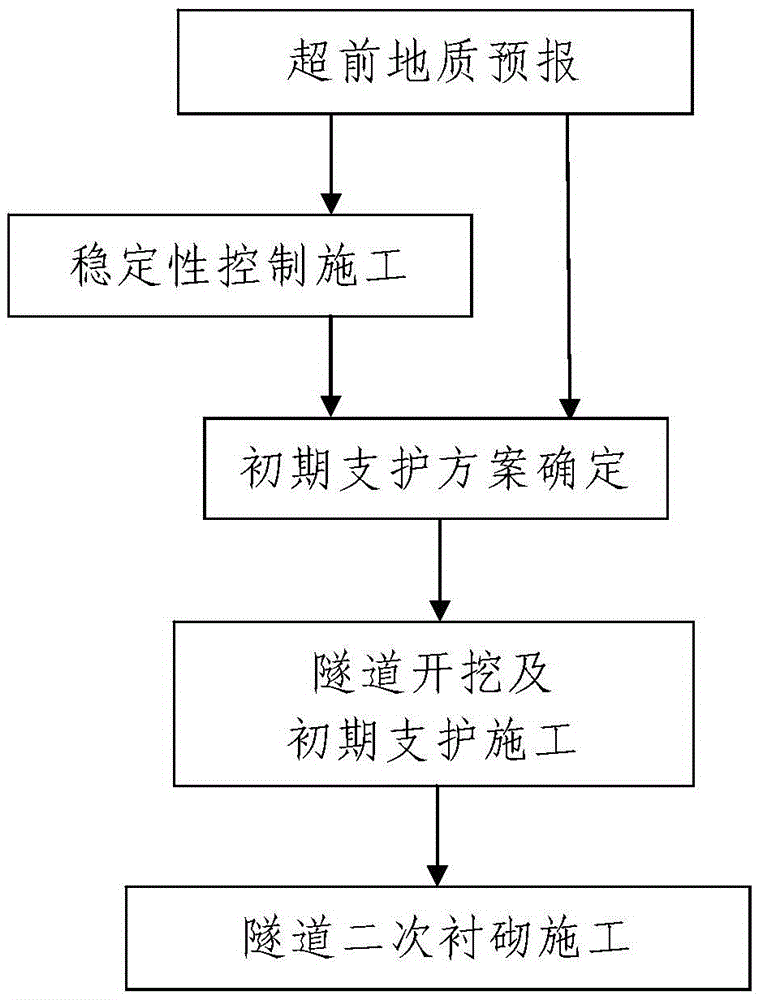

Water-rich weak surrounding rock long-and-big tunnel construction method

A technology for weak surrounding rocks and long tunnels, which is applied in the field of tunnel construction and can solve problems such as lack of successful experience, cold weather, and tight construction schedules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

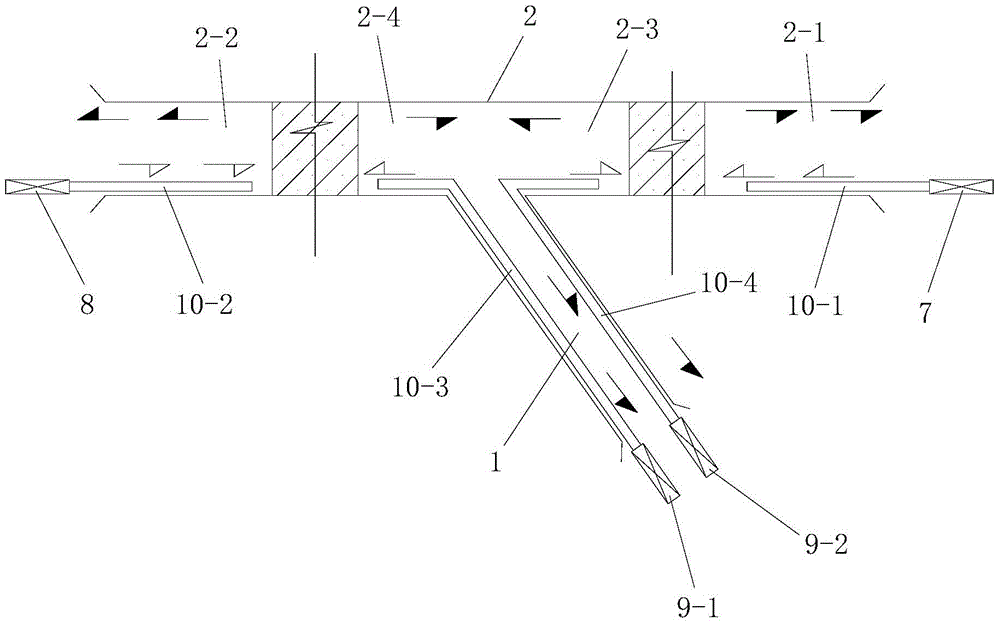

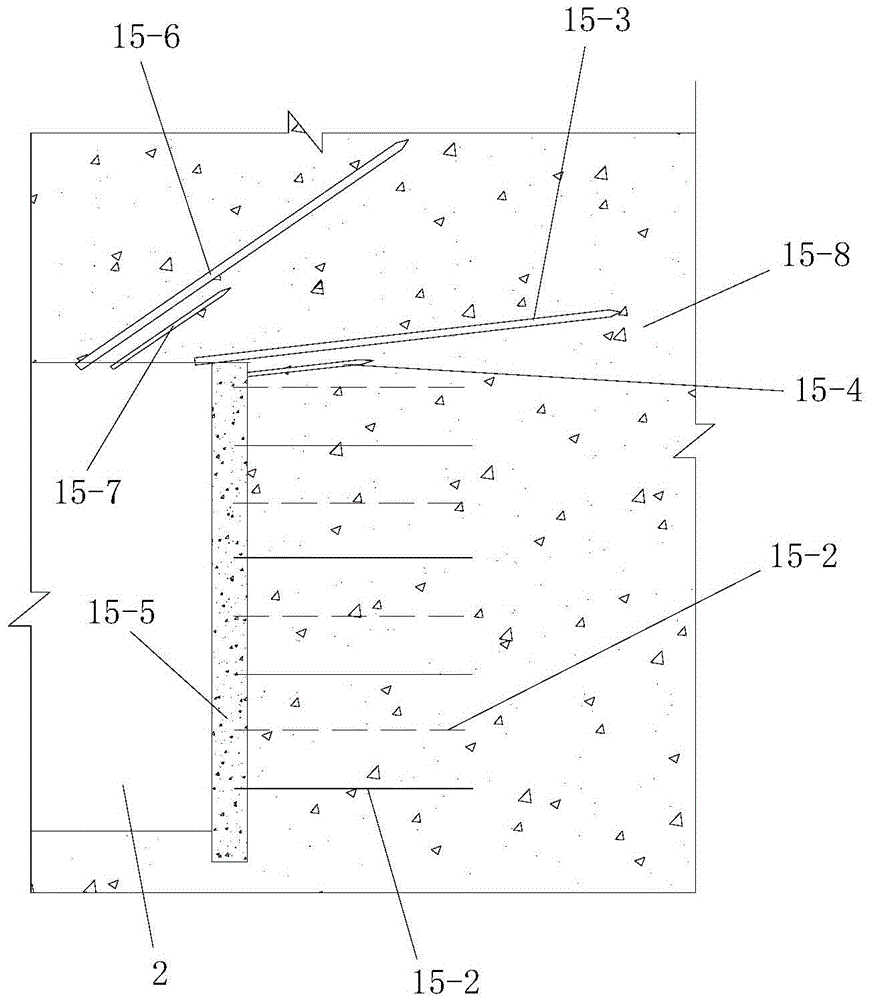

[0101] Such as figure 1 , figure 2 Shown, a kind of water-rich soft surrounding rock long tunnel construction method described in the present invention, the length of the constructed tunnel is greater than 5km and its excavation section is greater than 50m 2 ; One side of the main tunnel 2 of the constructed tunnel is provided with a tunnel inclined shaft 1 ; 2-2, the middle connection section between the tunnel inclined shaft 1 and the middle connection section intersects and the intersection between the two is the inclined shaft intersection, the middle connection section is the auxiliary construction section of the inclined shaft and its Taking the intersection of the inclined shaft as a boundary, it is divided into an auxiliary construction entrance section 2-3 of an inclined shaft and an auxiliary construction exit section 2-4 of an inclined shaft, the entrance section 2-1 of the tunnel, the auxiliary construction entrance section 2-3 of an inclined shaft, The auxiliar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com