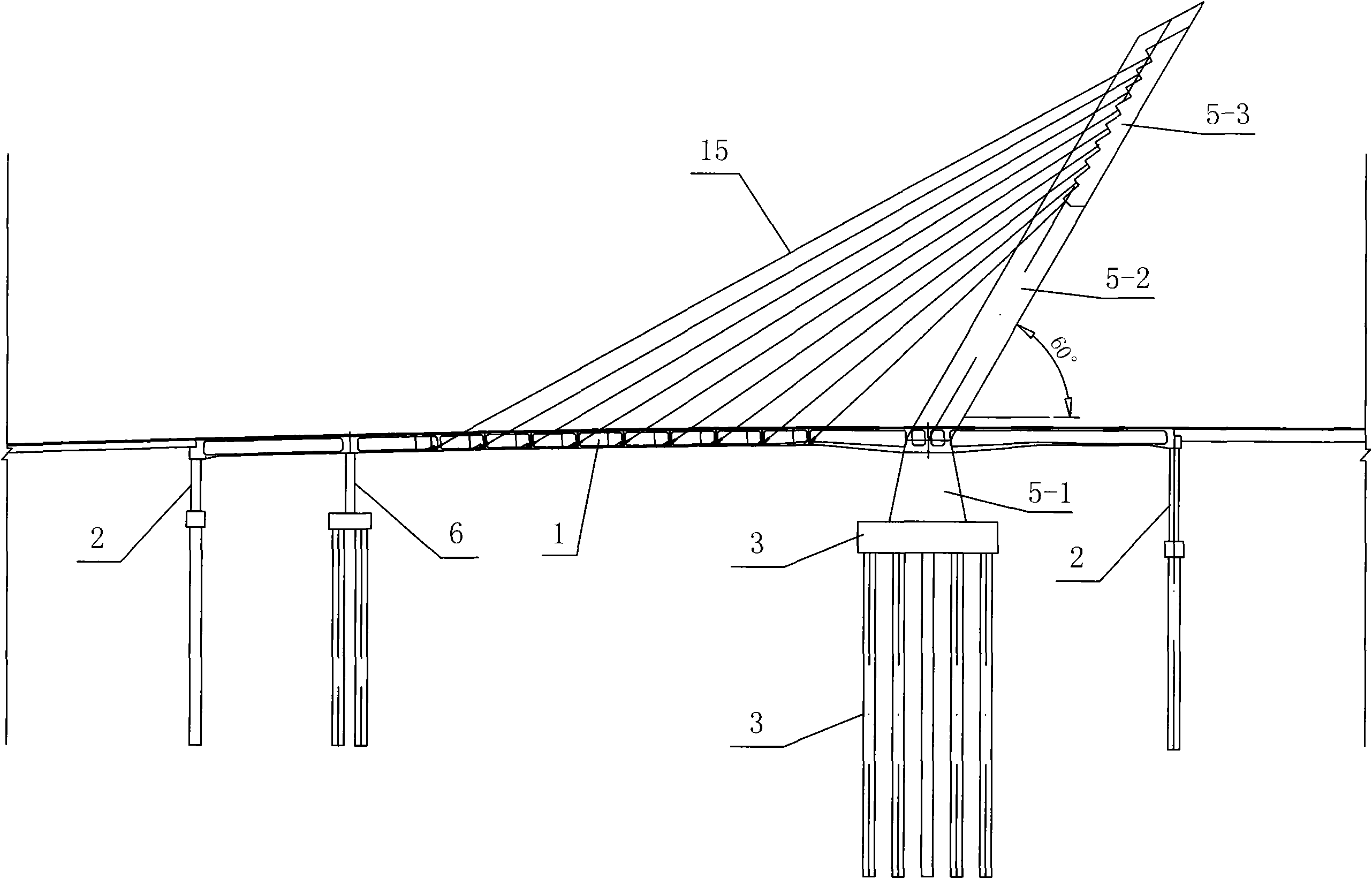

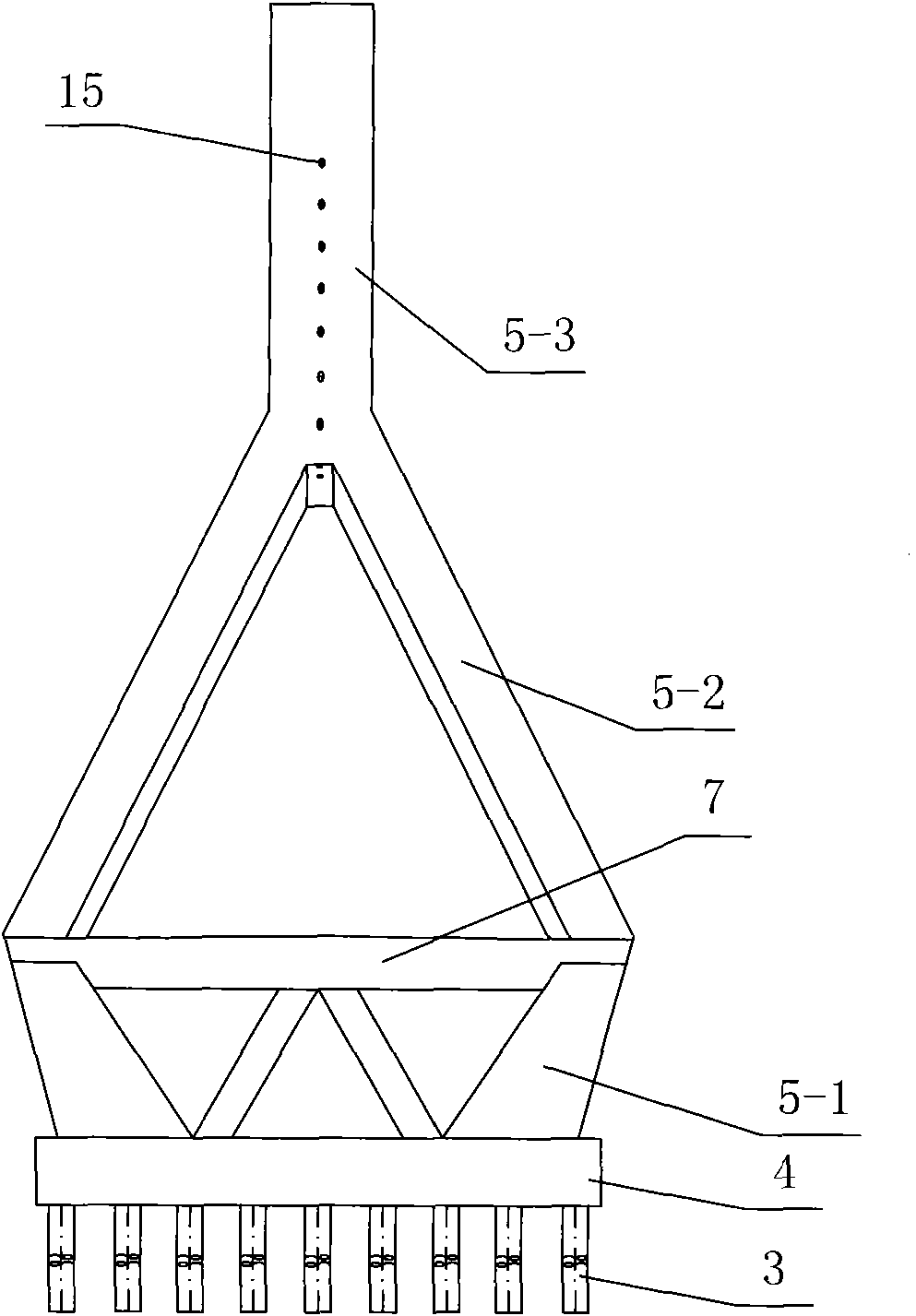

Construction method of single-pylon cable-stayed bridge without dorsal cables

ActiveCN101781879AStable structureGood construction performanceCable-stayed bridgeBridge erection/assemblyCable stayedSystem construction

The invention discloses a construction method of a single-pylon cable-stayed bridge without dorsal cables. The construction method comprises the following steps of: (1) preparation before construction; (2) lower bridge structure construction; (3) upper bridge structure construction, which comprises the following construction processes of: lower pylon concrete pouring construction, lower beam construction, middle pylon segmental pouring construction, alternate segmental pouring construction of an upper pylon and a middle suspension cable beam segment and stayed-cable mounting, wherein an integral lifting template is used for segmental construction on both the middle pylon and the upper pylon; and (4) bridge surface system construction. The construction method has reasonable step design, convenient construction, safe and reliable construction, high construction quality, short construction period and less and simple construction hardware equipment and can effectively overcomes the defects and deficiencies of complicated construction process, difficult guarantee of construction quality, various hardware equipment needed, and the like in the construction process of the single-pylon cable-stayed bridge without dorsal cables.

Owner:CHINA RAILWAY 20 BUREAU GRP +3

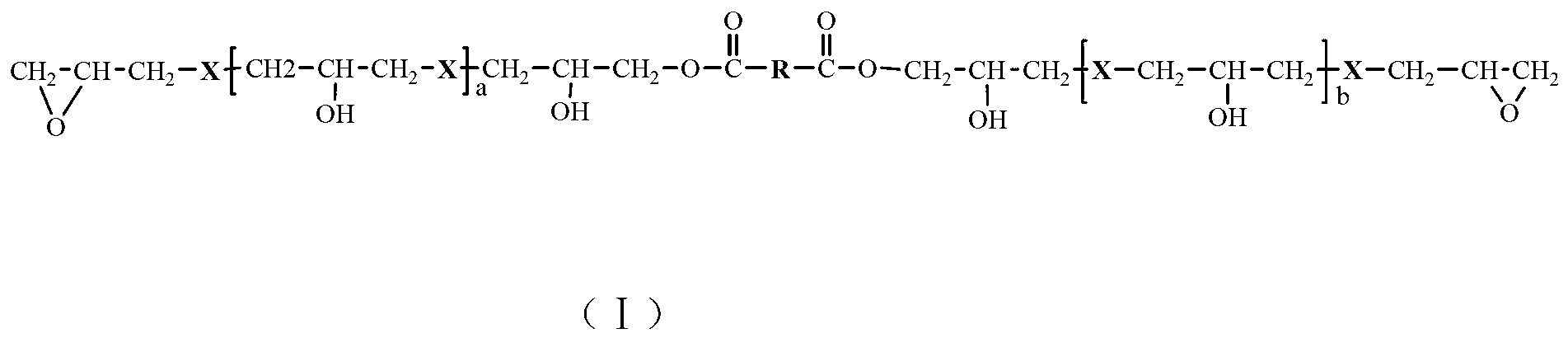

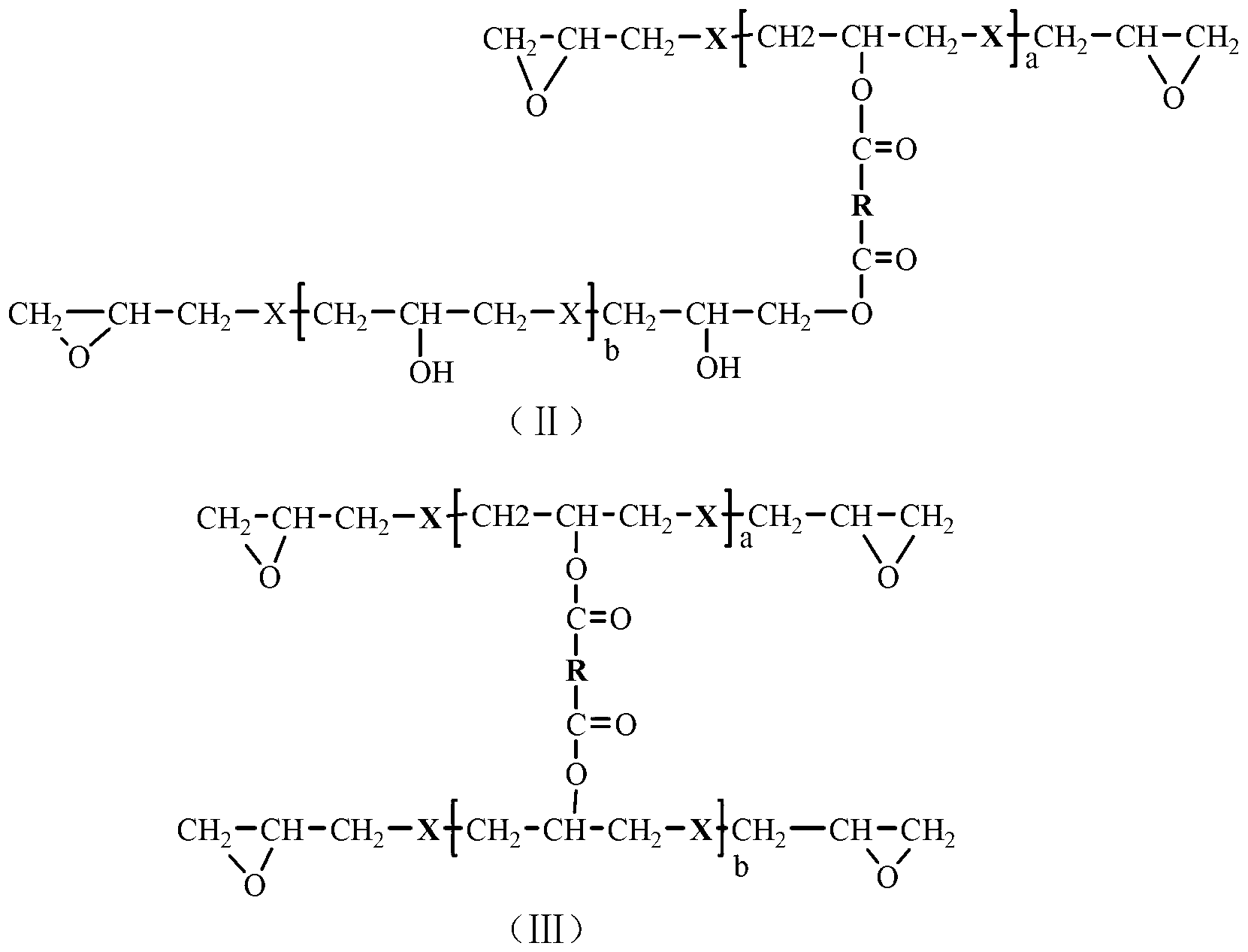

Fatty acid modified epoxy resin and preparation method thereof

ActiveCN103073701AReduce crosslink densityImproved film toughnessAnti-corrosive paintsEpoxy resin coatingsCross-linkEpoxy

The invention discloses a fatty acid modified epoxy resin and a preparation method thereof. Through uniformly mixing a liquid difunctional epoxy resin and fatty acid, reacting the liquid difunctional epoxy resin with the fatty acid under a condition with a catalyst and adding a fatty acid flexible chain segment to a low molecular weight liquid epoxy resin molecule, the cross-linking density of the obtained fatty acid modified epoxy resin after being cured is reduced, so that the toughness of a film is improved, the adhesion force of the film to a metal substrate is increased and the reaction activity of the film is not reduced; the fatty acid modified epoxy resin can be cured at a normal temperature, so that construction requirements of various heavy anti-corrosion coatings are satisfied.

Owner:EPOXY BASE ELECTRONICS MATERIAL

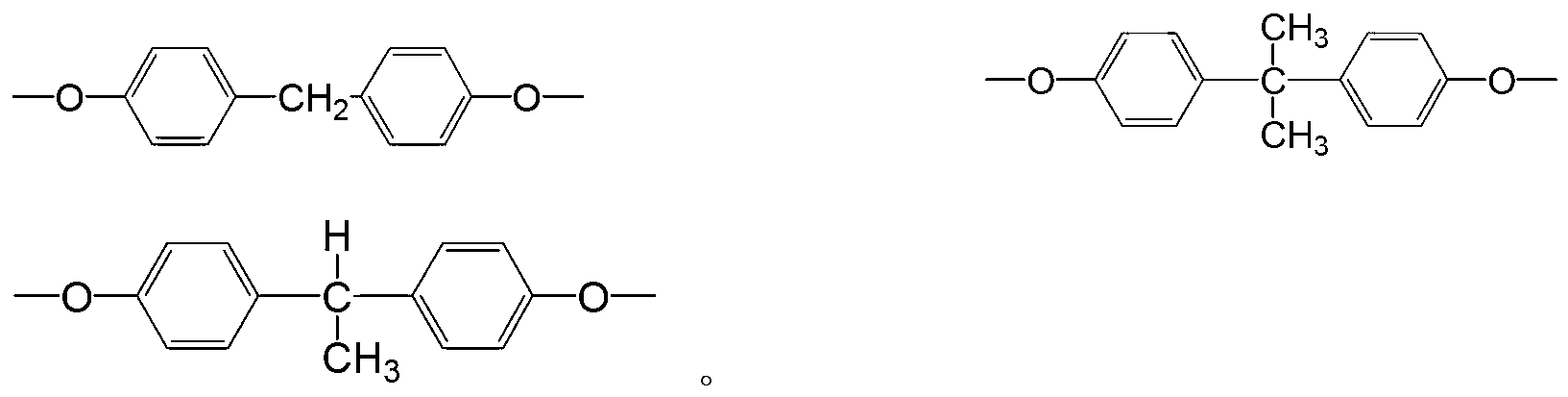

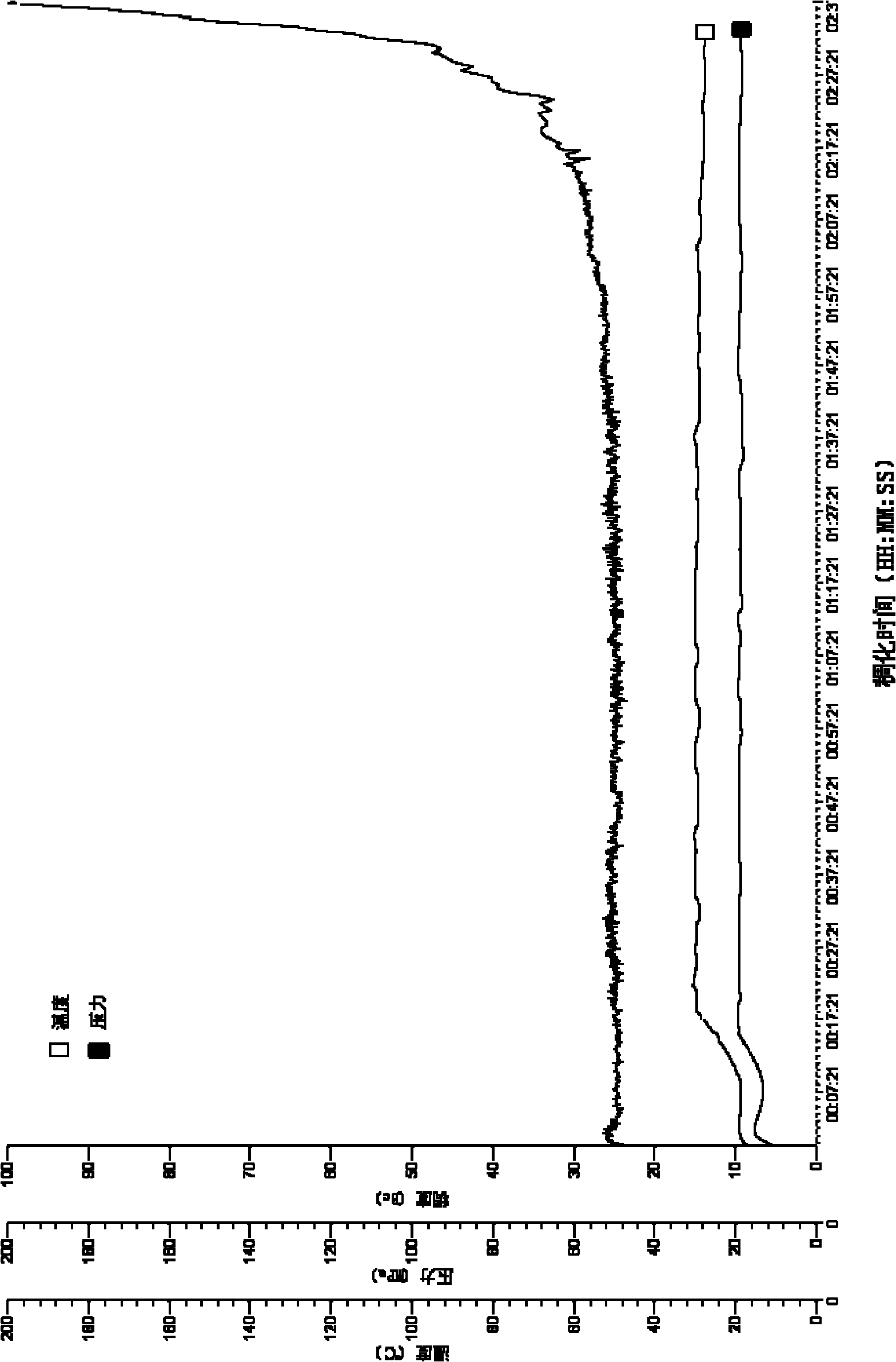

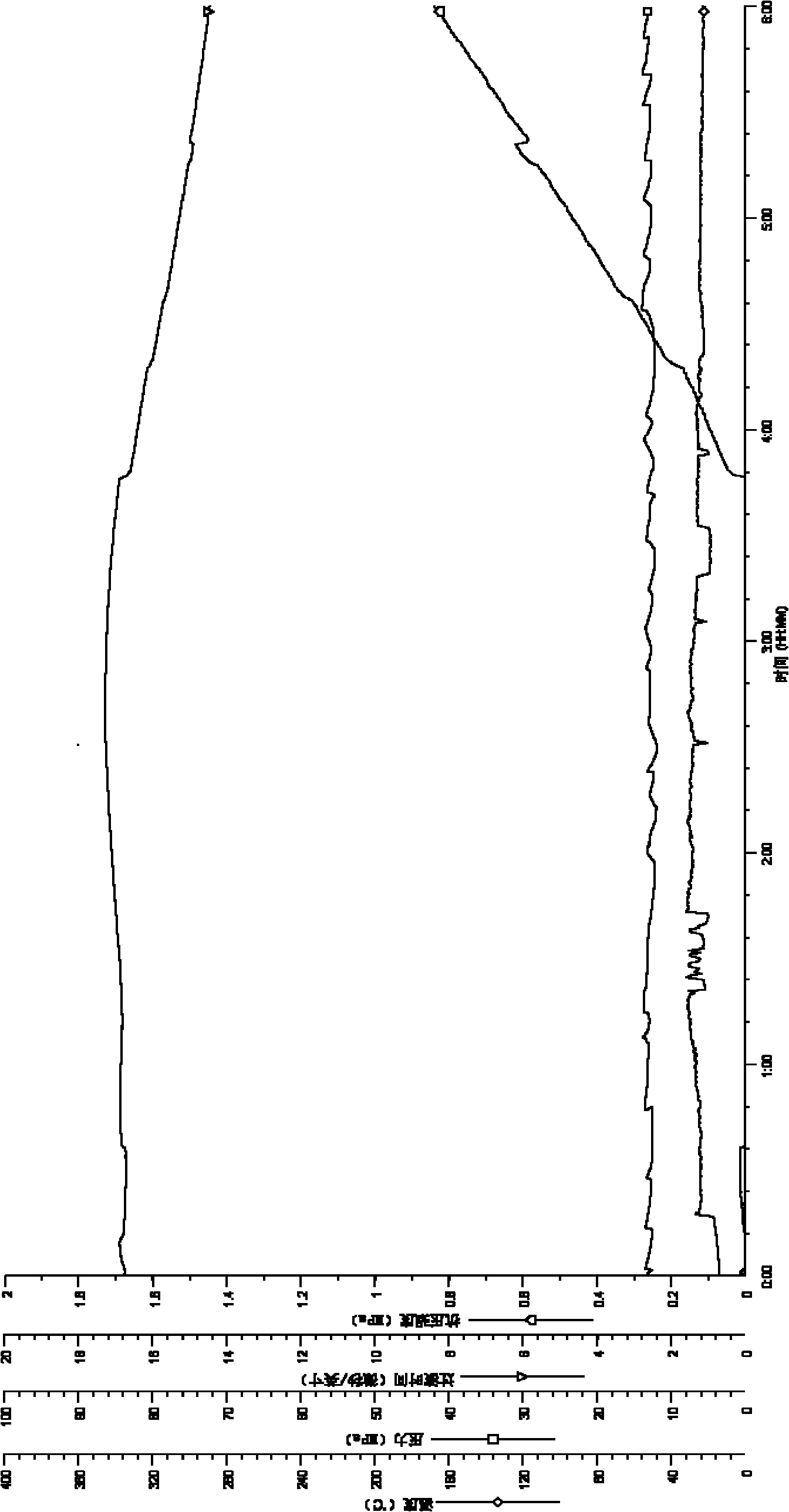

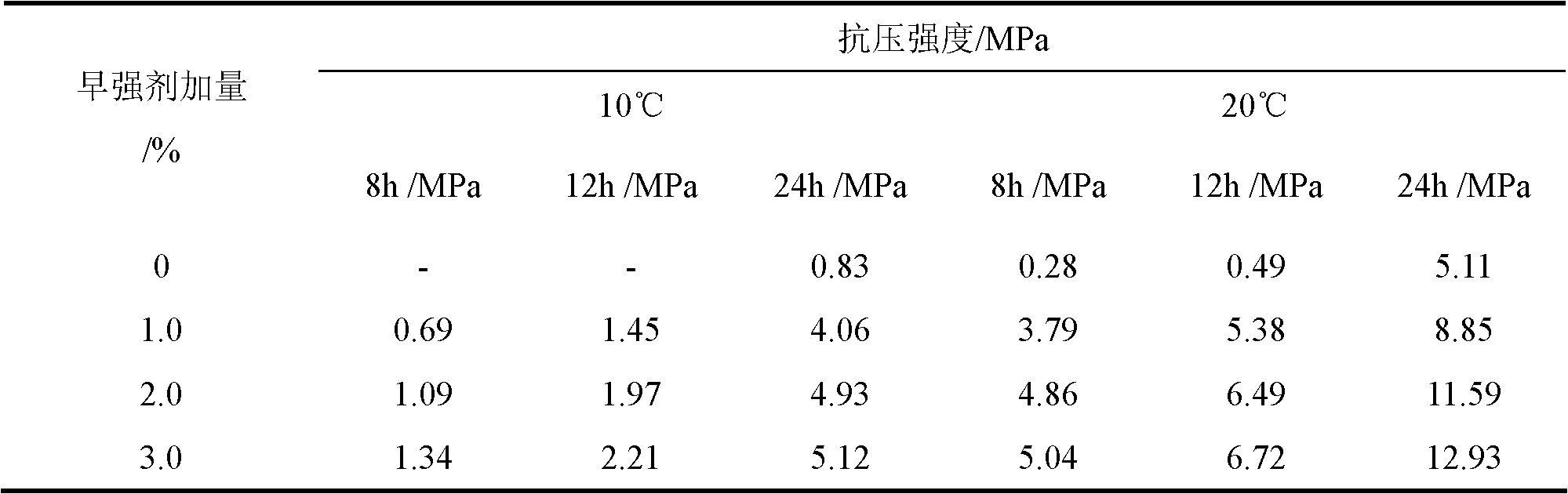

Deepwater cementing low-temperature early strength agent

InactiveCN101864285APromotes hydration processImprove compactnessDrilling compositionTriisopropanolamineCement paste

The invention relates to a deepwater cementing low-temperature early strength agent. The low-temperature early strength agent comprises the following components in percentage by weight: 33 to 66 percent of alkali metal bromides, 6 to 16 percent of sodium metaaluminate, 15 to 35 percent of alkali metal hydroxides, 8 to 15 percent of silicon dioxide and 0.8 to 1.5 percent of alcamines organics, wherein the alkali metal bromides are a mixture of one, two or more of NaBr, KBr and LiBr; the alkali metal hydroxides are NaOH, KOH or a mixture of the NaOH and KOH; and the alcamines organics are triethanolamine, triisopropanolamine or a mixture of the triethanolamine and triisopropanolamine. The deepwater cementing low-temperature early strength agent has small influence on rheological behaviour of cement paste at low temperature, can prompt the cement paste to be solidified rapidly at low temperature and reach higher early strength, shortens the thickening time of the cement paste at lower temperature and can well meet the requirements of the cementing construction of a surface casing under the conditions of low temperature, shallow gas and the like.

Owner:SOUTHWEST PETROLEUM UNIV

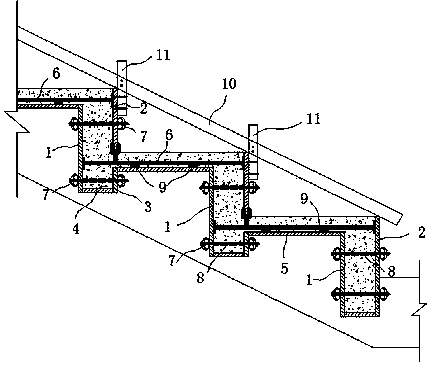

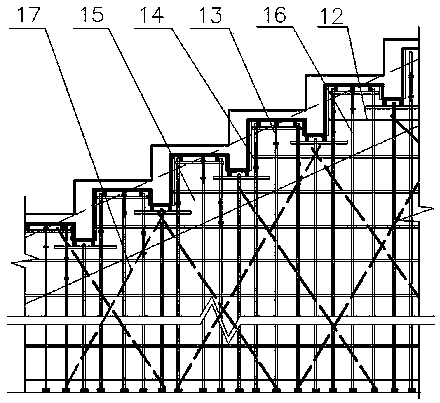

Template structure and method for template support of cast-in-place concrete arc-shaped terrace

ActiveCN103362300AMeet construction requirementsEasy constructionForms/shuttering/falseworksBuilding material handlingShaped beamEngineering

The invention discloses a template structure and a method for template support of a cast-in-place concrete arc-shaped terrace. The template structure comprises a template support frame body and a template fixing system, wherein the template fixing system comprises arc-shaped beam bottom plate templates, seat plate bottom templates, arc-shaped beam outside upper templates, arc-shaped beam outside lower templates and arc-shaped beam inside templates, wherein the arc-shaped beam outside lower templates are positioned below the arc-shaped beam outside upper templates; internal supports are arranged between the arc-shaped beam outside upper templates and the arc-shaped beam inside templates for supporting and enable the arc-shaped beam outside upper templates and the arc-shaped beam inside templates to keep set intervals; split bolts are used for connecting and fixing the arc-shaped beam outside upper templates and the arc-shaped beam inside templates; split bolts are used for connecting and fixing the arc-shaped beam outside lower templates and the arc-shaped beam inside templates; the arc-shaped beam bottom plate templates are respectively connected and fixed with the bottom ends of the arc-shaped beam outside lower templates and the arc-shaped beam inside templates; the seat plate bottom templates are respectively connected and fixed with the upper ends of the arc-shaped beam outside lower templates and the arc-shaped beam inside templates.

Owner:CHINA CONSTR SEVENTH ENG BUREAU THE SECOND CO LTD

Construction method for adding water lowering well in water collecting well

InactiveCN102433886ASimple construction methodFast constructionFoundation engineeringRebarPipe water

The invention discloses a construction method for adding a water lowering well in a water collecting well, which comprises the following steps of: driving a prepared round steel pipe water lowering well structure into a bottom wall of the water collecting well until the scale height required is met; removing the earth in the round steel pipe; refilling gravels on the bottom of the round steel pipe to form a water filtering layer; placing a water pump in the round steel pipe for pumping water according to water level situation; paving in sequence a cushion layer, a waterproof layer and a waterproof protection layer on a side wall and a bottom wall of the water collecting well for construction recovery; binding steel bars on the side wall and the bottom wall of the water collecting well out of the waterproof protection layer, and pouring concretes on the bottom wall and the side wall of the water collecting well; and blocking the top of the round steel pipe. By means of the construction method provided by the invention, the water lowering well has the advantages of simple and convenient construction method, fast construction speed, low cost and high intensity, is capable of effectively solving the problem that the water cannot be timely discharged to the specified depth below a bottom plate on the condition that a water stop curtain is slightly cracked to leak the water to damage the waterproof layer of the water collecting well nearby and satisfying the basement construction requirements, and is simple in structure.

Owner:天津住宅集团建设工程总承包有限公司

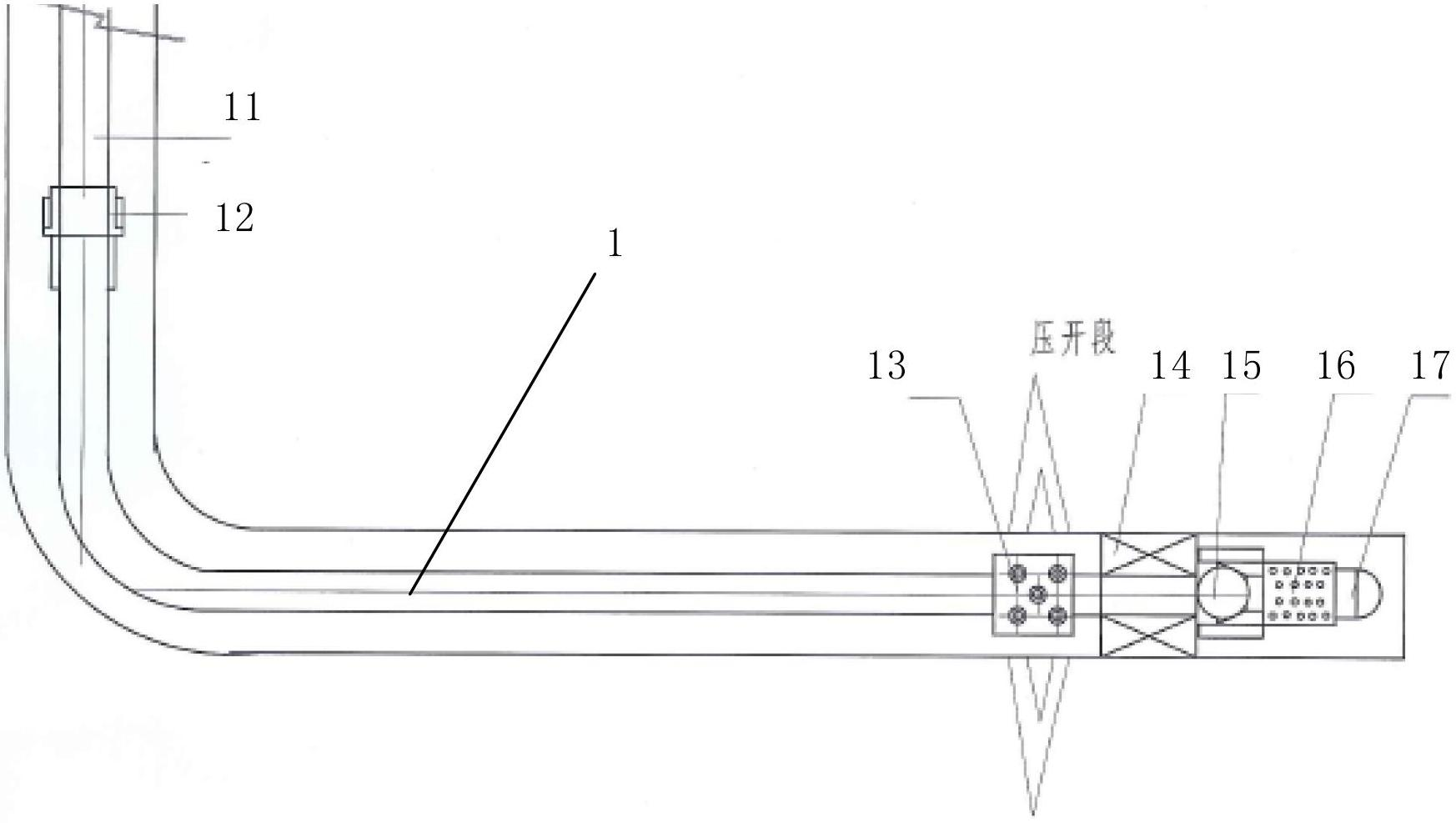

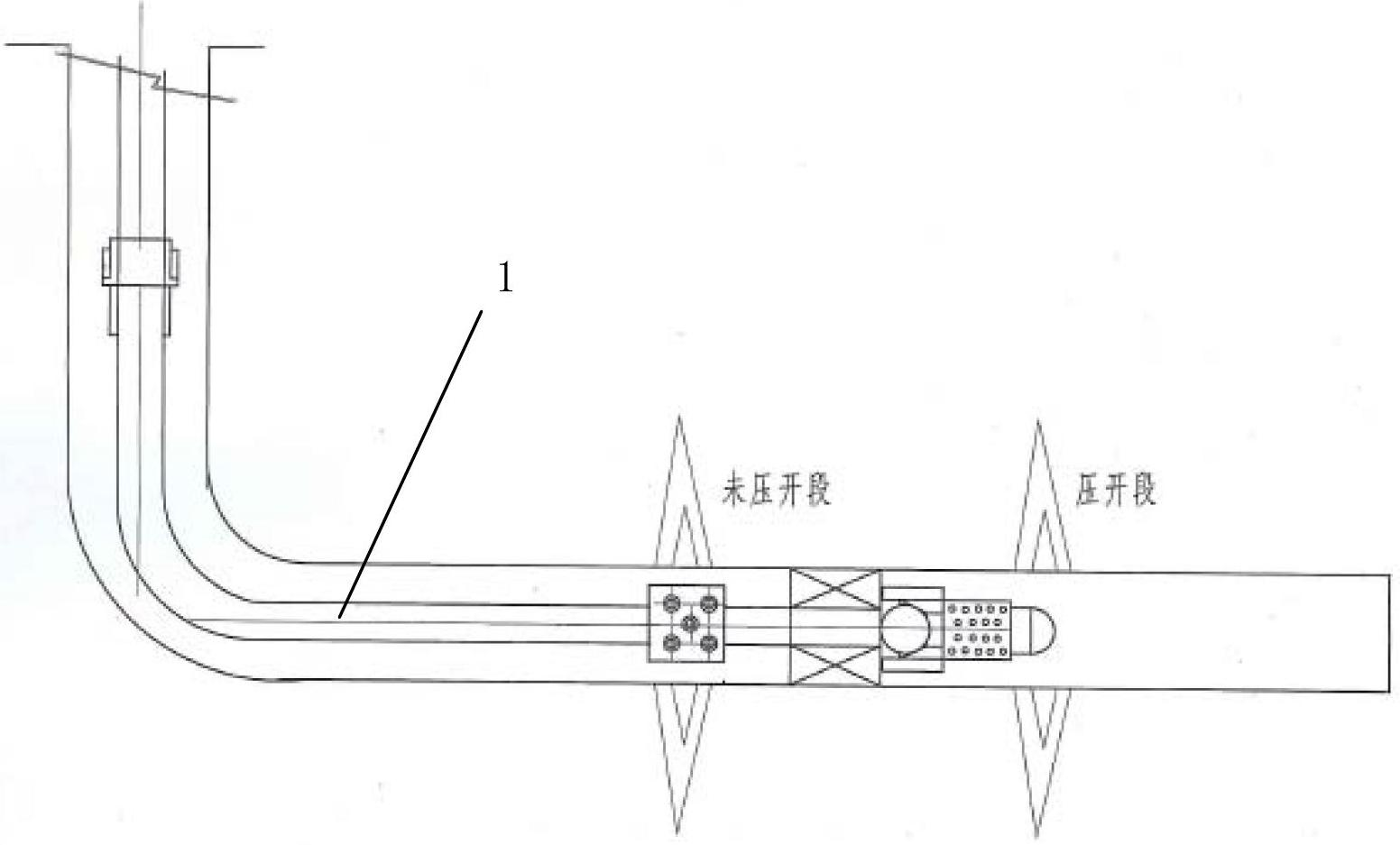

High-broken-pressure stratum horizontal well sectional-fracturing method for well cementation and completion of casing

InactiveCN102691495AMeet construction requirementsImprove efficiencyFluid removalPhysical propertyWellhead

The invention relates to a high-broken-pressure stratum horizontal well sectional-fracturing method for well cementation and completion of a casing. The high-broken-pressure stratum horizontal well section-fracturing method includes firstly perforating and fracturing all stratum layers by means of the hydraulic jetting fracturing technology for the horizontal well; then laying down a packer for fracturing a tubular pile sectionally and fracturing the stratum layers not fractured by the hydraulic jetting fracturing technology, wherein the maximum annular pressure of a well mouth is not higher than 45MPa during perforating and fracturing the tubular pile by hydraulic jetting. Hydraulic perforating and fracturing of the lower-broken-pressure stratum layers are integrated directly, construction requirements for high-broken-pressure stratum layers are met on the premise of keeping the requirements for mating of the well mouth and steel level of the casing without change or lower; for the high-broken-pressure stratum layers quite different in physical properties, hydraulic perforating is completed, and a basis is created for subsequent sectional fracturing by the packer. During sectional fracturing by the packer, the procedures of oil pipe transmission perforating and scraping can be omitted. The high-broken-pressure stratum horizontal well sectional-fracturing method for well cementation and completion of the casing has the advantages of flexibility in construction, simplicity to operate and high efficiency and safety.

Owner:PETROCHINA CO LTD

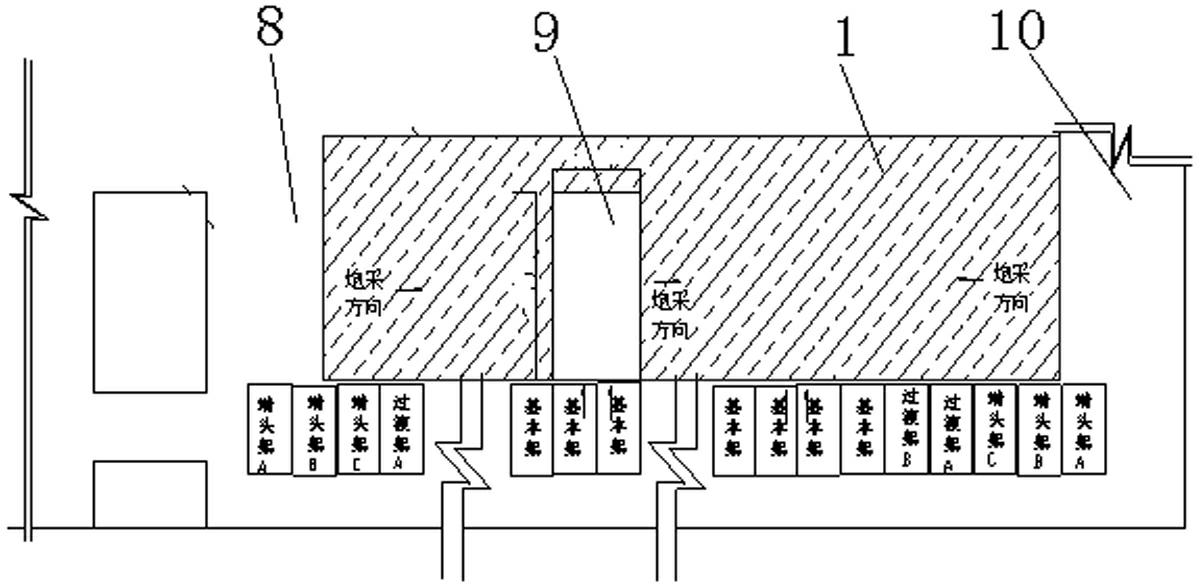

Construction method for high face mining support removing passage under complicated geological condition

InactiveCN102312676AShorten the lengthSuitable selectionProps/chocksAnchoring boltsPhysicsCoal mining

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD

Temperature resistant, non-crosslinked and biodegradable gel leak-stopping agent and preparation method thereof

ActiveCN102358771AImprove temperature resistanceMeet construction requirementsDrilling compositionFluid LeakStructure type

The present invention provides a temperature resistant, non-crosslinked and biodegradable gel leak-stopping agent and a preparation method thereof. The gel leak-stopping agent of the present invention has the following advantages that: the gel leak-stopping agent has extra-wide temperature adaptability, can adapt to a temperature range of 25-180 DEG C, and can meet requirements of oil field construction; the gel leak-stopping agent has rapid dissolution rate, and forms the structure type gel with good shear thinning behavior after dissolving, wherein the structure type gel is the liquid whichcan be pumped and flow; the gel leak-stopping agent does not require cross-linking; the real fluid leak-stopping is realized; the construction is convenient; the product is completely dissolved in water, no precipitate and flocculent insoluble matter are generated during the whole process, no insoluble matter is generated after the product is degraded, such that the flow back is easy or the flow back is not required, the reservoir is not damaged; the product is safe and environmental protection, and is synthesized by the multi-stage initiation, such that the product conversion rate is high, the stability is good, no toxic damage is generated to the stratum, the production layer can be protected.

Owner:北京爱普聚合科技有限公司

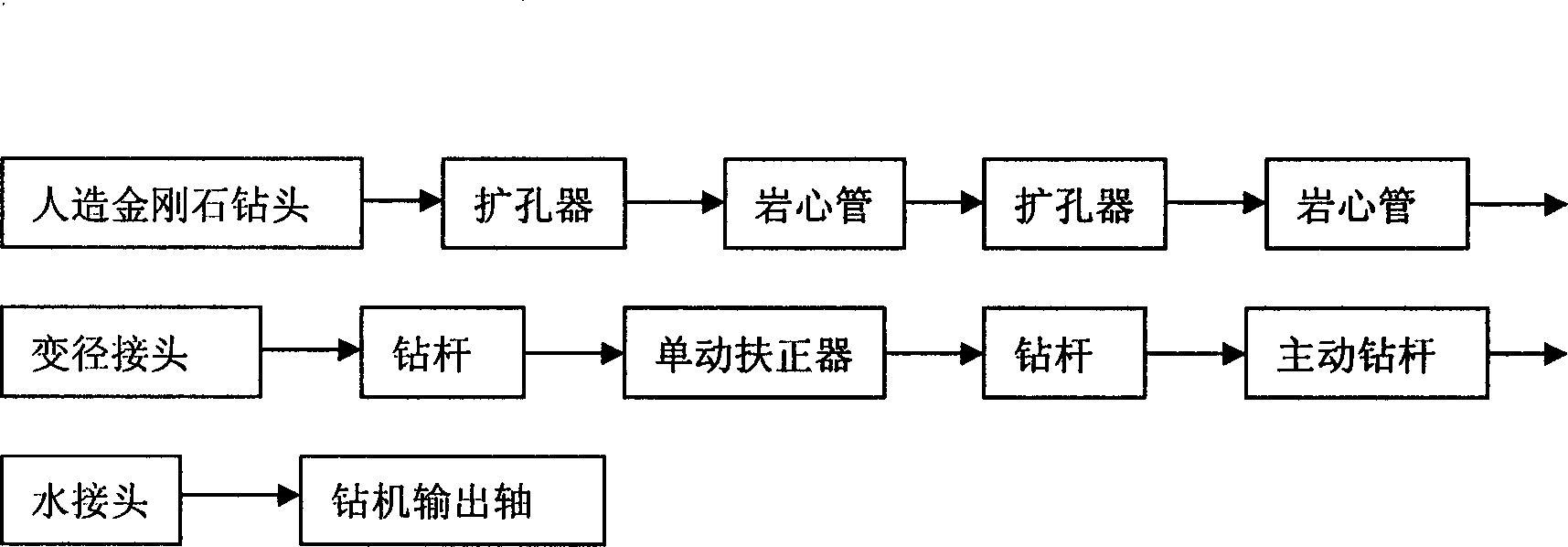

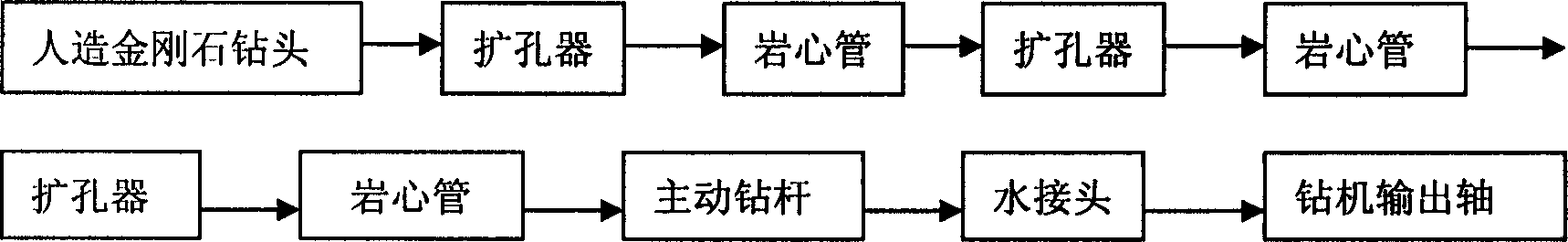

Method and apparatus for high precision horizontal drilling on reinforced concrete

ActiveCN1807827AMeet construction requirementsHigh precisionDrilling rodsDirectional drillingReinforced concreteMeasuring instrument

The invention relates to a method for processing high accuracy horizontal drilling on the concrete and relative device. The method comprises: selecting power and auxiliary device; according to the size and depth of drill hole, selecting the grade of drill device and drill head; selecting the diamond drill head; mounting and regulating the drill frame; presetting the ideal drill hole axes track; selecting and regulating the measuring device; designing and using the dig and guide corrector; matching the drill parameters as drill pressure, rotational speed and the pump amount; and when the drill hole axes inclined degree is over the standard, process correction and bidirectional drill method. Wherein, the adjustable frame, the hole guide corrector fixed on one end of frame and the diamond drill device are fixed on the steel beam of said frame; the base of said frame via four thread rods whose heights are adjustable are fixed on the ground; a horizontal adjustable thread rod is arranged between the base and the steel beam; the hole guide corrector is fixed on one end of steel beam, while the drill rod is through its limit hole; and the limit hole and the drill rod have clearance fit. The invention has high accuracy.

Owner:BEIJING FAYAN ENG TECH

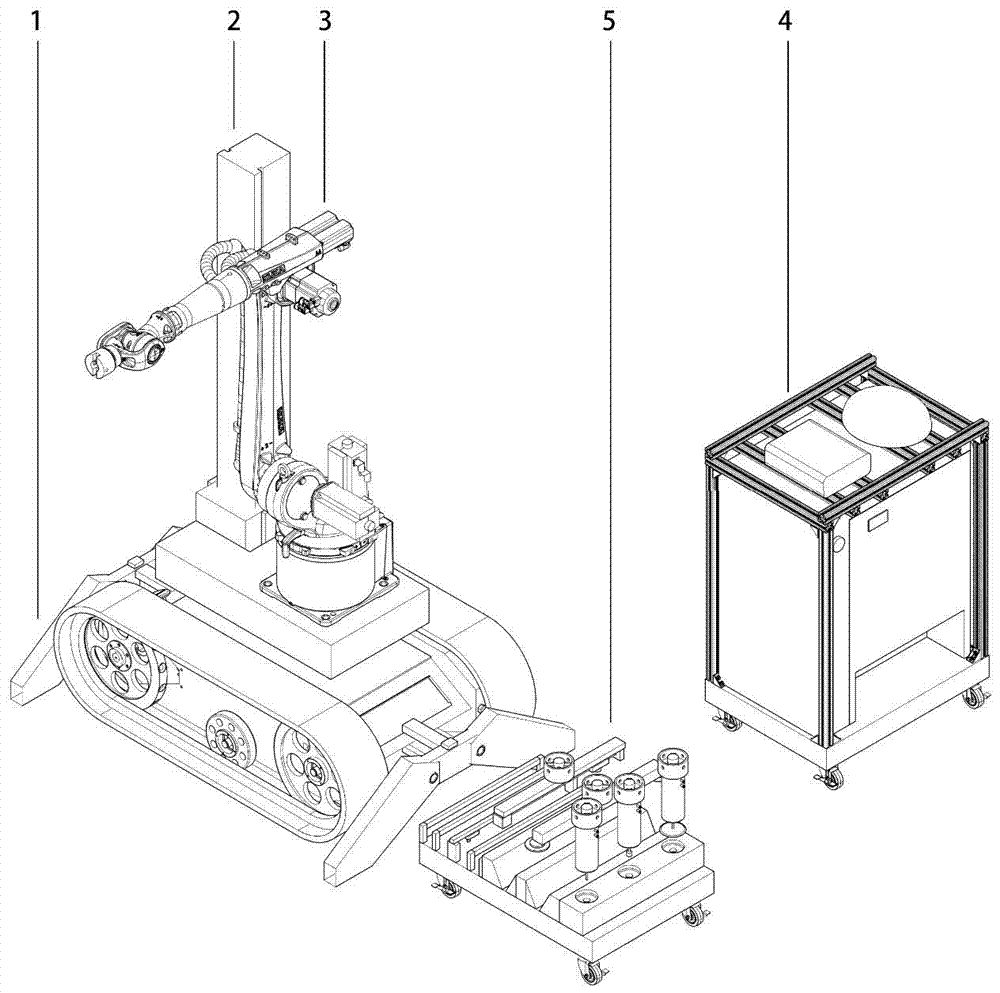

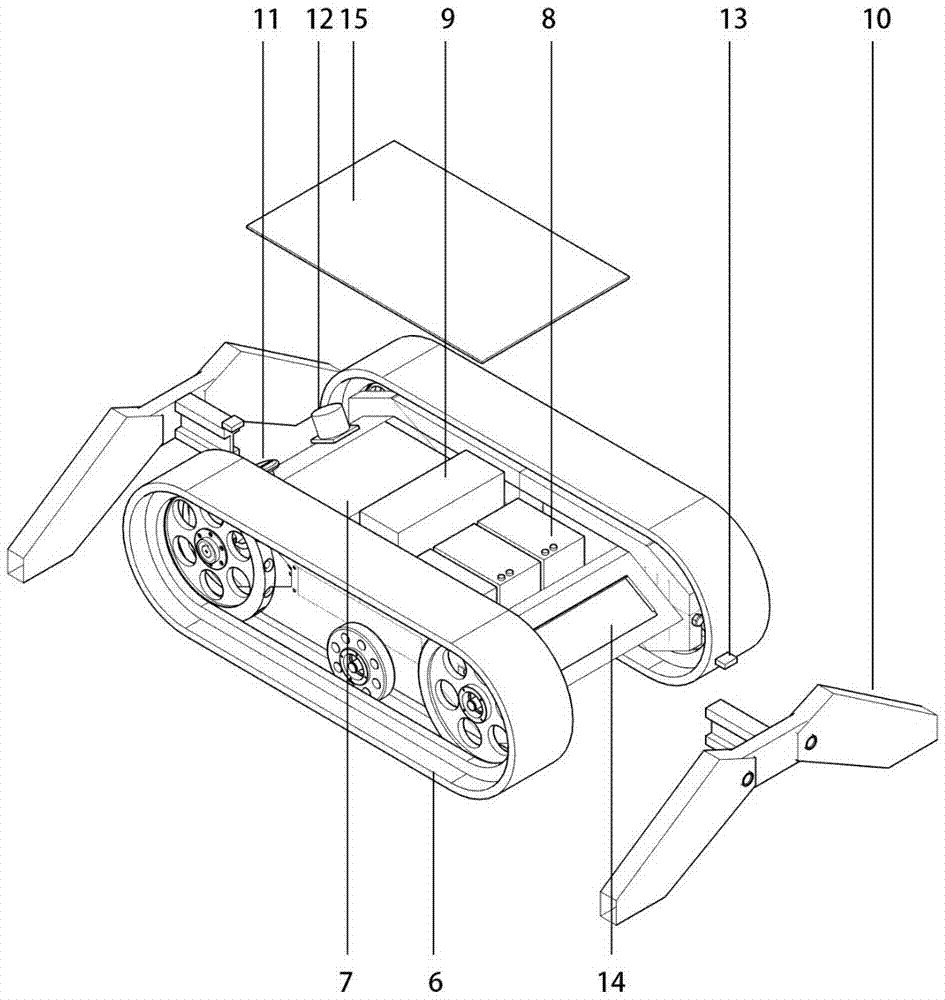

Crawler-type self-locating robot multifunctional intelligent construction platform

InactiveCN107127731AMeet construction requirementsConvenient construction requirementsProgramme-controlled manipulatorRemote controlControl system

The invention discloses a crawler-type self-locating robot multifunctional intelligent construction platform comprising a crawler-type self-locating platform, a hydraulic outer shaft, a six-axis mechanical arm, a mechanical arm and tool remote control system and a multifunctional construction tool system. According to the crawler-type self-locating robot multifunctional intelligent construction platform, on-site multifunctional construction can be achieved through self-walking and self-locating on the construction site, and multifunctional operations such as tile cutting and installation, wall drilling, glass installation and prefabricated part installation are included.

Owner:上海大界机器人科技有限公司

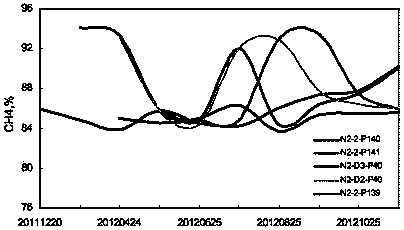

Indigenous microorganism activation and exogenous microorganism intensified oil production method in offshore oilfield

InactiveCN102926728AThe mechanism of action is clearScientific and reasonable designFluid removalDrilling compositionBioaugmentationNutrition

The invention relates to an indigenous microorganism activation and exogenous microorganism intensified oil production method in an offshore oilfield, which belongs to the technical field of producible oil index improvement, and includes the following steps: firstly, preparation of exogenous microorganism bacterial liquor: beneficial microorganisms separated from an oil deposit stratum are subjected to enrichment culture; secondly, preparation of indigenous microorganism activators: the mass percent of components are: 0.25%-0.5% byproduct molasses in sugar industry, 0.1%-0.2% byproduct corn steep liquor of corn starch, 0.2%-0.4% sodium nitrate and 0.1%-0.3% phosphate; and thirdly, underground activation of an indigenous microflora: the following stages are included: the first stage, exogenous microorganism bacterial solution is injected to improve amount of functional microorganisms and provide nutrition substrates for growth of anaerobic bacteria, and the second stage, indigenous microorganism activators are injected in the anaerobic part of a stratum to improve the oil recovery efficiency. The method has the advantages of simplicity in operation, strong suitability, no harm to an oil-bearing sand, zero pollution, improved recovery efficiency and the like.

Owner:E TECH ENERGY TECH DEV CORP

Cement paste toughening agent and application of cement paste toughening agent in preparation of cementing flexible cement paste

ActiveCN103305197ADoes not change inherent performanceGood settlement stabilityDrilling compositionPolymer sciencePortland cement

The invention relates to a cement paste toughening agent and application of the cement paste toughening agent in preparation of a cementing flexible cement paste. The toughening agent is prepared by modification of rubber powder; the modification of rubber powder includes the steps of cleaning, activating, etching and grafting; the cementing flexible cement paste prepared by the toughening agent is prepared from the following components in parts by weight: 100 parts of portland cement, 5-50 parts of modified rubber powder, 10-40 parts of a toughing agent, 15-80 parts of a density regulator, 35-65 parts of water, 0.5-2 parts of a dispersing agent, 0.5-3 parts of a fluid loss agent, 1.5-4 parts of a retarder and 0.1-2 parts of a defoamer. The inherent performance of a substrate is not changed by plasma treatment on the rubber powder; no pollution is generated; the cement paste toughening agent is simple in process, convenient to operate, stable in hydrophilism through the grafted rubber powder, small in effect from timeliness, and low in handling expense; the flexible cement paste prepared from the modified rubber is good in sedimentation stability; the mechanical property is obviously improved; the cement construction requirements of the scene can be completely met.

Owner:SOUTHWEST PETROLEUM UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com