Construction method for adding water lowering well in water collecting well

A construction method and a technology for collecting wells, which are applied in basic structure engineering, construction, etc., can solve problems such as no treatment method, and achieve the effects of fast construction speed, simple construction method and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

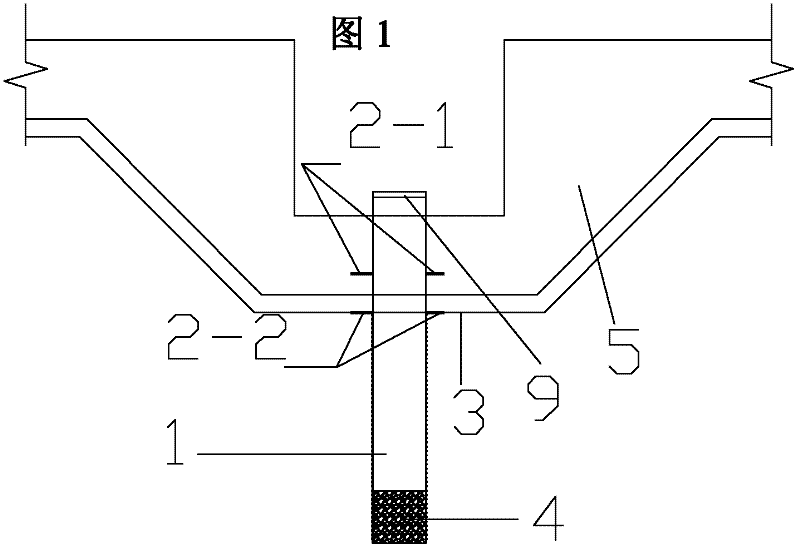

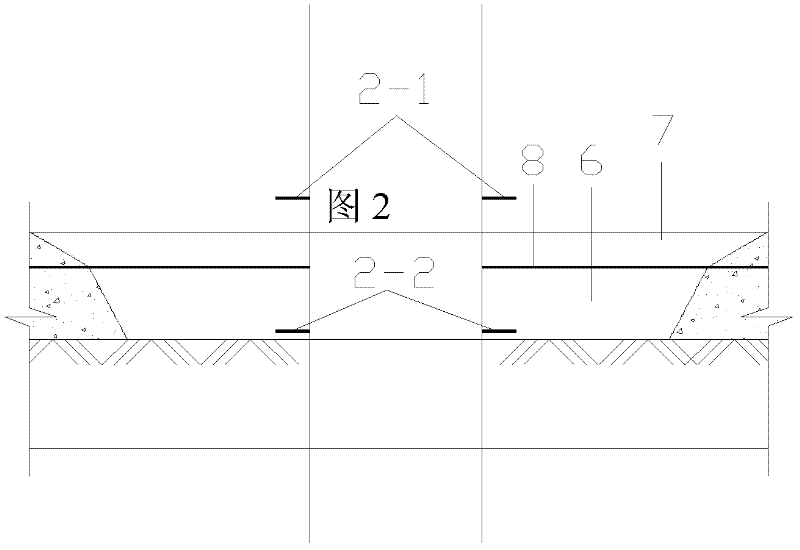

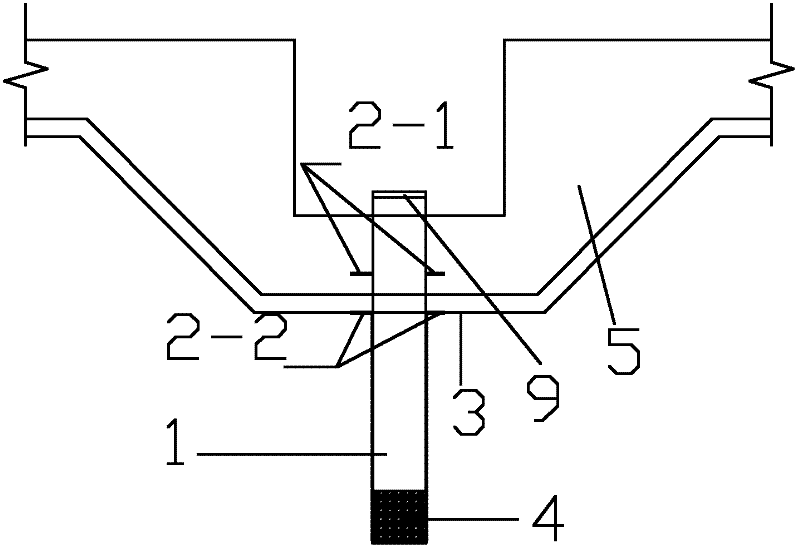

[0021] (1) On the side wall and the bottom wall of the well dug, lay the cushion 6, the waterproof layer 8 and the waterproof protective layer 7 successively. (2) drive the prepared circular steel pipe dewatering well structure into the bottom wall of the water collection well until the required elevation is reached, and the circular steel pipe dewatering well The structure includes a round steel pipe 1, an upper water stop ring 2-1 and a lower water stop ring 2-2 are welded at intervals on the outer wall of the round steel pipe, and there are holes on the part of the round steel pipe to be buried in the soil. A plurality of holes, steel wire mesh is wrapped on the outer wall of the round steel pipe provided with holes, and the lower water stop ring is located at the bottom wall of the water collection well; the diameter of the holes is 20mm, and the two adjacent holes (3) remove the soil in the round steel pipe; (4) backfill 250mm thick gravel at the bottom of the round steel...

Embodiment 2

[0024] (1) On the side wall and the bottom wall of the well dug, lay the cushion 6, the waterproof layer 8 and the waterproof protective layer 7 successively. (2) drive the prepared circular steel pipe dewatering well structure into the bottom wall of the water collection well until the required elevation is reached, and the circular steel pipe dewatering well The structure includes a round steel pipe 1, an upper water stop ring 2-1 and a lower water stop ring 2-2 are welded at intervals on the outer wall of the round steel pipe, and there are holes on the part of the round steel pipe to be buried in the soil. A plurality of holes, steel wire mesh is wrapped on the outer wall of the round steel pipe provided with holes, and the lower water stop ring is located at the bottom wall of the water collection well; the diameter of the holes is 16mm, and the two adjacent holes The distance between them is 55mm; (3) remove the soil in the round steel pipe; (4) backfill 350mm thick grav...

Embodiment 3

[0027] (1) On the side wall and the bottom wall of the well dug, lay the cushion 6, the waterproof layer 8 and the waterproof protective layer 7 successively. (2) drive the prepared circular steel pipe dewatering well structure into the bottom wall of the water collection well until the required elevation is reached, and the circular steel pipe dewatering well The structure includes a round steel pipe 1, an upper water stop ring 2-1 and a lower water stop ring 2-2 are welded at intervals on the outer wall of the round steel pipe, and there are holes on the part of the round steel pipe to be buried in the soil. A plurality of holes, steel wire mesh is wrapped on the outer wall of the round steel pipe provided with holes, and the lower water stop ring is located at the bottom wall of the water collection well; the diameter of the holes is 23mm, and the two adjacent holes The distance between them is 45mm; (3) remove the soil in the round steel pipe; (4) backfill 300mm thick grav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com