Temperature resistant, non-crosslinked and biodegradable gel leak-stopping agent and preparation method thereof

A technology of plugging agent and gel, applied in the field of degradable gel plugging agent and its preparation, temperature resistance, no cross-linking, can solve the problem of non-degradable or incomplete degradation, pollution of oil production channels and oil layers, Return to the wellbore and other issues to achieve the effects of fast dissolution, convenient construction and improved pressure bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

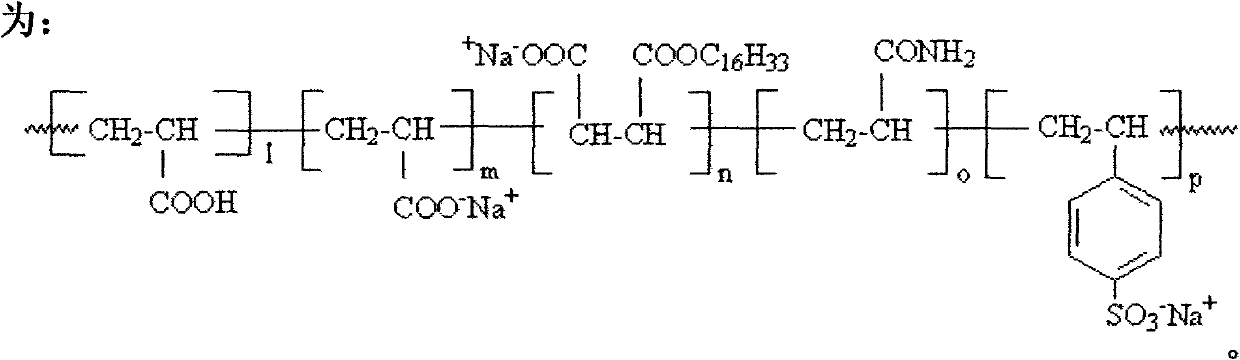

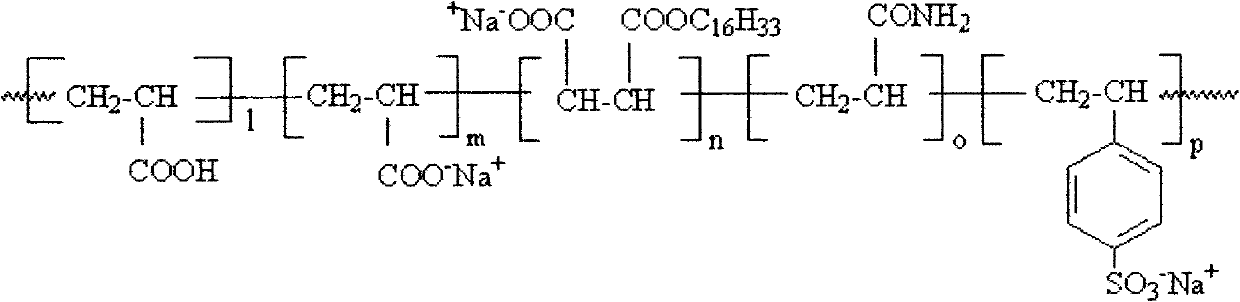

Method used

Image

Examples

Embodiment 1

[0036] Preparation and performance test of gel plugging agent 1:

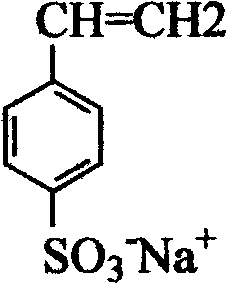

[0037] 1. Weigh 24g of maleic anhydride and dissolve it in 112.4g of toluene solvent, add 52g of n-hexadecanol, and add 1.6g of catalyst sodium p-toluenesulfonate to react at 62°C for 8 hours, then use 10g of hydrogen to oxidize After the sodium was neutralized for 1.5 hours, the solid obtained after cooling to room temperature and filtering was the sodium hexadecyl maleate, an association monomer.

[0038] 2. Weigh 7.2g of sodium hydroxide and dissolve it in 64.8g of deionized water to prepare a sodium hydroxide solution. Then take by weighing acrylic acid 15.6g, after the two carry out neutralization reaction 30min, weigh the association monomer monohexadecyl maleate sodium salt 9.6g synthesized in the first step, the anionic monomer is to vinyl Add 8.4g of sodium benzenesulfonate, 79.2g of acrylamide, add 115.2g of deionized water, and fully stir and dissolve at 20°C.

[0039] 3. Add 0.3g of potassium pers...

Embodiment 2

[0042] Preparation and performance test of gel plugging agent 2:

[0043]1. Weigh 56g of maleic anhydride and dissolve it in 197.6g of toluene solvent, add 120g of n-hexadecanol, and add 2.4g of catalyst sodium p-toluenesulfonate to react at 78°C for 6 hours, and then oxidize with 24g of hydroxide After the sodium was neutralized for 2 hours, the solid obtained after cooling to room temperature and filtering was the sodium hexadecyl maleate, an association monomer.

[0044] 2. Weigh 9.6g of sodium hydroxide and dissolve it in 70.4g of deionized water to prepare a sodium hydroxide solution. Then take by weighing acrylic acid 19.2g, after the two carry out neutralization reaction 30min, weigh the association monomer monohexadecyl maleate sodium salt 8.4g synthesized in the first step, the anionic monomer is to vinyl Add 6g of sodium benzenesulfonate, 76.8g of acrylamide, add 209.6g of deionized water, and fully stir and dissolve at 28°C.

[0045] 3. Add 0.8g of ammonium persul...

Embodiment 3

[0048] Preparation and performance test of gel plugging agent 3:

[0049] 1. Weigh 39g of maleic anhydride and dissolve it in 157.5g of toluene solvent, add 84g of n-hexadecanol, and add 3g of catalyst sodium p-toluenesulfonate to react at 71°C for 7 hours, then use 16.5g of hydrogen to oxidize After the sodium was neutralized for 1 hour, the solid obtained after cooling to room temperature and filtering was the sodium hexadecyl maleate, an association monomer.

[0050] 2. Weigh 4.9g of sodium hydroxide and dissolve it in 39.6g of deionized water to prepare a sodium hydroxide solution. Then take by weighing acrylic acid 10.2g, after the two carry out neutralization reaction 30min, weigh the association monomer hexadecyl maleate sodium salt 4.2g synthesized in the first step, anionic monomer to vinyl Sodium benzenesulfonate 4.2g, acrylamide 46.5g, add deionized water 90.4g, fully stir and dissolve at 12°C.

[0051] 3. Add 0.5g of potassium persulfate, 0.5g of sodium bisulfite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com