Electronic kanban system and data processing method and device

An electronic kanban and data technology, applied in the field of communication, can solve the problems of error-prone real-time, lack of objectivity, and low quality, so as to ensure the efficiency of data processing and realize the effect of electronic collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

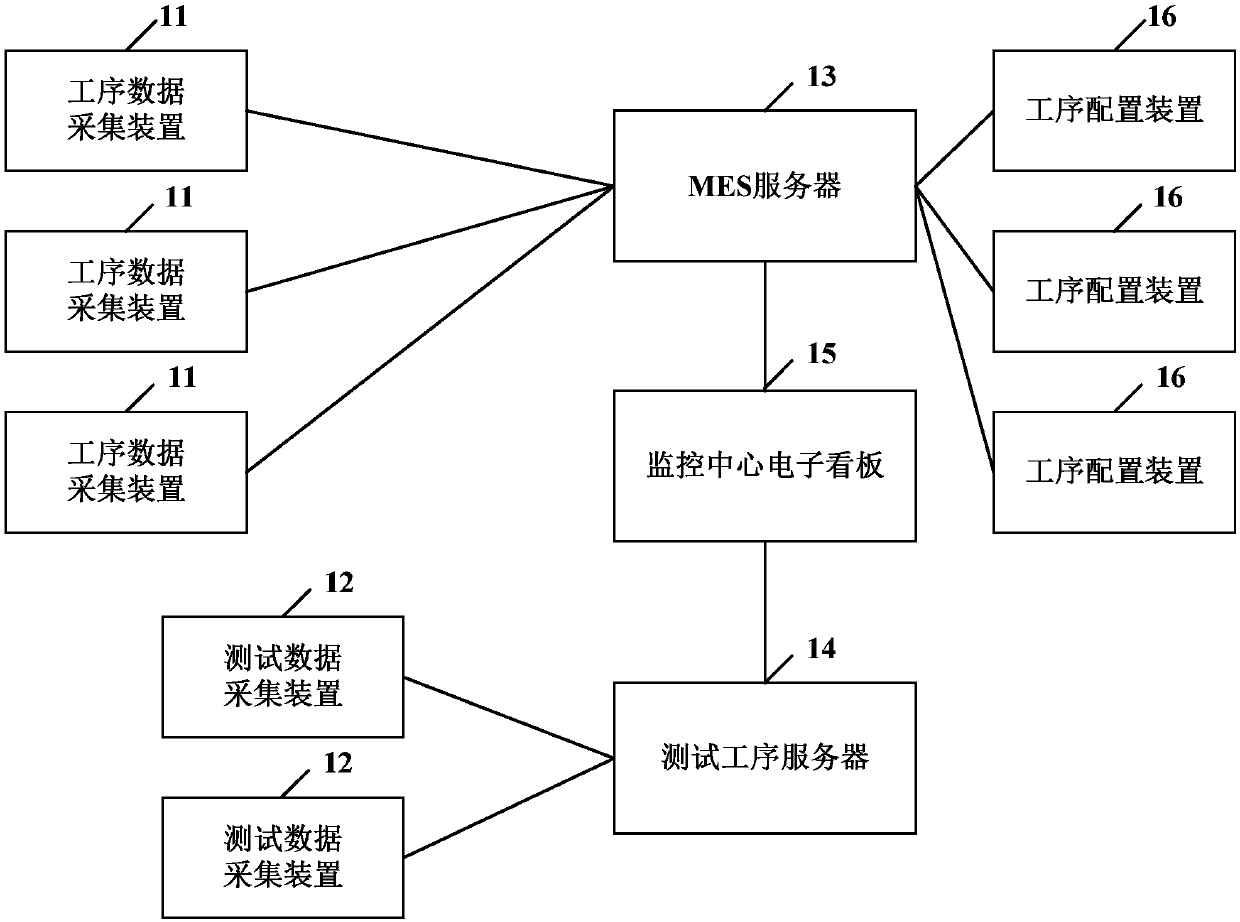

[0028] like figure 1 As shown, it is a schematic structural diagram of the electronic kanban system provided by the embodiment of the present application, including: a process data collection device 11, a test data collection device 12, a manufacturing execution system (manufacturing execution system, MES) server 13, a test process server 14 and Electronic Kanban 15 in the monitoring center; wherein, the process data acquisition device 11 corresponds to each process in the production line, that is, one process corresponds to one or more data acquisition devices, and the test data acquisition device 12 corresponds to the test process in the production line; the test process It can include one process or multiple processes.

[0029] The process data collection device 11 is used to collect process data, and transmit the collected process data to the MES server of the manufacturing execution system, wherein the process data is the data in the production site;

[0030] The test da...

Embodiment 2

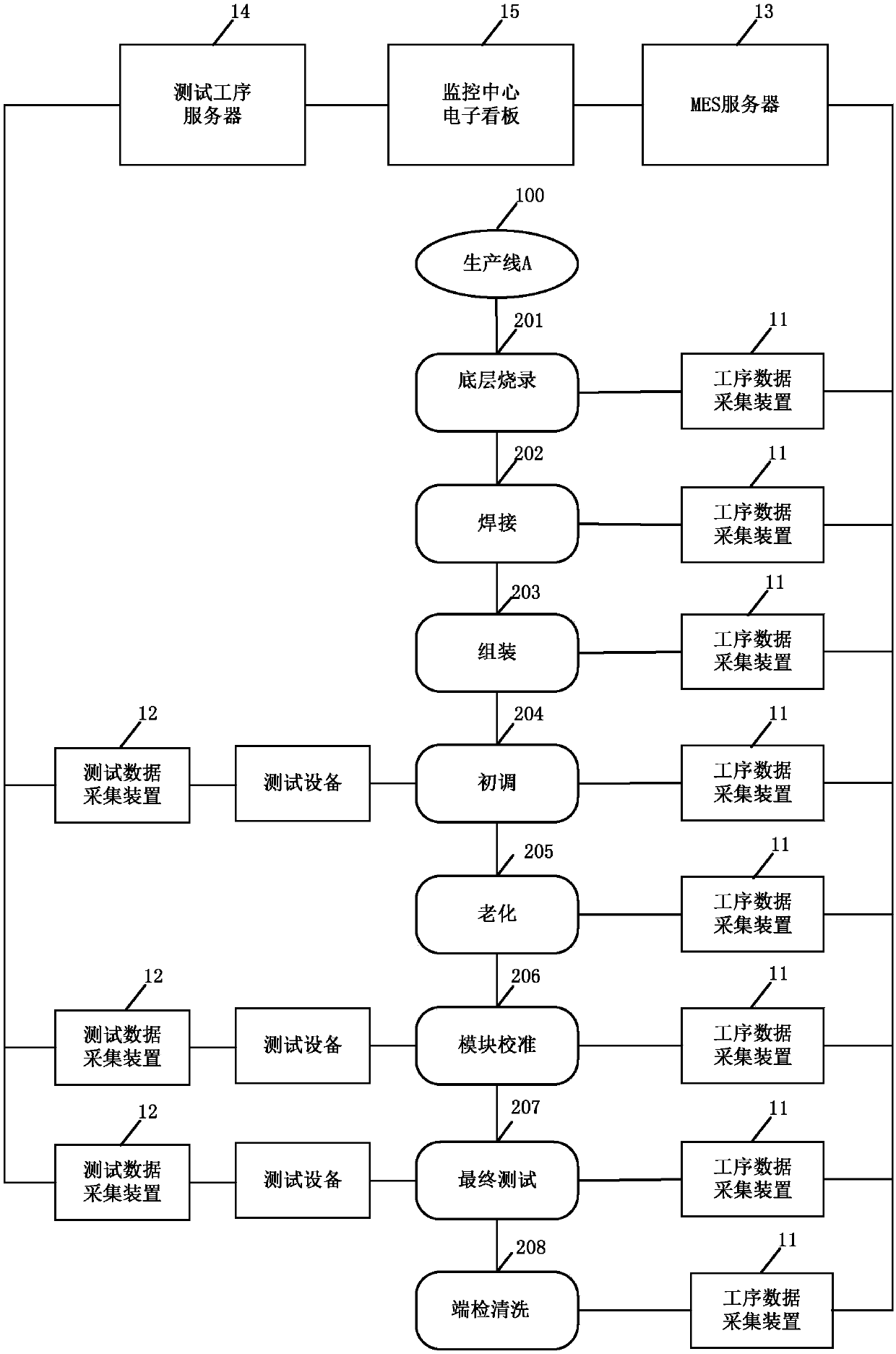

[0047] like figure 2As shown, it is a schematic structural diagram of the electronic kanban system provided in Embodiment 2 of the present application. The procedures in the photoelectric product production line A100 include bottom layer programming 201, welding 202, assembly 203, initial adjustment 204, burn-in 205, module calibration 206, final Test 207, terminal inspection and cleaning 208, and product inspection and storage 209. The testing process includes: initial adjustment 204, module calibration 206 and final test 207.

[0048] At this time, the MES server respectively receives the process data acquisition device corresponding to the bottom layer programming, the process data acquisition device corresponding to welding, the process data acquisition device corresponding to assembly, the process data acquisition device corresponding to initial adjustment, and the process data acquisition device corresponding to aging. Process data acquisition device, process data acqui...

Embodiment 3

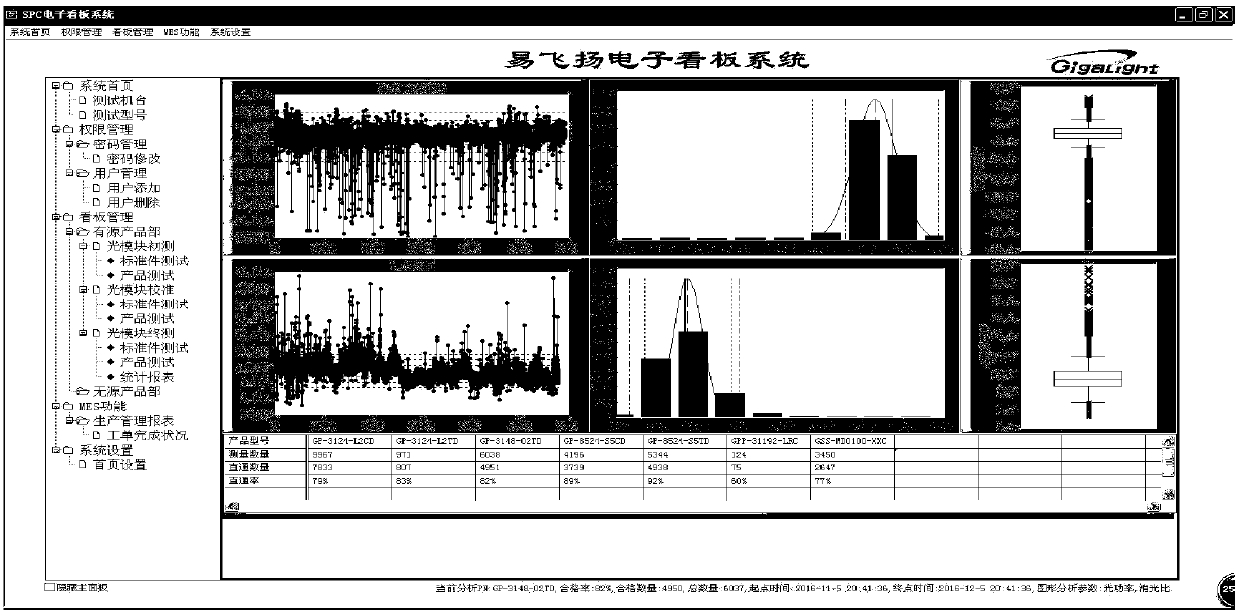

[0063] like Figure 5 The schematic diagram of the electronic kanban data processing method provided in the embodiment of this application includes the following steps:

[0064] Step 501: call the process data stored in the MES server and the test data stored in the test process server, wherein the process data is transmitted to the MES server by the process data acquisition device corresponding to each process in the production line, and the test data is The test data acquisition device corresponding to the test process in the production line is transmitted to the test process server;

[0065] Step 502: Perform statistical process control SPC and process capability index analysis on the transferred data to obtain SPC data and process capability data.

[0066] Preferably, the method also includes:

[0067] Based on the received query condition, find and display the data matching the query condition from the called data, SPC data or process capability data; or

[0068] Use S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com