Quenching steel plate for engineering machinery with 900MPa-grade yield strength and production method thereof

A yield strength, engineering machinery technology, applied in the field of quenched and tempered steel plates for engineering machinery, can solve problems such as steel plate toughness decline, hidden safety hazards in engineering construction, and fractures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Embodiment 1: the production process of 16×2500×10000mm (plate thickness mm×plate width mm×plate length mm) steel plate.

[0072] (1) Chemical composition design

[0073] C

mn

S

P

Si

Cr

Ni

Mo

V

Ti

Nb

B

Al

CE

0.15

1.38

0.001

0.012

0.27

0.23

0.30

0.49

0.03

0.012

0.025

0.002

0.035

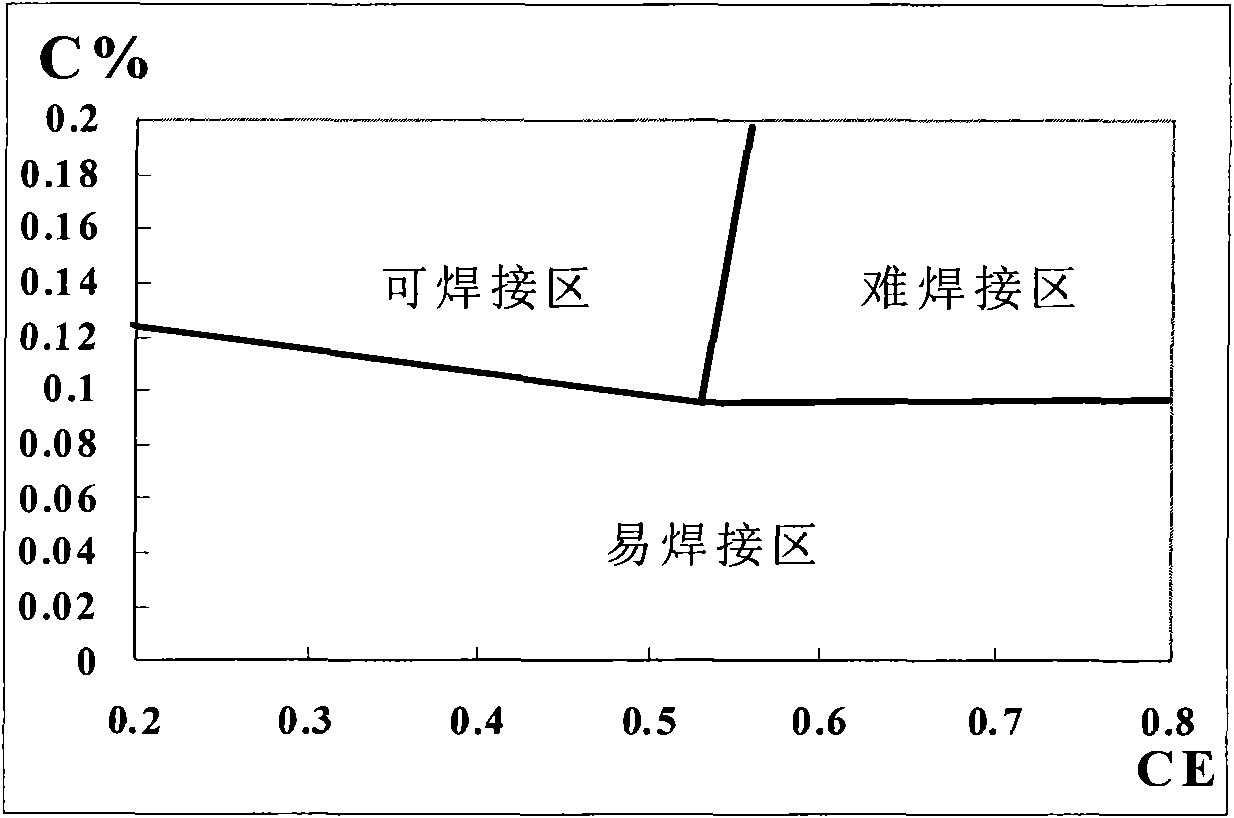

0.55

[0074] Note: The rest is Fe and other unavoidable impurities

[0075] (2) Molten steel smelting, continuous casting billets

[0076] ①The content of N in molten steel is 69ppm, and the temperature of molten steel is 1530℃;

[0077] ② The specific water ratio of the secondary cooling water is 0.4L / Kg steel, and the casting speed is 1m / min;

[0078] ③ The cross-sectional size of the formed billet is 200×1000mm.

[0079] (3) rolling

[0080] ① Heating system of continuous casting slab

[0081] Temperature of the first heating sectio...

Embodiment 2

[0121] Embodiment 2: the production process of 30×2500×10000mm (plate thickness mm×plate width mm×plate length mm) steel plate.

[0122] (1) Chemical composition design

[0123] C

mn

S

P

Si

Cr

Ni

Mo

V

Ti

Nb

B

Al

CE

0.15

1.40

0.005

0.013

0.26

0.21

0.31

0.49

0.02

0.010

0.012

0.002

0.038

0.548

[0124] Note: The rest is Fe and other unavoidable impurities

[0125] (2) Molten steel smelting, continuous casting billets

[0126] ① The content of N in molten steel is 72ppm, and the temperature of molten steel is 1532°C;

[0127] ② The specific water ratio of the secondary cooling water is 0.4L / Kg steel, and the casting speed is 0.9m / min;

[0128] ③ The cross-sectional size of the billet formed is 250×1500mm.

[0129] (3) rolling

[0130] ① Heating system of continuous casting slab

[0131] Temperature of the first heating s...

Embodiment 3 4 5

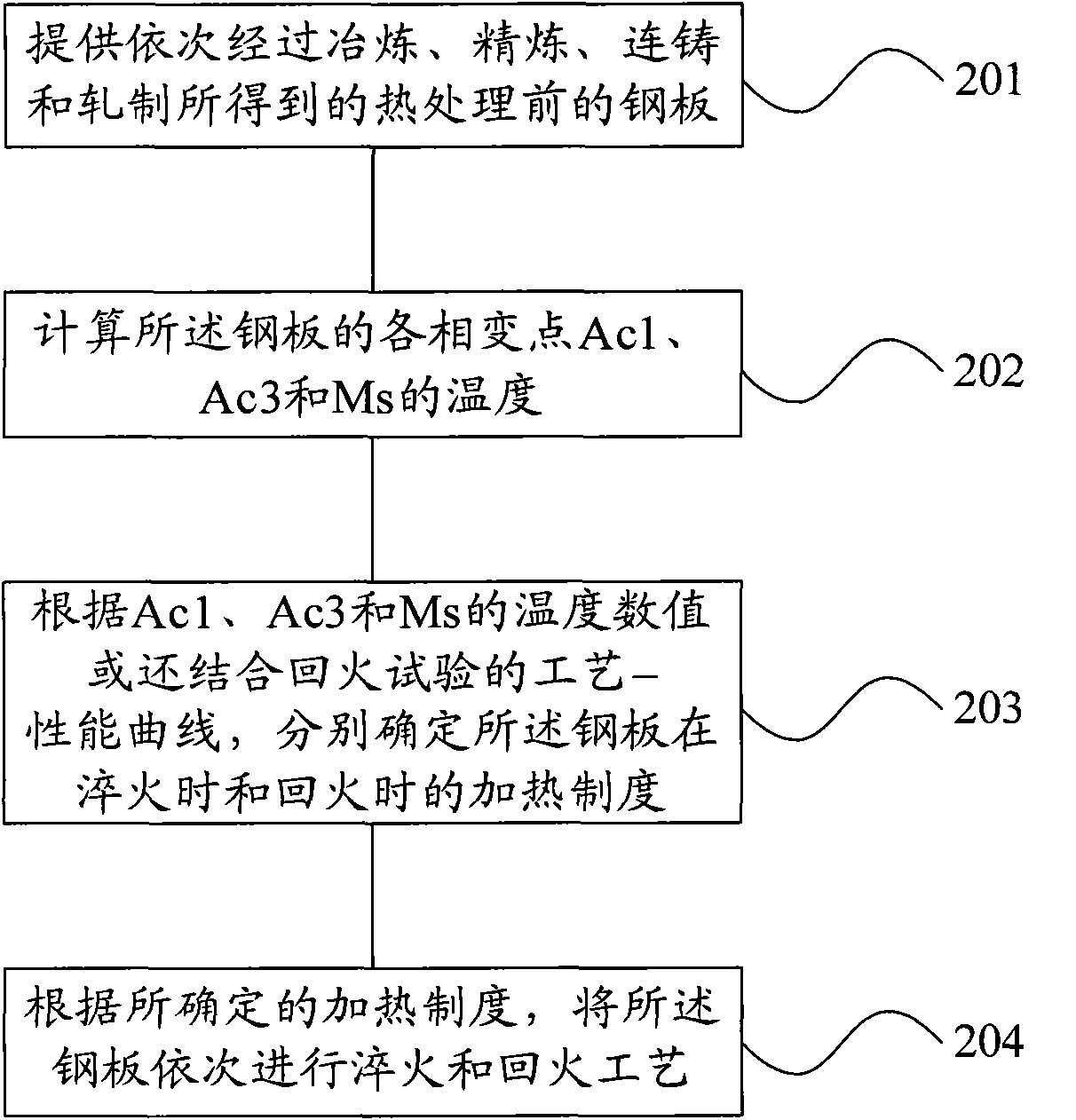

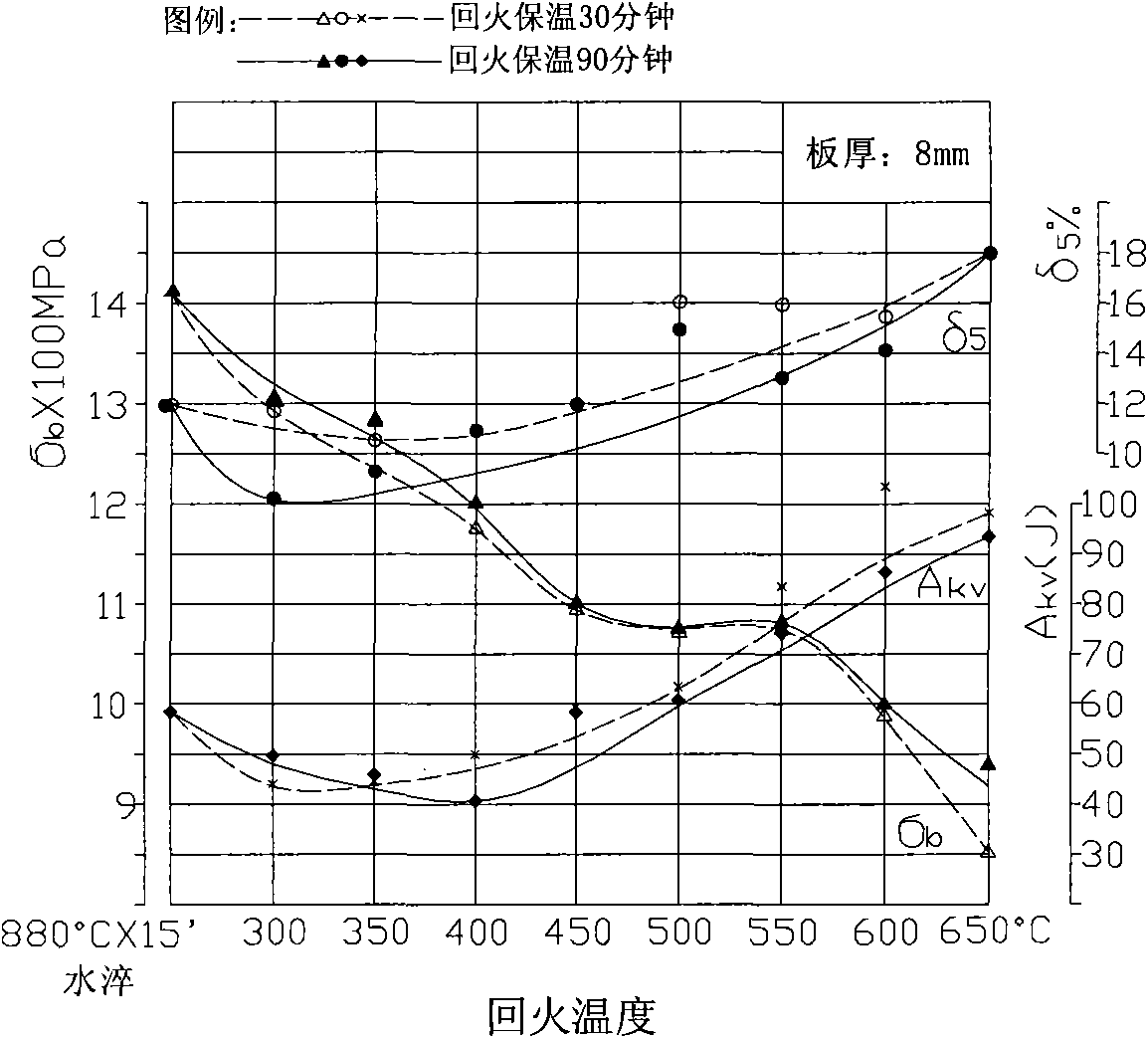

[0178] In the quenching and tempering process of the present invention, other processes are the same as in embodiment one or two except the tempering process, but the tempering process can also be combined with the orthogonal test method to optimize the test process and reduce the number of tests, and then according to the test results, draw into a process-performance curve. like Figure 3 to Figure 5 The process-performance curves used to determine the heating regime during tempering are drawn according to the results of the orthogonal test method for Embodiments 3, 4 and 5 of the present invention with plate thicknesses of 8mm, 12mm and 16mm, respectively. In the figure, σ b is the tensile strength, which is one of the strength indicators of the steel plate; Akv is the impact toughness, which is one of the toughness indicators of the steel plate; δ 5 It is elongation, which is one of the plasticity indicators of steel plate. Then, determine the most suitable heating syste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com