Method for designing thickness of underwater tunnel subsurface excavated construction grouting reinforcement ring

A technology for grouting reinforcement and underwater tunnels, which is applied in tunnels, tunnel linings, underground chambers, etc., and can solve problems such as large safety factors, uncertainties, and inability to meet the needs of rapid development of underwater tunnel construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0088] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment:

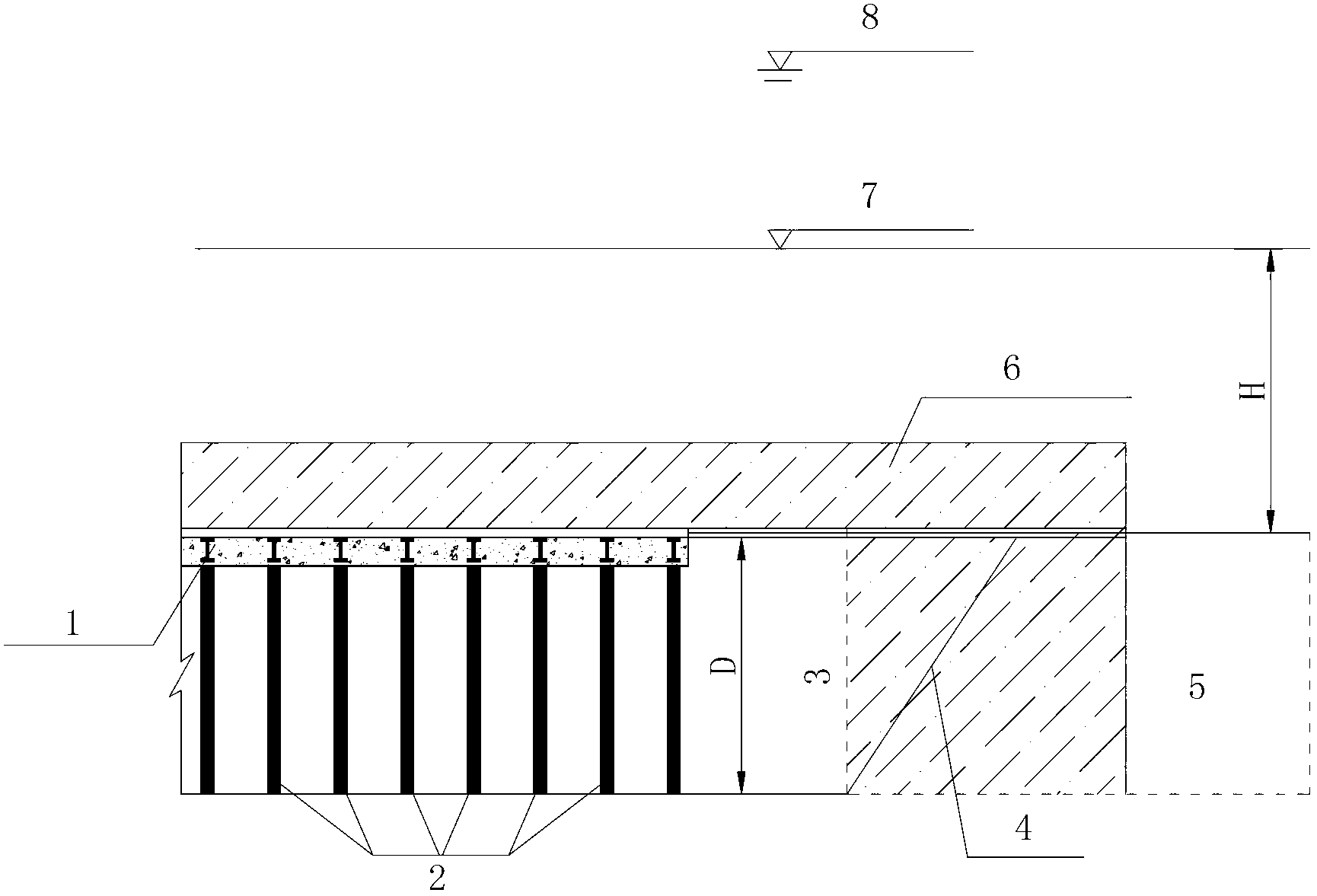

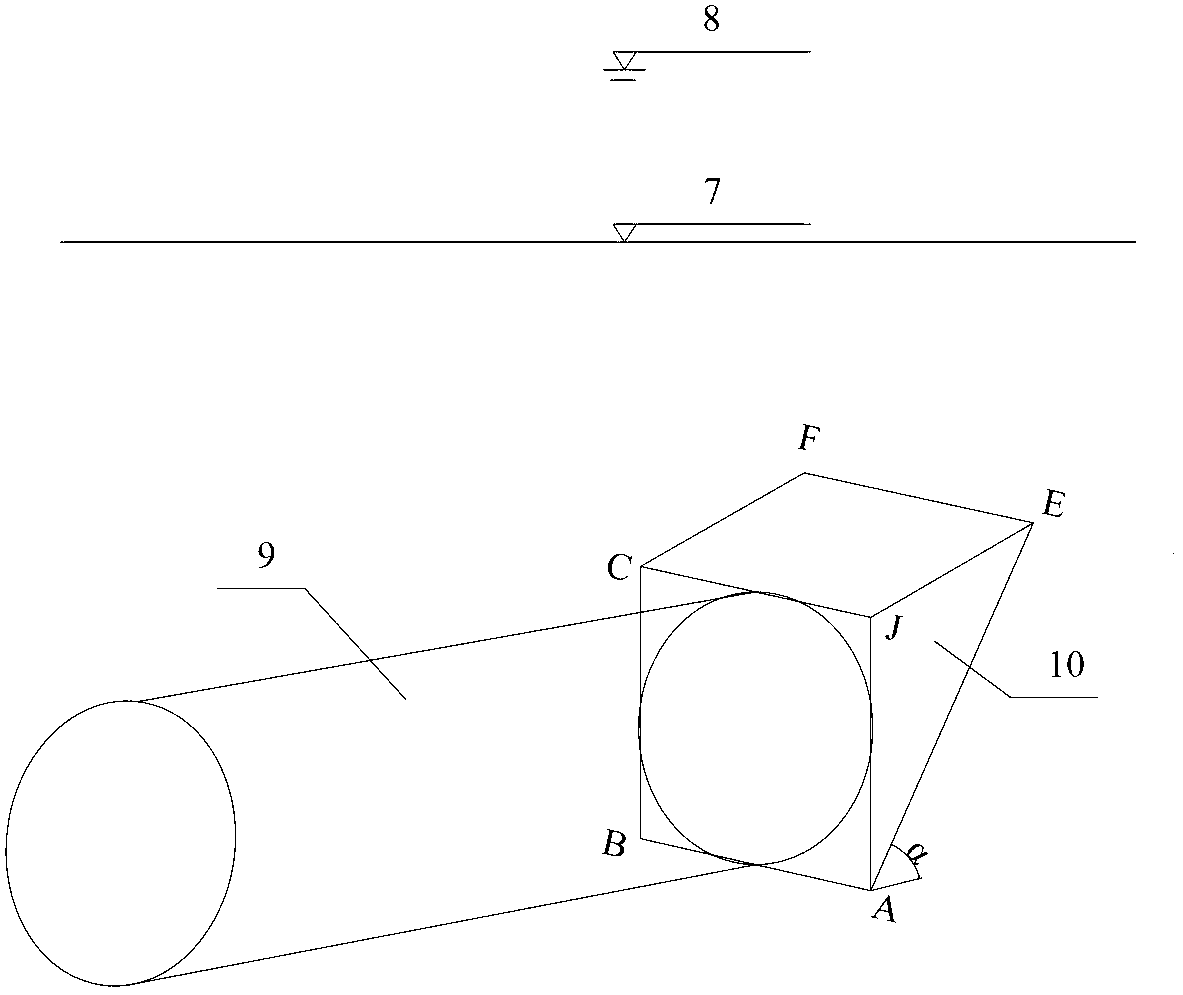

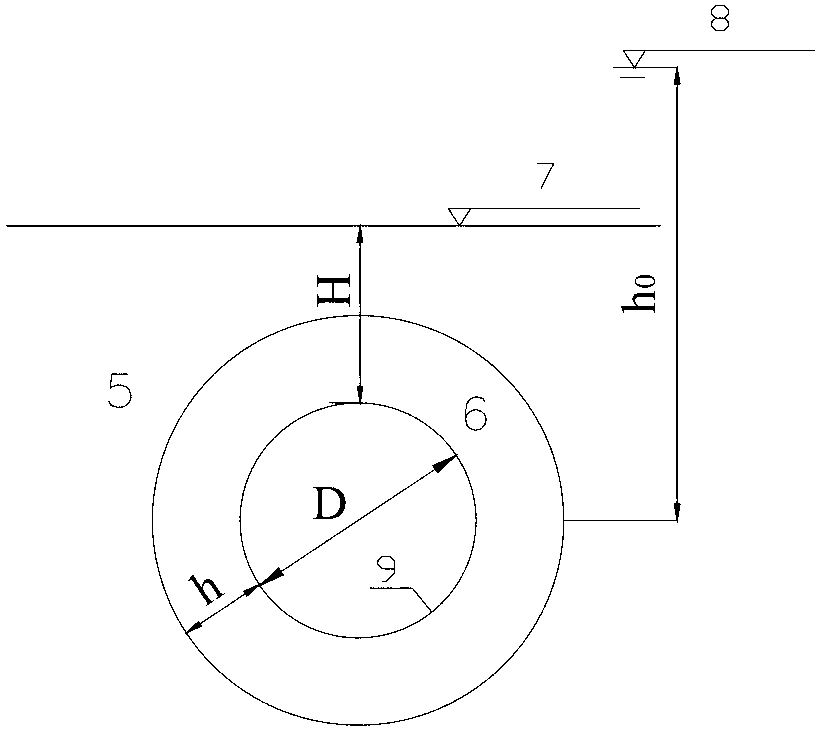

[0089] A design method of grouting reinforcement parameters for underwater tunnel excavation construction, see figure 1 , after tunnel excavation, under the joint action of surrounding rock pressure, hydrostatic pressure and seepage force, the underwater tunnel construction face will produce a potential wedge-shaped fracture body ( figure 2 ), through the stability analysis of the working face, the grouting reinforcement design is carried out to ensure the stability of the potential wedge-shaped fracture body. The specific design parameters of the grouting reinforcement include the thickness of the grouting ring, the permeability coefficient after grouting, and the mechanical parameters. The surrounding rock pressure is calculated according to the relevant tunnel design codes according to the different buried depths of the tunnel. The grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com