Patents

Literature

704 results about "Lean manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lean manufacturing or lean production is a systematic method originating in the Japanese manufacturing industry for the minimization of waste (無駄 muda) within a manufacturing system without sacrificing productivity, which can cause problems. Lean also takes into account waste created through overburden (無理 muri) and unevenness in work loads (斑 mura). Working from the perspective of the client who consumes a product or service, "value" is any action or process that a customer would be willing to pay for.

Energy management system

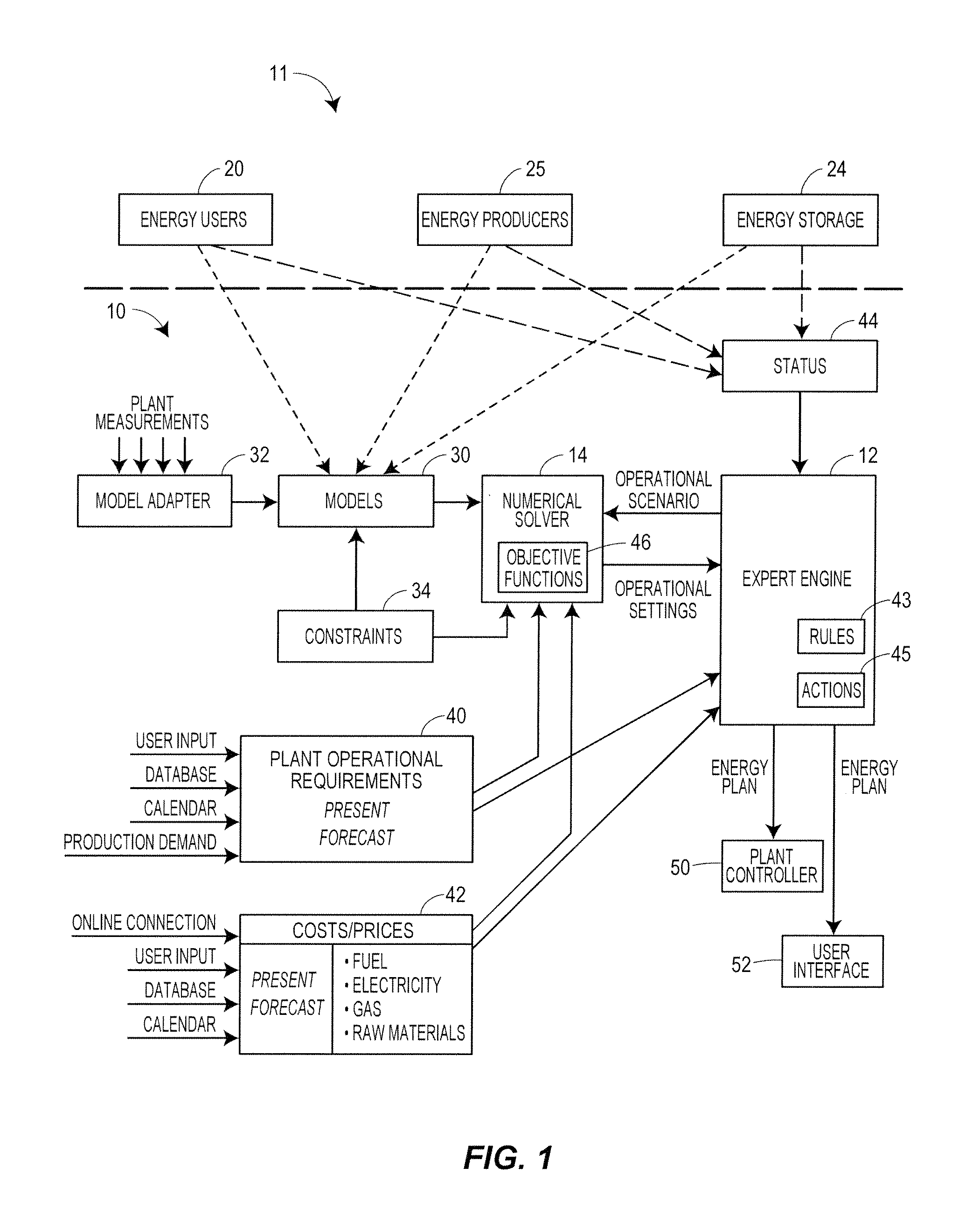

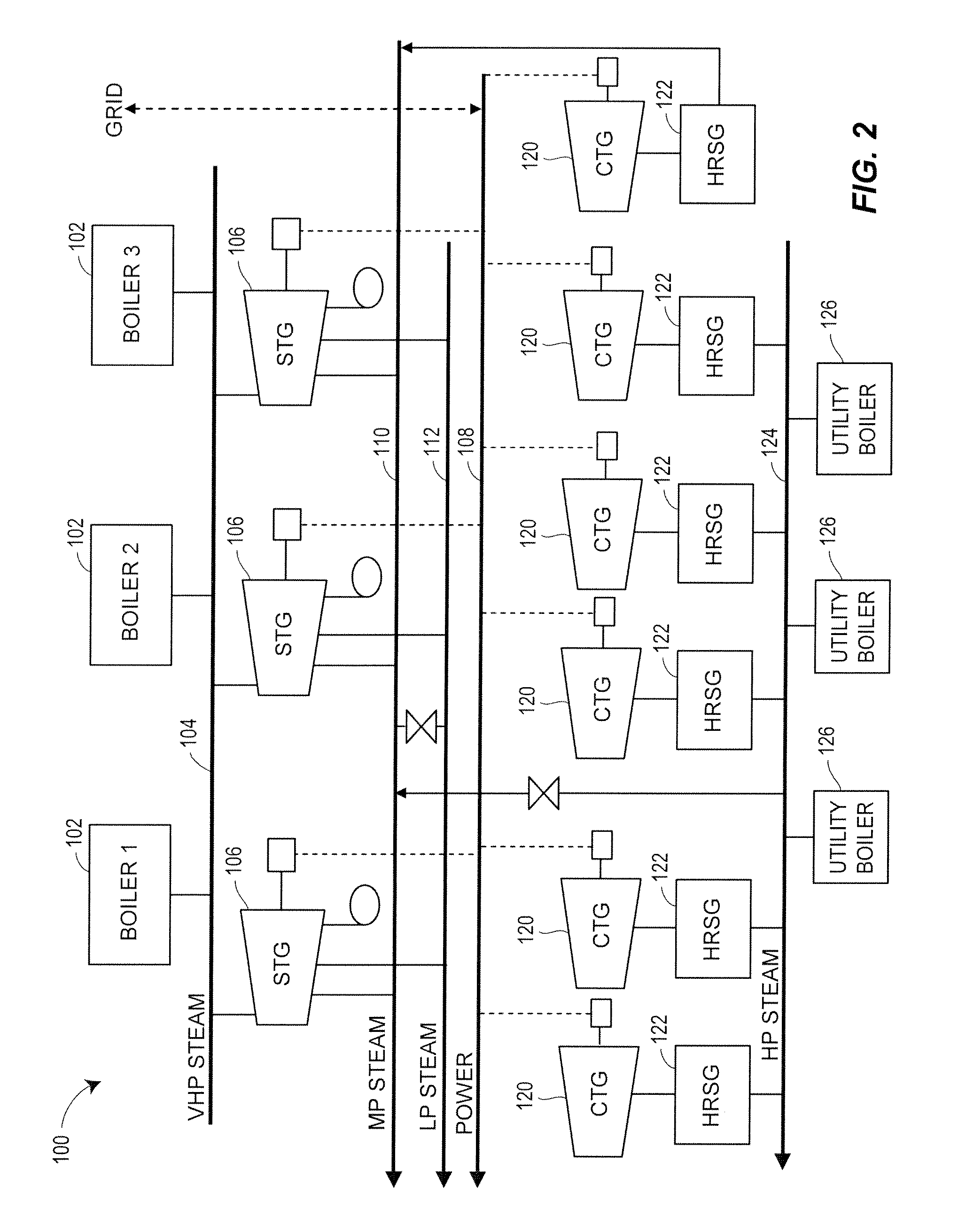

ActiveUS20120010757A1Reduce and optimize energy costLow costLevel controlVolume/mass flow measurementOperational systemEnergy depletion

An energy management system uses an expert engine and a numerical solver to determine an optimal manner of using and controlling the various energy consumption, producing and storage equipment in a plant / communities in order to for example reduce energy costs within the plant, and is especially applicable to plants that require or that are capable of using and / or producing different types of energy at different times. The energy management system operates the various energy manufacturing and energy usage components of the plant to minimize the cost of energy over time, or at various different times, while still meeting certain constraints or requirements within the operational system, such as producing a certain amount of heat or cooling, a certain power level, a certain level of production, etc. In some cases, the energy management system may cause the operational equipment of the plant to produce unneeded energy that can be stored until a later time and then used, or that can be sold back to a public utility, for example, so as to reduce the overall cost of energy within the plant.

Owner:EMERSON PROCESS MANAGEMENT POWER & WATER SOLUTIONS

Manufacturing system using topology optimization design software, novel three-dimensional printing mechanisms and structural composite materials

ActiveUS20150239178A1Adjusting operationGeometric CADProgramme controlThermoplasticComputer Aided Design

Owner:ARMSTRONG NATHAN

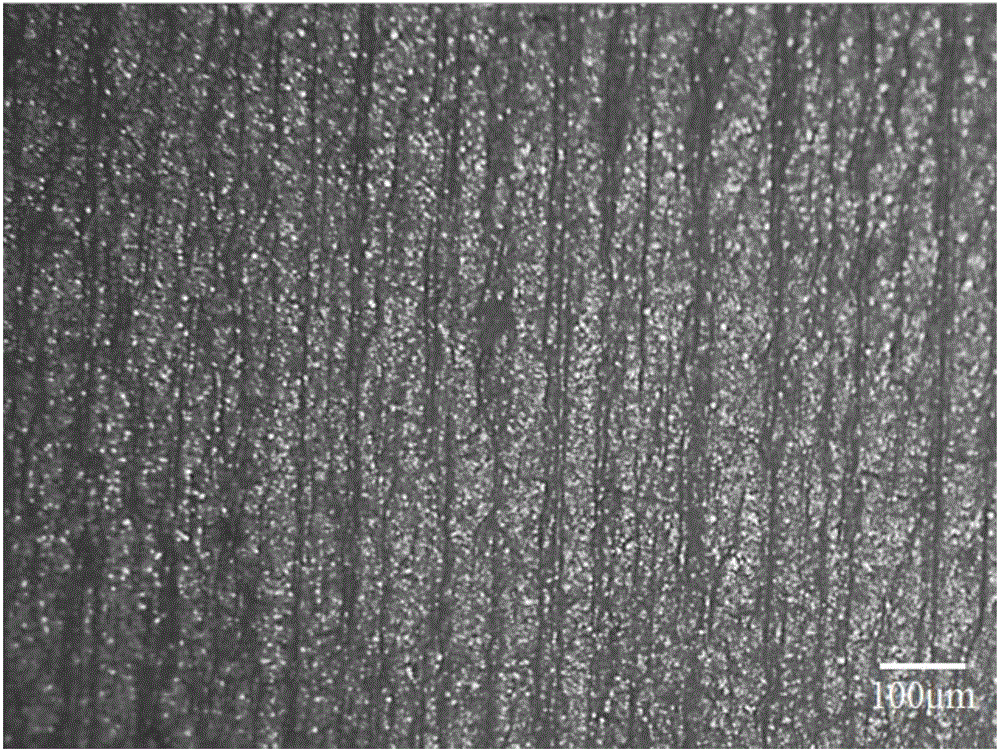

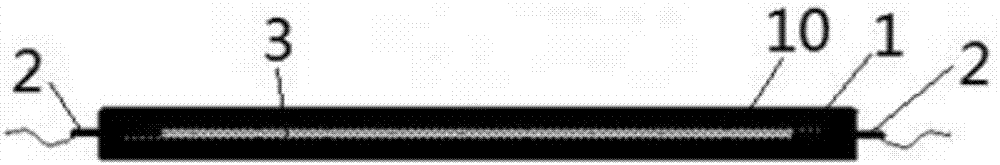

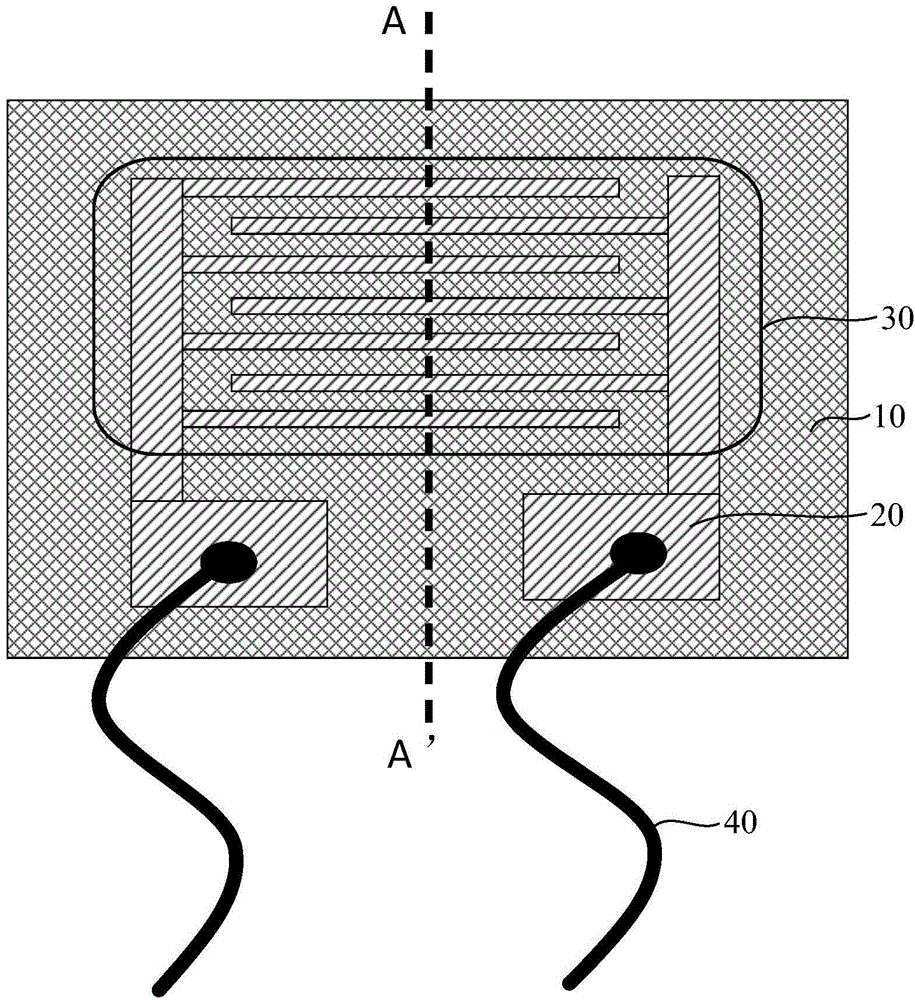

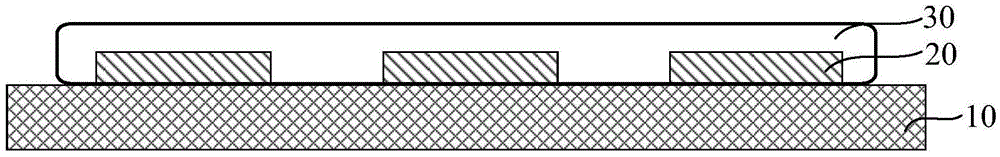

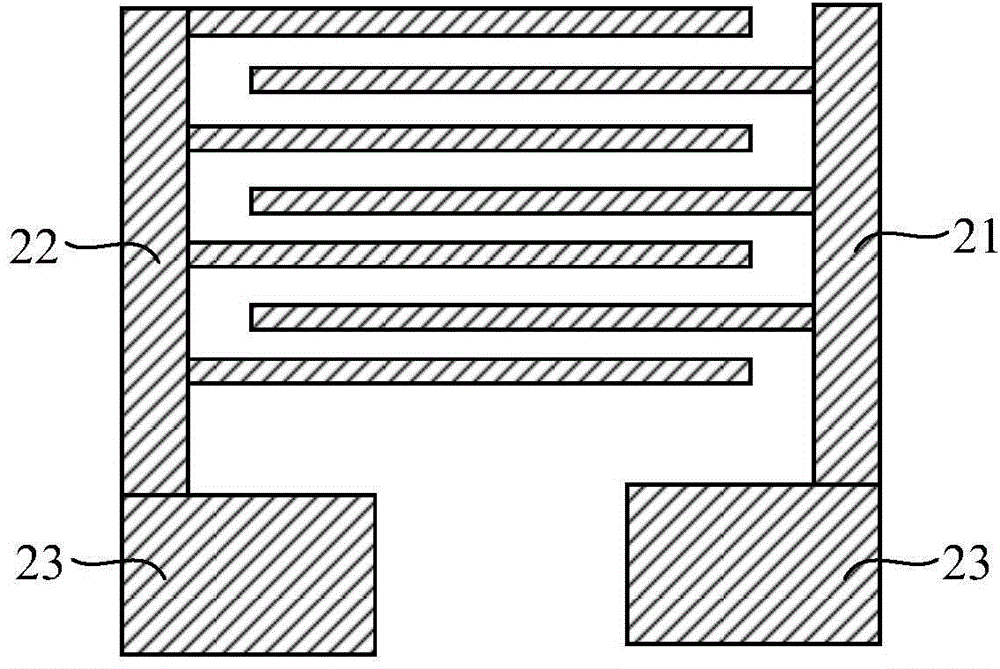

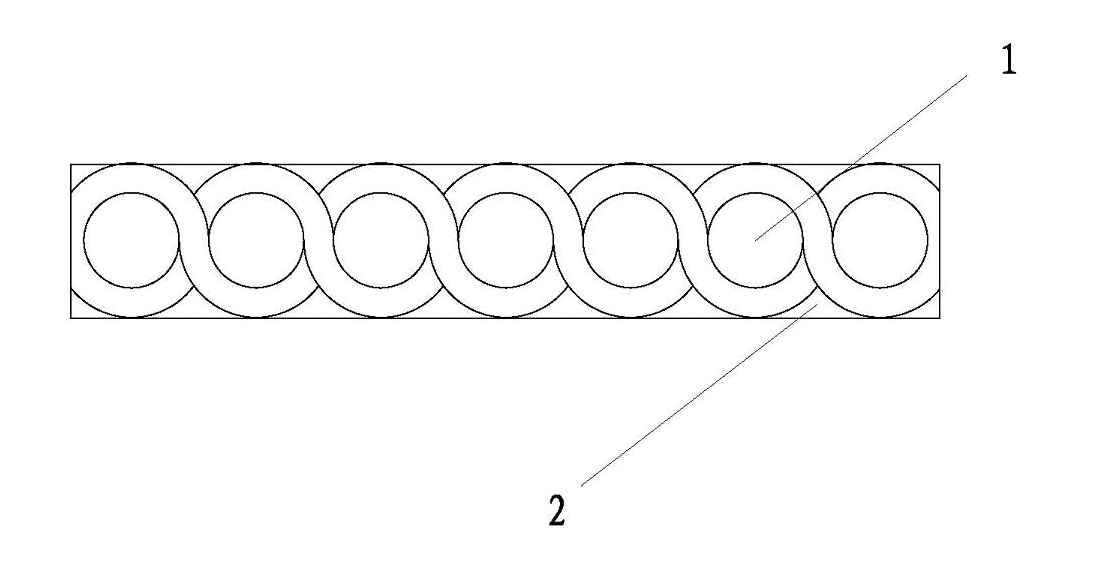

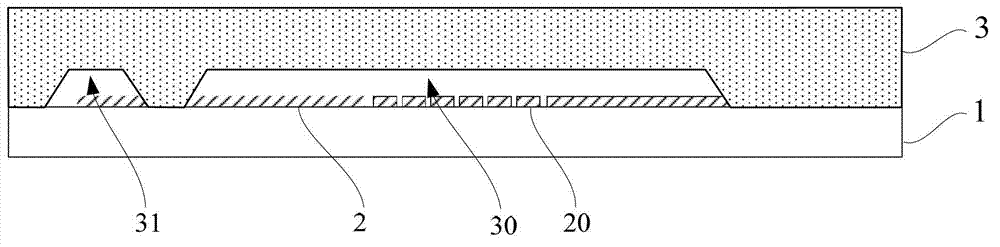

Flexible strain sensor with crack structure and preparation method thereof

ActiveCN105783697AHigh sensitivityLarge resistance changeElectrical/magnetic solid deformation measurementEngineeringProtection layer

The invention belongs to the technical field of sensor manufacturing and especially relates to a flexible strain sensor with a crack structure and a preparation method thereof. The invention provides a flexible strain sensor comprising a flexible substrate, a conducting coating which is coated on the flexible substrate and provided with a prefabricated crack structure, a pair of electrodes which are positioned at two ends of the conducting coating surface, and a protection layer which covers the conducting coating surface and is made from flexible polymer. By means of the flexible strain sensor provided by the invention, small strain changes can be accurately monitored; the preparation method is simple and low in cost; the flexible strain sensor has high sensitivity, good stability and long service life, and can be bended and twisted.

Owner:ZHENGZHOU UNIV

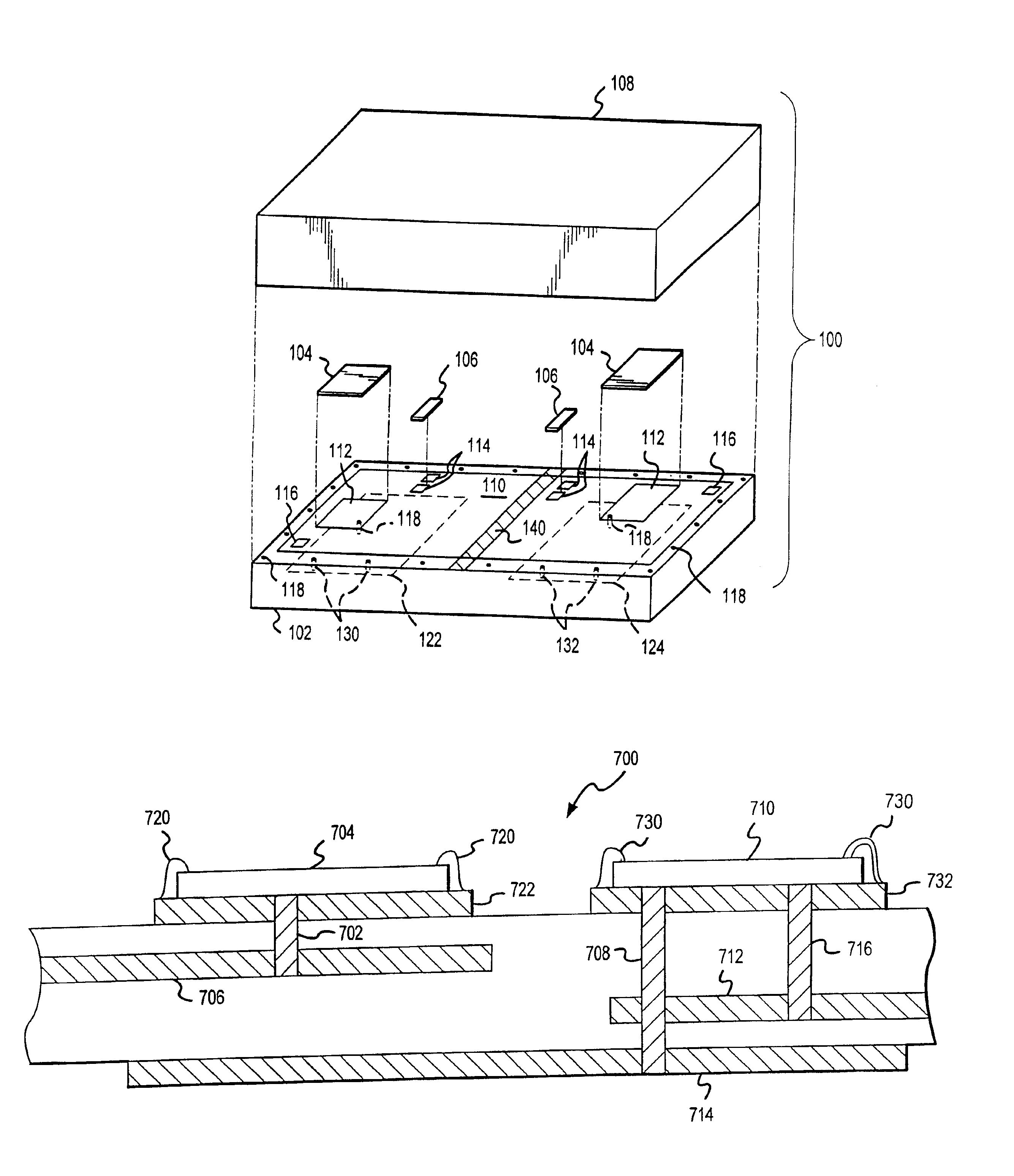

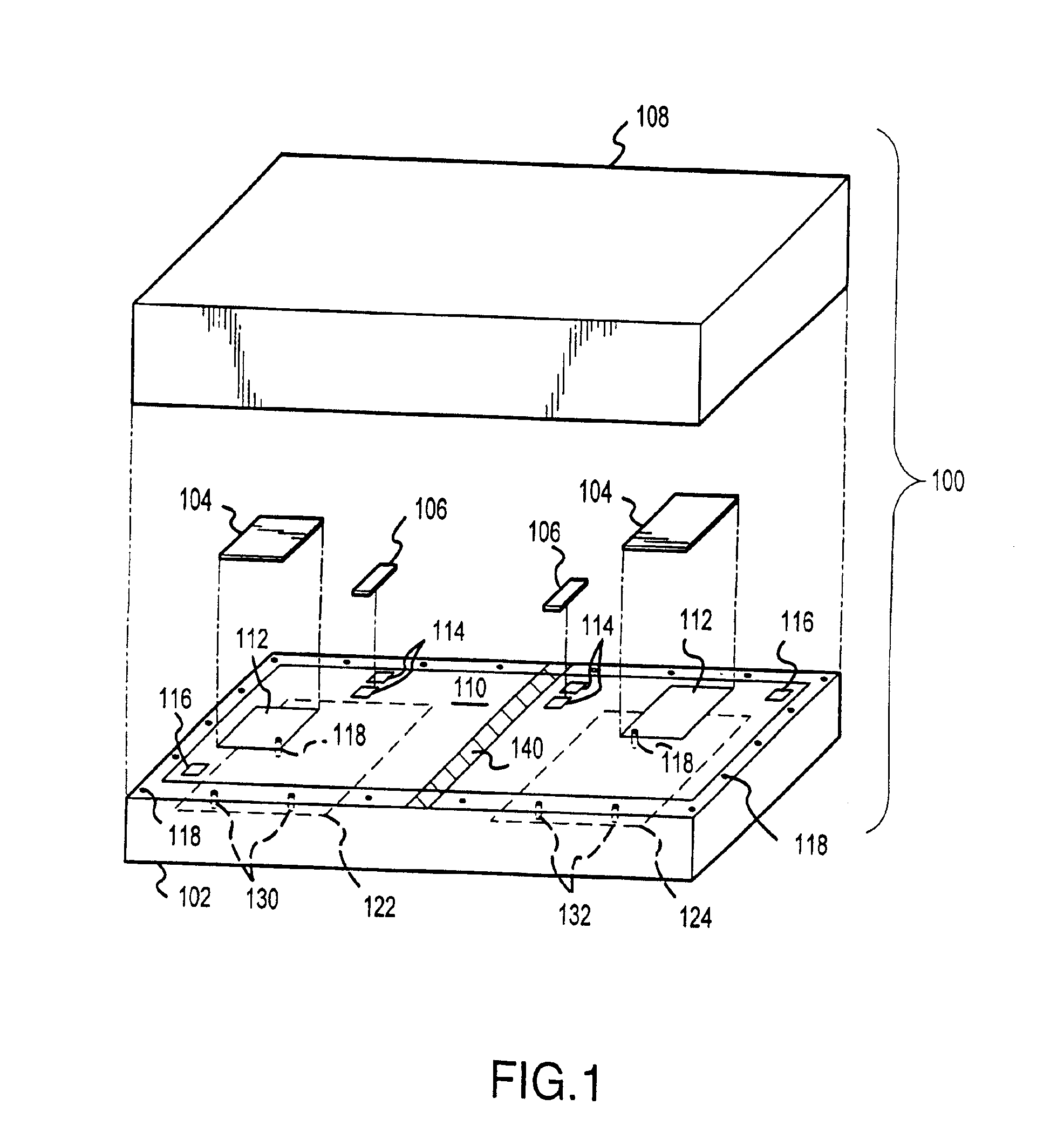

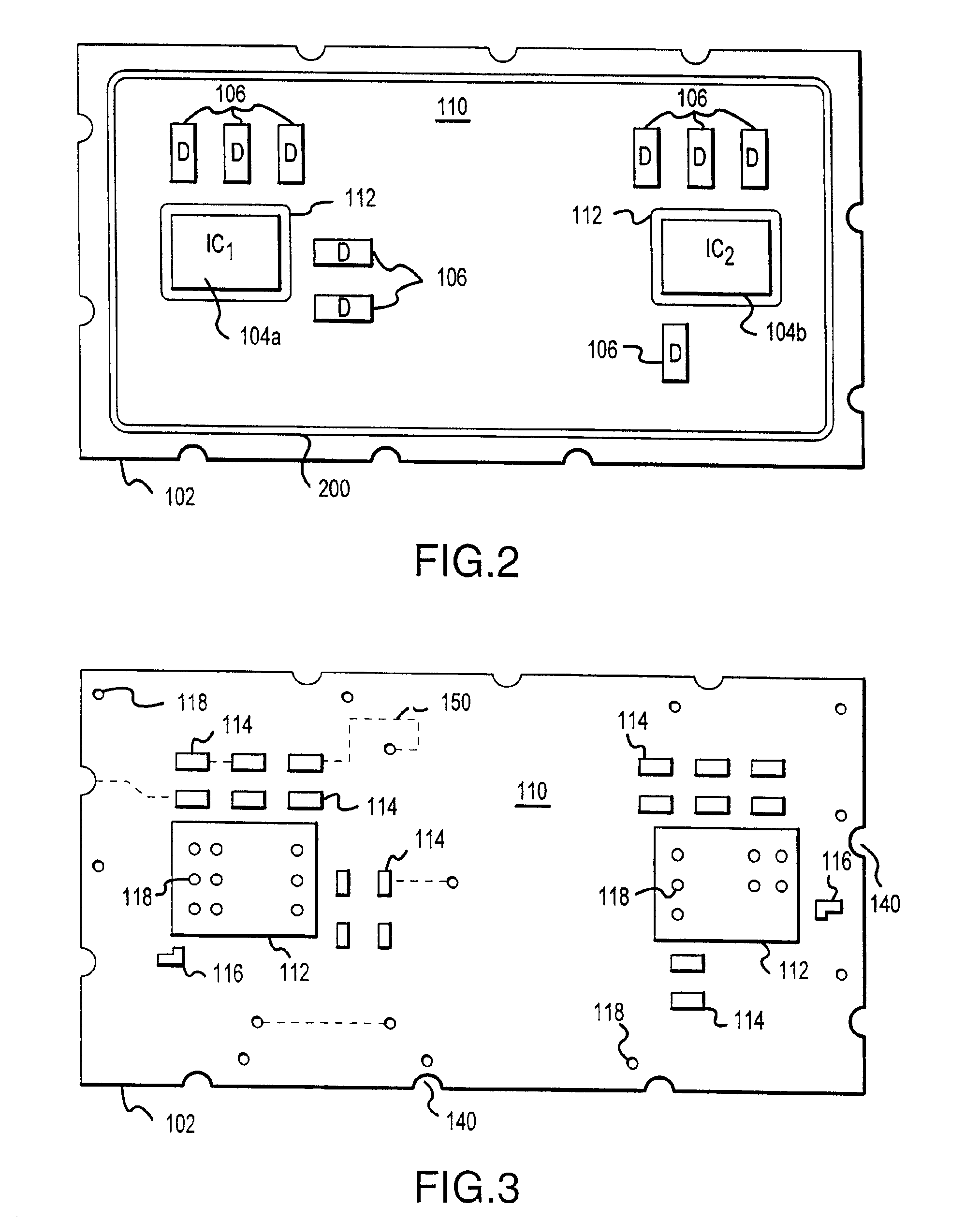

Multiple chip module with integrated RF capabilities

InactiveUS6885561B1Highly integratedMagnetic/electric field screeningSemiconductor/solid-state device detailsElectrical conductorHigh volume manufacturing

A multiple chip module (MCM) for use with baseband, RF, or IF applications includes a number of active circuit chips having a plurality of different functions. The active circuit chips are mounted on a substrate that is configured to provide an integrated subsystem in a single MCM package. The MCM includes a number of features that enable it to meet electrical performance, high-volume manufacturing, and low-cost requirements. The MCM may incorporate split ground planes to achieve electronic shielding and isolation, vias configured as both thermal sinks and grounding connections, and specifically configured die attach pads and exposed ground conductor pads.

Owner:SKYWORKS SOLUTIONS INC

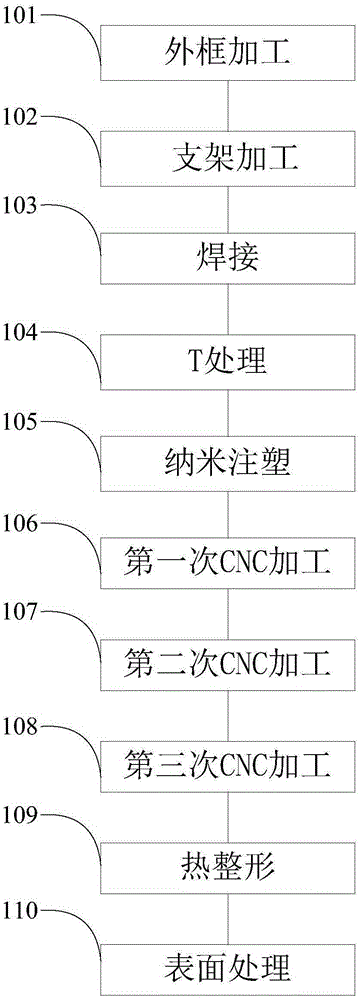

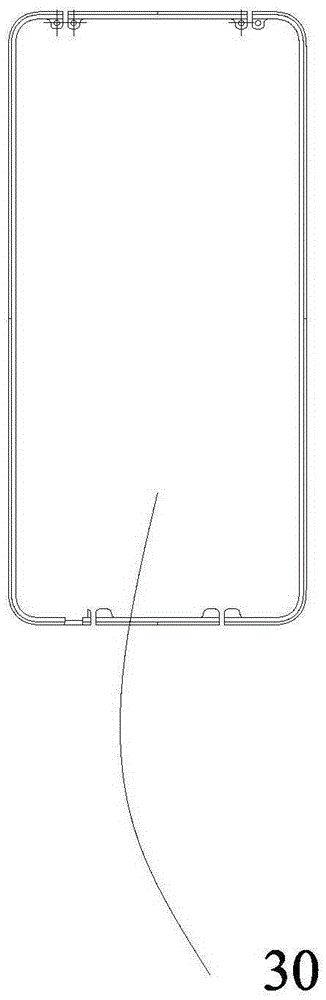

Mobile phone shell and shell manufacturing process thereof

InactiveCN105306632ASolve dense pore defectsImprove yield rateOther manufacturing equipments/toolsTelephone set constructionsMobile phoneTime processing

The invention provides a shell manufacturing process. The shell comprises an aluminum alloy frame and an aluminum alloy bracket combined with the aluminum alloy frame, the shell manufacturing process sequentially comprises frame manufacturing, bracket manufacturing, welding, T processing, nanometer injection molding, first time CNC processing, second time CNC processing, third time CNC processing, thermal shaping and surface processing steps, and the surface of the aluminum alloy shell of the shell has metal luster. By means of the manner, the shell manufacturing process provided by the invention has the advantages of few manufacturing procedures, short period, raw material saving, higher yield and lower manufacturing cost. The invention further provides a mobile phone shell with metal luster and manufactured by the shell manufacturing process.

Owner:SHENZHEN TINNO WIRELESS TECH

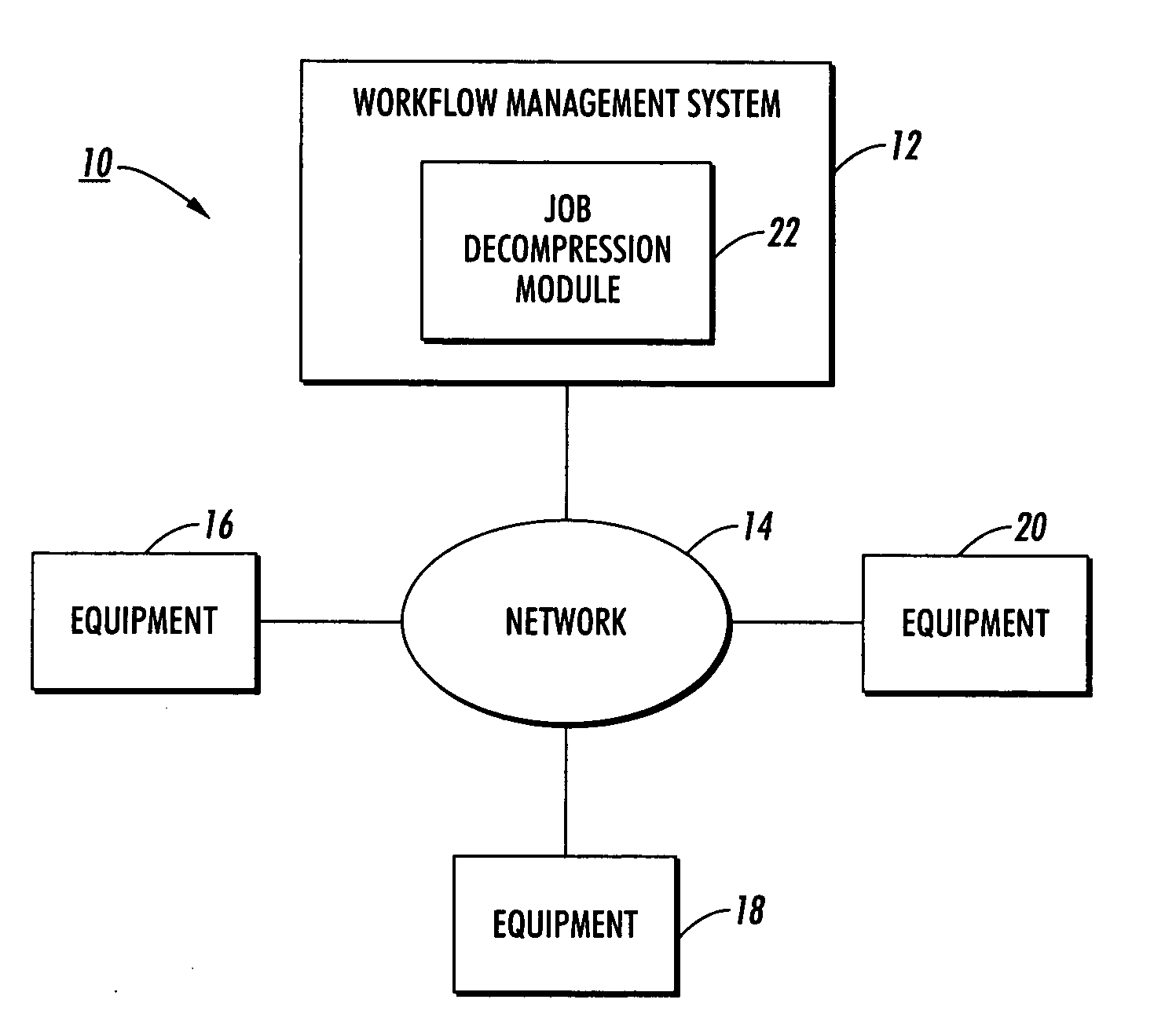

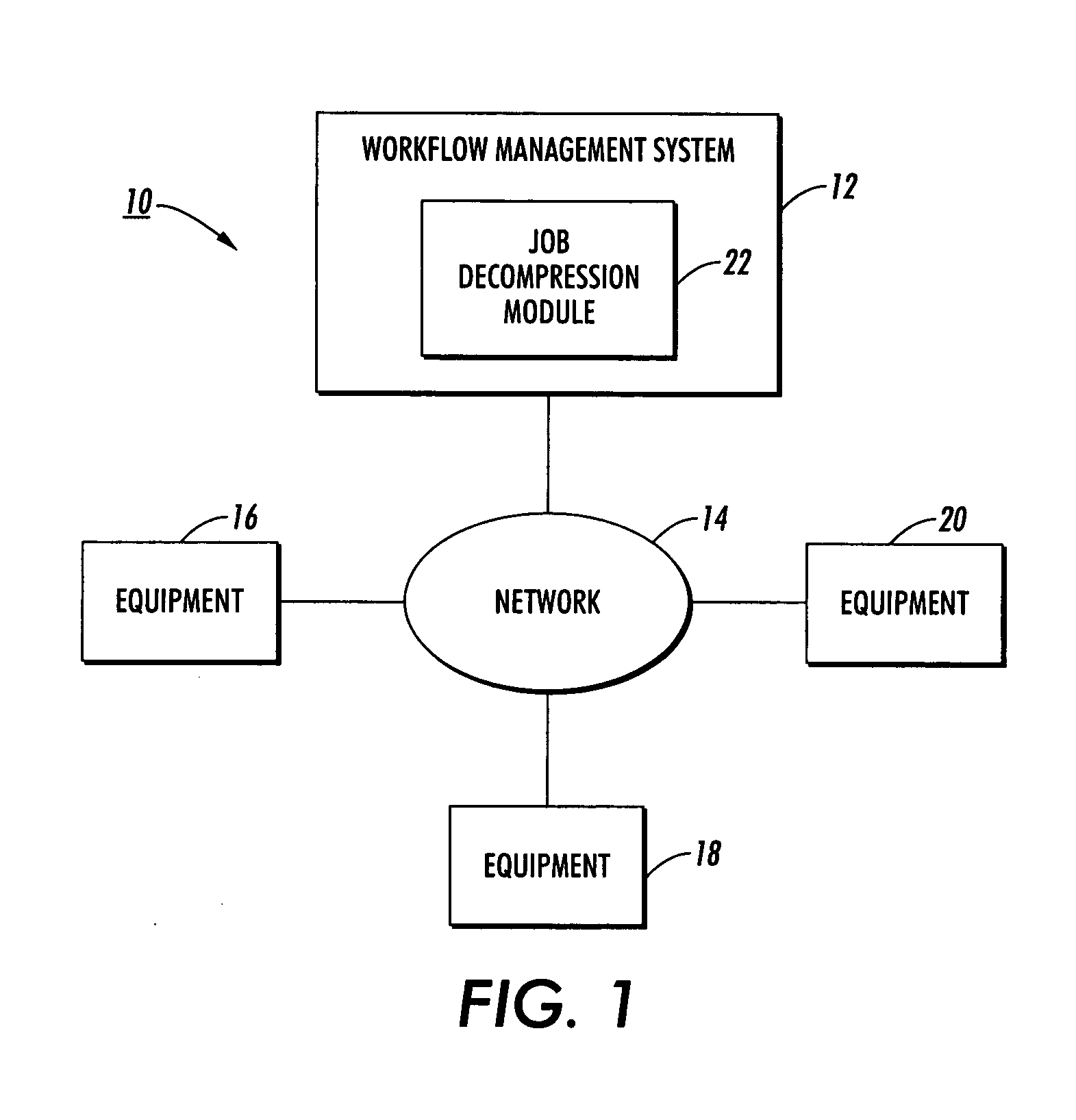

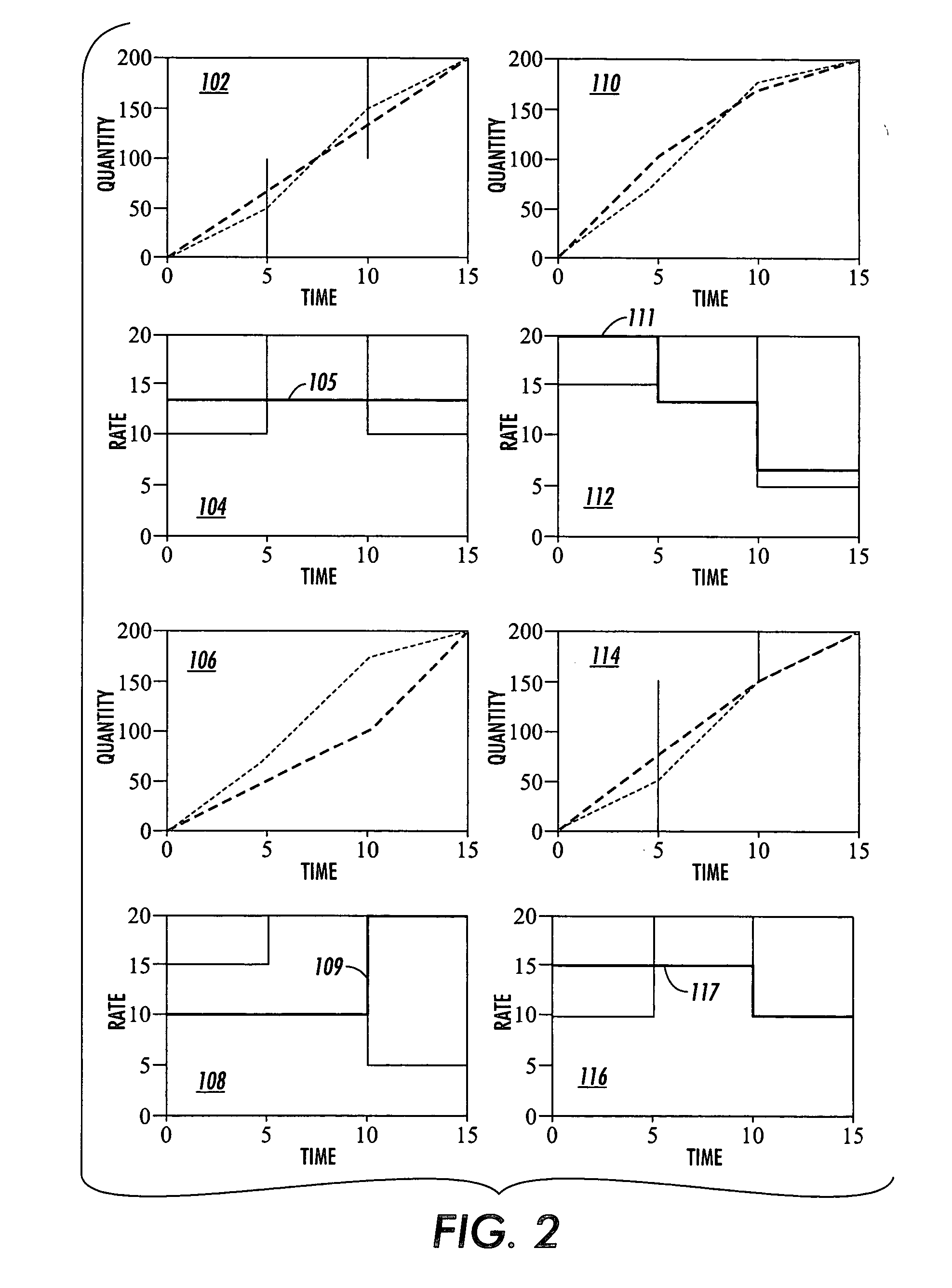

Methods and systems for determining resource capabilities for a lean production environment

ActiveUS20050151993A1Improve the environmentImage enhancementDigitally marking record carriersProduction rateEngineering

A plurality of printing jobs associated with a printing environment can be initially evaluated. Such a printing environment can be implemented as a print shop or another lean document production environment. A set of minimal resource capacities can then be calculated as a multi-objective optimization using a linear programming (LP) analysis. Alternatively, in a generalized geometrical algorithm, at least one peak-demand production rate associated with the most critical resource can first be estimated, in response to evaluating the plurality of printing jobs. Thereafter, minimal resource capacities of the plurality of resources of the printing environment can be hierarchically calculated based on estimating the previously determined peak-demand production rate of higher priority.

Owner:XEROX CORP

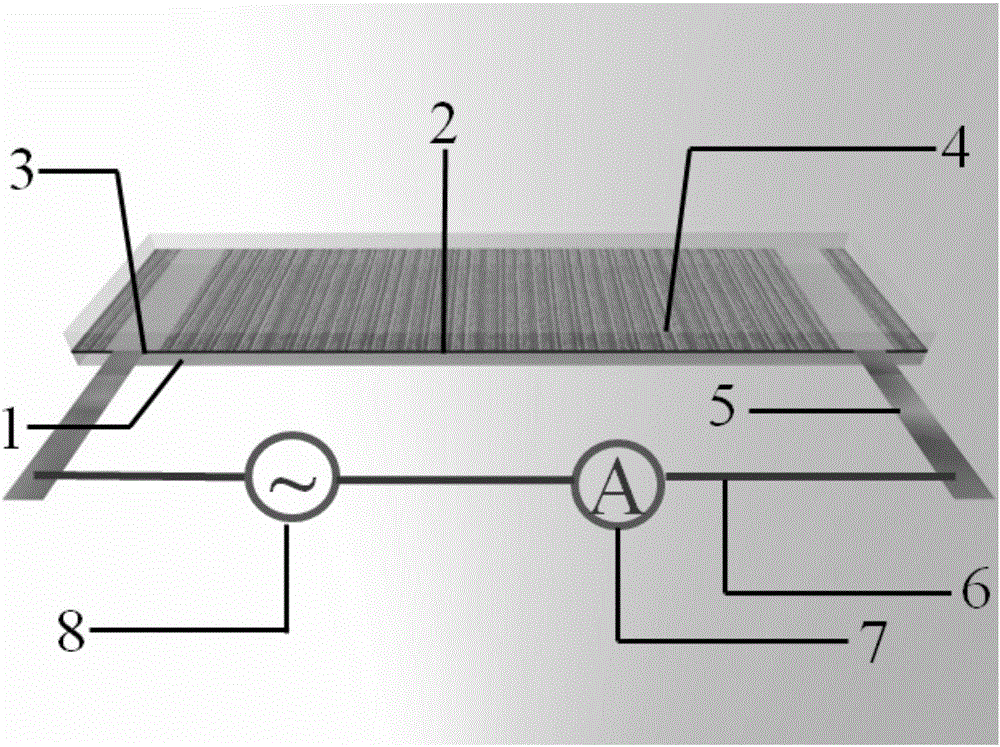

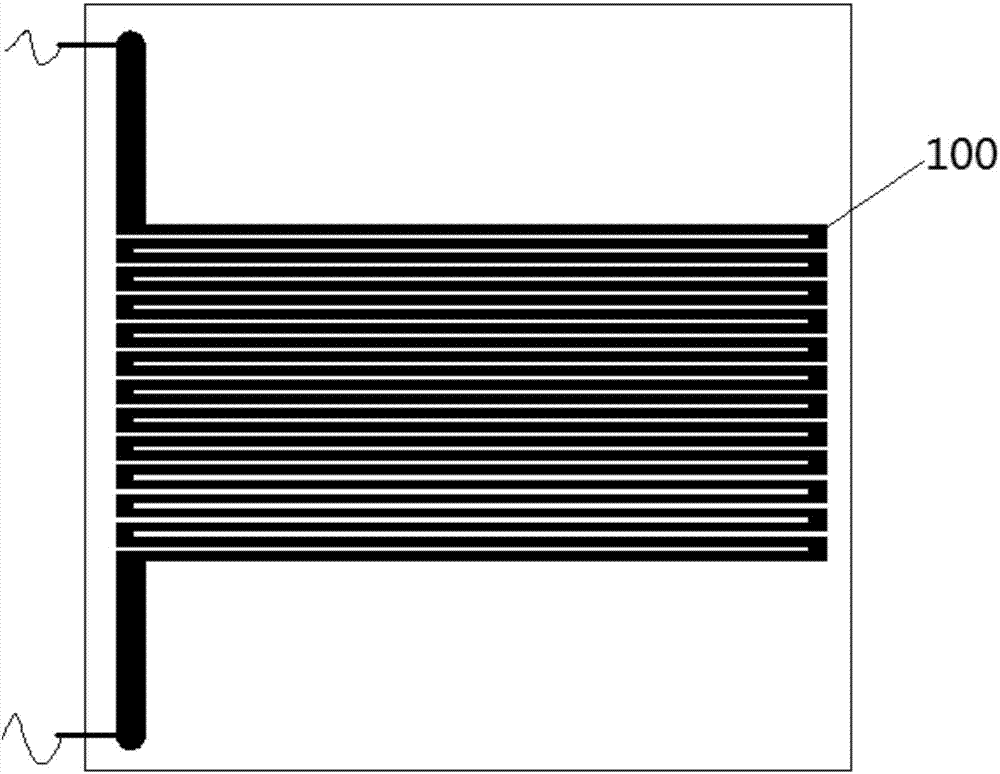

Flexible wearable electronic strain sensor and manufacturing method thereof

ActiveCN107478148AEasy to measureElectrical/magnetic solid deformation measurementElectrical conductorLiquid state

The invention relates to the sensor manufacturing and packaging technology field and discloses a flexible wearable electronic strain sensor and a manufacturing method thereof. The flexible wearable electronic strain sensor comprises a flexible substrate, wherein the flexible substrate internally has a flexible micro channel, the micro channel is internally provided with a liquid conductor or a semi-liquid conductor, and two ends of the micro channel are provided with electrodes. Wearable equipment has the flexible wearable electronic strain sensor. The manufacturing method of the flexible wearable electronic strain sensor comprises steps that the flexible substrate having the flexible micro channel is manufactured; the micro channel is internally injected with the liquid conductor or the semi-liquid conductor, and the electrodes are inserted at the two ends of the micro channel. The flexible wearable electronic strain sensor and the manufacturing method thereof are advantaged in that high flexibility, stretching property and thinness are realized, so the flexible wearable electronic strain sensor can be directly integrated with any flexible actuating mechanisms, sensitivity is high, anti-interference capability is strong, and the flexible wearable electronic strain sensor can normally operate even when strain reaches 300%.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

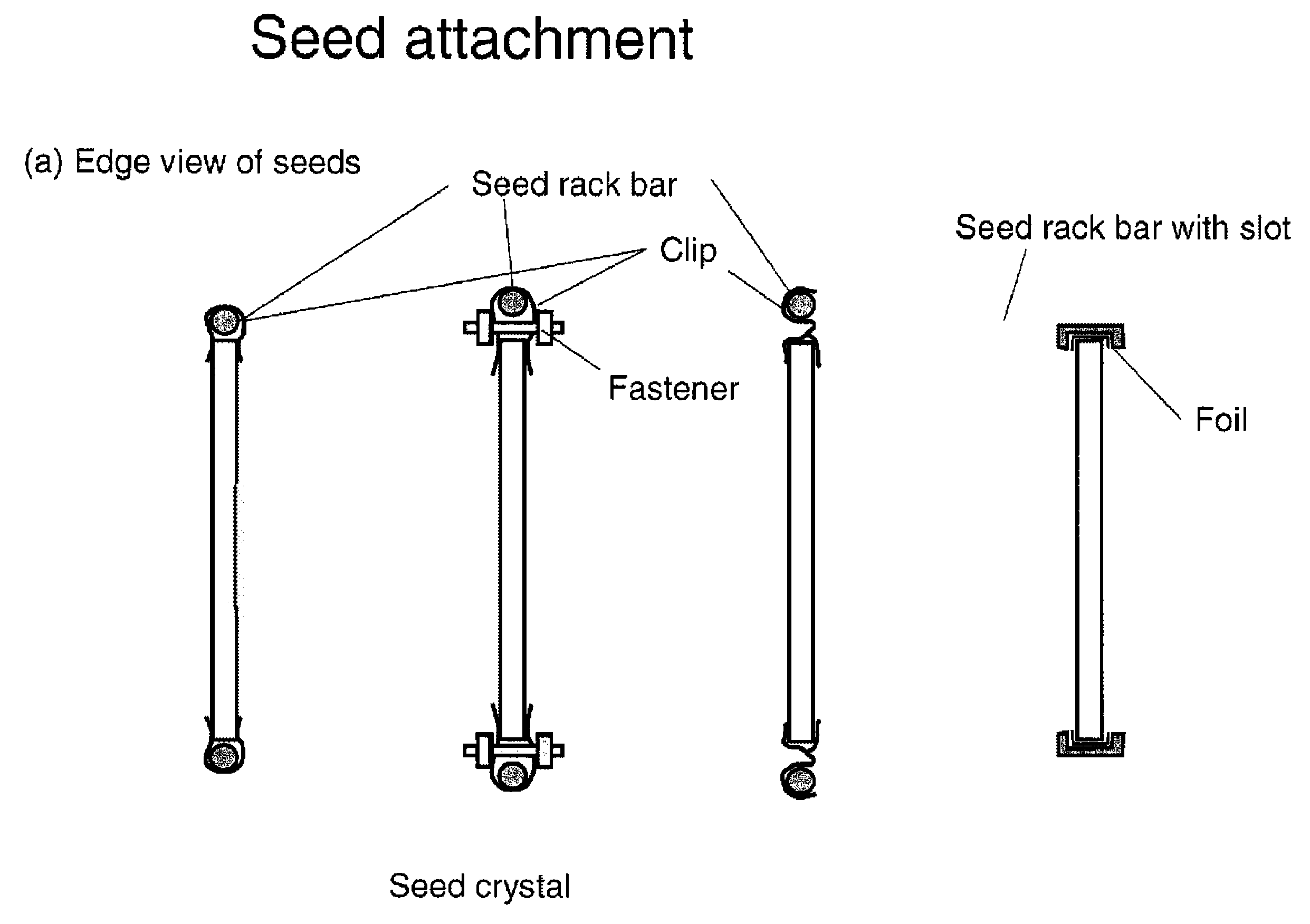

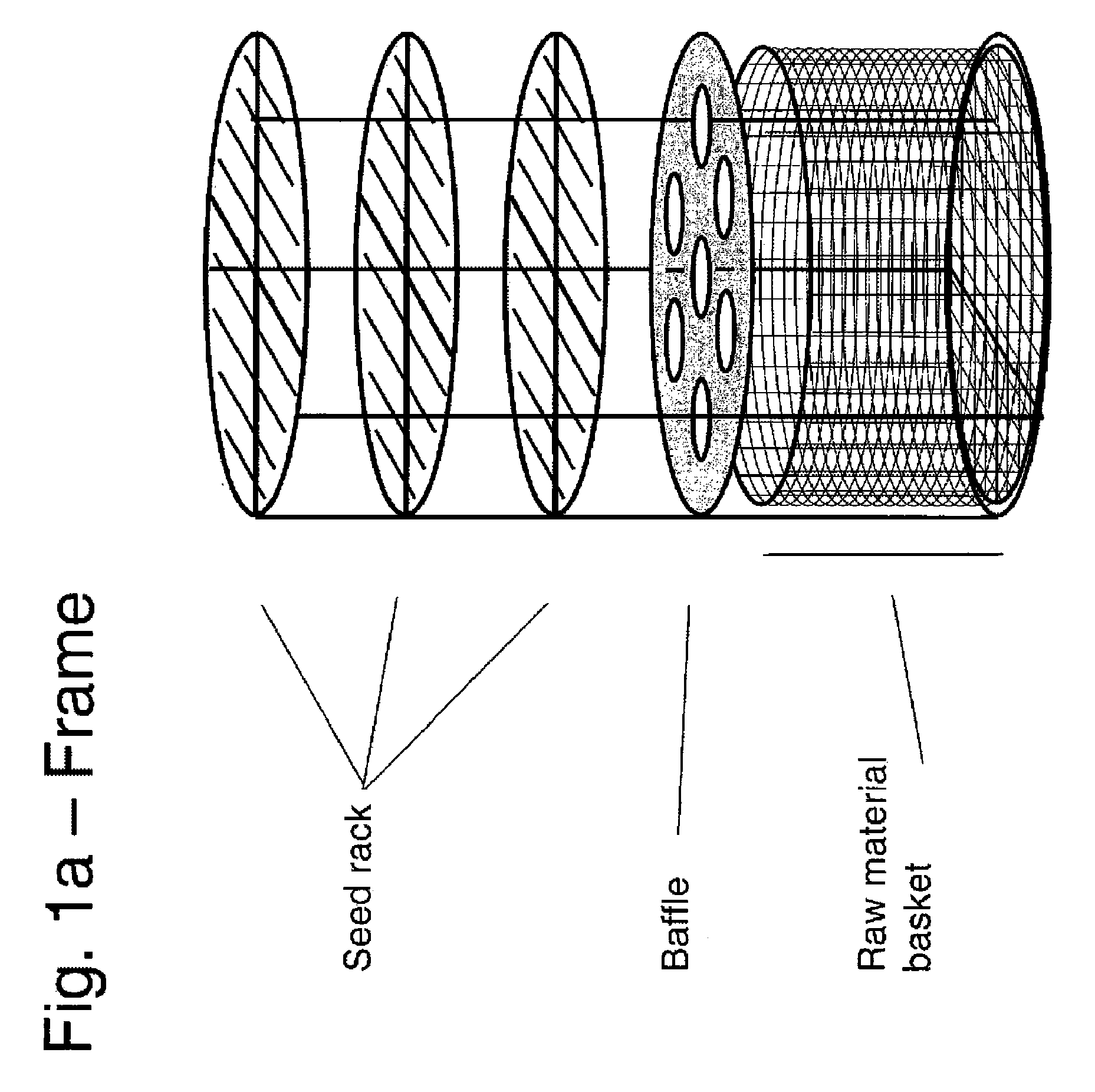

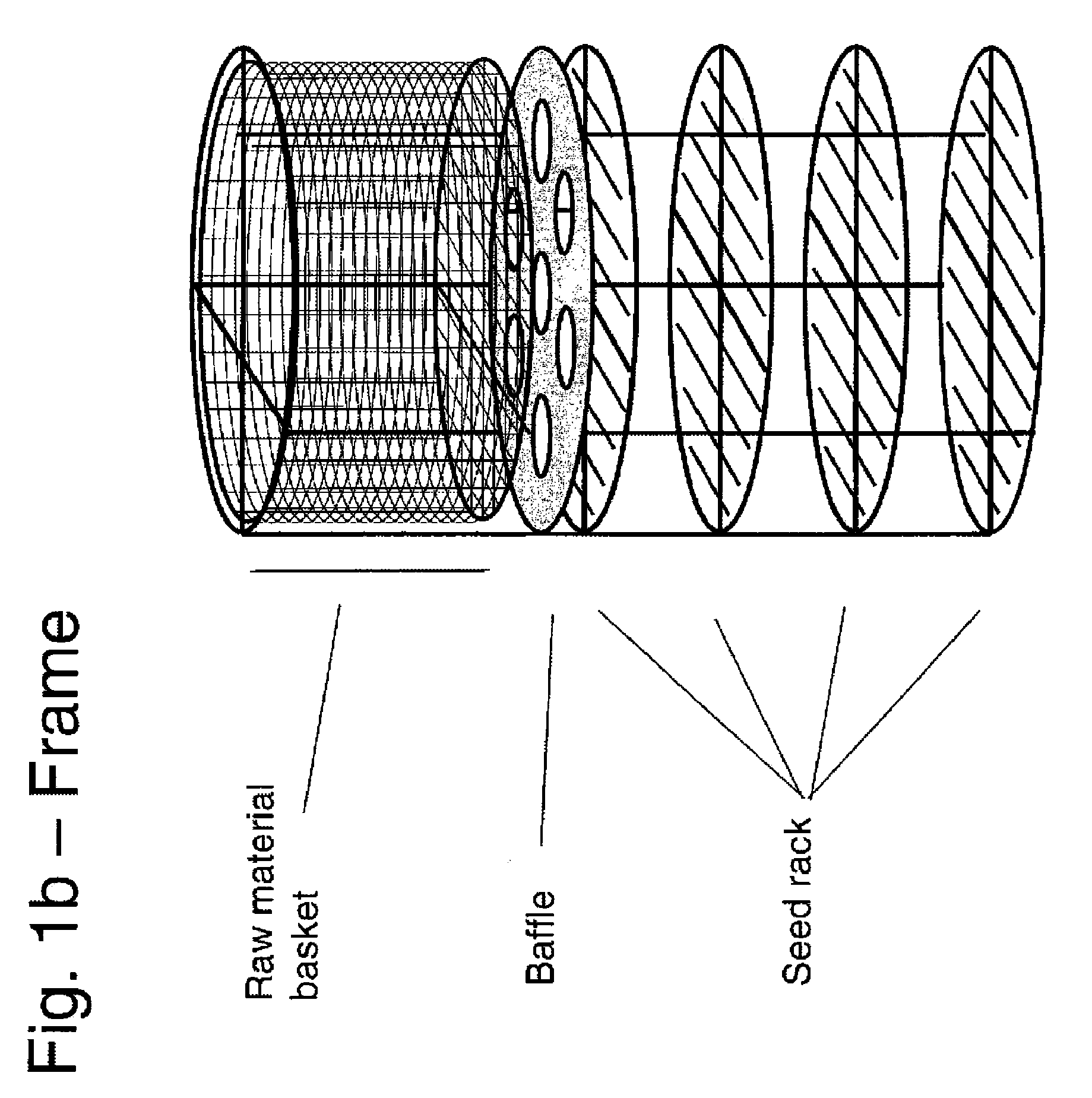

Apparatus and method for seed crystal utilization in large-scale manufacturing of gallium nitride

ActiveUS8430958B2Simple and cost-effective to manufactureIncrease pressureAfter-treatment apparatusPolycrystalline material growthCost effectivenessGallium nitride

An apparatus and associated method for large-scale manufacturing of gallium nitride. The apparatus comprises a large diameter autoclave or internally-heated high pressure vessel, a seed rack, and a raw material basket. Methods include effective means for utilization of seed crystals. The apparatus and methods are scalable up to very large volumes and are cost effective.

Owner:SLT TECH

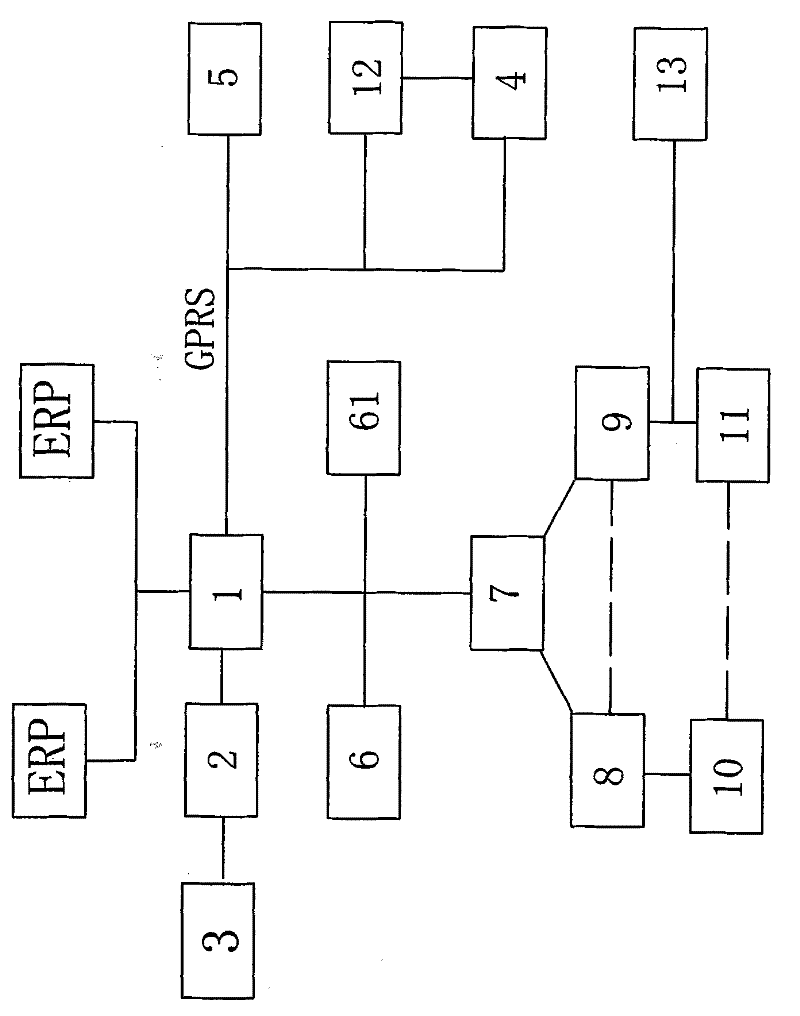

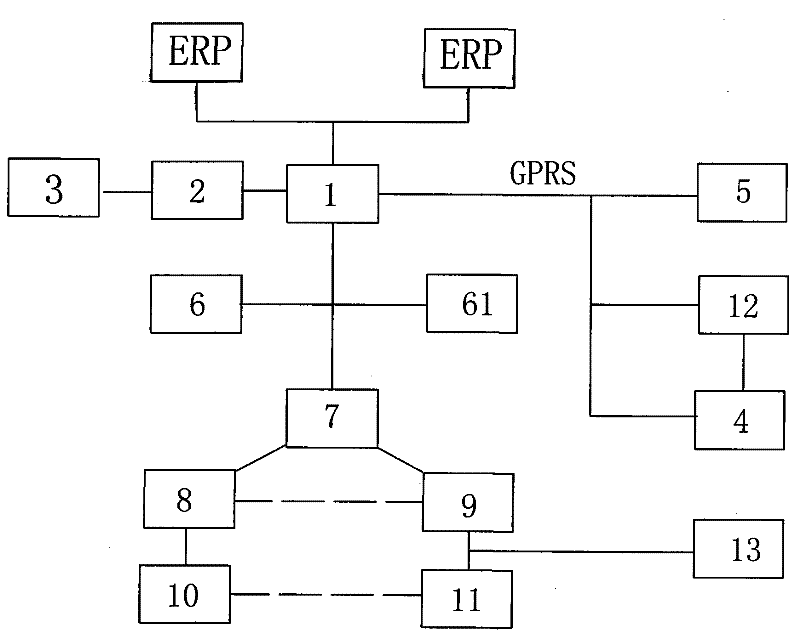

aps/mes lean manufacturing management system

InactiveCN102262757AImprove reaction speedImprove reaction efficiencyInstrumentsSoftware systemHand held

APS / MES lean manufacturing management system, including system hardware and system software, the software in the hardware is integrated in the main system software, and is seamlessly connected with the main system; the system hardware includes: industrial touch all-in-one machine connected to the host server and LED electronic kanban and The RFID card reader used to read the RFID card, the wireless receiving and transmitting device is connected with the host server, the handheld terminal and the terminal touch screen through the sensor, and the host server is also connected with the host of the logistics distribution center and the host of the delivery center; the system software includes: Supply chain management, sales management, procurement management, warehouse management, subcontract processing, production order, process route, workshop scheduling plan, handheld terminal module, terminal touch screen, material distribution, LED electronic kanban control system software module; system software The management module is divided into: basic data module, supply chain management module, equipment management module, production management module, and handheld terminal module; each module is composed of its corresponding sub-modules.

Owner:王圣亮

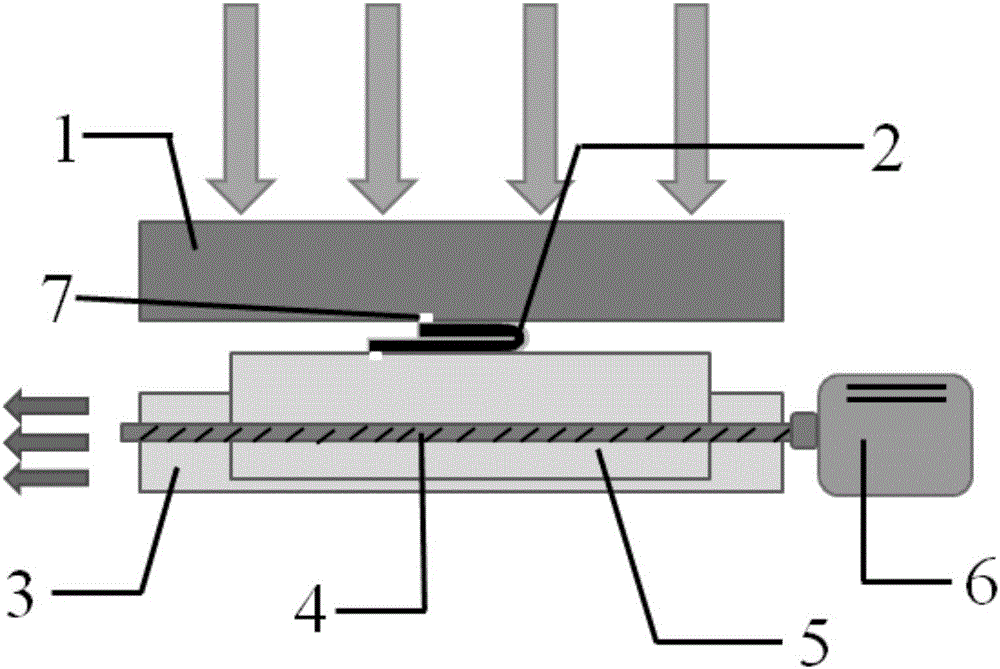

Humidity sensor, humidity sensor array and preparation method thereof

The invention relates to the field of sensor manufacturing and discloses a humidity sensor, a humidity sensor array and a preparation method thereof. According to the humidity sensor, a piece of sensitive thin film in the humidity sensor includes oxidized graphene, the oxidized graphene is capable of enabling the response time to be greatly reduced, enabling the response amplitude to be improved and analyzing the environment humidity and environment gas ingredients, and moreover, the structure is simple, the preparation is easy to realize, and the cost is low.

Owner:SHENZHEN GONGJIN ELECTRONICS CO LTD

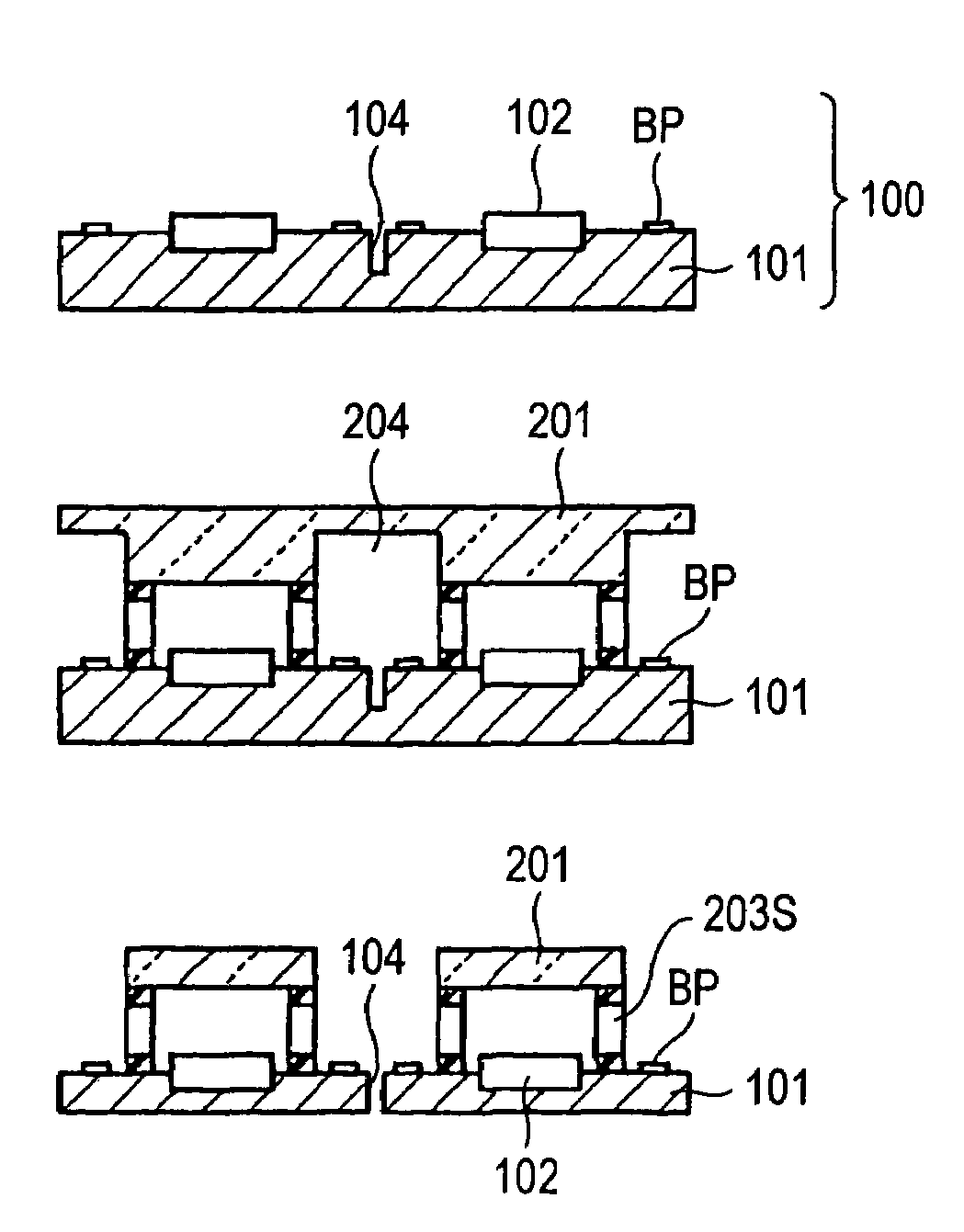

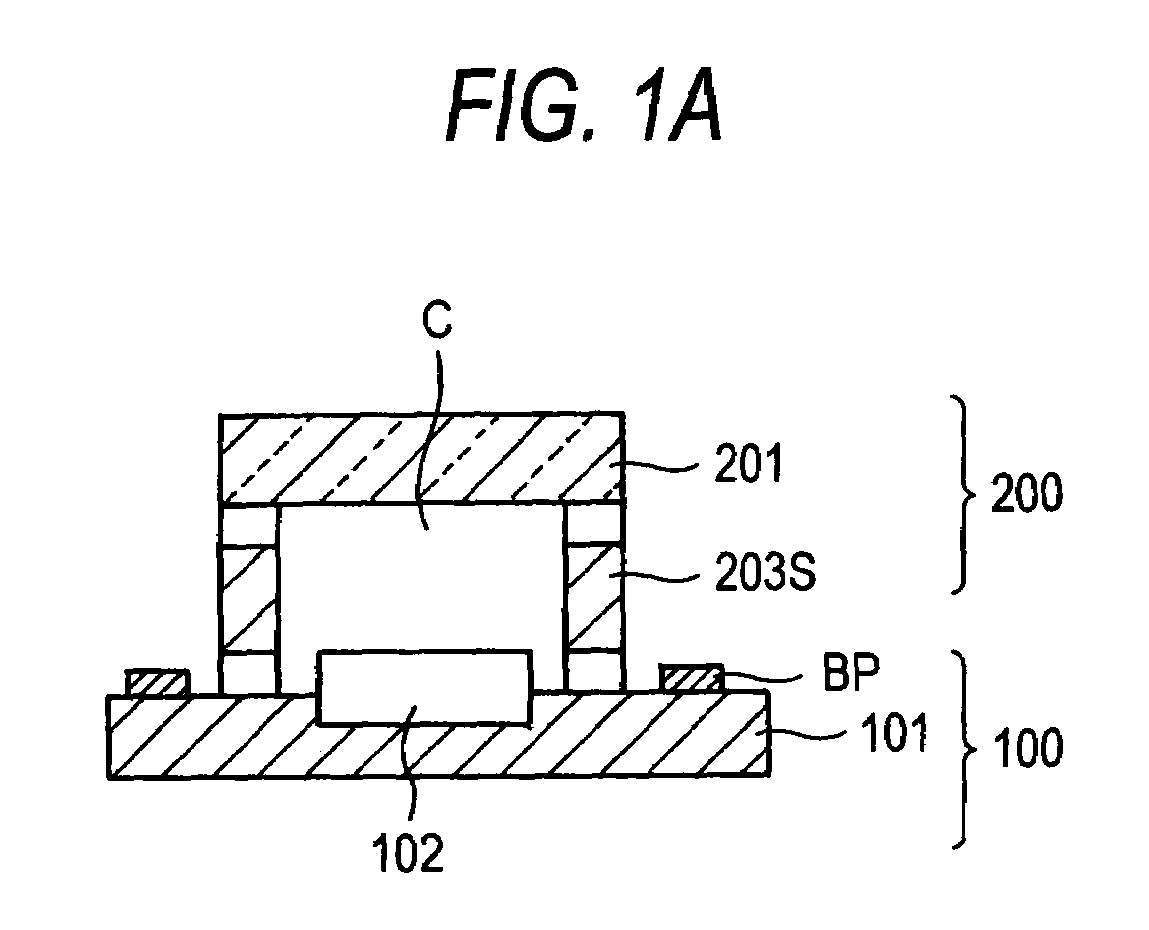

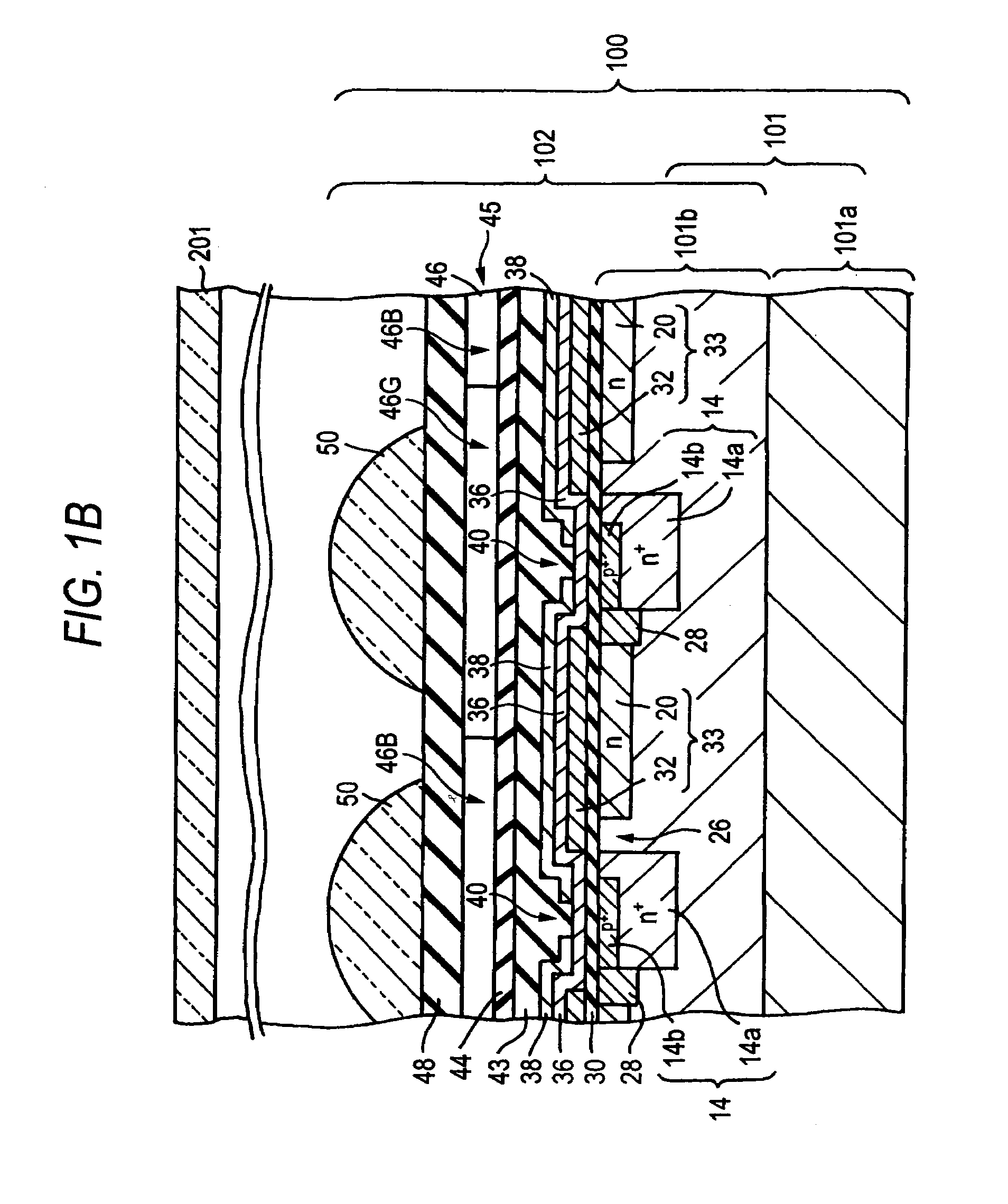

Solid-state imaging device and method of manufacturing said solid-state imaging device

InactiveUS7074638B2Easy to manufactureImprove reliabilitySolid-state devicesSemiconductor/solid-state device manufacturingEngineeringSemiconductor

It is an object to provide solid-state imaging device, which can easily be manufactured and has a high reliability, and a method of manufacturing the solid-state imaging device. In the present invention, a manufacturing method comprises the steps of forming a plurality of IT-CCDs on a surface of a semiconductor substrate, bonding a translucent member to the surface of the semiconductor substrate in order to have a gap opposite to each light receiving region of the IT-CCD, and isolating a bonded member obtained at the bonding step for each of the IT-CCDs.

Owner:FUJIFILM CORP

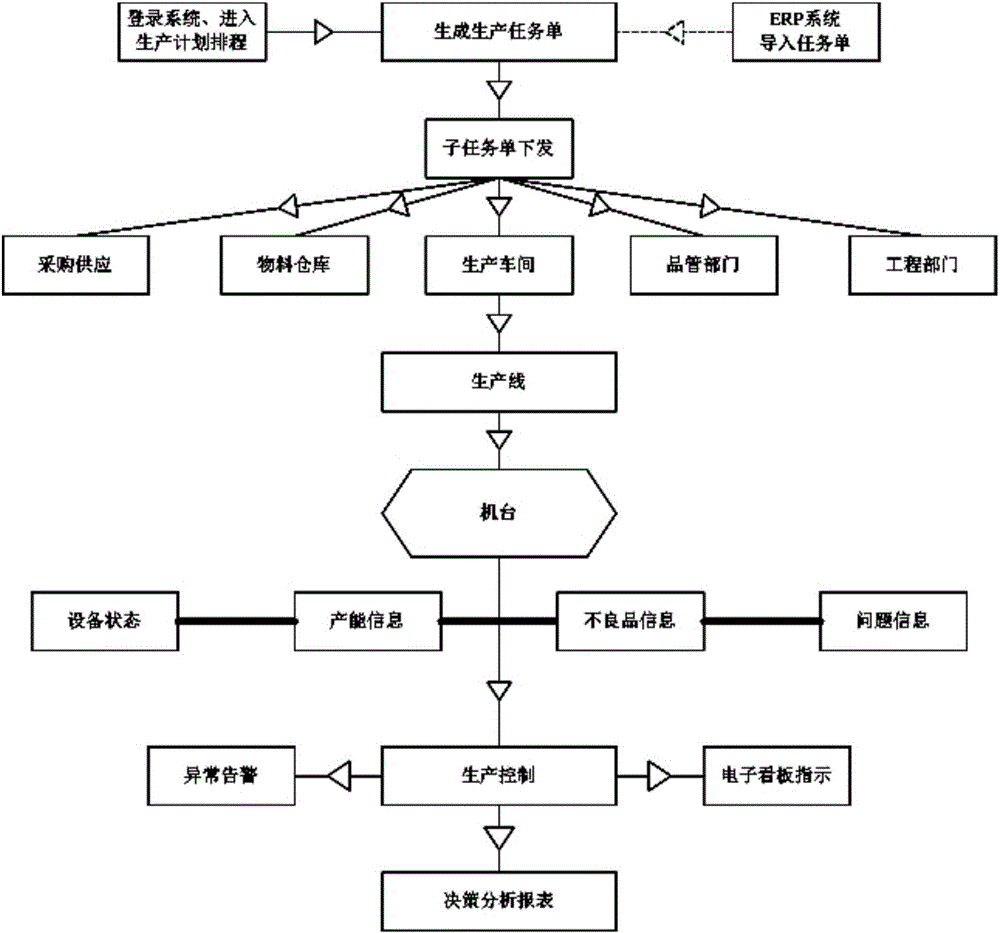

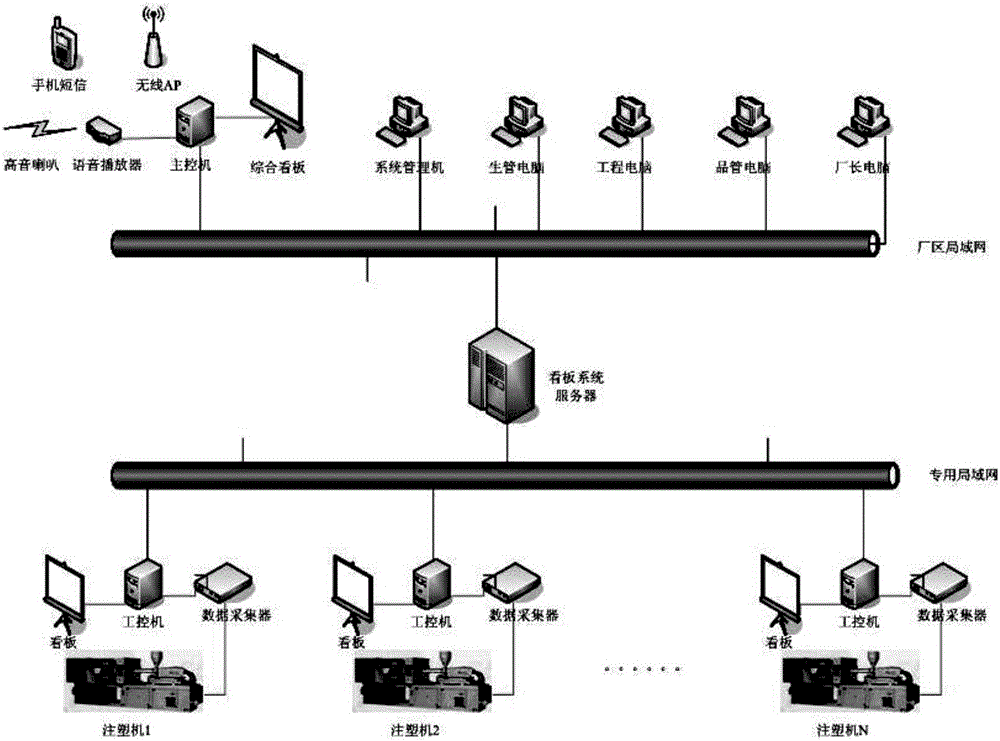

Lean production management kanban system and application method

InactiveCN106779592ASimple designAdvanced architectureOffice automationManufacturing computing systemsData acquisitionPersonal computer

The invention discloses a lean production management kanban system and an application method. The system mainly comprises machine table kanban, comprehensive kanban, a data collector, an industrial personal computer, a server, kanban system software, a call broadcast system, and a special local network. The system has the effects of real-time transmission of production information, transparent management and guarantee of production field work order, and is an effective tool for realizing lean production accurate management.

Owner:林冠良

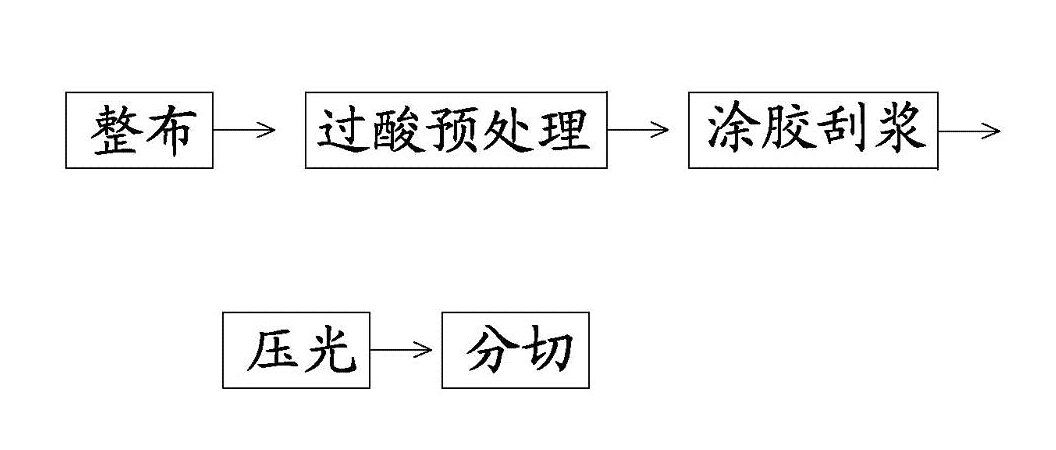

Environment-friendly non-fraying printed label tape and manufacturing method thereof

The invention relates to an environment-friendly non-fraying printed label tape and a manufacturing method thereof, belonging to the technical field of label tape manufacturing. The environment-friendly non-fraying printed label tape comprises a substrate layer and a colloid layer, the thickness of the substrate layer is within 150-170 microns, and the thickness of the colloid layer is within 20-30 microns; and the colloid layer is a synthetic resin scraping layer. The manufacturing method of the environment-friendly non-fraying printed label tape sequentially comprises the steps of cloth arranging, gelatinizing and scraping, calendering and cutting, wherein the gelatinizing and scraping step is as follows: gelatinizing a piece of grey cloth, in which the gelatinizing quantity is controlled within 20-40g / m<2>, and scraping the grey cloth by a scraping machine after gelatinizing, wherein the gelatinizing formula is as follows: 80-89wt% of synthetic resin, 10-15wt% of water and 1-5wt% of thickening agent. In the invention, the manufacturing method needs low production cost; and the product has the technical effect of non-fraying and meets the 0eko-tex standard100.

Owner:HUZHOU SINY LABEL MATERIAL

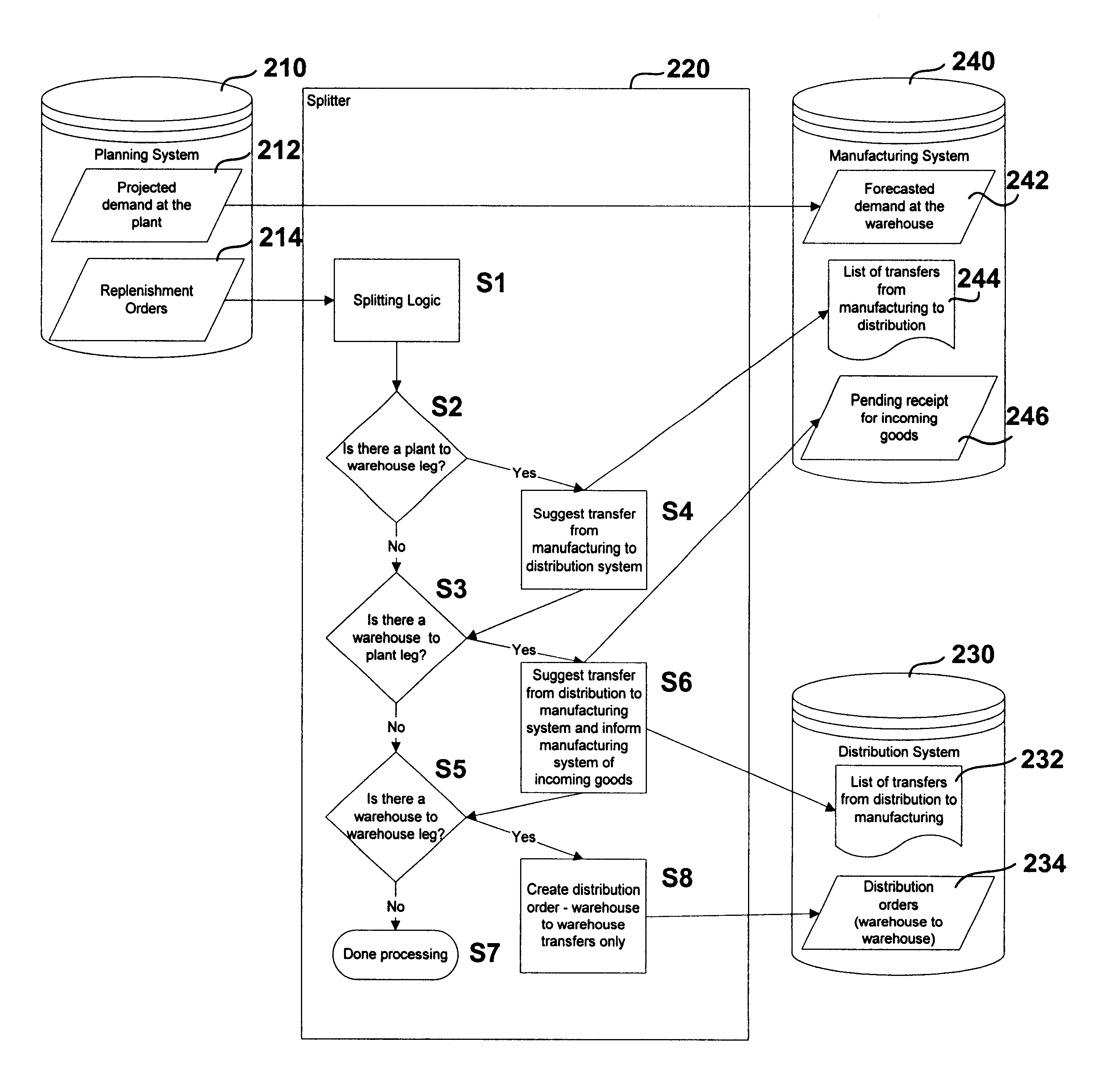

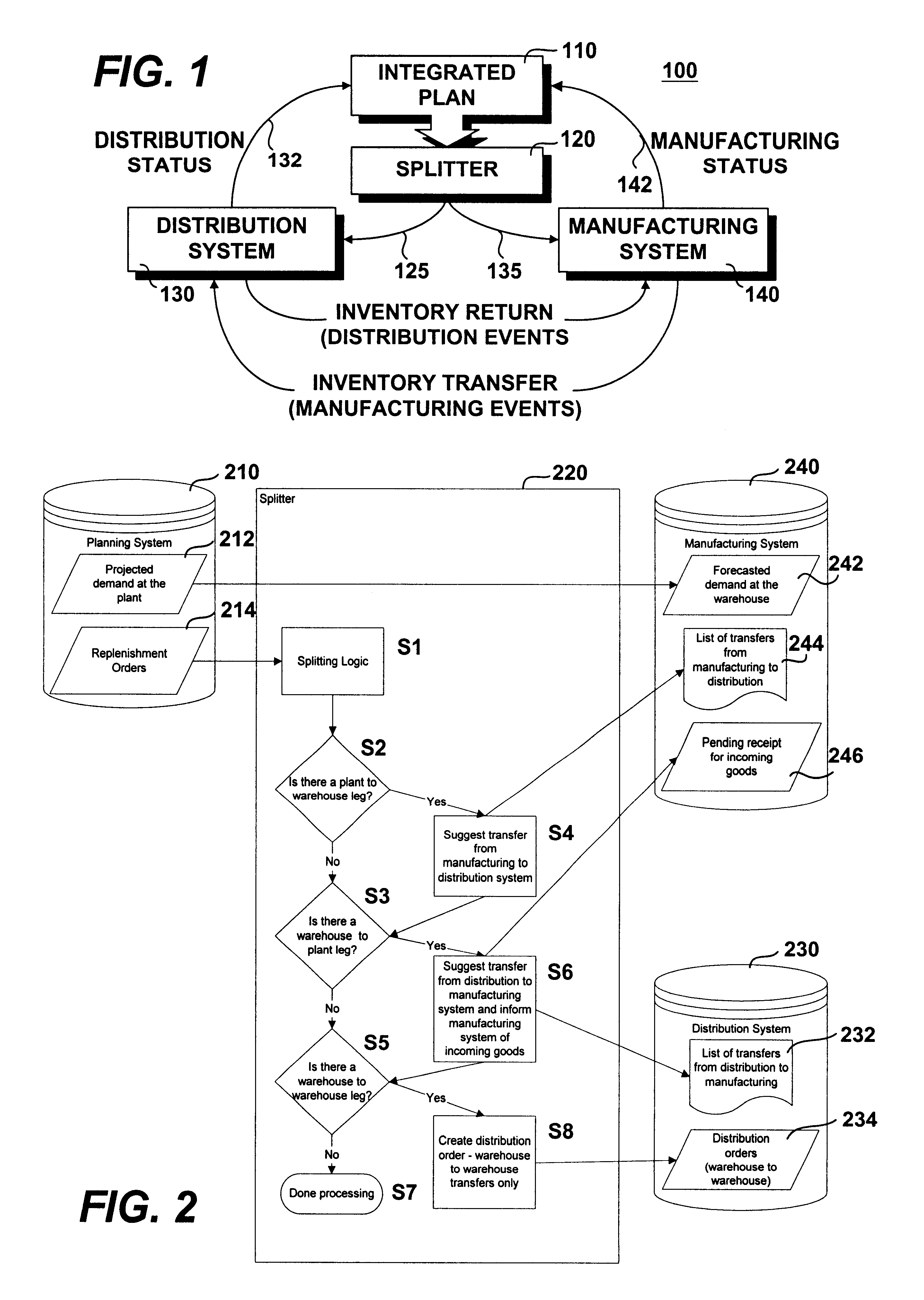

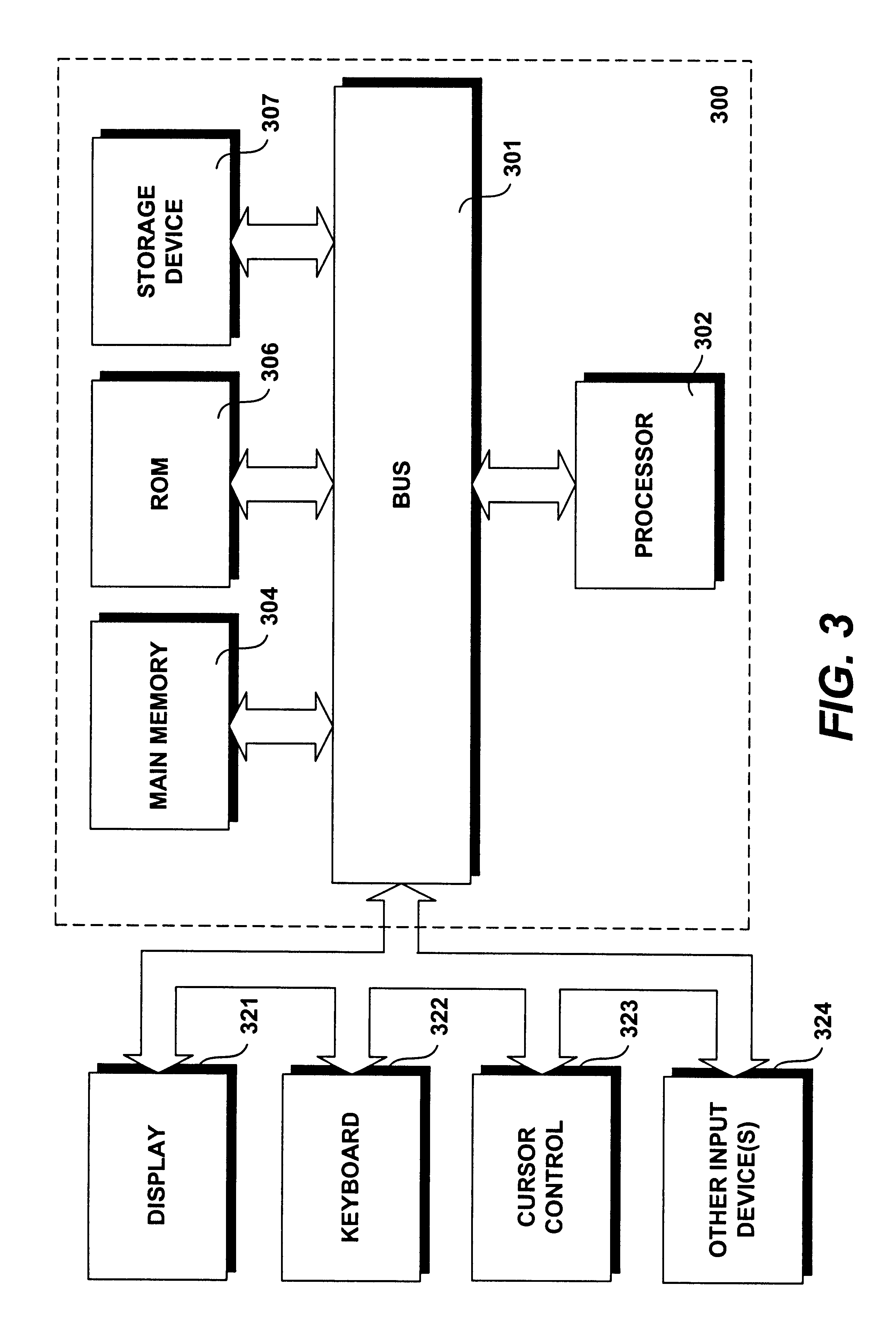

Methods, devices and systems for splitting an integrated manufacturing and distribution plan for use by separate manufacturing and distribution execution systems

A consolidated plan splitting methodology sends distribution orders to a distribution execution system and planned production to a manufacturing execution system. Instructions from the planning system involving only movements of inventory within the distribution s system (e.g., warehouse to warehouse transfers) are passed directly to the distribution execution system. Instructions from the planning system involving movements of inventory where either the source or destination is in the manufacturing system causes a splitter located between the planning system and the distribution and manufacturing execution systems to carry out a decisional process wherein the movement of inventory is broken down into a selected number of distinct intermediate legs. Control of inventory balances is passed between the distribution and manufacturing execution systems as appropriate as the inventory moves from one execution system to another.

Owner:ORACLE INT CORP

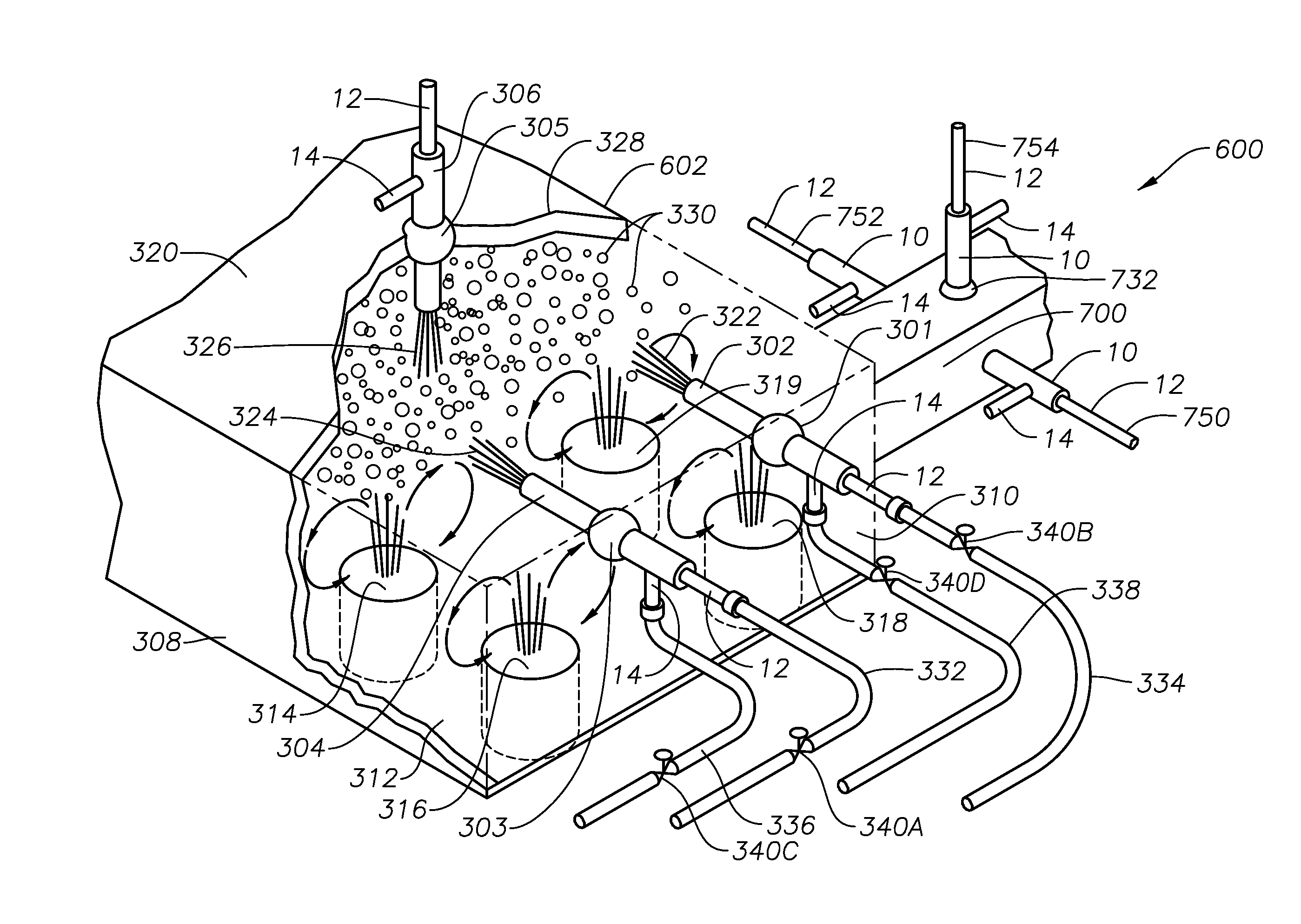

Systems and methods for glass manufacturing

Submerged combustion systems and methods of use to produce glass. One system includes a submerged combustion melter having a roof, a floor, a wall structure connecting the roof and floor, and an outlet, the melter producing an initial foamy molten glass. One or more non-submerged auxiliary burners are positioned in the roof and / or wall structure and configured to deliver combustion products to impact at least a portion of the bubbles with sufficient force and / or heat to burst at least some of the bubbles and form a reduced foam molten glass.

Owner:JOHNS MANVILLE CORP

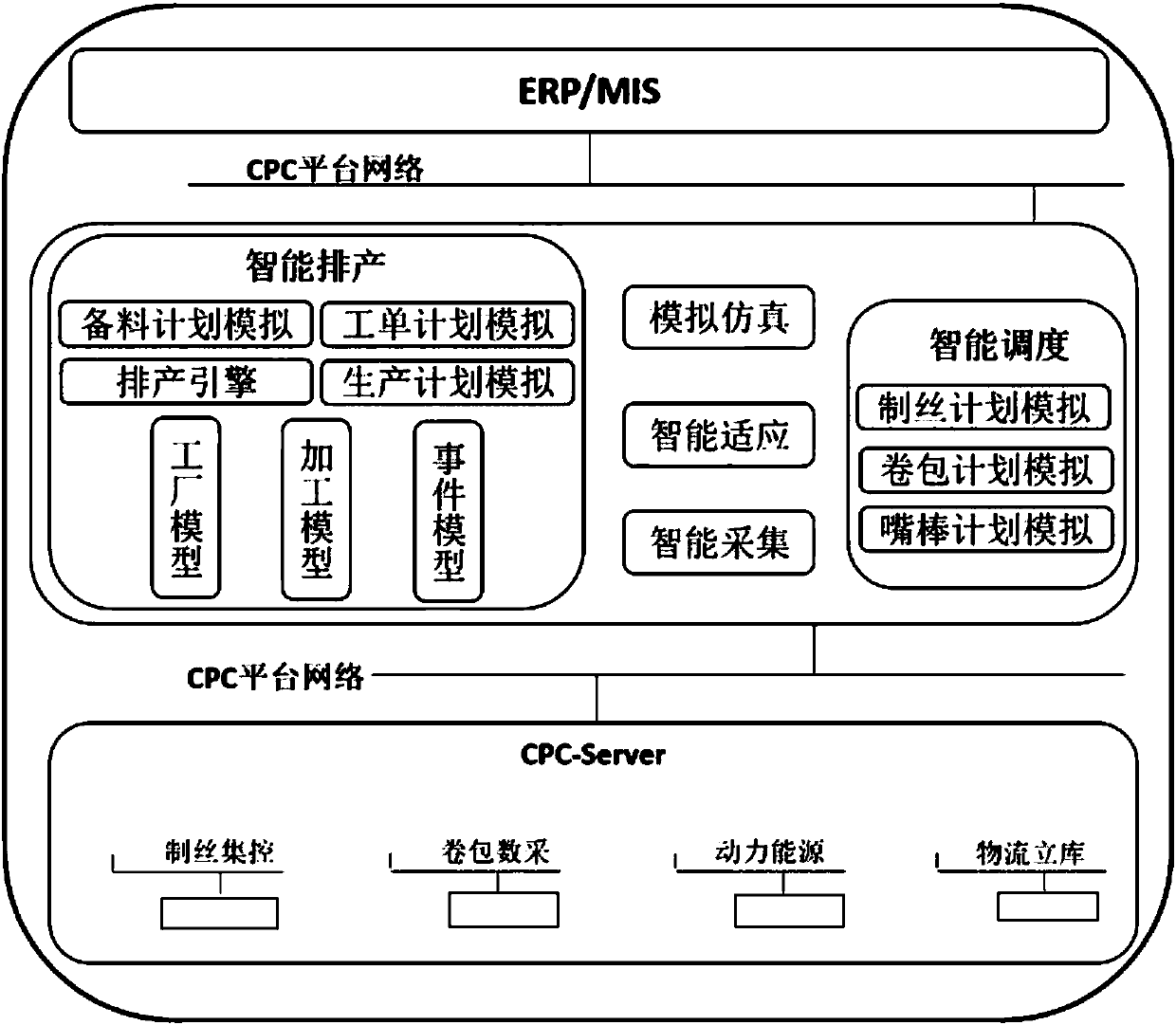

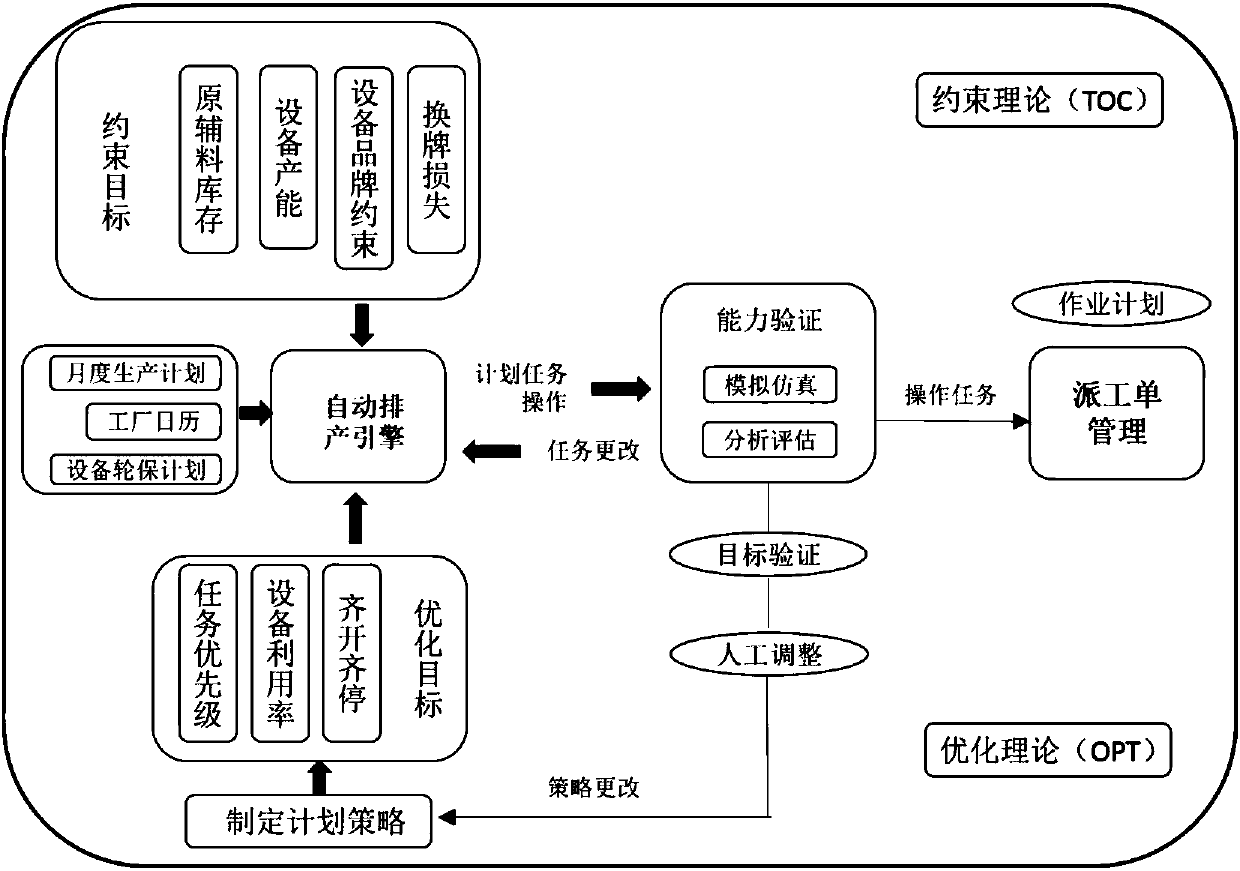

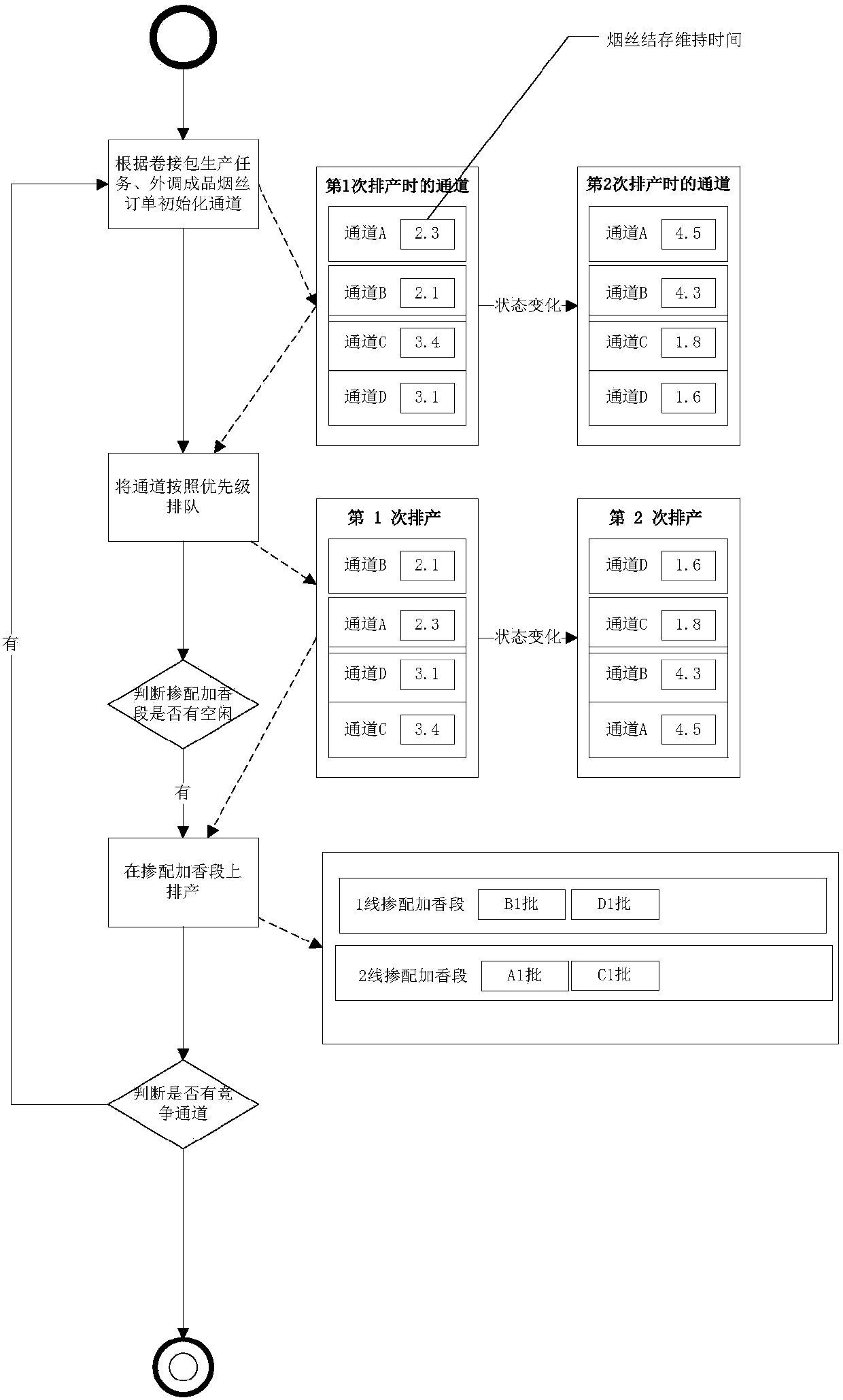

Lean production advanced planning and scheduling system and method

ActiveCN107767068AAchieve high efficiencyImprove timelinessResourcesManufacturing computing systemsWorkloadAdvanced planning and scheduling

The invention provides a lean production advanced planning and scheduling system and method. The lean production advanced planning and scheduling system comprises an intelligent acquisition module, anintelligent simulated scheduling module, an intelligent dispatching module, an intelligent adaption module and an analog simulation module. The beneficial effects are that fine control for the production and processing cost is achieved through optimized applications on the aspects such as product combination, brand switching and balanced production; high efficiency of a scheduling result is achieved; the timeliness and the accuracy of a production plan are improved, timely supply of production materials and the safety of material delivery are effectively coordinated; the equipment load is effectively allocated, and the workload of the planners is substantially reduced.

Owner:CHINA TOBACCO SHANDONG IND

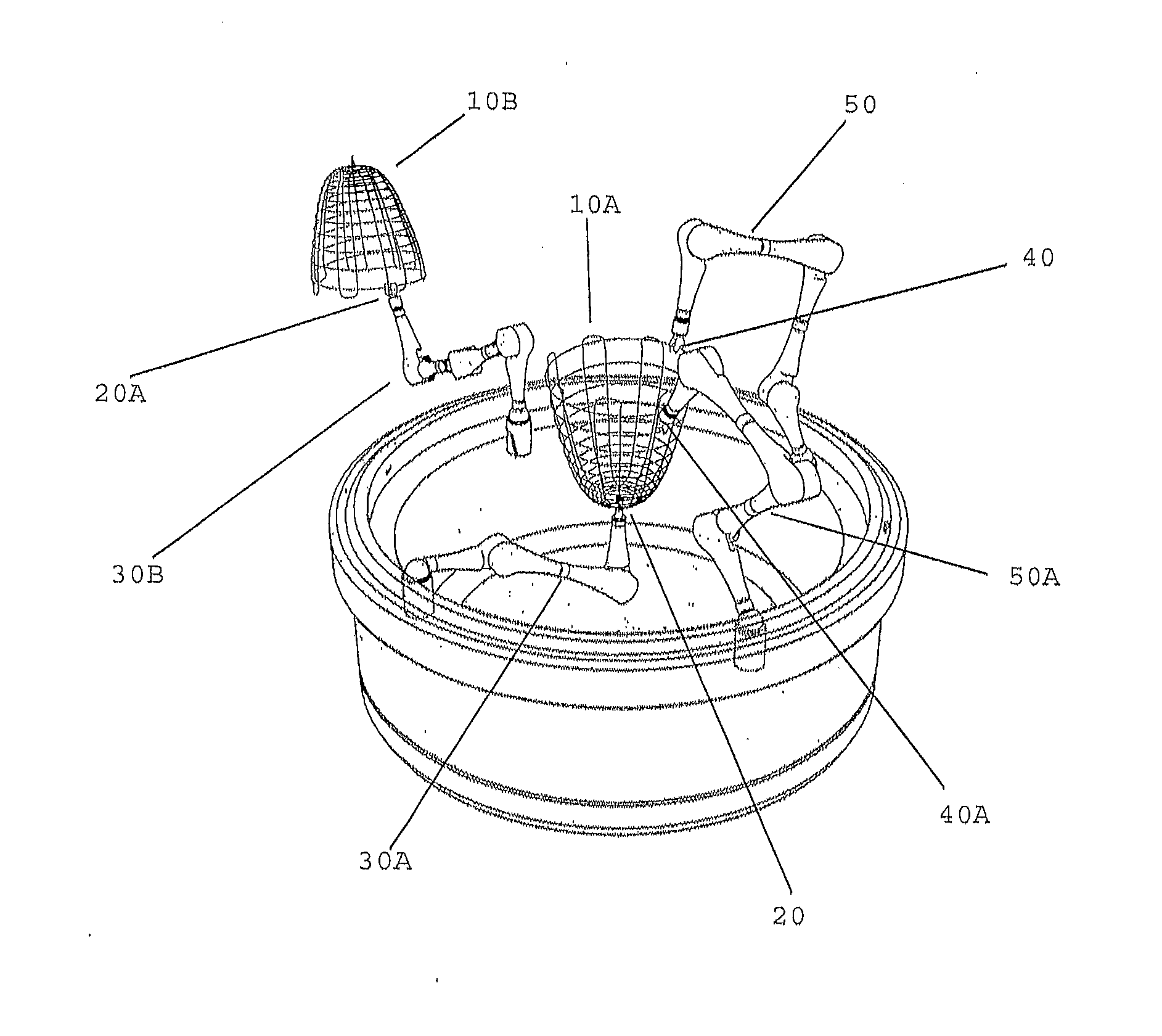

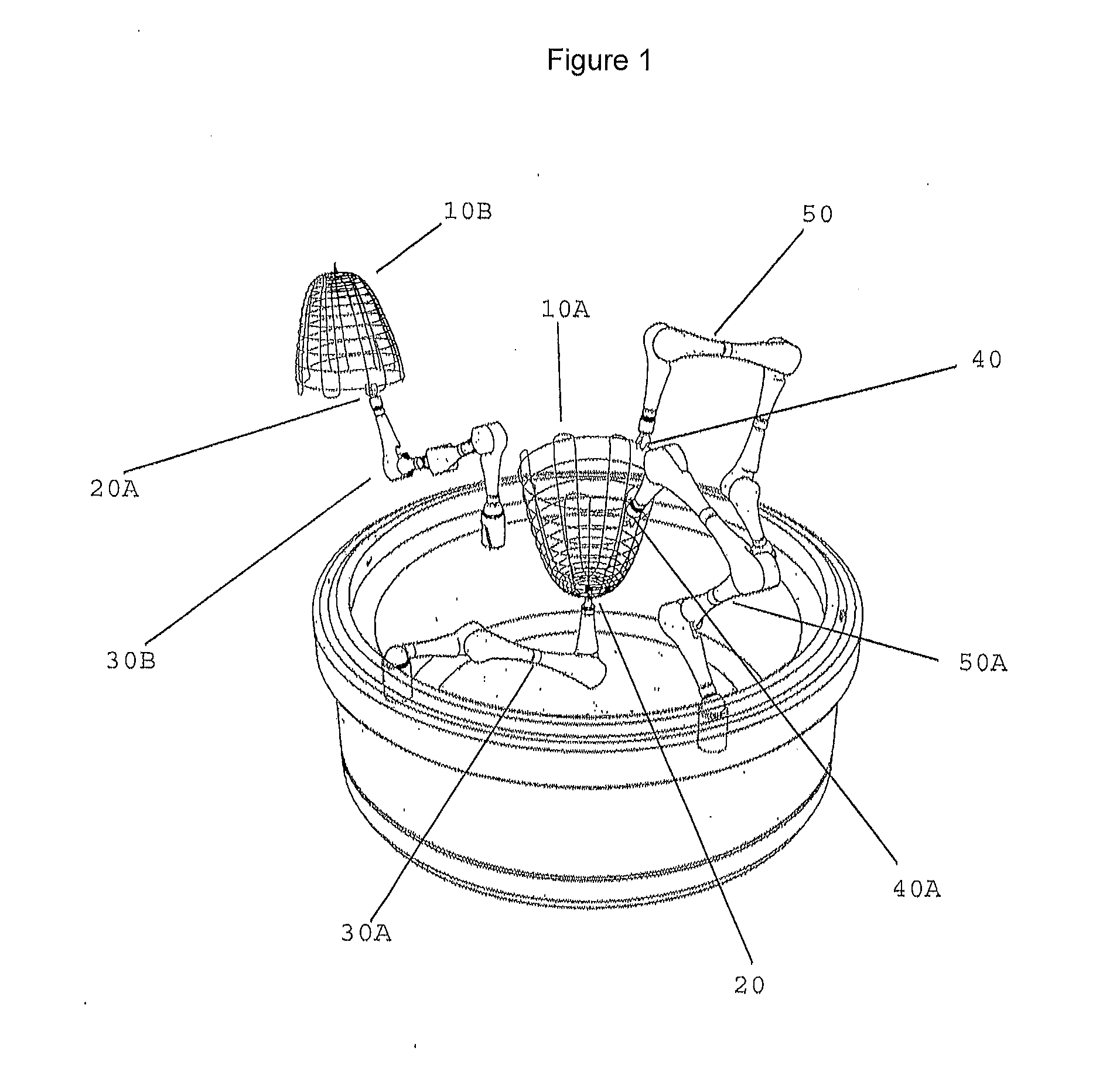

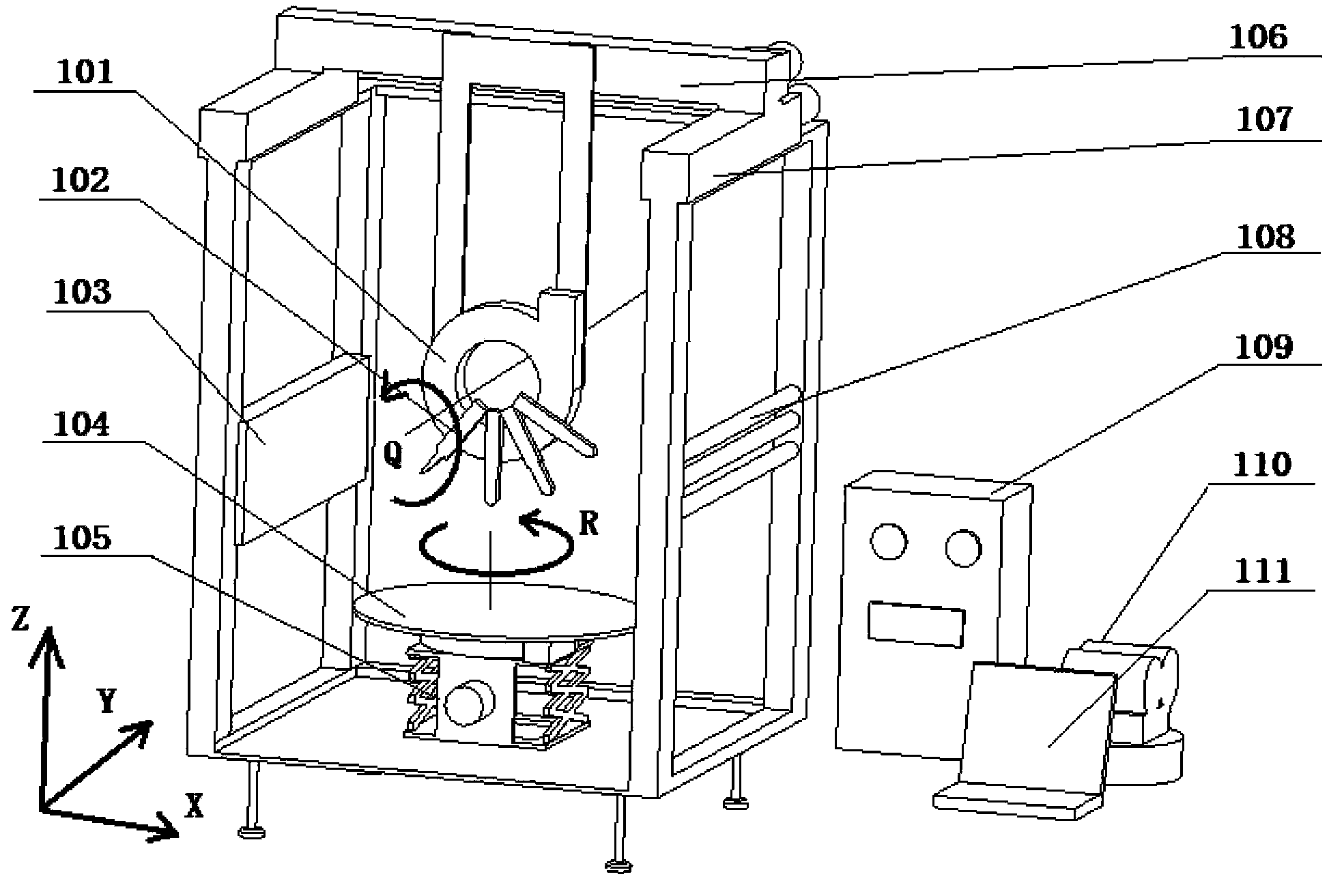

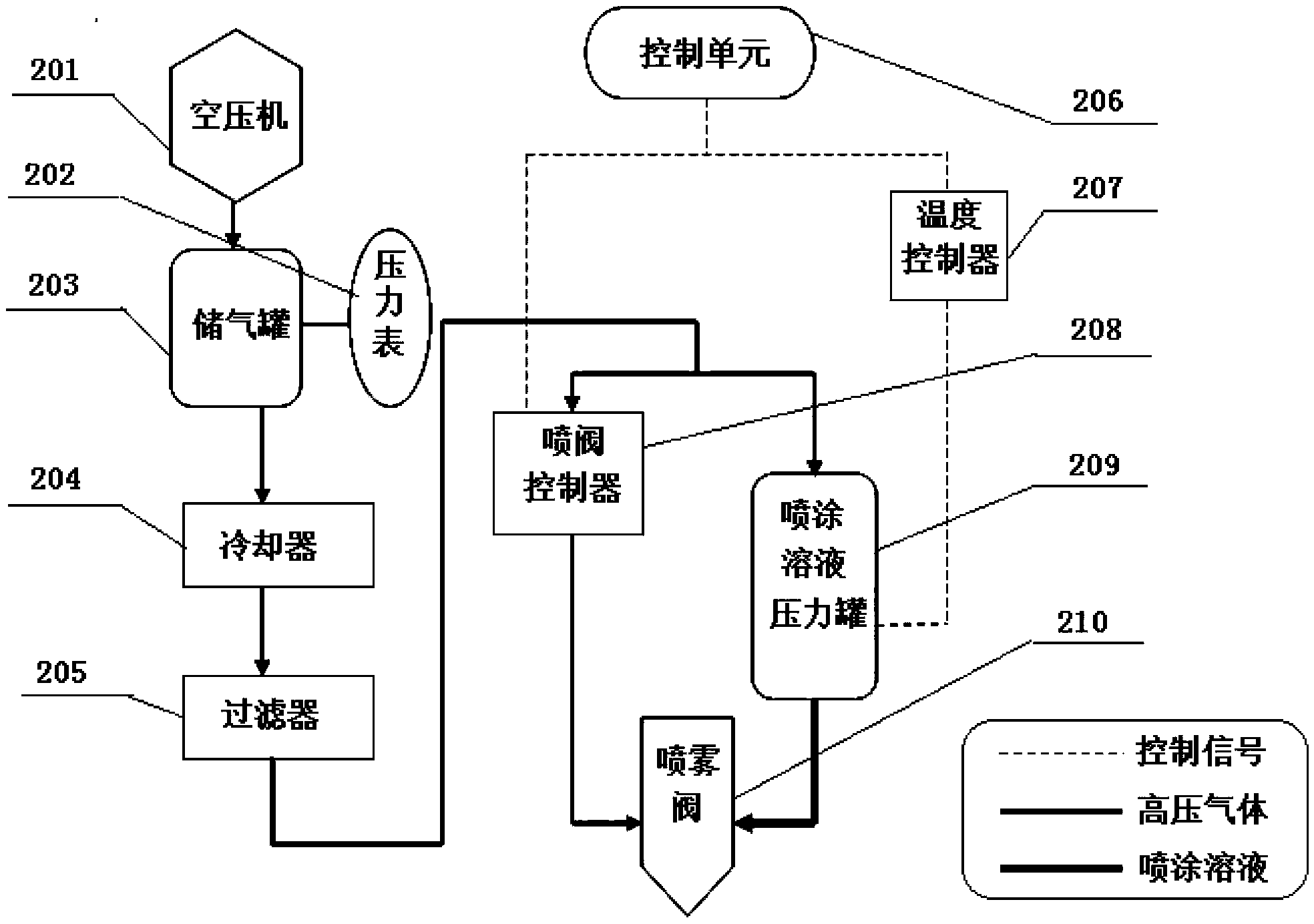

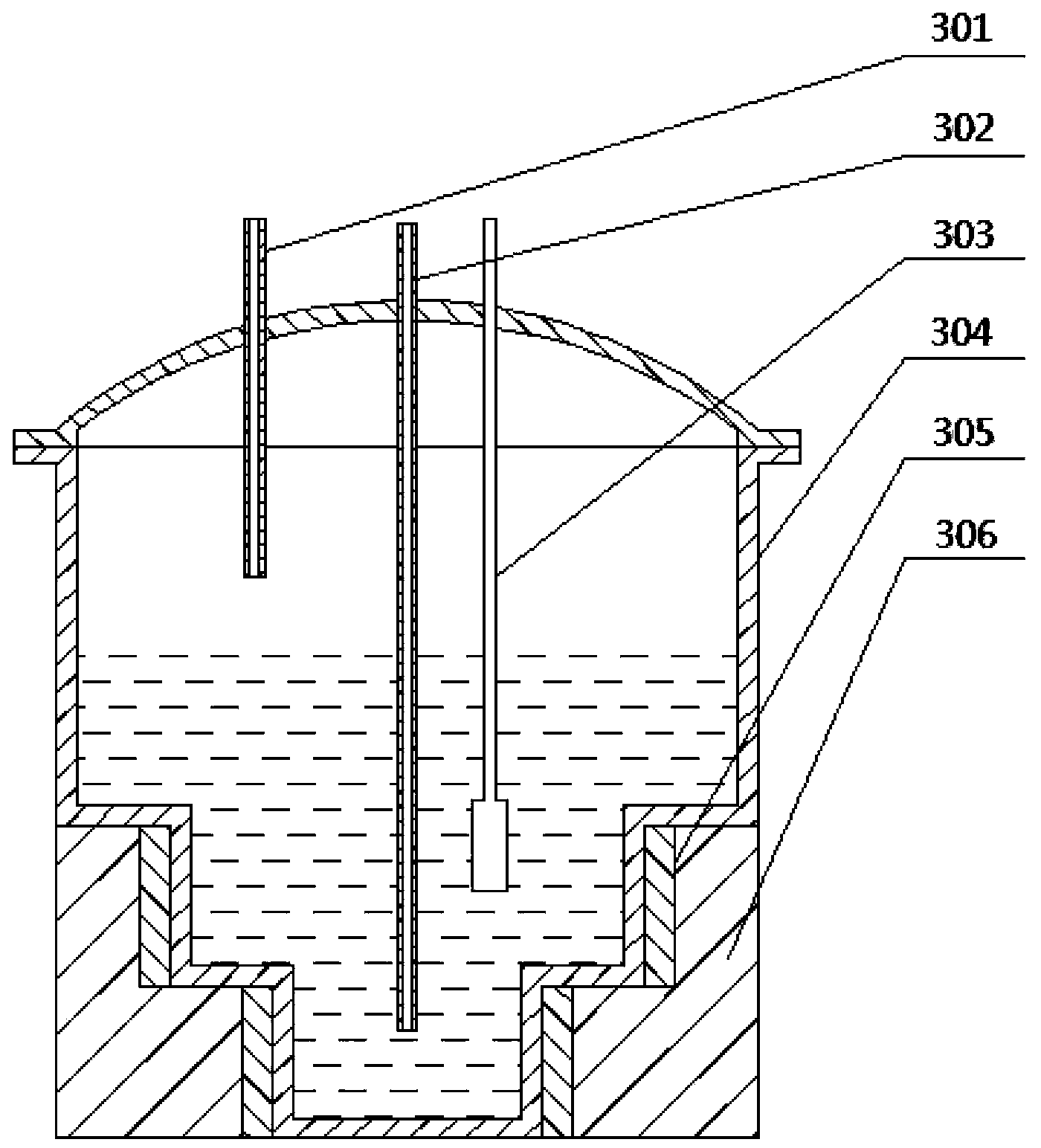

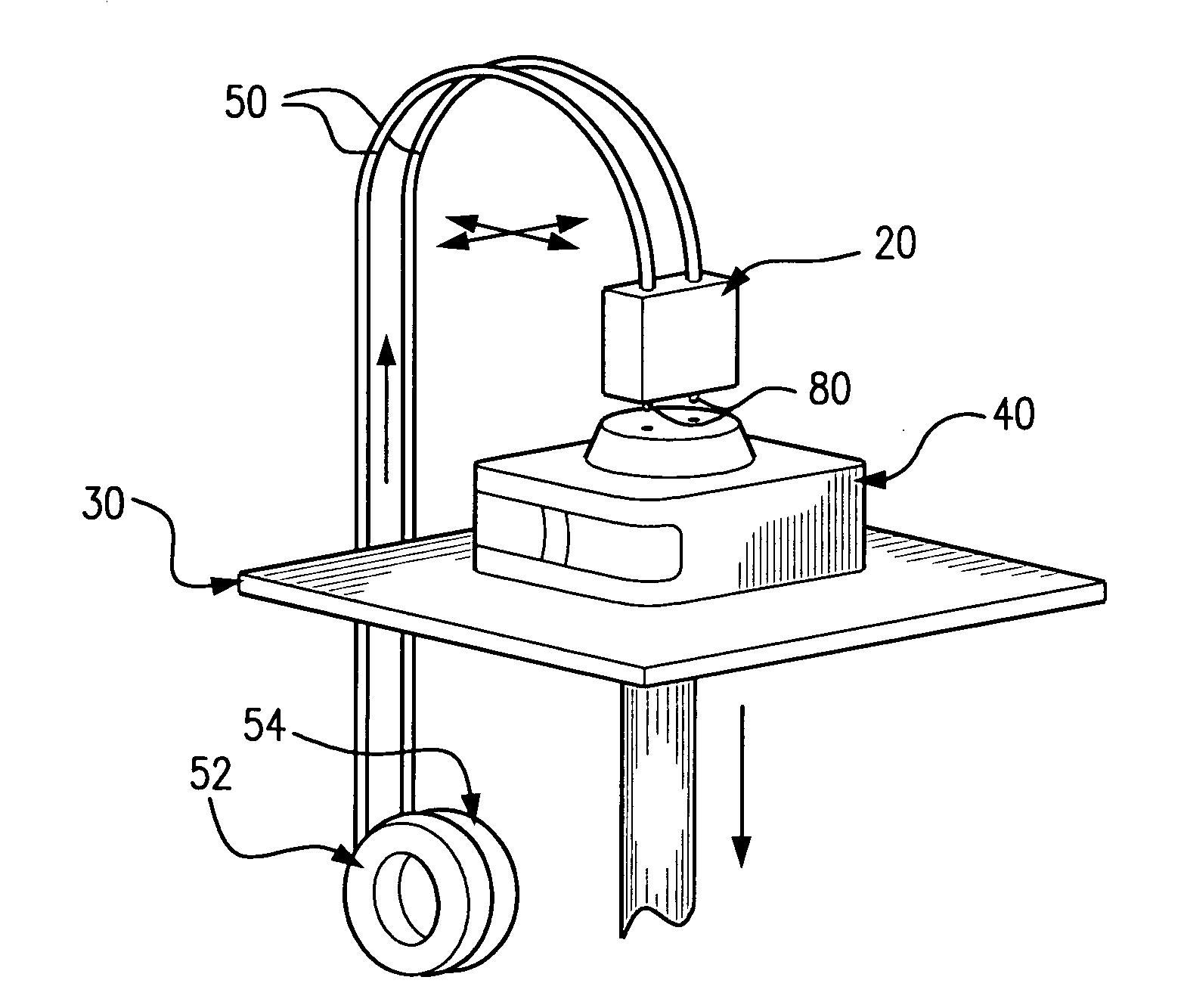

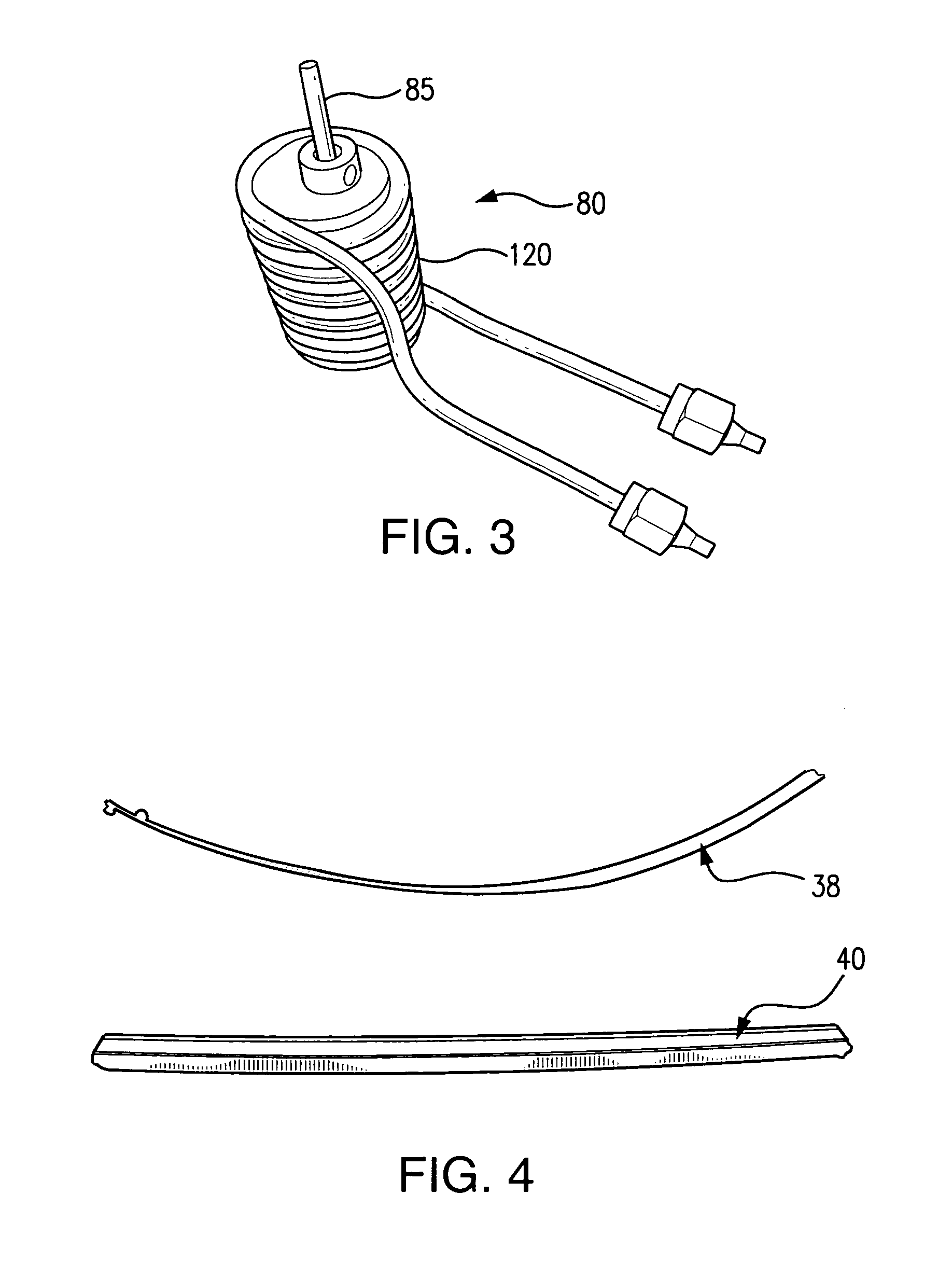

Pneumatic multi-nozzle complex tissue and organ manufacturing system with multiple degrees of freedom

InactiveCN103431925APrecise processingEasy to manufactureAdditive manufacturing apparatusAdditive manufacturing with liquidsEngineeringIn vivo

The invention relates to a pneumatic multi-nozzle complex tissue and organ manufacturing system with multiple degrees of freedom, belonging to the field of organ manufacturing. The system comprises an X-direction movement mechanism, a Y-direction movement mechanism, a Q-direction rotation mechanism, a lifting platform, a rotary forming table, a shell, a high-pressure air source, a multi-nozzle forming unit, a spray solution pressure tank, a temperature control device, a sterilization device and a control unit. Under the control of the control unit, the multi-nozzle unit moves according to the set path and can spray according to the set sequence, so that the forming size is wide in cover range; the relative angle formed between a center shaft of a spray valve and the surface of the rotary forming table can be changed, so that a complex curved surface can be conveniently manufactured. The system enables multiple cells and support materials to be arranged at the corresponding positions for once according to the computer instruction, and various subsequent processing processes can be completed at the same time; the formed three-dimensional structure is directly connected with the corresponding circulating system in vivo, and various physiological functions of the complex tissues and organs can be rapidly realized.

Owner:TSINGHUA UNIV

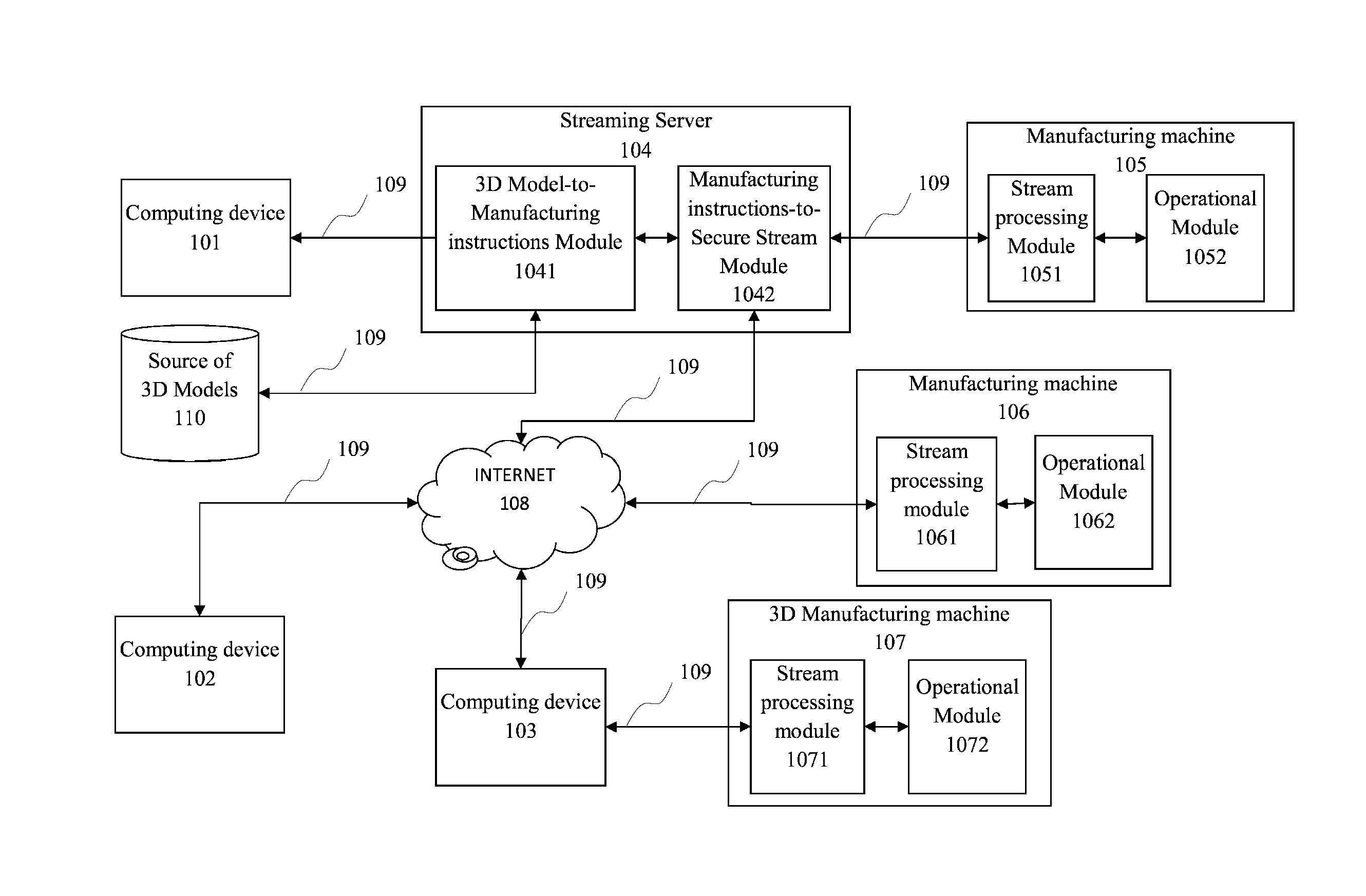

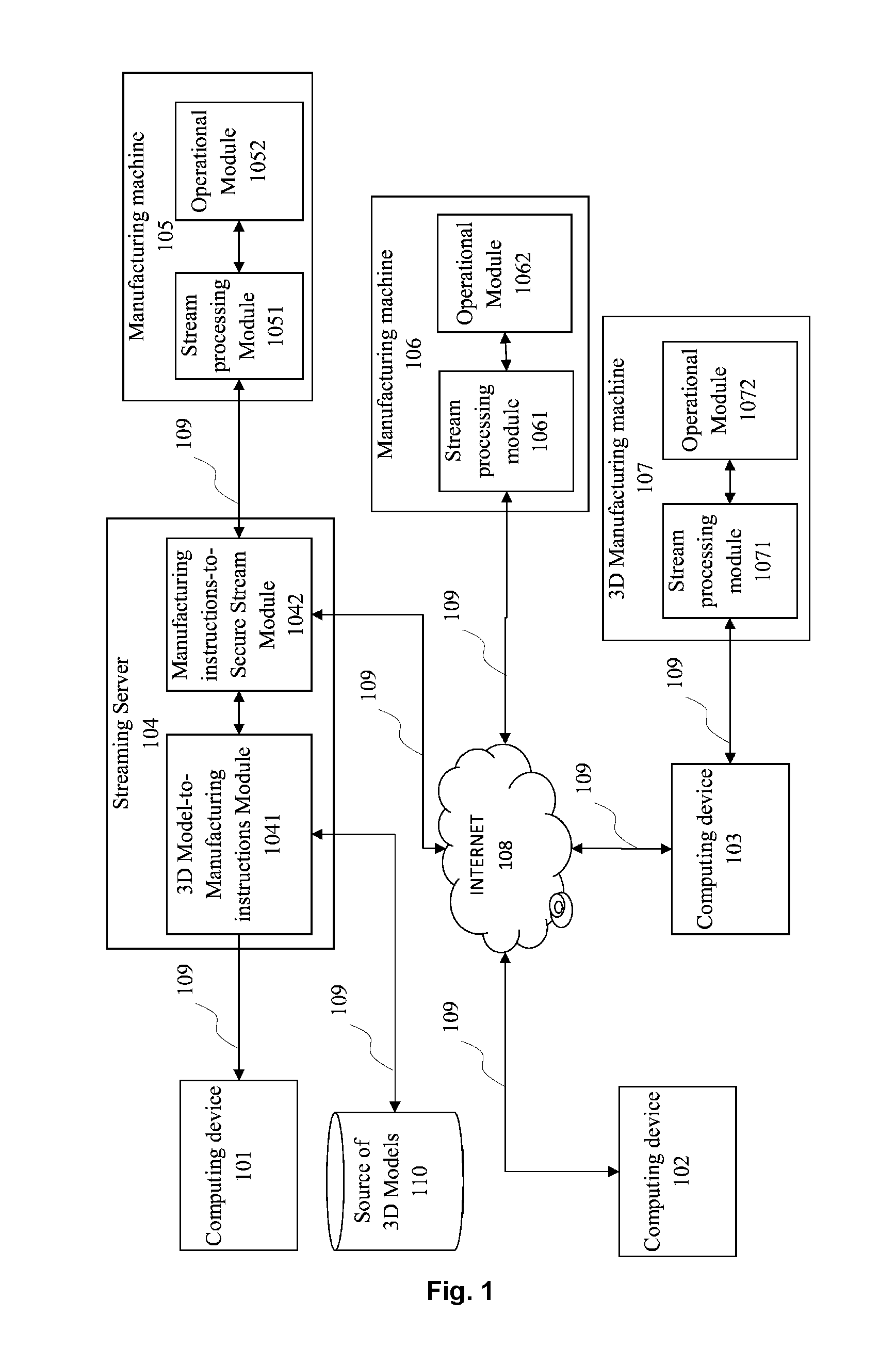

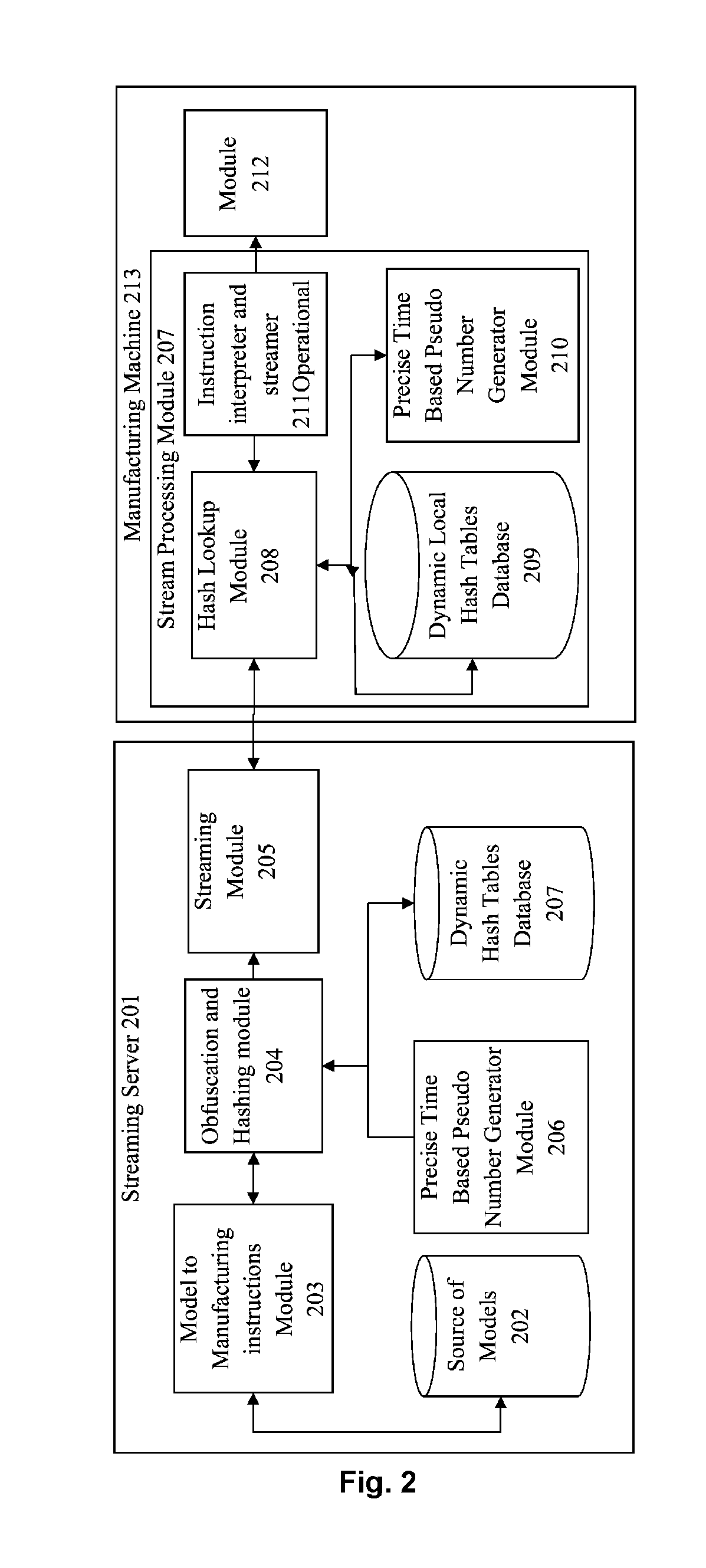

Secure streaming method in a numerically controlled manufacturing system, and a secure numerically controlled manufacturing system

InactiveUS20150350278A1Improve securityProgramme controlAdditive manufacturing apparatusG-codeComputer science

Secure streaming method in a numerically controlled manufacturing system, where the 3D file of the 3D object such as a CAD file or STL file is not sent to the manufacturing machine, but is kept in asecured system. Instead, only the instructions for controlling the manufacturing machine (e.g., so called G-codes) are streamed to the manufacturing machine. Such instructions are secured so that only a specific manufacturing machine can make use of them. To this end, the set of instructions may be encoded, e.g., hashed on a secure server, using a server hash table while the manufacturing machine is provided with a local lookup hash table that is synchronized, e.g., loosely synchronized with the serve's hash table for converting the hashed instructions back to instructions suitable for operating the manufacturing machine.

Owner:TRONDERT OU

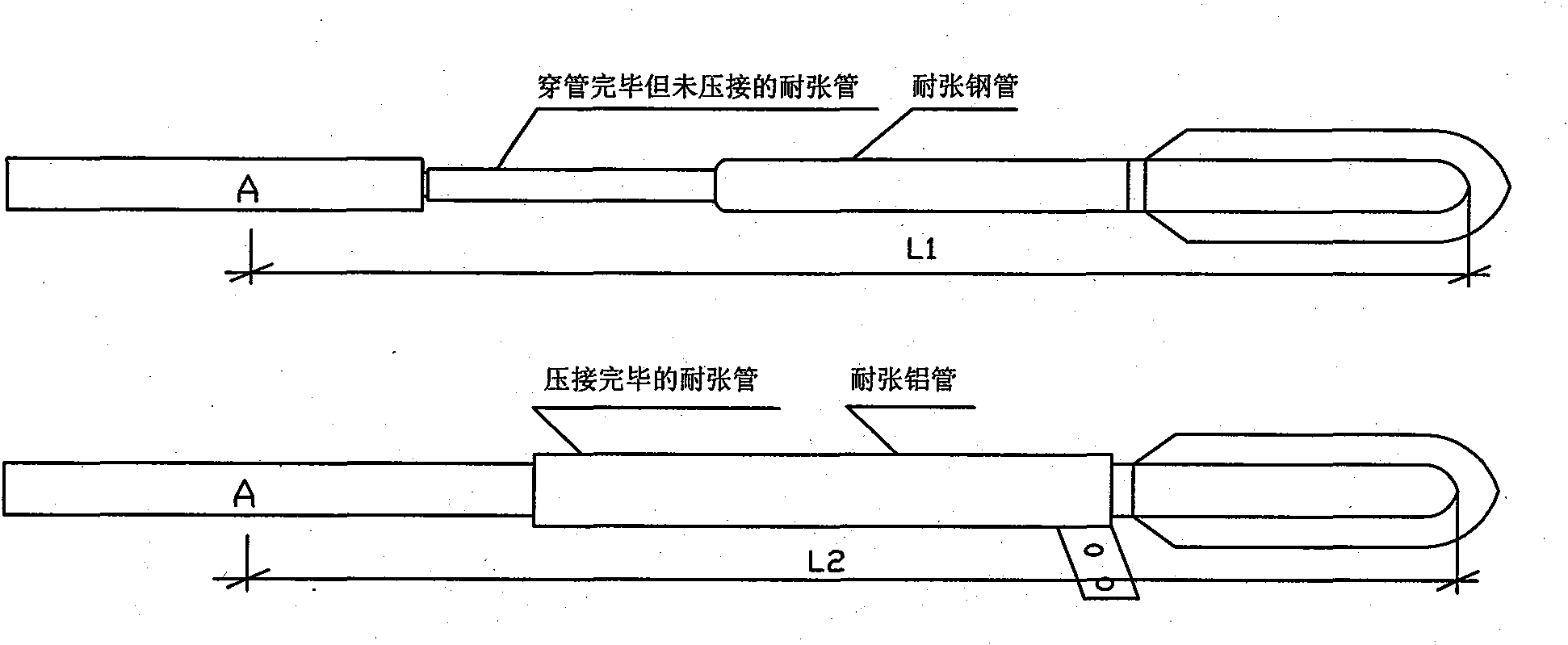

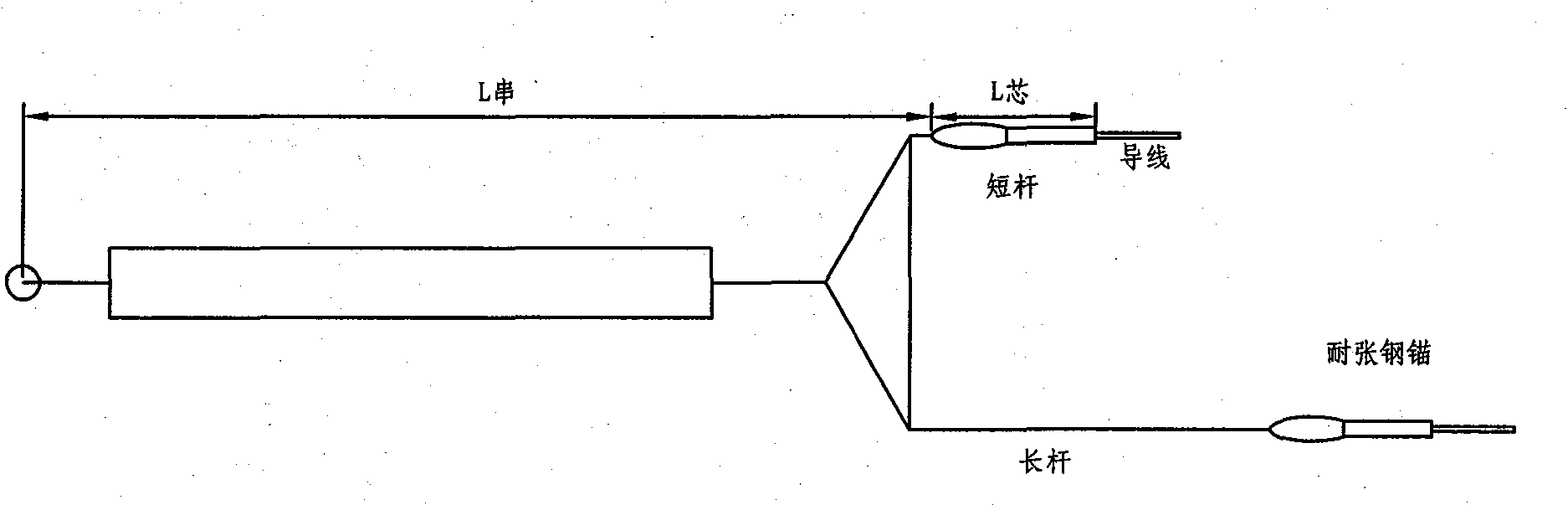

Assembly type overhead construction process

ActiveCN101859988AExemption from adjustmentAdvanced technologyApparatus for overhead lines/cablesQuality levelField data

The invention provides an overhead construction process, which comprises the following steps of measuring data and calculating the wire length, wherein field data and the influencing quantity of the pressure welding length of a strain clamp are collected and the length of a strain insulator-string is measured; and calculating the wire length according to a formula, wherein L is the wire length; H is the conductor tension; omega is the weight of the conductor per unit length; l is the horizontal distance between the hanging points of the conductor; h is the altitude difference between the hanging points of the conductor; performing fixed-length manufacturing and machining wires, wherein the length of each conductor is calculated according to a wire length calculation formula, the conductor allocation is performed based on the control of the longest conductor of each phase, and the length of the conductor of each coil to be machined is determined; releasing the wires; and tightly hanging the wires. In the overhead construction process, the length of the required wire of each span can be measured directly on the ground, the installation position of a suspension clamp is demarcated, and thus the wires are suspended to achieve the preset completion sag without wire sag observation. Meanwhile, the overhead construction process and the quality level are improved, while the construction quality and the safety are ensured.

Owner:HUBEI ELECTRIC POWER TRANSMISSION & DISTRIBUTION ENG

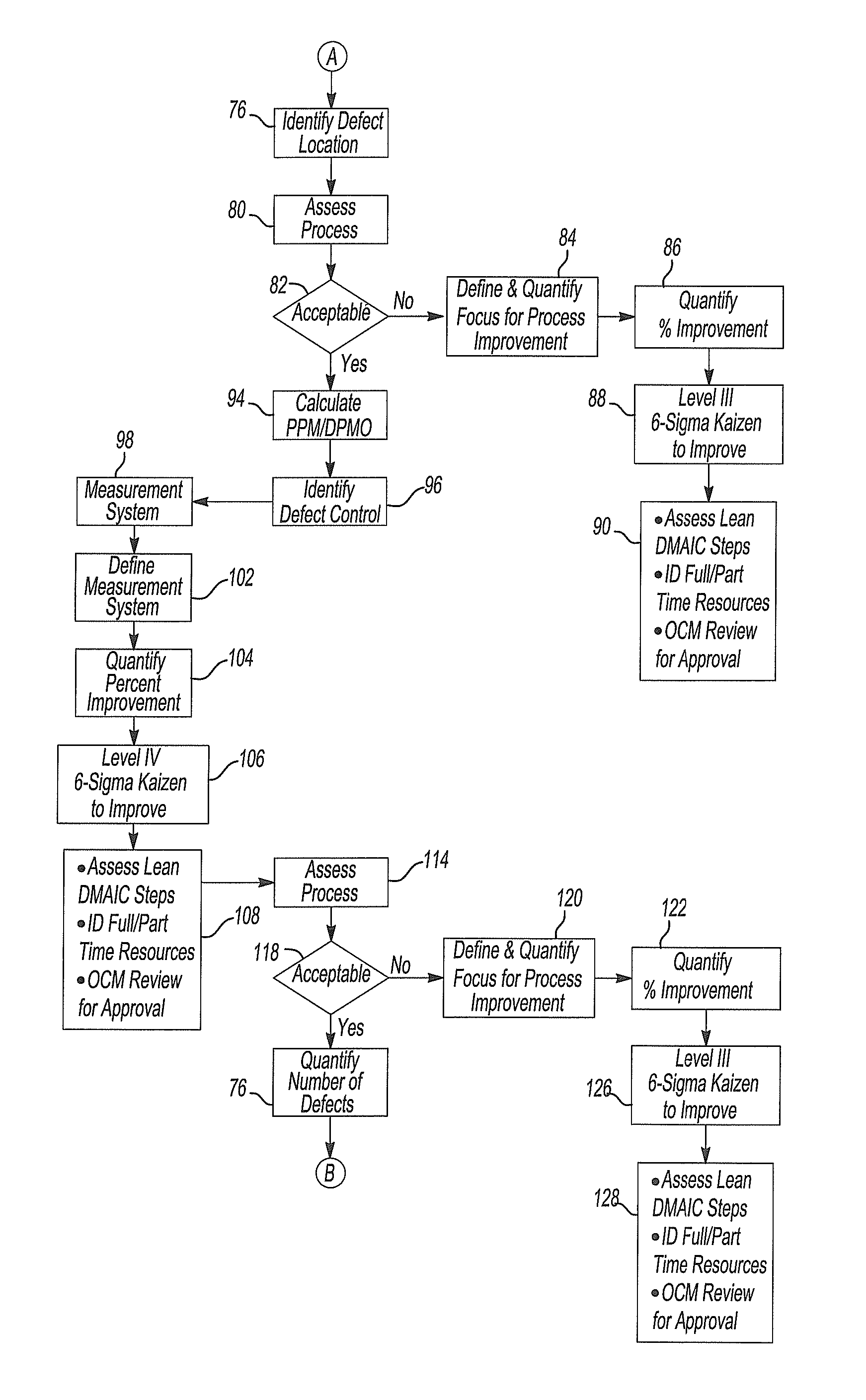

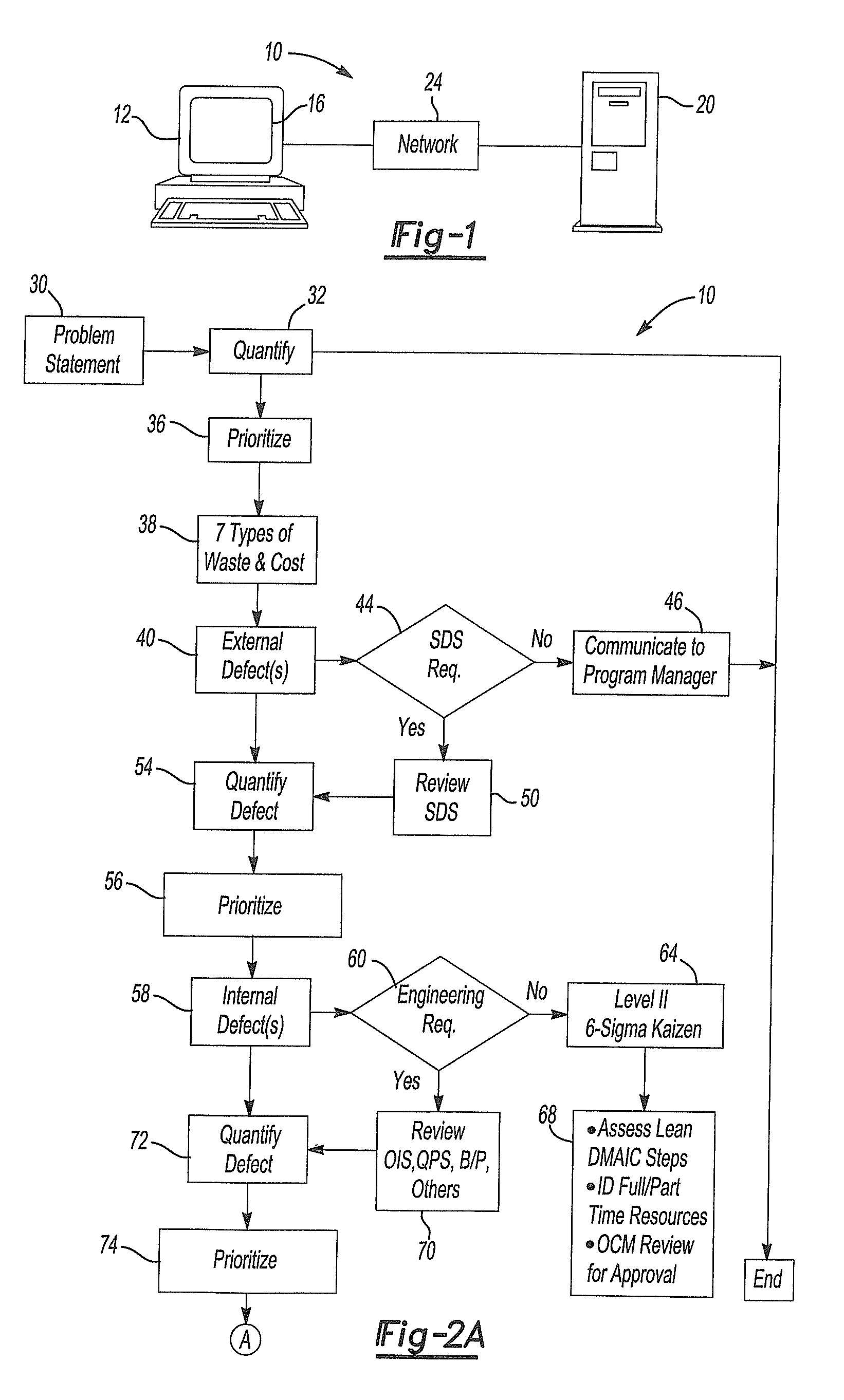

Computer-implemented method for analyzing a problem statement based on an integration of Six Sigma, Lean Manufacturing, and Kaizen analysis techniques

InactiveUS7006878B2Cost efficientEffective timeDigital computer detailsNuclear monitoringOperational definitionProblem statement

A computer-implemented method for analyzing problem statements. The method includes focusing the problem statement into an operation definition and then assigning a level indicator to the operation definition. The method further includes analyzing the problem statement based on the operational definition and the level indicator in a cost and time effective manner and without the need for an expert to customize an analysis schedule for each problem.

Owner:FORD MOTOR CO

Large scale room temperature polymer advanced manufacturing

InactiveUS20150183159A1Aid in structural stabilityHigh strengthAdditive manufacturing apparatusMouldsAtmospheric temperatureRoom temperature

A manufactured component, method and apparatus for advanced manufacturing that includes a nozzle for extruding a working material, wherein the polymeric working material includes a carbon fiber reinforced polymer. The build of the component takes place on a work surface at atmospheric temperatures.

Owner:UT BATTELLE LLC

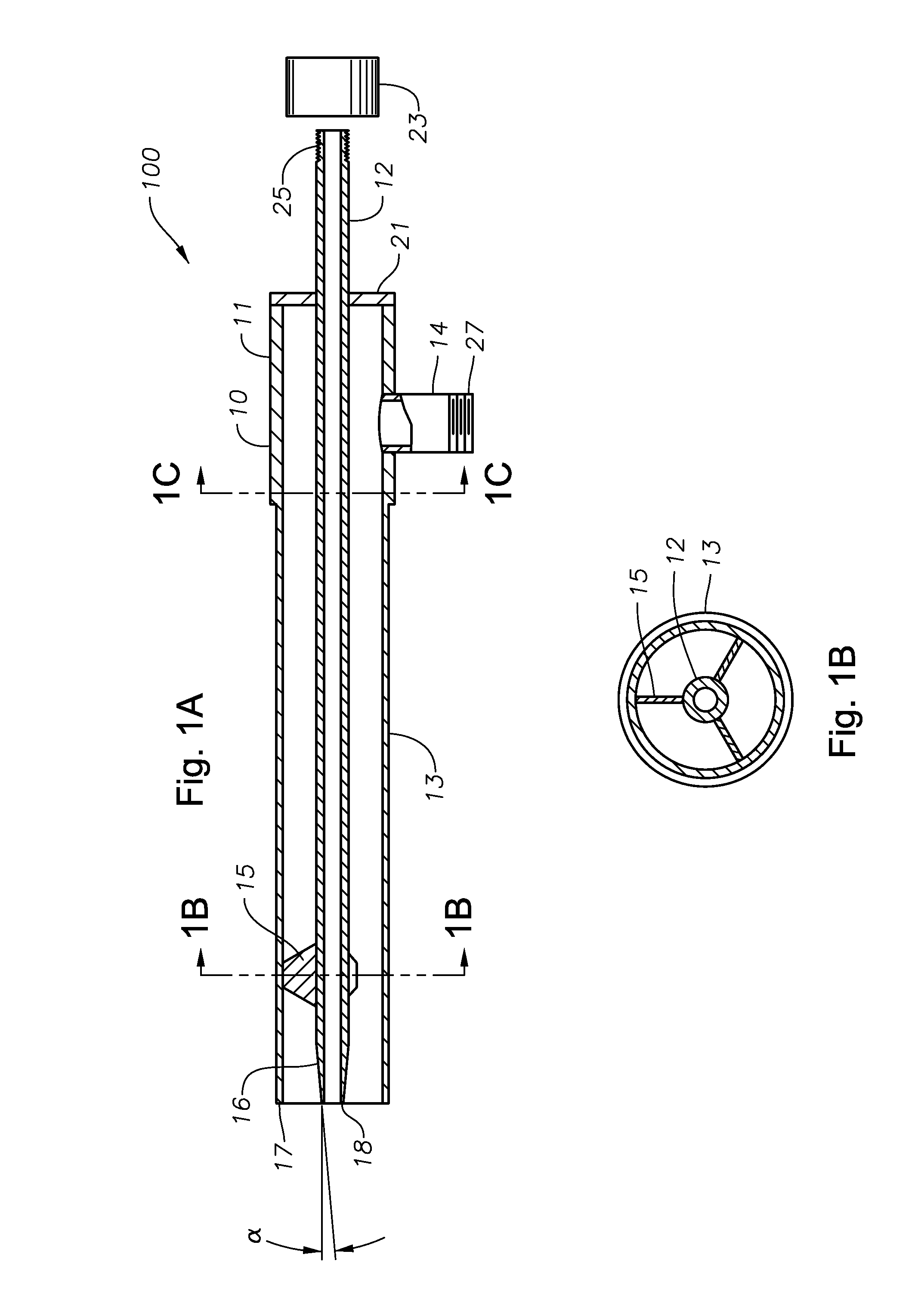

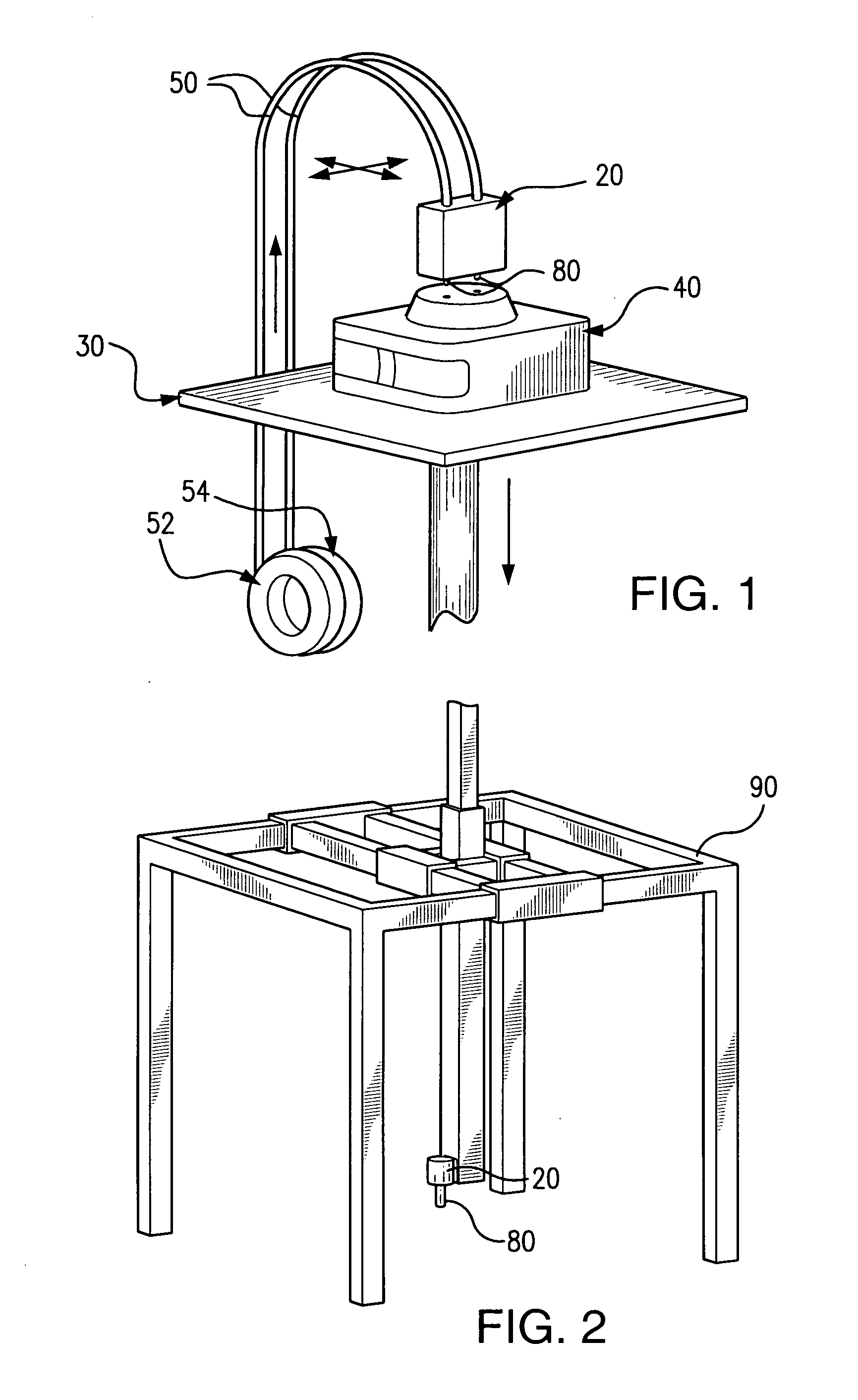

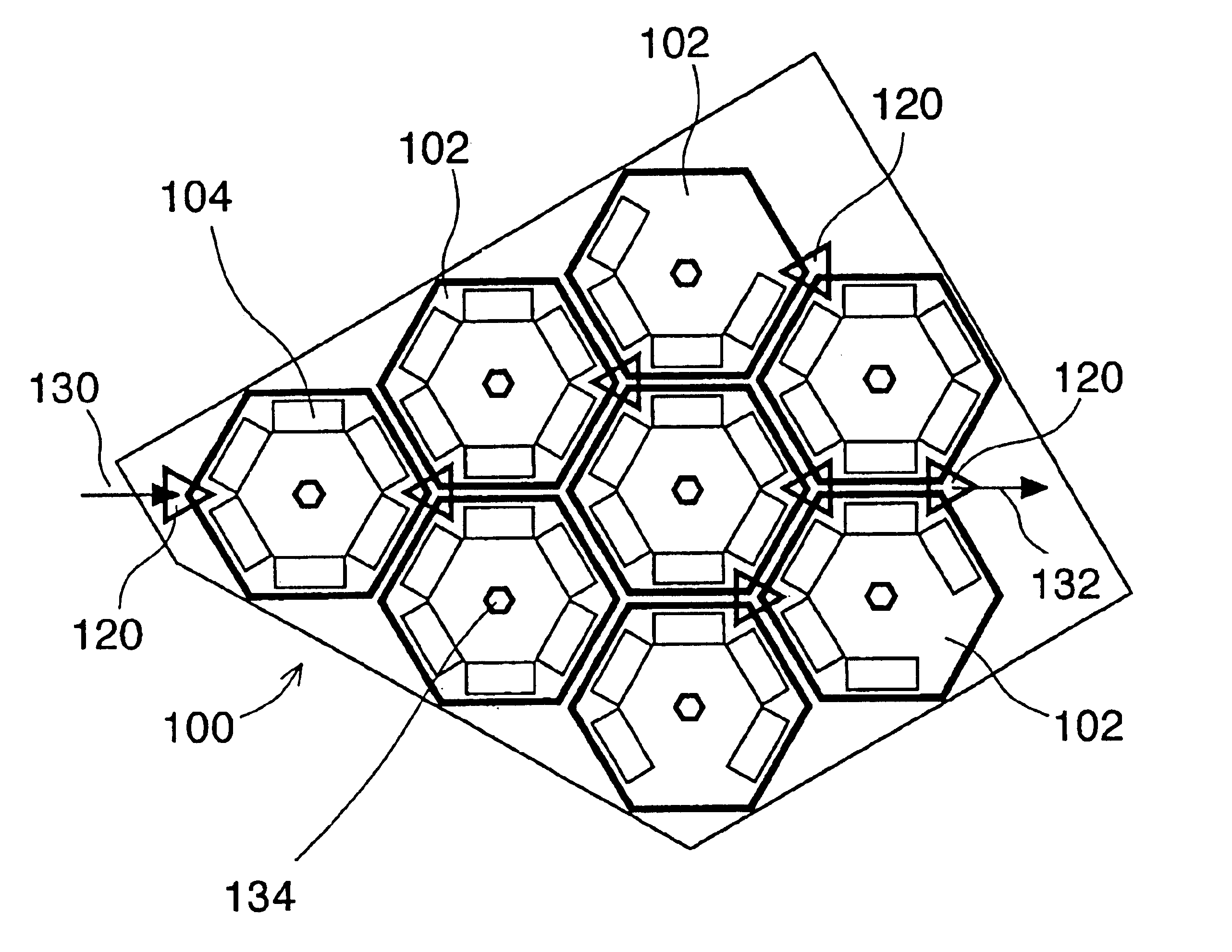

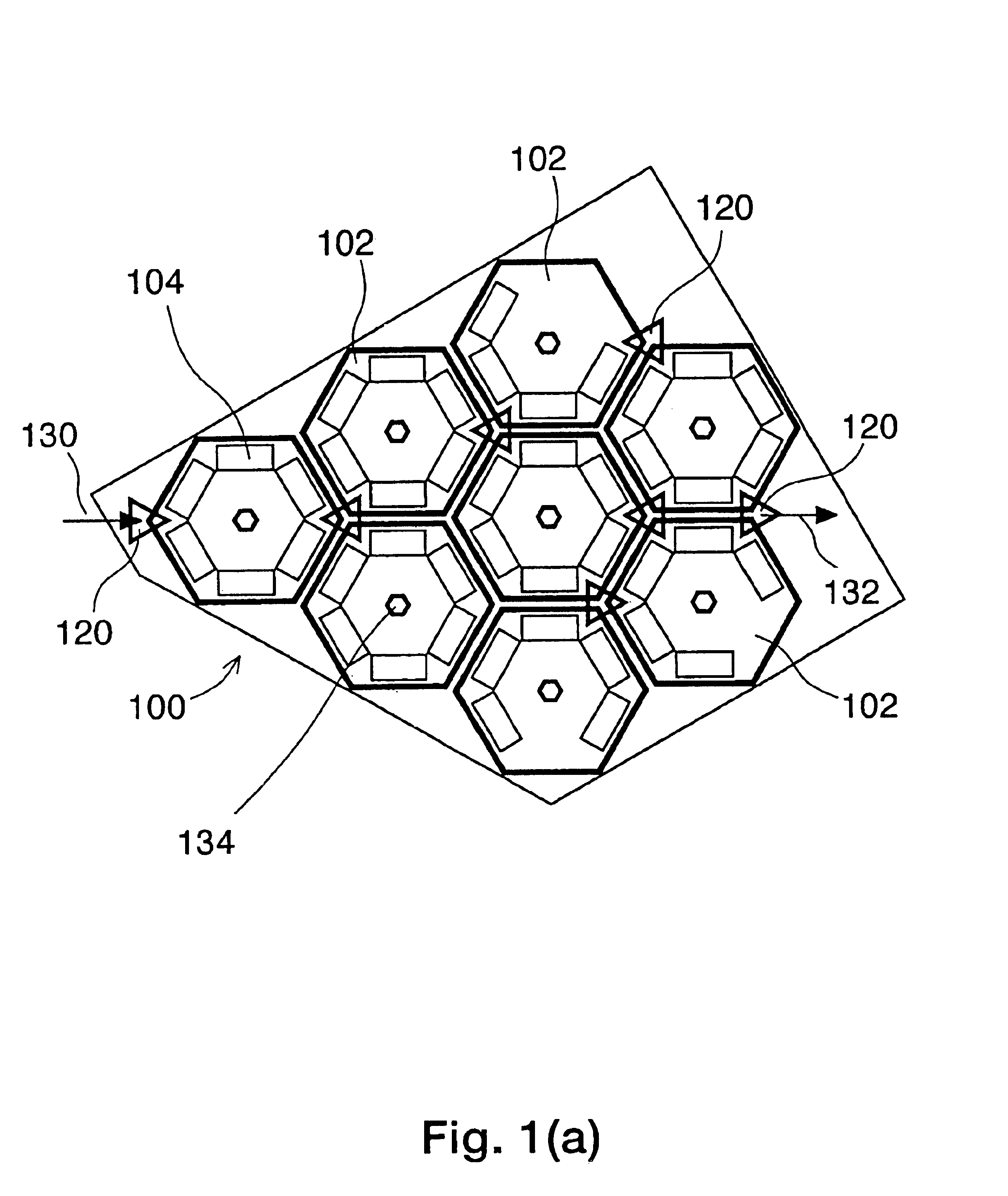

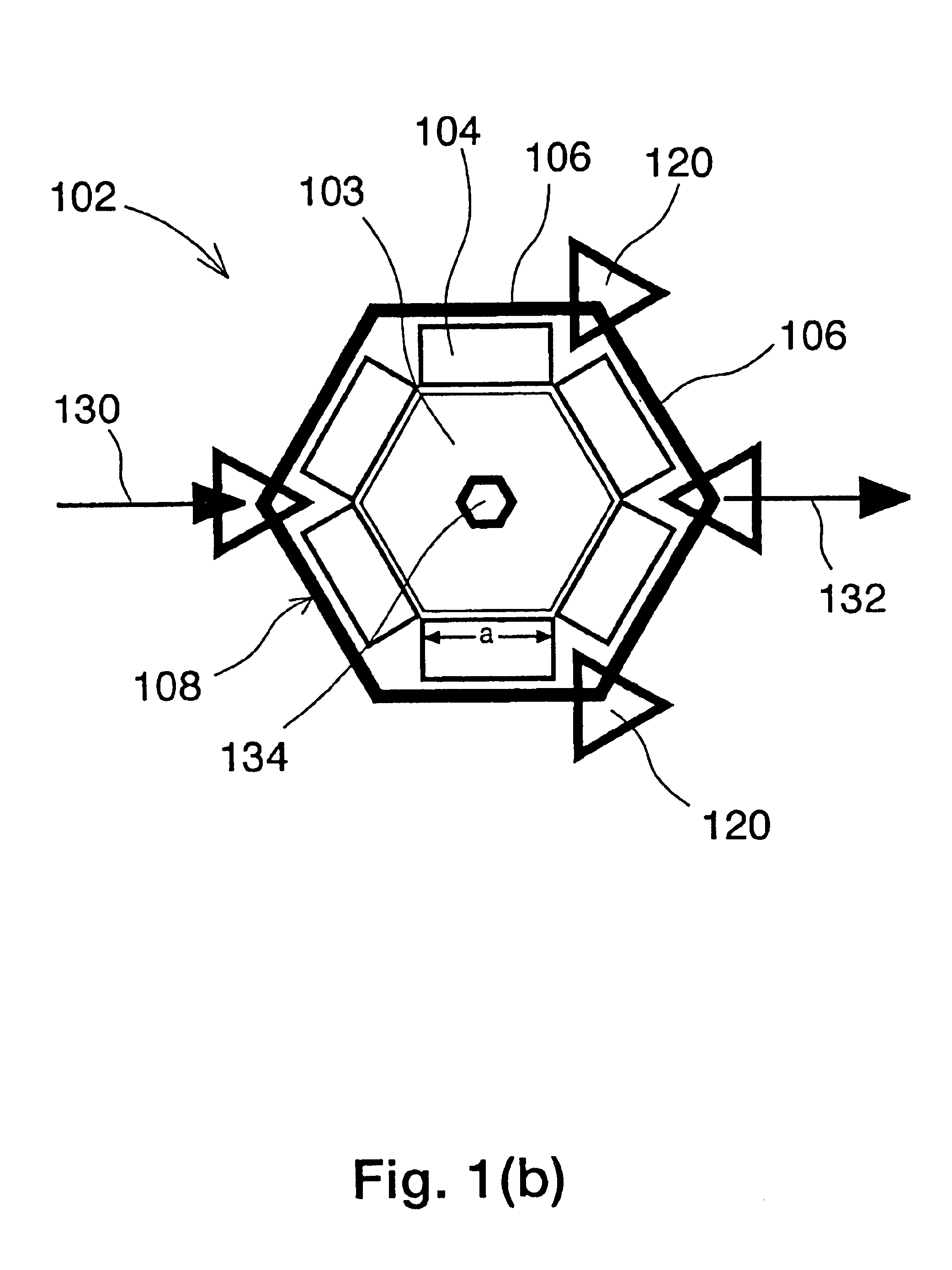

Integrated reconfigurable manufacturing system

An integrated reconfigurable multi-stage manufacturing system and associated methods. The system may include a plurality of manufacturing cells, each cell associated with at least one stage of a manufacturing process. The plurality of cells may include a first cell comprising at least one flexible manufacturing station, a second cell comprising at least one reconfigurable manufacturing station, and a third cell comprising at least one reconfigurable inspection machine. The system may also include a plurality of loop conveyors and a plurality of cell gantries. Each loop conveyor may connect at least two neighboring cells and each cell gantry may transport parts from the cell associated with the cell gantry to at least one loop conveyor. In one embodiment, each cell may be hexagonal, and the manufacturing system may have a honeycomb structure.

Owner:RGT UNIV OF MICHIGAN

Manufacturing method of carbonization heat treatment-modified solid wood flooring

ActiveCN102922580AAvoid influenceQuality impactWood treatment detailsWood charring/burningSolid woodCarbonization

The invention relates to a functional improvement method of woods, in particular to a manufacturing method of a carbonization heat treatment-modified solid wood flooring, belonging to the technical field of functional modification of the woods and wood product processing. The technical solution for the manufacturing method comprises the following steps: (1) a solid wood flooring blank manufacturing step; (2) a drying step; (3) a carbonization heat-treatment improving step; and (4) a solid wood flooring manufacturing step. Due to the technical solution for the manufacturing method of a carbonization heat treatment-modified solid wood flooring, a production method of a solid wood flooring designed special for fast-growing woods while the existing technical problems are solved. Compared with the prior art, the manufacturing method has the advantages of simple production process, short production cycle, low energy consumption, low production cost and the like, and technical indexes of obtained solid wood flooring made of fast-growing woods achieve the national standard quality requirement.

Owner:福建秦朝木业科技有限公司

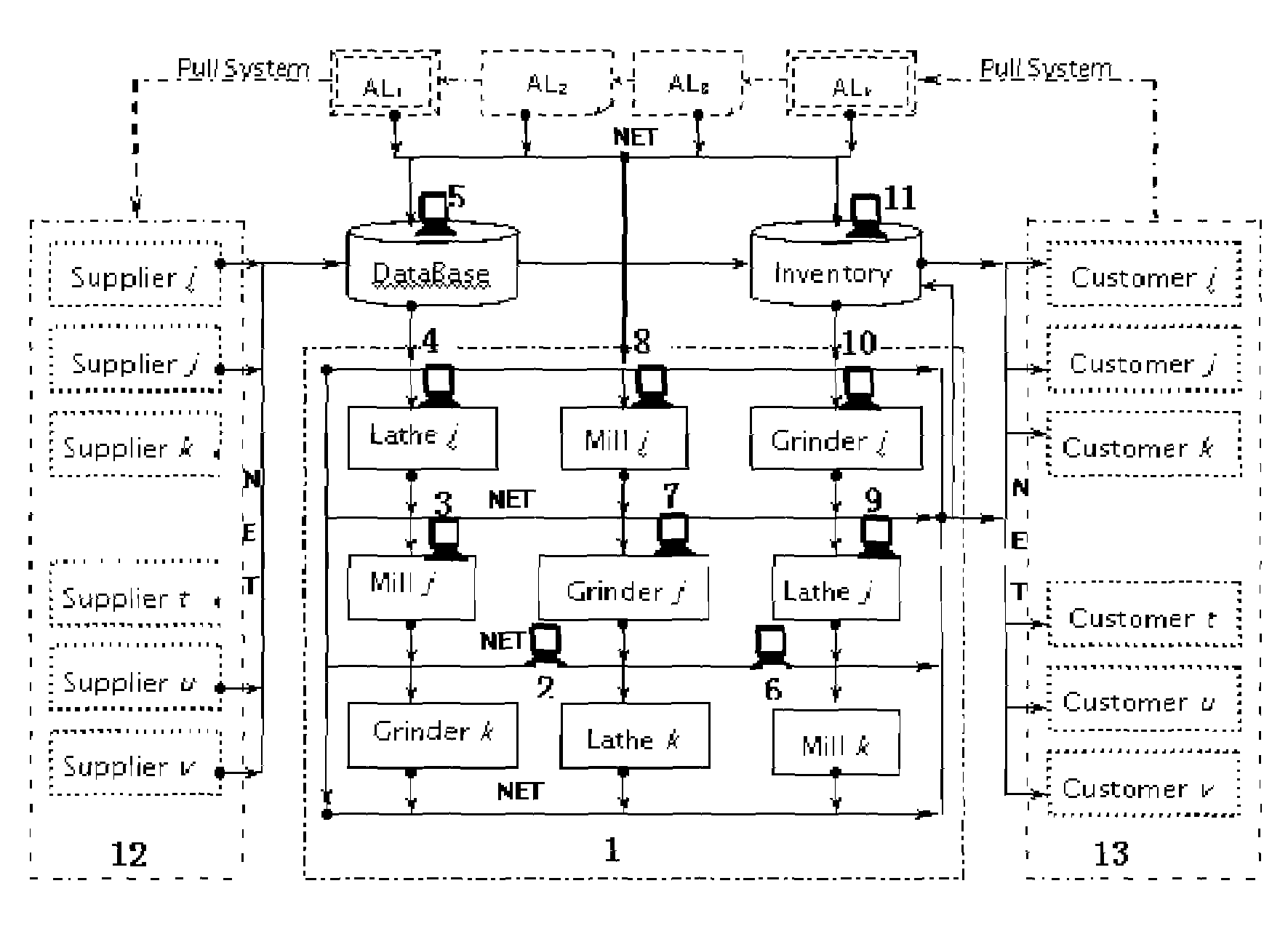

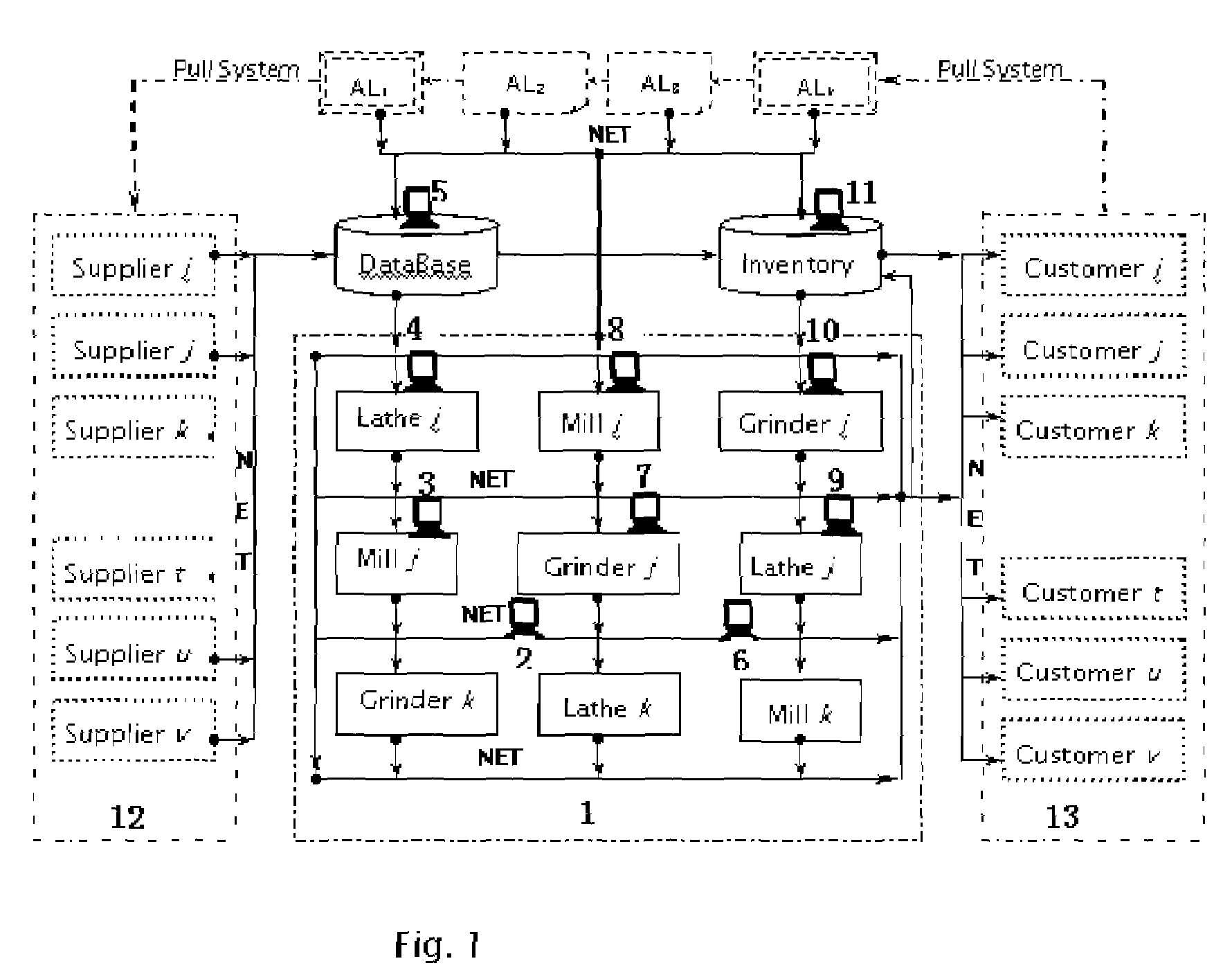

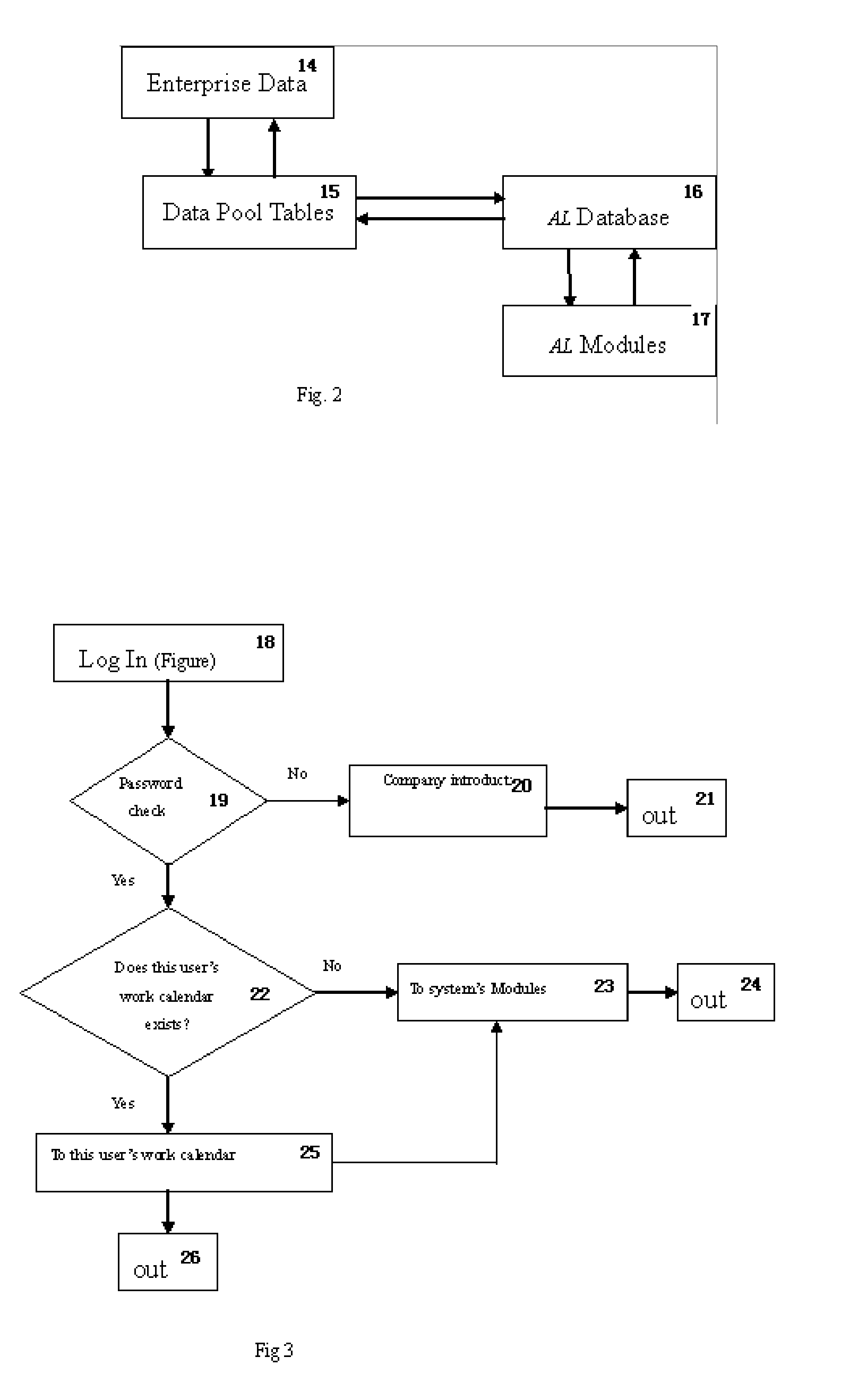

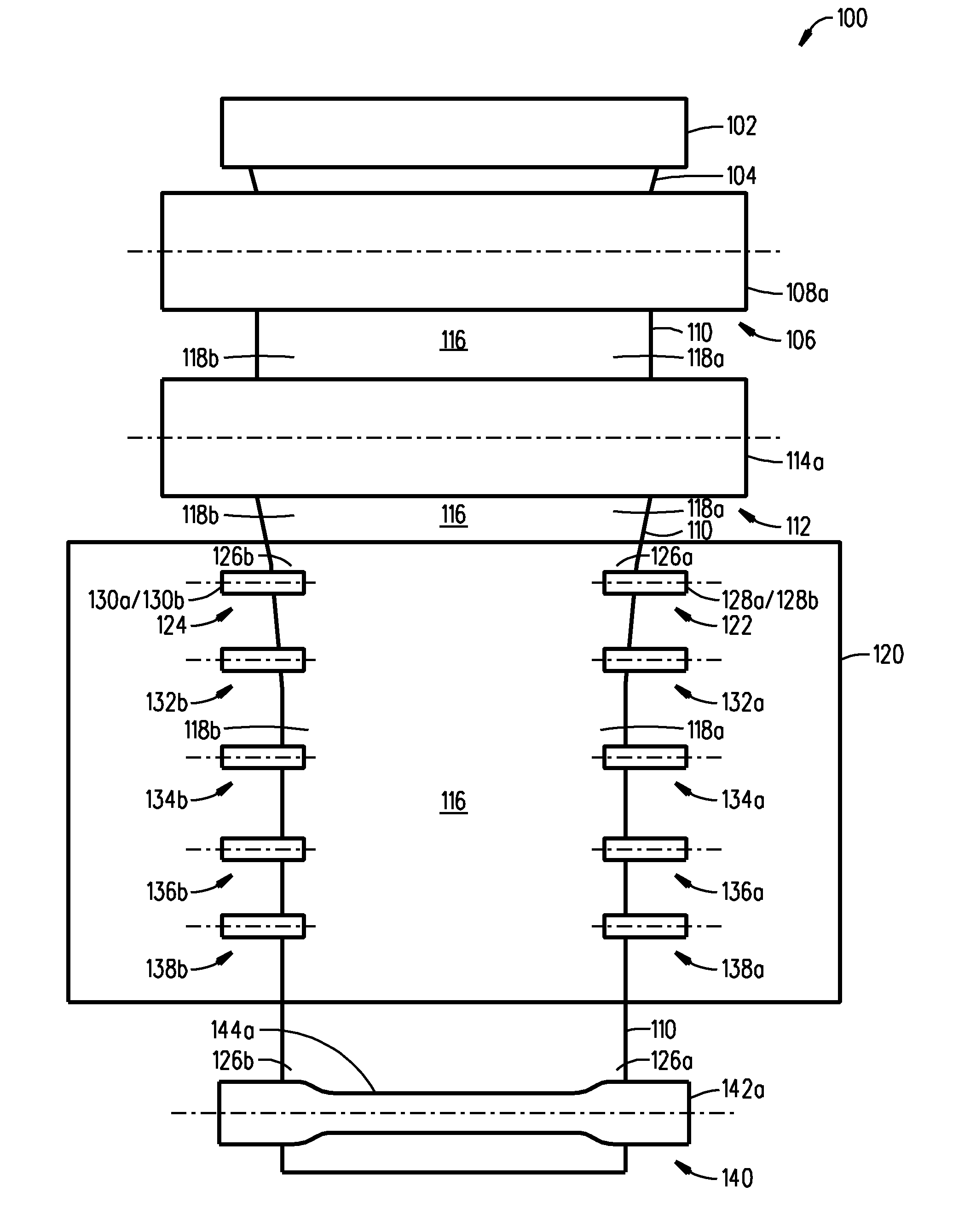

Web accessible real time system and software for agile and lean manufacturing

The present invention is directed to Lean and Agile methods and their applications to manufacturing operations on production floors. A web assessable, modular, user modifiable, and graphically-enriched system and software is disclosed in this document. It provides real time Lean and Agile solutions to reduce production wastes and to enhance productivity and efficiency for manufacturing organizations.

Owner:SIMPLE TECH

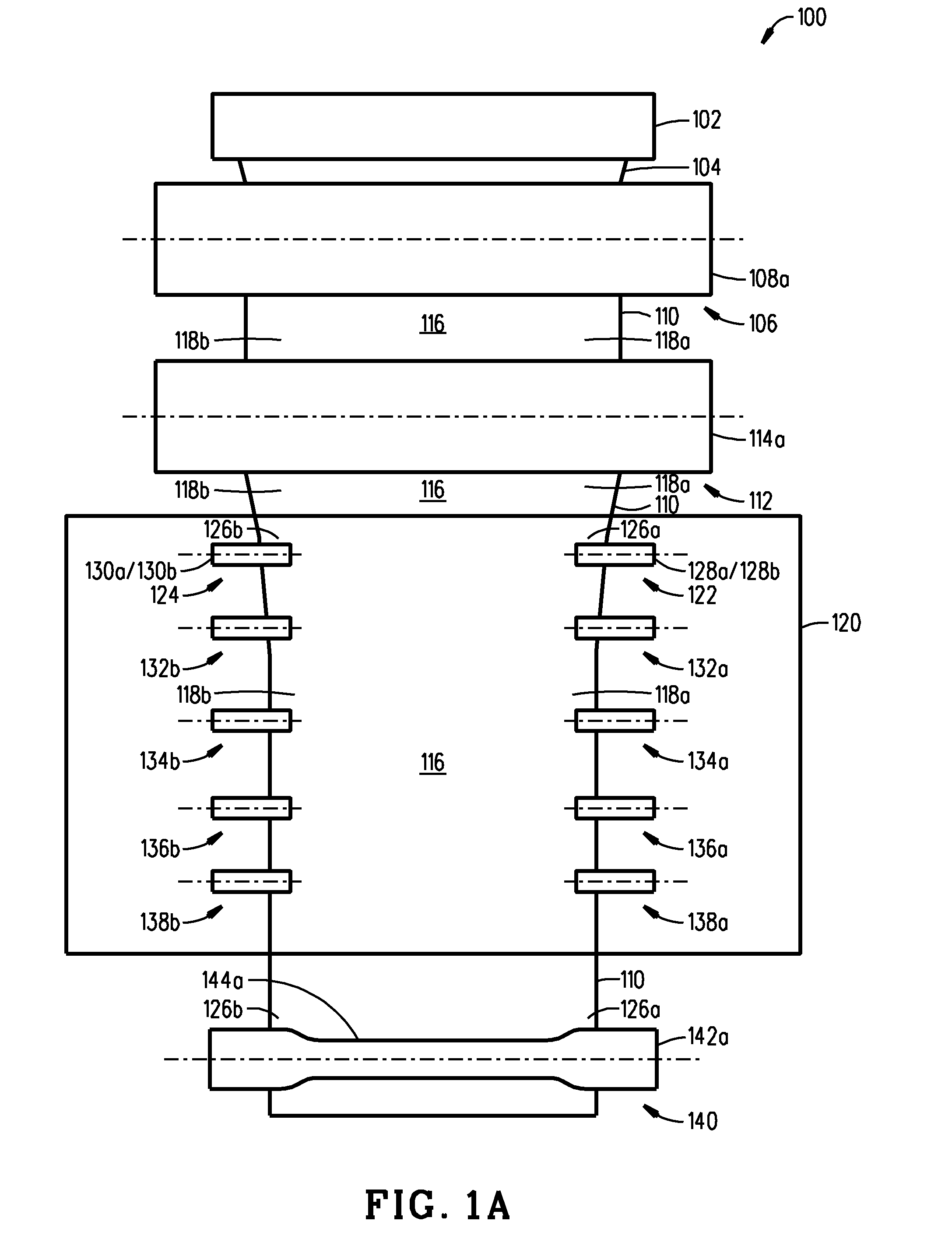

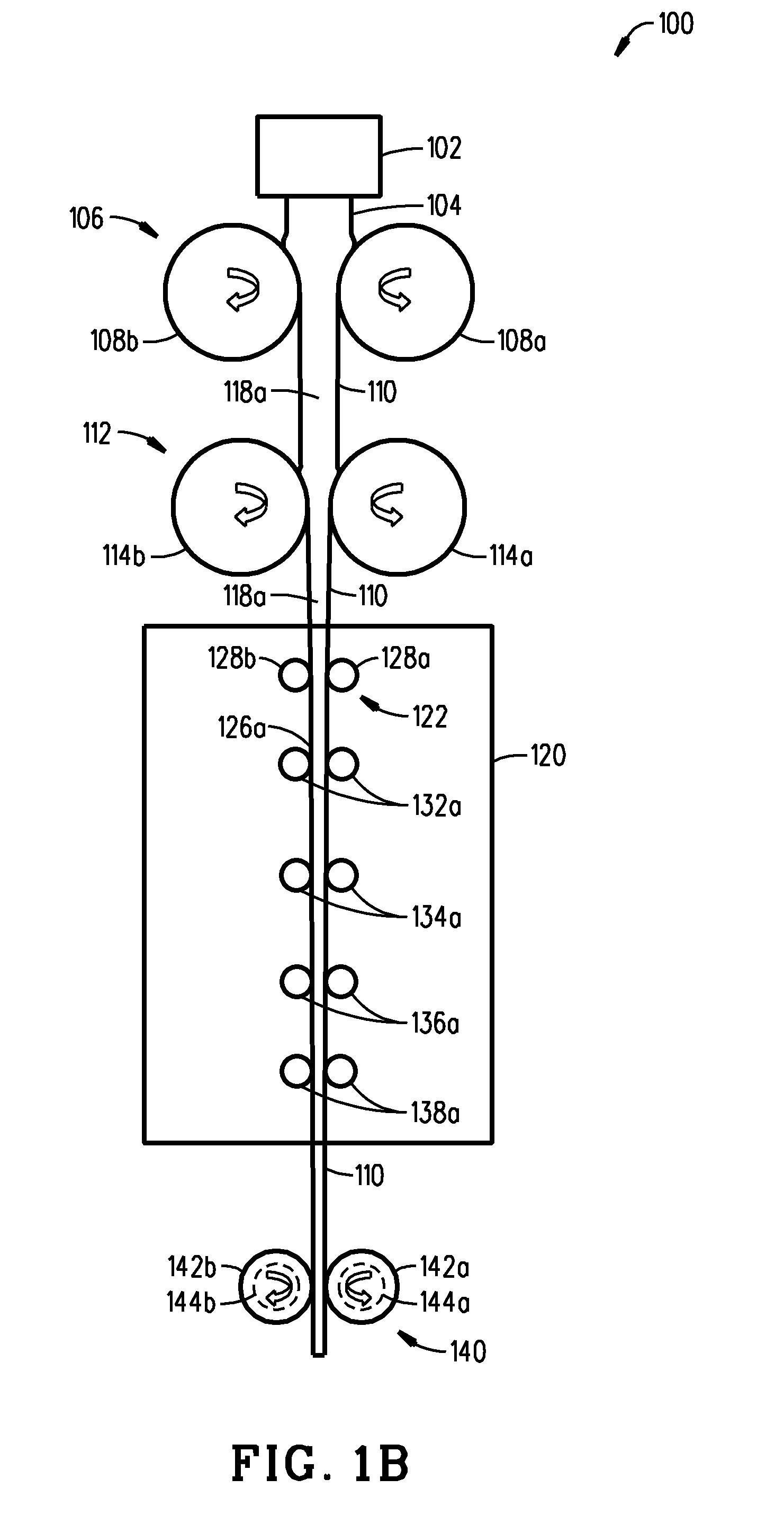

Glass manufacturing system and method for forming a high quality thin glass sheet

A glass manufacturing system (100, 100′, 100″) and method are described herein for forming a high quality thin glass sheet (110). In one embodiment, the glass manufacturing system and method use at least one of a compensated rolling roll (108a), a temperature controlled environment (120) and edge rolls (122, 124) to form a high quality thin glass sheet that has a thickness less than about 2 mm and more preferably less than about 100 μm.

Owner:CORNING INC

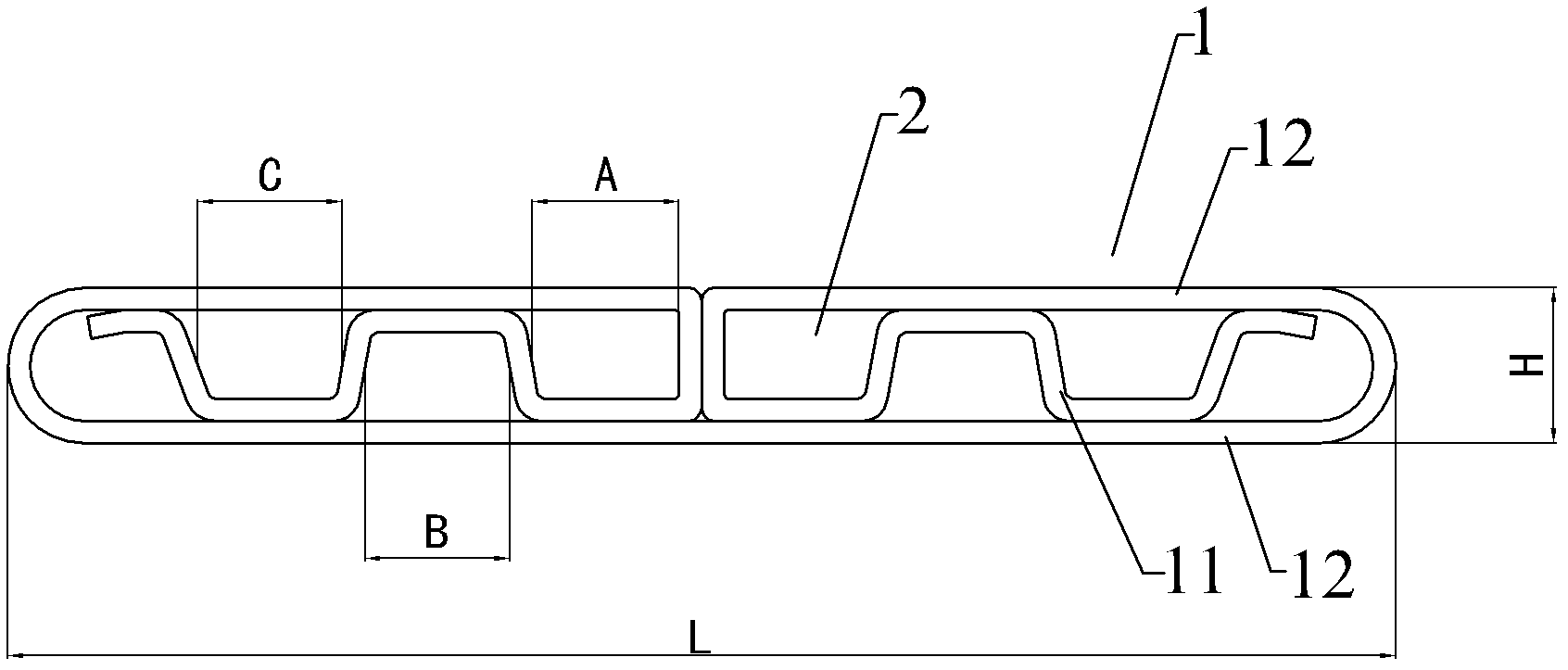

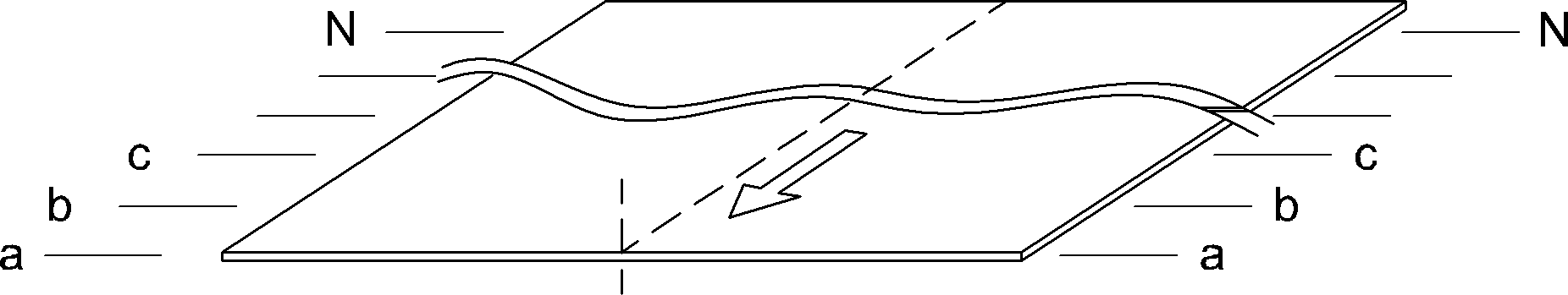

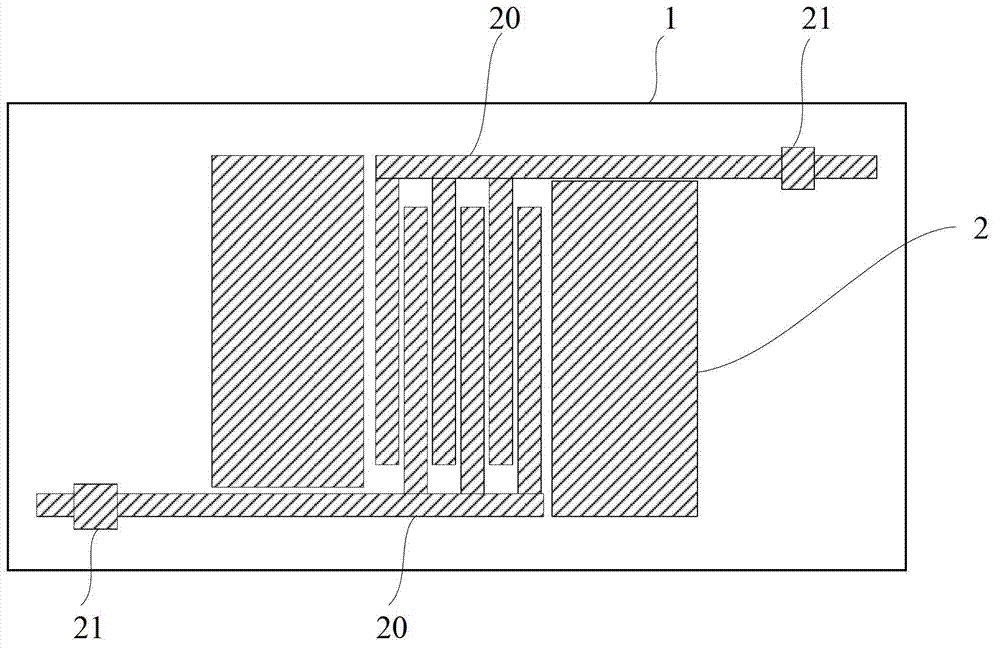

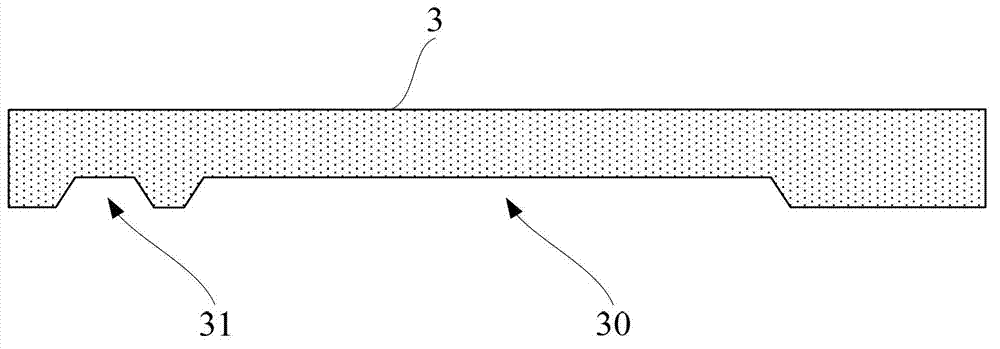

Folding-type microchannel porous flat pipe and molding method thereof

InactiveCN102353294AReduce weightHigh thermal conductivityHeat exchanger casingsTubular elementsControl mannerThin slab

The invention discloses a folding-type microchannel porous flat pipe and a molding method thereof. The flat pipe is formed by subjecting a single thin slab to integral molding, and the single thin slab is sequentially advanced by a mechanical bending mechanism in a multi-point molding control manner, wherein two ends of the single thin slab are respectively bent circuitously, then the circuitously bent parts are vertically bent twice and then horizontally turned and folded once and are butt-jointed at a mesal position of the single thin slab for integral molding, and thus, a porous flat pipe with mutually spaced fine pores is further formed. Compared with the prior art, the invention has the beneficial effects that: 1, the structural form of the flat pipe disclosed by the invention is suitable to being used in a light-weight heat exchanger with light weight and high heat conductivity; 2, the advantages of compact entire structure, high heat exchange efficiency, light weight, firmness, durability, and operation safety and reliability are achieved; 3, by adopting the integral folding and molding structure, the energy consumption of a product production process is low, and the pressure resistance of products is good; and 4, the effect of producing and yield can be achieved through mechanical control, the inventory level is greatly reduced, the product turnover efficiency is increased, and the requirement on lean production can be met.

Owner:YANGJIANG BAOMALI AUTO AIR CONDITIONER

Differential capacitive micro-acceleration transducer and manufacturing method thereof

ActiveCN102778586AIncrease stiffnessSize stiffnessDecorative surface effectsAcceleration measurementTransducerEngineering

The invention discloses a differential capacitive micro-acceleration transducer and a manufacturing method thereof. According to the method, the manufacturing of a movable mass block and an elastic beam is completed by using a bulk-silicon process, and the structure manufacturing and the releasing of a device structure are simultaneously completed by using a dry etching method; a movable electrode and the movable mass block are same in shape and size, so that an operation of repeated photoetching is avoided, thereby greatly simplifying the process; the stiffness of the designed elastic beam is small in the sensitive direction and large in the sensitive vertical direction, therefore, the elastic beam is higher in selectivity and anti-crosstalk capacity; and a device is simply and reliably packaged by using a wafer-level low-temperature vacuum aligned-bonding technology, thereby facilitating the large-scale manufacturing of the device. In addition, the differential capacitive micro-acceleration transducer disclosed by the invention adopts a variable-area type operating principle, so that the movable mass block is only damped by a sliding membrane in the process of moving, thereby improving the sensitivity.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

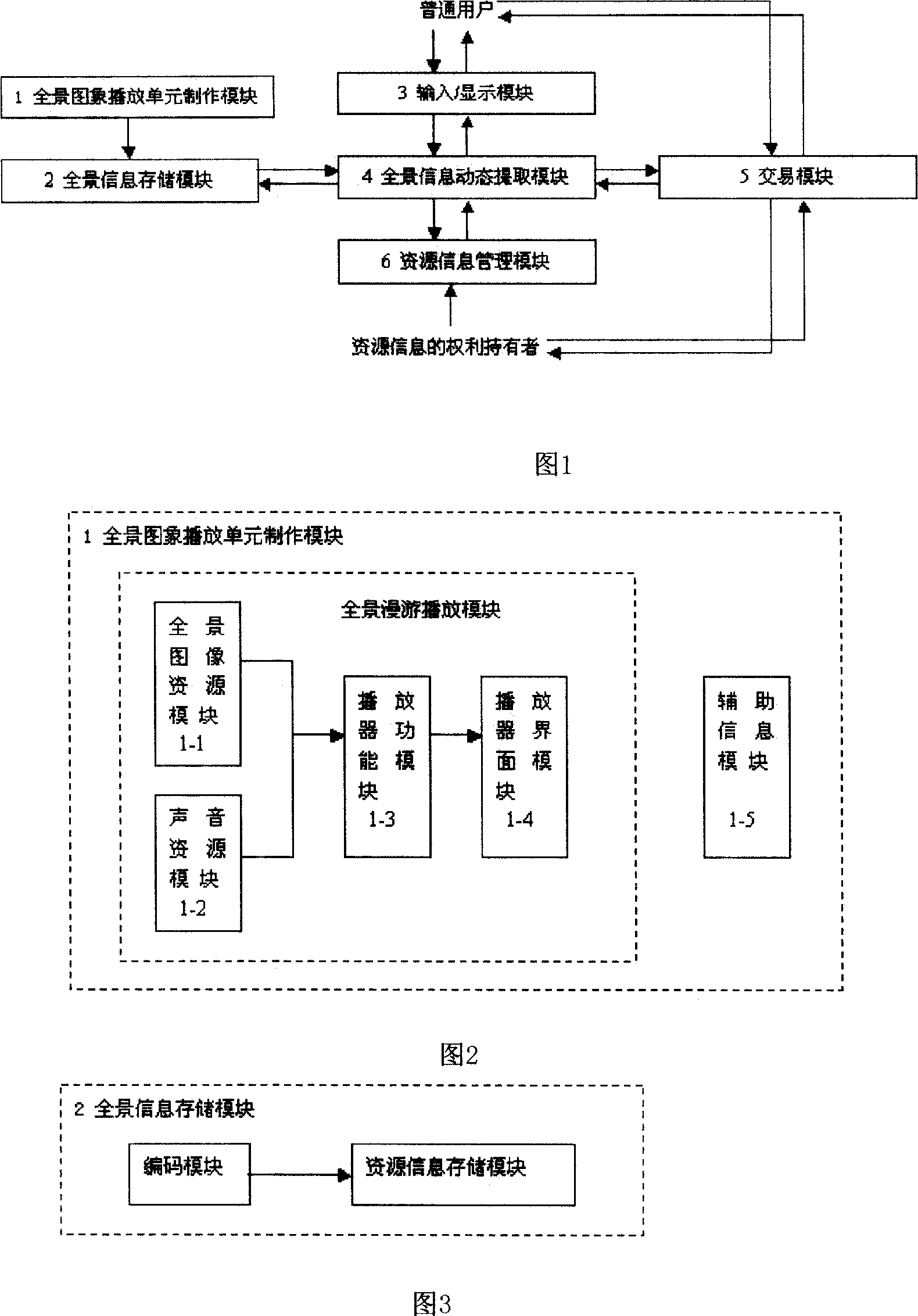

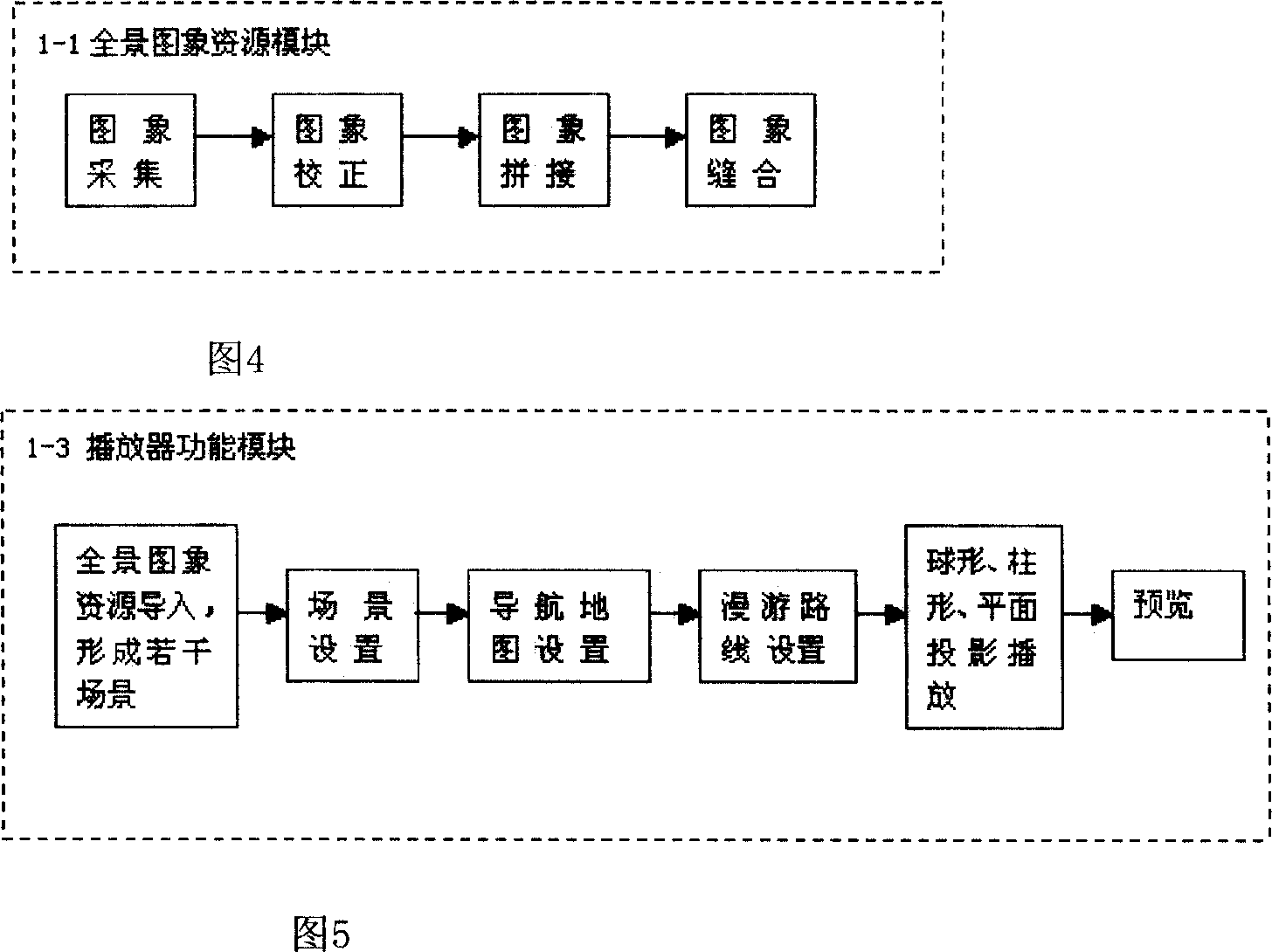

Panorama manufacturing and displaying system of resource information

InactiveCN101136022AEasy to manufactureEasy to manageImage data processing detailsSpecial data processing applicationsUser inputResource information

The system comprises: a panorama image of resource information play unit making module used for making encode for the panorama image play unit; a panorama information storage module for storing the panorama information; a display module for providing input operation for user and displaying its corresponding content; a panorama information dynamically extracting module; a transaction module used for providing the interaction information for the user and resource information owner; a resource information management module used for modifying the content of resource information.

Owner:李筑

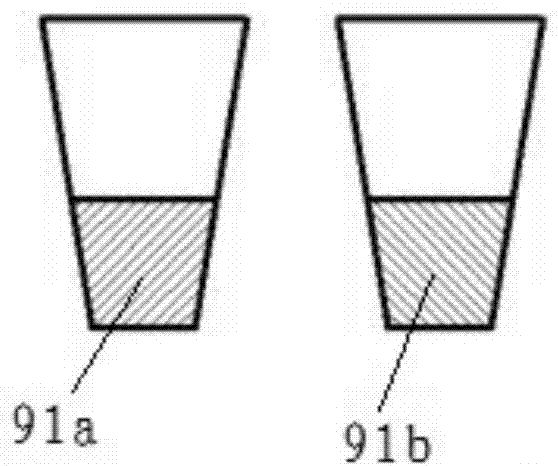

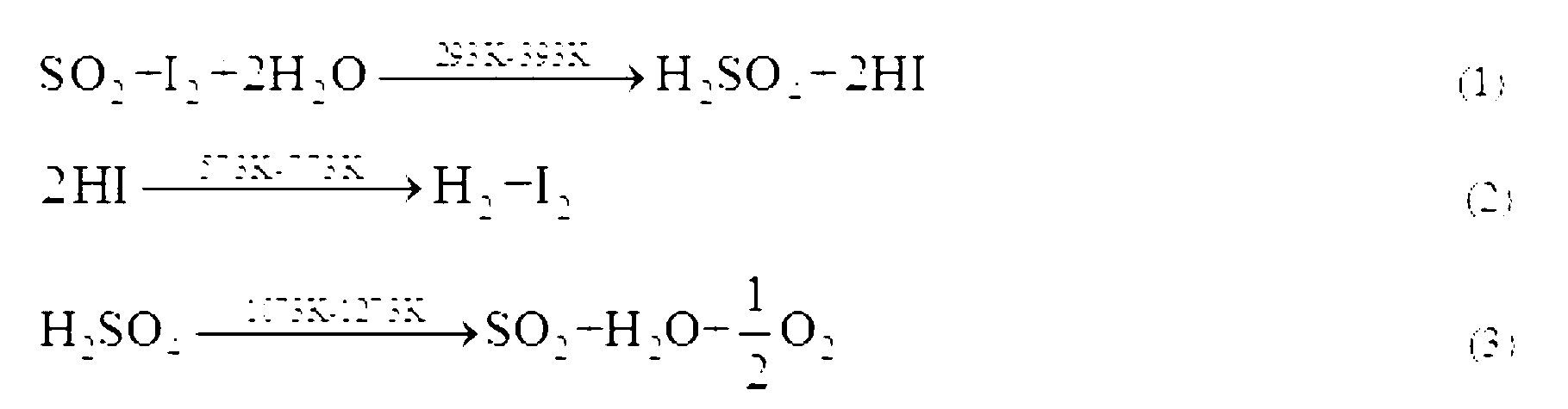

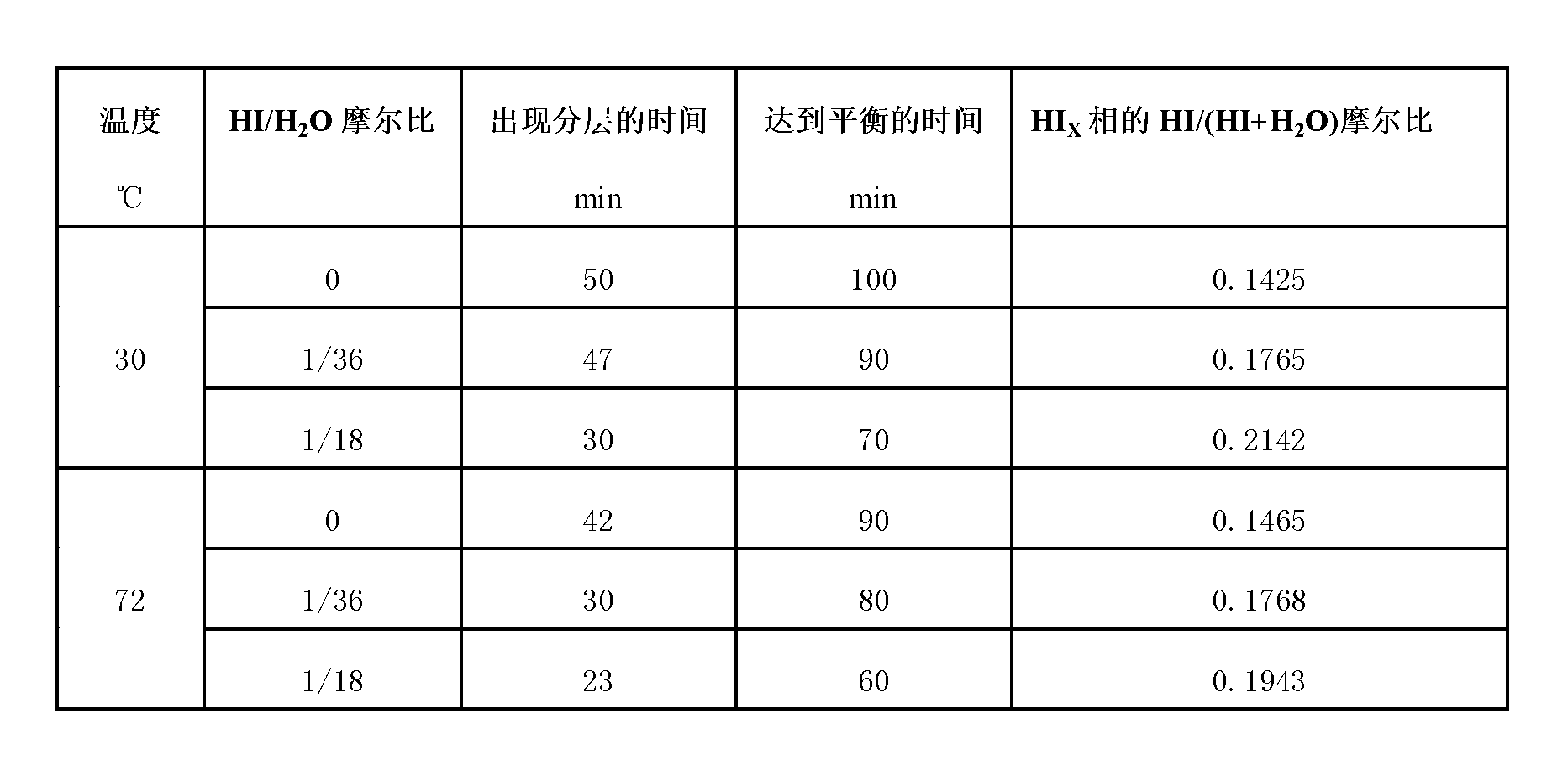

Method for promoting Bunsen reaction in thermochemical iodine-sulfur cycle for hydrogen manufacturing

ActiveCN103213945AOmit the concentration stepIncreased reaction kinetic rateHydrogen productionMass ratioDistillation

The invention relates to a technique of iodine cycles for hydrogen manufacturing, and aims to provide a method for promoting a Bunsen reaction in a thermochemical iodine-sulfur cycle for hydrogen manufacturing. The method comprises the following steps: adding I2 and H2O in a reactor, and heating a reaction solution to 30-72 DEG C; adding hydroiodic acid under the condition that the mass ratio of HI / H2O is 1 / 36-1 / 18: 1, and mixing the reaction solution at a uniform speed so as to ensure I2 is completely dissolved; feeding SO2 at a constant flow rate, and spontaneously carrying out the Bunsen reaction so as to obtain H2SO4 and HI; and in the presence of excessive iodine, carrying out the separation of liquid-liquid phases, so that the reaction achieves a liquid-liquid equilibrium state finally. According to the invention, the original gas-liquid-solid three-phase reaction is transferred into a gas-liquid reaction, and then the kinetic velocity of the Bunsen reaction is improved; and added HI has certain contribution to the improvement of the concentration of HI in a HIx phase in a thermodynamic equilibrium state, and HI achieves a super azeotropic concentration, so that the situation that pure HI steam is obtained through subsequent distillation is facilitated, and a HI concentration step can be cancelled, therefore, the method is extremely advantageous to the simplification of a whole SI circulation system and the improvement of the thermal efficiency of the system.

Owner:ZHEJIANG UNIV

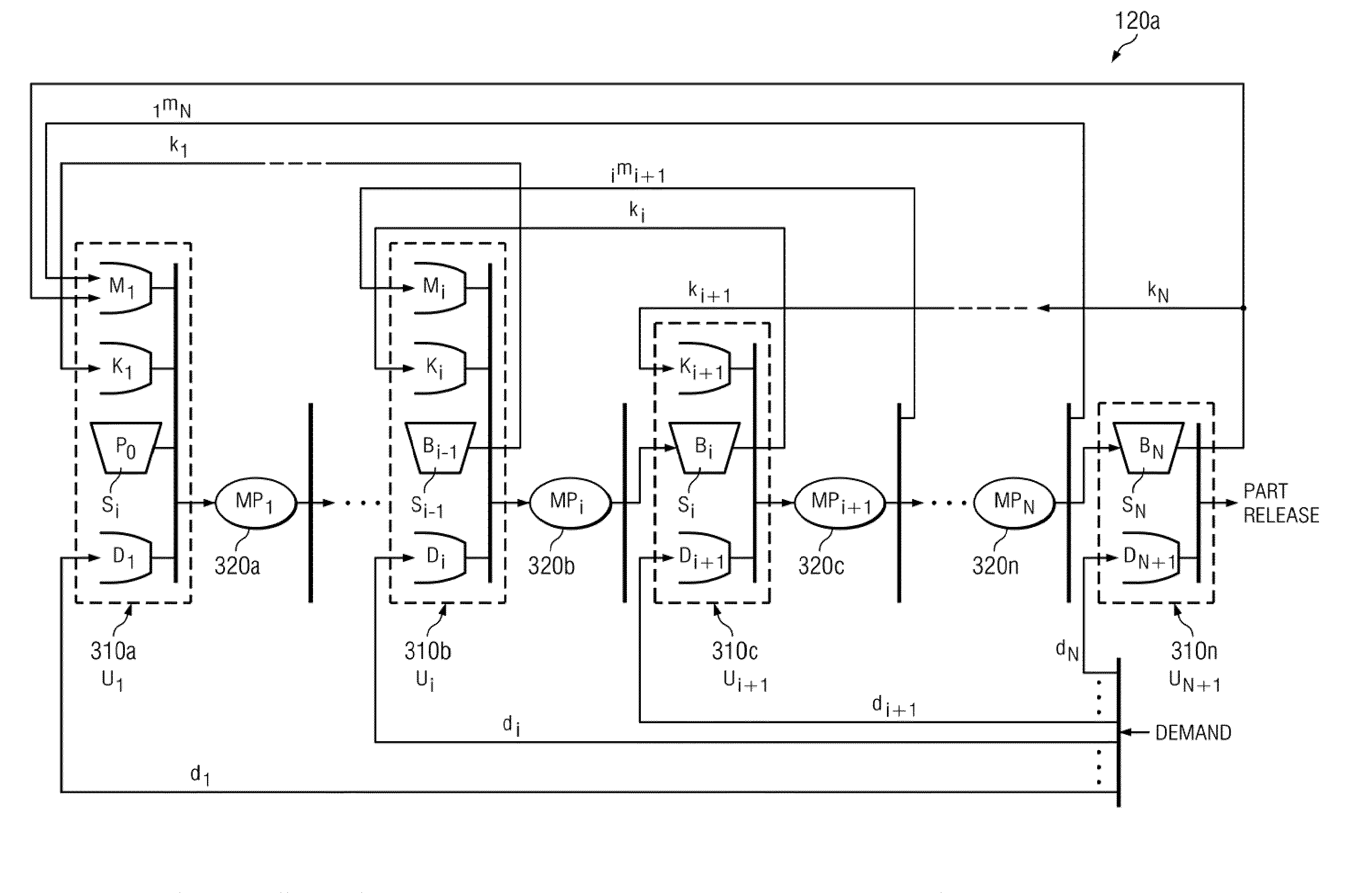

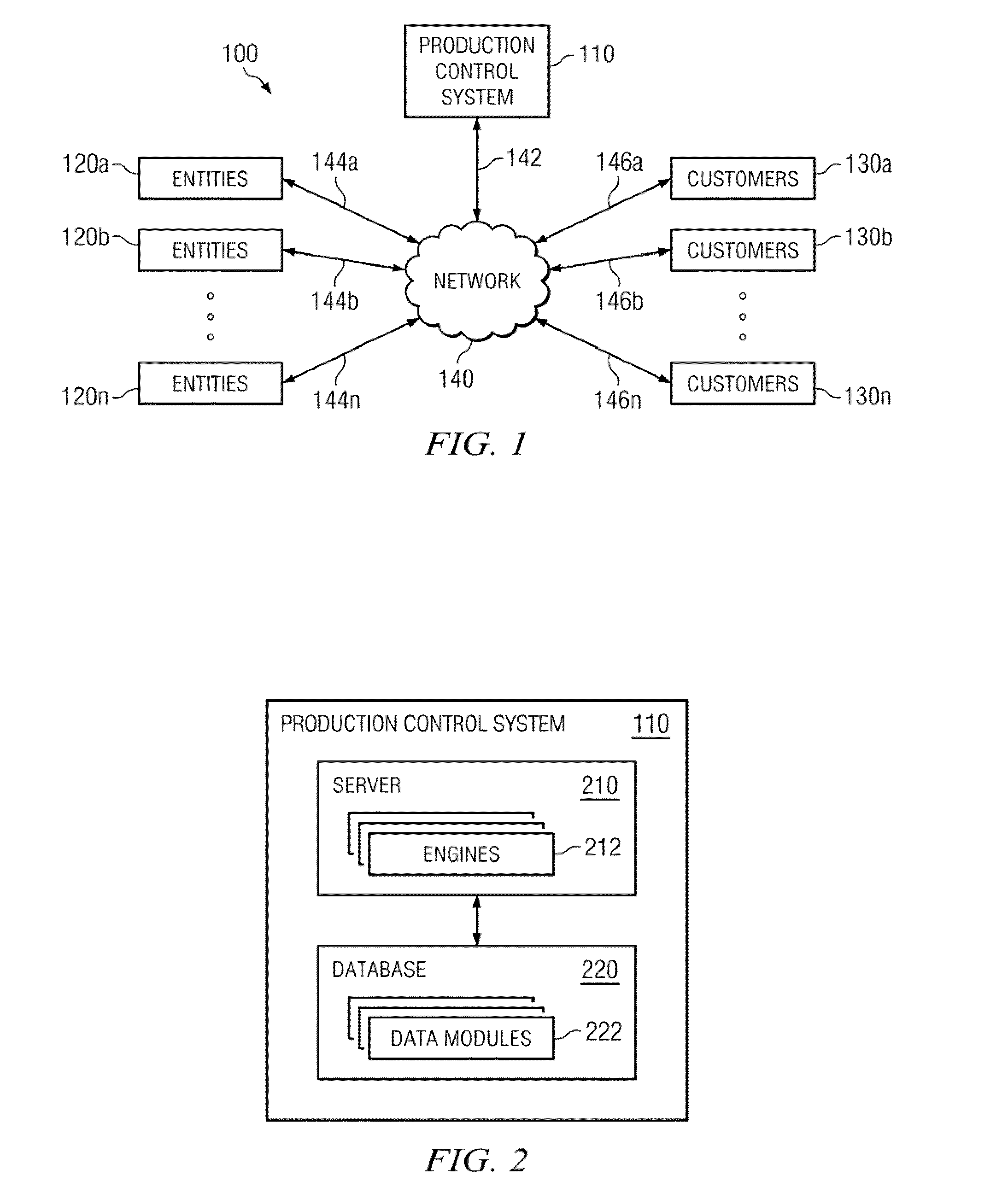

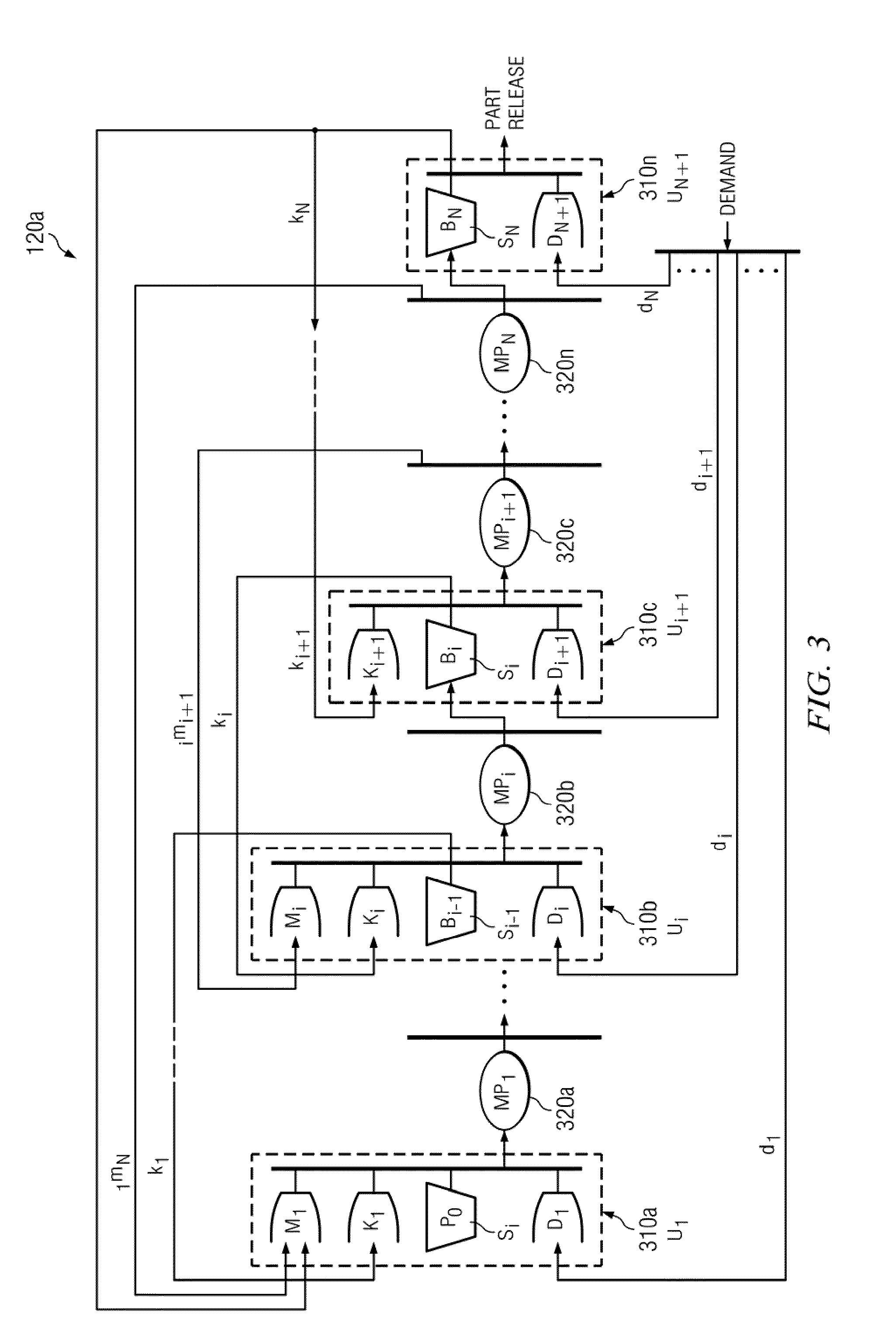

System and Method for a Demand Driven Lean Production Control System

A system is disclosed providing visualization of a production control framework. The system includes a database storing production control data associated with one or more entities and a production control system coupled with the database and configured to model a production control framework of the one or more entities. The production control system includes one or more work centers authorizing one or more tasks for one or more parts and one or more manufacturing processes that produce one or more finished parts using the one or more parts.

Owner:BLUE YONDER GRP INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com