Assembly type overhead construction process

A construction technology and stringing technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of increasing construction safety risks, failing to meet the high requirements of stringing construction technology, large errors, etc., to improve the process and quality level, and ensure construction Effects of quality and safety objectives, avoidance of sag observations and segmented tight lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] According to the sequence of the stringing construction technology of the present invention, the stringing construction technology of the preferred embodiment of the present invention can be summarized as follows:

[0033] 1. Measure the data and calculate the line length;

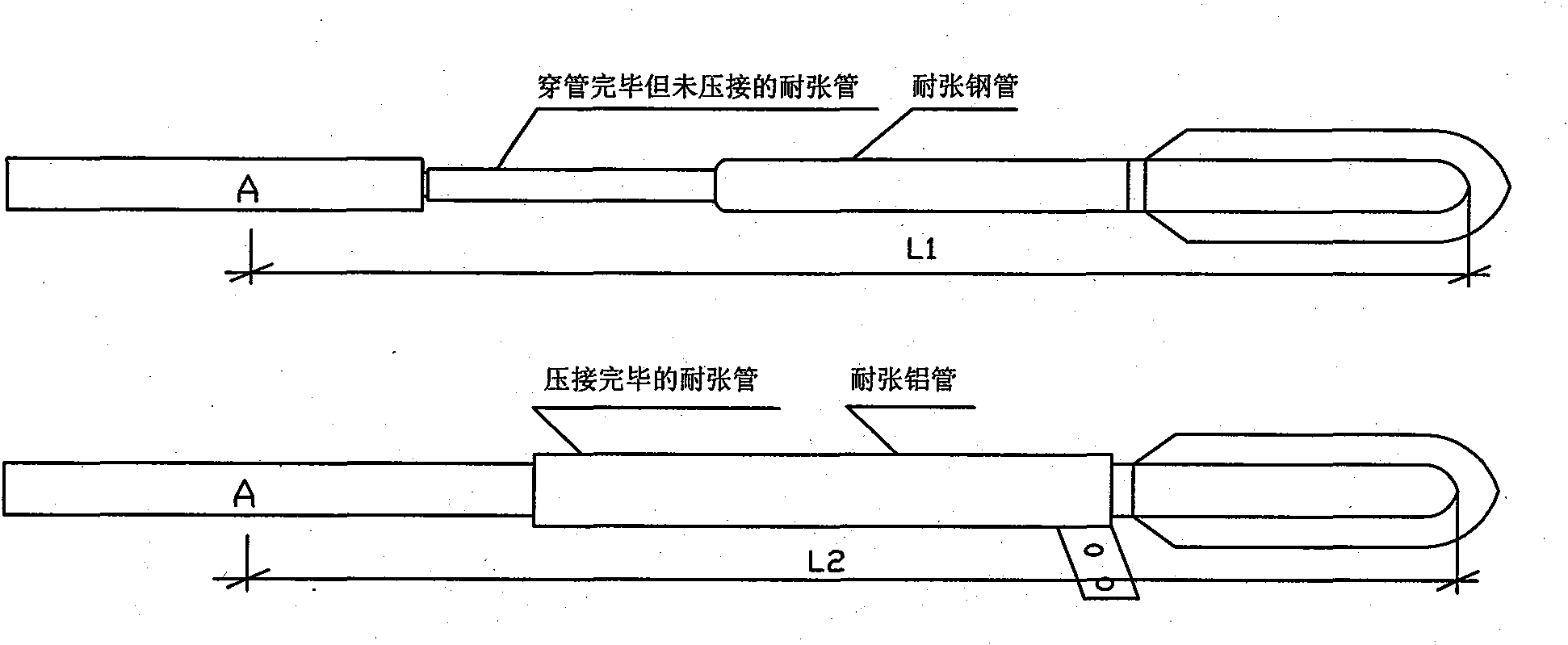

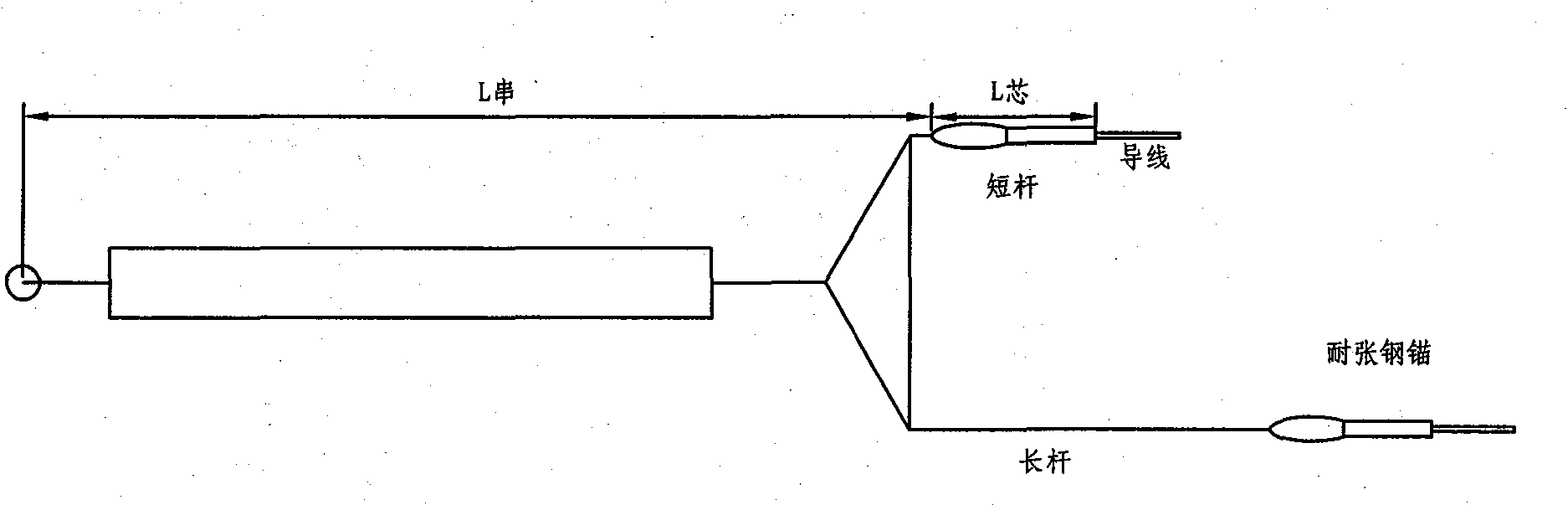

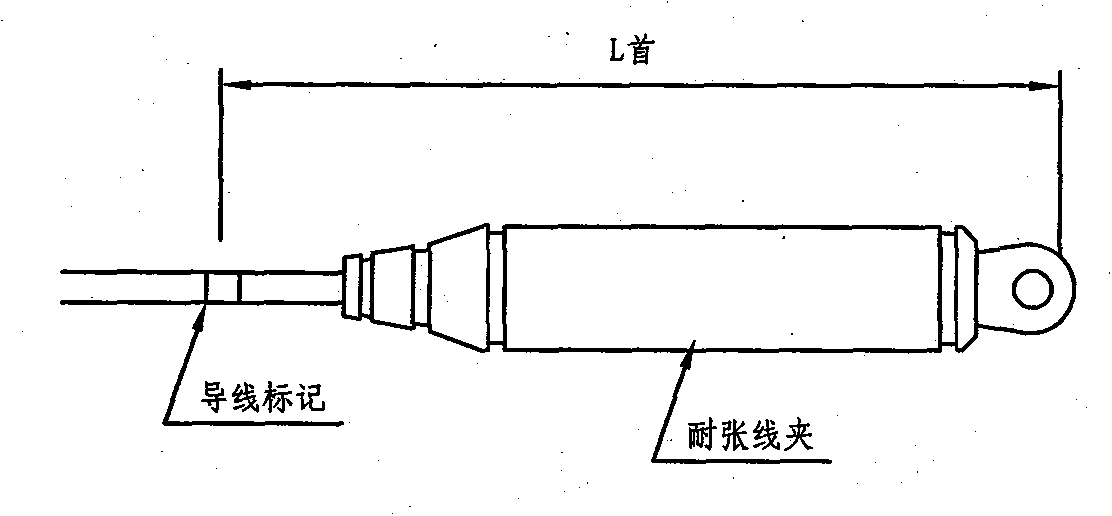

[0034] 2. Fixed-length manufacturing and processing wires;

[0035] 3. Spread out the wires; and

[0036] Fourth, hang the wire tightly.

[0037] In the following, each process will be described in detail according to the above four major process sequences.

[0038] 1. Measure the data and calculate the line length:

[0039] 1.1 Collect field data;

[0040] 1) After the foundation construction of the construction section is completed, use two or more than two kinds of equipment (such as GPS or total station, etc.) Accurate measurement, using two kinds of measuring equipment and two methods to compare and check the measurement results, and then on the basis of the measurement results, combined w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com