Patents

Literature

171 results about "Particle mixing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Systems for Efficient Staining and Sorting of Populations of Cells

ActiveUS20090176271A1Preventing initiationLow viscosityBioreactor/fermenter combinationsBiological substance pretreatmentsStainingControl cell

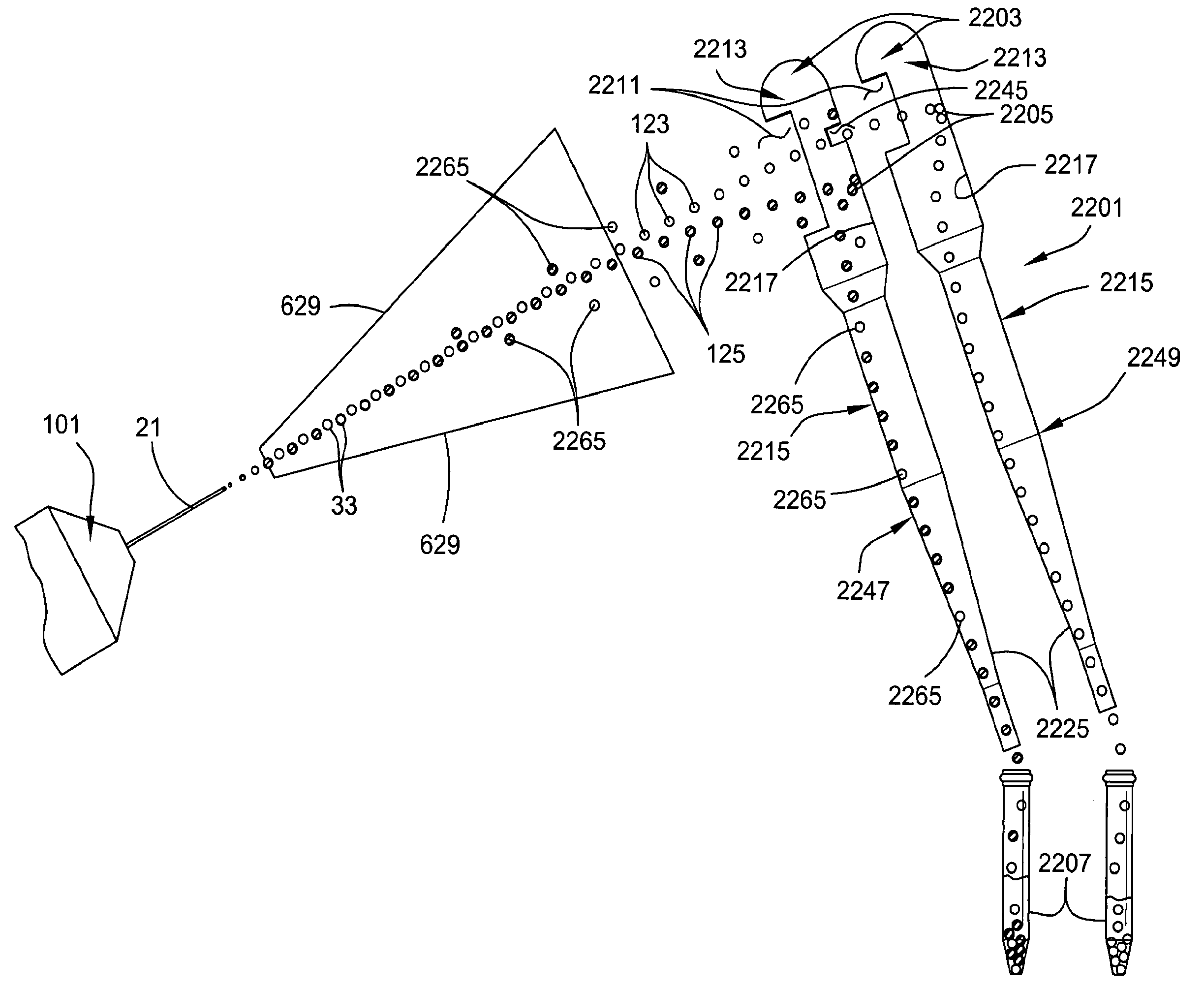

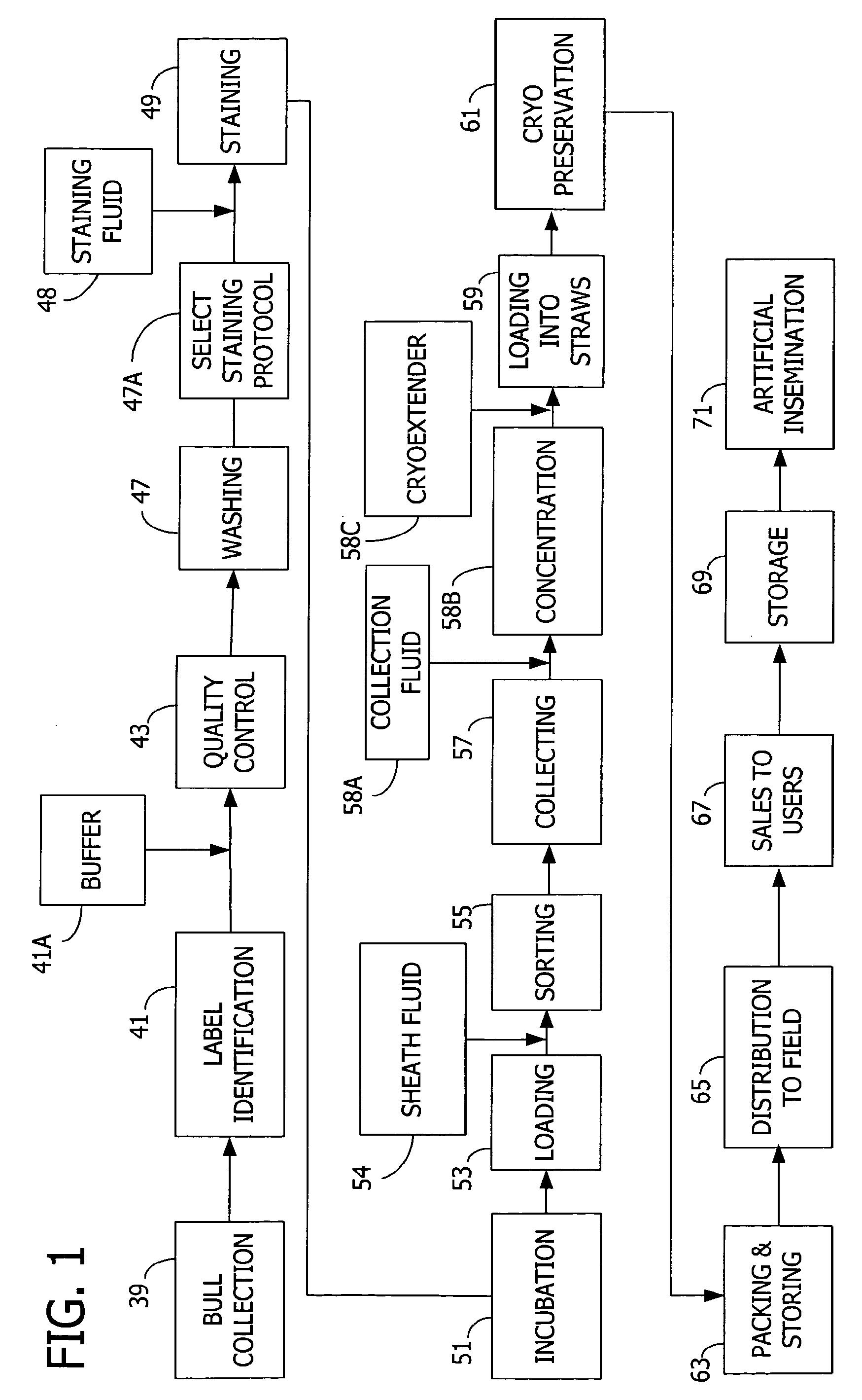

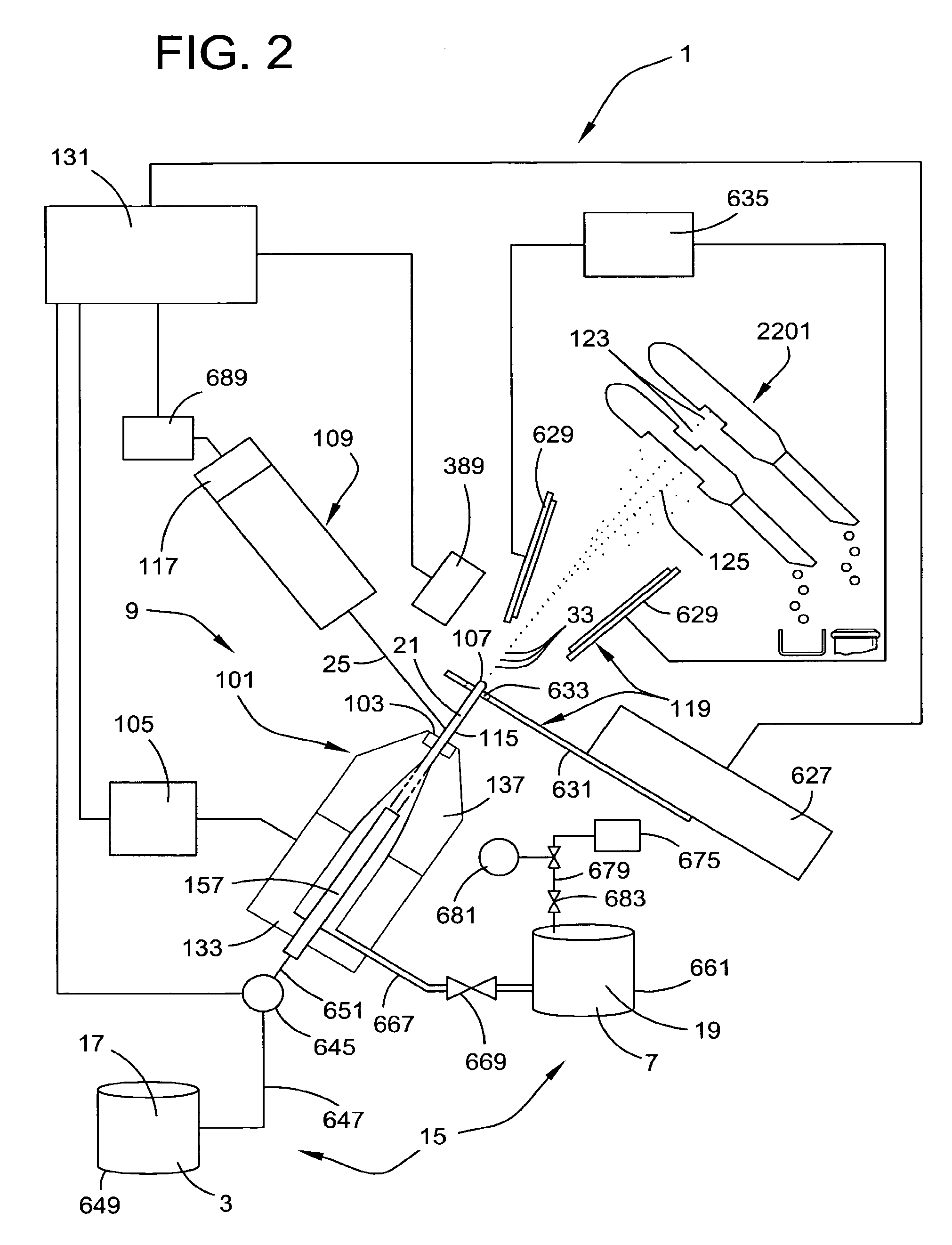

A multi-channel apparatus for classifying particles according to one or more particle characteristics. The apparatus comprises a plurality of flow cytometry units, each of which is operable to classify particles in a mixture of particles by interrogating a stream of fluid containing the particles with a beam of electromagnetic radiation. The flow cytometry units share an integrated platform comprising at least one of the following: (1) a common supply of particles; (2) a common housing; (3) a common processor for controlling operation of the units; (4) a common processor for receiving and processing information from the units; and (5) a common fluid delivery system. The integrated platform can include a common source of electromagnetic radiation. A method of the invention comprises using a plurality of flow cytometry units sharing the integrated platform to perform a flow kilometric operation, such as analyzing or sorting particles.

Owner:INGURAN LLC

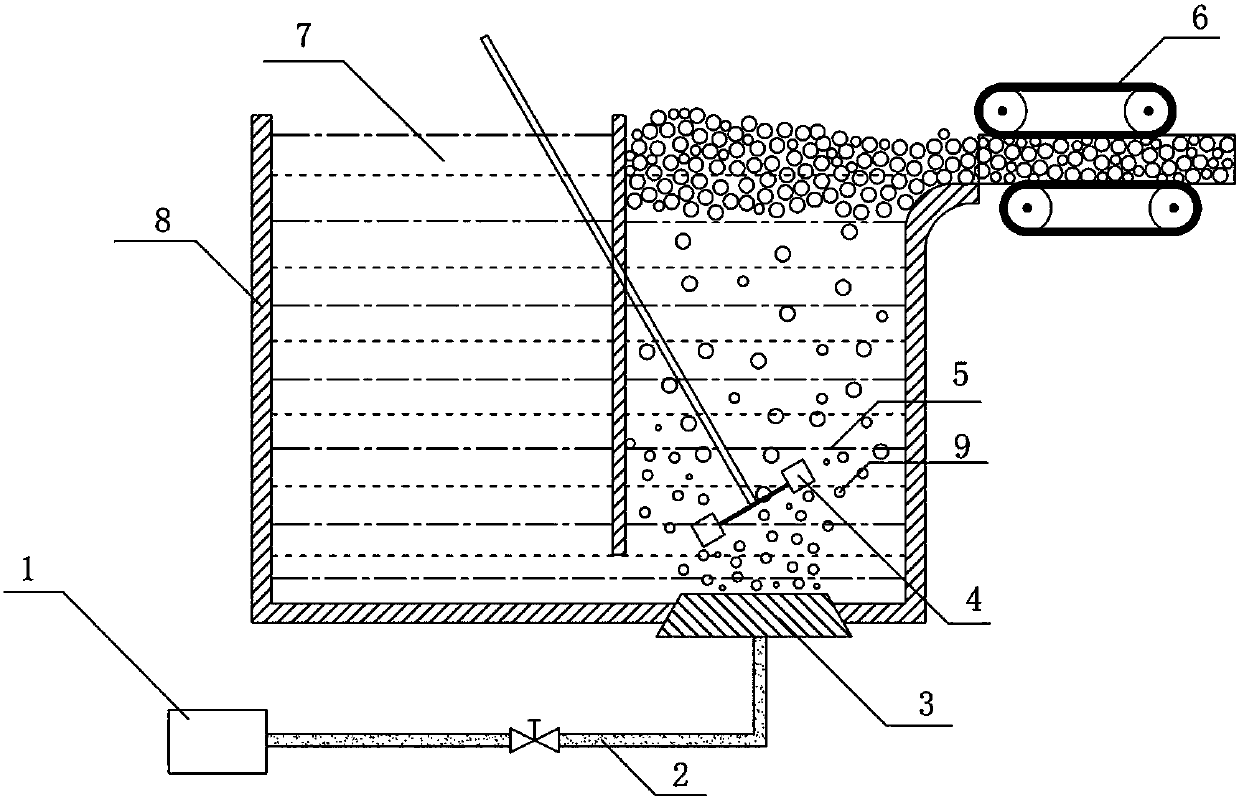

System for separating algae and other contaminants from a water stream

InactiveUS6332980B1Increase capacityReduces potential formationLiquid degasificationFlow mixersSuspended particlesFiltration

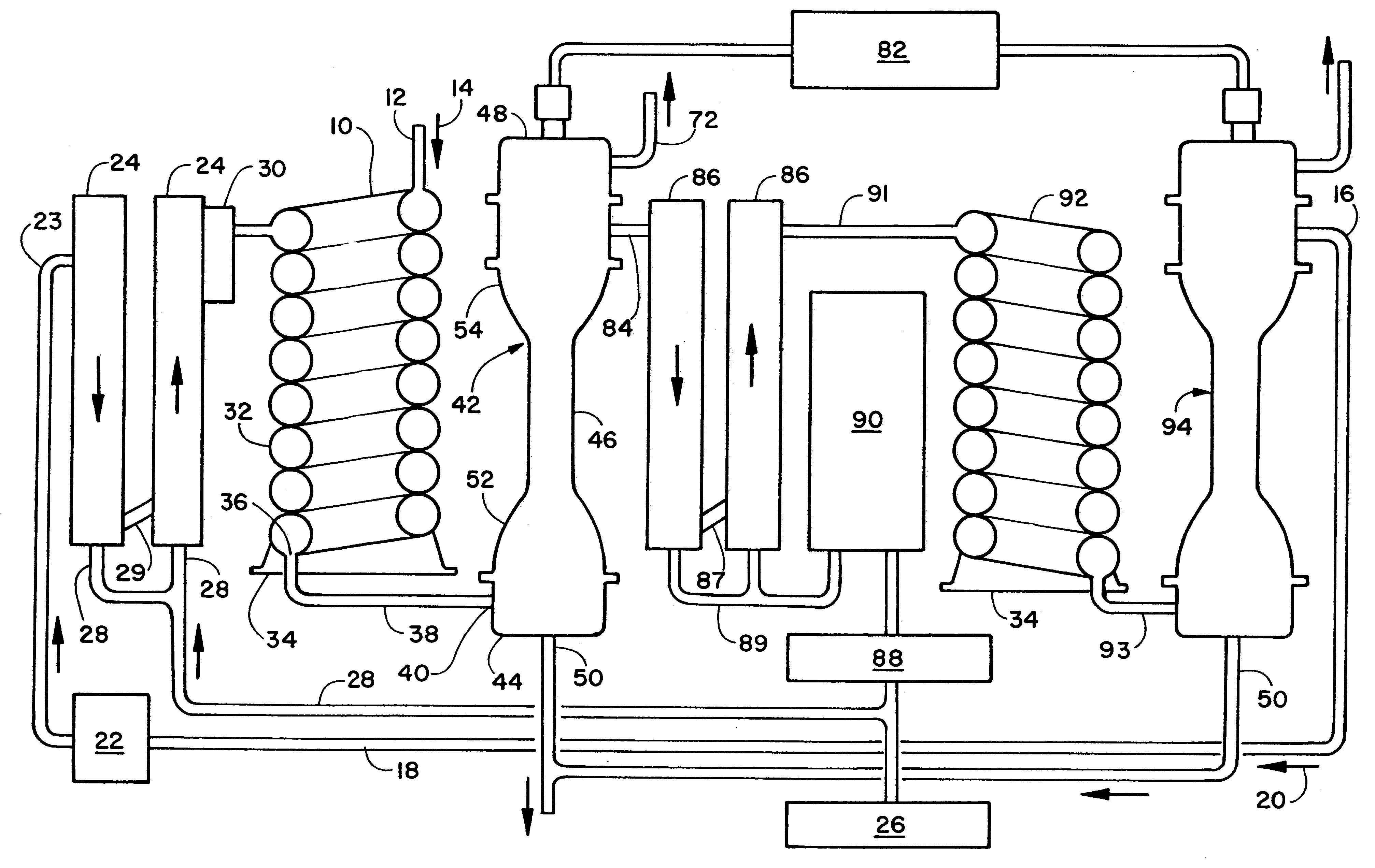

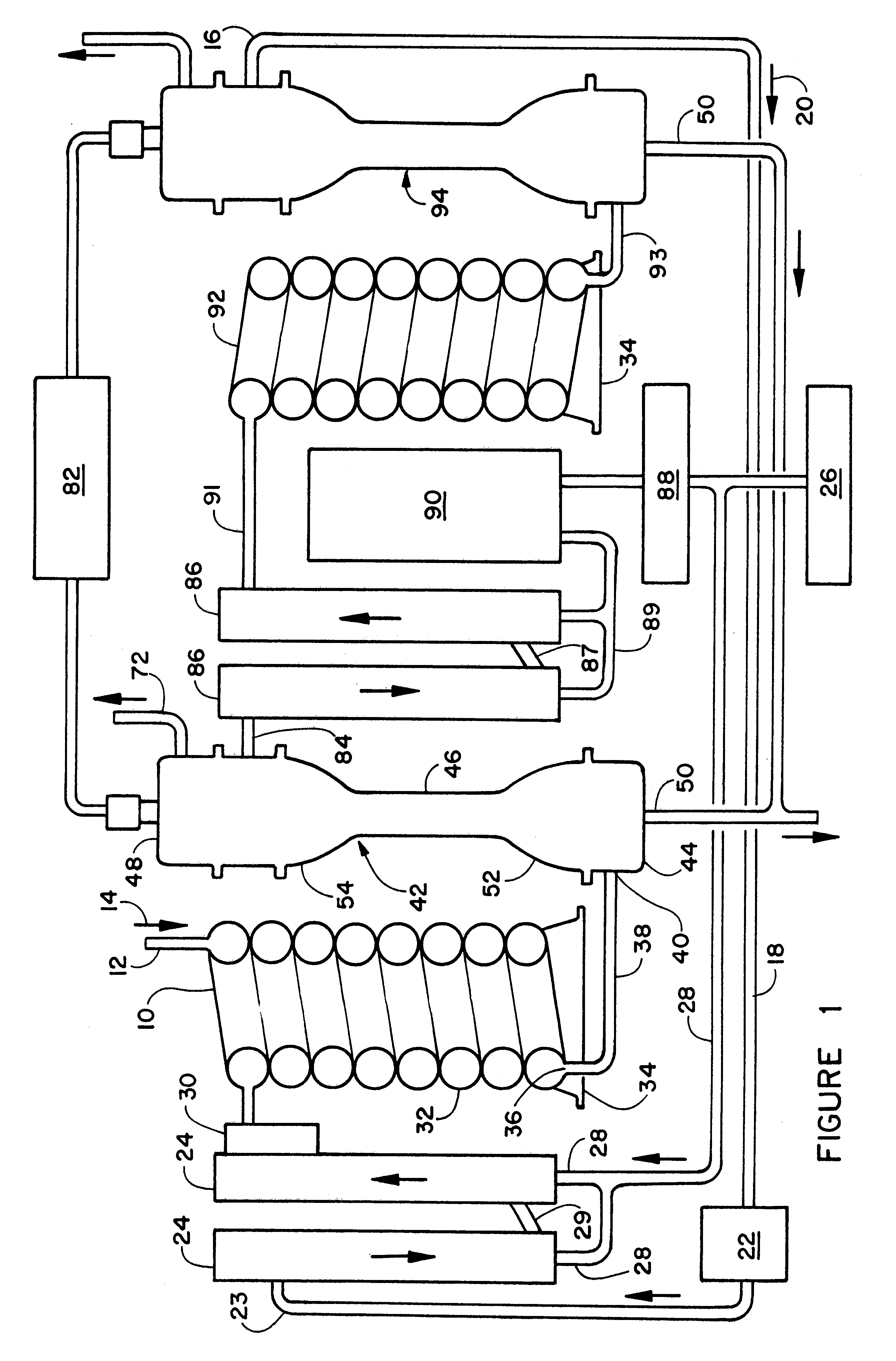

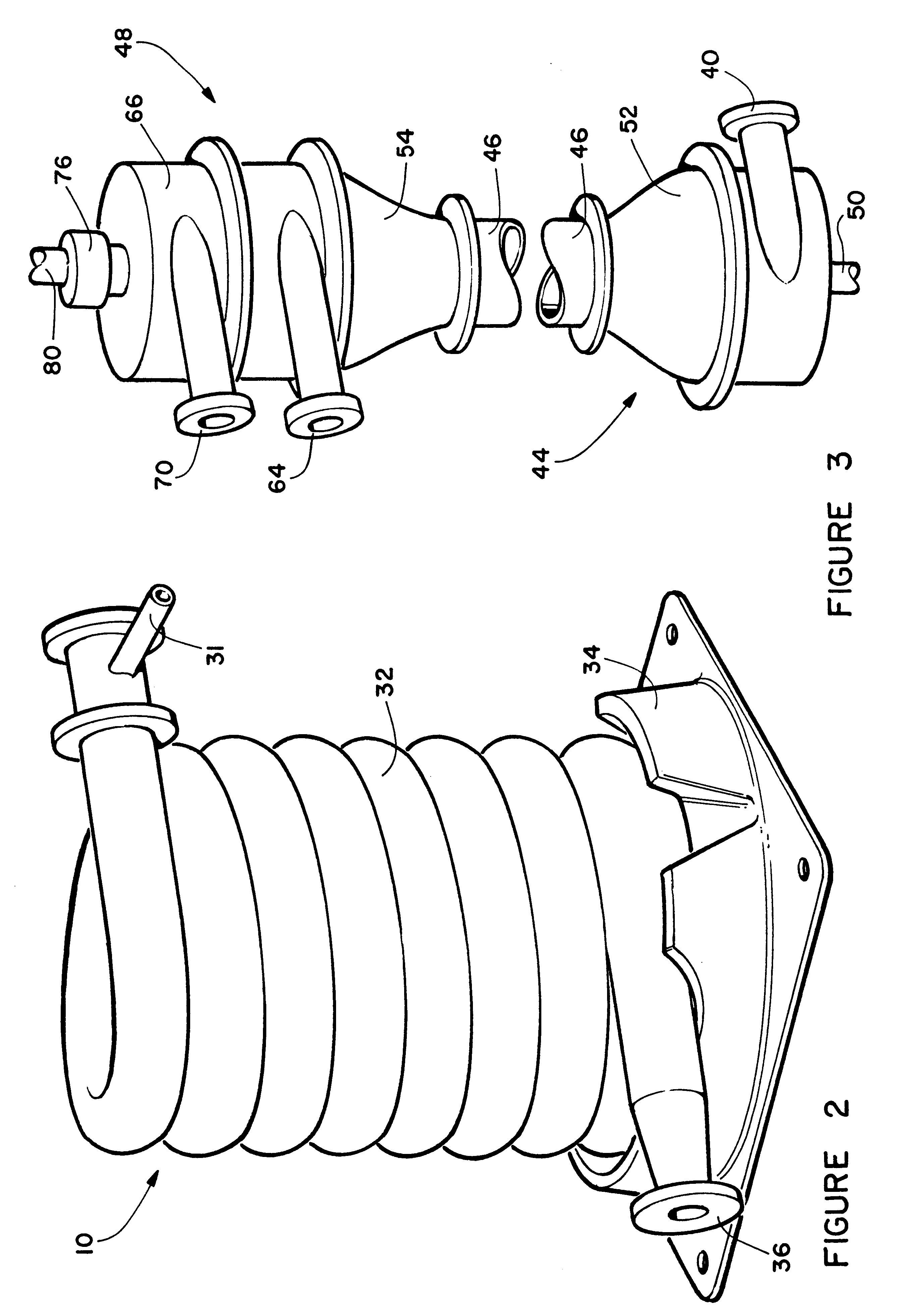

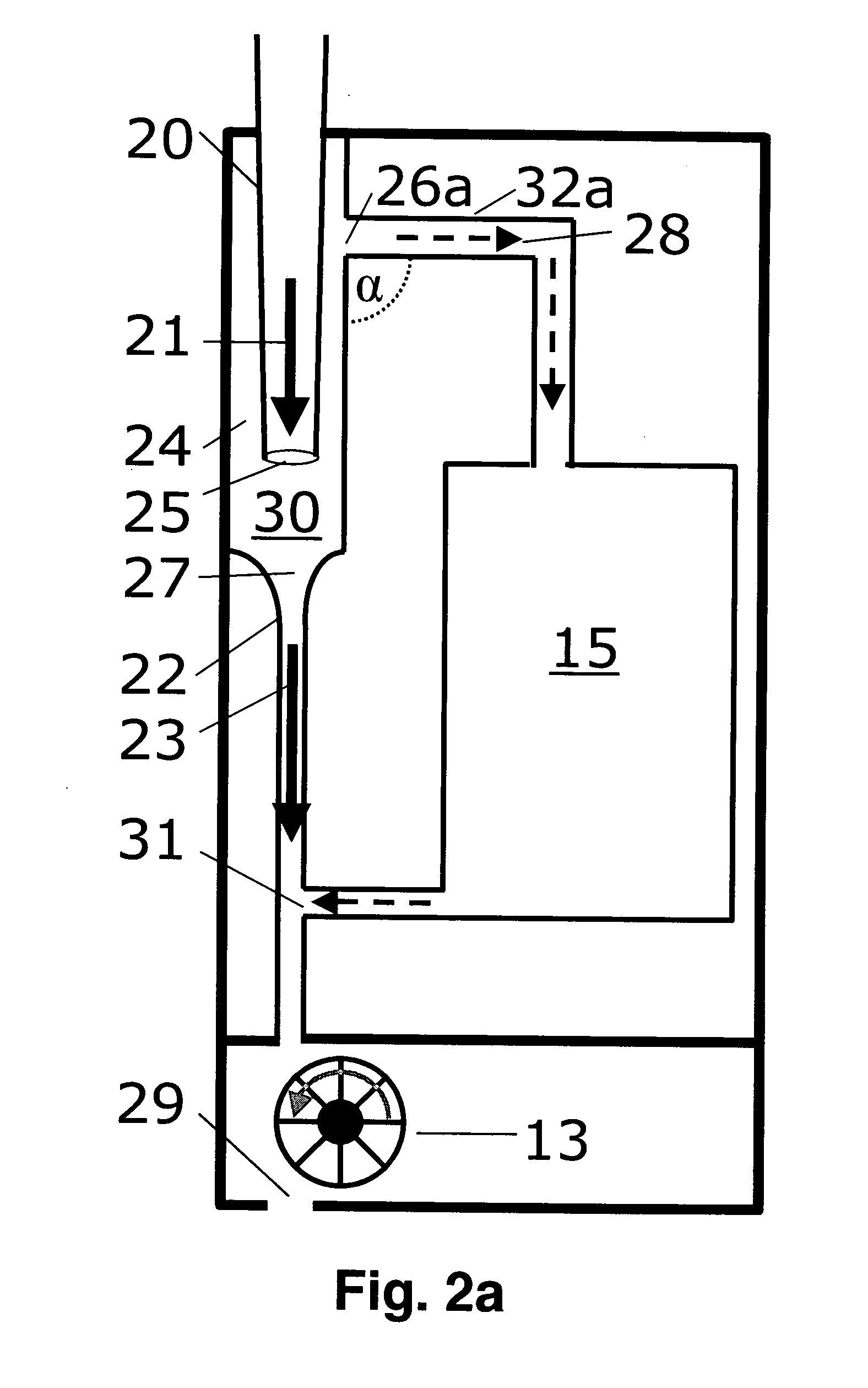

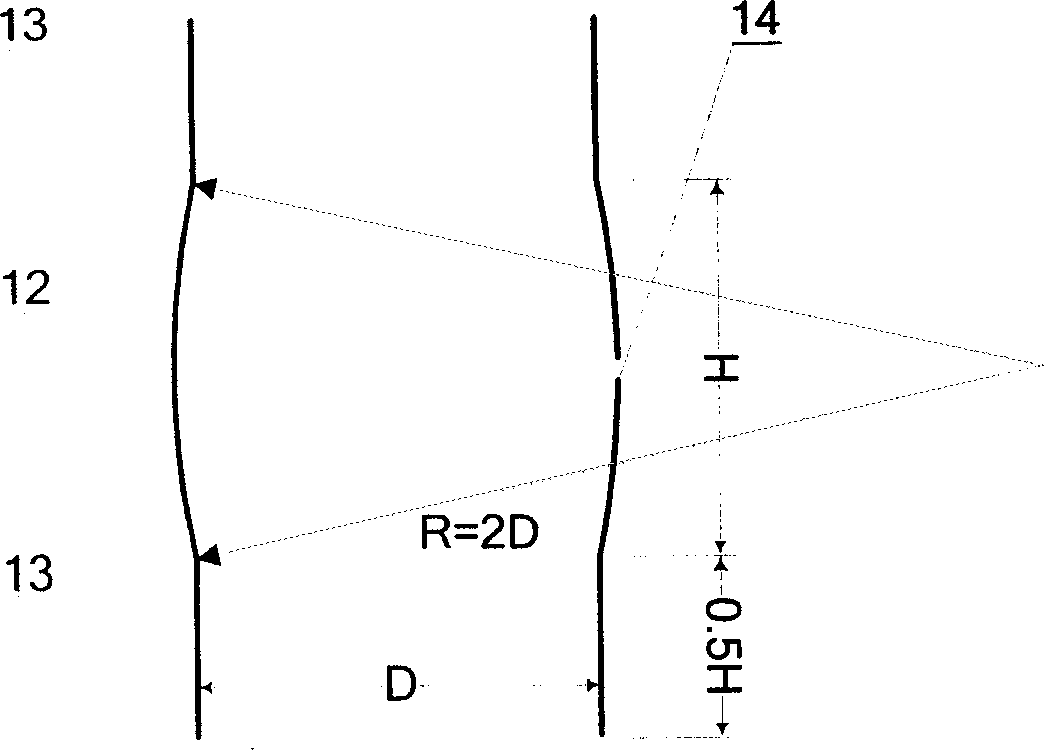

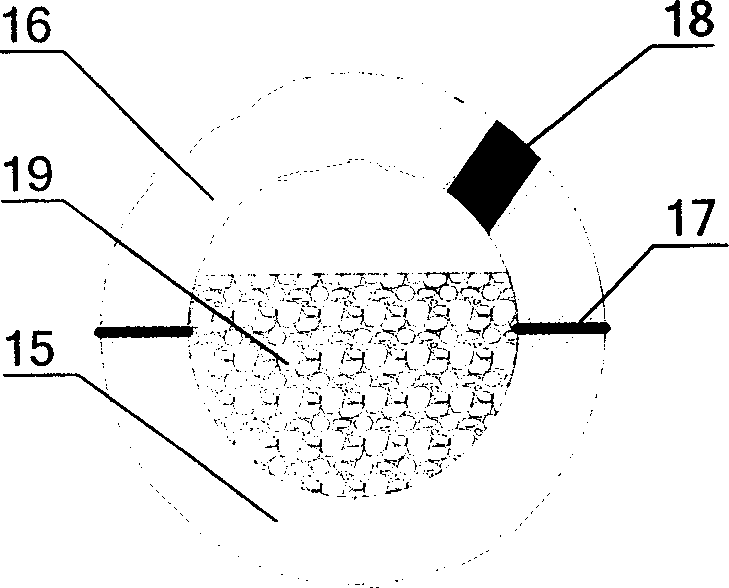

A method and apparatus for treating raw influent water to remove particles, algae and toxic chemicals from the water. Basically, air is dissolved in recirculated water under high pressure in an air contactor unit, the air saturated water is intimately mixed with the raw, particle bearing, water in a particle mixing system, and the water, particle and air mixture is passed through an air bubble separator wherein bubbles formed when the pressure on air saturated water is reduced carry away toxic gases and particulate material. If desired for further cleaning the water can be sent through a second series of air contactor, particle mixer and air bubble separation, but with a gas comprising ozone to further remove suspended particles and non-volatile dissolved organic matter. In order to improve mixing of the particles and the air saturated water passing through tubes, preferably a pattern of dimples is formed on at least part of the interior wall of the tubes. Upon completion of the process the water is ready for use or for further filtration in a conventional filtration plant.

Owner:NEWPORT ENVIRONMENTAL +1

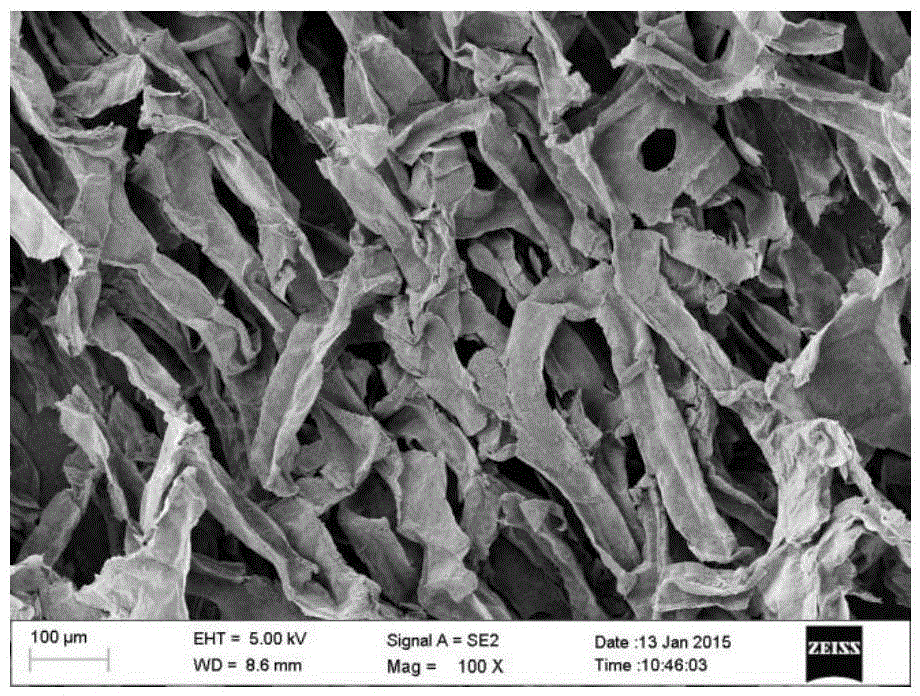

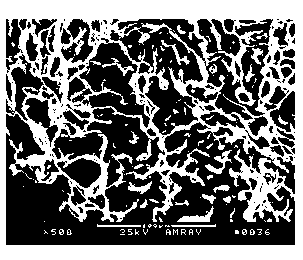

Preparation method of spongy graphene-based stretchable gas sensor

InactiveCN104807861APrecise control of growth temperatureDefect peak lowMaterial nanotechnologyMaterial resistanceElastic substrateGas phase

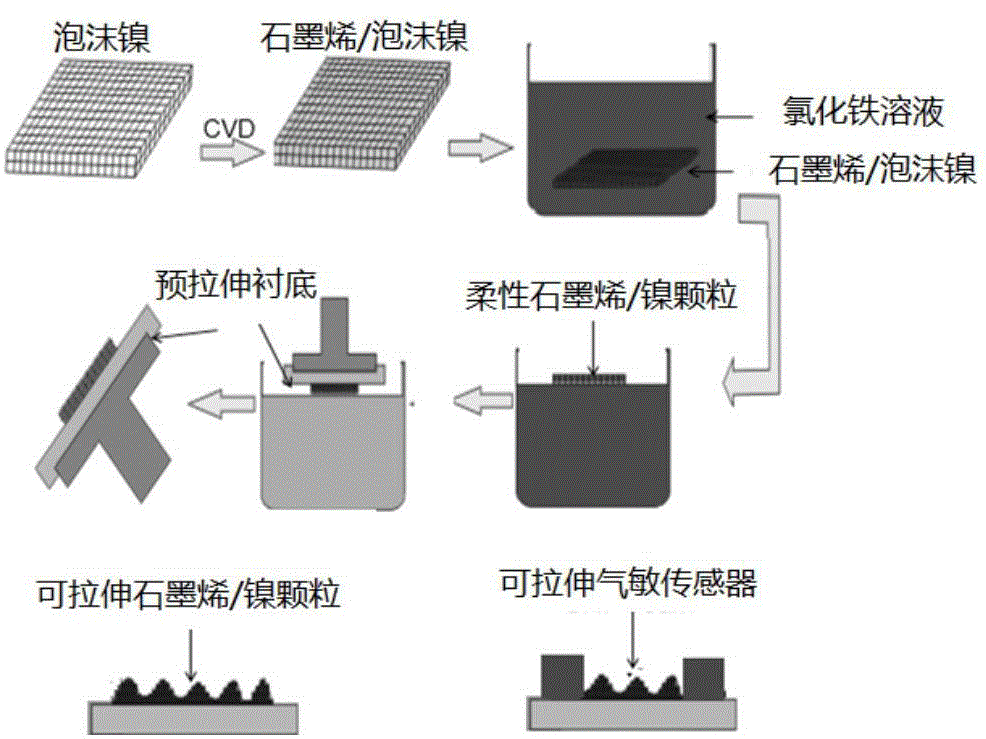

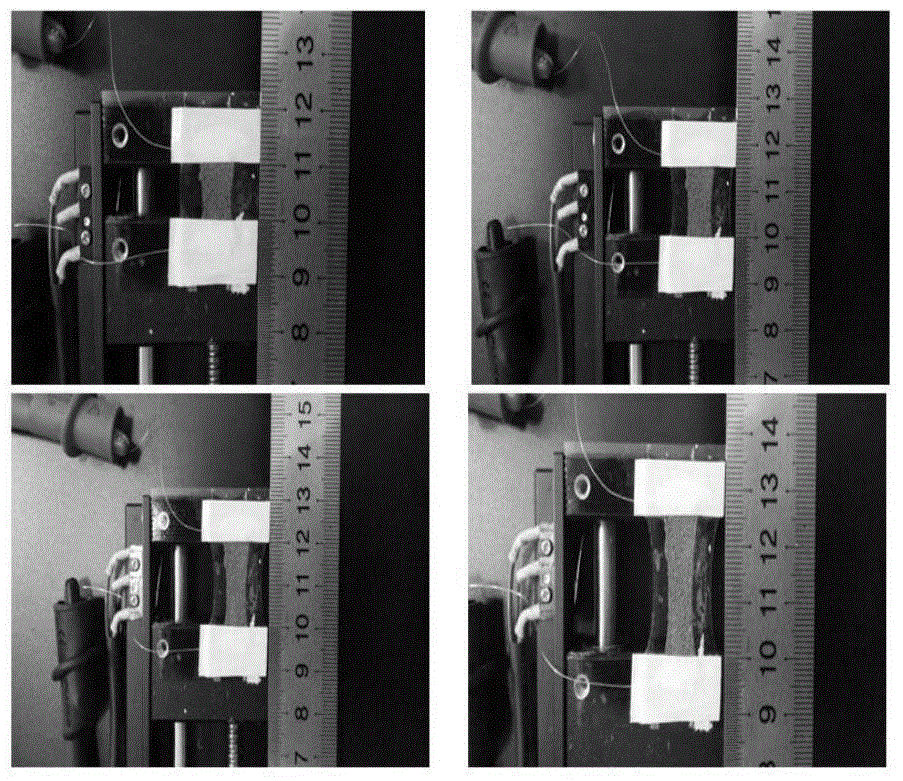

The invention relates to a preparation method of a spongy graphene-based stretchable gas sensor. Firstly, a spongy graphene material is prepared on nickel foam with a chemical vapor deposition method, the prepared graphene / nickel foam is immersed in an etching solution and slowly reacts, accordingly, most of nickel metal is replaced chemically, the nickel metal is turned into small nickel particles, a spongy graphene / nickel particle mixing structure is fished out of the etching solution with a seal type fishing method and then is cleaned and dried, a prestretching elastic substrate is slowly recovered to the original length or area, electrodes are prepared at two ends of the graphene / nickel particle mixing structure, and the stretchable gas sensor is obtained. The gas sensor has high conductivity and good gas sensitive characteristic, is low in cost and controllable and can realize large-area growth.

Owner:SHANDONG NORMAL UNIV

Nanoscale/micron size particle mixing type lead-free solder paste with size effect and manufacturing method thereof

ActiveCN103639614ARetain low melting point propertiesIncrease the proportionTransportation and packagingWelding/cutting media/materialsHybrid typeSolder paste

The invention provides nanoscale / micron size particle mixing type lead-free solder paste with a size effect and a manufacturing method thereof. The method comprises the following steps that nanoscale solder is slowly added into solder flux or a solder agent, after mechanical mixing, ultrasonic oscillation is lead in, mixing is continued, then the ultrasonic oscillation is stopped, micron size solder / flux is slowly added, and the mixed type solder paste which is uniformly mixed is obtained through continuously mixing. The manufacturing method has the advantages that process of the method is simple and feasible, the large size micron size solder is added in the nanoscale solder paste, the proportion of metal components in the solder paste is improved, and the low-melting-point property of nanometer brazing filler metal is maintained; mellow and full solder dots are formed at the low reflow soldering temperature; the obtained solder dots are polycrystal solder dots, and the grain sizes in the solder dots can be changed by adjusting the size distribution of micron size nanoscale solder, so that advance failure of the solder dots is avoided.

Owner:马鑫 +4

Aerosol Particle Analyzer for Measuring the Amount of Analyte in Airborne Particles

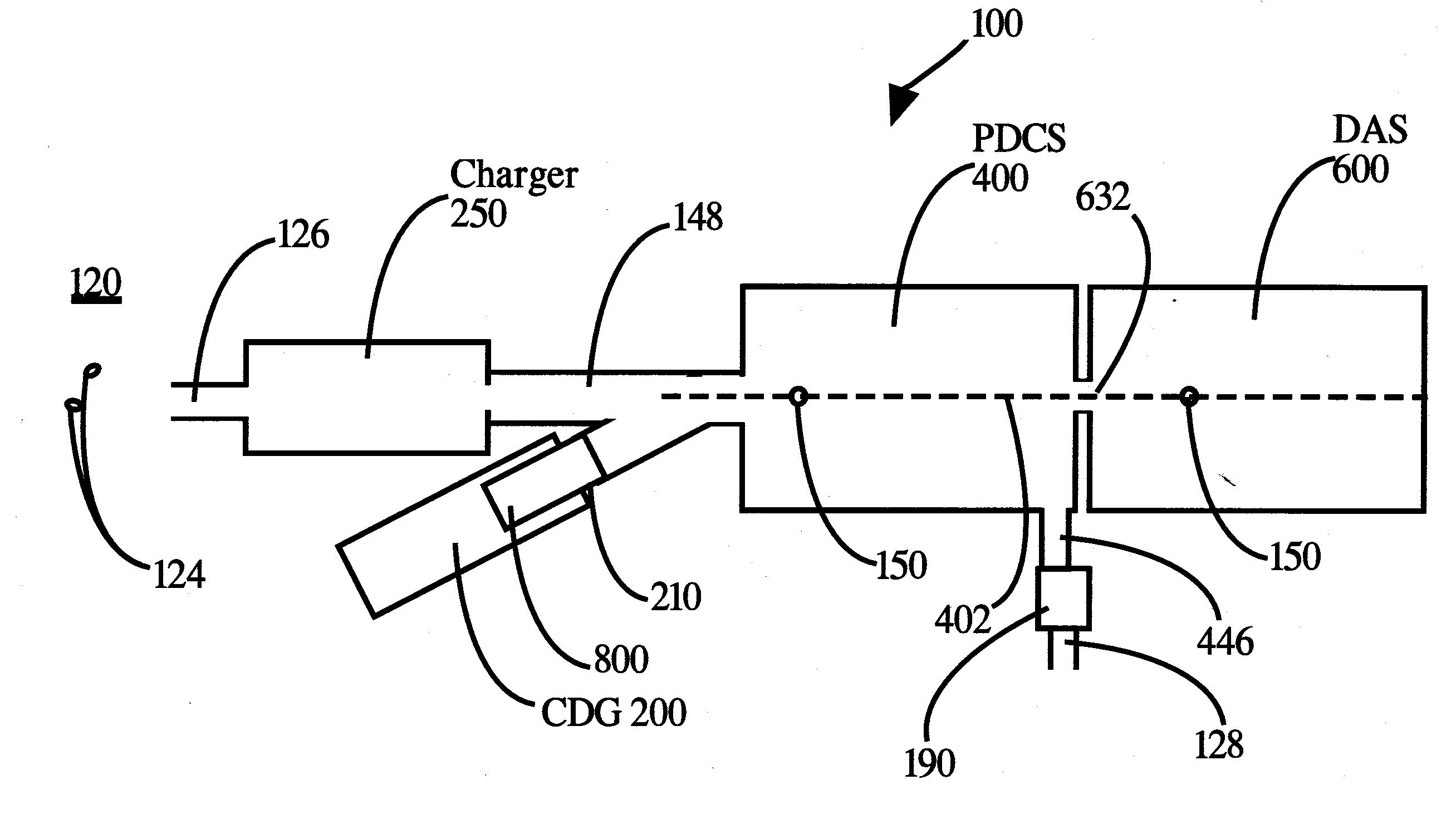

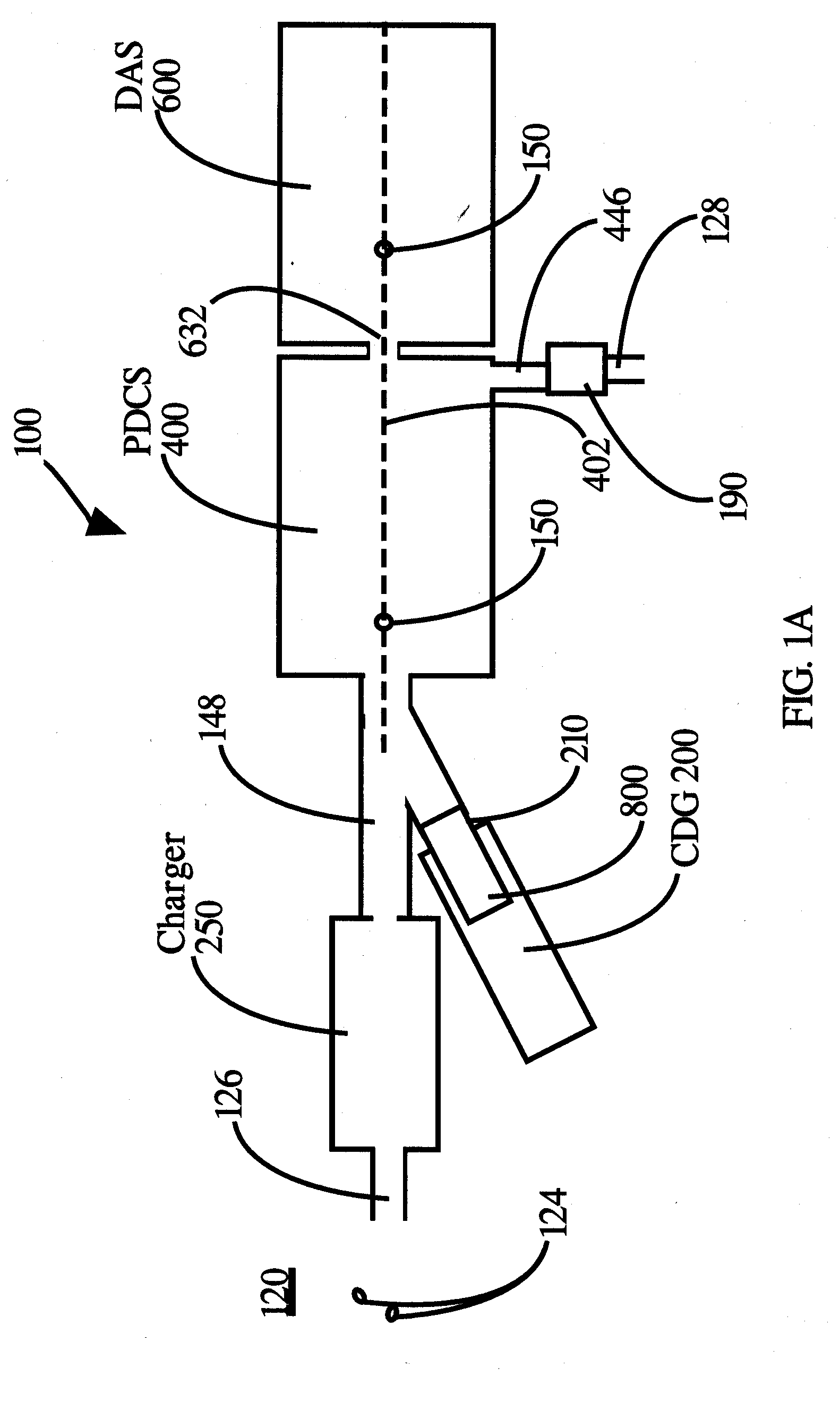

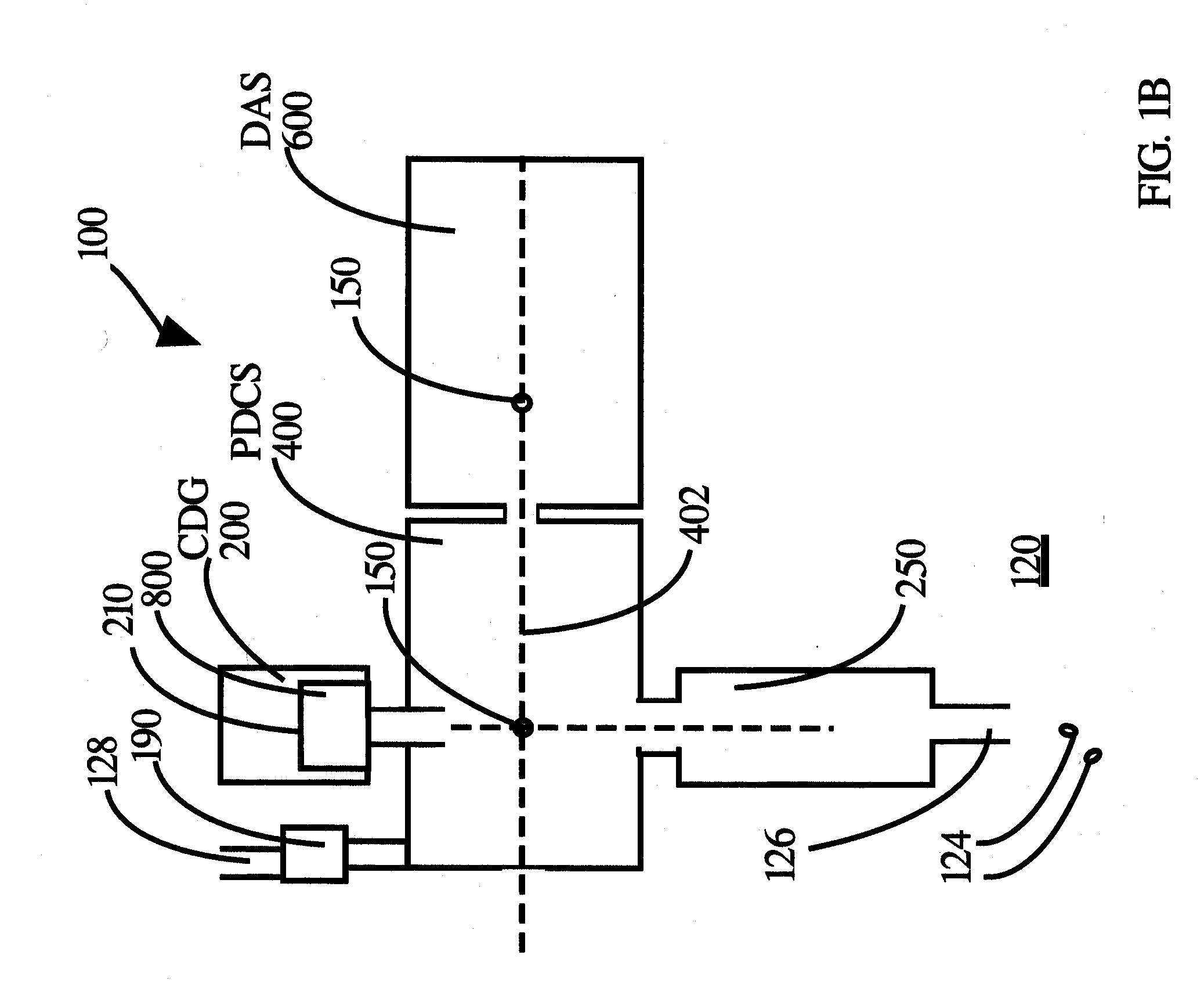

InactiveUS20050179893A1Rapid responseEfficient collectionOptical radiation measurementBioreactor/fermenter combinationsSuspended particlesAnalyte

Aerosol particle analyzer (APA) for measuring the amount of analyte in airborne particle is described. The APA uses an analysis liquid. When this analysis liquid is mixed with the particles, an optical property of the analysis liquid (CDAL) varies according to the amount of the analyte in the particles. A charged droplet of the analysis liquid is levitated. Airborne particles are drawn into the instrument and given a charge that is opposite that of the CDAL, and made to flow near the CDAL so that electrostatic forces greatly increase the probability that the CDAL and charged particles will combine. Then the CDAL is ejected into a horizontally oriented linear quadrupole that is in an airtight container, except for a small orifice to let the CDAL enter. The CDAL is levitated in a high humidity environment so that it evaporates slowly, so that there is time for the reaction between the analyte, if any, and the CDAL can take place, and so that the optical property, typically fluorescence, can be measured. The amount of the analyte in the particle is determined from the measured fluorescence or other optical property.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

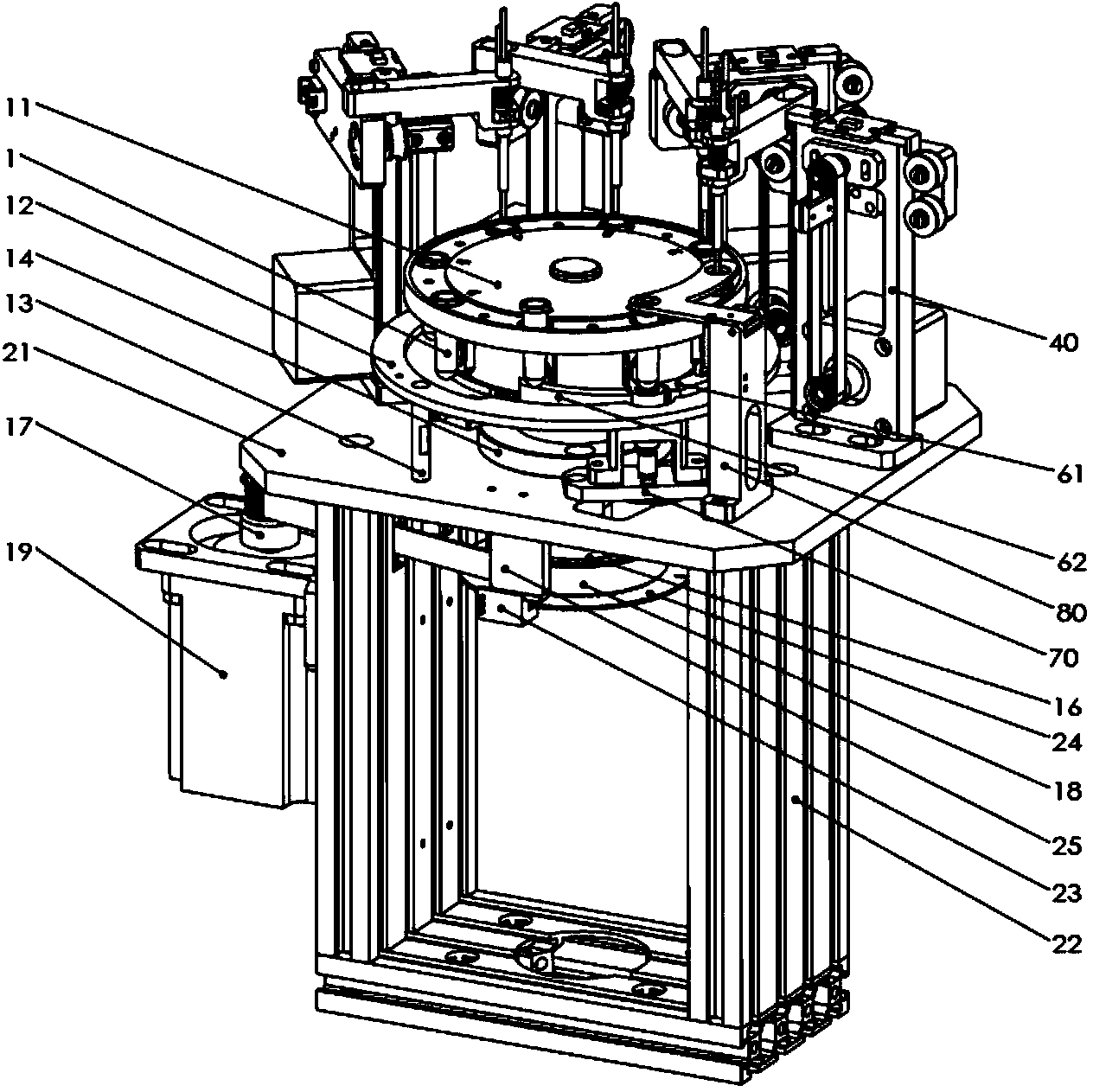

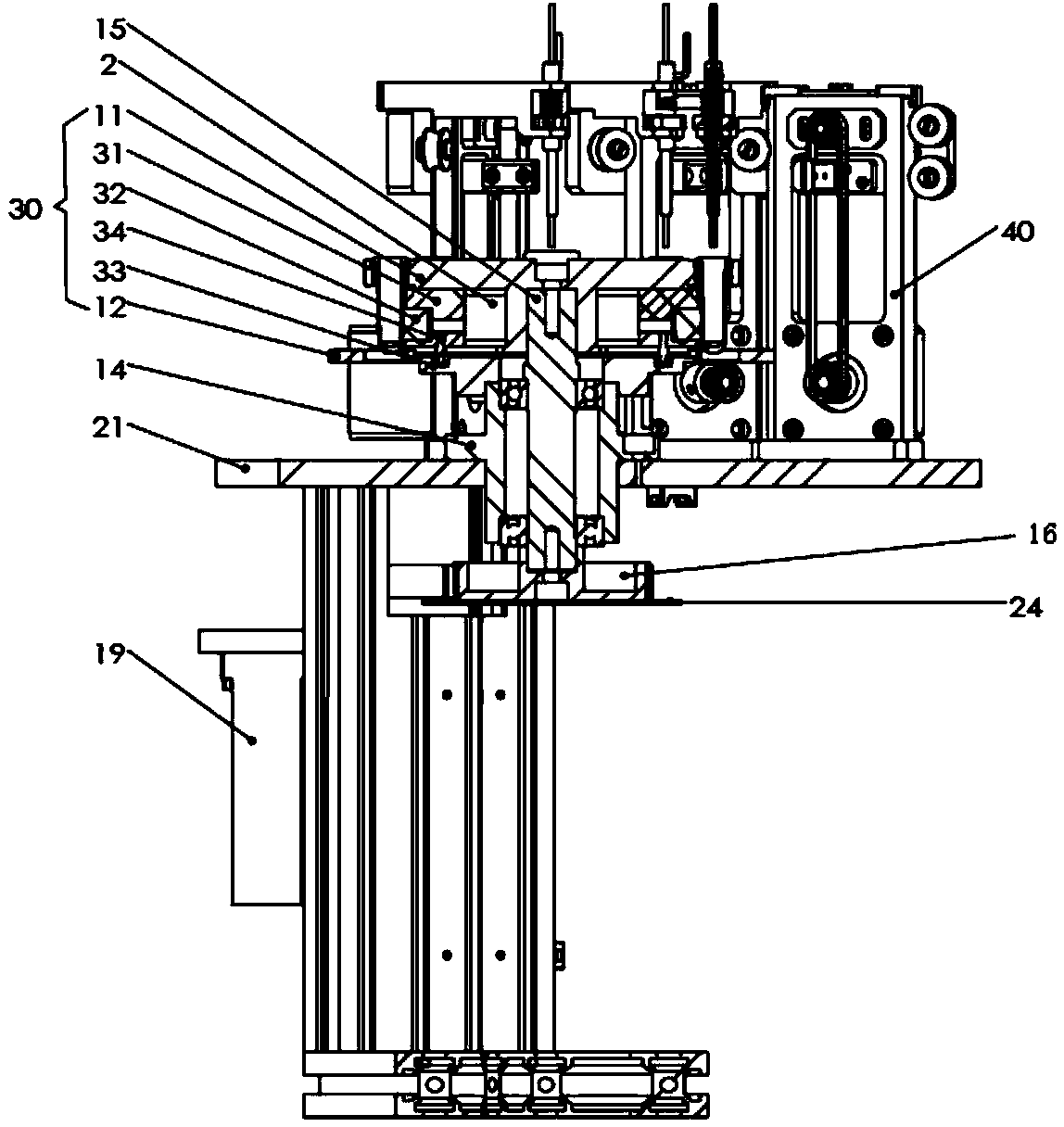

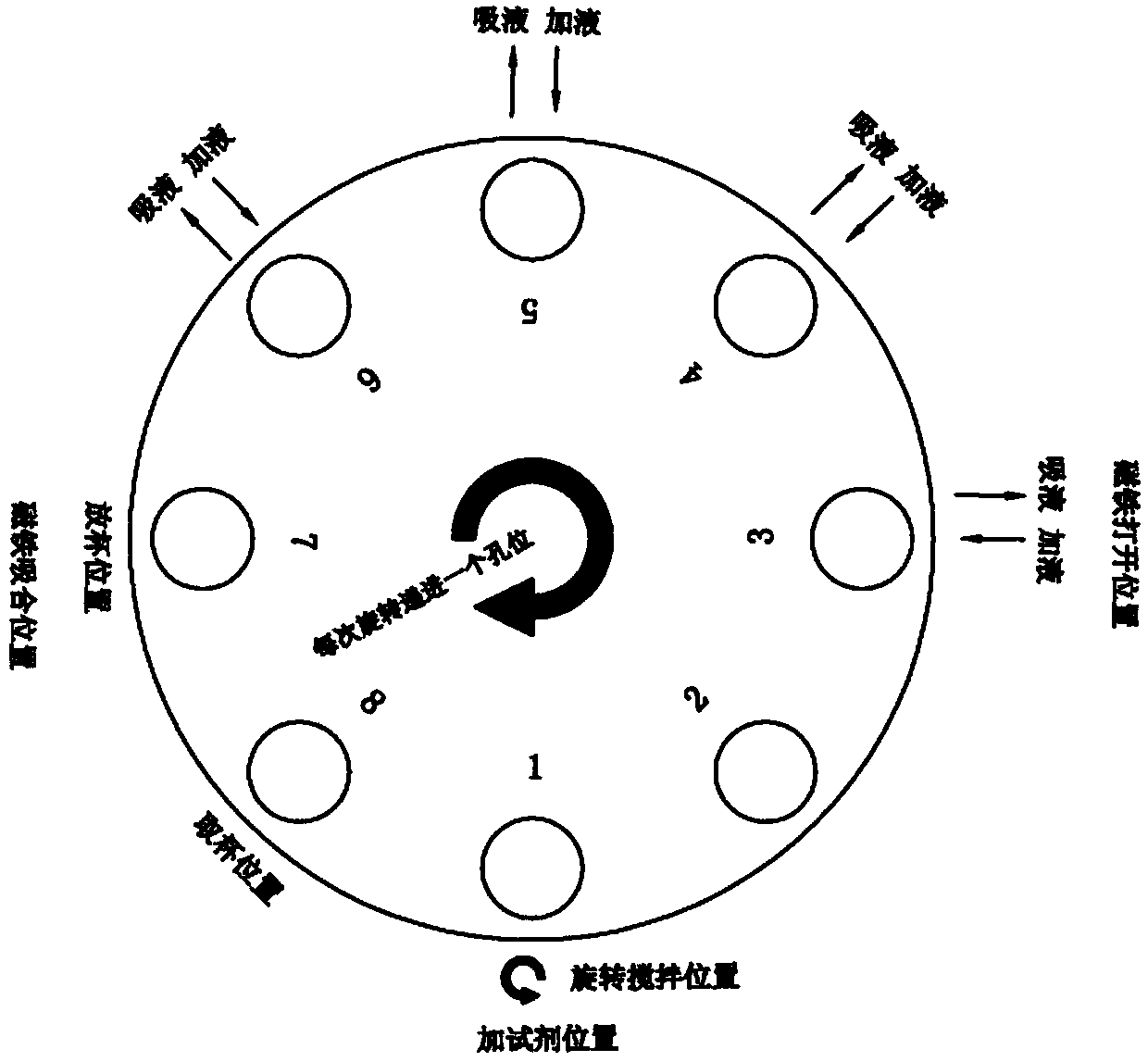

Novel magnetic separation mechanism

ActiveCN104297039ACompact structureSmall footprintPreparing sample for investigationMagnetic beadEngineering

Owner:TECH GENETICS LLC

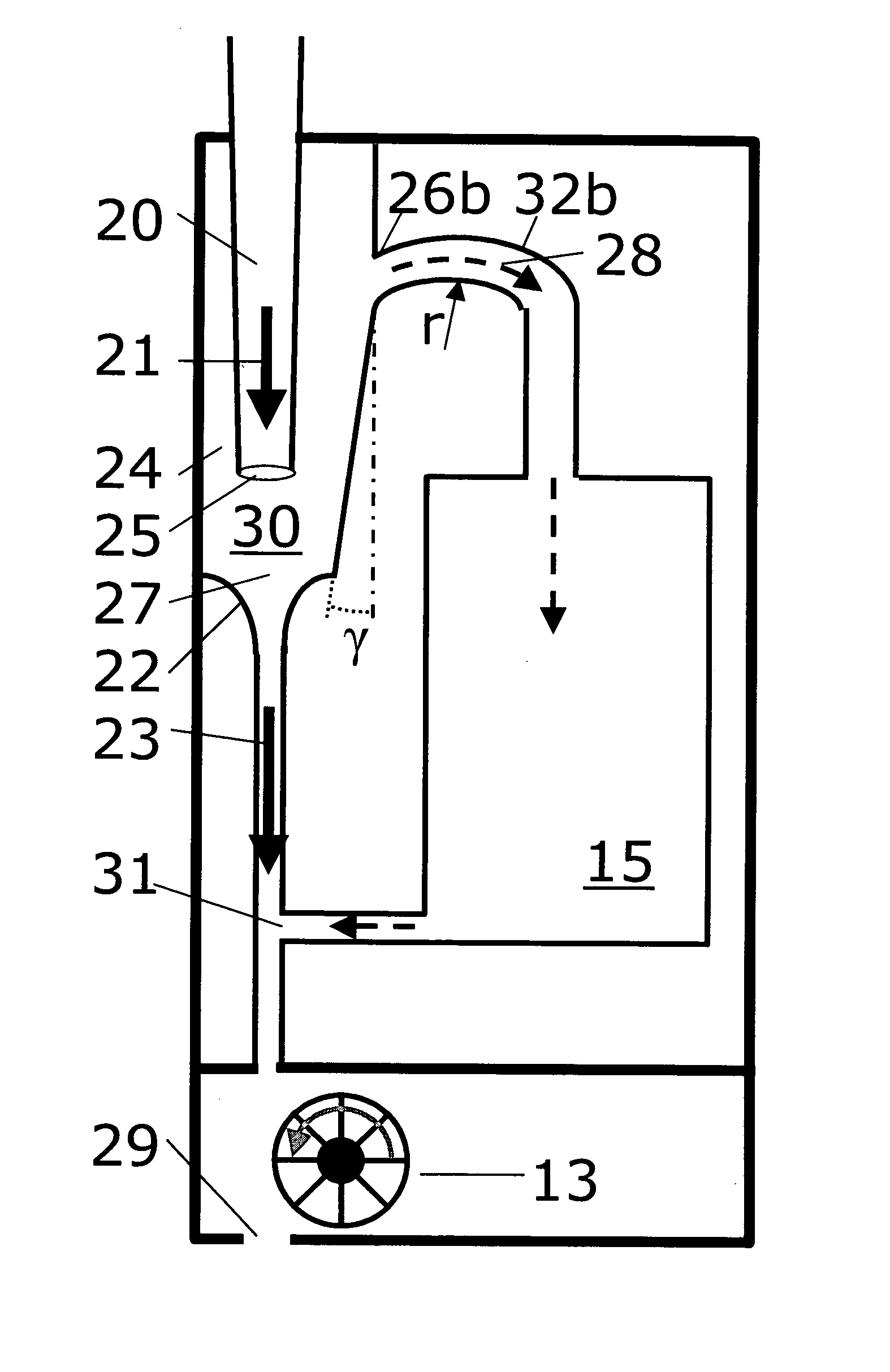

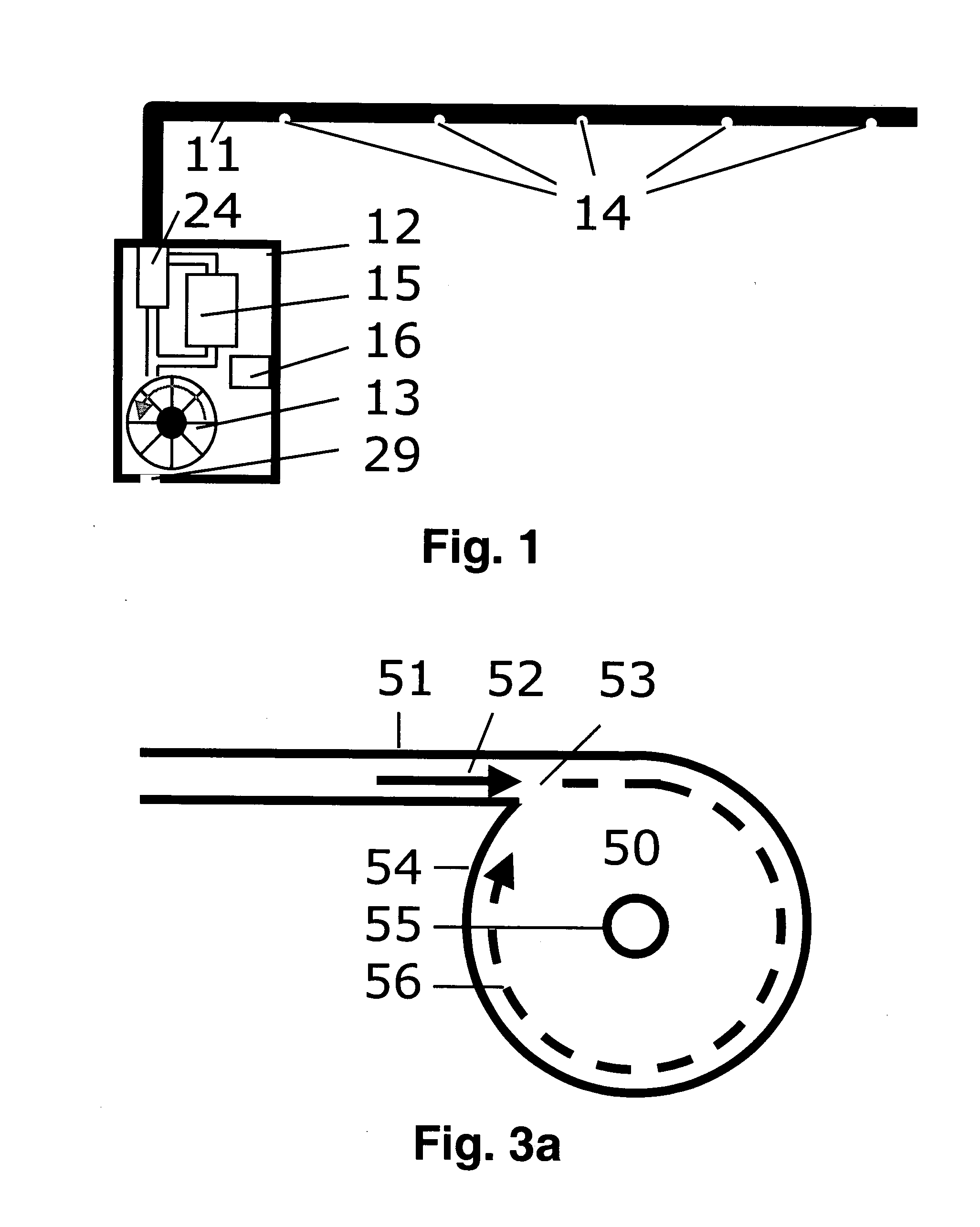

Analysis methods and devices for fluids

InactiveUS20110314902A1Lesser impairmentReduce the required powerWithdrawing sample devicesParticle suspension analysisParticle propertiesAnalysis method

The invention relates to novel methods and to devices for a measuring and analysis apparatus that measures impurities and / or particles in a gas or air. In a particle separation step, target particles having predetermined particle properties are separated from remaining particles from a gas or gas mixture such as air or a liquid, in short a fluid, that contains a particle mixture, and the occurrence and / or frequency of said target particles is determined in a measuring chamber. The likewise novel cooling of the radiation sources required for measurement permits the use of such having high power, as is required for measuring few particles or the smallest impurities. A further novel expansion of the electrical measurement range allows small but also abundant particles and impurities to be measured. In addition, a novel interface simplifies the start-up of the apparatus.

Owner:MAXDE TEC

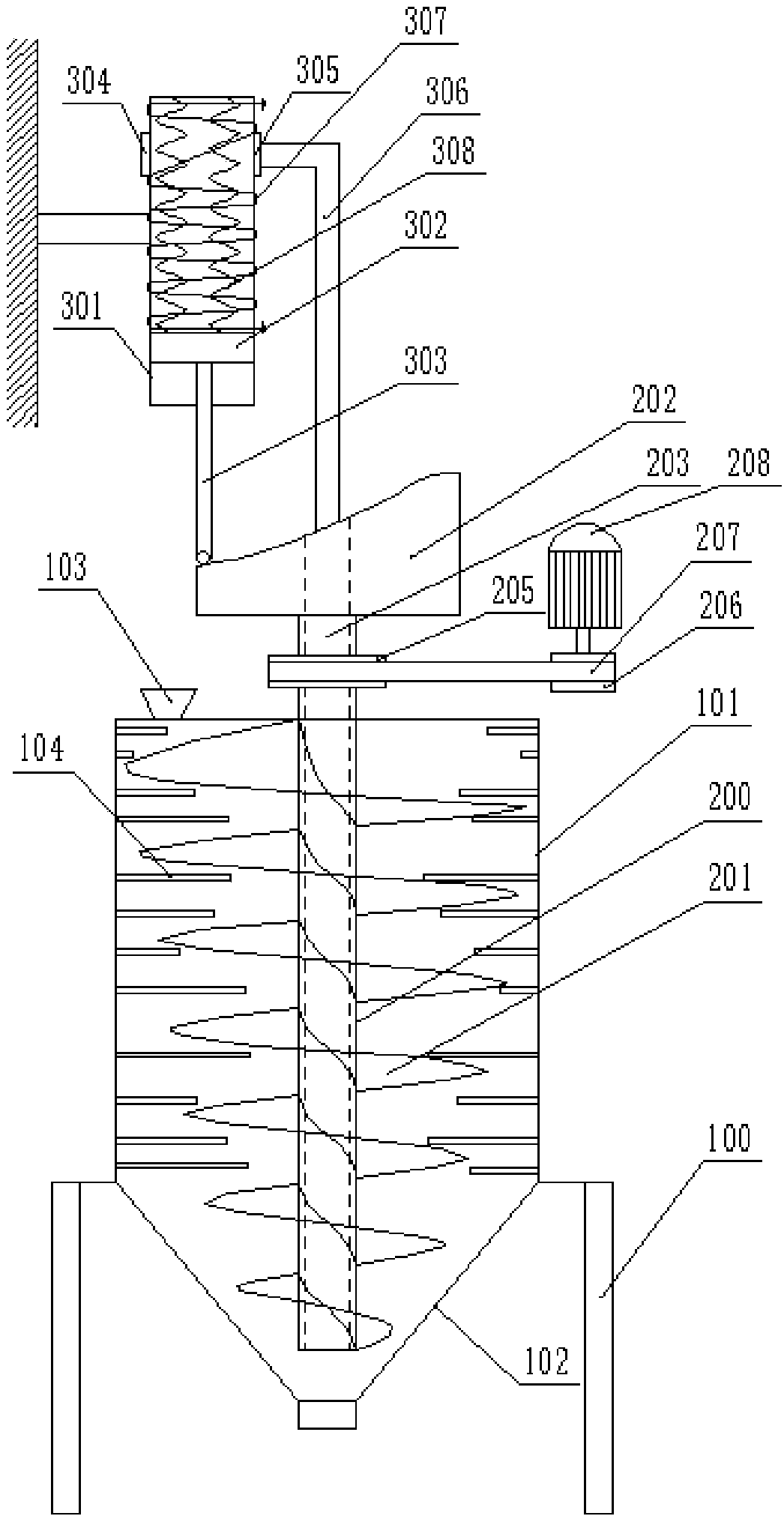

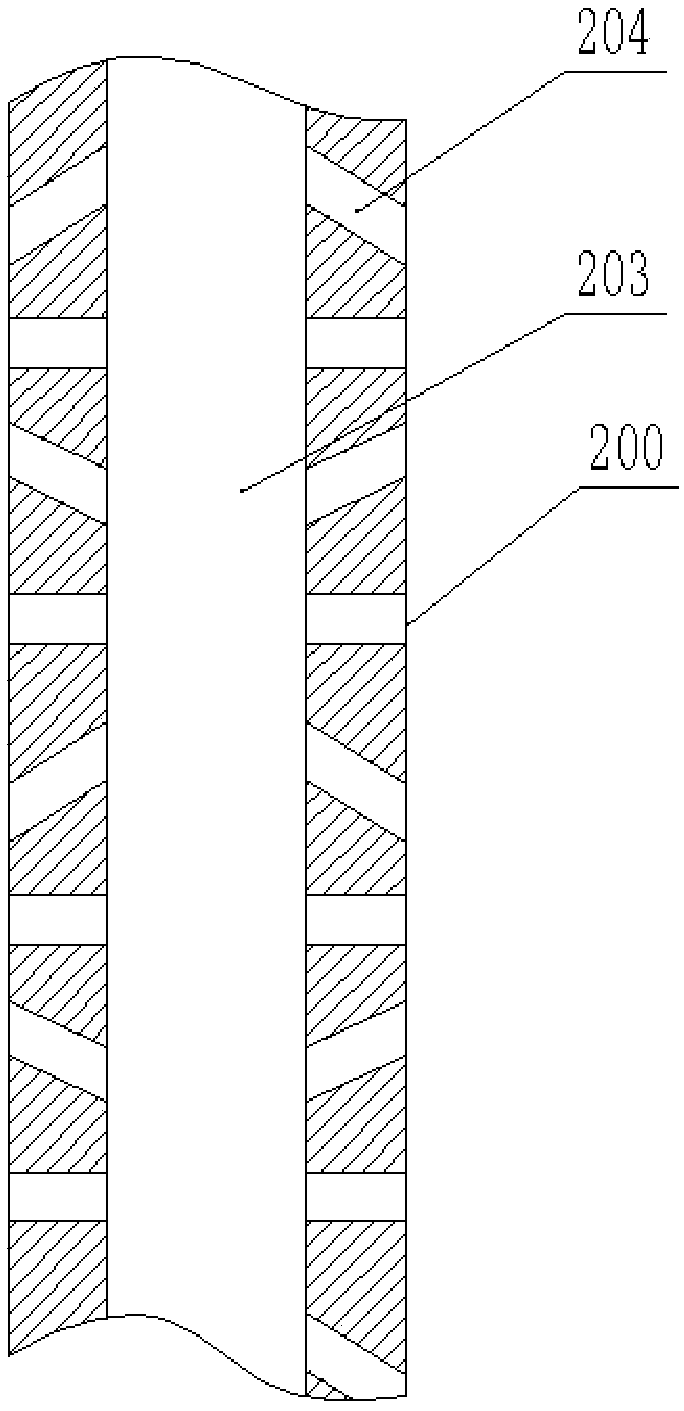

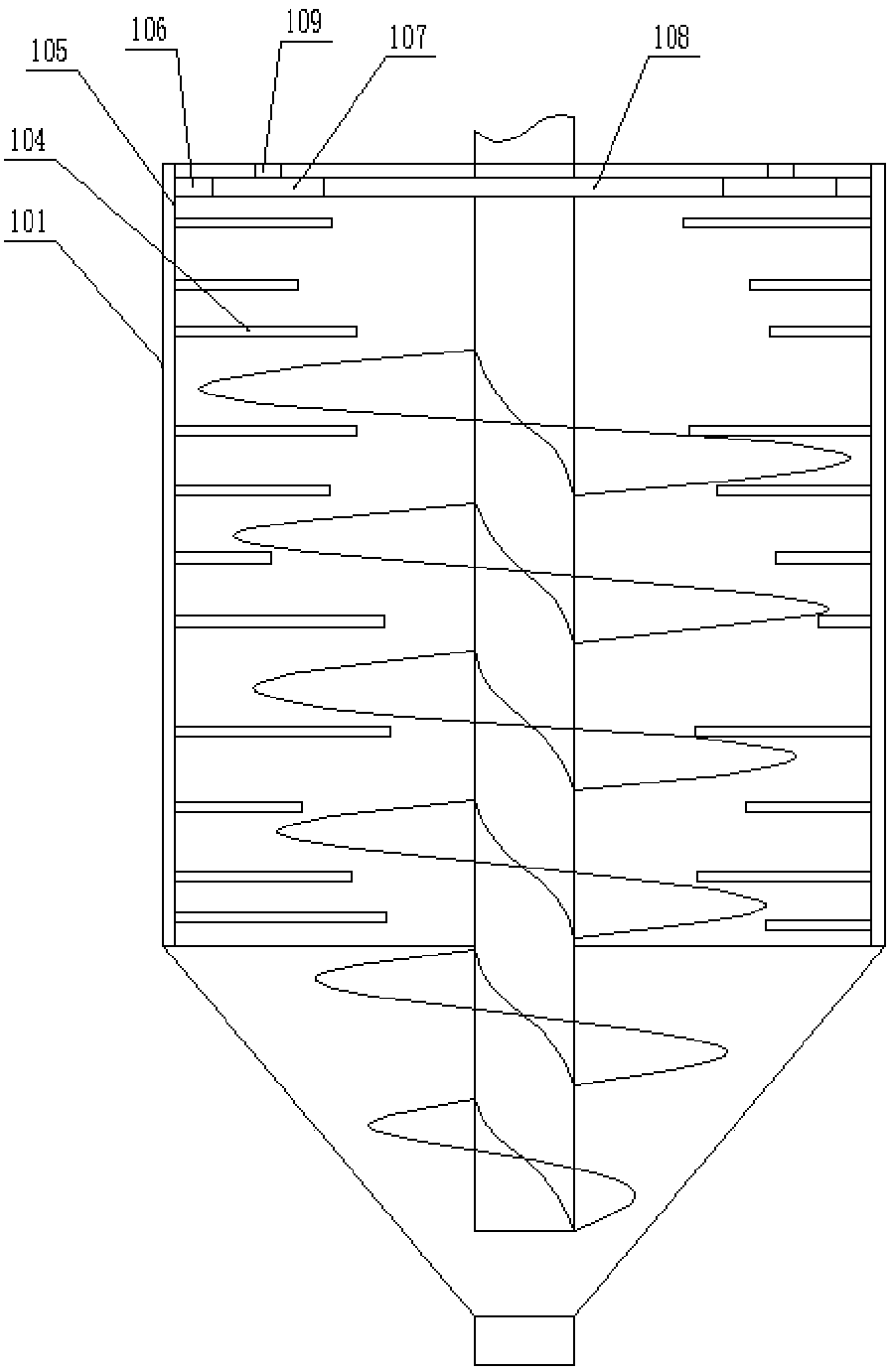

Gas-solid fluidized coupling equipment and coupling method for particle mixing-classifying by utilizing same

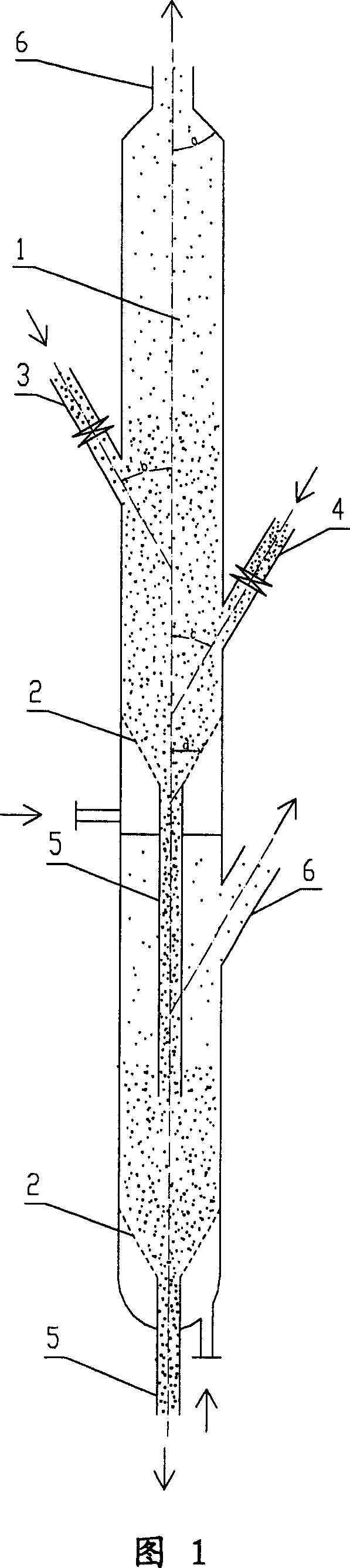

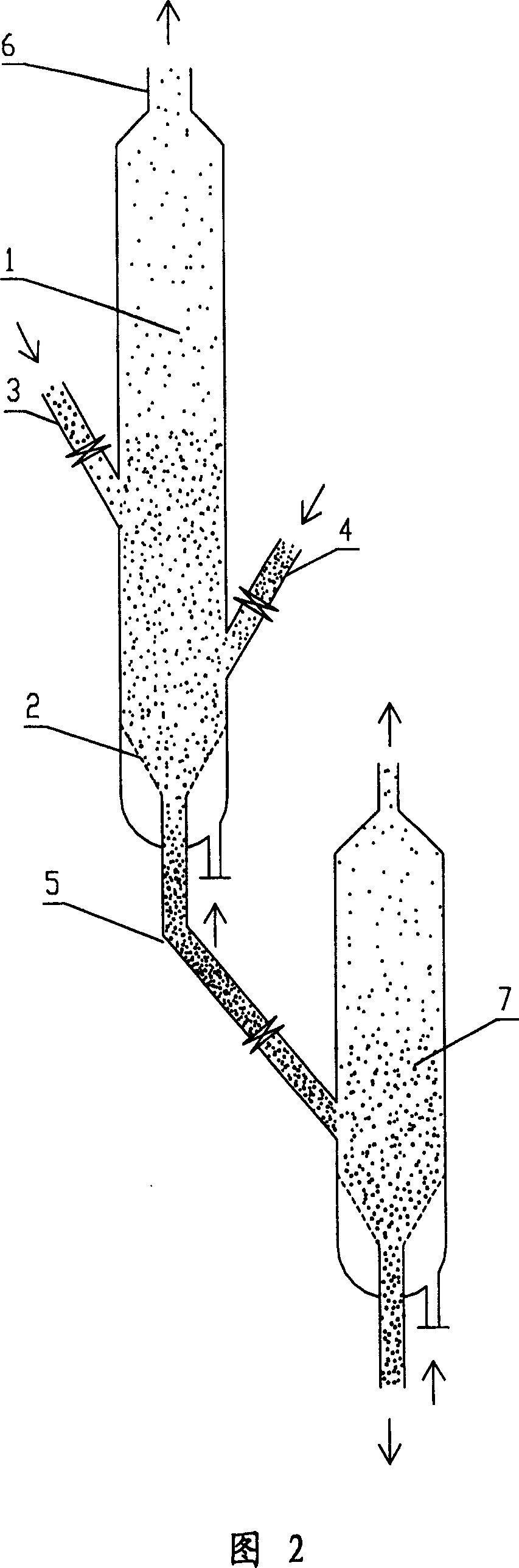

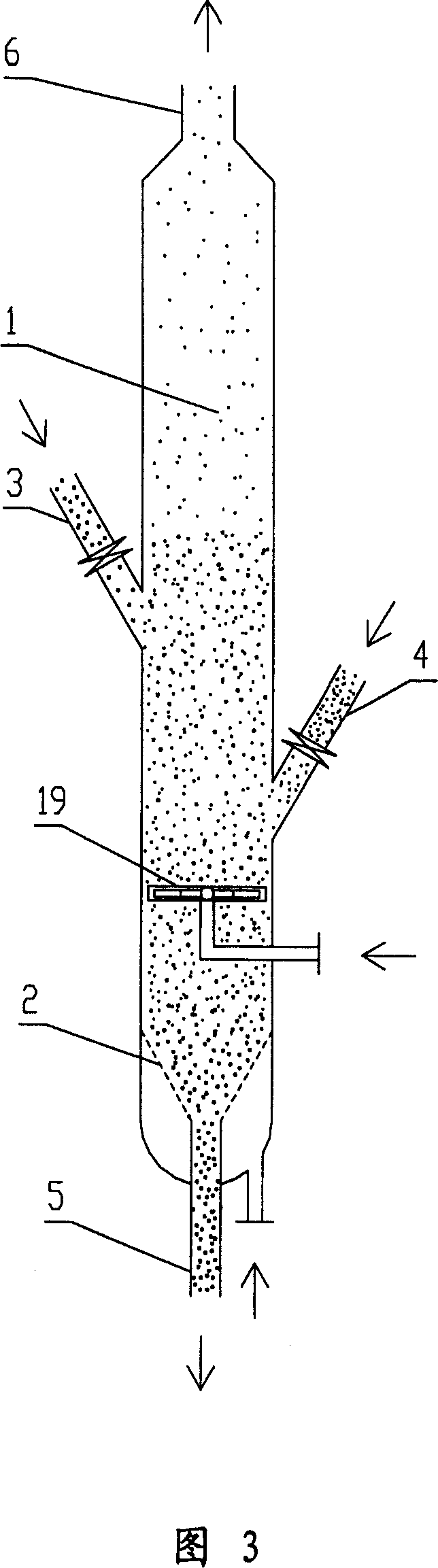

ActiveCN1935349AFully contactedImprove classification efficiencyChemical/physical processesGas solidCoupling

The present invention provides a gas-solids fluidization coupling equipment. It at least includes an one-stage gas-solids fluidized bed body, said fluidized bed body is a vertically-placed cylinder body. Said invention also provides the concrete structure of said gas-solids fluidized bed body. Besides, said invention also provides a coupling method capable of utilizing said equipment to implement multistage mixing, heat exchange, reaction and classification of granules with large difference.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Preparation method for ink-jet graphene and carbon nano tube conductive ink

InactiveCN104212242AReduce production processSimple manufacturing processInksCarbon nanotubeGraphite

The invention discloses a preparation method for ink-jet graphene and carbon nano tube conductive ink. The preparation method comprises the following steps: preparation of a graphite and carbon nano tube mixed dispersion liquid and mixing of ink, wherein the preparation of the graphite and carbon nano tube mixed dispersion liquid comprises the processes of ball-milling, initial separating, washing, separating and collecting. According to the preparation method, particle mixing, dispersing and particle dimension separating in the preparation of graphene and ink are organically combined, so that the preparation processes of the conductive ink are effectively reduced; and the process for preparing the graphene by selecting effective auxiliaries by use of a ball-milling method can be used for large-scale preparation, is simpler in comparison with the oxidization-reduction which is in common use at present as well as a CVD (chemical vapor deposition) method, efficient, and low in cost. After the ball-milling and separating processes, the particle dimension is controlled, so that fine filtration is not needed, and thus, the preparation process for the ink-jet conductive ink is continuously simplified.

Owner:李娟 +1

Nickel micro powder and manufacturing method thereof

ActiveCN102189252AHigh purityHigh crystallinityFixed capacitor electrodesFinal product manufactureProduct gasCrystallinity

An aim of the invention is to provide a nickel micro powder which is spherical and has excellent crystallinity and oversize particle mixing ratio that is greatly reduced than that of the prior-art product. The manufacturing method of the nickel micro powder comprises the following steps: raw material preparing step of preparing a nickel raw material through a mode that the sulfur content is 0.1-0.5% by mass; a micronizing step of gasifying the nickel raw material through hot plasma in a reducing gas environment for condensing the nickel steam and micronizing; an oversize particle removing step of continuously guiding the obtained micronized nickel into a water cooling jacket type cyclone separator for removing the oversize particles and cooling the micronized nickel; a recycling step of recycling the micronized nickel; and a slow oxidizing step of keeping the recycled micronized nickel in a weak oxidative non-active gas environment so the surface of the micronized nickel is slowly oxidized for obtaining the nickel micro powder.

Owner:SUMITOMO METAL MINING CO LTD

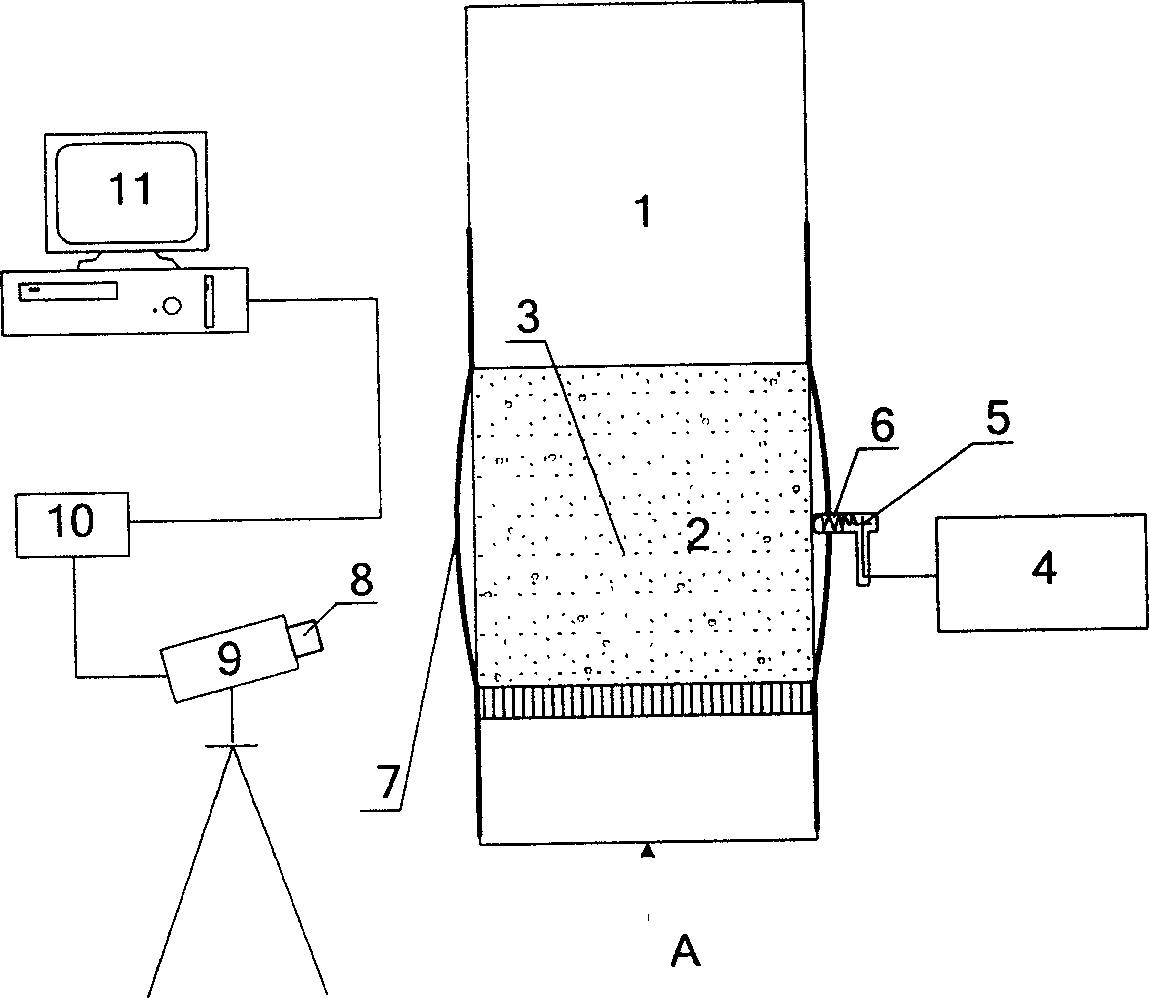

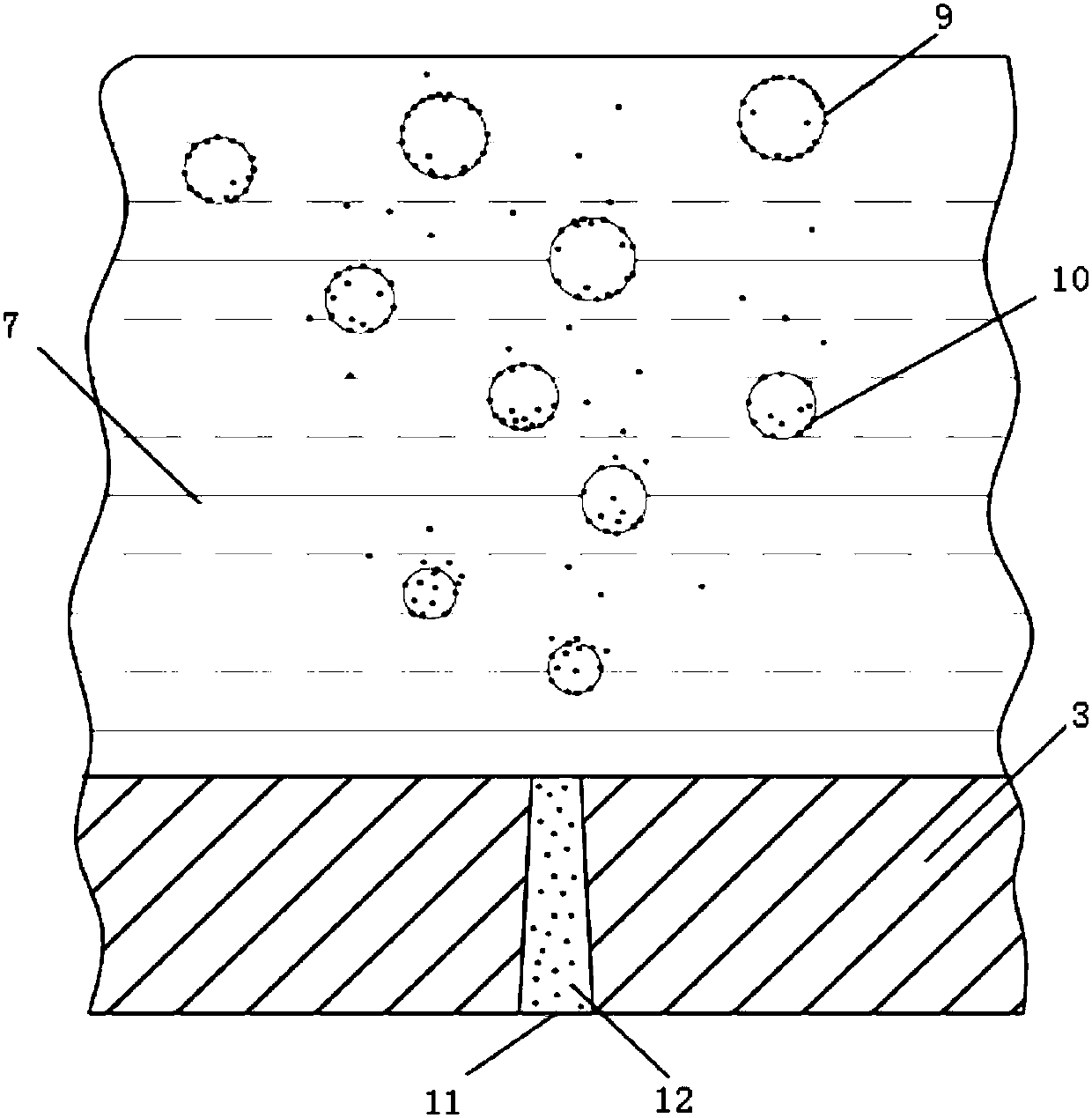

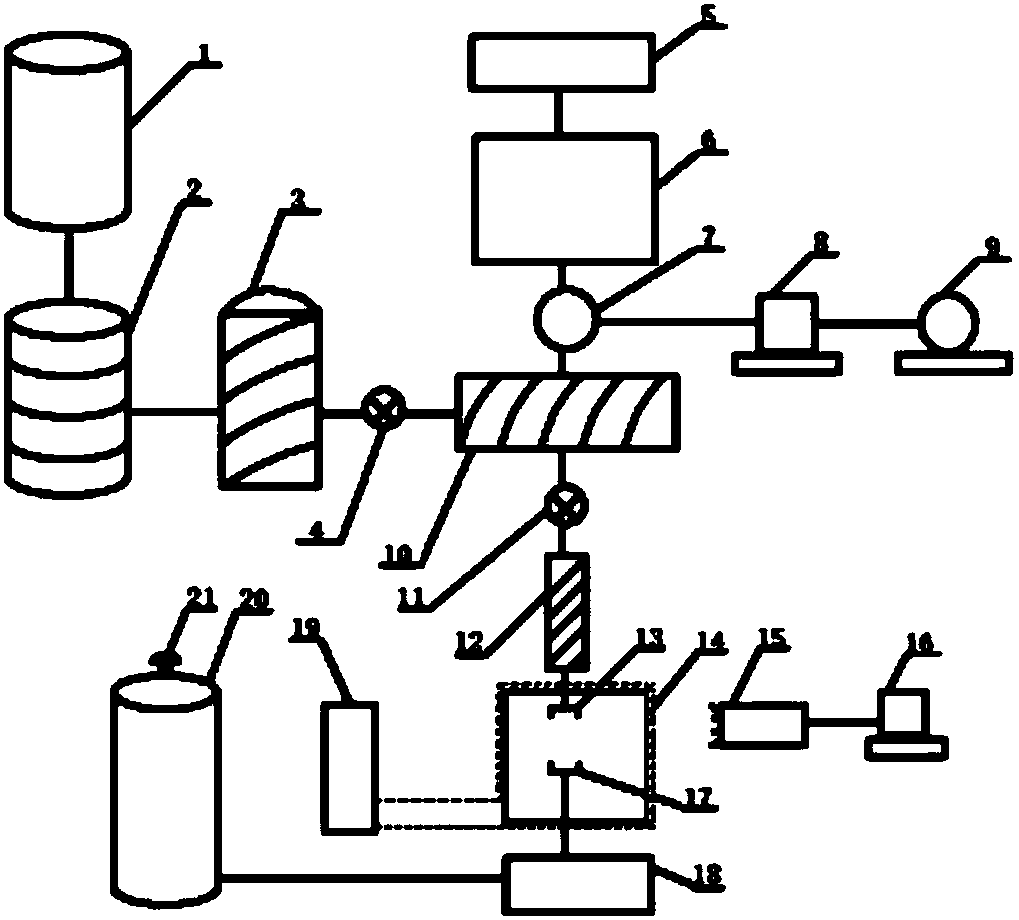

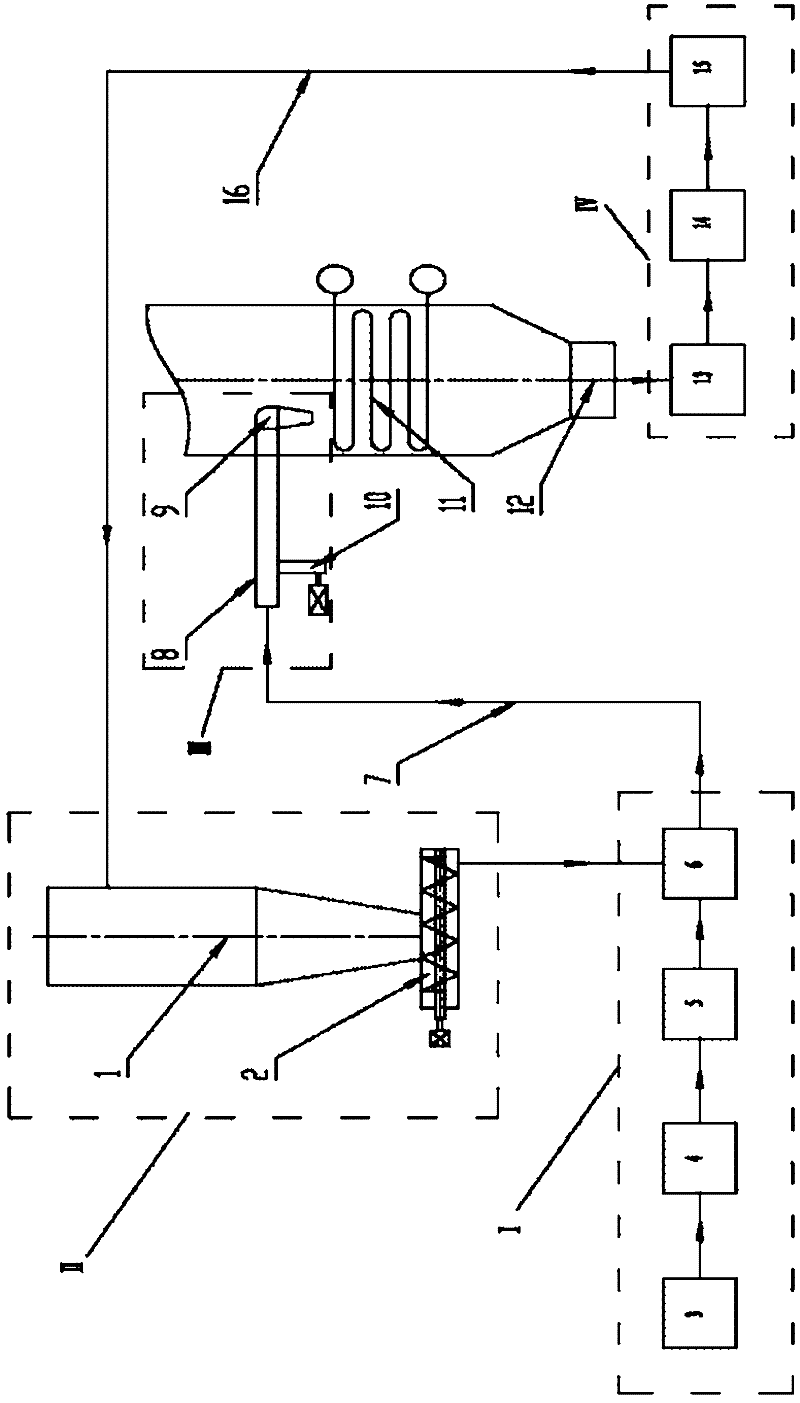

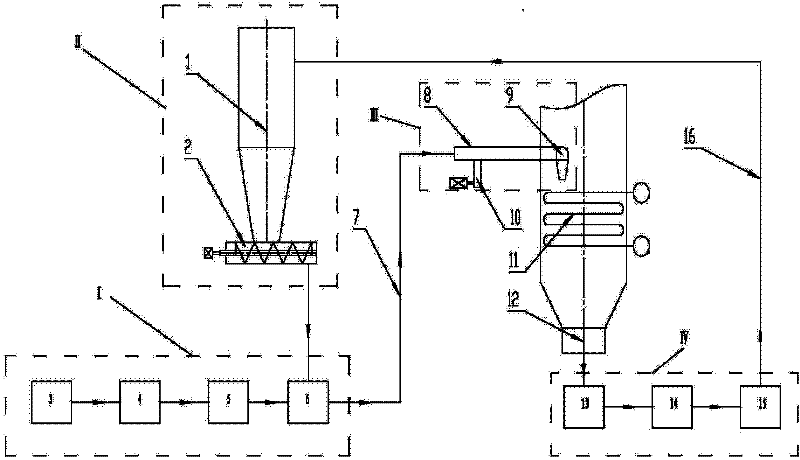

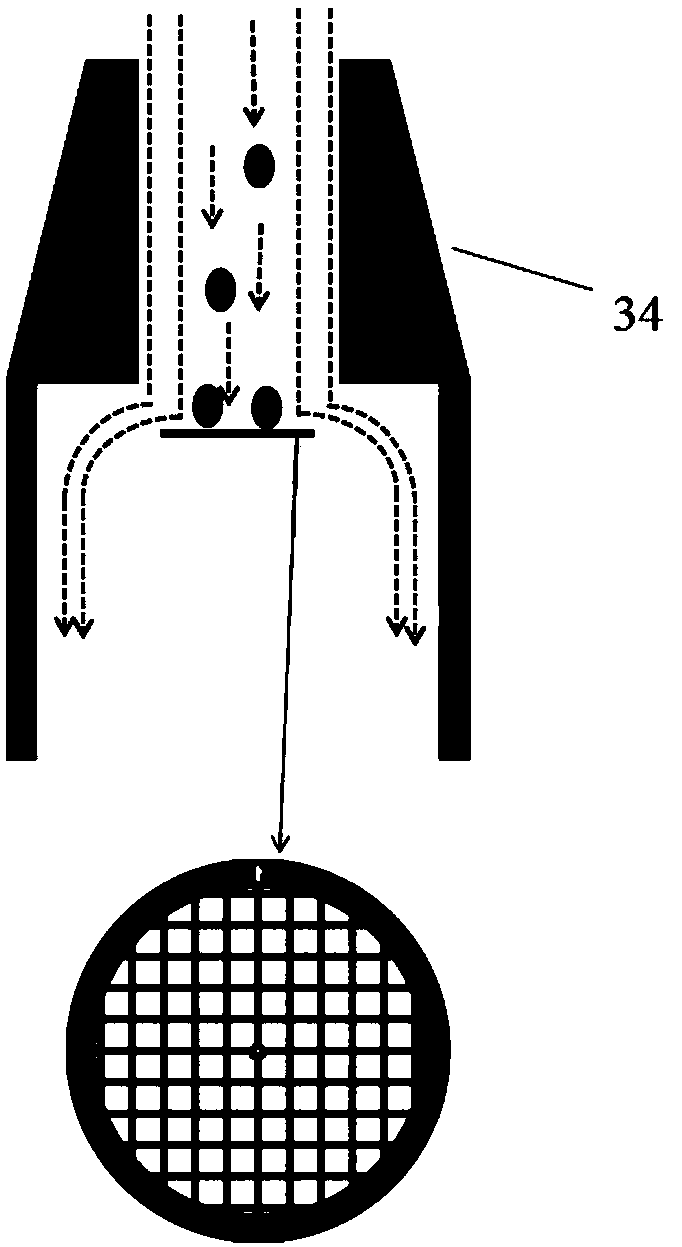

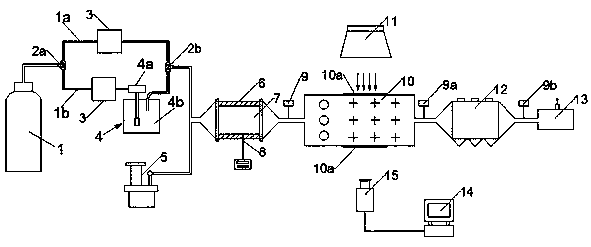

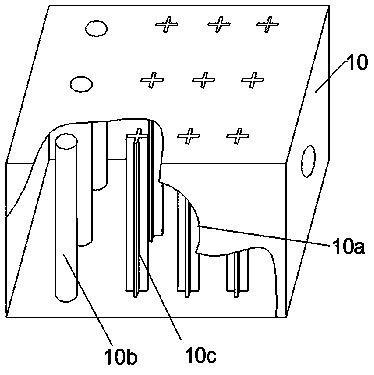

Measuring apparatus and measuring method for gas-solid fluidized bed particle mixing

InactiveCN1877294ADoes not interfere with gas-solid flowUniform microwave radiationHydrodynamic testingMaterial analysis using microwave meansGas solidFluidized bed

Disclosed are a device and a method for measuring air-solid fluidized bed particle mixture. The device comprises a microwave reflecting screen (7) set on the two sides of the fluidized bed (1); a microwave transmitting device is comprised with cascading the microwave generating device (4), a transmitting antenna (5) and a waveguide (6), wherein the waveguide (6) is installed in the middle of the microwave reflecting screen (7); a microwave receiving and processing device is comprised with an optical imaging object lens (8), a infrared probe (9), an amplifier (10) and a computer (11), wherein the optical imaging object lens (8) is locate on the other side of the fluidized bed (1) between two microwave reflecting screens (7). The method comprises that the microwave transmits to the fluidized bed layer via the guidance of the antenna and the waveguide; the tracking particles with polar H2O molecule are heated and employs the optical imaging object lens to receive the infrared radiation power distribution graph and reflect it to the infrared probe.

Owner:SOUTHEAST UNIV

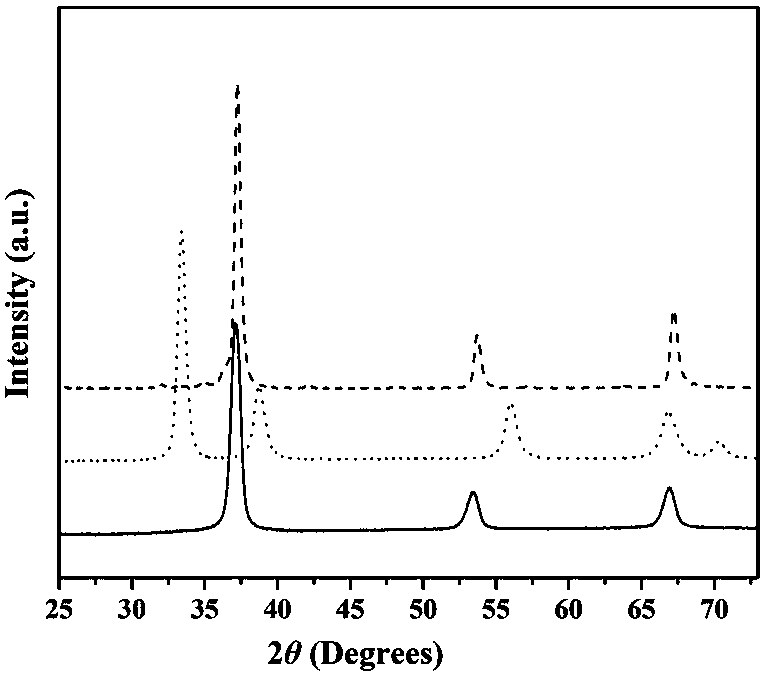

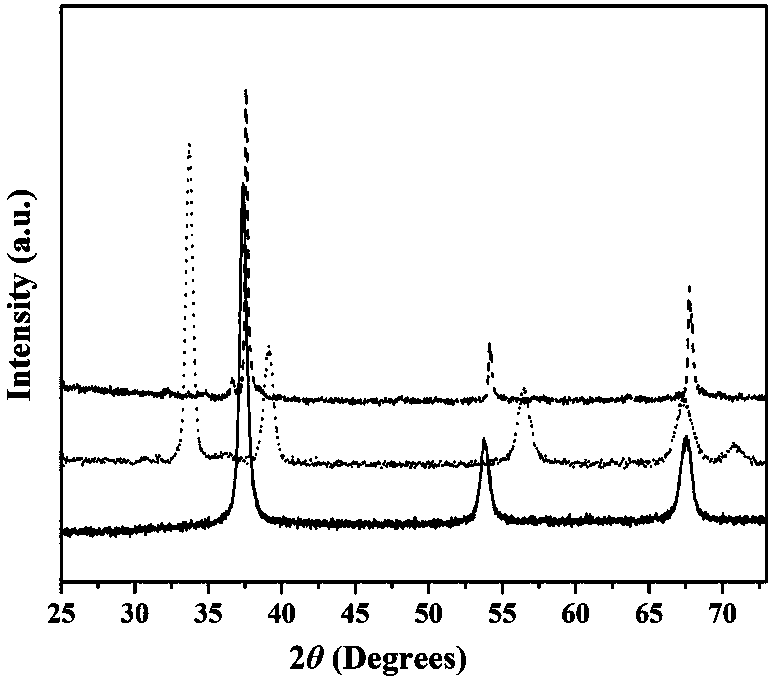

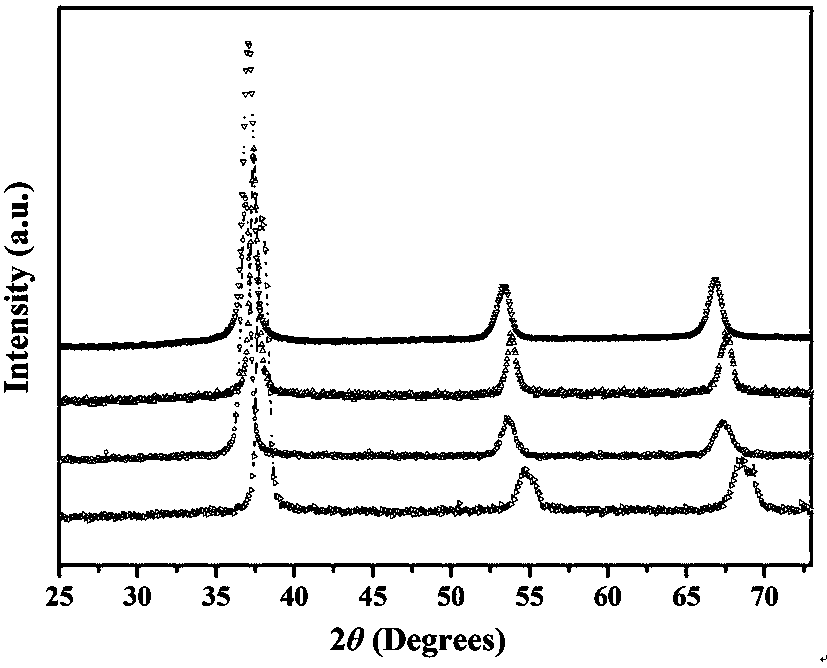

Single-phase reversible and oxidation-resistant hydrogen-storage high-entropy alloy and preparation method thereof

The invention discloses a single-phase reversible and oxidation-resistant hydrogen-storage high-entropy alloy and a preparation method thereof. A component expression of the high-entropy alloy is Ti0.2Zr0.2Hf0.2MoaNbb, wherein a is larger than or equal to 0 and smaller than or equal to 0.3, b is larger than or equal to 0.1 and smaller than or equal to 0.4, and the sum of a and b is equal to 4. Thepreparation method of the high-entropy alloy comprises the following steps of (1) raw material preparation, wherein various metal particles are weighed and prepared according to the atomic percent; (2) particle mixing, wherein the raw materials are screened and classified according to melting point characteristics of metals, and then the raw materials are mixed and put into a melting furnace crucible; and (3) alloy melting, wherein the metal particles are melted through a vacuum non-consumable arc-melting furnace. The high-entropy alloy has the advantages of being single in phase, single-phase reversible in phase before and after hydrogen absorption, high in oxidation resistance, high in speed for hydrogen absorbing and releasing and the like, and has a wide application prospect in the hydrogen energy field. According to the preparation method of the high-entropy alloy, preparation is conducted through the vacuum non-consumable arc-melting furnace, and therefore the preparation methodis simple, reliable, good in safety and high in economic value.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

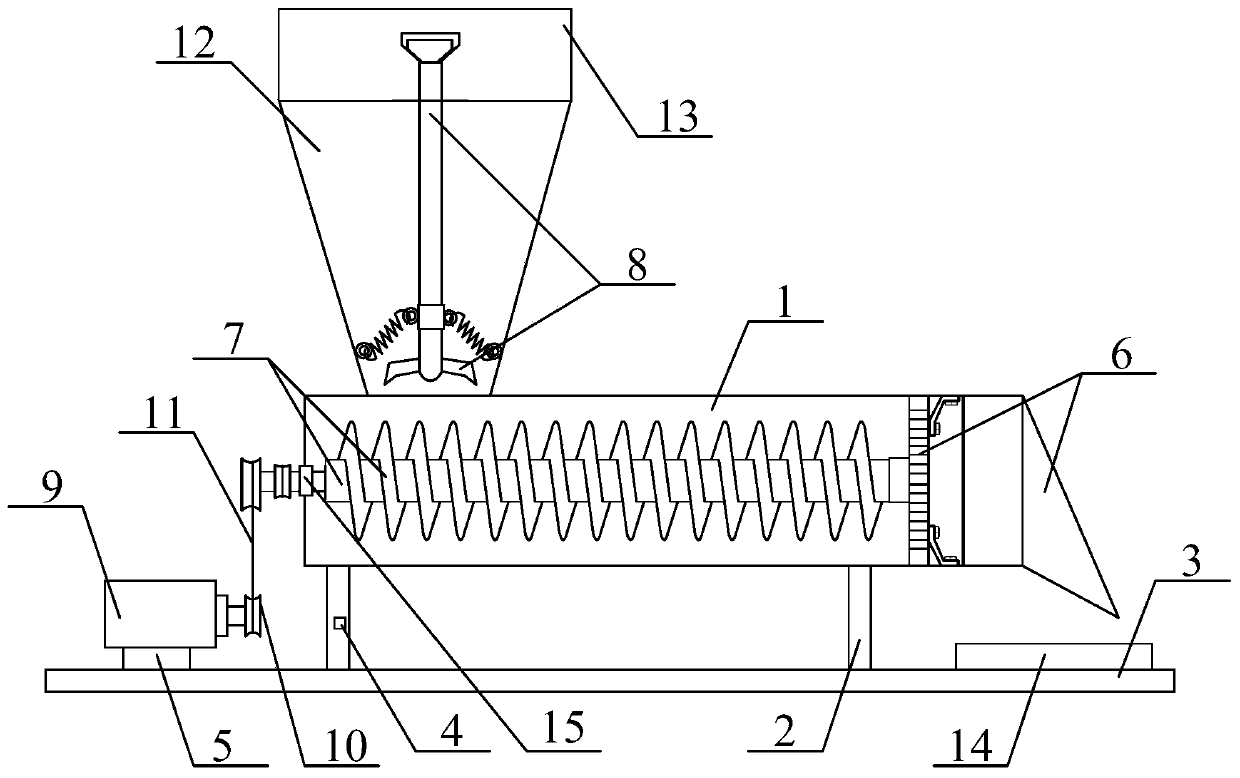

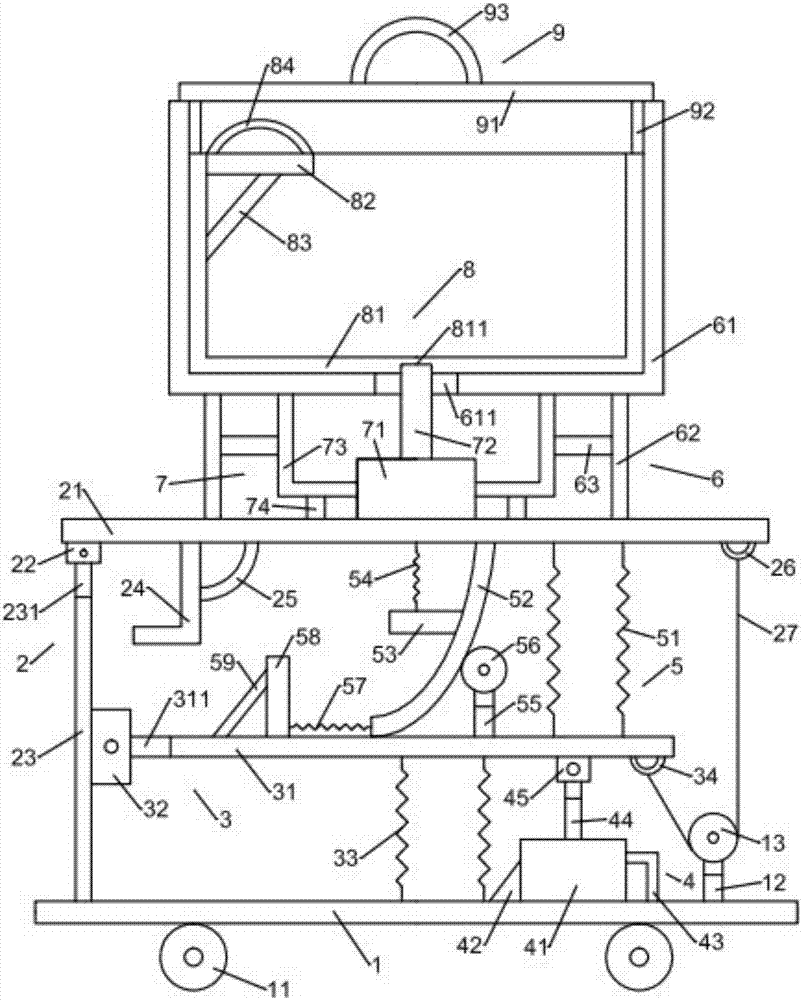

Plastic particle mixing dryer

InactiveCN108204732AStir wellAchieving stirringGranular material dryingDrying gas arrangementsHelical bladeReciprocating motion

The invention belongs to the technical field of plastic manufacturing, and specifically discloses a plastic particle mixing dryer comprising a material barrel and a discharging hopper. The inner wallof the material barrel is provided with a plurality of columnar bulges, and a rotating shaft is provided with helical blades; the top of the rotating shaft is provided with an end cam, and the rotating shaft and the end cam are internally provided with through holes which communicate with each other; the side wall of the rotating shaft in the material barrel is provided with air outlets which communicate with the through holes; a support frame is provided with a cylinder, and the lower end face of an ejector rod in the cylinder abuts against the concave side of the end cam; a coil is wound onthe outer wall of the cylinder, and connected to an AC motor; and the outer wall of the cylinder is provided with a one-way air inlet valve and a one-way air outlet valve, and a hot air pipe communicating with the through holes is installed between the one-way air outlet valve and the end cam. According to the technical scheme, hot air is intermittently discharged into a drying oven through the quick reciprocating motion of a cylinder piston, so that plastic particles are switched between two motion states, namely irregular movement and falling-down, and the plastic particles are mixed thoroughly.

Owner:重庆市中塑新材料有限公司

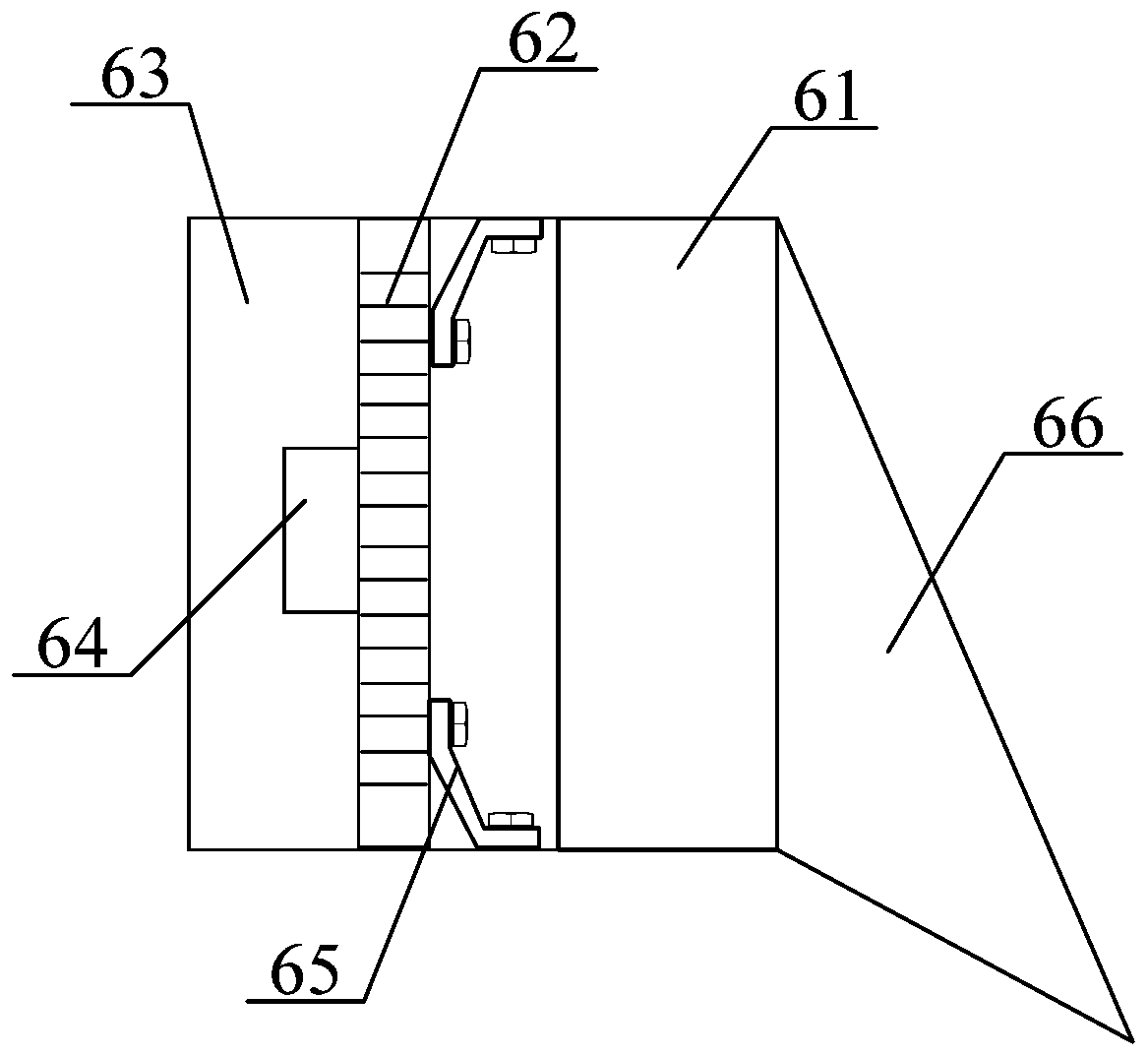

Dry particle mixing device

PendingCN109158000AIrregular direction of movementAvoid accumulationRotary stirring mixersTransportation and packagingParticle flowParticulates

The invention relates to a dry particle mixing device which comprises a mixing bin and a stirrer disposed in the mixing bin, wherein the stirrer comprises a stirring shaft and at least three stirringblades; fan-shaped ribs are disposed at joints between the stirring blades and the stirring shaft; an area of each of the stirring blades closed to the outer edge is a light plate area; a plurality ofmaterial mixing holes are formed in the stirring blades outside the light plate area in the lateral direction and the longitudinal direction; a plurality of material mixing bulges are simultaneouslydistributed on the stirring blades outside the light plate area; and the material mixing holes and the material mixing bulges are regularly distributed on the stirring blades. According to the deviceprovided by the invention, the light plate areas on the stirring blades are utilized to drive all particles to move, so that the particles flow on the stirring blades, and diverging flows and converging flows are generated continuously after the particles contact with the material mixing holes and the material mixing bulges; and the material mixing bulges can also change the original motion directions of the particles, so that the movement directions of the particles are more irregular, the particulate matter is loose, and finally the desired mixing uniformity is achieved.

Owner:UNIV OF SCI & TECH LIAONING

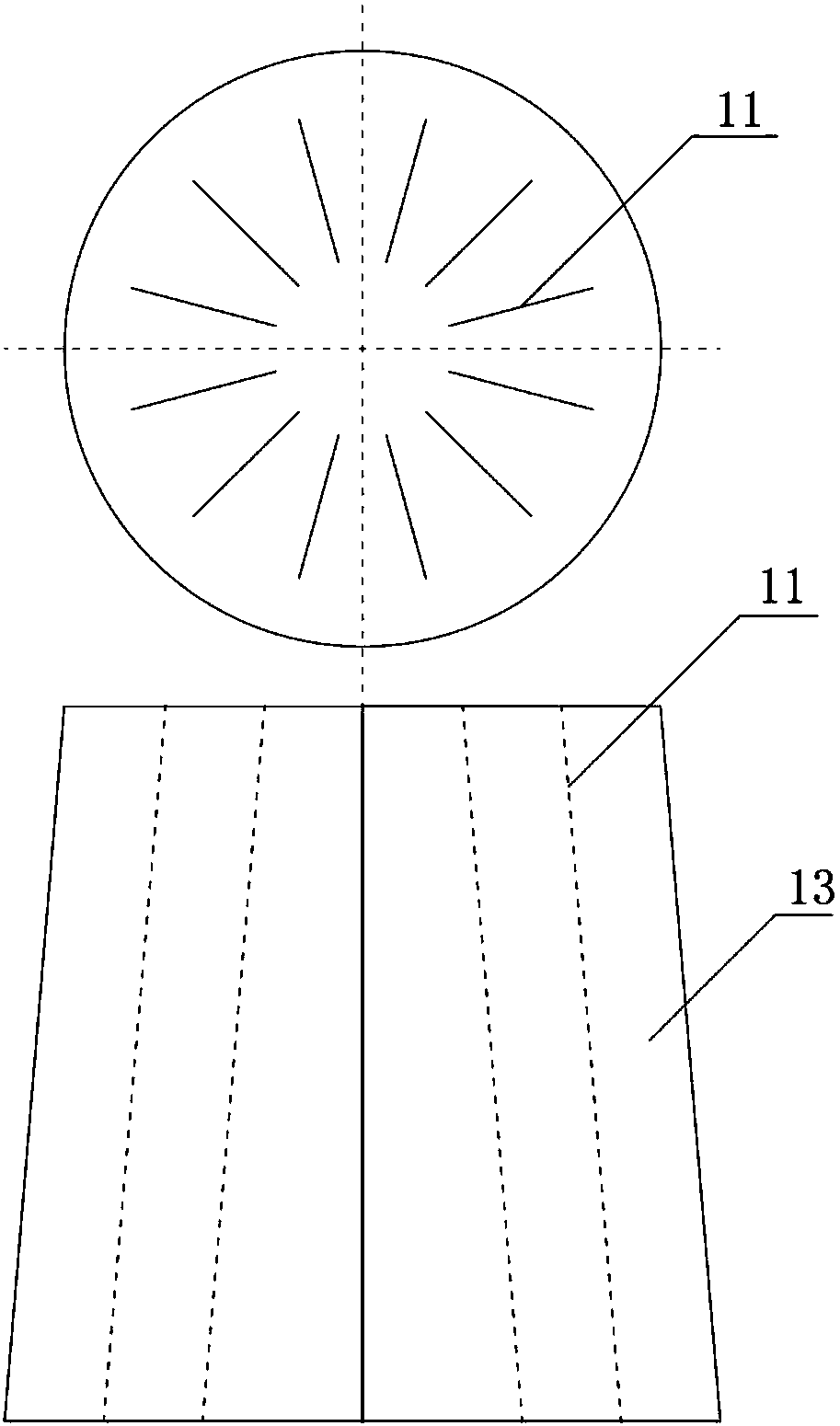

Device and method for preparing foam aluminum by bottom blowing powder spraying method

The invention belongs to the field of material preparation, and discloses a device and method for preparing foam aluminum by a bottom blowing powder spraying method. Foaming gas and fluidized additiveparticles are transported to a slit type air-permeable brick by a powder spraying system through an air blowing pipe, the foaming gas and the fluidized additive particles are blown from the bottom ofa foaming chamber into aluminum liquid by the slit type air-permeable brick, two process of additive particle mixing and air-blown foaming in a conventional foam aluminum preparation technology are simplified to the process that gas and particles are together blown into the aluminum liquid, bubbles float upward to form foams, and continuous production of foam aluminum is achieved through collection, cooling, annealing and rolling of a rolling system; and the device for preparing foam aluminum by the bottom blowing powder spraying method comprises the powder spraying system, the air blowing pipe, the slit type air-permeable brick, a crucible, an agitator, and the rolling system. According to the method for preparing foam aluminum by the bottom blowing powder spraying method, the gas and the particles are blown together into the aluminum liquid, the particles are uniformly dispersed and not prone to being agglomerated, the dispersibility of the particles is improved, the performance offoam aluminum materials is improved, and the production power consumption is reduced at the same time.

Owner:NORTHEASTERN UNIV

High-temperature high-pressure solid-containing multi-phase particle erosive wear testing device

InactiveCN109142025AControl deliveryControl speedInvestigating abrasion/wear resistanceEngineeringSolid particle

The invention discloses a high-temperature high-pressure solid-containing multi-phase particle erosive wear testing device which comprises an air heating device, a gas-solid mixing device, a wear simulating device and a tail gas dust removal device. An air compressor is connected with an air dryer, a high-temperature air heater, a gas flow meter and a pressure intensity tester. The gas flow meteris connected with a particle mixing and auxiliary heating chamber. A mixing and heating chamber is connected with a solid particle heating chamber and a particle size screening machine. Solid particles are controlled by an impeller feeder to fall. An outlet of the mixing and heating chamber extends into a tank body through a solid flow meter and an acceleration pipeline. The tank body is controlled by a surrounding water cooling system to be cooled and is internally provided with a porous nozzle and a sample supporting frame. A sample heater is arranged on the sample supporting frame. A water-cooled sedimentation type dust collector is connected with the bottom of the tank body. A doppler laser velocimeter is aligned with a to-be-tested material in the tank body. By means of the testing device, the movement conditions and erosive wear conditions of solid-containing multi-phase particles hit on the material under different temperatures and pressure intensities can be researched.

Owner:NANJING UNIV OF SCI & TECH

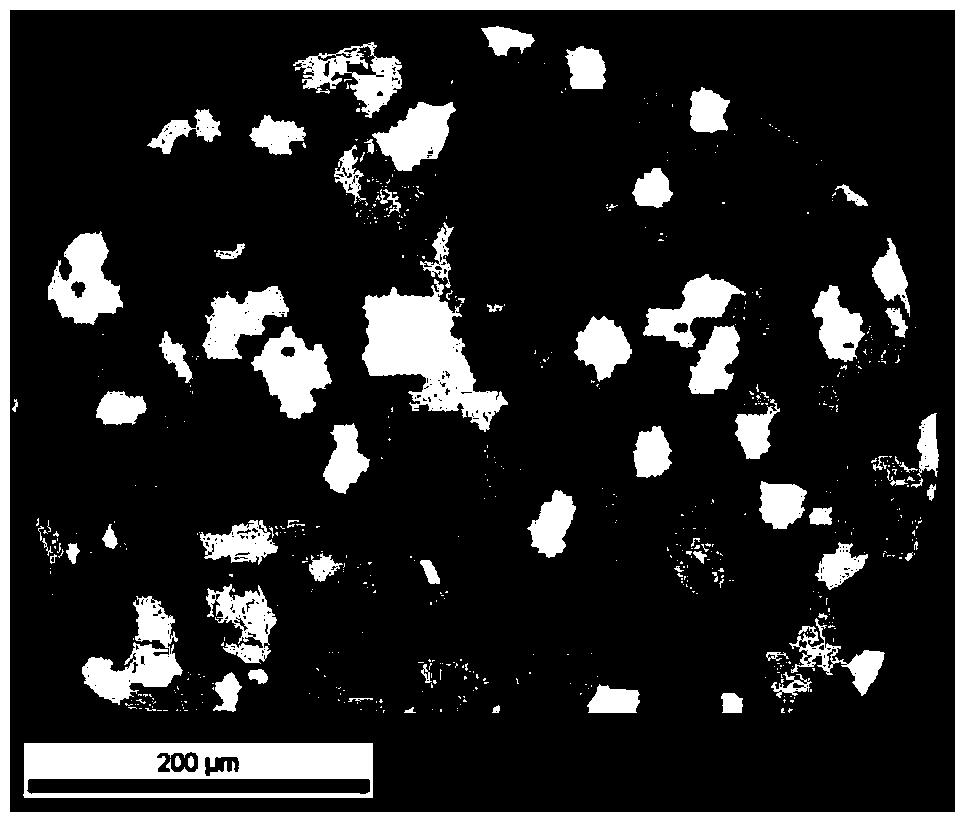

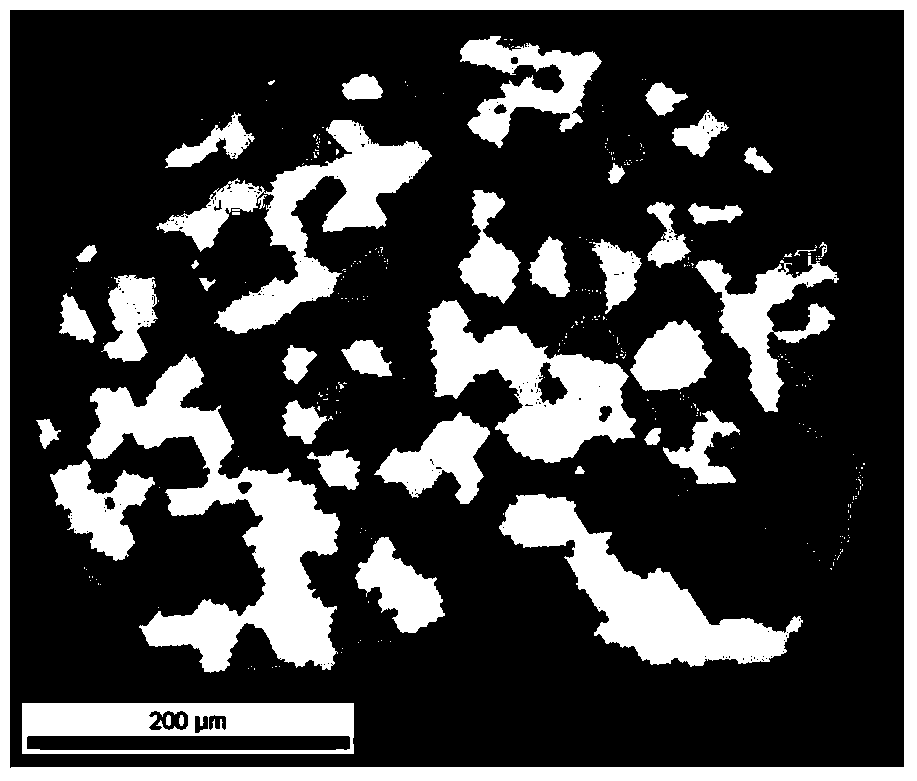

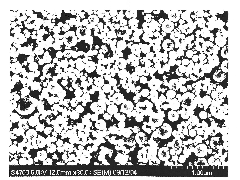

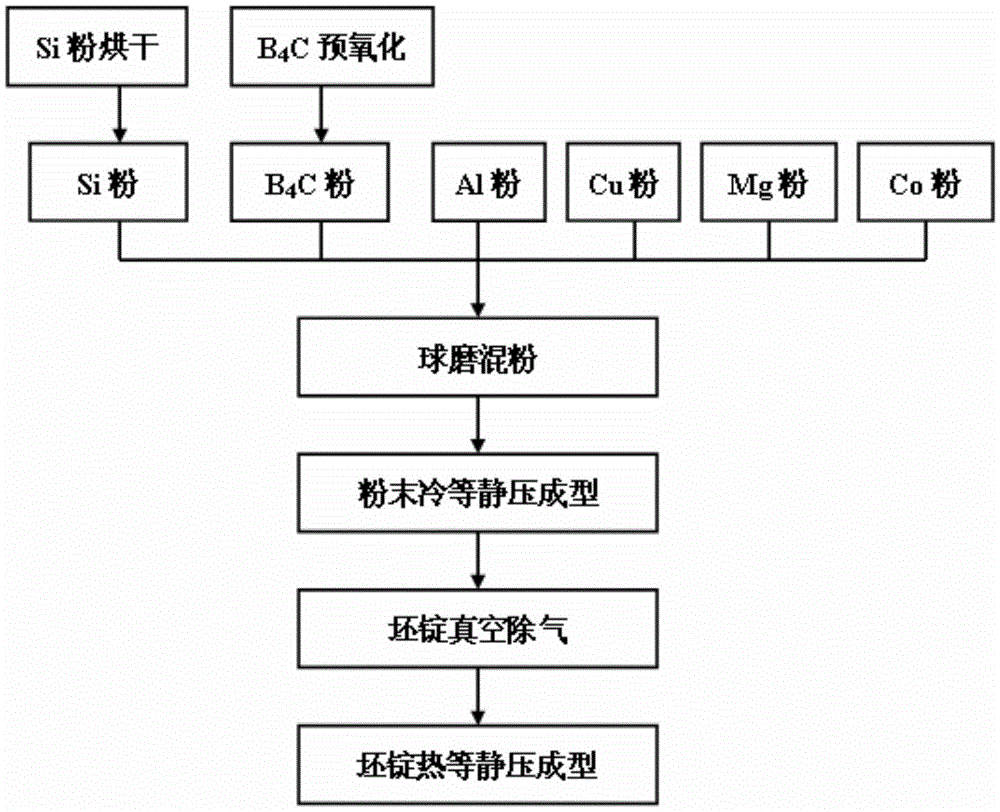

High-volume fraction B4C and Si particle mixing enhancement aluminum-based composite material and preparation process thereof

The invention discloses a high-volume fraction B4C and Si particle mixing enhancement aluminum-based composite material and a preparation process thereof. The aluminum-based composite material is composed of an Al-Cu-Mg-Co alloy base body and a mixing enhancement phase of B4C and Si. By volume percent, the content of the Al-Cu-Mg-Co alloy base body is 30%-45%, the content of the B4C is 55%-60%, the content of the Si is a, and a is larger than zero and smaller than or equal to 10%. The aluminum-based composite material is prepared through a powder metallurgy method. The preparation process mainly comprises the steps of pretreatment of the B4C and Si particles, ball mill mixing of the enhancement phase and Al alloy base body powder, powder cold isostatic pressing, vacuum degassing, hot isostatic pressing and the like. The density of the aluminum-based composite material is 2.55-2.60 g / cm<3>, the bending strength is 450-530 MPa, the elastic modulus is 180-220 GPa, the thermal expansion coefficient is 7.6-9.5*10<-6>K<-1>, and the thermal conductivity is 70-100 W / m.K. The excellent performance of the aluminum-based composite material can well meet the using requirements of spaceflight light high-strength structure function part materials.

Owner:有研金属复材技术有限公司

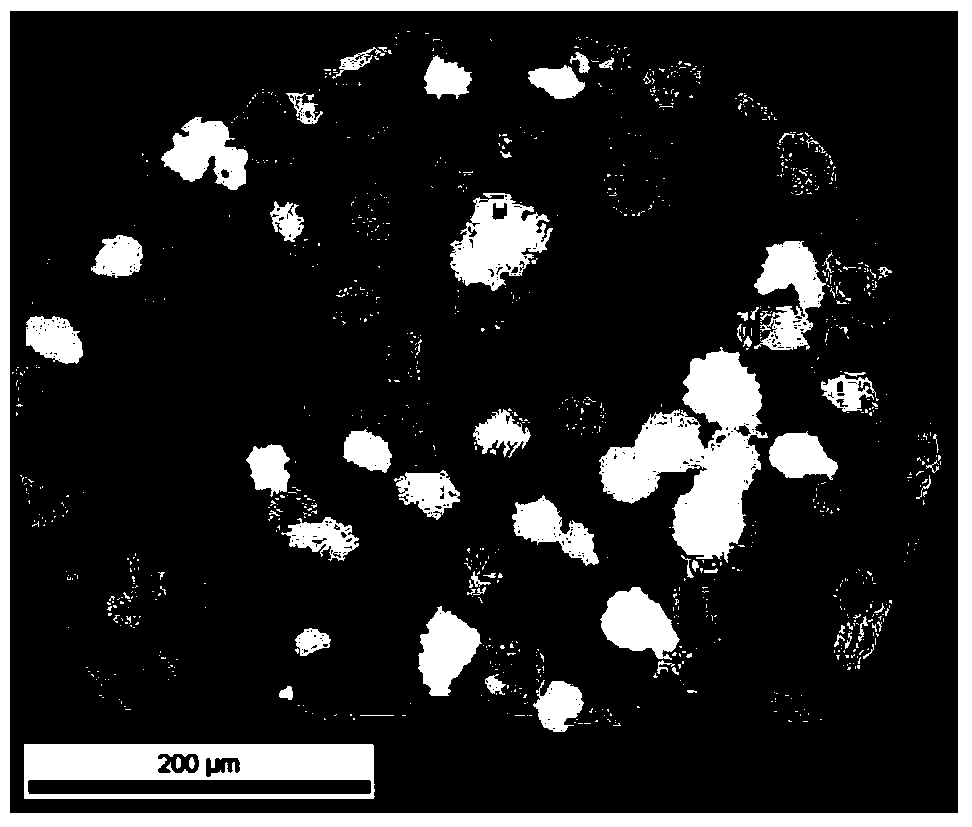

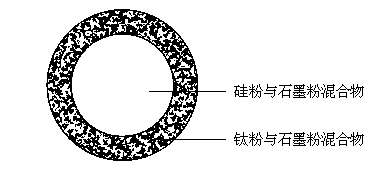

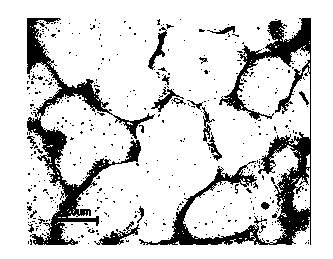

In-situ SiC-TiC particle mixing enhanced aluminum-based composite material and preparation process thereof

The invention relates to the technical field of non-continuous enhanced metal-based composite materials, and in particular relates to an in-situ SiC-TiC particle mixing enhanced aluminum-based composite material and a preparation process thereof. For overcoming the defects of high preparation cost, complicated process and poor wettability and compatibility of particles and substrates in the prior art, the invention provides the in-situ SiC-TiC particle mixing enhanced aluminum-based composite material and the preparation process thereof. The preparation process comprises the following steps: firstly, preparing in-situ reaction system press cakes: dividing the designed press cakes into inner and outer layers, wherein the mass ratio of the inner layer to the outer layer is 3:10, and then pressing by a pressure machine; then, preparing Al-4.5Cu based alloy by taking pure Al and Al-50% Cu as raw materials; and finally adding the press cakes in Al-4.5Cu melt to carry out in-situ reaction. Compared with the prior art, the preparation method disclosed by the invention has the advantages that the in-situ produced SiC particles are fine and reach micron scale.

Owner:XIAN TECH UNIV

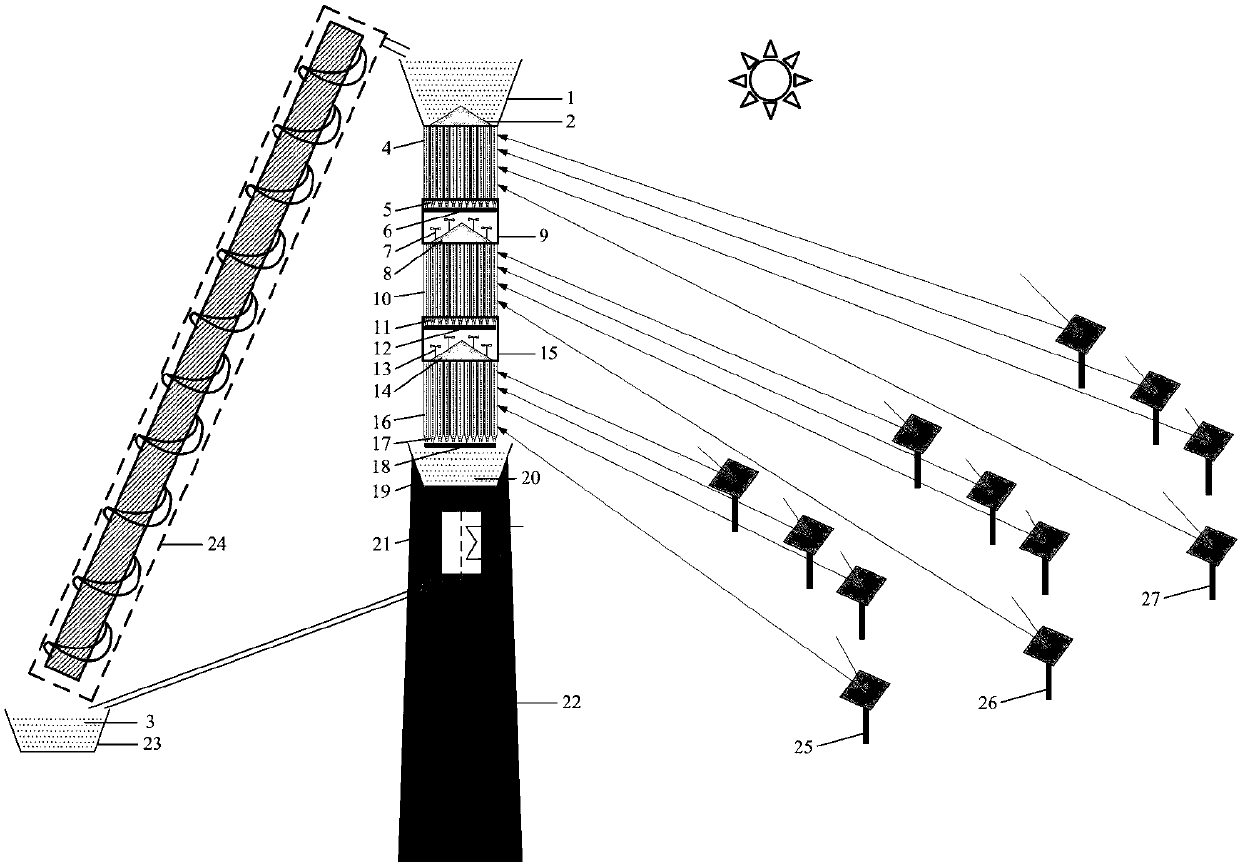

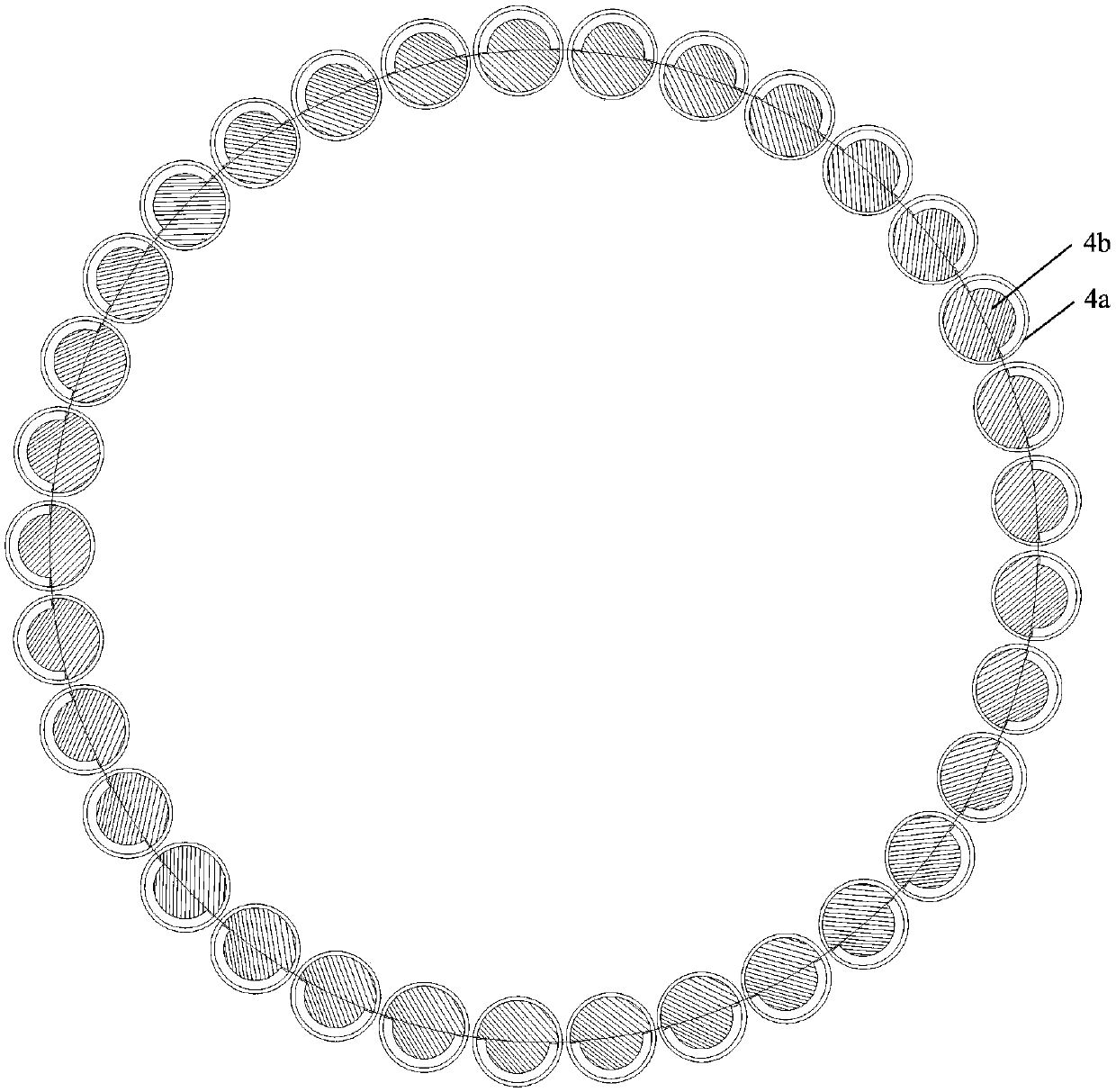

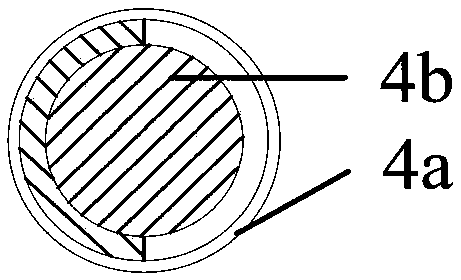

Multi-stage solid particle heat absorber for tower type solar thermal power generation

ActiveCN109668341AEasy to scale upUniform regulationSolar heating energySolar heat storageHeliostatSolid particle

A multi-stage solid particle heat absorber for solar thermal power generation is characterized in that heliostat fields (25, 26, 27) are used for correspondingly supplying radiation energy to a third-stage heat absorbing section (16), a second-stage heat absorbing section (10) and a first-stage heat absorbing section (4) which are annularly arranged at the upper part of a heat absorbing tower (22); low-temperature solid particles (3) in a low-temperature solid particle storing tank (23) are conveyed to a particle distributor (1) through a spiral lifting machine (24); the low-temperature solidparticles (3) flow into the first-stage heat absorbing section (4) for heating under the flow guide effect of a tapered insert (2) at the bottom part of the particle distributor (1); the heated low-temperature solid particles (3) enter a first-stage particle mixing chamber (9) and then enter the heat absorbing section at the next stage after temperature equalization; the low-temperature solid particles (3) flow into a high-temperature solid particle storing tank (20) through a tapered funnel (17) under the effect of a final-stage flow rate adjusting mechanism (18); after transferring heat to apower generation working medium, high-temperature solid particles (19) are transformed into the low-temperature solid particles (3) and then flow into the low-temperature solid particle storing tank(23).

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

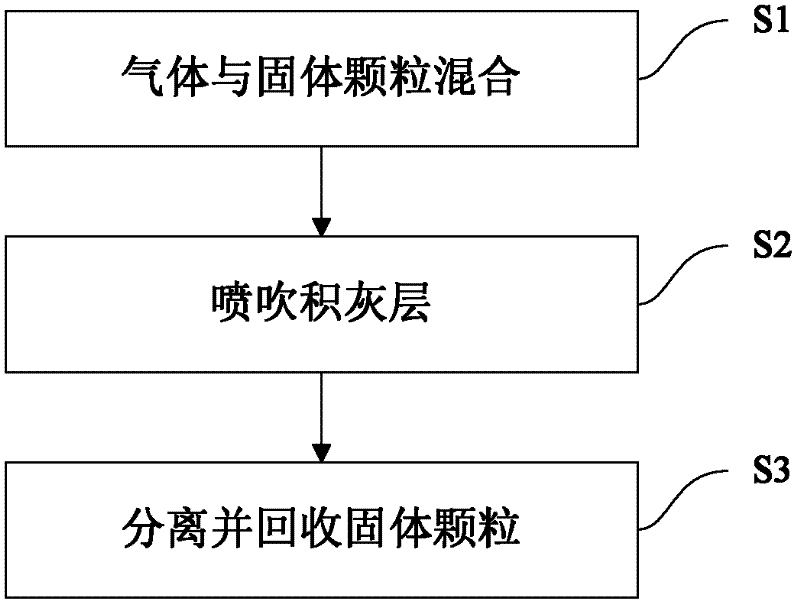

Dust deposition removing method and system

InactiveCN102313288AApparent density can be adjustedEasy to recycleSolid removalNon-rotary device cleaningParticle mixingAirflow

The invention discloses a dust deposition removing method and a system. The method comprises the following steps: gas and solid particles are mixed into dust blowing medium flow; and the dust blowing medium flow is sprayed onto a dust deposition layer. The system comprises a gas transmission device, a particle supply device, a gas and particle mixing device, a particle separation and recycle device and a dust blowing gun. In the method, the dust deposition layer on a heating surface is broken and peeled off through the continuous strike of the solid particles and dust deposition can be removed thoroughly by combining the blowing and sweeping action of air current, in particular to the highly cohesive dust deposition on the surface of the heating surface of a boiler. The dust deposition on the surfaces of a horizontal heating surface and a vertical heating surface can be effectively removed through the system provided by the invention.

Owner:BEIJING JIAOTONG UNIV

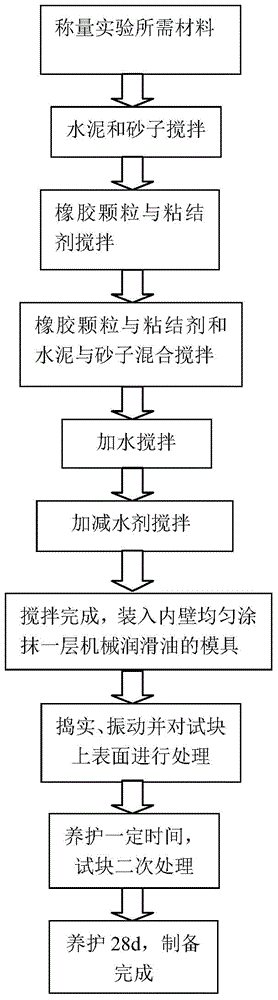

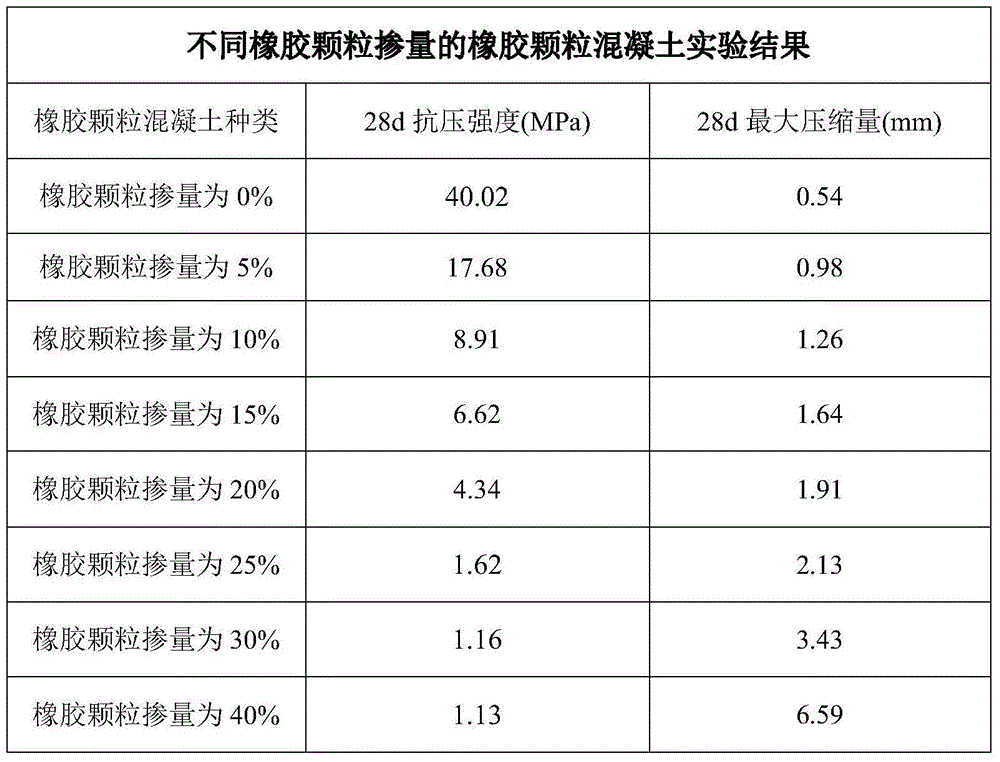

Experimental method for preparing rubber particle concrete

InactiveCN104788053AImprove physical and mechanical propertiesImprove integritySolid waste managementExperimental methodsPolymer science

The invention discloses an experimental method for preparing rubber particle concrete.The method comprises the steps of pretreating rubber particles, adding an adhesive agent for mixing, putting cement and sand at a matching ratio into a mixer for an experiment for uniform mixing, adding the rubber particles into the mixer for uniform mixing, adding water into the mixer for mixing, adding a water reducer for mixing, putting the rubber particle concrete into a standard mold for curing, curing for 28 days after secondary treatment of the rubber particle concrete in the mold after curing for a certain time period, preparing a rubber particle concrete test piece, removing the mold, and carrying out a physical mechanic characteristic experiment on the rubber particle concrete. The experimental method improves rubber particle and concrete combining integrity and stability. At the same time, the compressive strength and compressibility of the rubber particle concrete under different rubber particle mixing amounts are researched, and a powerful basis is provided for solving the problem of a large deformation surrounding rock support of a roadway.

Owner:SHANDONG UNIV OF SCI & TECH

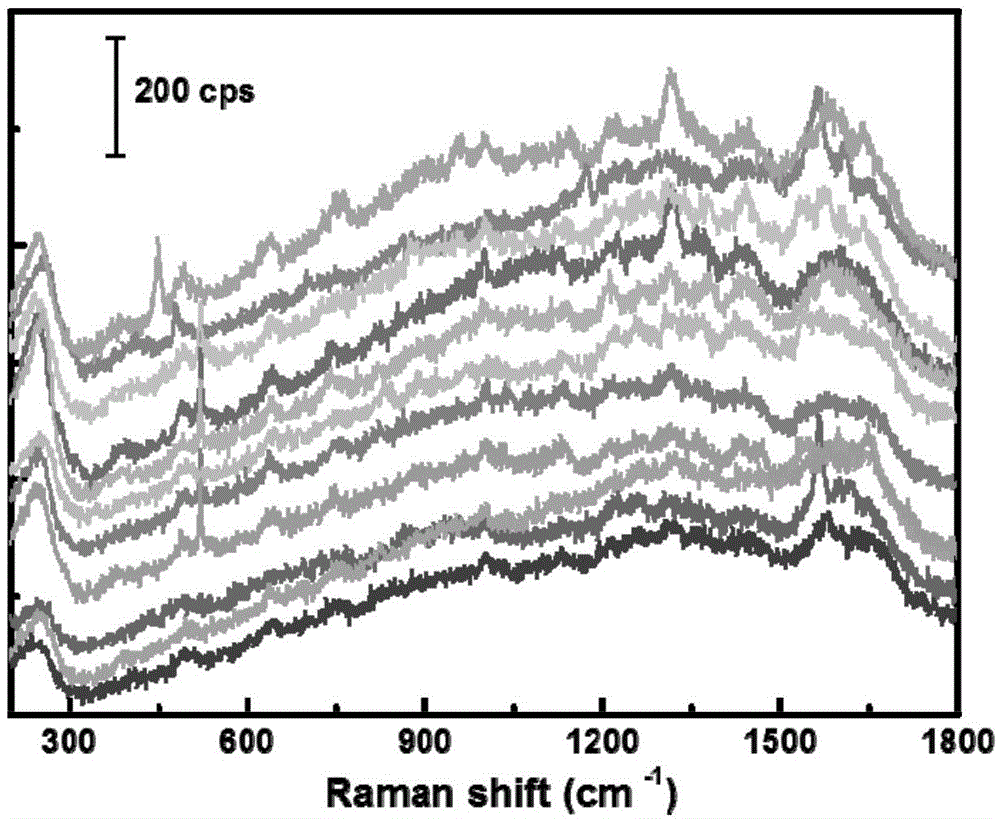

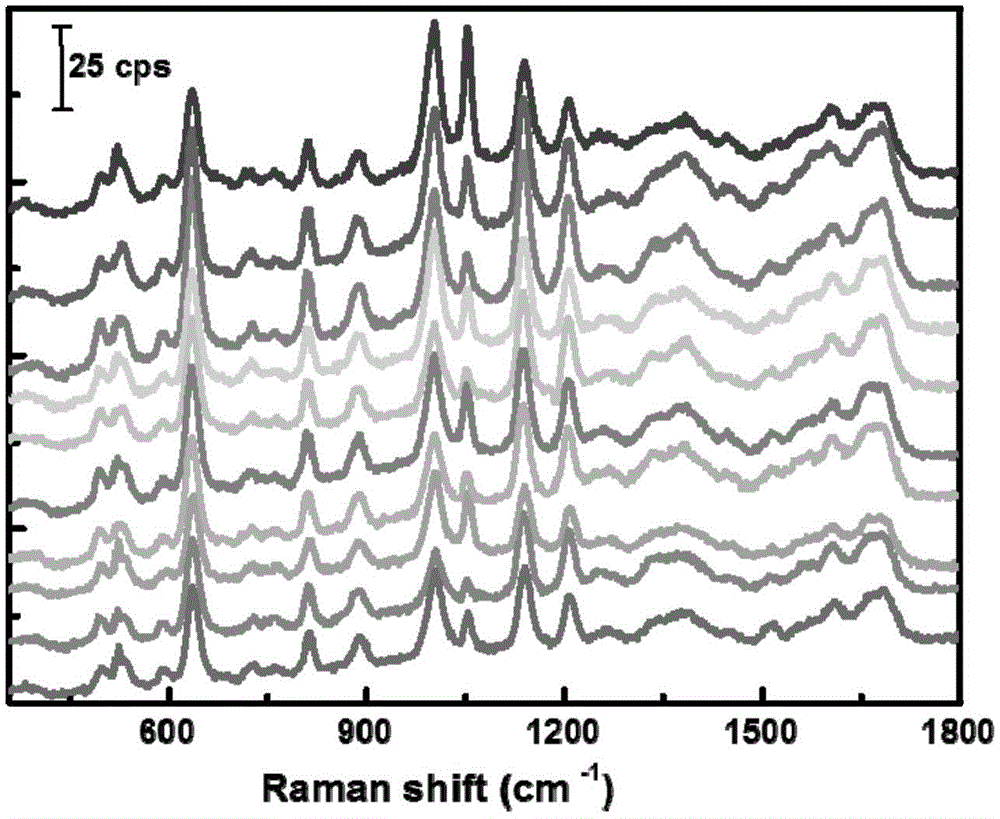

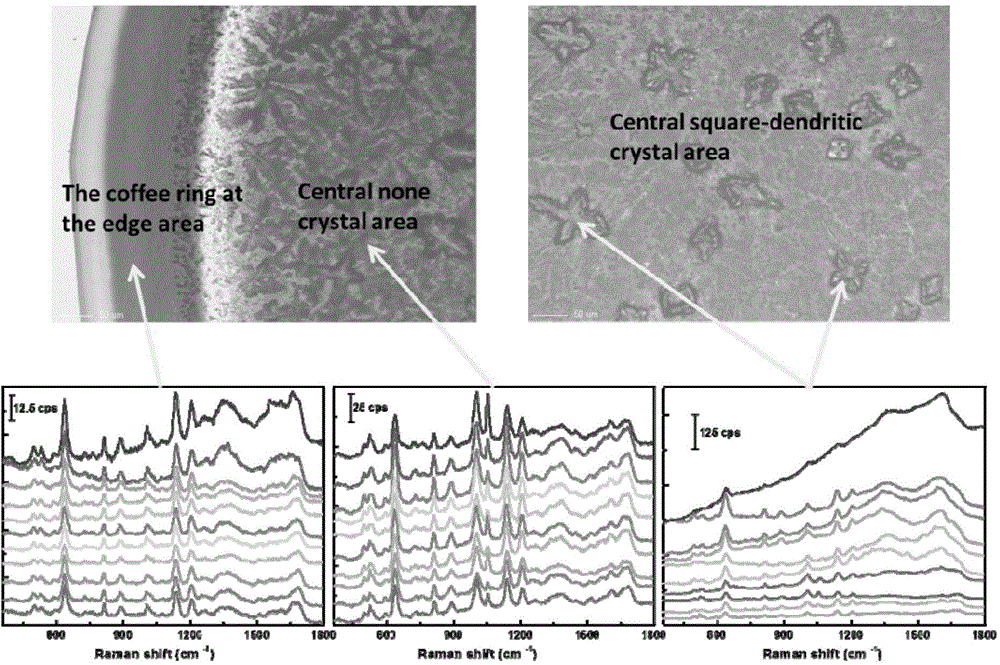

Tear test method based on surface-enhanced raman spectroscopy

The invention discloses a tear test method based on surface-enhanced raman spectroscopy. The tear test method comprises the steps of mixing nano particles and tears, and detecting a tear and particle mixture through a raman spectrometer, thus obtaining a tear component raman spectrogram, wherein the tear and particle mixture can be liquid, semi-liquid or a dried crystal. The invention aims at providing a novel, quick, noninvasive and sensitive method for detection and analysis of the tears.

Owner:XIAMEN UNIV

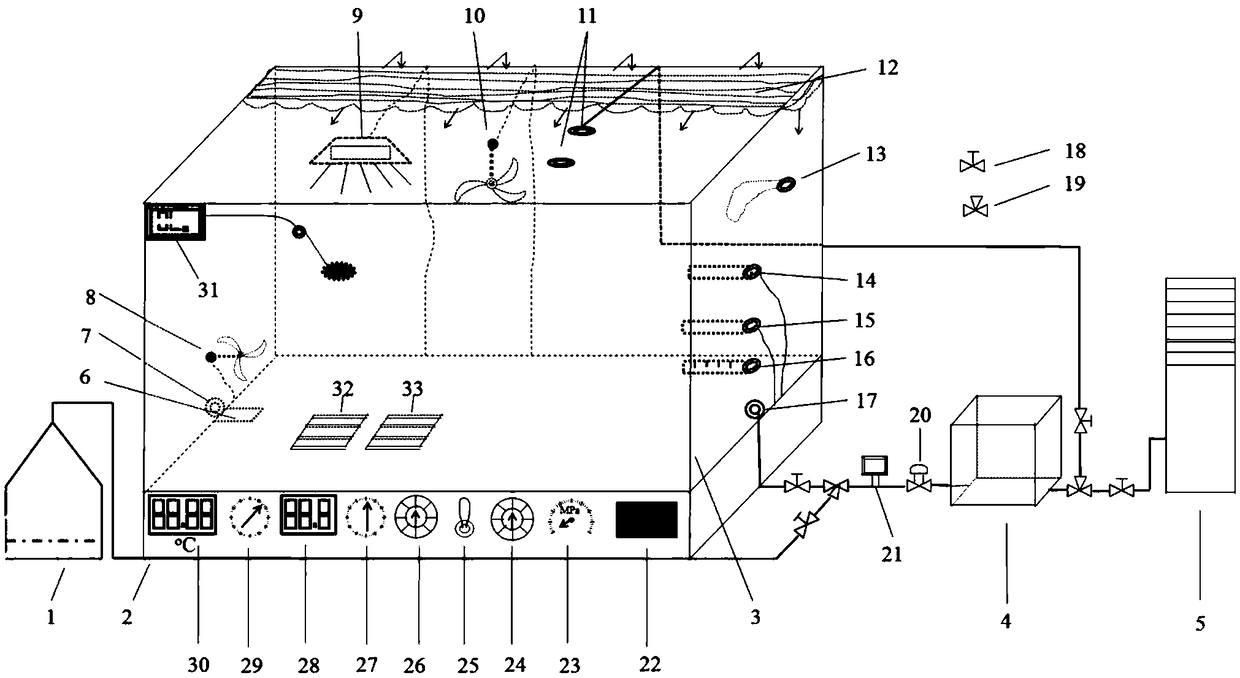

Haze particle formation simulator

ActiveCN108786938AScientific and reasonable structureThe effect of the simulation experiment is goodEnclosures/chambersMaterial analysisExhaust valveAtmospheric air

The invention discloses a haze particle formation simulator which comprises a combustion furnace, a control console, a growth simulation chamber, a light shield, a sucking pump, a flow meter, a three-way valve with a stop valve, a haze particle collector and an air purifier, wherein the growth simulation chamber is fixed on the control console; the combustion furnace, the growth simulation chamberand the air purifier are connected into a system by the sucking pump; the three-way valve with the stop valve realizes independent operation of a smoke dust source supply channel and a haze particlecollection channel; multiple feeding holes and an exhaust valve are formed in the growth simulation chamber, and the growth simulation chamber is equipped with temperature, humidity, airspeed and light intensity detection sensors as well as a light source, a fan and a supercharging balloon; and a temperature control device, a humidifier and a pressure gage are arranged in the control console. By detecting and regulating the temperature, pressure, humidity, airspeed and light intensity in the growth simulation chamber, the outdoor environment formed by haze is simulated, a research is conductedon formation of single haze particles or a multi-haze particle mixing system, and the haze particle formation simulator has obvious value on treatment of the atmospheric environment.

Owner:SHANGHAI UNIV

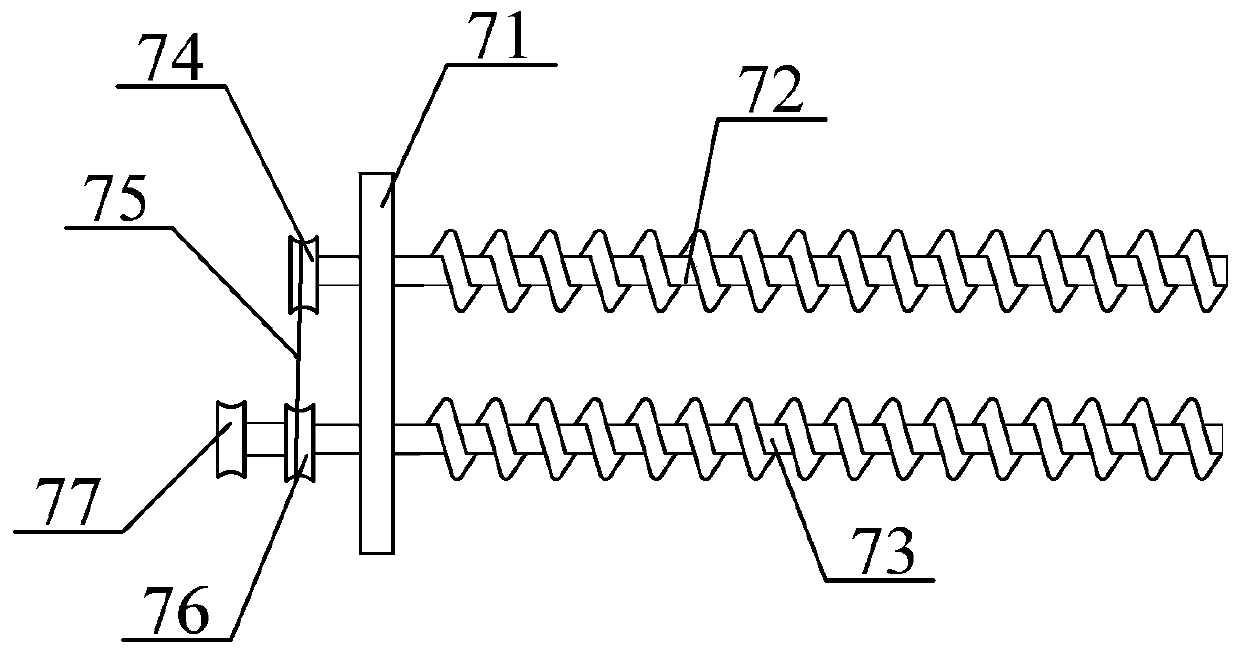

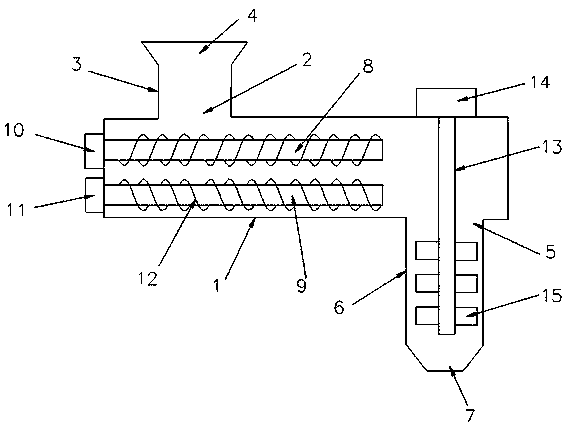

PVC powder particle mixing double-screw material feeding machine

PendingCN110171072APrevents impact on feeding efficiencyPlay the role of stirring and dredgingGrain treatmentsMixed materialsEngineering

The invention discloses a PVC powder particle mixing double-screw material feeding machine. The PVC powder particle mixing double-screw material feeding machine comprises a mixing barrel, supporting posts, a supporting base plate, a control switch, a motor base, a material outlet pipe structure capable of limiting filtering, a double-screw supporting driving plate structure, a stirring diversion rod structure capable of being dredging, a driving motor, a driving belt wheel, a driving V-belt, a buffering hopper, a material stuffing hopper, an anti-leakage receiving disc and a sealing ring pad;and the supporting posts are separately connected to the four corners of the lower surface of the mixing barrel through bolts. According to the PVC powder particle mixing double-screw material feedingmachine, through the arrangement of the dredging stirring rod, a lifting handle and stirring blades, the effects of stirring and dredging are favorably realized; clogging of PVC powder is avoided, and material feeding efficiency is prevented from being affected; the buffering hopper and the material stuffing hopper are arranged, so that PVC raw materials requiring mixed material feeding can be favorably stored temporarily, and using convenience is increased; and a filtering limiting mesh plate is arranged, so that the effects of baffling and limiting are favorably realized, and the raw materials can be fully stirred by a first material conveying auger rod and a second material conveying auger rod and then conveyed to a material outlet hopper.

Owner:江苏民扬塑胶科技有限公司

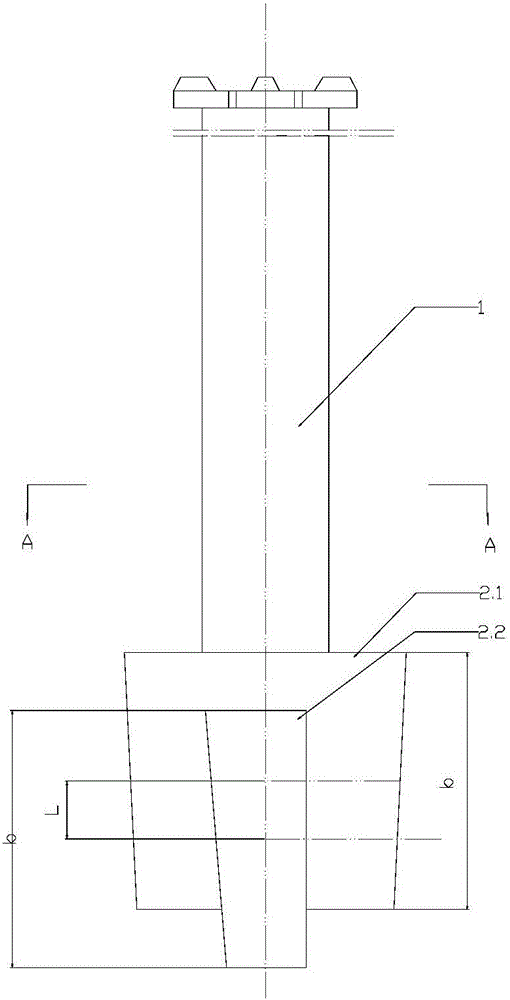

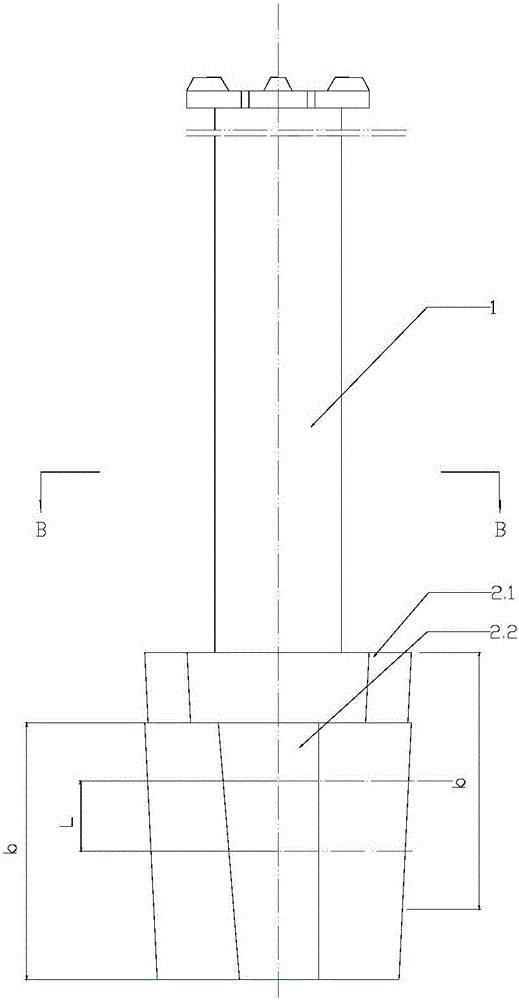

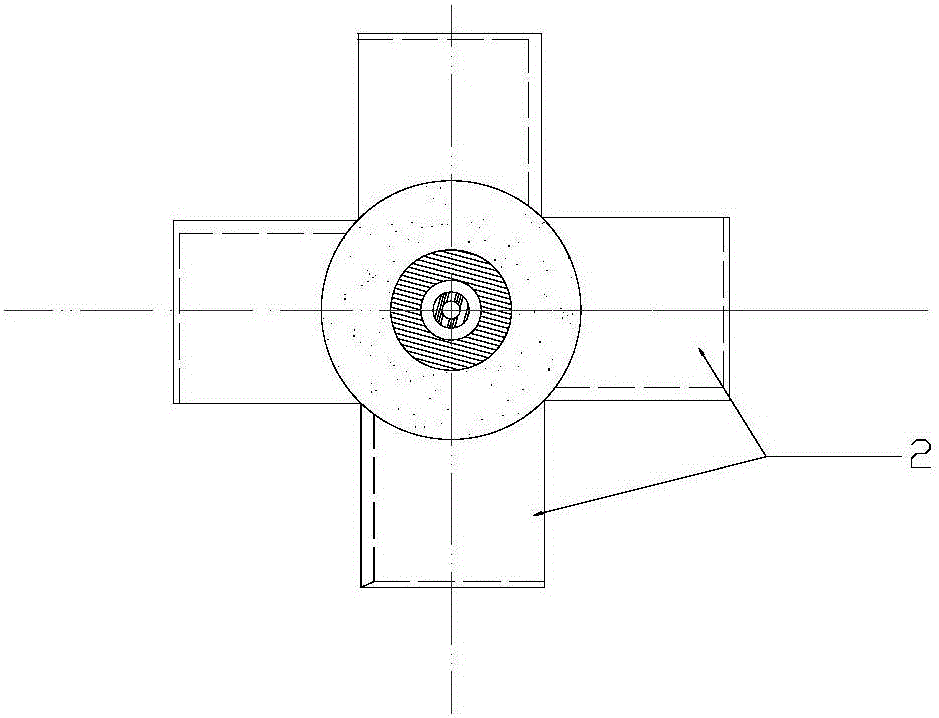

High-performance stirrer used for molten iron mechanical-stirring desulfuration

The invention discloses a high-performance stirrer used for molten iron mechanical-stirring desulfuration. The stirrer comprises a stirring shaft and stirring blades. The stirring blades are divided into the upper layer stirring blades and the lower layer stirring blades. The upper layer stirring blades and the lower layer stirring blades are all evenly distributed in the circumferential direction of the stirring shaft. The number of the upper layer stirring blades is the same as that of the lower layer stirring blades. The upper layer stirring blades and the lower layer stirring blades are distributed in a staggered manner. By means of the high-performance stirrer, the aims of enlarging the desulfurizing agent stirring and mixing area, prolonging the entrainment floating circulation stroke of a desulfurizing agent in molten iron and improving the desulfurizing agent particle mixing dispersion degree and the molten iron desulfuration efficiency can be achieved during actual production.

Owner:武汉钢铁有限公司

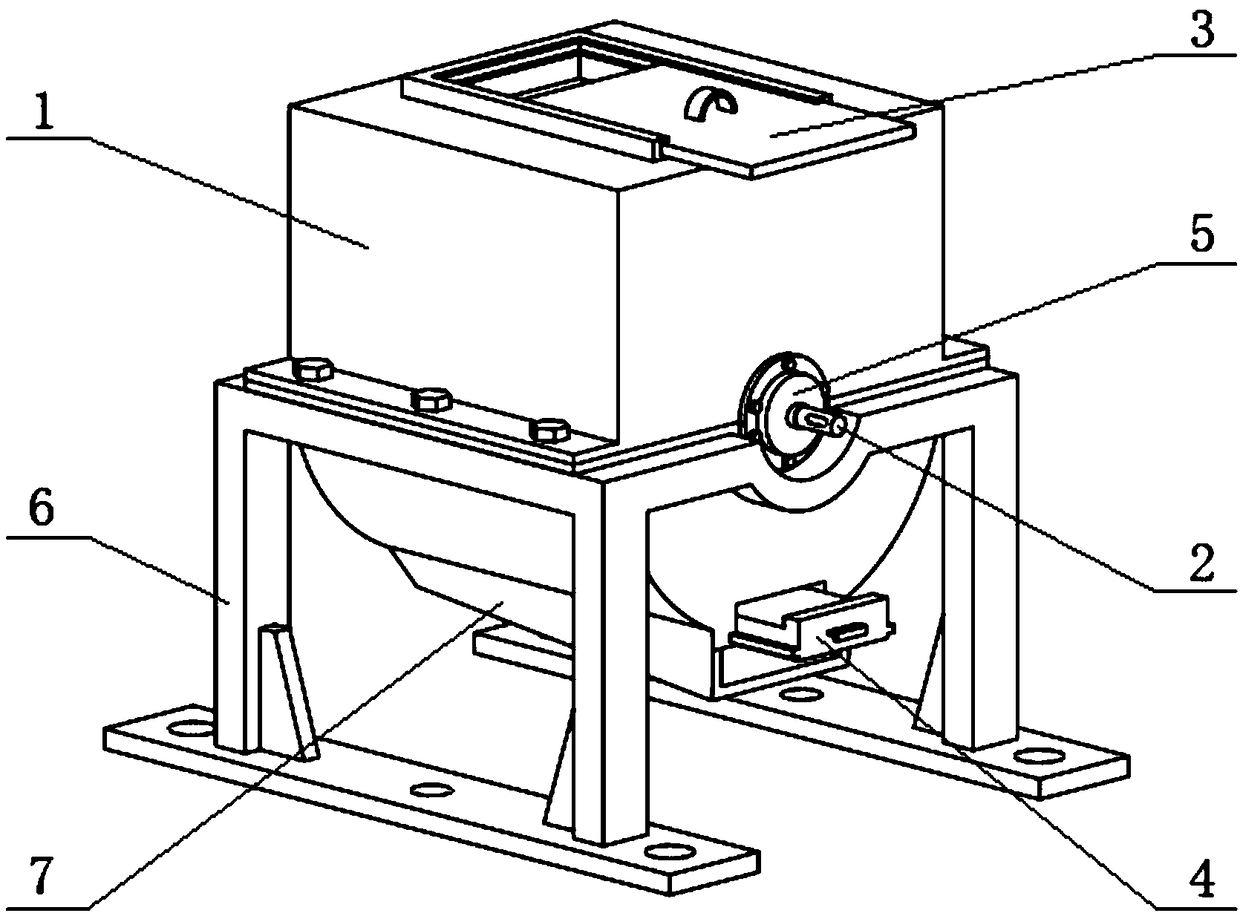

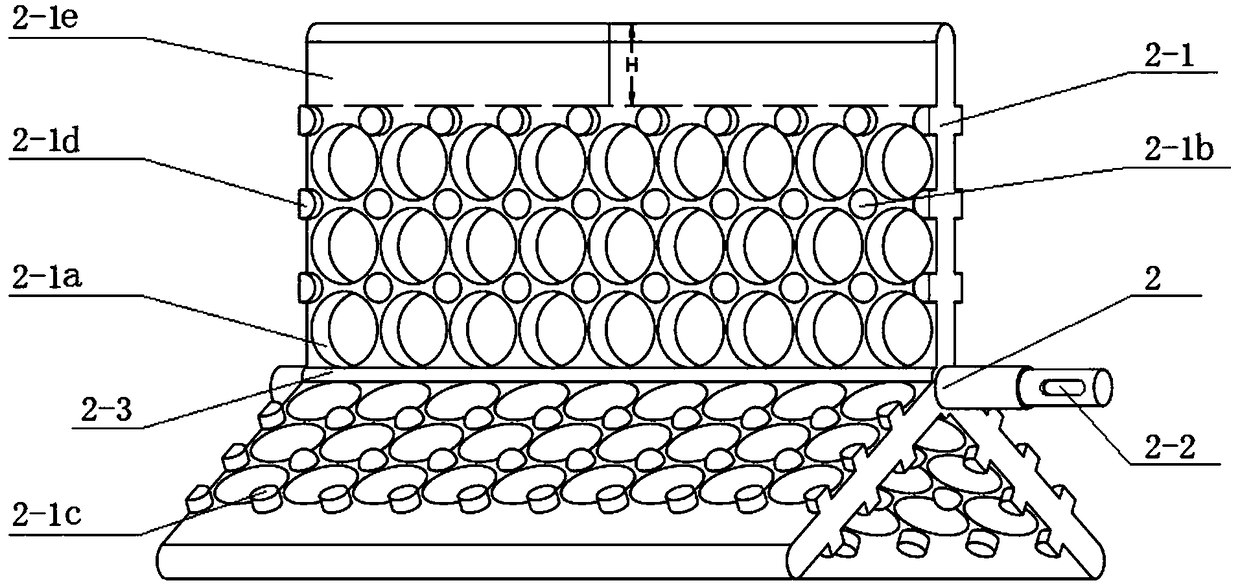

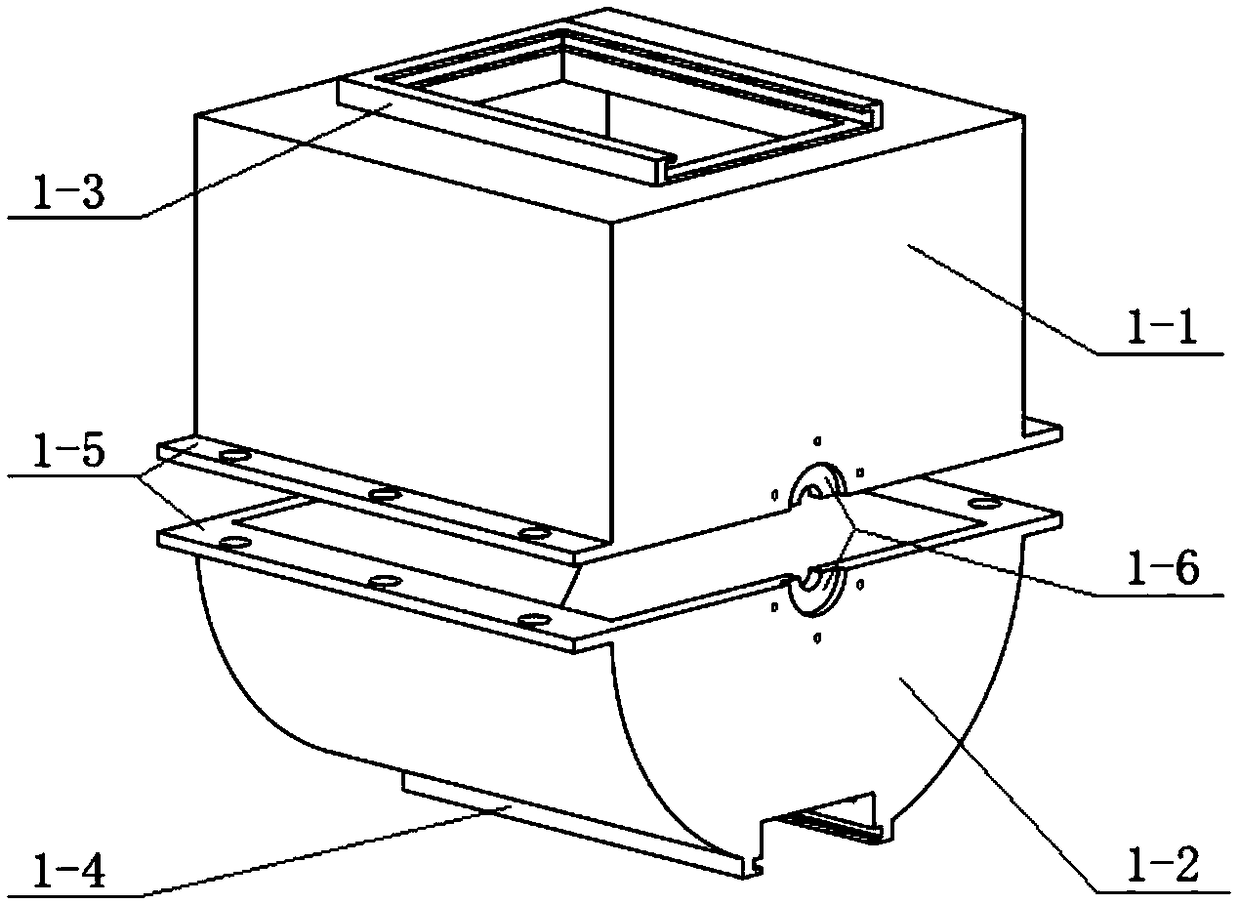

Environment-friendly centrifugal powder and particle mixing system for chemical production

InactiveCN107020028AWell mixedWon't breakRotating receptacle mixersShaking/oscillating/vibrating mixersEnvironmental resistanceHybrid system

The invention discloses an environment-friendly centrifugal powder and particle mixing system for chemical production. The system comprises a bottom plate, a rotating device, a rotating plate device, an electric cylinder device, a supporting device, a frame body device, a motor device, a rotating frame device and a cover plate device, wherein universal wheels, a first vertical rod and a first idler wheel are arranged on the bottom plate; the rotating device comprises a first supporting rod, a first connecting block, a supporting plate, a limiting frame, a first fixed rod, a first connecting ring and a first pull line; the rotating plate device comprises a second connecting block, a rotating plate, a first spring and a second connecting ring; the electric cylinder device comprises an electric cylinder, a first support, a fixed block, a push rod and a third connecting block; the supporting device comprises a second spring, an elastic rod, a second fixed rod, a third spring, a second supporting rod, a second idler wheel, a fourth spring, a limiting rod and a third fixed rod; the frame body device comprises a frame body, a third supporting rod and a fourth fixed rod. The system disclosed by the invention can fully mix powder and particle raw materials, has high mixing efficiency, can mix evenly and reduces labor intensity of workers.

Owner:SHENZHEN LEYE TECH CO LTD

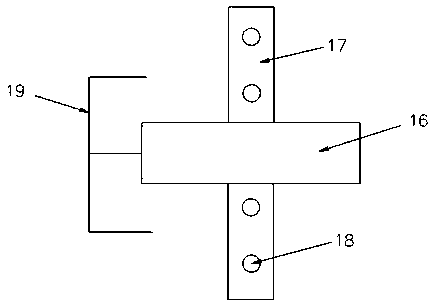

Plastic particle mixing machine and method

InactiveCN108748766AEfficient mixingImprove the quality of subsequent processingSpiral bladeMechanical engineering

The invention discloses a plastic particle mixing machine and a method. The plastic particle mixing machine comprises a material mixing cylinder, wherein the upper end of one side of the material mixing cylinder is provided with a material inlet; a material charge bin is arranged above the material inlet; a material charge hopper is arranged at the upper end of the material charge bin; the lower end of the other side of the material mixing cylinder is provided with a material outlet; a stirring cylinder is arranged under the material outlet; the bottom part of the stirring cylinder is providedwith a material discharge port; a material mixing mechanism is arranged in an inner cavity of the material mixing cylinder, and comprises a first screw rod, a second screw rod, a first motor and a second motor, the first screw rod is parallel with the second screw rod, the first screw rod and the second screw rod are respectively connected with the first motor and the second motor which are arranged at the outer wall of the material mixing cylinder, and spiral blades are respectively welded at the outer walls of the first screw rod and the second screw rod; a stirring assembly is arranged inthe stirring cylinder. The plastic particle mixing machine has the advantages that the structure principle is simple, and the convenience in use is realized; the plastic particles can be mixed at highefficiency, the mixing uniformity is good, and the subsequent processing quality of the plastic particles is improved.

Owner:伊婕

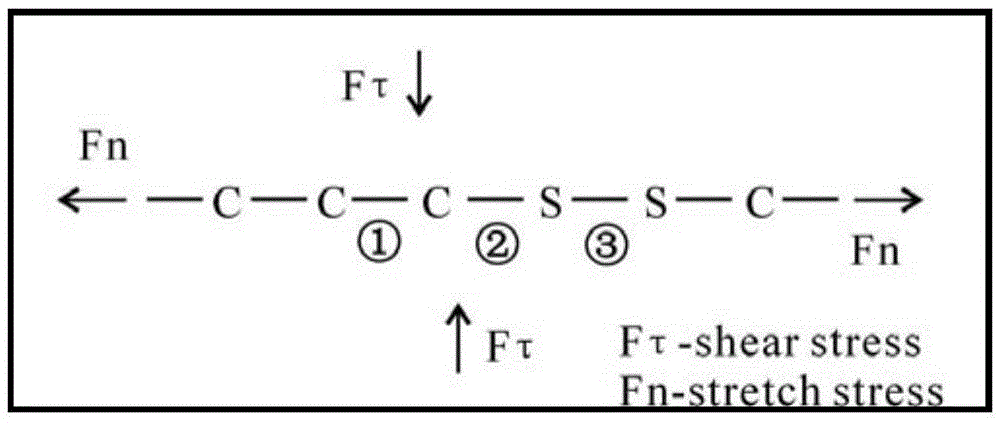

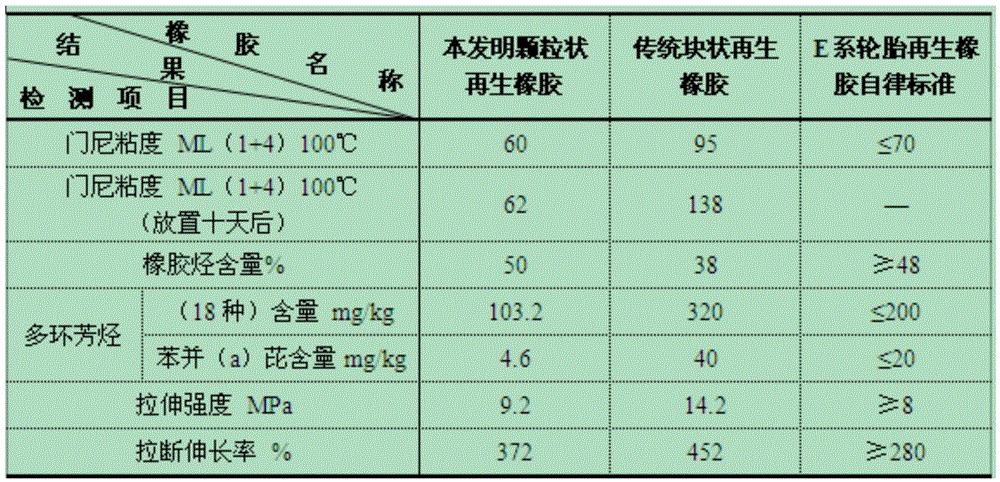

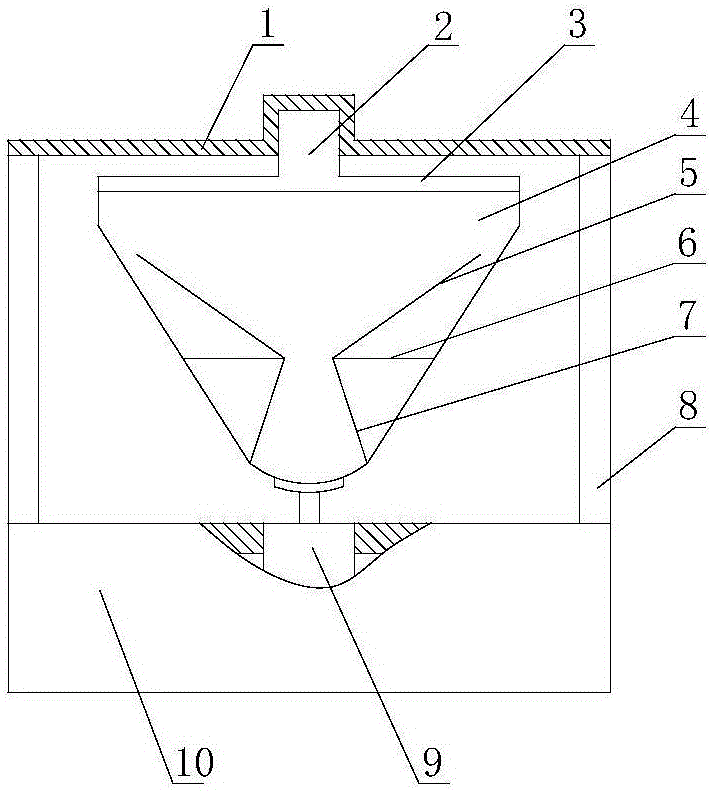

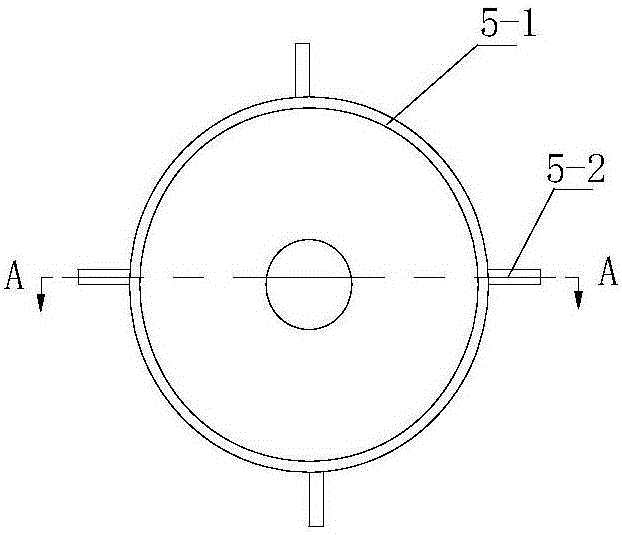

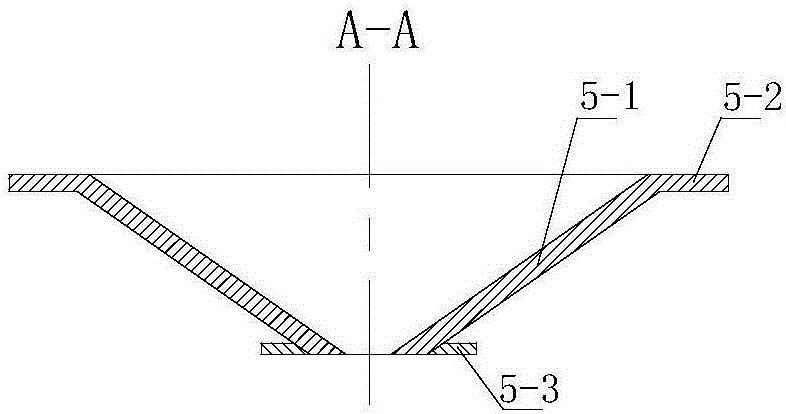

Supercritical assisted green regeneration process combining double-rotator continuous mixer with screw extruder

InactiveCN105479613ARealize sulfur break and regenerationUniform sulfur removal and regenerationPlastic recyclingChemical reactionWaste rubber

The invention discloses a supercritical assisted green regeneration process combining a double-rotator continuous mixer with a screw extruder. The supercritical assisted green regeneration process comprises the following steps: feeding rubber particles obtained by crushing and separating a waste tire into the double-rotator continuous mixer, wherein in a supercritical fluid environment, rubber particles are subjected to high-shearing and strong stretching effects of a double-rotator mixing flow field, so that the rubber particles are promoted to carry out low-temperature green devulcanizing regeneration; then, performing extruding forming on the rubber particles by the screw extruder, and finally, sealing, cooling and drying the rubber particles to obtain granular regenerated rubber, and packaging and warehousing the granular regenerated rubber. According to the process, a granular restored regenerated rubber product is prepared by virtue of directed selective green devulcanizing regeneration through low-temperature / high-shearing / strong stretching of the supercritical fluid assisted waste rubber particle mixing flow field of the double-rotator mixer; and by not requiring to add any chemical auxiliaries and only depending on the mechanical force chemical reaction principle in the production process, continuous, green and safe production of the granular regenerated rubber product is realized from waste rubber particles by utilizing stress inducing to break a three-dimensional grid structure in the product.

Owner:ANHUI GVG NEW MATERIAL CO LTD

Centrifugal powder particle mixing device

ActiveCN106422914AEasy to mix multiple timesMove at the same speedRotating receptacle mixersTransportation and packagingCircular discChemical industry

The invention relates to a centrifugal powder particle mixing device. A motor is arranged on a middle part of a base; a powder mixing tank is arranged on a power output shaft of the motor; a lower screen, an upper screen and a baffle drum are successively arranged in the powder mixing tank from bottom to top; holes in same diameter are formed in the center of each of the lower screen, the upper screen and the baffle drum; slots are formed between the baffle drum and the four walls of the powder mixing tank; a powder mixing tank cover is arranged on the powder mixing tank; a short shaft which is integrally connected with the powder mixing tank cover is arranged at the center of the outer surface of the powder mixing tank cover; a support rod is arranged on the base; a positioning disc is arranged on the support rod; and a groove which is matched with the short shaft is formed in the middle part of the positioning disc. The centrifugal powder particle mixing device has the advantages of simple operation, low cost, less damage to powder crystals, high mixing efficiency and wide popularization and application in the field of chemical industry production.

Owner:NORTHWEST UNIV(CN)

Temperature and humidity controllable micron-sized particle turbulence agglomeration experimental device

InactiveCN111337394AEffective simulationStable supportMonitoring particle agglomerationMicron scaleEngineering

The invention discloses a temperature and humidity controllable micron-sized particle turbulence agglomeration experimental device, and belongs to the field of temperature and humidity controllable turbulence field collision agglomeration experimental devices. The temperature and humidity controllable micron-sized particle turbulence agglomeration experimental device comprises a gas particle generation device, a gas particle mixing and heating device, a turbulence collision agglomeration device, a high-speed camera device and a gas particle discharge treatment device, by means of the device, the airflow speed can be controlled to be 0.5-20 m / s, and the airflow temperature can be controlled to be 220-230 DEG C; therefore, the environment condition and the temperature and humidity controllable condition are realized; the collision agglomeration experiment research work among micron-scale particles can effectively simulate the actual industrial processes such as the particle deposition process in a flue gas pipeline, the deposition process when particles in an electrostatic dust collector reach a dust collecting plate and the ash deposition on the surface of a heat exchange pipe, Meanwhile, effective support is provided for the theoretical research of the collision agglomeration process among the particles.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com