Innocent treatment equipment and method for naphthalene-bearing hazardous wastes

A harmless treatment, air technology, applied in the direction of combustion method, incinerator, combustion type, etc., to achieve the effect of avoiding sublimation, improving combustion efficiency, and strong promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

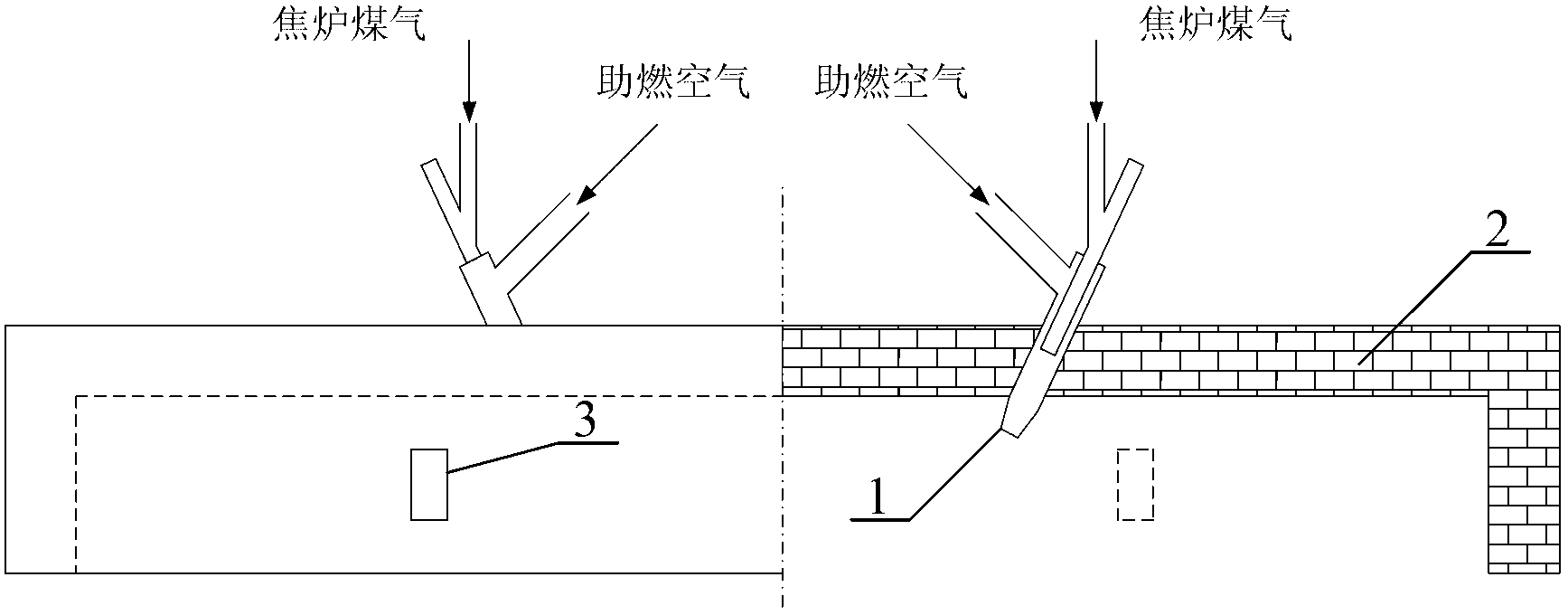

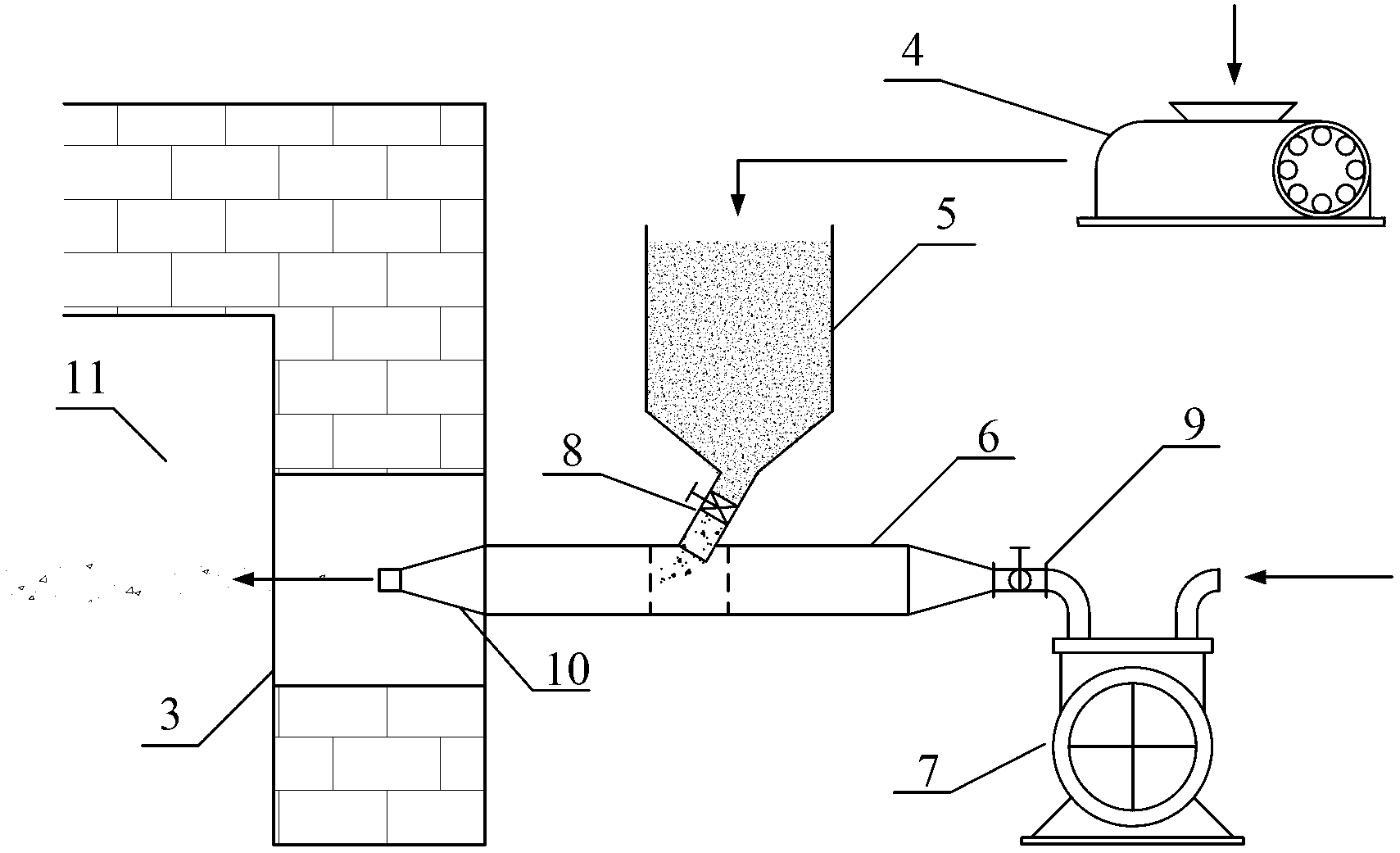

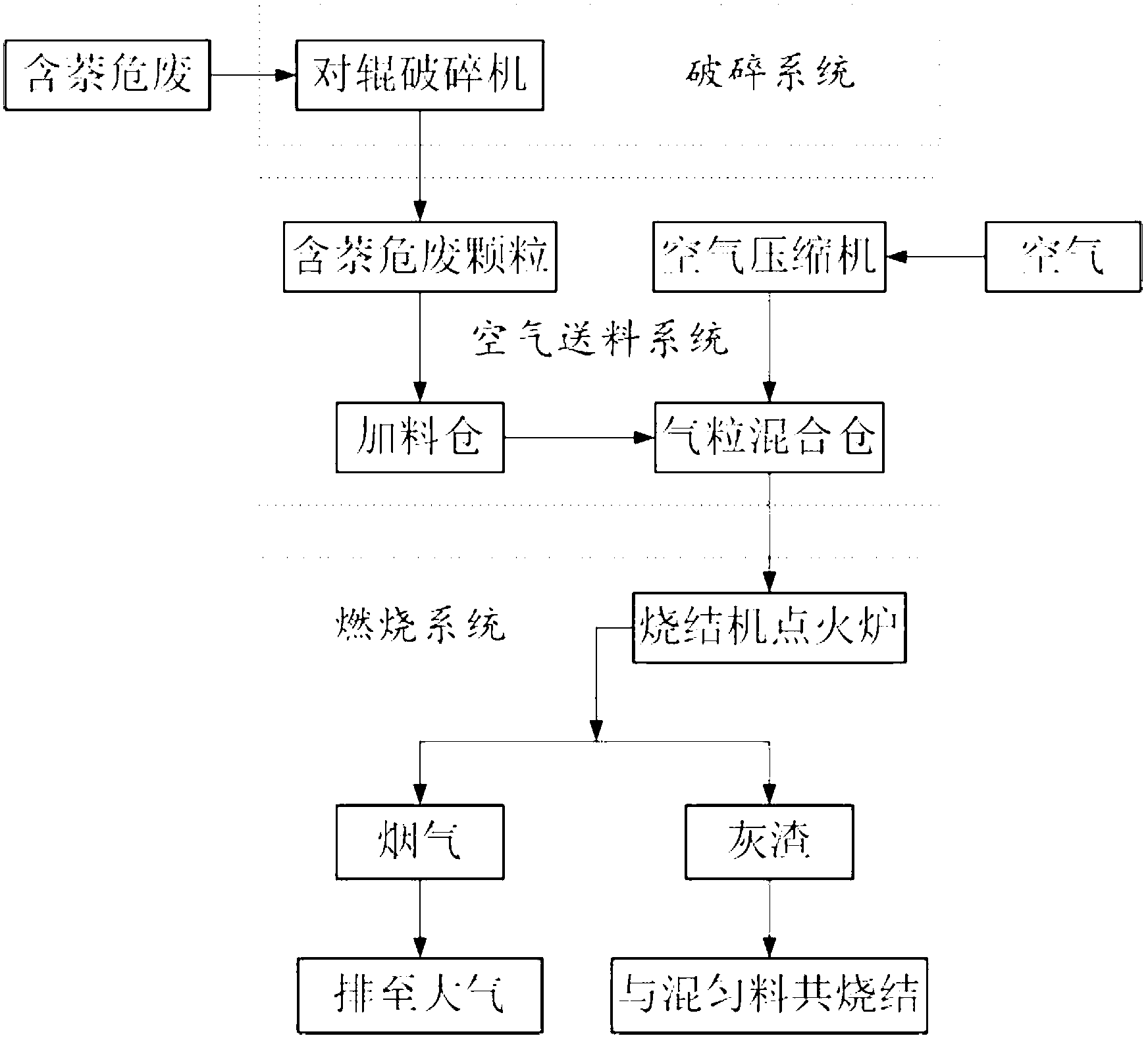

[0021] The device for harmless treatment of naphthalene-containing hazardous waste includes a crushing system, an air feeding system and a combustion system. The crushing system is a crusher; the air feeding system includes a feeding bin, an air particle mixing bin, an air compressor, a feed inlet valve, an air inlet valve and a high temperature resistant nozzle; the combustion system is a sintering machine ignition furnace, including a furnace, a burner, Refractory bricks and viewing ports.

[0022] The air feeding system is the core part of the present invention. Its main body is the air particle mixing chamber, which is made of steel pipe. The upper part is connected to the feeding chamber through the feed valve. The particle movement direction is opposite to prevent particle backflow caused by excessive internal pressure of the gas particle mixing chamber. The left side of the gas particle mixing chamber is connected to the air compressor through the air inlet valve, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com