Patents

Literature

45results about How to "Increased air turbulence" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

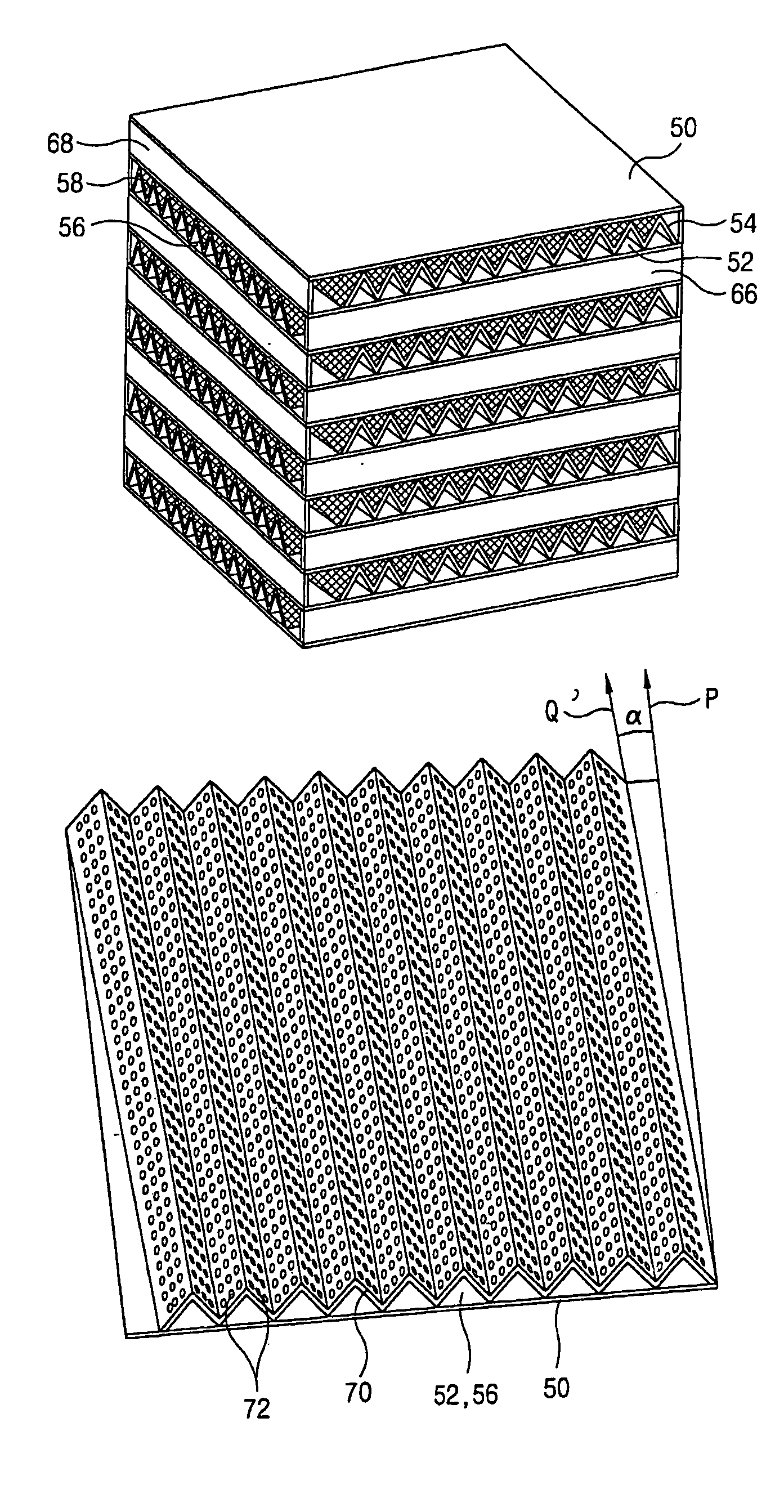

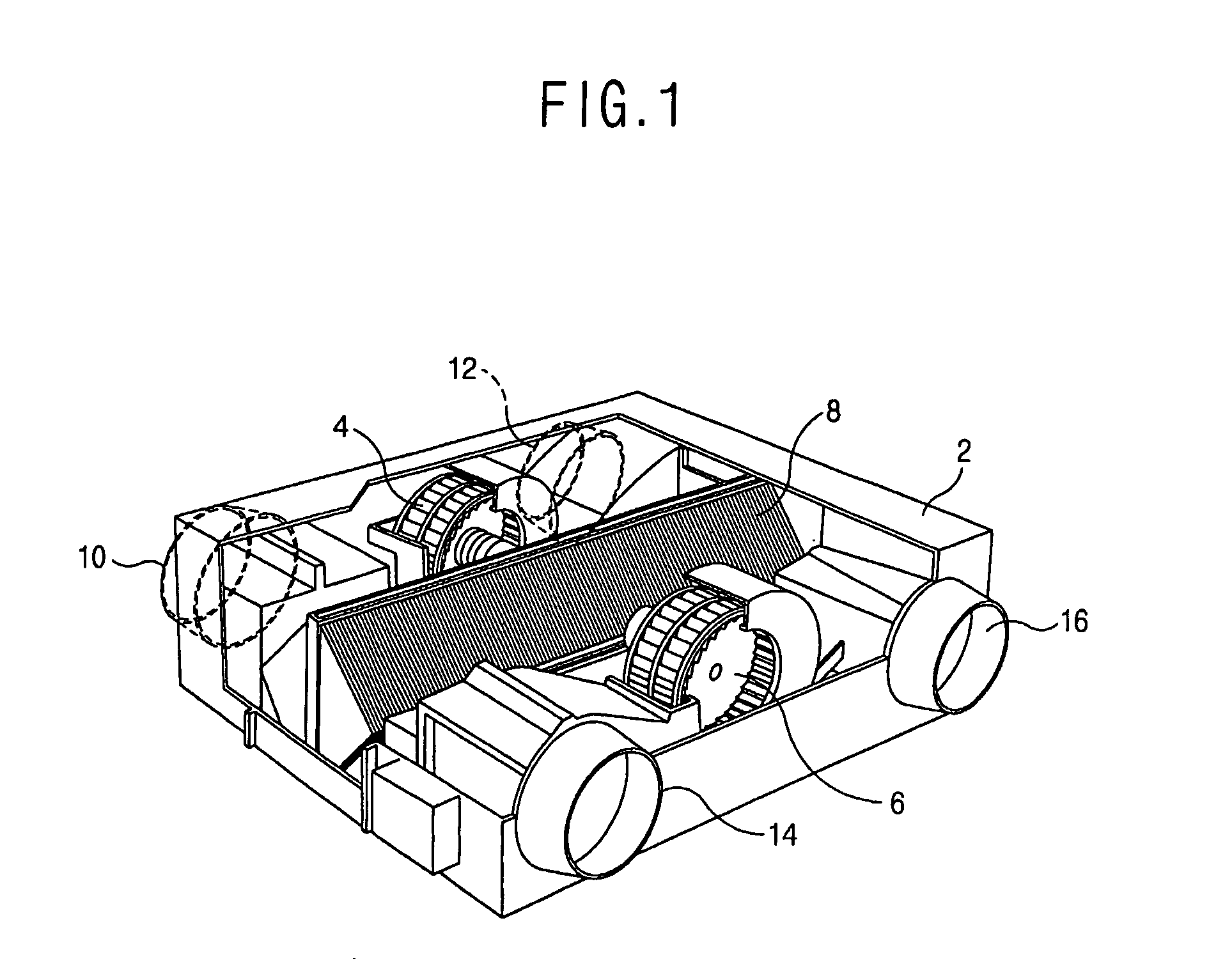

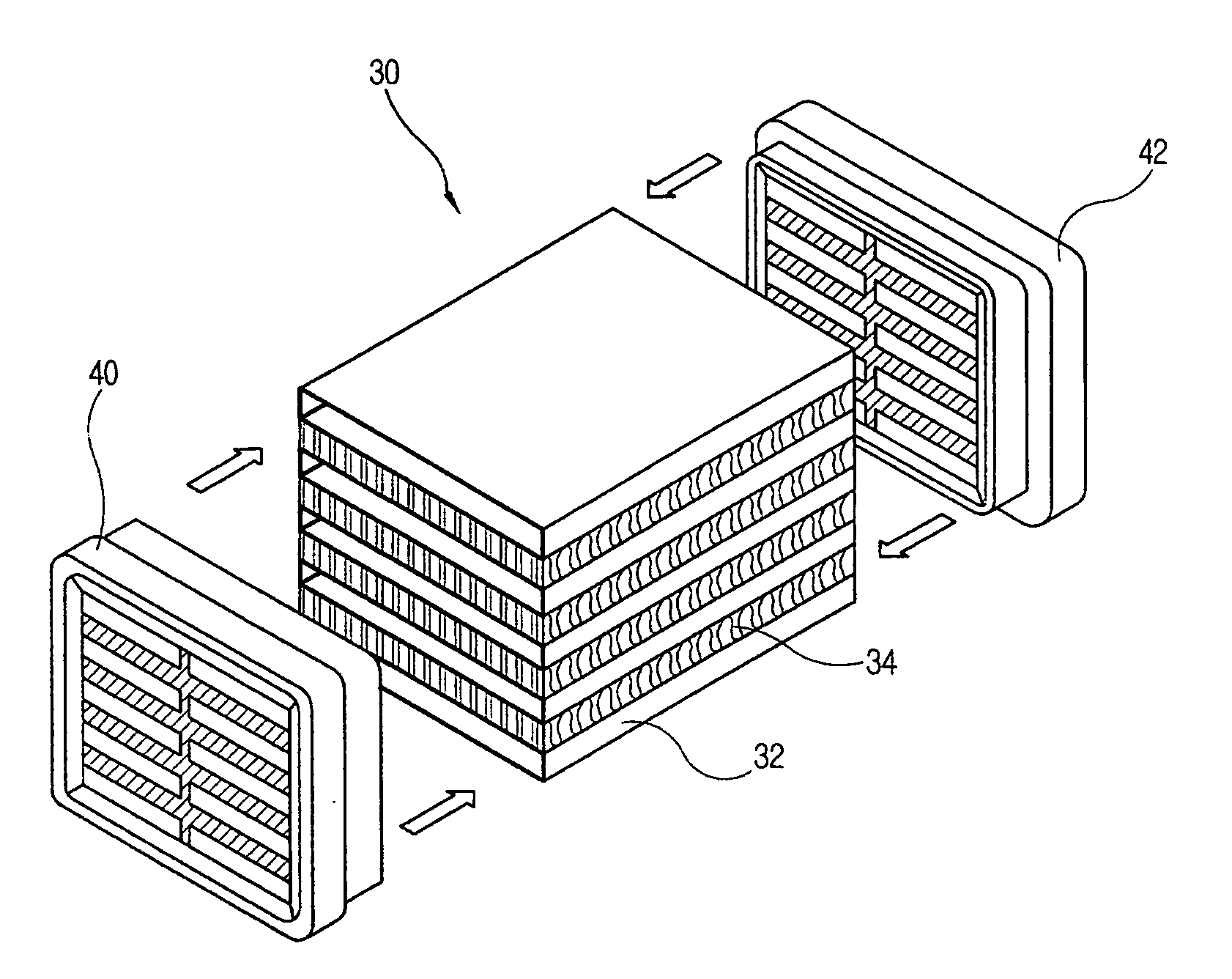

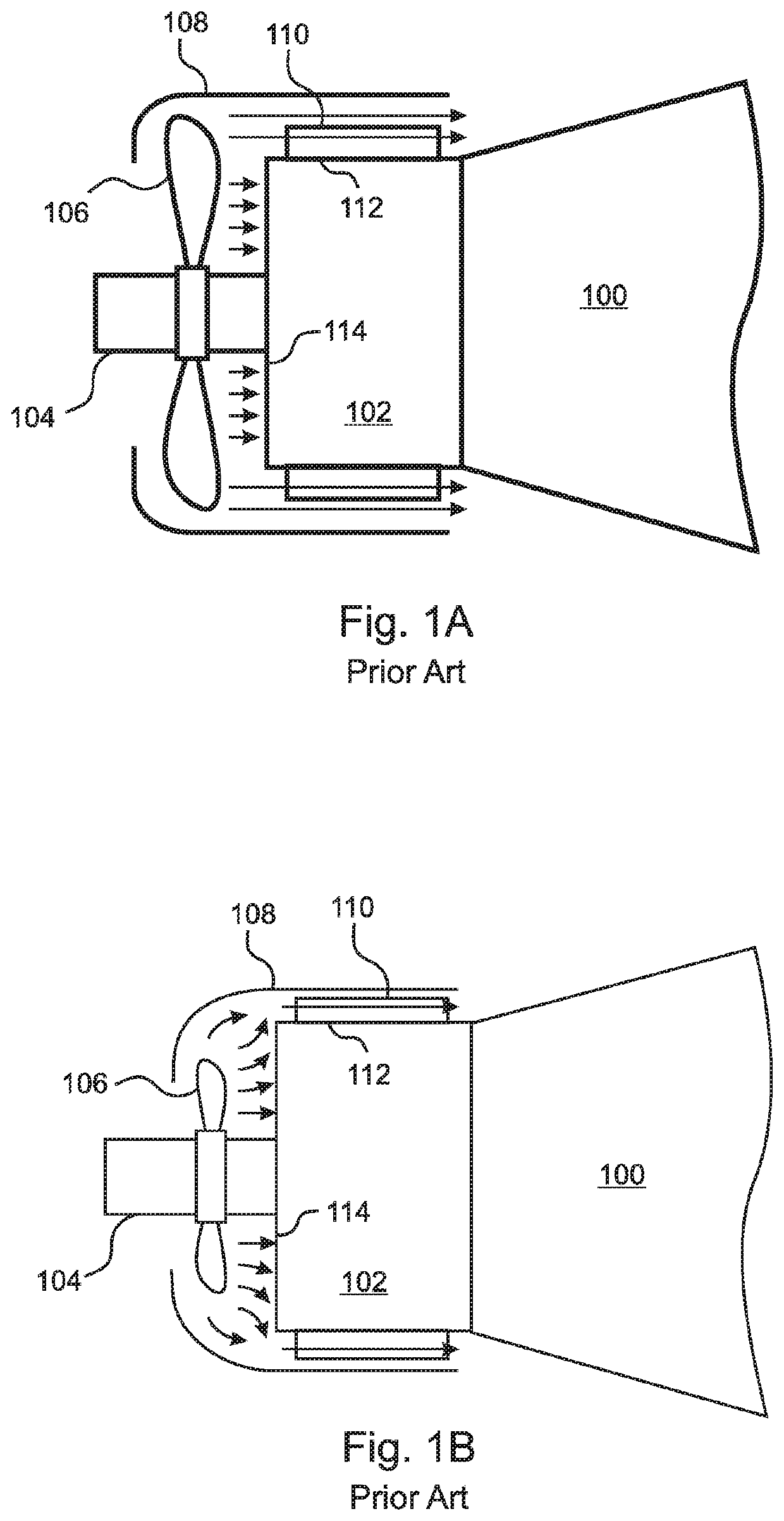

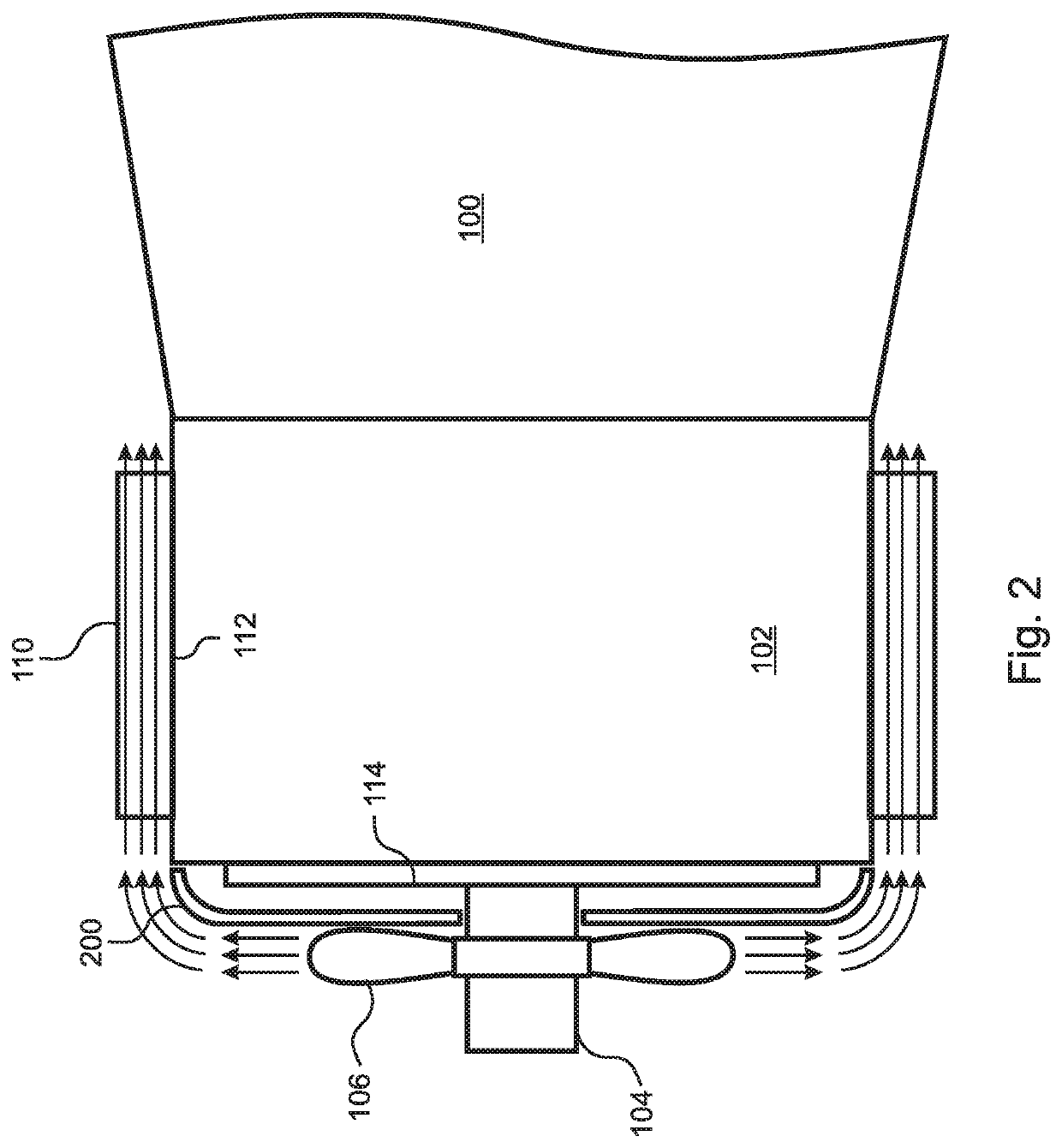

Heat exchanger of ventilating system

InactiveUS7228891B2Improve heat transfer performanceIncreased air turbulenceEnergy recovery in ventilation and heatingHeat recovery systemsPlate heat exchangerEngineering

A heat exchanger of a ventilating system, including a plurality of heat exchanging plates which are laminated at a predetermined interval, a first heat exchange member which is laminated among the heat exchanging plates and is formed in a mesh type to increase turbulence of the outdoor air which flows while being attached on a first air path through which outdoor air passes and a second heat exchange member which is laminated among the heat exchanging plates crossed with the first heat exchange member and is formed in a mesh type to increase turbulence of indoor air which flows while being attached on a second air path through which the outdoor air passes can improve heat transfer performance by increasing turbulence of air by positioning a mesh type heat exchange in a air path through which outdoor and indoor air passes.

Owner:LG ELECTRONICS INC

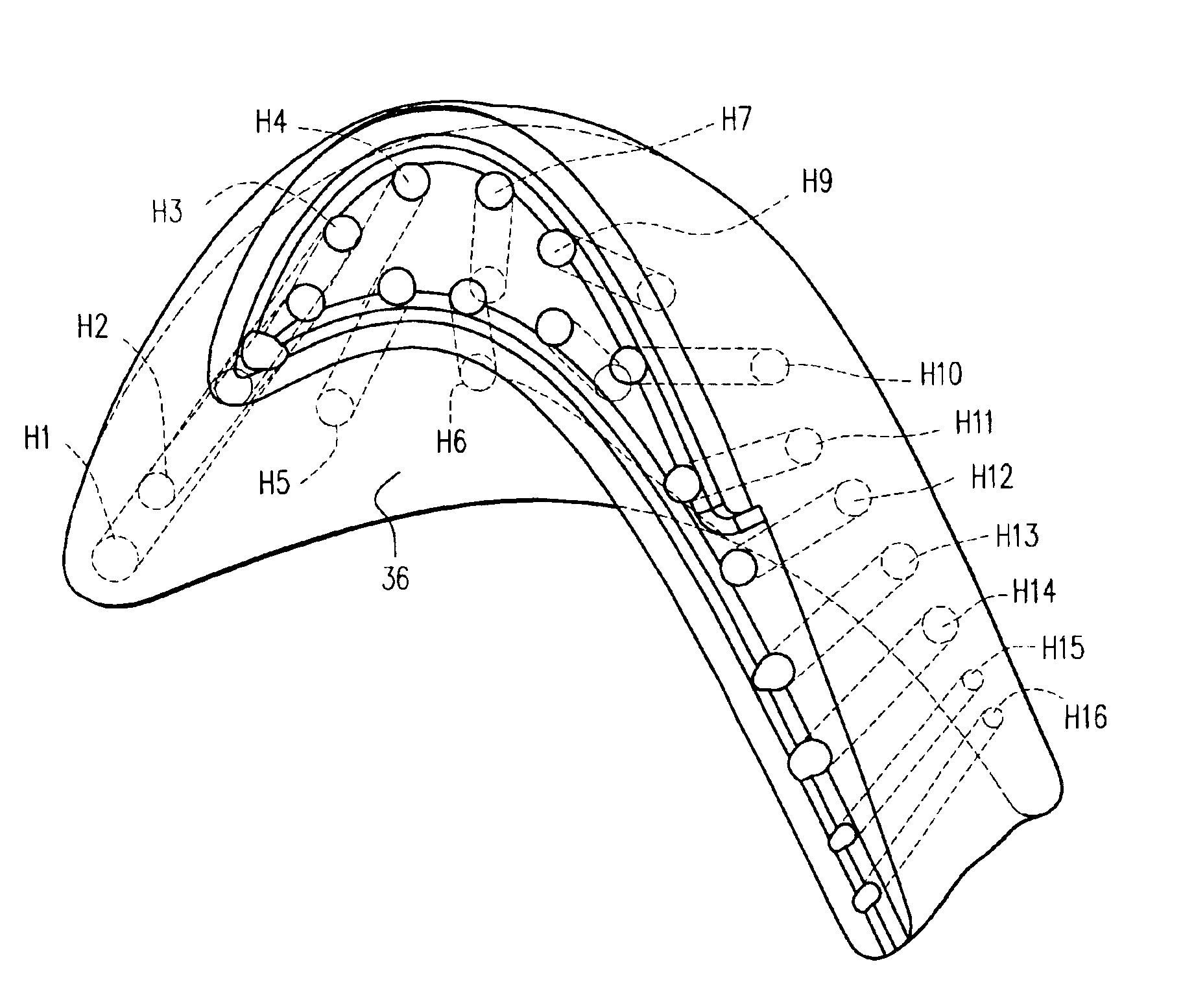

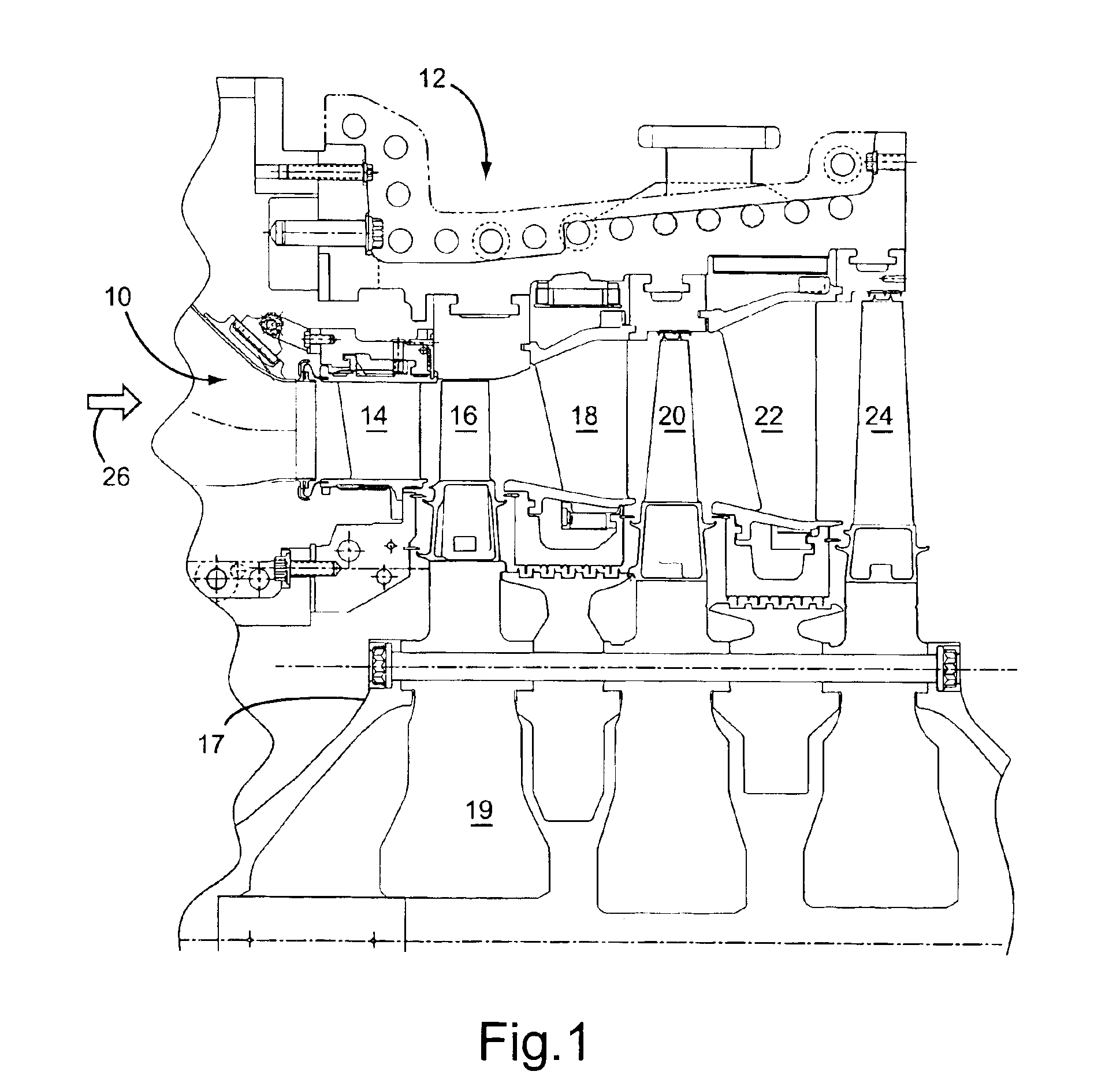

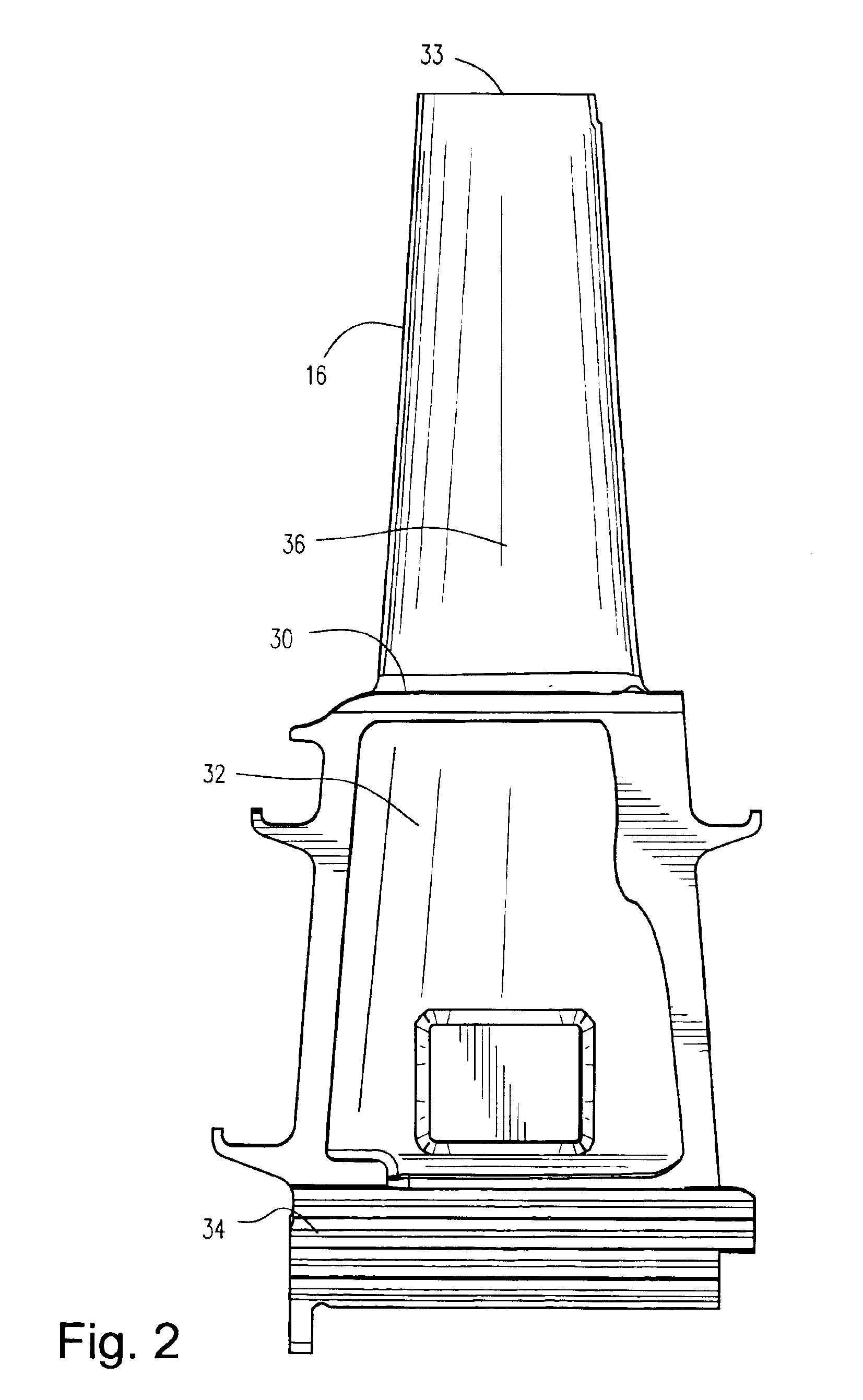

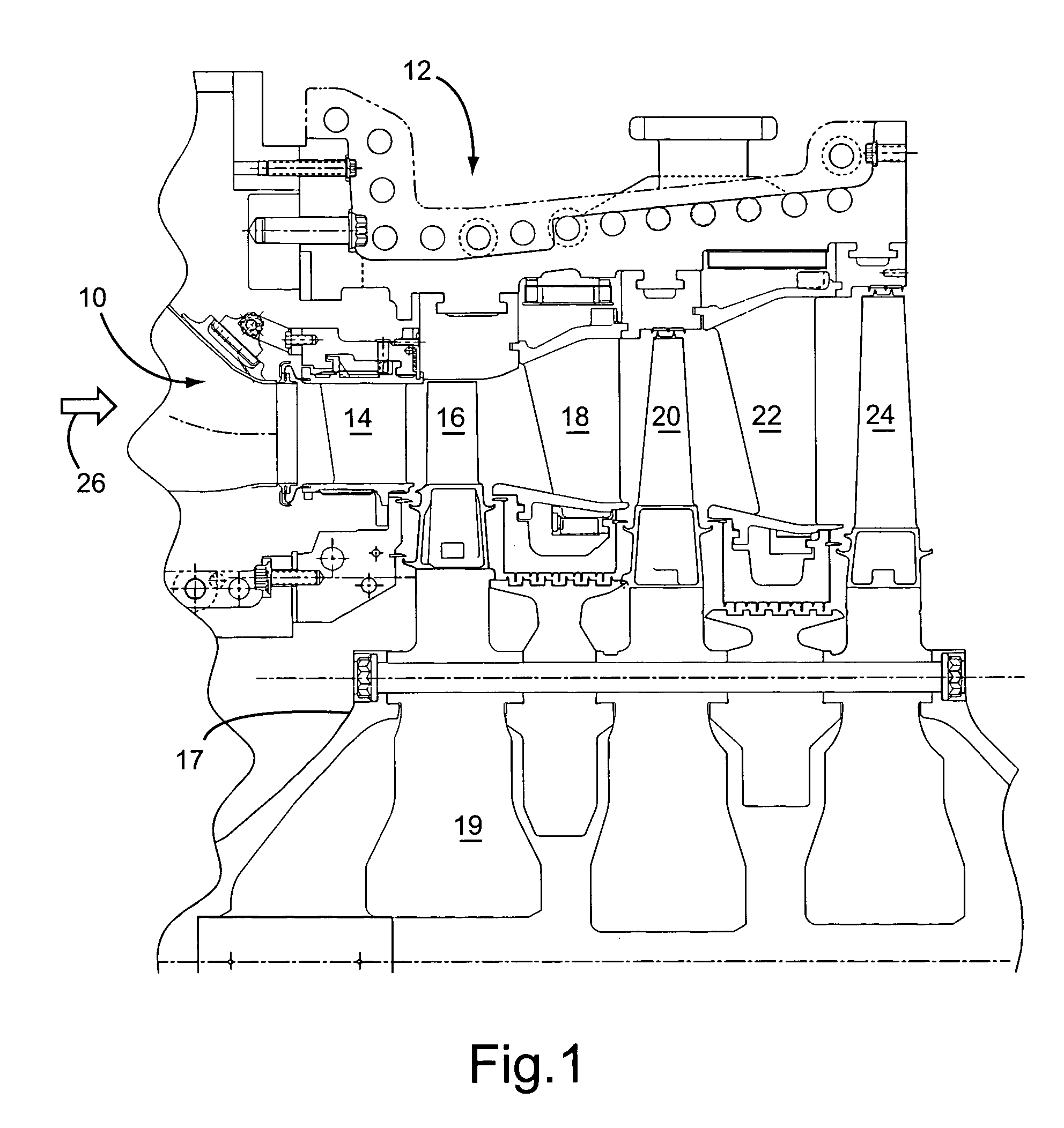

Perimeter-cooled turbine bucket airfoil cooling hole location, style and configuration

InactiveUS6923623B2Improve turbine efficiencyPromote turbulenceOther chemical processesEngine fuctionsTurbine bladeZ-Coordinate

A turbine stage one bucket has an airfoil having a plurality of cooling holes passing through the airfoil from 0% span to 100% span whereby cooling air exits the airfoil tip into the hot gas path. X and Y coordinate values are given in Table I, locating the holes relative to the airfoil profile at airfoil profile sections of 5%, 50% and 90% span, Table I also giving the hole diameters. In this manner, cooling hole optimization for this turbine bucket airfoil is achieved. The cooling holes are also located in relation to the profile of the bucket airfoil given by the X, Y and Z coordinate values of Table II, the two coordinate systems having the same origin.

Owner:GENERAL ELECTRIC CO

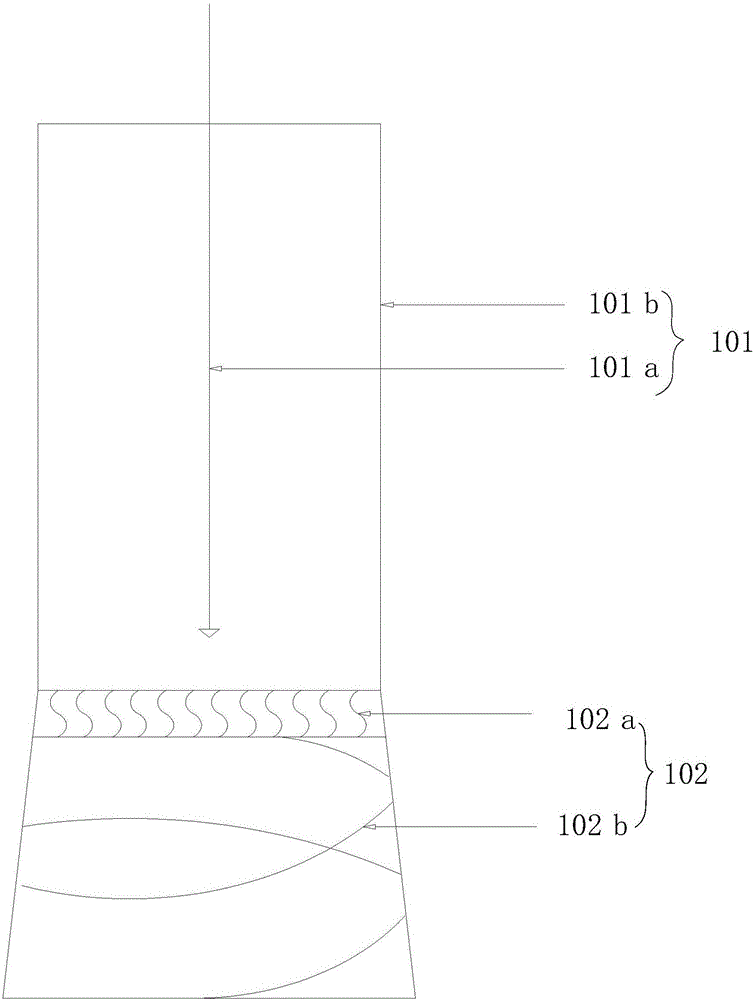

Cable-stayed bridge stay rope capable of resisting aerodynamic instability

InactiveCN102345272AWell formedAvoid wind and rainBridge structural detailsTextile cablesStructural engineeringStormwater

The invention relates to a cable-stayed bridge stay rope capable of resisting the aerodynamic instability, which comprises a center steel wire cable and a surface sheath, wherein the surface sheath covers the center steel wire cable, a wave-shaped open hole outer cover is covered on the periphery of the surface sheath, rain can be leaked from holes of the outer cover, the formation of rain lines on the surface of the outer cover is blocked, and the wave-shaped open hole outer cover can also damage the regularity of the Karman vortex street in the tail current region of the stay rope and the regularity of the axial flow and the axial vortex, so the occurrence of the stay rope wind-rain induced vibration can be avoided, the occurrence condition of dry galloping can be damaged, and the safety of the stay cable is improved.

Owner:SHANGHAI UNIV

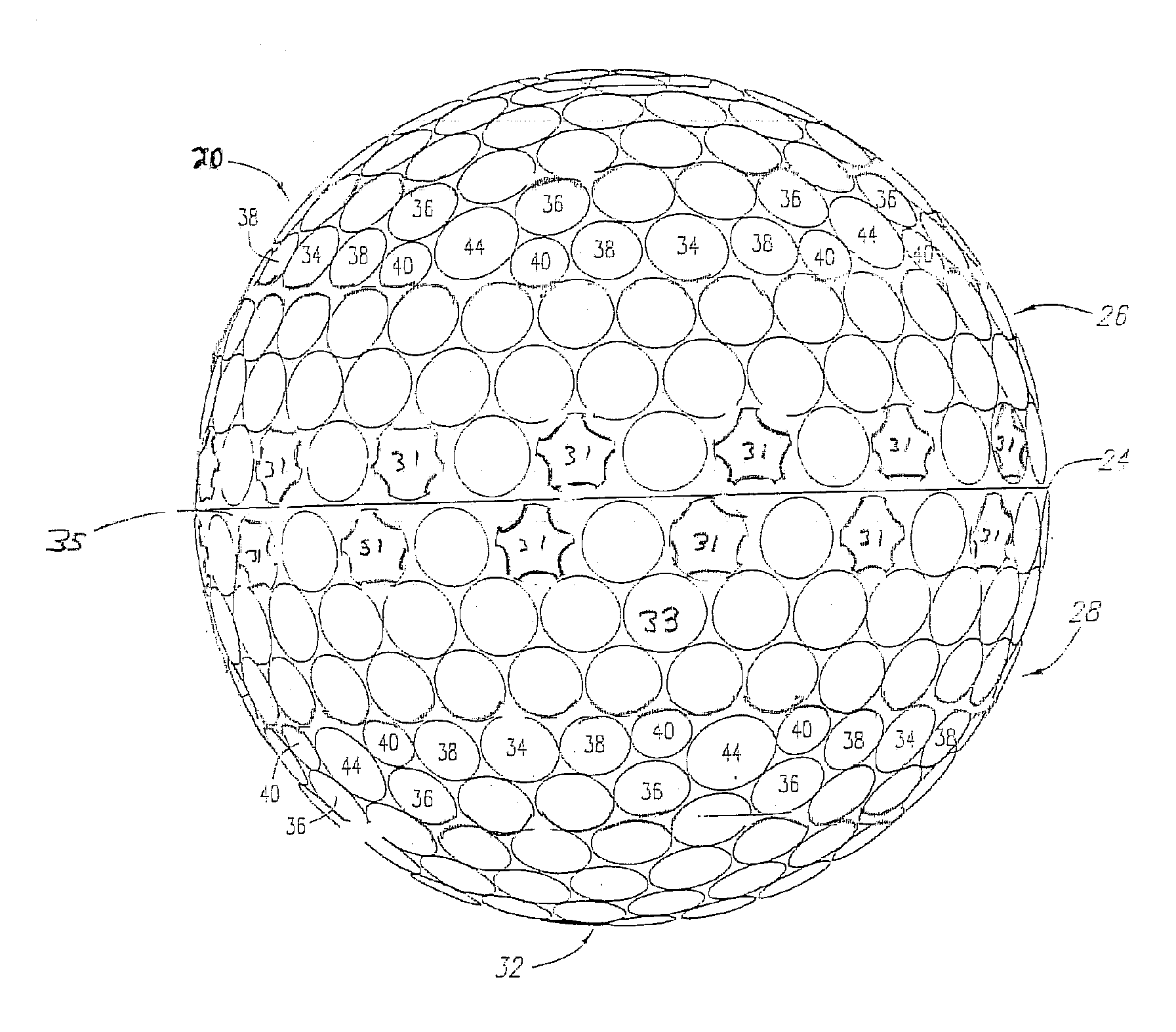

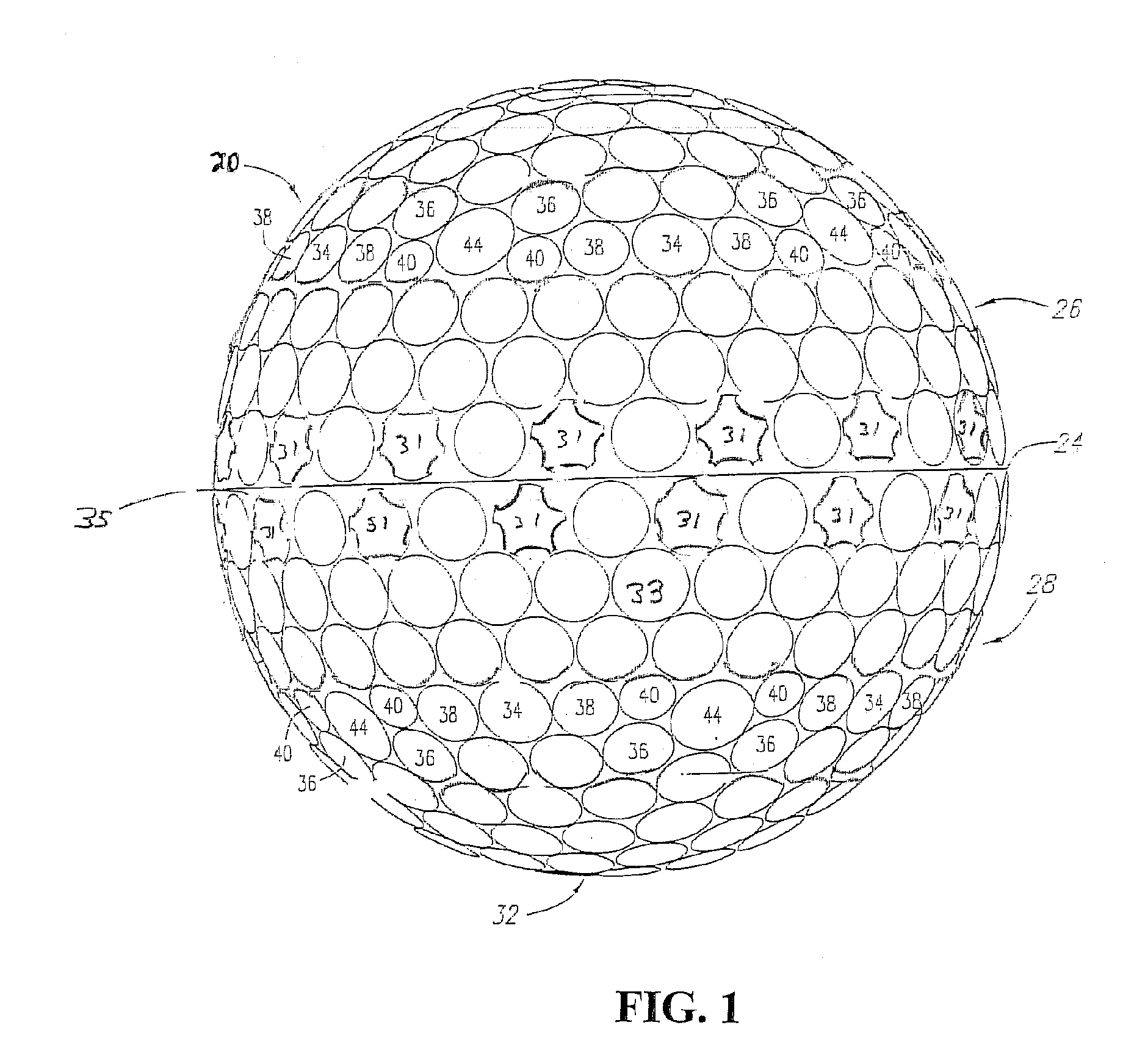

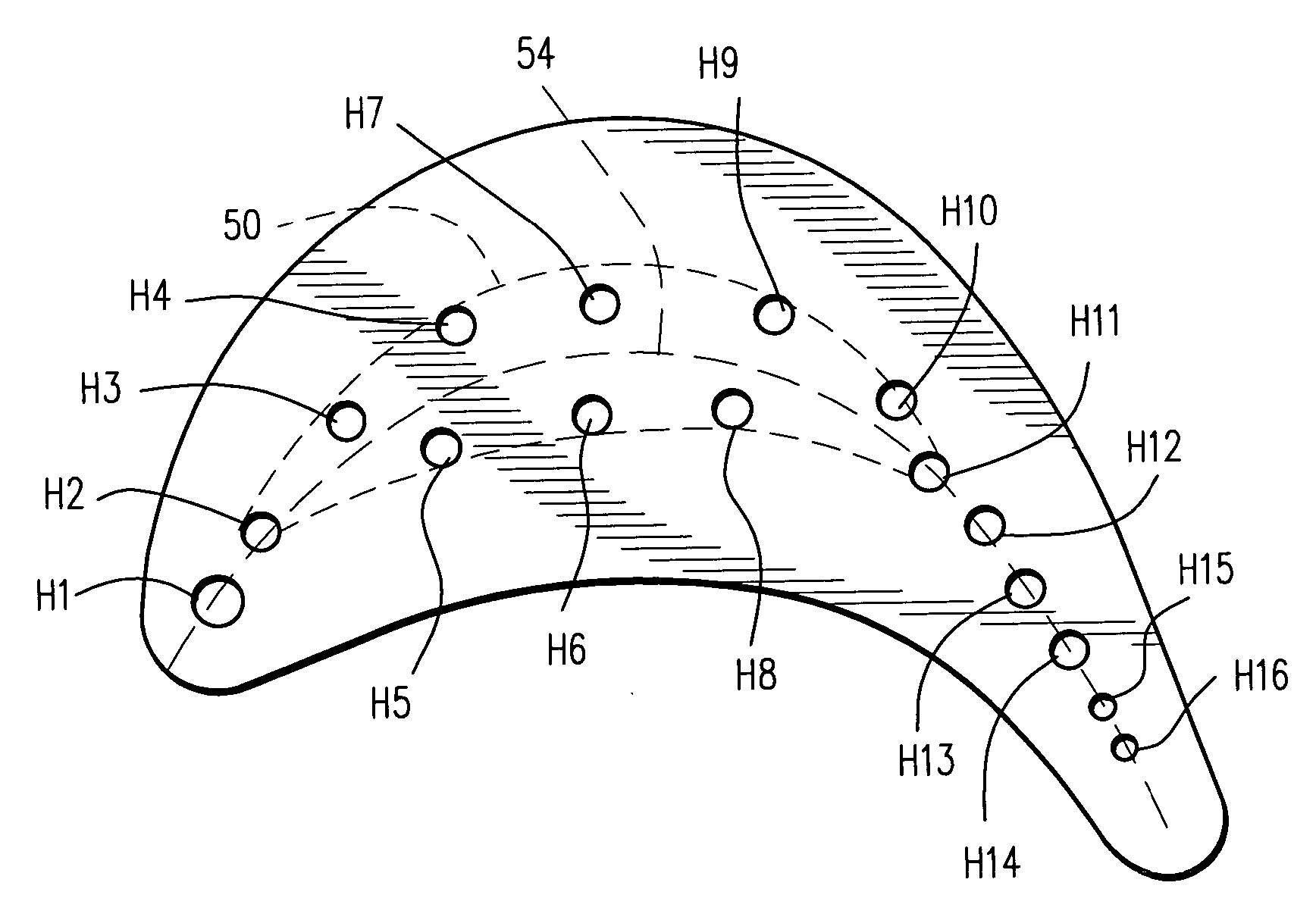

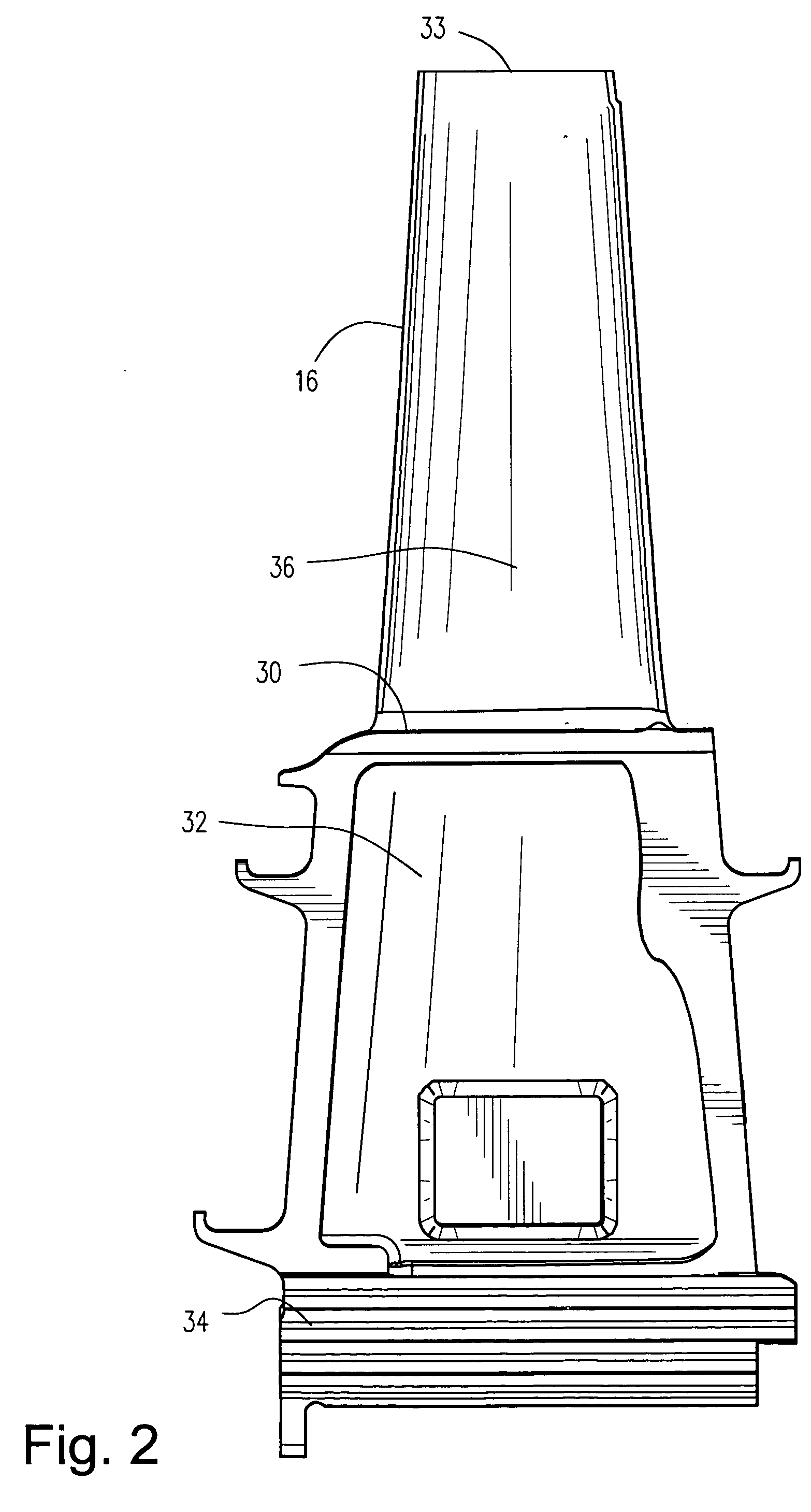

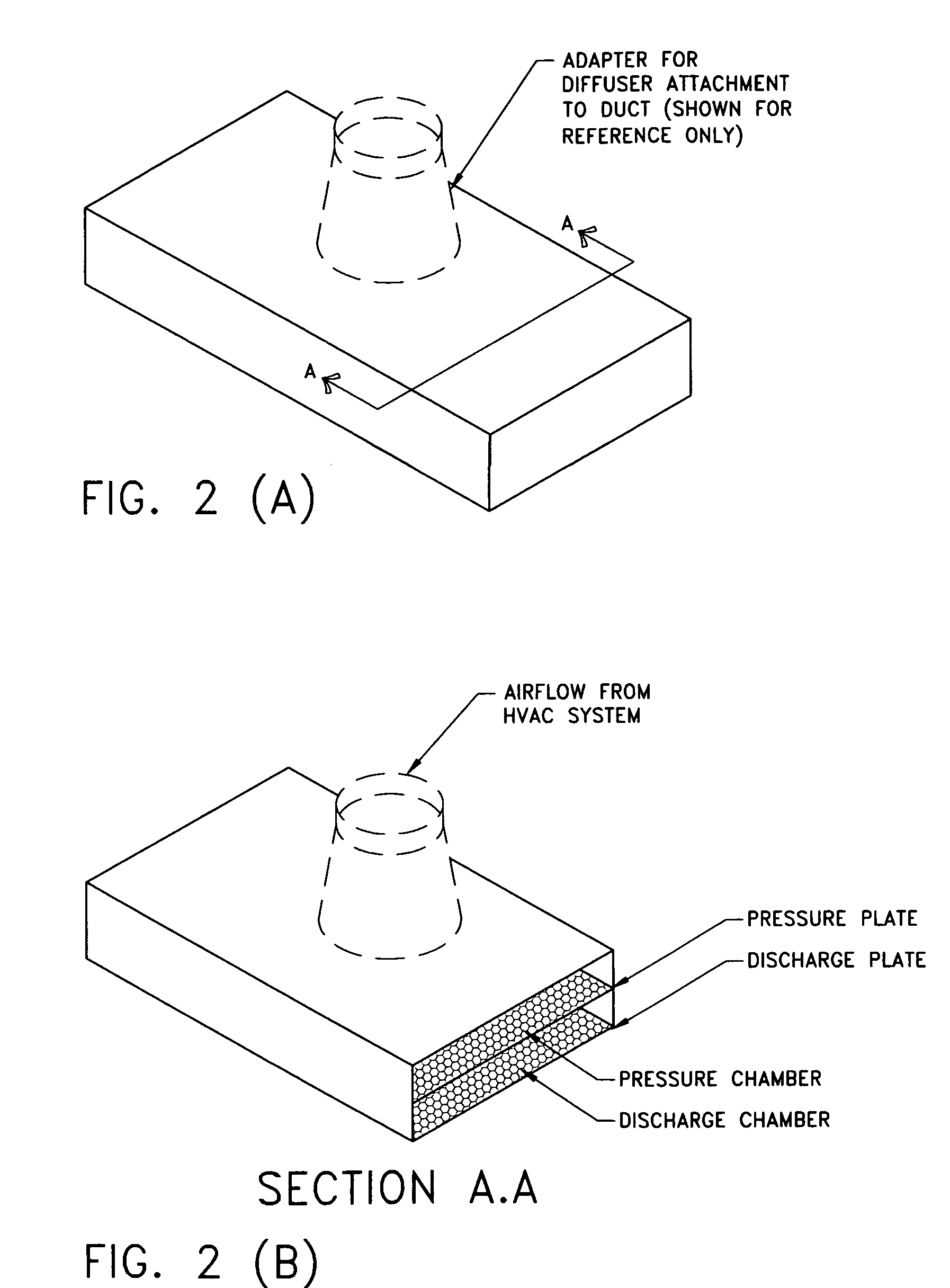

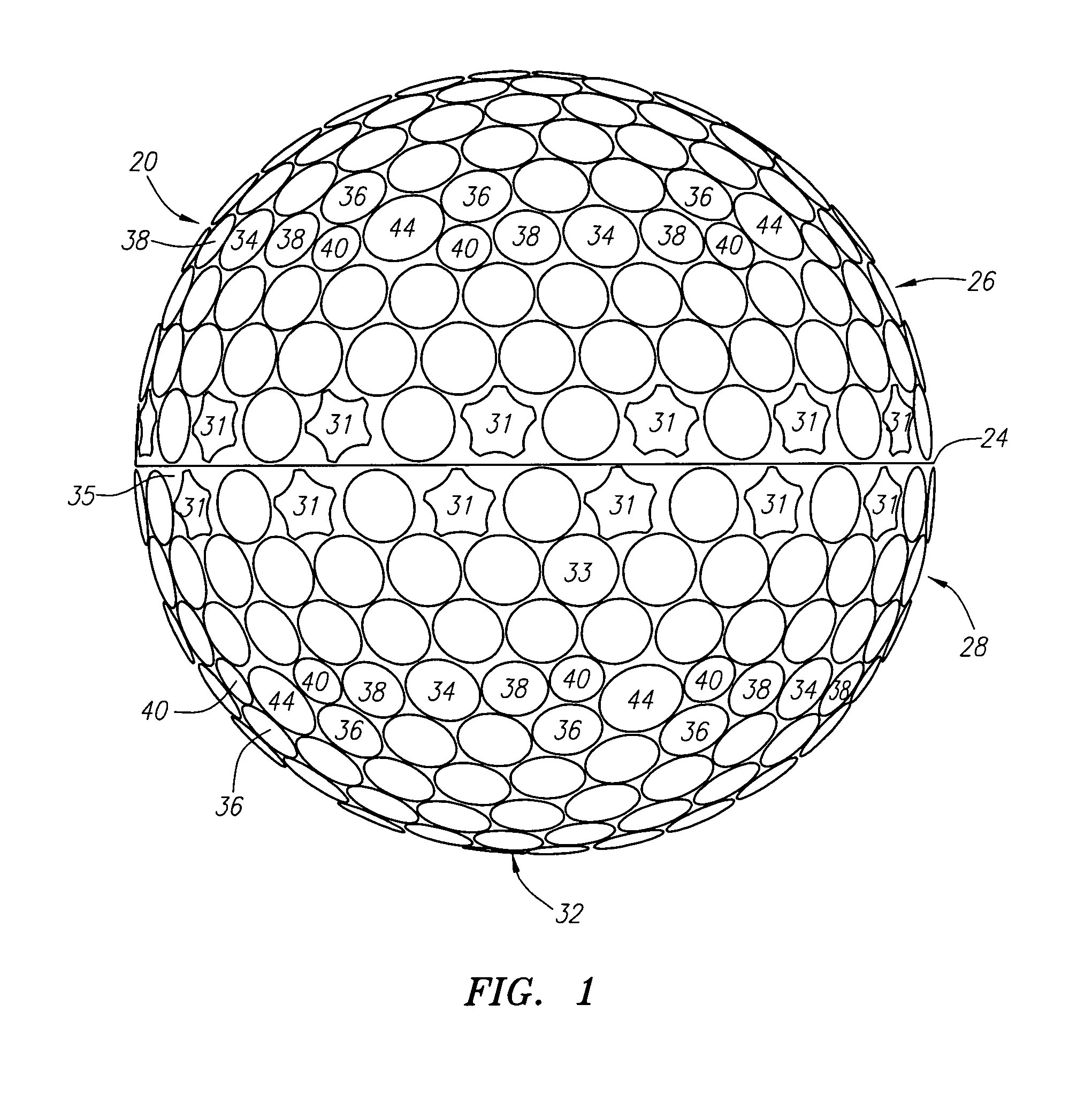

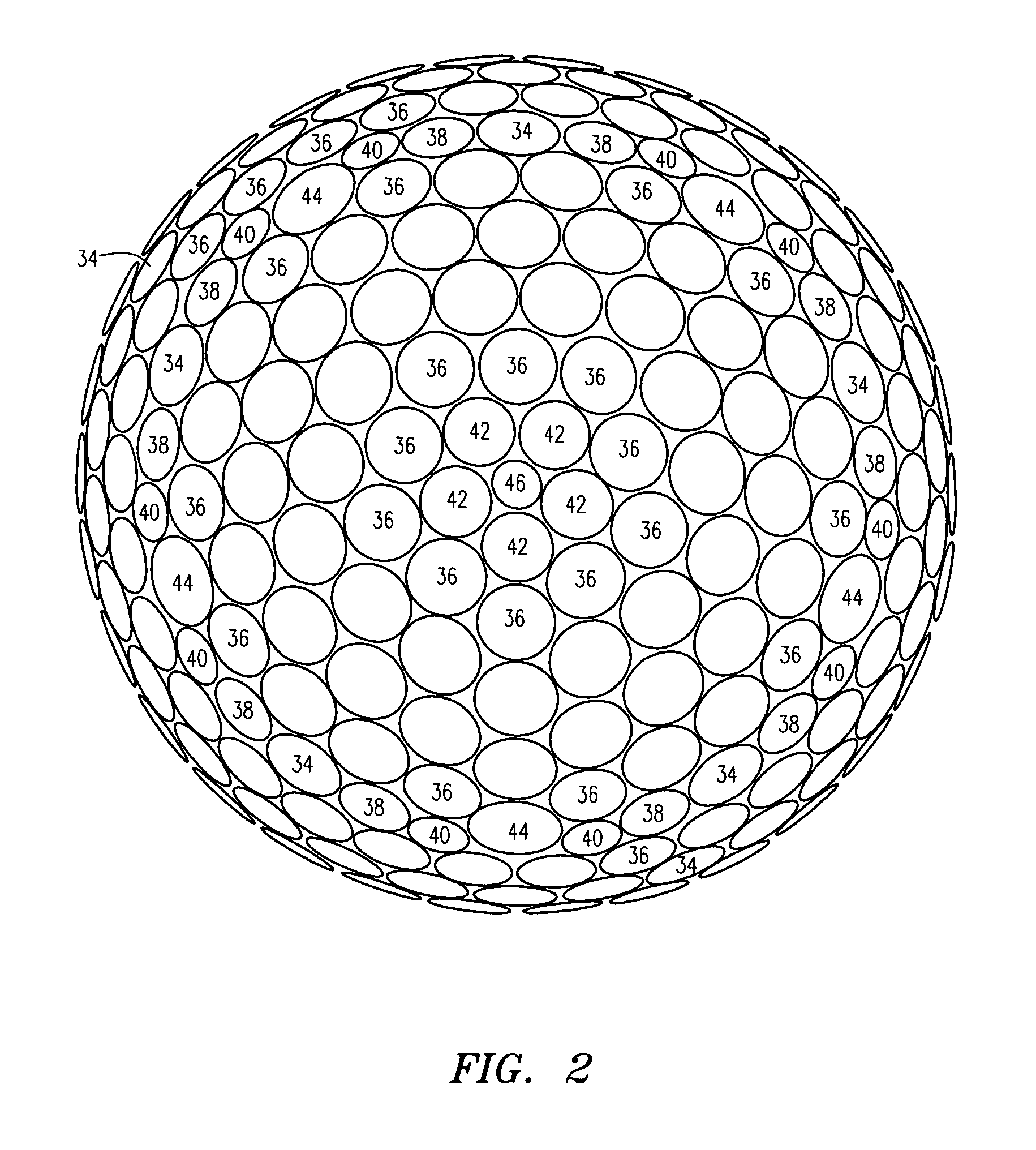

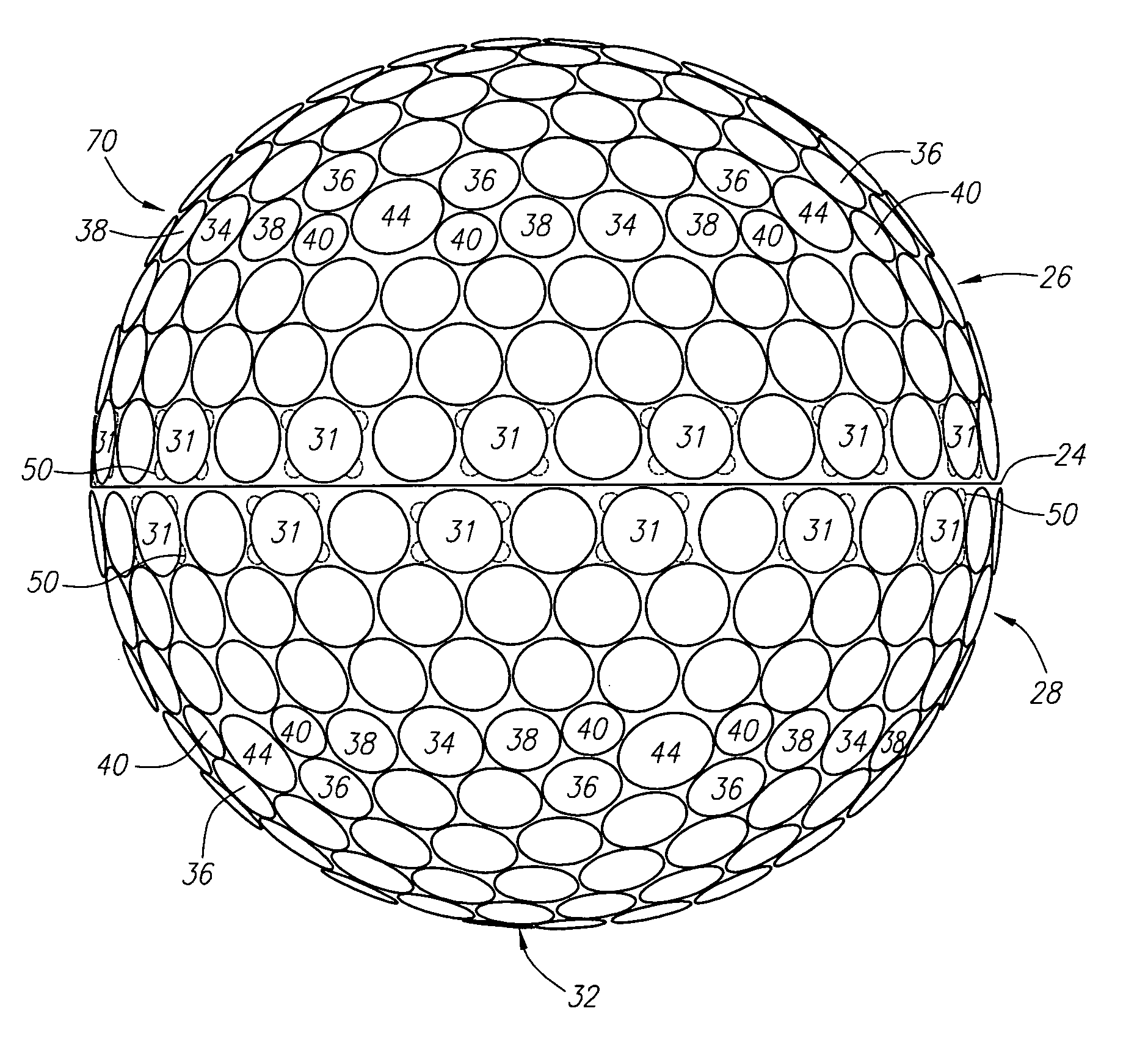

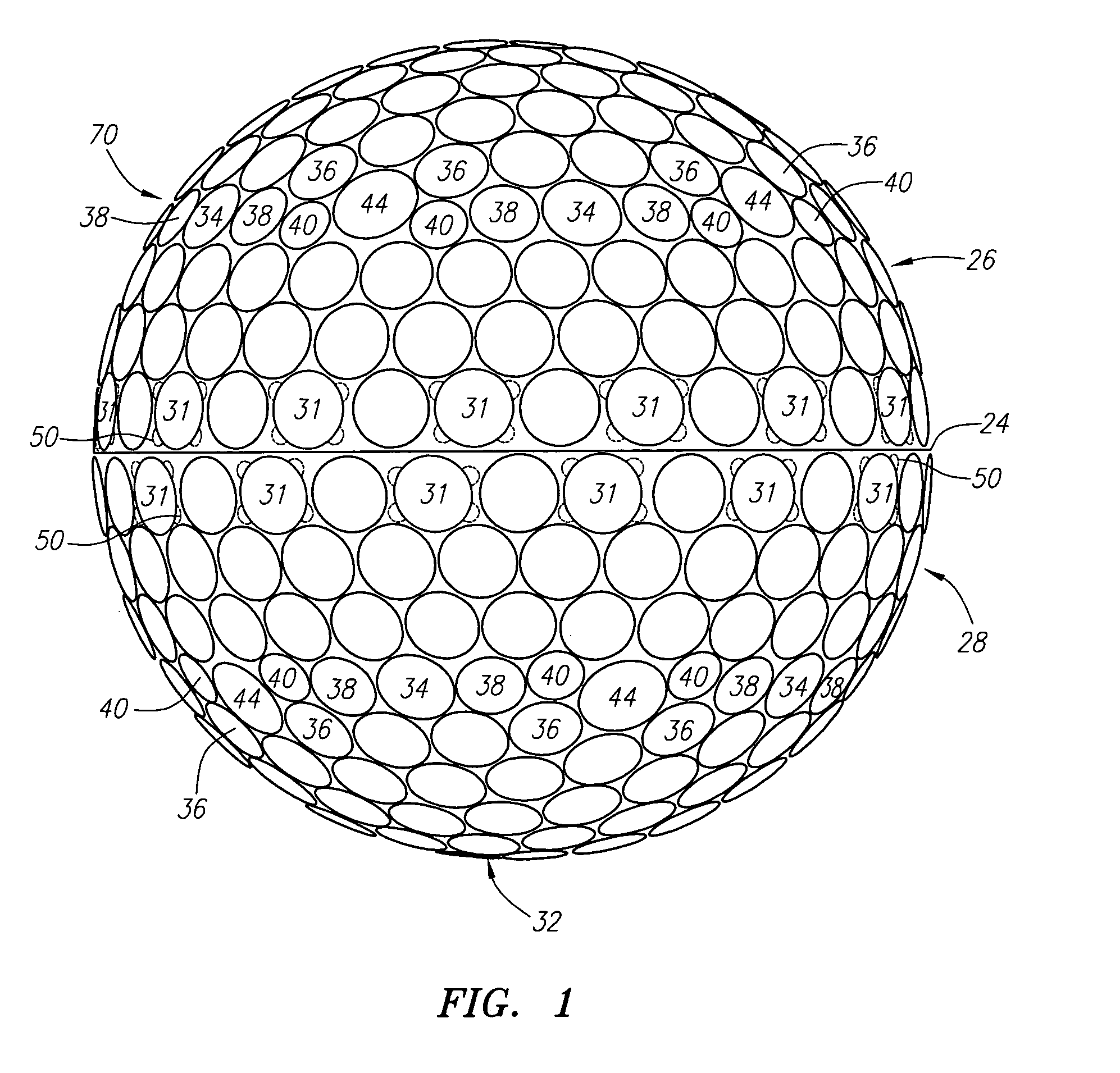

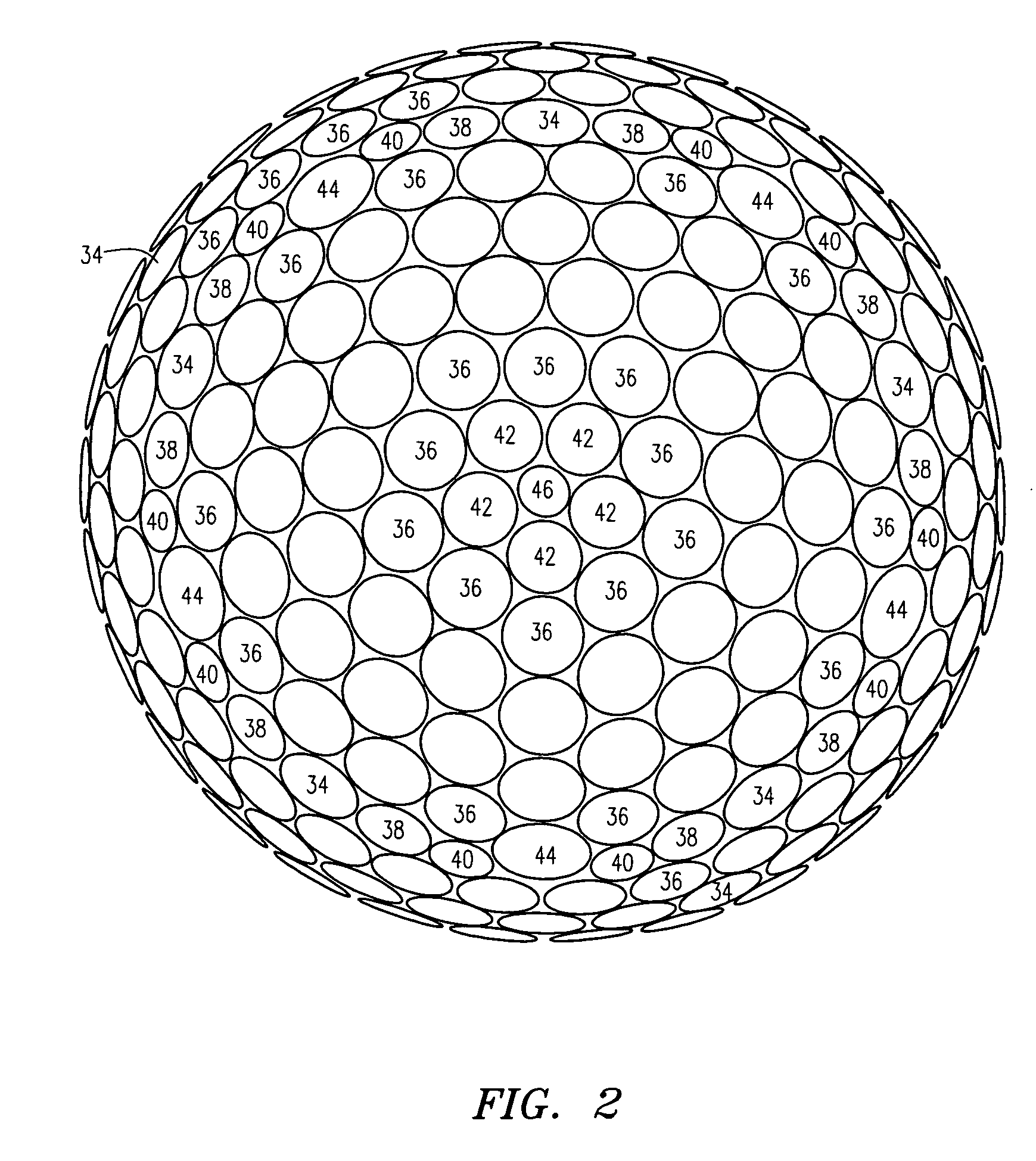

Golf ball with covered dimples

InactiveUS20050090335A1Increased turbulenceReduce resistanceGolf ballsSolid ballsEngineeringGolf Ball

A golf ball (20) having a plurality of standard dimples (33) and a plurality of covered dimples (31) is disclosed herein. Each of the plurality of covered dimples (31) has at least one overhang land area portion (50) that covers a portion of a concavity (55) of the covered dimple (31). A covered region (70) under the overhang land area portion (50) generates eddy currents during the flight of the golf ball (20) which creates greater turbulence at the surface (22) of the golf ball (20) allowing for greater distance.

Owner:TOPGOLF CALLAWAY BRANDS CORP

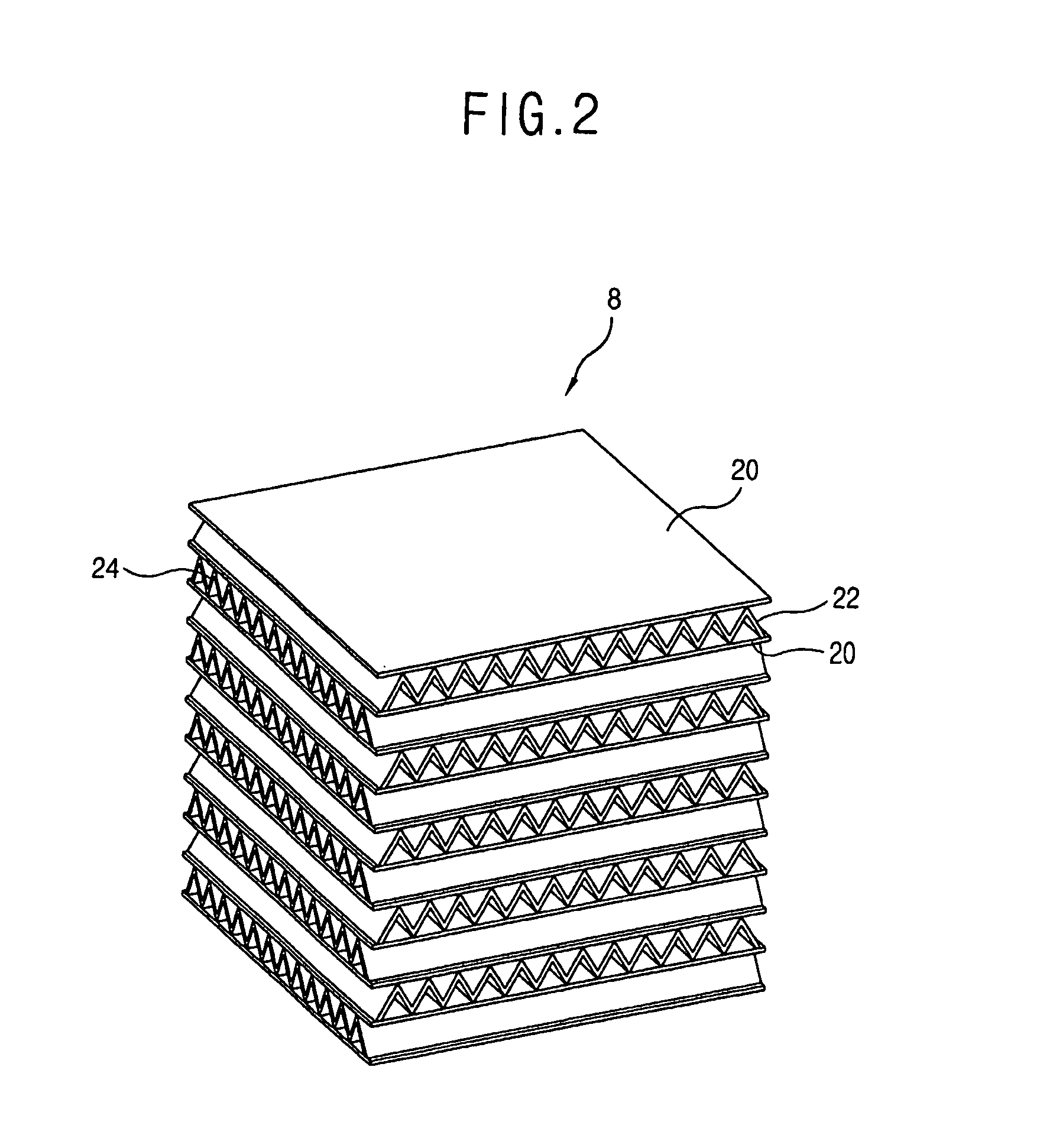

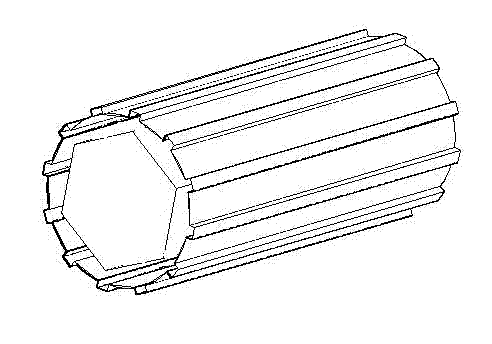

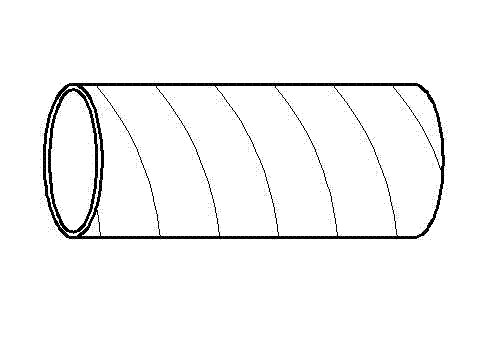

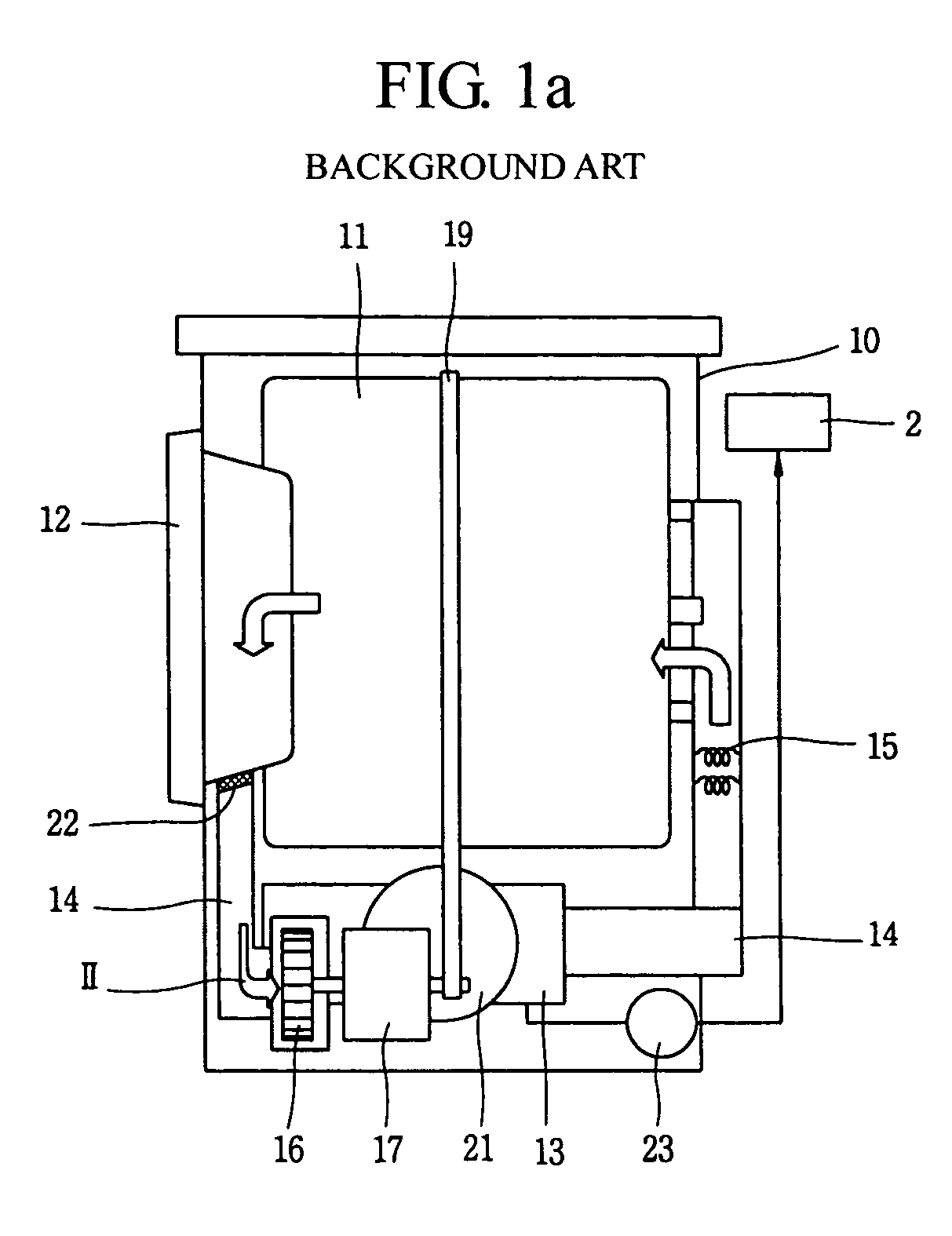

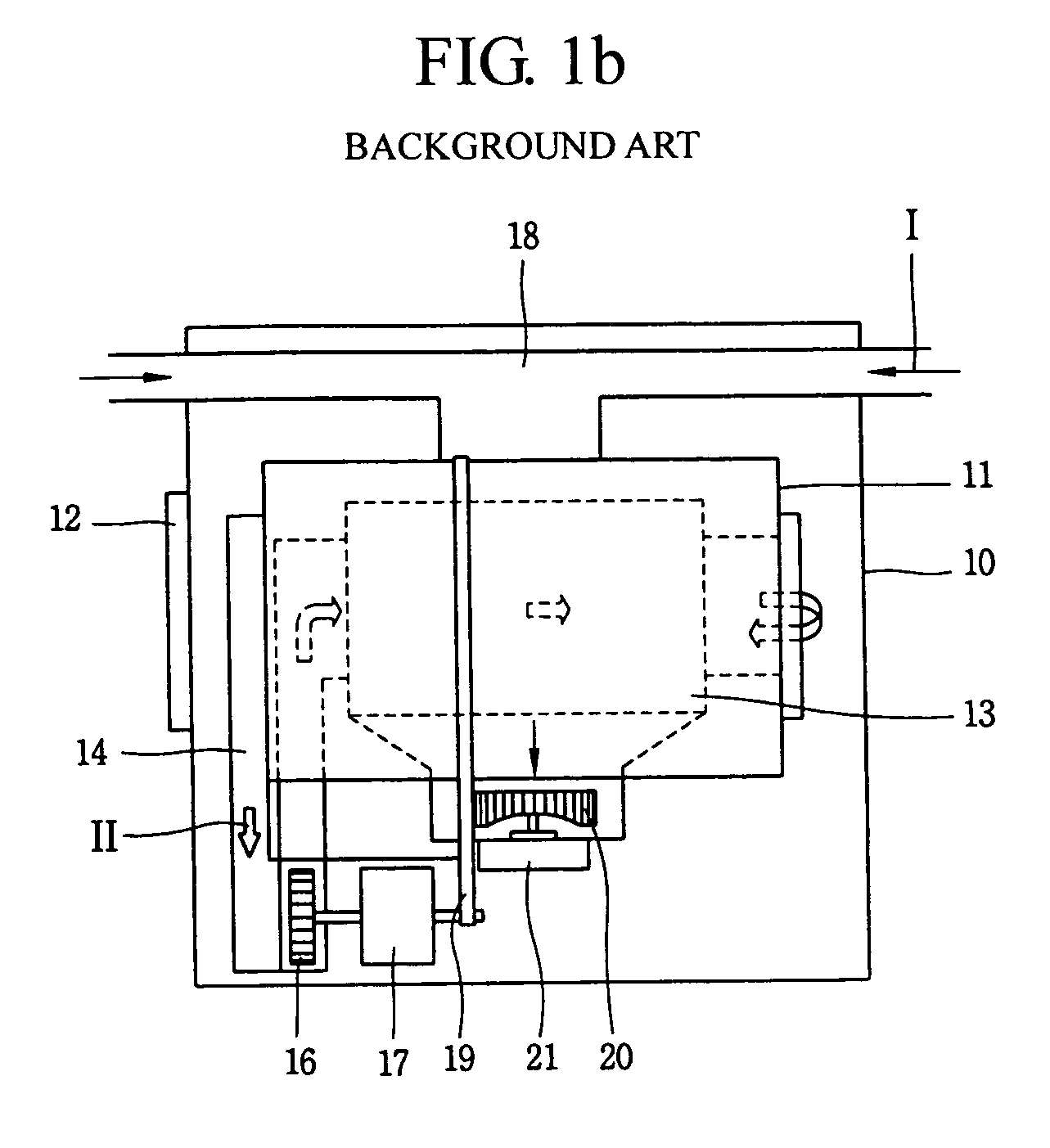

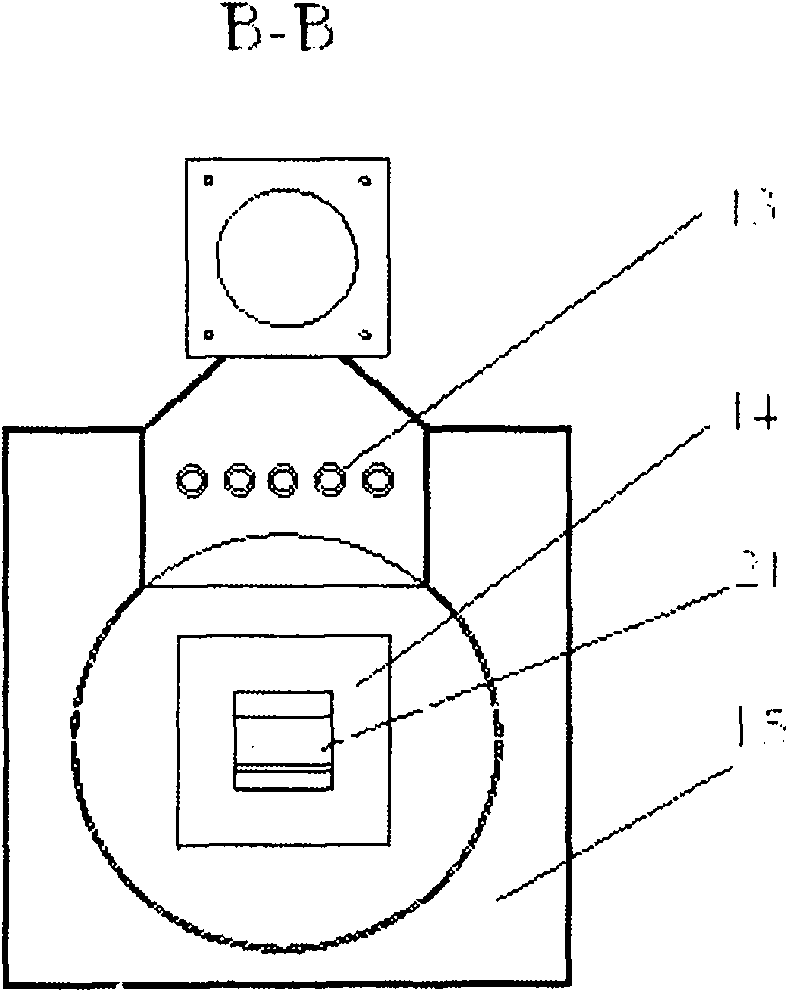

Heat exchanger for dryer and condensing type dryer using the same

InactiveUS20060288602A1Improve heat transfer efficiencyInexpensive to fabricateStationary conduit assembliesTextiles and paperAmbient airElectrical and Electronics engineering

A heat exchanger for a dryer includes a plurality of tube units configured to conduct warm humid air and a plurality of fin units configured to conduct a flow of ambient air. The tube units and fin units are alternately stacked to form a core. The fin units includes a plurality of air channels formed by repeatedly bending a flat metal plate in a zigzag fashion and a plurality of fins formed on surfaces of the air channels. The tube units have a duct form with both ends opened. The tube units may be formed by extrusion. A plurality of channel walls can be formed inside the tube units. A plurality of grooves or fins can also be formed inside the tube units. A plurality of channel walls can also be vertically formed inside the tube units. In this case, the grooves or fins can be formed on the channel walls. The grooves or fins can also be formed in a spiral form on the inner surfaces of the tube units.

Owner:LG ELECTRONICS INC

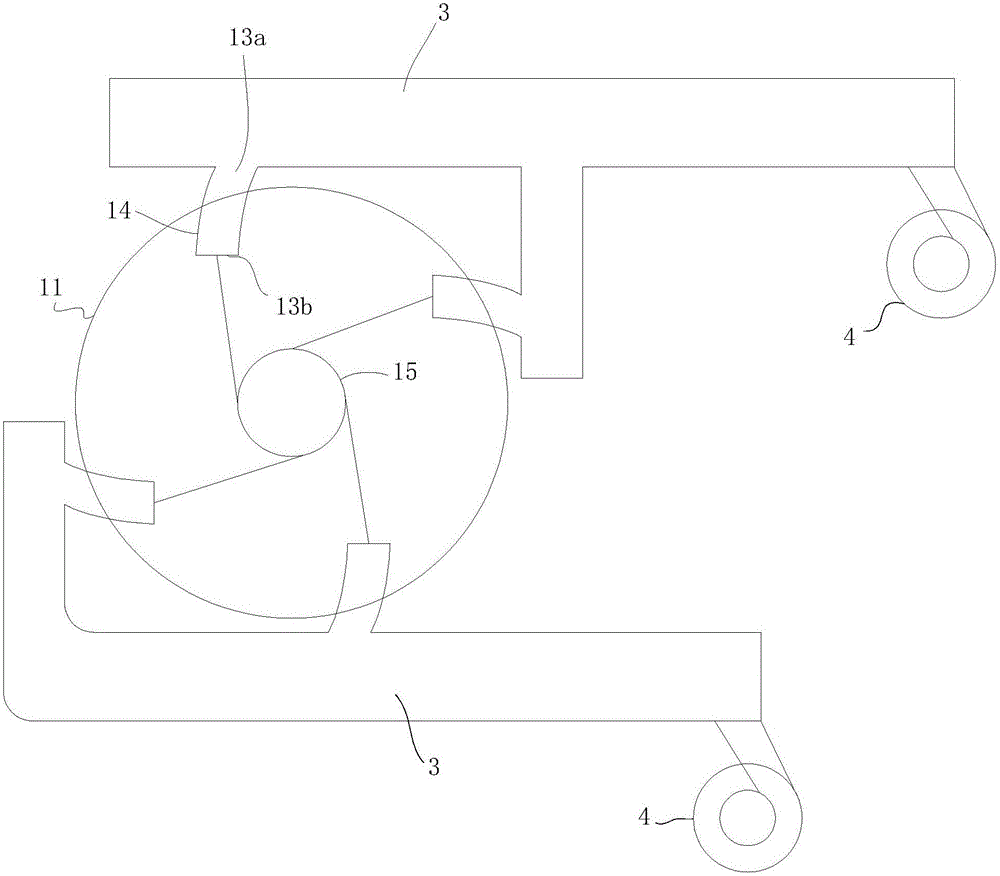

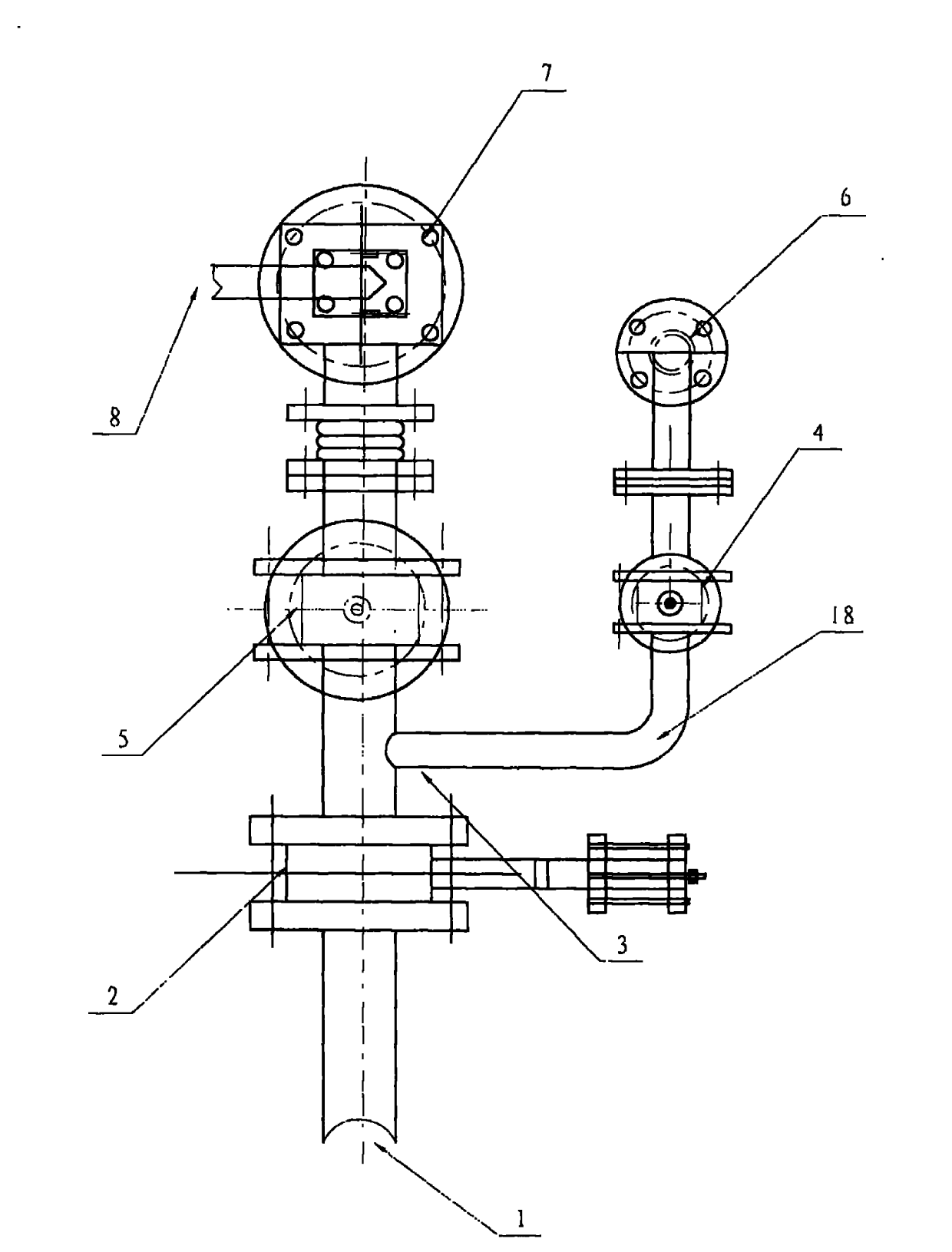

Desulfurization tower flue gas nozzle and desulfurization apparatus

InactiveCN104984646AEvenly distributedMake the most of the momentumDispersed particle separationFlue gasTower

The invention provides a desulfurization tower flue gas nozzle and a desulfurization and dust removal apparatus. The desulfurization tower flue gas nozzle comprises a cylindrical nozzle body; the periphery of the nozzle body is provided with a group of spray holes for making flue gas entering the nozzle body form eddy flow; one end of the spray holes away from the center of the nozzle body is a flue gas inlet; and one end of the spray holes close to the center of the nozzle body is a flue gas outlet. Flue gas enters through the flue gas inlet, is ejected through the flue gas outlet, and enters an absorbing tower to form the eddy flow, the pressure of the flue gas is large, the flow of the flue gas is strong, and the flue gas goes through the spray holes and enters in an incircle manner, so the flue gas in the absorbing tower rotates, the contact and reaction time of the flue gas and a desulfurization liquid is prolonged, the contact area is increased, the flue gas power is fully used, the gas flow disturbance in the tower is improved, the desulfurization efficiency is improved, the desulfurization effect is achieved even though the absorbing tower is not high, the size of the absorbing tower is reduced, and the cost is reduced.

Owner:武金玉

Perimeter-cooled turbine bucket airfoil cooling hole location, style and configuration

InactiveUS20050031449A1Improve turbine efficiencyPromote turbulenceOther chemical processesEngine fuctionsTurbine bladeZ-Coordinate

A turbine stage one bucket has an airfoil having a plurality of cooling holes passing through the airfoil from 0% span to 100% span whereby cooling air exits the airfoil tip into the hot gas path. X and Y coordinate values are given in Table I, locating the holes relative to the airfoil profile at airfoil profile sections of 5%, 50% and 90% span, Table I also giving the hole diameters. In this manner, cooling hole optimization for this turbine bucket airfoil is achieved. The cooling holes are also located in relation to the profile of the bucket airfoil given by the X, Y and Z coordinate values of Table II, the two coordinate systems having the same origin.

Owner:GENERAL ELECTRIC CO

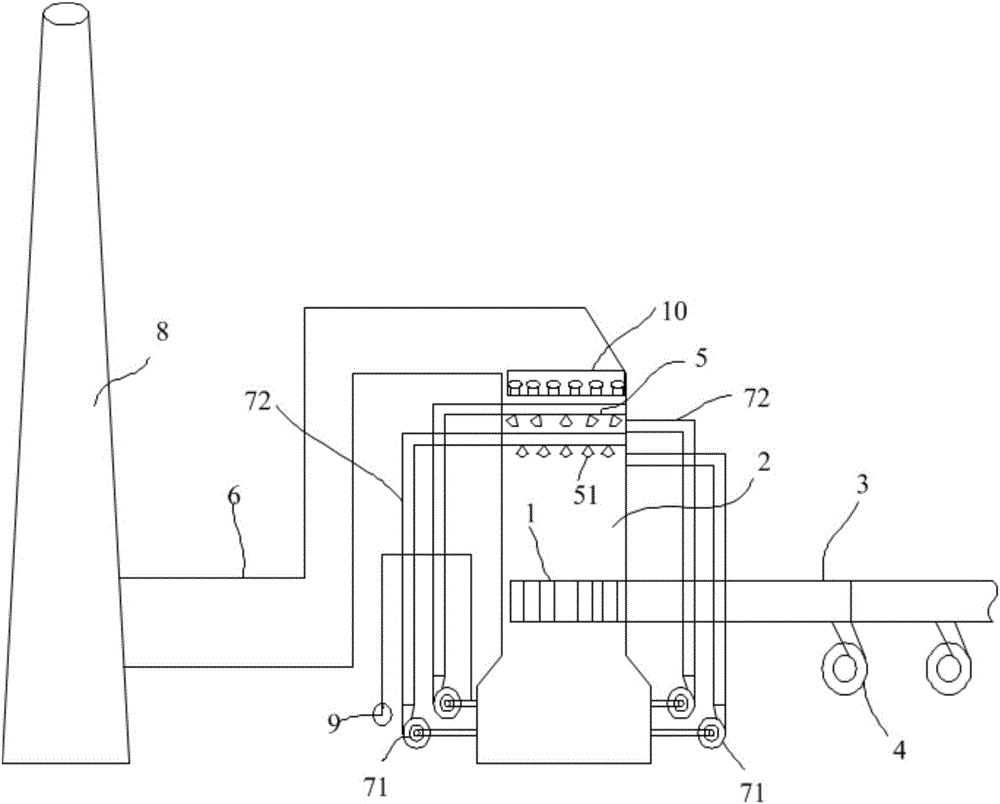

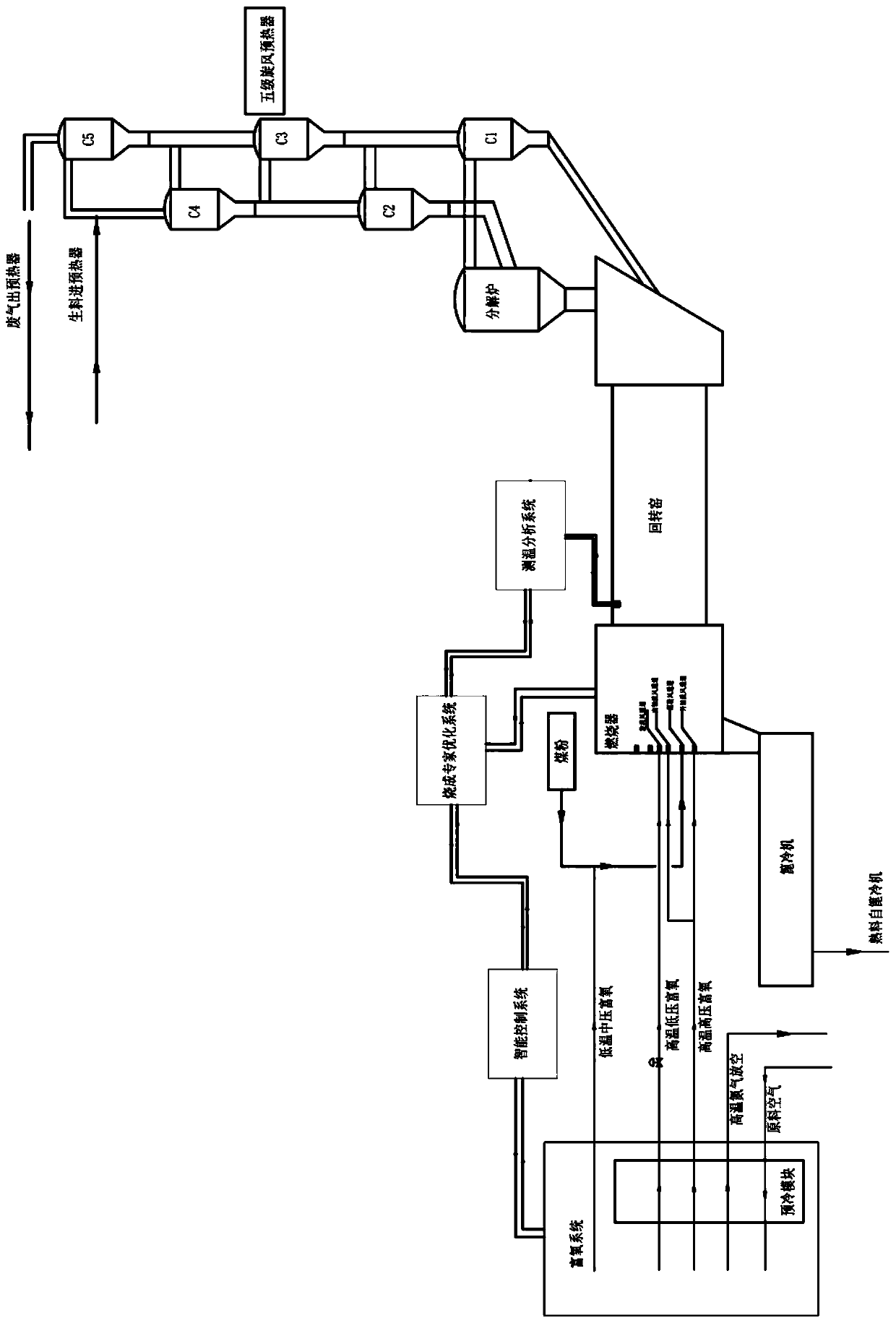

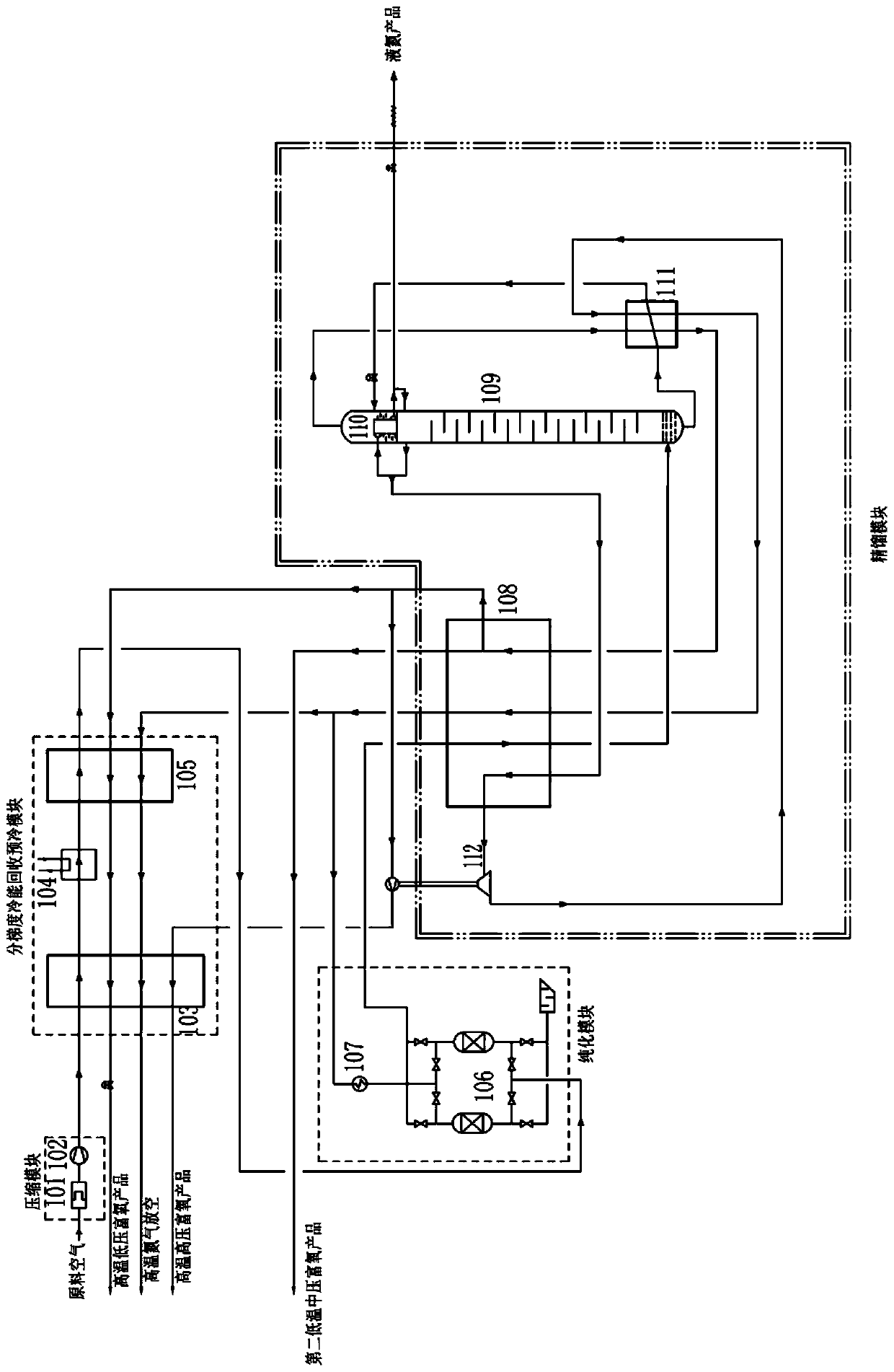

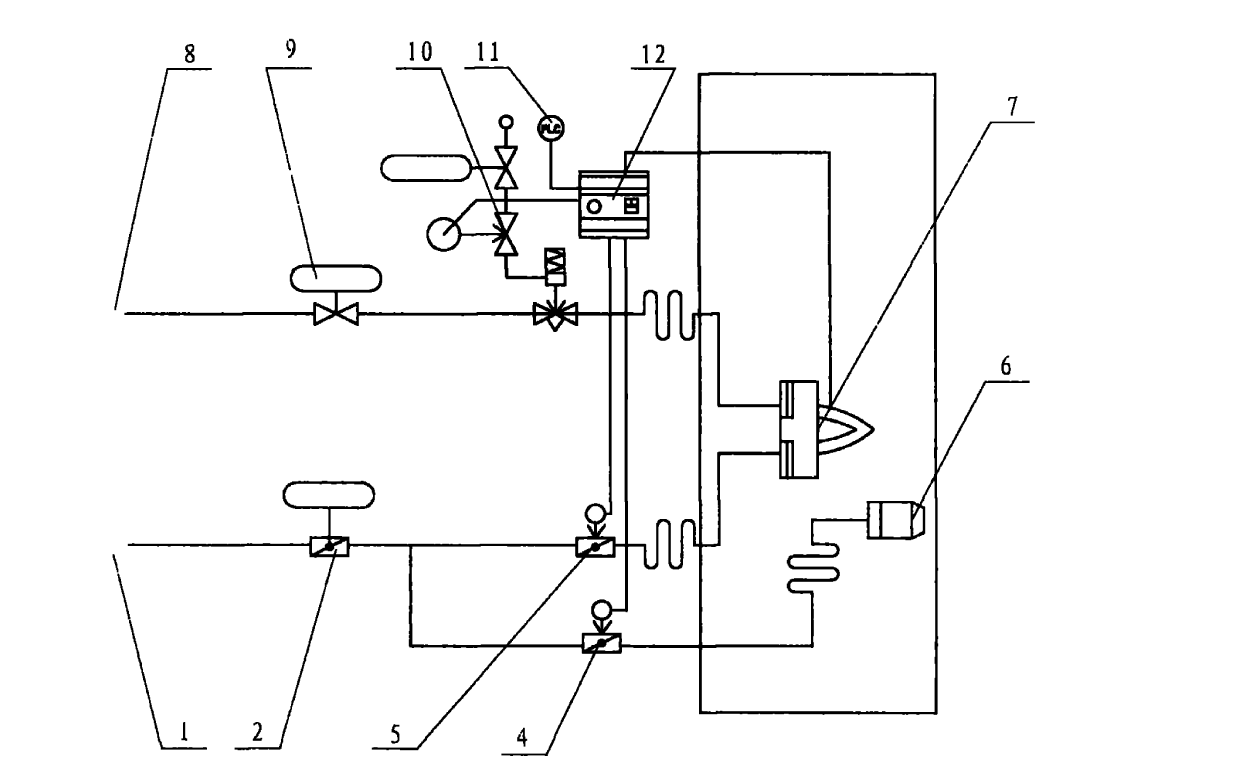

Intelligent control oxygen-enriched firing system and method for kiln

ActiveCN111521003ASmall fluctuationReduce dosageSolidificationLiquefactionThermodynamicsProcess engineering

The invention discloses an intelligent control oxygen-enriched firing system for a kiln. The intelligent control oxygen-enriched firing system for the kiln comprises an oxygen-enriched system, an oxygen-enriched burner, a temperature measurement and analysis system, a firing expert optimization system and an intelligent control system. According to the intelligent control oxygen-enriched firing system for the kiln, the oxygen enrichment is produced and provided by a special oxygen-enriched system; the novel oxygen-enriched burner is adopted; according to different coal powder types, coal powder amount and grinding granularity of a kiln system, the shapes and temperature distribution of flames are obtained by the accurate temperature measurement and analysis system, all on-site actual thermal parameters and on-site states of the kiln are combined, the system analysis and the prediction and judgment are carried out by the firing expert optimization system, and the intelligent regulationand dynamic matching of the special oxygen-enriched system are controlled by the intelligent control system, so that the optimal operation state of the firing system of the kiln is kept, the efficientand stable burning of coal powder in the oxygen-enriched burner is realized, the consumption of the coal powder is reduced, the quality of burned materials is improved, the generation and emission ofNOx are effectively reduced, meanwhile, the fluctuation of the kiln system caused by the debugging experience and level difference of operators is reduced, and the normal and stable operation of thekiln system is guaranteed.

Owner:HANGZHOU TURNING ENERGY TECH DEV CO LTD

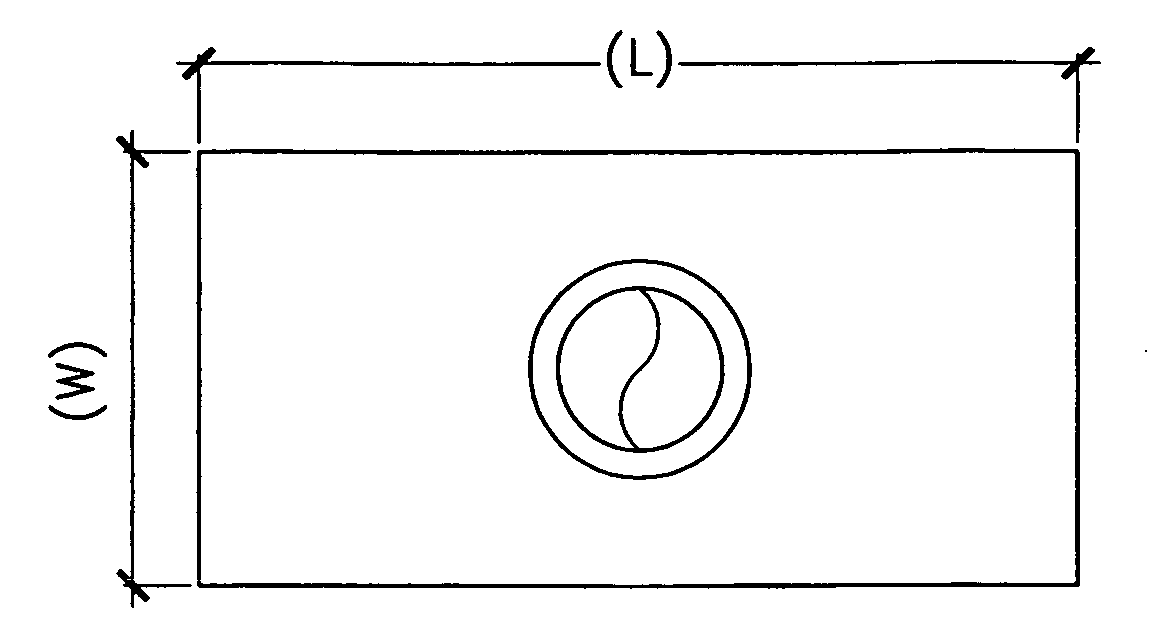

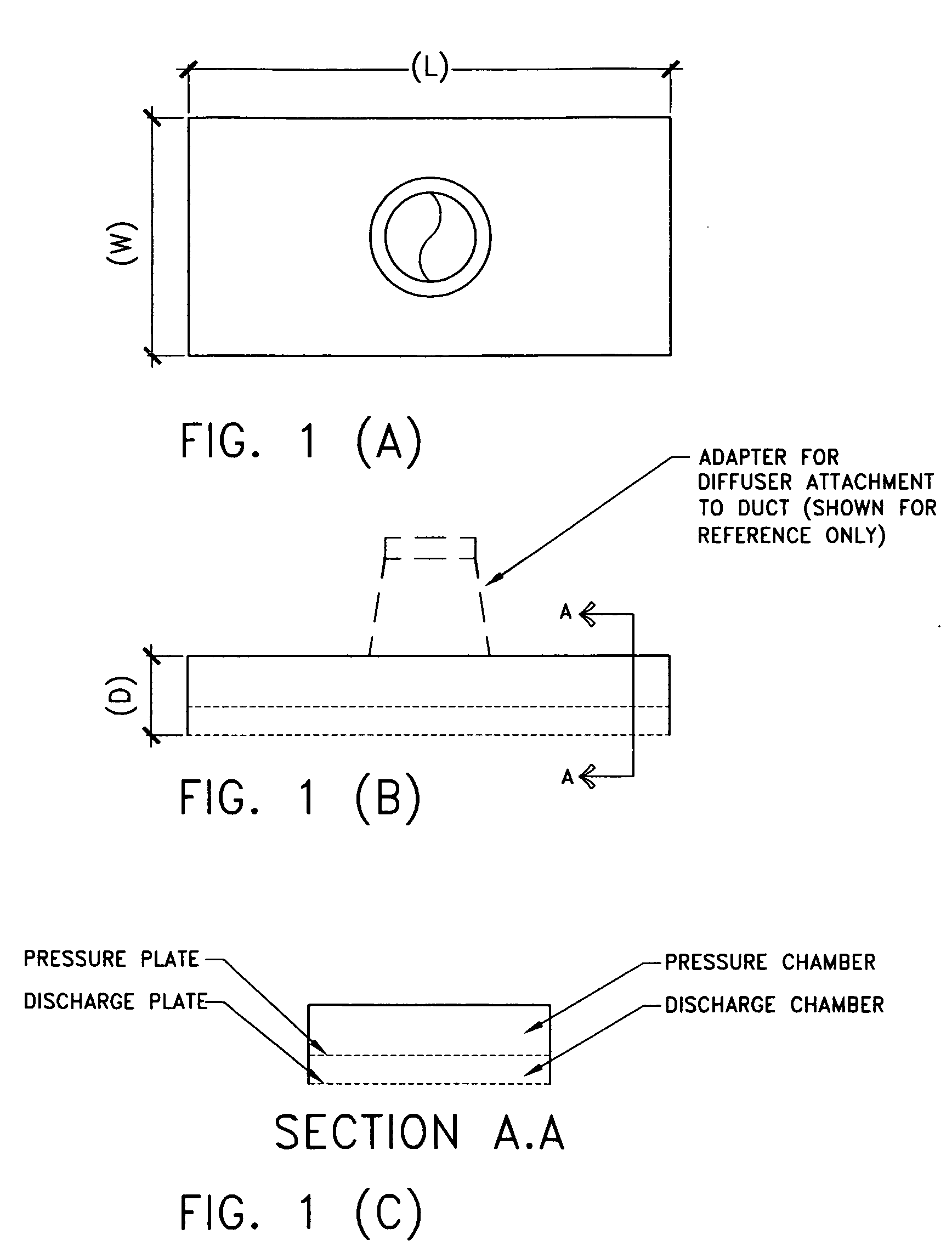

Diffuser assembly for non-turbulent air flow

InactiveUS20100159820A1Avoid captureIncreased air turbulenceLighting and heating apparatusAir-flow control membersWaste managementAirflow

The invention is an air flow diffuser that produces an even and non-turbulent flow of air from ventilation or A / C. The diffuser combines a pressure chamber and a discharge chamber to produce a non-turbulent even flow of air perpendicular to the face of the discharge chamber. The pressure and discharge chambers are contiguous with the ducted air flowing first into the pressure chamber and then into the discharge chamber from which chamber the non-turbulent, evenly flowing air flows into the space. Though the diffuser is developed for a downward air flow, the diffuser can be constructed in several shapes, such as triangular, allowing air flow in any direction that is perpendicular to the plane of the discharge plate.

Owner:HIRSCH H HENRY

Golf ball with covered dimples

InactiveUS7179177B2Reduce resistanceIncreased air turbulenceGolf ballsSolid ballsEngineeringGolf Ball

A golf ball (20) having a plurality of standard dimples (33) and a plurality of covered dimples (31) is disclosed herein. Each of the plurality of covered dimples (31) has at least one overhang land area portion (50) that covers a portion of a concavity (55) of the covered dimple (31). A covered region (70) under the overhang land area portion (50) generates eddy currents during the flight of the golf ball (20) which creates greater turbulence at the surface (22) of the golf ball (20) allowing for greater distance.

Owner:TOPGOLF CALLAWAY BRANDS CORP

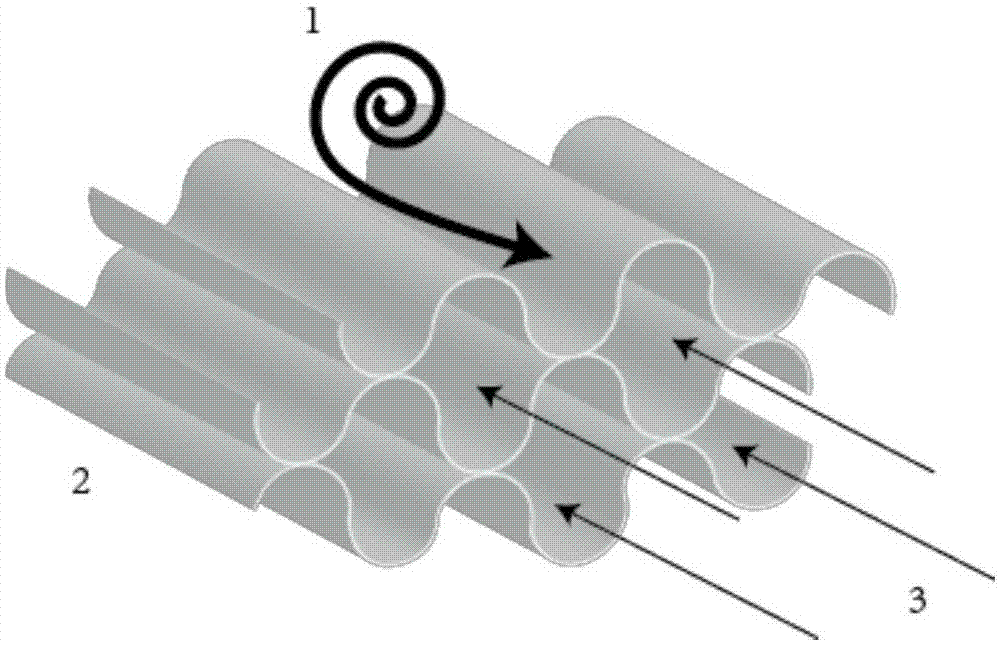

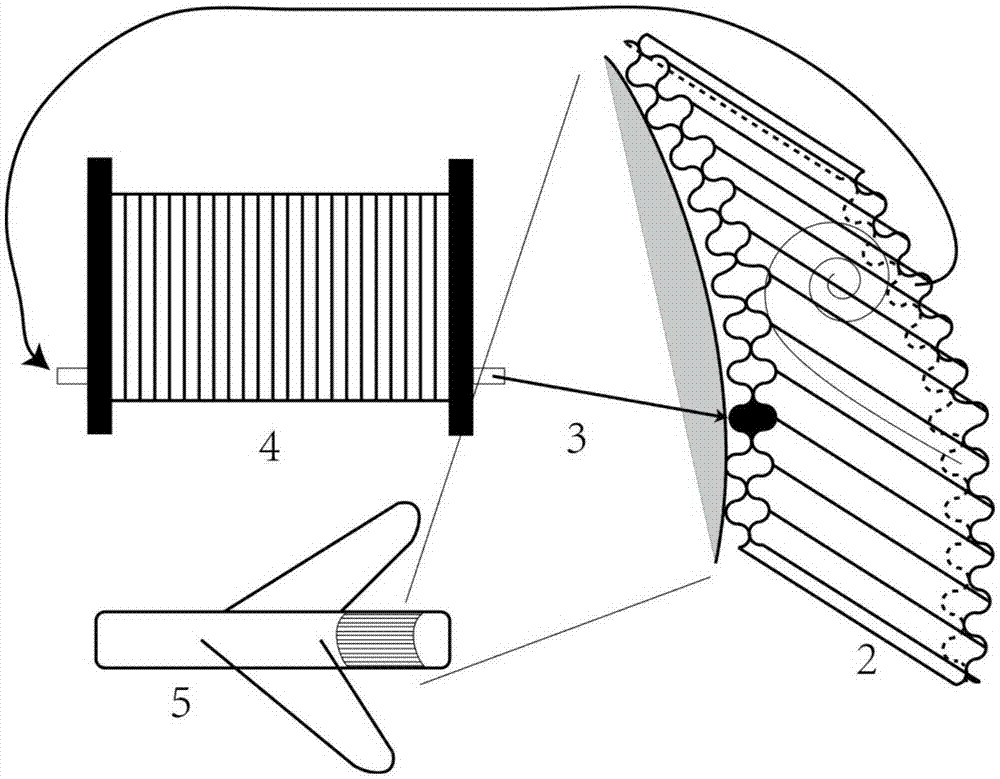

Aviation-used fuel cell system radiator and aviation-used fuel cell system

ActiveCN106910960ARealize heat dissipationSimple structureSecondary cellsFuel cellsJet aeroplaneAviation

The invention discloses an aviation-used fuel cell system radiator which comprises N layers of laminatedly superimposed corrugated pieces, wherein the N is a natural number larger than or equal to 2; ridges and grooves which are alternately arranged at intervals are arranged on the surfaces of the two side surfaces of the corrugated pieces, adjacent corrugated piece layers are welded through the ridges to form (N-1) layers of channel structures, and the condition that the adjacent corrugated piece layers are welded through the ridges means that the ridges on the upper surfaces of the lower-layer corrugated pieces and the ridges on the lower surfaces of the upper-layer corrugated pieces are welded in a one-to-one corresponding mode; the radiator further comprises sealing end sockets arranged at the two ends of channels, wherein gaps are reserved between the sealing end sockets and the opening ends of the channels; a heat radiation work medium inlet is formed in one sealing end socket, and a heat radiation work medium outlet is formed in the other sealing end socket. Compared with the prior art, the radiator disclosed by the invention has a simple structure and avoids additional fans; meanwhile, cooling fins of the radiator are in shapes of thin-plate-shaped corrugated pieces; air turbulence of a heat radiating surface is improved by utilizing aviation flying airflow, a heat radiating effect is good, and flying resistance of an airplane is prevented from being increased.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

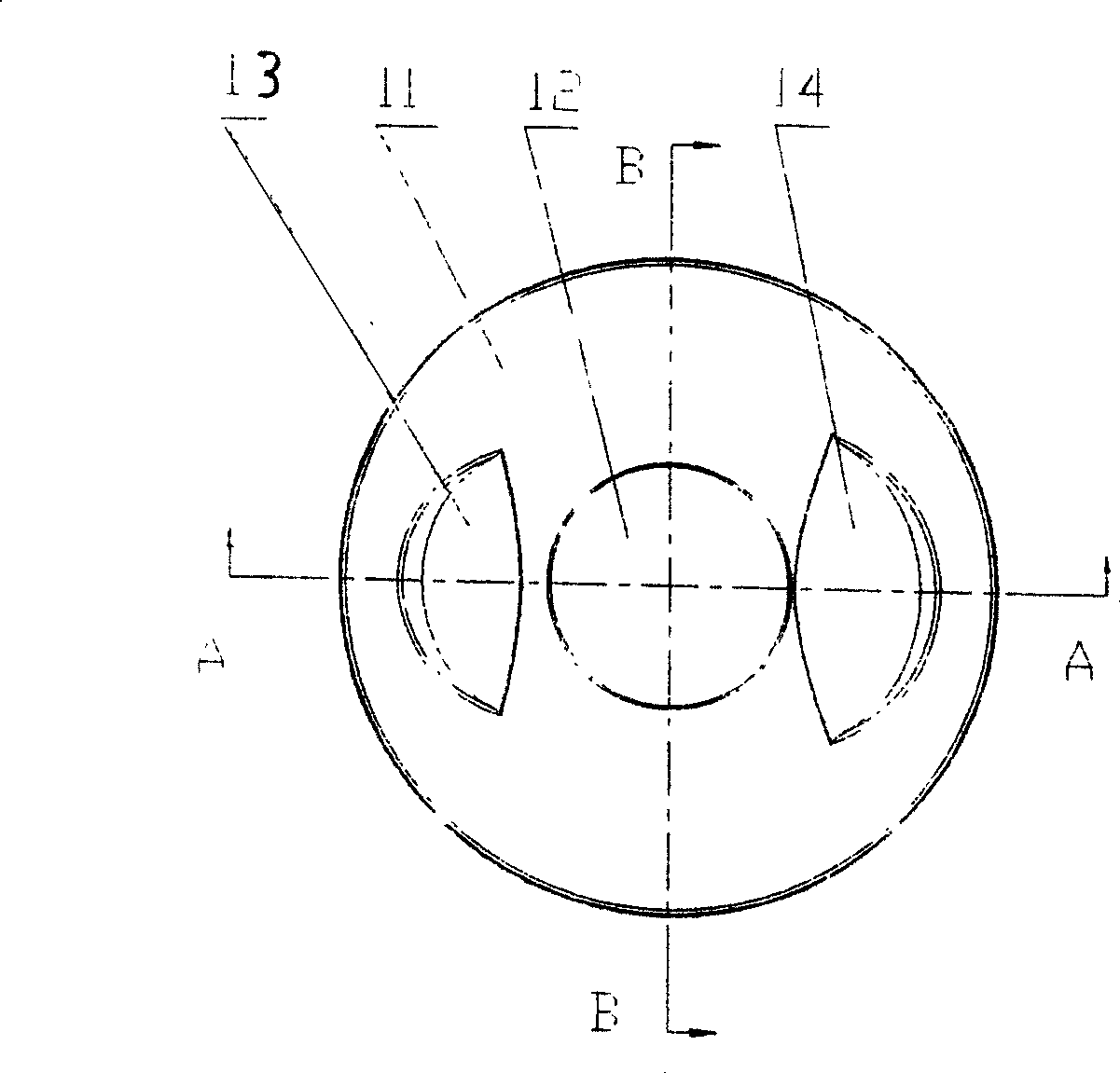

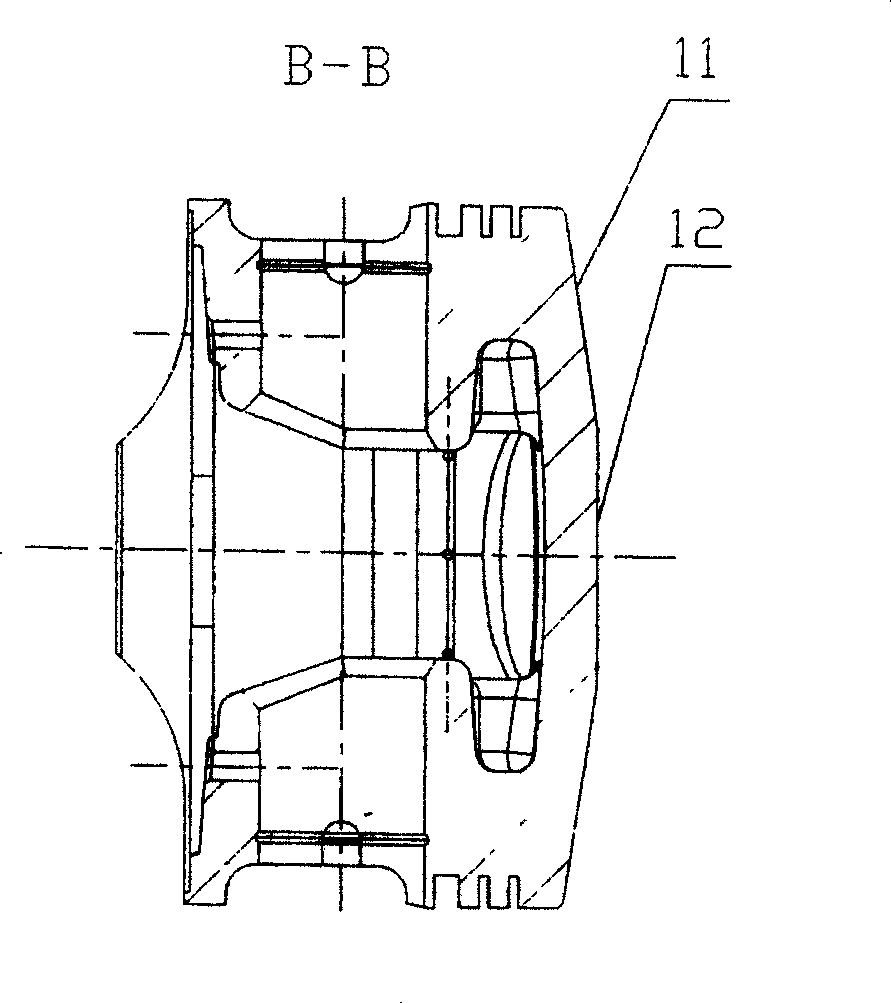

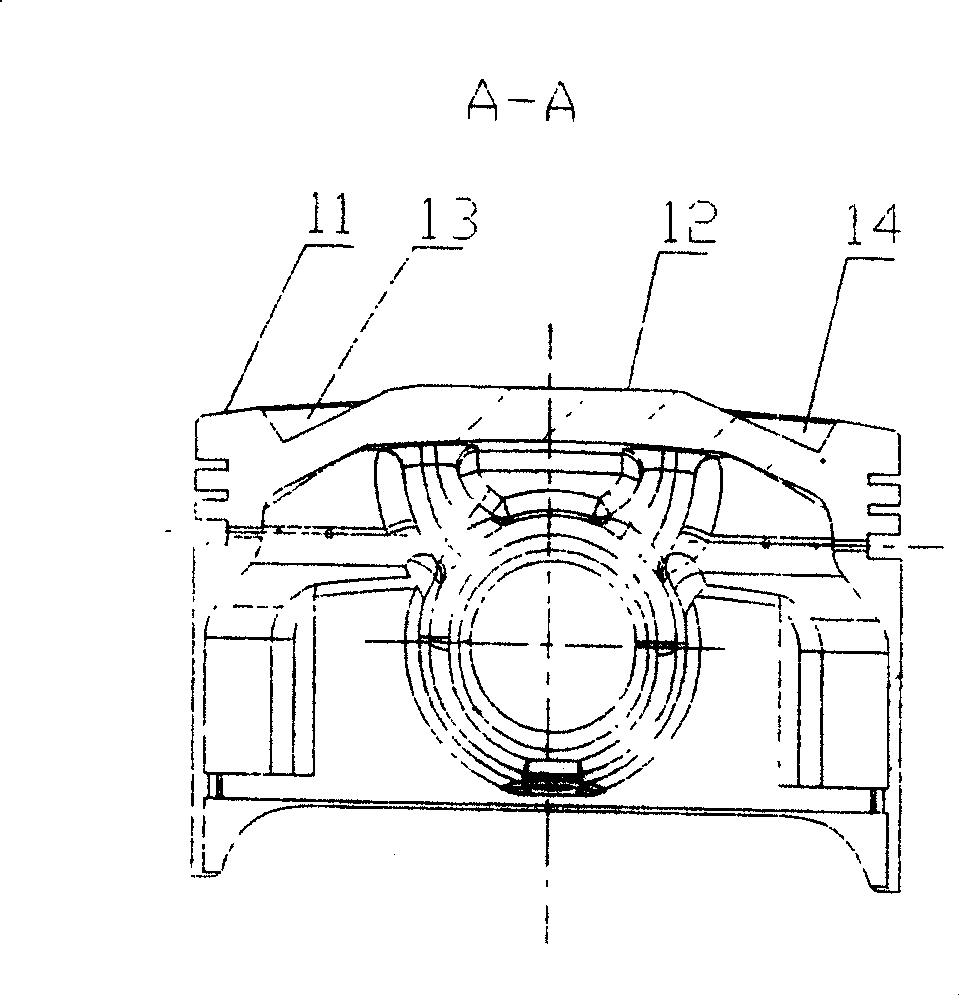

Spherical motorcycle engine combustion chamber

InactiveCN100460637CIncreased air turbulencePromote disseminationInternal combustion piston enginesCylinder headsCombustorCombustion chamber

The invention discloses a combustor of ellipsoidal motorcycle engine, which is constituted by the space between the cylinder cover and the piston. There are intake and outtake channels set at two ends of cylinder cover. The intake channel is high-level tangent air channel and the outtake channel is screw curved air channel. The top face of piston is cone-like convex face. On the cone-like convex face two concave surfaces are set, which are intersected with the cone-like convex face. The space formed by the first concave surface is the collision prevention pit of intake door and the space formed by the second concave surface is the collision prevention pit of outtake door. The space with petal-shape at the side face is formed by the bottom of cylinder cover, spherical concave pit and ellipsoidal pit, which are communicated from the top to the bottom. The space with petal-shape at the side face of cylinder cover is corresponding to the cone-like convex face at the top of piston. After the piston is assembled with the cylinder cover, the ellipsoidal combustor with petal-shape squish flow face is formed by the cone-like convex face on the piston and the space at the side face of cylinder cover. The combustor can strengthen the air flow disturbance of mixed air very well. It can improve burning and decrease HC discharge.

Owner:TIANJIN INTERNAL COMBUSTION ENGINE RES INST

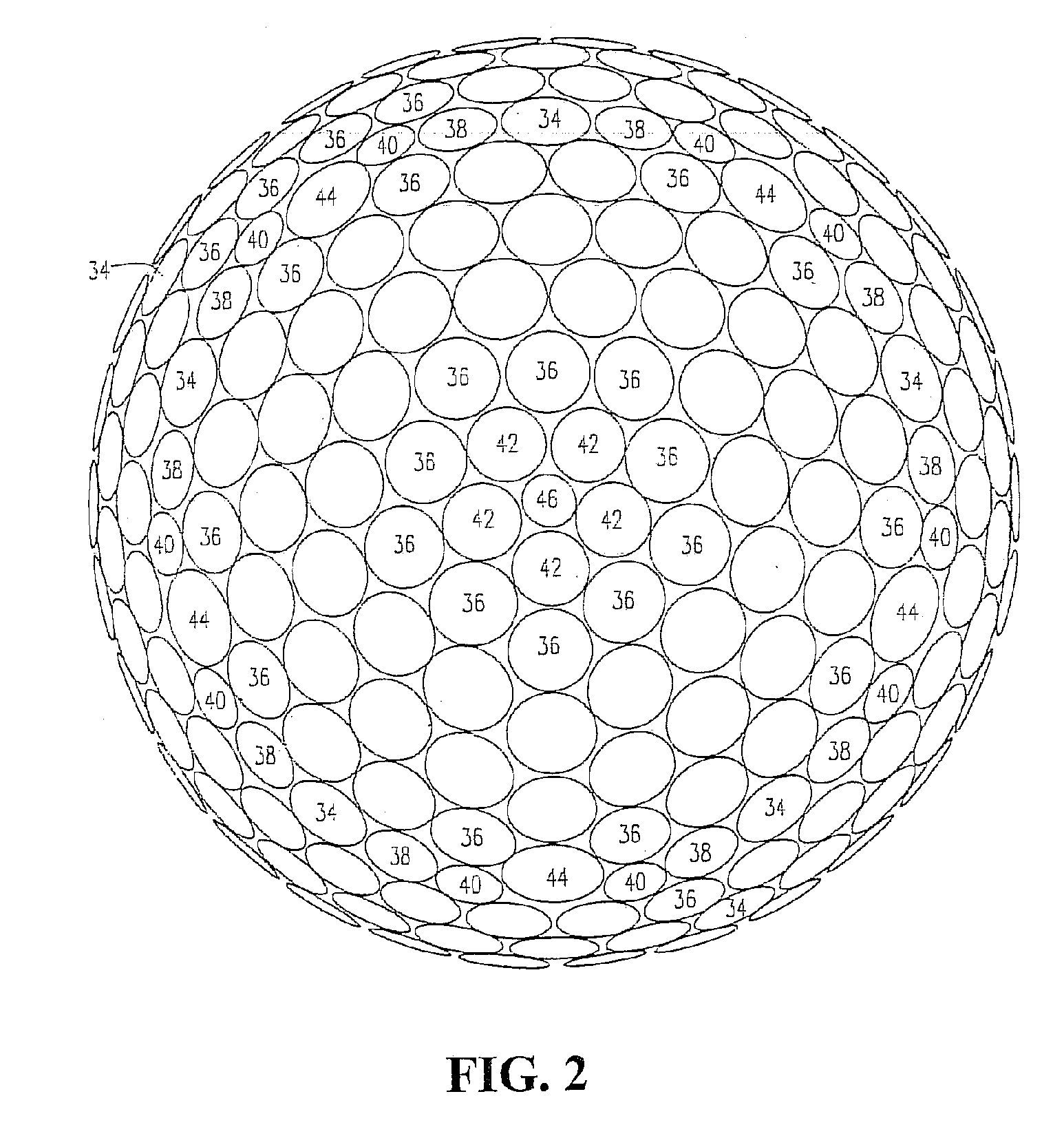

Golf ball with undercut dimples

InactiveUS20050187039A1Reduce resistanceIncreased air turbulenceGolf ballsSolid ballsEngineeringGolf Ball

A golf ball (20) having a plurality of standard dimples (33) and a plurality of undercut dimples (31) is disclosed herein. Each of the plurality of undercut dimples (31) has at least one undercut area portion (50) that extends into a portion of a concavity (55) of the undercut dimple (31). A covered region (70) defined by the undercut area portion (50) generates eddy currents during the flight of the golf ball (20) which creates greater turbulence at the surface (22) of the golf ball (20) allowing for greater distance.

Owner:TOPGOLF CALLAWAY BRANDS CORP

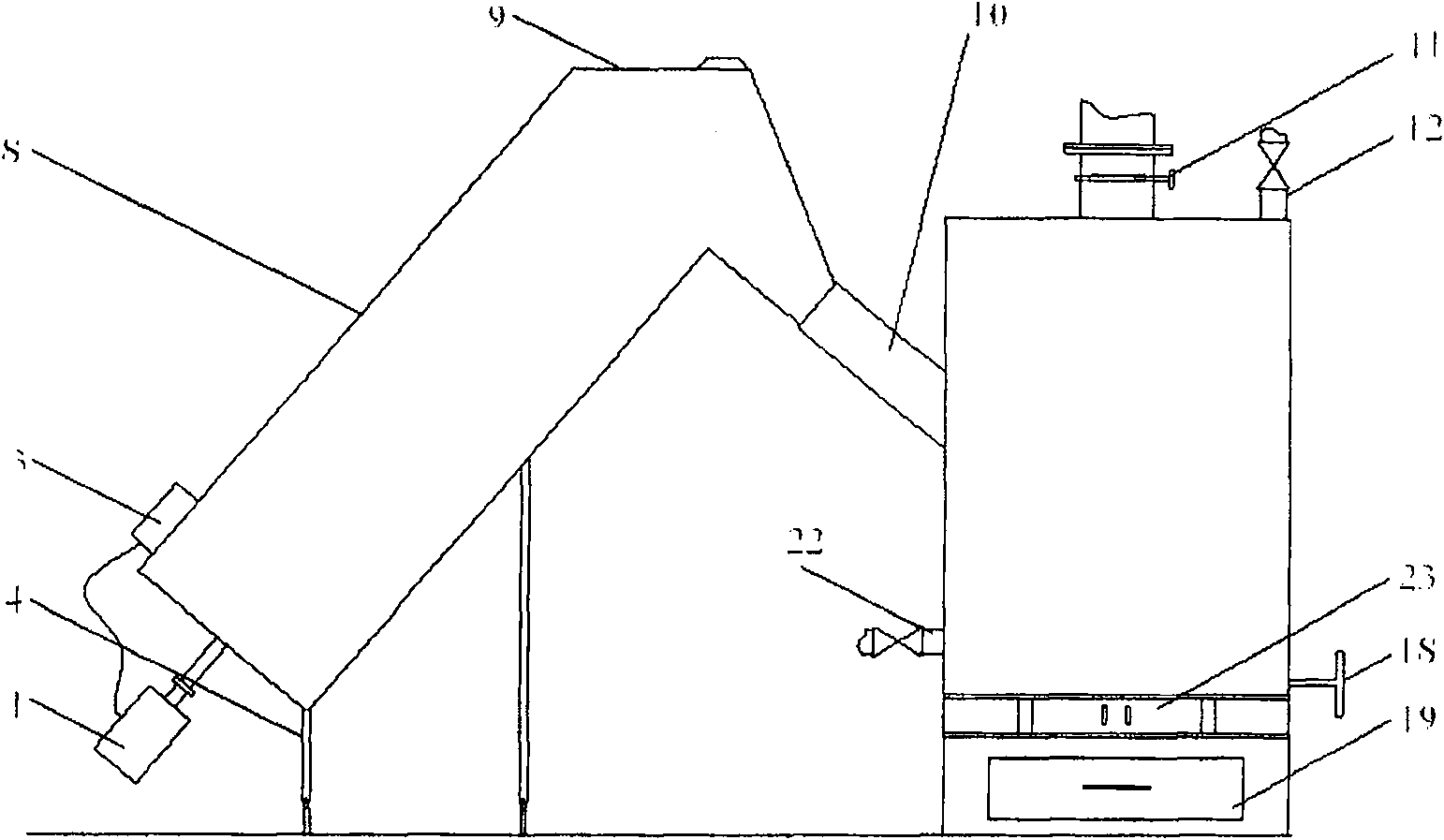

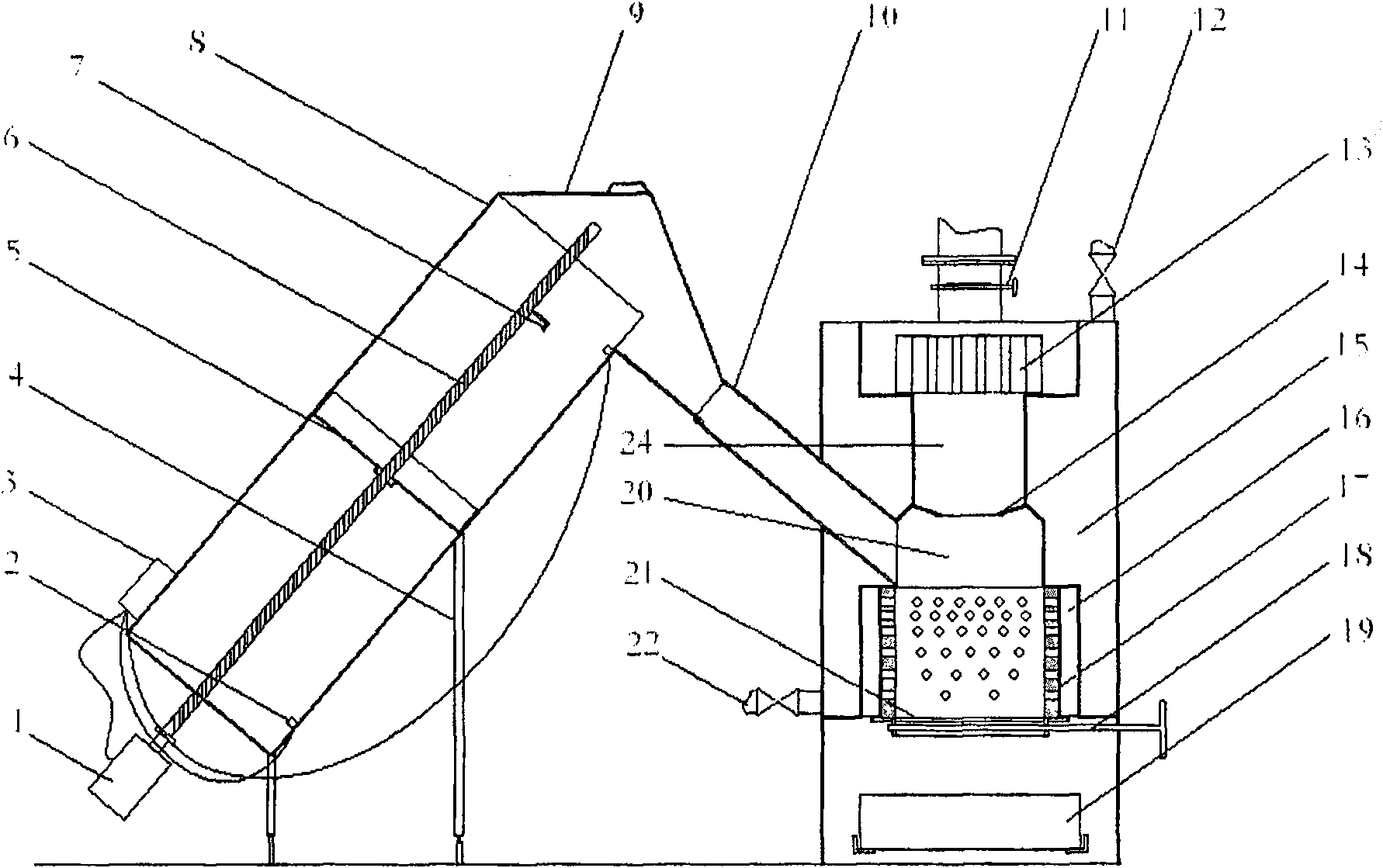

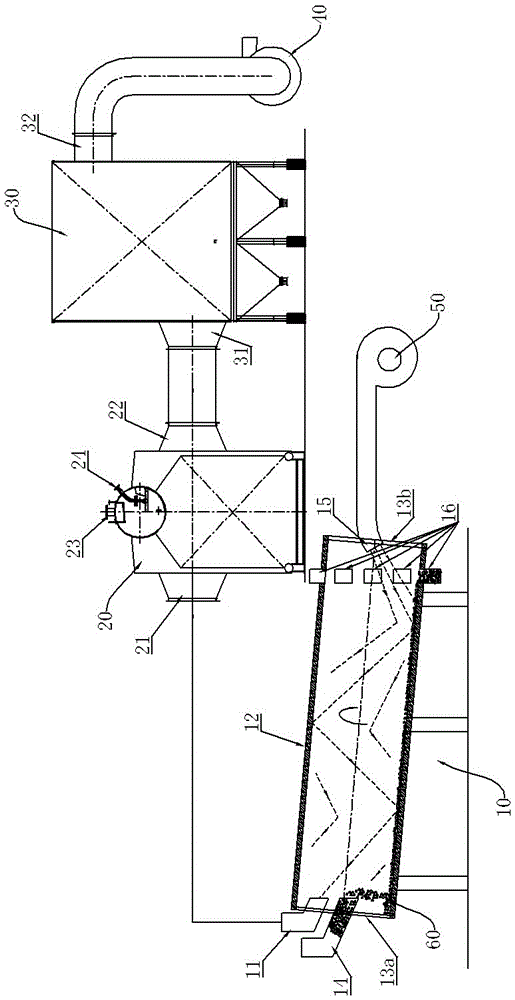

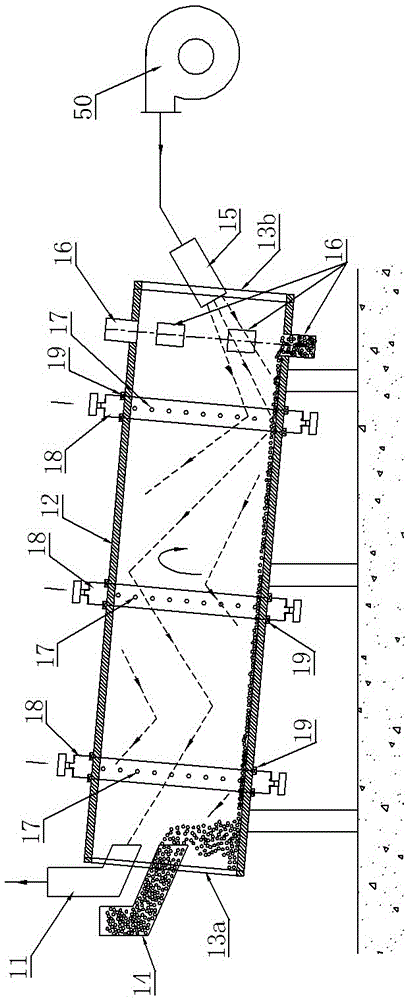

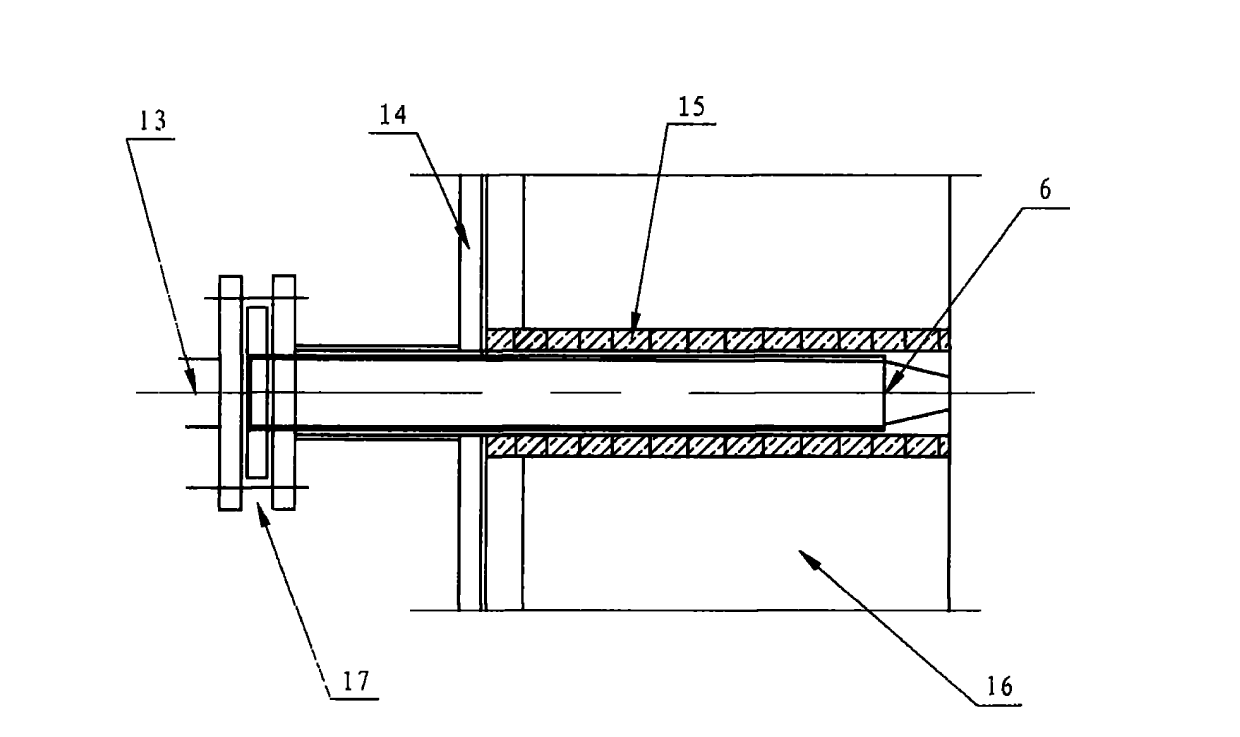

Civil heating stove for automatically feeding with stalk briquette as fuel

ActiveCN100570219CRealize manual feedingRealize automatic feedingStove/ranges for heating waterHome appliance efficiency improvementCombustion chamberWater jacket

The invention relates to a civil heating stove feeding automatically and taking haulm briquettes as fuel, which comprises two parts, namely, a stove body and an automatic feeding device. The stove body essentially comprises a combustion chamber, a wind box, a rocking grate, a flue channel and a water jacket. The automatic feeding device essentially comprises a motor, a screw rod, a stock driving groove, a limit switch and a hopper and can realize 8 hours to 12 hours of timed and rationed automatic feeding. The civil heating stove is applicable to the clean combustion process of biomass fuels, has the advantages of high combustion efficiency, high thermal efficiency, low emission of contaminants, low generation of tar and labor conservation and the like, does not cause problems like indoor contamination resulted from condensation of the tar, and has simple structure, low cost and broad application prospect.

Owner:HEBEI UNIV OF TECH

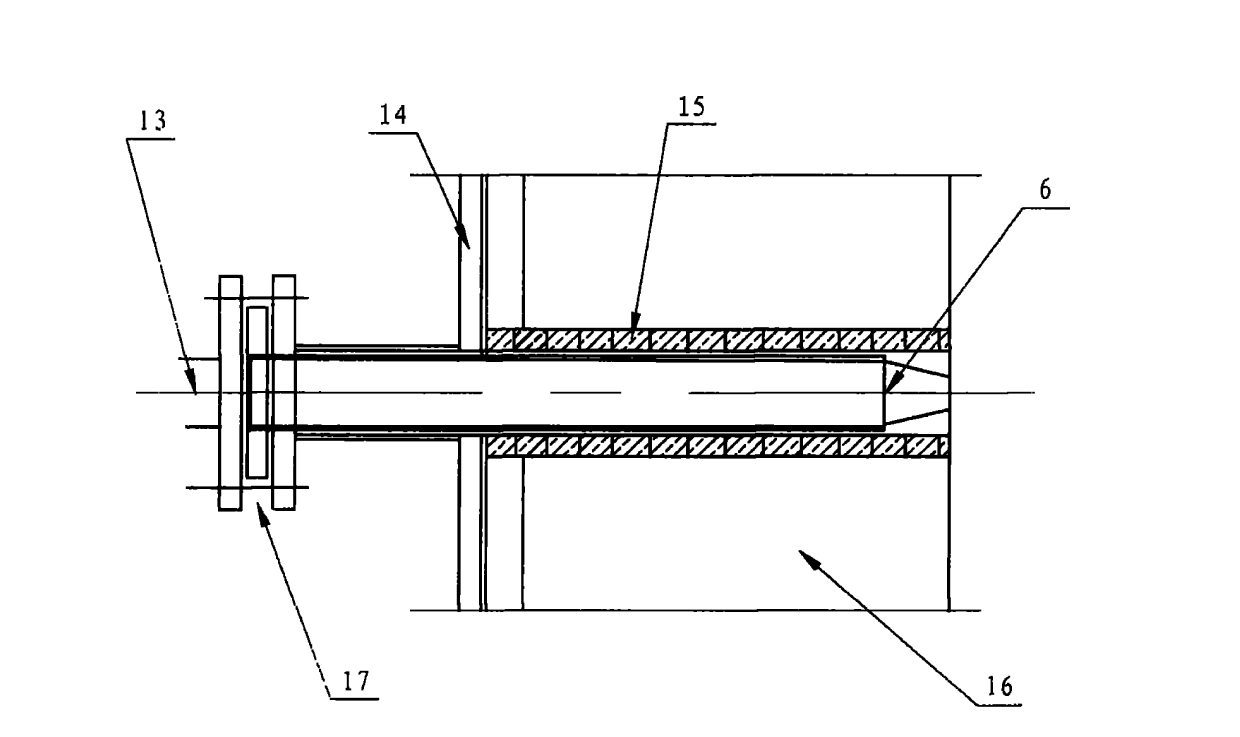

Cooling device used for solid thermal carrier waste heat utilization system

The invention provides a cooling device used for a solid thermal carrier waste heat utilization system. The cooling device is capable of solving a problem that cooling of high temperature solid thermal carriers via conventional cooling devices is insufficient. The cooling device comprises a rotary kiln; the two ends of the rotary kiln are sealed with end covers respectively, and the rotary kiln is capable of rotating relative to the two end covers; one of the end covers is provided with a thermal carrier inlet and a high temperature exhaust gas outlet, and the other end cover is provided with a cooling wind inlet; the cooling wind inlet is connected with an air blower; one end of the rotary kiln close to the cooling wind inlet is provided with thermal carrier outlets; the periphery of the rotary kiln is provided with a plurality of air inlets along the circumferential direction in lines; each line of the air inlets on the periphery of the rotary kiln is provided with an annular air inlet cabin; the annular air inlet cabins are capable of rotating relative to the rotary kiln; cooling wind is delivered into the annular air inlet cabins; and an air outlet channel of each annular air inlet cabin is arranged to towards the corresponding line of air inlets on the rotary kiln.

Owner:JIANGSU TAIHU BOILER

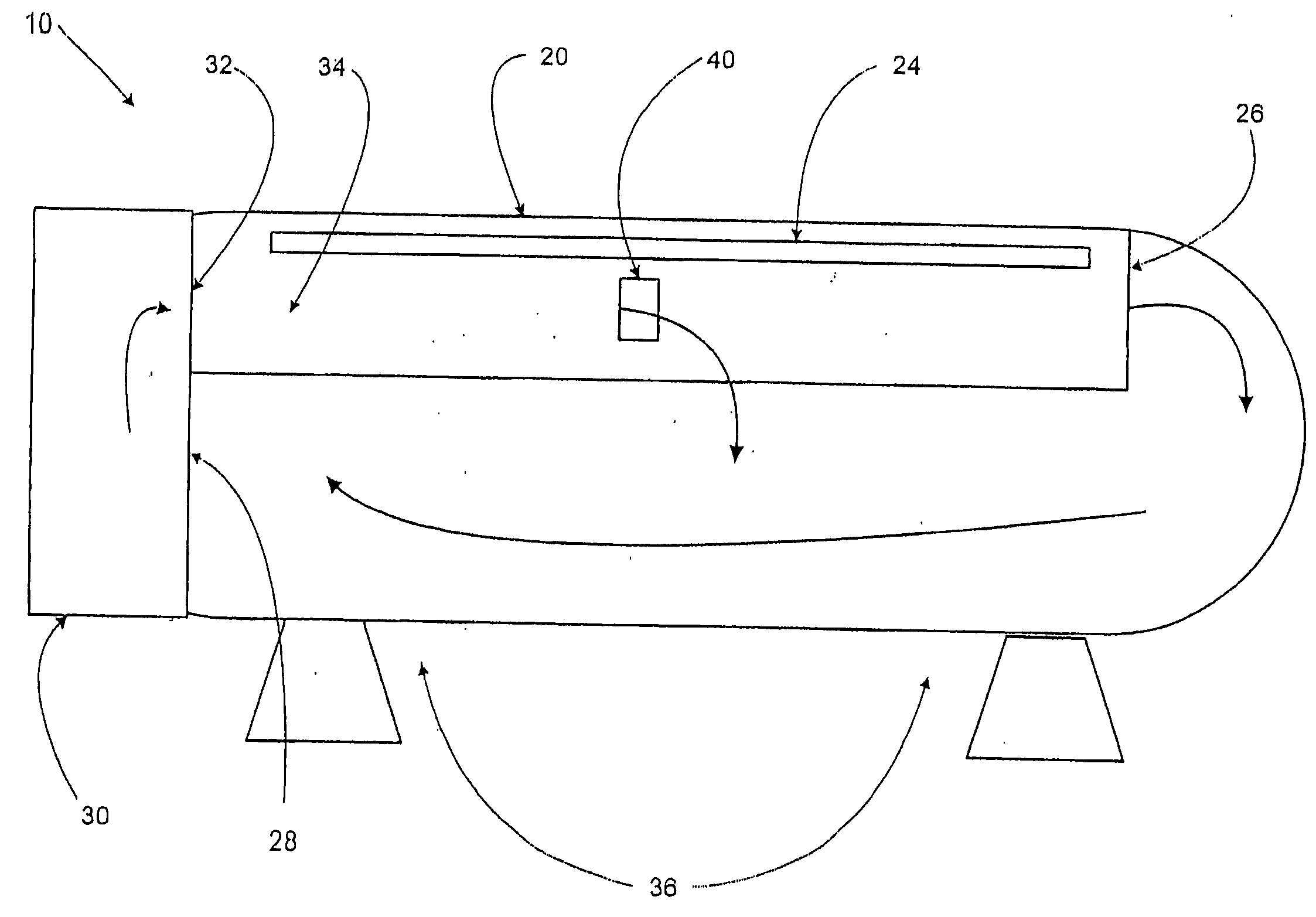

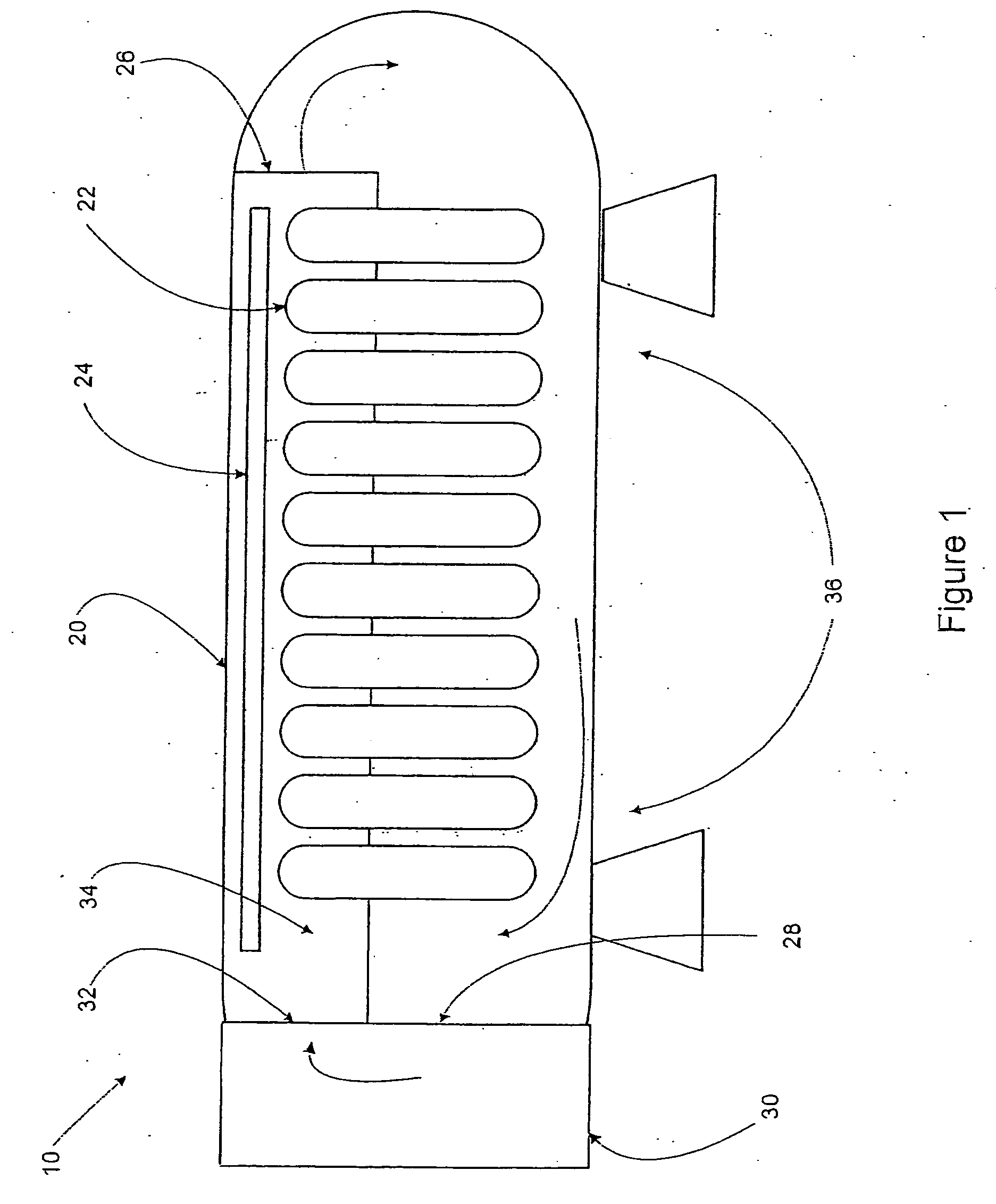

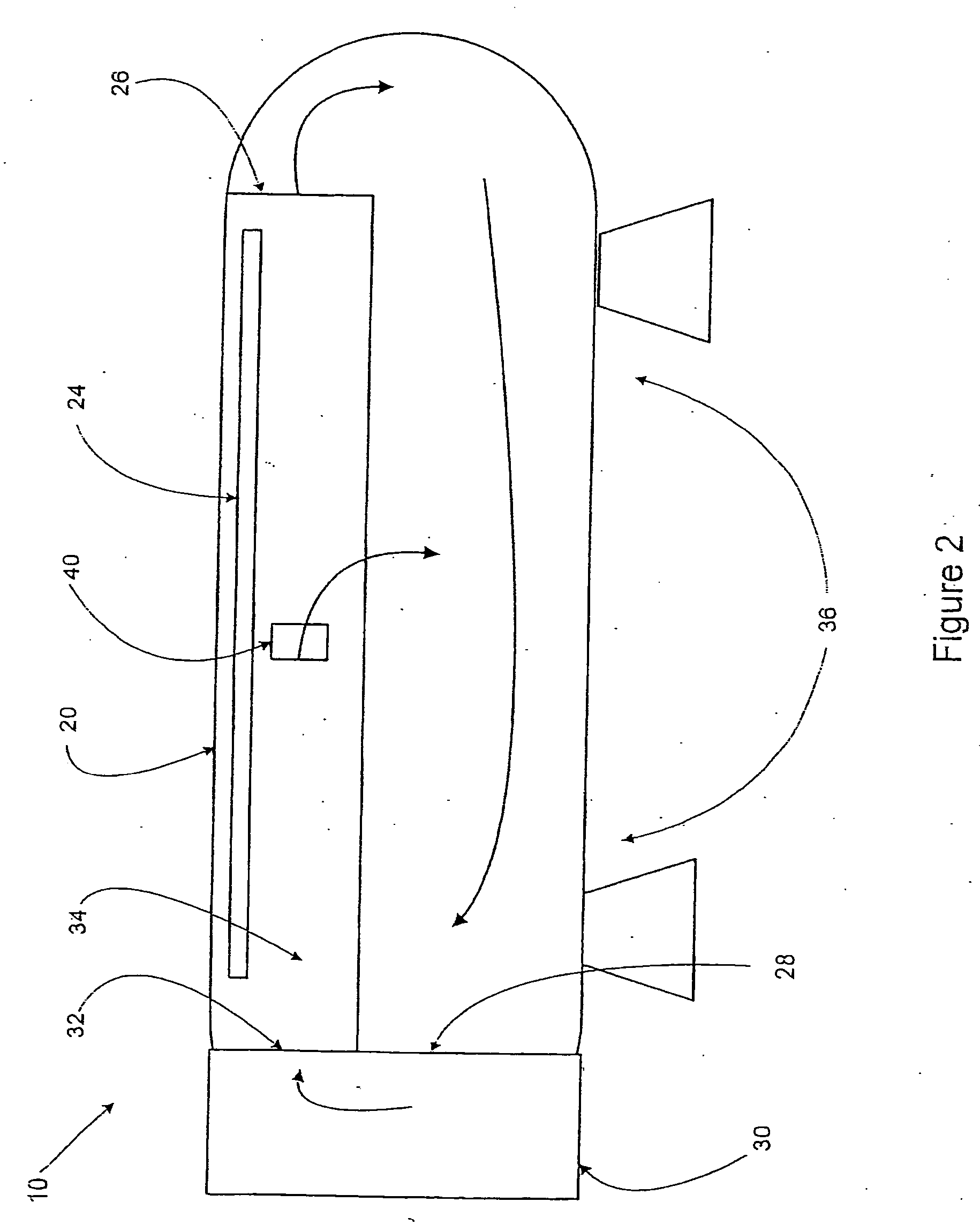

Autoclave for curing retreaded tires

InactiveUS20070079937A1Less-efficient heat transferImprove heat transfer performanceMuffle furnacesLaminationRetreadAutoclave

An improved autoclave for curing retread tires includes a chamber with circulating air flow having turbulence generating devices located in a middle length-wise portion of the chamber. The turbulence generating devices include apertures to guide air from a supply duct into the chamber, and / or wedge-shaped elements or fins mounted on the interior wall of the chamber to disrupt the air flow and cause turbulence.

Owner:MICHELIN RECH & TECH SA

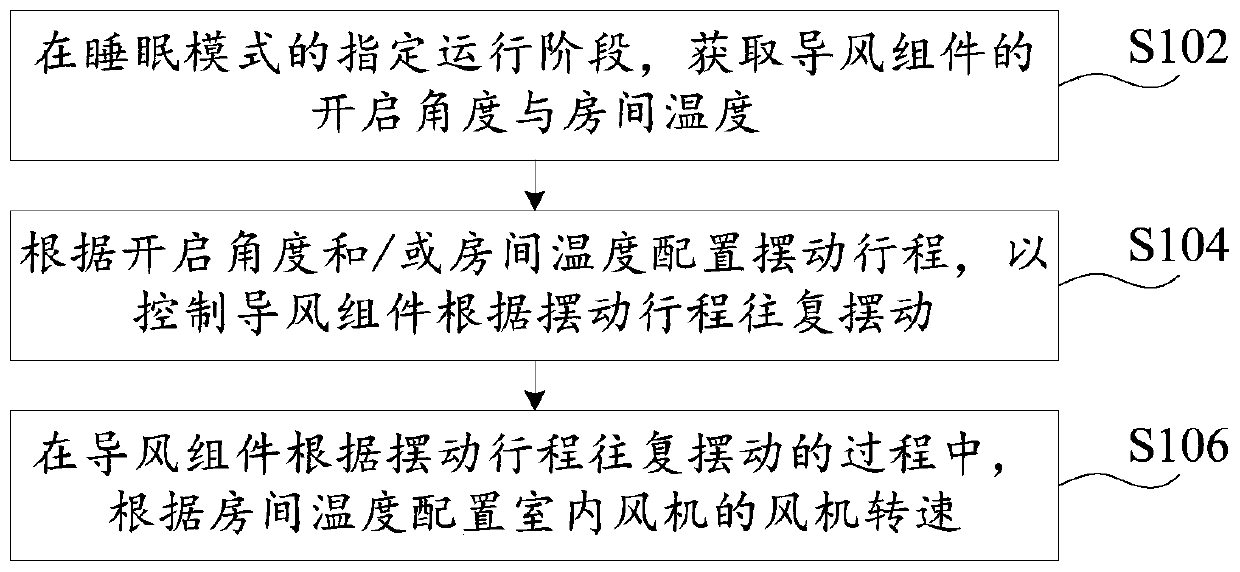

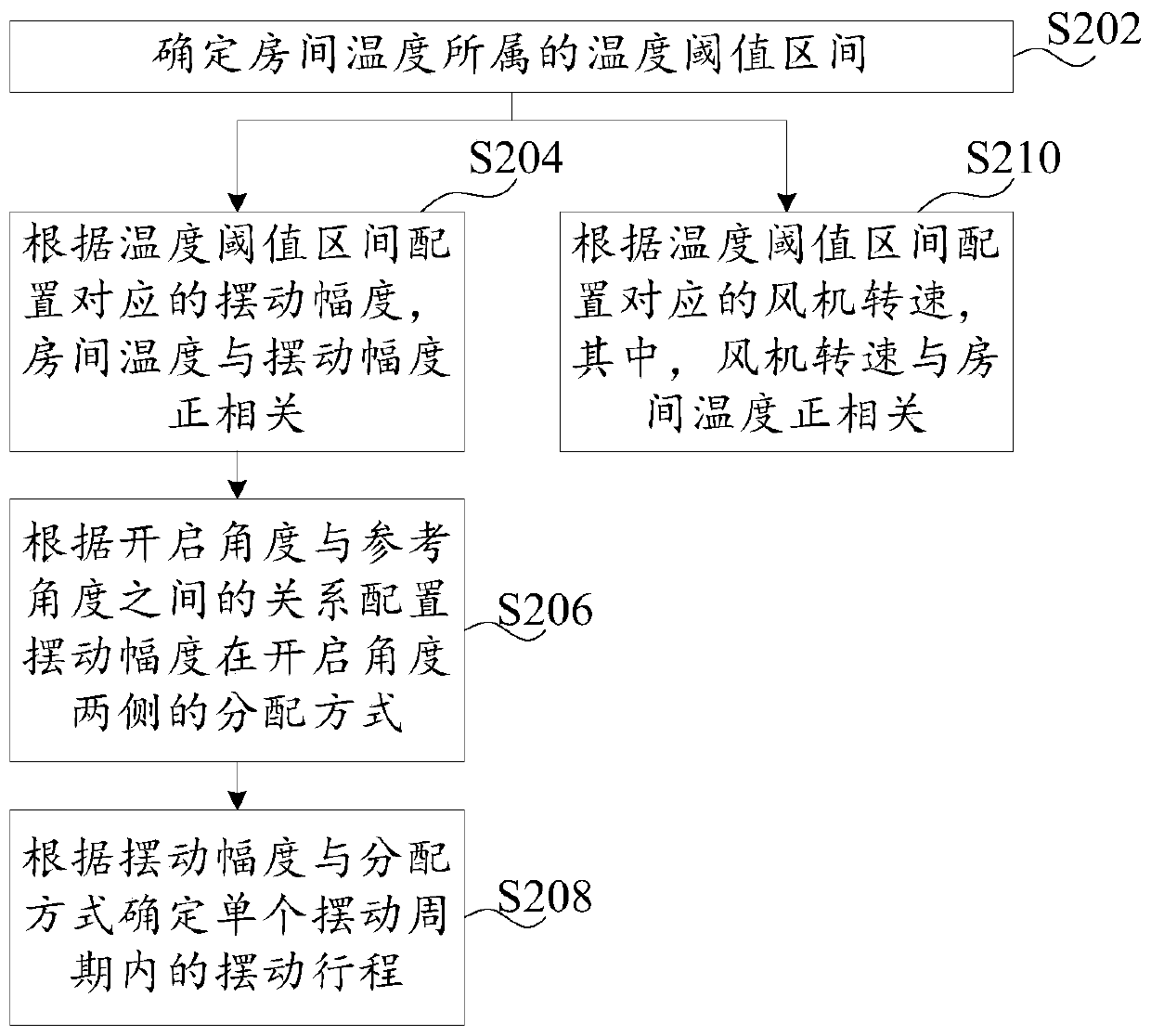

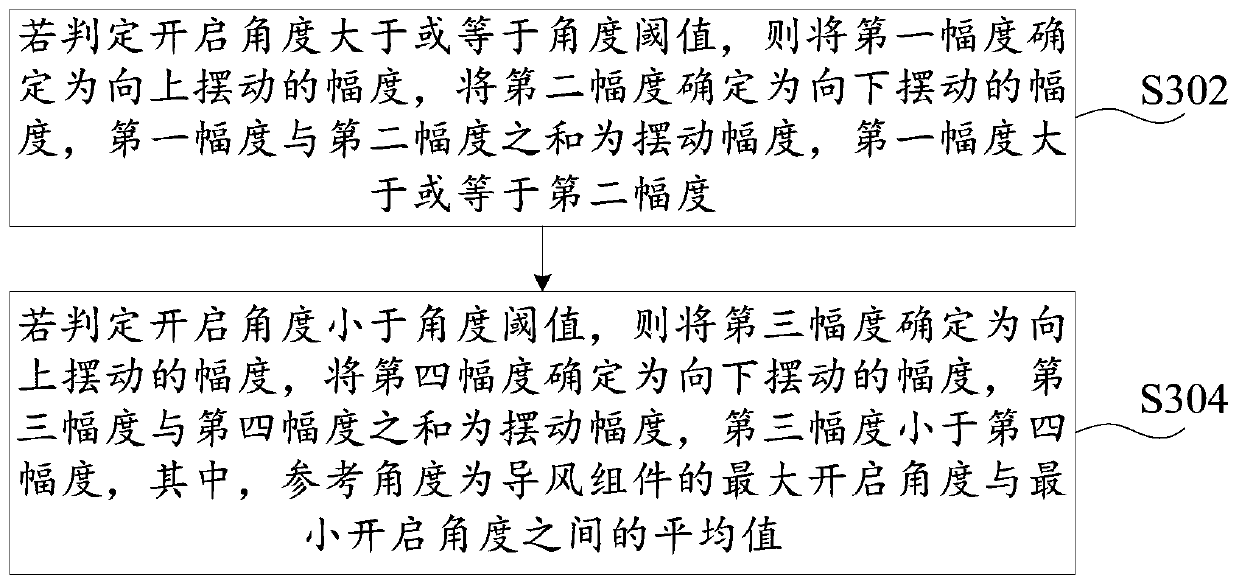

Operation control method, operation control device, air conditioner and storage medium

ActiveCN110701751AImprove uniformityImprove comfortMechanical apparatusLighting and heating apparatusControl engineeringRoom temperature

The invention provides an air conditioner, an operation control method of the air conditioner, an operation control device of the air conditioner and a readable storage medium, wherein the operation control method of the air conditioner comprises the following steps of obtaining the opening angle and the room temperature of an air guide assembly at a specified operation stage; and configuring a swinging stroke according to the opening angle and / or the room temperature so as to control the air guide assembly to swing in a reciprocating way according to the swinging stroke. By executing the technical scheme, on one hand, the uniformity of the temperature in a room can be improved; on the other hand, the airflow disturbance in the room can be increased; and the body feeling comfort of users is improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

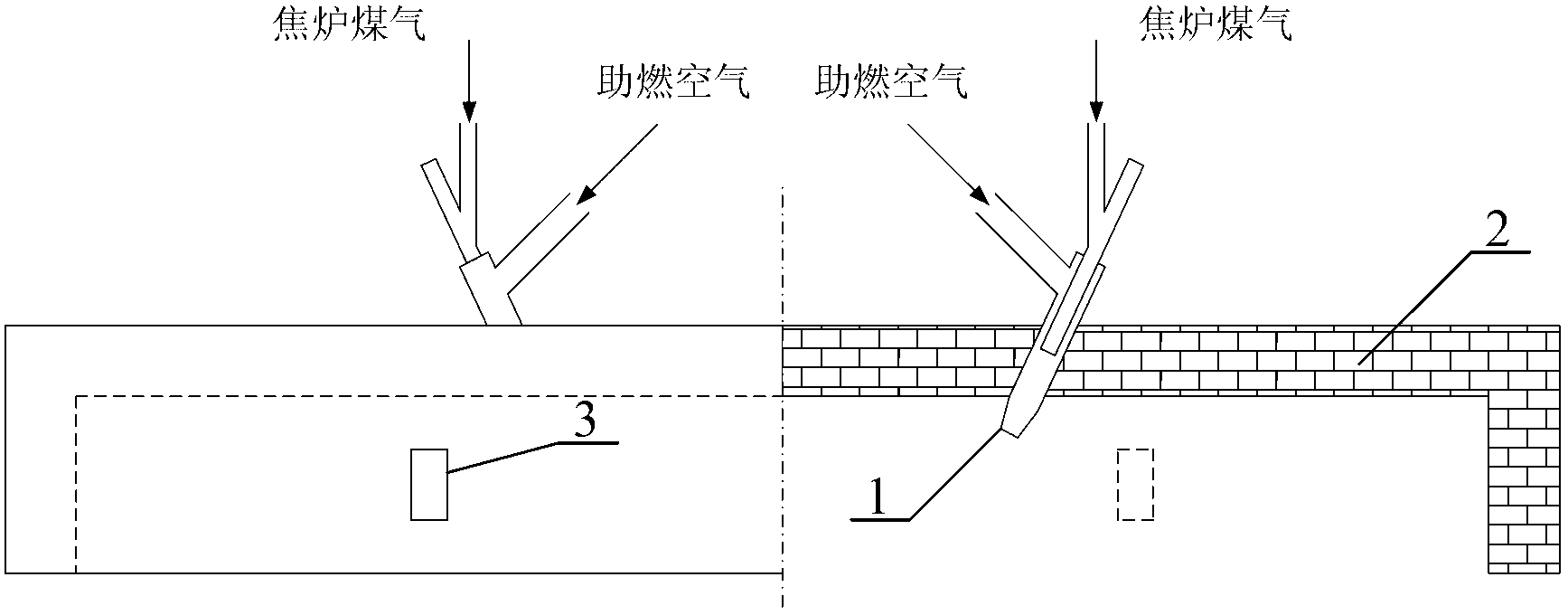

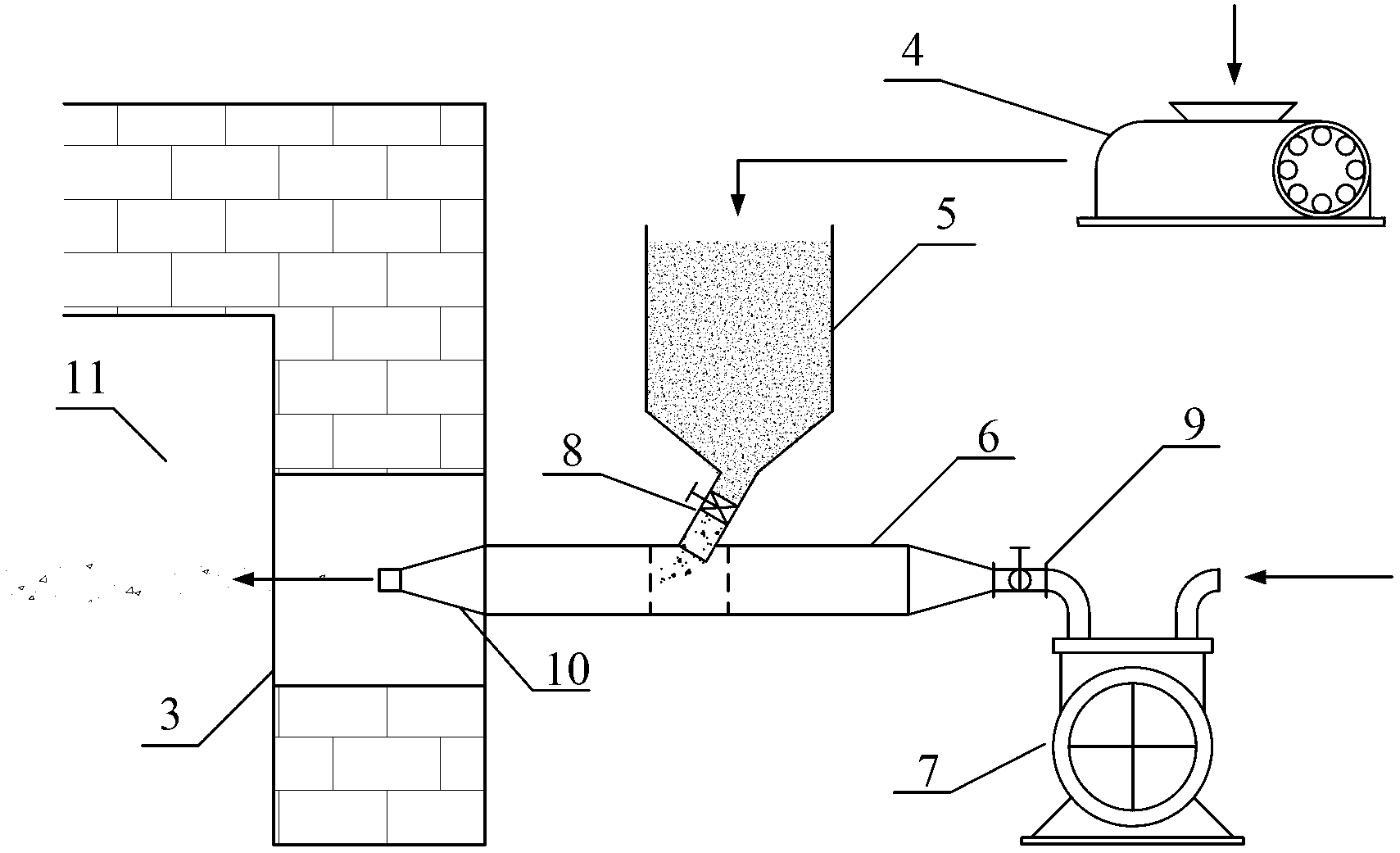

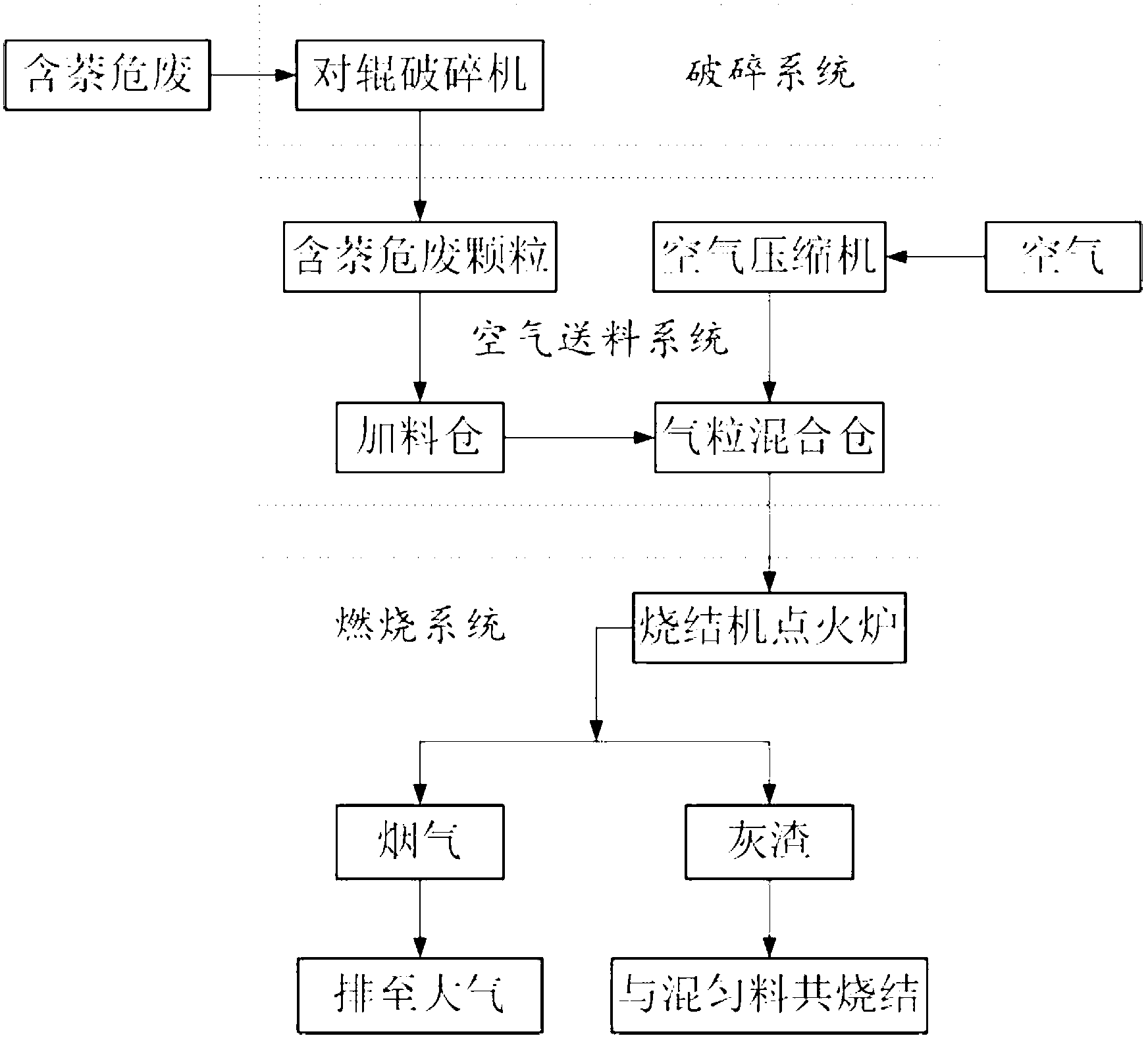

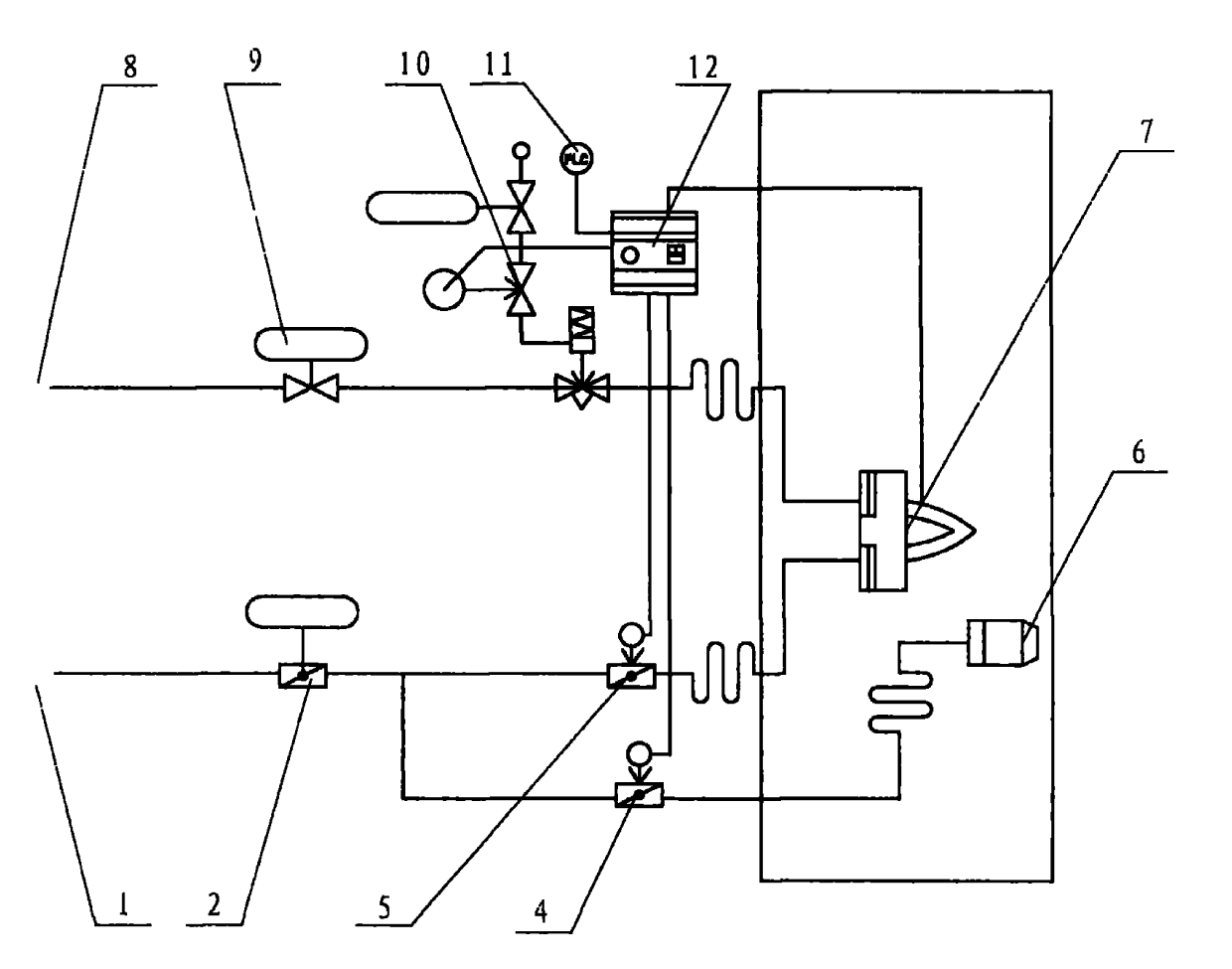

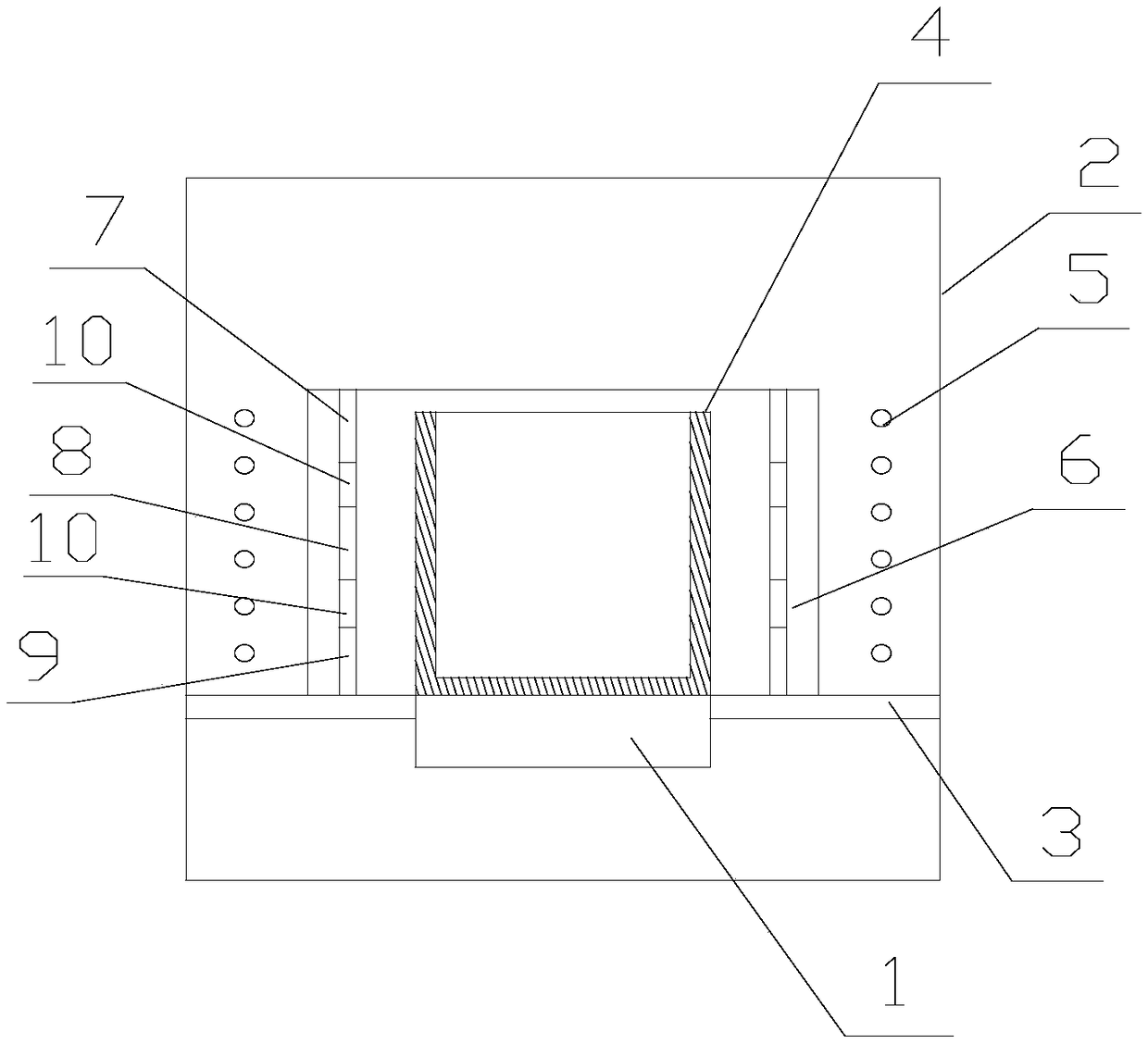

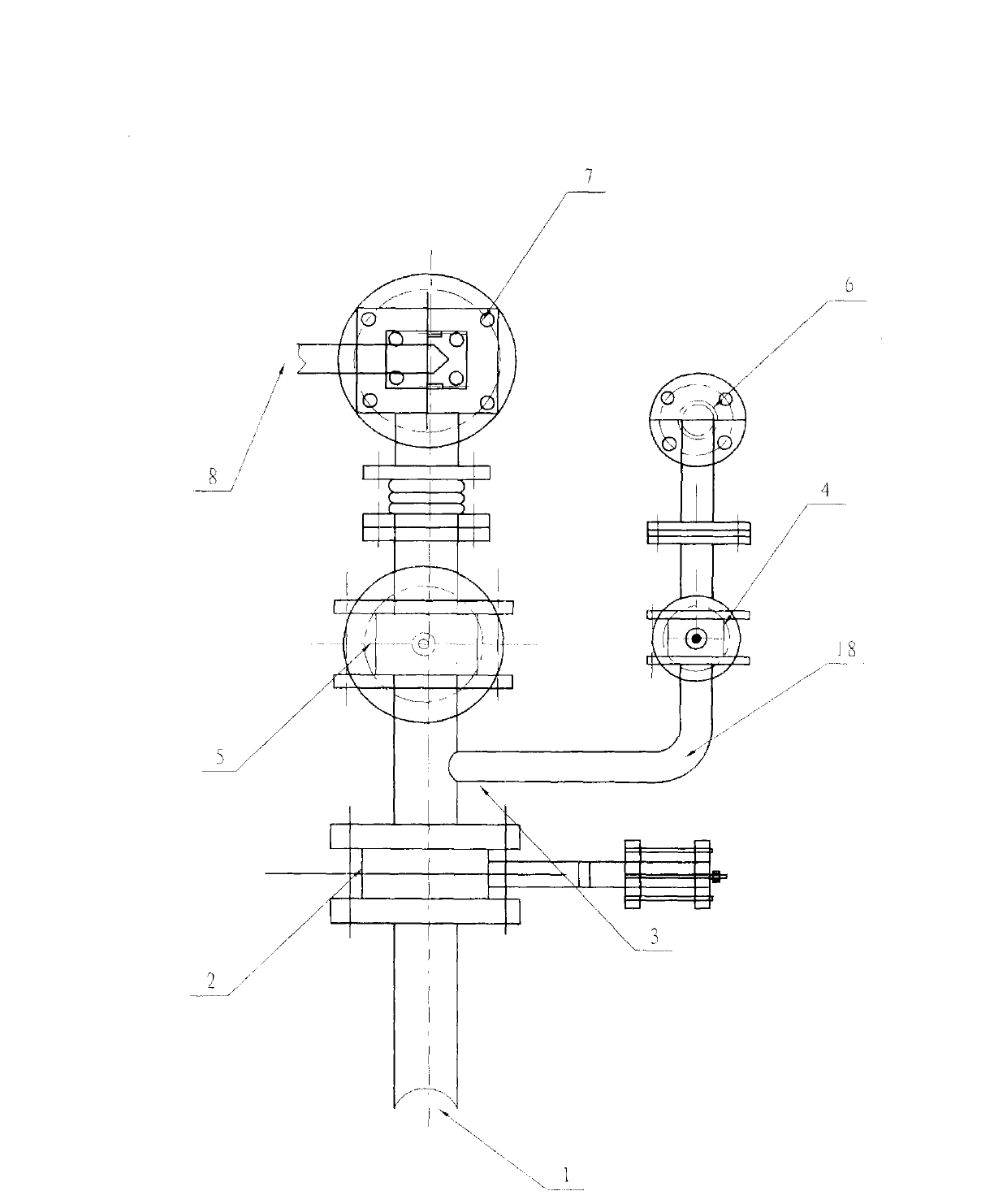

Innocent treatment equipment and method for naphthalene-bearing hazardous wastes

InactiveCN103196147ANo secondary pollutionAvoid sublimationIncinerator apparatusCombustion systemBrick

The invention discloses innocent treatment equipment and method for naphthalene-bearing hazardous wastes. The equipment comprises a crushing system, an air delivery system and a combustion system. A sinterer ignition furnace of the combustion system comprises a flame nozzle (1), refractory bricks (2), an observation window (3) and a hearth (11). The air delivery system is connected with the combustion system through a high temperature resistant nozzle (10). The crushing system is connected with the air delivery system. An inlet of a feed bin (5) is connected with a roll crushing mill (4). An outlet of the feed bin (5) is connected with an air-particle mixing bin (6) through a feed inlet valve (8). An entry end of the air-particle mixing bin (6) is connected with an air compressor (7) through an air inlet valve (9), and an exit end of the air-particle mixing bin is connected with a high temperature resistant nozzle (10). After mixed with air through the air delivery system, naphthalene-bearing hazardous waste particles are ejected into the sinterer ignition furnace of the combustion system and boil-combusted under the action of high-temperature environment more than 900 DEG C. Air-particle mixing ratio is regulated by regulating the feed inlet valve (8) and the air inlet valve (9).

Owner:SOUTHEAST UNIV

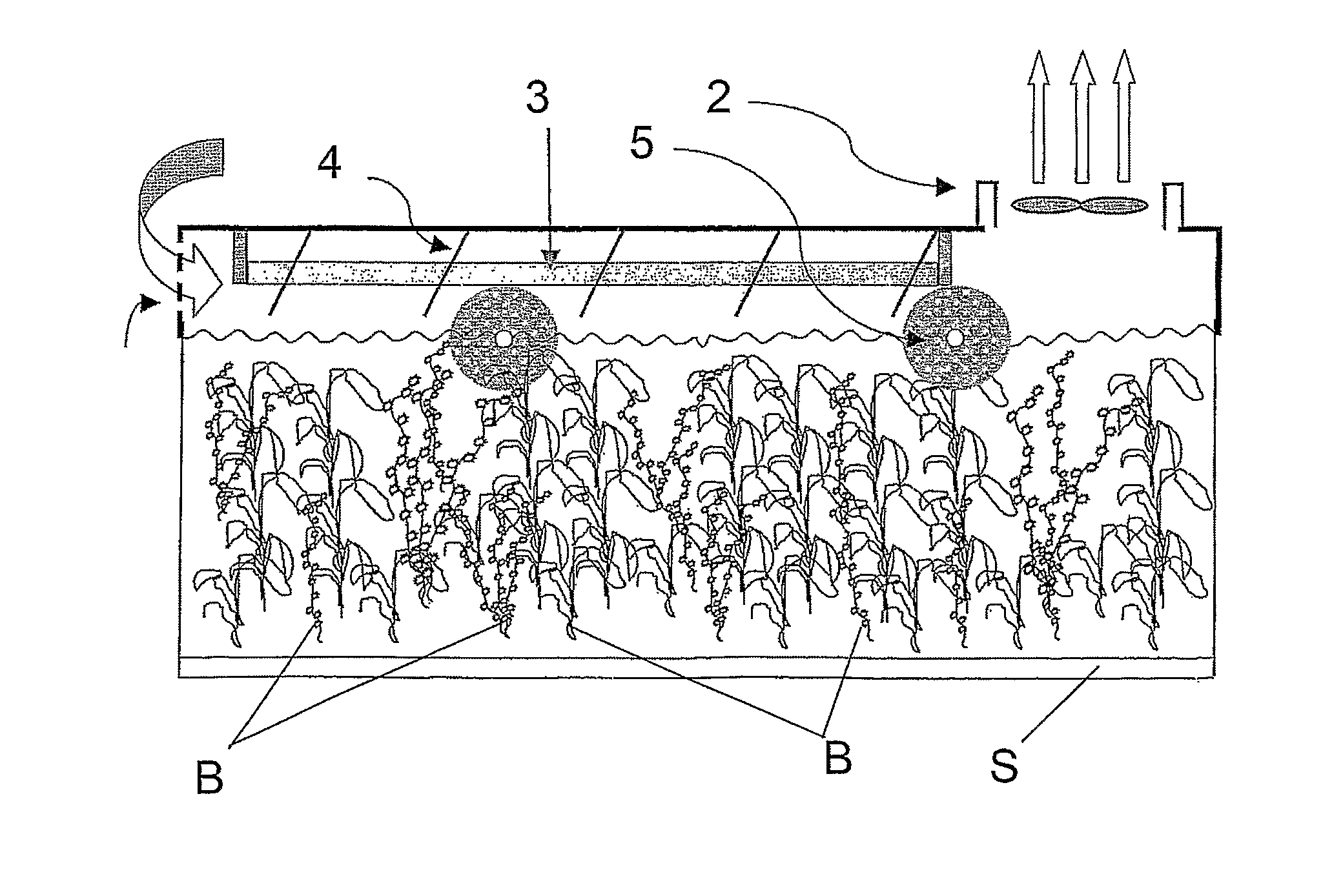

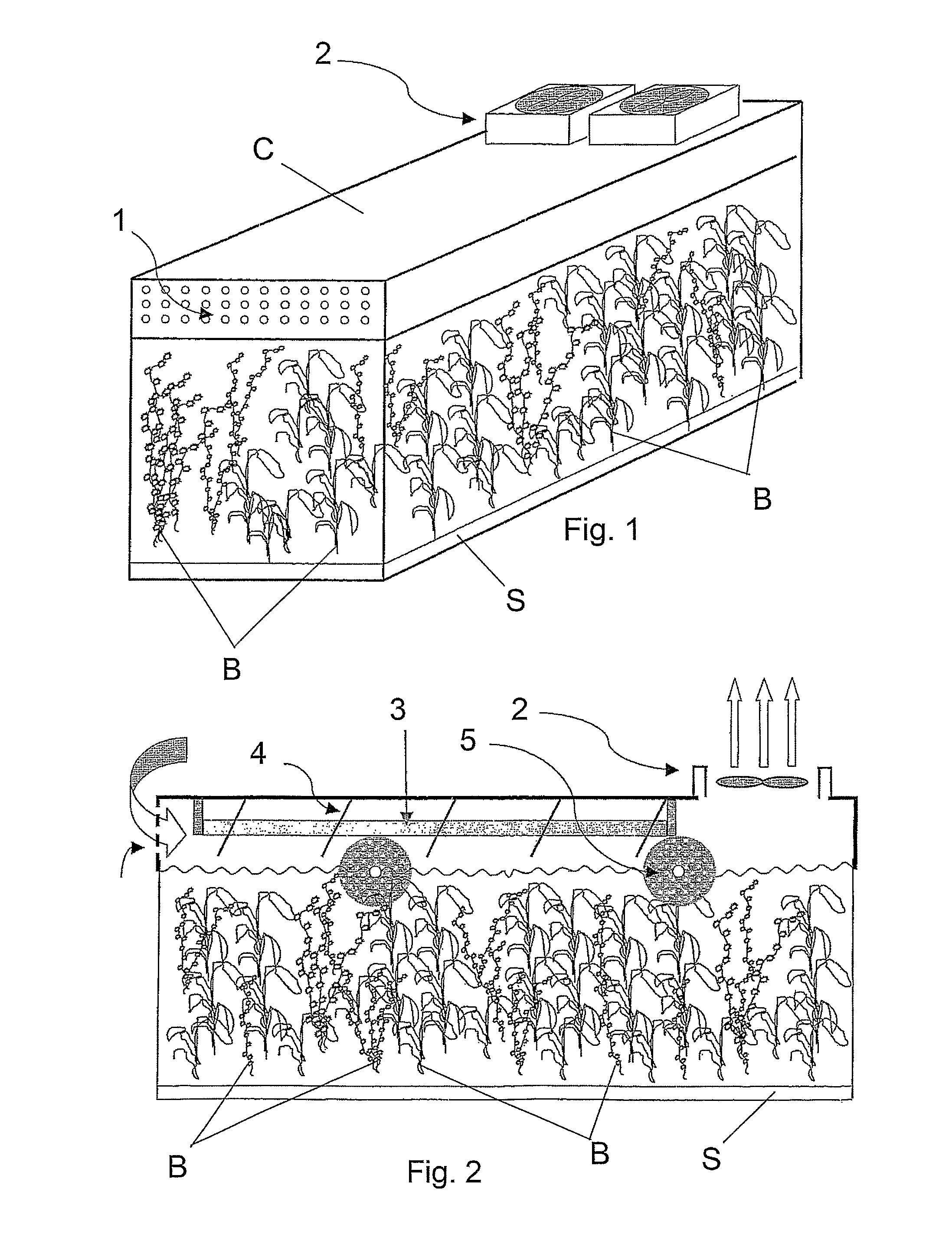

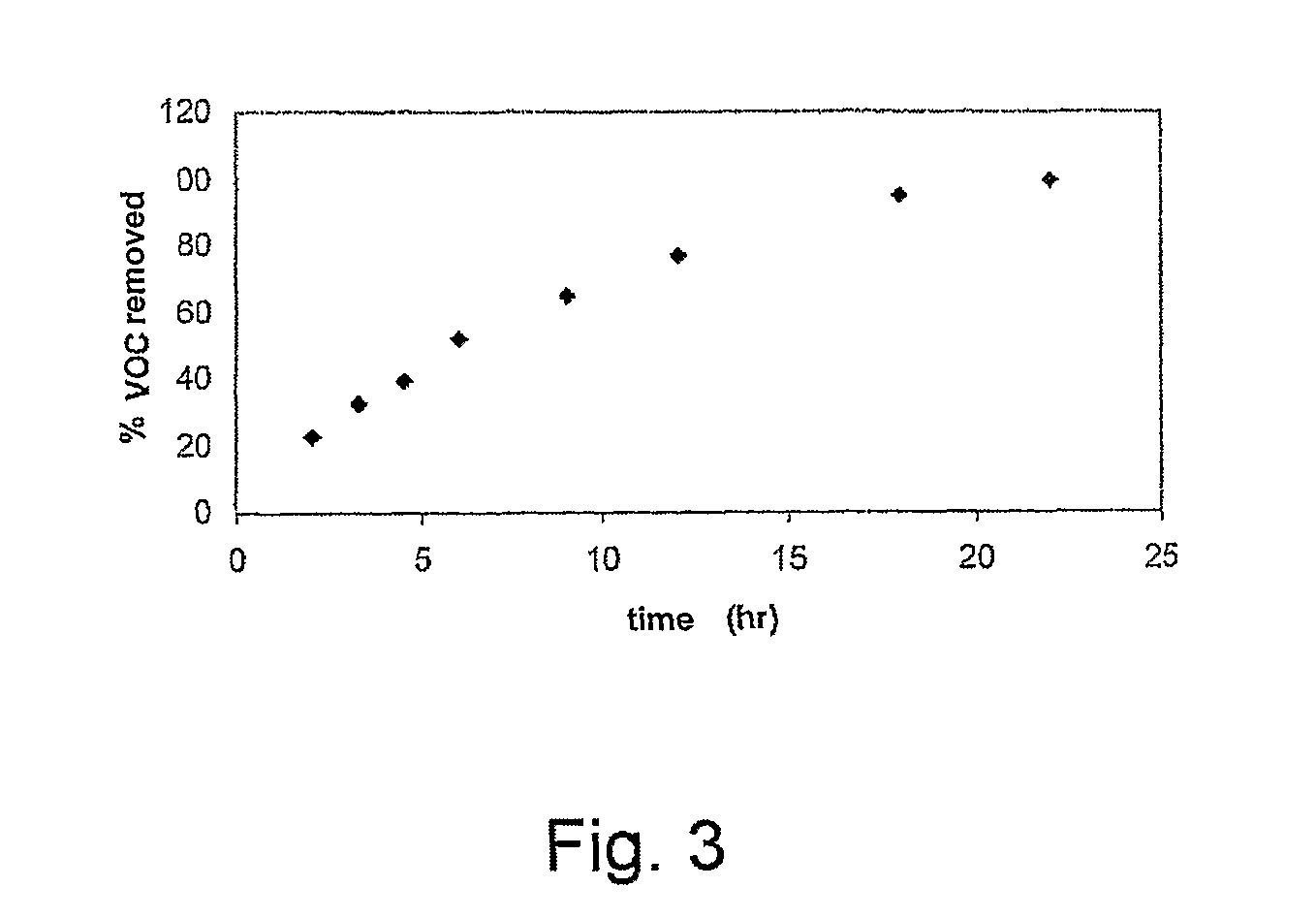

Biological process for purifying air in confined rooms and apparatus thereof

InactiveUS8083837B2Reduce pollutionEliminate itBioreactor/fermenter combinationsMechanical apparatusEngineeringPollution

A deputation process and corresponding apparatus for purification of the air of a closed environment characterized by indoor pollution, in which, in order to reduce the pollution, a water tank is provided that contains a multiplicity of active biomasses designed to absorb and metabolize the pollutant substances that are contained in the water and come from the air of the closed environment, and elements of water-air contact, designed precisely to transfer the pollutant substances from the closed environment into the water within the tank.

Owner:URANIO MAZZANTI

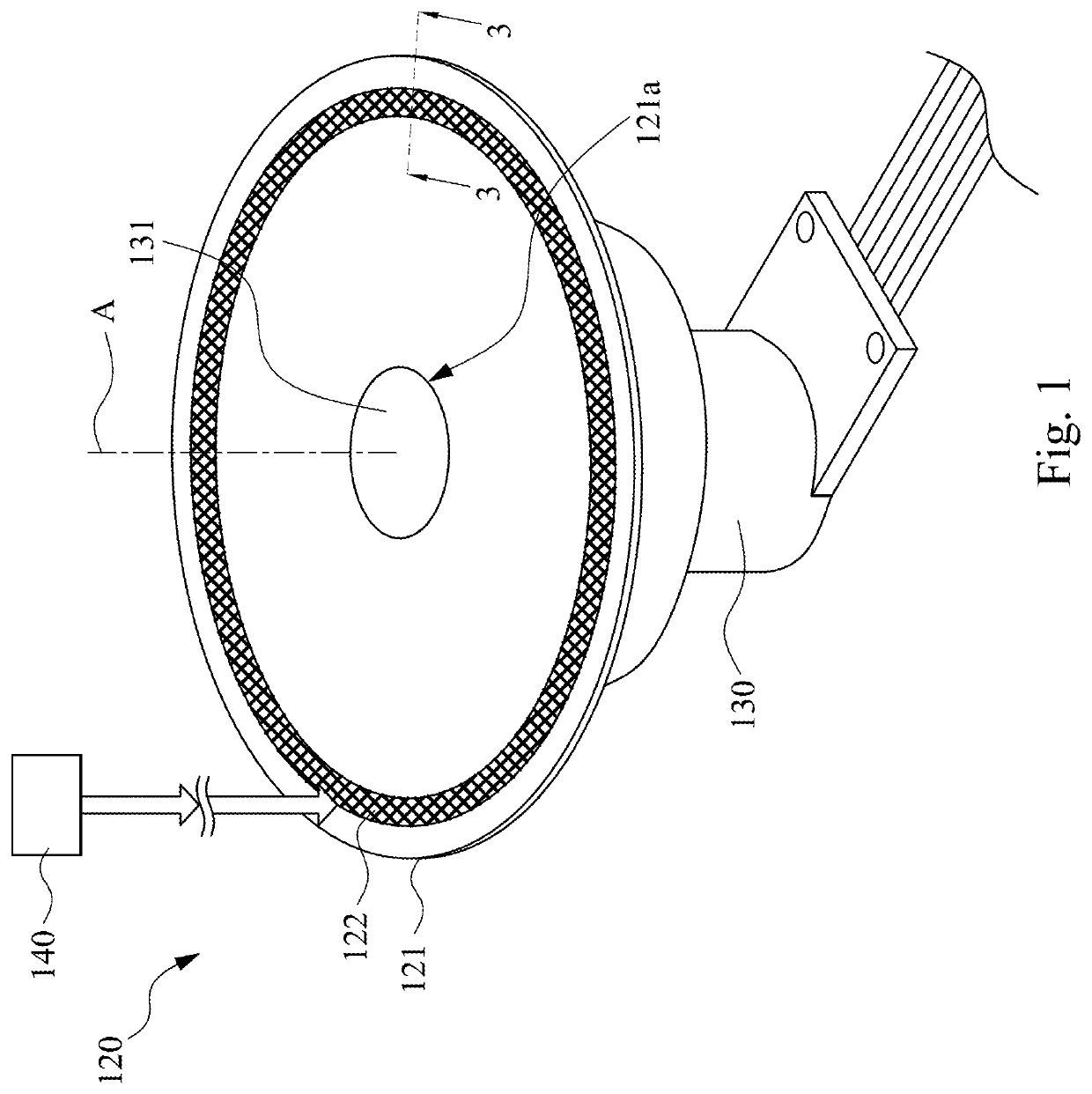

Wavelength conversion member and light source module

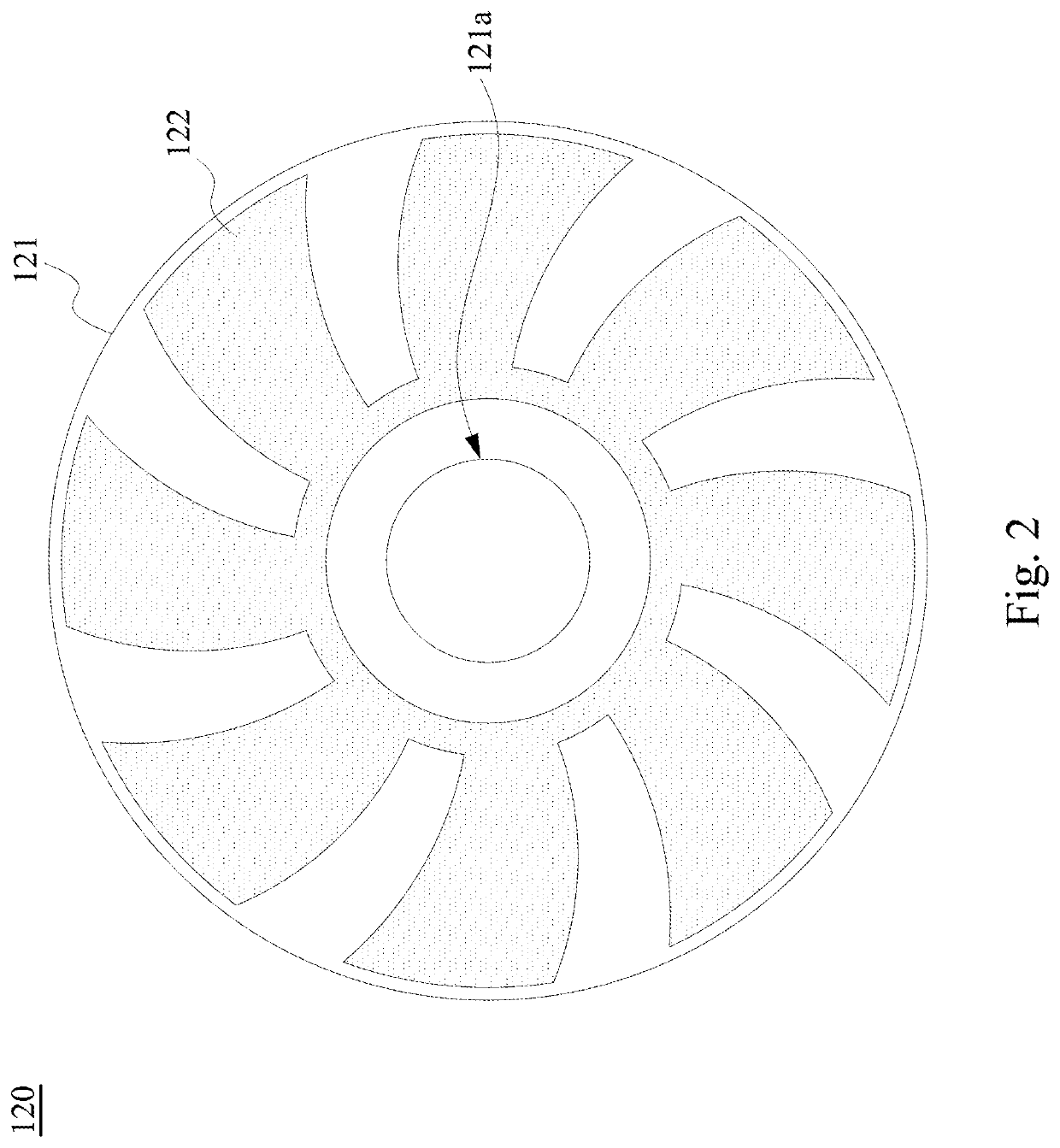

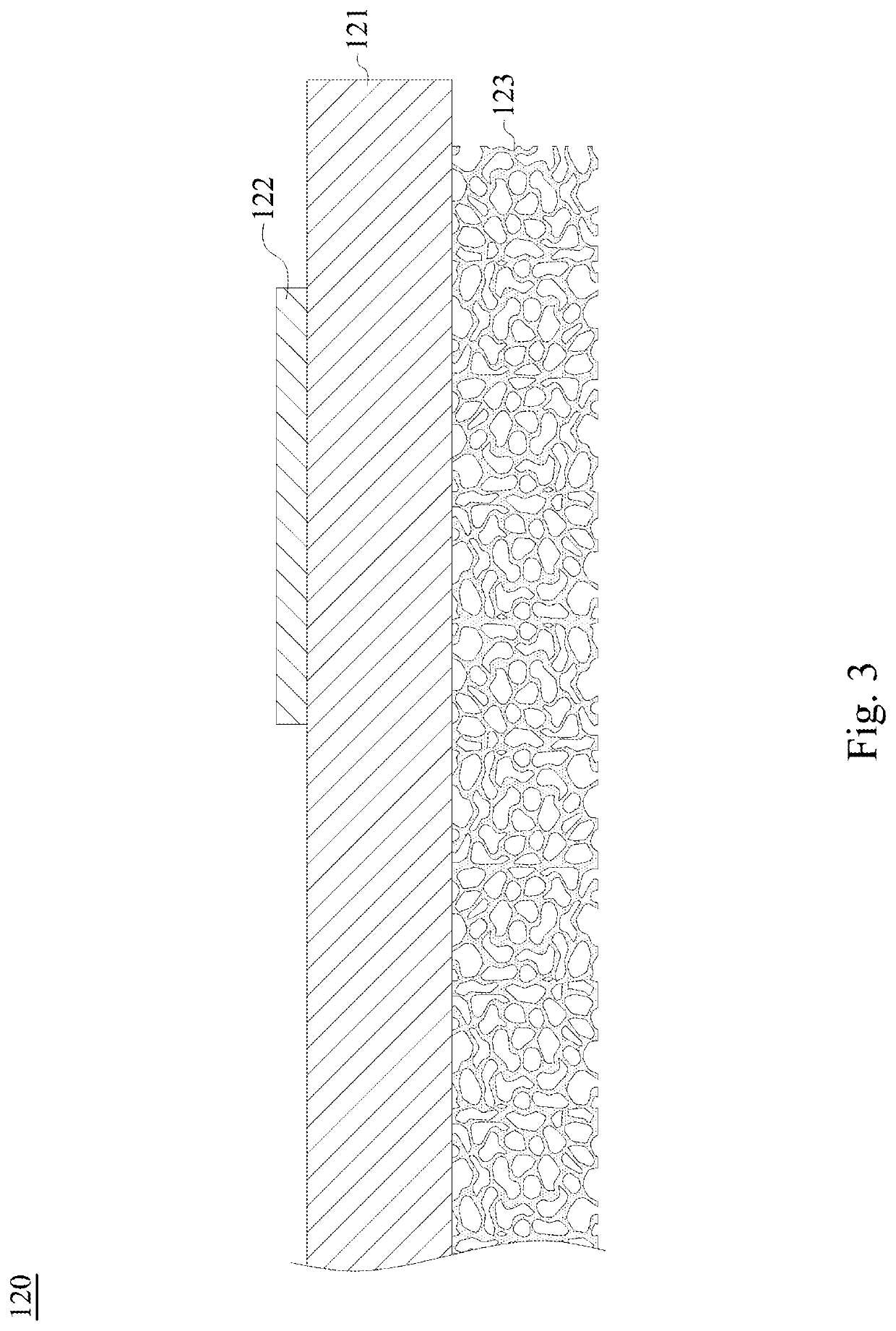

PendingUS20220059733A1Efficient solutionIncreased air turbulenceProjectorsSemiconductor devicesEngineeringWavelength conversion

A wavelength conversion member includes a substrate, a phosphor layer, and a ventilated blade. The substrate is configured to rotate based on an axis. The phosphor layer is disposed on the substrate. The ventilated blade is disposed on the substrate and has a pore density between 10 ppi and 500 ppi or a volume porosity between 5% and 95%.

Owner:DELTA ELECTRONICS INC

Method for realizing low temperature tempering by medium-high temperature tempering furnace

The invention discloses a method for realizing low temperature tempering by a medium-high temperature tempering furnace. The method comprises the following steps that each burner nozzle of the medium-high temperature tempering furnace stops burning and hot blast is injected into the medium-high temperature tempering furnace through a hot blast injection pipe, wherein the hot blast injection pipe is led out from a joint between an air automatic valve and an air manual valve of an air pipeline connected with each burner nozzle. According to the method disclosed by the invention, the temperatureuniformity of the low temperature tempering can be improved, the heating efficiency is improved, the high temperature tempering and the low temperature tempering can be totally carried out on one stove, and the investment cost is reduced.

Owner:LAIWU IRON & STEEL GRP

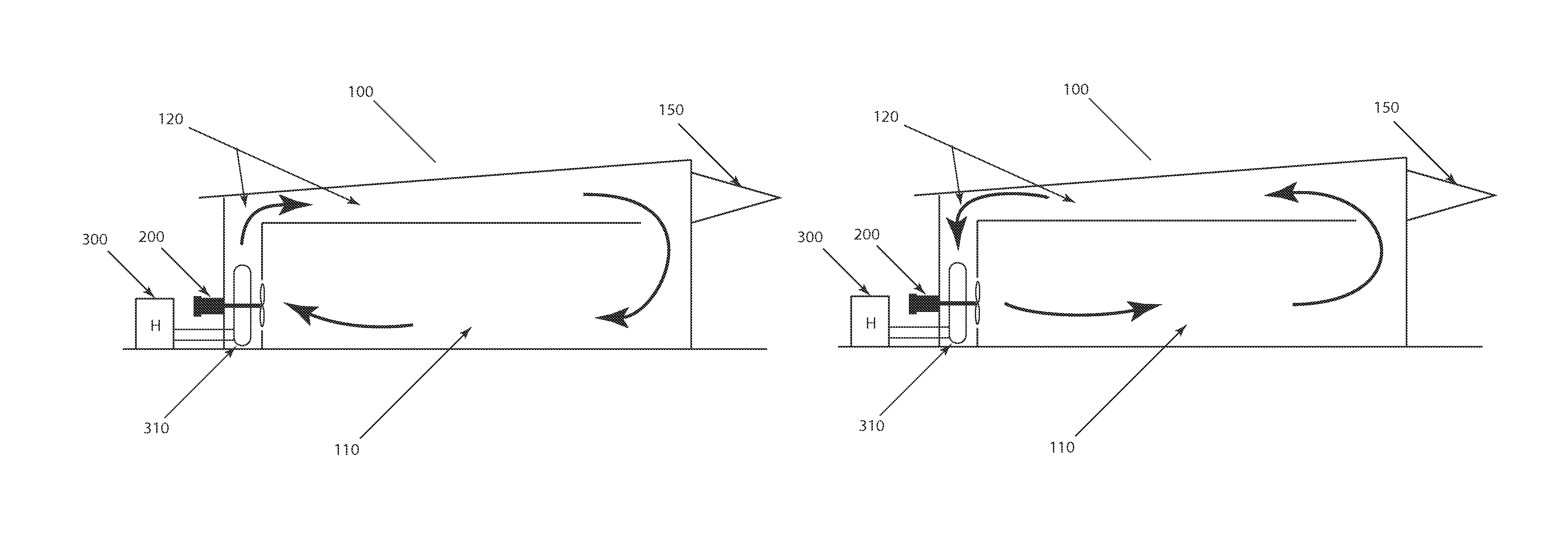

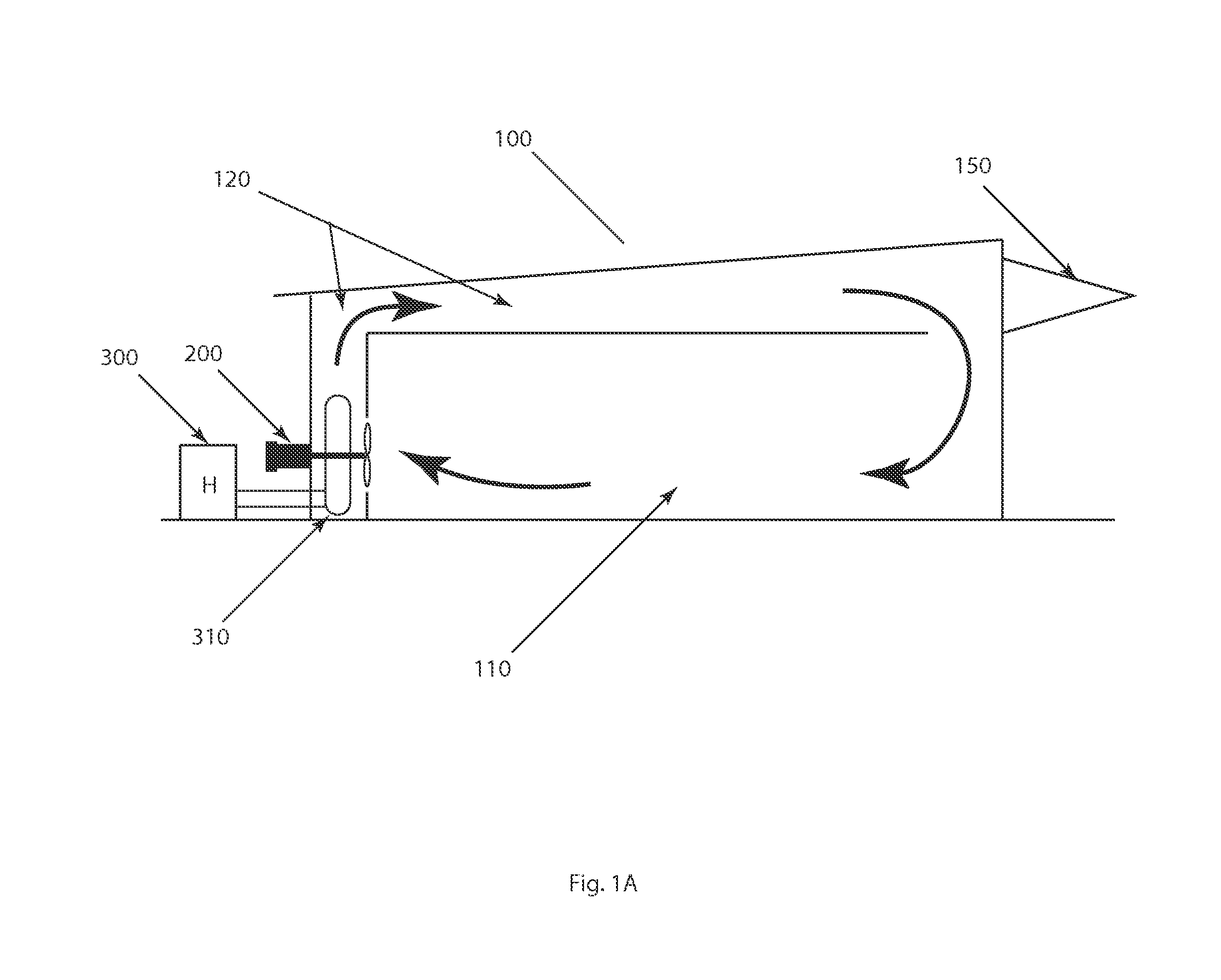

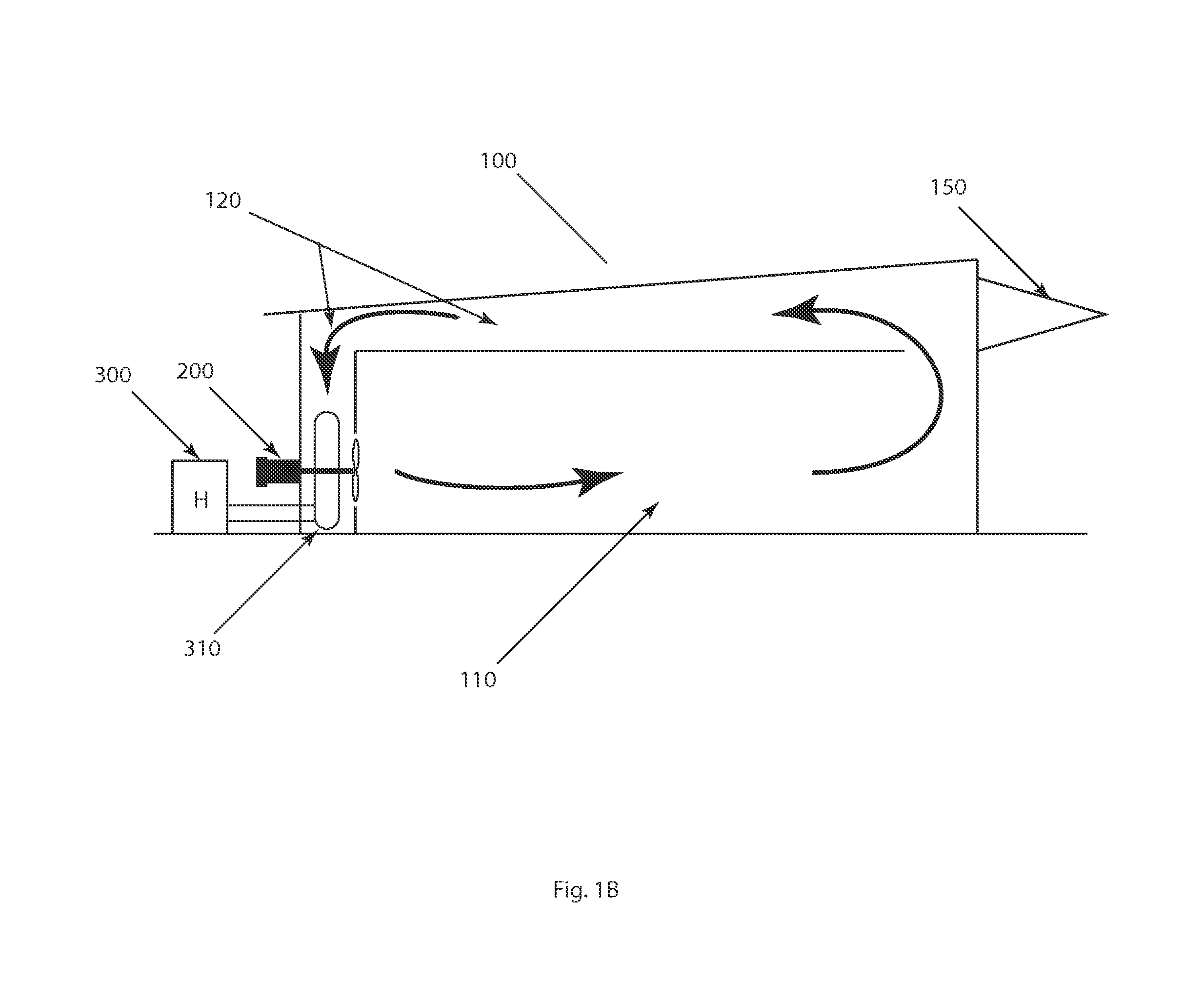

Modified heat chamber and method to improve heat cycle efficiency using airflow control

The present invention relates to improvements in the art of operating large heat chambers so as to reduce both the time and the cost required for heating materials. More specifically, the modified heat chamber of the present invention provides a programmable control mechanism capable of significantly reducing areas with temperature variations or hot and cold spots. A programmable heat chamber leads to significant reductions in the required processing time and in the cost of the required energy.

Owner:LAFFLER DONALD L +1

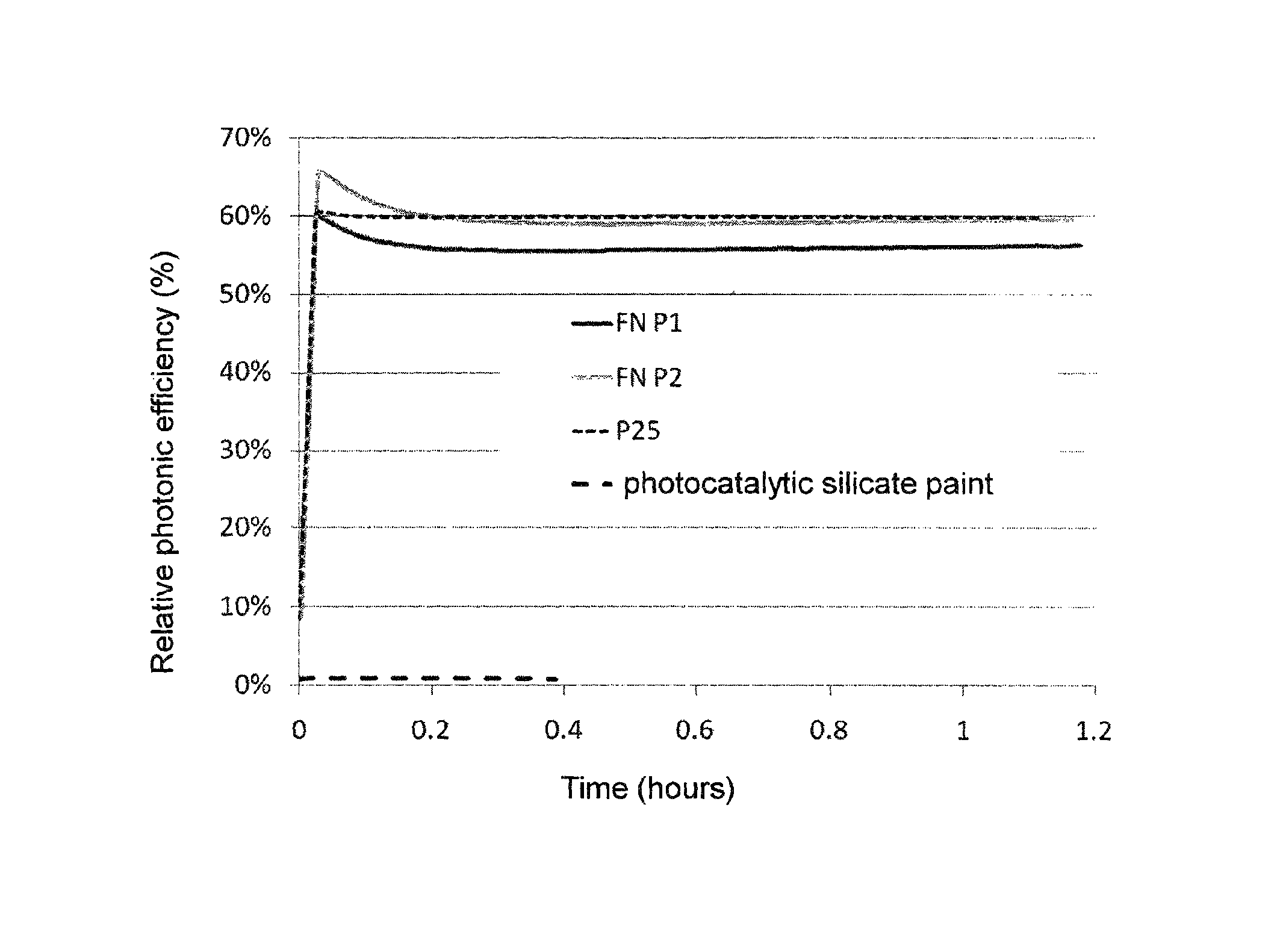

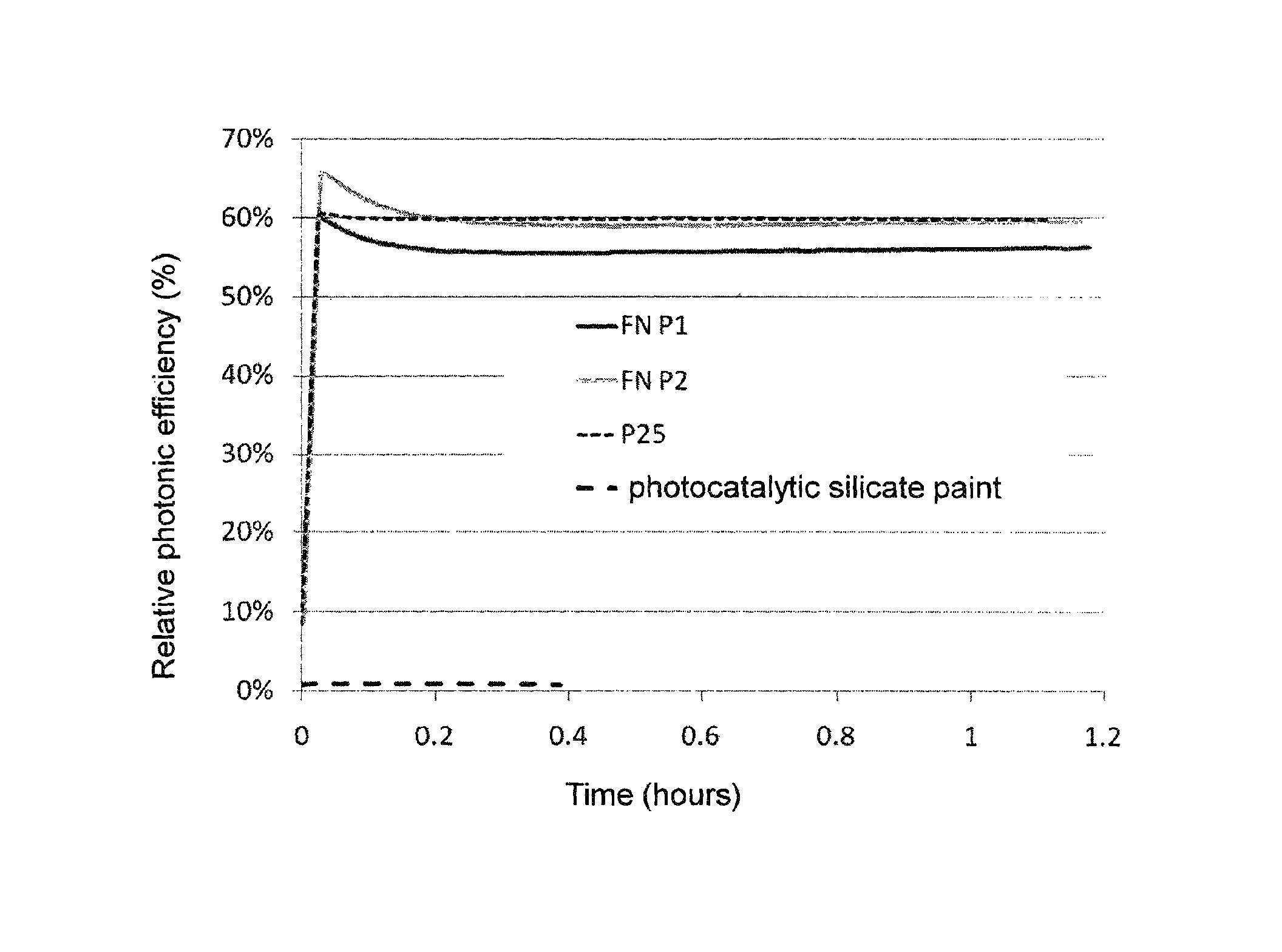

Surface treatment agent with high photocatalytic and sanitary effects

ActiveUS9200163B2Improve photocatalytic performanceImprove deodorization efficiencyAntifouling/underwater paintsPaints with biocidesNanoparticleAdditive ingredient

Surface treatment agent with high photocatalytic and sanitary effects based on TiO2 nanoparticles comprising 10 to 500 g of TiO2 nanoparticles per 1 liter of water, and binding ingredient A, which is an inorganic binder selected from the group comprising ZnO, MgO, CaO, Ca(OH)2, Mg(OH)2, CaCO3, MgCO3, Na2CO3, K2CO3 in the amount of 0.1 to 10% by weight related to the N weight of TiO2. Agent for treatment of surfaces for application on surfaces, which comprise a minimum of 50% of substances selected from the group formed by CaCO3, MgCO3 ZnO, MgO, CaO, Ca(OH)2, Mg(OH)2 or their mixtures, where the agent contains 10 to 500 g of TiO2 nanoparticles per 1 liter of water, and optionally contains a minimum of 0.1 wt % H2CO3 related to the weight of TiO2.

Owner:ADVANCED MATERIALS JTJ

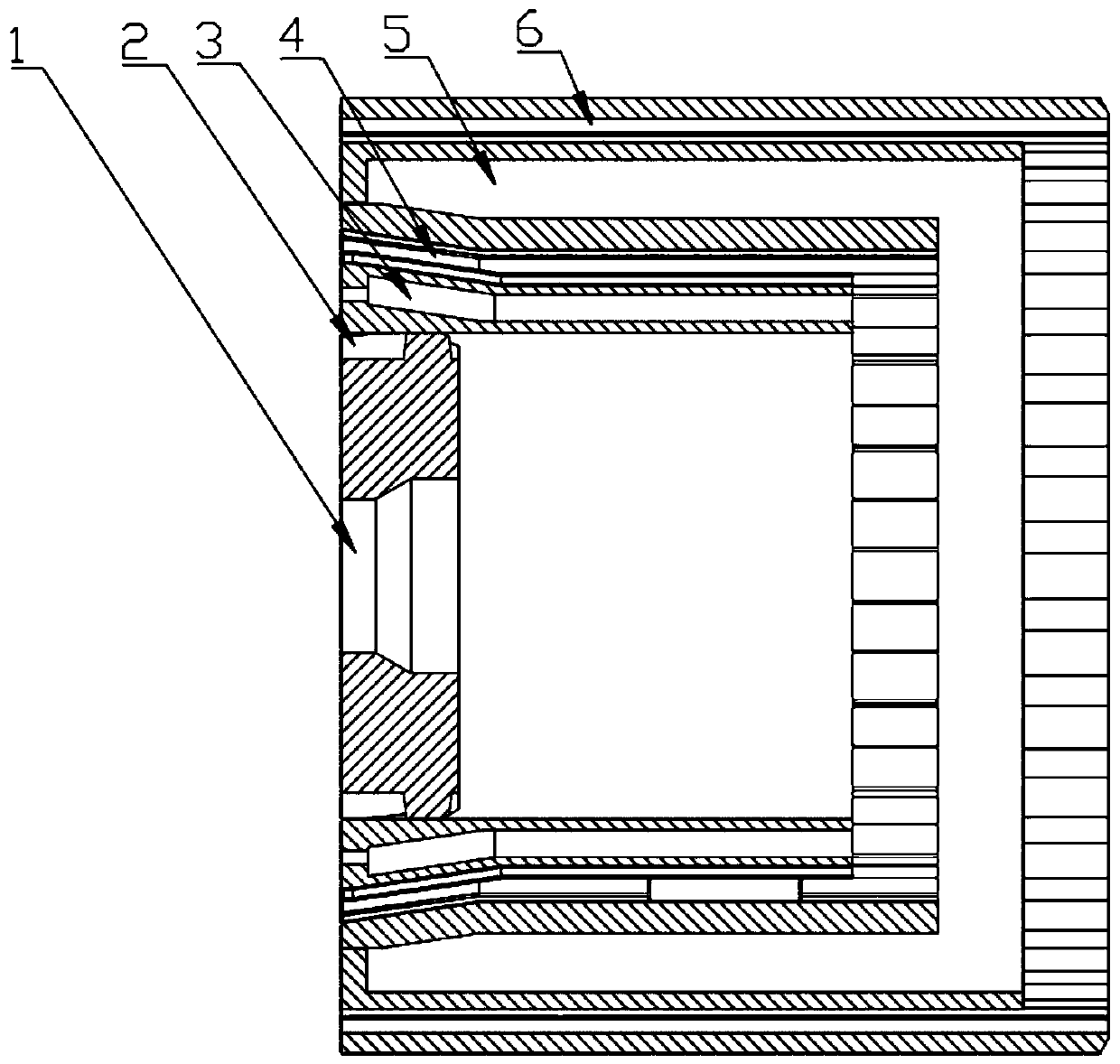

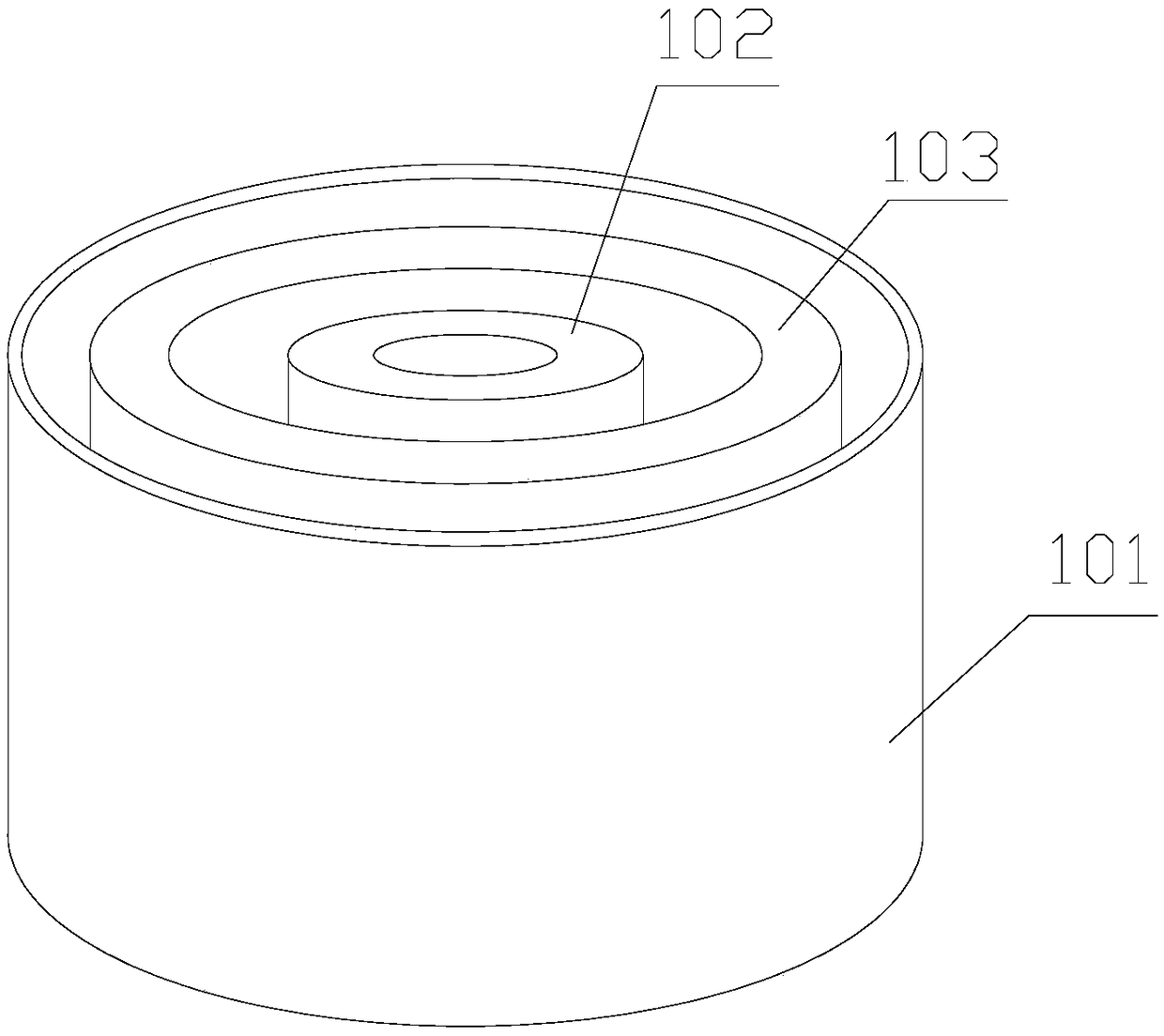

Device and process for controlling heating temperature field to purify and prepare polycrystalline silicon

ActiveCN109252216AIncreased air turbulenceGood for even distributionPolycrystalline material growthSilicon compoundsPolycrystalline siliconMetallurgy

The invention discloses a device for controlling a heating temperature field to purify and prepare polycrystalline silicon. The furnace body is provided therein with a heat insulation plate, a coolingplate, a crucible, a heating induction ring and a heat preservation tube. The heat preservation tube is provided therein with an upper graphite heating ring, a middle graphite heating ring and a lower graphite heating ring, connection rings are arranged between the upper graphite heating ring and the middle graphite heating ring, and between the middle graphite heating ring and the lower graphiteheating ring, respectively, and the connection rings are made from a high temperature resistant material with heat conduction coefficient of 10-50 W / m.k. A purification process comprises the steps: introducing a cooling gas into a cooling plate; introducing an inert gas into a furnace body, and meanwhile discharging through an exhaust pipe provided at the top of the furnace body to ensure a certain gas pressure existing in the furnace body; and controlling the upper graphite heating ring, the middle graphite heating ring, and the lower graphite heating ring to cool according to a certain procedure. The device and process for controlling heating temperature field to purify and prepare polycrystalline silicon facilitates the formation of a uniform temperature gradient, being favorable for crystal growth, and can effectively prevent the stepwise sudden change of a stepwise heat field from top down.

Owner:CHENGDU SILICON TECH CO LTD

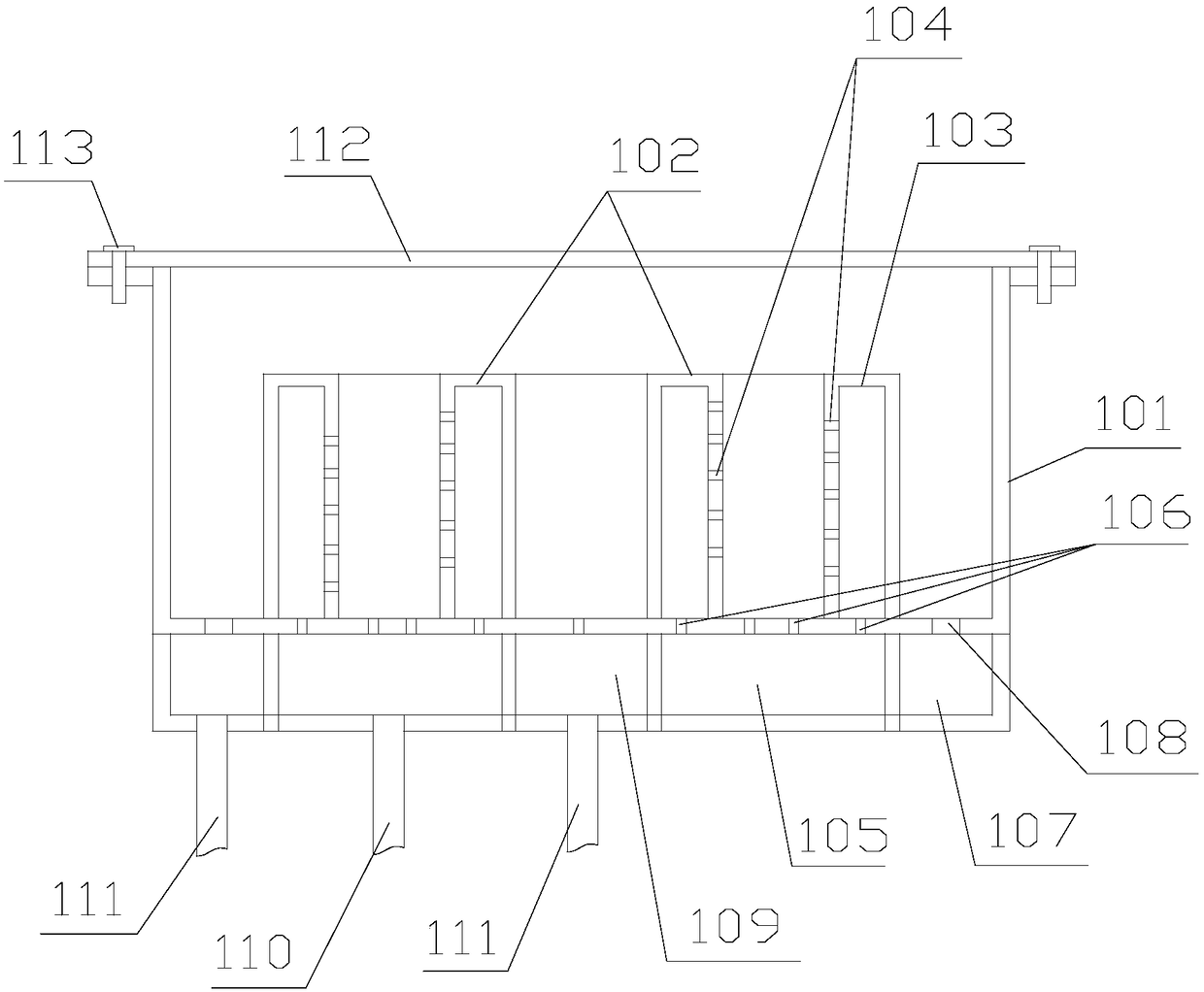

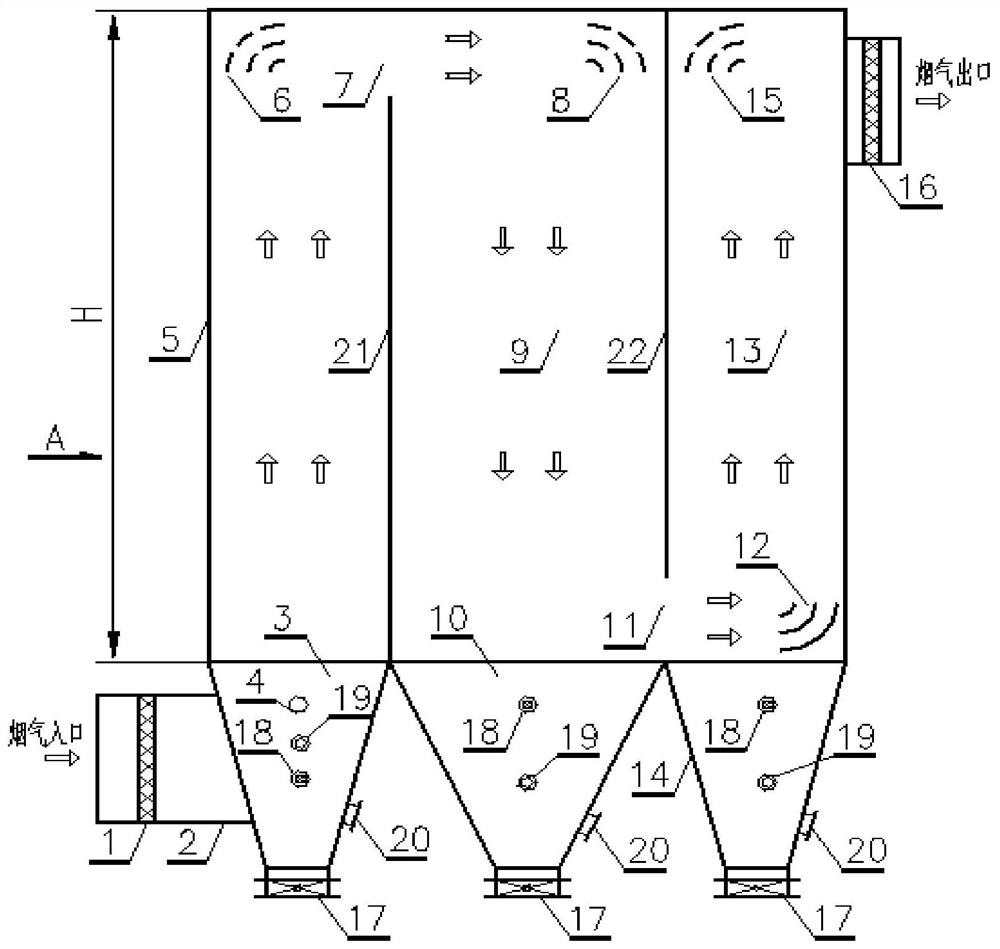

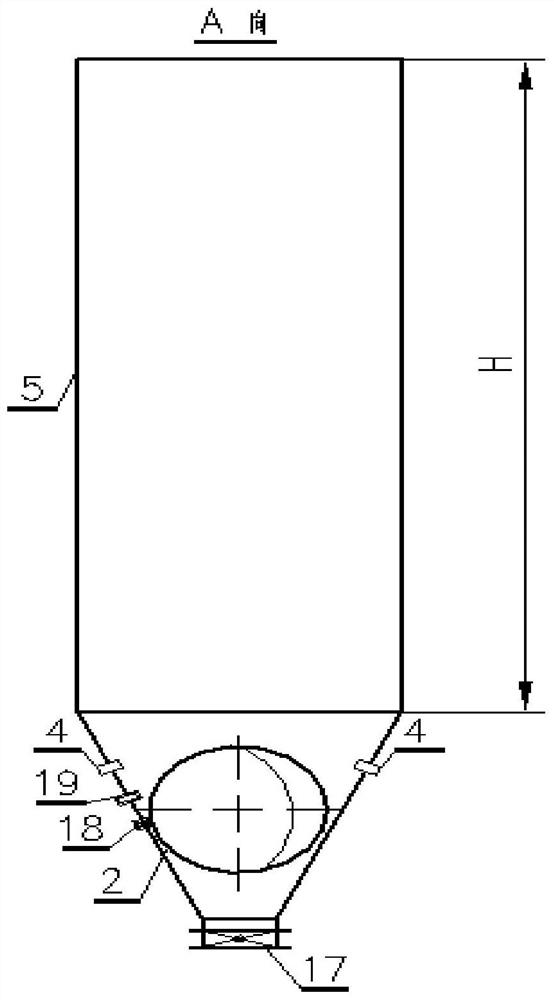

Efficient turn-back type SDS (sodium dodecyl sulfate) desulfurizing tower device

PendingCN113477069AIncreased air turbulenceImprove mixing uniformityGas treatmentDispersed particle separationProcess engineeringFlue gas

An efficient turn-back type SDS (sodium dodecyl sulfate) desulfurization tower device belongs to the technical field of flue gas desulfurization and purification. The device comprises an inlet compensator, an inlet flue, a first ascending bin ash bucket, a spraying hole, a first ascending bin, a flow guide plate, a communication opening, a flow guide plate, a descending bin, a descending bin ash bucket, a communication opening, a flow guide plate, a second ascending bin, a second ascending bin ash bucket, a flow guide plate, an outlet compensator, an ash discharging valve, a level gage, a vibrator, an access hole, a first partition plate and a second partition plate. The device has the advantage that the problems of short contact time of flue gas and a desulfurizing agent, low desulfurization efficiency, poor matching effect with a dust removal system and the like in a sodium-based dry desulfurization system are solved.

Owner:BEIJING SHOUGANG INT ENG TECH

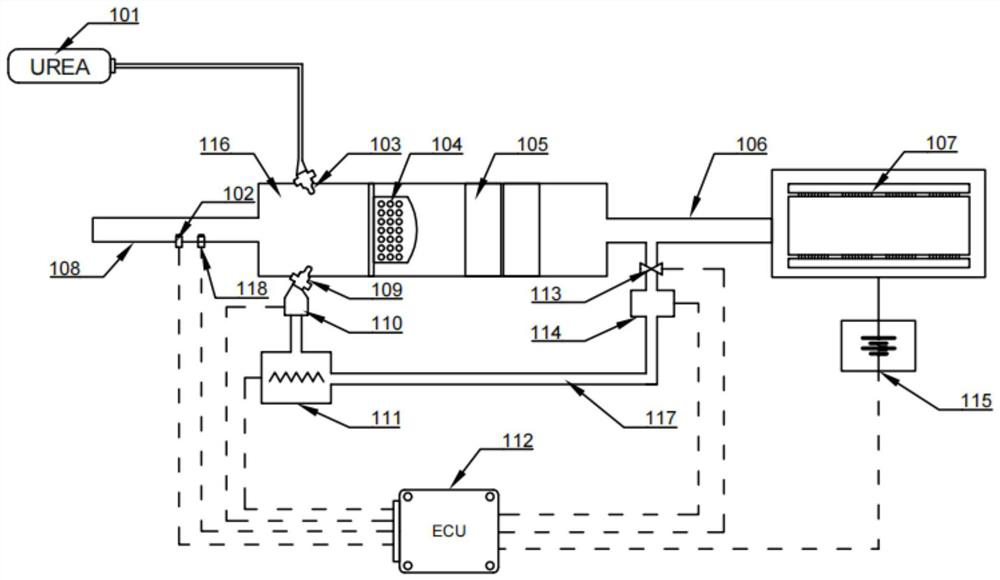

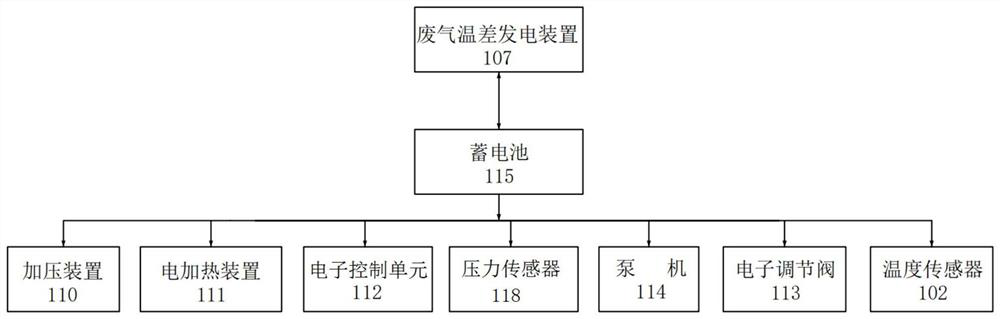

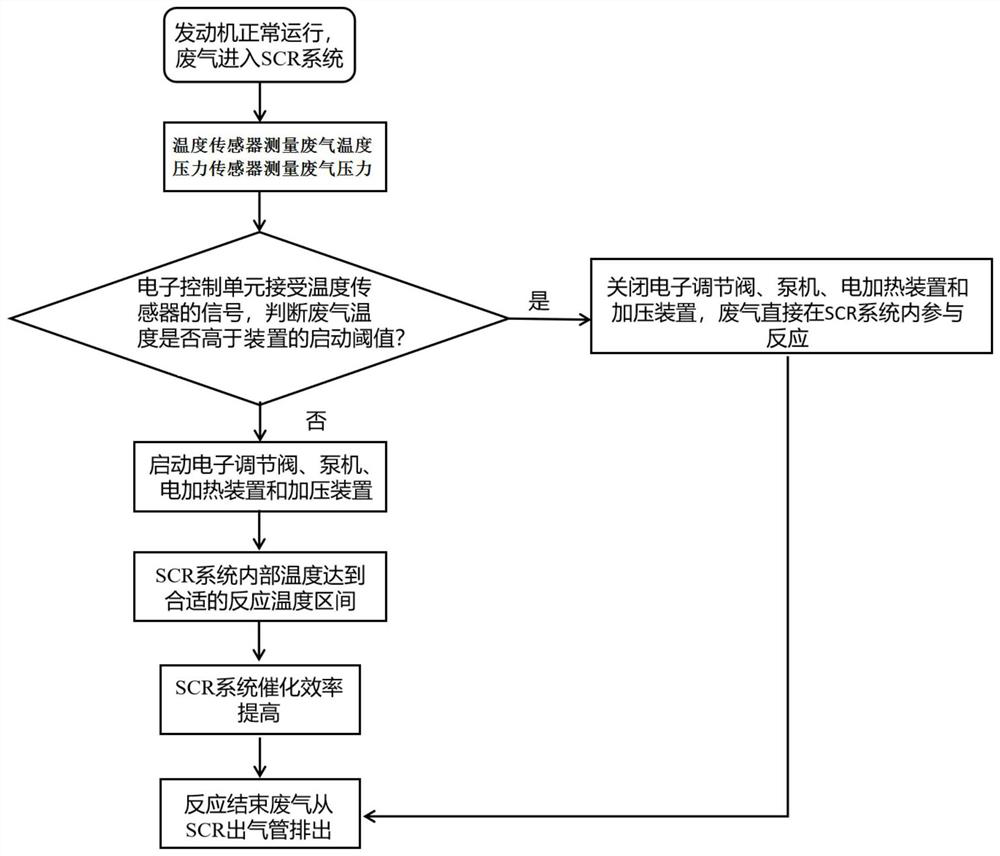

Device and method for reducing urea crystals of SCR system

PendingCN113931723ARaise the reaction temperatureImprove flow uniformityInternal combustion piston enginesExhaust apparatusProcess engineeringWaste gas

The invention discloses a device and method for reducing urea crystals of an SCR system. The device comprises a temperature sensor, a pressure sensor, a heating and pressurizing gas nozzle, a pressurizing device, an electric heating device, an electronic regulating valve, a pump machine, a waste gas temperature difference power generation device, a storage battery, a recycling waste gas pipe and an electronic control unit. By means of the device, aiming at the low-temperature working condition, waste gas reduced by the SCR system is heated, recycled and injected into the SCR system, and therefore the reaction temperature of NOx and a urea aqueous solution is increased. The reaction temperature is increased, so that the probability of forming a liquid film is reduced, and the generation of the urea crystals is reduced. Meanwhile, the urea aqueous solution and the heated recycled waste gas are oppositely jetted in the SCR system, so that airflow disturbance in a pipe is increased, the probability of forming the liquid film is reduced, and the urea aqueous solution and the recycled waste gas are fully mixed and fully reacted. Meanwhile, heat in waste gas is utilized to generate power by adopting a waste gas temperature difference power generation technology, power is supplied to electric appliances in the device, and energy conservation and emission reduction are achieved.

Owner:HEBEI UNIV OF TECH

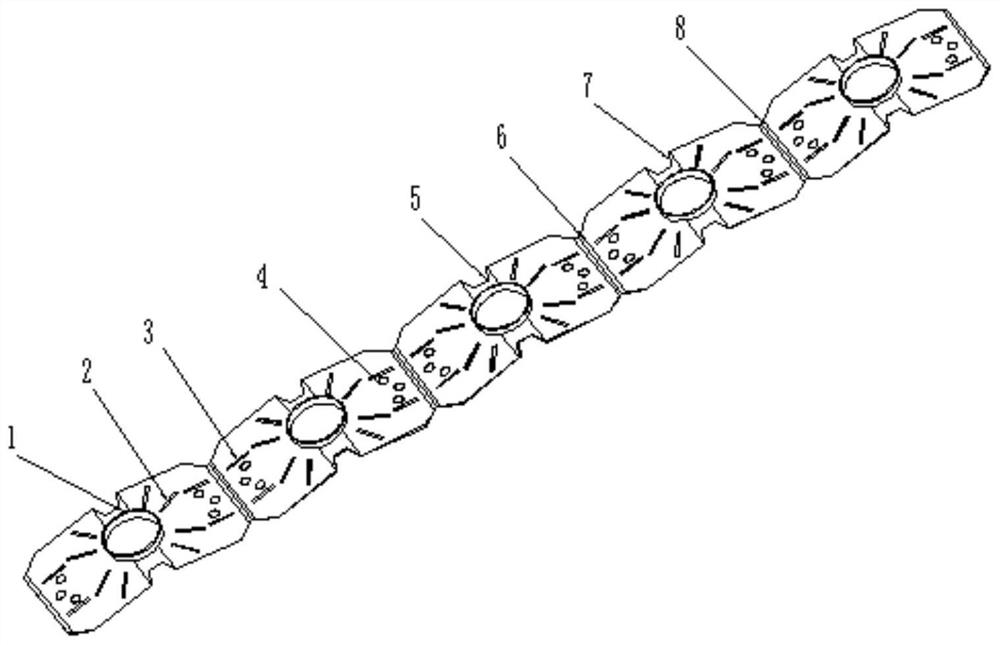

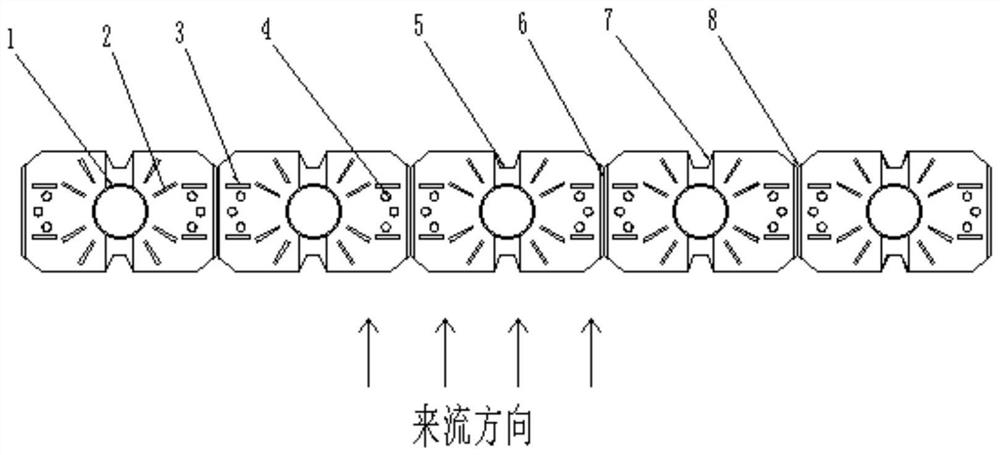

Heat exchange fin, heat exchanger and air conditioner

PendingCN113432477AImprove air disturbance effectImprove year-round coefficient of performanceEvaporators/condensersHeat exhanger finsEngineeringMechanical engineering

The invention discloses a heat exchange fin, a heat exchanger and an air conditioner. The heat exchange fin comprises at least one fin unit, each fin unit is provided with a plate-shaped body, and each plate-shaped body is a curved plate. A pipe hole is formed in the convex top of each plate-shaped body, a flange surrounding each pipe hole is formed, and the convex extending direction of each flange is the same as the convex direction of the corresponding plate-shaped body. First hollowed structures extending to the periphery in a divergent manner by taking the corresponding pipe hole as the center are formed at the position, around the corresponding pipe hole, of each plate-shaped body. First flow guide grooves are formed in one side or two sides of the pipe hole in each plate-shaped body in the radial direction of the pipe hole, one end of each first flow guide groove extends to the edge of the corresponding plate-shaped body, and the other end of each first flow guide groove extends to the corresponding flange. The first hollowed structures are distributed on the two sides of the first flow guide grooves.

Owner:GREE ELECTRIC APPLIANCES INC

Method for realizing low temperature tempering by medium-high temperature tempering furnace

The invention discloses a method for realizing low temperature tempering by a medium-high temperature tempering furnace. The method comprises the following steps that each burner nozzle of the medium-high temperature tempering furnace stops burning and hot blast is injected into the medium-high temperature tempering furnace through a hot blast injection pipe, wherein the hot blast injection pipe is led out from a joint between an air automatic valve and an air manual valve of an air pipeline connected with each burner nozzle. According to the method disclosed by the invention, the temperatureuniformity of the low temperature tempering can be improved, the heating efficiency is improved, the high temperature tempering and the low temperature tempering can be totally carried out on one stove, and the investment cost is reduced.

Owner:LAIWU IRON & STEEL GRP

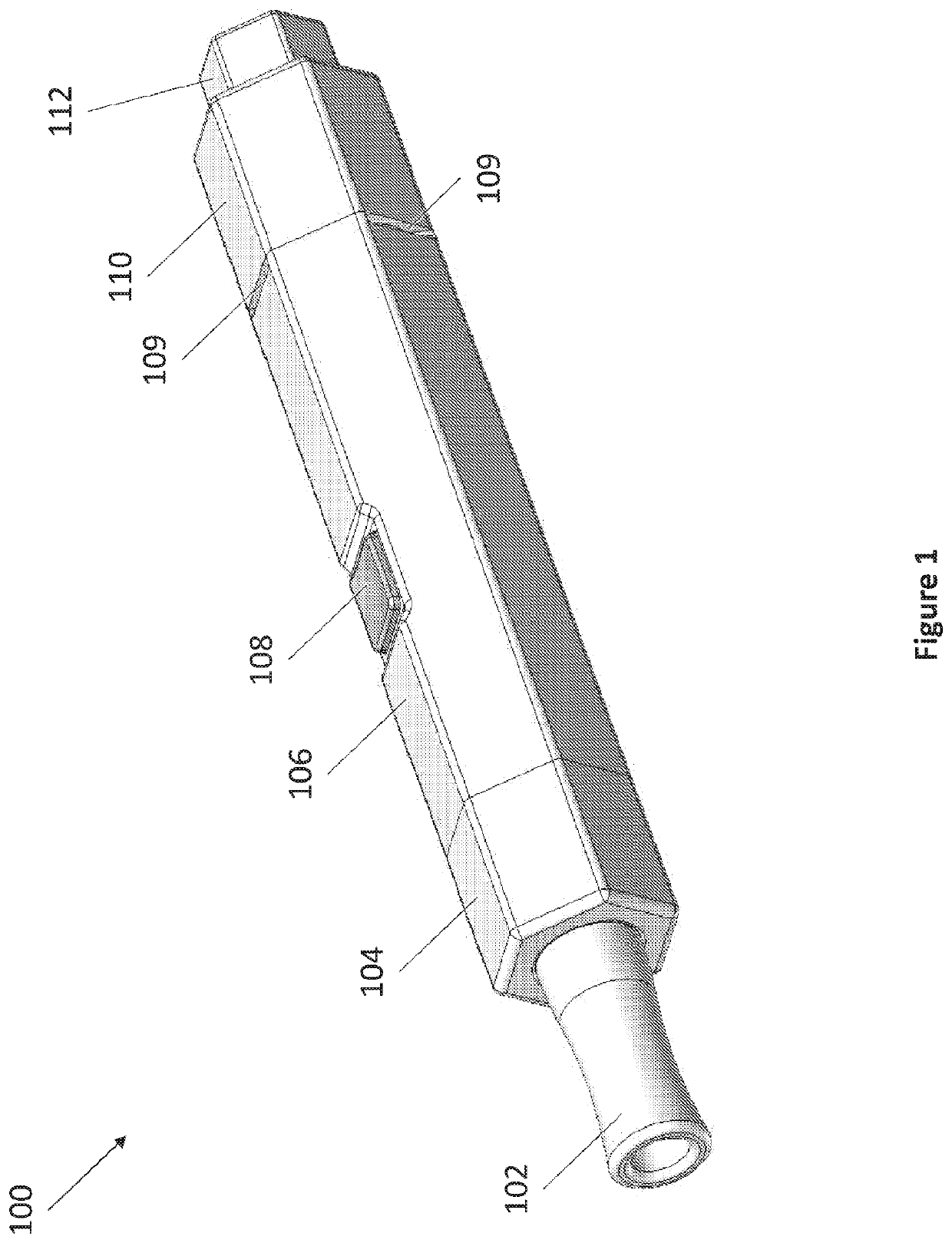

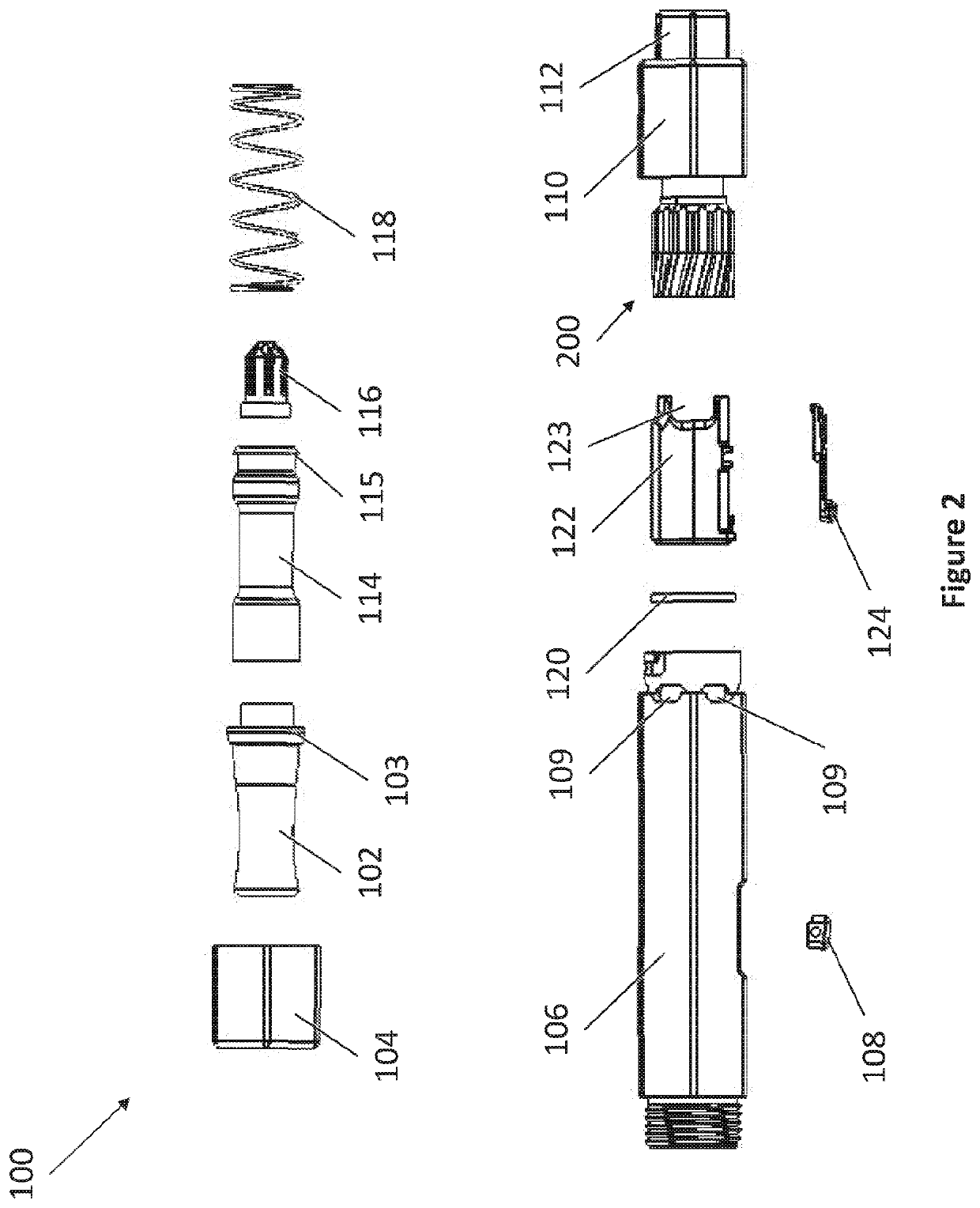

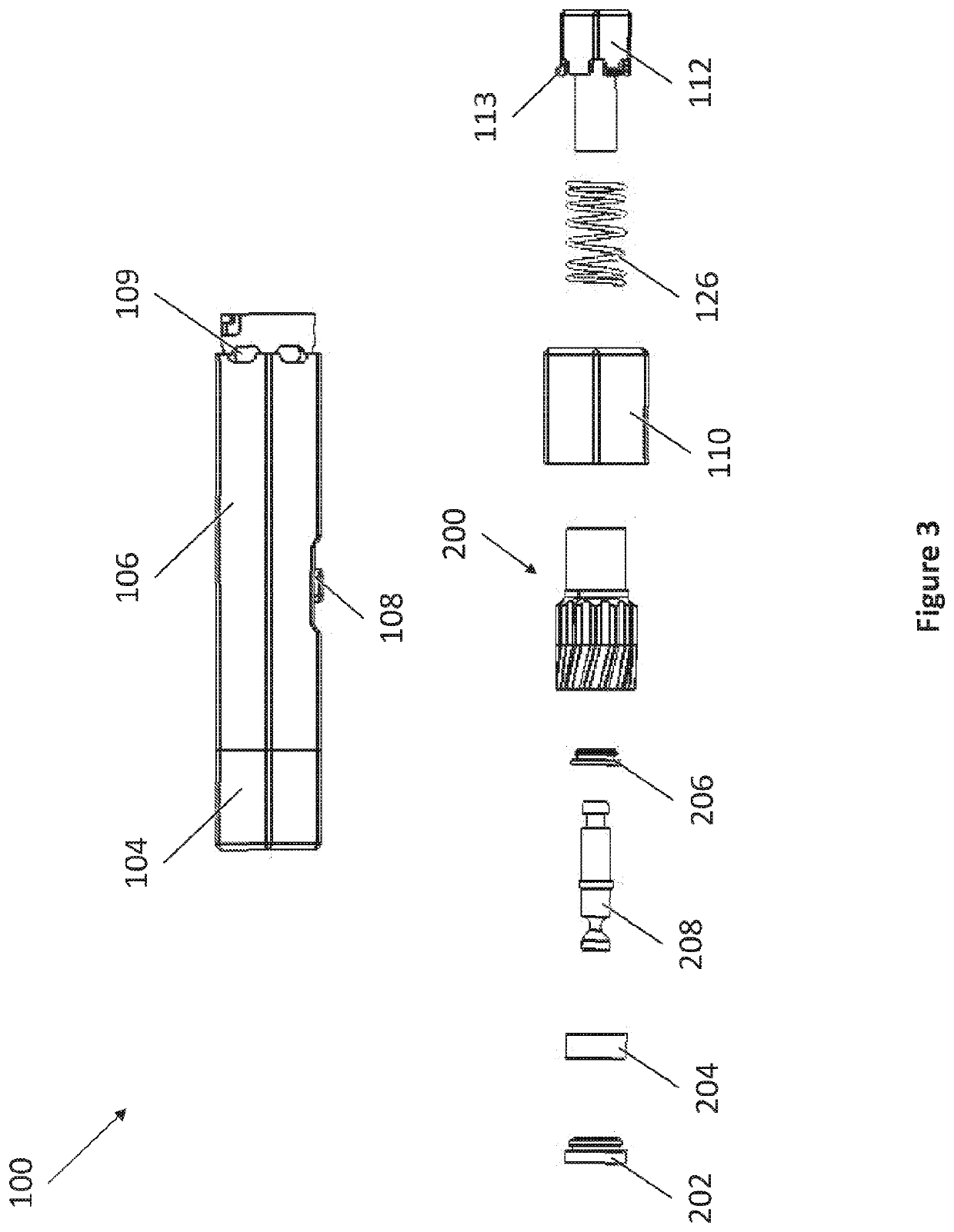

Dry powder inhaler

PendingUS20210402113A1Increase surface areaIncreased air turbulenceMedical devicesTobacco pipesPowder InhalerIntensive care medicine

The present invention provides dry powder inhaler (DPI) devices (100) for dispensing dry powder and methods for using the same. The DPI devices feature vortex mechanisms for directing air in a turbulent manner sufficient to entrain an amount of a dry powder dose for delivery into a user's lungs. The DPI devices feature replaceable dry powder cartridges (200). The DPI devices also feature a retractable configuration for storage and for accidental dispensing of dry powder. The DPI devices dispense dry powder in controlled dosages.

Owner:PHILIP MORRIS PROD SA

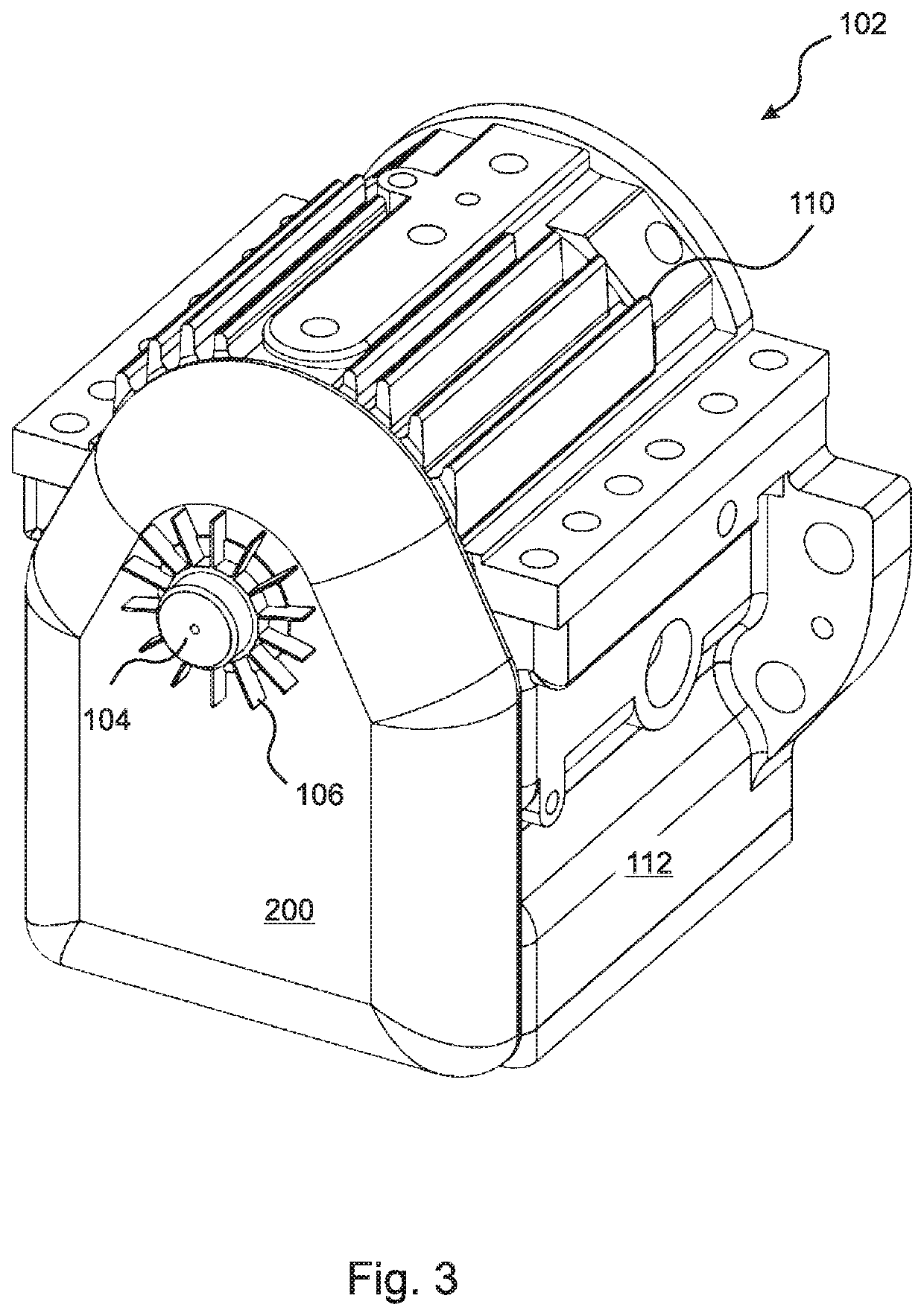

Coanda effect bearing cooler

ActiveUS20200056662A1Improve uniformityBulk and cost be reducePump componentsEngine fuctionsPhysicsAir cooling system

A compact, energy efficient air cooling system for a rotating shaft bearing module includes a Coanda surface having a periphery that smoothly curves from a radial center to axial alignment with a side of the module. A fan blade mounted on the shaft directs an airflow radially parallel and adjacent to the Coanda surface, causing the airflow to be bent by the Coanda effect from radial to axial, and to be directed along the side of the housing. Embodiments that can be applied to existing housings include a Coanda panel adjacent to the housing end face. A double suction fan blade can draw both external air and air from between the panel and the housing. In other embodiments the housing end face itself is a Coanda surface. A fan cover can have an inwardly curved periphery that forms a reduced gap or nozzle with the Coanda surface.

Owner:FLOWSERVE MANAGEMENT CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com