Compact type organic working medium high-temperature and high-voltage electric heater

A compact, high-voltage electrical technology, applied in ohmic resistance heating parts, heating element shapes, etc., can solve problems such as uncontrollable risks and large radiation, and achieve compact structure, fast fluid velocity, and enhanced fluid turbulence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

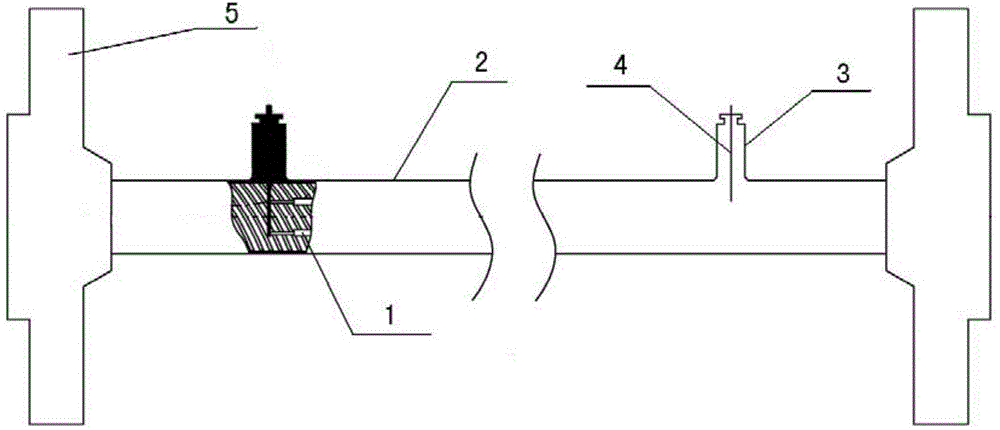

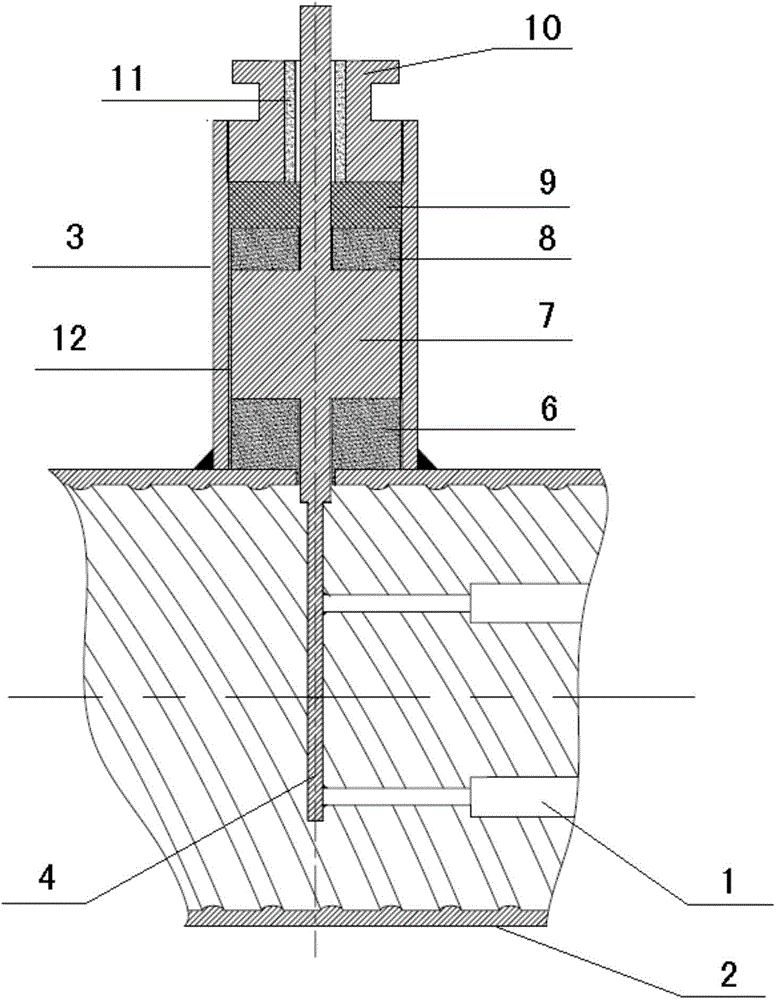

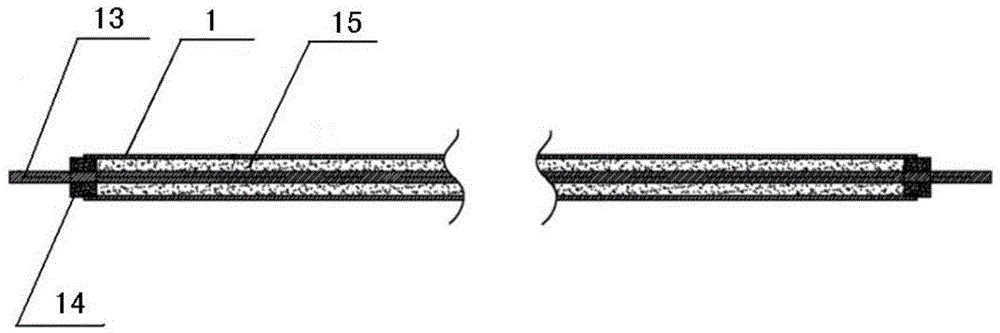

[0024] Such as Figure 1 to Figure 3 Shown: a compact high-temperature and high-voltage electric heater with organic working fluid, including a heating tube 1, the inside of the heating tube 1 is provided with a heating wire 13, and the ends of the heating tube 1 are provided with sealing and insulating The ceramic plug 14, the middle hole and the outer surface of the ceramic plug 14 are provided with threads, which are used to thread the connection head of the heating pipe 1 and the heating wire 13, and the inside of the heating pipe 1 is filled with high-quality Magnesia 15, magnesia 15 is filled by powder filling machine, and compaction is guaranteed;

[0025] The heating pipe 1 is arranged inside the outer pipe 2 of the heating section, and the outer pipe 2 of the heating section is composed of a stainless steel internal thread pipe to strengthen the disturbance o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com