Patents

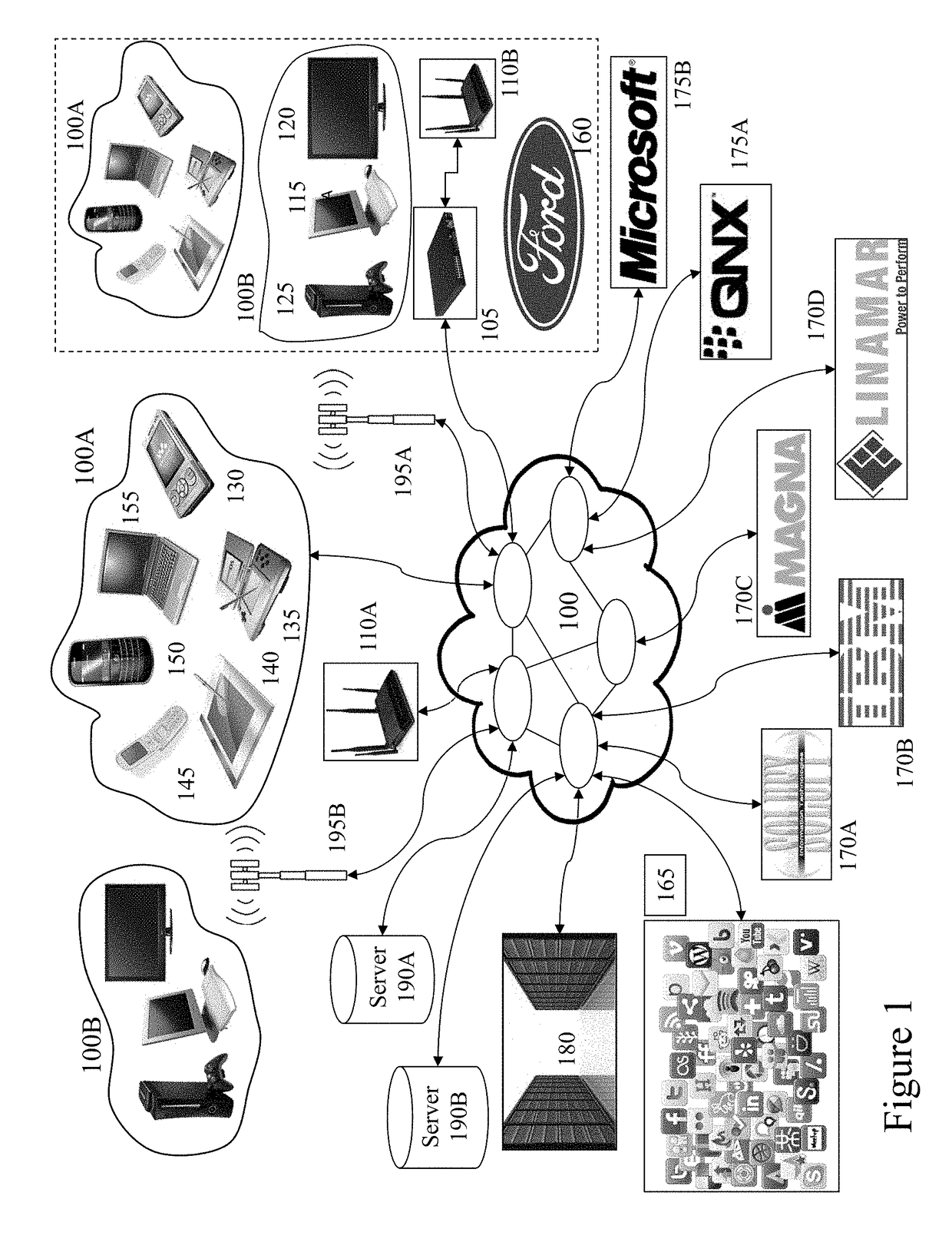

Literature

103 results about "Kanban" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Kanban (看板) (signboard or billboard in Japanese) is a scheduling system for lean manufacturing and just-in-time manufacturing (JIT). Taiichi Ohno, an industrial engineer at Toyota, developed kanban to improve manufacturing efficiency. Kanban is one method to achieve JIT. The system takes its name from the cards that track production within a factory. For many in the automotive sector, kanban is known as the "Toyota nameplate system" and as such the term is not used by some other automakers.

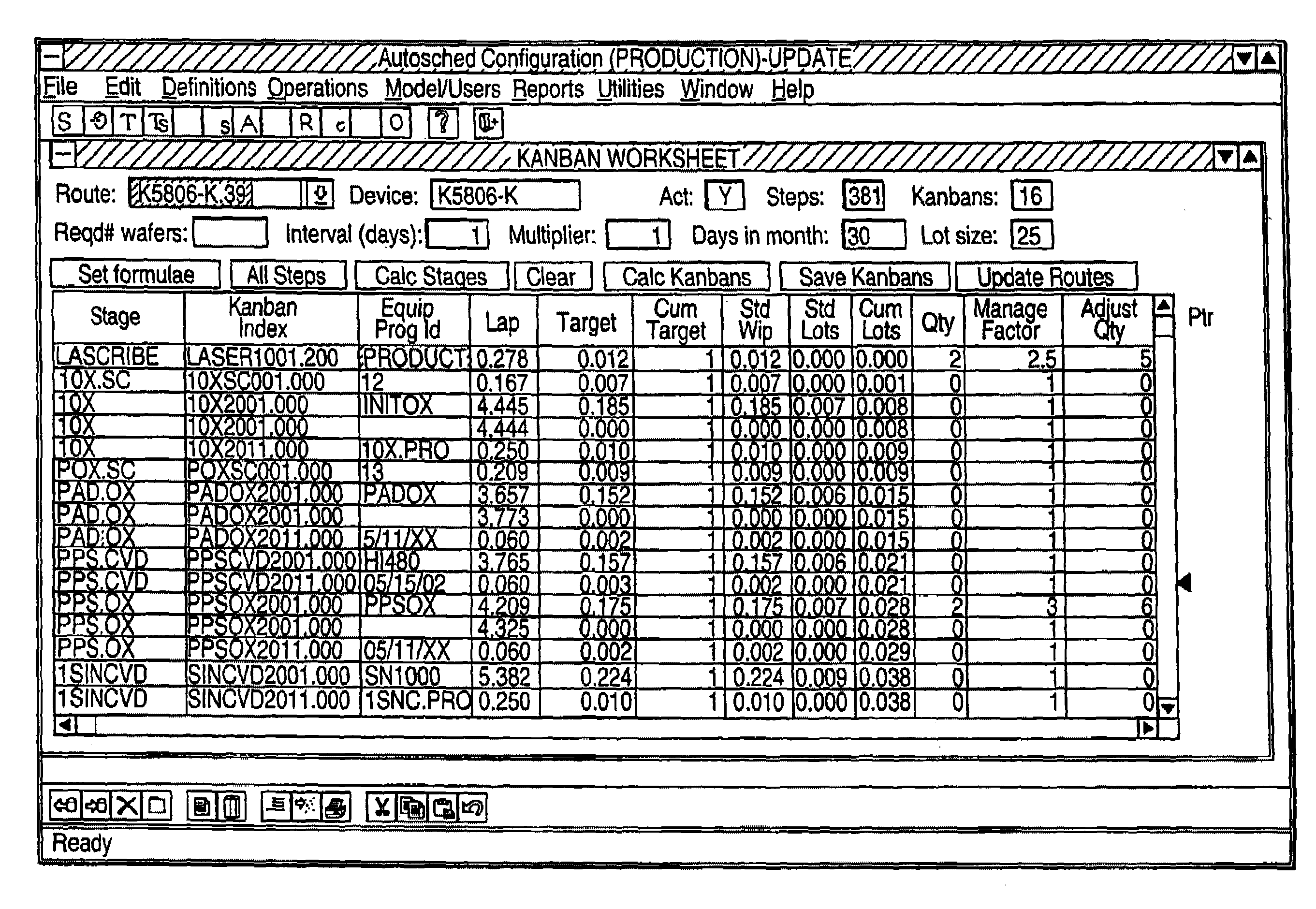

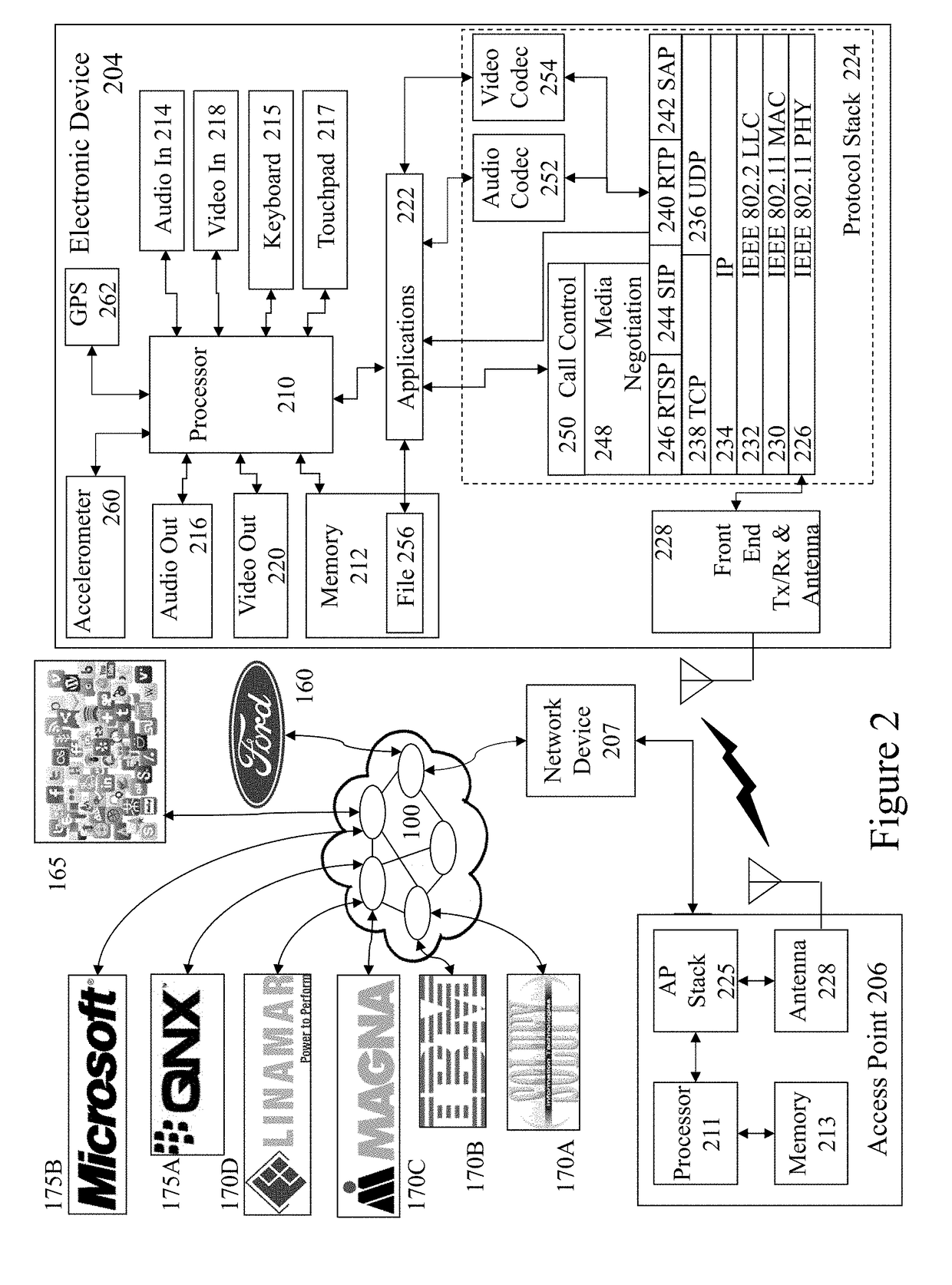

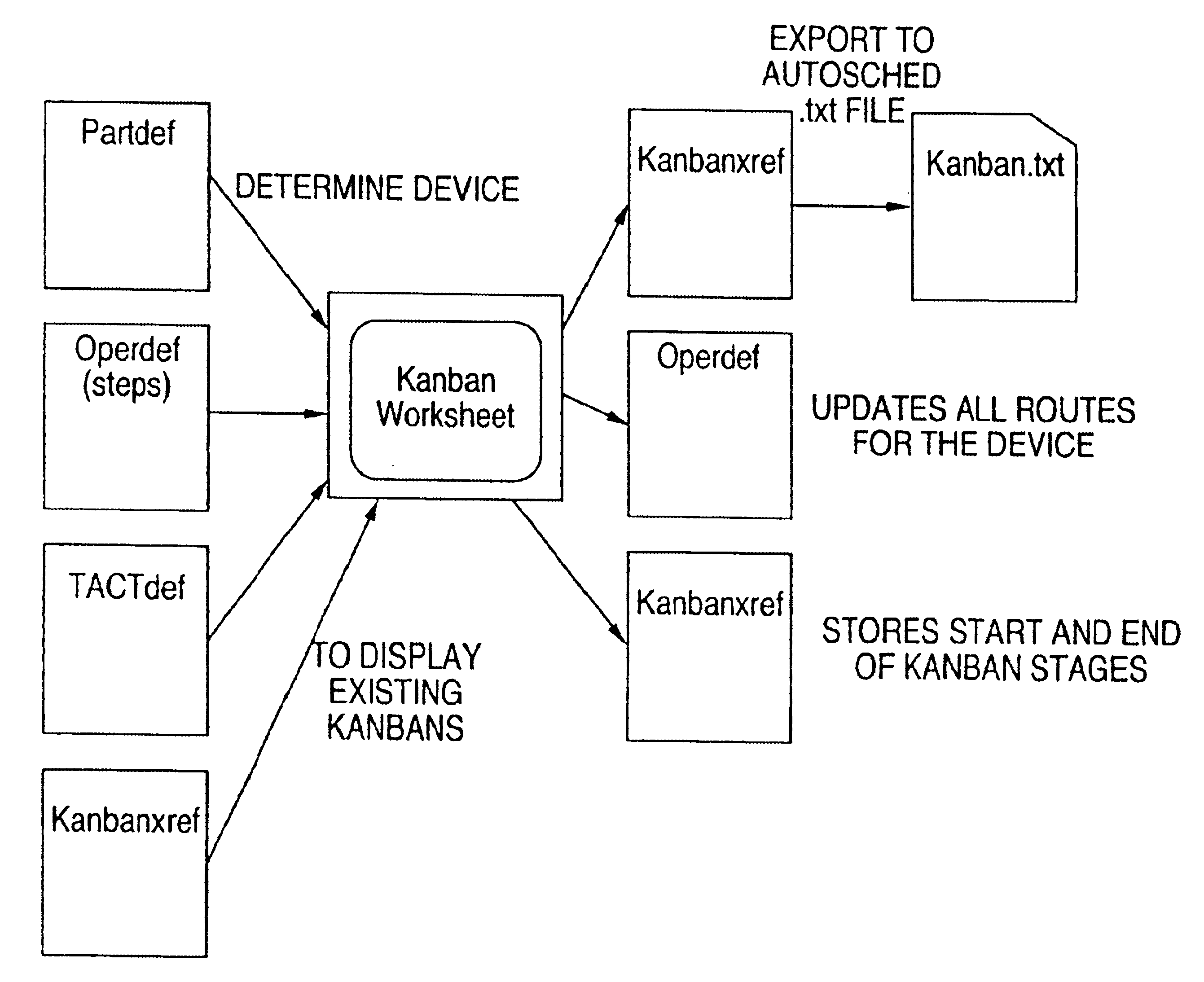

Electronic Kanban worksheet for the design and implementation of virtual or electronic Kanban systems

InactiveUS7020594B1ForecastingSpecial data processing applicationsManufacture execution systemSystems design

An integrated wafer fab production characterization and scheduling system incorporates a manufacturing execution system with a scheduling system based on simulation. The integrated characterization / scheduling system provides manufacturing with a simulation tool integrated with the manufacturing execution system to evaluate proposed production control logic as a practical alternative to expensive experimentation on actual production system. Furthermore, simulation models are used to create short term dispatch schedules to steer daily manufacturing operations towards planned performance goals. Innovative features include integration of preventive maintenance scheduling, Kanban based WIP control, an integrated time standard database, a, and real time lot move updates.

Owner:SONY CORP +1

Project and resource planning methods and systems

InactiveUS20180053127A1Improve visualizationResourcesDigital output to display deviceInventory levelProject planning

The Kanban process-management approach establishes inventory levels at different stages in manufacturing, standardizes batch sizes and signals production / delivery of a new shipment only as a previous shipment is consumed. However, users viewing Kanban charts whilst able to view tasks by different stages within a process have little comprehension of the timing associated with the tasks individually or as a sequence nor of resource workload and availability. Accordingly, a planning and resource tool allowing disparate project planning methodologies to be combined would allow a user to view not only their tasks within a graphical user interface providing comparable features to the user friendly KanBan format but also to allow them to rapidly visualize the inter-relationship of their tasks with the overall process. Such a tool would allow for quick visual identification of issues relating to their and others workload and availability.

Owner:BOILEAU MARIO MR

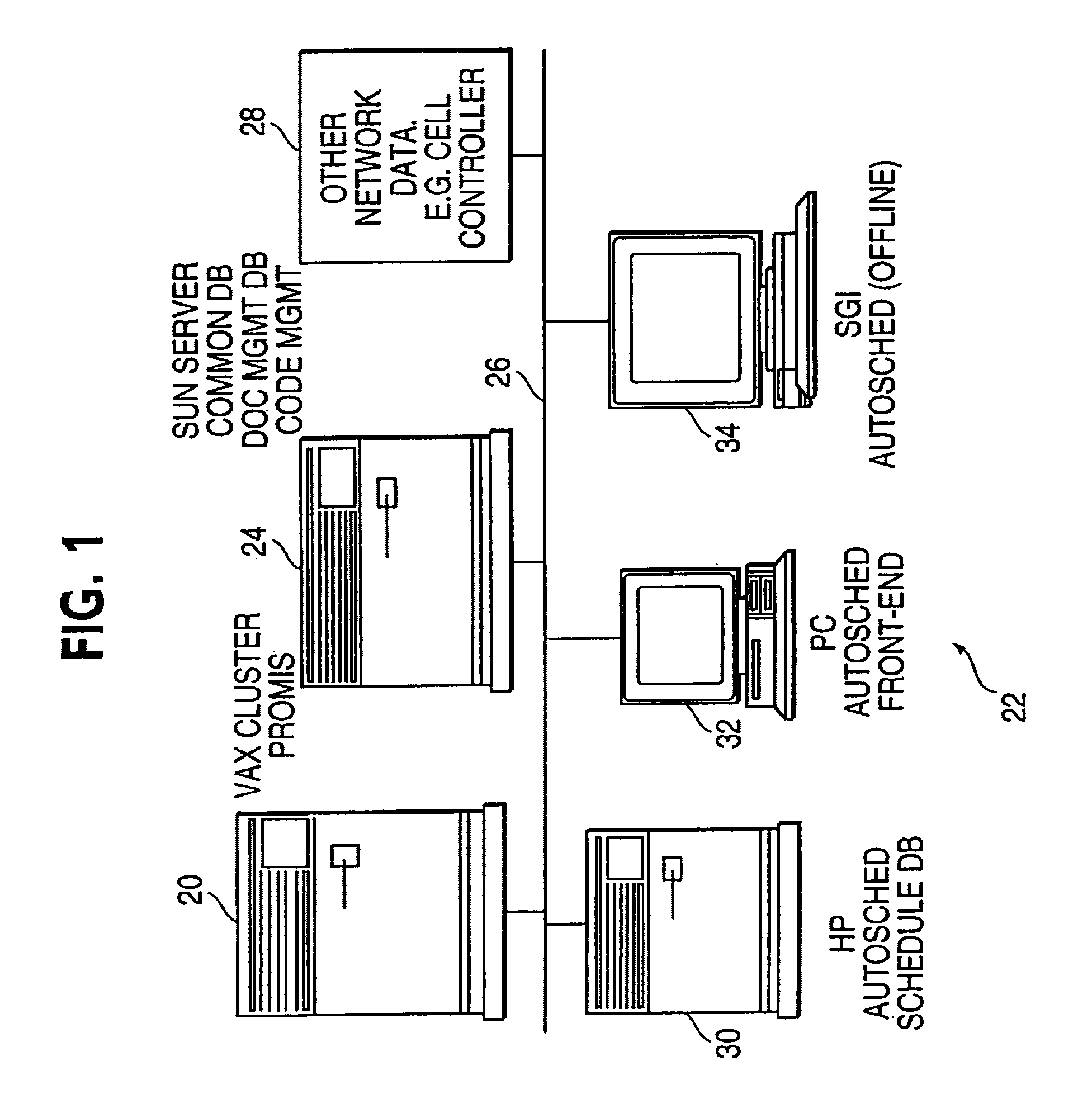

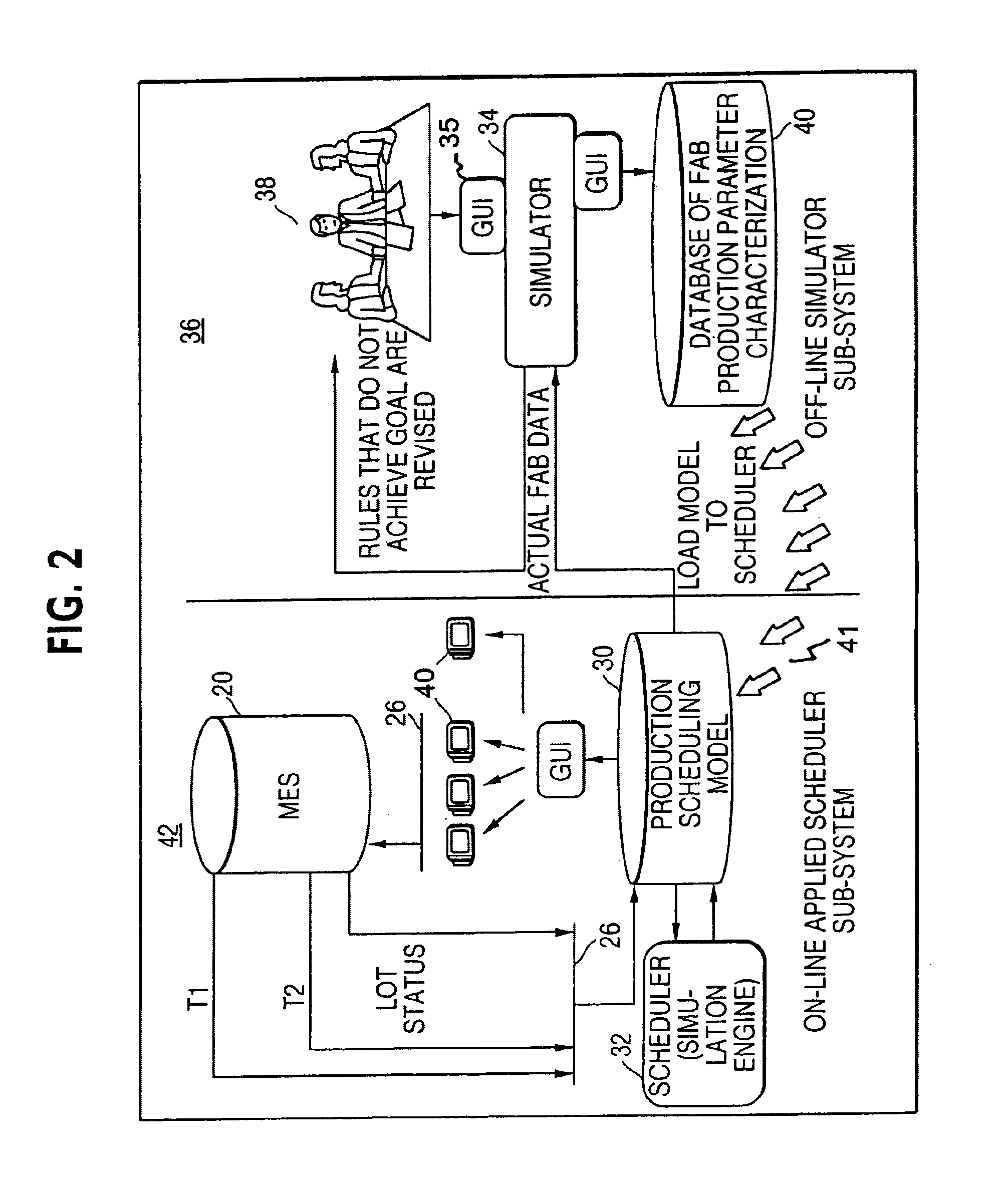

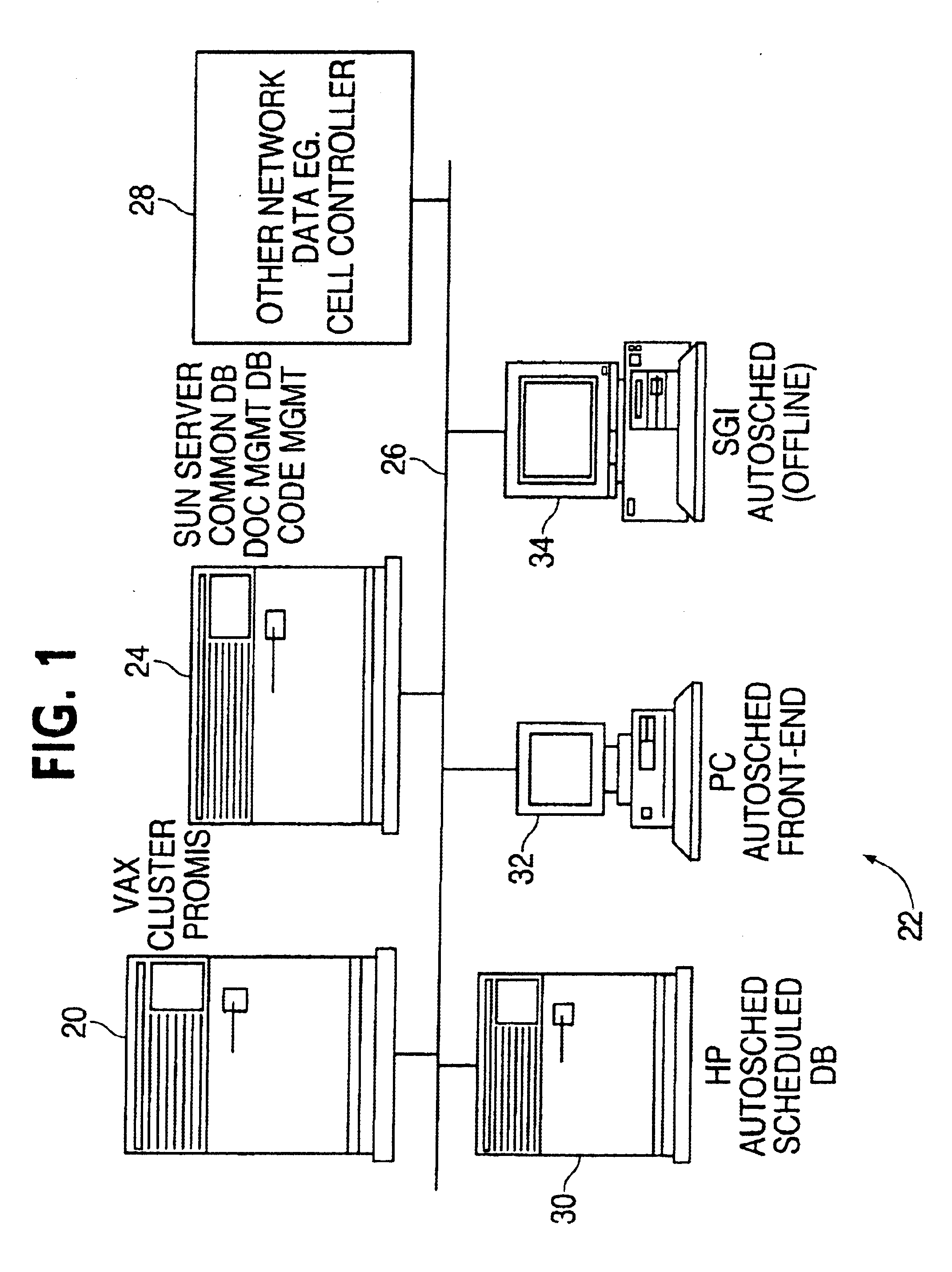

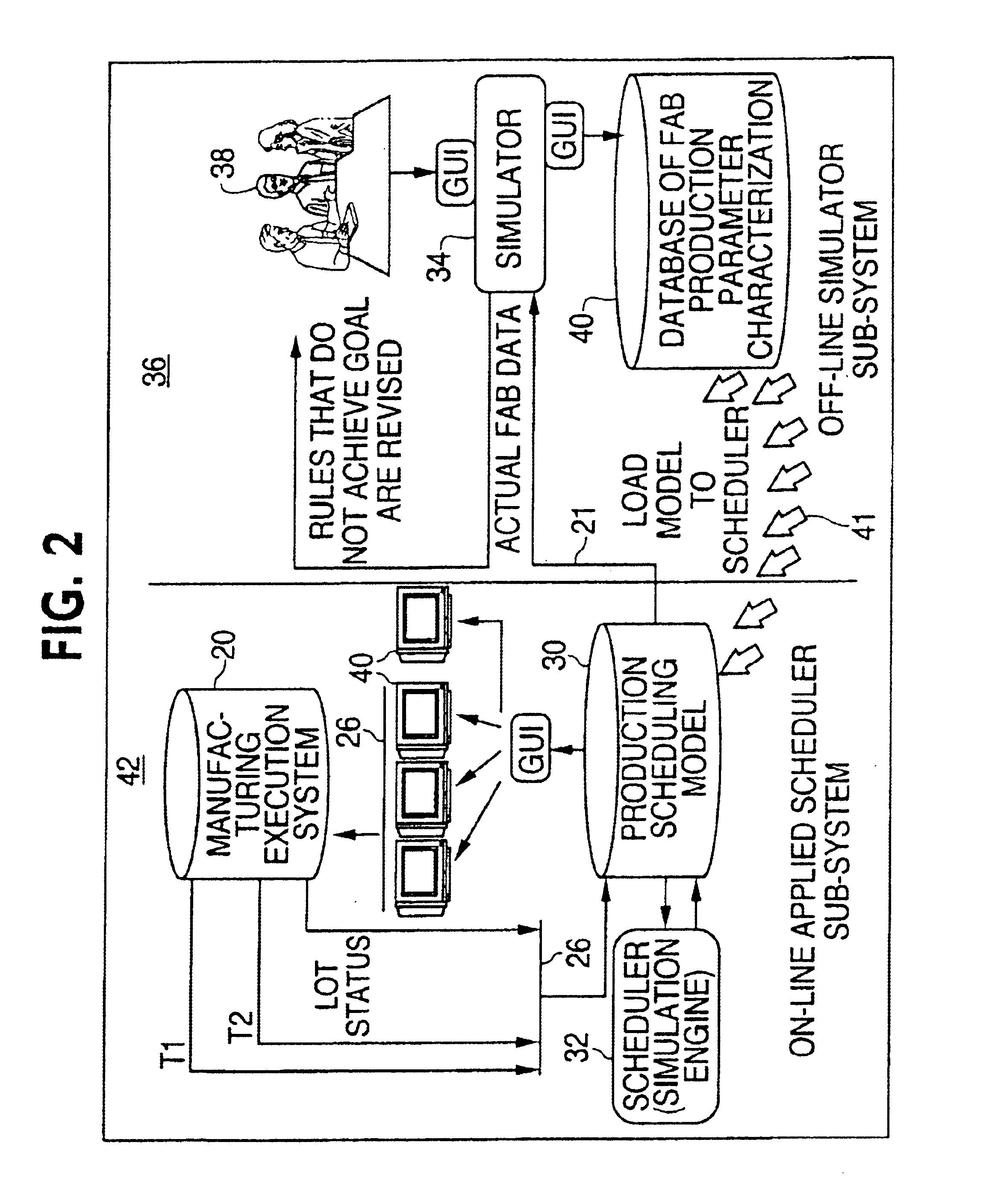

Integrated wafer fabrication production characterization and scheduling system

InactiveUS6889178B1Technology managementTotal factory controlManufacture execution systemWafer fabrication

An integrated wafer fab production scheduling and simulation system incorporates a manufacturing execution system with a scheduling system based on simulation. The integrated system provides manufacturers with a simulation tool integrated with the manufacturing execution system to evaluate proposed production control logic as a practical alternative to expensive experimentation on an actual production system. Furthermore, simulation models are used to create short-term dispatch schedules to steer daily manufacturing operations towards planned performance goals. Innovative features include integration of preventive maintenance scheduling, Kanban based WIP control, an integrated time standard database, and real time lot move updates.

Owner:SONY CORP +1

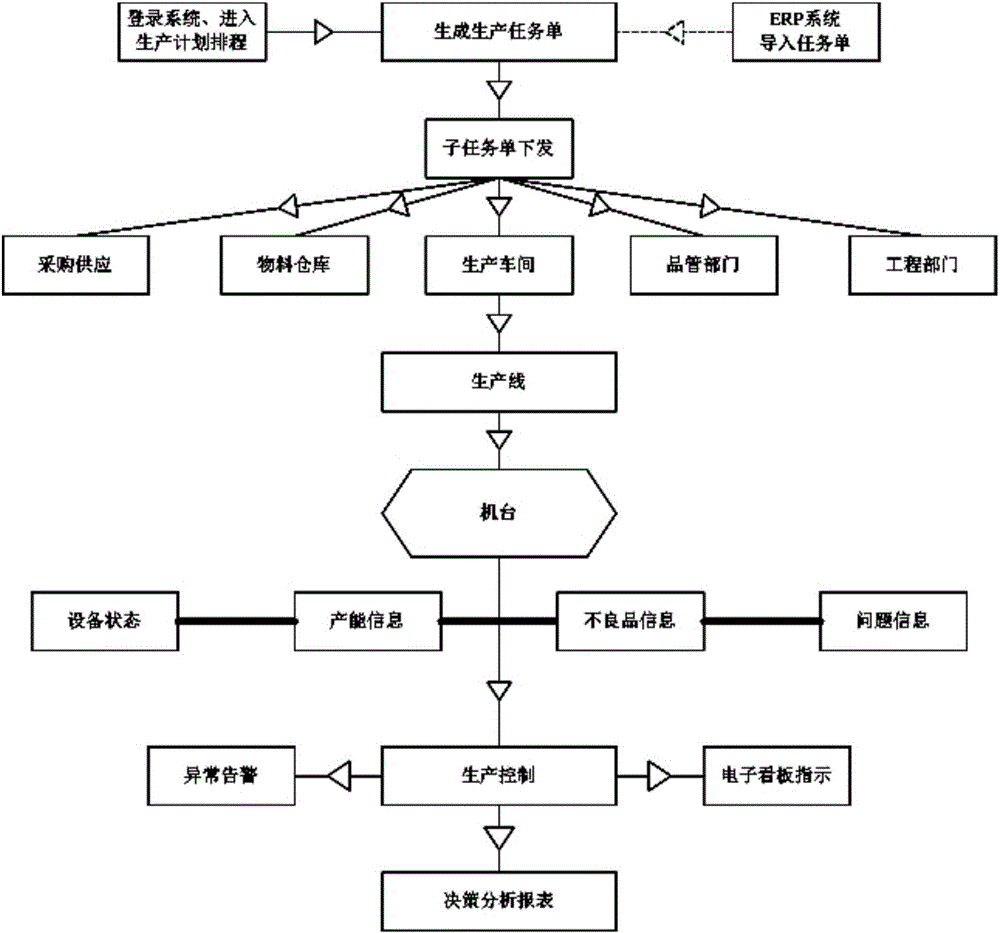

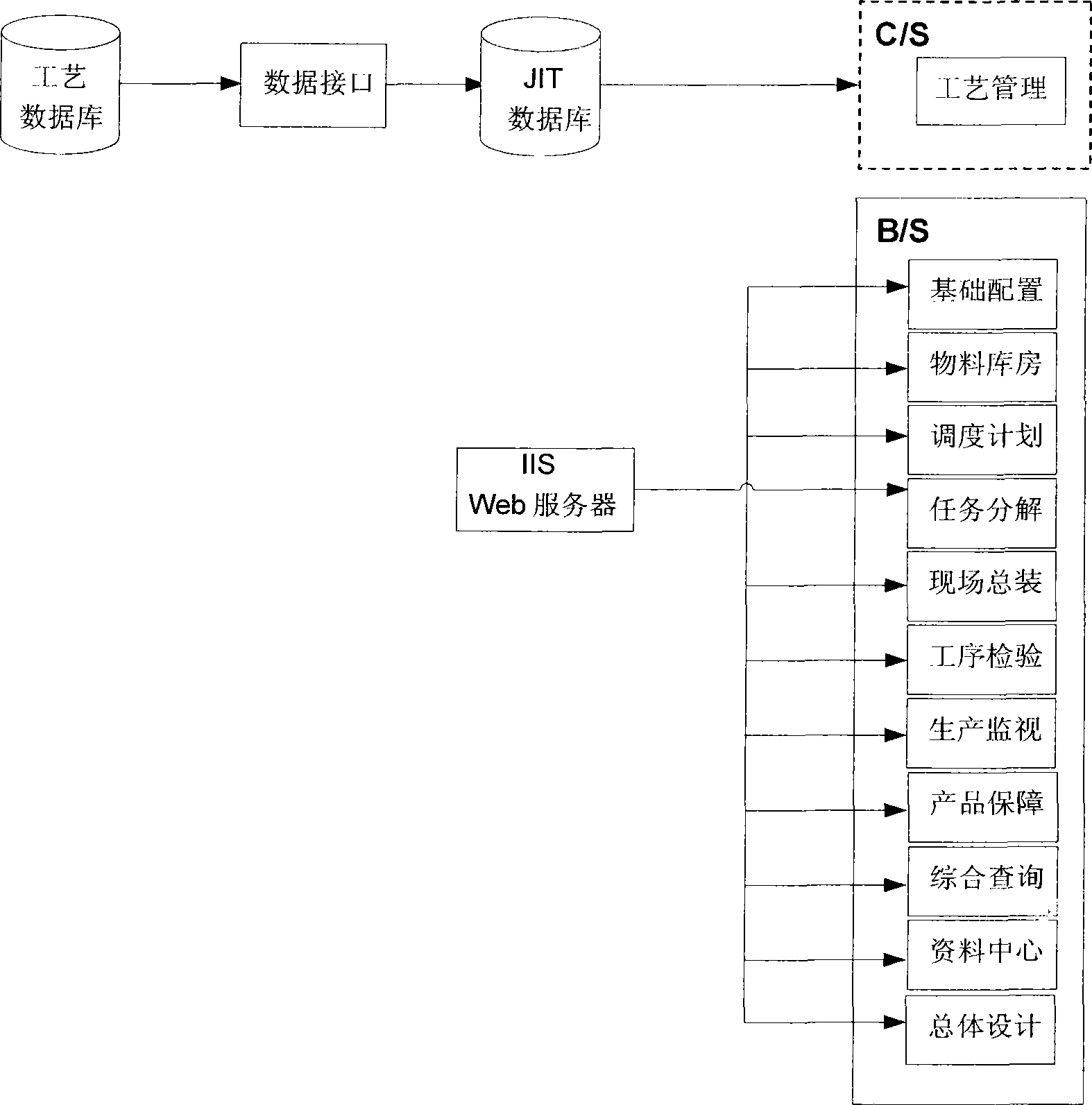

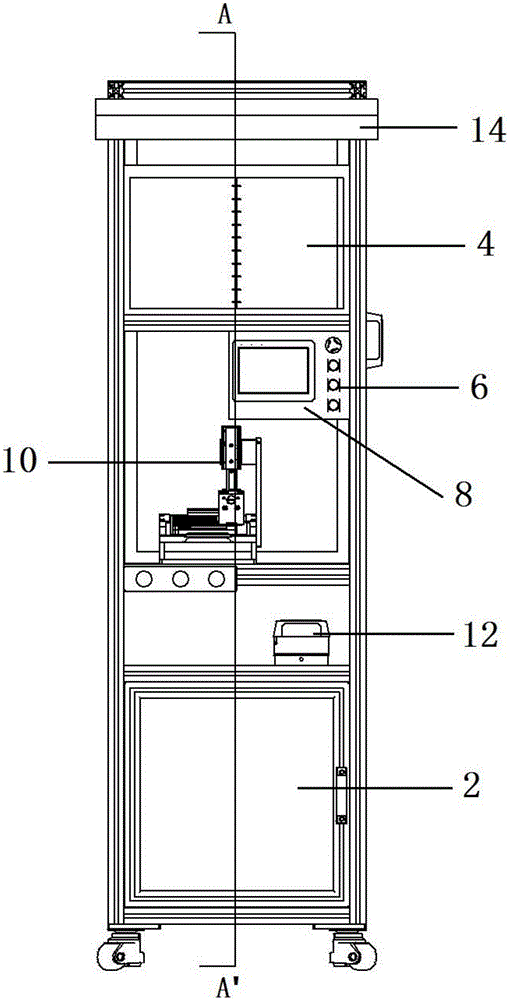

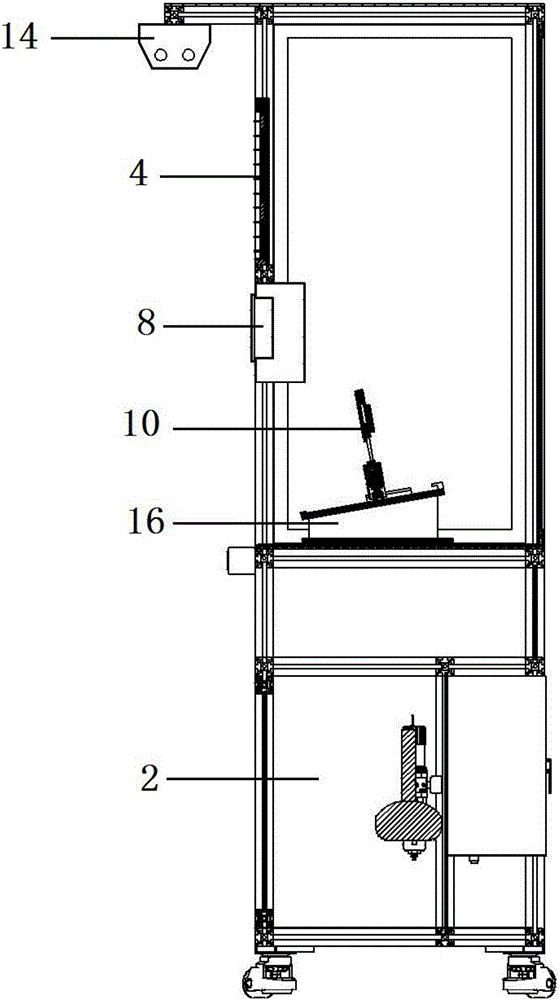

Lean production management kanban system and application method

InactiveCN106779592ASimple designAdvanced architectureOffice automationManufacturing computing systemsData acquisitionPersonal computer

The invention discloses a lean production management kanban system and an application method. The system mainly comprises machine table kanban, comprehensive kanban, a data collector, an industrial personal computer, a server, kanban system software, a call broadcast system, and a special local network. The system has the effects of real-time transmission of production information, transparent management and guarantee of production field work order, and is an effective tool for realizing lean production accurate management.

Owner:林冠良

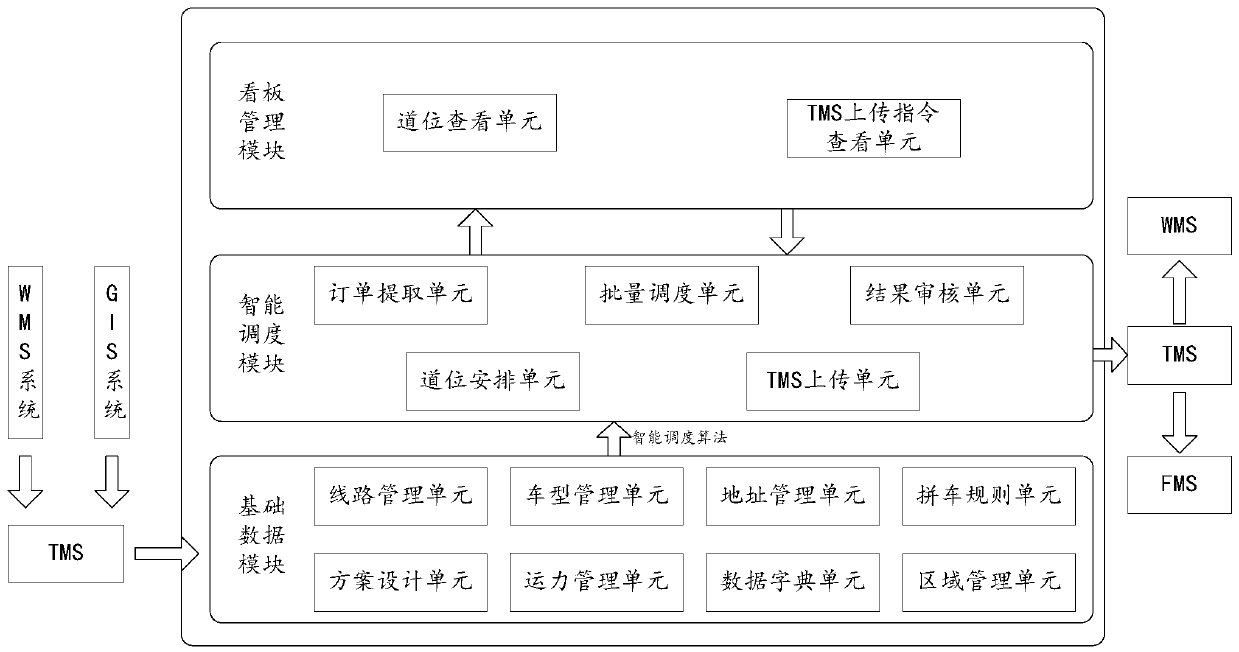

Intelligent optimized scheduling system for logistics

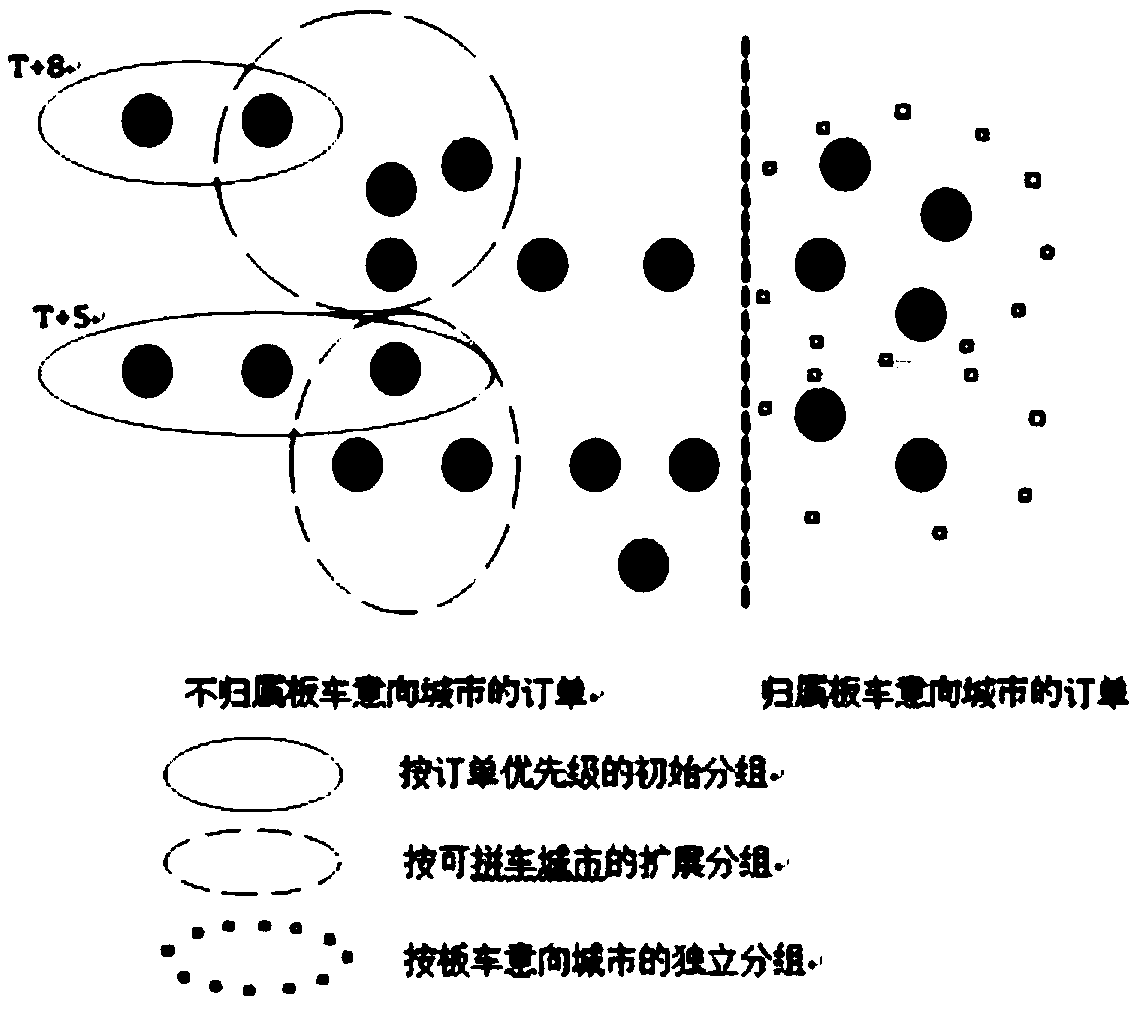

ActiveCN105512747AAvoid load imbalanceImprove performanceForecastingLogisticsManagement unitScheduling function

The invention discloses an intelligent optimized scheduling system for logistics. The system is composed of a basic data module, an intelligent scheduling module and a board management module. The basic data module consists of a line management unit, a vehicle type management unit, an address management unit, a car pooling rule unit, a scheme design unit, a transport capacity management unit, a data dictionary unit, and an area management unit. The intelligent scheduling module is used for realizing the complete intelligent scheduling function and is mainly responsible for order extraction and scheduling calculation, carrying out examination on a calculation result, carrying out proper arrangement after successful examination, and writing back to a TMS. The board management module mainly includes an arrangement checking unit and a TMS uploading instruction checking unit; the arrangement checking unit is used for realizing a function of real-time arrangement situation checking of a warehouse in the system; and the TMS uploading instruction checking unit is used for realizing a function of uploading instruction checking. According to the system, the inventory, manpower and transport costs can be lowered; the punctual delivery ratio can be improved; the profitable operation can be realized; and the competitive advantage can be obtained.

Owner:ANJI AUTOMOTIVE LOGISTICS

Billboard management system and method

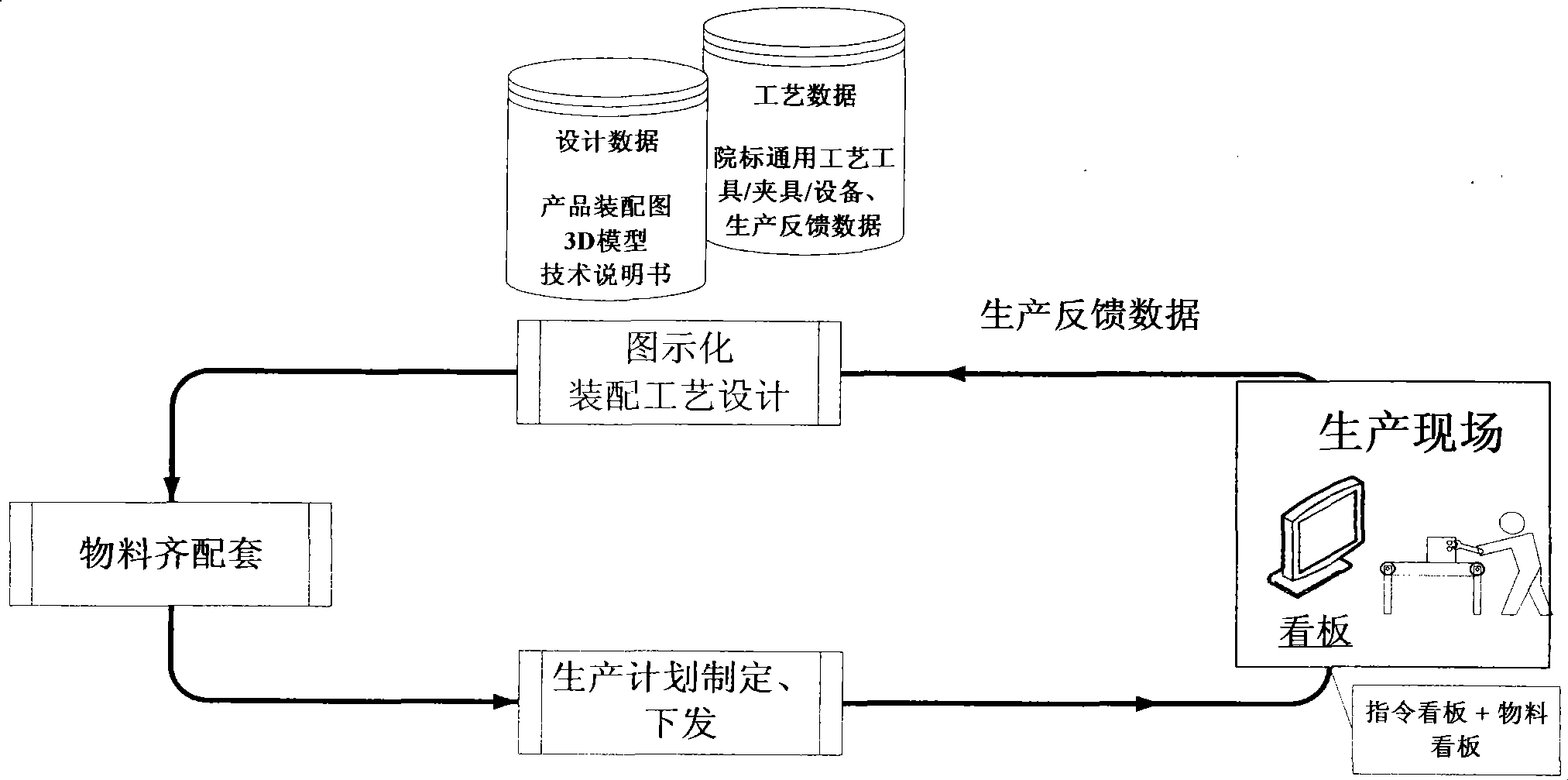

InactiveCN101546393AImprove work efficiencyAccelerate the development progressResourcesManufacturing computing systemsDocumentation procedureDecomposition

The invention discloses a billboard management system and a billboard management method, wherein the system comprises: a basic configuration module, which establishes a data interface with the system, performs debug on process faults, inputs models, fascicules, working procedures, process steps, assorted tables and key working procedures, and maintains correlative information of a structure tree; a material warehouse module, which manages material assorted information, performs material distribution, warehousing and ex-warehouse management, and finishes allocation management of the materials between models; a process management billboard module, which is used for achieving temporary process documentation and process modification, solving on-site technical problems and compiling process rated details; a production plan management module, which is used for finishing production flow design and production route design, and establishing and adjusting or distributing a production arrangement plan; a workshop operation plan billboard module, which generates an intraday task list according to a scheduled production plan and distributes the task list to each working position billboard for instructing the intraday work; a execution billboard module, which finishes plan decomposition and appoints the starting time and ending time of the plan for each working procedure task, inspects the completed working procedures in the system at the first time when the working procedures are completed, and fills in inspection records and prints assembling process cards; and an on-site inspection module, which fills in quality control cards of the key working procedures and manages a single closed loop for soling the technical problems. The billboard management system and the billboard management method optimize the general assembly working mode and the production flow and solve various links unadaptable to a batch production mode in the process of the general assembly currently.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

A Hierarchical and Detailed Electronic Kanban System

InactiveCN102289720AReduce manual operationsAccurate responseIdentification meansInteraction timeComputer module

A layered and refined electronic kanban system, which is composed of a server, a database and a client. The server is connected to the database, and the client is connected to the server through the network. The client is equipped with a display device, and the server runs a data interaction program. The data interaction program There are a time axis display module, a kanban operation module and a kanban adjustment module. The time axis display module is used to display the continuous time axis, and the kanban operation module is used to obtain the required data from the database, and the progress of each task of the project to be displayed The time data is transformed into the length of the corresponding time axis, and the vml-based electronic kanban is displayed, and the kanban adjustment module is used to judge whether the actual business process has changed, and when the change is found, according to the actual task node of the latest business process, relative to the time axis Reorder and display related boards via the client's display device. The invention effectively improves the utilization rate of the system by the administrator. The display of project progress is well organized.

Owner:上海络杰软件有限公司 +1

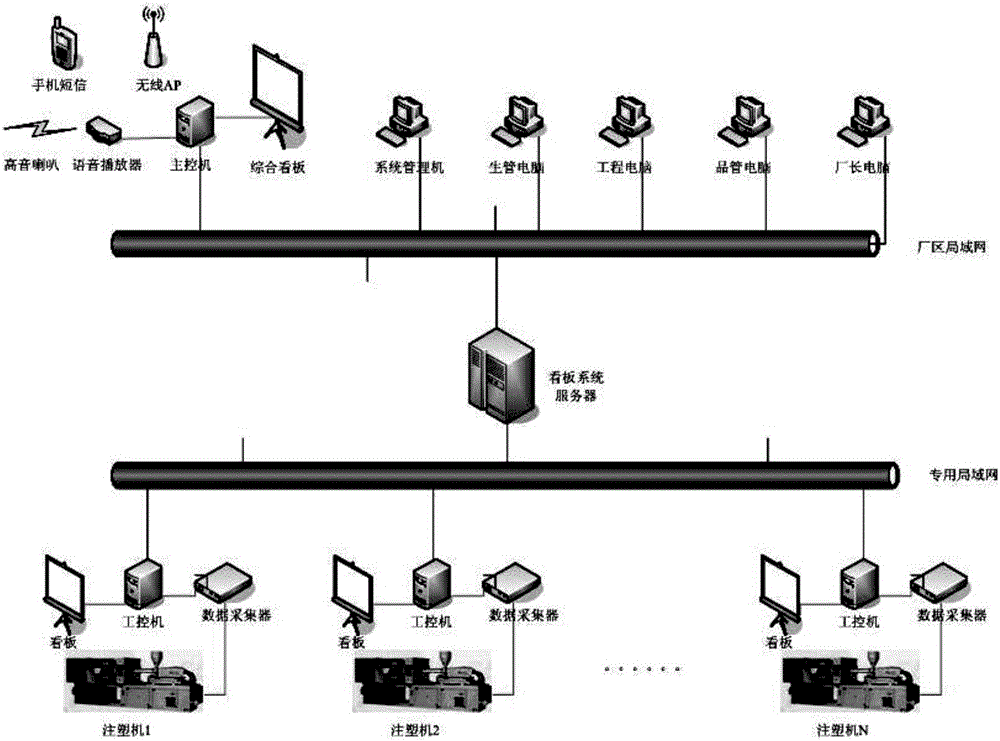

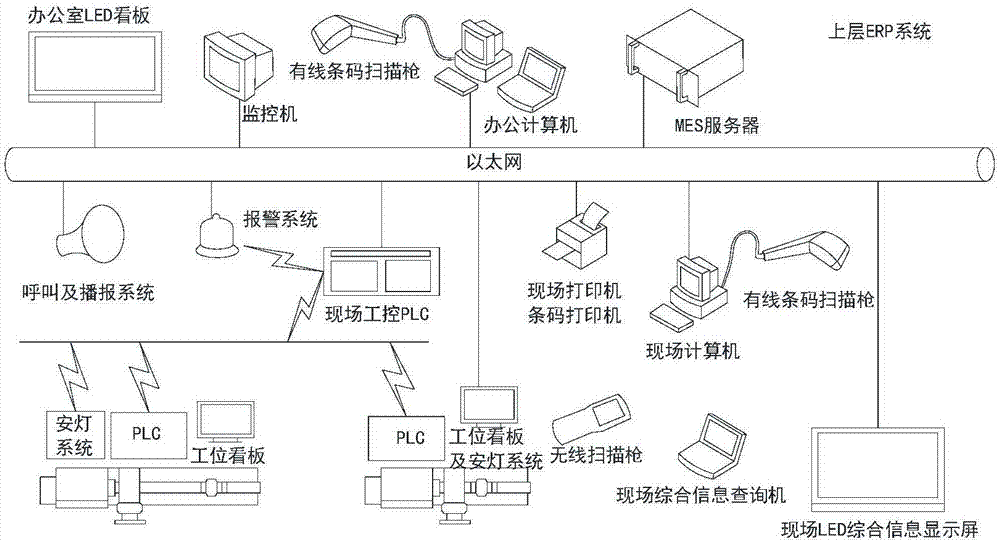

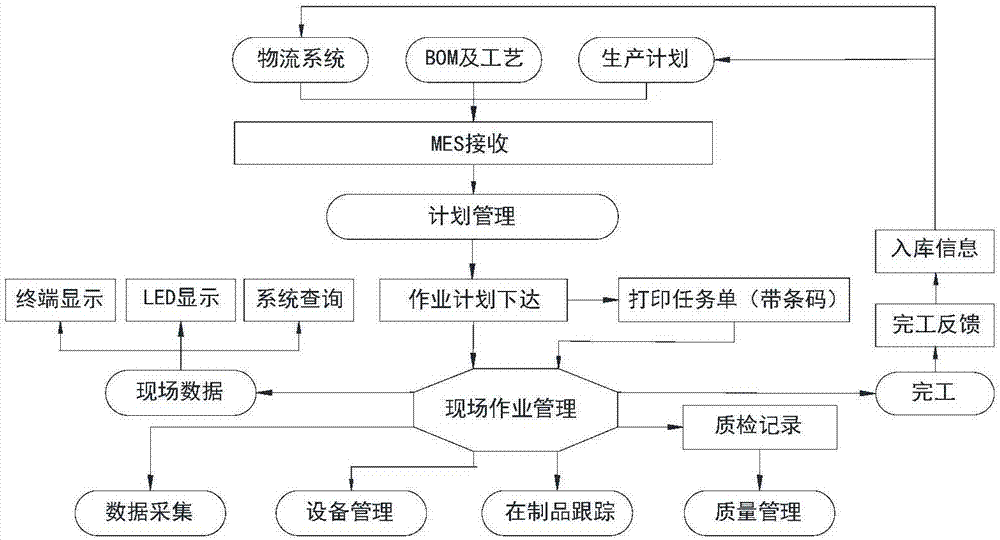

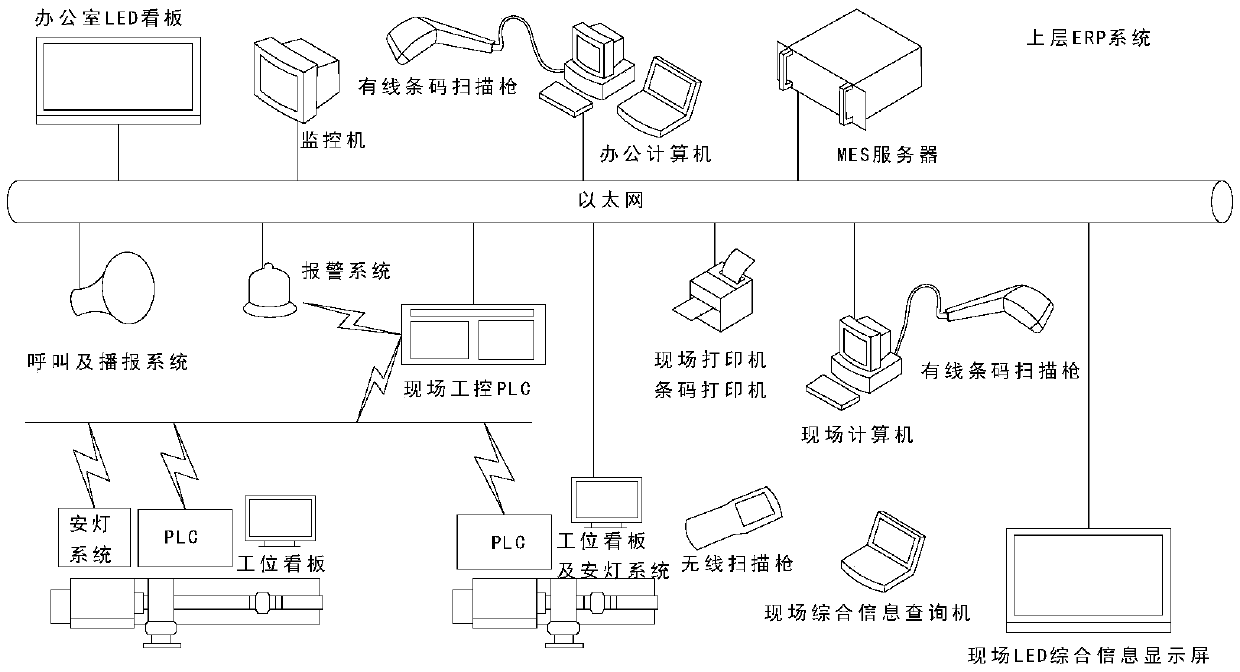

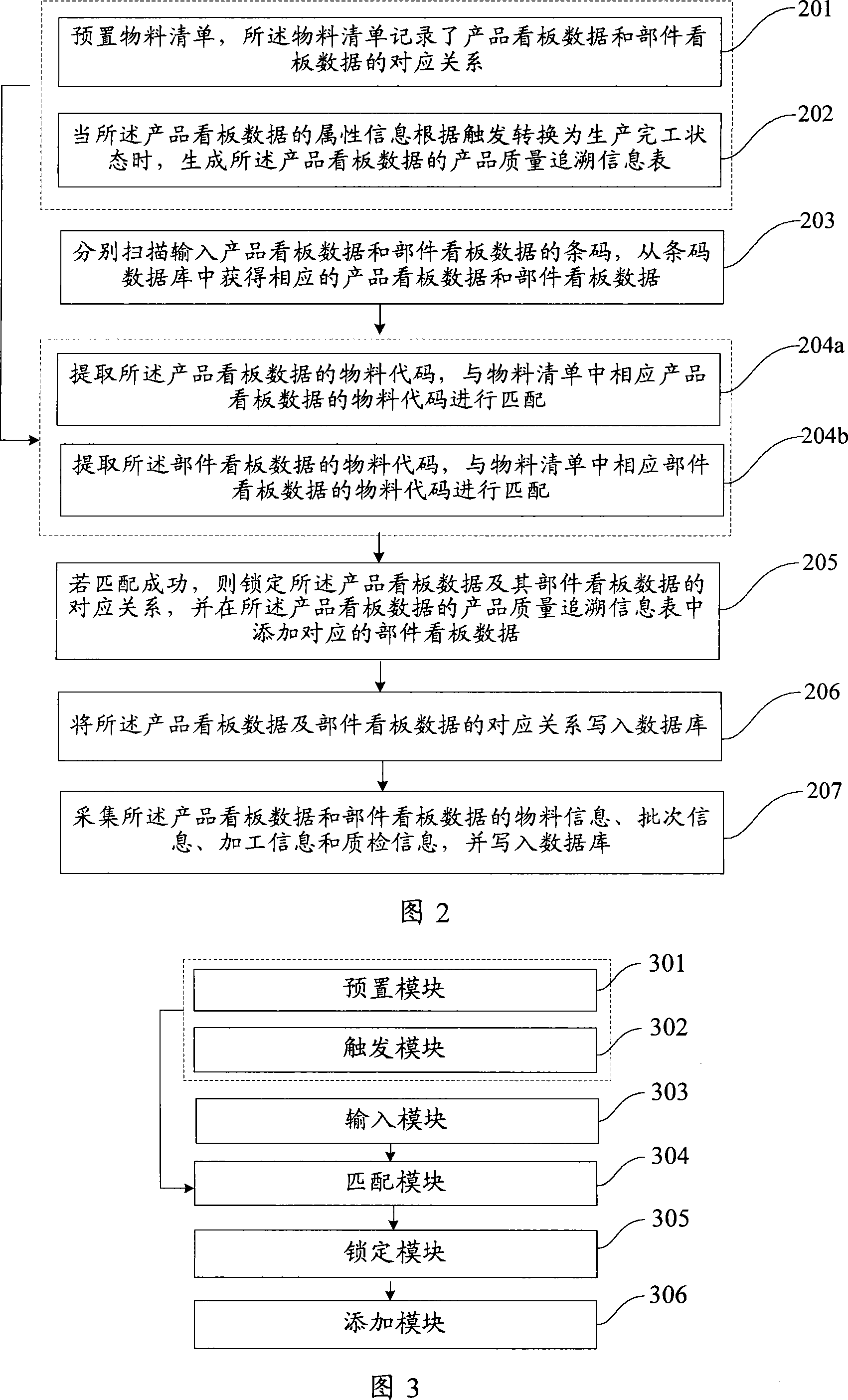

Production line data acquisition and billboard management system and method for manufacturing enterprise

InactiveCN106990761AAdjust production balanceRealize automatic countingTotal factory controlProgramme total factory controlManufacture execution systemBill of materials

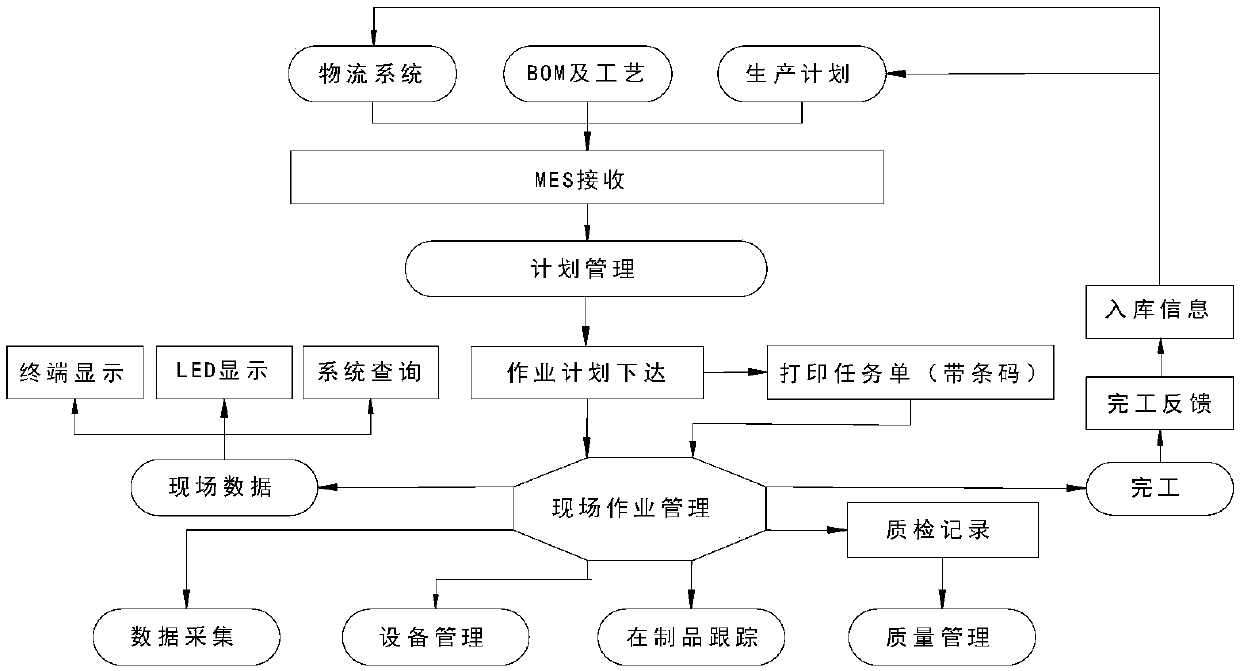

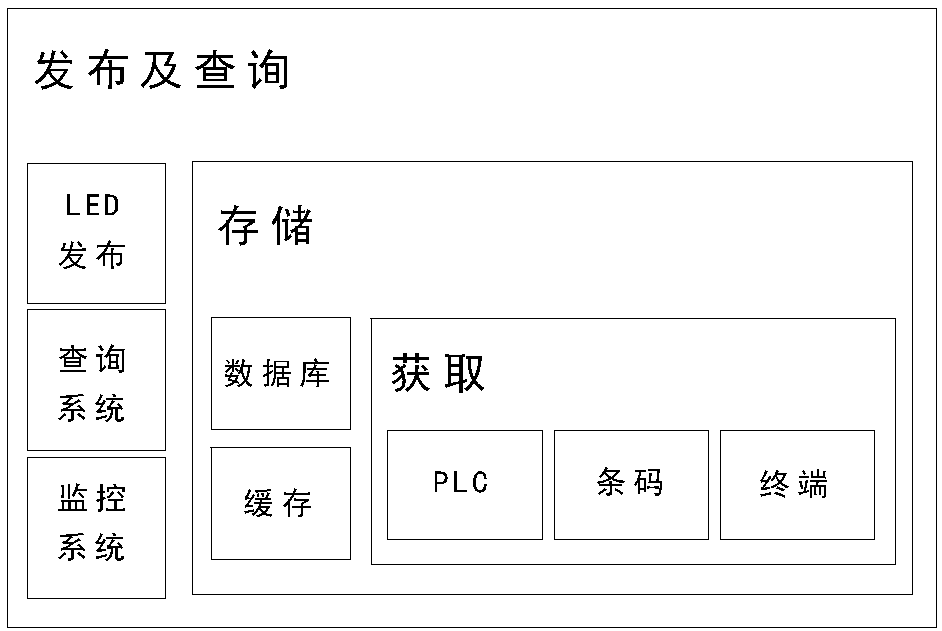

The invention provides a production line data acquisition and billboard management system for a manufacturing enterprise. The production line data acquisition and billboard management system for a manufacturing enterprise includes a production line data acquisition system and a billboard management system, wherein the production line data acquisition system and the billboard management system are communicated through Ethernet. The invention also provides a production line data acquisition and billboard management method for a manufacturing enterprise. The production line data acquisition and billboard management method for a manufacturing enterprise includes an MES reception process, an on-site operation management process, an MES (Manufacturing Execution System) reception logistics system, BOM (Bill of Material) and technology, information of production plan, and plan management, wherein the operation plan in plan management is issued, and then on-site operation management is executed; the on-site operation management process includes data acquisition, equipment management, tracking of articles being processed, and quality inspection recording; after collection of the quality inspection record information, quality management is performed; during the on-site operation management process, the on-site data is formed, and terminal display, LED display and system query are performed on the on-site data; the warehousing information is formed during the completion feedback process; and the warehousing information, the production plan and the logistics system are merged, and then the MES reception process begins.

Owner:ZHEJIANG BLUE CLOUD INFORMATION TECH CO LTD

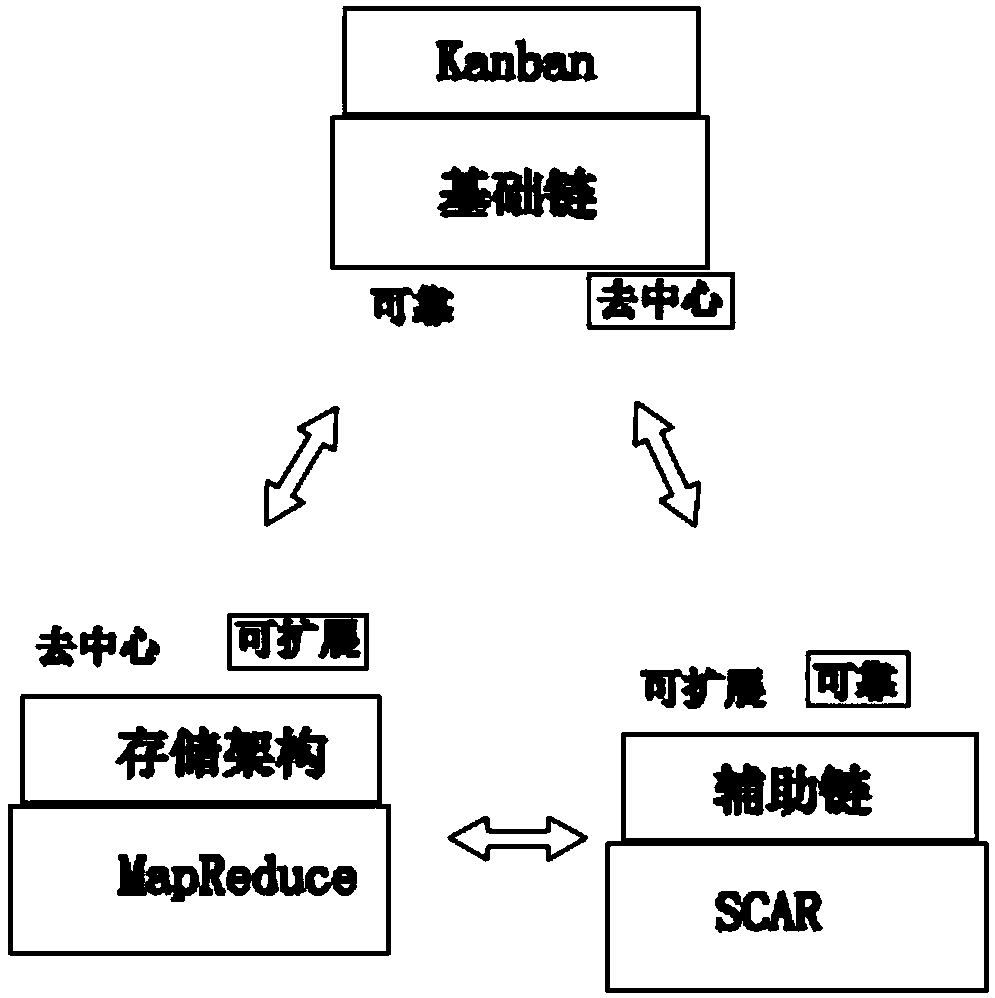

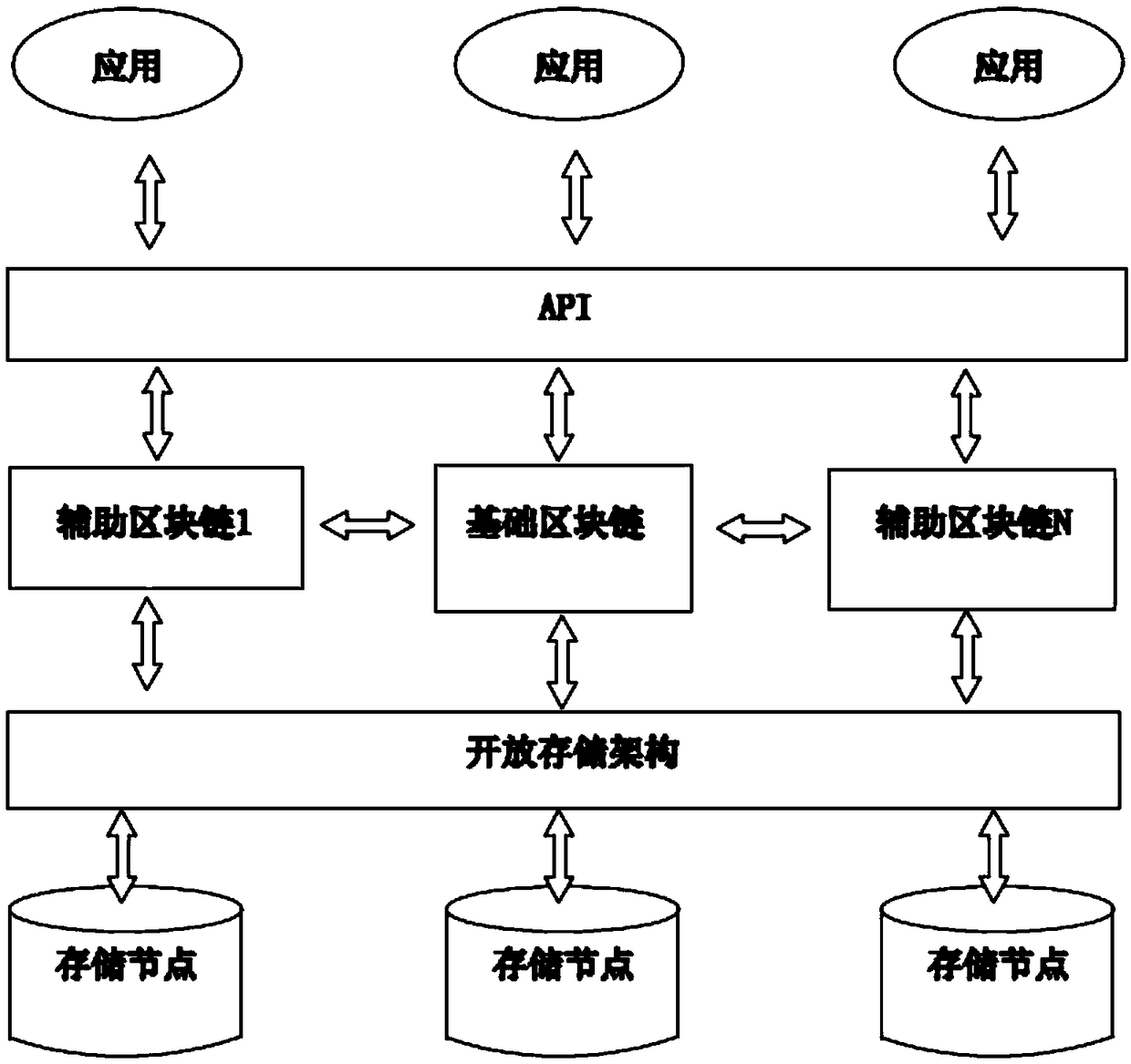

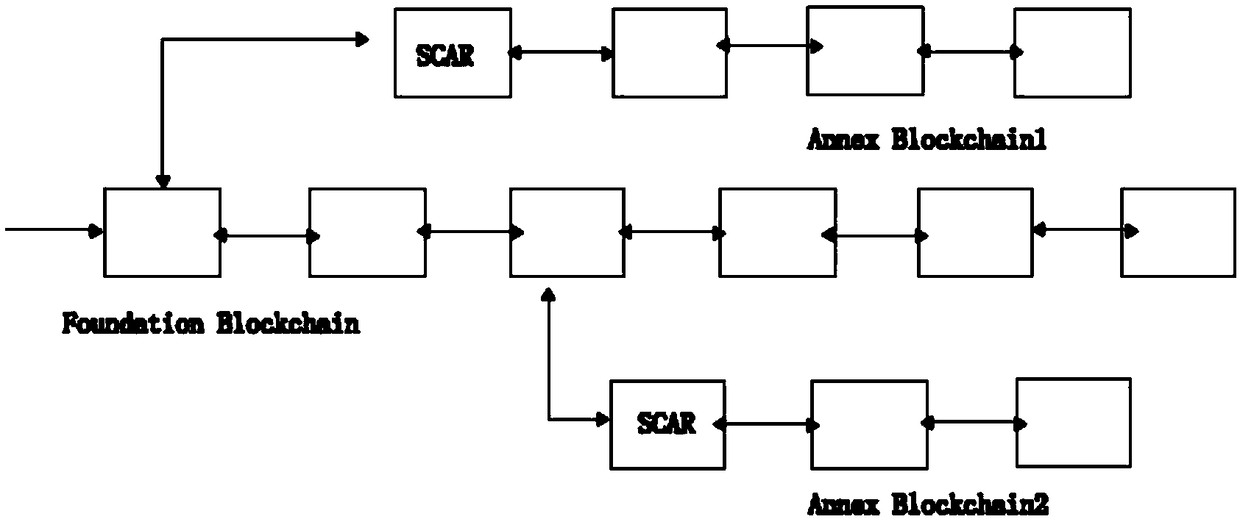

High extensible public block chain system for actual application

InactiveCN108881459APrevent double spendingMeet the requirements of decentralized large-scale real-time transactionsTransmissionSmart contractBasic block

The invention discloses a high extensible public block chain system for an actual application. The system is characterized by comprising a basic block chain, an auxiliary bock chain N, an auxiliary block chain 1 and an open storage framework, wherein the auxiliary bock chain N and the auxiliary block chain 1 are auxiliary bock chains, the basic block chain, the auxiliary block chains and the openstorage framework are separately fit with Kanban SCAR and MapReduce to form a system cyclic constraint dislocation guarantee mechanism; the design of the basic block chain takes the minimum data size,minimum computation amount and minimum network bandwidth requirements as a target; a basic protocol, an account book, a smart contract, and a value system are provided; the highest adjudication is achieved; the system provided by the invention is composed of three component parts, consisting of the basic block chain, the auxiliary block chains and the open storage framework, that are integrally designed; the three parts are integrated and matched with one another; and a high performance block chain complete framework that has a unified protocol base, mutual coordinated functions, whole coursevalidity and effectiveness verification, and is truly decentralized, safe and reliable.

Owner:甘肃山呼信息技术有限公司

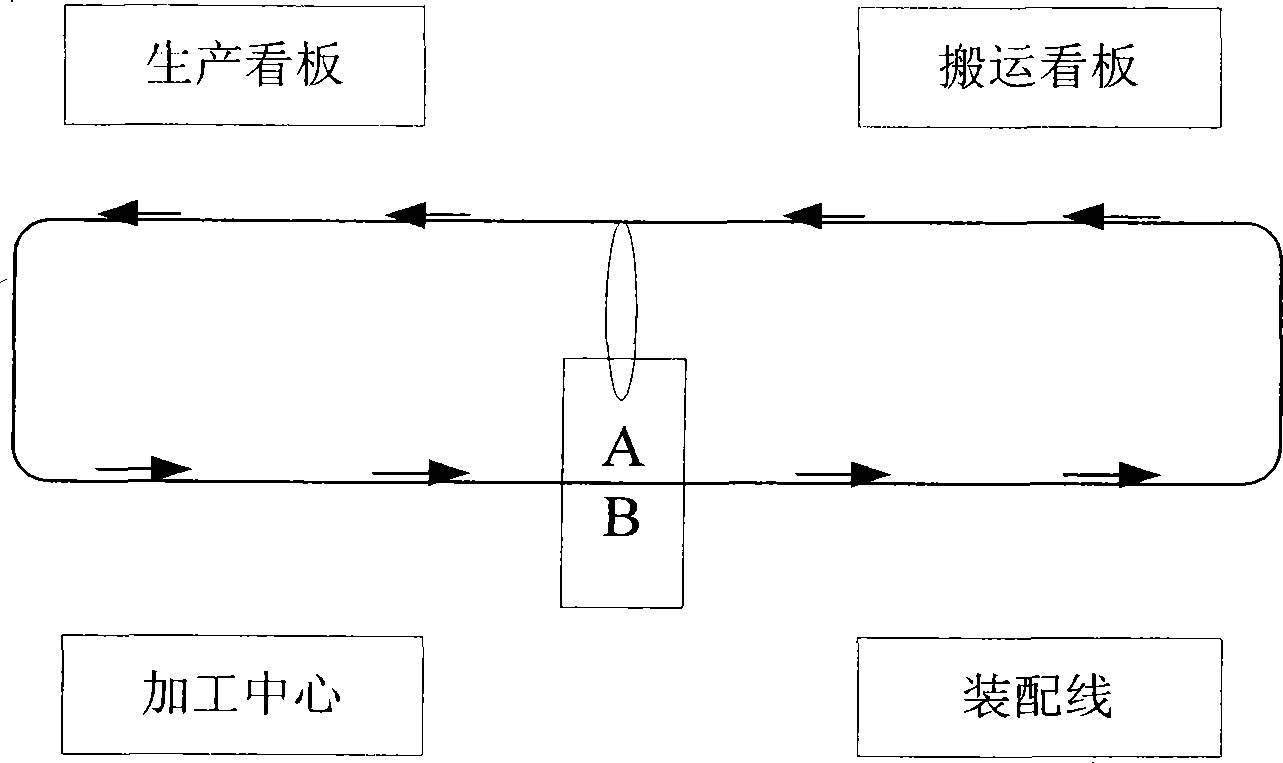

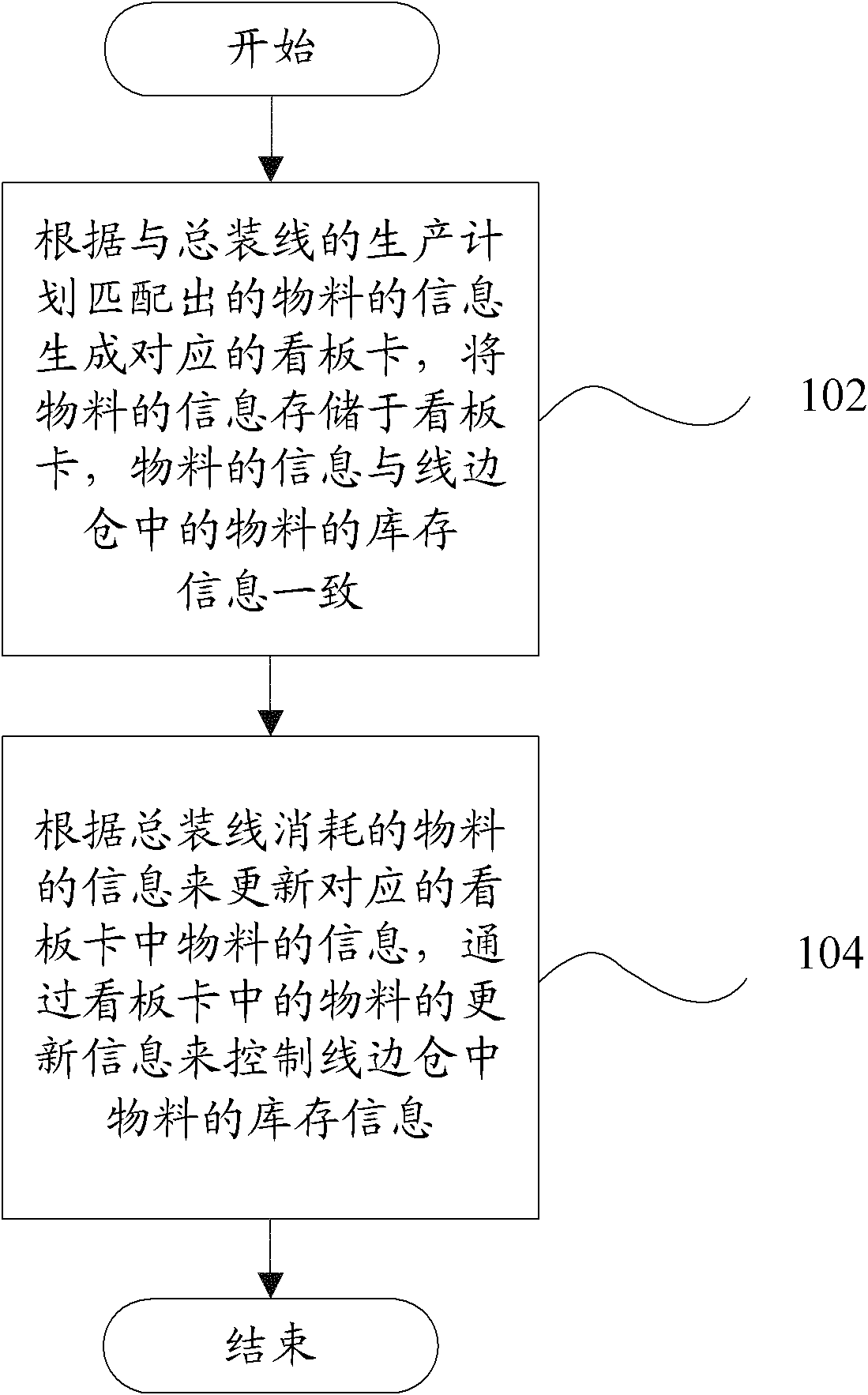

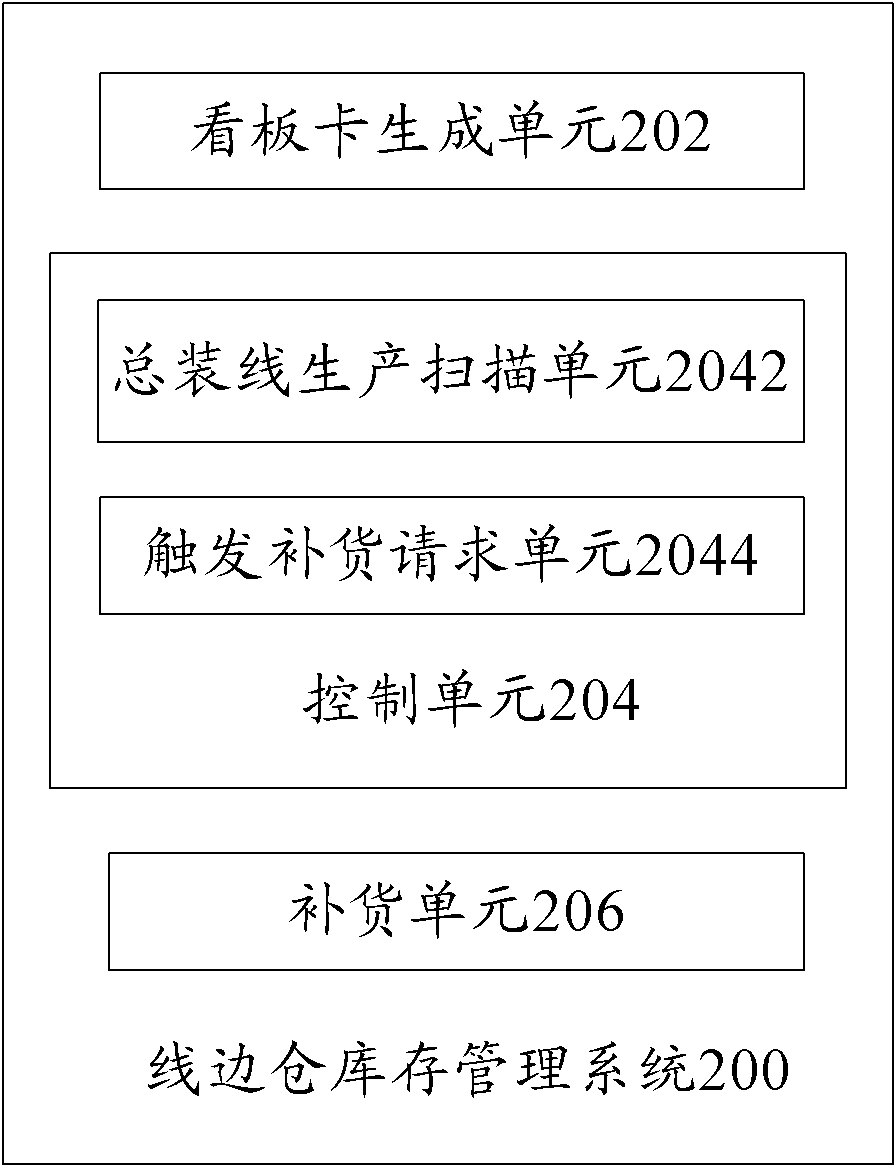

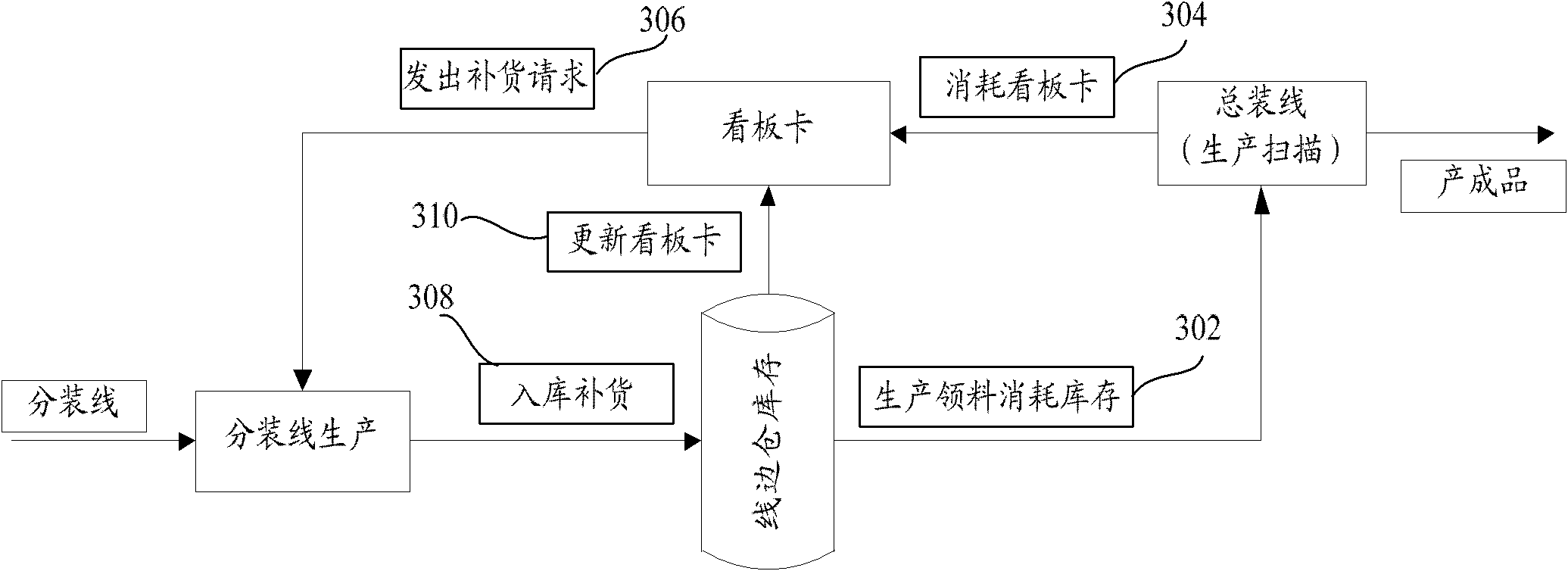

Inventory management method and system for line edge warehouse

InactiveCN102054226ARealize intelligent controlTimely supplementLogisticsComputer scienceManagement system

The invention discloses an inventory management method for a line edge warehouse, comprising the following steps of: step 102, generating corresponding Kanban cards according to material information matched with the production plane of an assembling line, storing the material information into the Kanban cards and keeping the material information consistent with inventory information of the materials in the line edge warehouse; and step 104, updating the material information in the corresponding Kanban cards according to the information of the materials consumed by the assembling line and controlling the inventory information of the materials in the line edge warehouse according to the material update information in the Kanban cards. The invention also provides an inventory management system for the line edge warehouse. According to the technical scheme of the invention, the consumption condition of the line edge warehouse can be fed back in time and the required materials can be supplemented in time, thereby realizing the intelligent control on the line edge warehouse and enabling the inventory quantity of the line edge warehouse to ensure the production supply; meanwhile, the material accumulation due to the idle surplus of the material can be avoided.

Owner:YONYOU

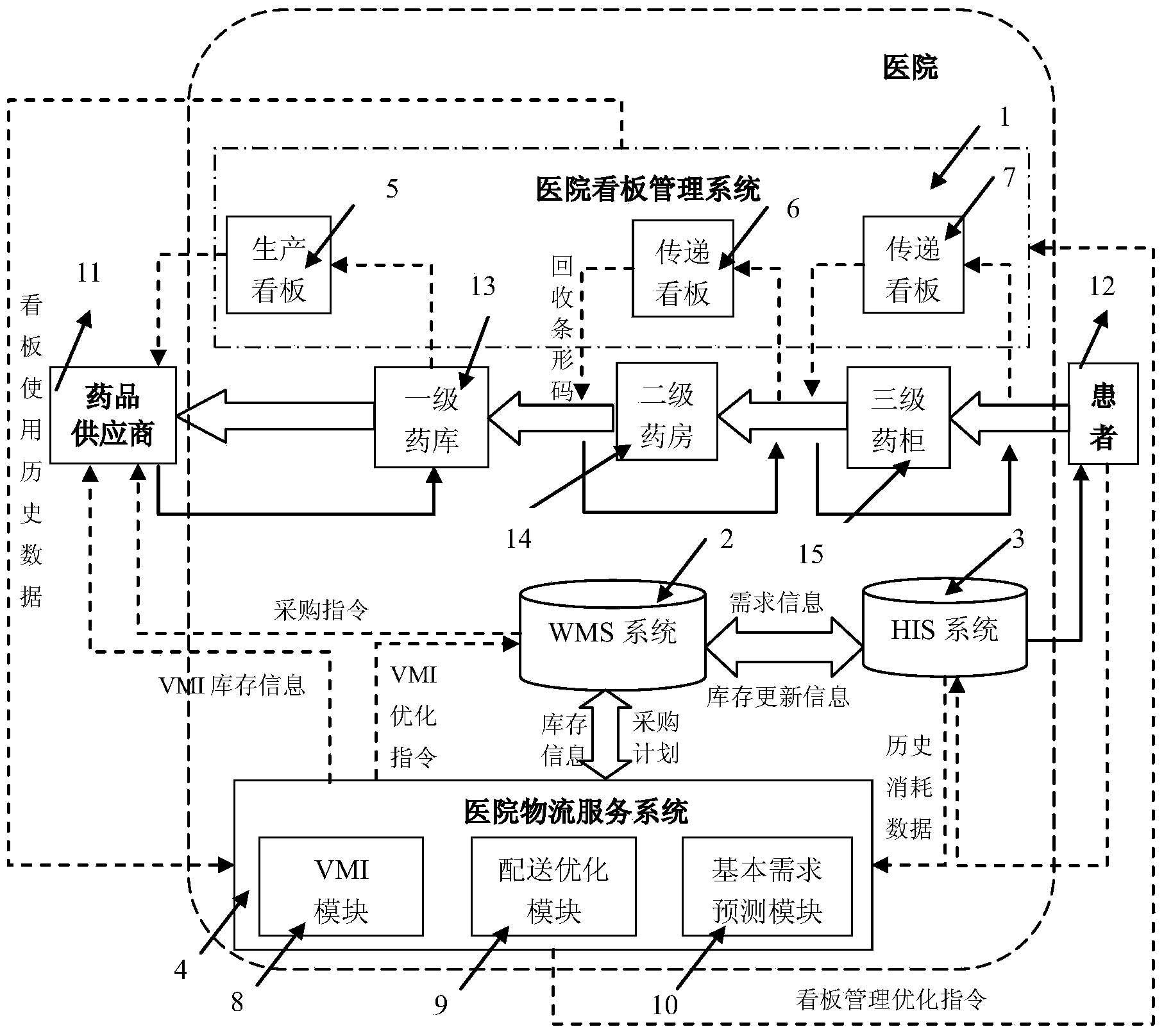

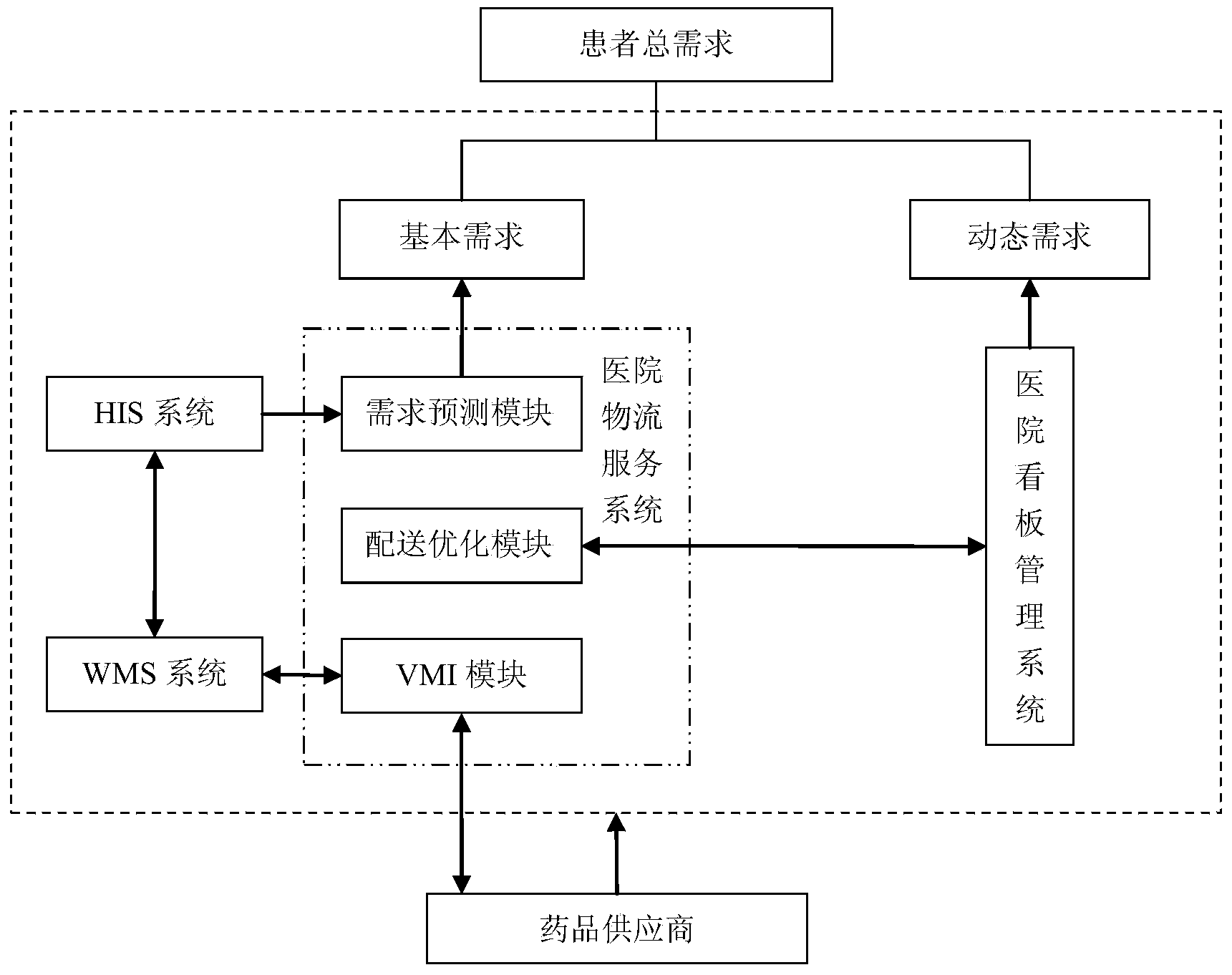

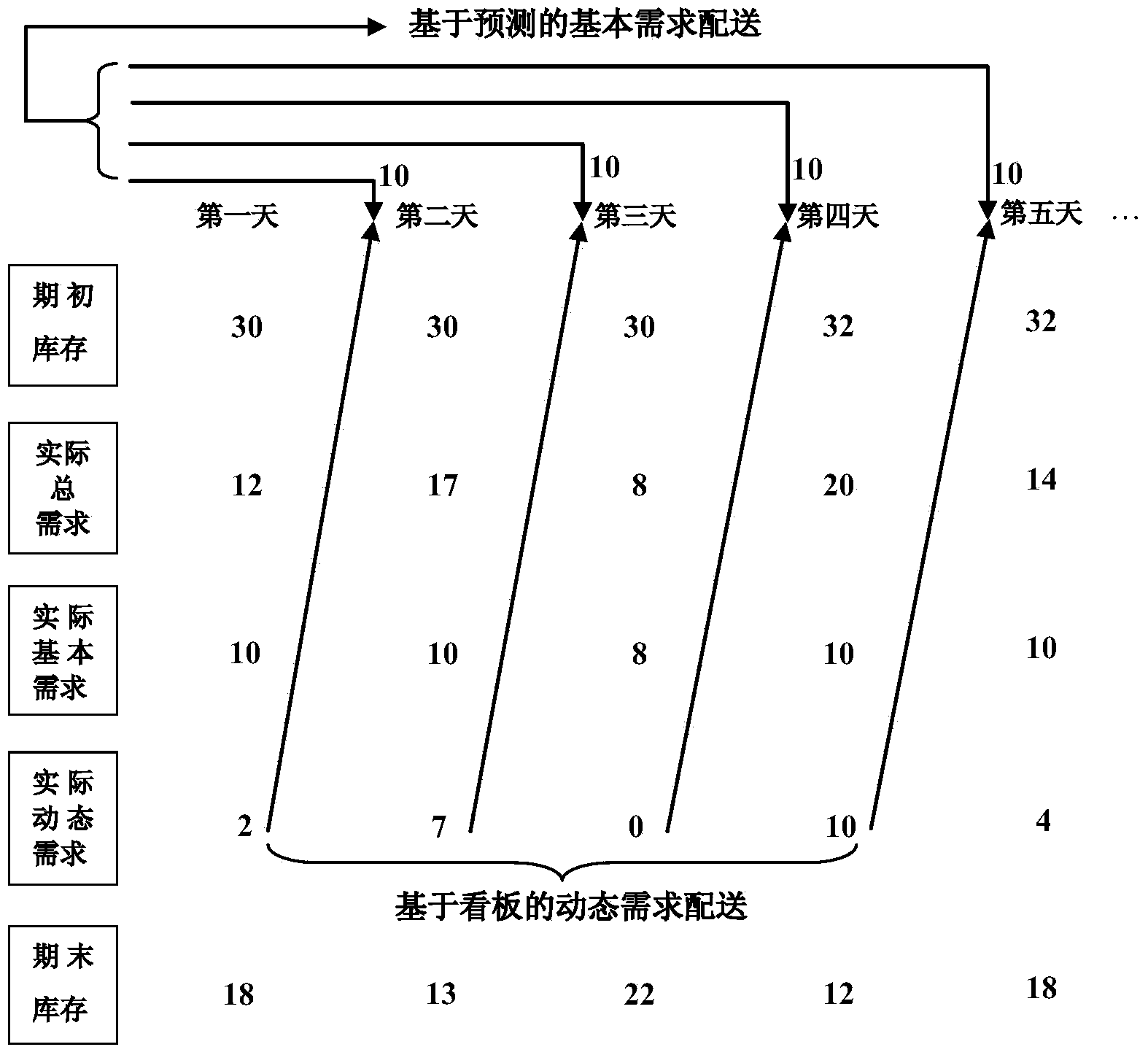

Hospital drug delivery method based on push-and-pull combination of dashboard

ActiveCN103927642AImprove efficiencyReduce the impact of dynamic demand uncertaintyLogisticsDashboardEmergency medicine

The invention discloses a hospital drug delivery method based on the push-and-pull combination of a dashboard. According to the method, a hospital dashboard management system, a hospital warehouse management system, a hospital information system and a hospital logistic service system are included; all the systems are closely matched, a daily demand rule of each department and each drug is analyzed and excavated according to historical data, the daily demand of each drug is divided into the basic demand and the dynamic demand, and then the delivery amount of the drugs is optimized in the mode of combination of the pushing type delivery management and the pulling type dashboard management. On the premise of ensuring the normal marketing activity of hospital drugs, the efficient and low-cost delivery of the hospital drugs is achieved.

Owner:SOUTHEAST UNIV

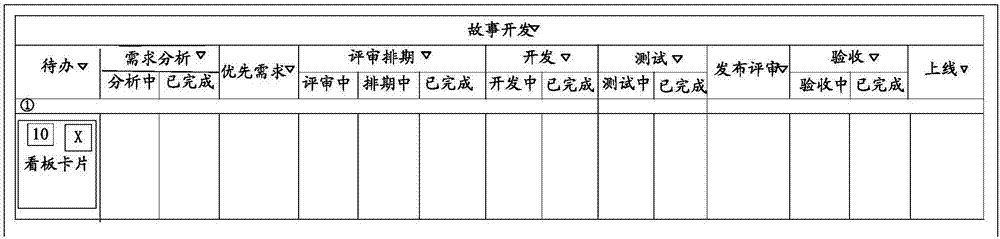

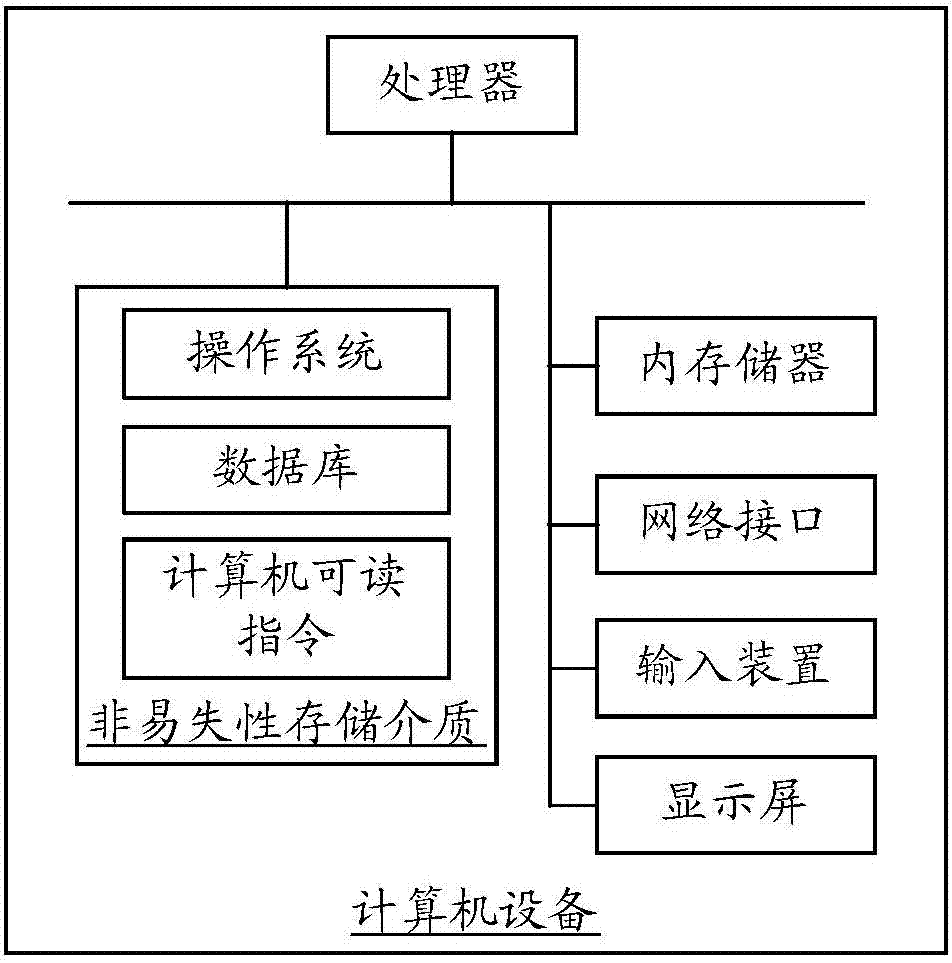

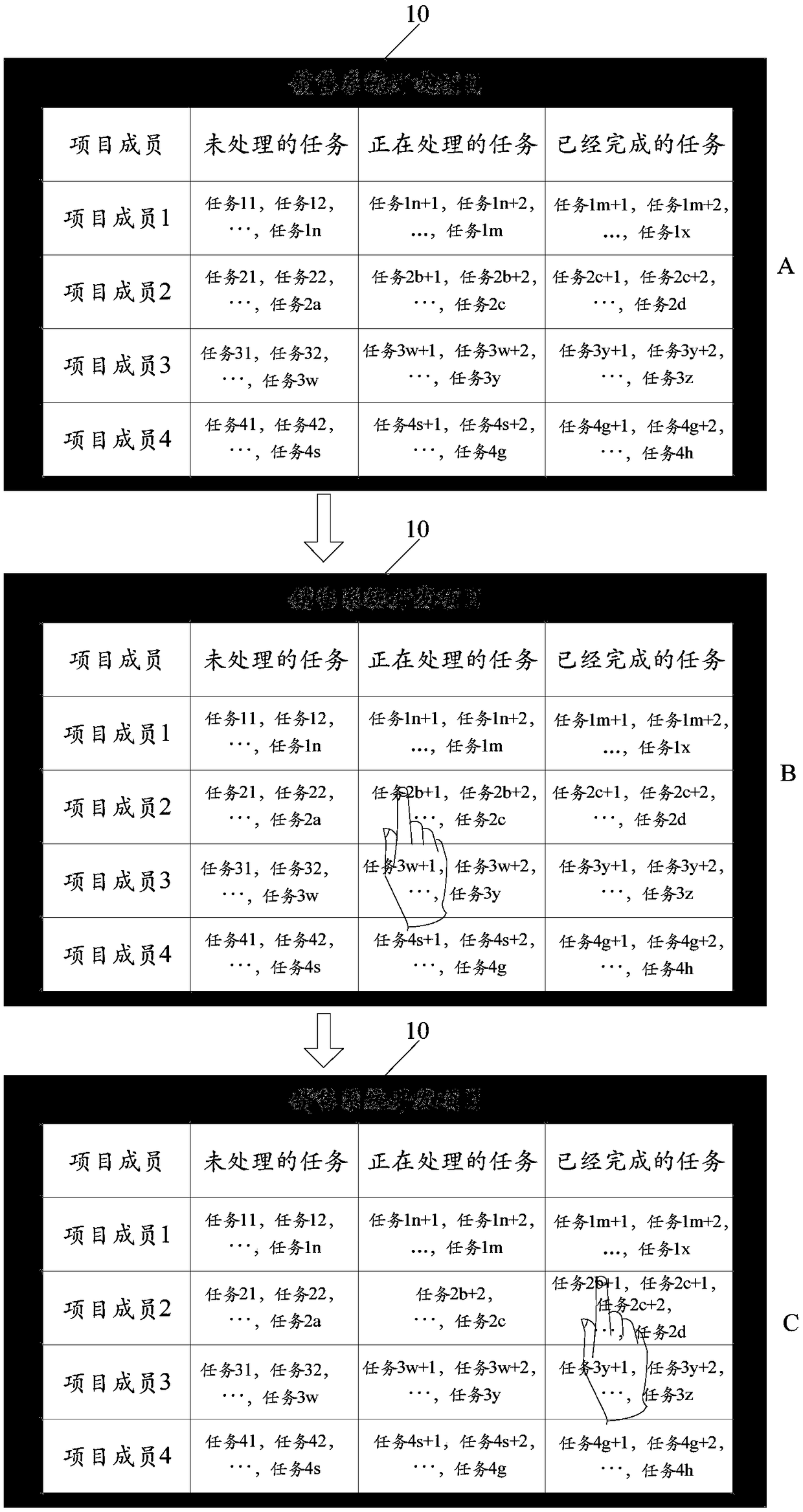

Kanban card management method and device, computer device and storage medium

InactiveCN107886300AImprove efficiency with Kanban toolsOffice automationResourcesSimulationComputer device

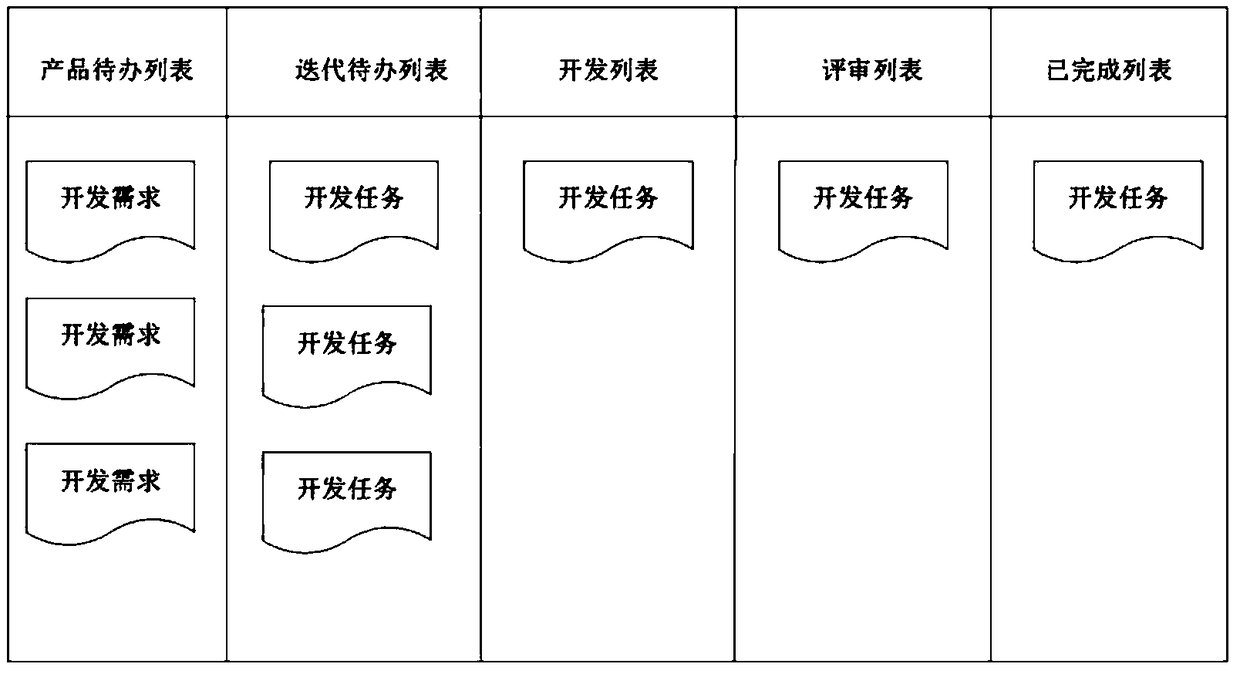

The present invention relates to a Kanban card management method. a preset task flow is displayed at a Kanban display interface, wherein the task flow comprises at least one lane, at least one vertical column and at least one Kanban card; a dragging instruction, triggered by a first responsible person account ,of dragging the at least one Kanban card from a first vertical column to a second vertical column is obtained, and the dragging instruction carries a Kanban card identifier; the Kanban card corresponding to the Kanban card identifier is displayed in the second vertical column in the samelane according to the dragging instruction; and a second responsible person account corresponding to the first responsible person account is obtained according to a preset responsible person accountcorresponding relation, and the second responsible person account is displayed on the Kanban cards in the second vertical columns. Responsible person accounts are conveniently and rapidly displayed onthe Kanban cards, task items corresponding to the Kanban cards are distributed, and therefore the efficiency of using the Kanban tool is improved.

Owner:爱捷软件开发(深圳)有限公司

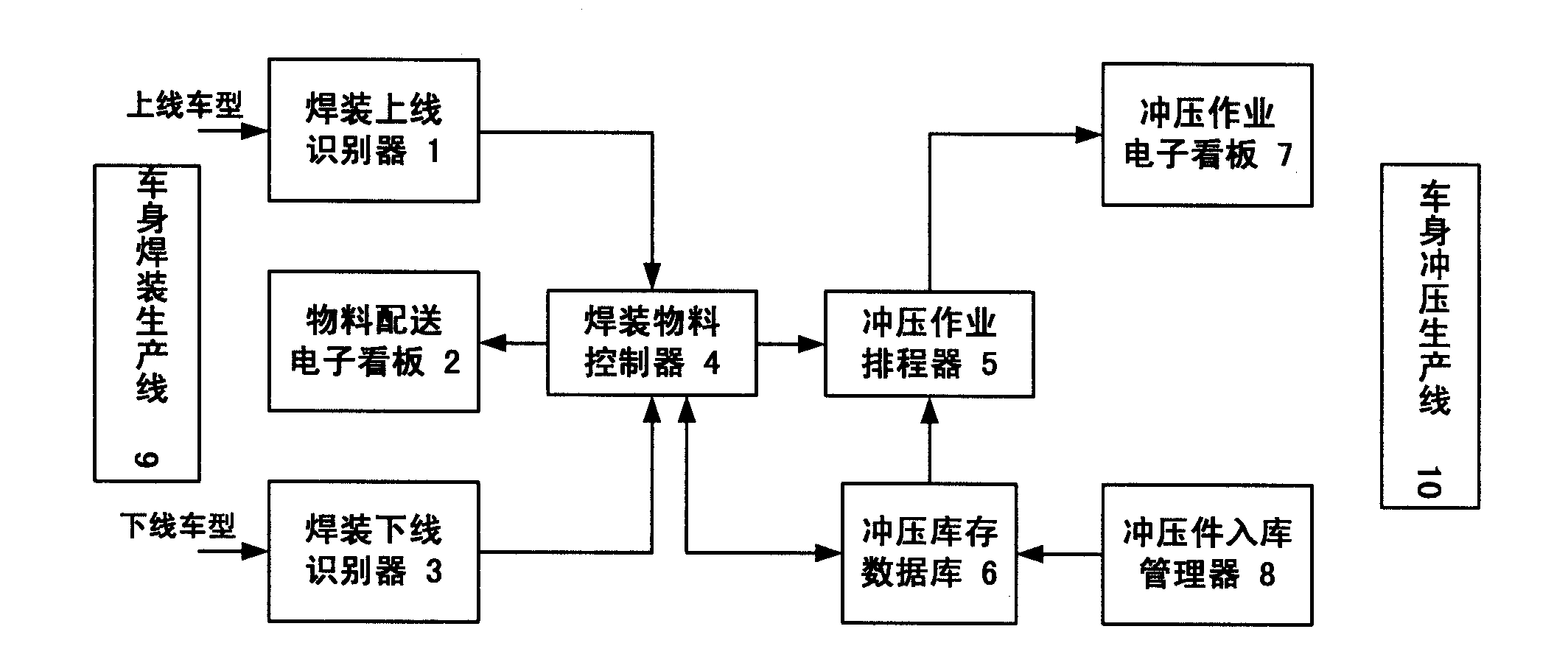

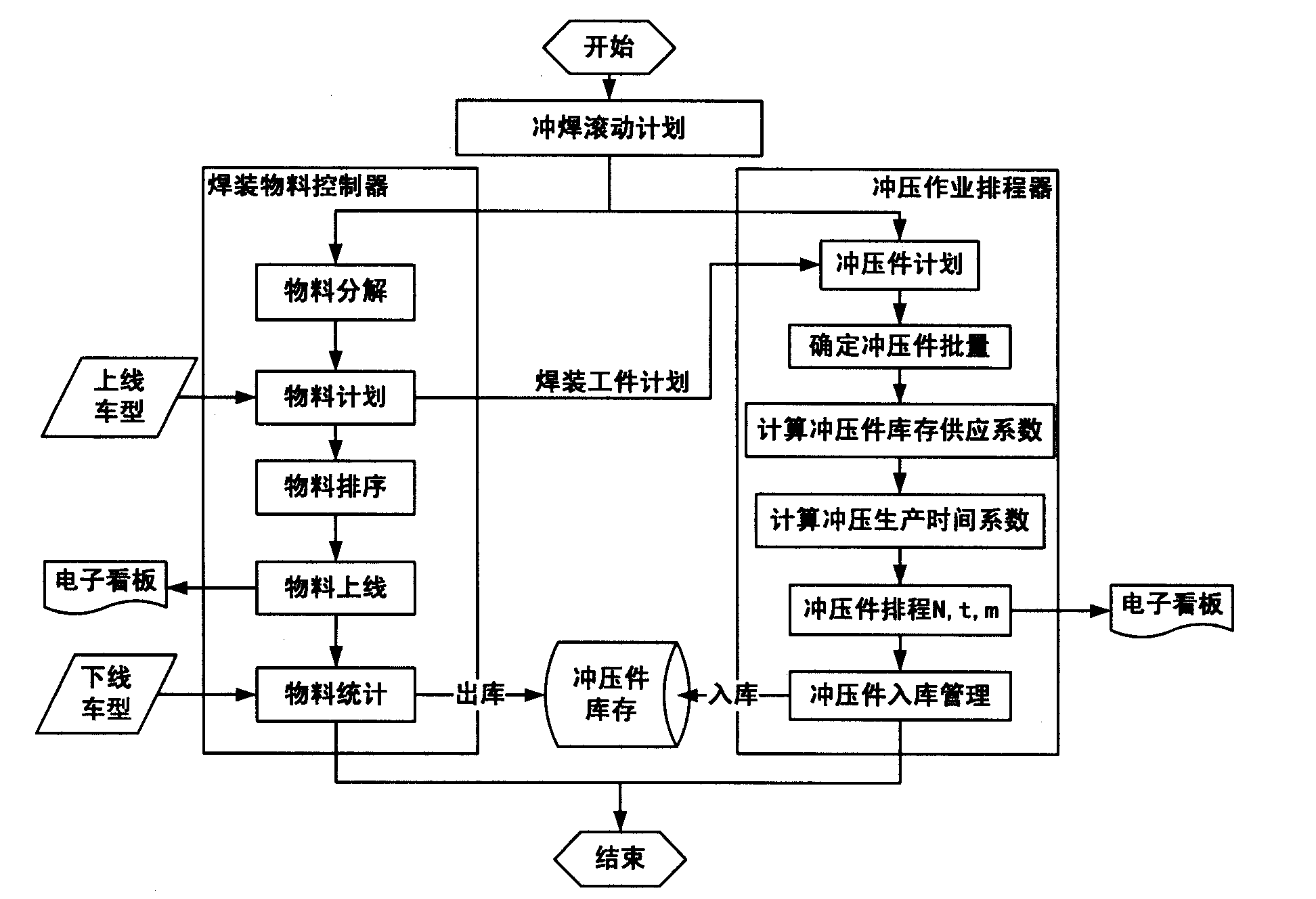

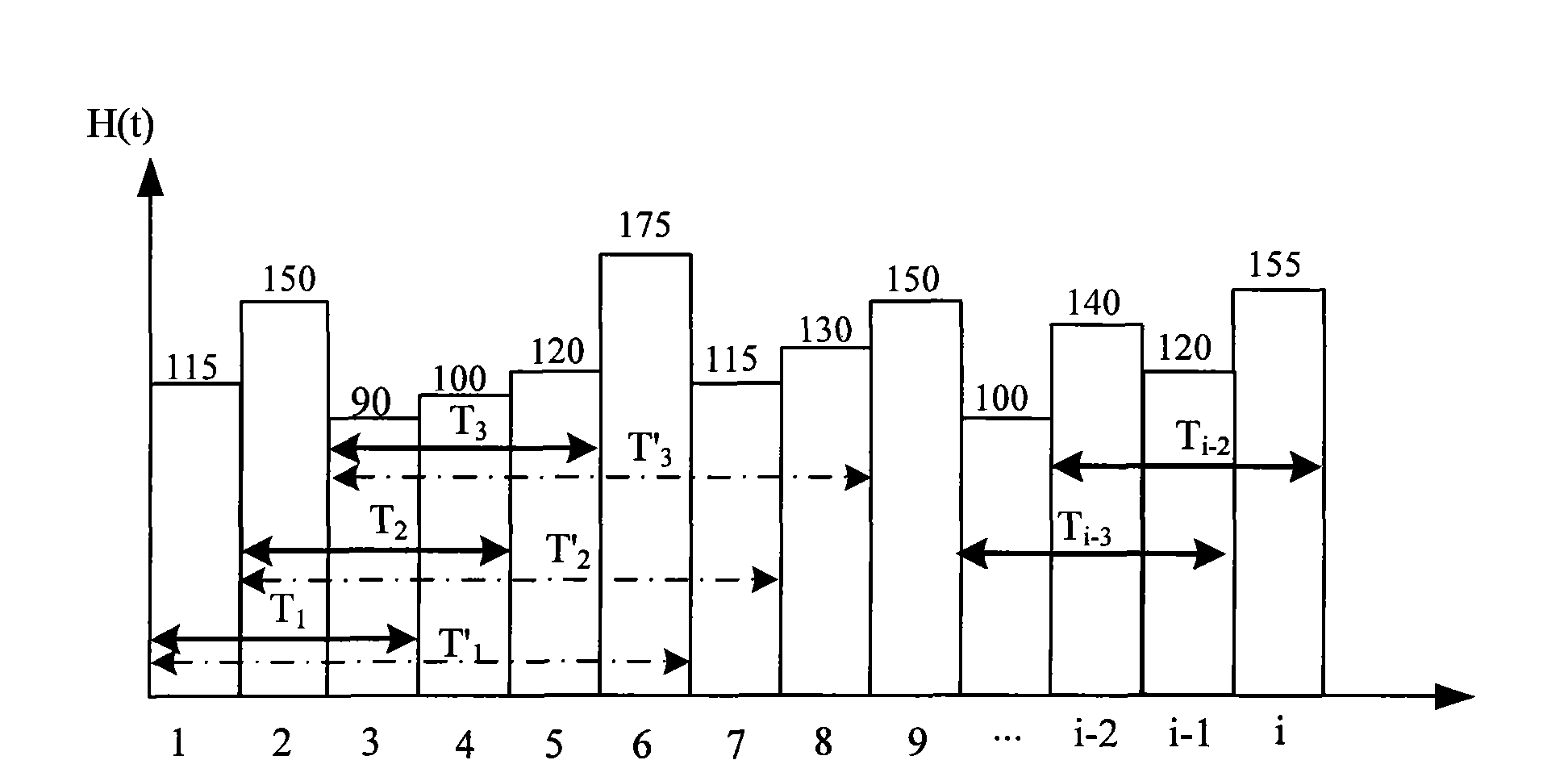

Vehicle body soldering, and drop forging shop work integration control system

InactiveCN101493693ADecrease stockGuaranteed timely supplyTotal factory controlProgramme total factory controlProduction lineRelevant information

The invention discloses an integrated control system of welding of car body and punching workshop operation; a welding material controller is connected with a welding upper and lower line recognizer so that the upper and lower line car body information of the welding production line is received; subsequently, the material decomposition is carried out according to the process material list corresponding to the car body; the material information required by welding production is generated; relevant information is sent to a material delivery electronic kanban; the welding material controller also sends the welding workpiece require plan to a punching operation scheduler; the data of the punching storage database is updated; the punching operation scheduler obtains the welding workpiece require plan from the welding material controller, obtains the punching part storage quantity from the punching storage database, carries out the scheduling control to the punching operation according to the welding rolling production plan, the welding workpiece require plan and the punching part storage, and updates the data of the punching storage database. The integrated control system of welding of car body and punching workshop operation realizes the running of the car body punching and welding production at high efficiency and low cost, reduces the storage and ensures smooth production with meeting the welding requirements.

Owner:HUAZHONG UNIV OF SCI & TECH

Production line data collection and kanban management system and method for smart factory

InactiveCN108681878AIncrease competitivenessAdjust production balanceOffice automationResourcesSmart factoryData acquisition

The invention provides a production line data collection and kanban management system for a smart factory. The system includes a production line data acquisition system and a kanban management systemthat are connected through an Ethernet; a production line data collection and kanban management method for the smart factory is also put forward and includes an MES receiving process and an on-site operation management process; an MES receives logistics system information, BOM and technique information, production plan information; plan management is carried out, an operation plan in plan management is issued, and on-site operation management is performed; the on-site operation management process includes data collection, equipment management, work-in-progress tracking and quality inspection records; quality management is carried out after the quality inspection records are gathered, and field data is formed during the on-site operation management; terminal display, LED display and systemquery of field data are performed, warehousing information is formed during completion feedback processes, and an MES receiving process is carried out after the warehousing information merges with theproduction plan information and the logistics system information.

Owner:浙江优勝科技有限公司

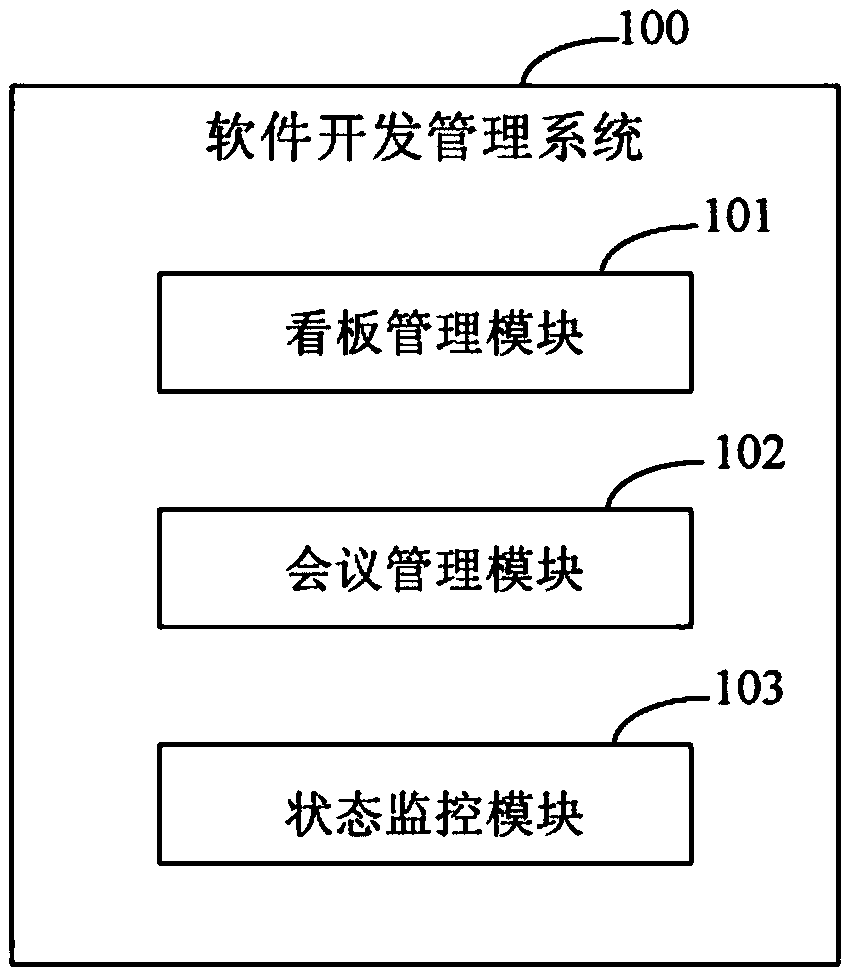

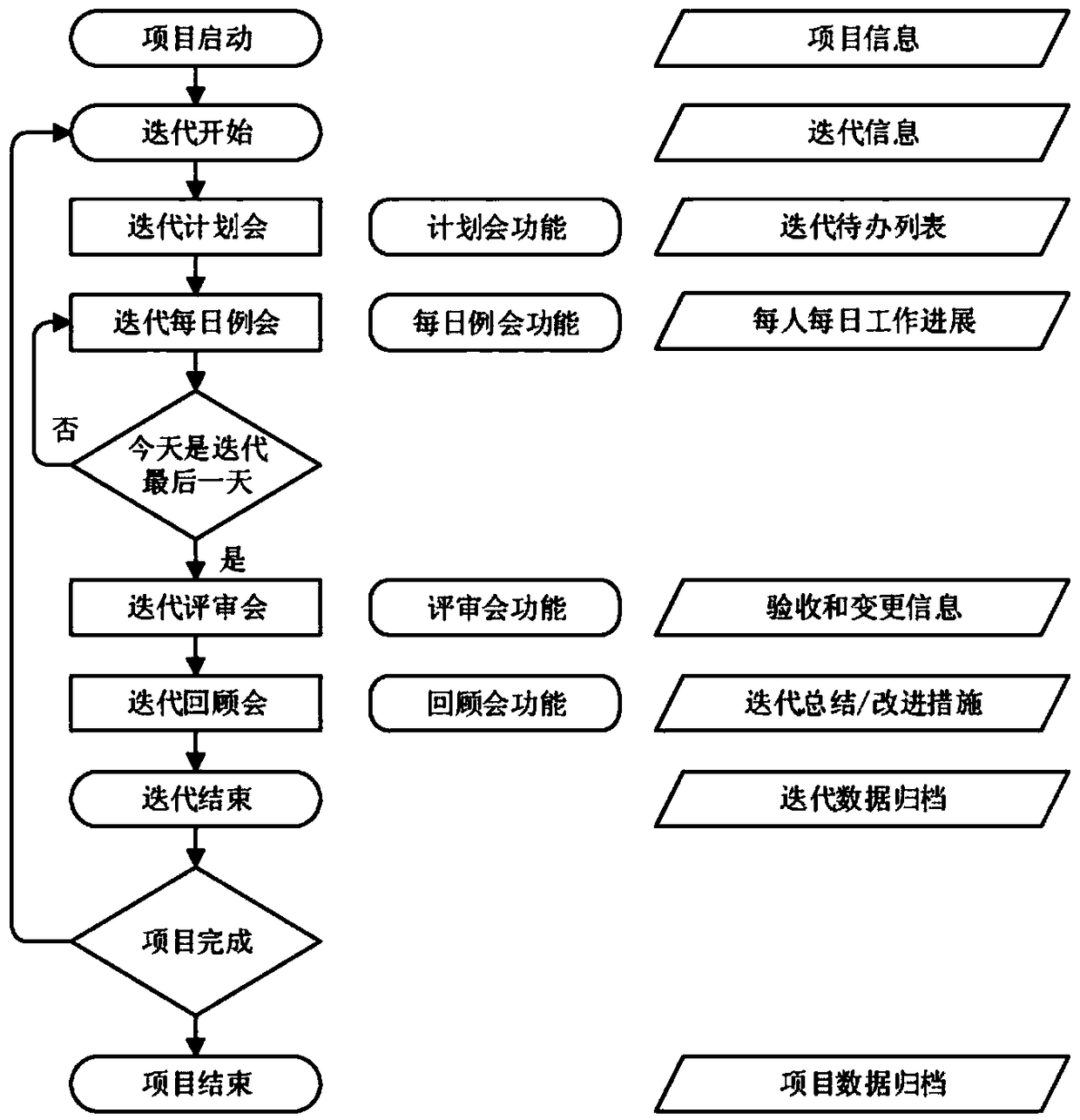

Software development and management system

ActiveCN108629558AImprove team meetingsImprove efficiencyOffice automationCreation/generation of source codeSoftware development processDevelopment team

The invention discloses a software development and management system, which relates to the technical field of computers. One specific implementation mode of the software development and management system comprises a billboard management module and a conference management module. The embodiment of the invention can solve the limitation that an existing software development collaboration tool cannotsupport full-process activities and cannot realize effective project monitoring, and can assist the software development team to carry out software development. While the team meeting and cooperationefficiency is improved, unnecessary pre-conference document preparation, content recording, post-conference content carding and the like can be reduced. The key data of the software development process is collected and summarized without sensing, which can provide analysis based on real and effective data for development teams and managers. The analysis is used for state monitoring, process improvement and performance evaluation.

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD +1

Barrel plating method

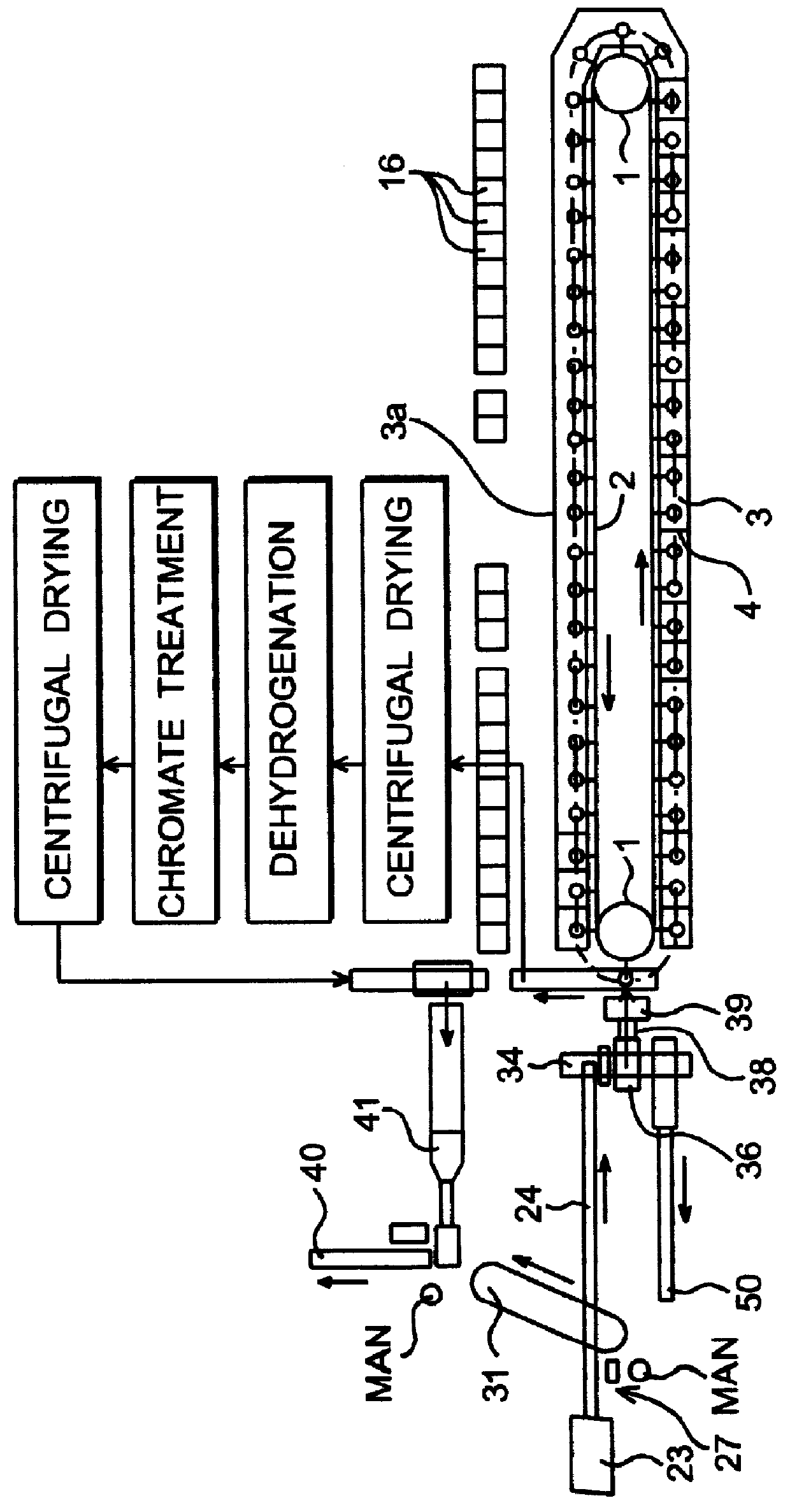

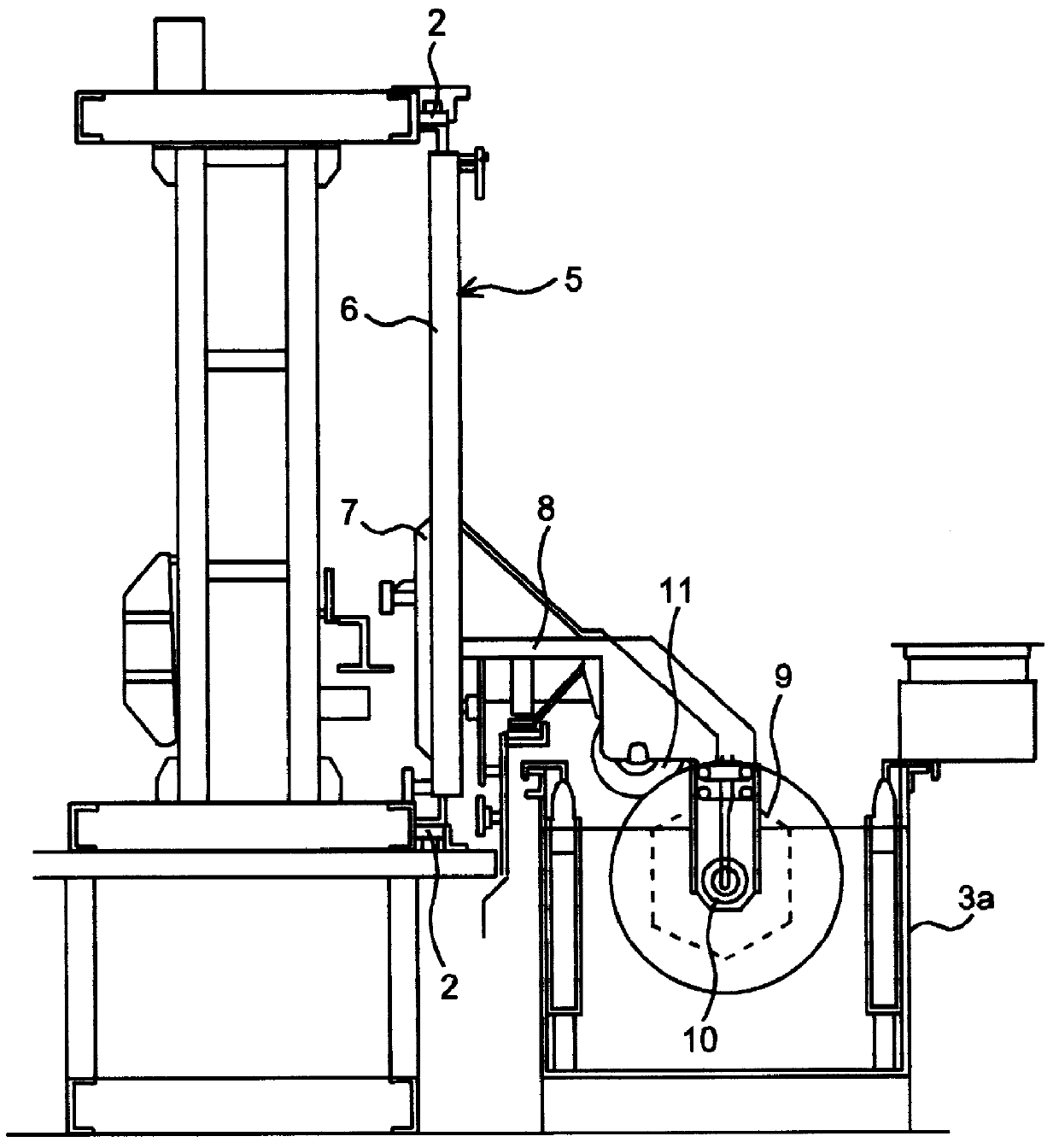

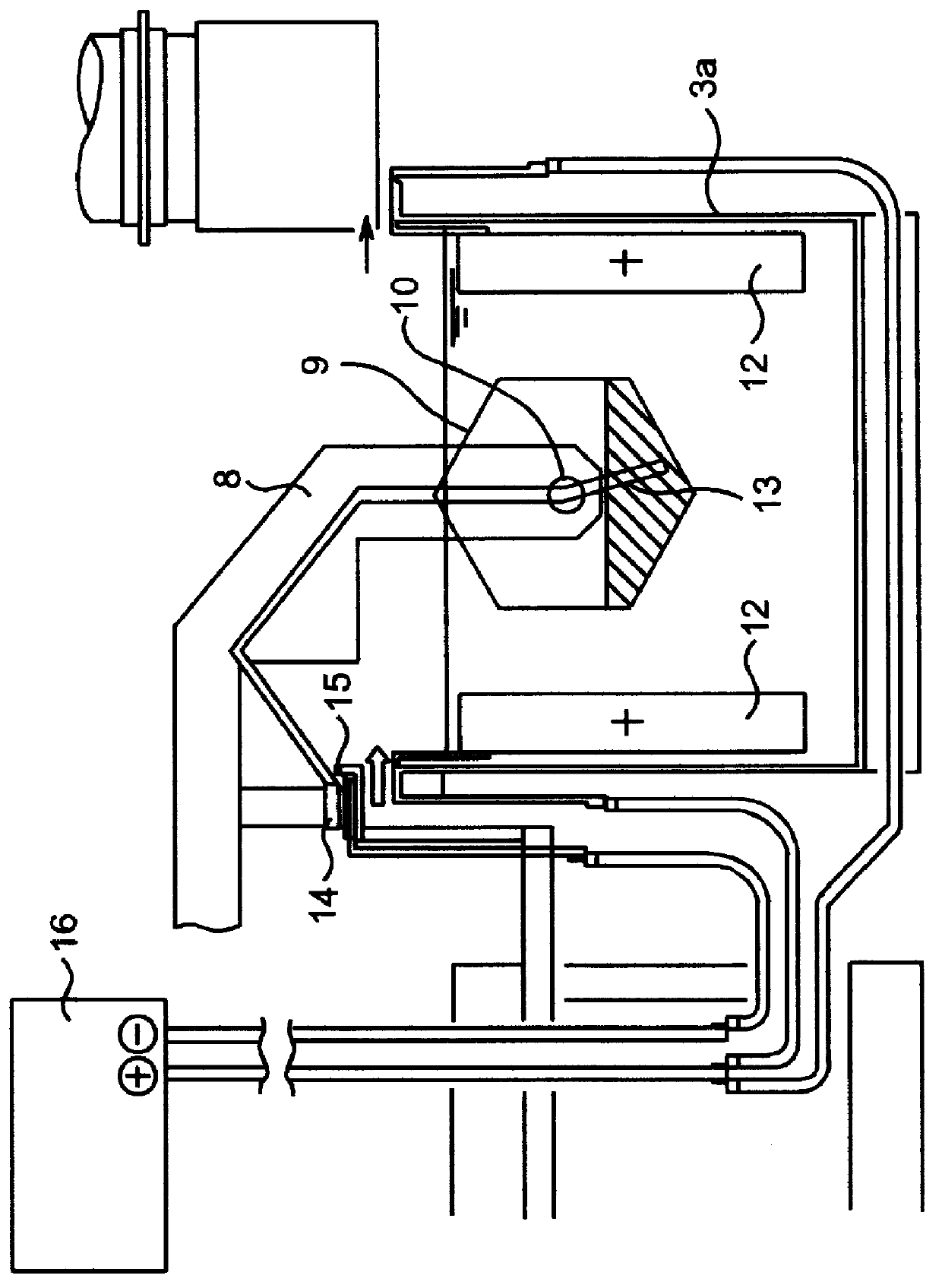

A barrel plating method wherein each box containing pieces to be plated is provided with a kanban corresponding to the pieces contained in the box. The kanban of each box is read by an apparatus before the pieces are transferred from the box to a plating barrel, so that a plating coefficient corresponding to the information read from the kanban is retrieved from a host computer in which plating coefficients for various kinds of pieces are stored. The plating coefficient retrieved corresponding to the kanban of each box is proportional to a value of plating current to be supplied to a unit weight of pieces contained in the box. A value of plating current for each barrel is automatically calculated by multiplying the plating coefficient by the measured weight of the pieces put in the barrel. Barrel plating is performed by supplying each barrel with the value of the calculated plating current from power sources that correspond in number to barrels that are subjected to a plating process at a given time.

Owner:AOYAMA SEISAKUSHO CO LTD +1

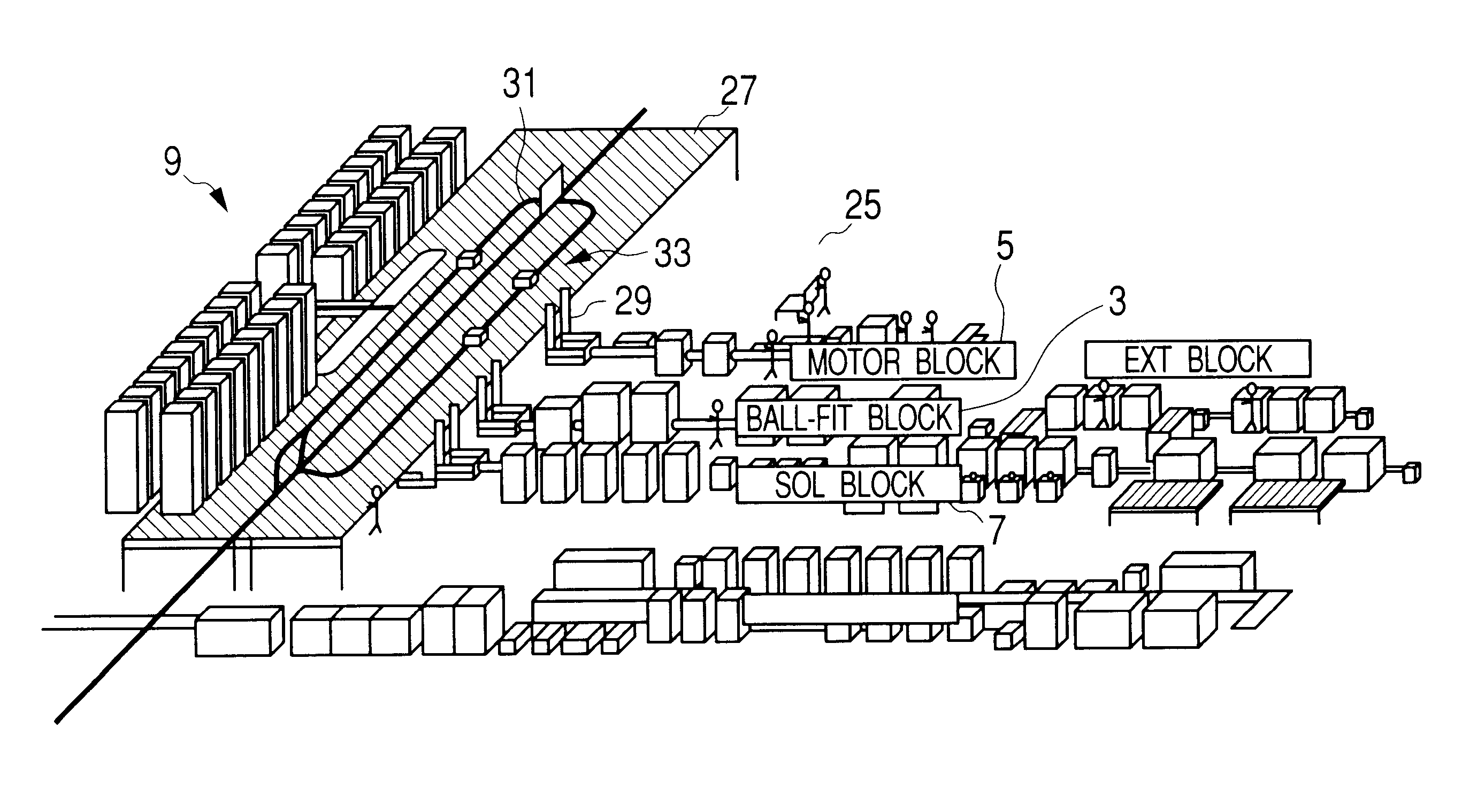

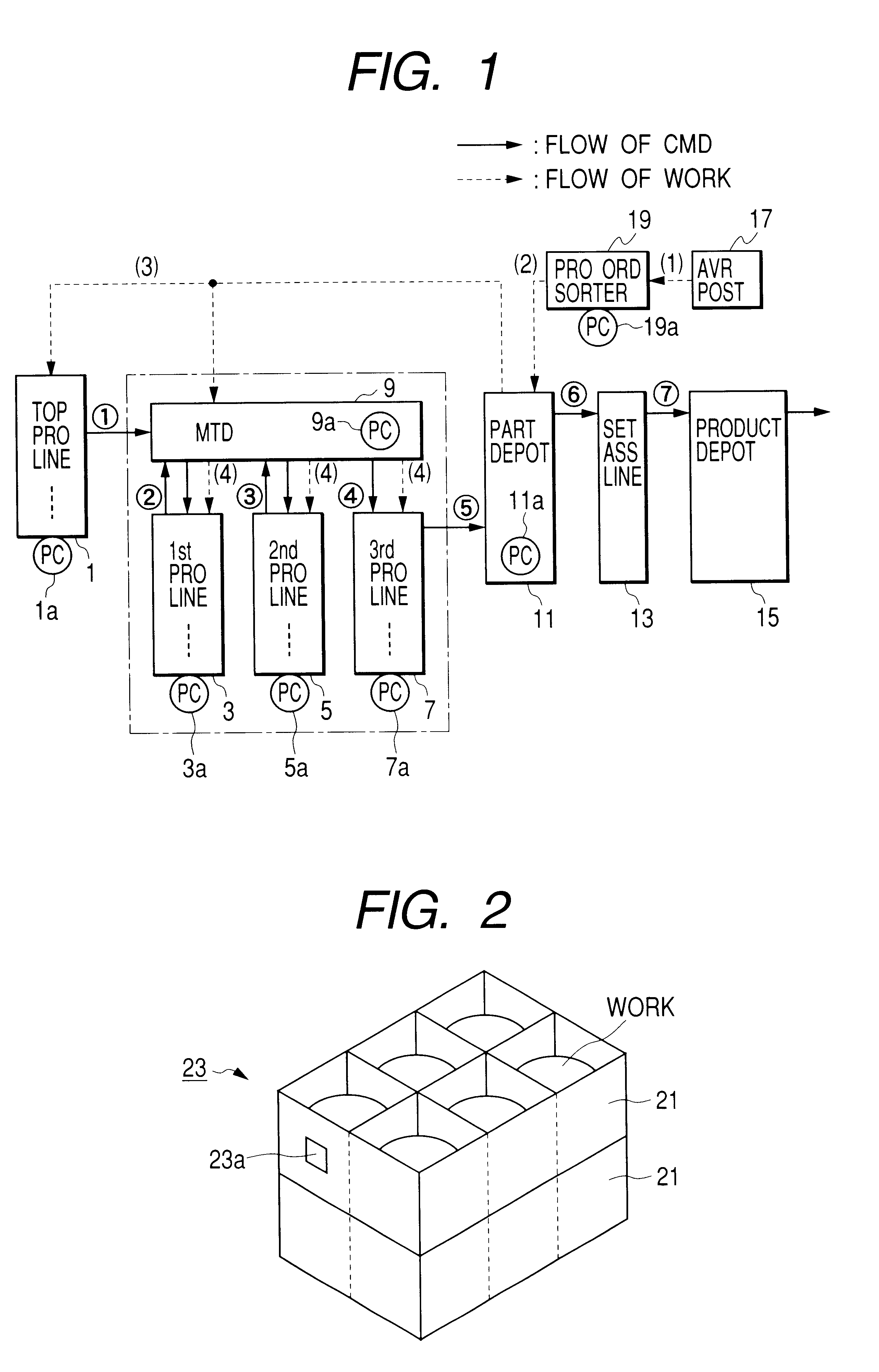

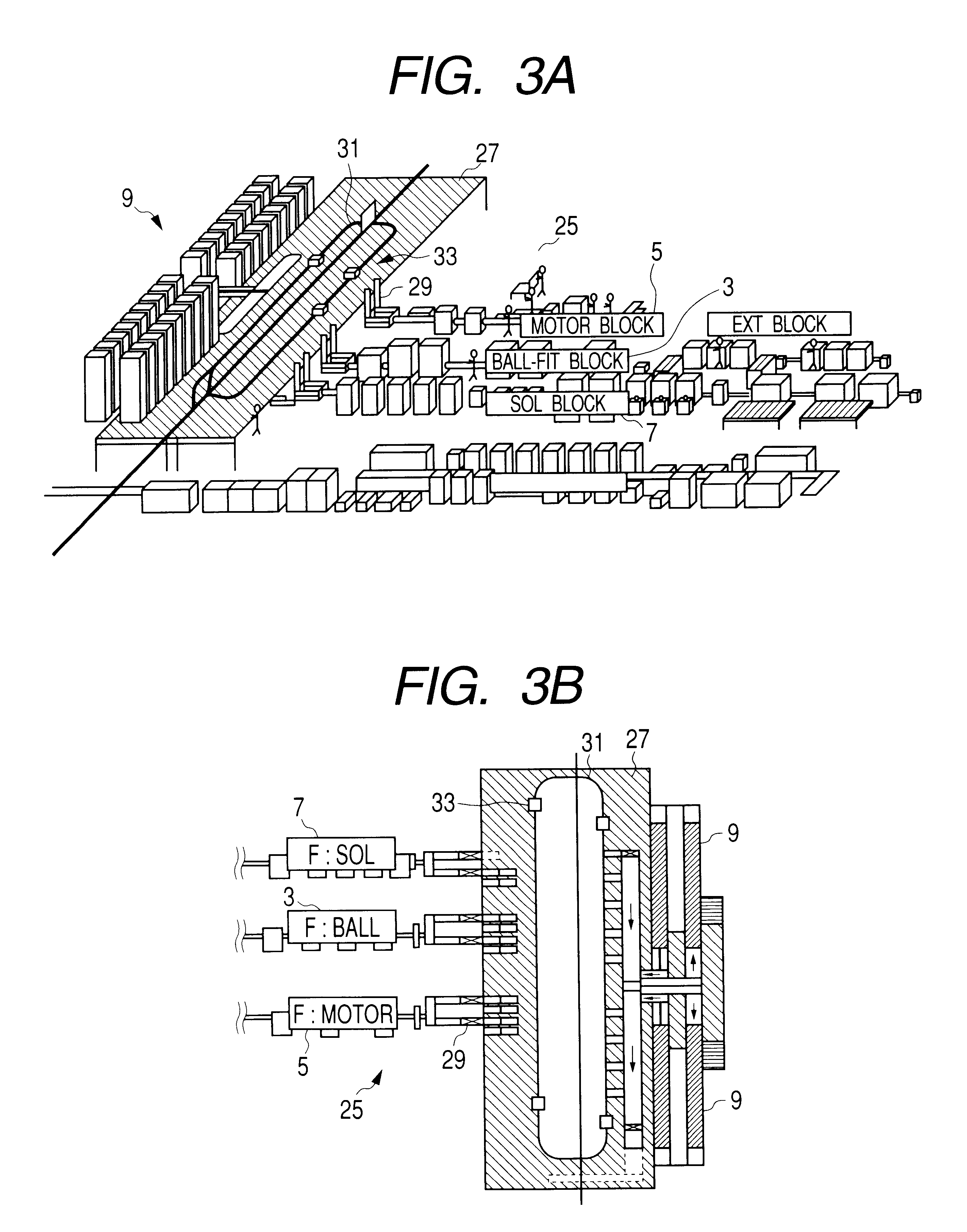

Production method and a production system

InactiveUS6862487B2Simple methodOptimize production systemData processing applicationsBraking action transmissionProduction lineMethods of production

Various models of brake parts (products) are produced with a mixedly transferring production system. The mixedly transferring production system includes a top line, a first production line, a second production line, and a third production line, a mixedly transferring depot, a part depot, and a set assembling line, and a product depot (mentioned in order of processing flow). Out of them, the first to third production lines, the mixedly transferring depot form the mixedly transferring block division type of production system. In addition, an averaging post and a production order plate (kanban) sorter are provided (mentioned in order of production command flow).

Owner:DENSO CORP

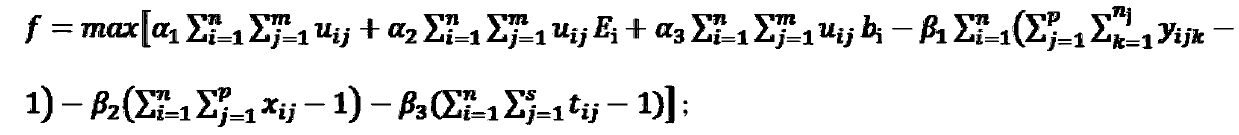

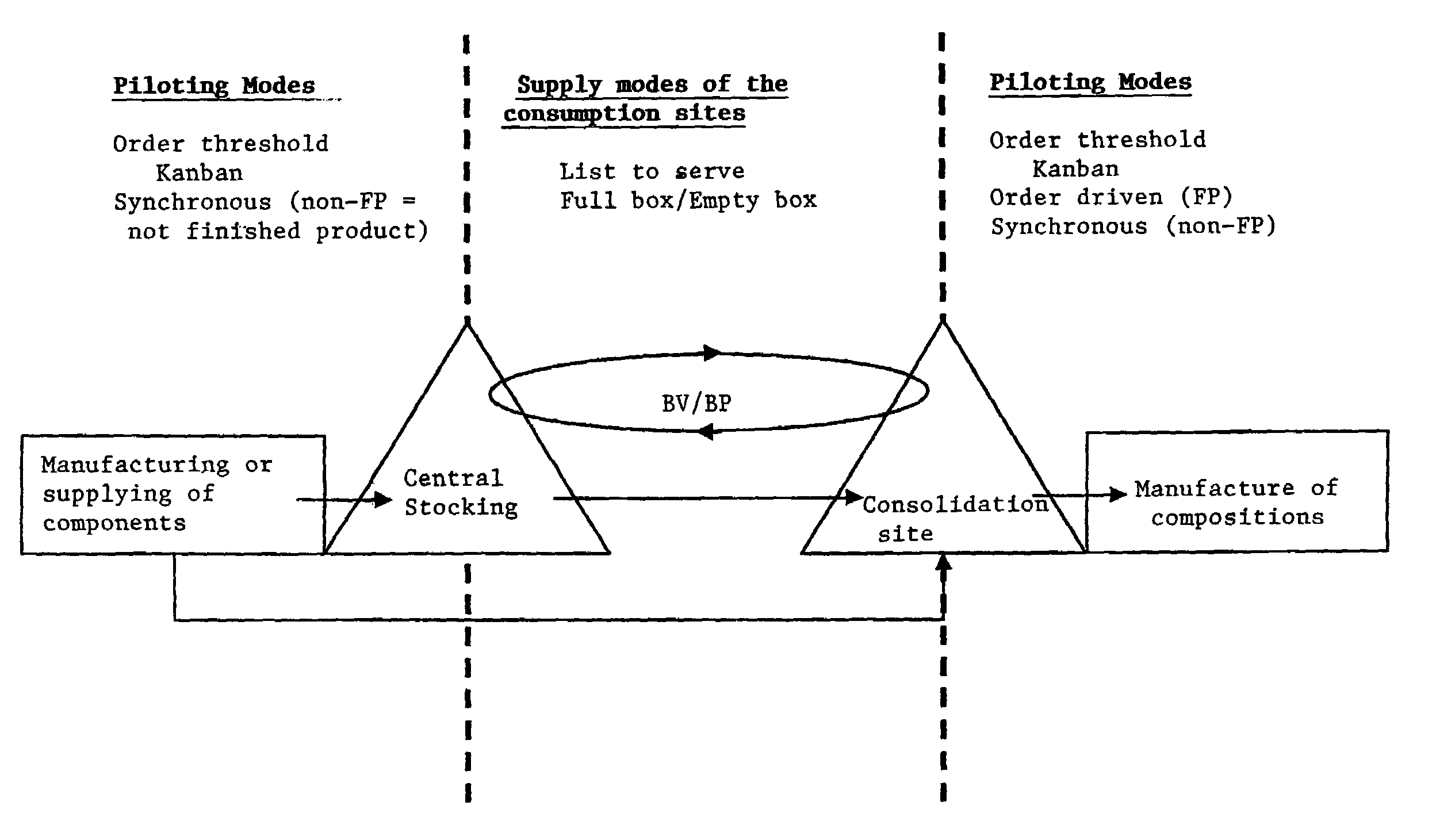

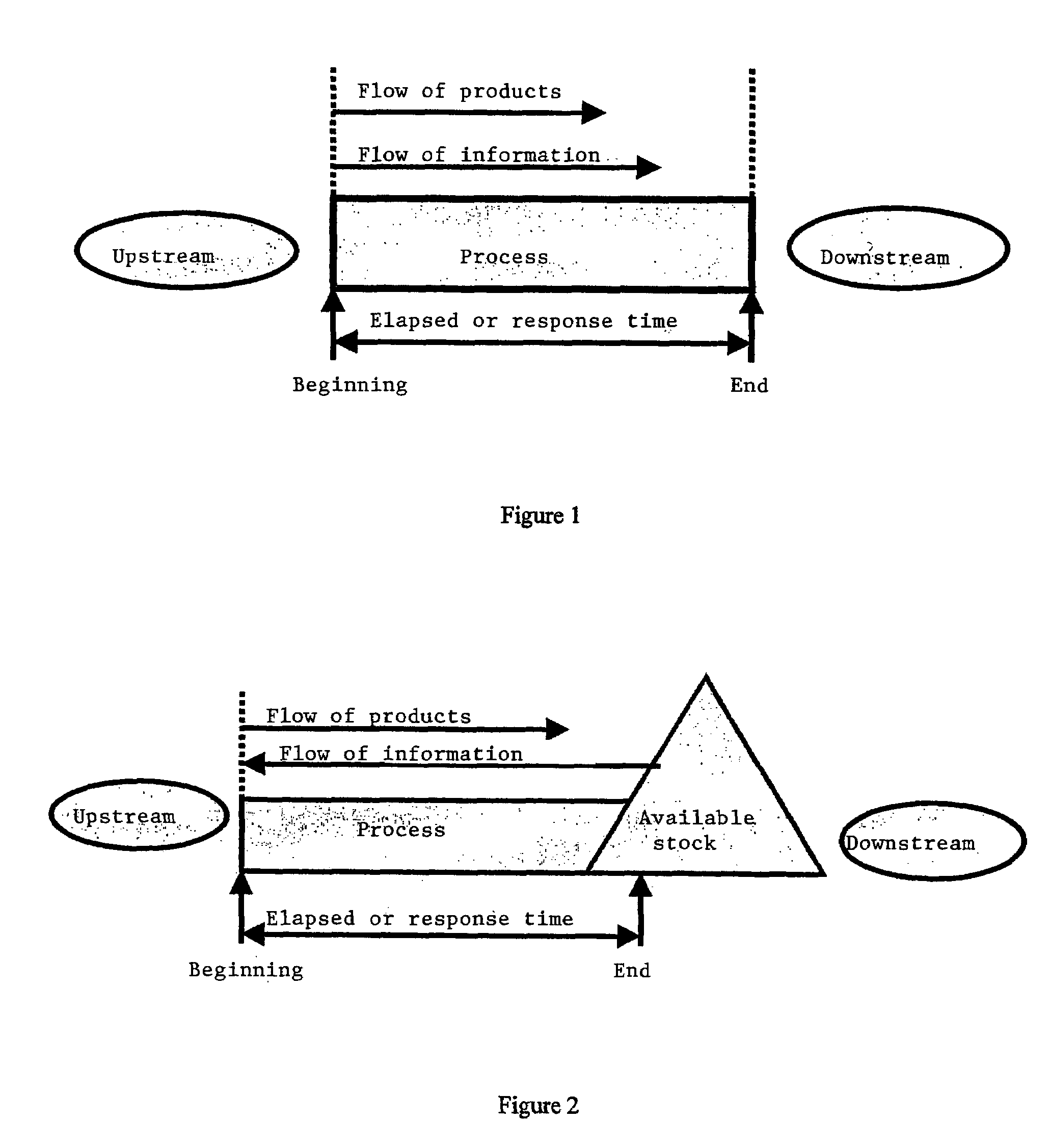

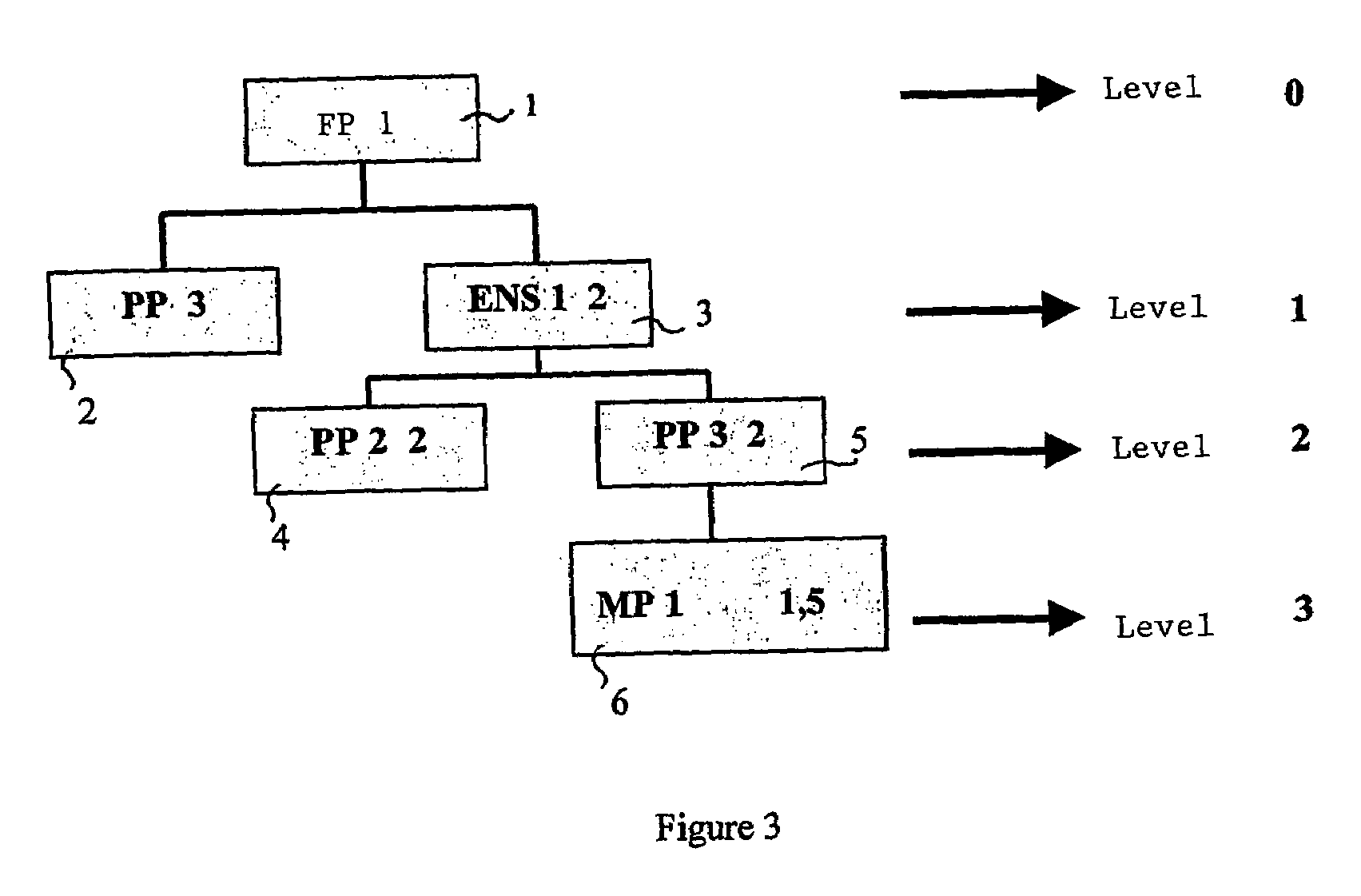

Computer-assisted pull flow production management method

A method for computer-aided pulled-flow production management including constructing a nomenclature as a numerical table including information relative to links between a finished product and components composing the finished product, constructing a numerical table pertaining to parameters of each of the components, and determining the number of product requirements including constructing a numerical table of calendar requirements over a period of time, wherein each component for the components whose descriptor has a kanban step is associated with a numerical table including counter descriptors counter C0 in which is recorded a state of a number of kanban in circulation with a preceding calculation of requirements, counter C1 in which is recorded a state of a total number of kanban after a last calculation of the requirements, counter C2 in which is recorded a state of a number of kanban available in stock, pending counter C3 in which is recorded a state of a number of pending kanban and not transmitted to counter C4, and counter C4 in which is recorded a state of a number of kanban in the process of manufacture or in the process of ordering.

Owner:CALVASOFT BV

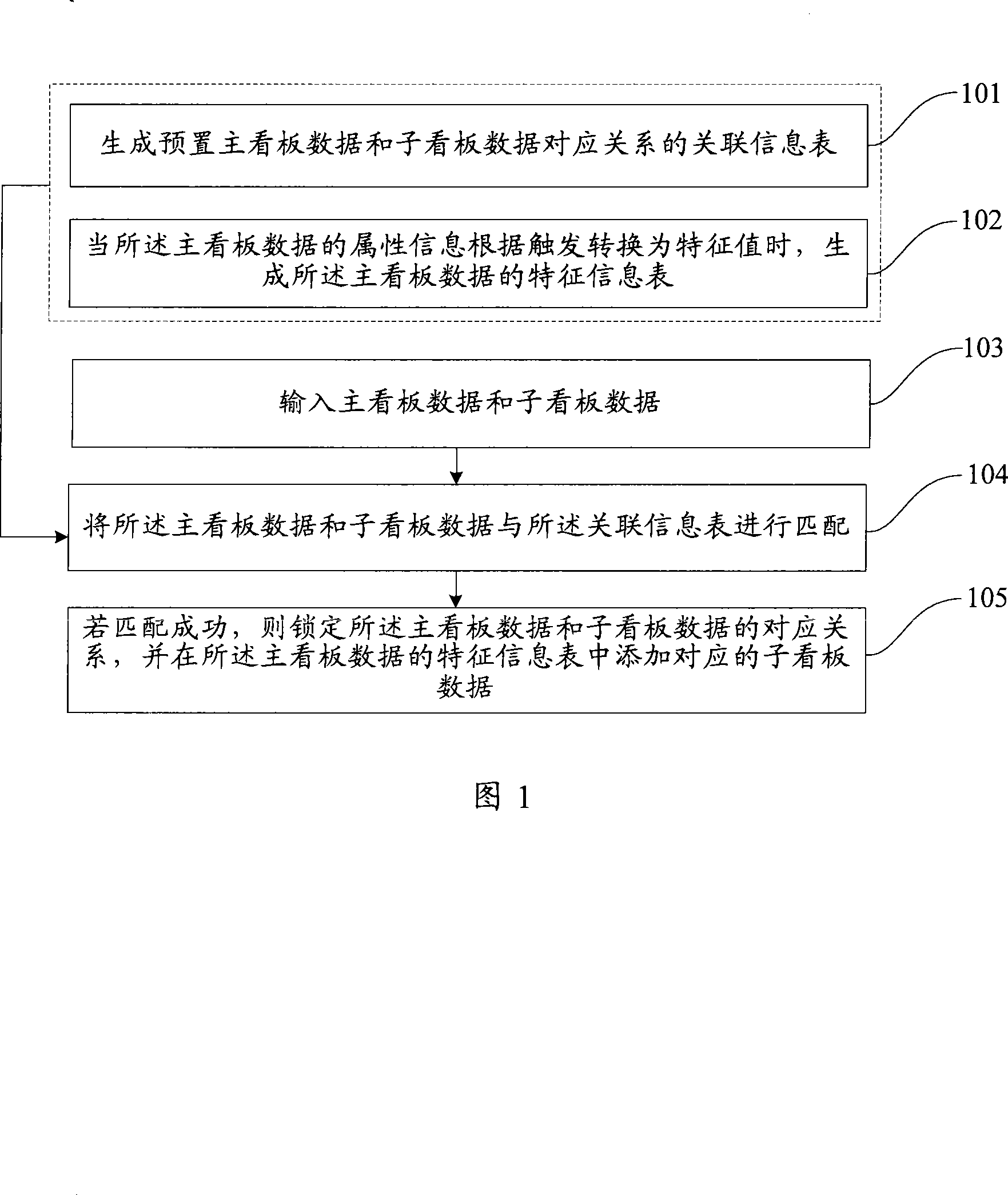

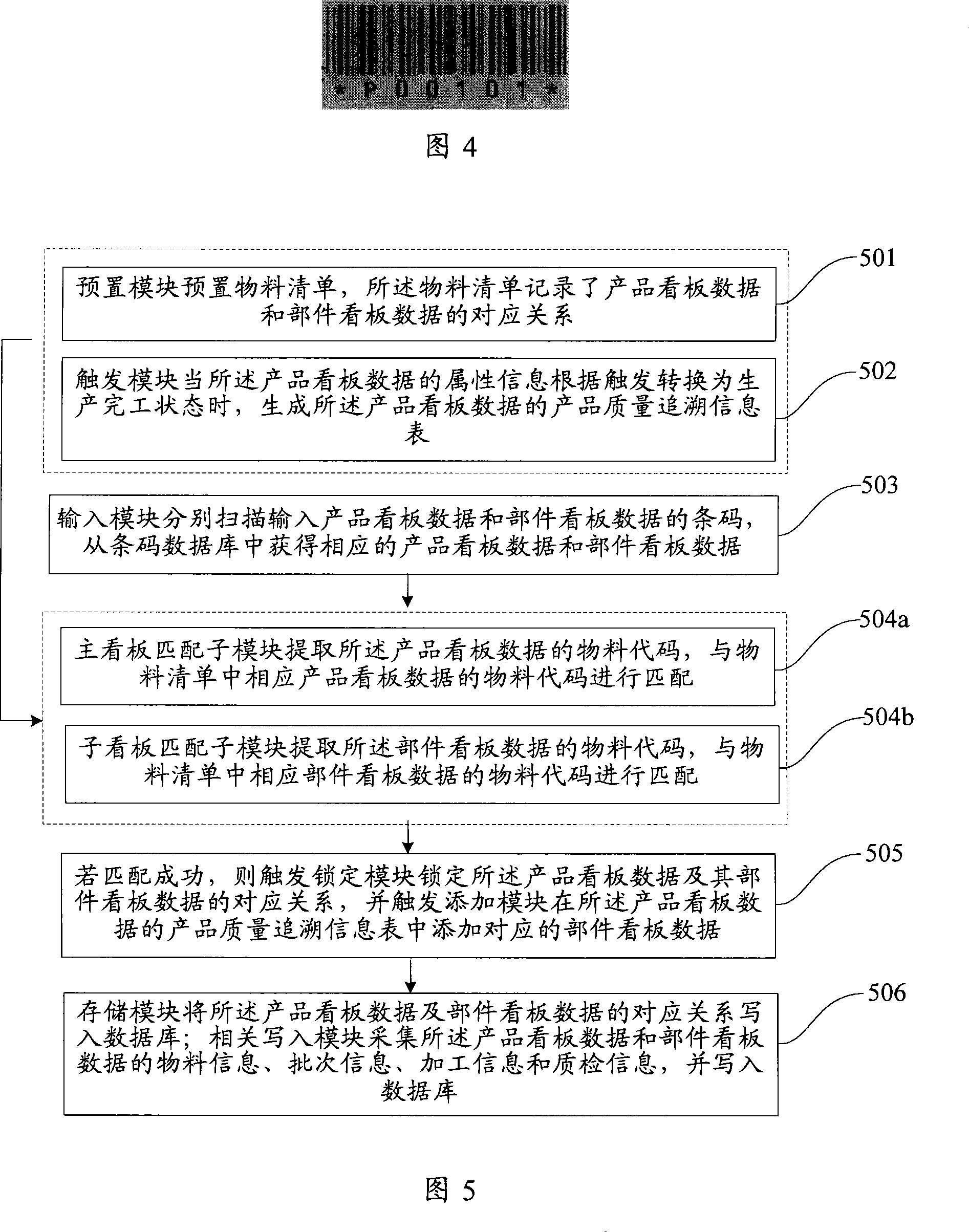

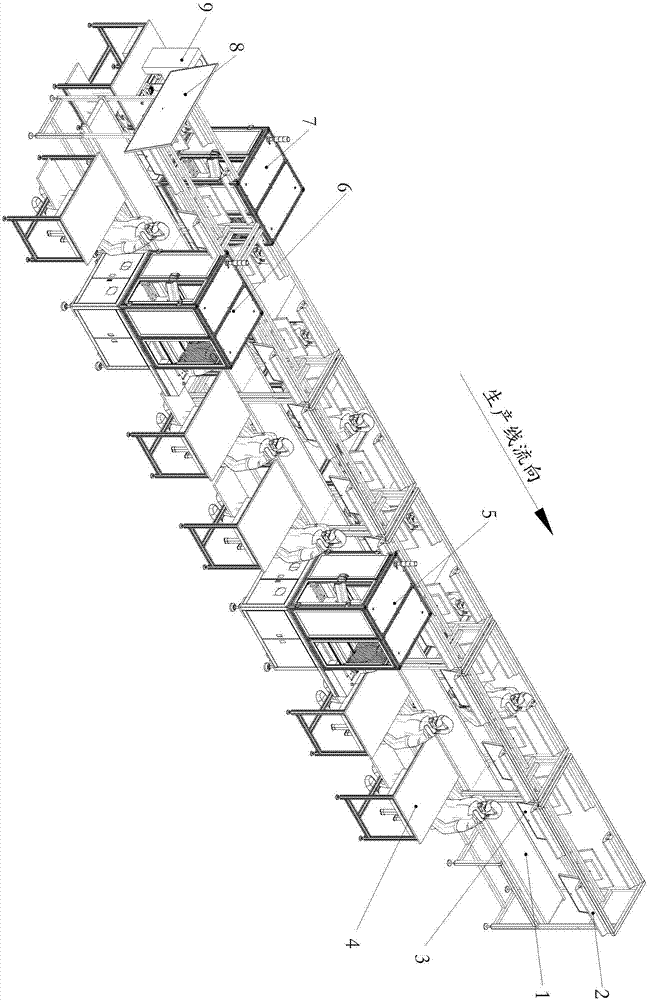

Kanban data processing method and kanban data processing system

InactiveCN101169846AGuaranteed timelinessGuaranteed accuracyResourcesSpecial data processing applicationsData processing systemData science

The invention provides a signboard data processing method. The signboard data includes main signboard data and sub signboard data. The main signboard data has property information. The method includes generating a correlated information table preset corresponding relations of the main signboard data and the sub signboard data; generating a characteristic information table of the main signboard data when the property information of the main signboard data is triggered to be converted to the characteristic value; inputting the main signboard data and the sub signboard data; matching the main signboard data and the sub signboard data with the correlated information table; and locking the corresponding relation of the main signboard data and the sub signboard data and adding corresponding sub signboard data into characteristic information table of the main signboard data when the matching is success. The invention can ensure real-time, accuracy and integrity of the data to save man load cost and reduce failure chance.

Owner:KINGDEE SOFTWARE(CHINA) CO LTD

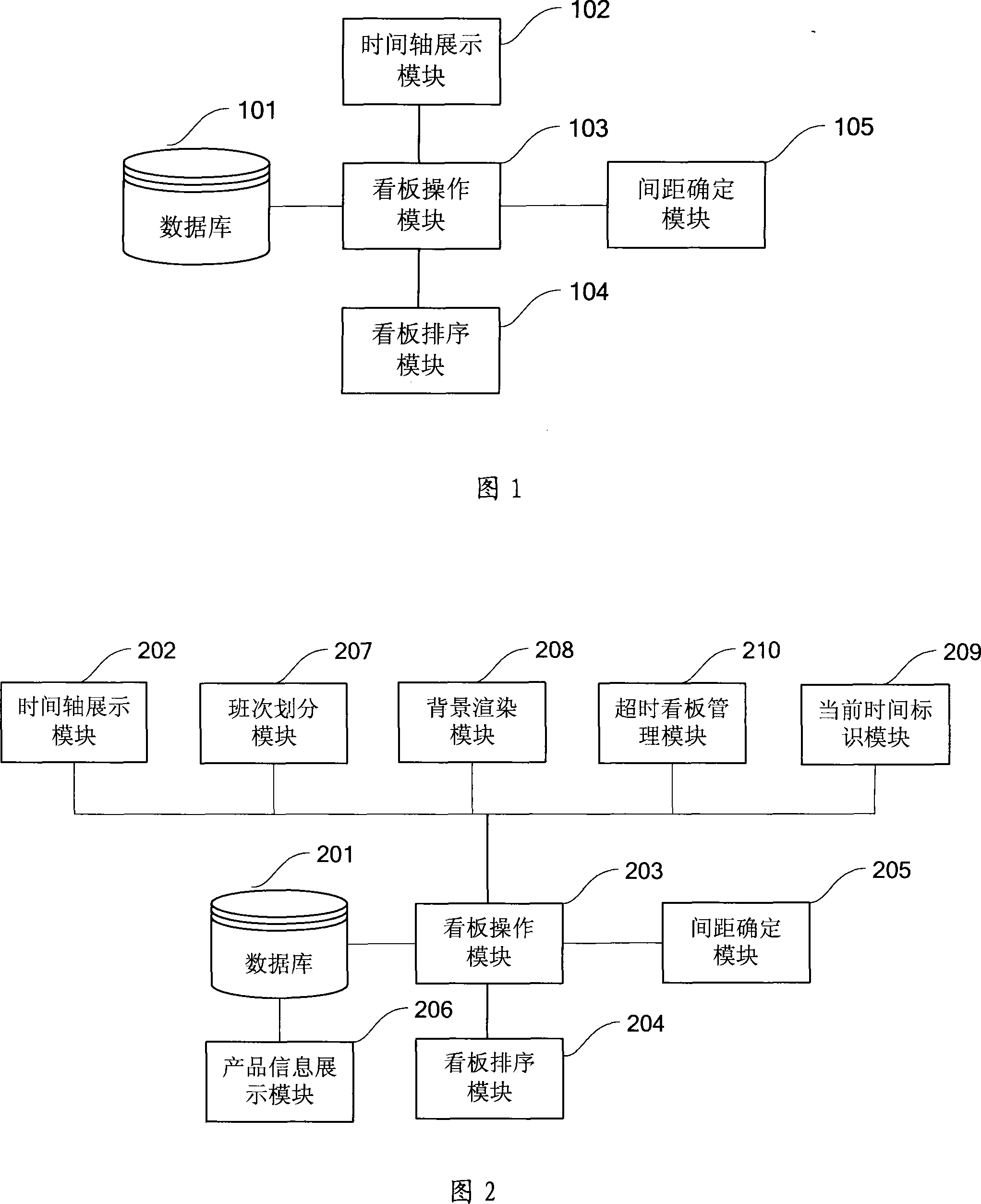

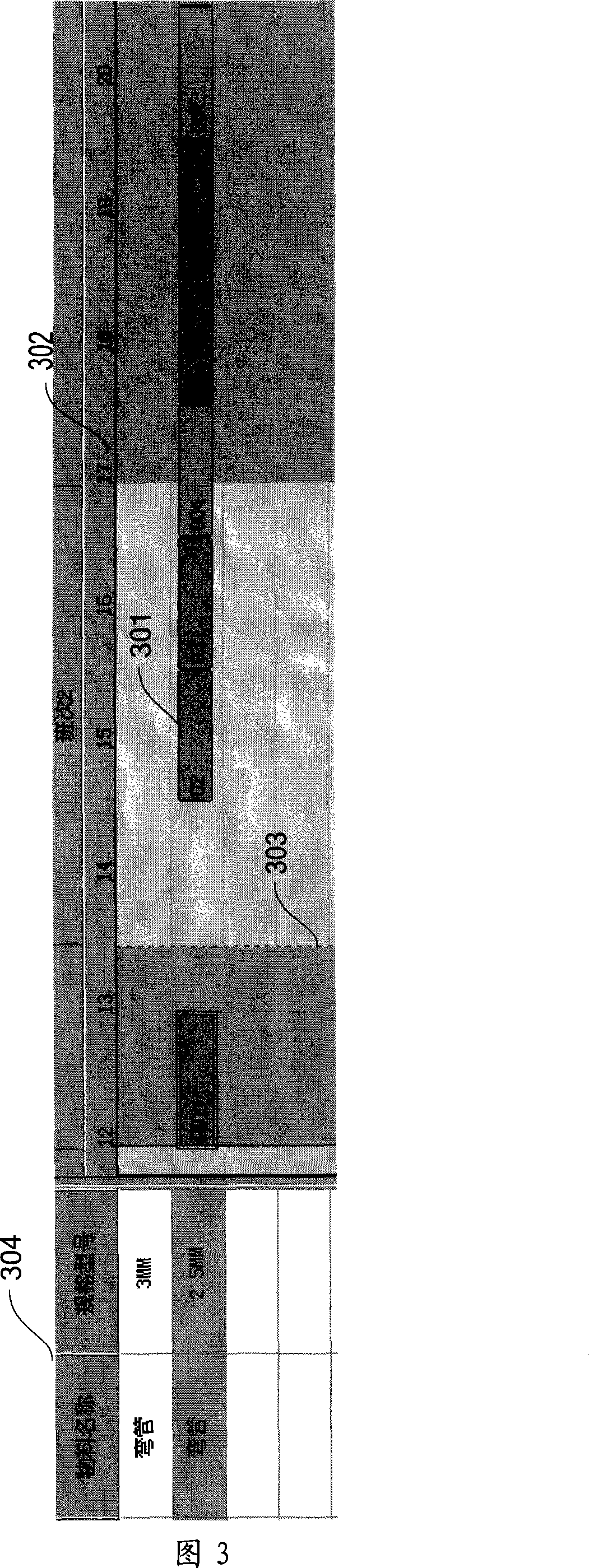

Kanban scheduling control system

InactiveCN101169844AIncrease productivityRealize electronicResourcesSpecial data processing applicationsGraphicsControl system

The invention provides a signboard scheduler control system. The system is used for performing signboard scheduler control aiming at a production unit, and particularly includes a database for storing basic information correlated to the production unit and processing time of each signboard in the production unit; a time axis exhibiting module for exhibiting a continuous time axis; a signboard operation module for acquiring required data from the database, converting processing time of the to-be-scheduled signboard into corresponding length of the time axis, displaying patterned signboard, receiving operation command from a user, and setting the patterned signboard at a position corresponding to the time axis; and a signboard ordering module for judging whether repeated signboards are present at the same time point, and automatically reordering the correlated signboards according to the time axis via a backward pressing mode if the judging result is yes. The invention can help a user to conveniently perform optimized scheduler of signboards and improve production efficiency.

Owner:KINGDEE SOFTWARE(CHINA) CO LTD

Combustible gas monitor assembly line and assembly method

InactiveCN107962374AImprove assembly efficiencySave spaceAssembly machinesMetal working apparatusDesiccantAgricultural engineering

The invention discloses an assembly line for a combustible gas monitor, which includes a transmission mechanism, an illuminating lamp, an SOP kanban, and an operation platform. The operation platforms are alternately arranged on both sides of the transmission mechanism. An illuminating lamp, an SOP kanban is provided under the illuminating lamp, and the SOP kanban is rotatably connected to the bracket of the transmission mechanism, and a wire end kanban is fixed on the entrance bracket of the transmission mechanism; the first one at the entrance of the transmission mechanism A desiccant weighing machine is fixed on the top of the operating platform, followed by a sensor locking screw machine, an air nozzle locking screw machine and a lower shell locking screw machine in sequence. The invention also discloses a specific assembly method for the modified assembly line. The assembly line and its matching assembly method of the present invention have a high degree of automation, can greatly reduce personnel costs, reduce labor intensity, and improve product quality.

Owner:ANHUI HONGSHI AUTOMATION EQUIP CO LTD

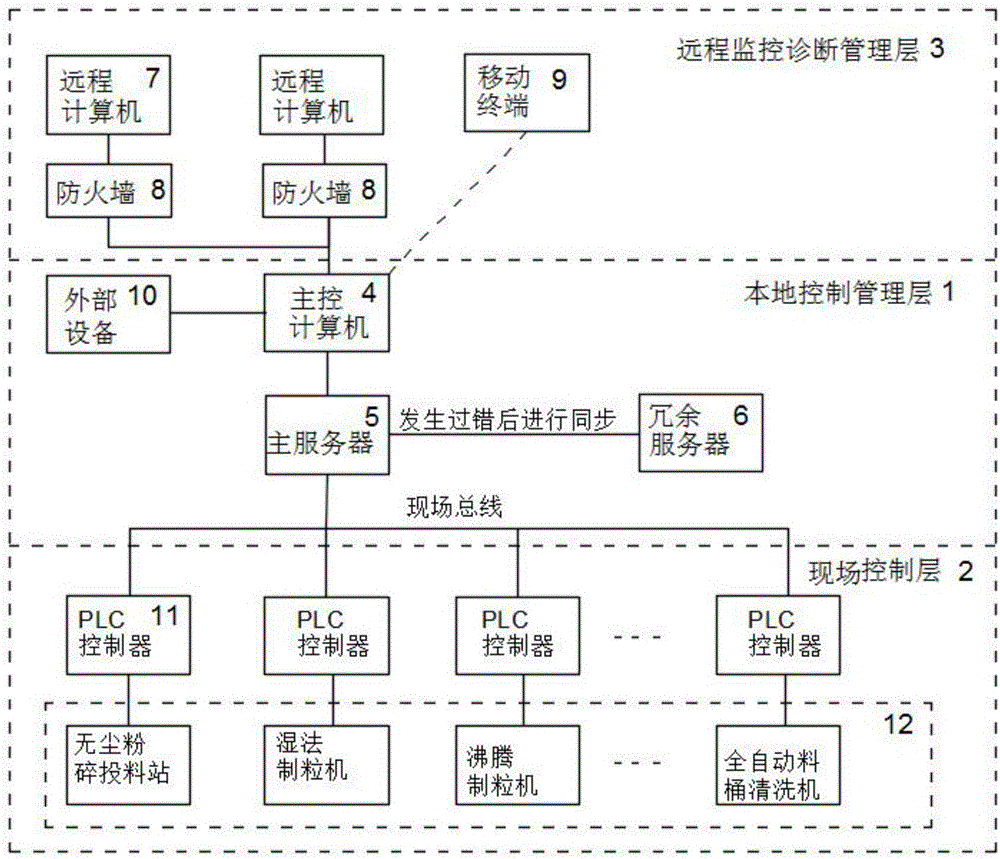

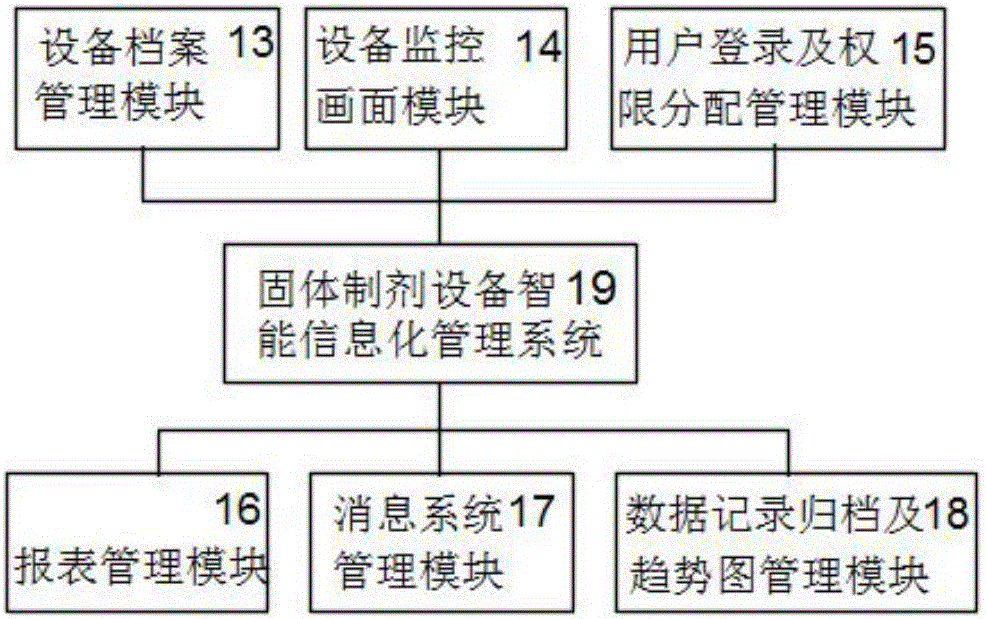

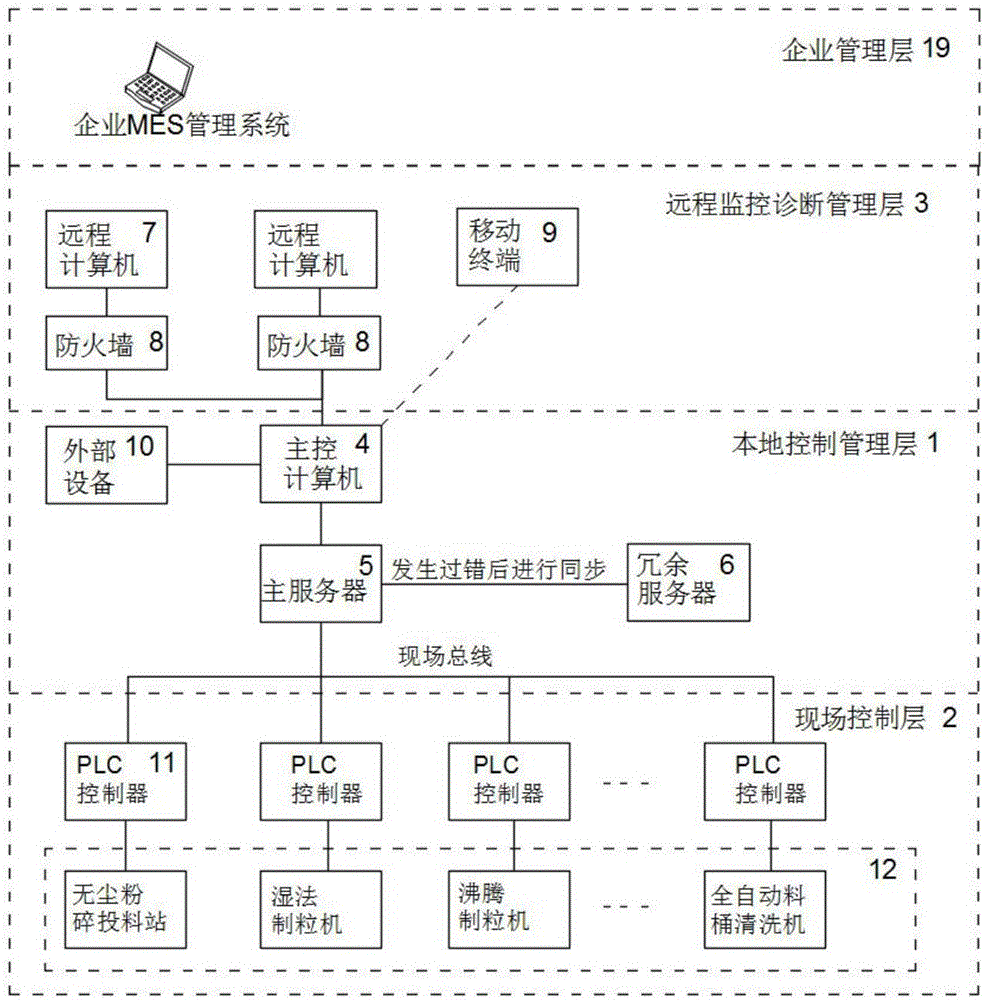

Production process execution system for pharmaceutical company

InactiveCN106527375AAvoid wastingOperation coordinationTotal factory controlProgramme total factory controlControl layerDecomposition

The invention discloses a production process execution system for a pharmaceutical company, and the production process execution system can realize on-site, local and / or remote automatic monitoring and management. The production process execution system comprises a local control management layer which is respectively connected to an on-site control layer of the local control management layer and a remote monitoring and management layer. The production process execution system further comprises a company management layer connected to the remote monitoring and management layer. Key task information related to product behavior is provided in the company and an entire pharmaceutical product supply chain through bidirectional direct communication of the system. The production process execution system further comprises management modules for manufacture data management, plan scheduling management, production scheduling management, stock management, quality management, human resource management, work center / equipment management, tool management, purchase management, cost management, project billboard management, production process control, underlying data integration and analyzing and upper layer data integration and decomposition for the company.

Owner:YICHUN WANSHEN PHARMA MACHINERY

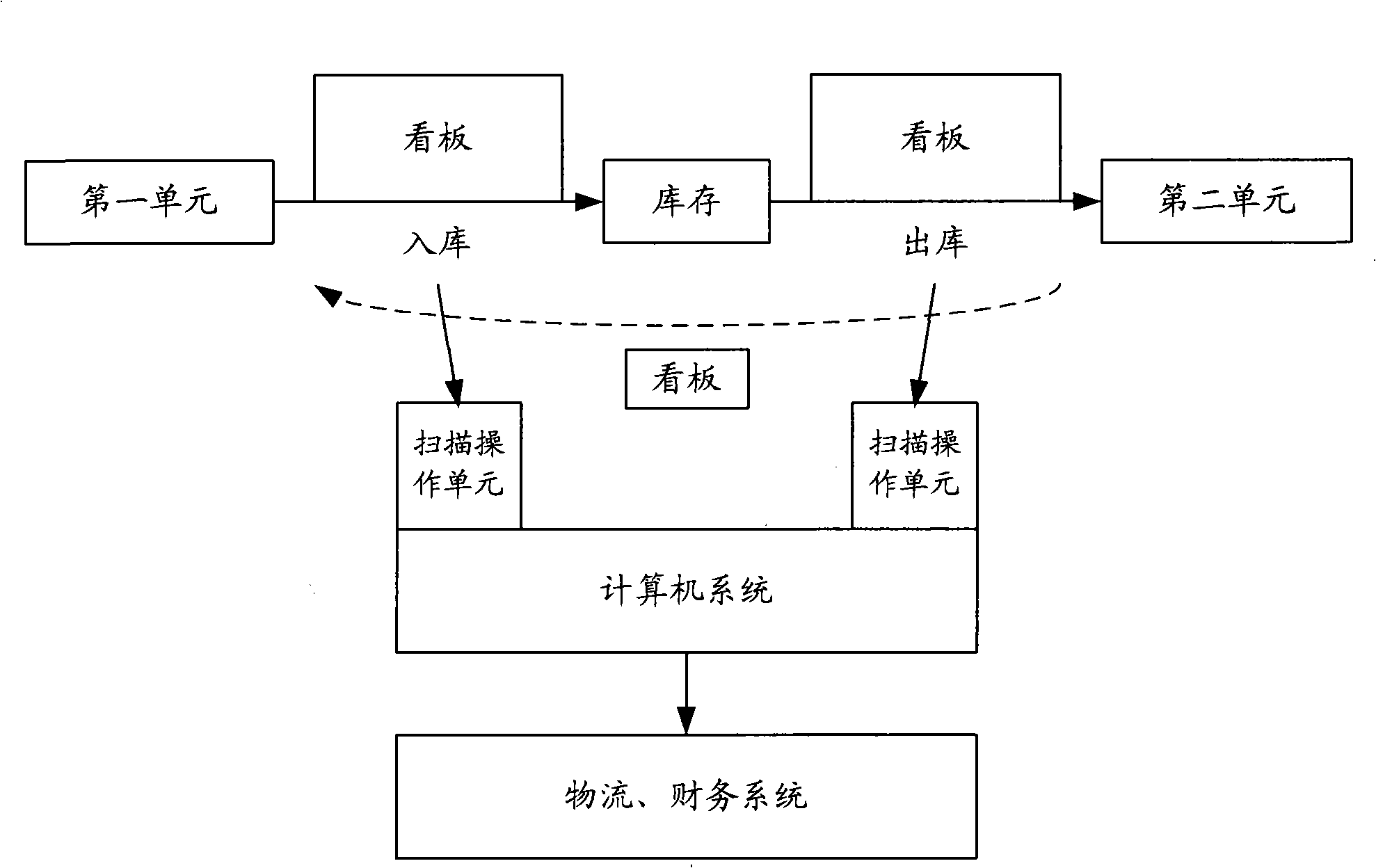

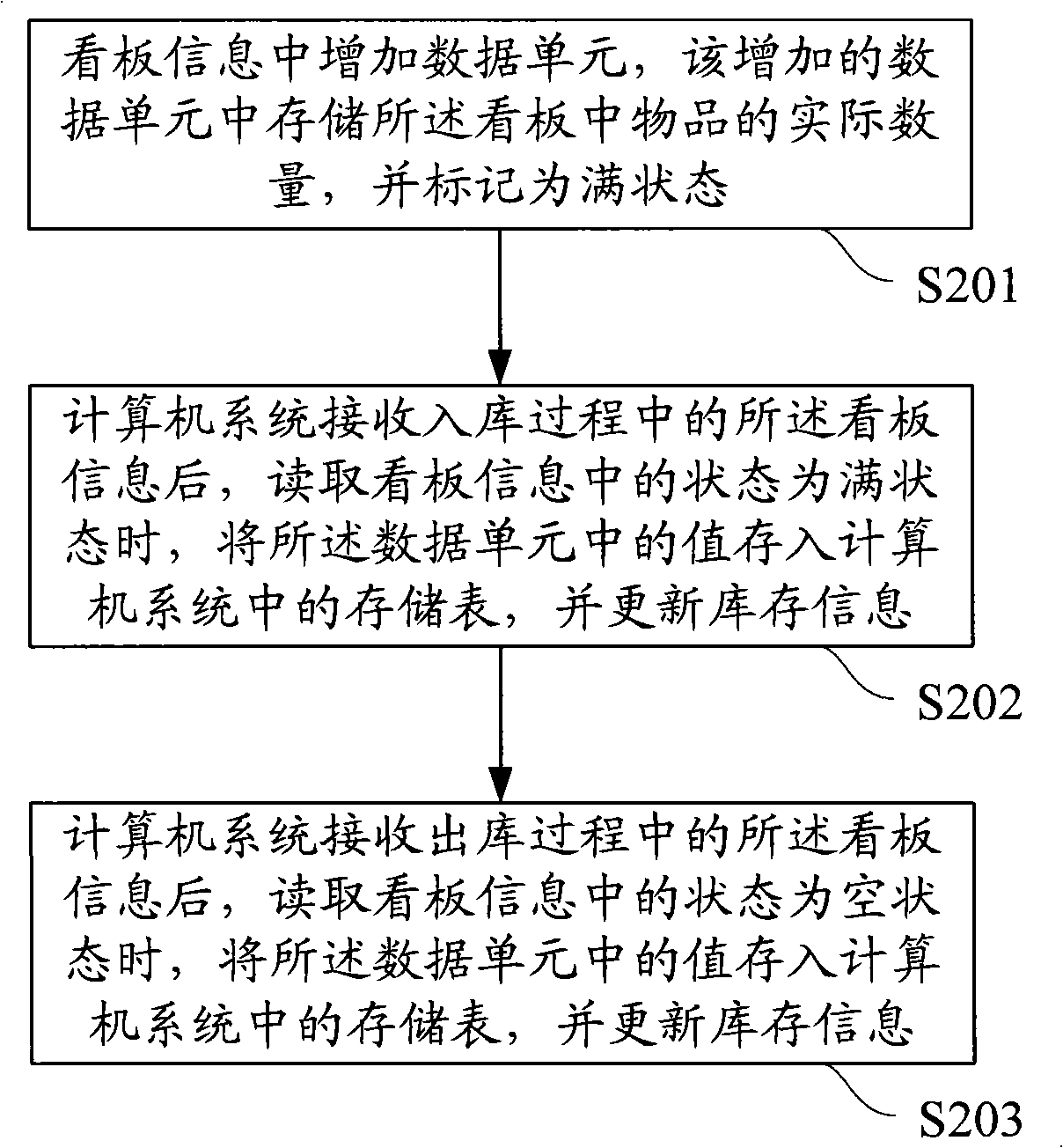

Statistics method and system for billboard import and export

InactiveCN101404093ASolve consumptionSolve productivityRegistering/indicating working of machinesLogisticsComputerized systemOperating system

The invention relates to a Kanban warehouse-in and warehouse-out statistical method and a system. The Kanban warehouse-in and warehouse-out statistical method comprises: S1: a data unit is added in Kanban information, the added data unit stores actual number of items in a Kanban and is marked as the full state; S2: when the state in the Kanban information is read as the full state after a computer system receives the Kanban information during the warehouse-in process, the value in the data unit is stored in a storage table in the computer system and the inventory is updated; S3: when the state in the Kanban information is read as the empty state after the computer system receives the Kanban information during the warehouse-out process, the value in the data unit is stored in the storage table in the computer system and the inventory information is updated. The use of the statistical method and the system can avoid the problem that accounts are inconsistent with physical inventory during the production process.

Owner:KINGDEE SOFTWARE(CHINA) CO LTD

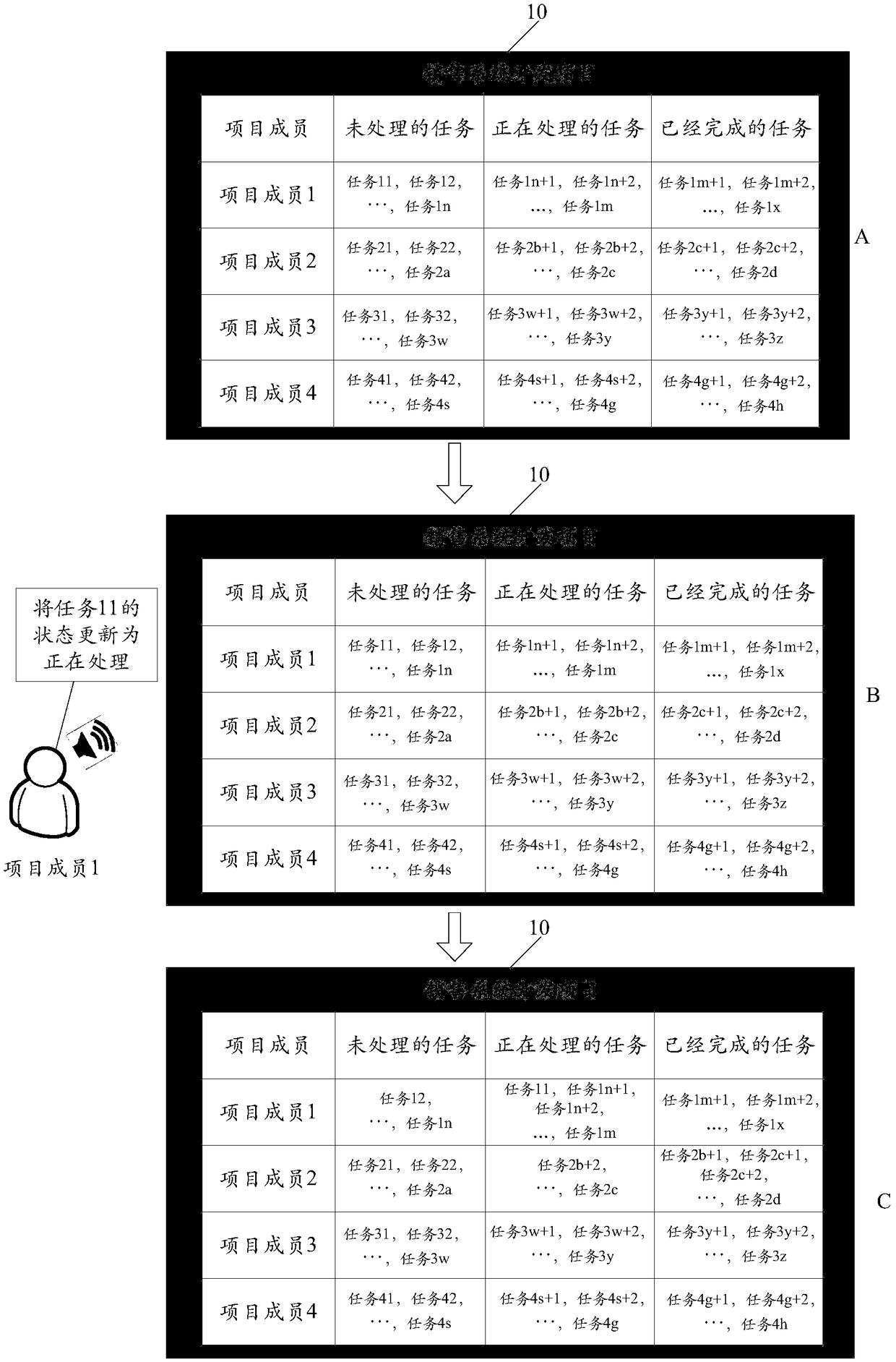

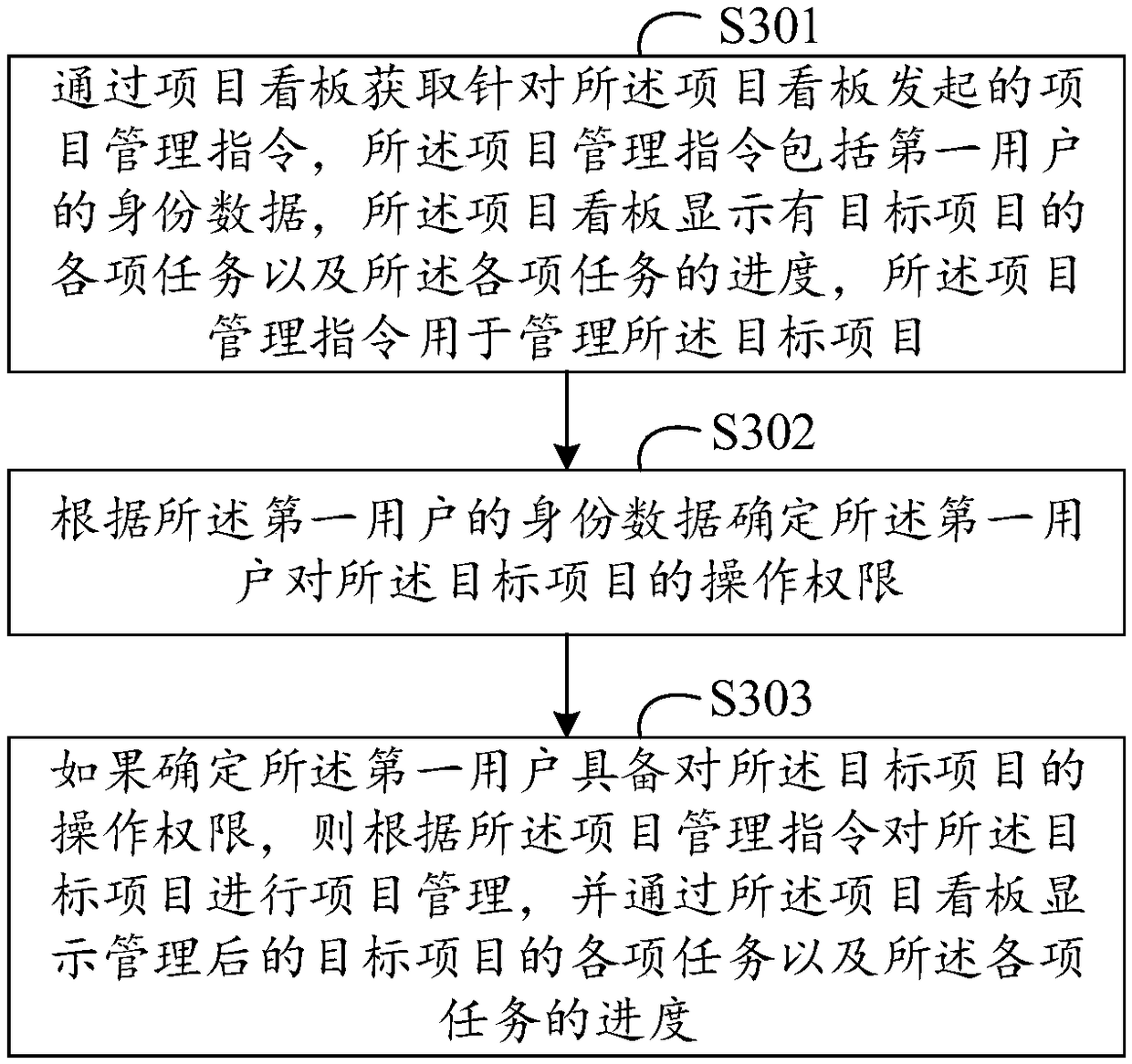

Project kanban management method and device based on biometrics

The invention provides an item kanban management method and device based on biometrics, The method comprises the following steps: acquiring a project management instruction initiated for the project kanban through the project kanban, wherein the project management instruction comprises identity data of a first user, the project kanban displays tasks of a target project and progress of the tasks, and the project management instruction is used for managing the target project; Determining an operation right of the first user to the target item according to the identity data of the first user; Ifit is determined that the first user has the operation right to the target project, managing the target project according to the project management instruction, and displaying the tasks of the managedtarget project and the progress of the tasks through the project kanban. The technical scheme enables the user to directly manage the project in the project kanban through the project kanban, and theoperation is simple and convenient.

Owner:ONE CONNECT SMART TECH CO LTD SHENZHEN

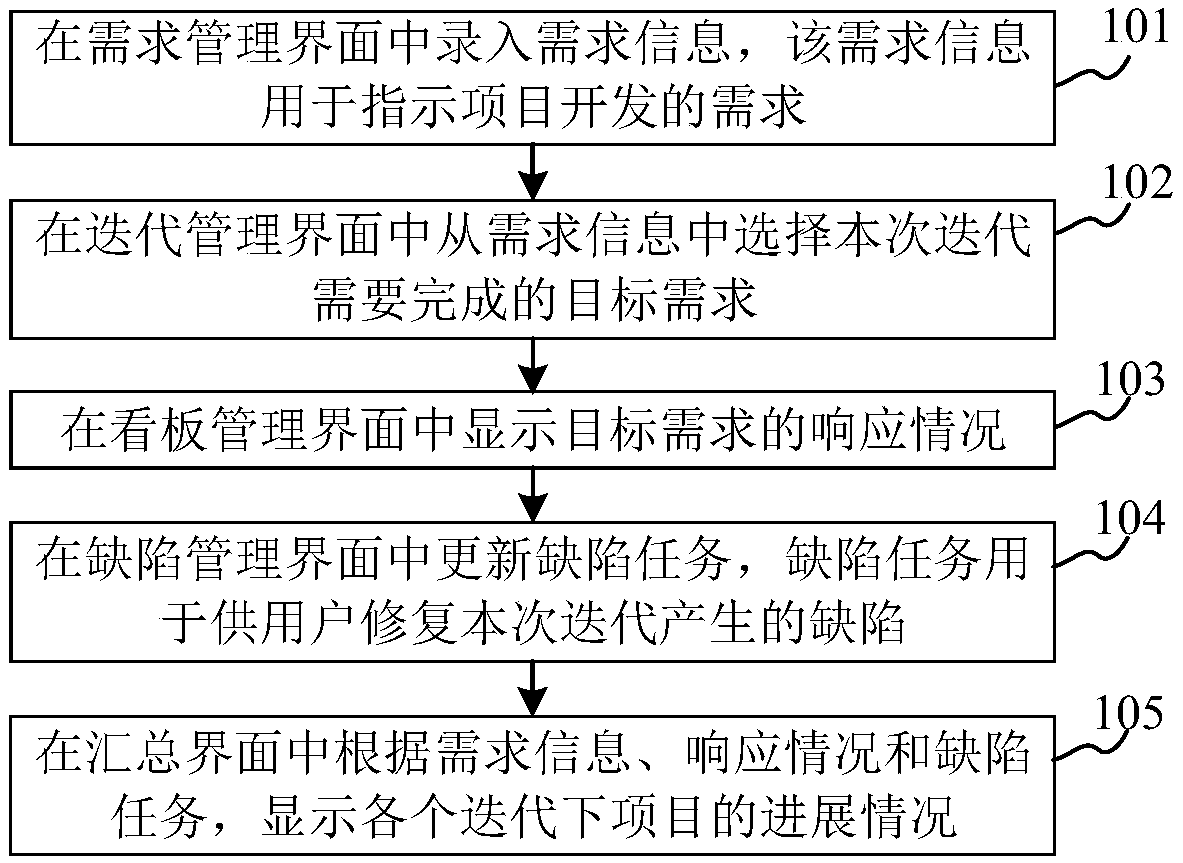

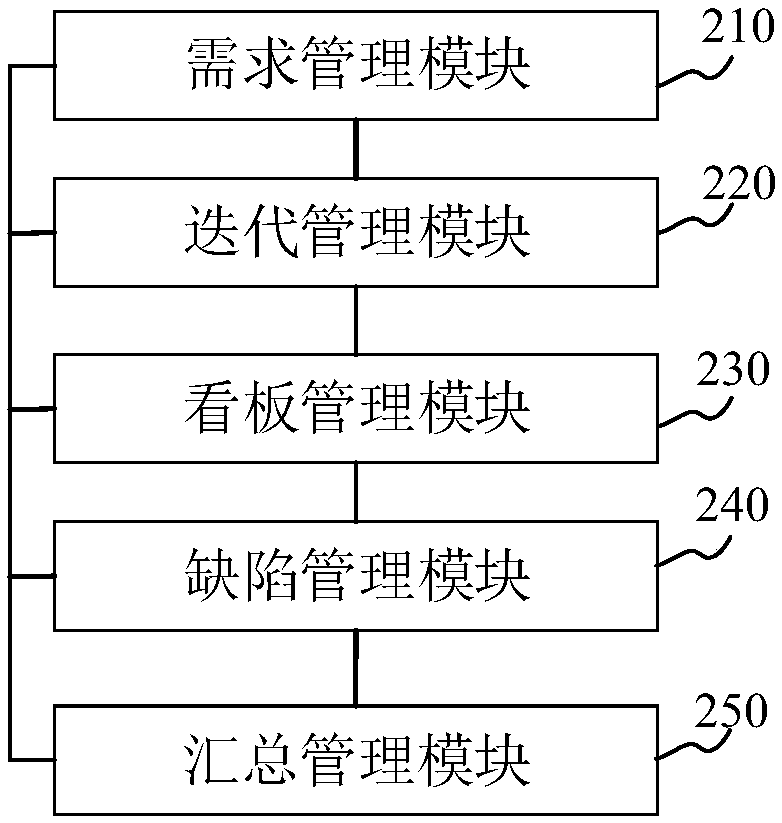

Project development management method and device

InactiveCN109377195ASimplified management stepsReduce landing timeOffice automationCompletion StatusRequirements management

The invention relates to a project development management method and a device, belonging to the technical field of project development. In the iteration management interface, selecting the target requirements to be completed in this iteration from the requirements information; Displaying the response of target requirements in the Kanban Management interface; Updating defect tasks in the defect management interface; Displaying the progress of the project under each iteration according to the requirement information, responsing status and defect task in the summary interface; It can solve the problems of understanding deviation and misunderstanding caused by independent development in each stage of development. As the completion status of each stage of the project can be displayed in the Kanban management interface, developers at a certain stage can know the development progress of the project through the Kanban management interface without manual inquiry; Therefore, it can simplify theproject management steps, improve the development efficiency and shorten the project landing time.

Owner:江苏风云网络服务有限公司

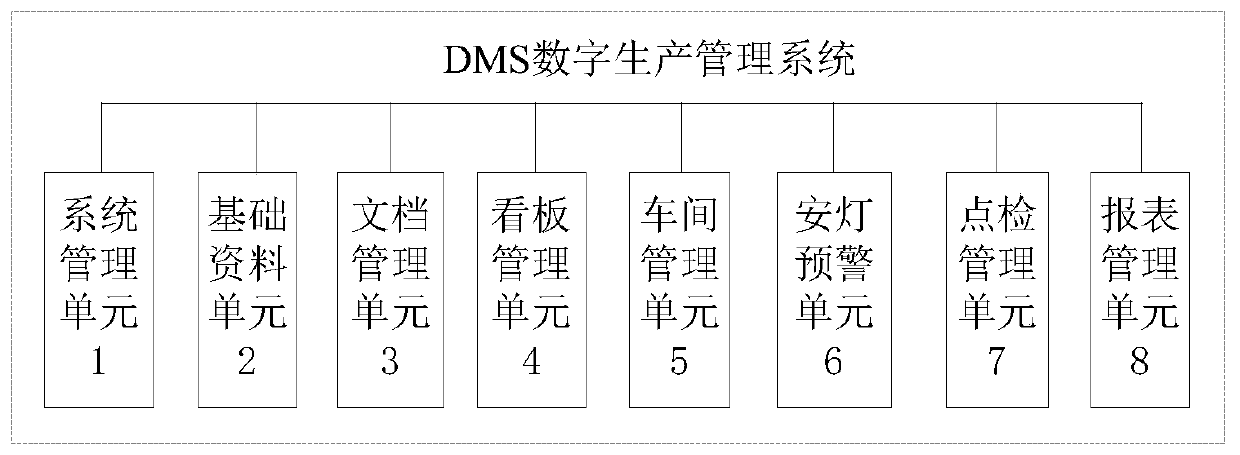

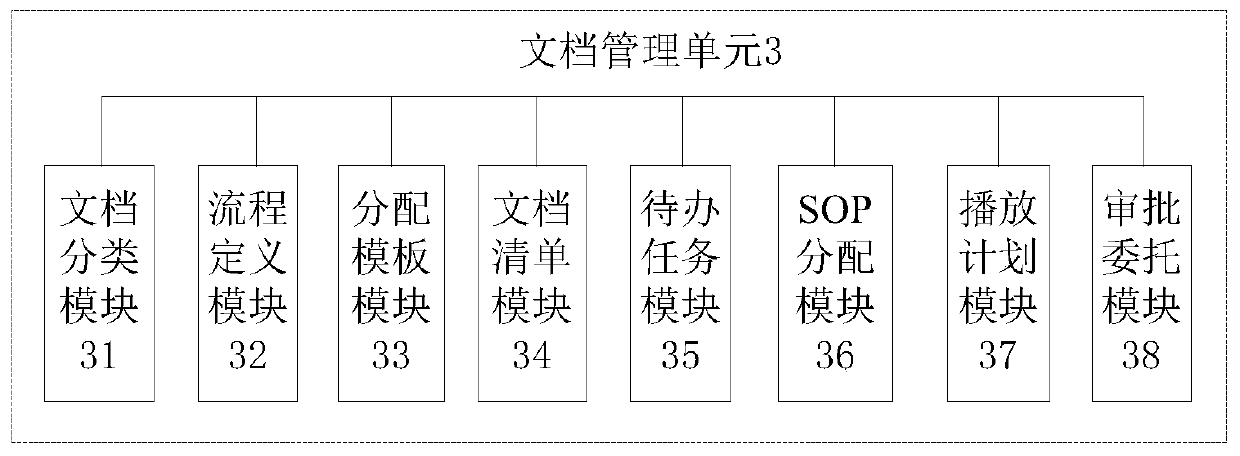

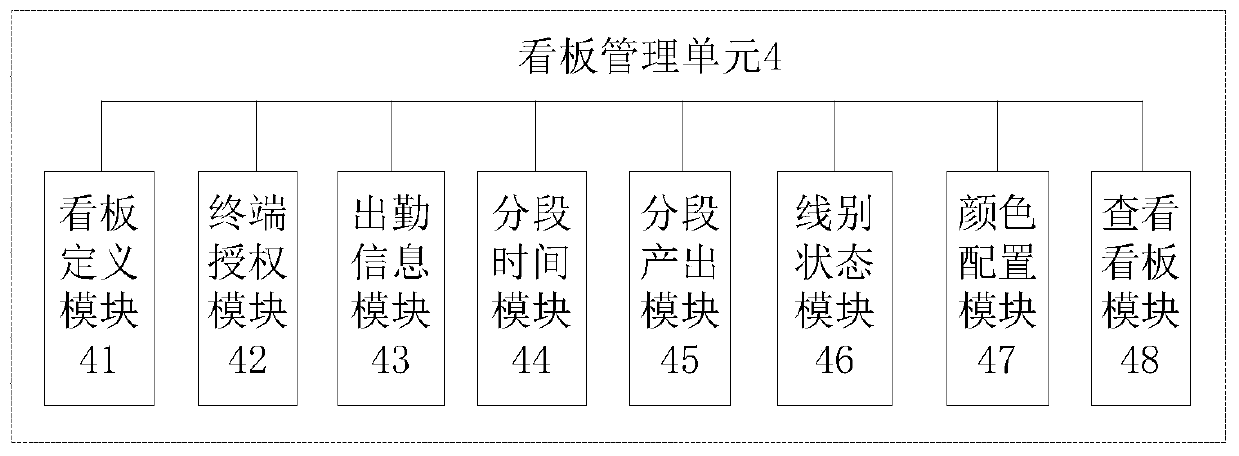

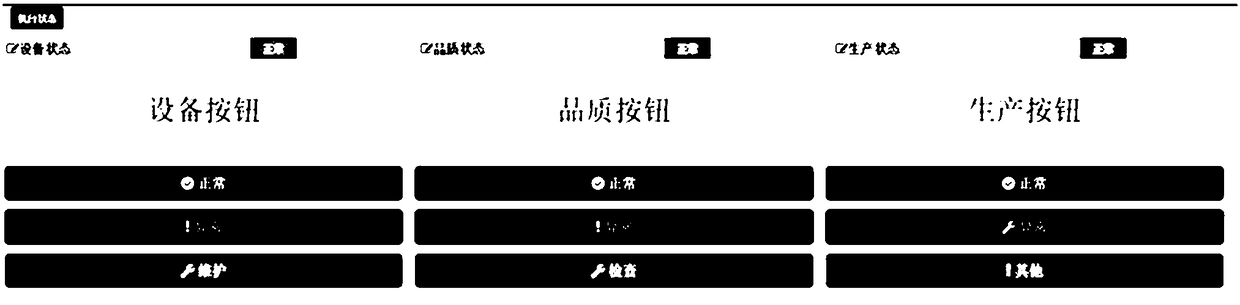

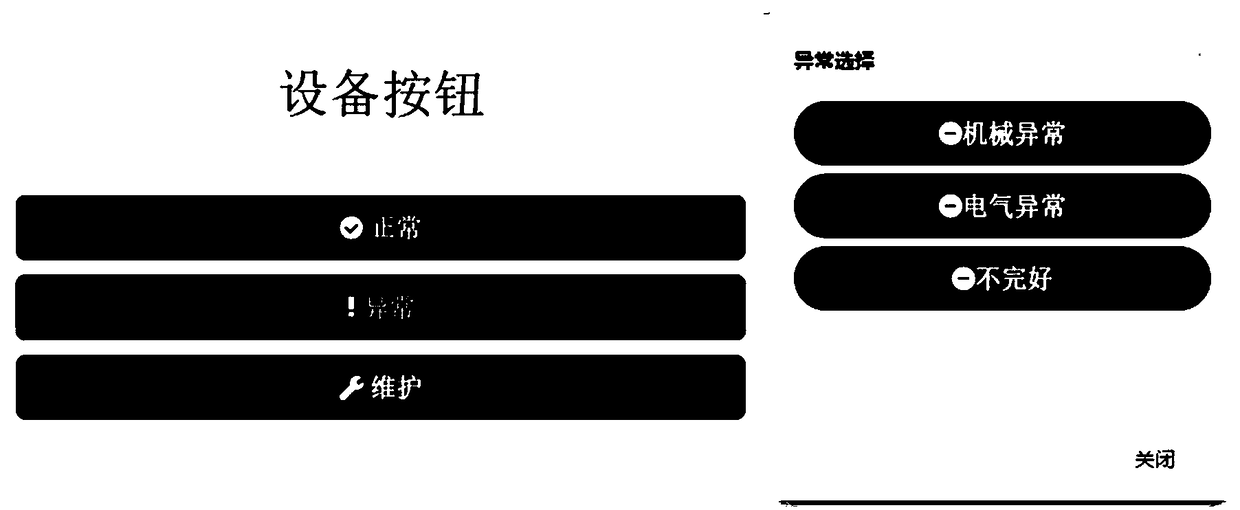

DMS digital production management system

A DMS digital production management system comprises a system management unit, a basic data unit, a document management unit, a billboard management unit, a workshop management unit, a lamp installation early warning unit, a point inspection management unit and a report management unit which are connected with one another. The system management unit is used for carrying out system configuration and authority management, the basic data unit is used for maintaining basic data, the document management unit is used for managing documents, the billboard management unit is used for carrying out billboard management, the workshop management unit is used for managing workshops and realizing paperless workshops, the safety lamp early warning unit is used for carrying out safety lamp calling and processing, the spot inspection management unit is used for spot inspection management, and the report management unit is used for displaying the statistical report. The DMS digital production managementsystem disclosed by the invention has the beneficial effects that the paperless, visual, decision-making on-site and problem digital management of a production site can be effectively realized.

Owner:广州智企信息技术有限公司

Novel intelligent lamp fixing system for production management and an abnormal maintenance processing method

PendingCN109344985AComprehensive ability assessment is accurateImprove communication efficiencyAlarmsResourcesComputer scienceCommunication device

Owner:天津市伟星新型建材有限公司

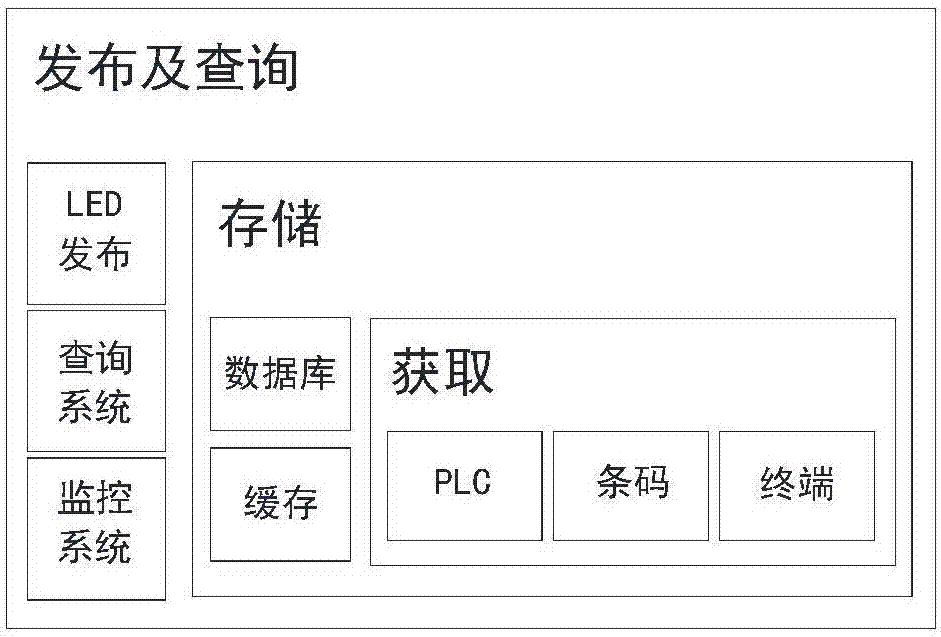

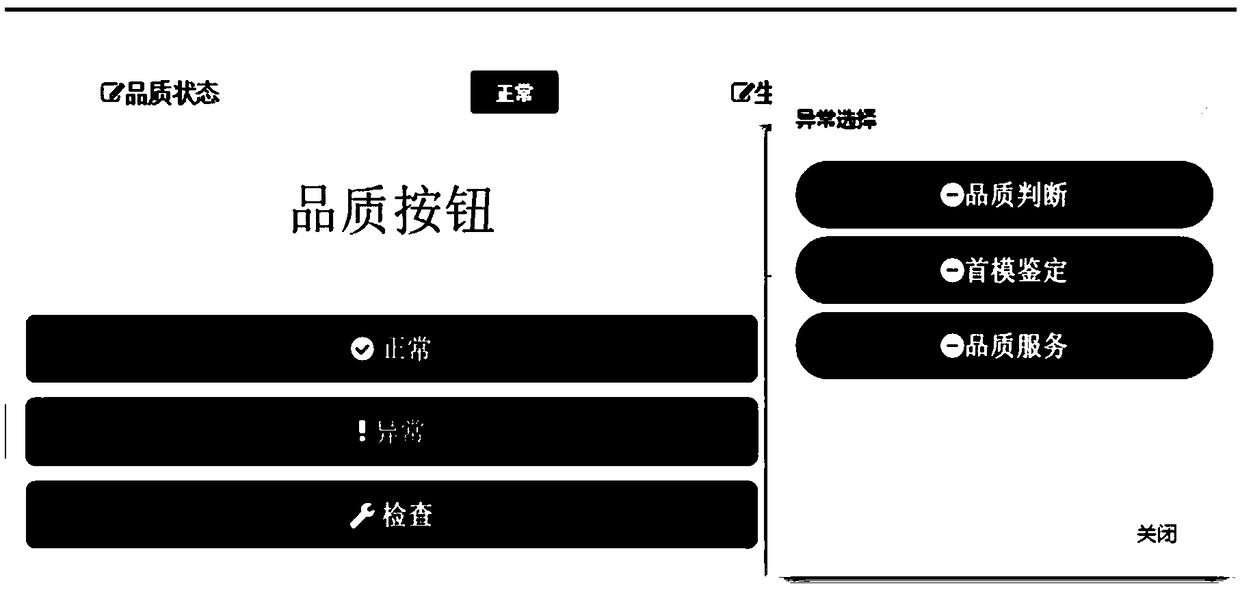

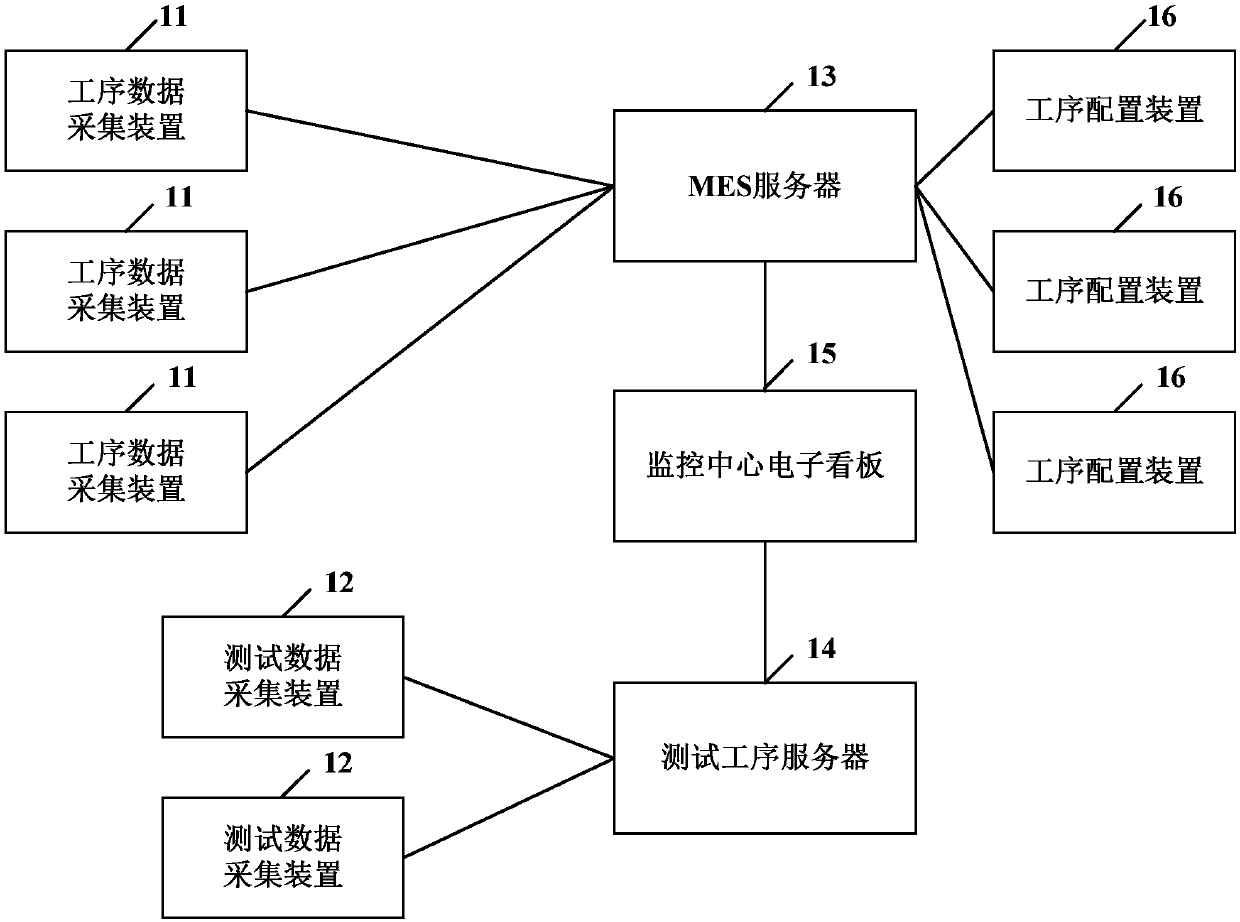

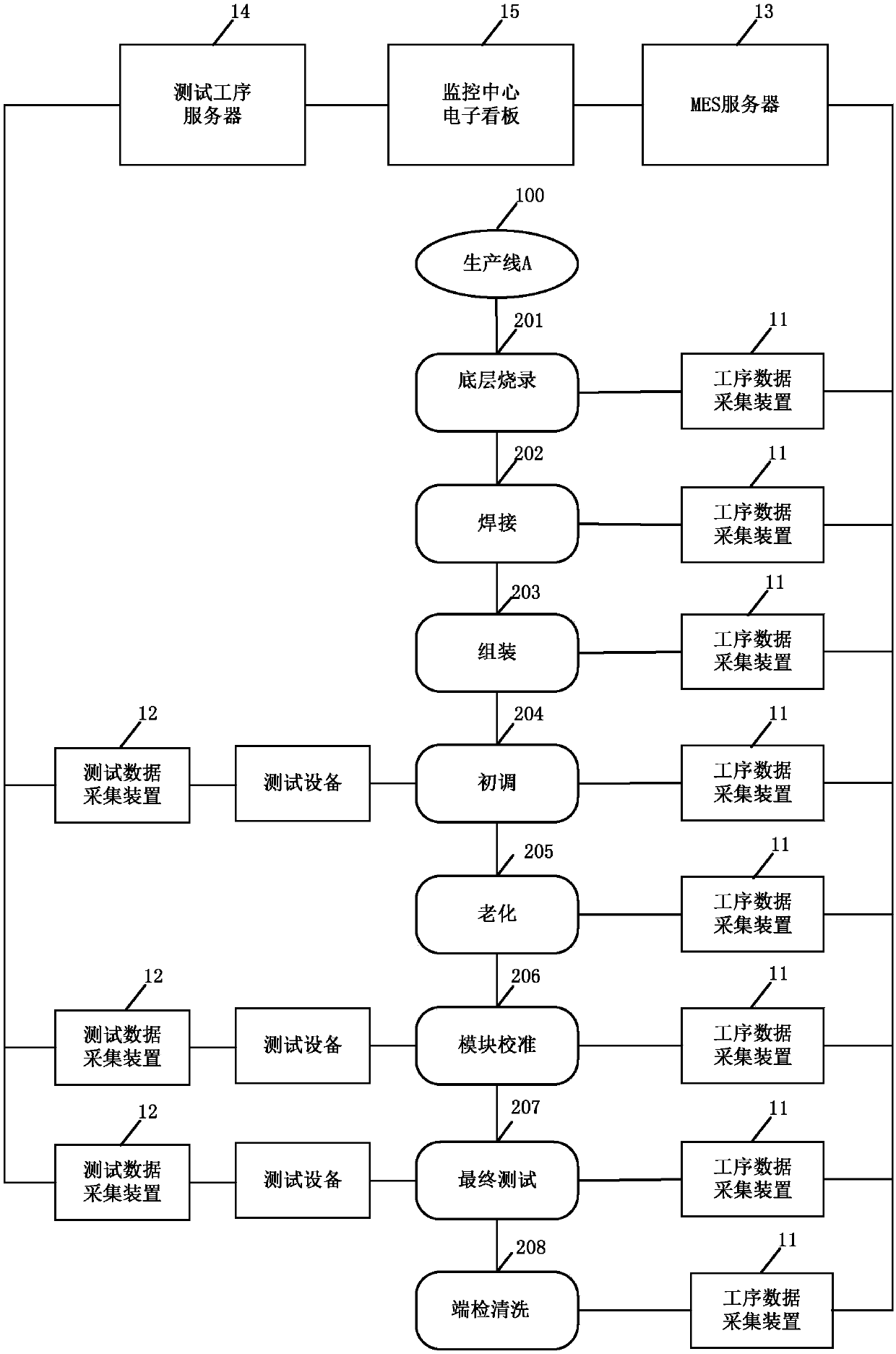

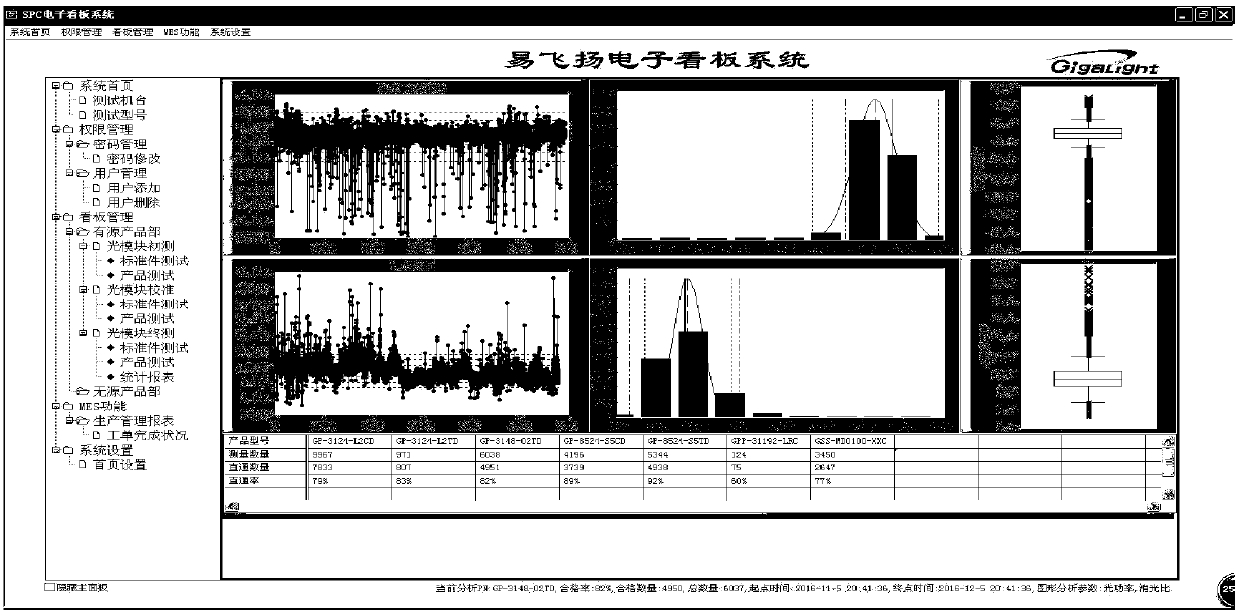

Electronic kanban system and data processing method and device

InactiveCN107833147AGuaranteed processing efficiencyRealize electronic collectionDatabase queryingResourcesData acquisitionManufacturing execution system

The embodiment of the present application provides an electronic kanban system and a data processing method and device to solve the problems of lack of objectivity and easy errors caused by manual recording of process data with paper in the prior art. The method comprises a step of calling process data stored in an MES server of a manufacturing execution system and test data stored in a test process server, and a step of performing statistical process control SPC and process capability index analysis on the called data, wherein the process data and test data are from data acquisition devices.In data acquisition, a process data acquisition device is used to collect the process data, a test data collection device is used to collect the test data, and the electronic and automatic collectionof the data is achieved, and the problems that the data is lack of objectivity and is easy to go wrong are avoided. A monitoring center electronic kanban carries out professional analysis on the collected process data and test data, the data processing efficiency is ensured, the data processing efficiency is ensured, and an effective support is provided for production field management and technical improvement.

Owner:深圳易飞扬通信技术有限公司

Box airtightness test device

InactiveCN106017826AImplement automatic detectionRealize the popularization of operationMeasurement of fluid loss/gain ratePressure transmissionSolenoid valve

The invention relates to a box airtightness test equipment, comprising a power supply device and a box body arranged on the power supply device, the power supply device includes a voltage regulator and a relay, and the box body is equipped with a test system, an air pressure transmission system, a data export system and Display instrument, test system includes PLC, solenoid valve, fixture, air pressure transmission system includes air circuit joint and air pressure regulating valve, air circuit joint is connected to the fixture, air pressure regulating valve is connected to external compressed air, display instrument is connected to PLC, and display instrument includes Touch screen and sound and light indicator light, there is also a board on the box. The box airtightness testing equipment of the present invention is an automatic airtightness testing instrument, which can reduce manual work as much as possible, realize popularization of operation, improve precision, and improve detection efficiency.

Owner:SUZHOU ICOOLMACH EQUIP MFG

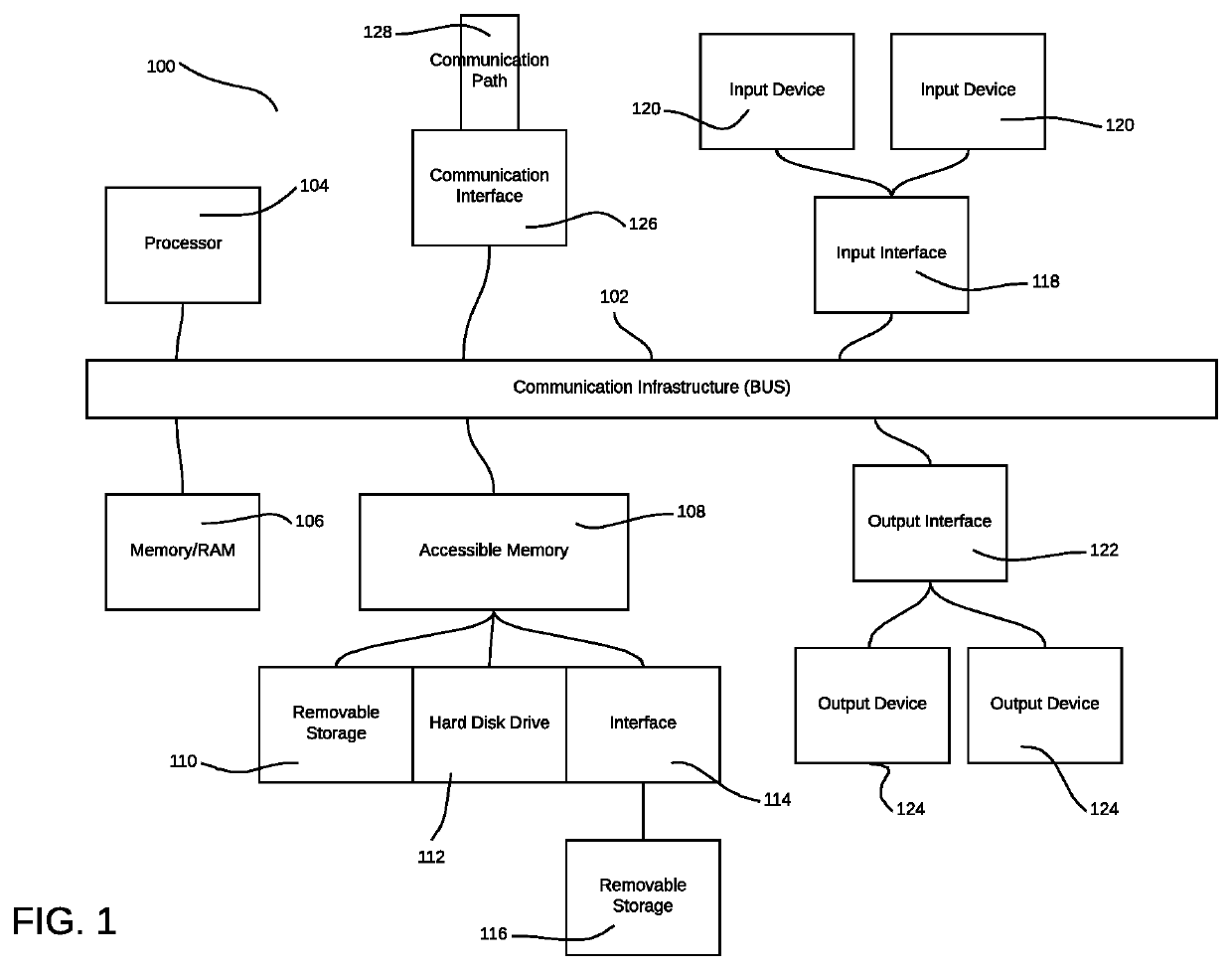

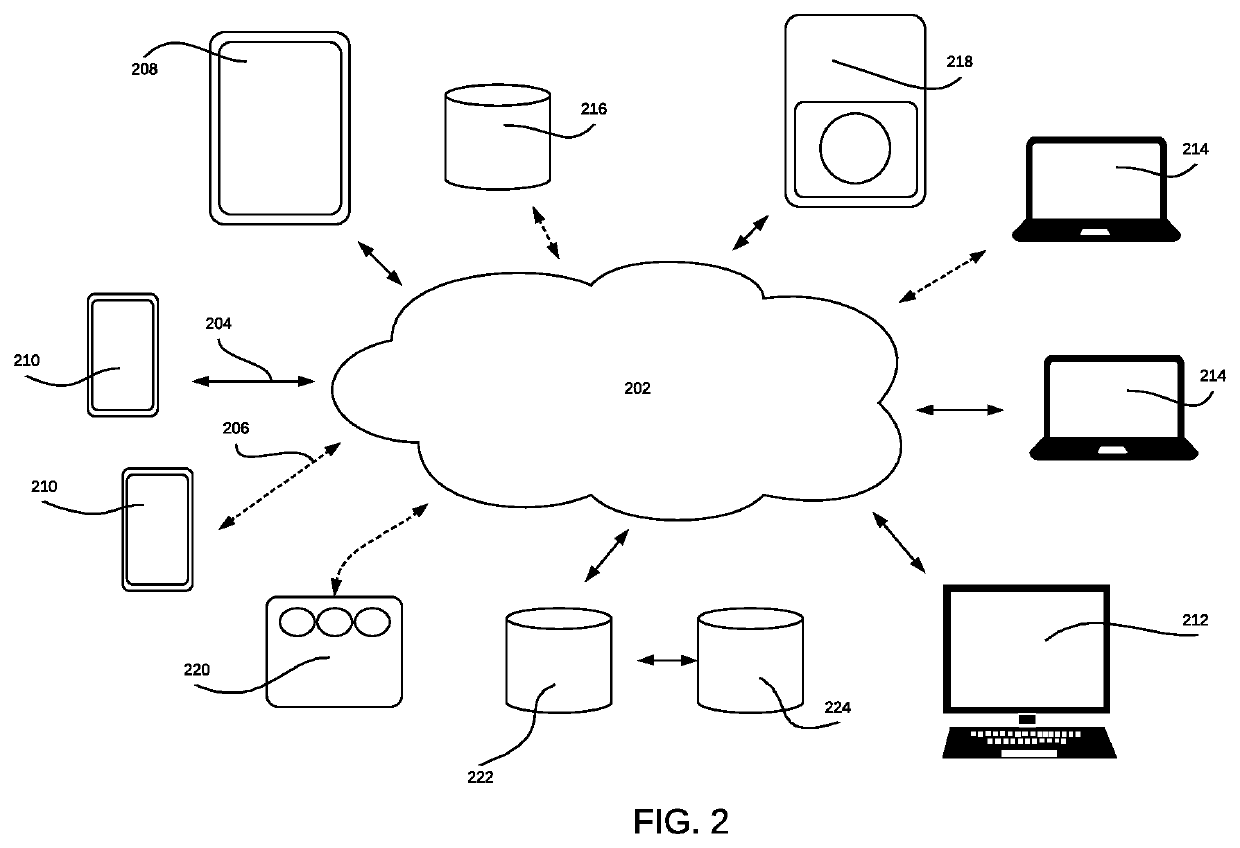

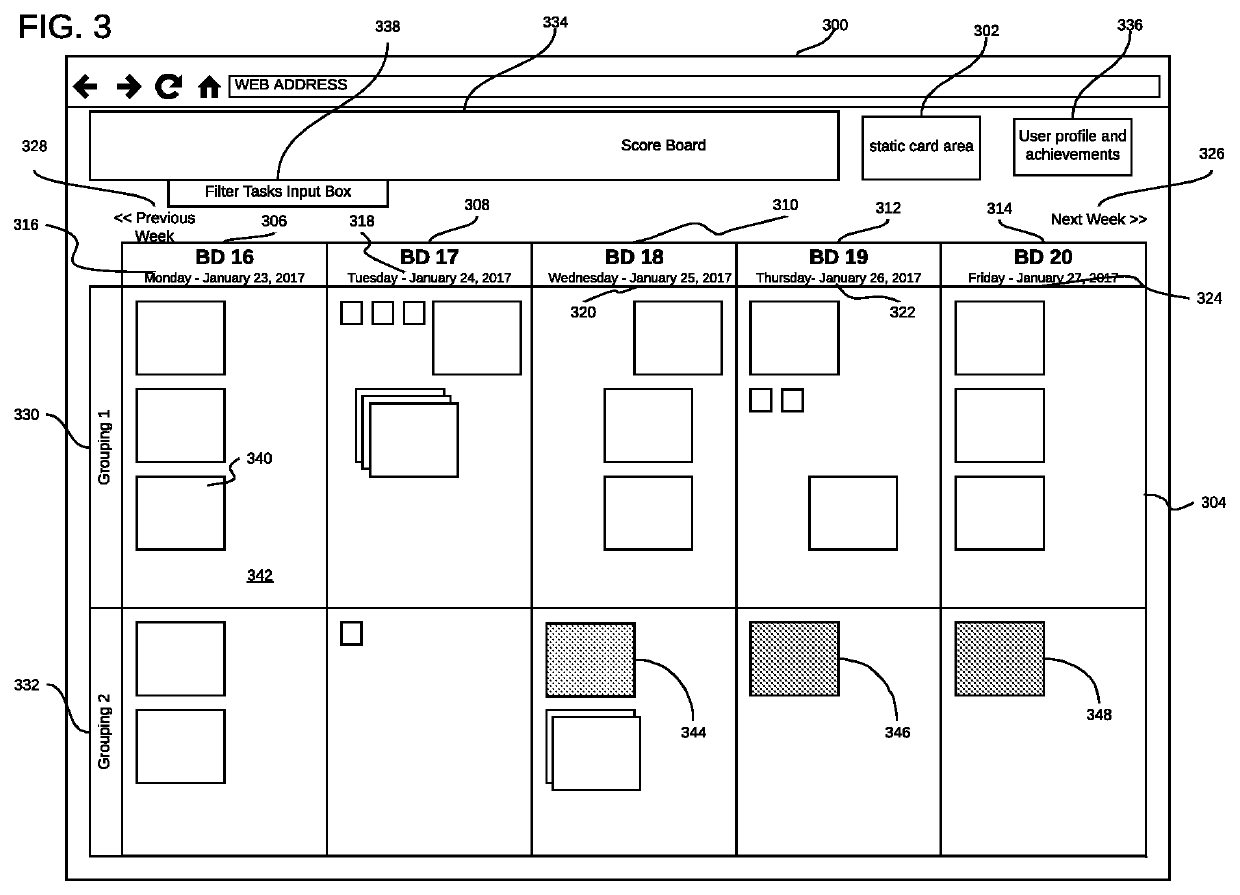

Dynamic digital calendar day kanban board

ActiveUS10496962B1Office automationInput/output processes for data processingVisual perceptionWorld Wide Web

The invention described herein with reference to the drawing figures, with portions of the drawings enumerated and referenced herein. An embodiment in accordance with the present invention discloses and describes the computer implemented method for creating and manipulating a dynamic digital business day Kanban board on a computing device with cards available to users with local and remote access, which allows the users and events to create cards associated with a progress status and behaviors, stored instructions, combined with the ability to group, view, and organize the created cards in a plurality of sections some of which are associated to calendar days. Based on user interactions with the dynamic digital business day Kanban board point value calculations results are created, aggregated, stores, transmitted, and displayed to a number of users. The invention includes a network connected electronic device for receiving instructions from the computing device to represent the dynamic digital business day Kanban board's activity and point value calculation results in a numeric, visual, and auditory manner.

Owner:BARTELS BRYAN GREGORY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com