Construction method of single-pylon cable-stayed bridge without dorsal cables

A technology of single tower without back cable slanting and construction method, applied in cable-stayed bridges, bridges, bridge forms and other directions, can solve the problems of difficult to guarantee construction quality and complex construction technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

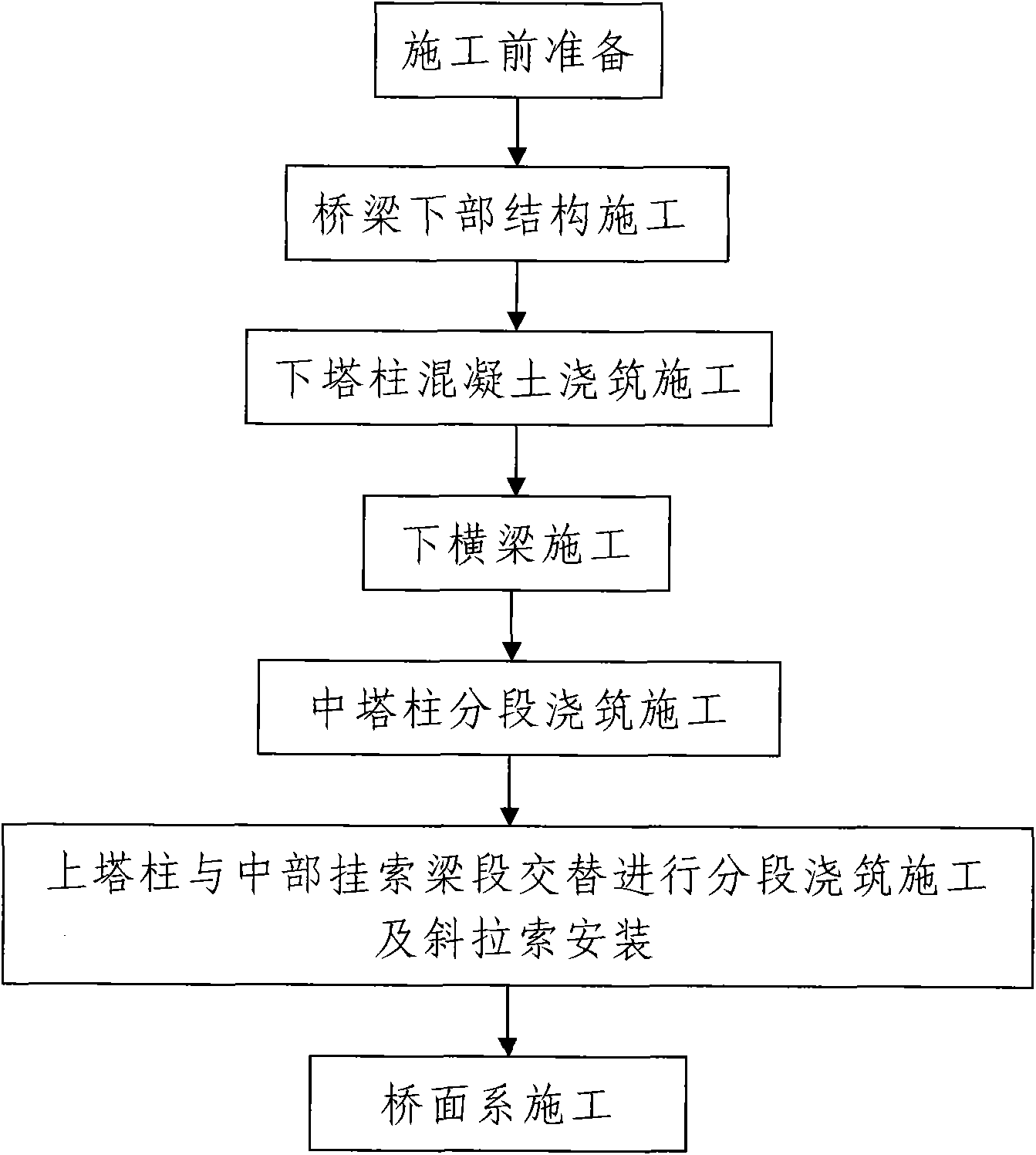

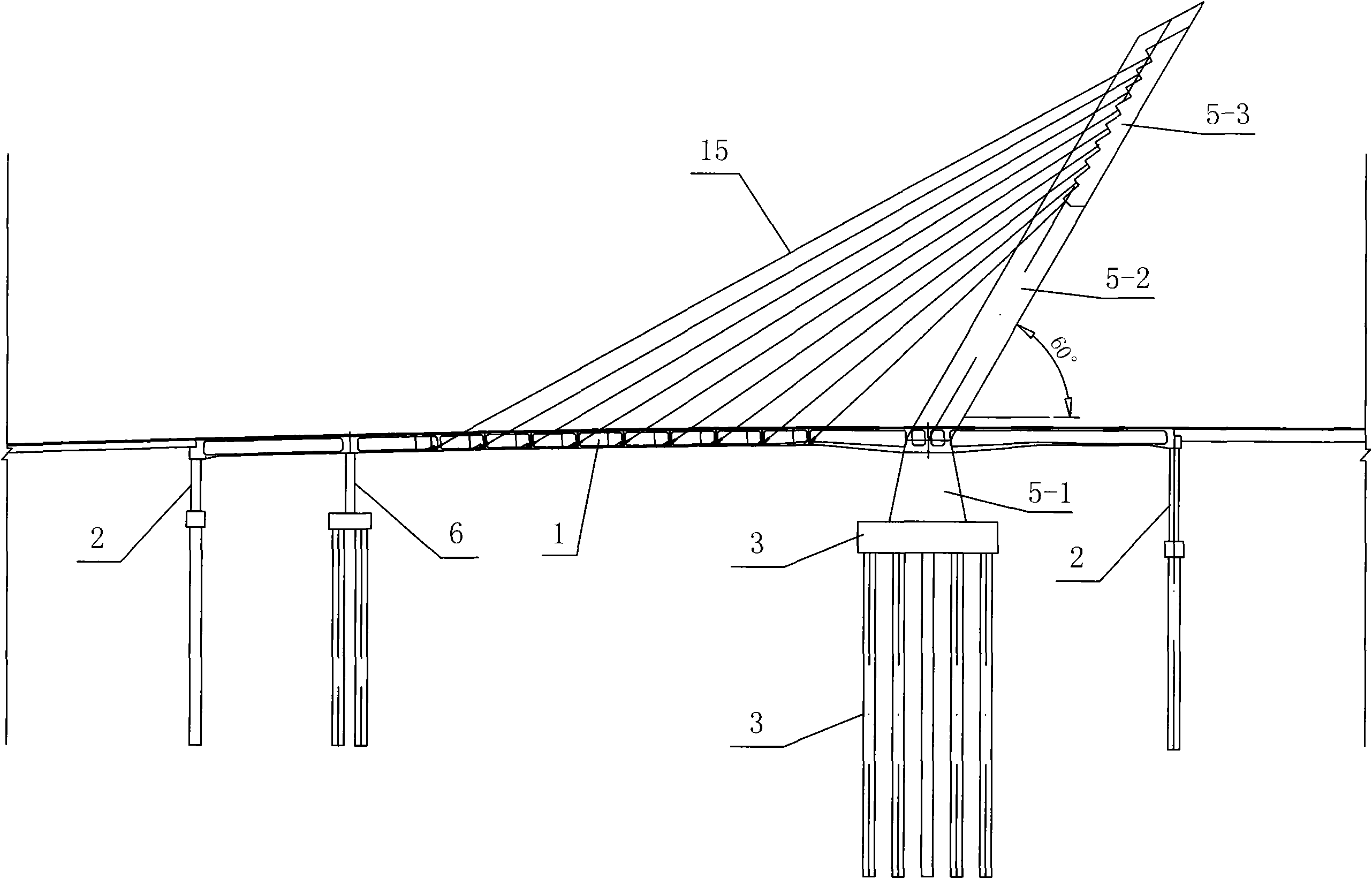

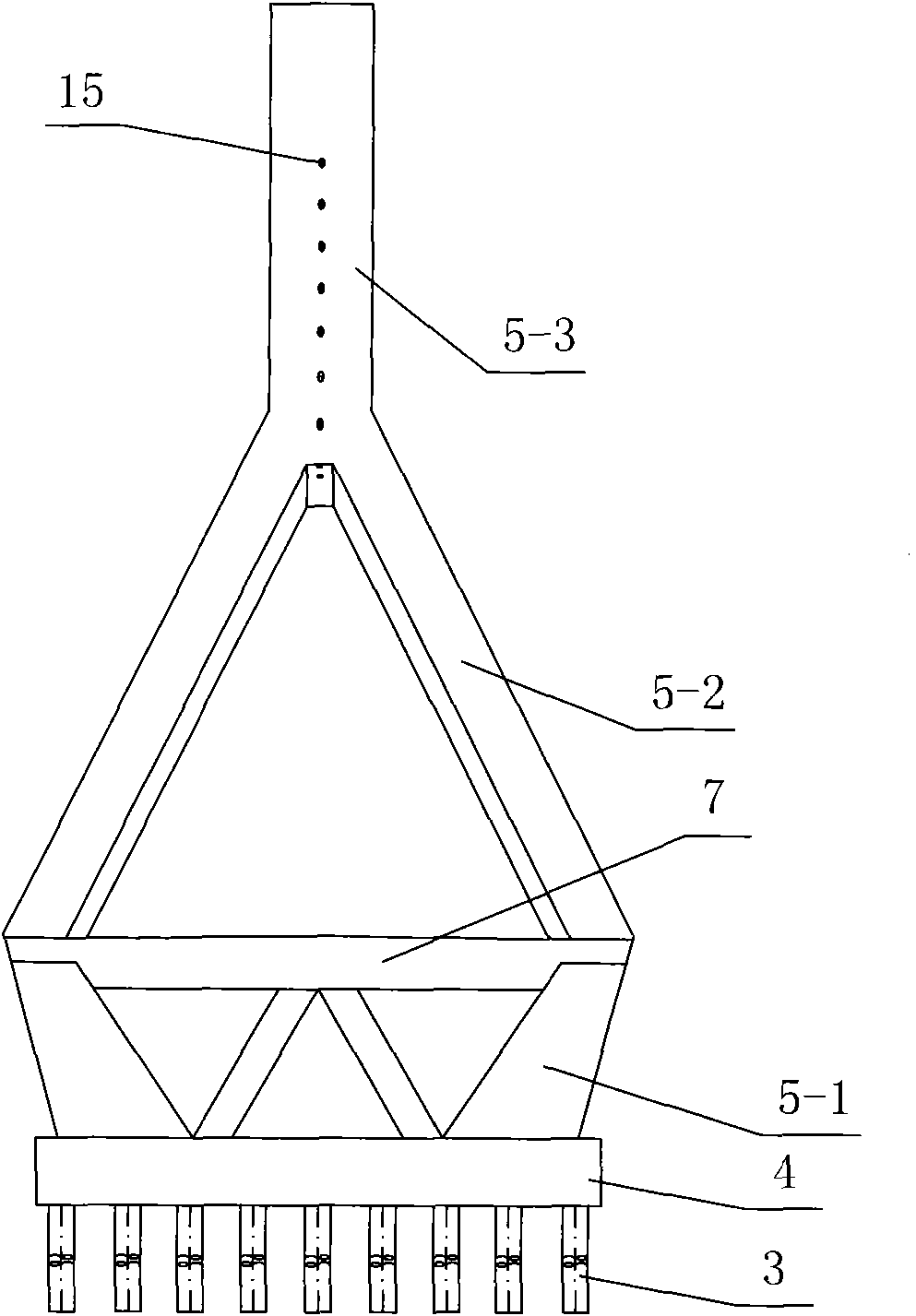

[0075] Such as figure 2 , image 3 and Figure 4 As shown, the main tower of the single-tower cable-stayed bridge without back cables is composed of the lower tower column 5-1, the middle tower column 5-2 and the upper tower column 5-3 from bottom to top, and the two ends of the main beam 1 span respectively On the left and right transition piers 2, the middle tower column 5-2 and the upper tower column 5-3 form a leaning tower located above the bridge deck of the main girder 1 and inclined to the right along the bridge direction, and the pouring construction of the leaning tower is integrated And the whole is an inverted "Y" shape structure, and the middle tower column 5-2 is two left and right bifurcated sections arranged on the lower part of the upper tower column 5-3, and the two bifurcated sections are arranged symmetrically across the bridge. In this embodiment, the total length of the cable-stayed bridge constructed is 127 meters, the specific span layout is 32+75+20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com