Multi-stage varied-diameter screw oil-water separator

A technology of oil-water separator and three-stage spiral, which is applied in the direction of liquid separation, separation methods, chemical instruments and methods, etc., can solve problems such as difficult and efficient separation, and achieve the effect of enhancing oil-water two-phase separation and reducing cross-sectional area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing:

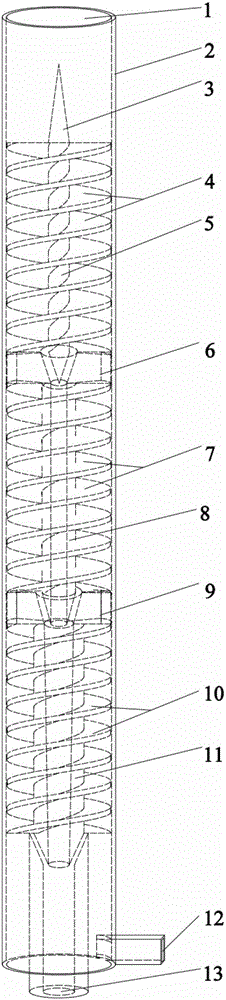

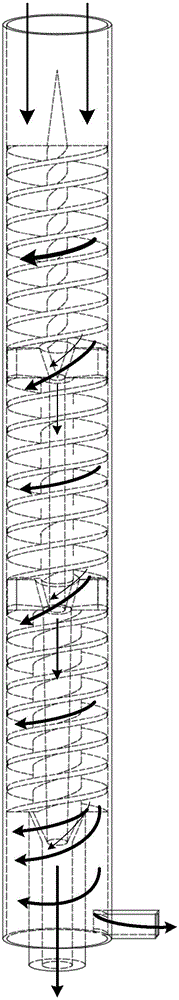

[0026] Depend on Figure 1 to Figure 10 As shown, this kind of multi-stage variable-diameter spiral oil-water separator has a wall tube 2 and an underflow tube 12, and the bottom flow tube 12 is tangentially connected to the bottom end of the wall tube 2. Its unique feature is that the upper end opening of the wall tube 2 is Inlet 1; contains at least a secondary separation unit in the wall tube 2. In practice, the entrance can be axial, inclined or tangential, and the inclined or tangential entrance can be single or multi-entry. This patent takes the axial entrance and the three-stage separation unit in the wall cylinder as an example. .

[0027] The first-stage separation unit is composed of a first-stage spiral piece 4, a first-stage inner tube 5, and a first-stage sub-fluid 6 after being connected. The inner wall of the wall tube 2, the first-stage spiral piece, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com