High-energy density lithium manganate positive electrode material and preparation method thereof

A density lithium manganate, cathode material technology, applied in manganate/permanganate, battery electrodes, electrical components, etc., can solve the problems of poor cycle performance, low compaction density, low gram capacity, etc. Improve tap density and compaction density, improve compaction density, increase the effect of gram capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

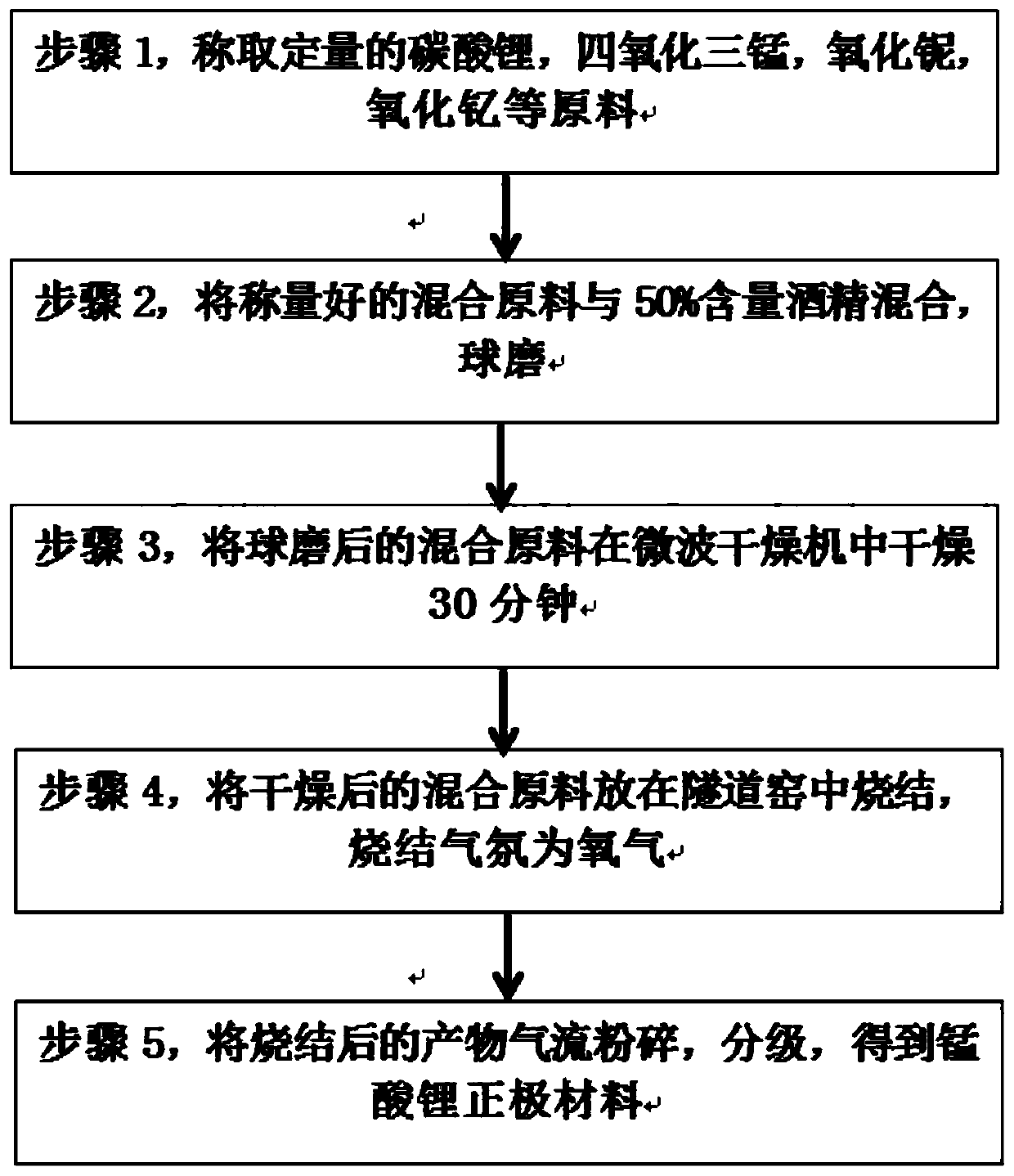

[0032] Such as figure 1 Shown, a kind of preparation method of lithium manganate cathode material of high energy density comprises the following steps:

[0033] S1. Mix lithium salt, trimanganese tetraoxide precursor, niobium oxide and yttrium oxide according to the designed ratio, then add ethanol solution and mix evenly to obtain mixed raw material A;

[0034]S2. Fully drying the mixed raw material A in a microwave dryer to obtain a dry mixed raw material B;

[0035] S3, placing the dry mixed raw material B in an orbital kiln for sintering to obtain a sintered product C;

[0036] S4. After jet crushing the sintered product C, a lithium manganate positive electrode material with high energy density is obtained.

[0037] Further, in order to better implement the present invention, in step S1, the mass percentage of each raw material is: lithium salt 22-32%, trimanganese tetraoxide precursor 62-81%, niobium oxide 1.6-2.5%, yttrium oxide 0.7% -1.4%, the sum of the total mass ...

Embodiment 1

[0045] A preparation method of high energy density lithium manganate cathode material, which comprises the following steps:

[0046] Step 1. Weigh the following raw materials: 0.427g of lithium carbonate, 1.54g of spherical or quasi-spherical manganese tetraoxide, 0.147g of niobium oxide, and 0.0327g of yttrium oxide;

[0047] Step 2. Add all the raw materials weighed in step 1 into the ball mill tank, add 1.07g of 50% alcohol and 50% high-purity water mixture (i.e. ethanol solution), the ball milling time is 3h, the ball milling speed is 1500r / min, and the mixed raw material A is obtained ;

[0048] Step 3. Place the mixture prepared in step 2 in a microwave dryer and dry it in microwave for 30 minutes to obtain dry mixed raw material B;

[0049] Step 4. Put the mixed raw material B prepared in step 3 into a tunnel kiln for sintering, the sintering atmosphere is oxygen, and the sintering conditions are: pre-firing temperature 540°C, heat preservation for 4 hours, then raise ...

Embodiment 2

[0058] A preparation method of high energy density lithium manganate cathode material, which comprises the following steps:

[0059] Step 1, 0.5245g of lithium carbonate, 2.02g of spherical or quasi-spherical trimanganese tetraoxide, 0.215g of niobium oxide, and 0.052g of yttrium oxide;

[0060] Step 2. Add all the raw materials weighed in step 1 into a ball mill tank, add 1.45g of 50% alcohol and 50% high-purity water mixture, the ball milling time is 2h, the ball milling speed is 1500r / min, and the mixed raw material A is obtained;

[0061] Step 3. Place the mixture prepared in step 2 in a microwave dryer and dry it in microwave for 30 minutes to obtain dry mixed raw material B;

[0062] Step 4. Put the mixed raw material B obtained in step 3 into a tunnel kiln for sintering, the sintering atmosphere is oxygen, and the sintering conditions are: pre-firing temperature 560°C, heat preservation 6h, then raise the temperature to 785°C, heat preservation 10h, wherein, the heating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com