Fluorine-containing polymer mixing material and method for preparing bulb buffer ball keyway by same

A technology of mixing materials and polymers, applied in the field of automobile suspension arms, can solve the problems of high friction coefficient, poor wear resistance and chemical corrosion resistance, limiting the performance of suspension control arms, etc., to achieve high mechanical strength, high mechanical strength, excellent chemical The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

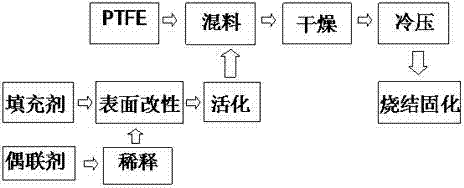

Method used

Image

Examples

Embodiment 1

[0033] Powder-grade PTFE resin is selected, the filler is surface-modified by KH550 (γ-aminopropyltriethoxysilane) (the amount accounts for 5% of the filler mass), activated, and then mixed with powder-grade PTFE resin at 25- Dry mixing and stirring at 35°C, drying in an oven at 90°C, molding, and sintering and solidification at 350-400°C (heating to above the melting point of polytetrafluoroethylene, keeping it warm for 5-8 hours, and then cooling down to room temperature) . The particle size of the selected powder-grade polytetrafluoroethylene resin is controlled below 50 microns.

[0034] This embodiment lists the ratio relationship between powder grade PTFE resin and 11 kinds of fillers for mixed modification treatment, the mass fraction of powder grade PTFE resin used, the type of filler selected and the surface modification by coupling agent. The used mass parts of the filler after is shown in Table 1:

[0035] The mass parts of powder PTFE resin Type of fi...

Embodiment 2

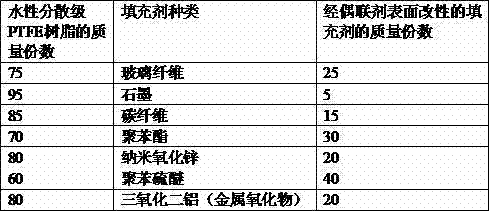

[0037] Use water-based dispersion grade PTFE resin, the filler is surface-modified by coupling agent A-171 (vinyltrimethoxysilane) (accounting for 10% of the filler mass), activated, and water-based dispersant PTFE resin at 25-35 ° C Mix and stir evenly under the dry method, after drying in an oven at 90 ° C, hydroforming, sintering and solidification at 350-400 ° C (that is, heating to above the melting point of polytetrafluoroethylene, keeping it warm for 5-10 hours, and then cooling to room temperature).

[0038] This example lists the proportioning relationship between water-based dispersion grade PTFE resin and 7 kinds of fillers for mixed modification treatment, the mass fraction of powder grade PTFE resin used, the type of filler selected and the surface modified by coupling agent. The mass parts of the filler after curing are shown in Table 2:

[0039] Table 2

[0040]

Embodiment 3

[0042] Polyvinylidene fluoride PVDF resin powder is selected, and the filler is surface-modified by coupling agent KH-570 (γ-methacryloxypropyltrimethoxysilane) (accounting for 40% of the filler mass). After activation , mixed with PVDF resin powder at 25-35°C in a dry method, dried in an oven at 90°C, extruded, sintered and solidified at 180-200°C (heating to above the melting point of polyvinylidene fluoride, heat preservation 6-8 hours, then cool down to room temperature).

[0043] This example lists the ratio relationship between PCDF resin and 11 kinds of fillers for mixed modification treatment, the mass fraction of powder-grade PVDF resin used, the type of filler selected and the surface modification of the coupling agent. The mass parts of filler are shown in Table 3:

[0044] The mass parts of PVDF resin powder Type of filler The mass fraction of the filler surface modified by the coupling agent 90 glass fiber 10 85 graphite 15 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com