Mobile phone shell and shell manufacturing process thereof

A processing technology and shell technology, which is applied in the field of shell processing technology with metallic luster, can solve the problems of poor appearance, many process steps and high cost, and achieve the effects of high yield, low manufacturing cost and short cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

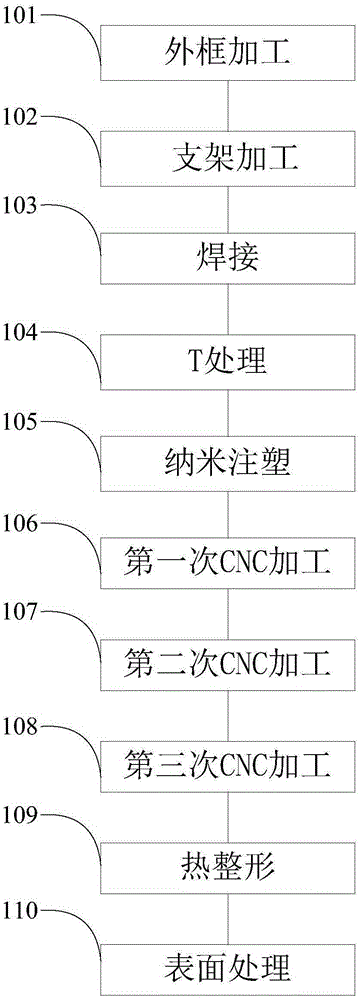

[0032] refer to Figure 1 to Figure 4 , the present invention provides a shell processing technology, the shell includes an aluminum alloy frame and an aluminum alloy bracket combined with the aluminum alloy frame, the shell processing process includes the following steps in sequence:

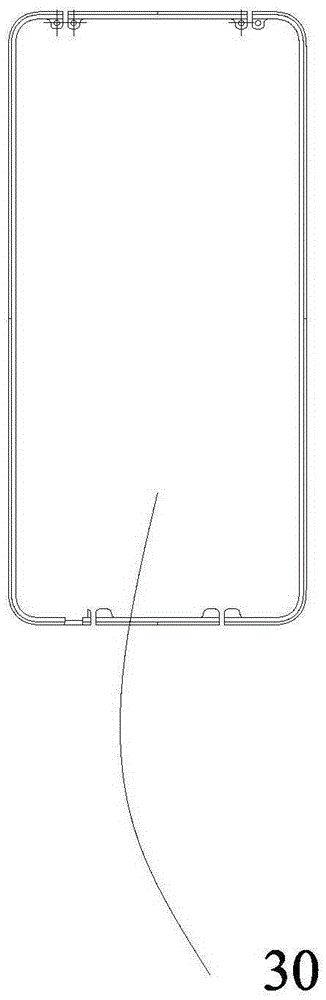

[0033] 101 Outer frame processing: processing the aluminum alloy outer frame 30 blank by using the aluminum drawing process, and adopting a mechanical processing method to open several grooves on the inner circumference of the aluminum alloy outer frame 30 blank to form the aluminum alloy outer frame 30;

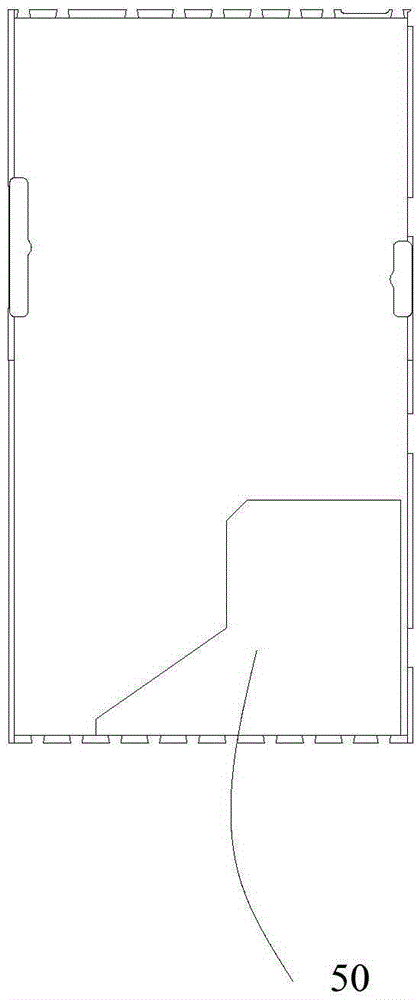

[0034] 102. Bracket processing: process the aluminum alloy bracket 50 blank by die-casting process, and then perform punching, trimming, skin film and shaping to obtain the aluminum alloy bracket 50;

[0035] 103 Welding: connecting the aluminum alloy outer frame 30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com