Power and energy storage lithium-ion battery and preparation method thereof

A lithium-ion battery and energy storage technology, applied in the field of lithium-ion batteries, can solve the problems of low overall battery capacity, low initial efficiency, difficult to exert excellent performance, etc., to achieve overall capacity and initial efficiency improvement, improve energy density, good safety Effects of Features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

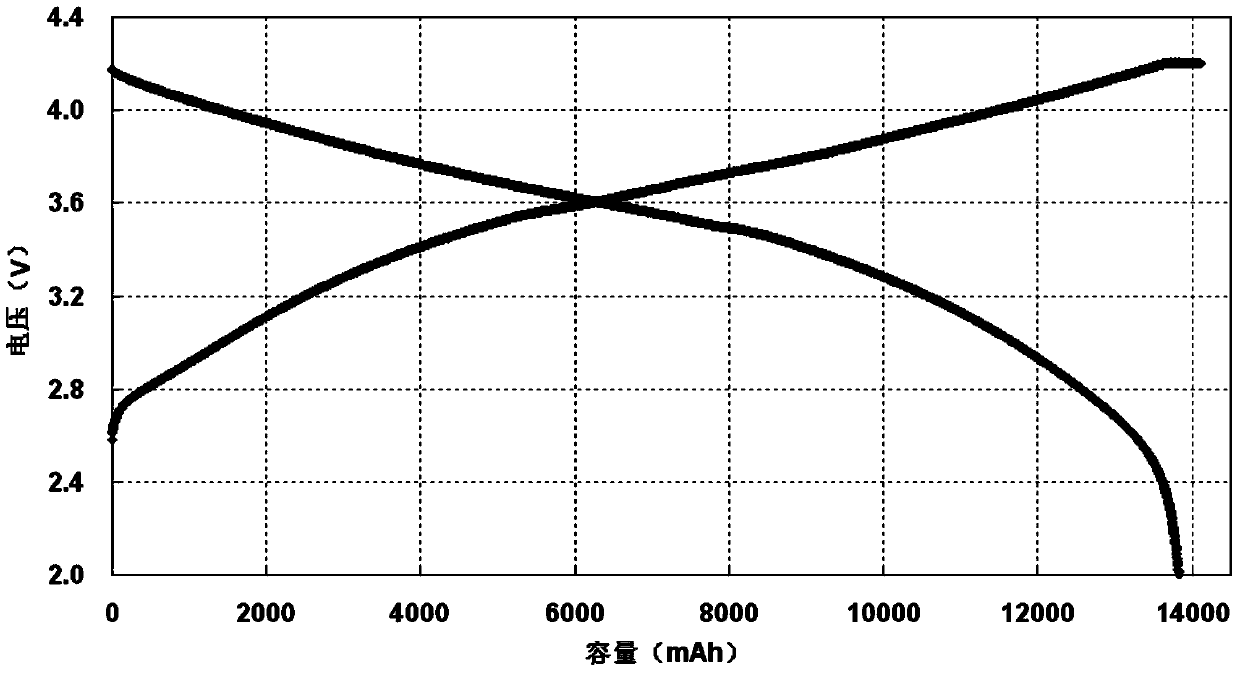

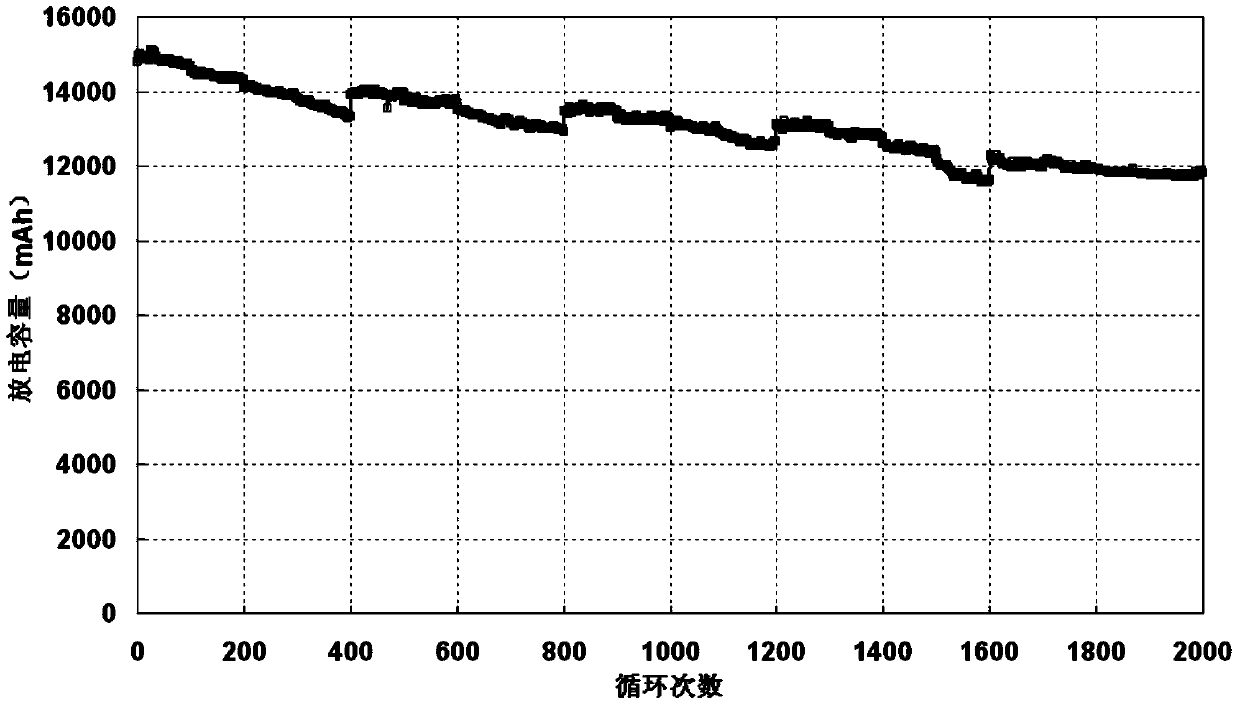

[0045] The model of the prepared battery is P85120190 / 14Ah. The cells are laminated and packaged with aluminum-plastic film to form a soft pack power and energy storage lithium battery. The physical and chemical indicators of the negative active material soft carbon are shown in Table 1. The gram capacity of the positive and negative active materials is designed according to the gram capacity of the first delithiation and the first lithium intercalation, respectively, and the capacity matching design of the positive and negative electrodes is designed according to the ratio of the negative electrode capacity to the positive electrode capacity of 108%. The specific design method is shown in Table 2.

[0046] (1) Mix 94.5wt% soft carbon, 2.0wt% carbon black, 1.5wt% carboxymethyl cellulose, 2.0wt% styrene-butadiene rubber and solvent water to form a slurry, and evenly coat it on the copper foil Above, the coating surface density is 140g / m on both sides 2 , after baking, rolling, ...

Embodiment 2

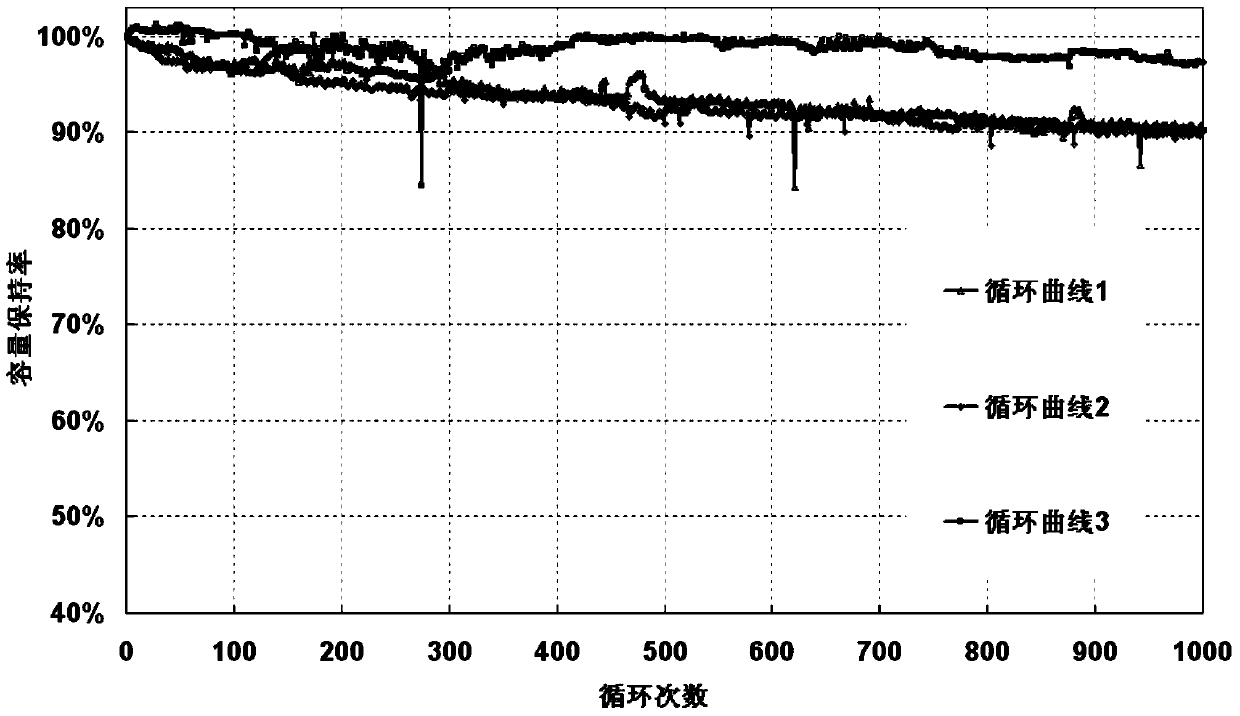

[0065] The battery was prepared by the same method as in Example 1, except that the capacity matching design of the positive and negative electrodes was designed according to the ratio of the capacity of the negative electrode to the capacity of the positive electrode as 100%.

[0066] After capacity analysis, the actual 1C capacity of the battery is more than 14.8Ah, the energy density of the battery cell is more than 150Wh / Kg, the 1C gram capacity of the positive electrode active material is 158mAh / g or more, and the 1C gram capacity of the negative electrode active material is 258mAh / g or more. The first discharge efficiency is over 85%.

[0067] Then, the battery was subjected to a charge-discharge cycle performance test at room temperature at 5C. After testing, the capacity retention rate of the battery after 1000 cycles was 86.7%.

[0068] After putting the battery at -40°C for 8 hours, discharge it at 1C, and the discharge capacity is greater than 53%.

[0069] After t...

Embodiment 3

[0072] The battery was prepared by the same method as in Example 1, except that the capacity matching design of the positive and negative electrodes was designed according to the ratio of the capacity of the negative electrode to the capacity of the positive electrode at 150%.

[0073]After capacity analysis, the actual 1C capacity of the battery is more than 13.2Ah, the 1C gram capacity of the positive electrode active material is more than 142mAh / g, the 1C gram capacity of the negative electrode active material is more than 237mAh / g, and the first charge and discharge efficiency is 81.6%.

[0074] Then, the battery was subjected to a charge-discharge cycle performance test at room temperature at 5C. After testing, the capacity retention rate of the battery was 84.7% after 1000 cycles.

[0075] After the battery is fully charged and overcharged at 3C / 12V, the battery has no fire or explosion, and the highest temperature on the battery surface is 42°C.

[0076] The voltage ran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com