PVC powder particle mixing double-screw material feeding machine

A powder particle, twin-screw technology, applied in the field of feeders, can solve the problems of inconvenient powder discharge, lack of anti-blocking and dredging functions, low feeding efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing:

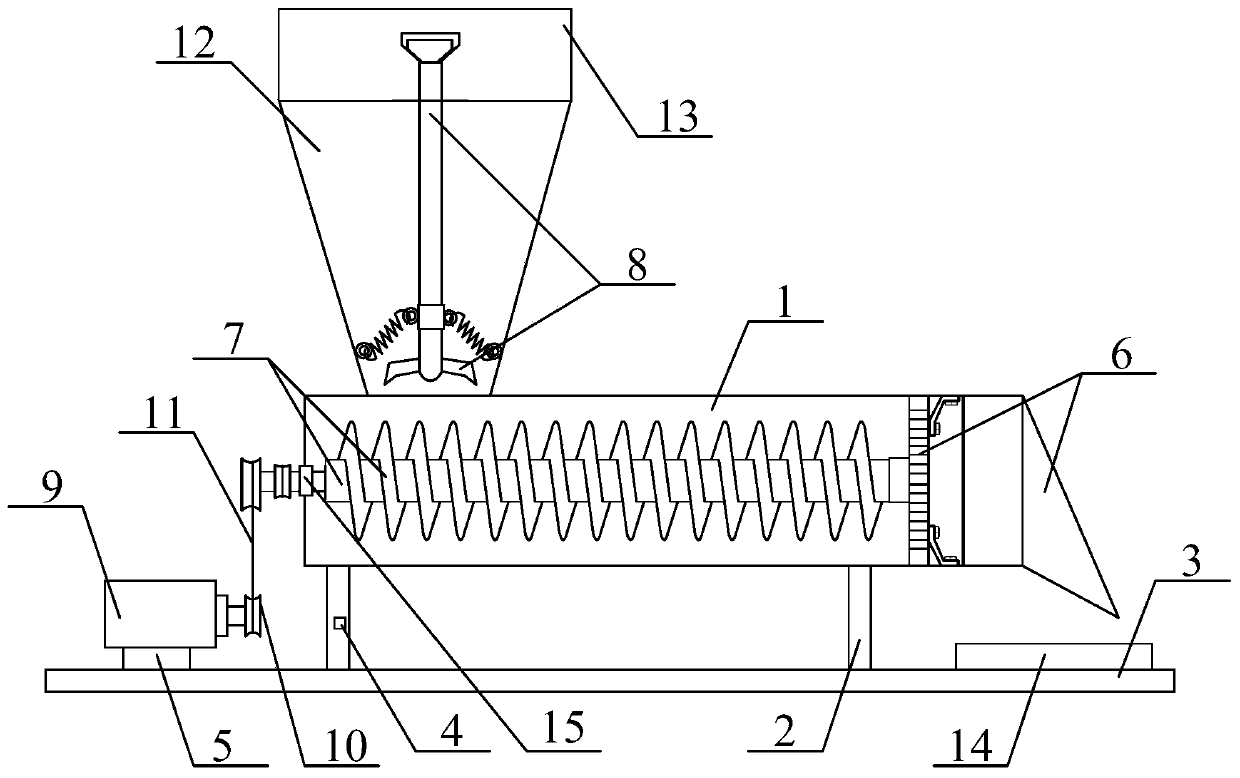

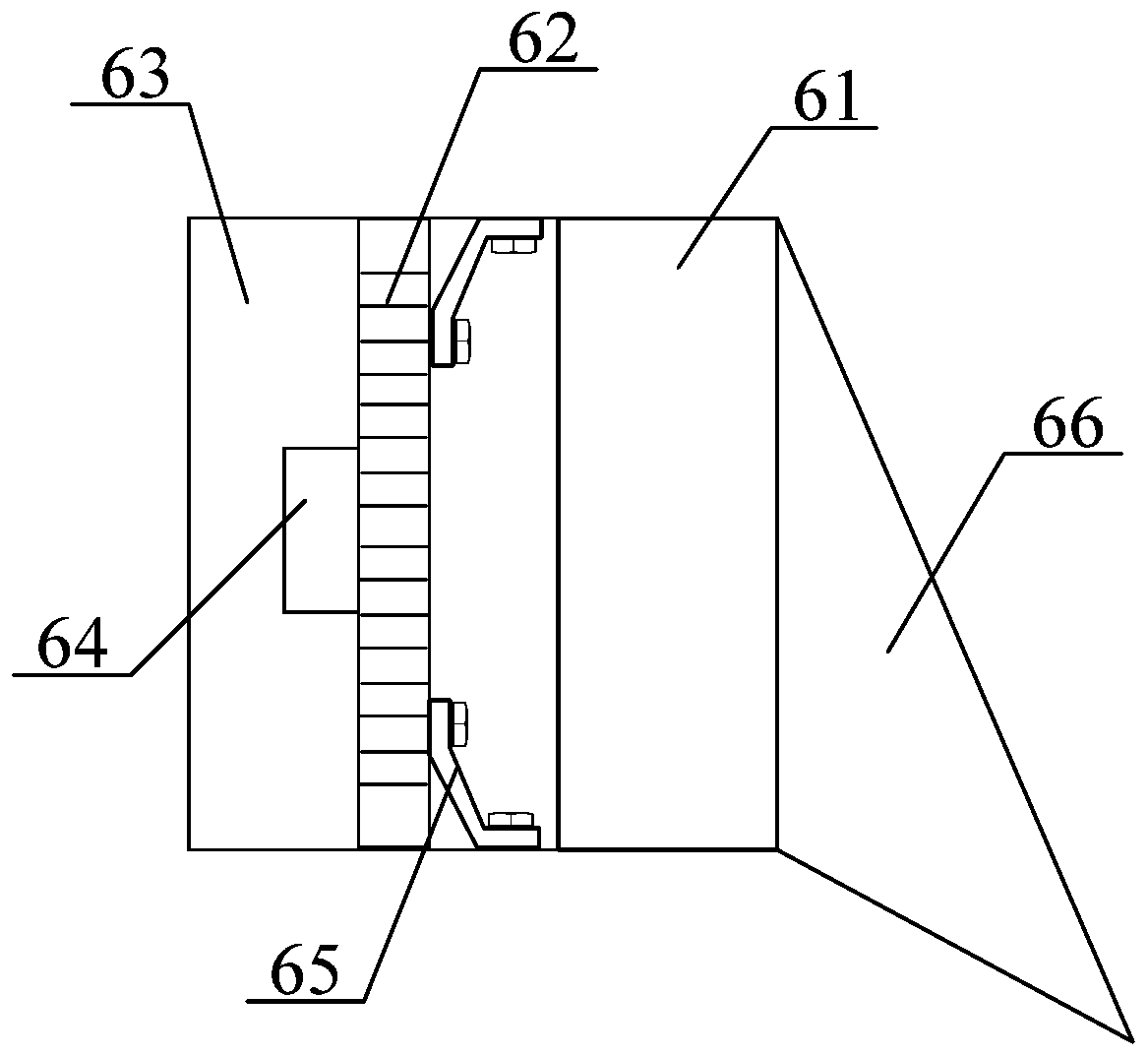

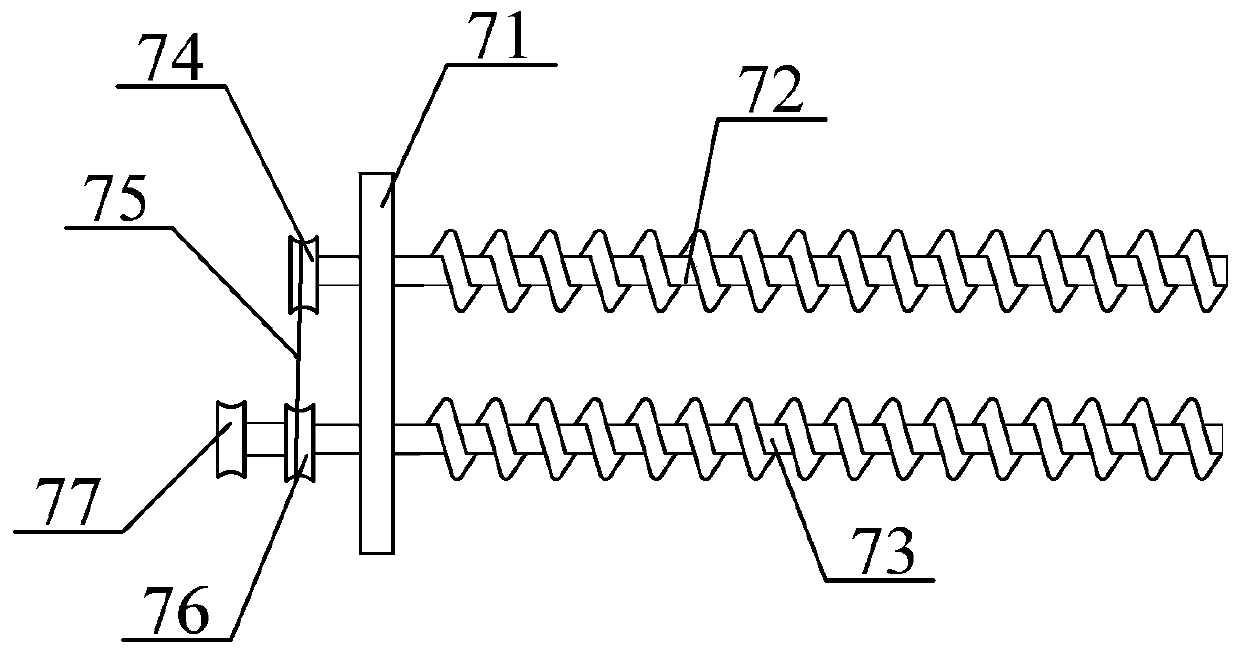

[0035] as attached figure 1 to attach figure 2As shown, the present invention provides a PVC powder particle mixing twin-screw feeder, including a mixing cylinder 1, a support column 2, a support base plate 3, a control switch 4, a motor seat 5, and a discharge pipe structure 6 capable of limit filtering , double-screw supporting drive plate structure 7, dredging stirring and diverting rod structure 8, driving motor 9, driving pulley 10, driving V-belt 11, buffer bucket 12, stuffing bucket 13, leak-proof receiving plate 14 and sealing ring gasket 15 The support columns 2 are respectively bolted to the four corners of the lower surface of the mixing cylinder 1; the support base plate 3 is connected to the lower end of the support column 2 with bolts; the control switch 4 is embedded in the left front part. The middle position of the front surface of the support column 2; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com