High-broken-pressure stratum horizontal well sectional-fracturing method for well cementation and completion of casing

A technology for staged fracturing and horizontal wells, which is applied in wellbore/well components, earthwork drilling and production, and production fluids, etc., and can solve the problems of unopened formations, large hole friction, and high formation pressure failures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

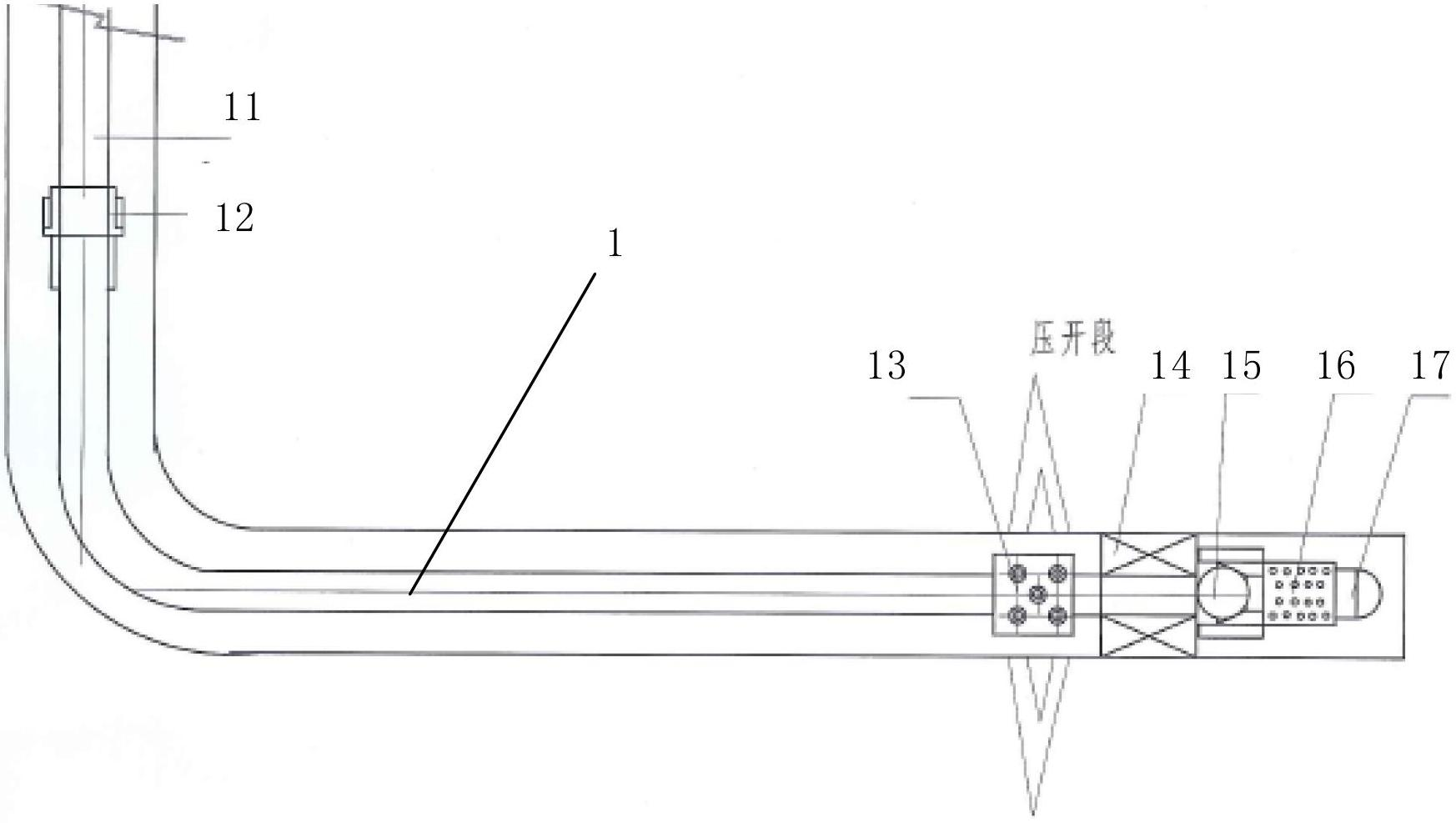

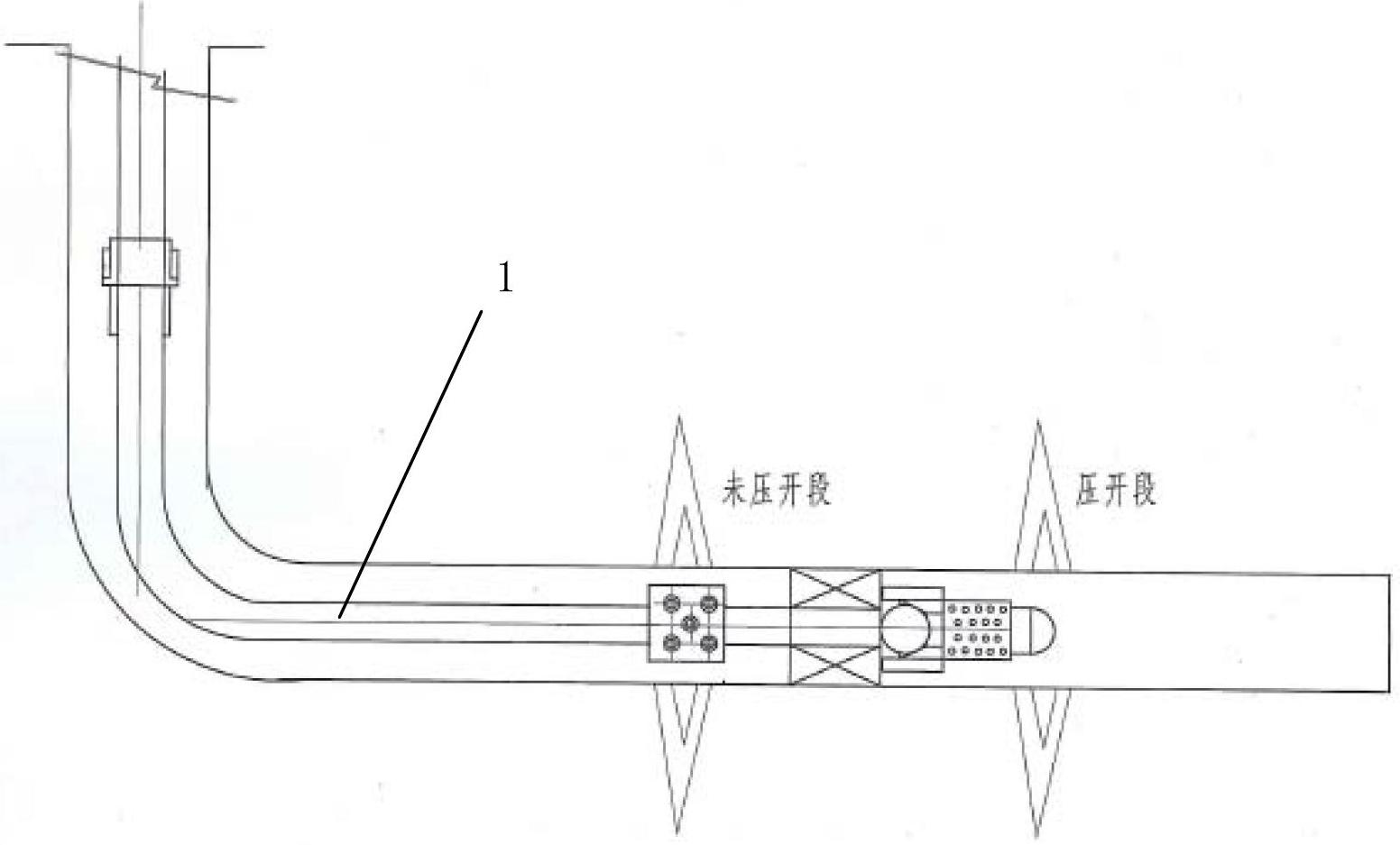

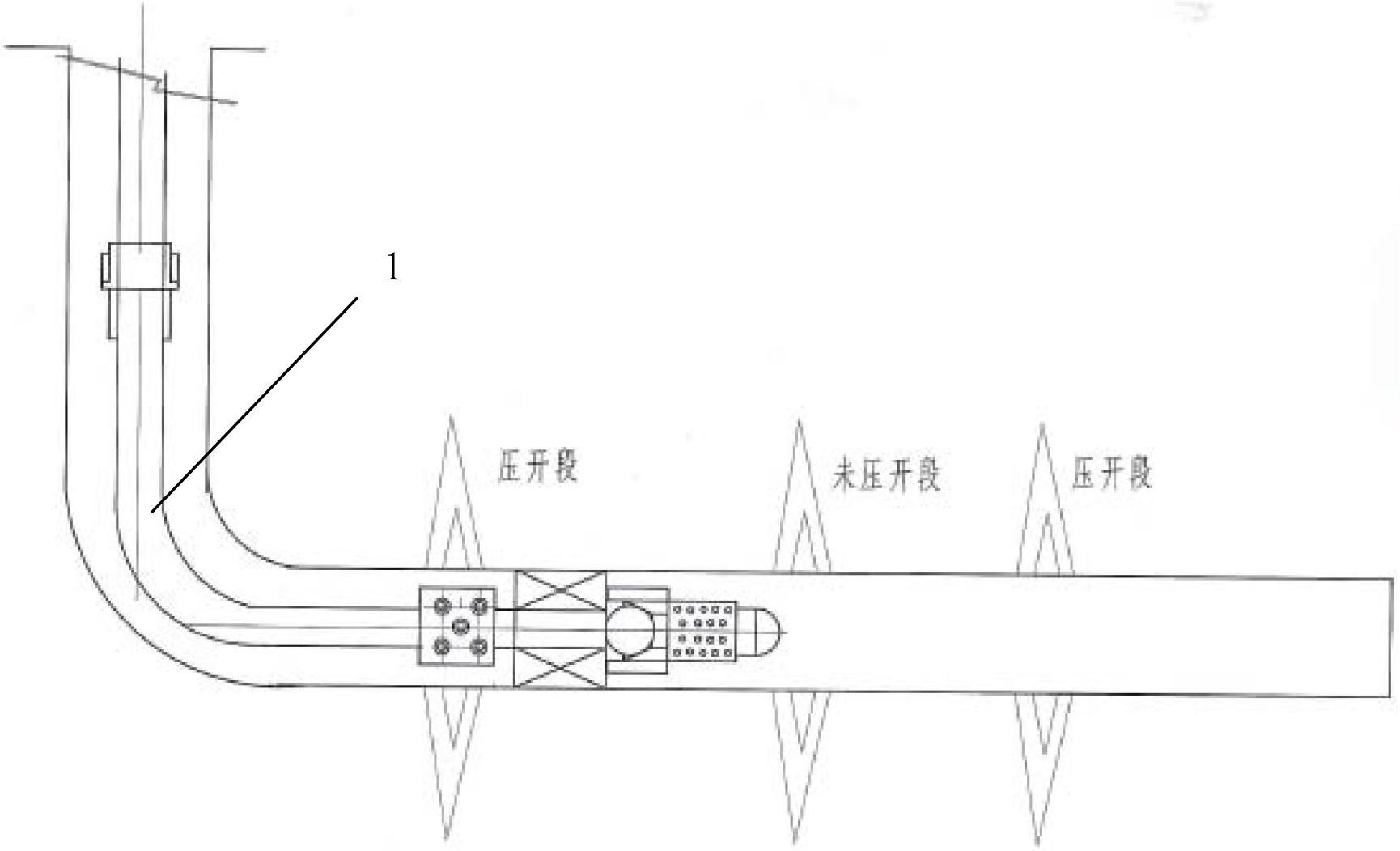

[0021] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

[0022] The present invention proposes a segmented fracturing method for casing cementing and completion of horizontal wells in high-pressure-breaking strata. When the jet fracturing string is used for perforation and fracturing operations, the maximum pressure in the wellhead annulus should not exceed 45 MPa; then the packer segmental fracturing string is run in to perform segmental fracturing of the unfractured layers in the hydraulic jet fracturing process cracked construction.

[0023] As mentioned above, the staged fracturing method first adopts hydraulic sandblasting and perforating fracturing technology as much as possible to carry out staged reconstruction of all the designed and reconstructed intervals, and directly reali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com