Multichannel plasma area igniting burner

A plasma and combustion device technology, which is applied to gas turbine devices, combustion methods, combustion ignition, etc., can solve the problems of poor working conditions in the combustion chamber, reduced combustion efficiency, and poor combustion stability, and achieve efficient and reliable flame stability and improved combustion performance. , the effect of strong flame rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

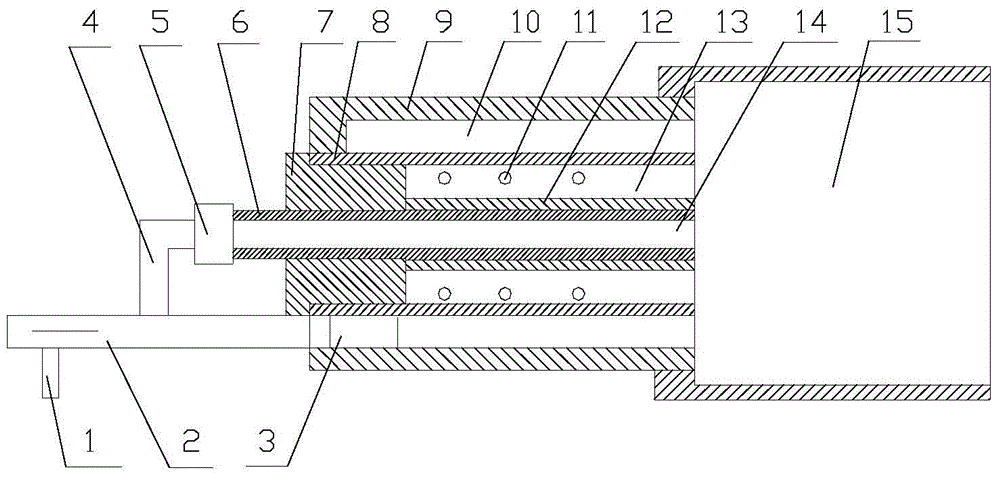

[0038] Such as figure 1 As shown, a multi-channel plasma area ignition and combustion device mainly includes a nozzle 1, an intake fish mouth 2, a tangential air hole 3, a gas pipe 4, a hollow insulator 5, a high-voltage electrode 6, an insulator 7, a low-voltage electrode 8, and a shell 9. Swirl chamber 10, air hole 11, barrier medium 12, low velocity zone 13, center jet 14, flame stabilization chamber 15; said nozzle 1 refers to a direct-flow nozzle or other nozzles, which are installed in the pipe wall of the intake fish mouth for a certain period of time. position; the air intake mouth 2 refers to the air intake pipe with splash plate atomization in the middle, which is installed on the inlet end of the shell 9 and the low-voltage electrode 8, and is sealed with the inlet; the tangential air hole 3 refers to Intake fish mouth 2 air outlet holes, the outlet hole of intake fish mouth 2 is provided with one or more blades, the outlet blades make the air flow rotate at high sp...

Embodiment 2

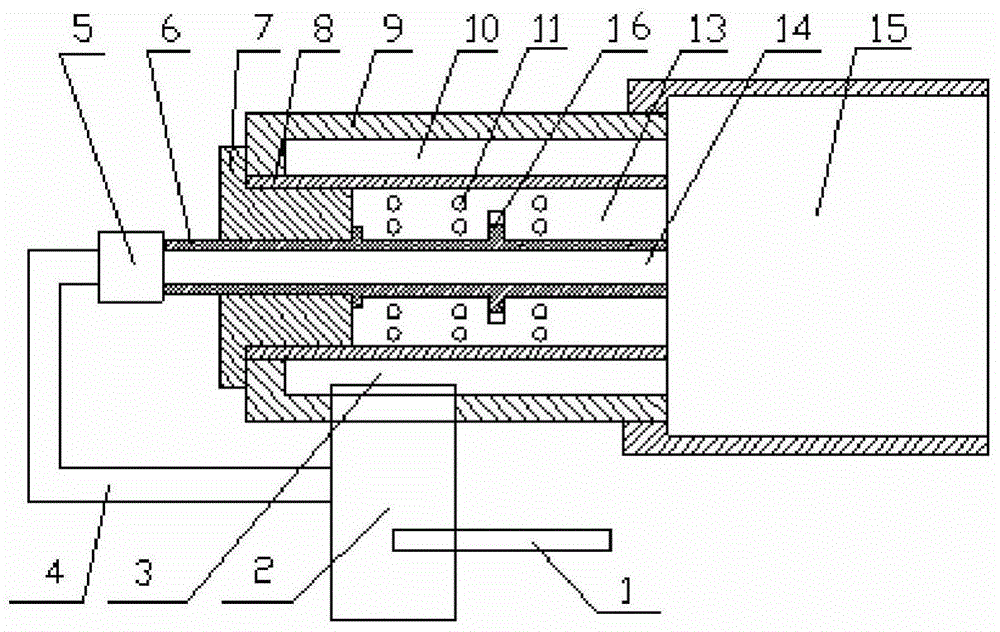

[0040] Such as figure 2 As shown, a multi-channel plasma area ignition and combustion device mainly includes a nozzle 1, an intake fish mouth 2, a tangential air hole 3, a gas pipe 4, a hollow insulator 5, a high-voltage electrode 6, an insulator 7, a low-voltage electrode 8, and a shell 9. Swirl chamber 10, air holes 11, protrusions 16, low-velocity zone 13, center jet 14, flame stabilization chamber 15; the nozzle 1 refers to a direct-flow nozzle or other nozzles, which are installed in the wall of the intake fish mouth A certain position; the air intake mouth 2 refers to the air intake pipe with a splash plate atomization in the middle, which is installed at the upstream of the shell and is sealed with the shell; the tangential air hole 3 refers to a rectangular air intake , whose height is the same as the radial distance of the swirl chamber, which is arranged at the upstream of the shell to ensure that the high-speed airflow enters the swirl chamber to generate a high-sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com