Patents

Literature

350 results about "Glasses type" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Glass-type terminal and method of controlling the same

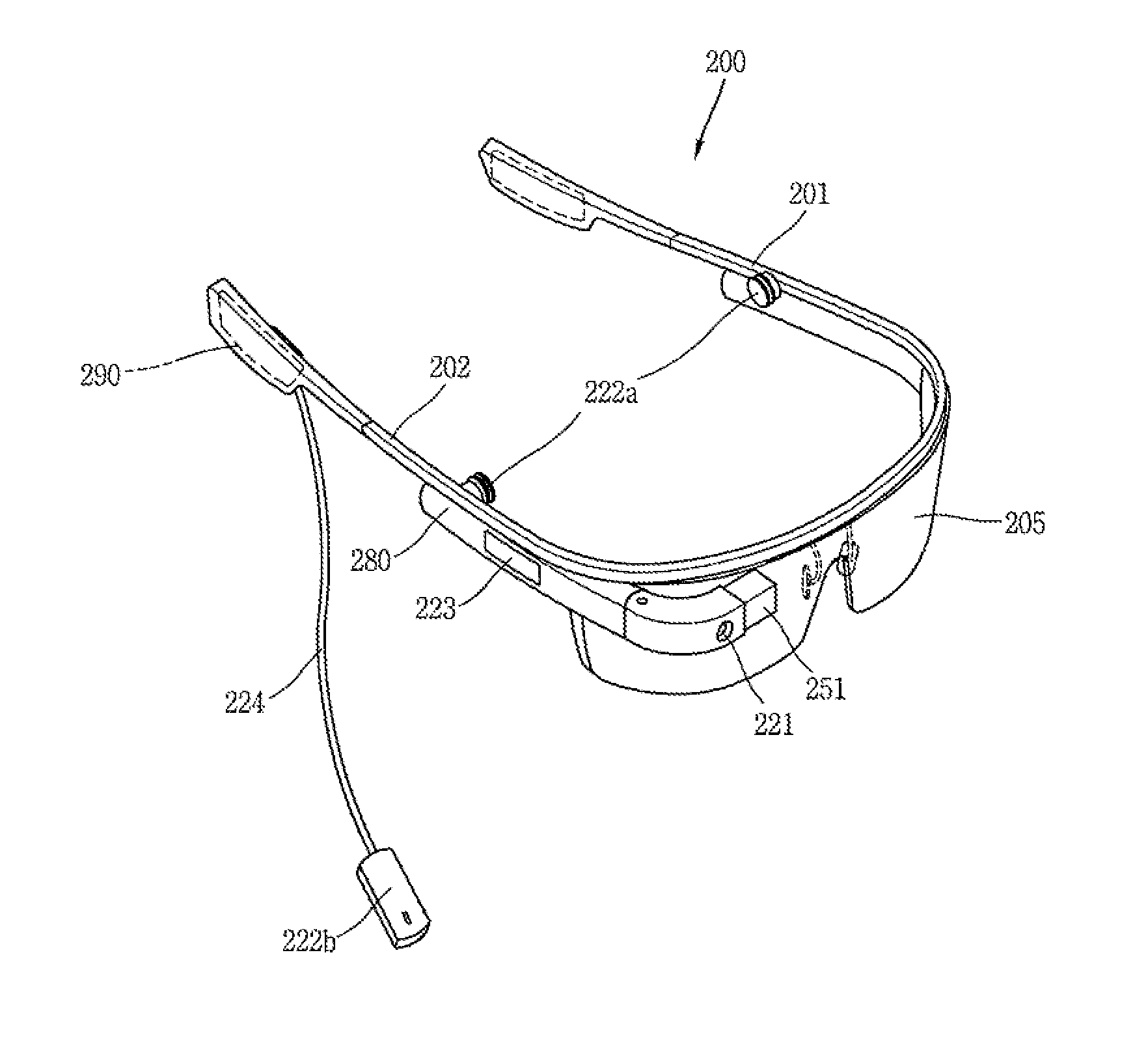

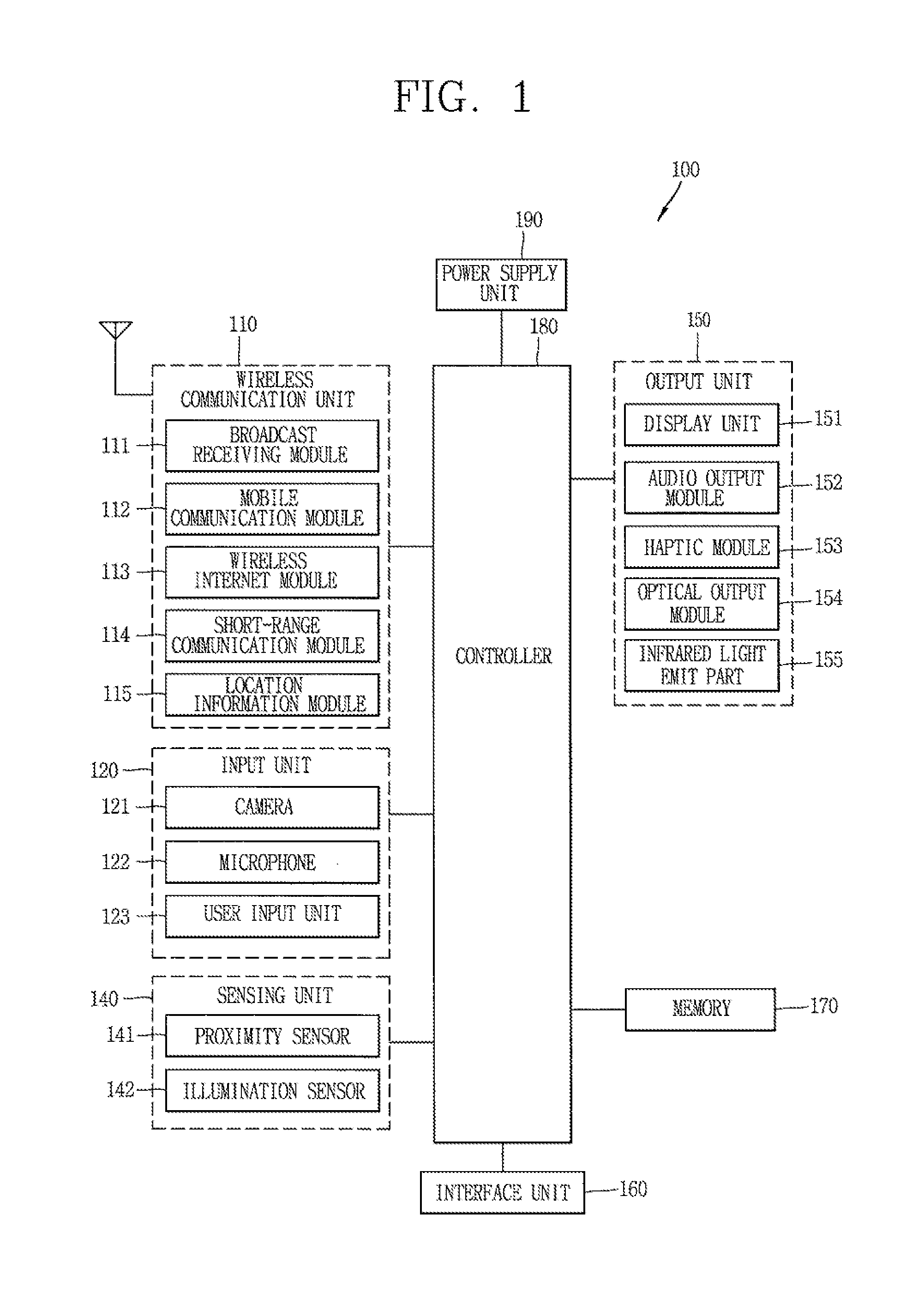

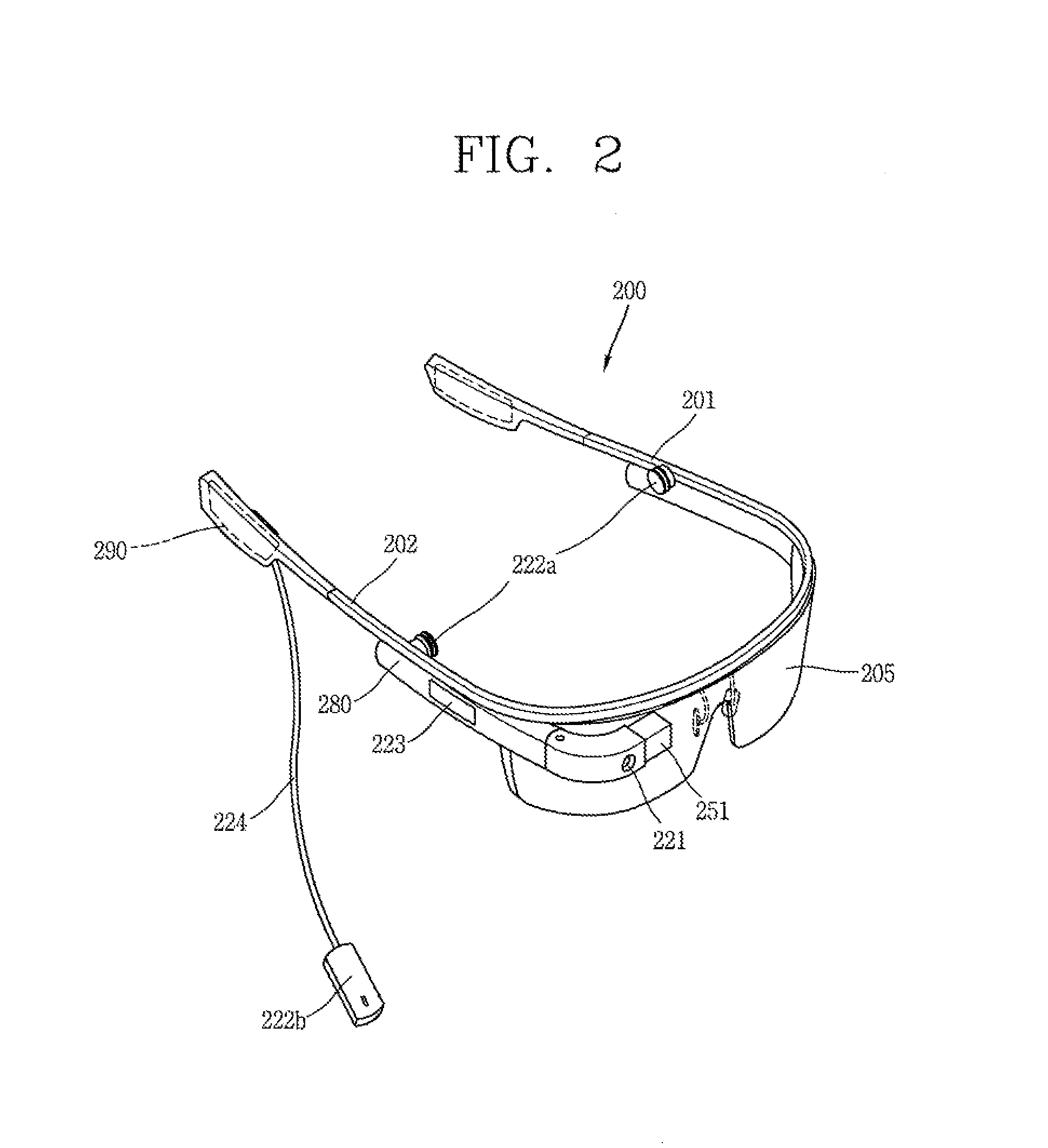

A glasses-type terminal including a main body configured to be worn as glasses on a user's head; a first microphone configured to detect a vibration signal through a skull portion of the user in which a voice being input propagates through the skull portion of the user; a second microphone configured to detect a voice signal in which the voice being input propagates over the air; a memory configured to store a pre-registered vibration signal and a pre-registered voice signal corresponding to a pre-registered voice; and a controller configured to switch a locked state to an unlocked state when the vibration signal detected through the first microphone is matched to the pre-registered vibration signal and the voice signal detected through the second microphone is matched to the pre-registered voice signal.

Owner:LG ELECTRONICS INC

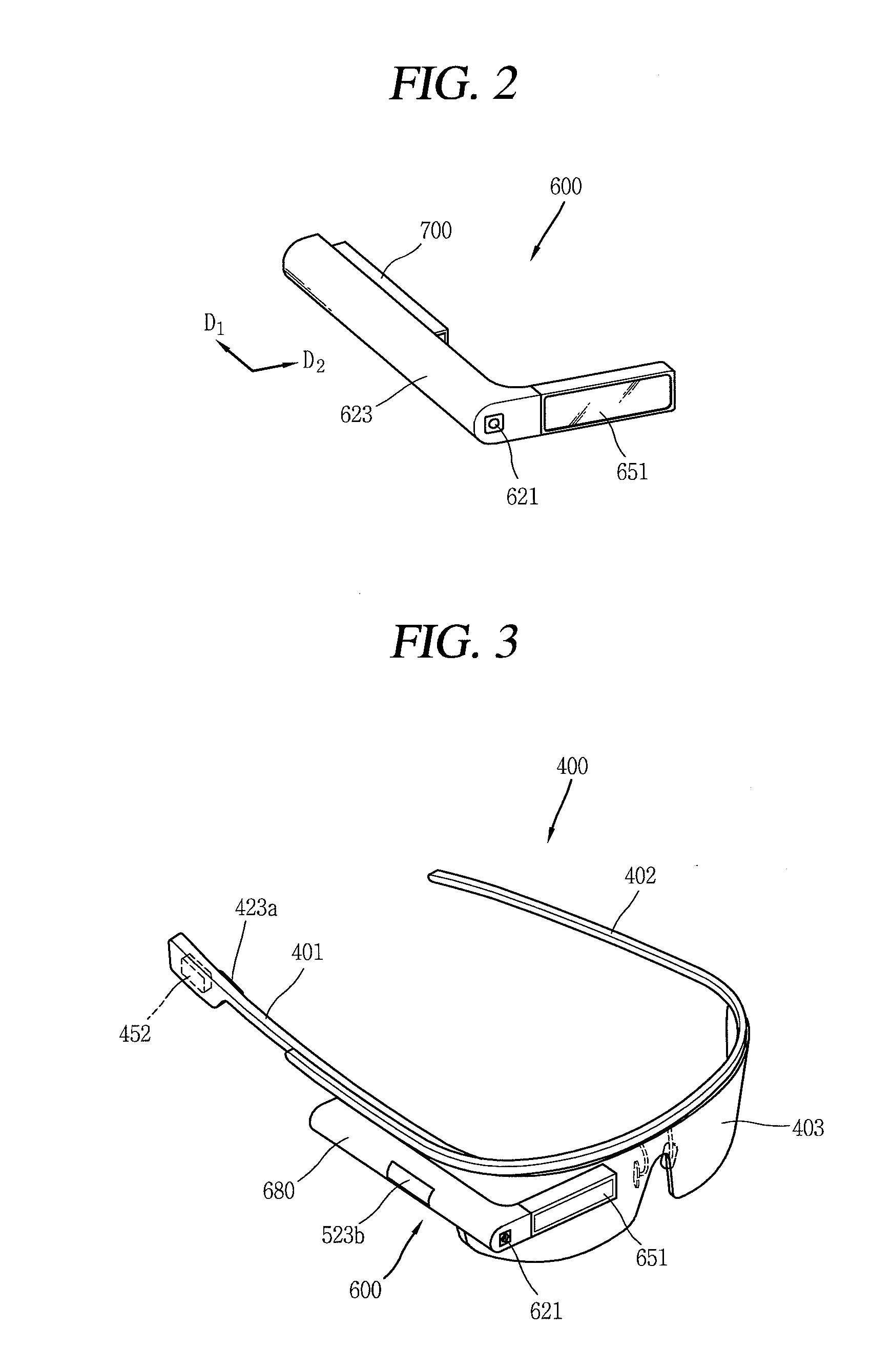

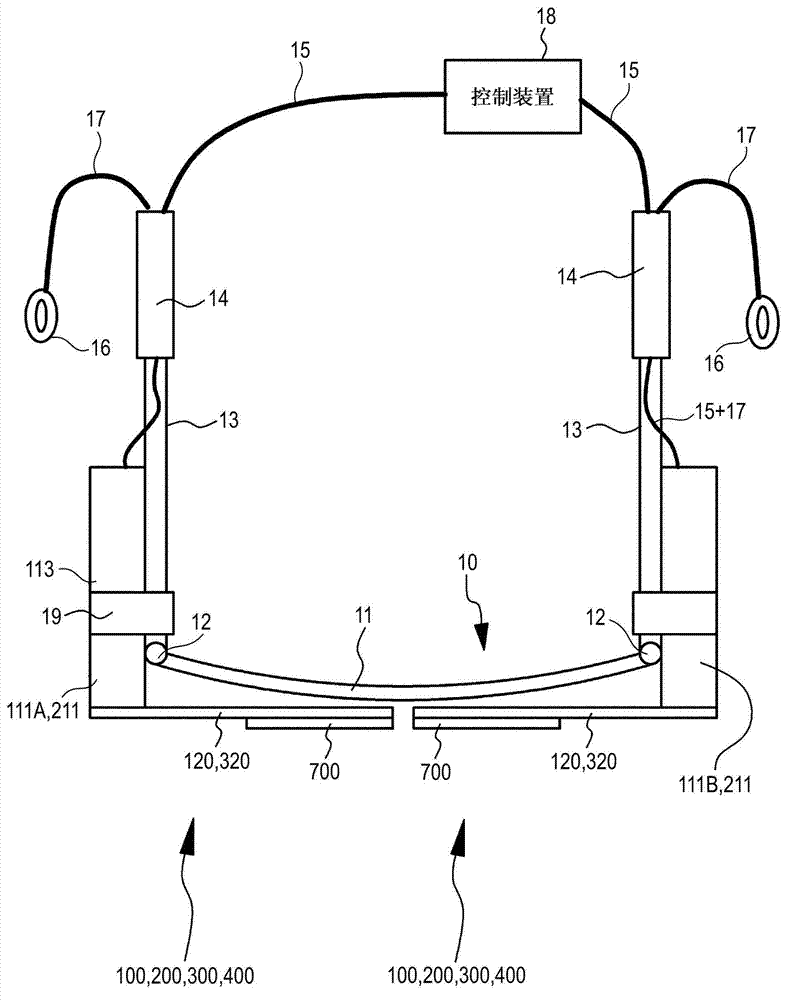

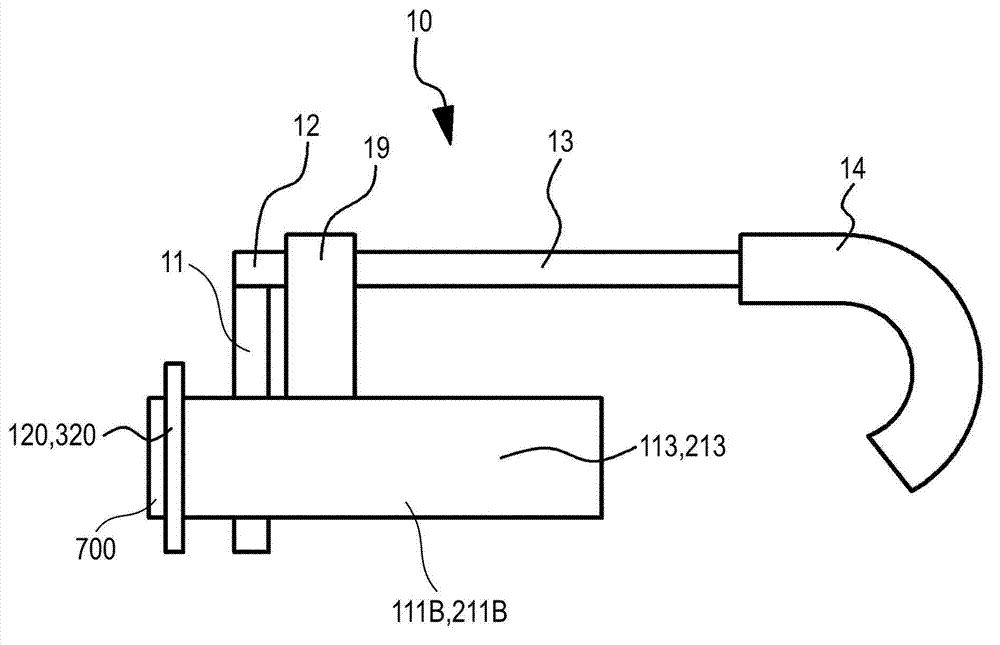

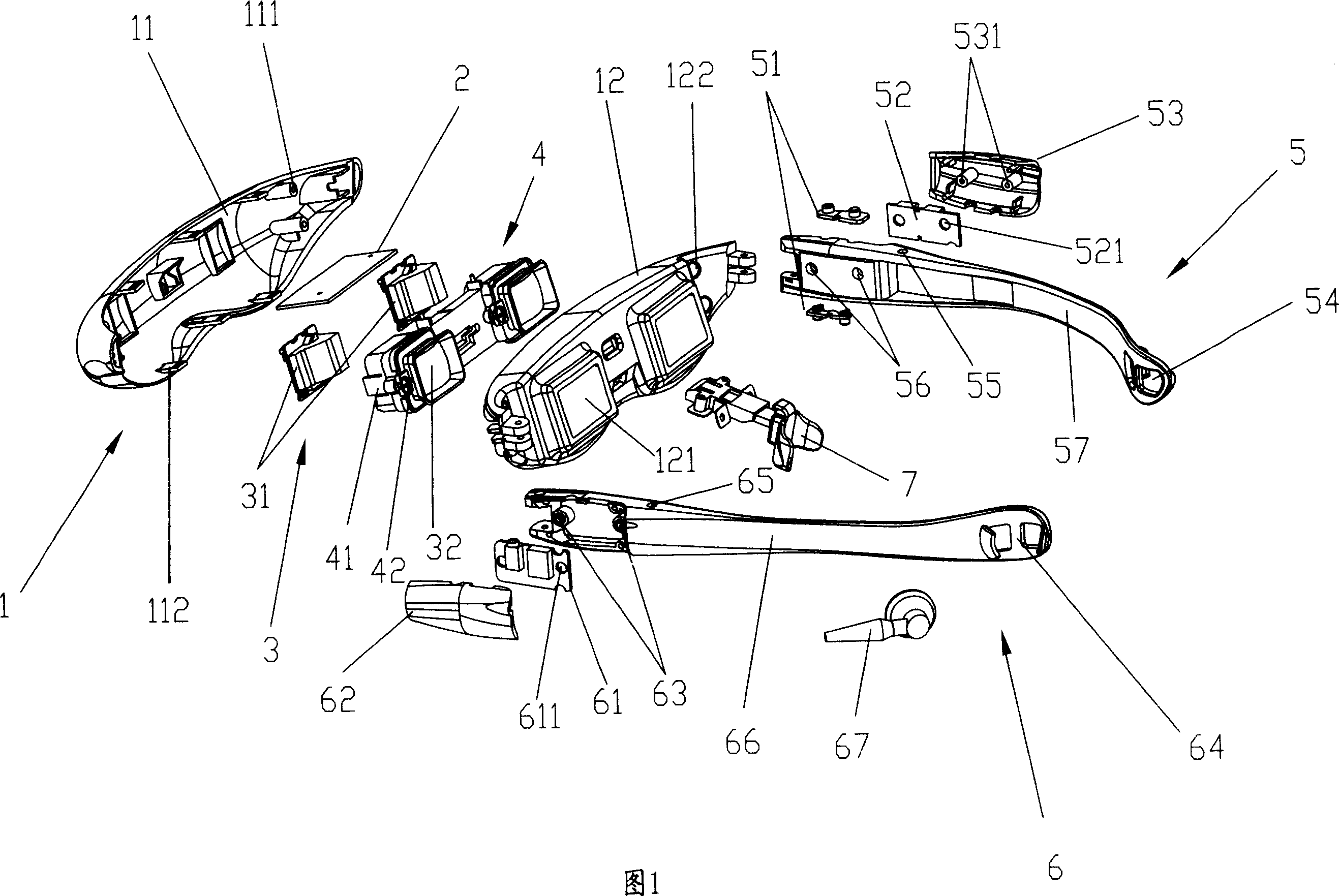

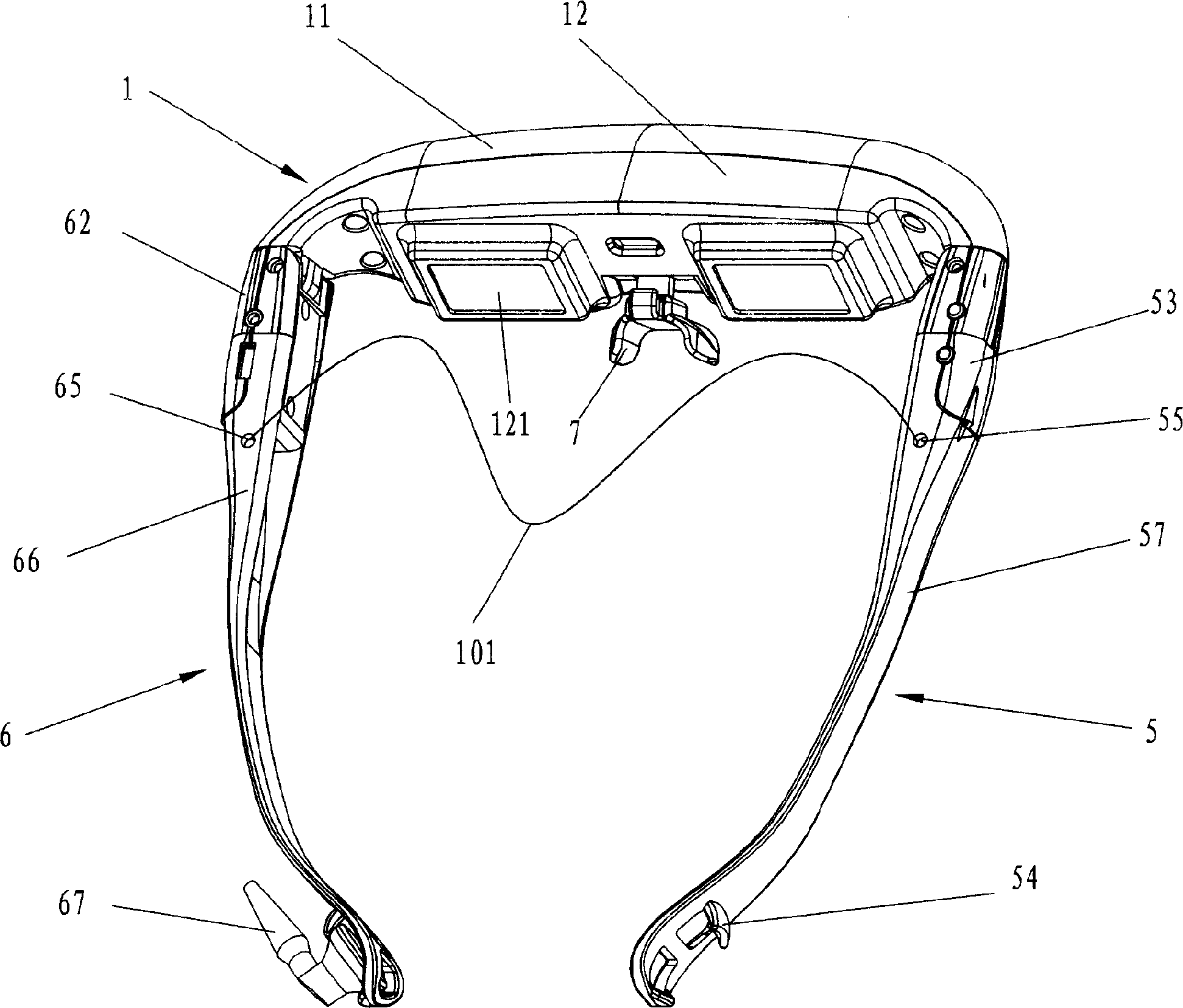

Clip type display module and glass type terminal having the same

ActiveUS20150261015A1Contact stabilityEasy to assembleSpectales/gogglesAuxillary optical partsGlasses typeDisplay device

Owner:LG ELECTRONICS INC

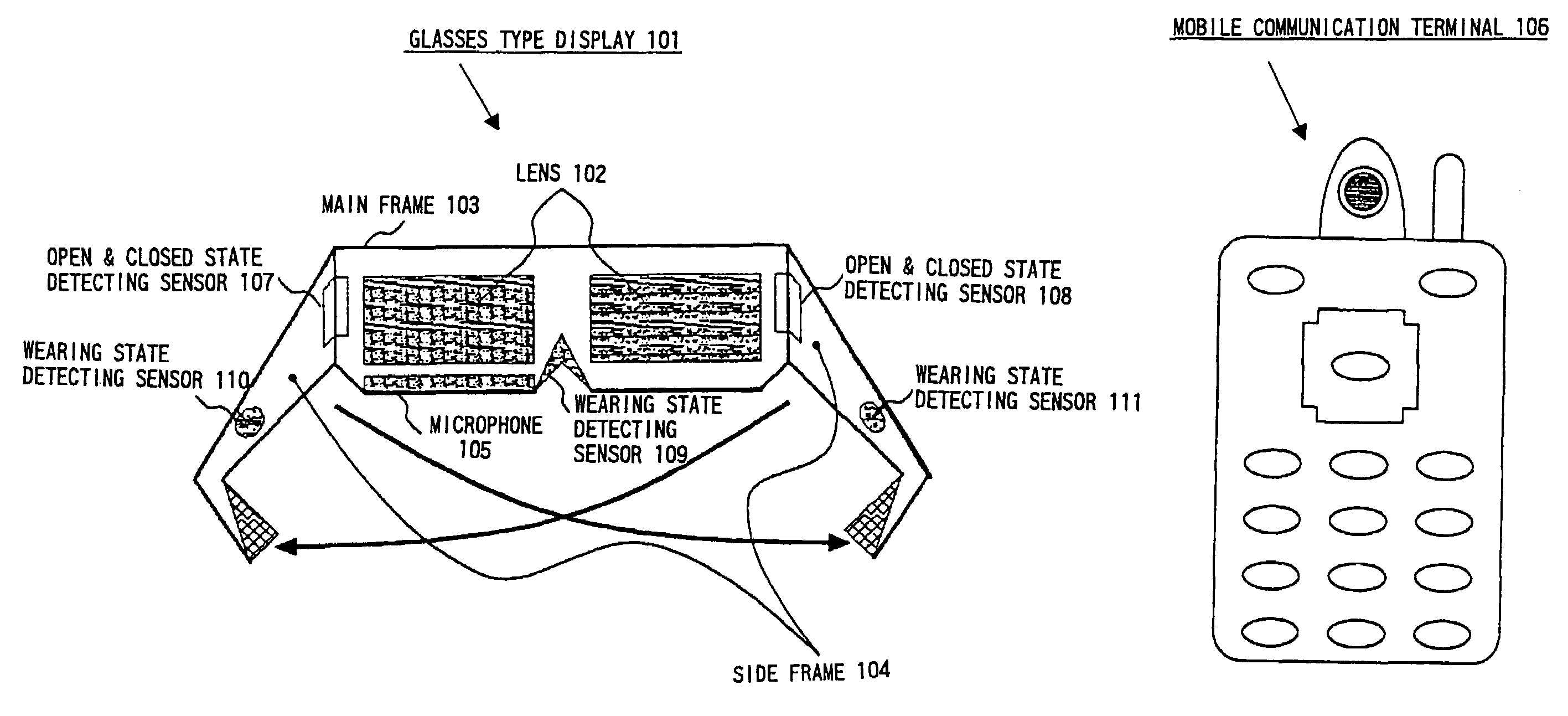

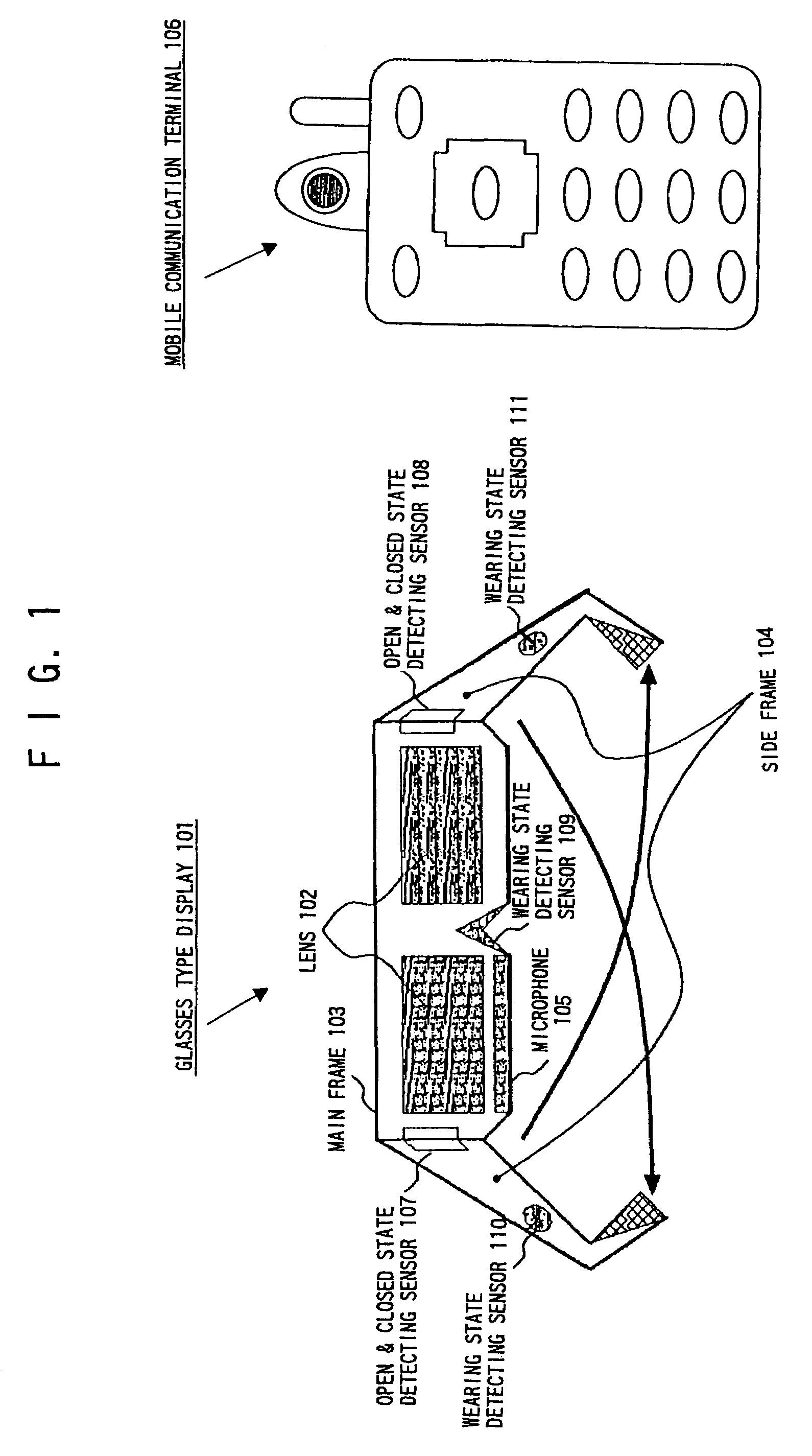

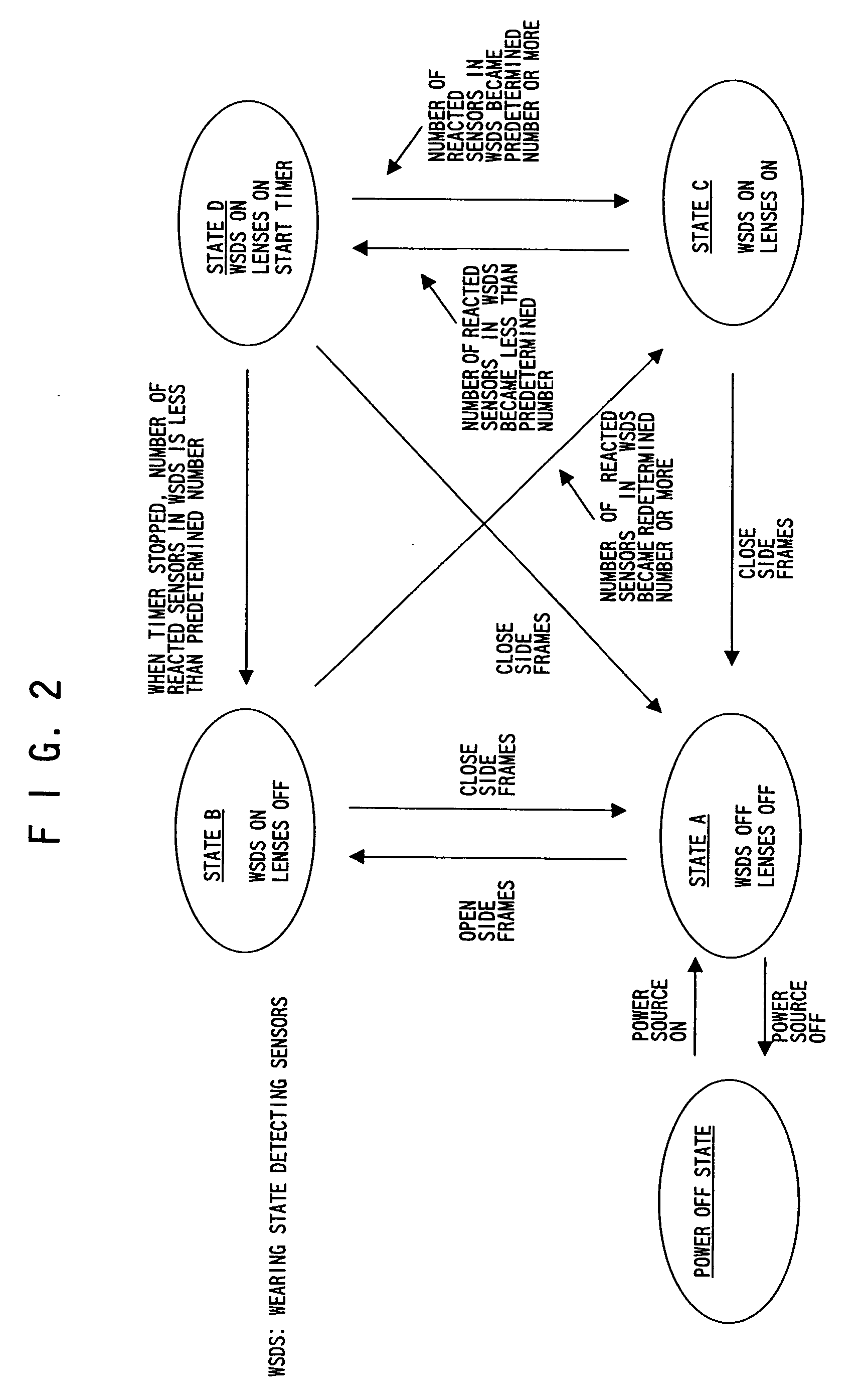

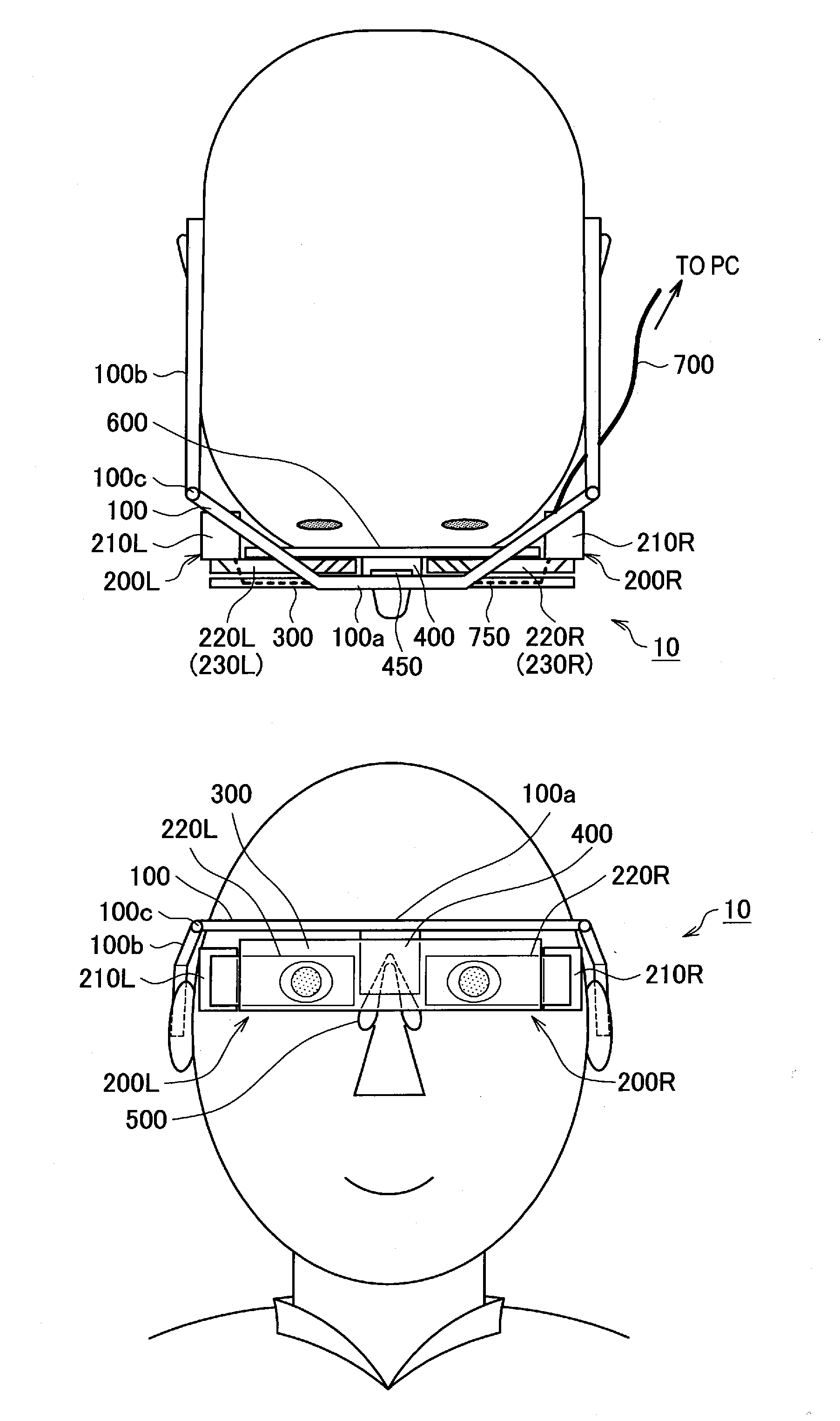

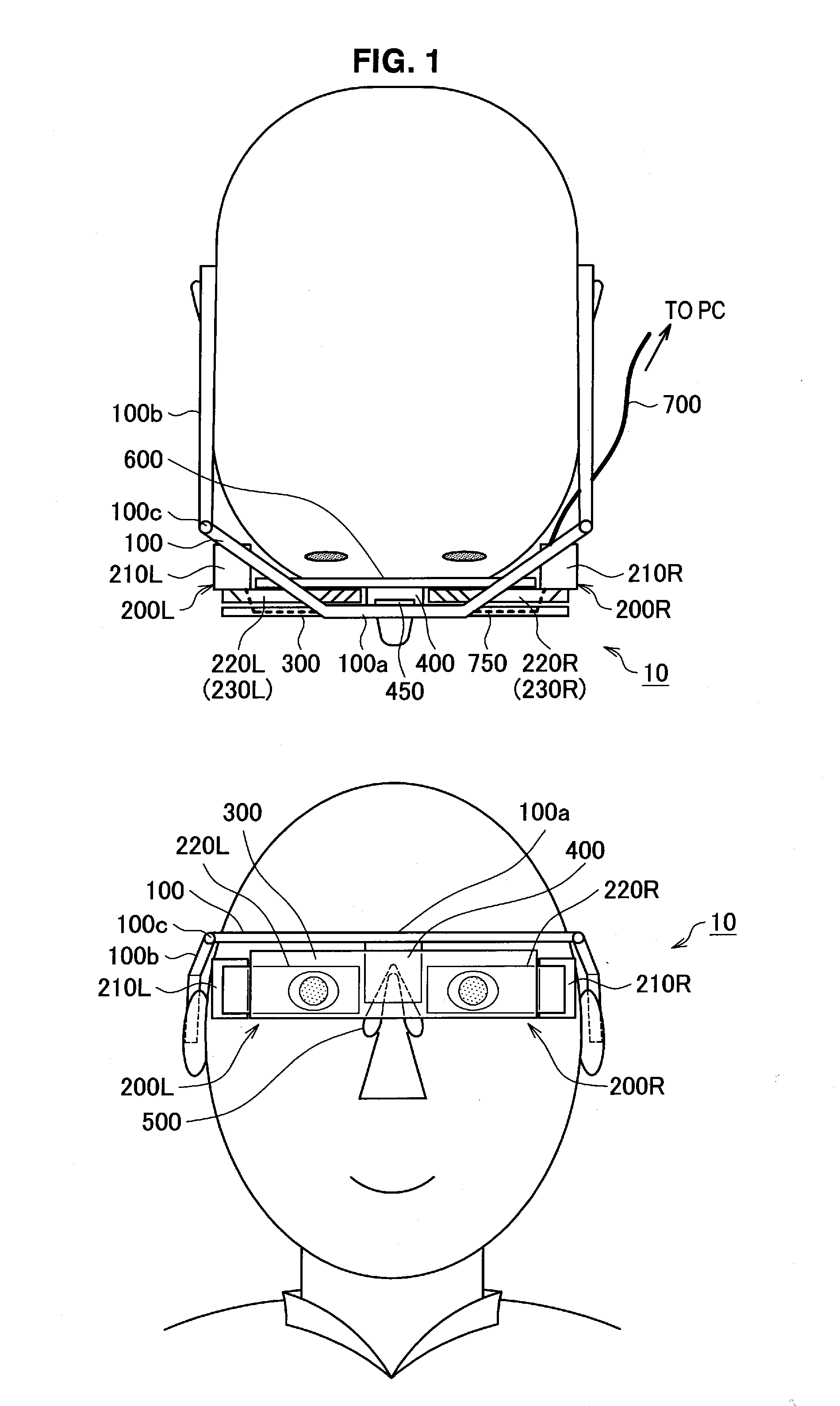

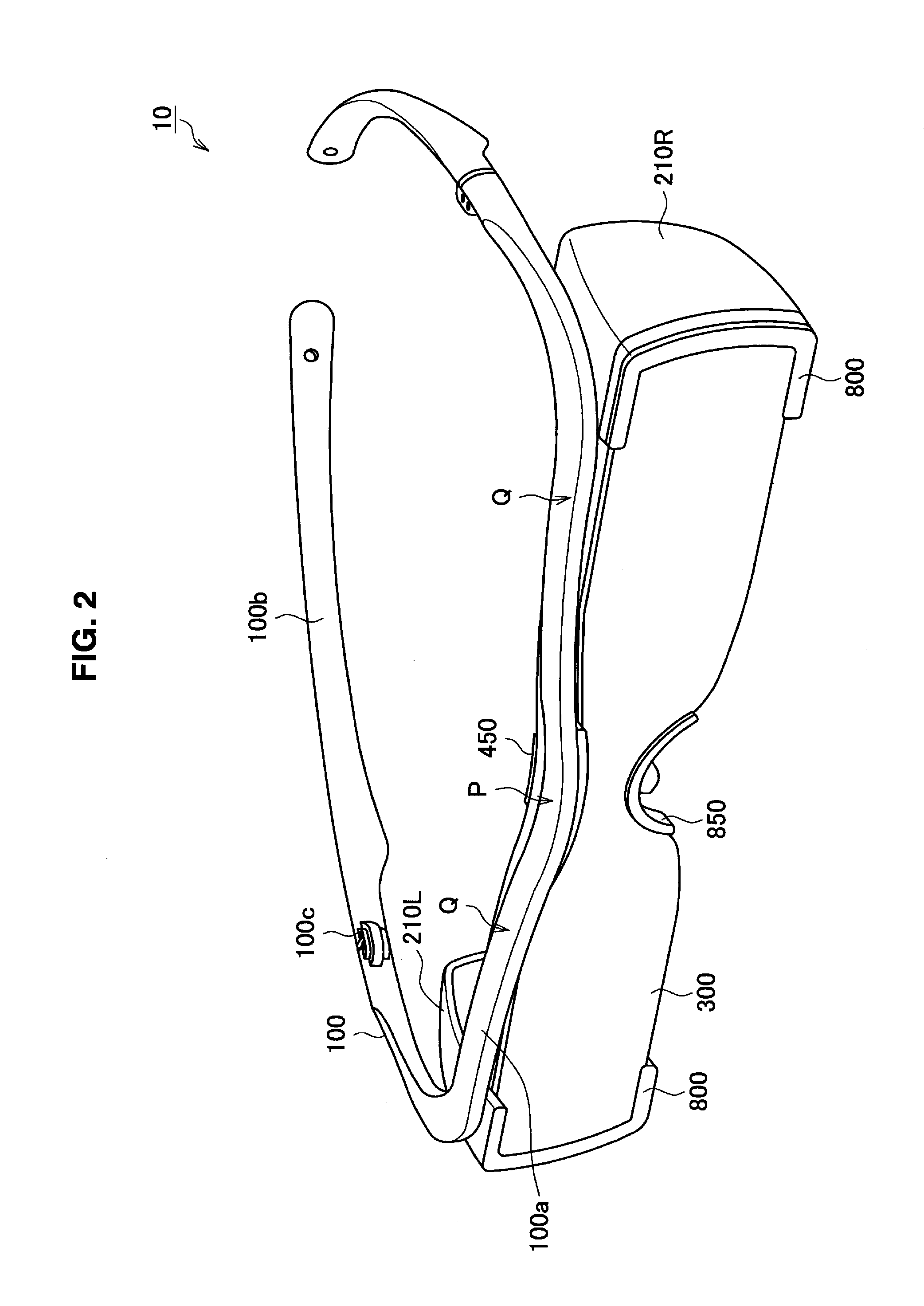

Glasses type display and controlling method thereof

ActiveUS7123215B2Simple processReduce stepsTelevision system detailsSubstation speech amplifiersCamera lensGlasses type

A glasses type display that is connected to an information communication terminal via a wire line or a wireless line, in which the operation by the user is made simple by preventing error operation and the power consumption is decreased by not consuming the unnecessary power, is provided. The glasses type display provides lenses, a main frame, side frames, a microphone, a speaker(s), open and closed state detecting sensors, wearing state detecting sensors. When the user opened the side frames, the open and closed state detecting sensors react, and the wearing state detecting sensors become the on state. When the user put on the glasses type display, the lenses automatically become the on state by that the wearing state detecting sensors detected the wearing state. And when the reaction from a part of the wearing state detecting sensors was turned off, caused by some vibration, the lenses are not immediately turned off. Therefore, an error operation is avoided. When the side frames were closed, the lenses were turned off automatically by the operation of the open and closed state detecting sensors. Therefore, the unnecessary power consumption is avoided.

Owner:NEC CORP

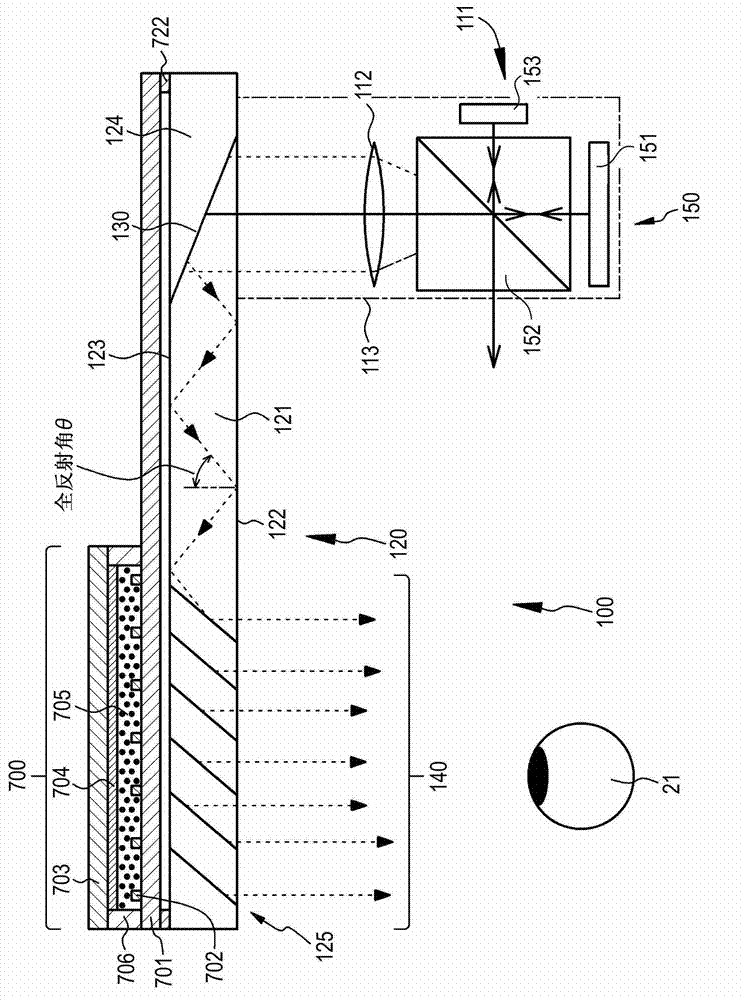

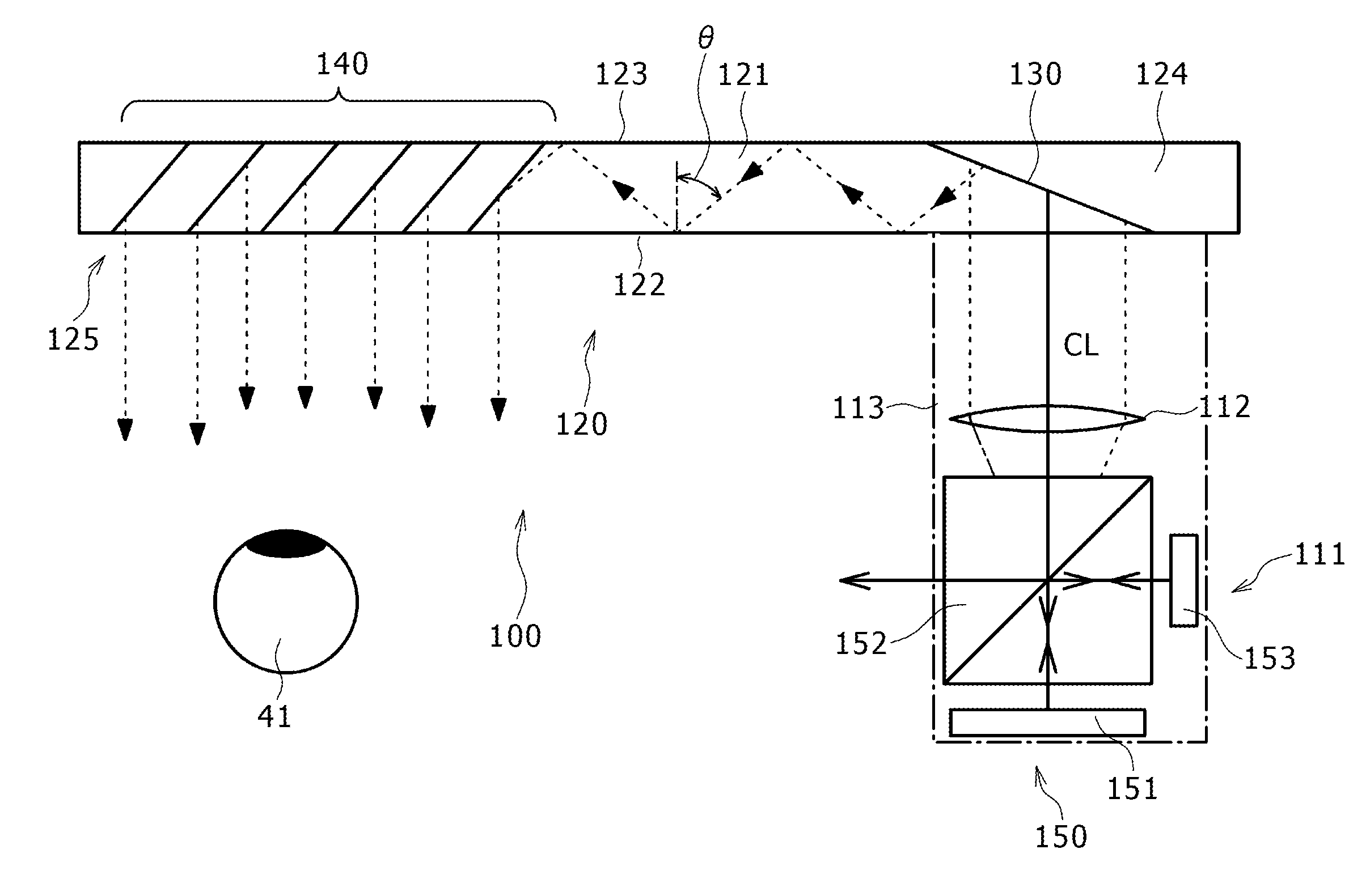

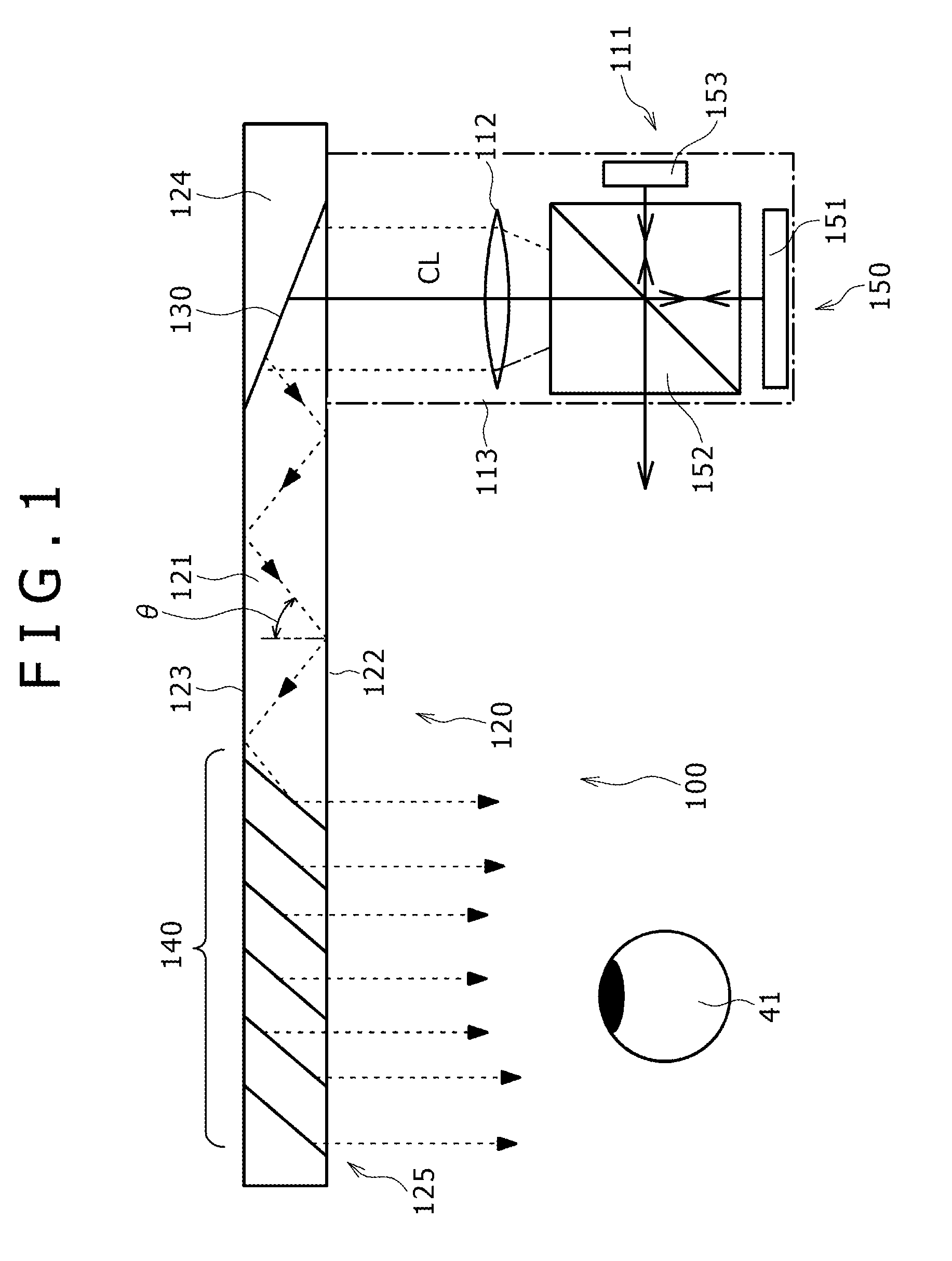

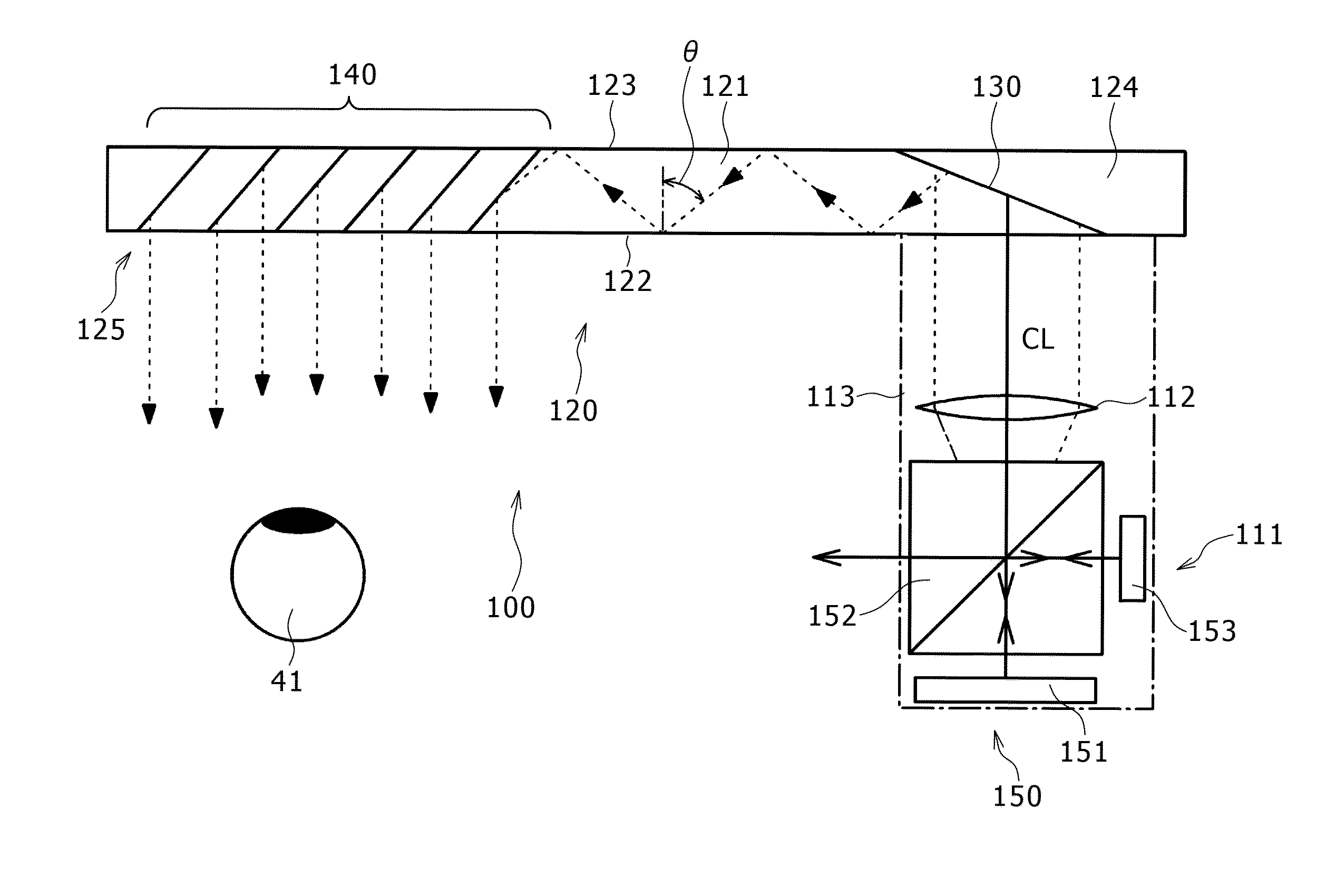

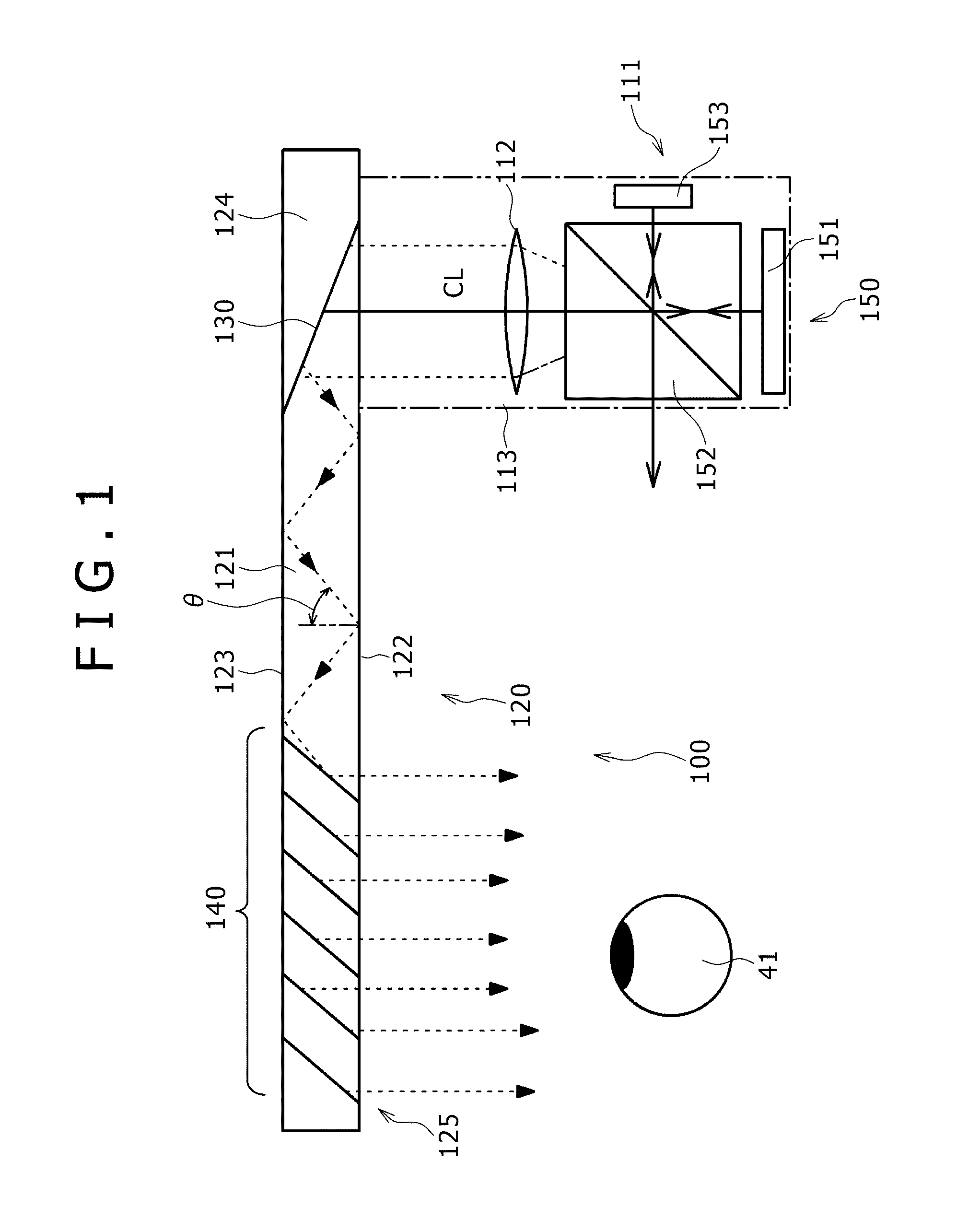

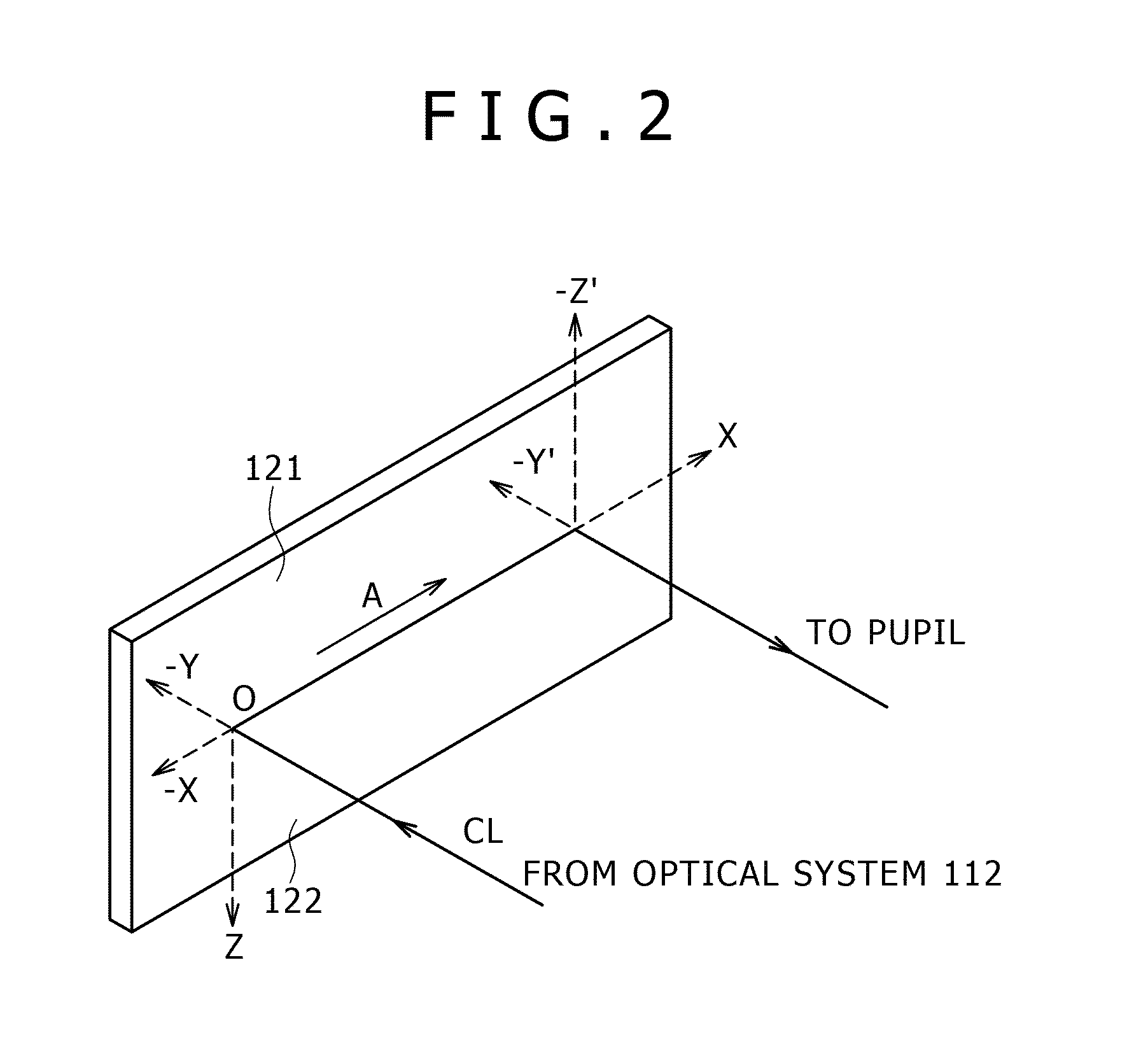

Head mounted display

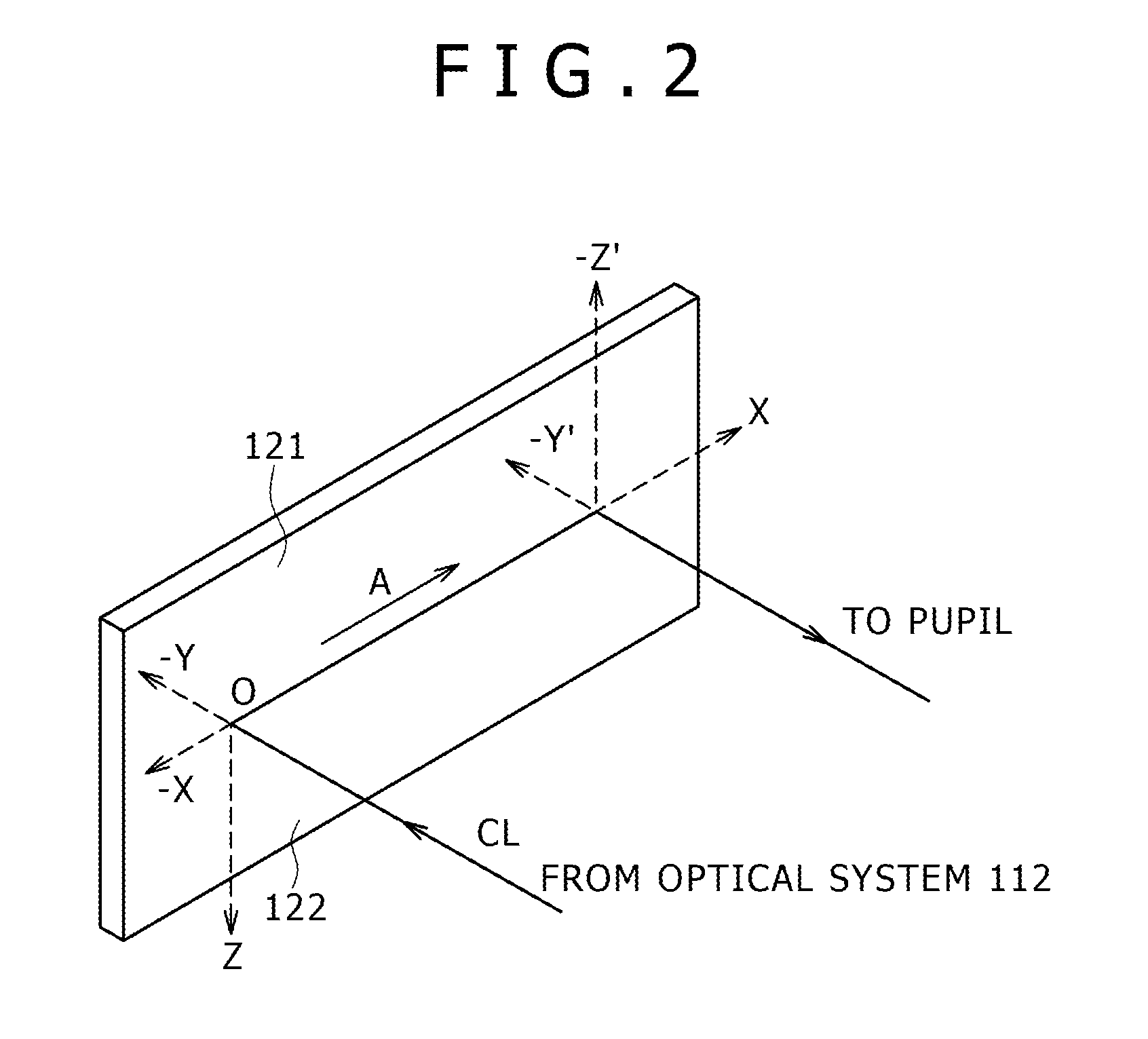

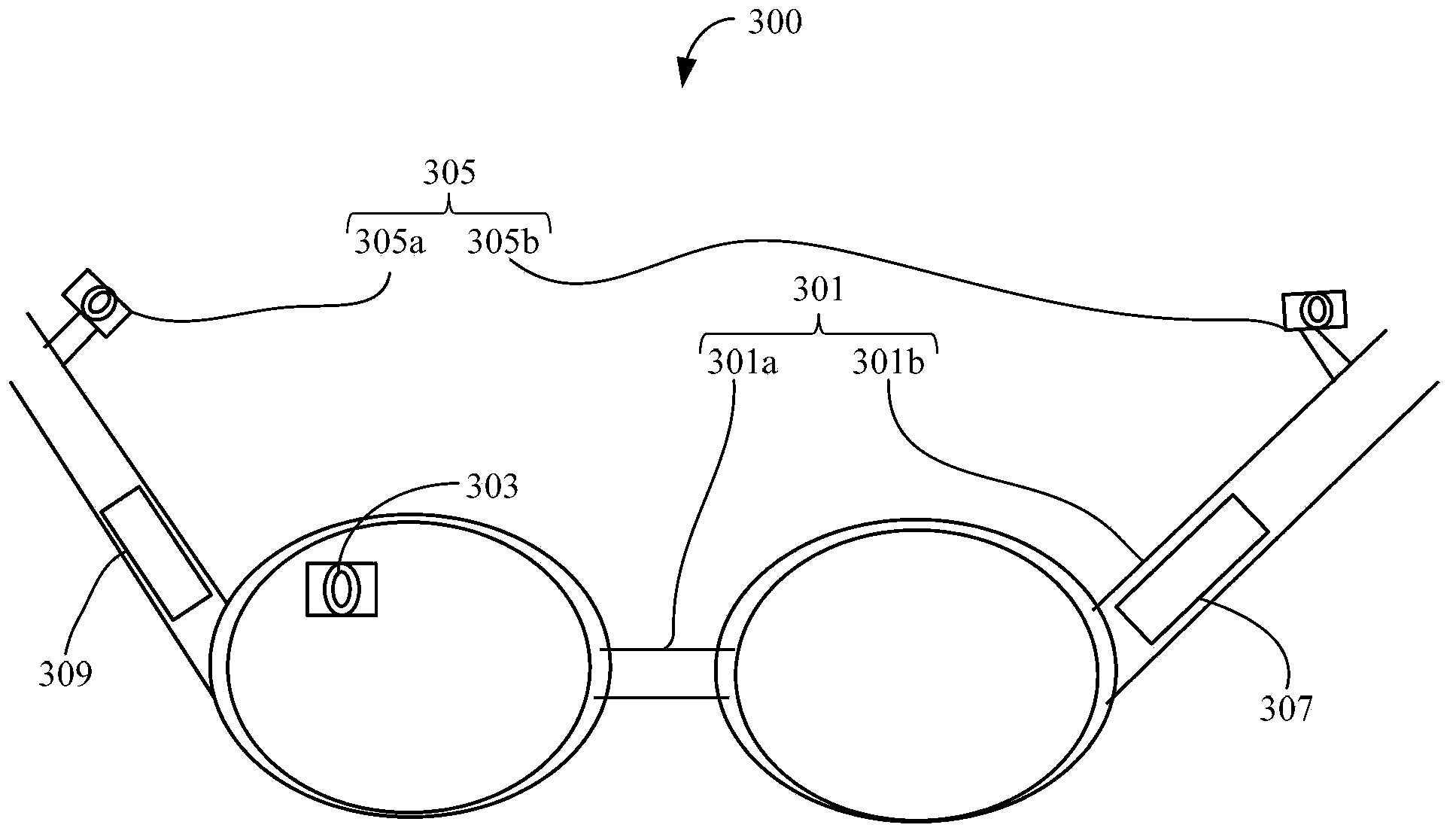

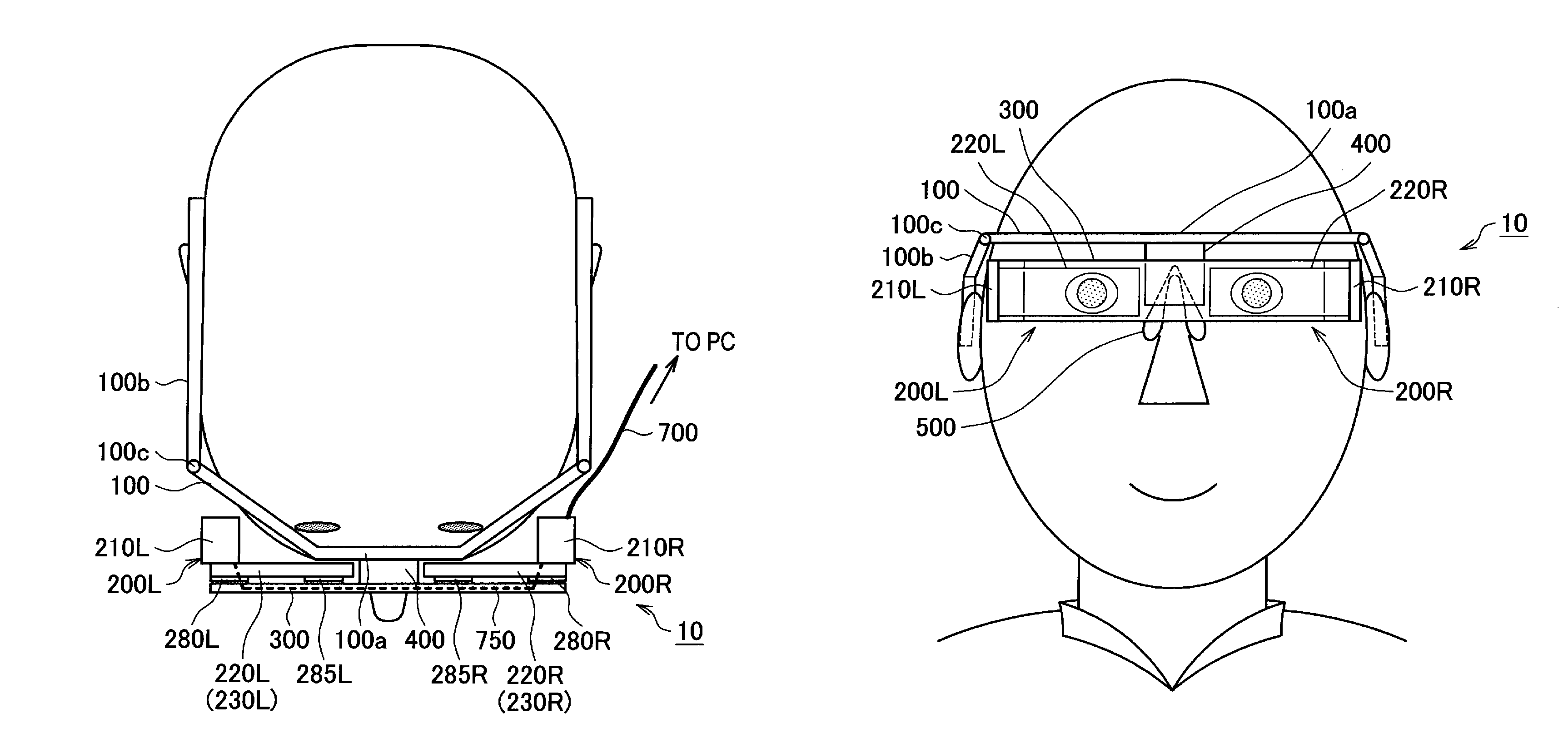

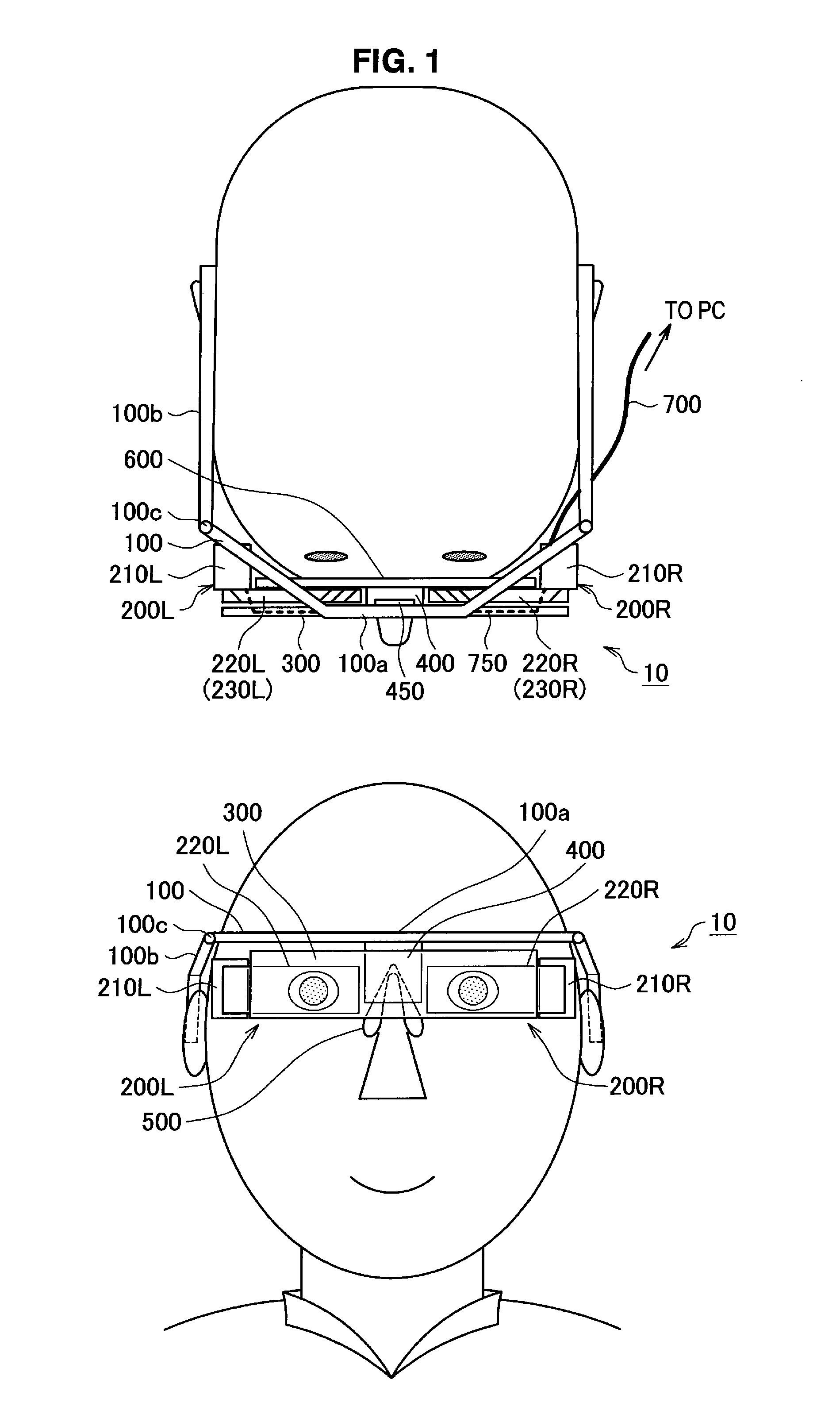

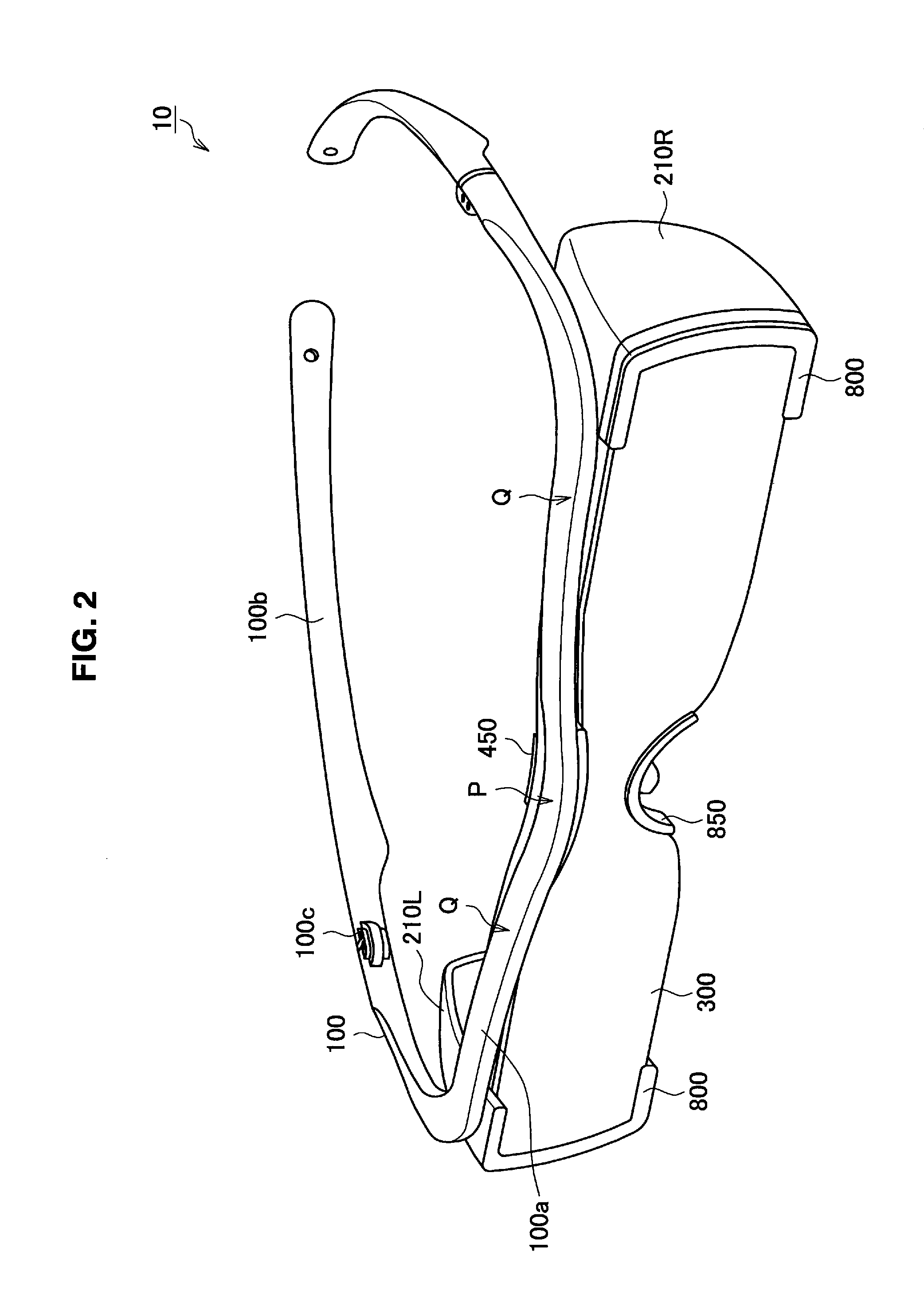

InactiveUS20110241975A1Minimizing effect of deformationHigh designCathode-ray tube indicatorsOptical light guidesGlasses typeOptical Module

There is provided a head mounted display including a glasses-type frame to be worn on a head of an observer; two optical modules including two image creation devices, and two light guides having two light guide plates coupled one-to-one with the two image creation devices and placed closer to a center of a face of the observer than the image creation devices are as a whole, that guide light beams output from the image creation devices and output the light beams toward pupils of the observer; and an optical plate supporting the two light guides, wherein the optical plate is attached to a center part of the frame.

Owner:SONY CORP

Display apparatus

ActiveCN102809821AOptimizing Observation StatusIncrease contrastStatic indicating devicesPlanar/plate-like light guidesGlasses typeDisplay device

A display apparatus includes: (i) a glasses-type frame that is mounted on the head of an observer; and (ii) an image display device that is attached to the frame, wherein the image display device includes (A) an image forming device, and (B) an optical device on which light emitted from the image forming device is incident, in which the light is guided, and from which the light is emitted, a light control device that adjusts an amount of external light incident from the outside is provided in a region of the optical device from which light is emitted, and the light control device includes two opposite transparent substrates, electrodes that are provided on the substrates, and an electrophoretic dispersion liquid that is sealed between the two substrates.

Owner:SONY CORP

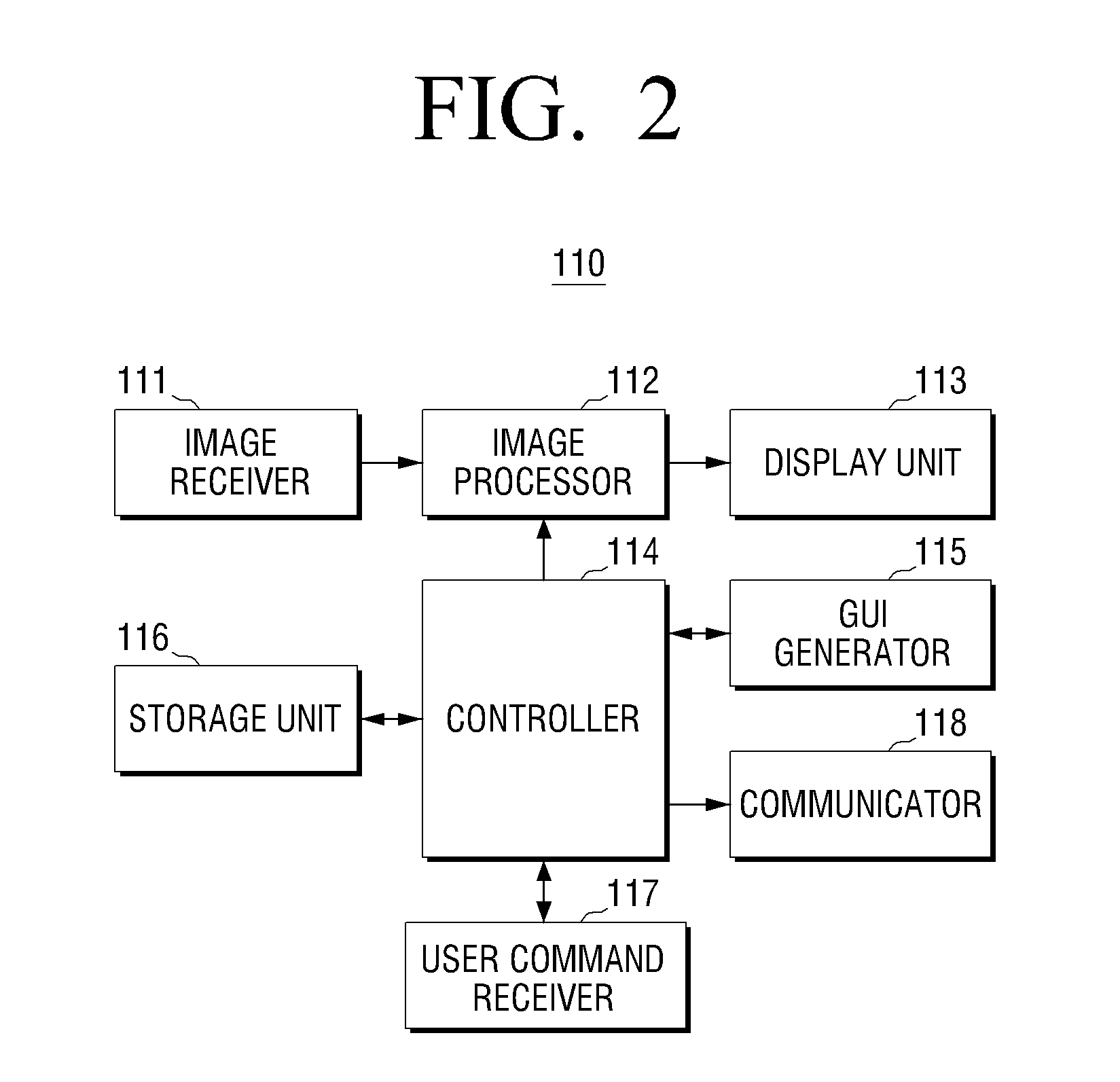

Method for adjusting 3D image quality, 3D display apparatus, 3D glasses, and system for providing 3D image

ActiveUS20110221874A1Increase brightnessIncrease contrastSteroscopic systemsOptical elementsGlasses typeImaging quality

A method for adjusting an image quality of a 3-dimension (3D) image, a 3D display apparatus, 3D glasses, and a system for providing a 3D image are provided. Attribute information of the 3D glasses is acquired from the 3D glasses to adjust an image quality of a displayed 3D image according to the attribute information of the 3D glasses. Therefore, if a viewer views a 3D image through a glasses type 3D display apparatus, brightness of the 3D image is prevented from being darker by 3D glasses or a color hue of the 3D image is prevented from being degraded by the 3D glasses. Accordingly, the viewer views the 3D image with an optimal image quality.

Owner:SAMSUNG ELECTRONICS CO LTD

Image displaying method for a head-mounted type display unit

ActiveUS20110248905A1Easy to displayCathode-ray tube indicatorsImage data processingComputer hardwareTime information

Disclosed herein is an image displaying method for a head-mounted type display unit which includes a frame of the glasses type for being mounted on the head of an observer, an image display apparatus attached to the frame, and a control section for controlling image display of the image display apparatus. The image display apparatus includes an image forming apparatus, and an optical apparatus. The image displaying method includes the steps of: storing a data group configured from a plurality of data in a storage section; adding a data identification code to each of the data; sending a designation identification code and display time information at predetermined intervals of time; and reading out the data whose data identification code coincides with the received designation identification code from the storage section and controlling the image forming apparatus to display an image based on the read out data.

Owner:SONY CORP

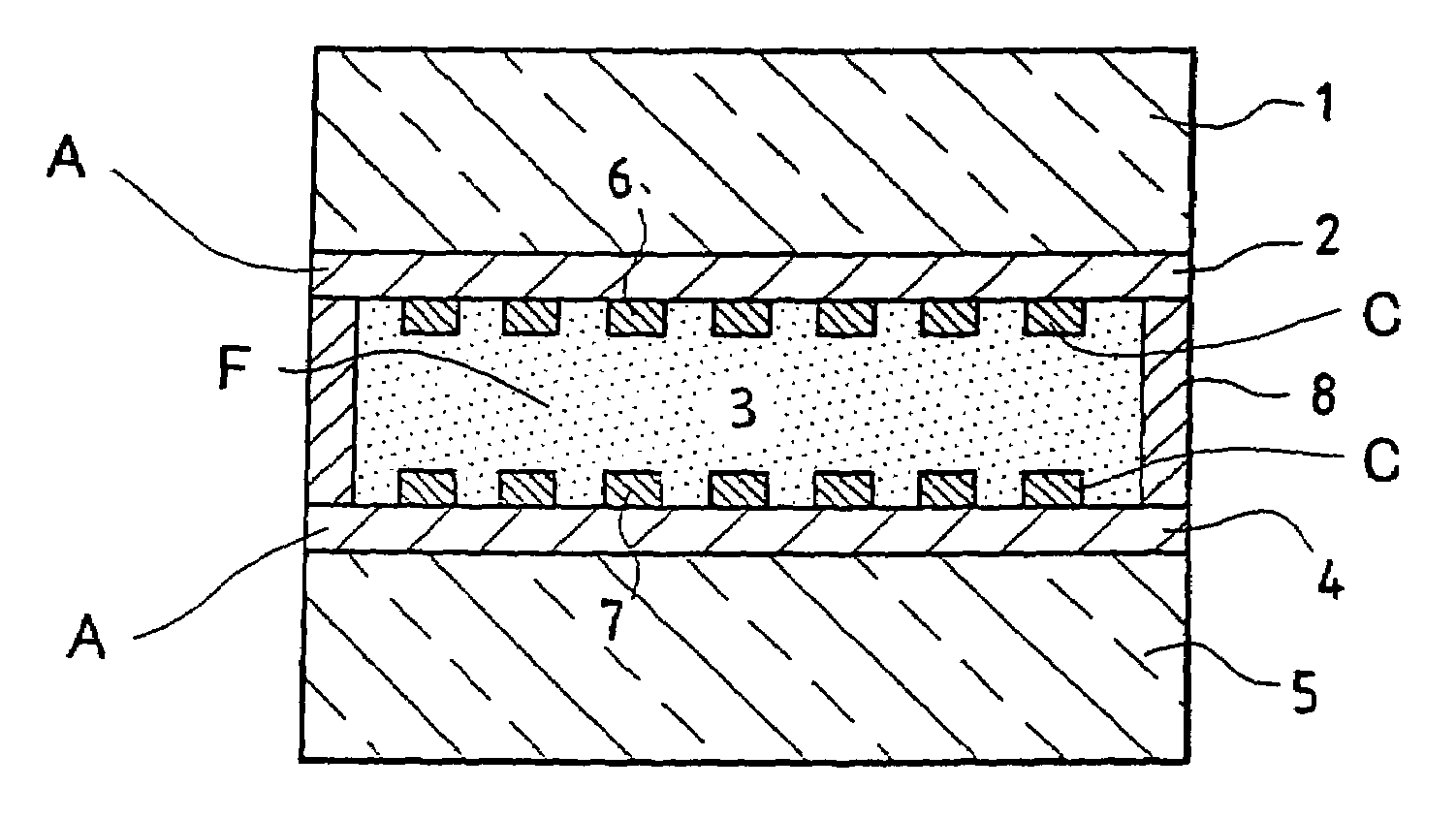

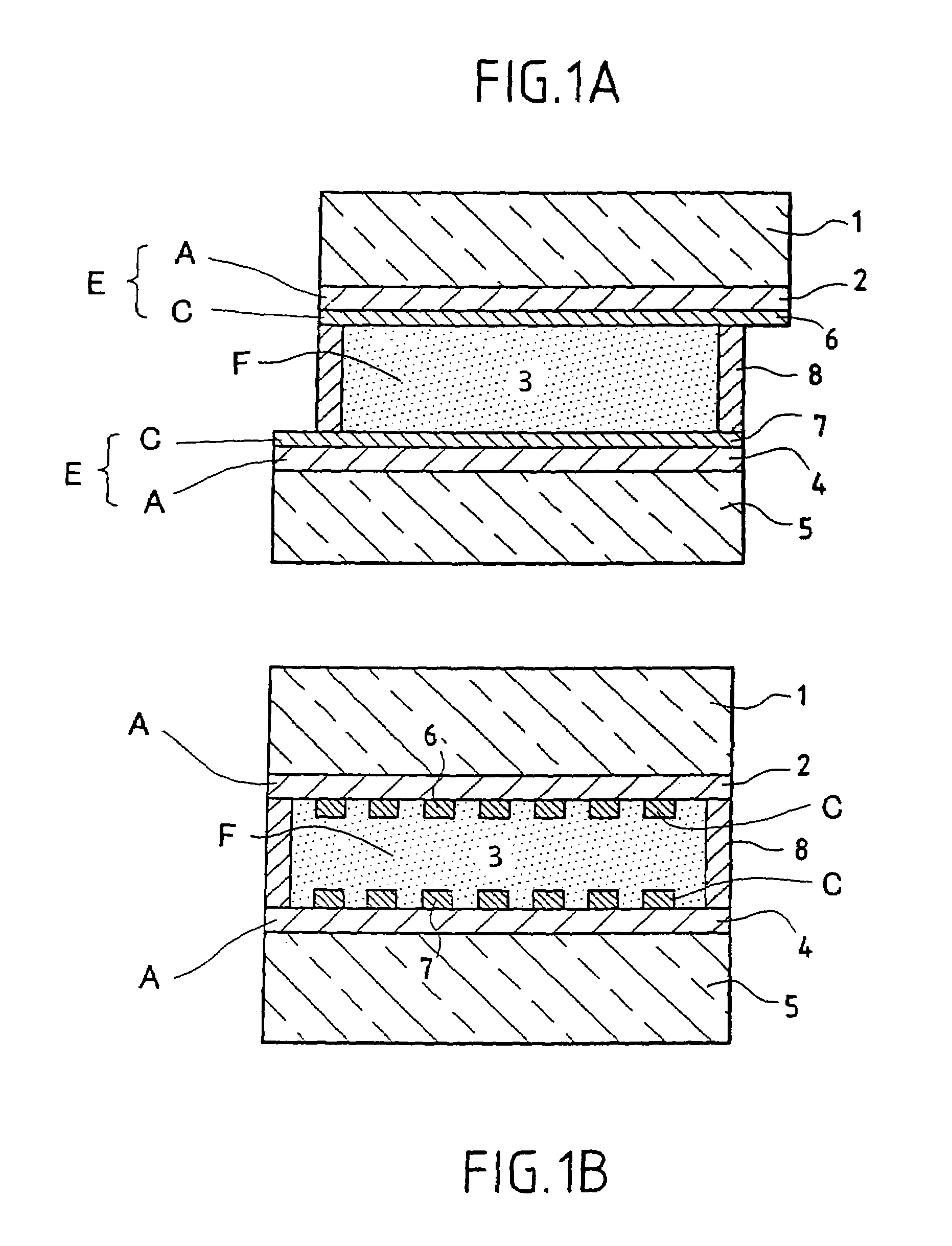

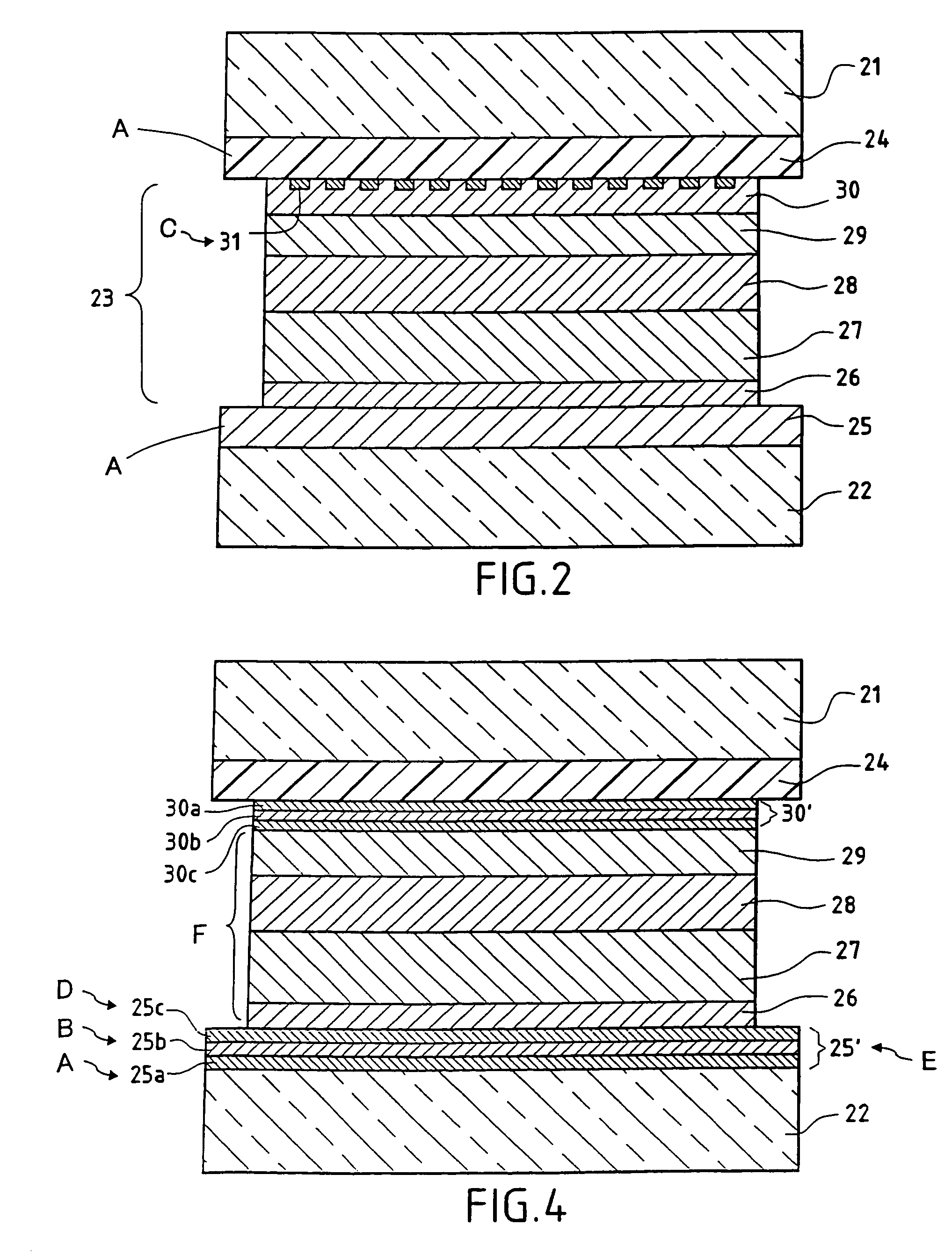

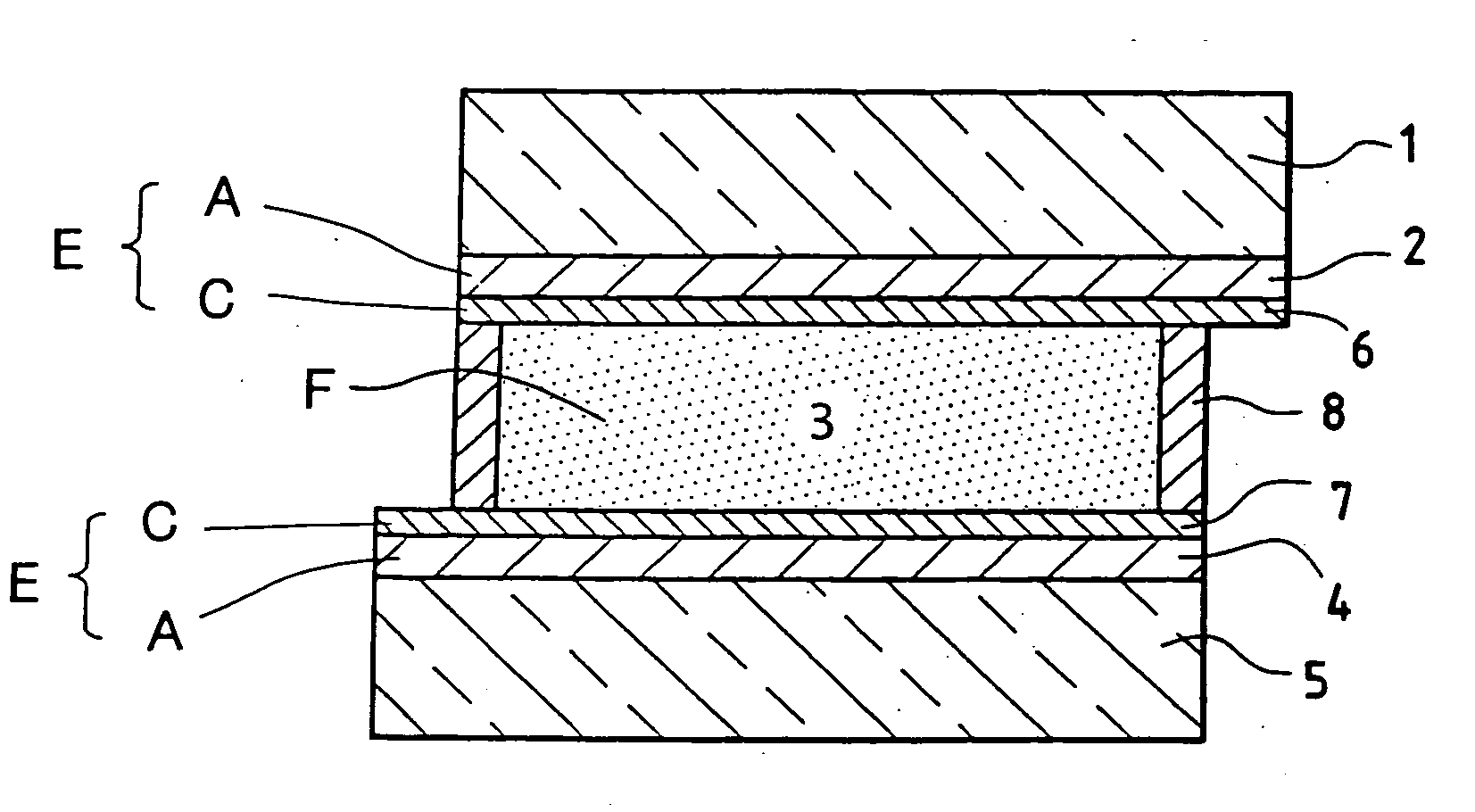

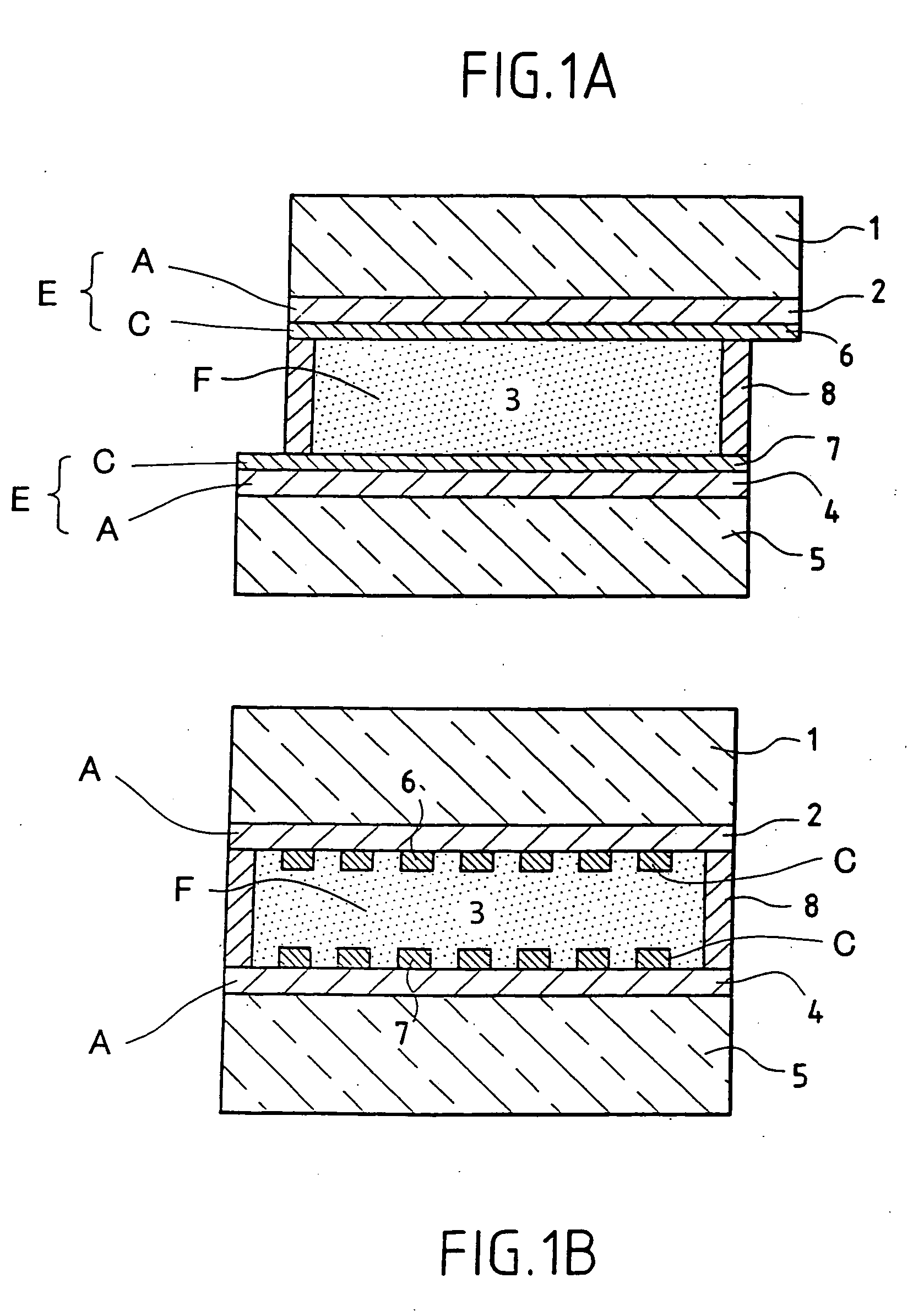

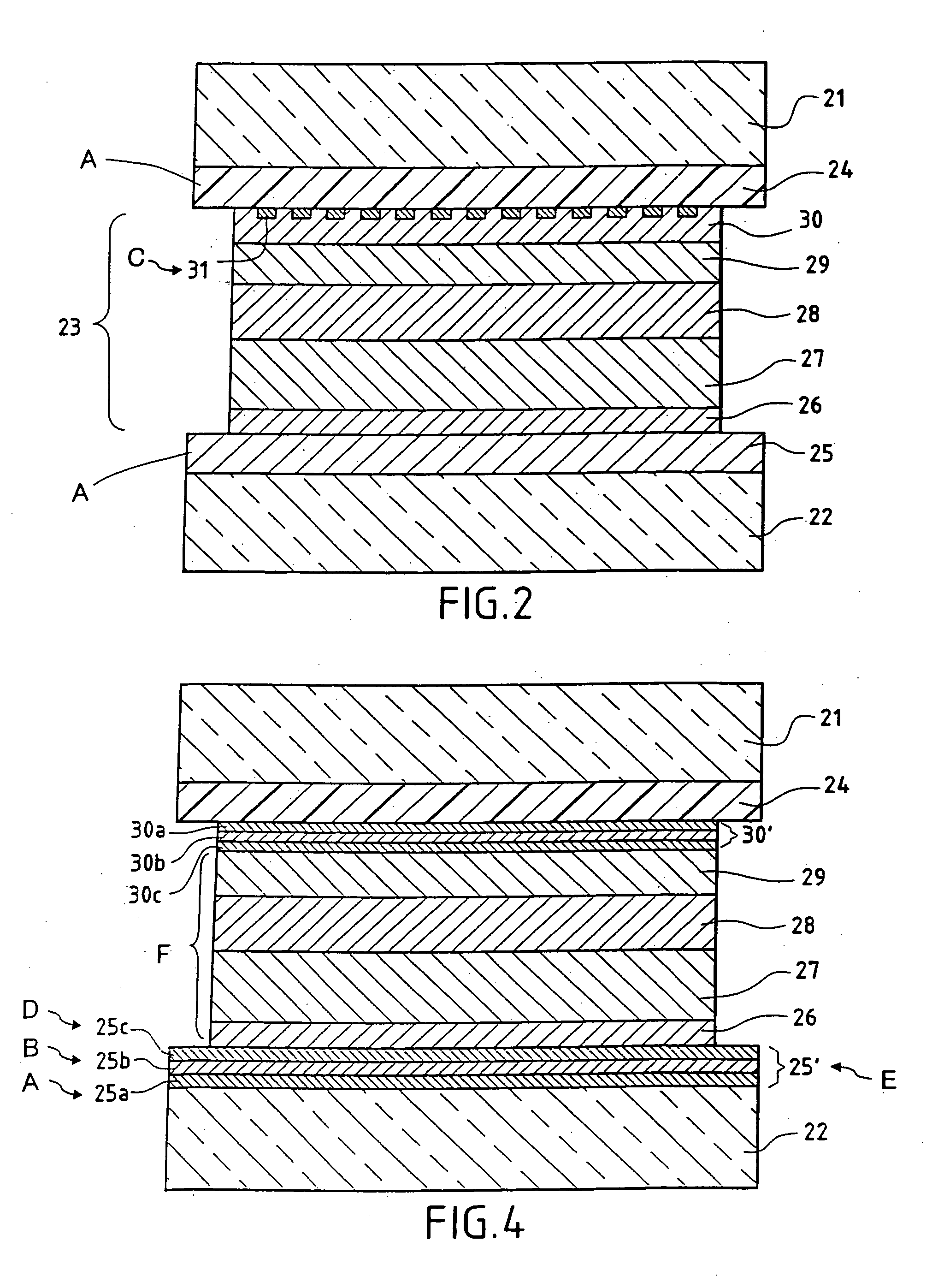

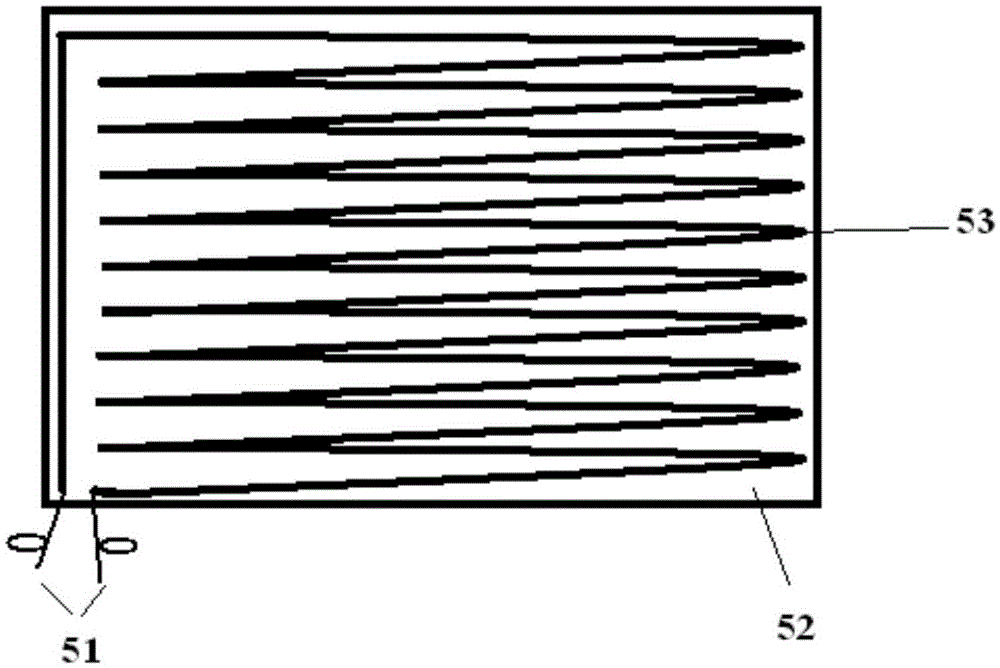

Electrochemical device, such as an electrically controlled system with variable optical and/or energy properties

InactiveUS7012728B2Improve conductivityNot possible to discernElectric lighting sourcesElectrode carriers/collectorsElectrical resistance and conductanceGlasses type

An electrochemical device includes at least one carrier substrate, and a stack of functional layers including at least one electrically conducting layer that includes metal oxide(s), and a multicomponent electrode including at least one electrochemically active layer, at least one higher-conductivity material and at least one network of one of conducting wires and conducting strips. The higher-conductivity material has a surface resistance that is lower than a surface resistance of the electrically conducting layer. The stack of functional layers is arranged between two substrates, and each may be rigid, of glass type or rigid polymer or semi-rigid or flexible of PET type.

Owner:SAINT GOBAIN VITRAGE SA

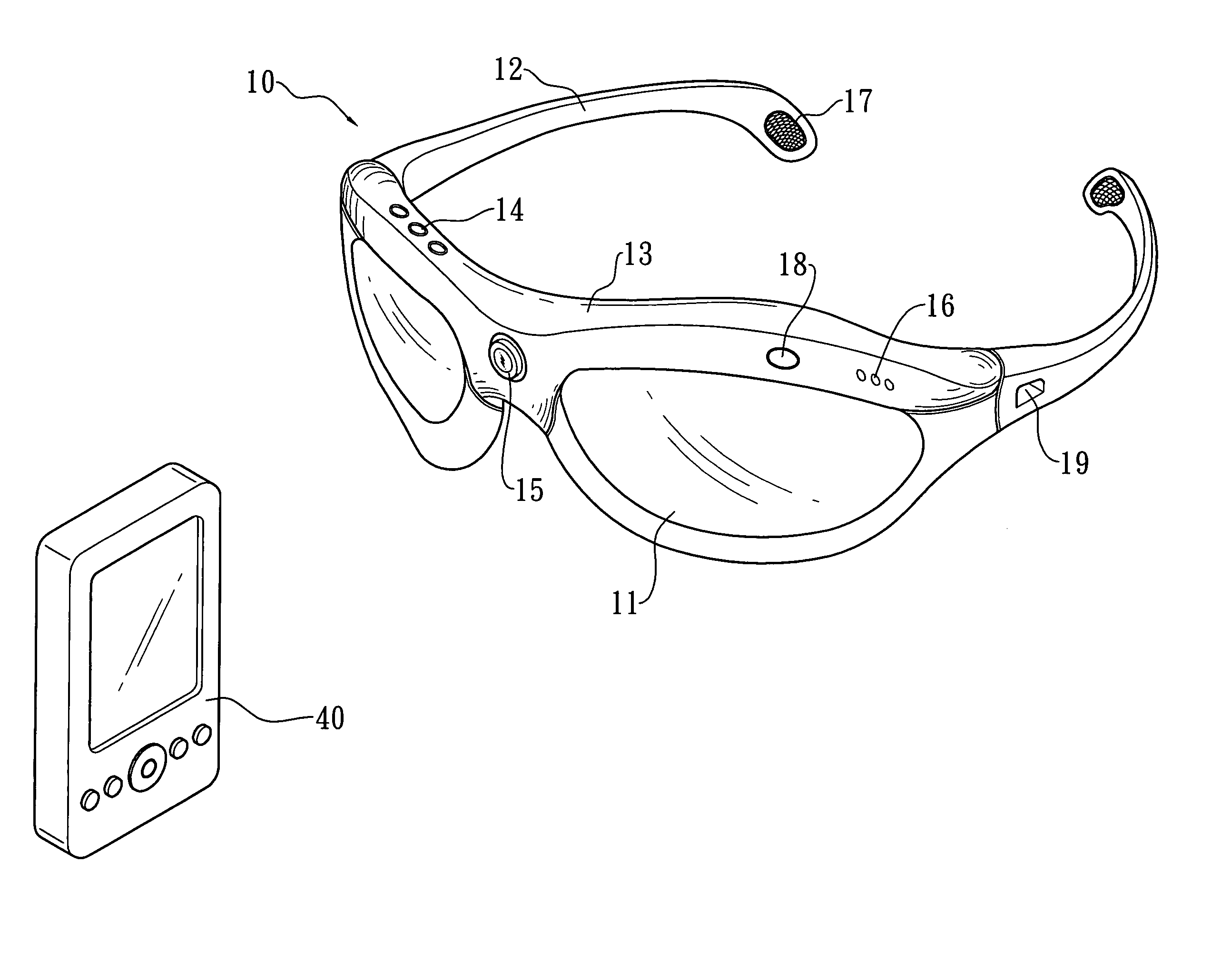

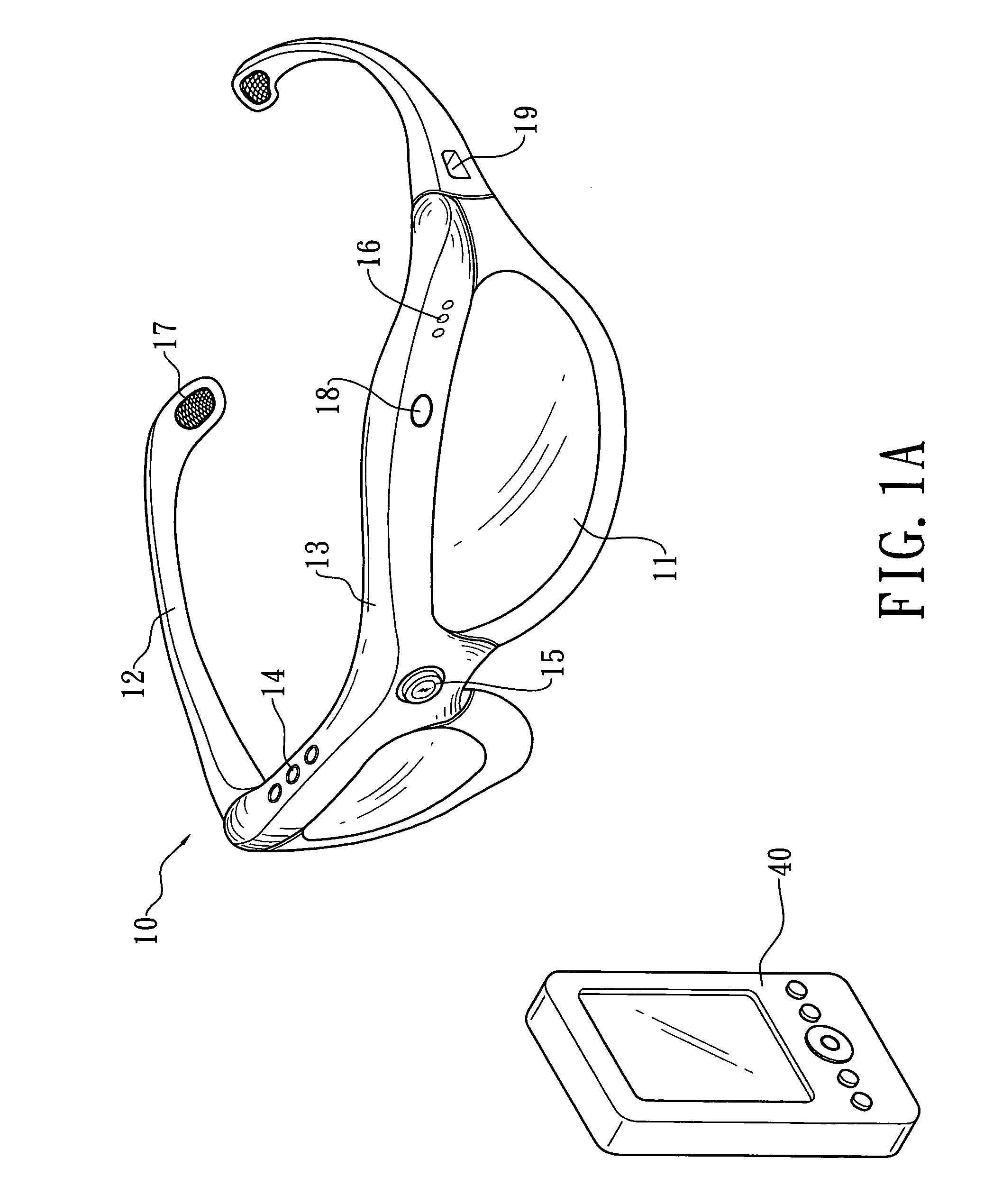

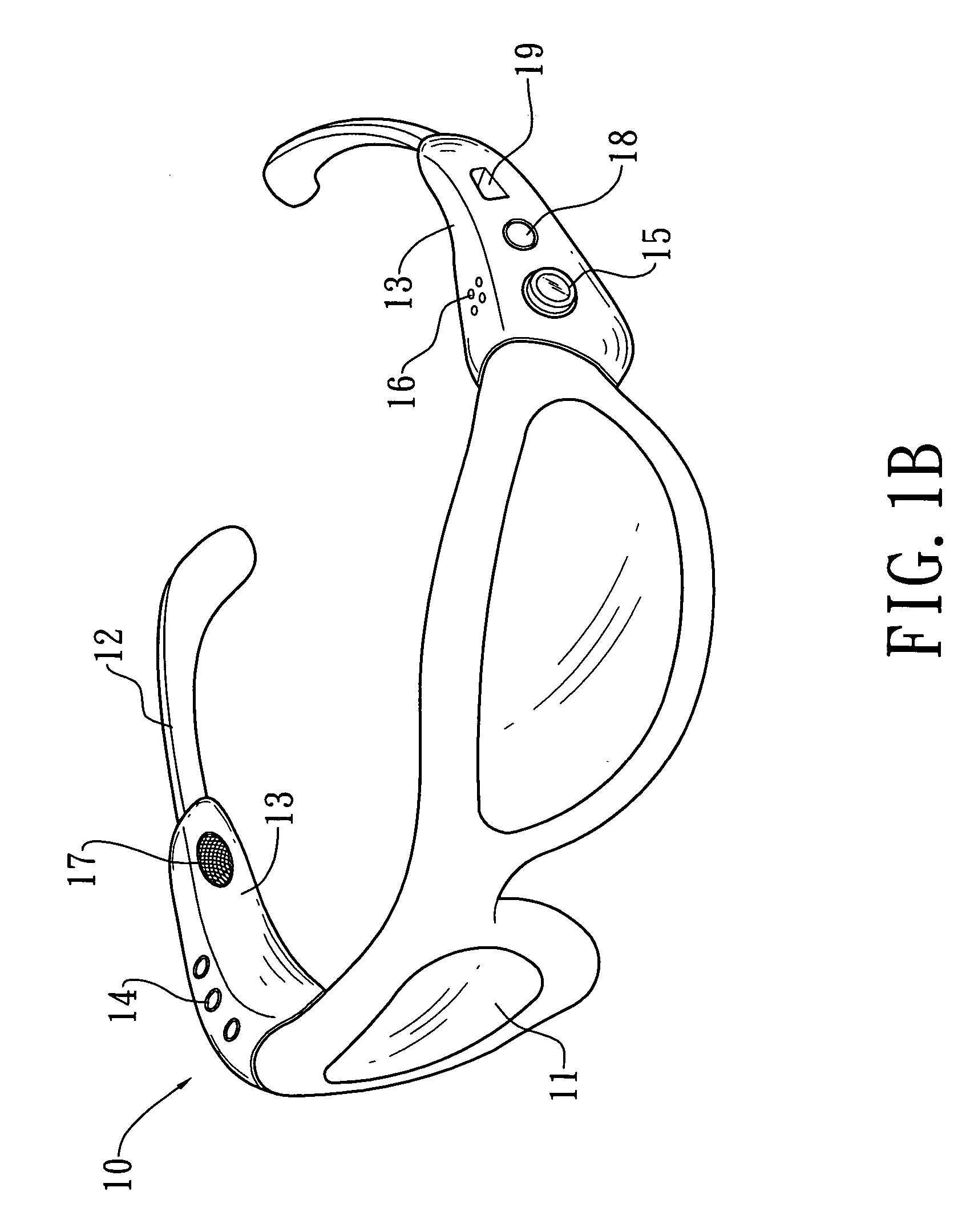

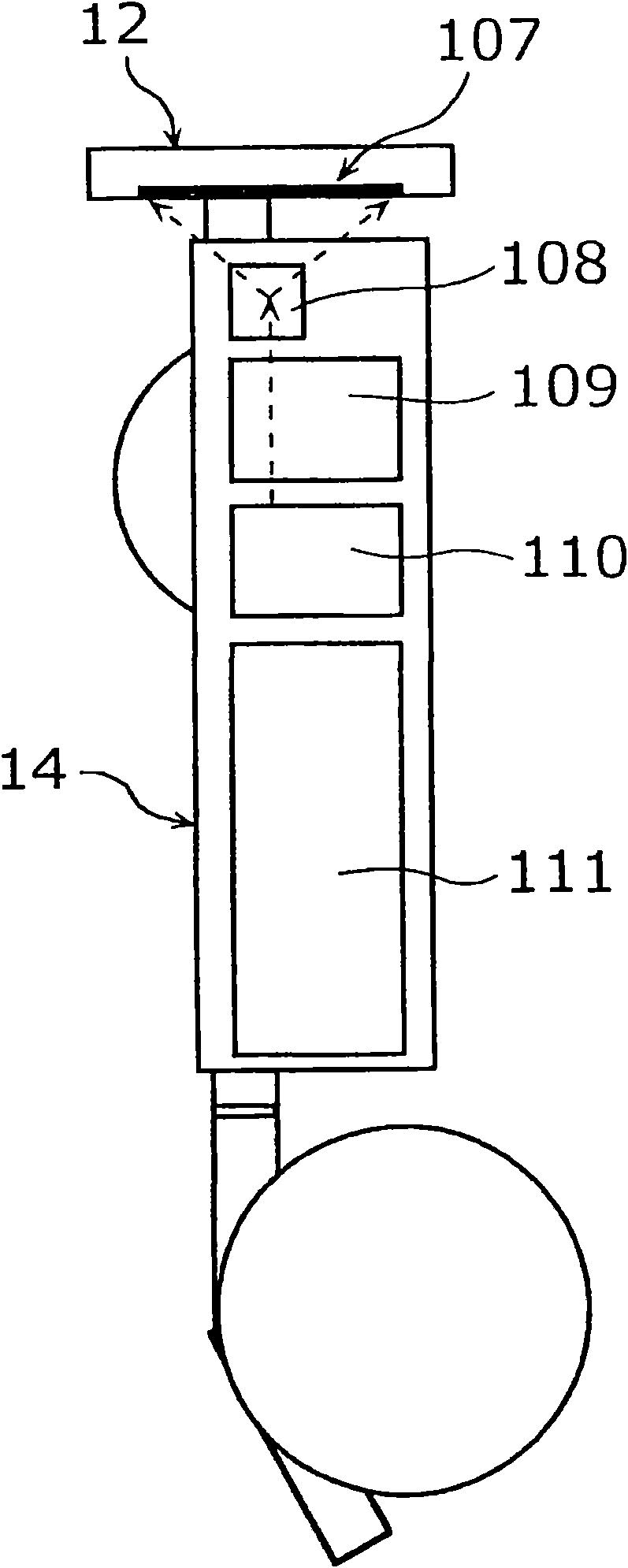

Glasses type audio-visual recording apparatus

InactiveUS20060109350A1Easy to listen toTelevision system detailsPicture signal generatorsGlasses typeEyewear

A glasses type audio-visual recording apparatus is disclosed. The glasses type audio-visual recording apparatus mainly comprises a pair of glasses and an audio-visual recording apparatus mounted on a distal end of a frame of the glasses so as to integrate the glasses and the audio-visual recording apparatus into unity. Consequently, user is able to readily listen to digital music stored in the audio-visual recording apparatus by wearing the glasses such that the audio-visual recording apparatus is closest to the ear. The problem caused by the winding earphone wires is thus prevented.

Owner:YEH MING HSIANG

Electrochemical device, such as an electrically controlled system with variable optical and/or energy properties

InactiveUS20060033978A1Improve conductivityNot possible to discernElectrode carriers/collectorsElectric lighting sourcesElectrical resistance and conductanceGlasses type

An electrochemical device includes at least one carrier substrate, and a stack of functional layers including at least one electrically conducting layer that includes metal oxide(s), and a multicomponent electrode including at least one electrochemically active layer, at least one higher-conductivity material and at least one network of one of conducting wires and conducting strips. The higher-conductivity material has a surface resistance that is lower than a surface resistance of the electrically conducting layer. The stack of functional layers is arranged between two substrates, and each may be rigid, of glass type or rigid polymer or semi-rigid or flexible of PET type.

Owner:SAINT-GOBAIN GLASS FRANCE

Glasses type communication apparatus, system and method

InactiveCN103888163AProsperous lifeEasy to useNon-optical adjunctsCommmunication supplementary servicesComputer hardwareGlasses type

The embodiments of the invention provide a glasses type communication apparatus. The glasses type communication apparatus is characterized by comprising a lens frame which is used for allowing a user to wear the glasses type communication apparatus on the head, a display module which is arranged on the lens frame for receiving data information and generating a corresponding visual picture according to the data information for the user to watch, a shooting module which is arranged on the lens frame for obtaining image information and outputting the image information, and a communication module which is arranged on the lens frame and establishes a communication channel with an external processing device through a communication protocol. The communication module receives data emitted by the external processing device through the communication channel so as to parse the data information from the data and sends the data information to the display module. The communication module is also used for receiving the image information outputted by the shooting module and transmitting the image information to the extern al processing device through the communication channel.

Owner:HUAWEI TECH CO LTD

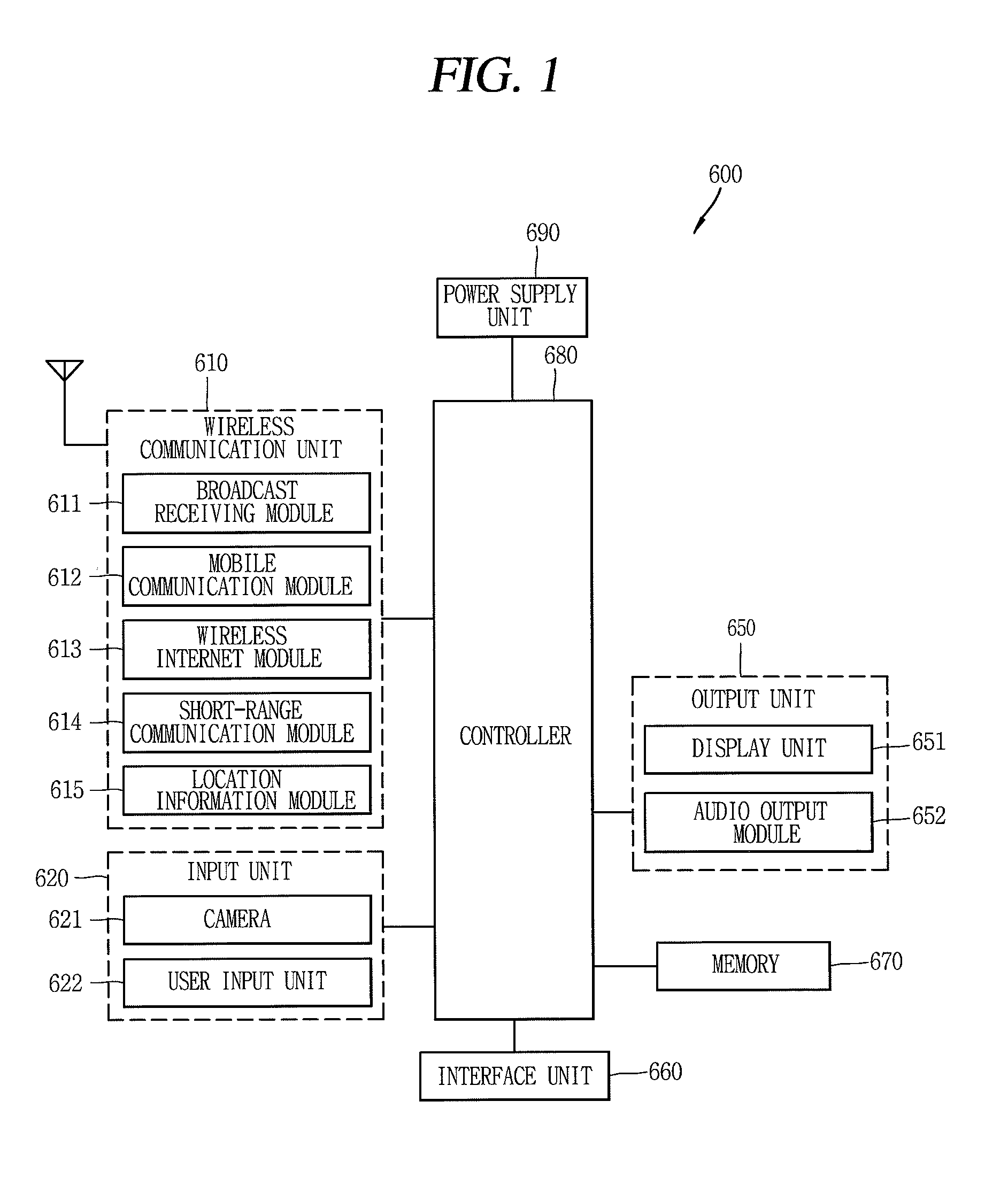

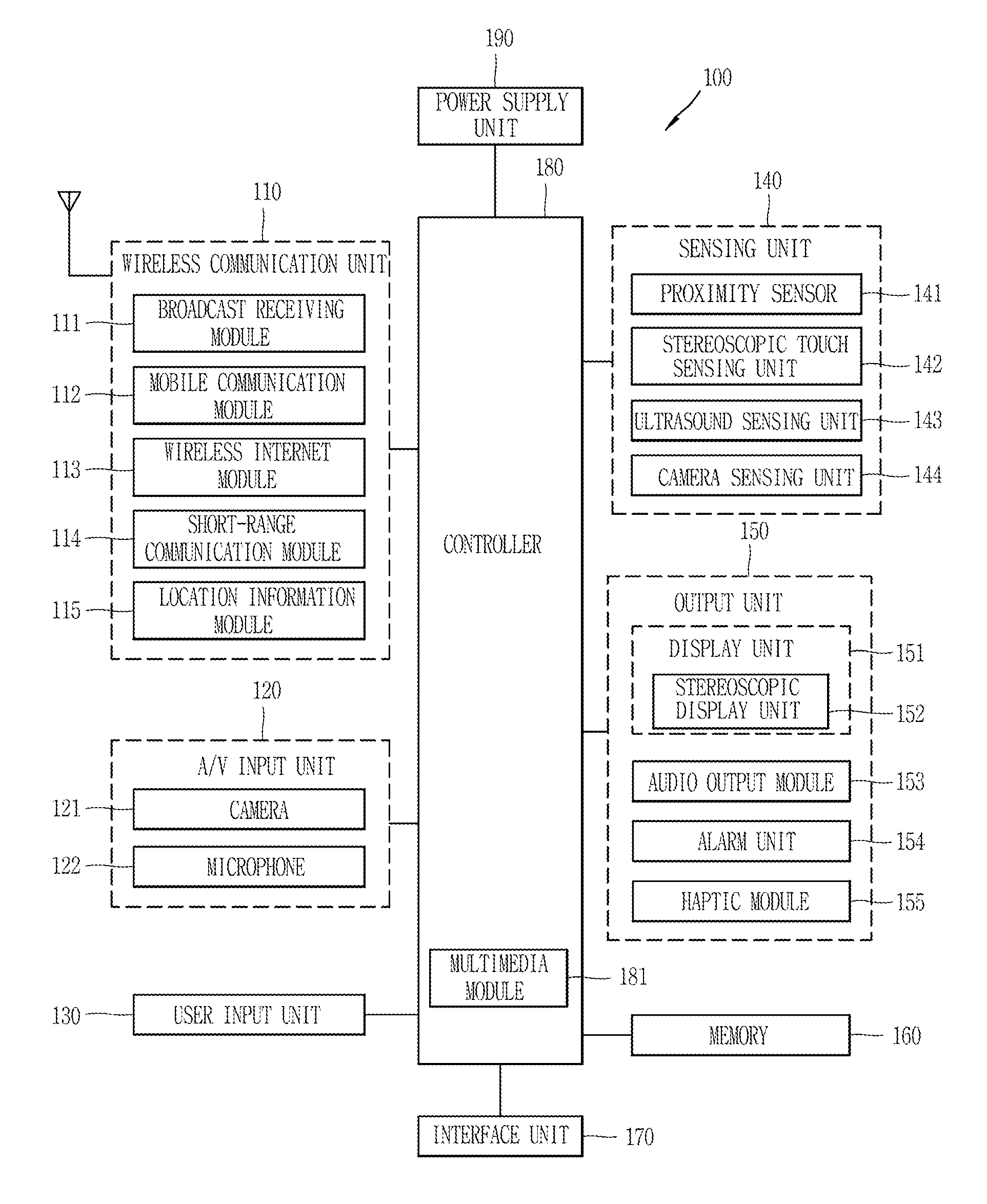

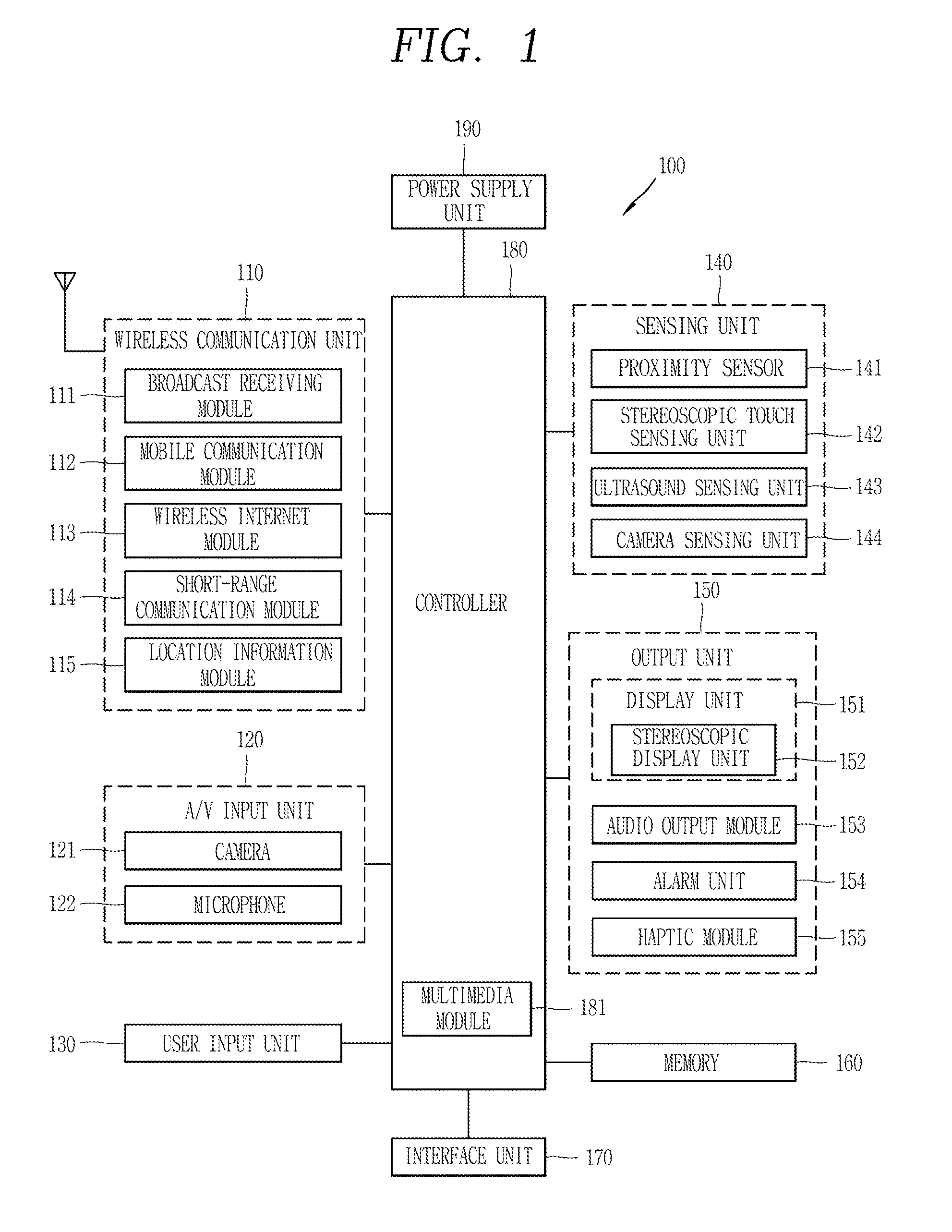

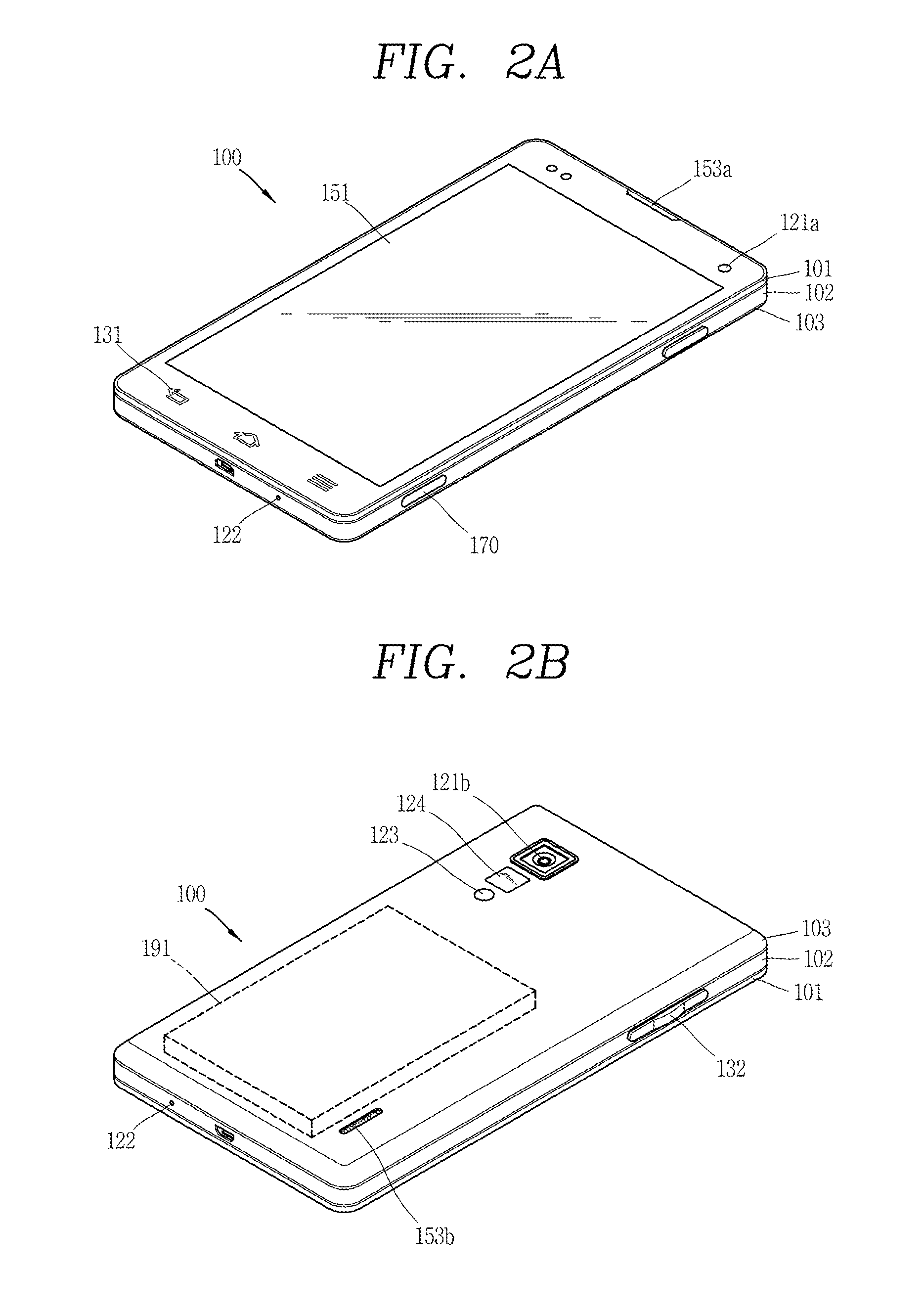

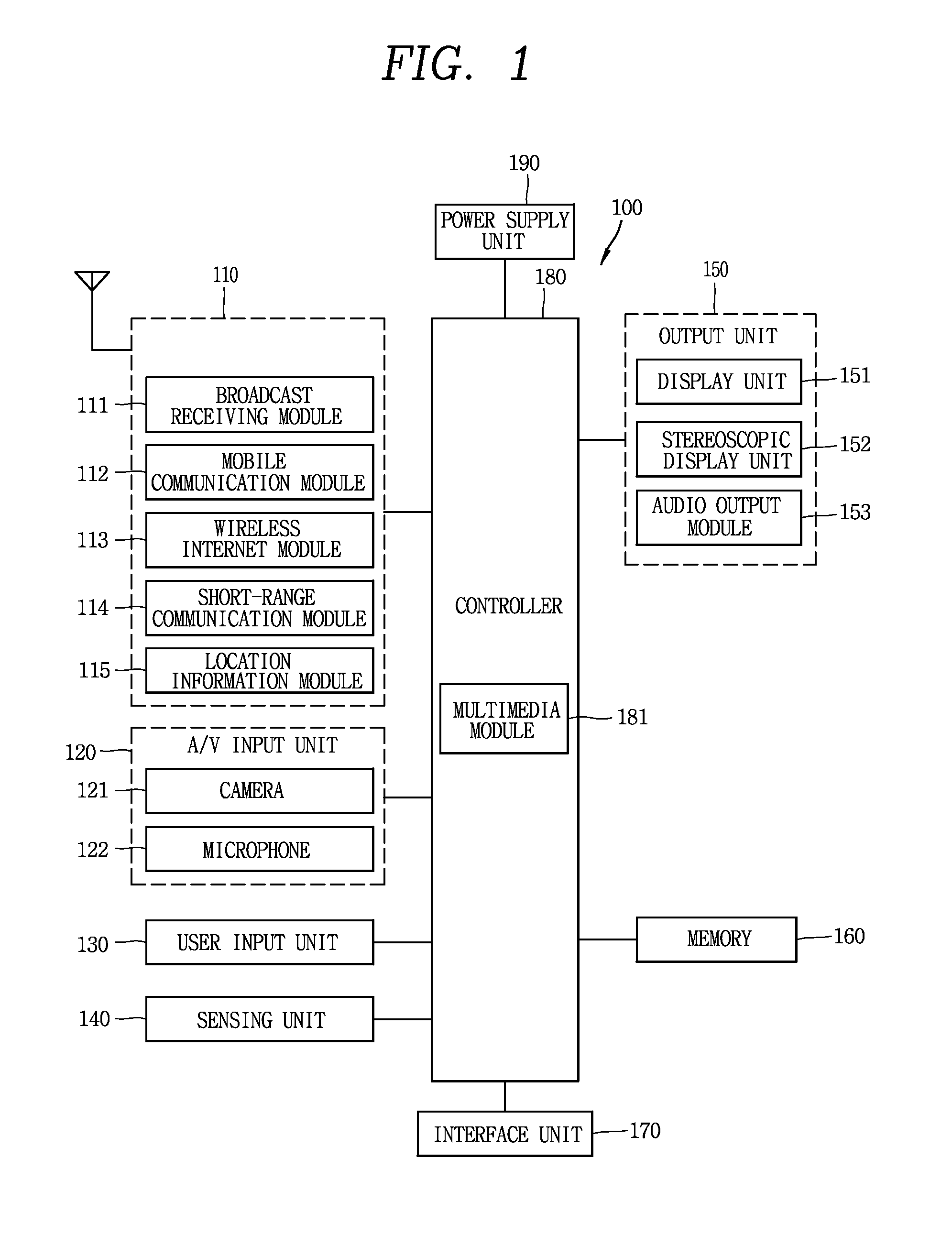

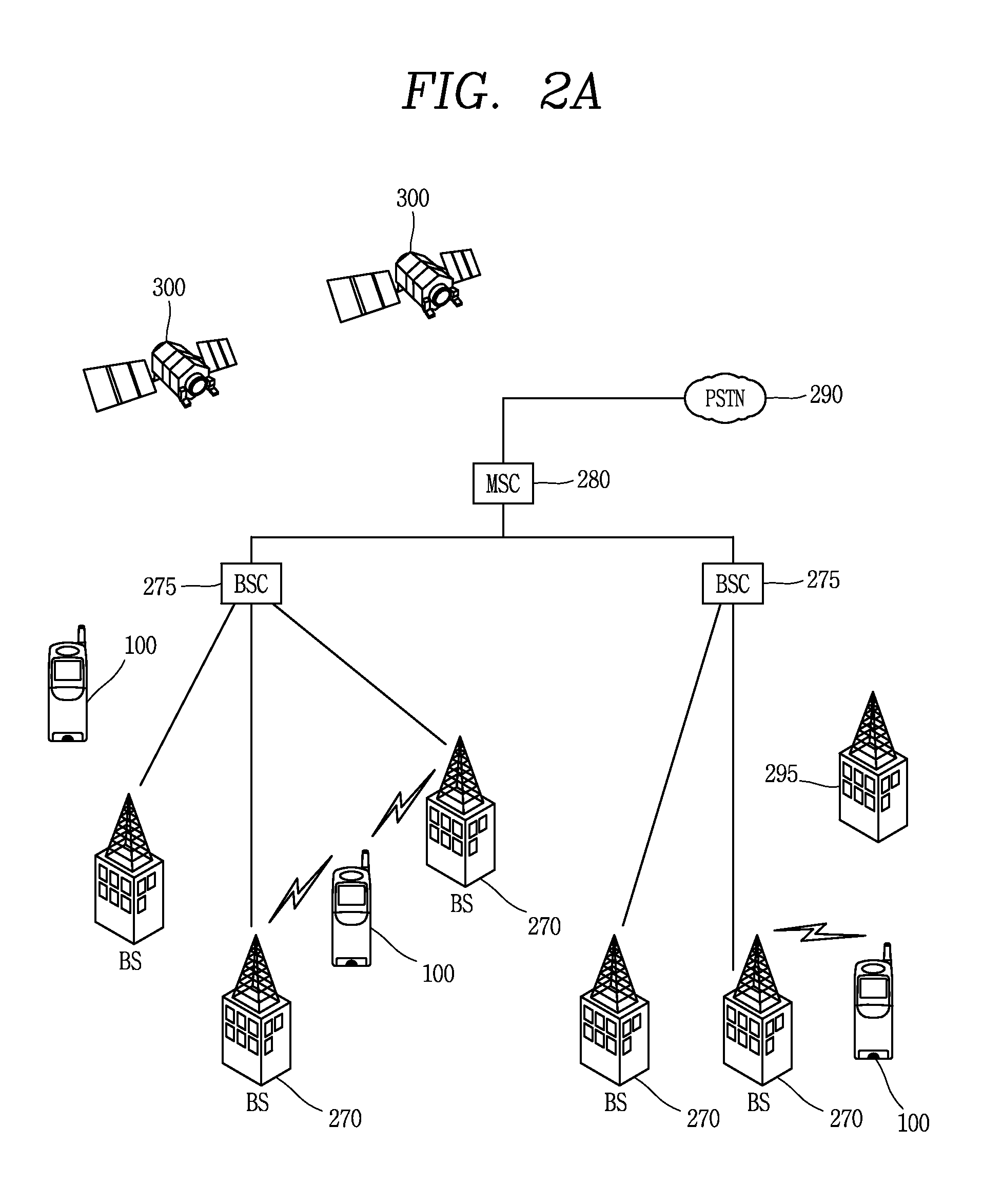

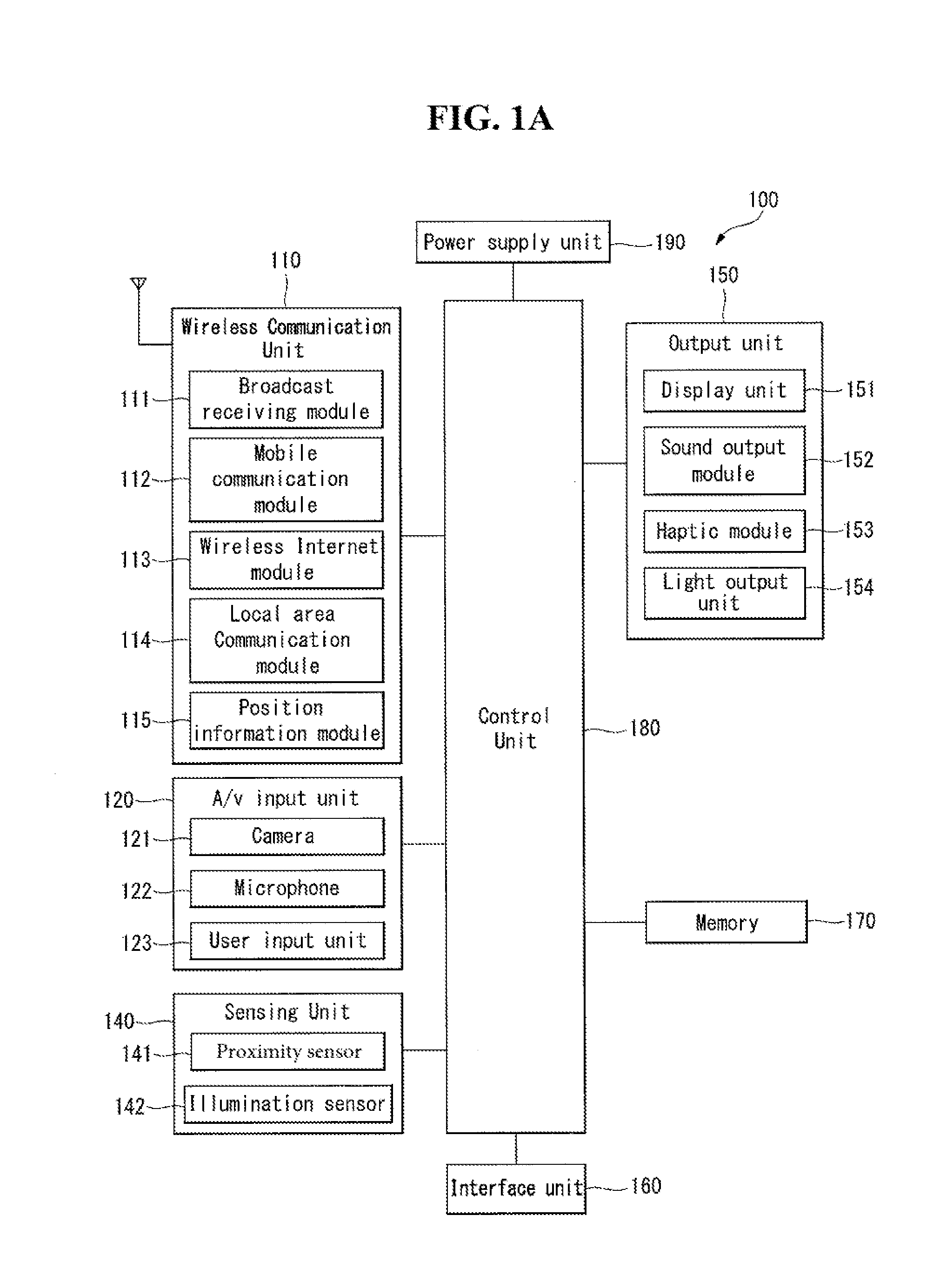

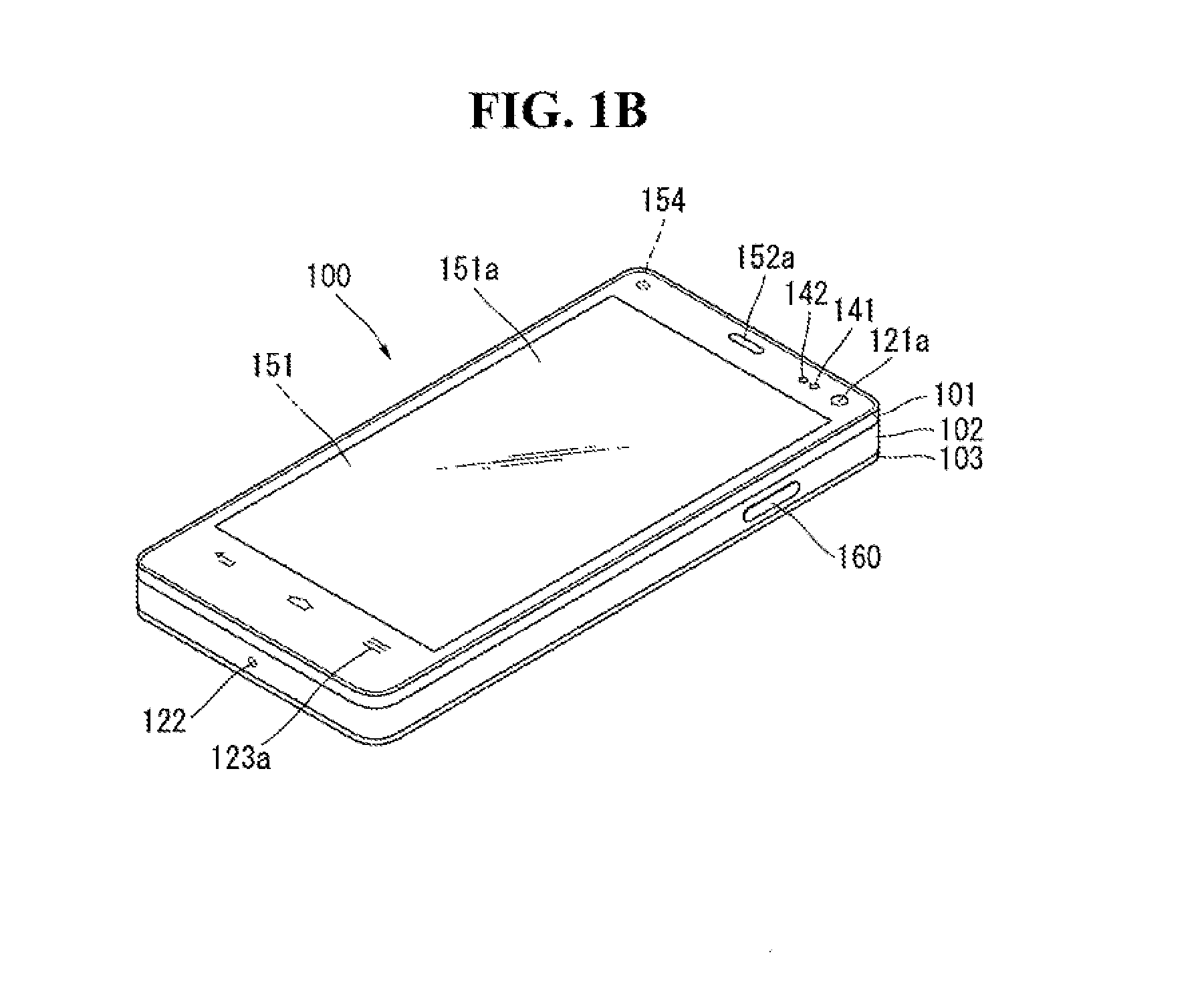

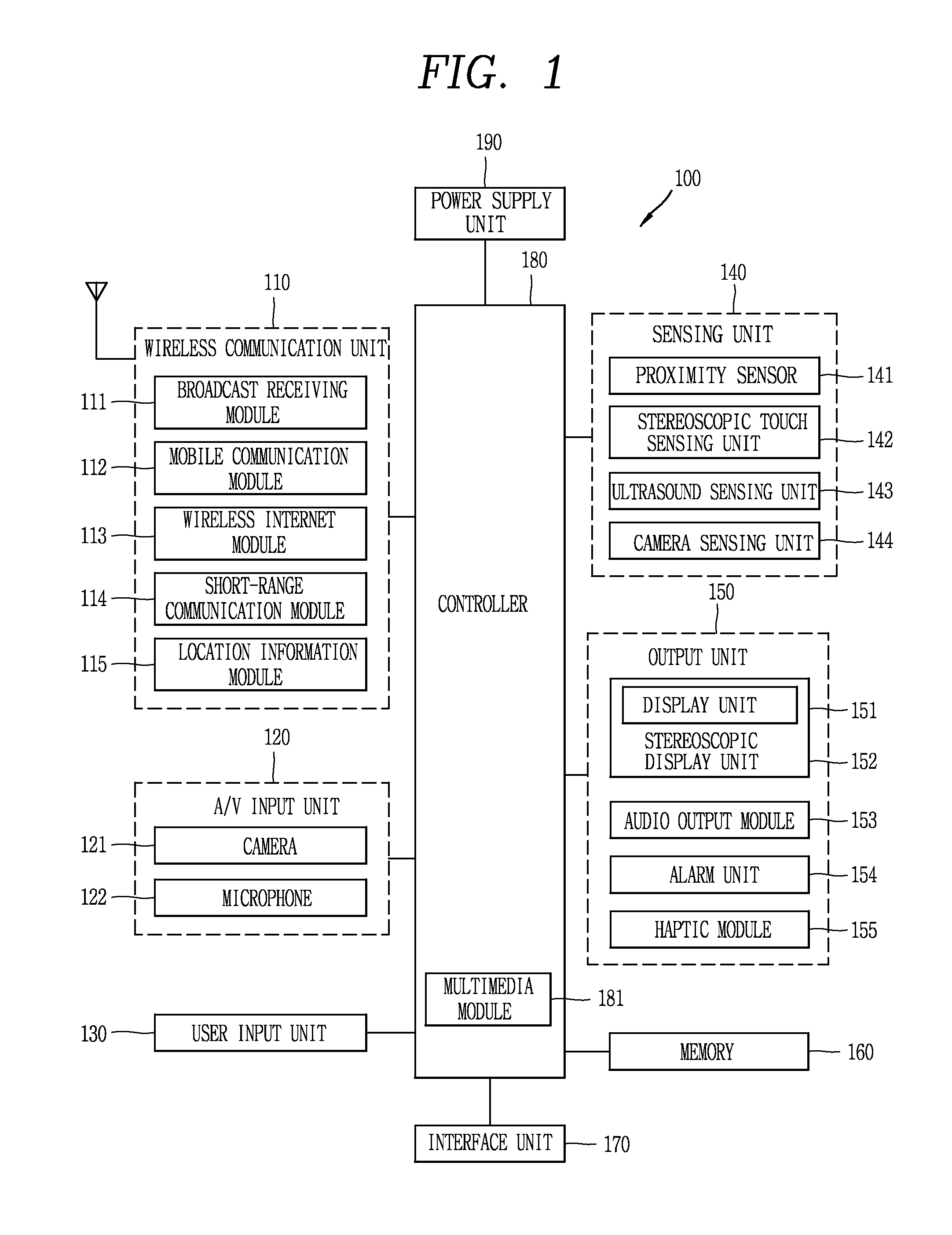

Mobile terminal and method for controlling the same

ActiveUS20150128251A1Unauthorised/fraudulent call preventionDigital data processing detailsTelecommunicationsCommunication unit

The disclosure relates to a mobile terminal communicable with a glass-type terminal and a method for controlling the same. The mobile terminal comprises a wireless communication unit configured to communicate with a glass-type terminal, a display unit configured to display visual information, and a controller configured to transmit output-limited information having a limitation in output on the display unit to the glass-type terminal so that the output-limited information may be output on the glass-type terminal when the mobile terminal is in communication with the glass-type terminal.

Owner:LG ELECTRONICS INC

Head mounted display

InactiveUS8988315B2Minimizing effect of deformationHigh designCathode-ray tube indicatorsOptical light guidesGlasses typeOptical Module

There is provided a head mounted display including a glasses-type frame to be worn on a head of an observer; two optical modules including two image creation devices, and two light guides having two light guide plates coupled one-to-one with the two image creation devices and placed closer to a center of a face of the observer than the image creation devices are as a whole, that guide light beams output from the image creation devices and output the light beams toward pupils of the observer; and an optical plate supporting the two light guides, wherein the optical plate is attached to a center part of the frame.

Owner:SONY CORP

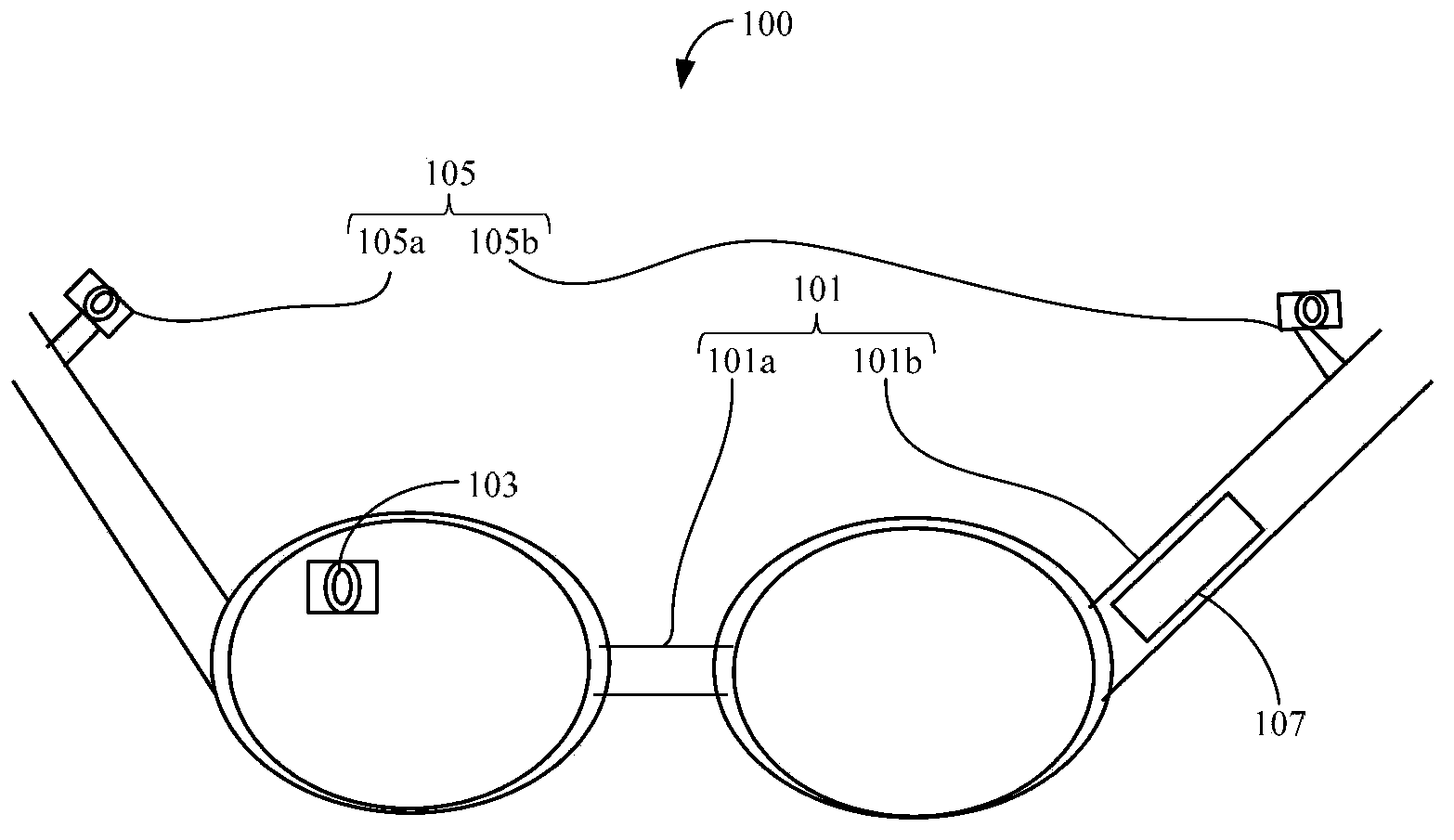

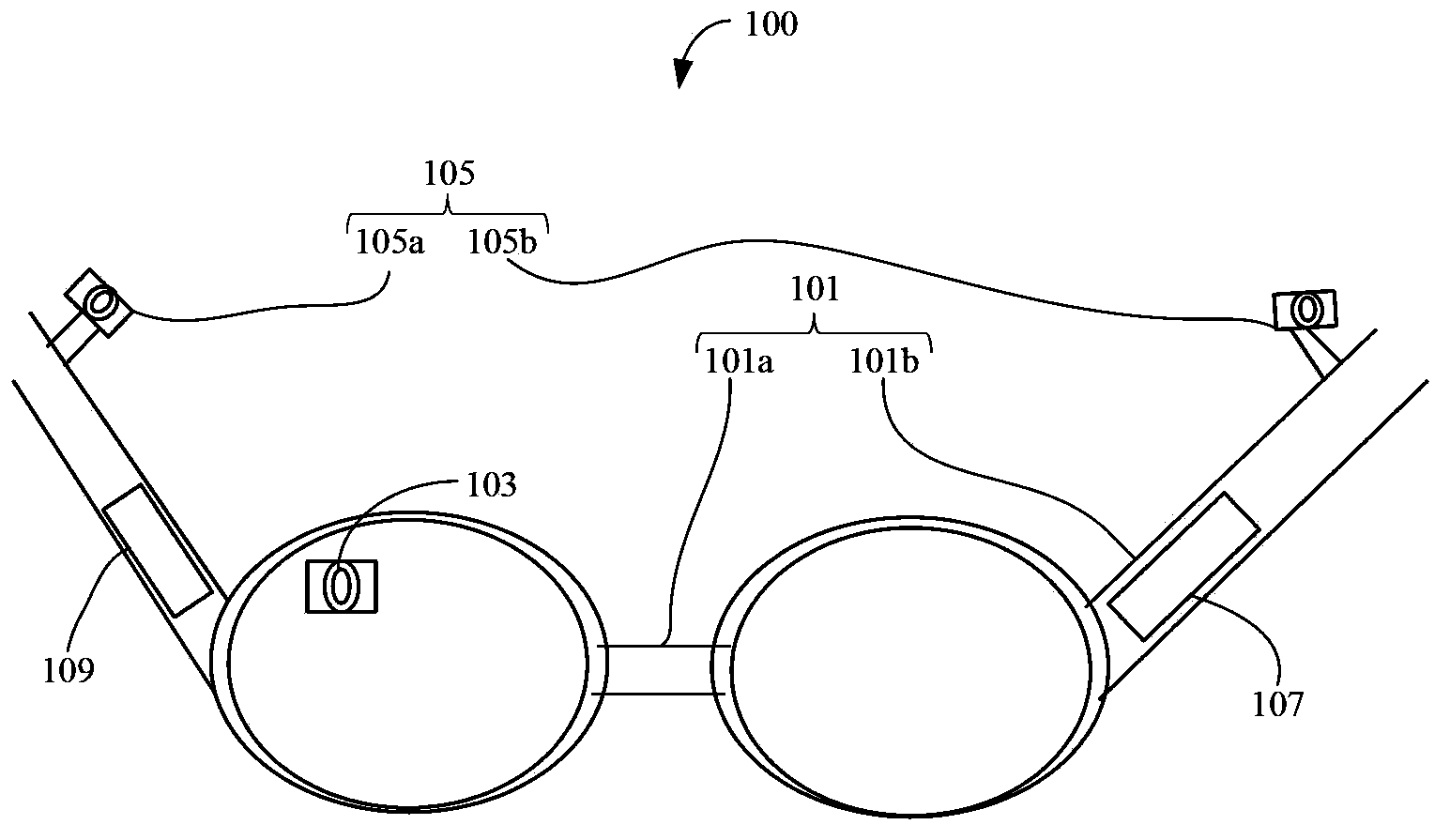

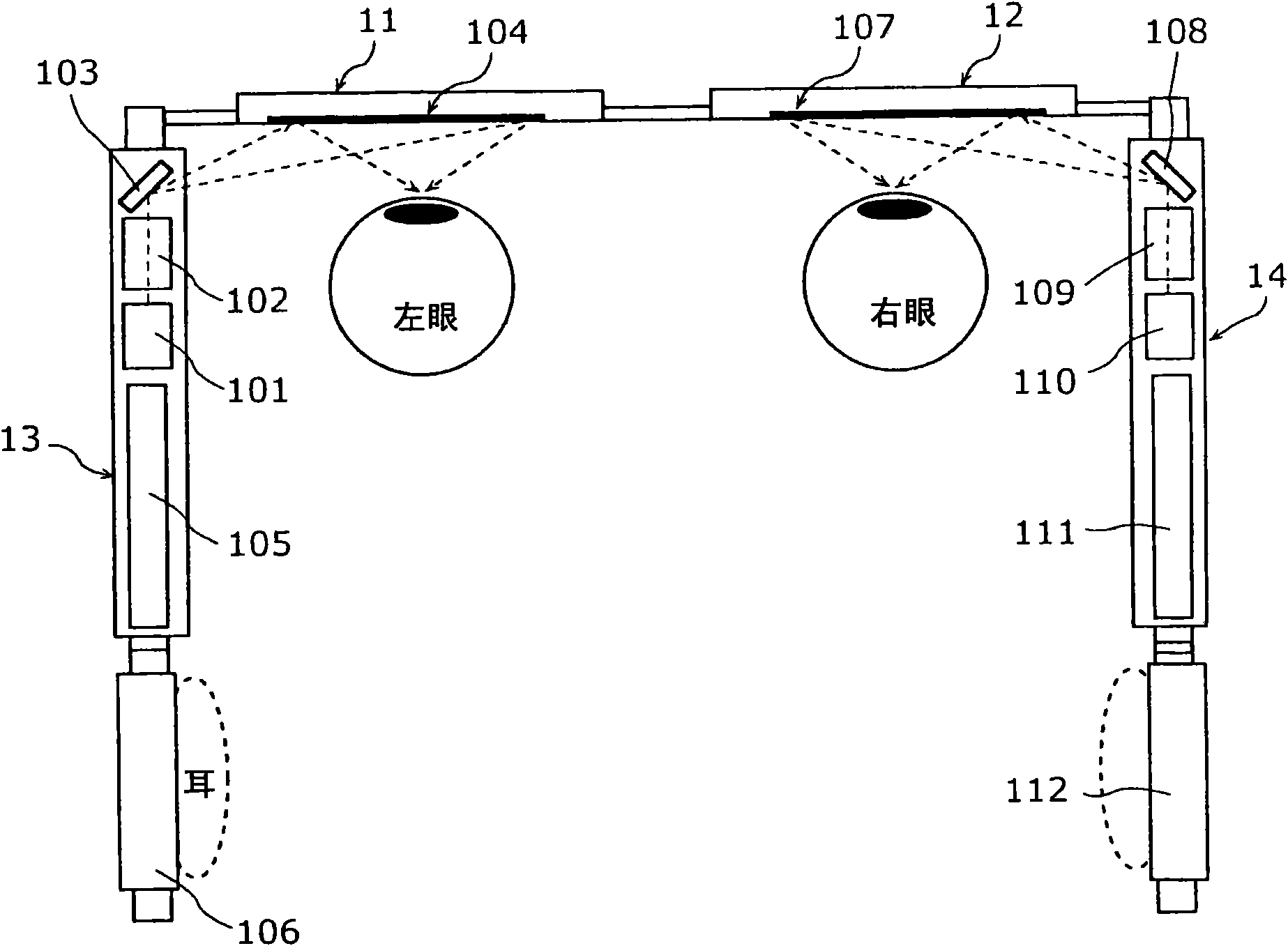

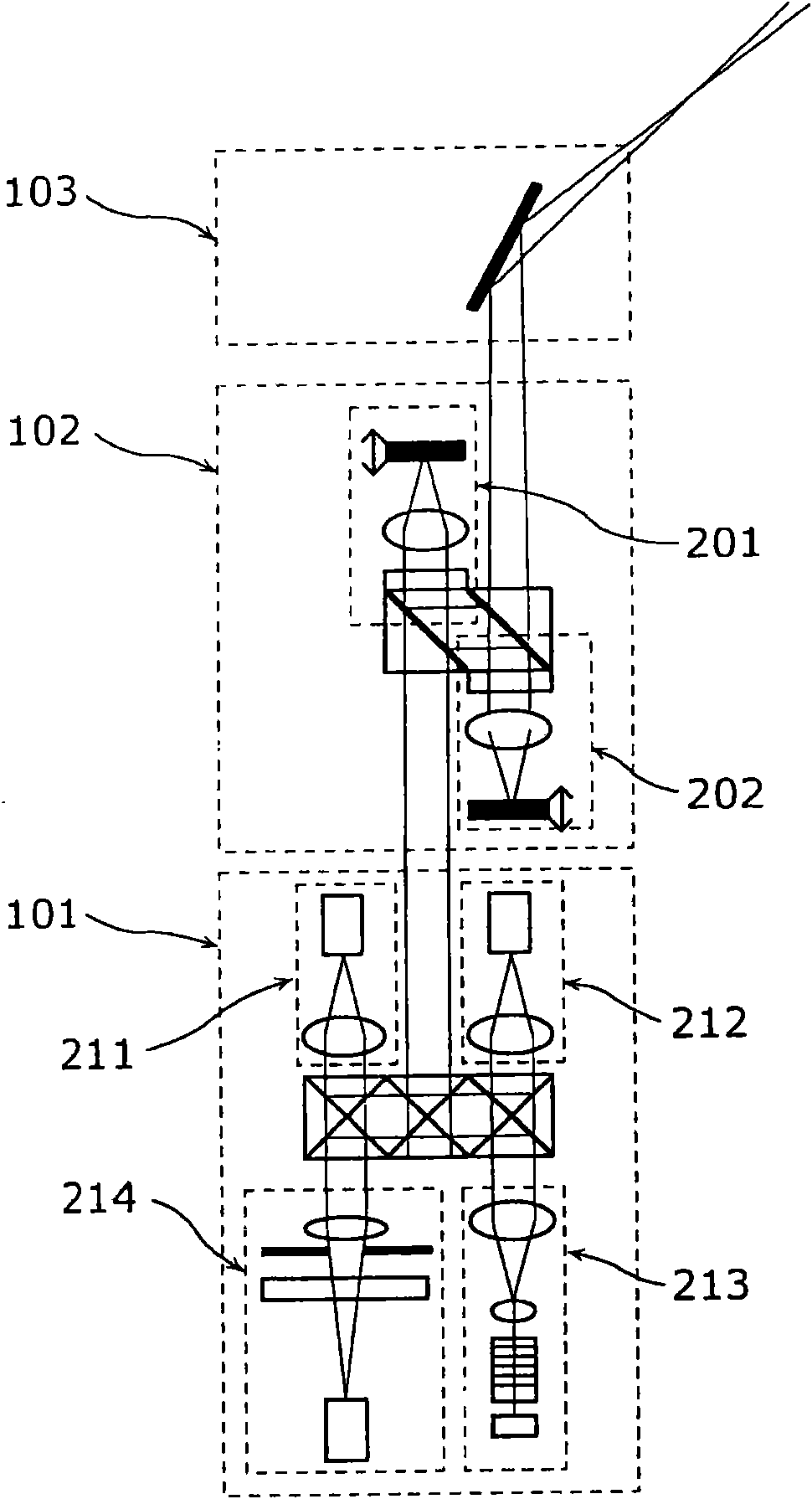

Image display device, display method thereof, program, integrated circuit, glasses type head mounted display, automobile, binoculars, and desktop type display

InactiveCN101589328AIncrease frame rateHigh-resolutionTelevision system detailsColor television detailsDisplay deviceFrame rate

An image display device comprises a light source for left eye (101) for outputting an image for left eye that configures a part or all of an original image, a deflection unit for left eye (104) for deflecting the image for left eye outputted by the light source for left eye (101) in direction to a user's left eye, a light source for right eye (110) for outputting an image for right eye that configures a part or all of the original image, a deflection unit for right eye (107) for deflecting the image for right eye outputted by the light source for right eye (110) in direction to a user's right eye, and control units (105, 111) for controlling an image output unit for left eye and an image output unit for right eye so as to output the image for left eye and the image for right eye of which at least one of a position of a pixel, a shape of the image, a size of the image, resolution of the image, and a display frame rate is different from each other so that the user can recognize the original image from the image for left eye and the image for right eye by an image fusion effect.

Owner:PANASONIC CORP

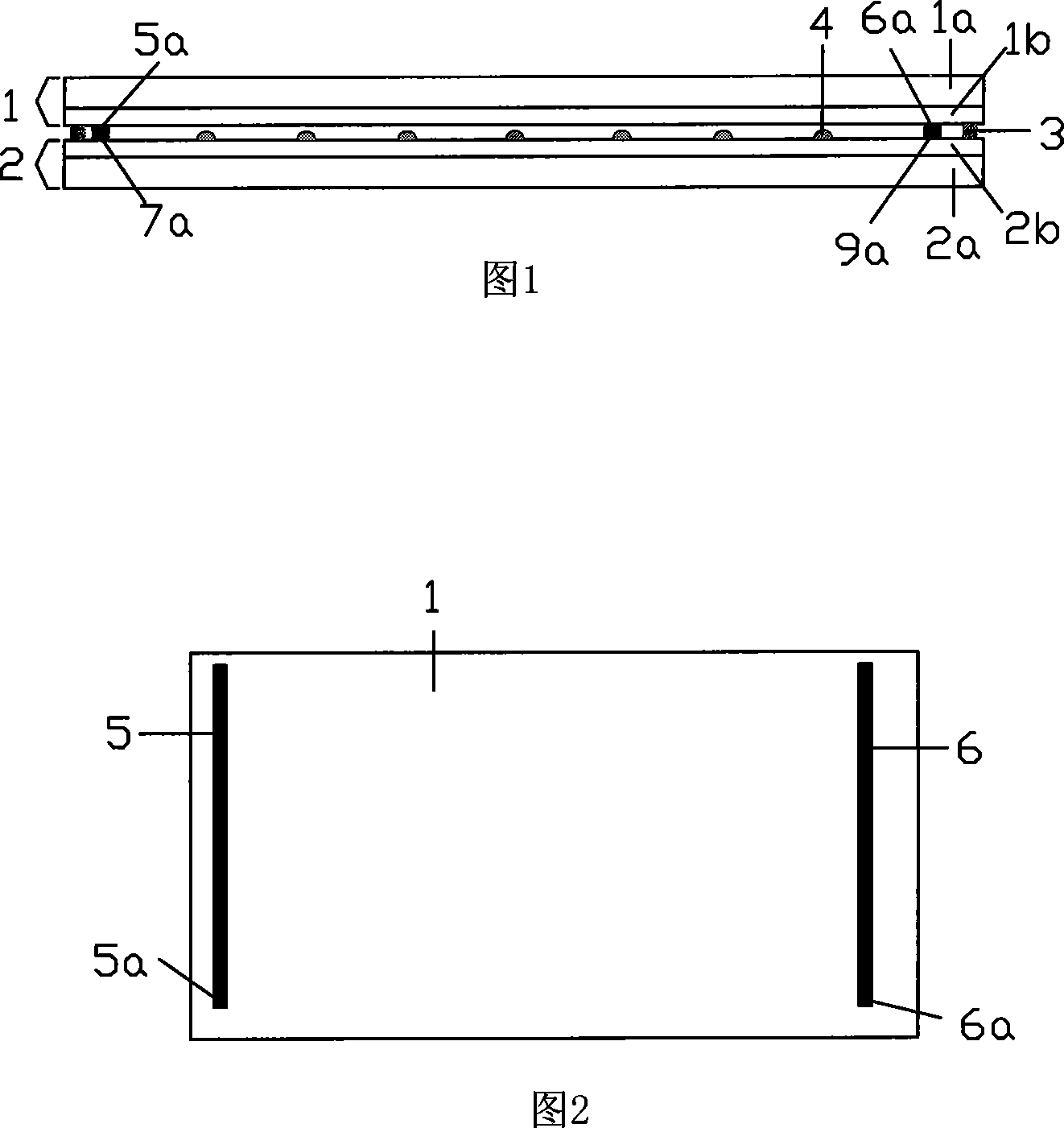

Method for making Electric impedance type glass/glass type touch screen

ActiveCN101082713AAvoid breakingImprove yield rateStatic indicating devicesGlass/slag layered productsGlasses typeAdhesive

The invention discloses a making method of resistance-typed glass / glass typed touching screen, which comprises the following steps: etching pattern on the transparent conductive layer of lower glass base to make dispersing separating point; making electrode and binder on the lower glass base; etching pattern on the transparent conductive layer of upper glass base to make electrode thereon; binding upper and lower glass bases; sealing the rim; using etching liquid to etch to the needed depth; cutting two pieces of glass base according to the size of touching screen; obtaining the product. The invention has high reliability, simple technique and low cost, which can prevent glass from cracking.

Owner:TRULY OPTO ELECTRONICS

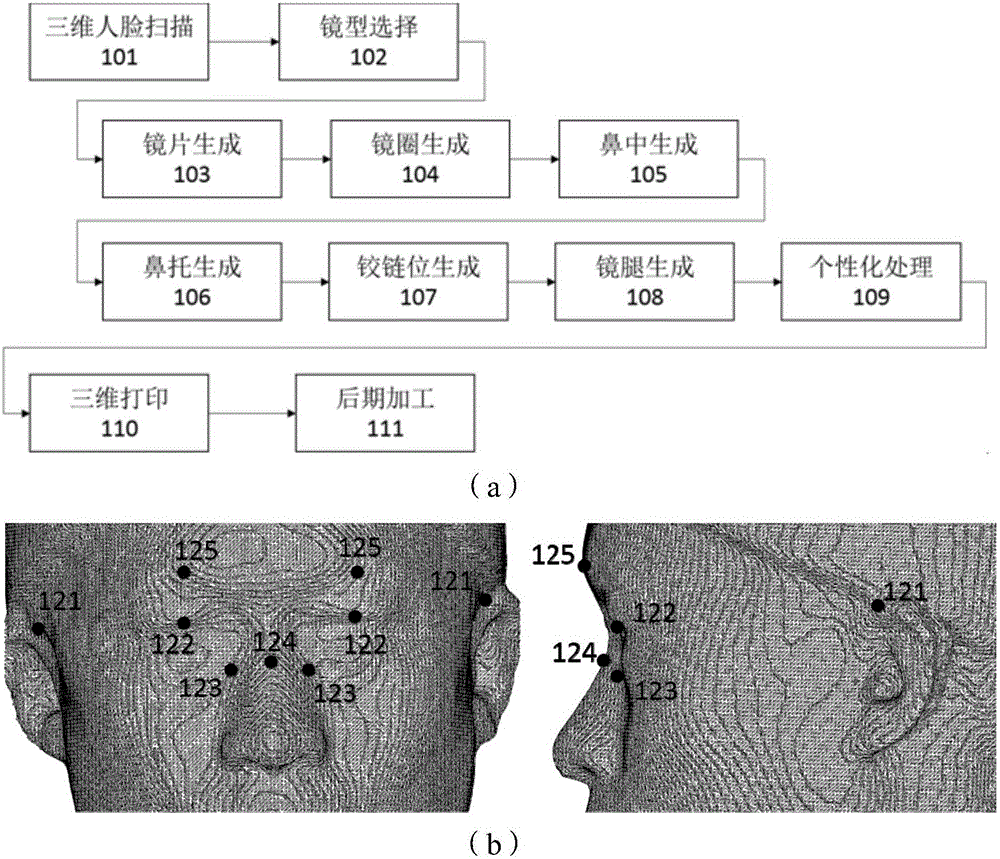

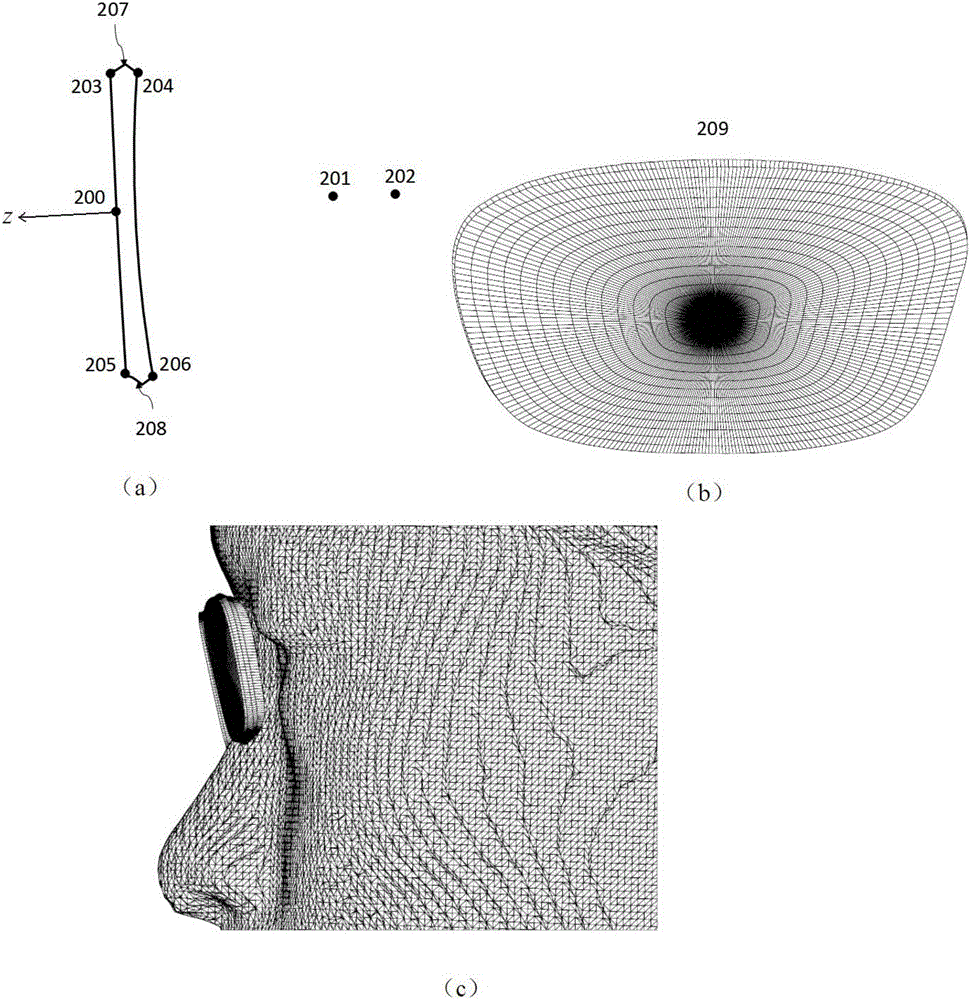

Method for designing glasses frame based on facial three-dimensional measurement

ActiveCN105842875AAdapt to asymmetryImprove fitUsing optical meansOptical partsFrame basedGlasses type

The invention discloses a method for designing a glasses frame based on facial three-dimensional measurement, comprising: (1), acquiring a three-dimensional grid model of a facial area and a three-dimensional facial feature point set; (2), selecting a glasses type and setting glasses generation parameters; (3), acquiring two complete lens grids composed of a plurality of rows of curves and a plurality of columns of curves; (4), acquiring two complete rim grids; (5), generating a complete nose bridge grid between the rim grids; (6), moving points, closest to the nose, from nose pads to the surface of the nose, and after iteration, updating a position of an apex of the nose pad grid to the rim grids to obtain a combined lens frame grid; (7), generating two hinge positions of a hinge and legs to finish the designing of the glasses frame. The shapes of the nose pads are optimized automatically according to the nose shape of a user, fitting degree is high, and adaptation to asymmetry of the face is achieved; the length and orientation of the legs are adjusted automatically according to positions of ears, providing comfort of wearing and rarity of sliding; manufacture cost is reduced greatly.

Owner:HANGZHOU MEIDAI TECH CO LTD

Image displaying method for a head-mounted type display unit

ActiveUS8570242B2Easy to displayCathode-ray tube indicatorsImage data processingComputer hardwareData display

Disclosed herein is an image displaying method for a head-mounted type display unit which includes a frame of the glasses type for being mounted on the head of an observer, an image display apparatus attached to the frame, and a control section for controlling image display of the image display apparatus. The image display apparatus includes an image forming apparatus, and an optical apparatus. The image displaying method includes the steps of: storing a data group configured from a plurality of data in a storage section; adding a data identification code to each of the data; sending a designation identification code and display time information at predetermined intervals of time; and reading out the data whose data identification code coincides with the received designation identification code from the storage section and controlling the image forming apparatus to display an image based on the read out data.

Owner:SONY CORP

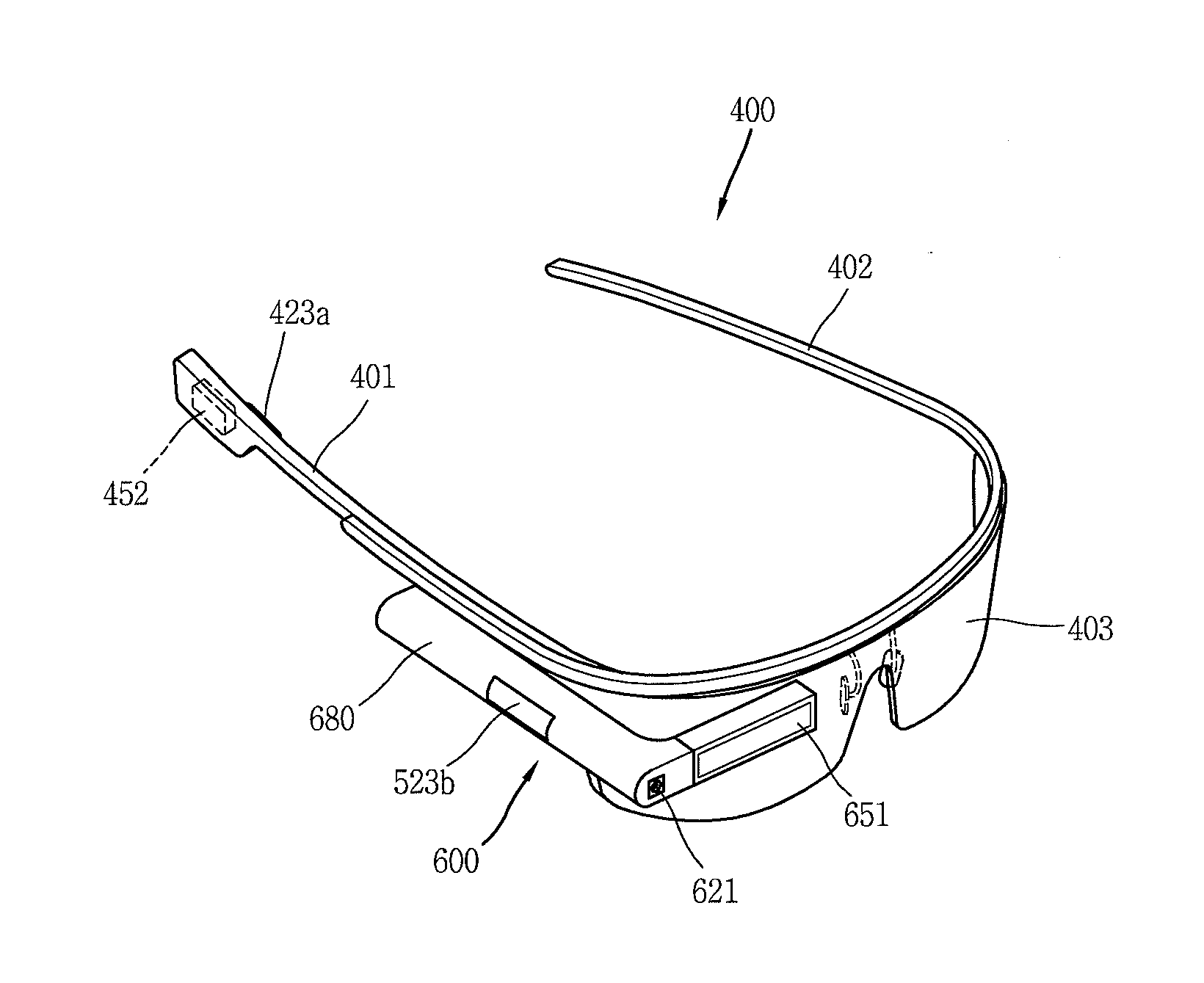

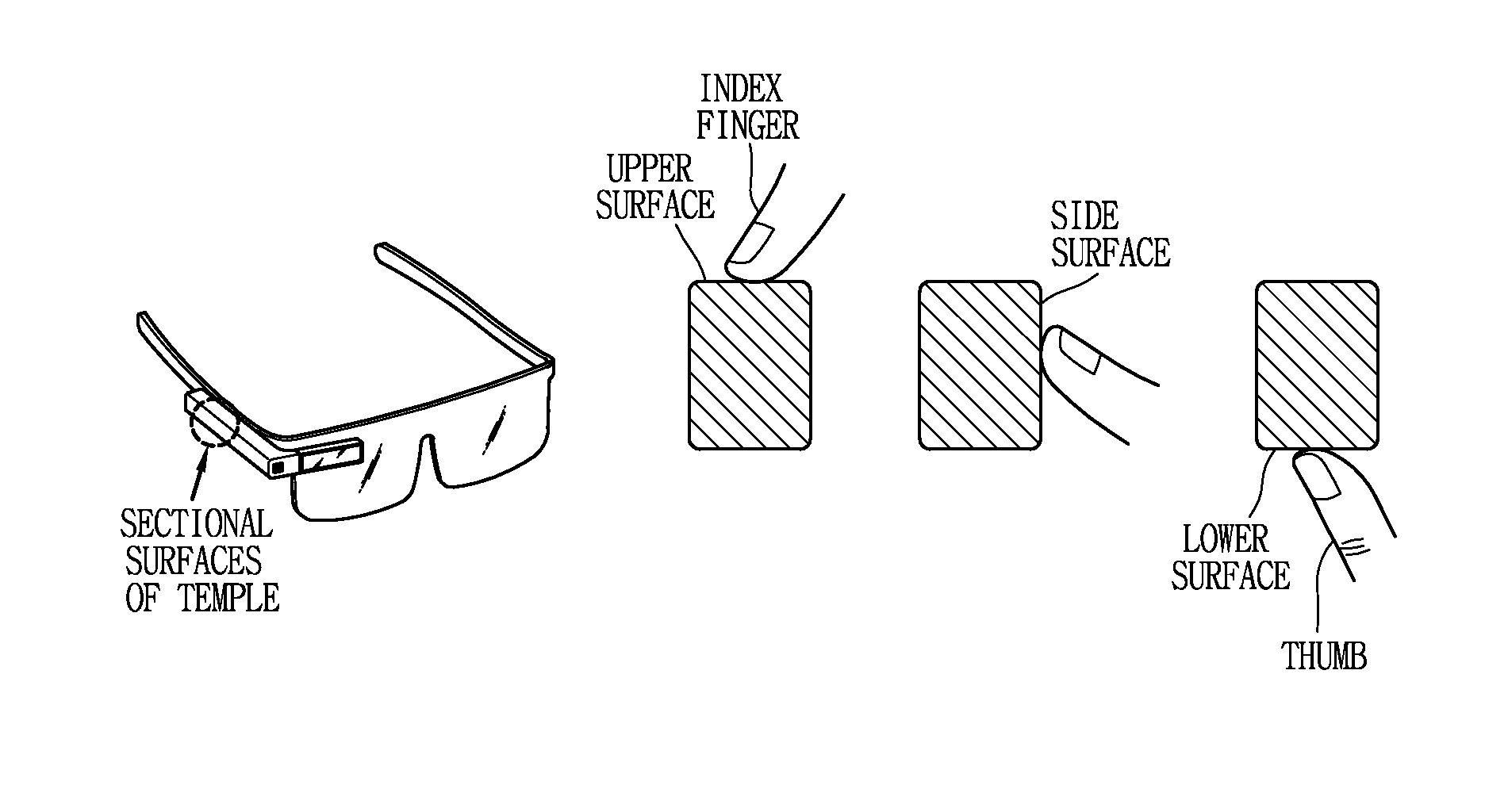

Glass type terminal having three-dimensional input device and screen control method thereof

ActiveUS20150103021A1Rapid and convenient mannerInput/output for user-computer interactionDetails for portable computersGlasses typeEngineering

Disclosed are a glass type terminal capable of supporting gestures using one finger or two fingers by providing a three-dimensional input device at a temple hinged to a rim of a lens, and an input method thereof. For three-dimensional touch inputs, the temple is configured to have an upper surface, a lower surface, an inner side surface and an outer side surface provided touch sensor, respectively. Upon sensing of a touch input applied onto said one or more surfaces of the temple using one finger or two fingers, a screen displayed on a lens is controlled in correspondence to the sensed touch input. Under such configuration, a user can control the screen in a more convenient manner.

Owner:LG ELECTRONICS INC

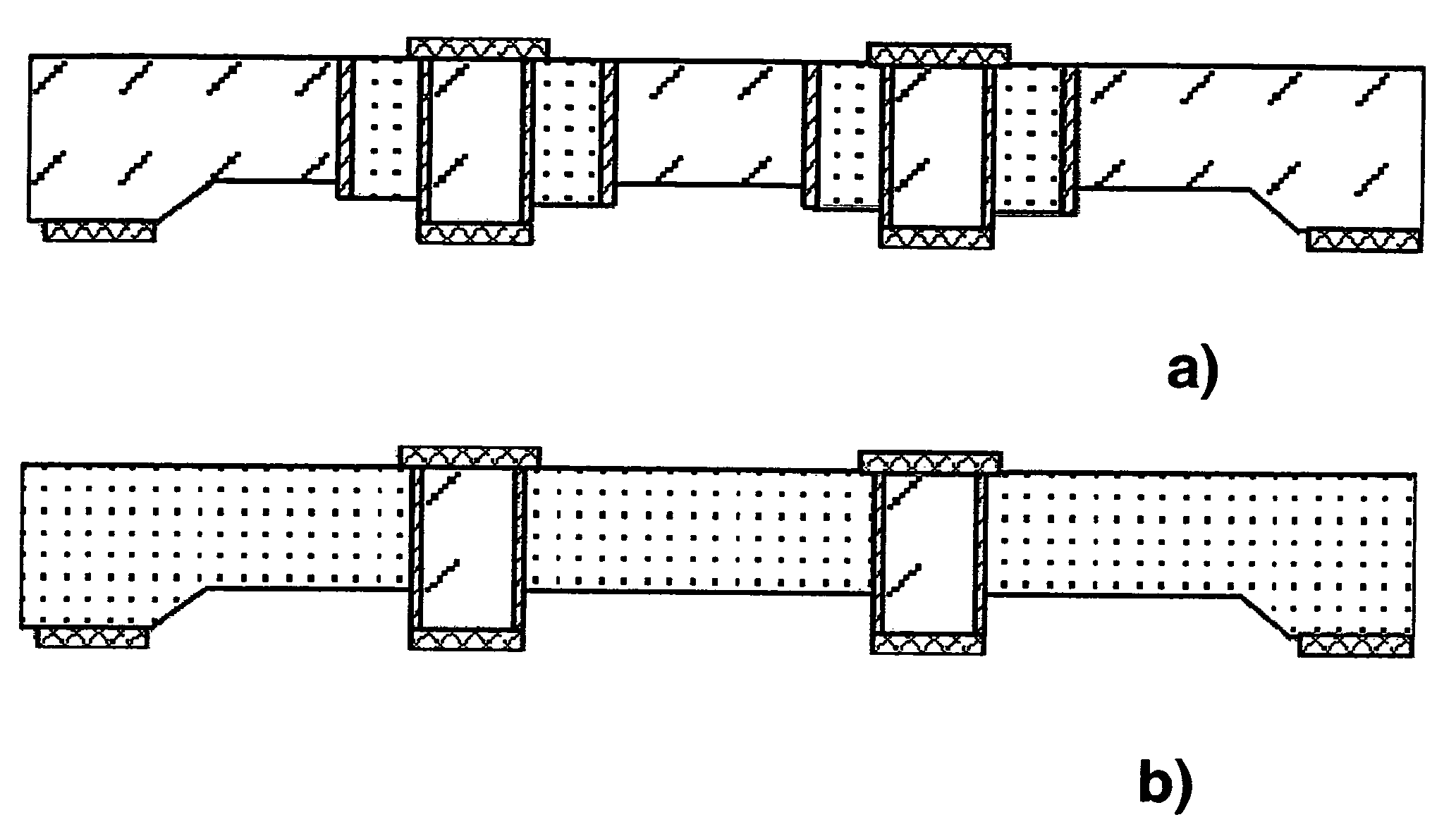

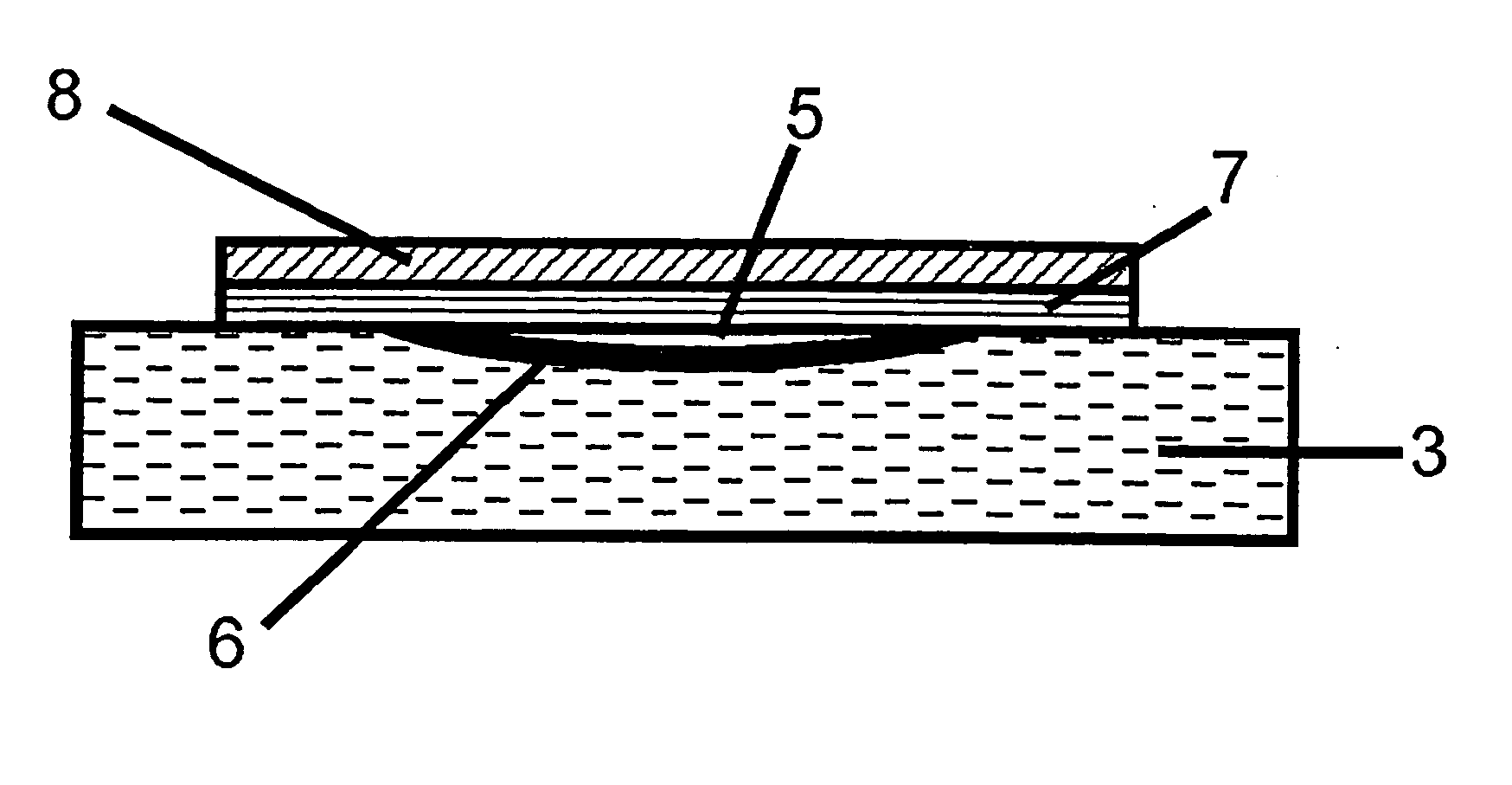

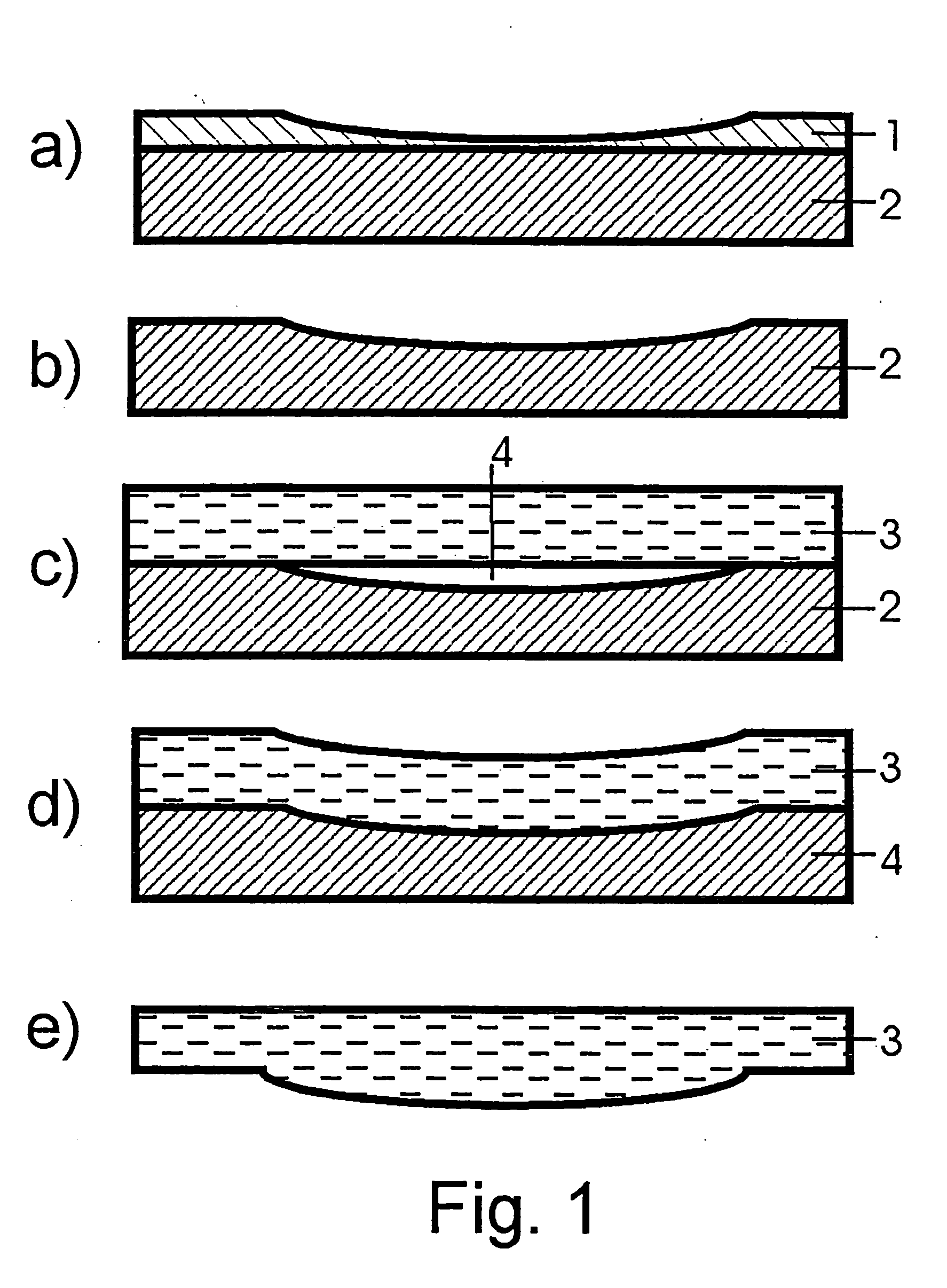

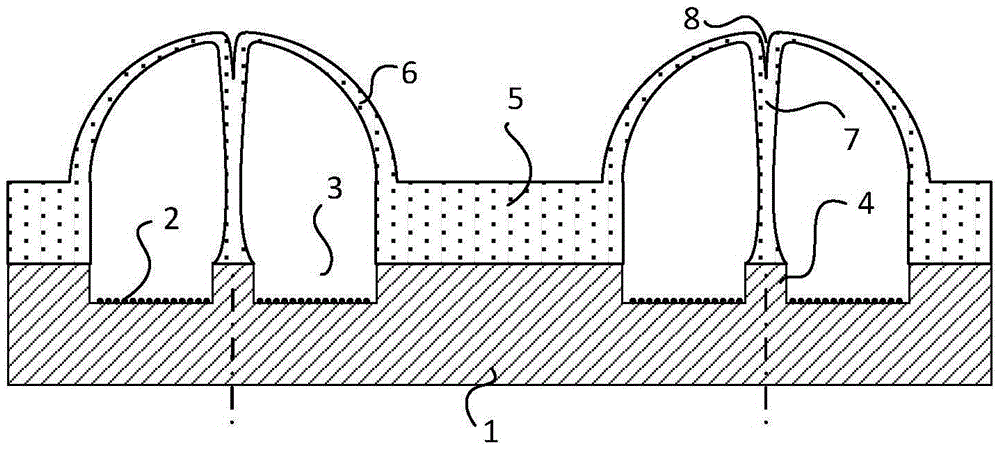

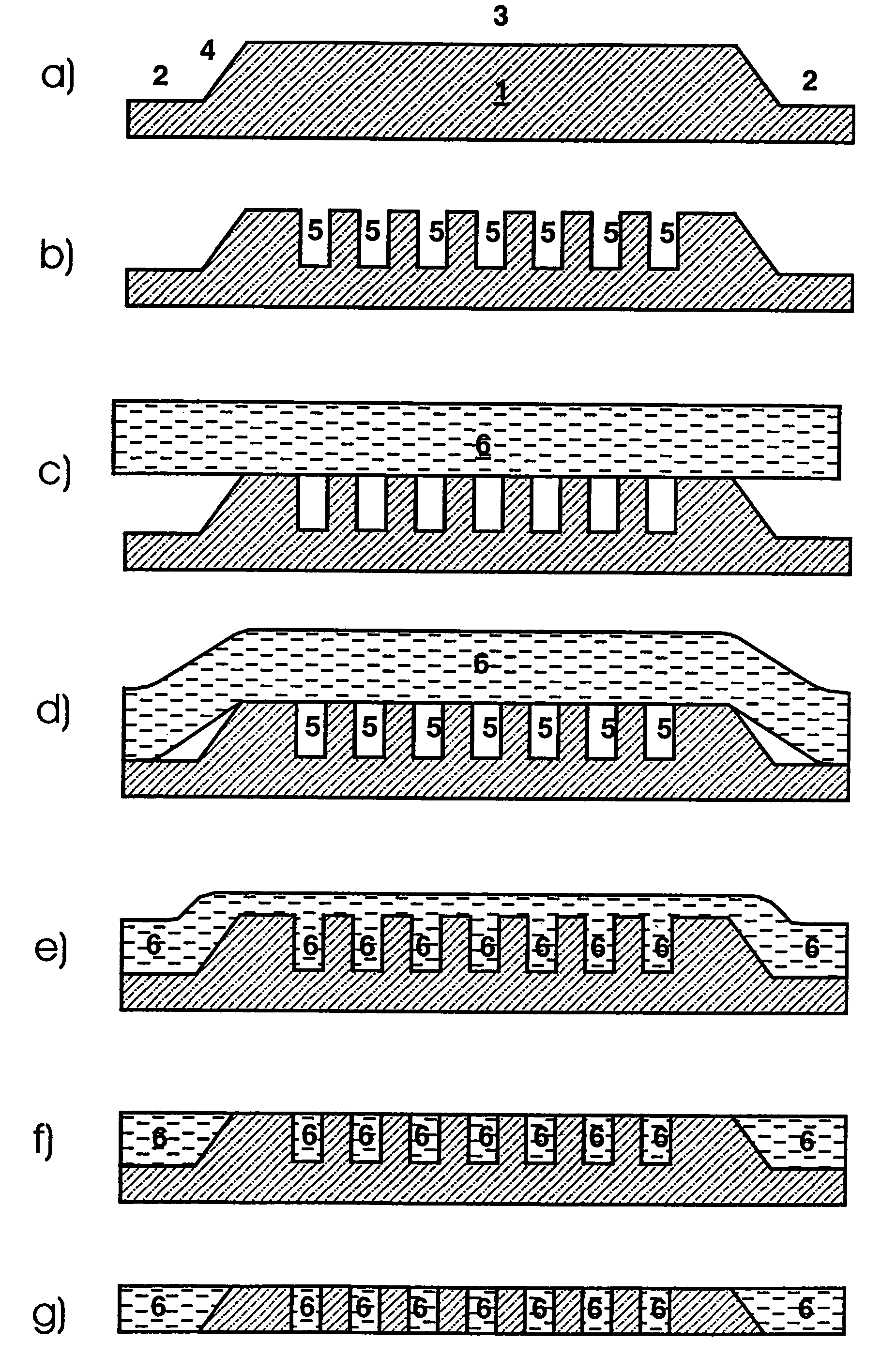

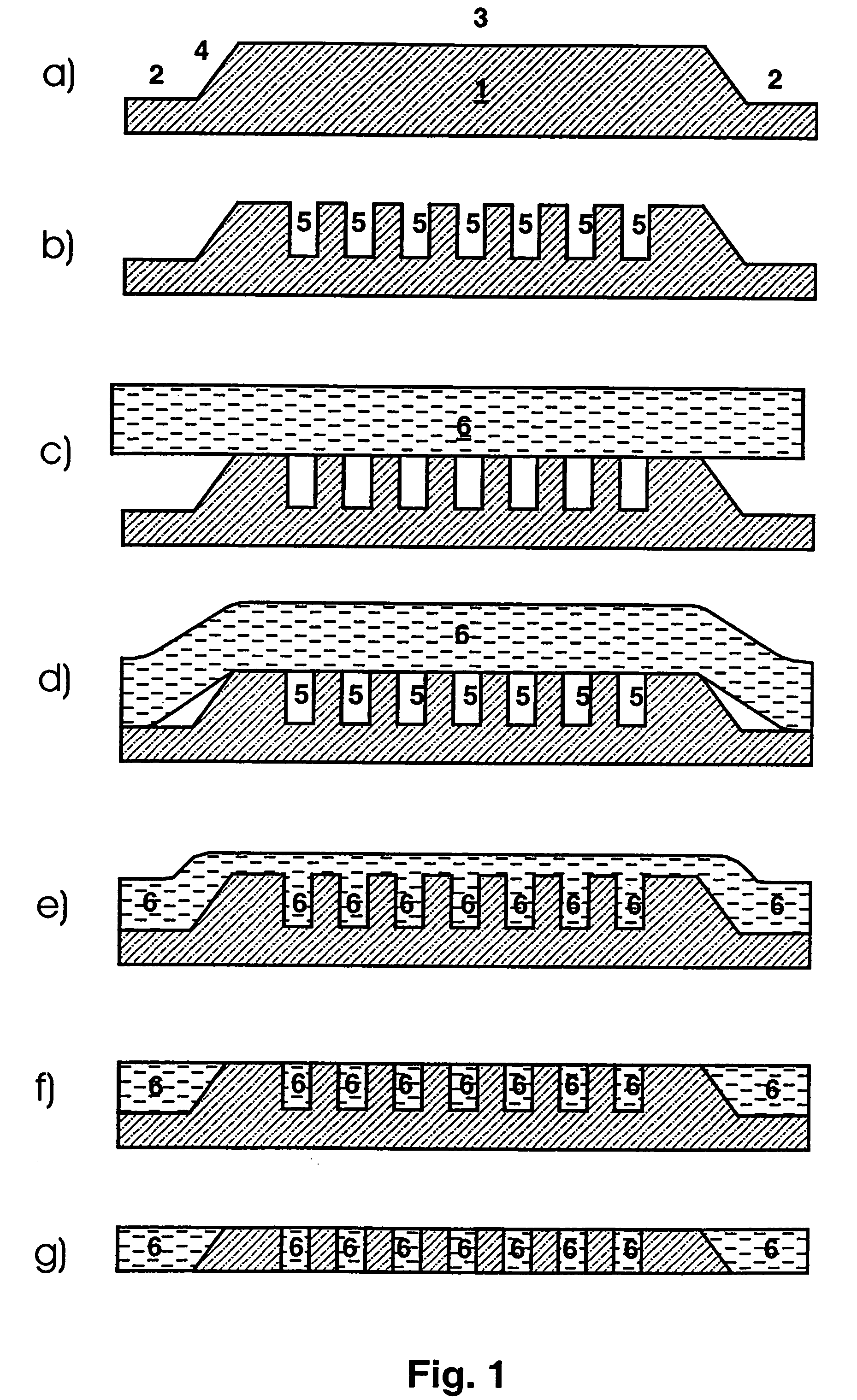

Glass-type planar substrate, use thereof, and method for the production thereof

InactiveUS7259080B2Low costCost-effective removalDecorative surface effectsSemiconductor/solid-state device detailsGlasses typeSemiconductor materials

The invented method is distinguished by a combination of the following method steps:provision of a semiconductor planar substrate composed of a semiconductor material,reduction of the thickness of the semiconductor planar substrate inside at least one surface region of the semiconductor planar substrate in order to form a raised surface region in relation to the surface planar region of reduced thickness,structuring the raised surface region of the semiconductor planar substrate by means of local mechanical removal of material in order to place impressions inside the raised surface regions,joining the structured surface of the semiconductor planar substrate with the glasslike planar substrate in such a manner that the glasslike planar substrate at least partially covers the surface planar region of reduced thickness,tempering the joined planar substrates in such a manner that in a first tempering phase, which is conducted under vacuum conditions, the glasslike planar substrate covering the surface region of reduced thickness forms a fluid-tight bond with the surface region of reduced thickness, with the planar substrate covering the impressions in a fluid-tight manner under vacuum conditions, and that in a second tempering phase, at least partial areas of the glasslike material flow into the impressions of the structured surface of the semiconductor planar substrate.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

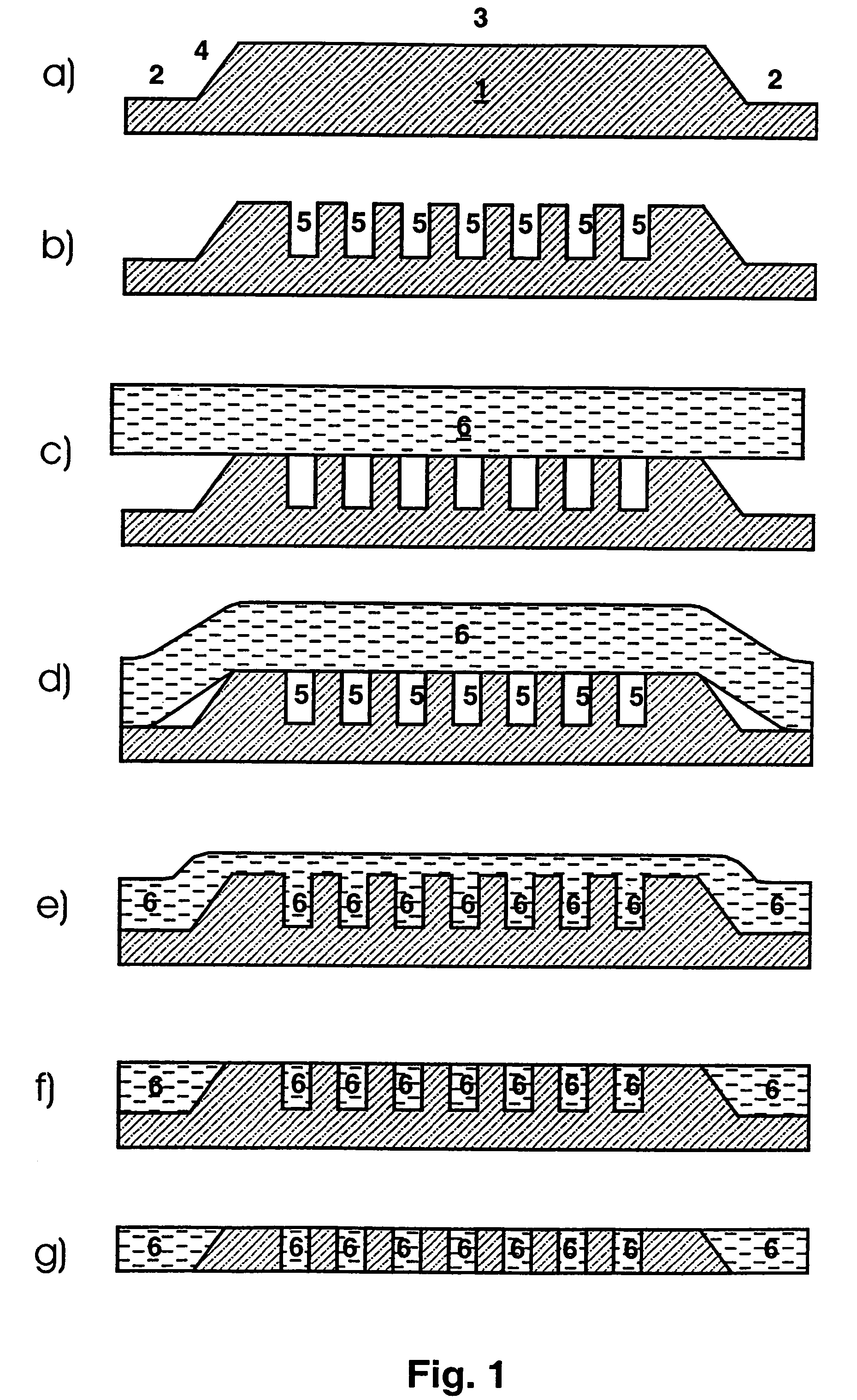

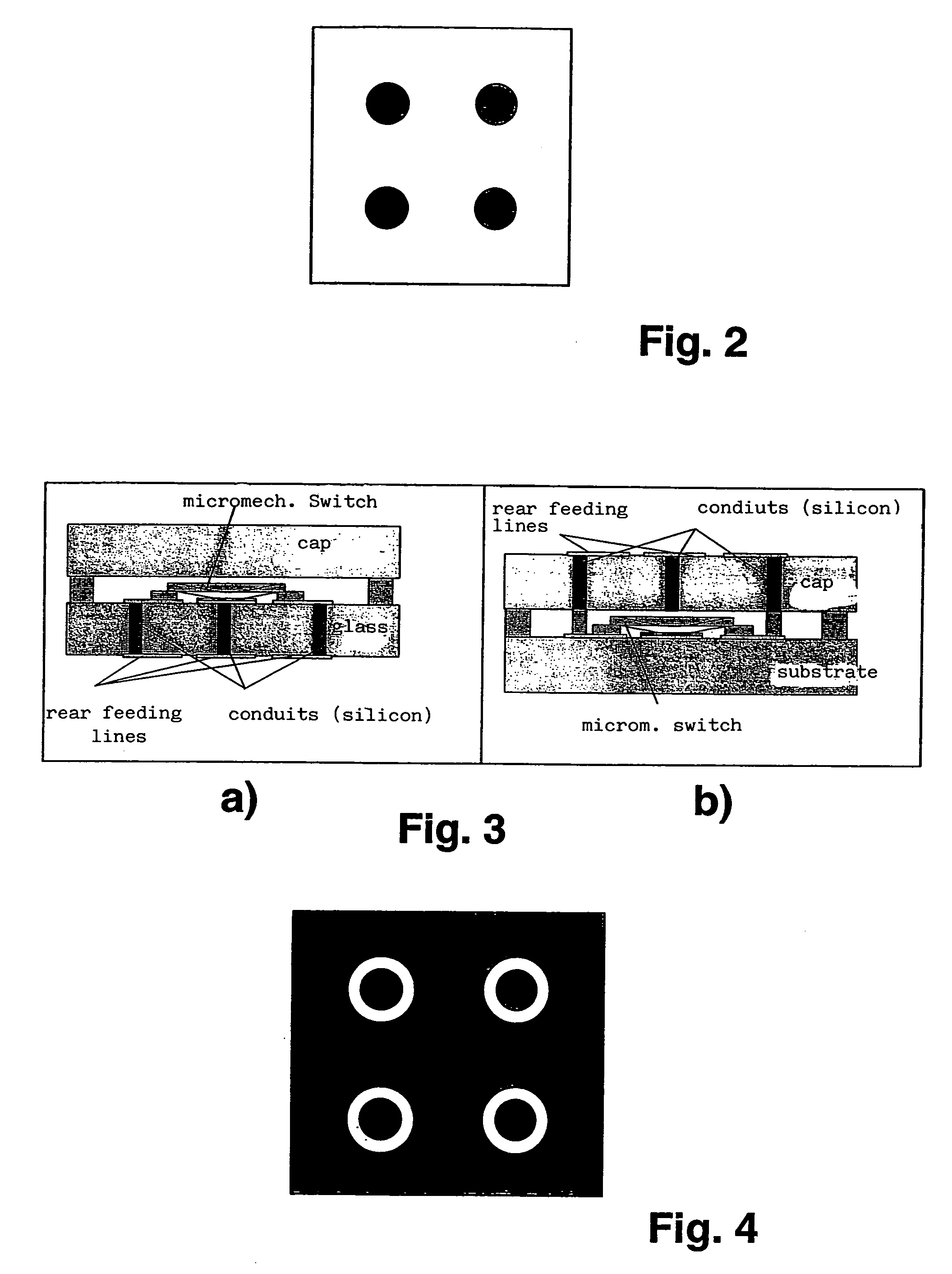

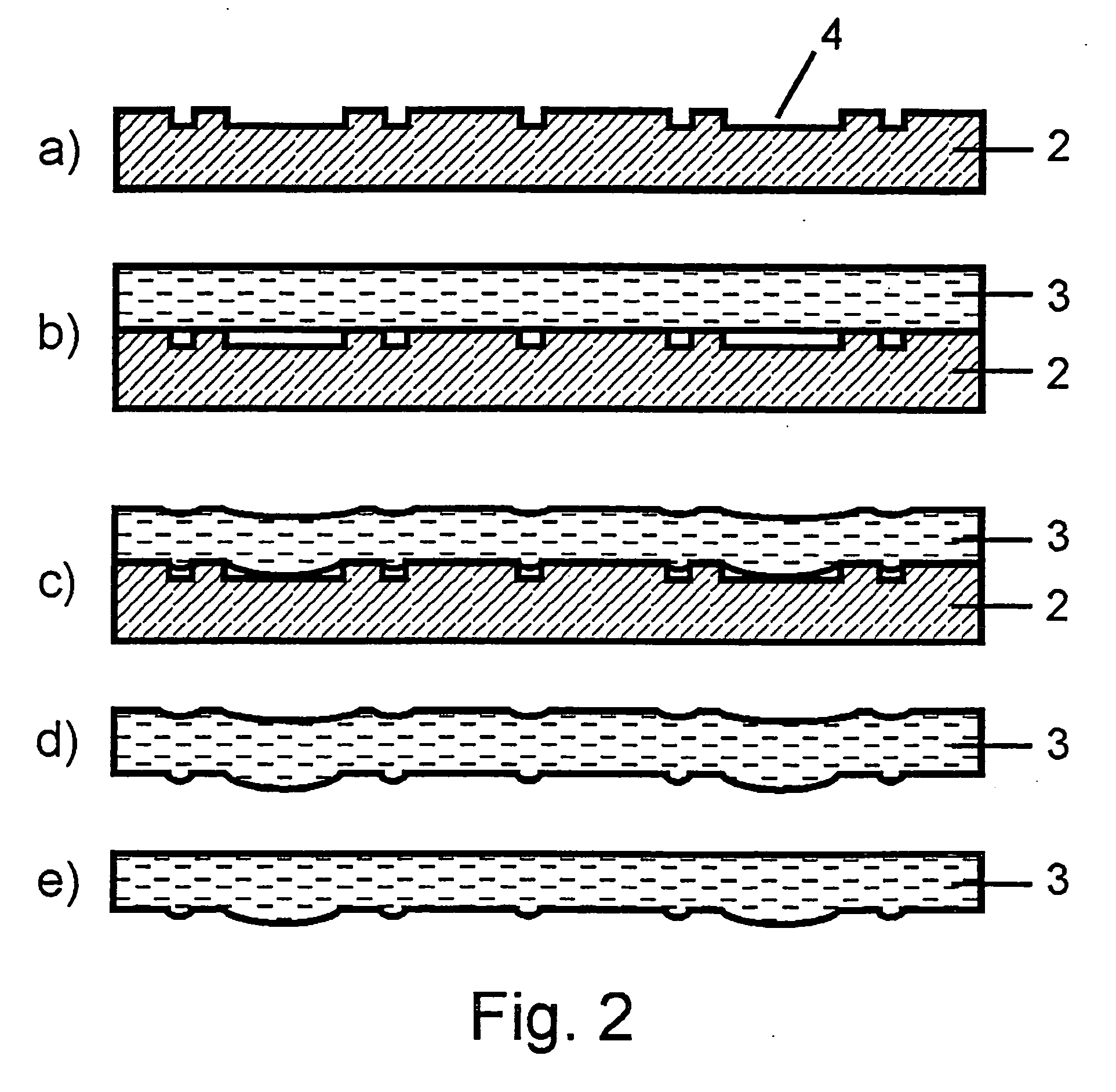

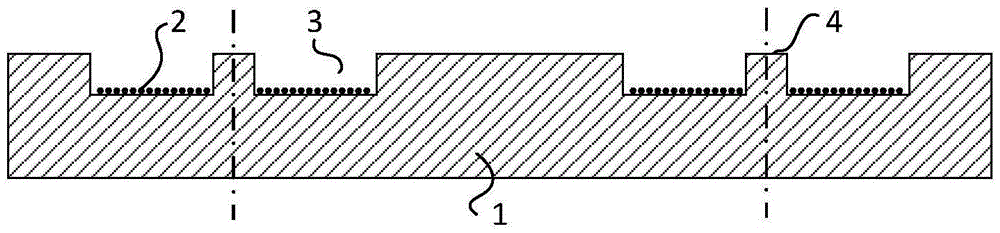

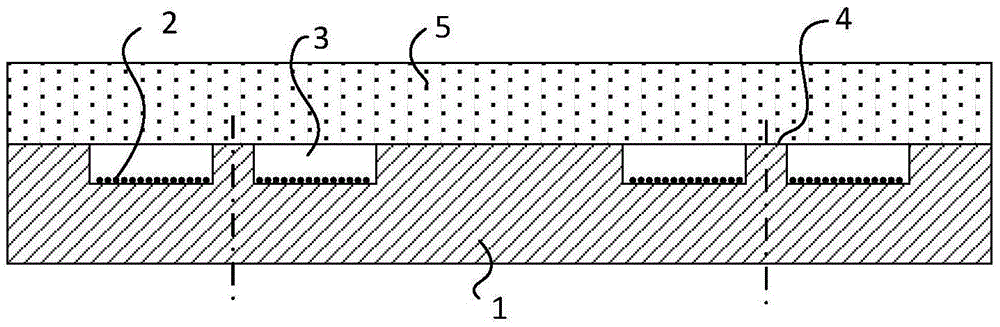

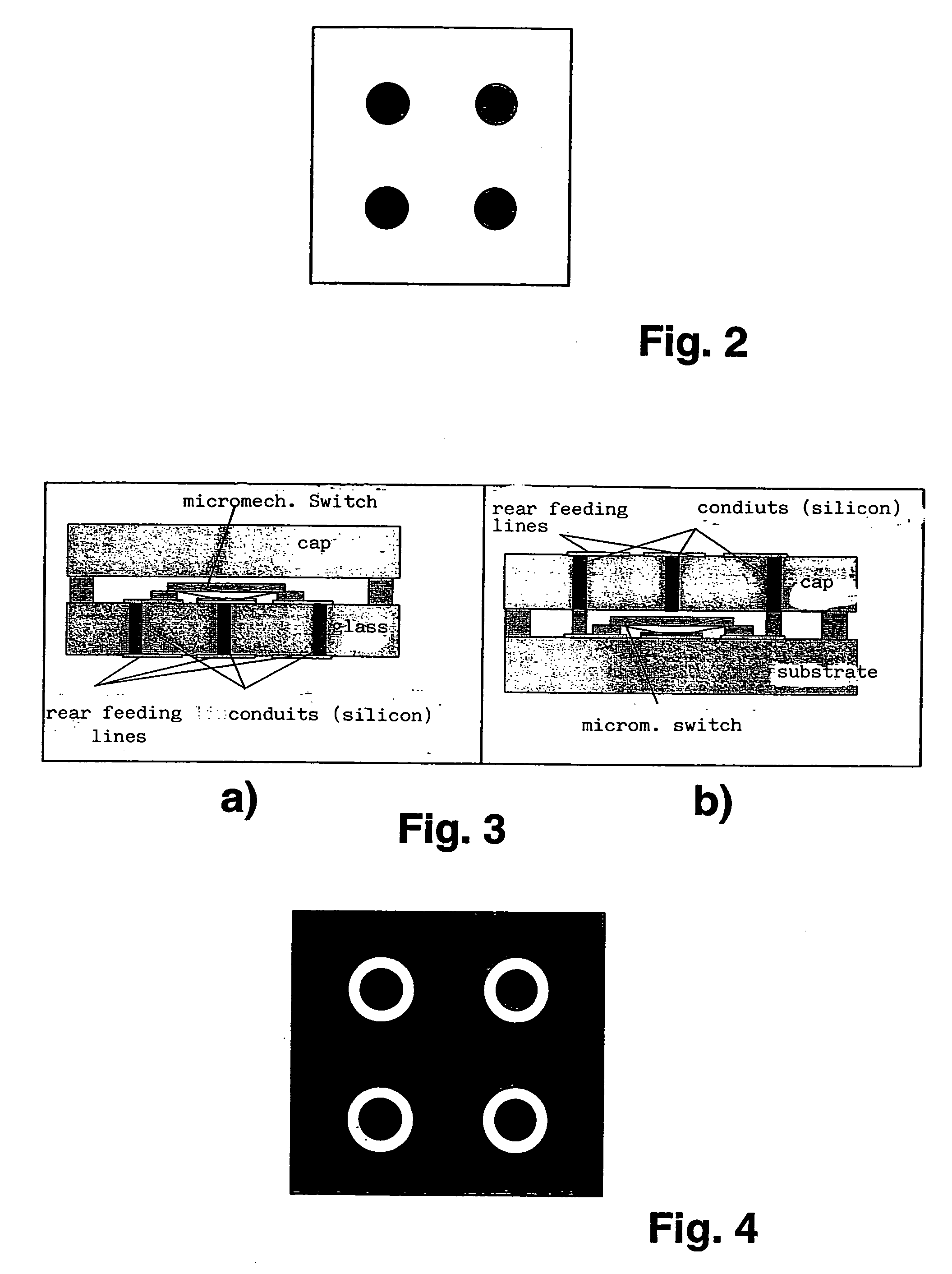

Method for producing micromechanical and micro-optic components consisting of glass-type materials

InactiveUS20050239228A1Precise and low-cost shapingAvoid stickingSolid-state devicesSemiconductor/solid-state device manufacturingMechanical componentsGlasses type

What is proposed here is a method of structuring surfaces of glass-type materials and variants of this method, comprising the following steps of operation: providing a semiconductor substrate, structuring, with the formation of recesses, of at least one surface of the semiconductor substrate, providing a substrate of glass-type material, joining the semiconductor substrate to the glass-type substrate, with a structured surface of the semiconductor substrate being joined to a surface of the glass-type surface in an at least partly overlapping relationship, and heating the substrates so bonded by annealing in a way so as to induce an inflow of the glass-type material into the recesses of the structured surface of the semiconductor substrate. The variants of the method are particularly well suitable for the manufacture of micro-optical lenses and micro-mechanical components such as micro-relays or micro-valves.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

Micro-glass hemispherical resonator gyro and wafer level preparation method thereof

ActiveCN105540530AAvoid alignment problemsReduce volume costTelevision system detailsImpedence networksRefluxPlanar electrode

The invention discloses a micro-glass hemispherical resonator gyro and a wafer level preparation method thereof. The micro-glass hemispherical resonator gyro comprises a composite structure substrate; a glass hemispherical resonator; a silicon non-planar electrode embedded in the composite structure substrate; and a packaging glass shell cover; wherein the glass hemispherical resonator consists of a hemispherical shell and a self-aligned column, and the inner surface of the hemispherical shell and the surface of the self-aligned column are coated with a metal conductive layer which is led out by connecting with a silicon leading out channel through another metal layer; the silicon leading out channel and the silicon non-planar electrode are led out on the back of the composite structure substrate by a metal wire. The preparation method includes wafer-level preparing the micro-glass hemispherical resonator by using a thermal foaming process, wafer-level preparing a glass-type silicon non-planar electrode by using a hot reflux process, assembling the glass hemispherical resonator and the glass-type silicon non-planar electrode, and performing vacuum packaging. The hemispherical resonator prepared by the invention has a diameter of 1-10mm, and has high electrode resonator alignment accuracy at the same time.

Owner:SOUTHEAST UNIV

Slurry for preparation of glass fluorescent layer used for LED encapsulation

InactiveCN102730974AUniform thicknessExtended service lifeSemiconductor devicesGlasses typeFluorescence

The invention provides a slurry for preparation of a glass fluorescent layer used for LED encapsulation. The slurry comprises glass powder with a low melting point, fluorescent powder and slurry additives. Low-melting-point glass has a softening temperature in a range of 630 to 700 DEG C. Through preparation of solution systems consisting of the glass powder with a low melting point, the fluorescent powder and other additives with different content, slurries with viscosity and luminescent properties meeting different coating processes and luminescence requirements can be obtained after ball milling of the solution systems. Through adjusting composition of the slurry for a glass fluorescent layer provided in the invention and glass, coating slurry with a the thermal expansion coefficient matching with a substrate can be prepared and can be printed onto the surface of substrates like glass and ceramics, and a glass fluorescent layer can be obtained after sintering of the printed substrates; the prepared glass fluorescent layer can be used to replace a silica gel or integral glass type white light LED fluorescent layer and enables the problems of easy aging and air-slaking of silica gel, high cost and complex preparation of the integral glass type white light LED fluorescent layer and the like to be overcome; the preparation process for the glass fluorescent layer prepared in the invention costs little, and the prepared glass fluorescent layer has good luminous performance and is applicable to the fields like packaging application of LEDs.

Owner:王双喜

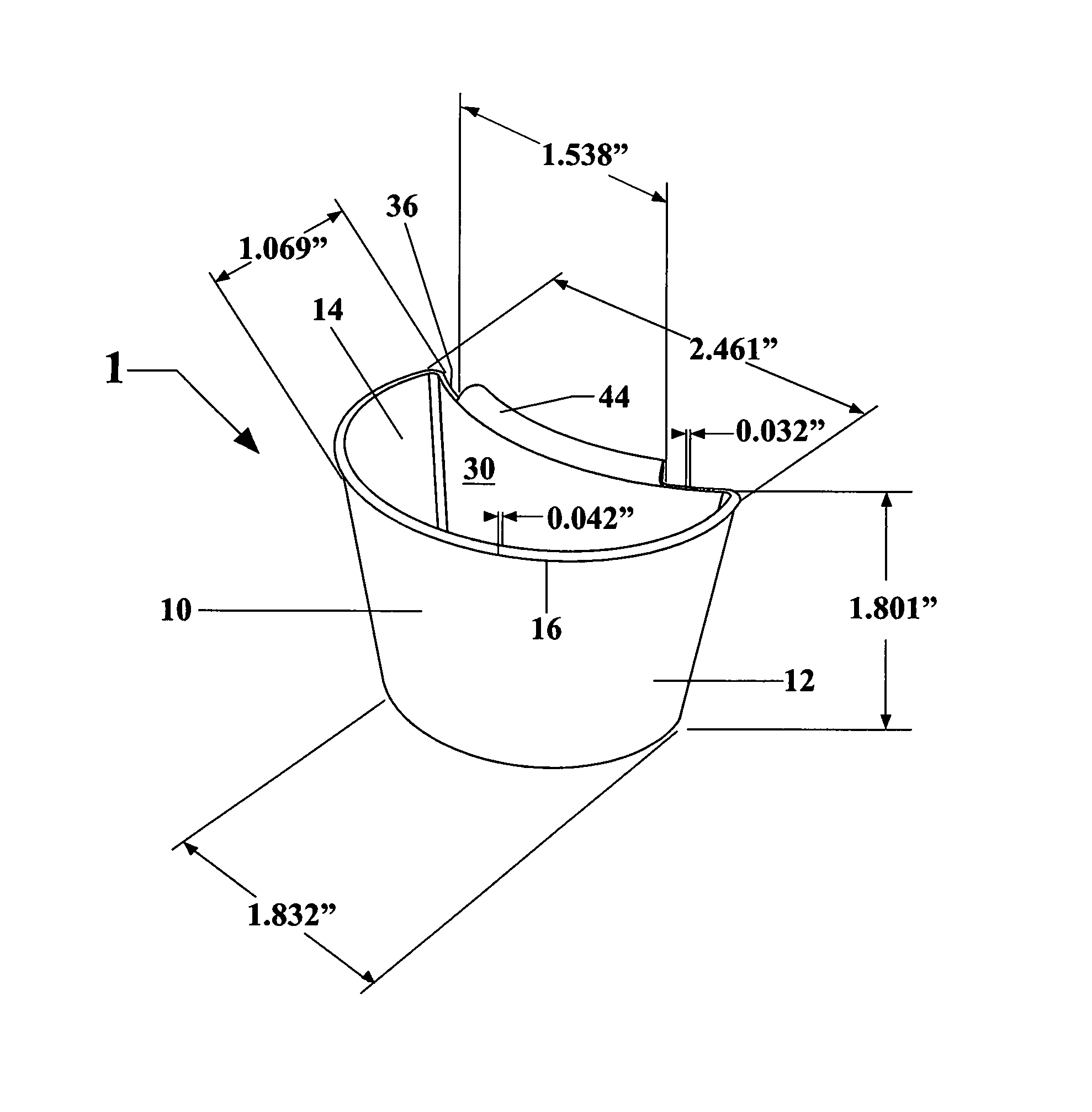

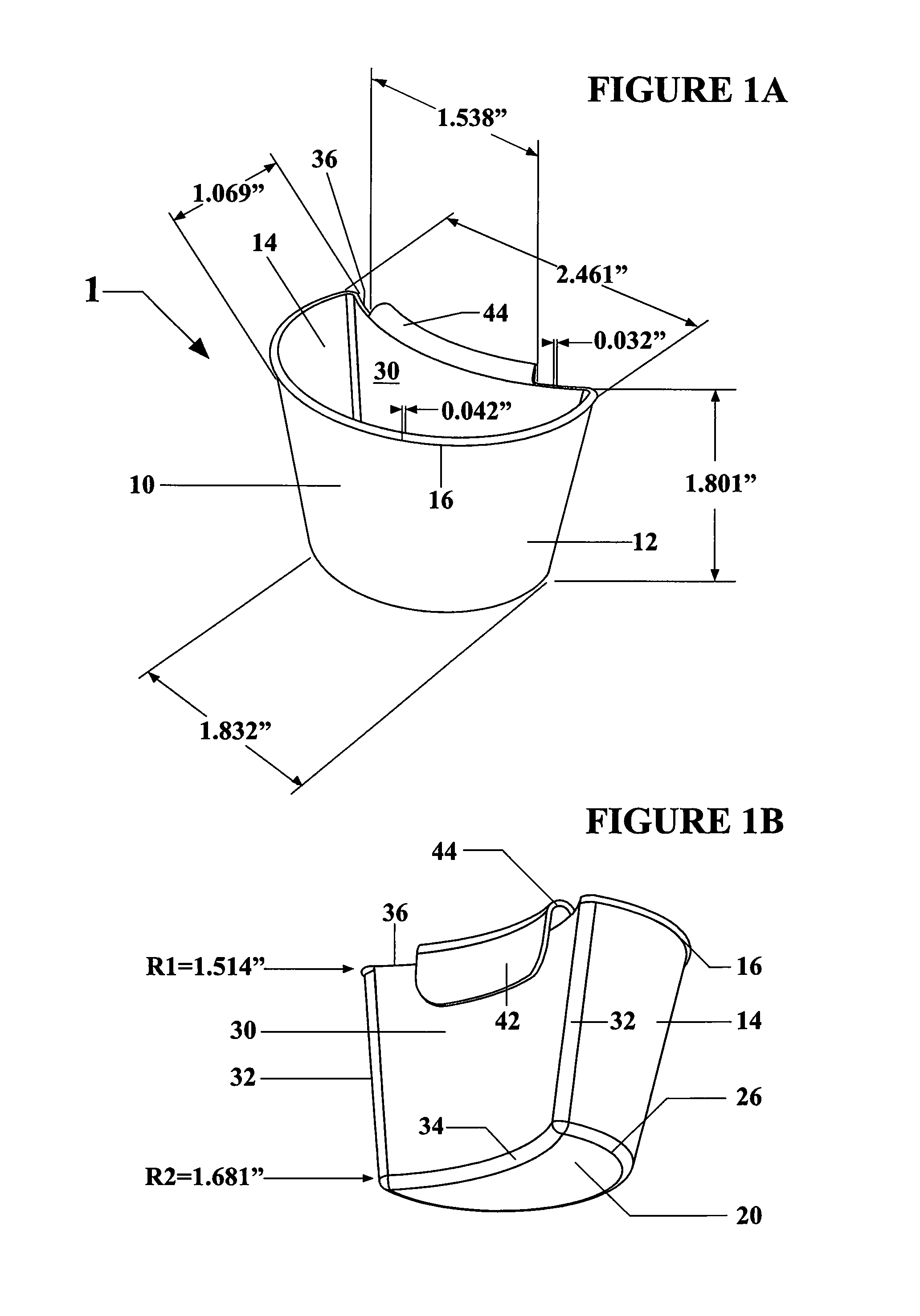

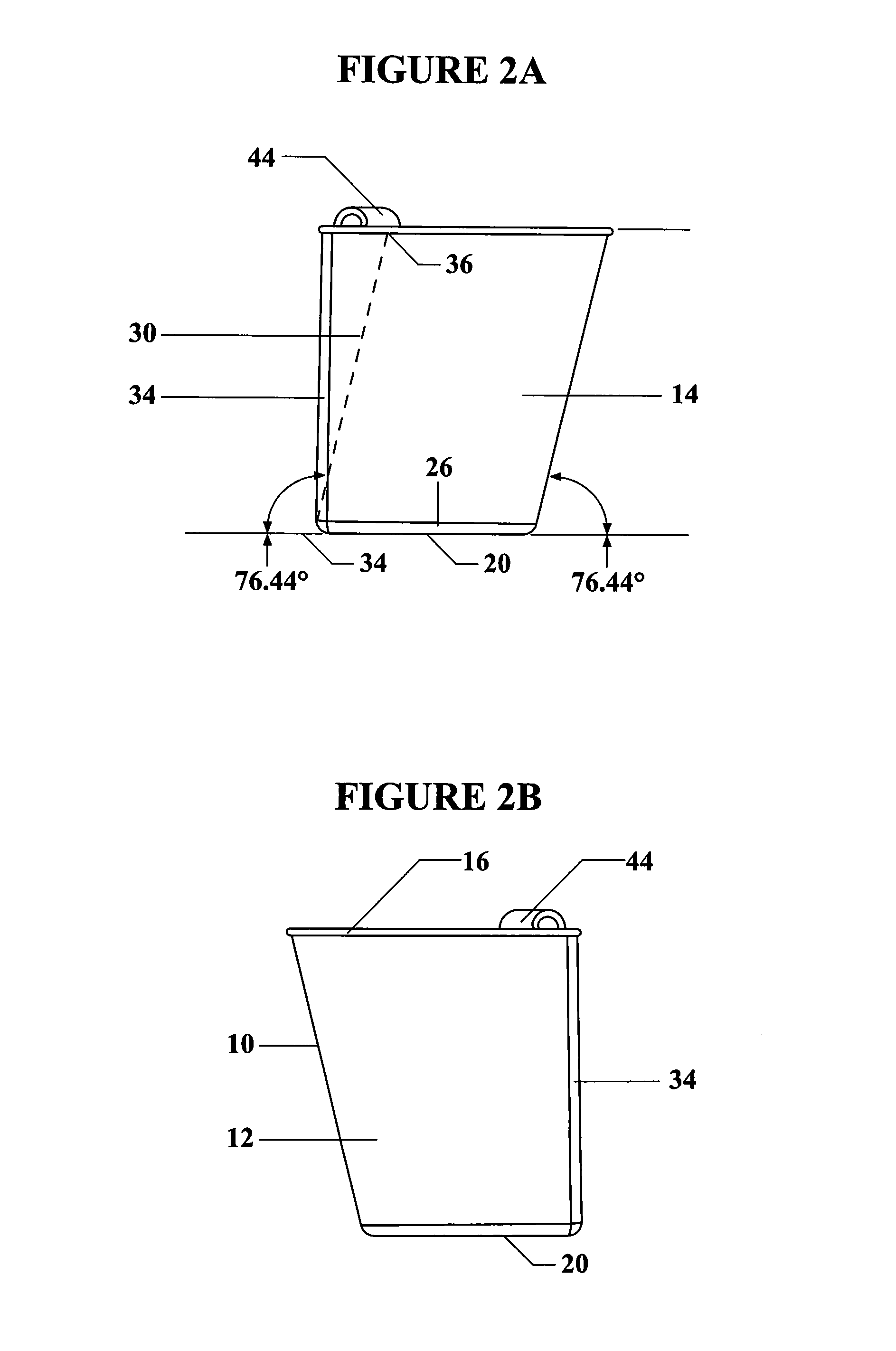

Clip on shot glasses and clip on pockets

InactiveUS9119490B1Increase salesEasy to packServing trayOther artistic work equipmentsCardboardGlasses type

Attachable and detachable shot glass and pocket type accessories having a clip on one side for allowing the shot glass type accessories to securely clip onto exterior edges of larger beverage containers, such as glasses, plastic container, paper and cardboard cups, while keeping top of the shot glass and the liquid contents in the shot glass level with the top of and the liquid contents in the larger beverage container, such as beverage glasses, coffee and tea and beverage cups, on insulation sleeves on cups, and the like. The shot glass can hold extra liquids, such as alcohol and non-alcohol therein, as well as hold sweeteners, creams, and the like. The shot glass is attachable to containers of other edible substances, such as desserts to hold toppings in the shot glasses. Shot glasses can be used to hold paints clipped on a container holding painting supplies, such as brushes.

Owner:GETMUGSHOT

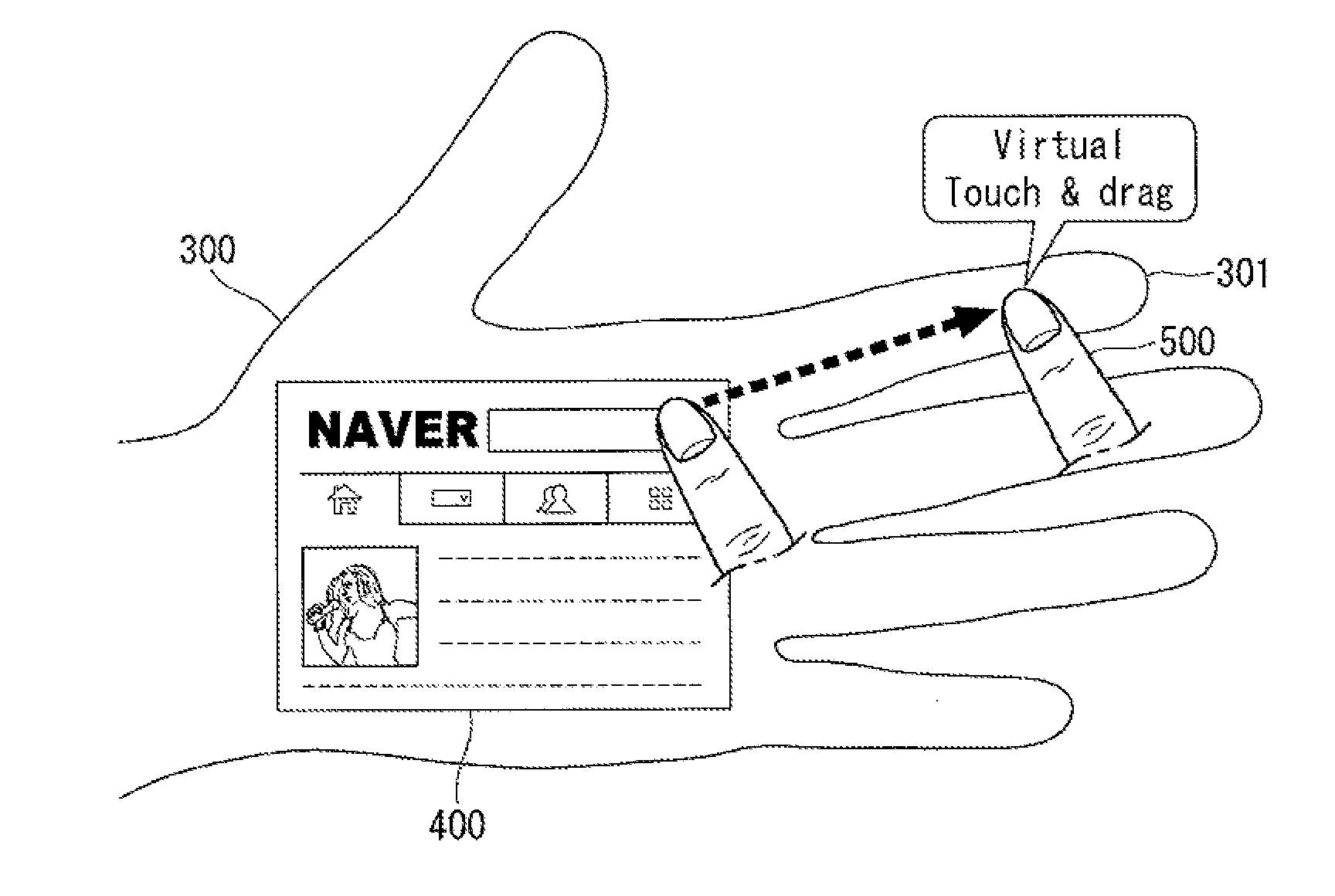

Glass type mobile terminal

ActiveUS20150253862A1Stop executionInput/output for user-computer interactionCathode-ray tube indicatorsGlasses typeDisplay device

A glasses type mobile terminal including a camera configured to obtain an image; a display unit including a transparent display; and a controller configured to recognize a user is gazing at their hand, display an execution screen in a first transparent display area corresponding to a palm of the hand, recognize a first gesture corresponding to a virtual connection between the execution screen and a specific finger, associate the execution screen with the specific finger upon recognition of the first gesture, display a first item indicating association of the execution screen with the specific finger in a second transparent display area corresponding to the specific finger, recognize a second gesture of virtually connecting the first item with the displayed execution screen corresponding to the palm of the hand, and display a result of executing the first item to the application in the first transparent display area.

Owner:LG ELECTRONICS INC

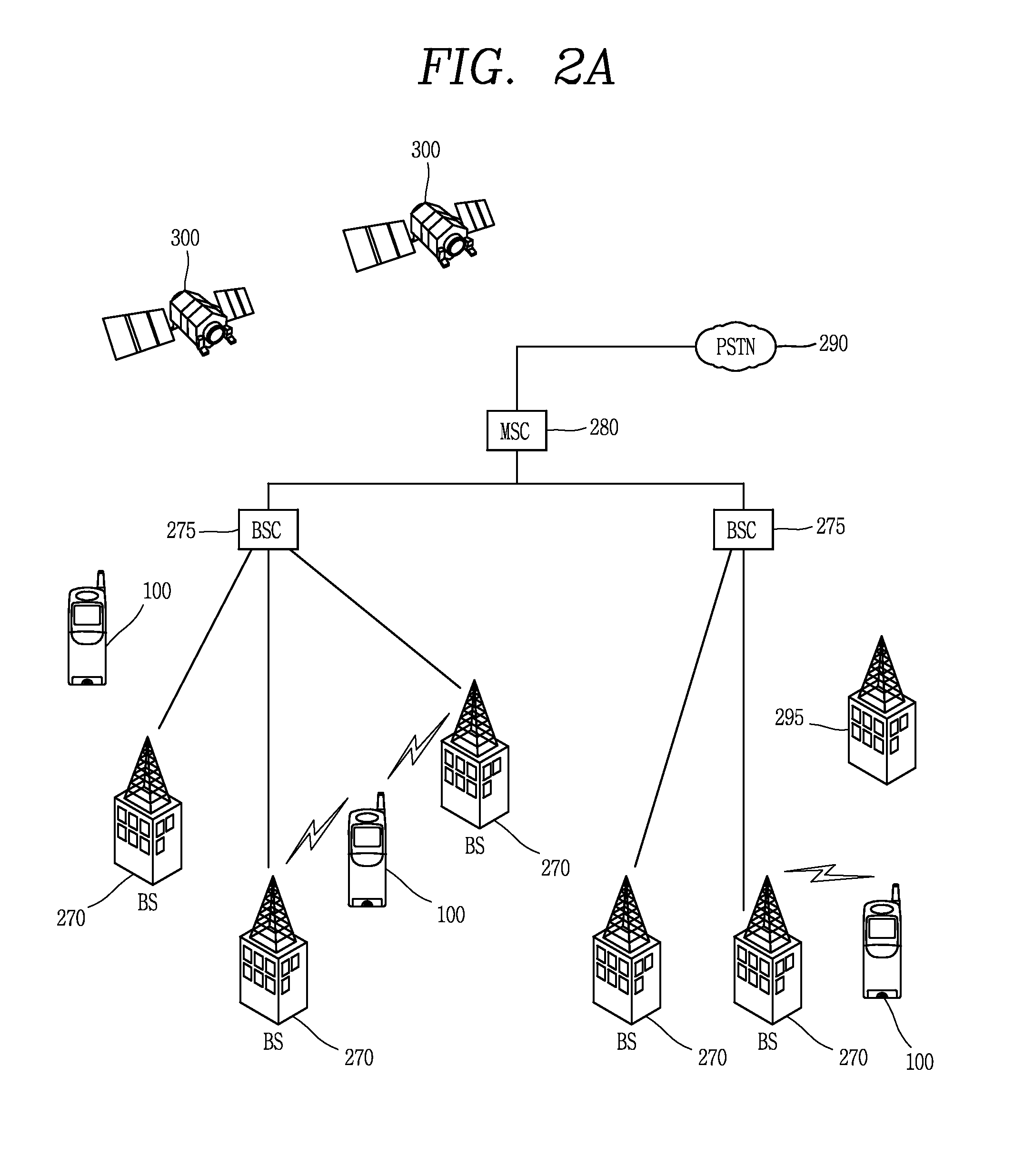

Wearable glass-type terminal, system having the same and method of controlling the terminal

ActiveUS20150061969A1Restrict transmissionInput/output for user-computer interactionCathode-ray tube indicatorsCommunication unitGlasses type

The present disclosure provides a wearable glass-type terminal including a body that is formed to be worn on a user's face, a wireless communication unit that is wirelessly connected to an input device and a plurality of output devices and configured to receive data from the input device and transmit data to the output devices, a camera that is mounted to the body and configured to detect one of the plurality of output devices, and a controller that is configured to control the wireless communication unit to transmit data received from the input device to the output device detected by the camera.

Owner:LG ELECTRONICS INC

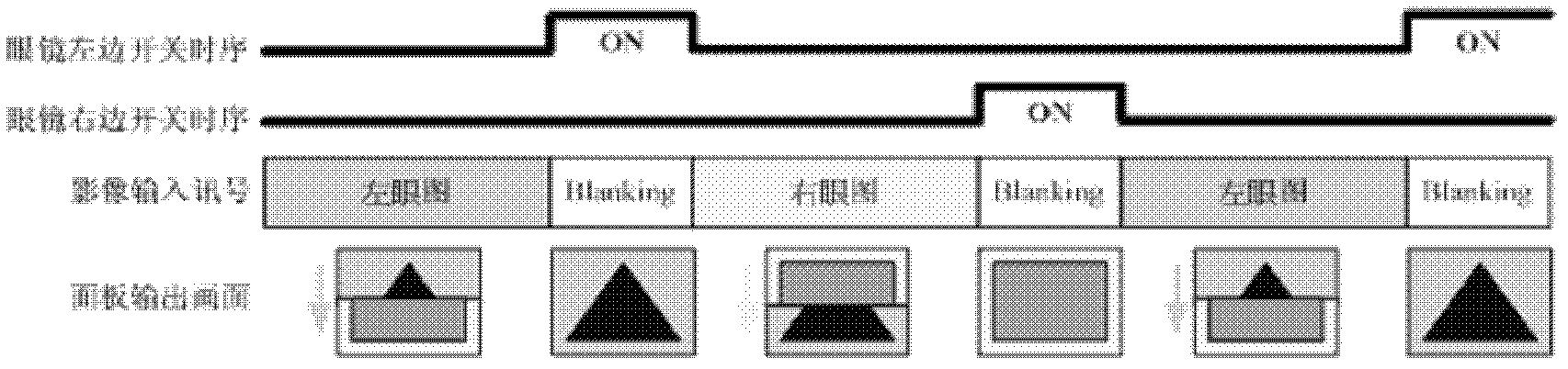

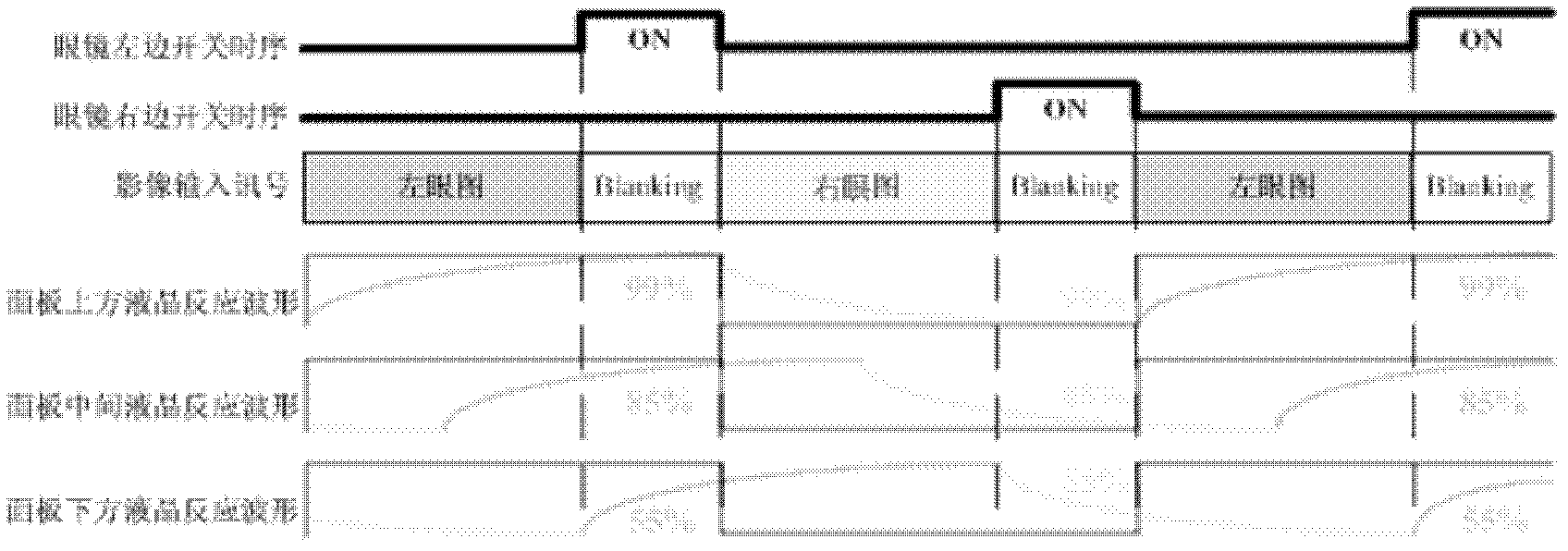

Stereoscopic display

InactiveCN102196293AImprove efficiencyLow costStatic indicating devicesSteroscopic systemsDisplay deviceService efficiency

The invention discloses a stereoscopic display which comprises a display panel, a controller for glasses, an image controller and a backlight controller, wherein the display panel is divided into N blocks; the controller for the glasses is used to control open and close of a left glass and a right glass; the image controller is used to generate an image data enable signal; the backlight controller is used to control open and close of each block backlight; the display panel receives a left eye image signal, a right eye image signal, a left eye backlight signal and a right eye backlight signal and displays a left eye picture or a right eye picture based on these signals. In the invention, a region type backlight is adopted, the synchronization of backlight and liquid crystal display scanning is utilized and the problem of left and right images interference (Corsstalk) of the stereoscopic display is solved without increasing circuit cost; as the backlight of the display disclosed by the invention can be lightened when opening the glasses (the left glass or right glass), therefore, the service efficiency of the backlight is higher than that of the traditional on-and-off glass type stereoscopic display with a constant light of backlight and the power consumption can be saved.

Owner:NANJING CEC PANDA LCD TECH

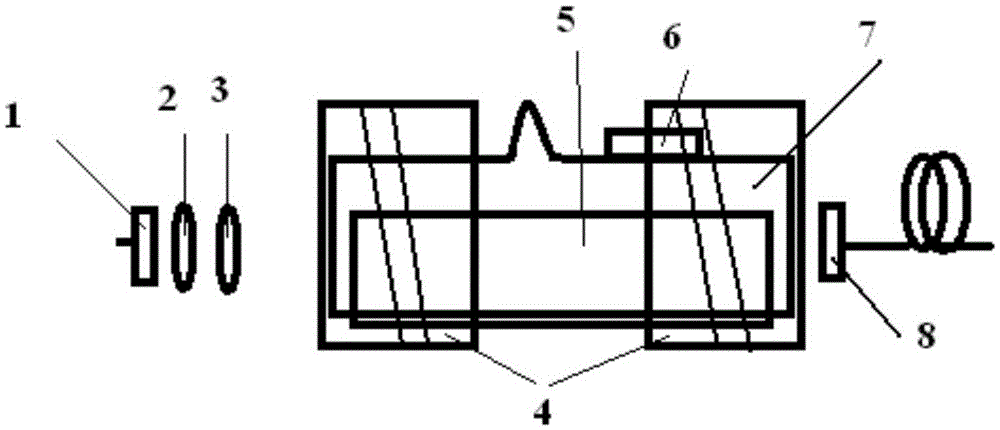

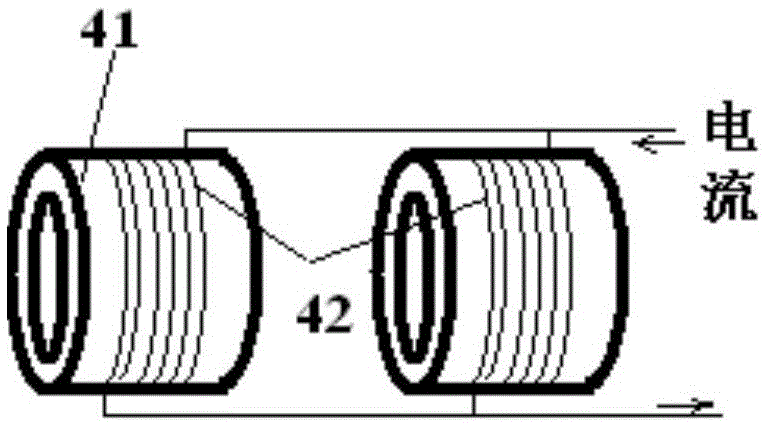

Small CPT atomic clock physical system

ActiveCN105467822AImprove stabilityUniform magnetic field distributionApparatus using atomic clocksFrequency stabilizationHelmholtz coil

The invention relates to a small CPT atomic clock physical system, and belongs to the technical field of atomic frequency standard. The physical system comprises a laser portion and an atom air chamber portion. The laser portion comprises a VCSEL laser tube, an aperture diaphragm, and a [lambda] / 4 wave plate. The atom air chamber portion comprises an atom air chamber, a C field coil, a thermistor, a low electromagnetic film electric heating sheet, and a photoelectric detector. The C field coil uses a reverse Helmholtz coil structure to realize. Heating methods of the low electromagnetic film electric heating sheet and high-frequency AC electric heating are used to heat the atom air chamber. The system uses a vacuum heat insulation technology to package. The output frequency of the physical system is high in stability, stable in performance, small in volume, low in power consumption, and low in cost, and is especially suitable to be used for a glass type atom air chamber whose sealing port is on the central position of a cylindrical surface.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

Glass-type planar substrate, use thereof, and method for the production thereof

ActiveUS20060110893A1Good thermal compatibility of materialLow costDecorative surface effectsSemiconductor/solid-state device detailsGlasses typeSemiconductor materials

The invented method is distinguished by a combination of the following method steps: provision of a semiconductor planar substrate composed of a semiconductor material, reduction of the thickness of the semiconductor planar substrate inside at least one surface region of the semiconductor planar substrate in order to form a raised surface region in relation to the surface planar region of reduced thickness, structuring the raised surface region of the semiconductor planar substrate by means of local mechanical removal of material in order to place impressions inside the raised surface regions, joining the structured surface of the semiconductor planar substrate with the glasslike planar substrate in such a manner that the glasslike planar substrate at least partially covers the surface planar region of reduced thickness, tempering the joined planar substrates in such a manner that in a first tempering phase, which is conducted under vacuum conditions, the glasslike planar substrate covering the surface region of reduced thickness forms a fluid-tight bond with the surface region of reduced thickness, with the planar substrate covering the impressions in a fluid-tight manner under vacuum conditions, and that in a second tempering phase, at least partial areas of the glasslike material flow into the impressions of the structured surface of the semiconductor planar substrate.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

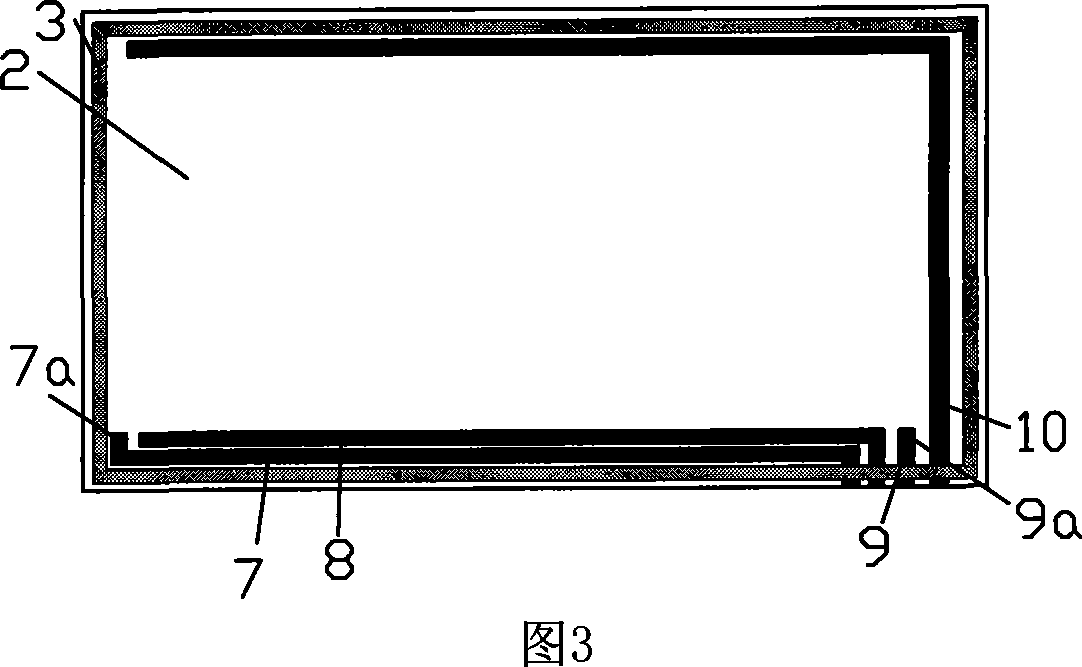

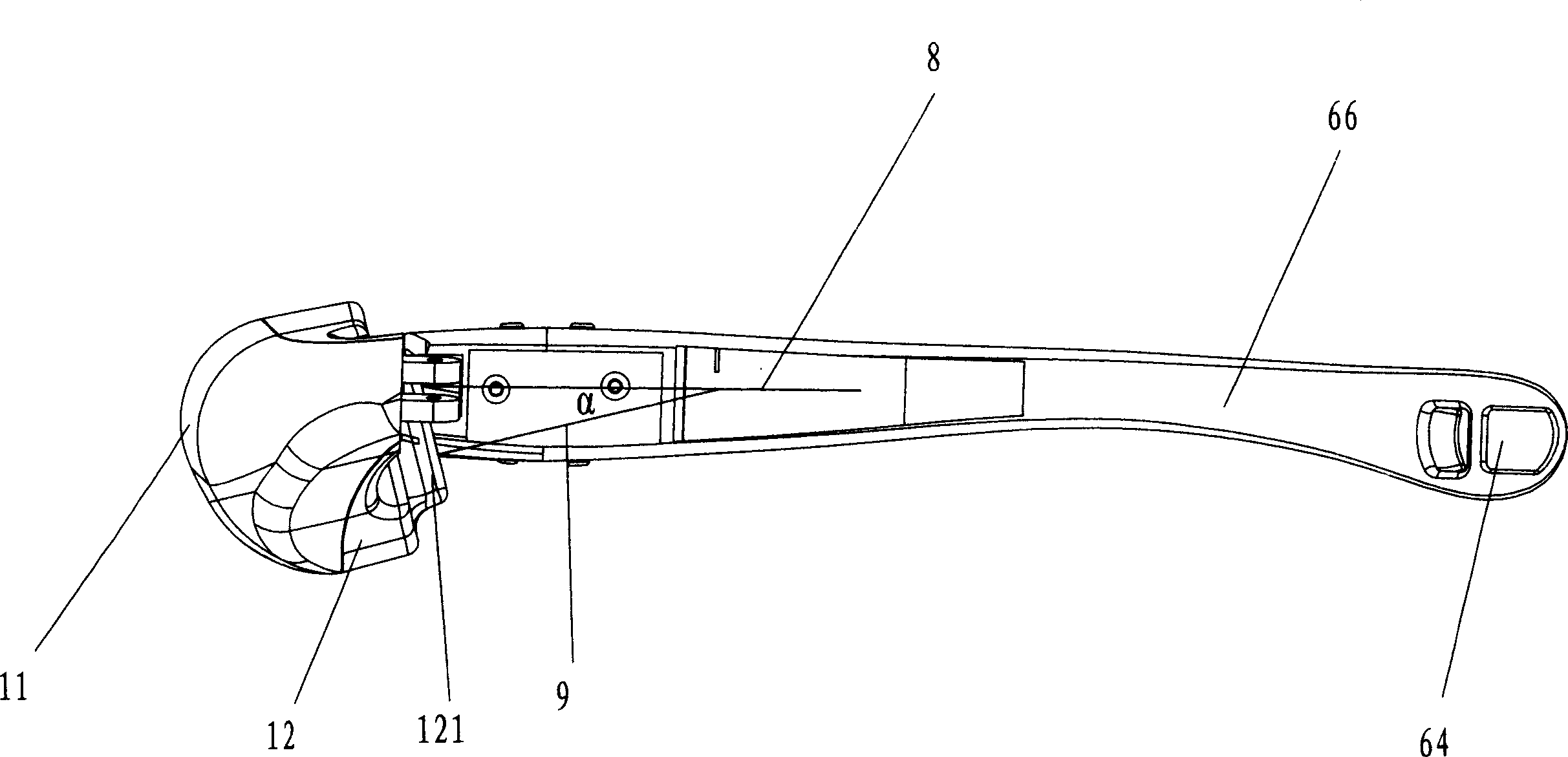

Method and device for preventing eye tiredness in wearing head-wearing glasses display

InactiveCN1908729ADoes not cause eye fatigueEliminate or reduce stressOptical elementsGlasses typeNose

The disclosed method to prevent fatigue when wearing glass-type display comprises: letting the top edge of system image level or lower than people horizontal sight line, and keeping the included angle alpha between horizontal sight line and image normal line in -25~-10deg, wherein the device comprises: a body 1 with front / back shell 11 / 12, a left / right lens root 6 / 5, a glass frame 4, a PCB 2, an image display module 3, a glass interface 61 connected with input end of PCB 2 and external signal, an image wafer 3 connected with output of 61, a window plane 121 behind 12, and a nose frame 7. This invention has benefit for people health.

Owner:深圳市亿特联合显示技术有限公司

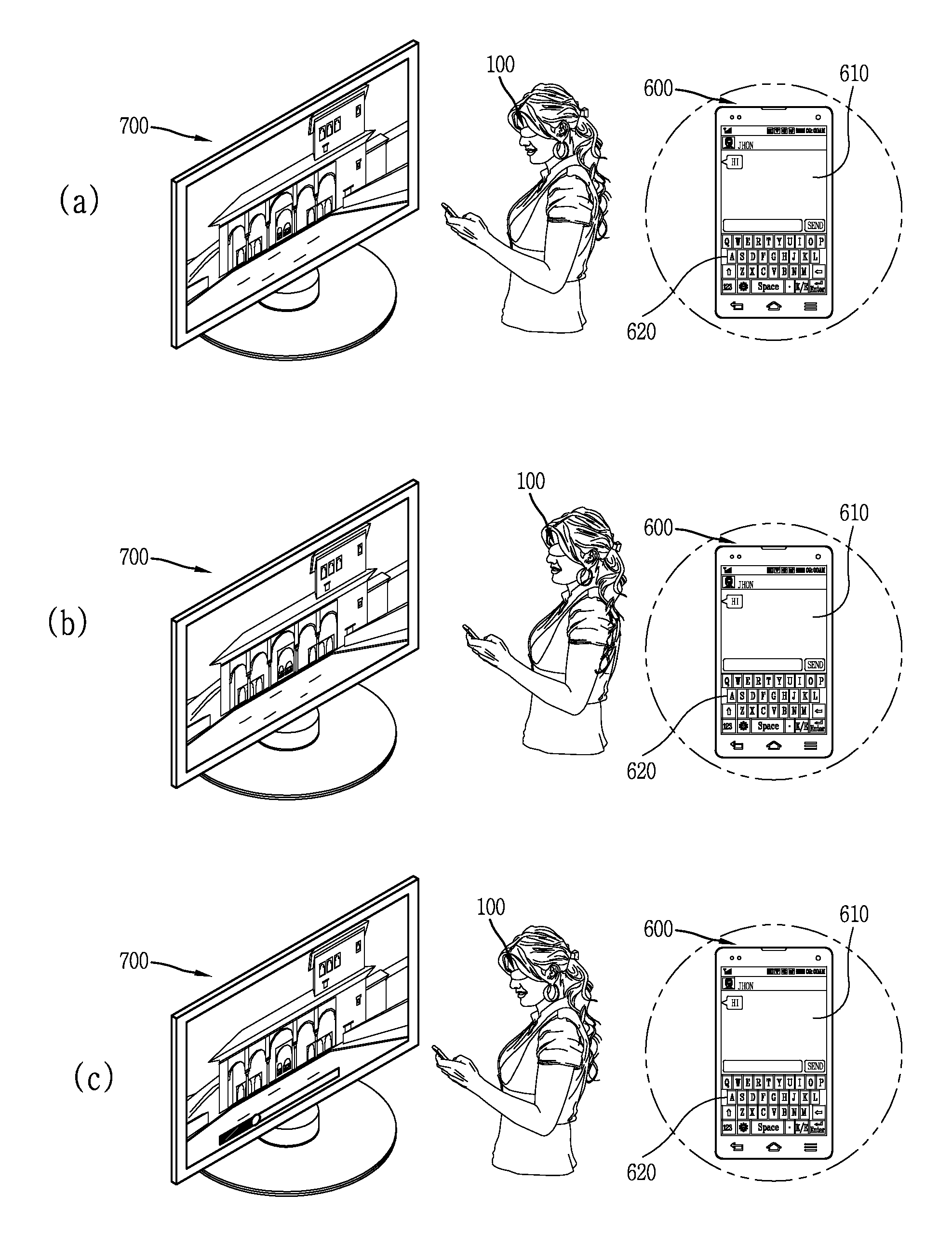

Mobile terminal, glasses-type terminal, and mutual interworking method using screens thereof

InactiveUS20160054567A1Privacy protectionCharacter and pattern recognitionCathode-ray tube indicatorsGlasses typeScreen sharing

Disclosed are a mobile terminal, a glasses-type terminal, and a mutual interworking method through sharing of screens thereof. The mobile terminal includes: a memory configured to store therein a setting for a screen sharing mode; a display unit configured to display a terminal screen; and a controller configured to execute content sharing by changing the terminal screen according to a function being executed on a glass screen, if the terminal screen and the glass screen are overlapped with each other, after the terminal screen enters a camera region of the glass terminal.

Owner:LG ELECTRONICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com