Patents

Literature

1963results about How to "Improve overall lifespan" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

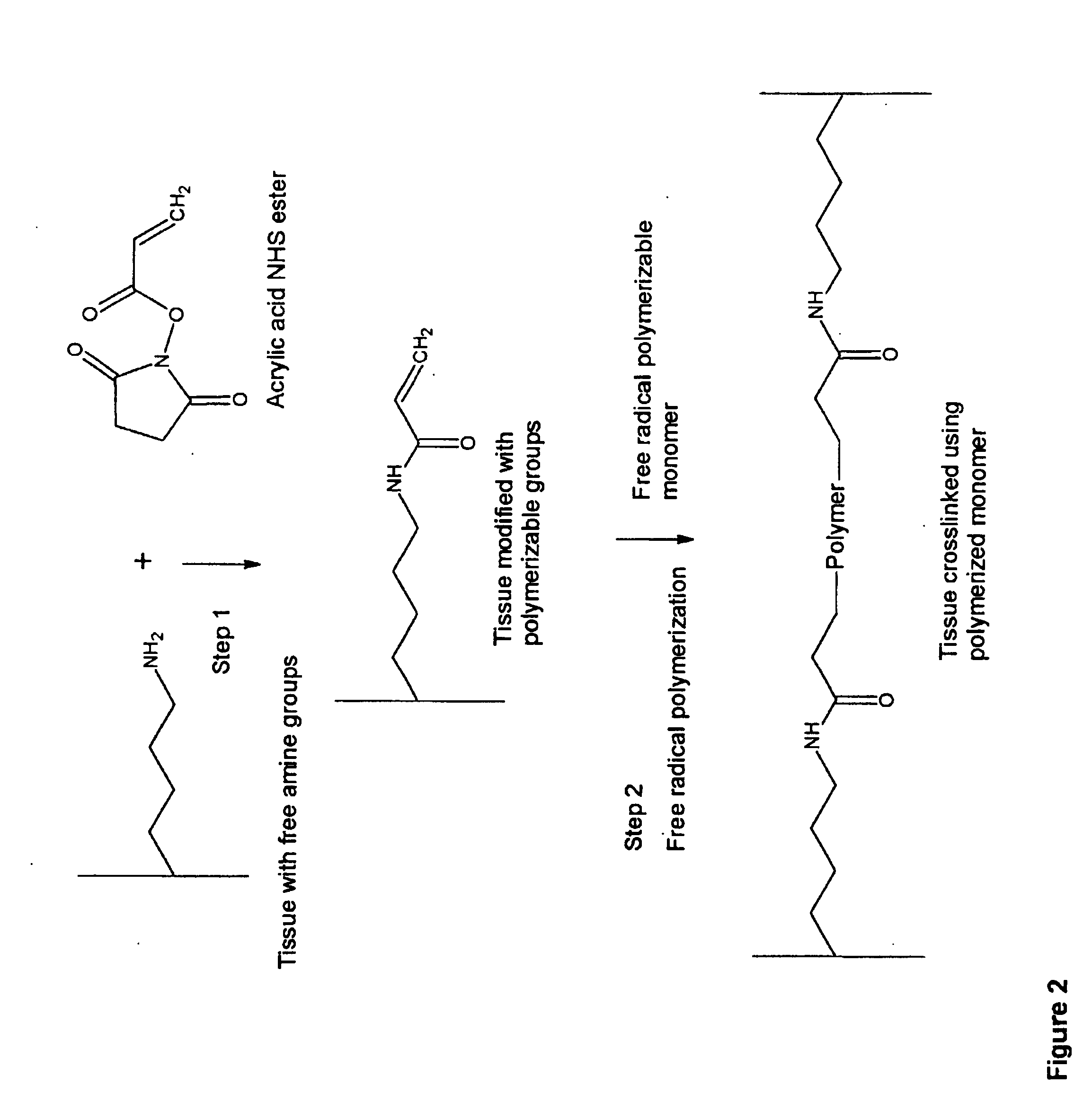

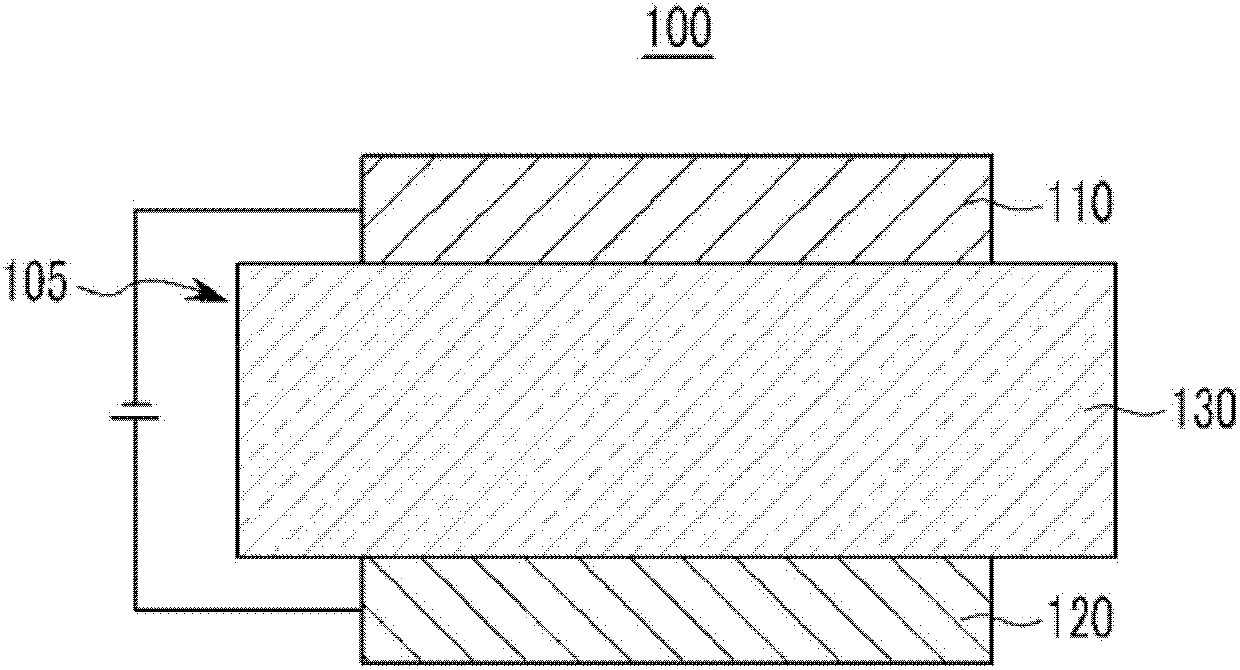

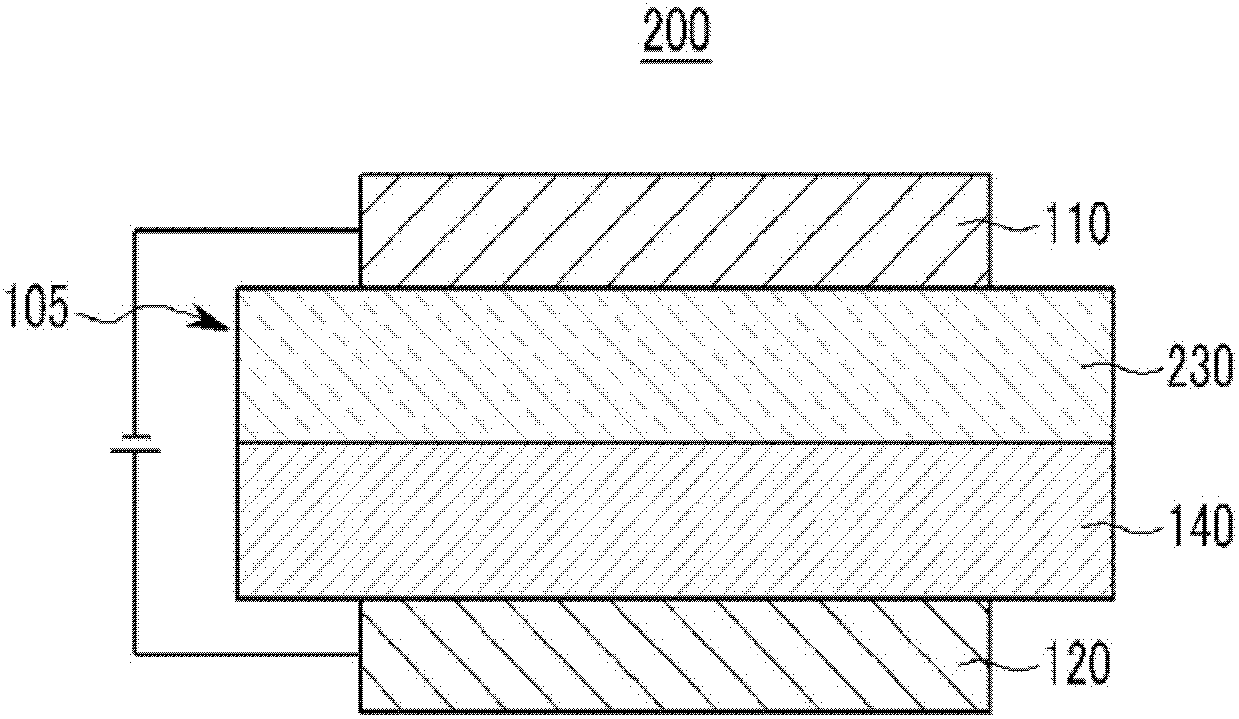

Implantable Tissue Compositions and Method

InactiveUS20070254005A1Promotes localized deliveryImprove overall lifespanNervous disorderAntipyreticWater insolubleFixation method

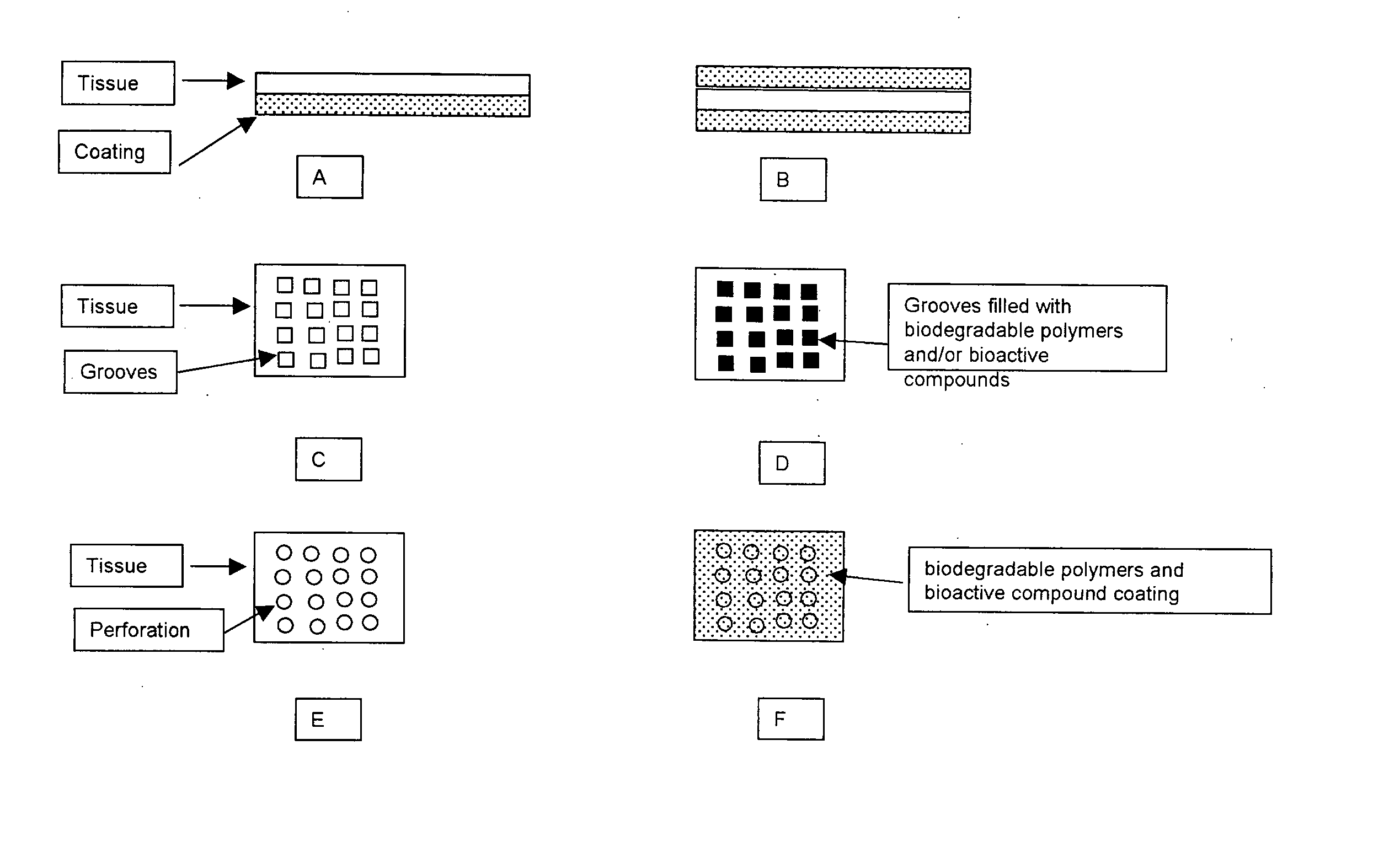

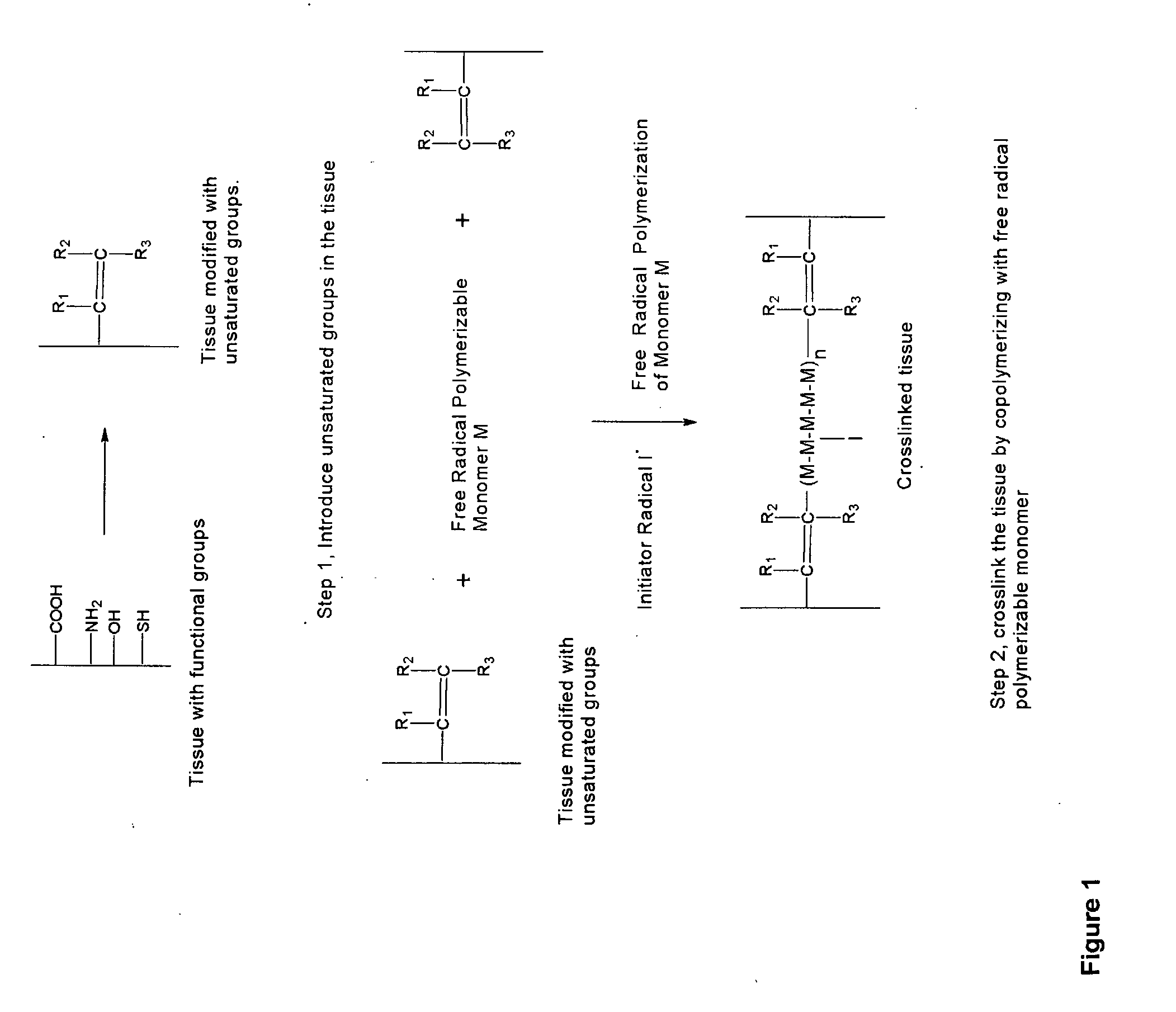

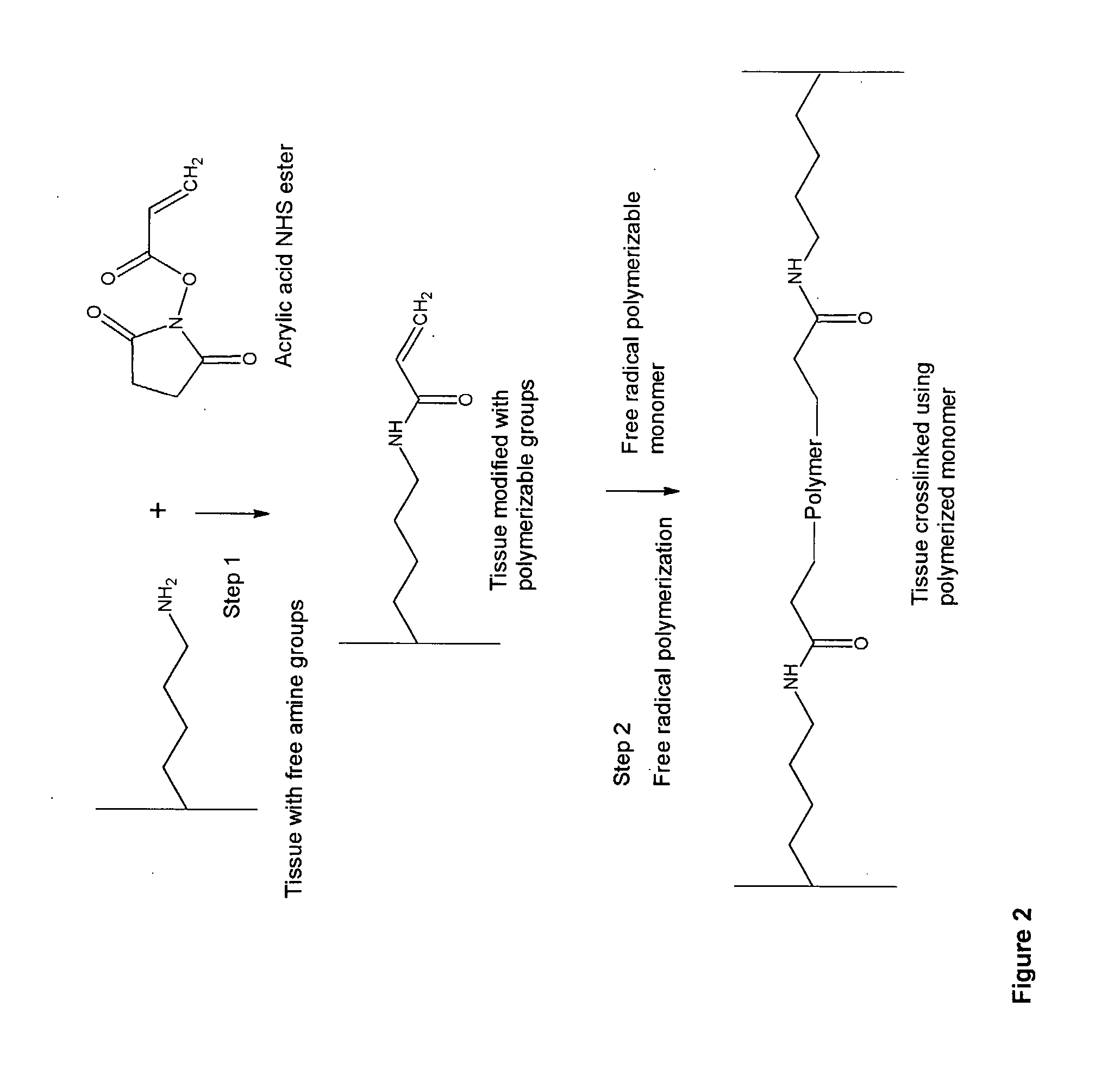

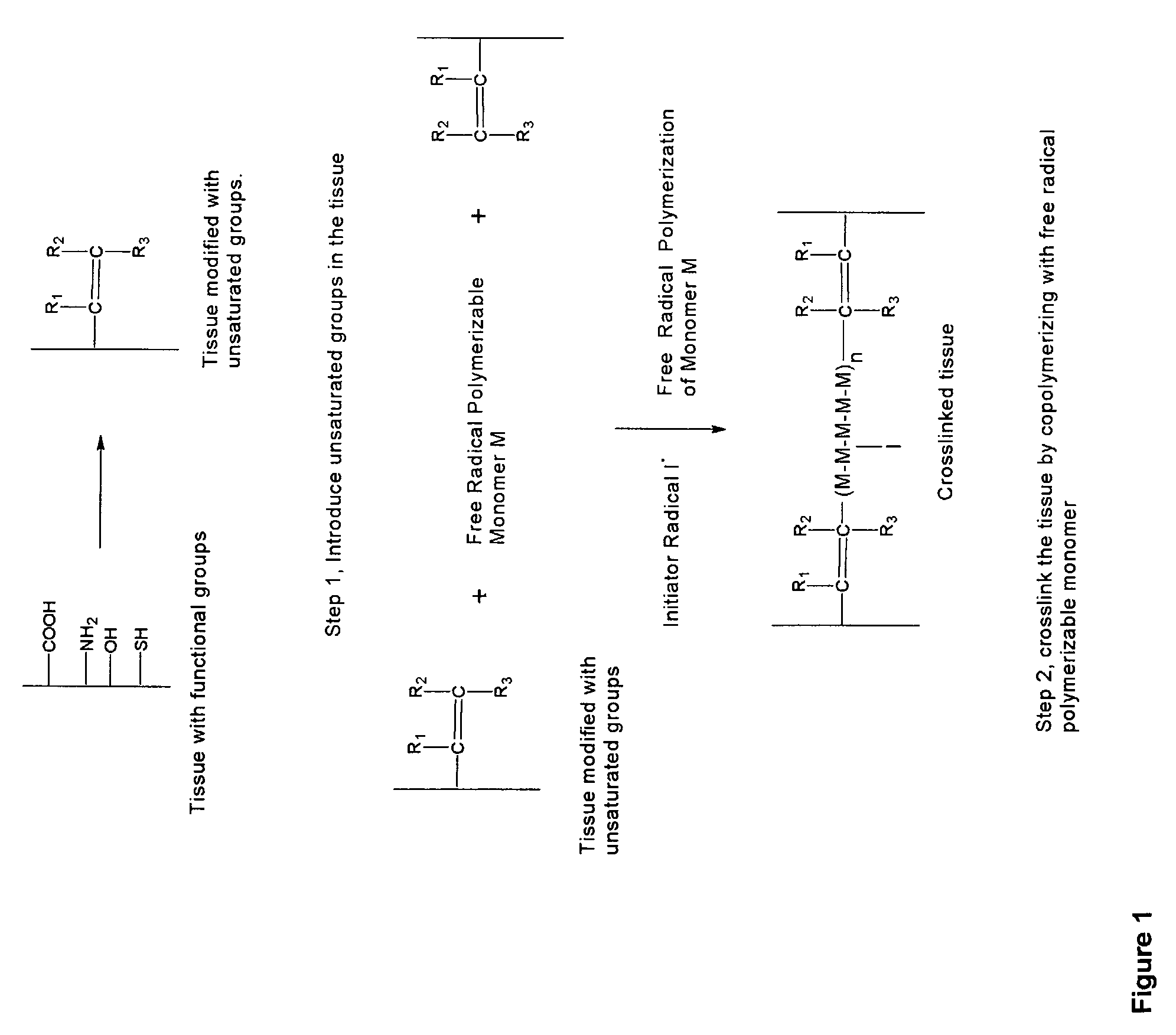

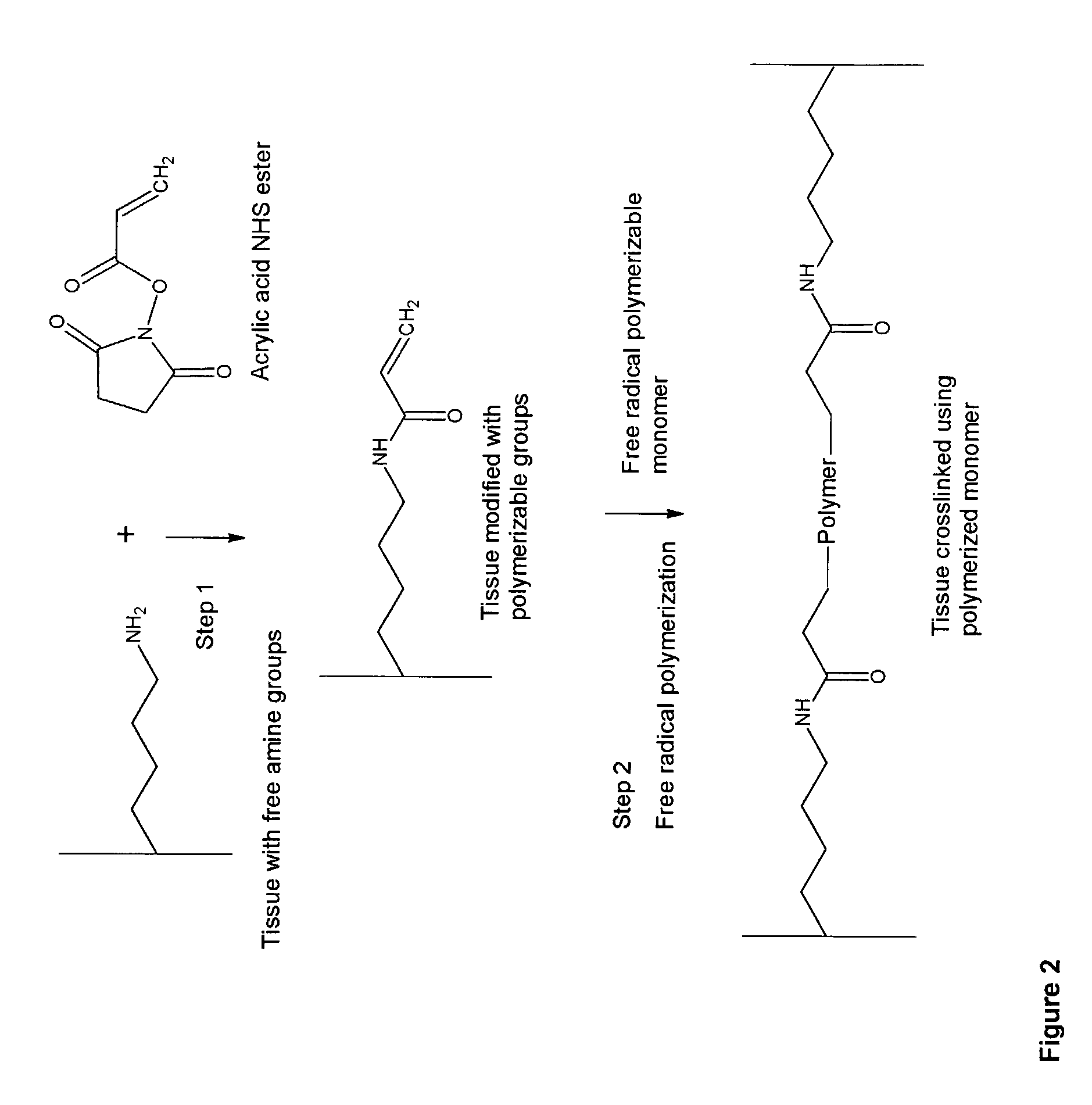

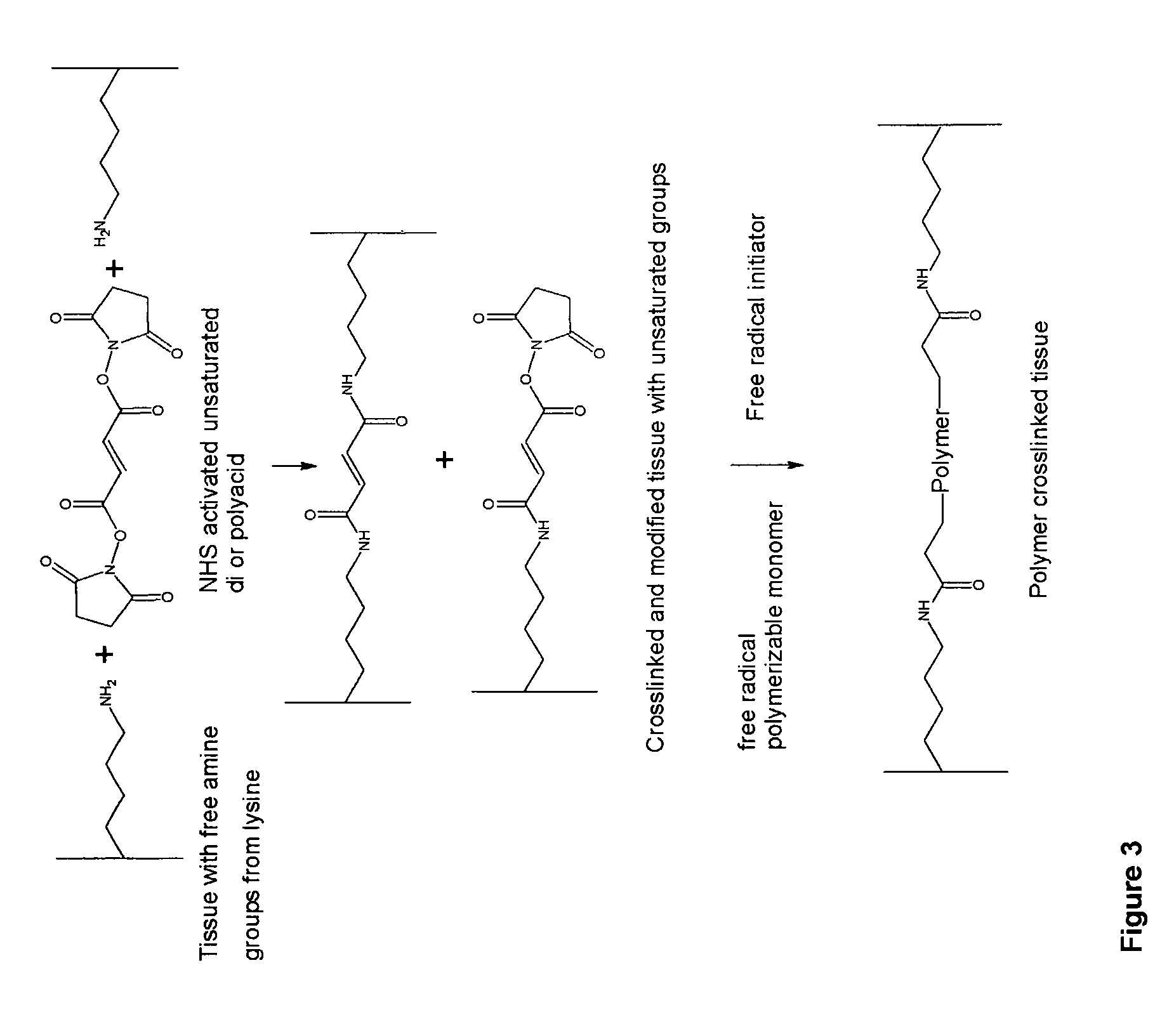

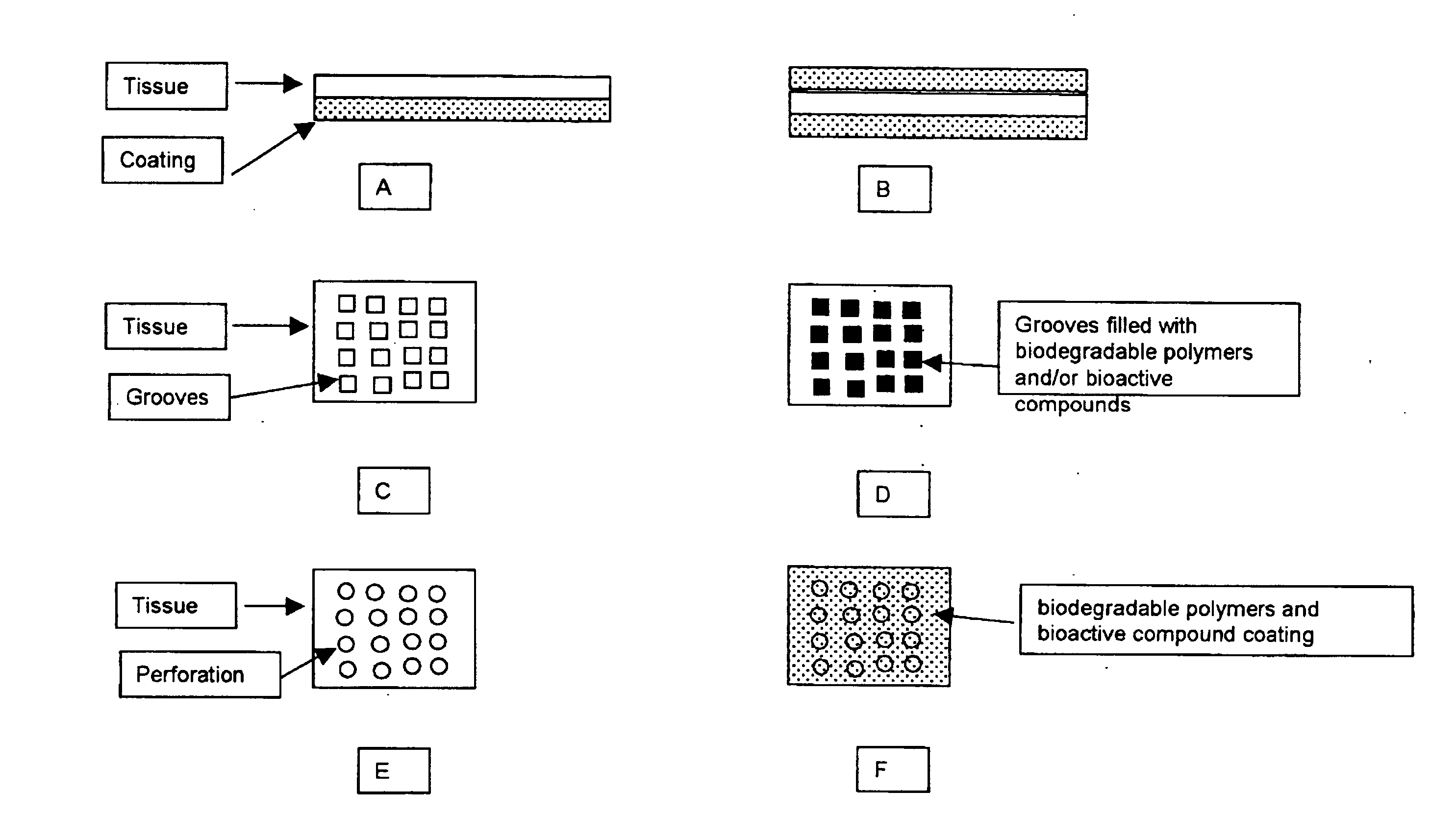

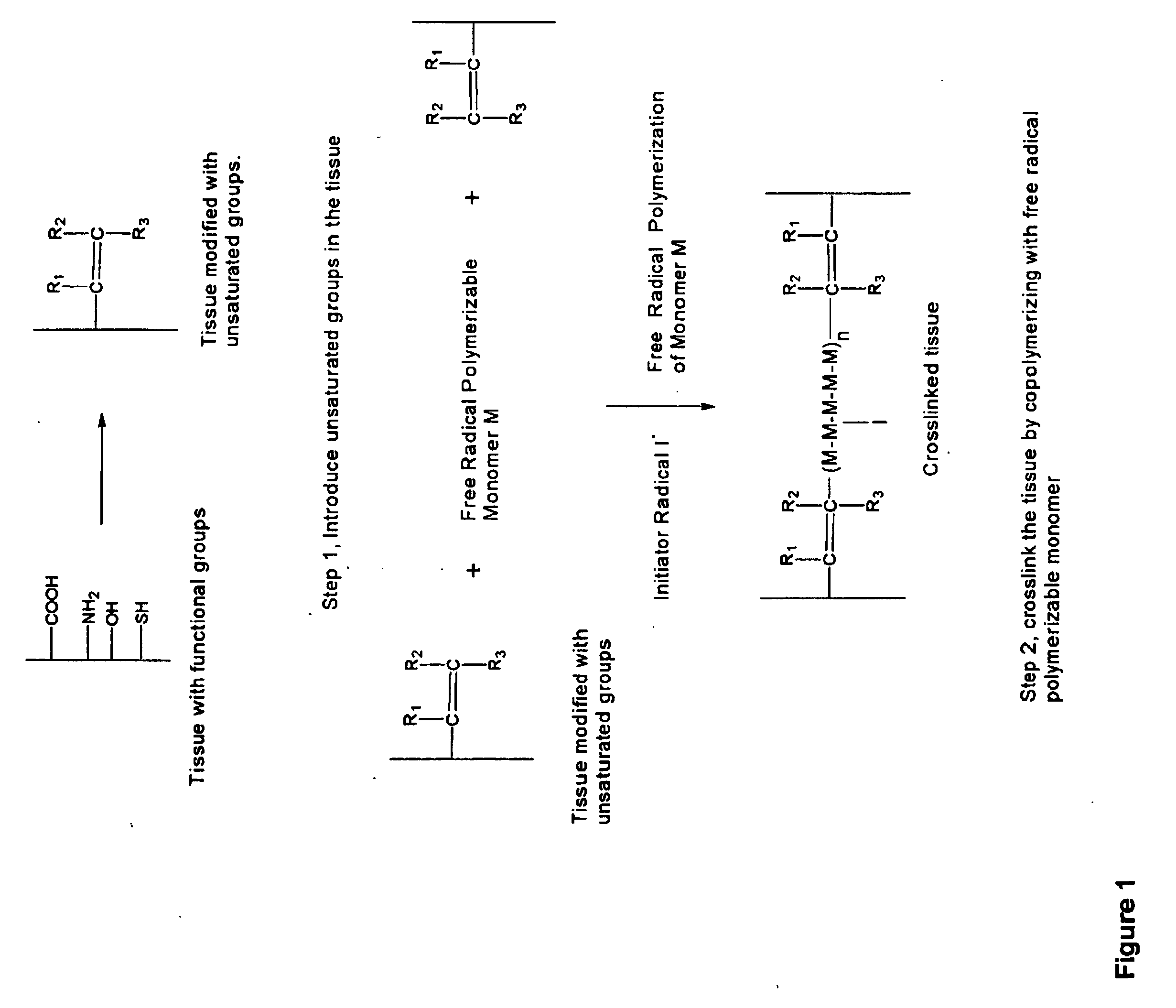

Novel implantable tissue fixation methods and compositions are disclosed. Methods and compositions of tissue, fixed using polymeric and / or variable length crosslinks, and di- or polymercapto compounds are described. Also described are the methods and compositions wherein the tissue is fixed using biodegradable crosslinkers. Methods and compositions for making radioopaque tissue are also described. Methods and compositions to obtain a degradable implantable tissue-synthetic biodegradable polymer composite are also described. Compositions and methods of incorporating substantially water-insoluble bioactive compounds in the implantable tissue are also disclosed. The use of membrane-like implantable tissue to make an implantable drug delivery patch are also disclosed. Also described are the compositions and methods to obtain a coated implantable tissue. Medical applications implantable tissue such as heart valve bioprosthesis, vascular grafts, meniscus implant, drug delivery patch are also disclosed.

Owner:PATHAK HLDG

Implantable tissue compositions and method

InactiveUS7919112B2Improve overall lifespanPromotes localized deliveryNervous disorderAntipyreticWater insolubleFixation method

Novel implantable tissue fixation methods and compositions are disclosed. Methods and compositions of tissue, fixed using polymeric and / or variable length crosslinks, and di- or polymercapto compounds are described. Also described are the methods and compositions wherein the tissue is fixed using biodegradable crosslinkers. Methods and compositions for making radio-opaque tissue are also described. Methods and compositions to obtain a degradable implantable tissue-synthetic biodegradable polymer composite are also described. Compositions and methods of incorporating substantially water-insoluble bioactive compounds in the implantable tissue are also disclosed. The use of membrane-like implantable tissue to make an implantable drug delivery patch are also disclosed. Also described are the compositions and methods to obtain a coated implantable tissue. Medical applications implantable tissue such as heart valve bioprosthesis, vascular grafts, meniscus implant, drug delivery patch are also disclosed.

Owner:PATHAK HLDG

Implantable tissue compositions and method

InactiveUS20090130162A2Improve overall lifespanPromotes localized deliveryNervous disorderAntipyreticWater insolubleFixation method

Novel implantable tissue fixation methods and compositions are disclosed. Methods and compositions of tissue, fixed using polymeric and / or variable length crosslinks, and di- or polymercapto compounds are described. Also described are the methods and compositions wherein the tissue is fixed using biodegradable crosslinkers. Methods and compositions for making radio-opaque tissue are also described. Methods and compositions to obtain a degradable implantable tissue-synthetic biodegradable polymer composite are also described. Compositions and methods of incorporating substantially water-insoluble bioactive compounds in the implantable tissue are also disclosed. The use of membrane-like implantable tissue to make an implantable drug delivery patch are also disclosed. Also described are the compositions and methods to obtain a coated implantable tissue. Medical applications implantable tissue such as heart valve bioprosthesis, vascular grafts, meniscus implant, drug delivery patch are also disclosed.

Owner:PATHAK HLDG

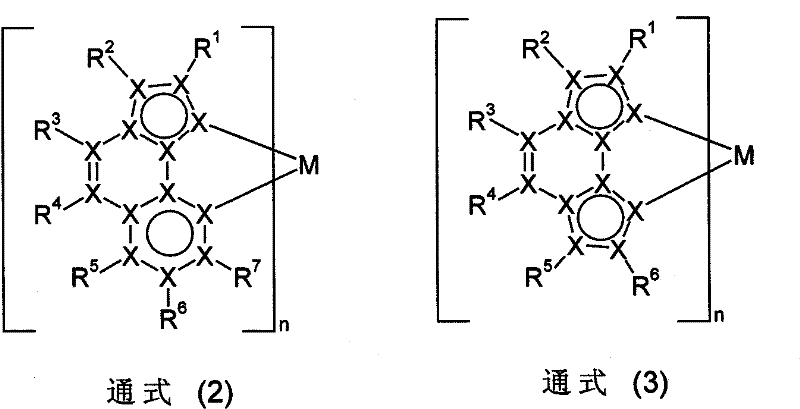

metal complex

ActiveCN102282150AImprove overall lifespanImprove efficiencyIndium organic compoundsElectroluminescent light sourcesEngineeringOrganic electroluminescence

Owner:UDC IRELAND

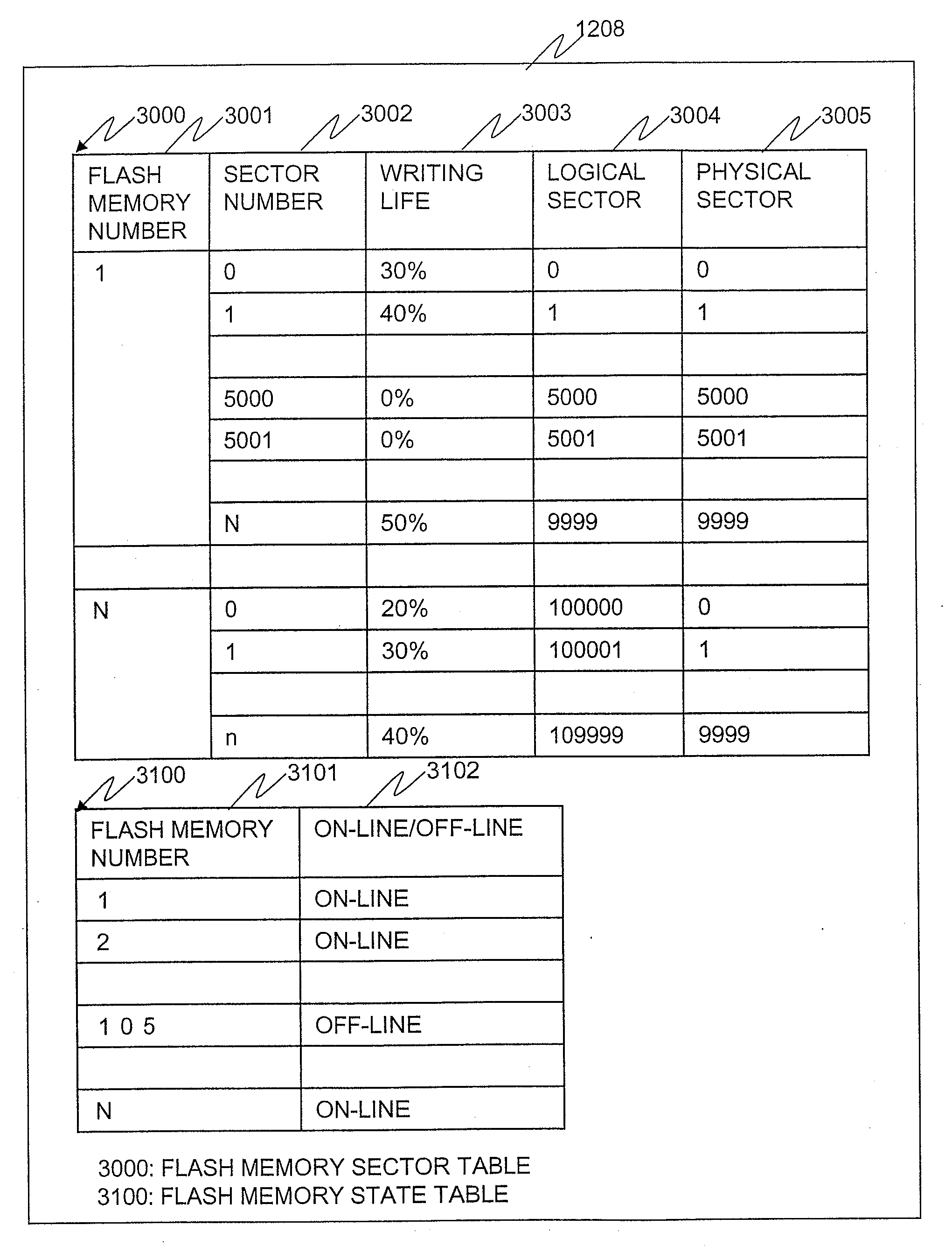

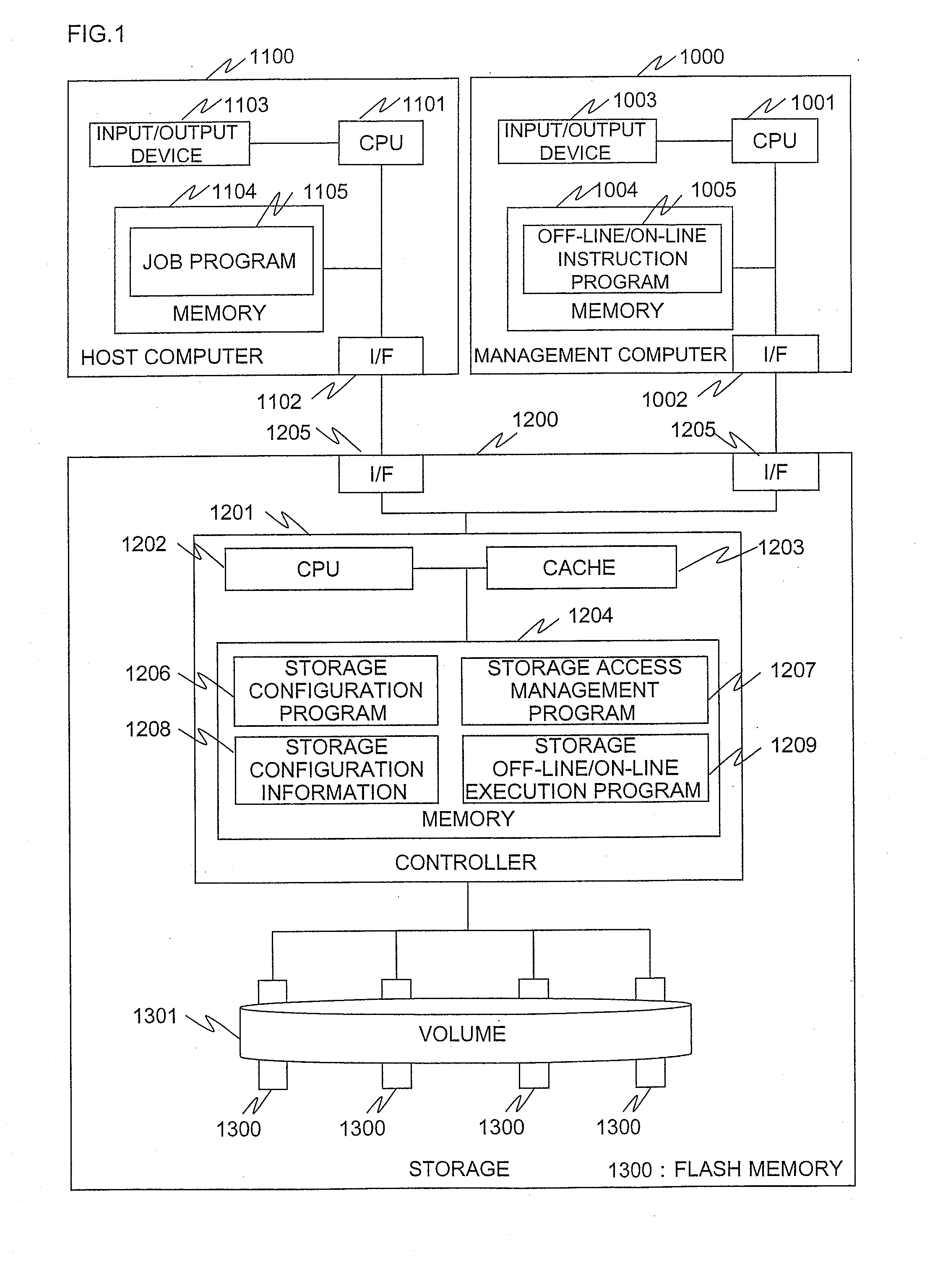

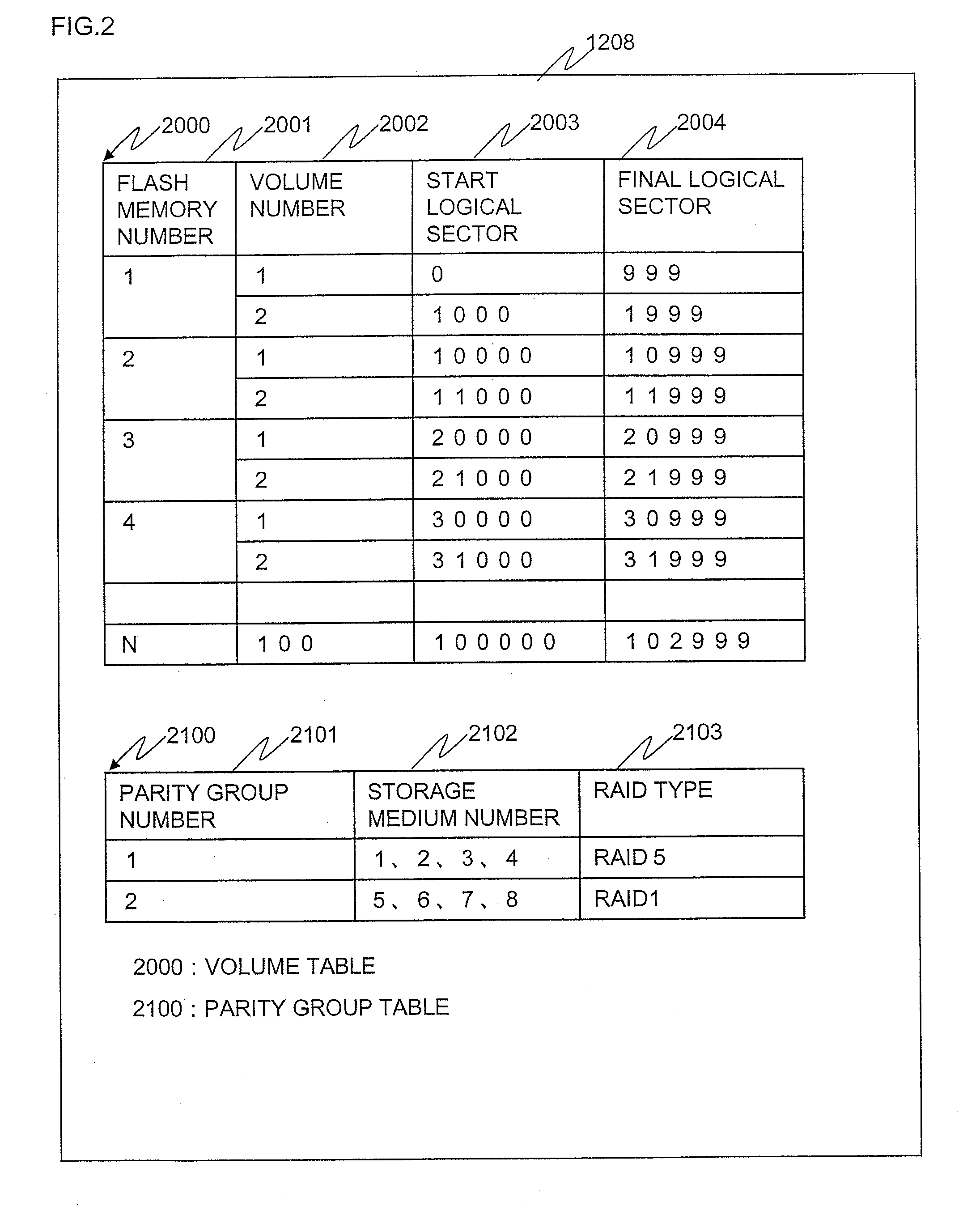

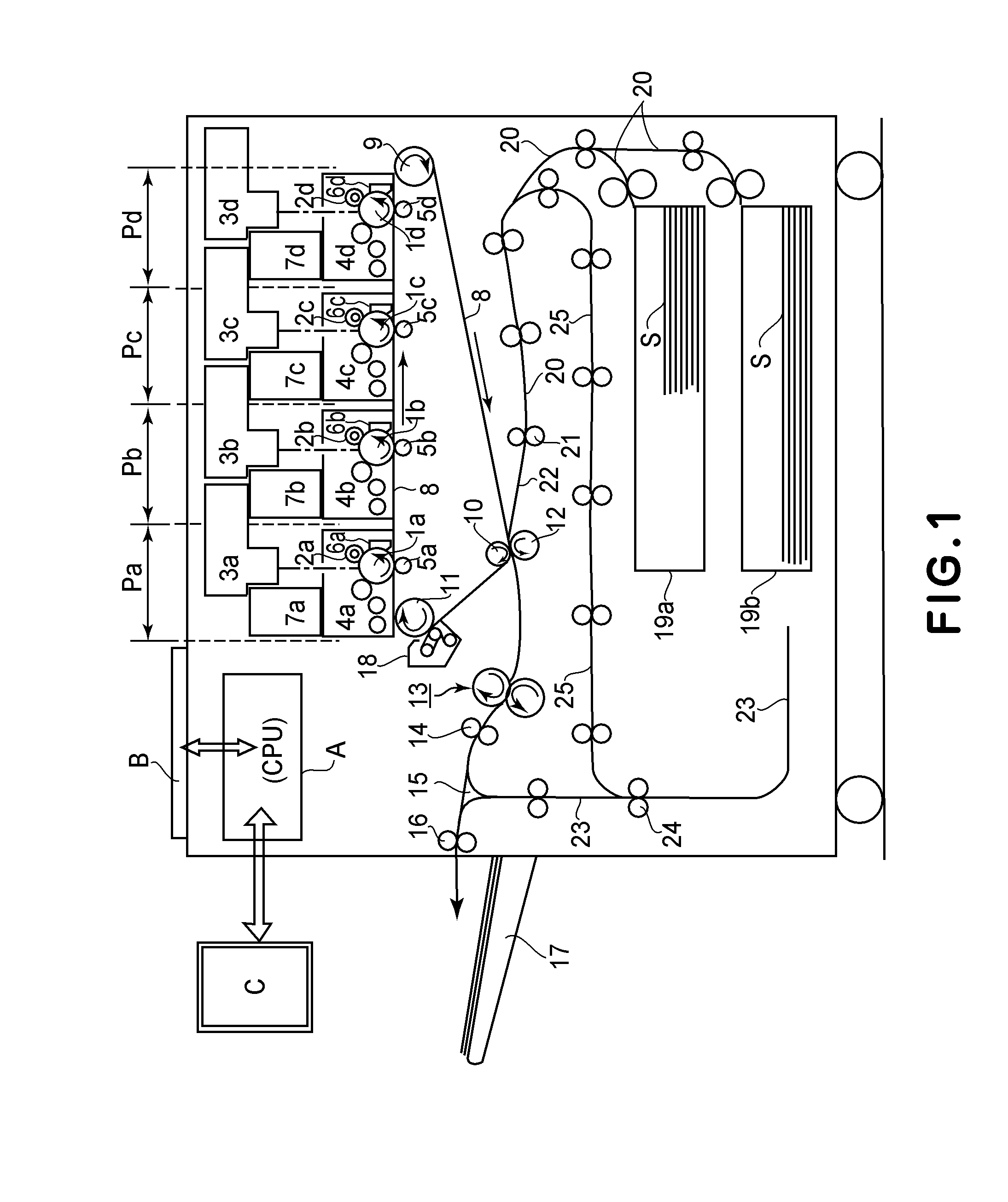

Storage system and storage management method

ActiveUS20080189477A1Reduce frequencyAvoid shortening of lifeMemory architecture accessing/allocationMemory adressing/allocation/relocationStorage managementManagement area

An object of the present invention is to provide a storage system and storage management method, which prevent a problem in the operation of stored data from being caused by unknown states of volume information and life information, when flash memories are placed in off-line mode and again placed in on-line mode. According to the present invention, there is provided a storage system 1200 which has flash memories 1300 constituting a storage area and a function of placing and handling the flash memories in off-line mode and on-line mode, and which stores and manages management information of the flash memories in on-line mode, the storage system including: when some or all of the flash memories in on-line mode are placed in off-line mode, creating a management area in off-line mode in the flash memories by moving existing data in an area used as the management area to an area other than the management area; writing the management information of the flash memories to the created management area; and placing the flash memories in off-line mode.

Owner:HITACHI LTD

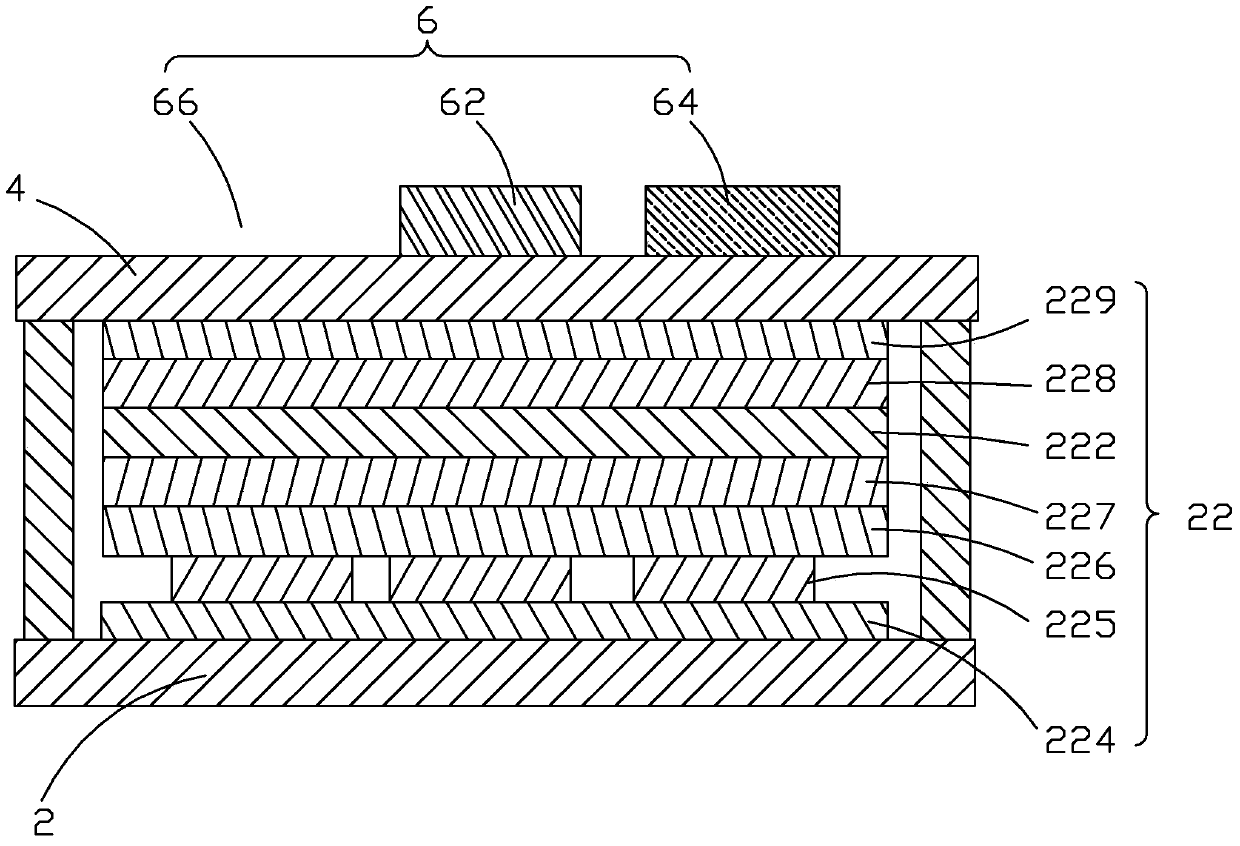

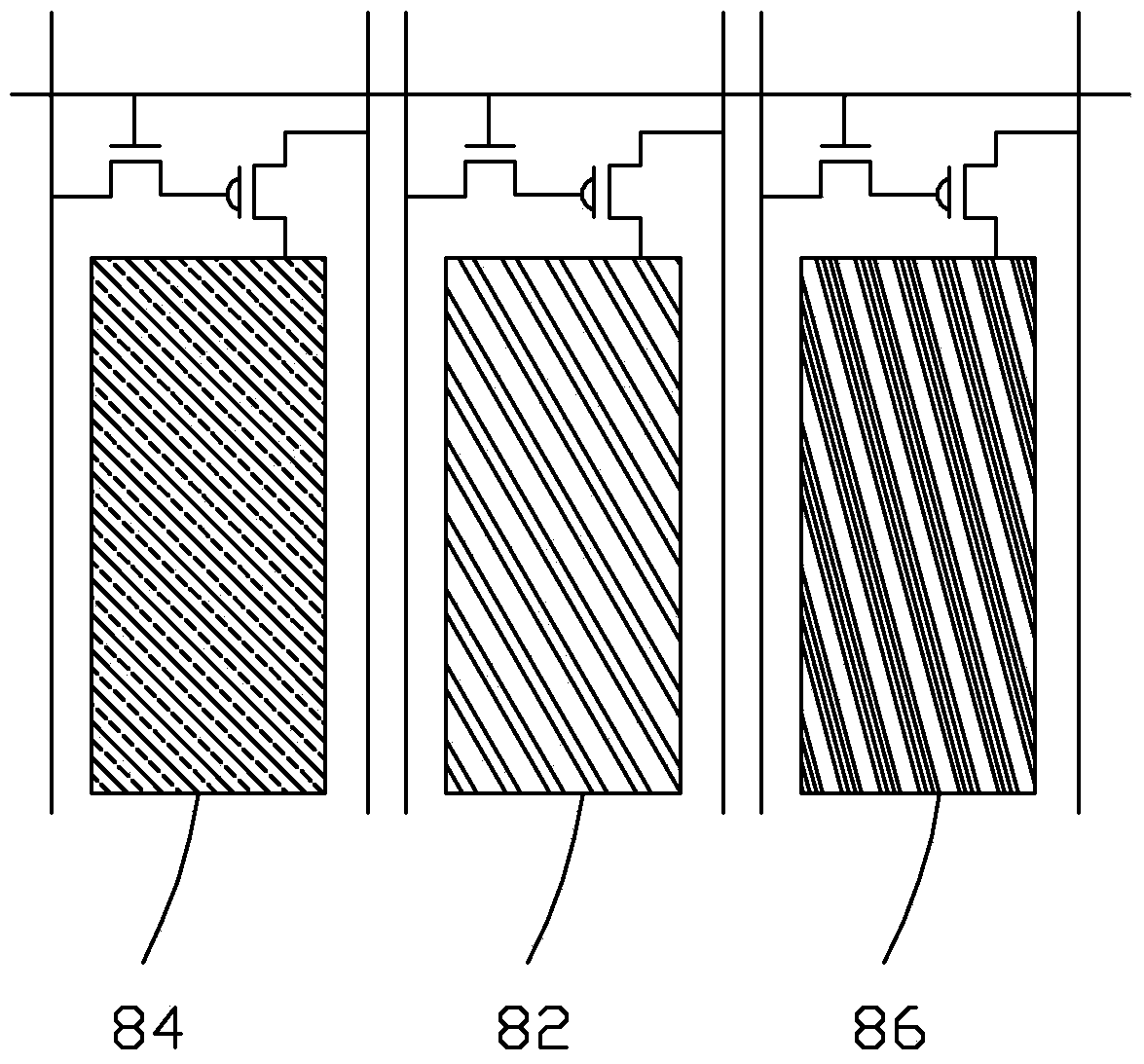

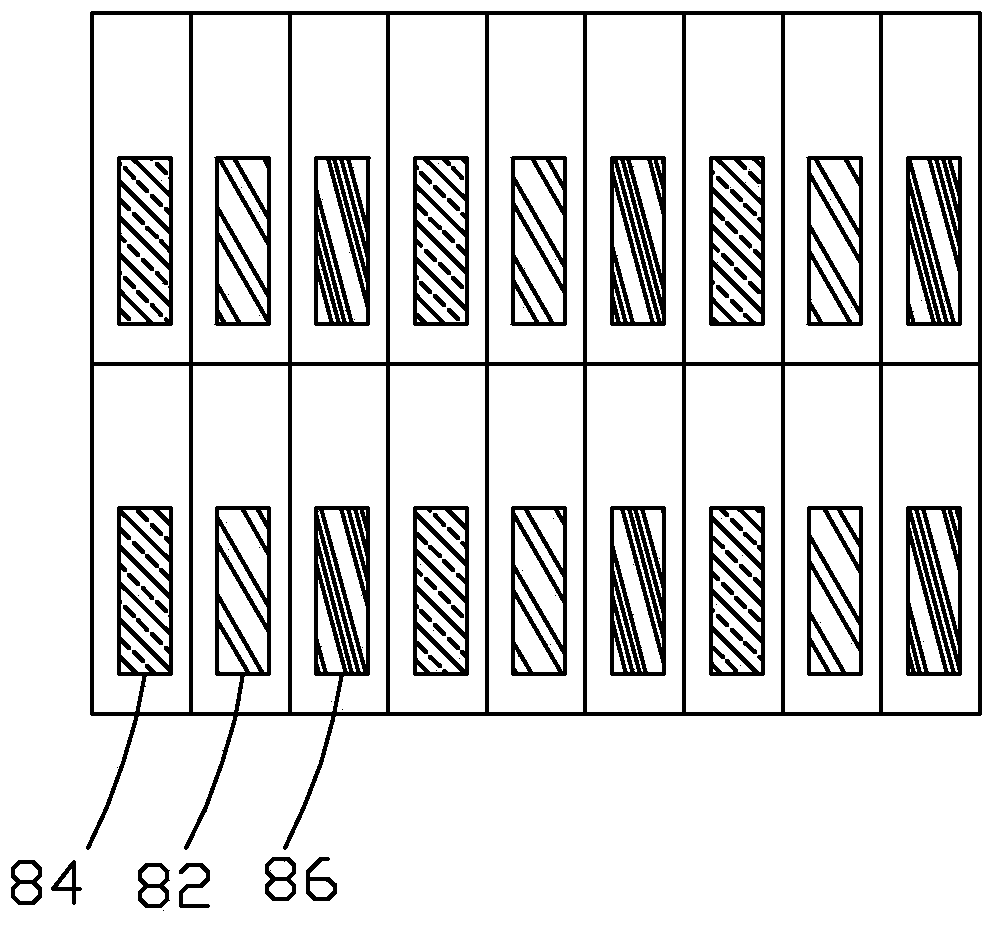

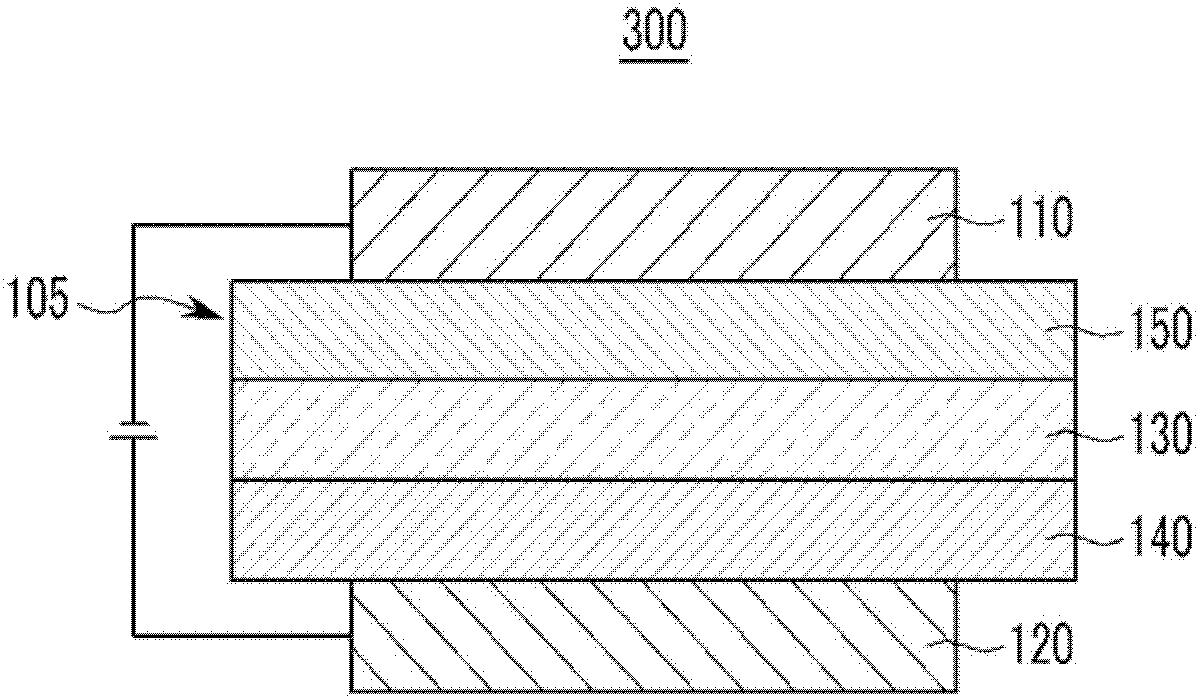

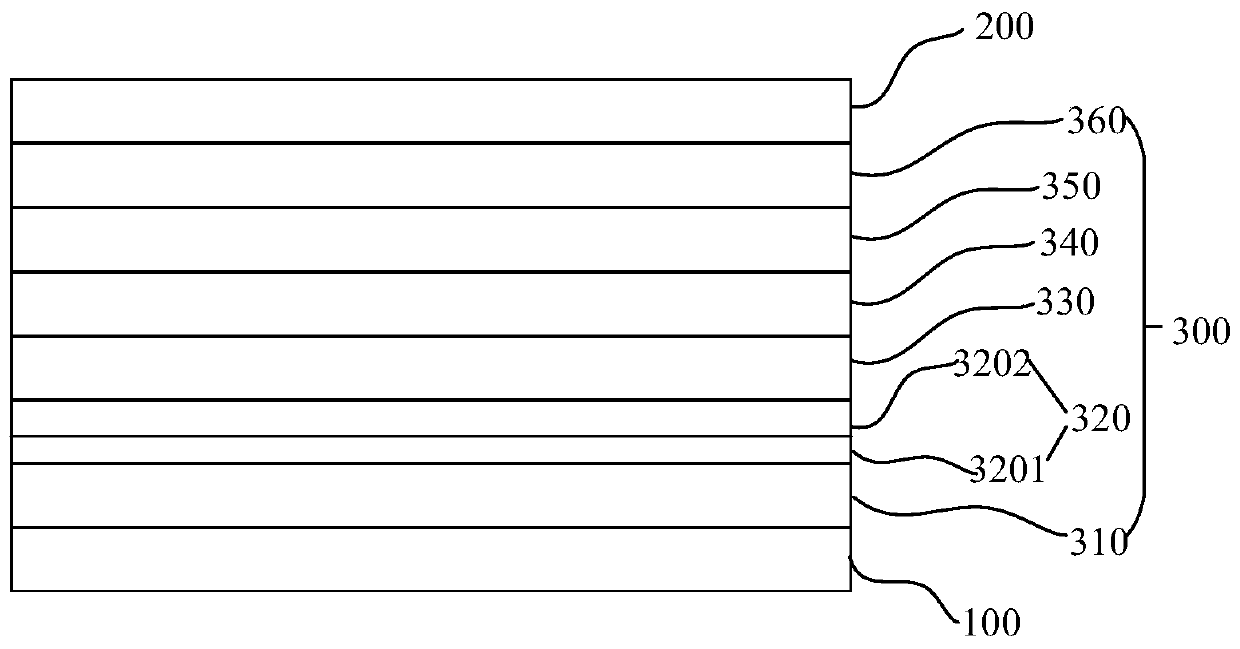

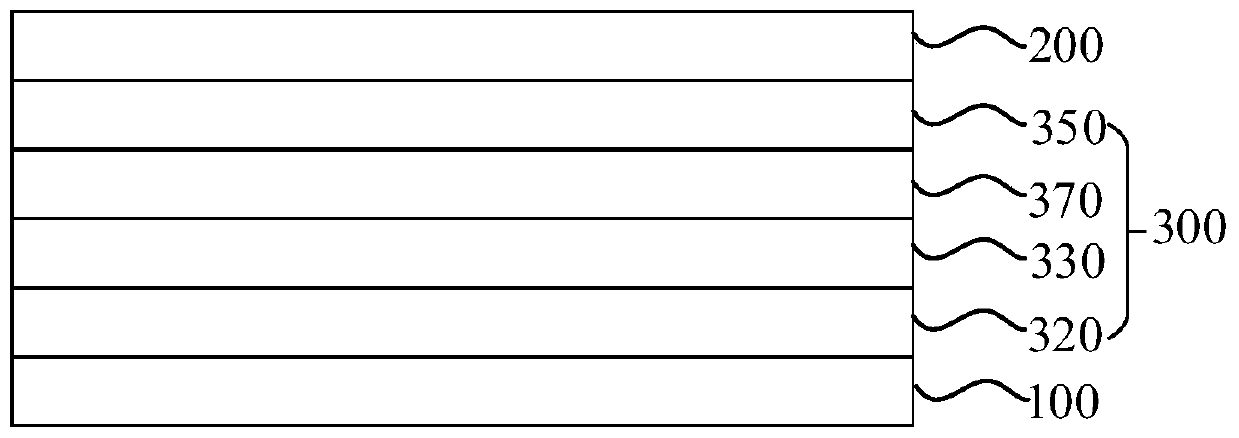

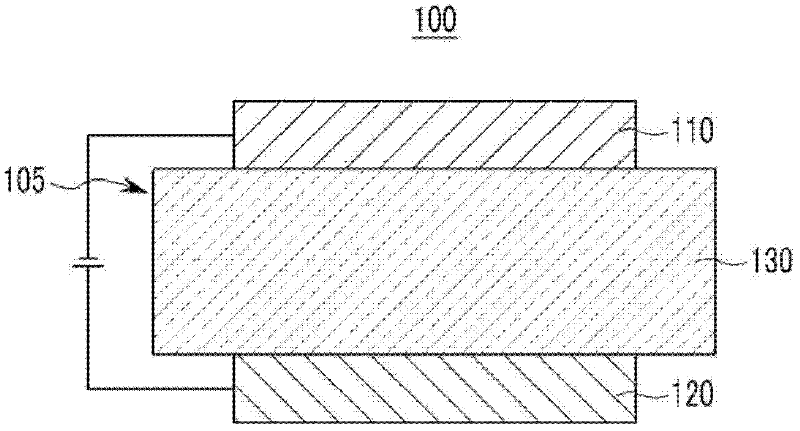

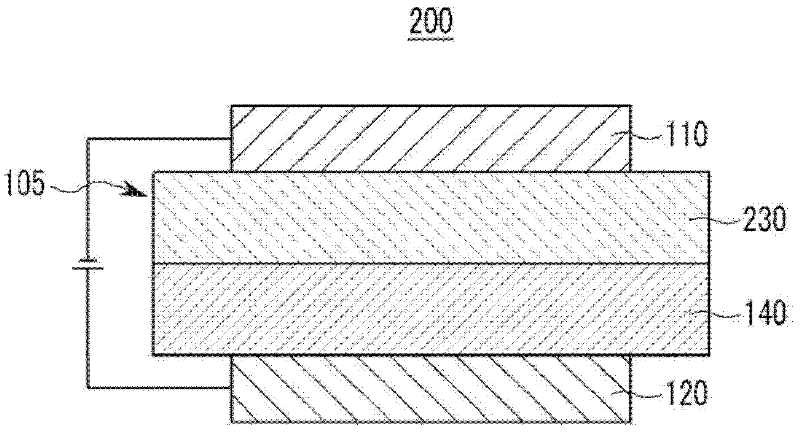

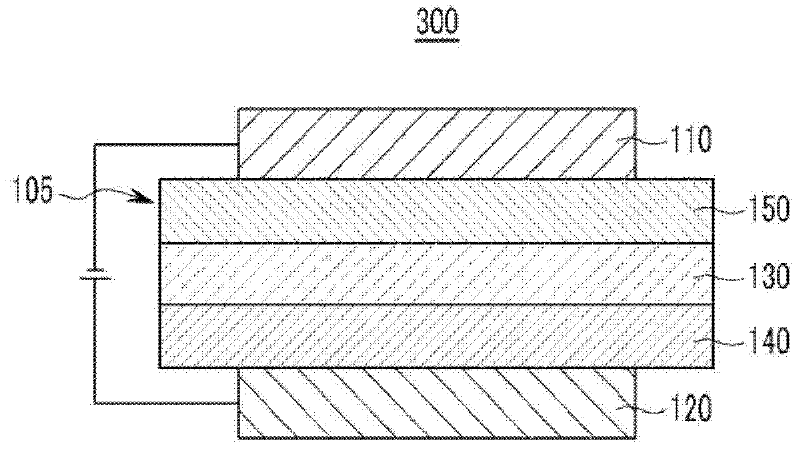

Colored OLED device and manufacturing method thereof

InactiveCN103474451AExtended service lifeSimple processSolid-state devicesSemiconductor/solid-state device manufacturingQuantum dotEngineering

The invention provides a colored OLED device and a manufacturing method thereof. The device comprises an OLED substrate (2), an OLED cover plate (4) attached to the OLED substrate (2), and a color conversion layer (6) formed on the OLED cover plate (4), wherein an OLED element (22) is formed on the OLED substrate (2), the OLED element (22) comprises a light-emitting layer (222), the color conversion layer (6) comprises a plurality of quantum dot units, and light emitted by the light-emitting layer (222) is converted through the quantum dot units of the color conversion layer (6) to achieve colorization. According to the colored OLED device and the manufacturing method, colorization display is achieved through the light-emitting layer and the quantum dot units, the thickness of the light-emitting layer is reduced, and then the thickness of the whole colored OLED device is reduced; besides, quantum dots further have the advantages of being good in stability, long in service life, good in color purity and the like, so the service life of the colored OLED device is prolonged, and color purity is improved; meanwhile, the colored OLED device is simple in manufacturing process and low in cost.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

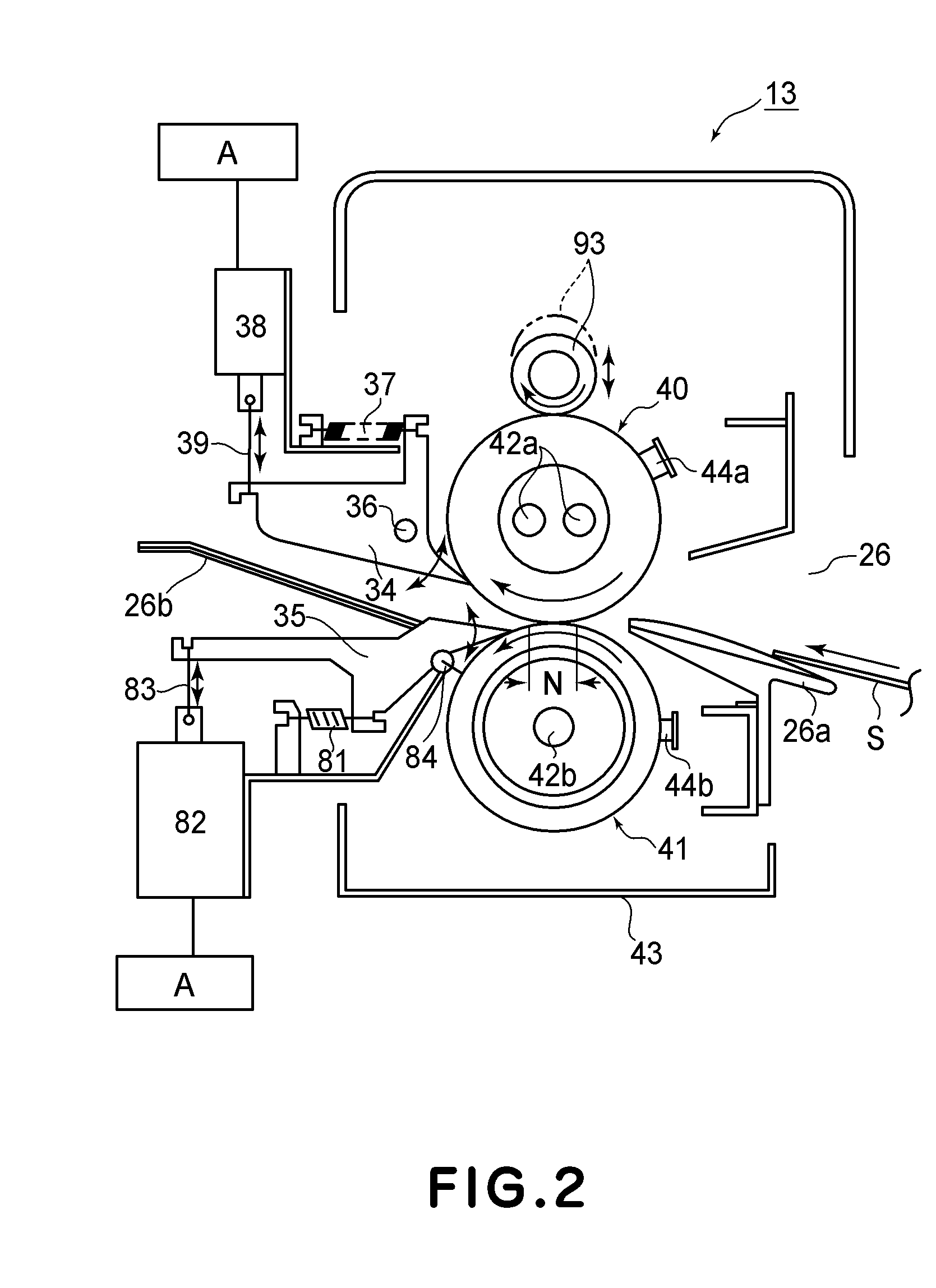

Image heating apparatus

InactiveUS20090297233A1Improve overall lifespanElectrographic process apparatusEngineeringElectrical and Electronics engineering

Owner:CANON KK

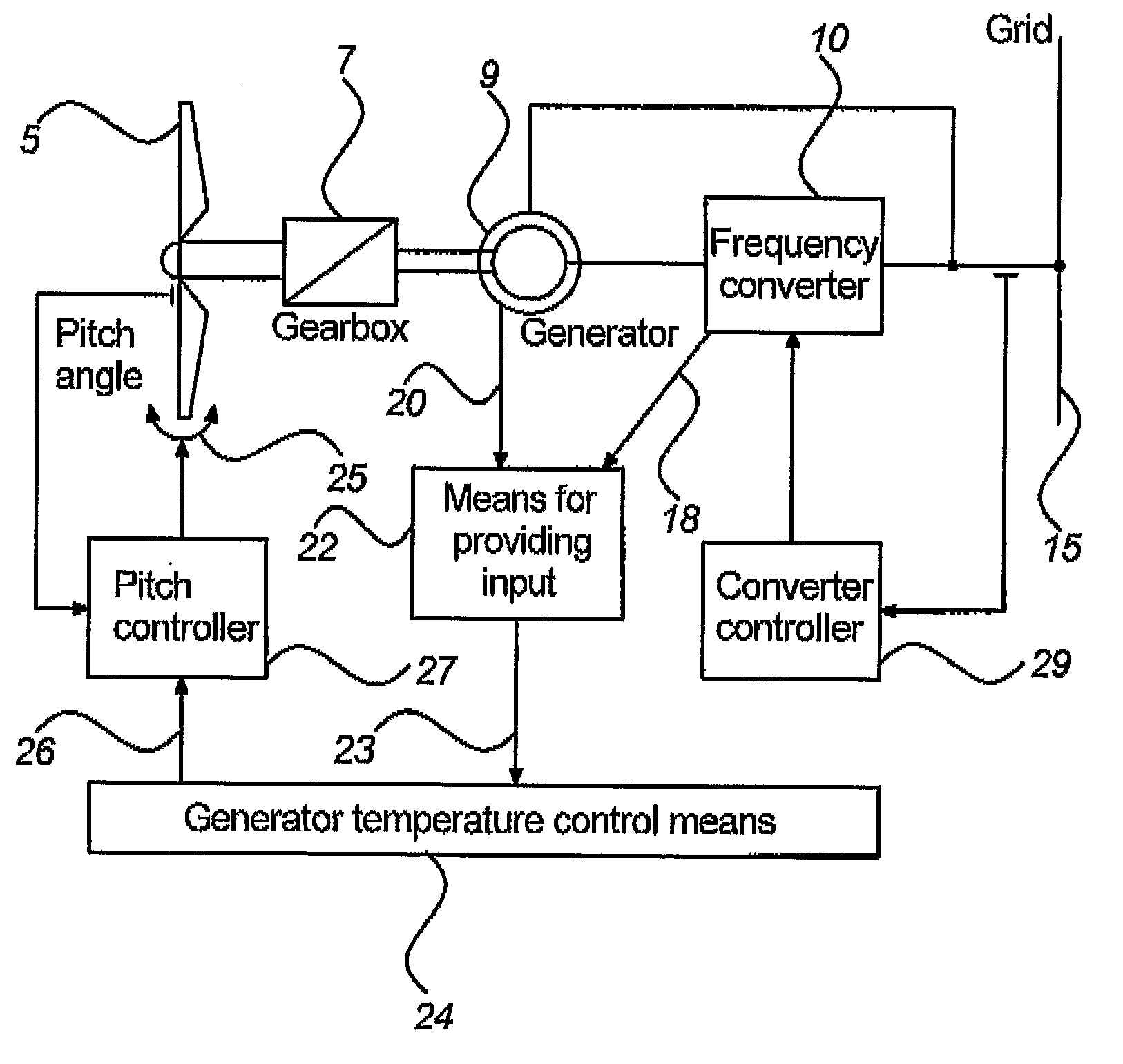

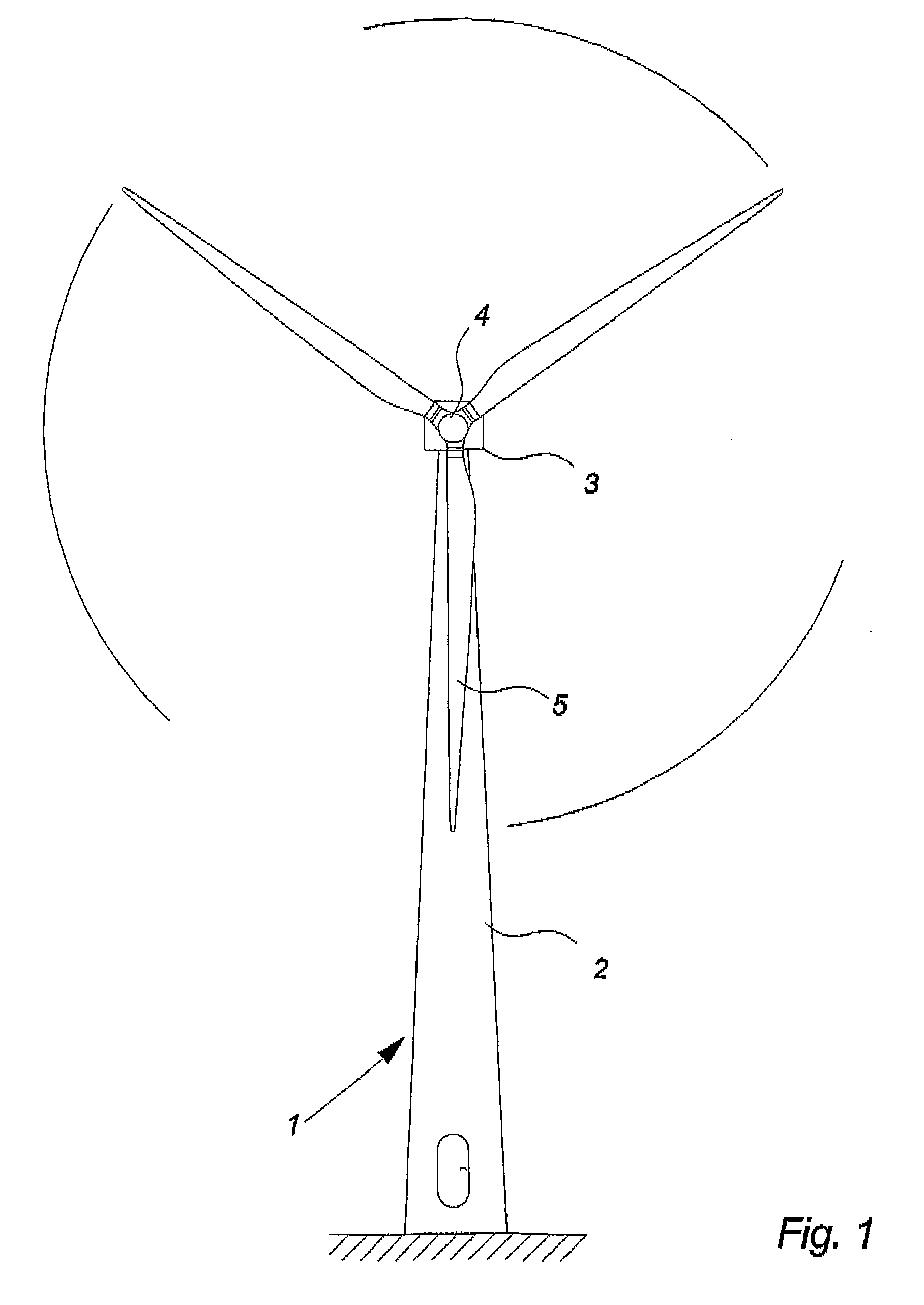

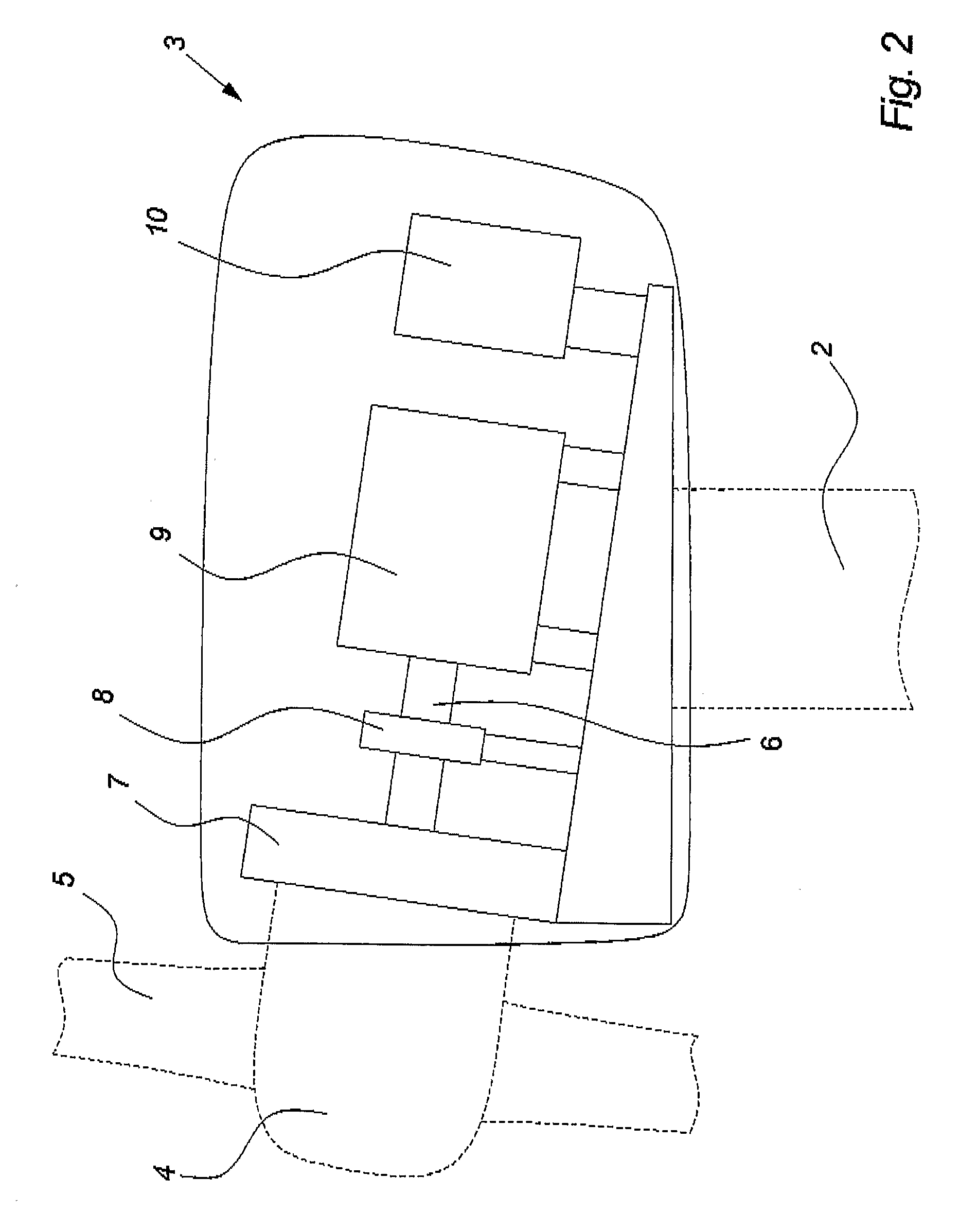

Lifetime optimization of a wind turbine generator by controlling the generator temperature

ActiveUS20100270798A1Reduce amount of powerReducing fluctuation and variation of temperatureWind motor controlEngine fuctionsTemperature controlClosed loop

A wind turbine and a method for controlling the temperature of a wind turbine generator are disclosed, the wind turbine comprising a generator, generator temperature control means and means for providing input representative of at least one temperature of the generator to the generator temperature control means, the generator temperature control means including a closed-loop regulation arranged to determine a deviation of the input from at least one desired value, compute the magnitude of at least one control output in dependency of the determined deviation, and feed the control output to at least one controller of the wind turbine in order to reduce the deviation, the controller comprising control means for controlling the operation of the wind turbine in response to the at least one control output by changing one or more operational parameters of the wind turbine, which parameters influence the at least one temperature of the generator.

Owner:VESTAS WIND SYST AS

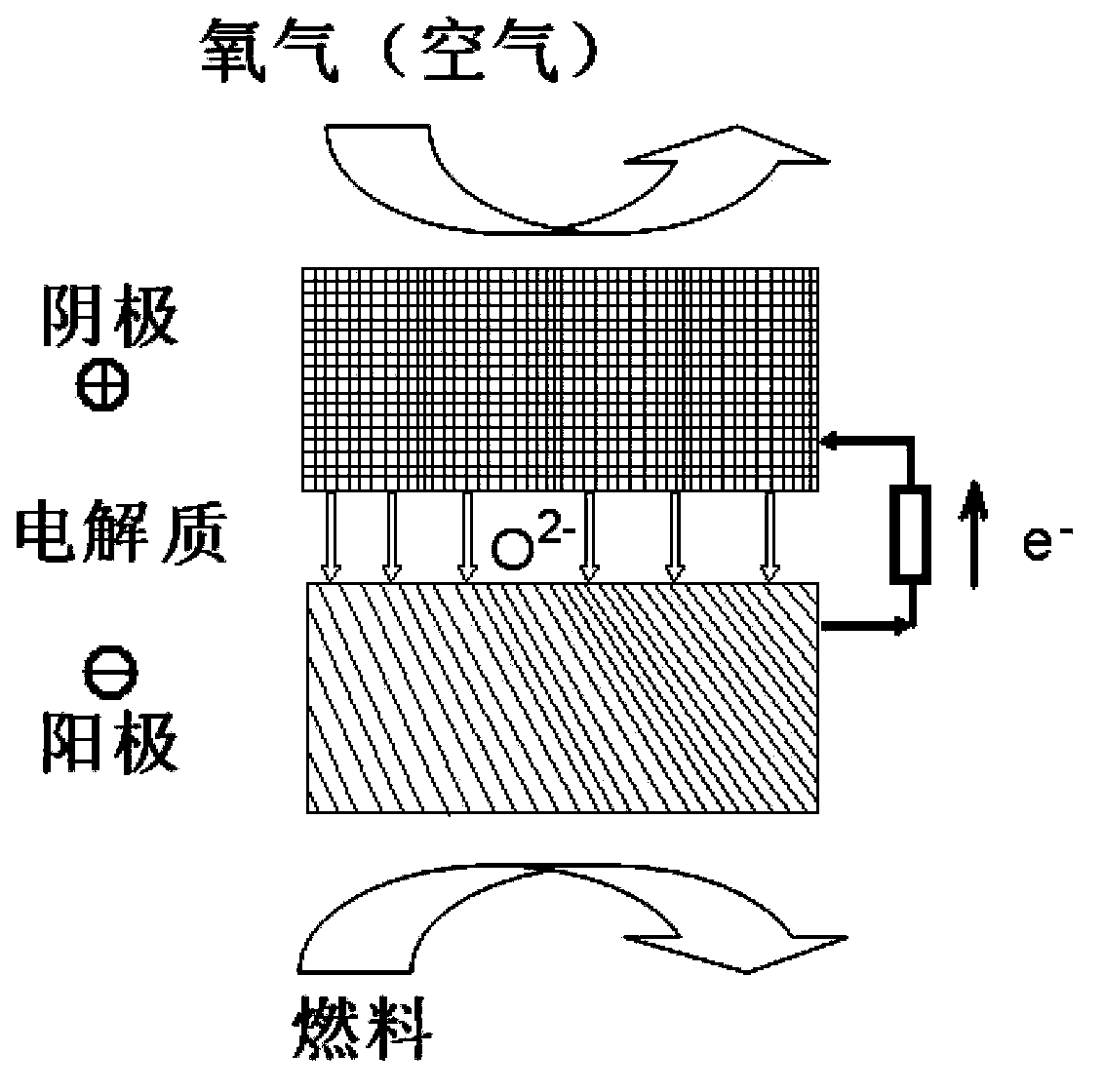

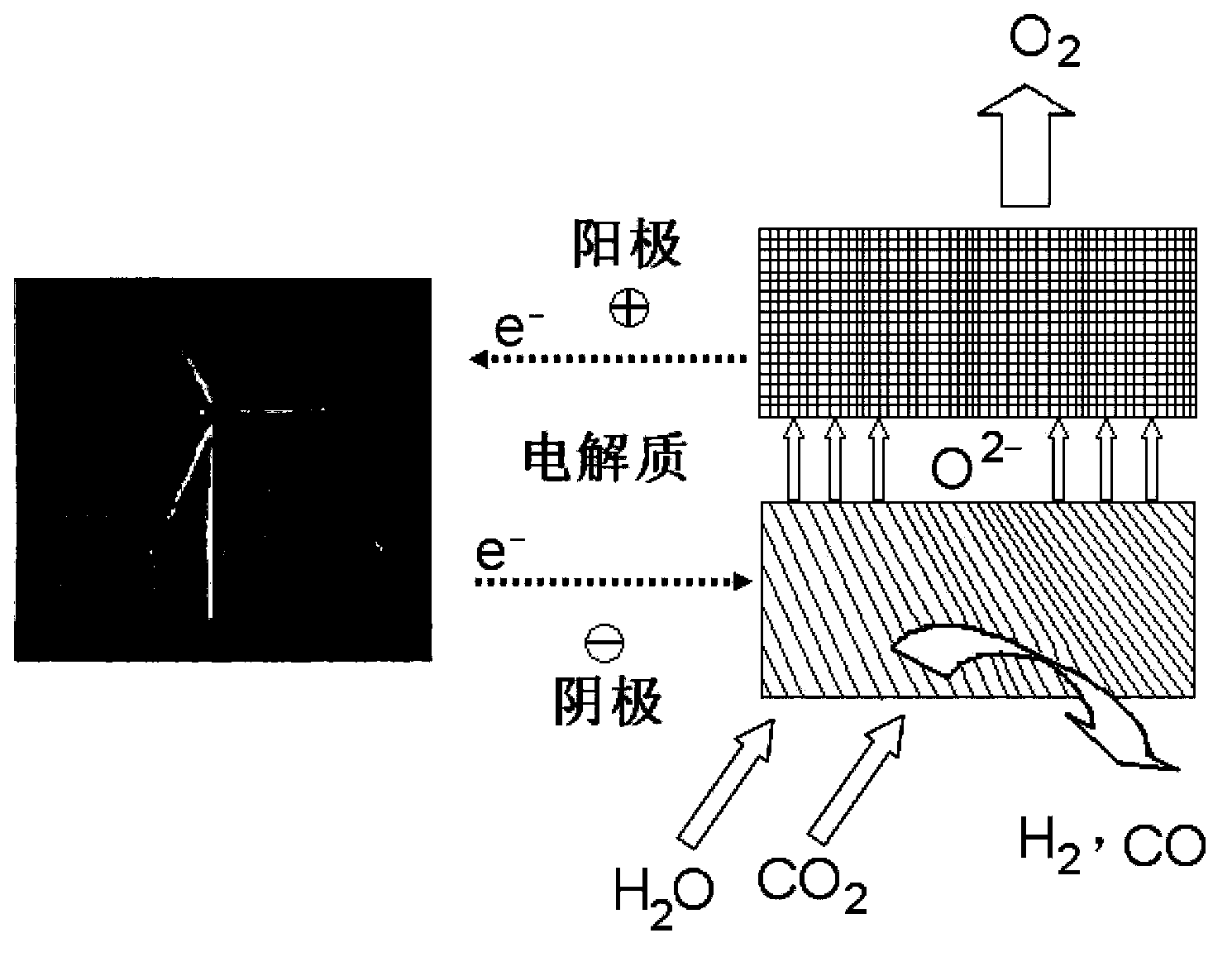

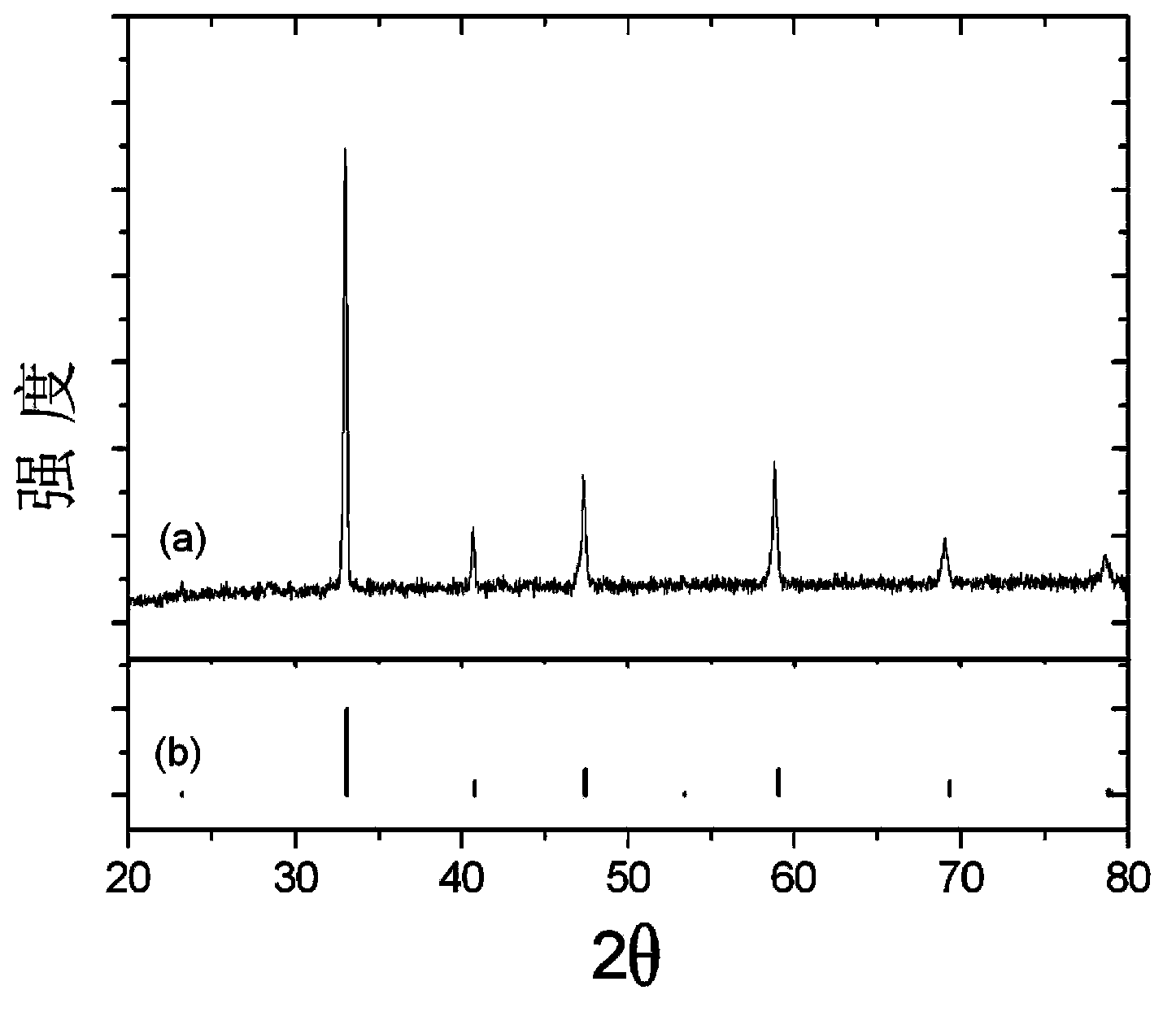

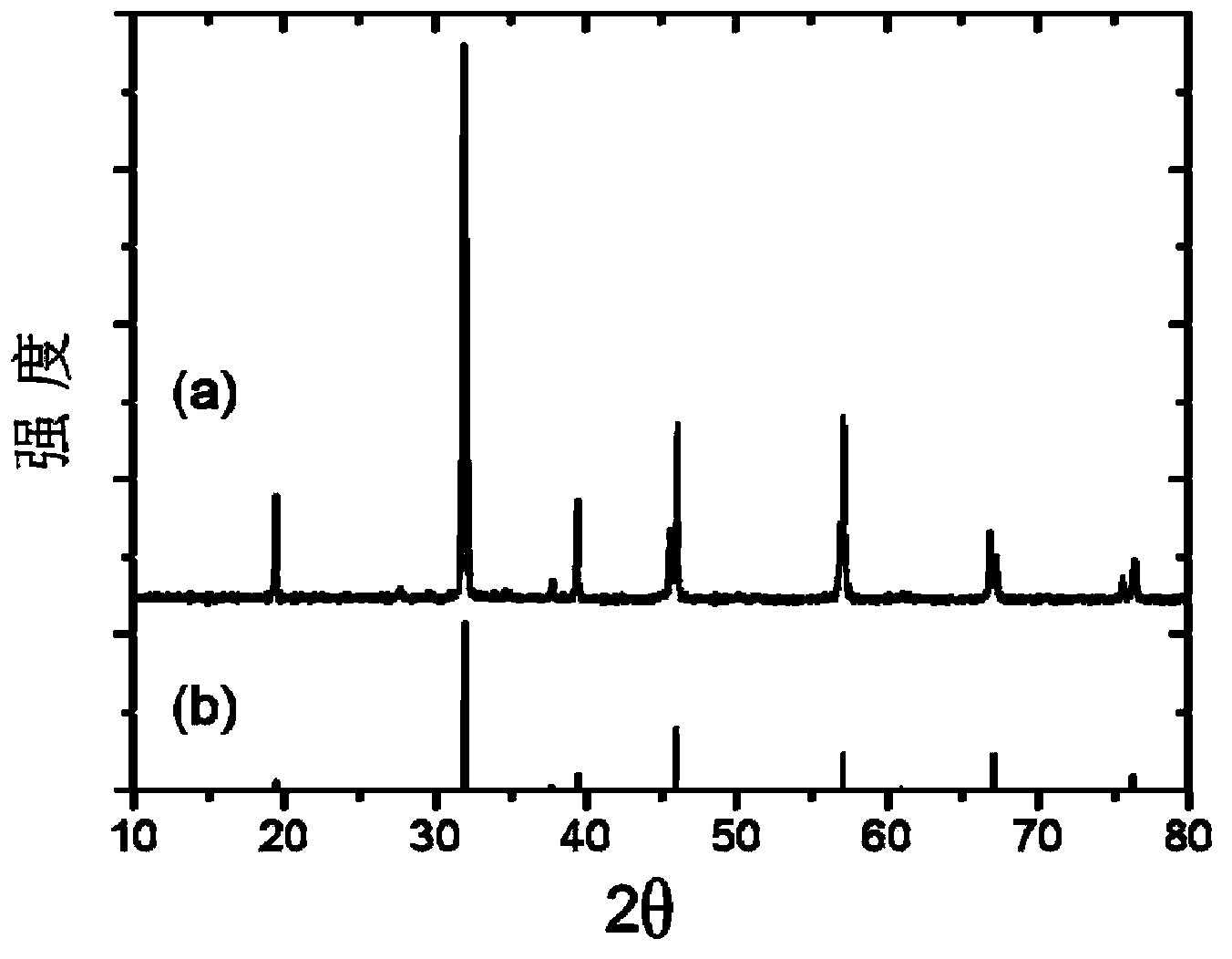

Composite material containing perovskite structure oxide, preparation method and application thereof

The invention provides a composite material containing a perovskite structure oxide, a preparation method and application thereof. The composite material contains, by weight, 20%-99.99% of the perovskite structure oxide and 0.01%-80% of an oxygen ion conductor oxide. According to the invention, a sol-gel method can be employed to prepare the perovskite structure oxide, a combustion method can be employed to prepare the oxygen ion conductor oxide, and then the perovskite structure oxide and the oxygen ion conductor oxide can be mixed uniformly by means of ball milling or mechanical grinding, thus obtaining the composite material. The invention also relates to application of the composite material in solid oxide fuel cells and solid oxide electrolysis cells.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

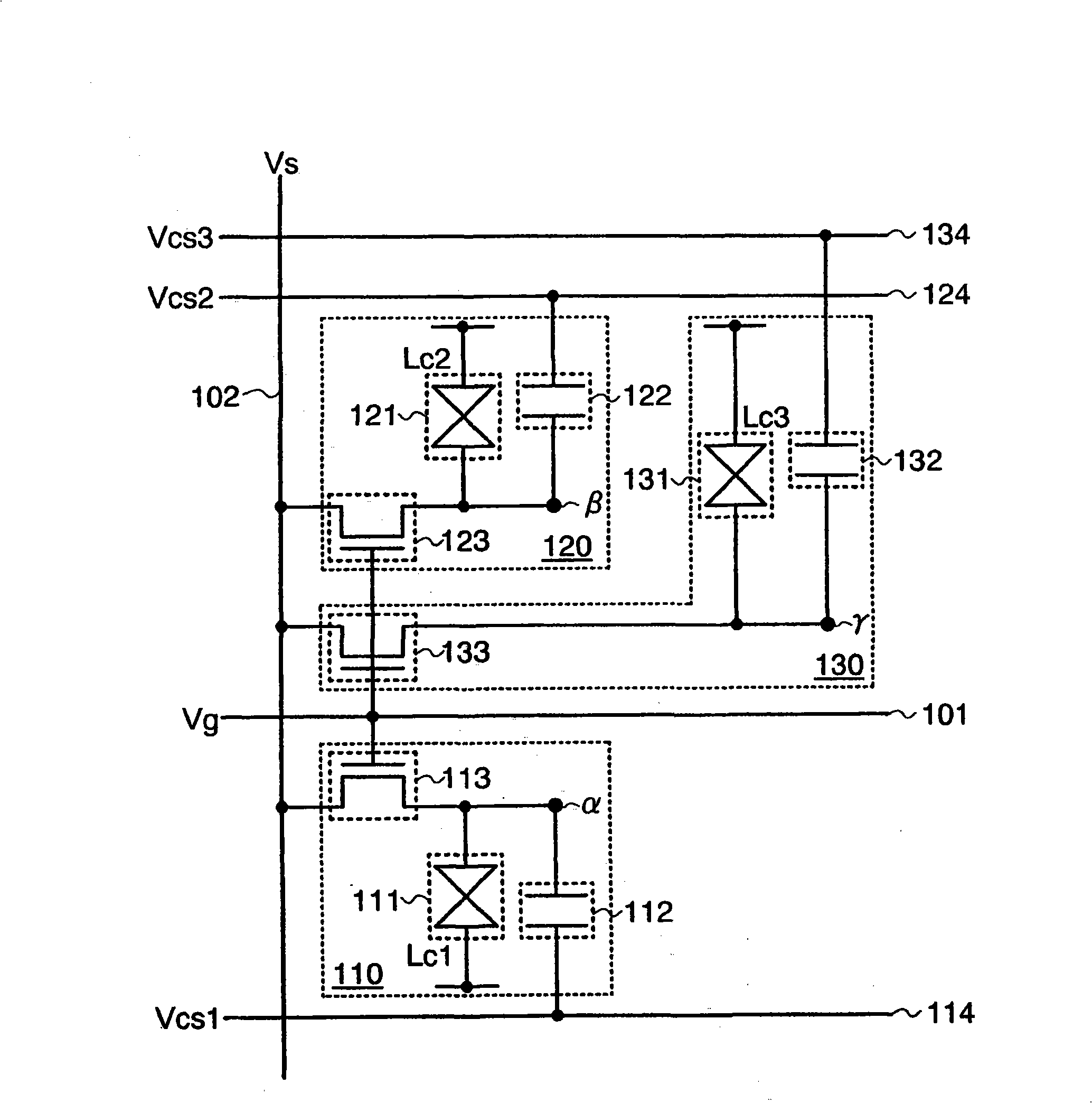

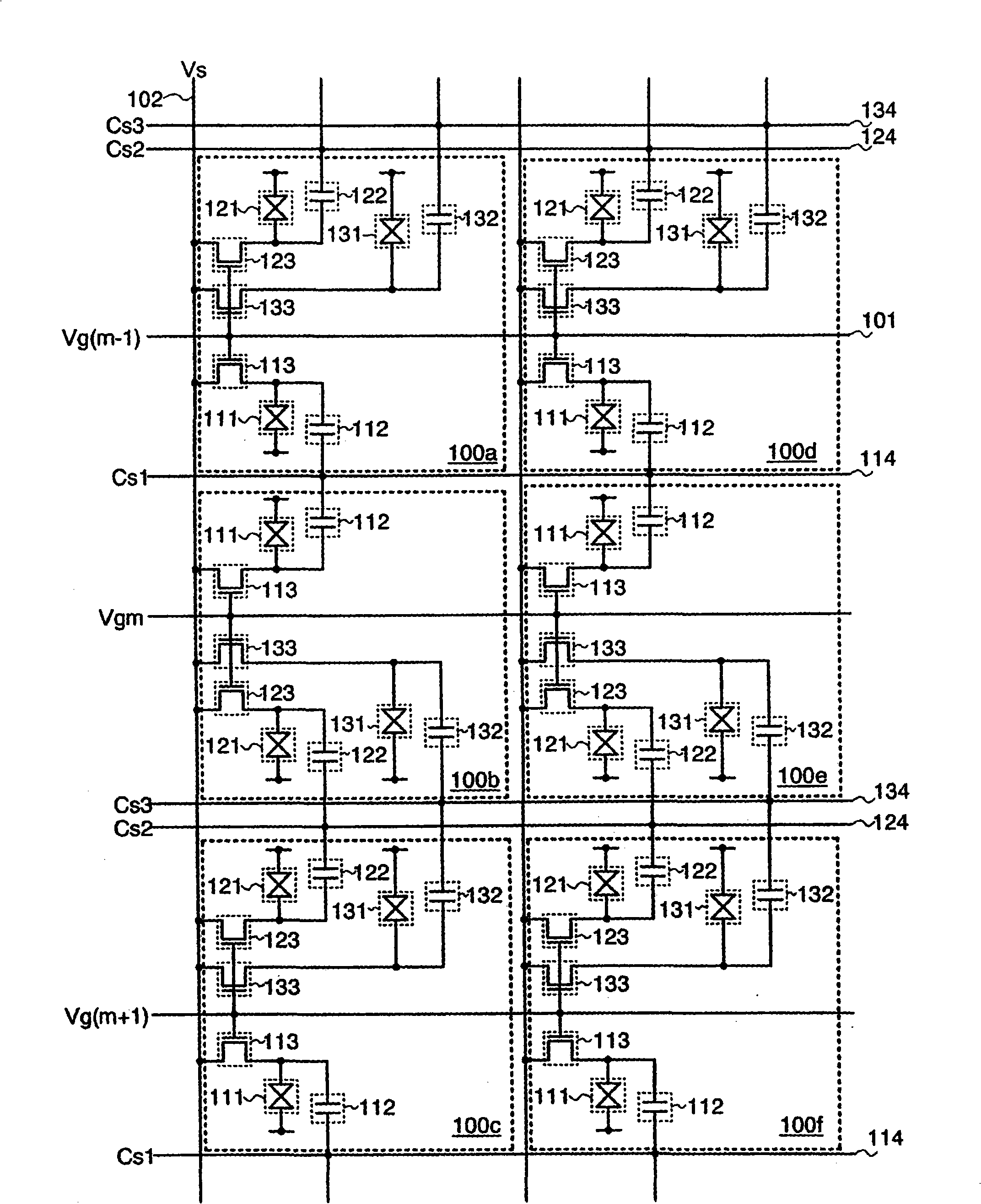

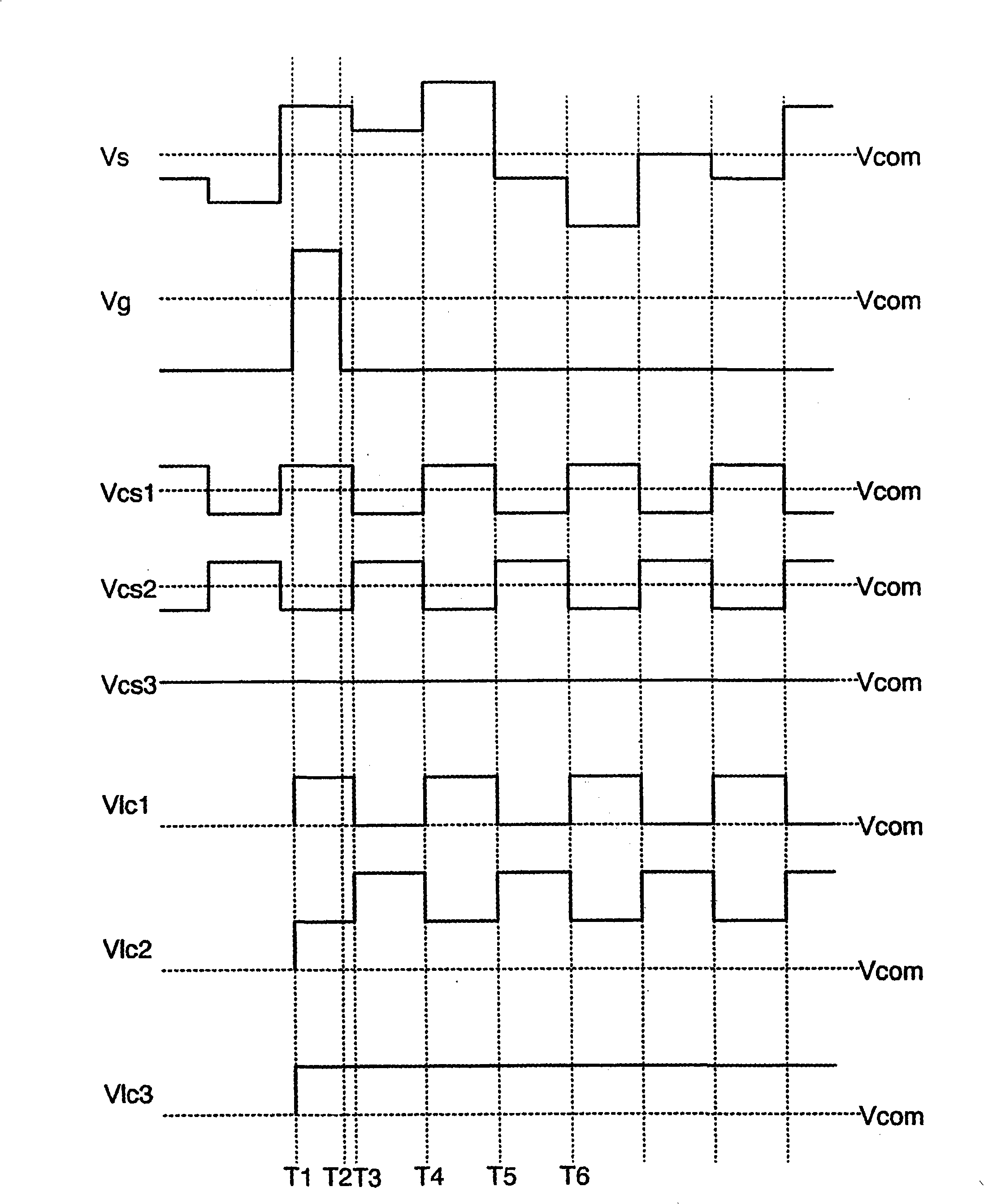

Liquid crystal display device

InactiveCN101308301AIncrease contrastImprove display qualityStatic indicating devicesNon-linear opticsCapacitanceElectricity

The target of this invention is to provide a display device in which a viewing angle characteristic is improved by providing a plurality of sub-pixels to one pixel. Alternatively, to provide a display device in which an aperture ratio is suppressed even when a plurality of sub-pixels is provided. A pixel including first sub-pixel, a second sub-pixel, and a third sub-pixel, a scanning line, a signal line, a first capacitor wiring, a second capacitor wiring and a third capacitor wiring are provided. Pixel electrodes each electrically connected to one electrode of the first to third capacitor elements, and the first to third capacitor wirings, respectively, are provided to the first to third sub-pixels electrodes, respectively. Potentials of the first capacitor wiring and the second capacitor wiring are changed and a potential of the third capacitor wiring is kept almost constant.

Owner:SEMICON ENERGY LAB CO LTD

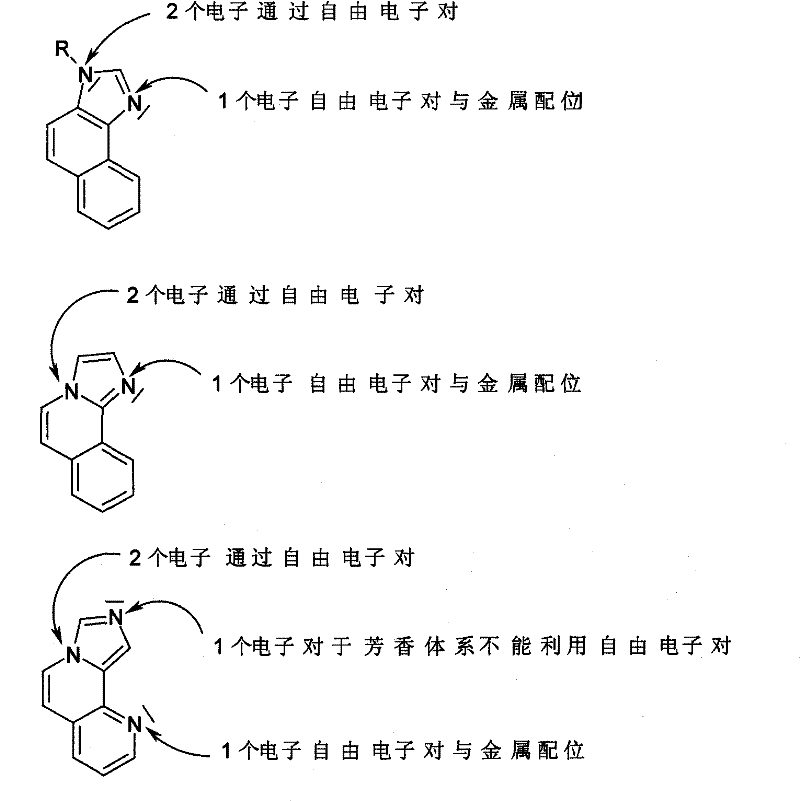

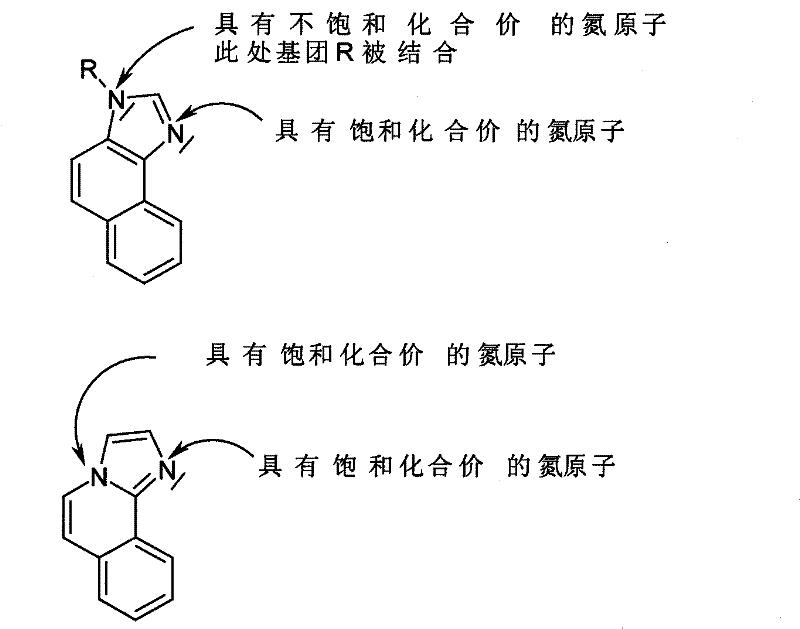

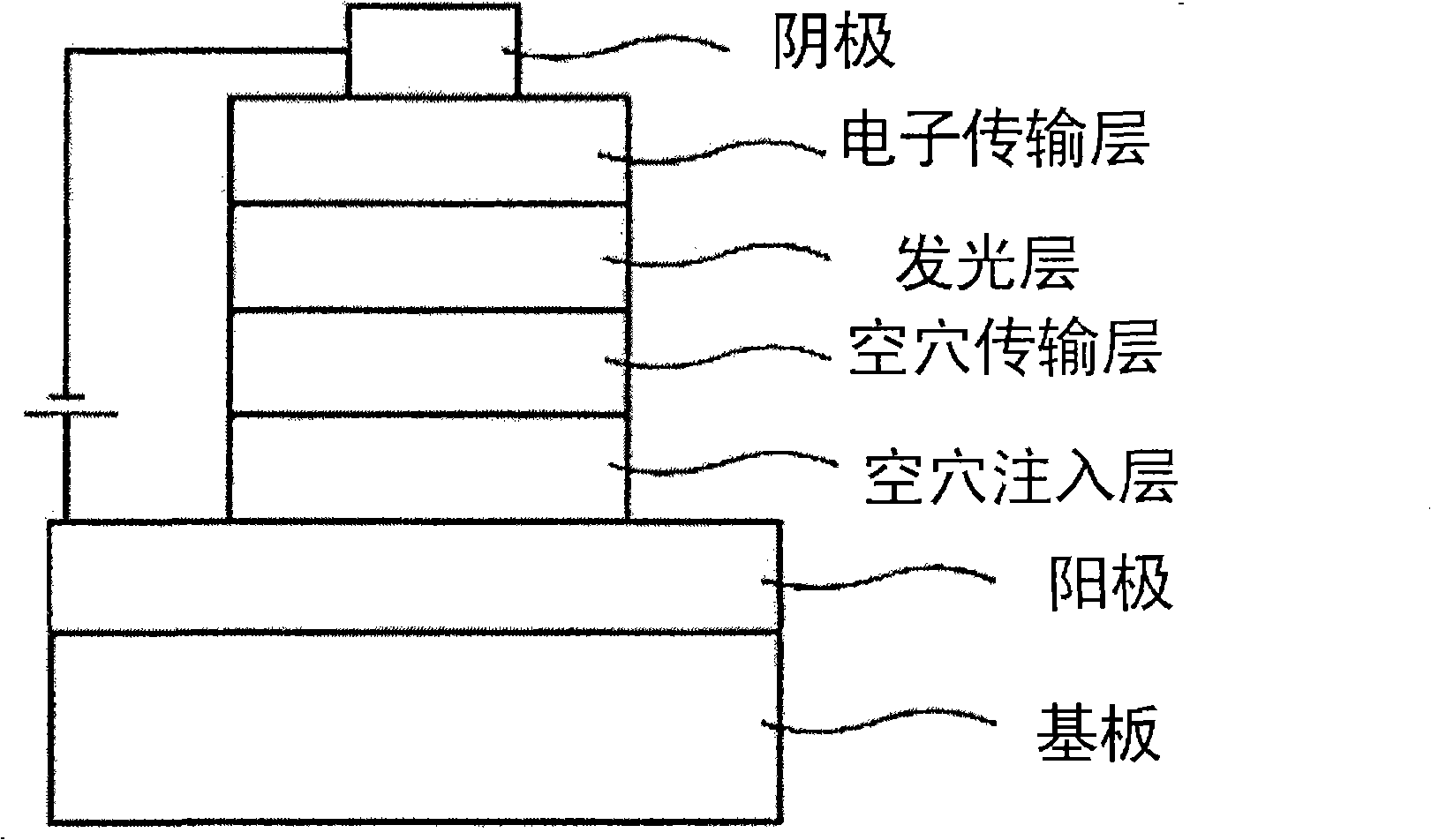

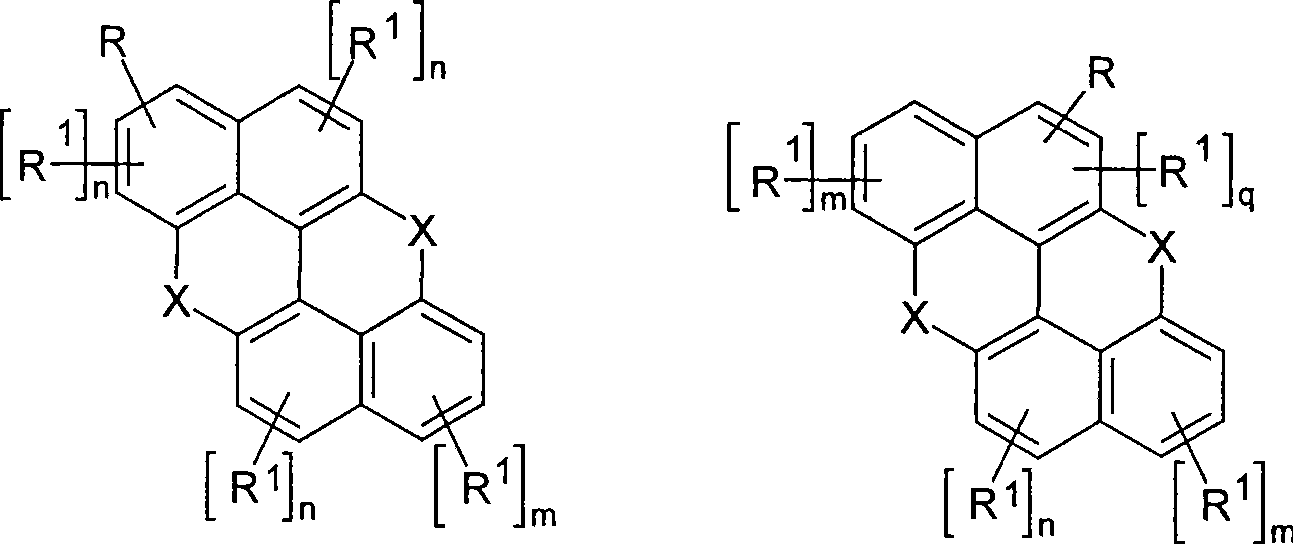

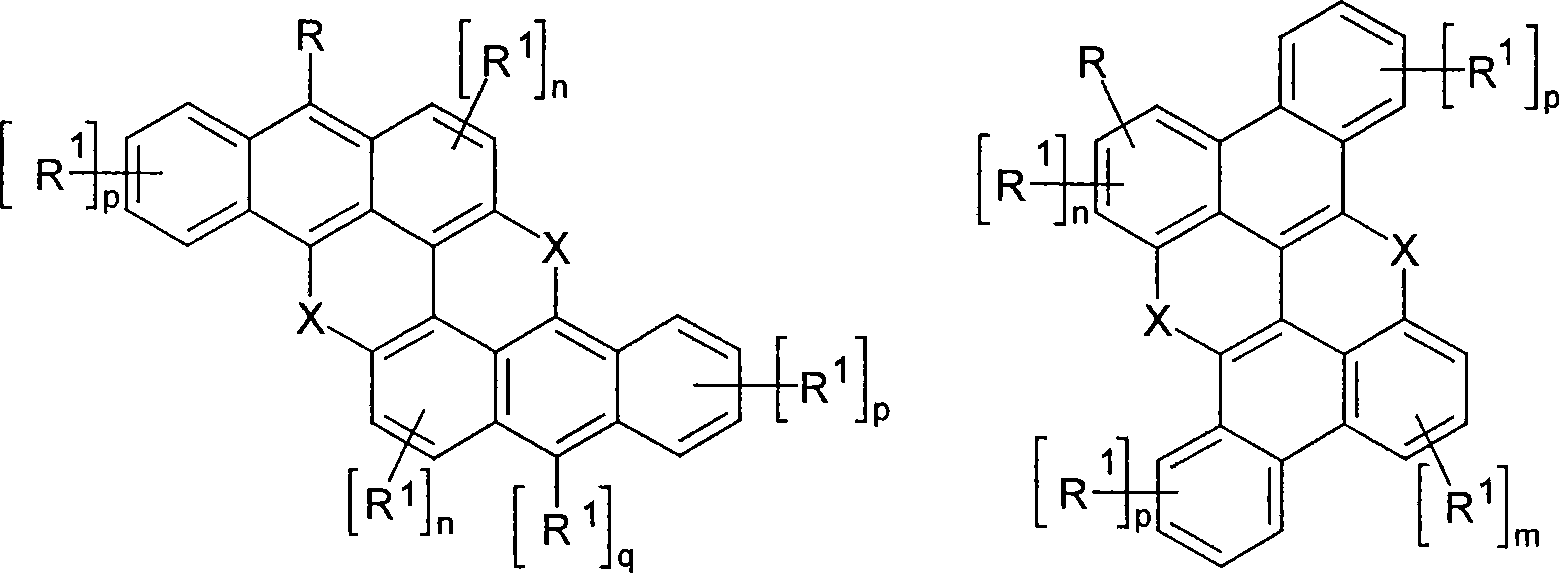

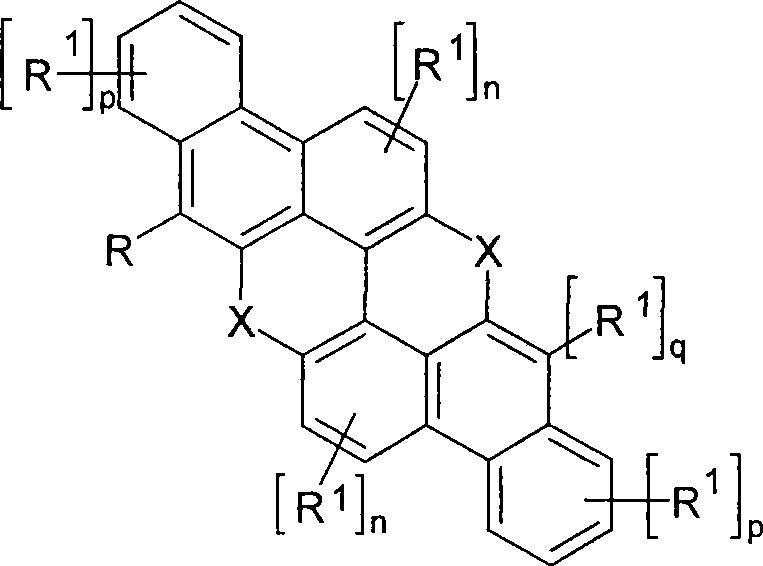

Compound for organic optoelectronic device, organic light emitting diode and display device

ActiveCN102558121AImprove overall lifespanImprove efficiencyOrganic chemistryElectroluminescent light sourcesDisplay deviceThermal stability

The present invention relates to a compound for an organic optoelectronic device, organic light emitting diode and display device. The compound for an organic optoelectronic device may be represented by the following Chemical Formulas 1 to 4 and have excellent electrochemical and thermal stability and thus, provide an organic photoelectric device with excellent life-span characteristics and high luminous efficiency at a low driving voltage. The above Chemical Formulas 1 to 4 are the same as described in the specification.

Owner:CHEIL IND INC

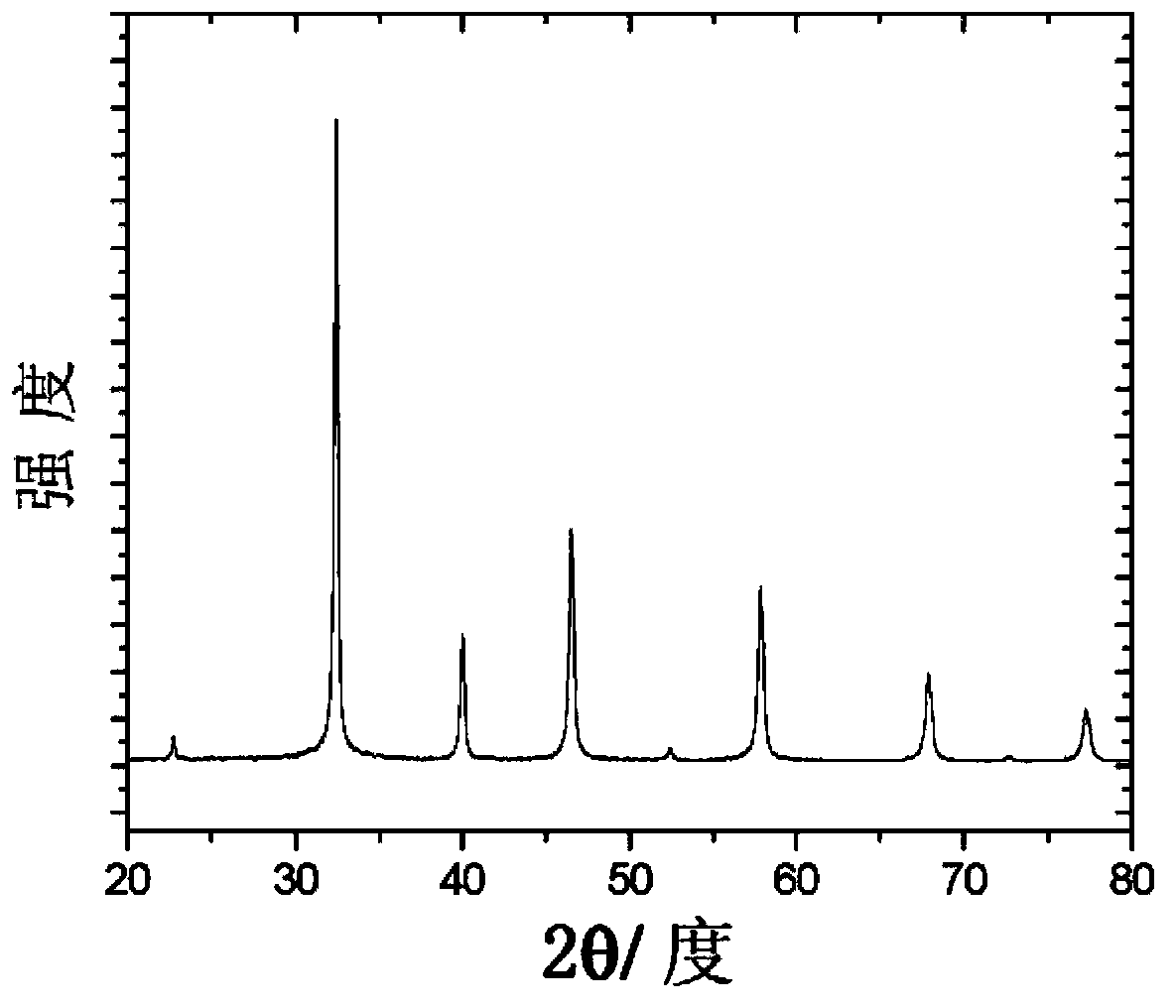

Anode material containing alkali metal or alkaline-earth metal element of solid oxide fuel cell and preparation method and application thereof

The invention provides an anode material containing an alkali metal or alkaline-earth metal element of a solid oxide fuel cell and a preparation method and application thereof. The alkali metal element can be introduced into the anode material by a doping method, or alkali metal or alkaline-earth metal carbonate, acetate, oxide or mixture thereof also can be introduced into the anode material by a loading method. The anode material has the characteristics of improving catalytic activity and long-term stability. The invention also relates to application of the anode material in a solid oxide electrolytic tank.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Supported palladium catalyst for producing hydrogen peroxide by anthraquinone process and preparing method thereof

InactiveCN1435277AImprove catalytic performanceImprove overall lifespanPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesMetal/metal-oxides/metal-hydroxide catalystsPhosphateActive component

A carried Pd-alumina catalyst for preparing hydrogen peroxide by anthraquinone method is prepared from Pd as main active component and Al2O3 as carrier through impregnation. Said Al2O3 has been coated by RE oxide and calcined at 900-1000 deg.C. It has high hydrogenating efficiency of 8-9 gH2O2 / L for 2-ethyl anthraquinone / heavy arene plus trioctyl phosphate or 10-13 gH2O2 / L for (2-tert-butyl anthraquinone plus 2-ethyl anthraquinone) / (heavy arene plus tetrabutyl urea).

Owner:FUZHOU UNIV

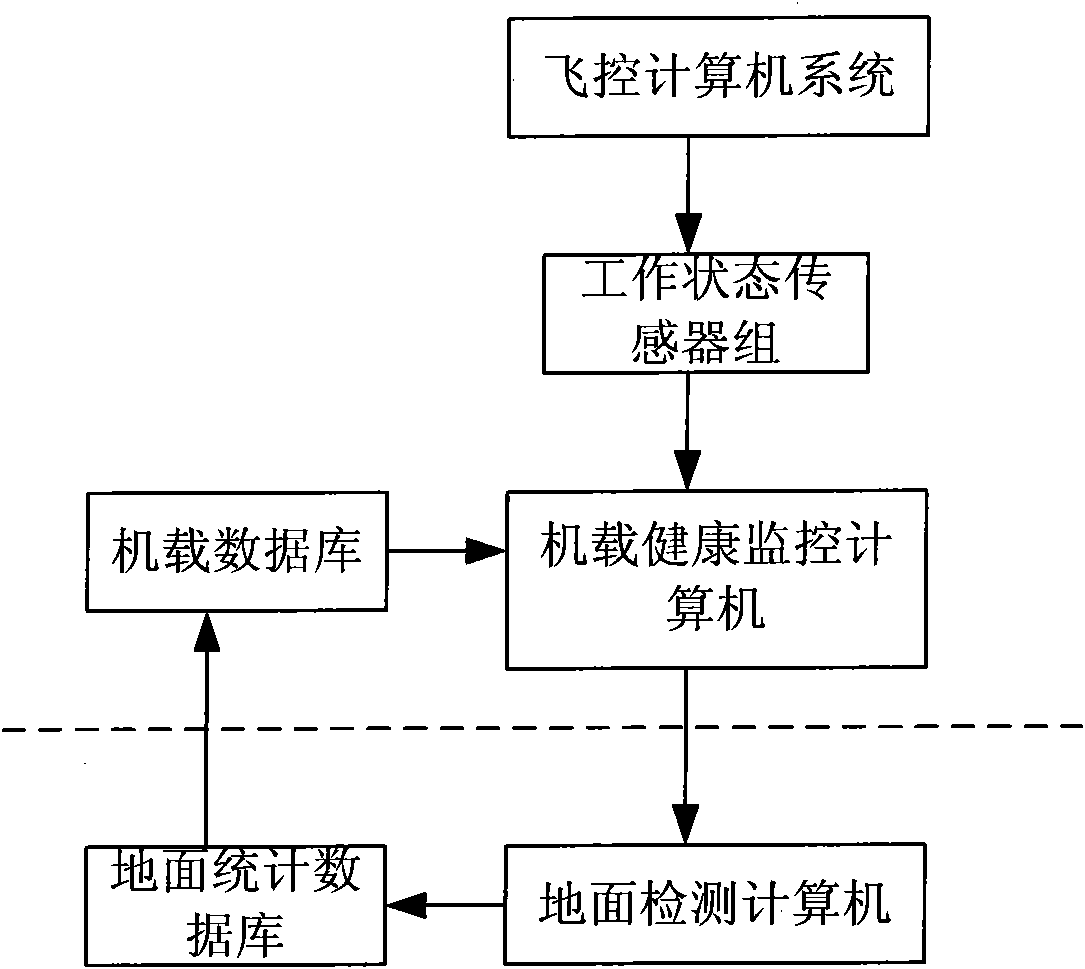

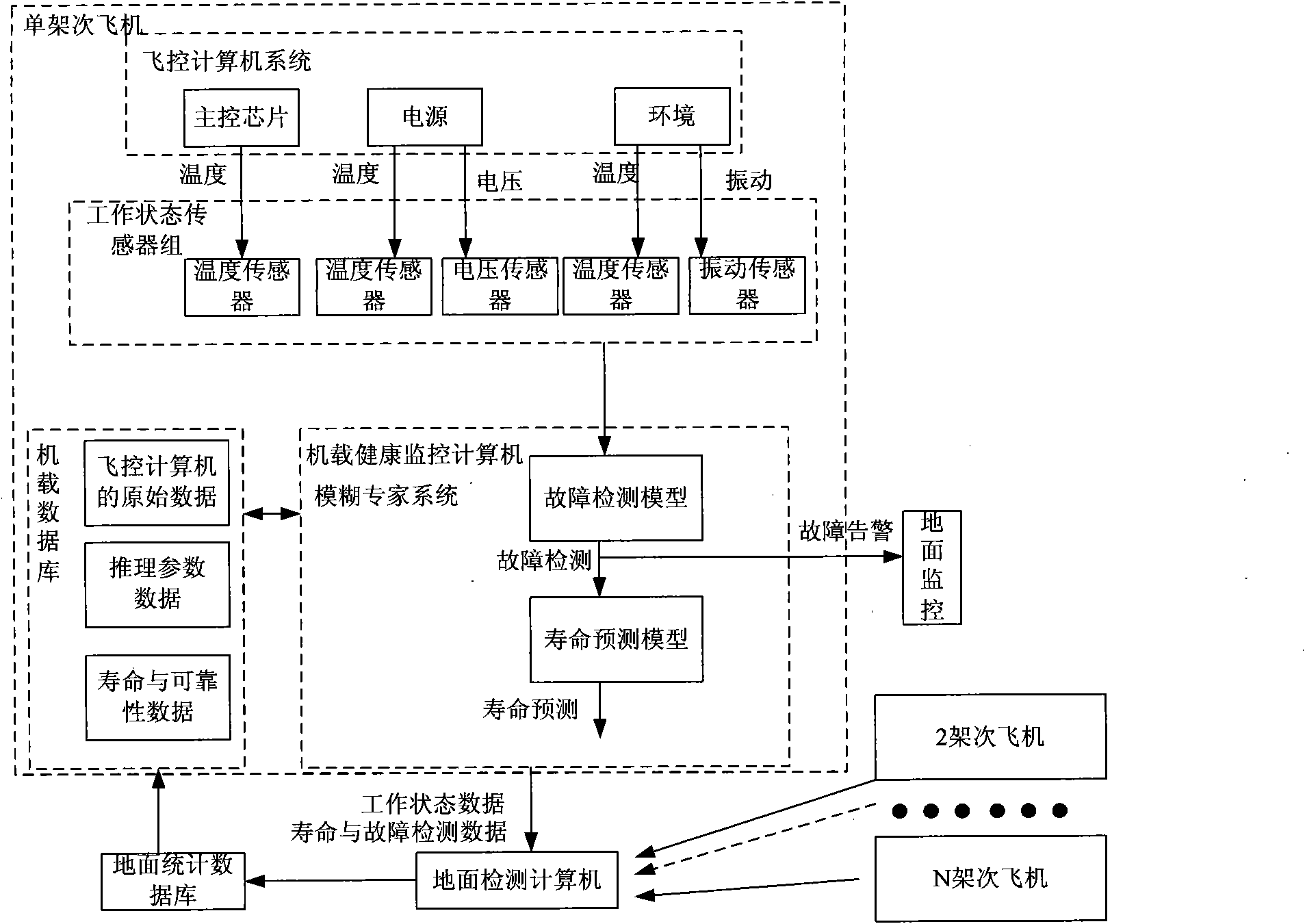

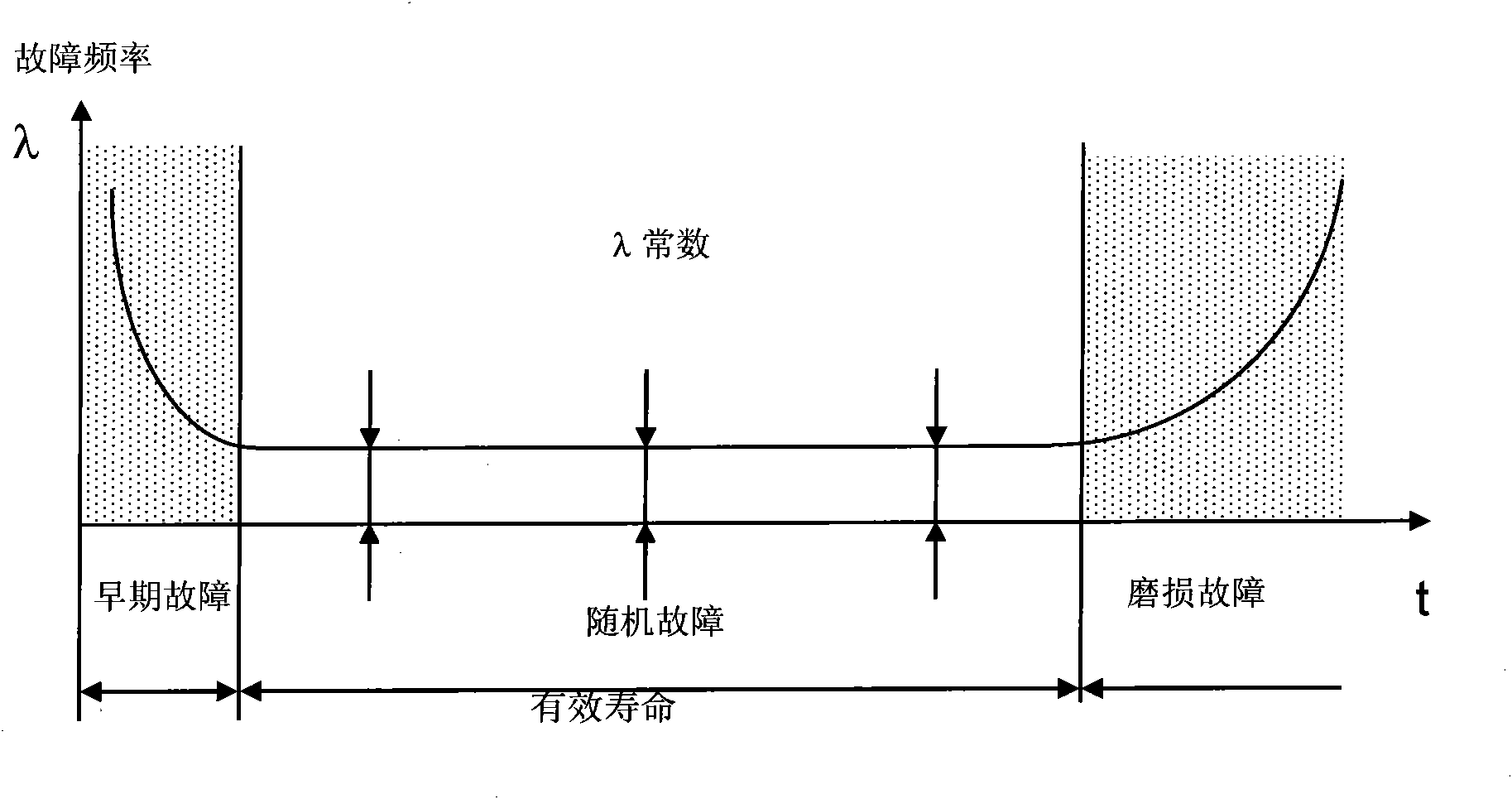

Method for predicting residual service life of flight control computer system

ActiveCN101963937AQuantitative prediction of remaining lifeAvoid economic lossHardware monitoringFlight computerFuzzy rule

The invention discloses a method for predicting residual service life of a flight control computer system, which comprises the steps of: storing historical reliability data of the flight control computer system by using an onboard health monitoring computer, obtaining working state data, and executing failure detection, reliability analysis and service life prediction of the flight control computer by using a fuzzy expert system. The working state data is obtained from a state sensor group. The development of the fuzzy expert system is used for modeling the reliability of the flight computer system, and the working condition of the flight control computer system is estimated according to the working state data and the fuzzy based reasoning for carrying out failure detection and predicting residual service life. The invention has the advantage of being capable of estimating the residual service life of the flight control computer system on line.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Organic compound, electronic element comprising same, and electronic device

ActiveCN111018797AIncrease space volumeHigh glass transition temperatureOrganic chemistrySolid-state devicesArylSimple Organic Compounds

The invention relates to the technical field of organic photoelectric materials, and in particular, relates to an organic compound, an electronic element containing the same and an electronic device.The compound has a structure represented by a chemical formula 1', wherein one of R1, R2, R3 and R4 is a group defined in the specification, and the other three are selected from substituents such asalkyl, halogen and cyano; one of R5, R6, R7 and R8 is a group defined in the specification, the other three are selected from substituents such as alkyl, halogen and cyano, Y and Y1 are respectively and independently a group defined in the specification, and L and L1 are single bonds, aryl, heteroaryl and the like. By using the organic compound in an electronic component, the driving voltage, luminous efficiency, and life of the electronic component are improved.

Owner:SHAANXI LIGHTE OPTOELECTRONICS MATERIAL CO LTD

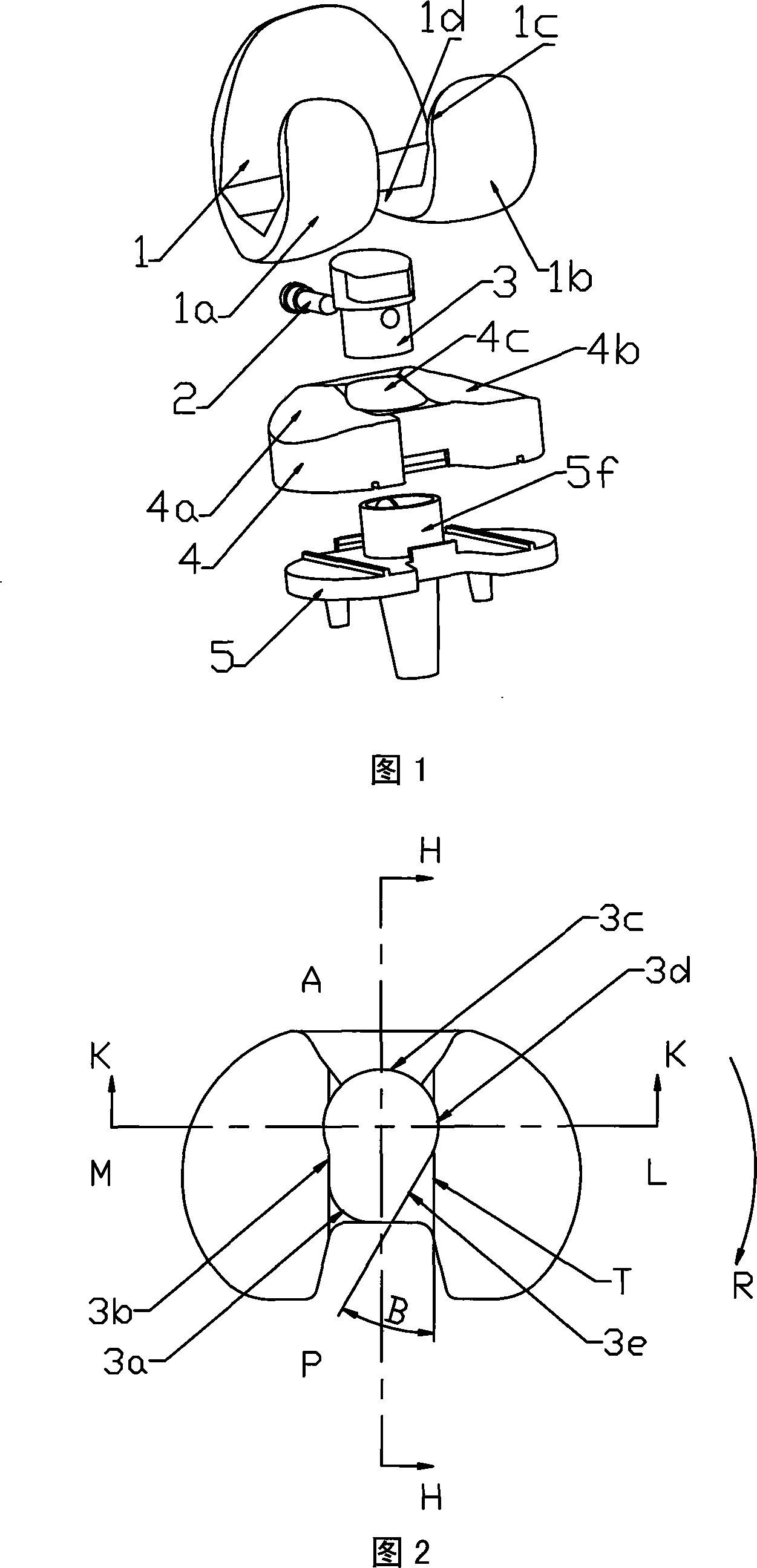

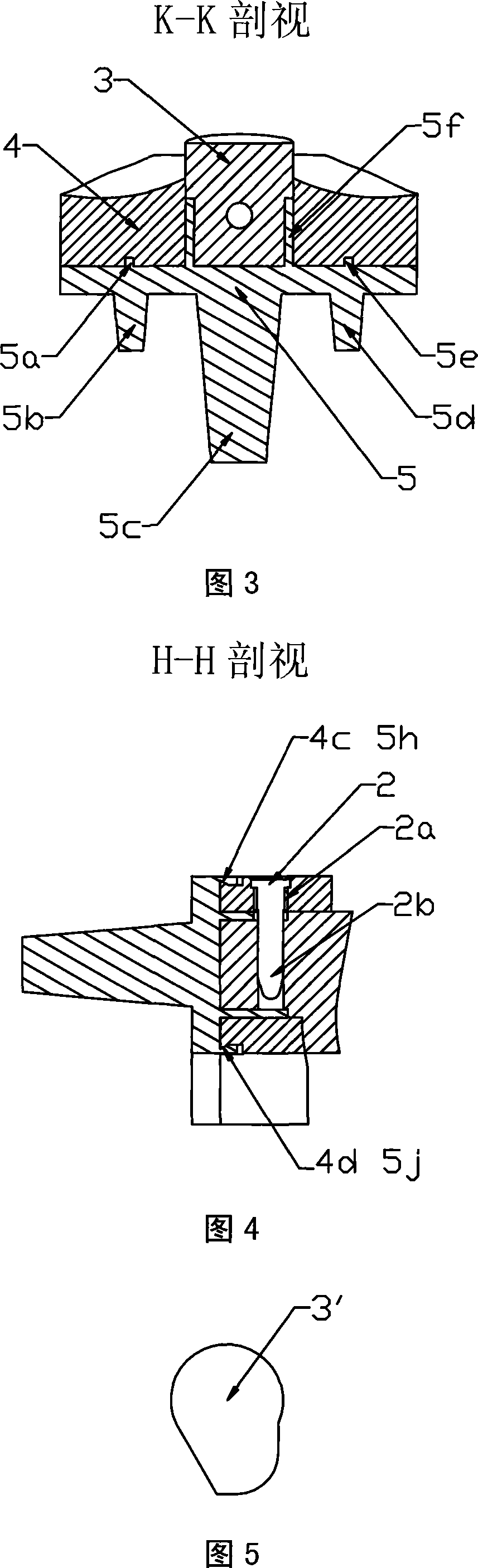

Knee joint endoprosthesis

InactiveCN101214175AImprove overall lifespanEnsure movement stabilityJoint implantsKnee jointsKnee extensionFemoral prosthesis

The present invention provides an internal knee joint prosthesis which comprises a femoral prosthesis (1) which is connected with the far end of the femoral, a tibial gasket (4) which is fixed at a tibial support (5), the tibial support which is connected with the close end of a tibia, a tibial intercondylar eminence (3) filled into the intercondylar hole (4c) of the tibial gasket (4) and the protrudent platform (5f) hole of the tibial support (5) and a bolt (2) which ensures the opposite position of the tibial intercondylar eminence (3) with the tibial gasket (4) and the tibial support (5). The inner condylar (4a) and outer condylar (4b) joint faces of the tibial gasket (4) are respectively opposite to the inner condylar (1a) and outer condylar (1b) joint faces of the femoral prosthesis (1), so as to ensure that the femoral prosthesis (1) can realize the actions of extending, bending and backwards rolling at the tibial gasket (4). The tibial intercondylar eminence (3) is extended into the condylar interval area (1d) of the femoral prosthesis, so as to ensure the knee extension stability of the knee joint. The part of the tibial intercondylar eminence (3) near the outer condyle (1b) of the femoral prosthesis (1) is excised to ensure that the femoral prosthesis (1) has larger outwards rotation angle at the bending knee position, so as to realize the deep bend of the knee joint.

Owner:SICHUAN UNIV

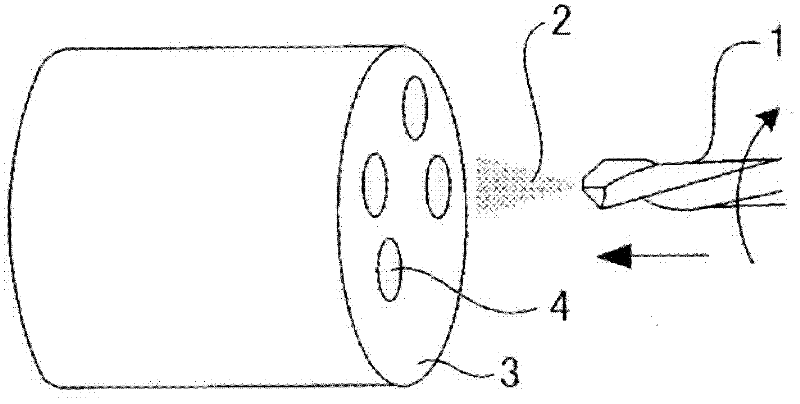

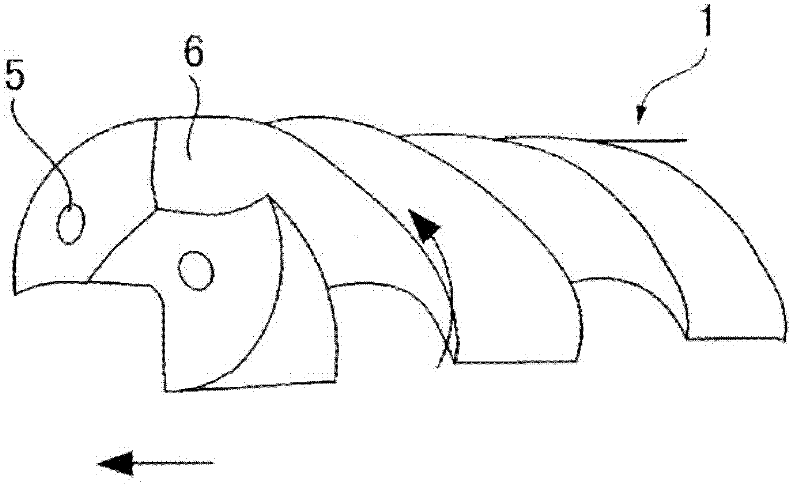

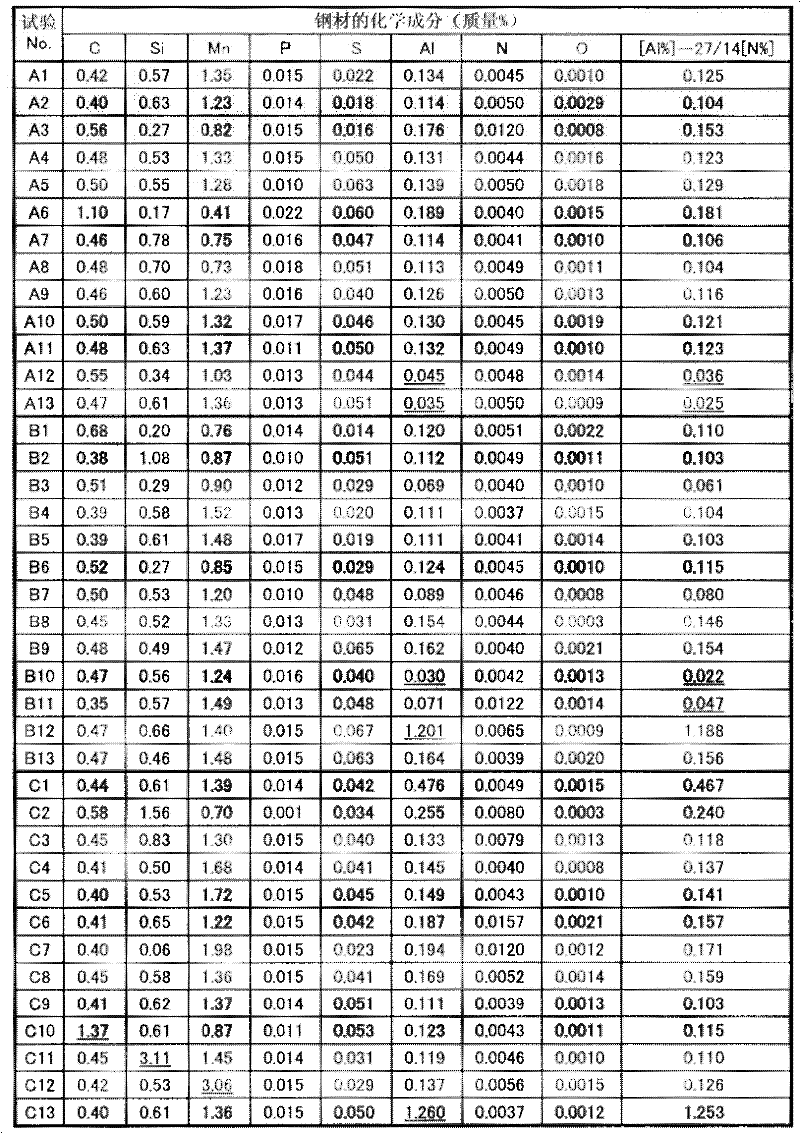

Cutting method for steel for use in machine structure

InactiveCN102470502AImprove overall lifespanMilling cuttersWorkpiecesMechanical engineeringGas mixing

Owner:NIPPON STEEL CORP

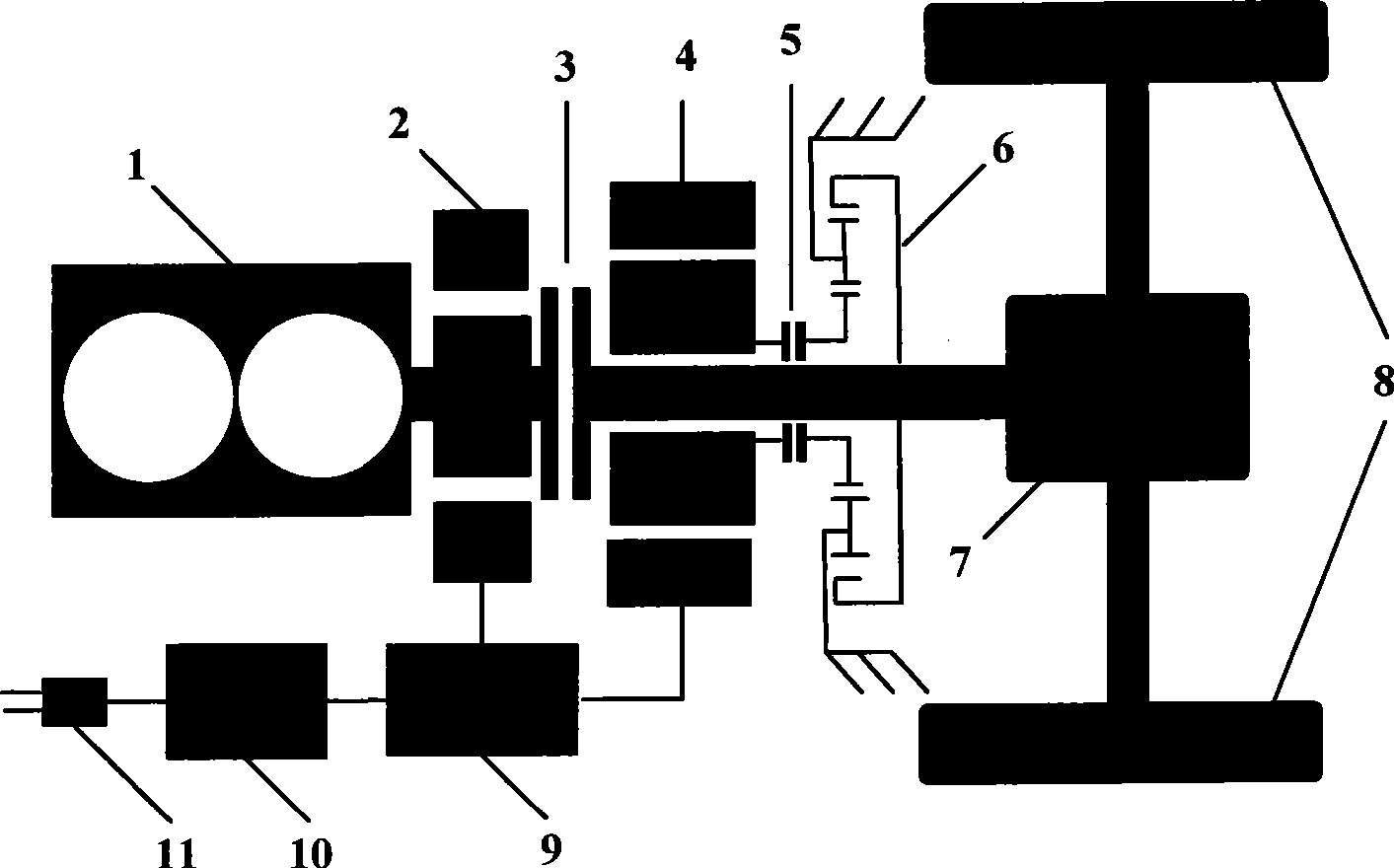

Hybrid power car driving system containing driving motor work mode switching device

ActiveCN101380887ALow powerReduce fuel consumption and emissionsGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingCar drivingClutch

The invention discloses a hybrid car driving system which comprises a driving motor operating mode switching device, and belongs to the technical field of vehicle engineering, wherein, an engine is connected with an integral start generator coaxially; the integral start generator is connected with a first automatic clutch driving disc; a first automatic clutch driven disc is connected with a planetary gear mechanism by a driving motor; one side of the planetary gear mechanism is connected with the driving motor by a second automatic clutch, and the other side thereof is connected with a main reducer-differential mechanism; the main reducer-differential mechanism is connected with wheels by a driving axle; a power battery pack is respectively connected with a motor controller and an external power supply plug by cables; and the motor controller is respectively connected with the integral start generator and the driving motor by the cables. An outer gear ring of the planetary gear mechanism is connected with a frame fixedly. The hybrid car driving system reserves the traditional vehicle structure to a maximum extent and optimizes the working point of the engine by using double motors, thus leading the engine to operating stably in a high-efficiency and low-discharge area, simultaneously optimizing the working condition of the driving motor and prolonging the service life of the motor.

Owner:上海智能网联汽车技术中心有限公司

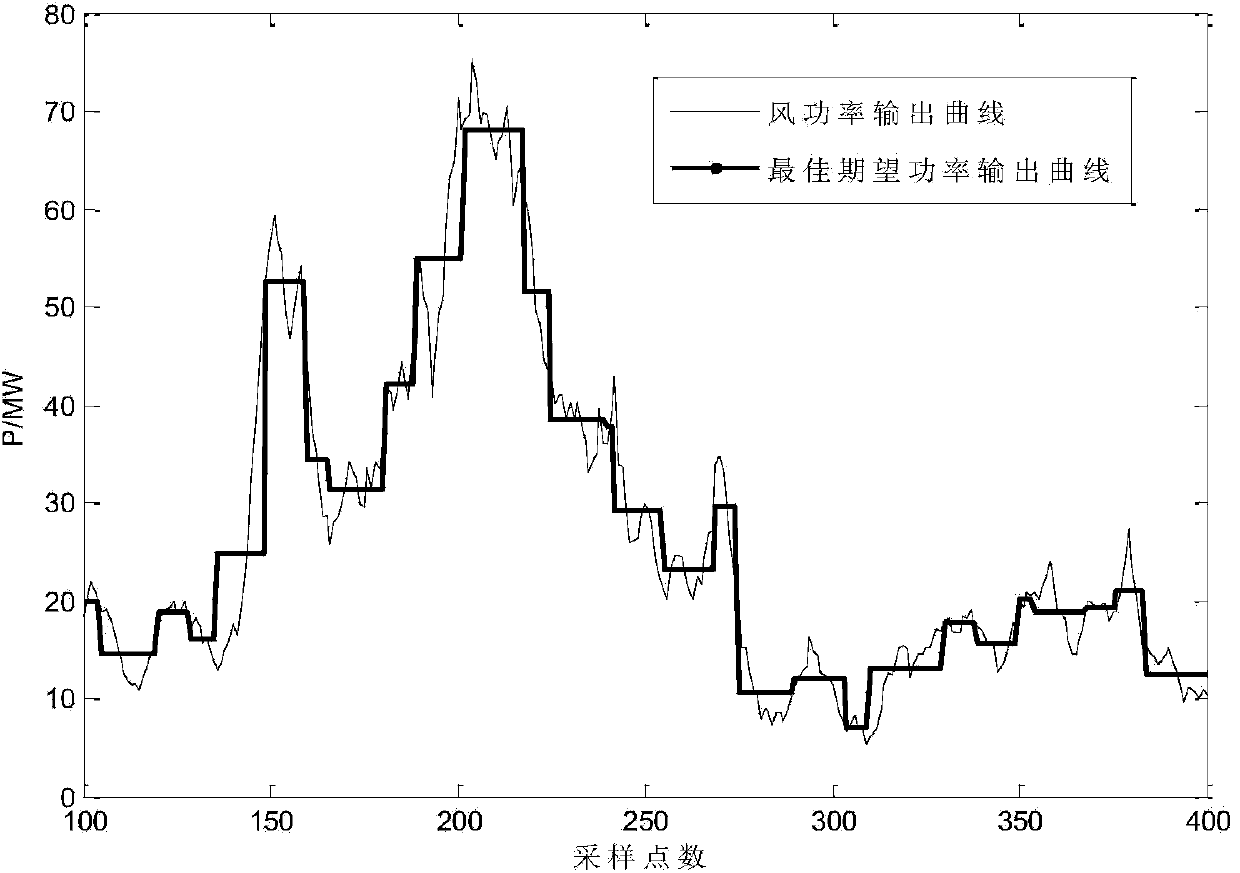

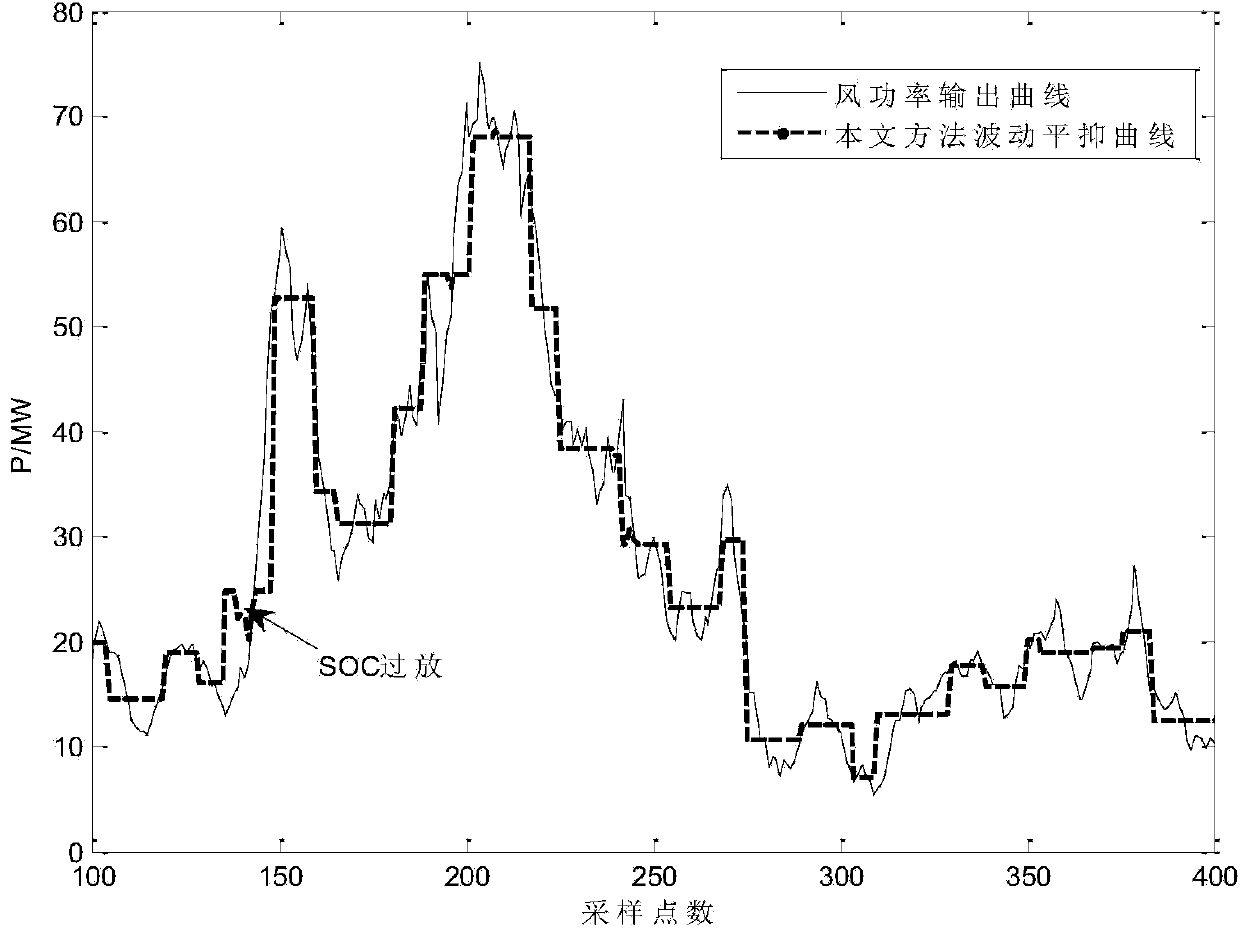

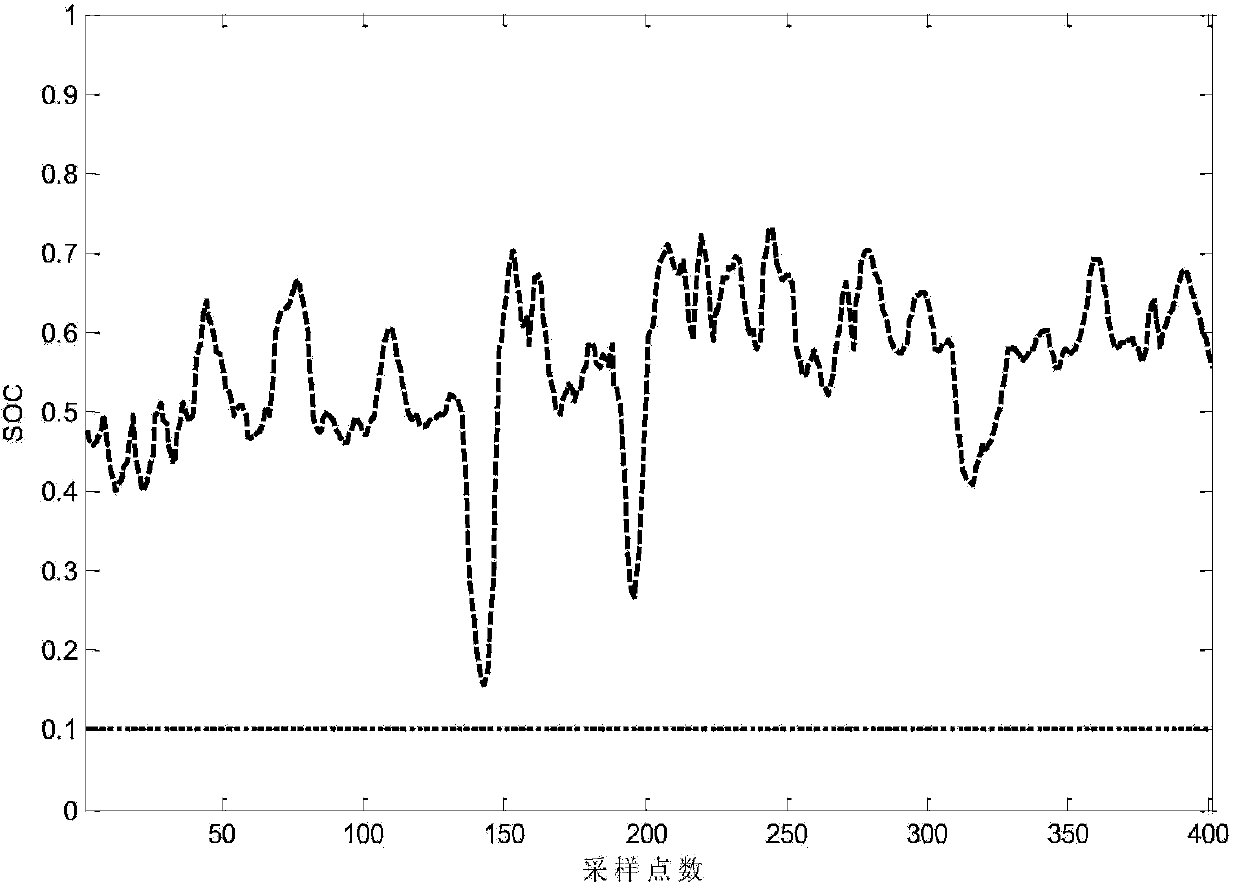

Energy storage station capacity optimizing calculation method considering dynamic adjustment of electrically charged state

ActiveCN103779869AEffective combinationRealize Adjustment StrategiesSingle network parallel feeding arrangementsEnergy storageStored energySystem capacity

The invention discloses an energy storage station capacity optimizing calculation method considering dynamic adjustment of an electrically charged state. The optimizing calculation method includes the steps that a wind power plant energy storage system battery electrically charged state model is set up, and battery overcharging and overdischarging protective control is performed on the model; a wind power plant energy storage system capacity optimizing objective function is built with the optimal comprehensive benefit of stored energy as an objective, and energy storage station charging and discharging power constraint conditions and wind power plant output power fluctuation horizontal constraint conditions are built; the energy storage system capacity optimizing objective function is solved through calculation by selecting a PSO algorithm to determine the optimal wind power plant energy storage system capacity value. The energy storage station capacity optimizing calculation method has the advantages that energy storage station arrangement and overall economy in the operation process are considered comprehensively for the capacity optimizing calculation model, effective combination on site is facilitated, and theoretical premises and guarantees are provided for energy storage capacity optimization.

Owner:STATE GRID CORP OF CHINA +2

Composite-oxide catalyst and process for production of acrylic acid using said catalyst

InactiveCN1524615AGood choiceImprove overall lifespanOrganic compound preparationOrganic chemistry methodsNiobiumCobalt

Owner:NIPPON SHOKUBAI CO LTD

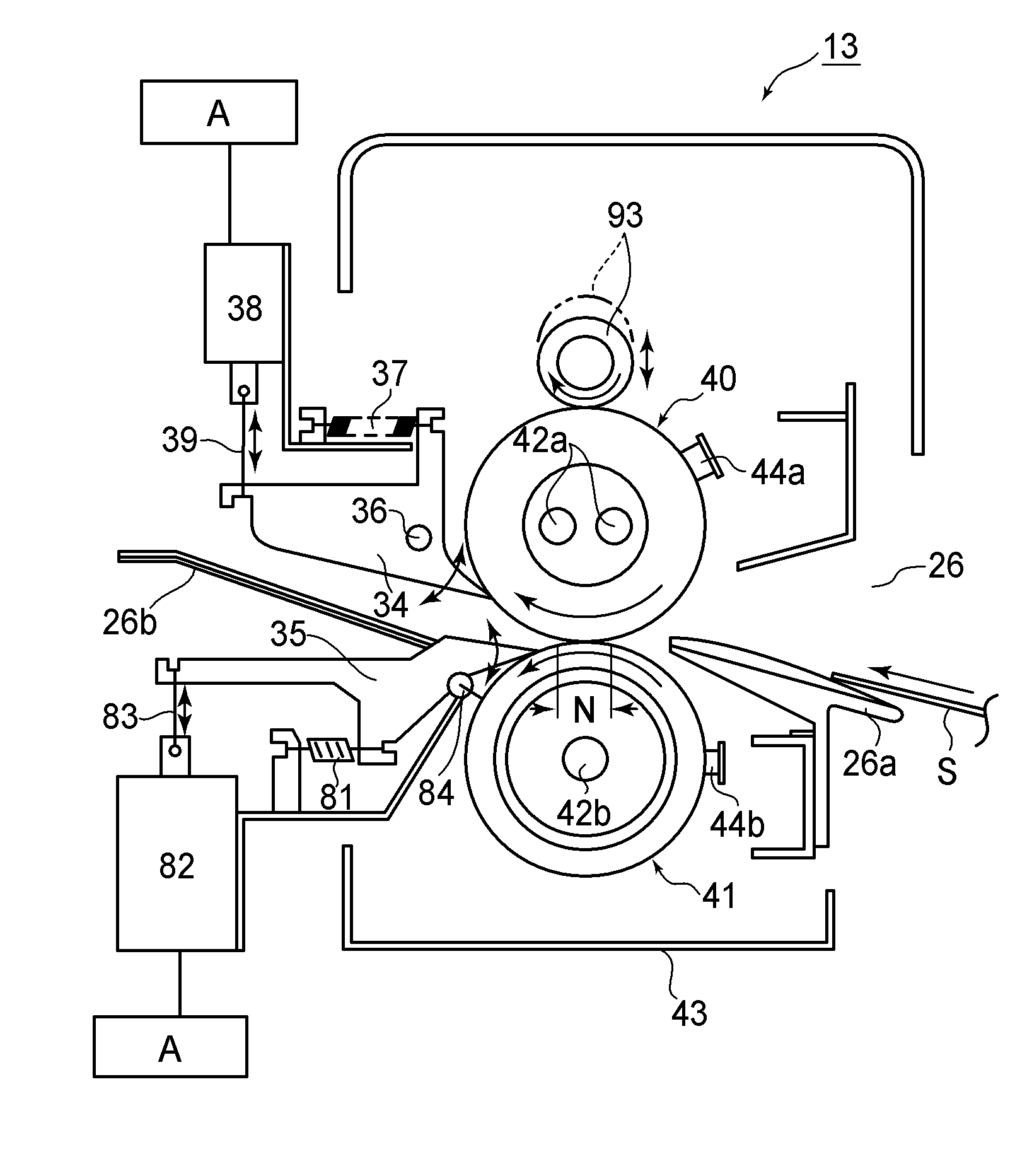

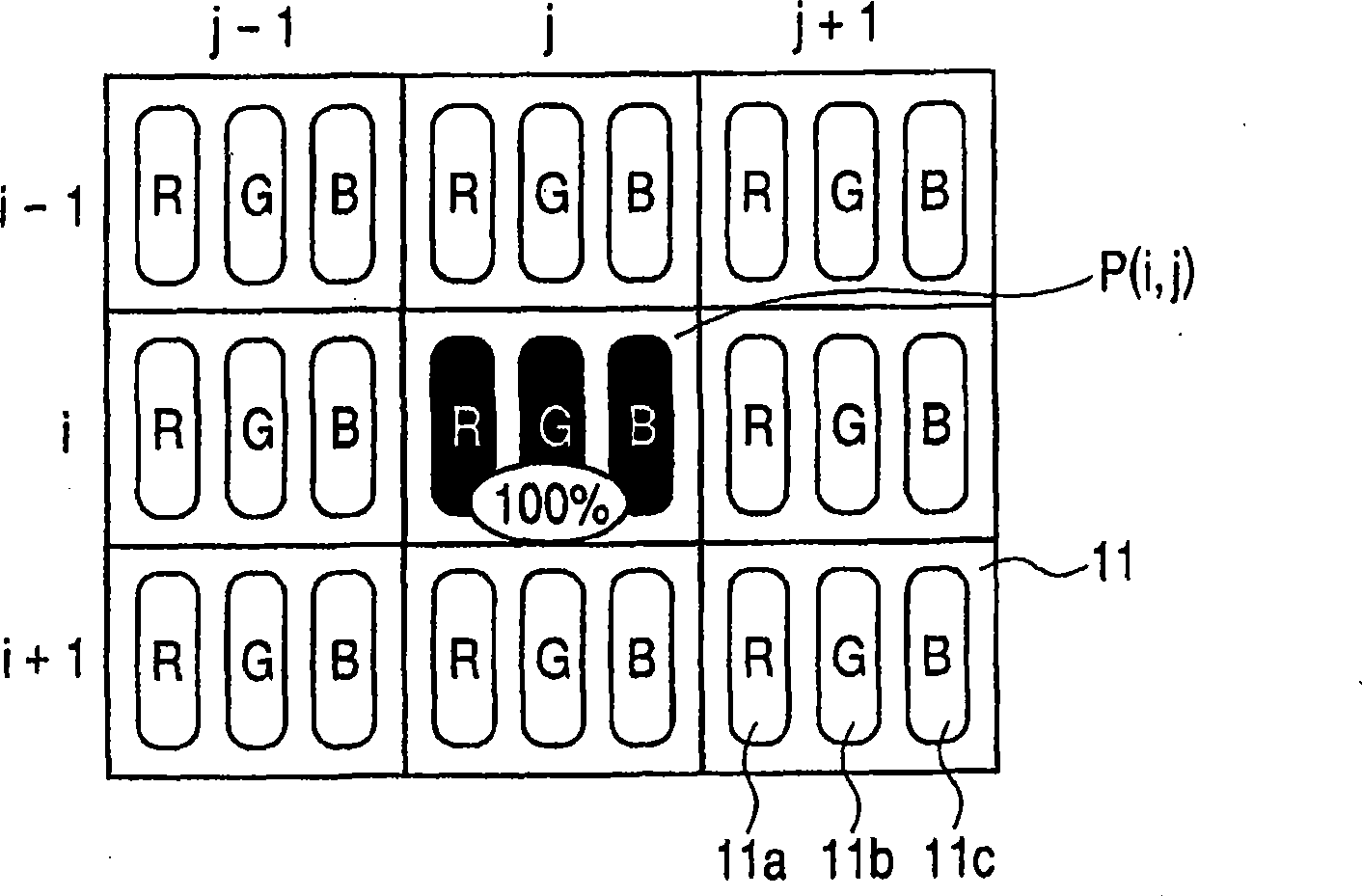

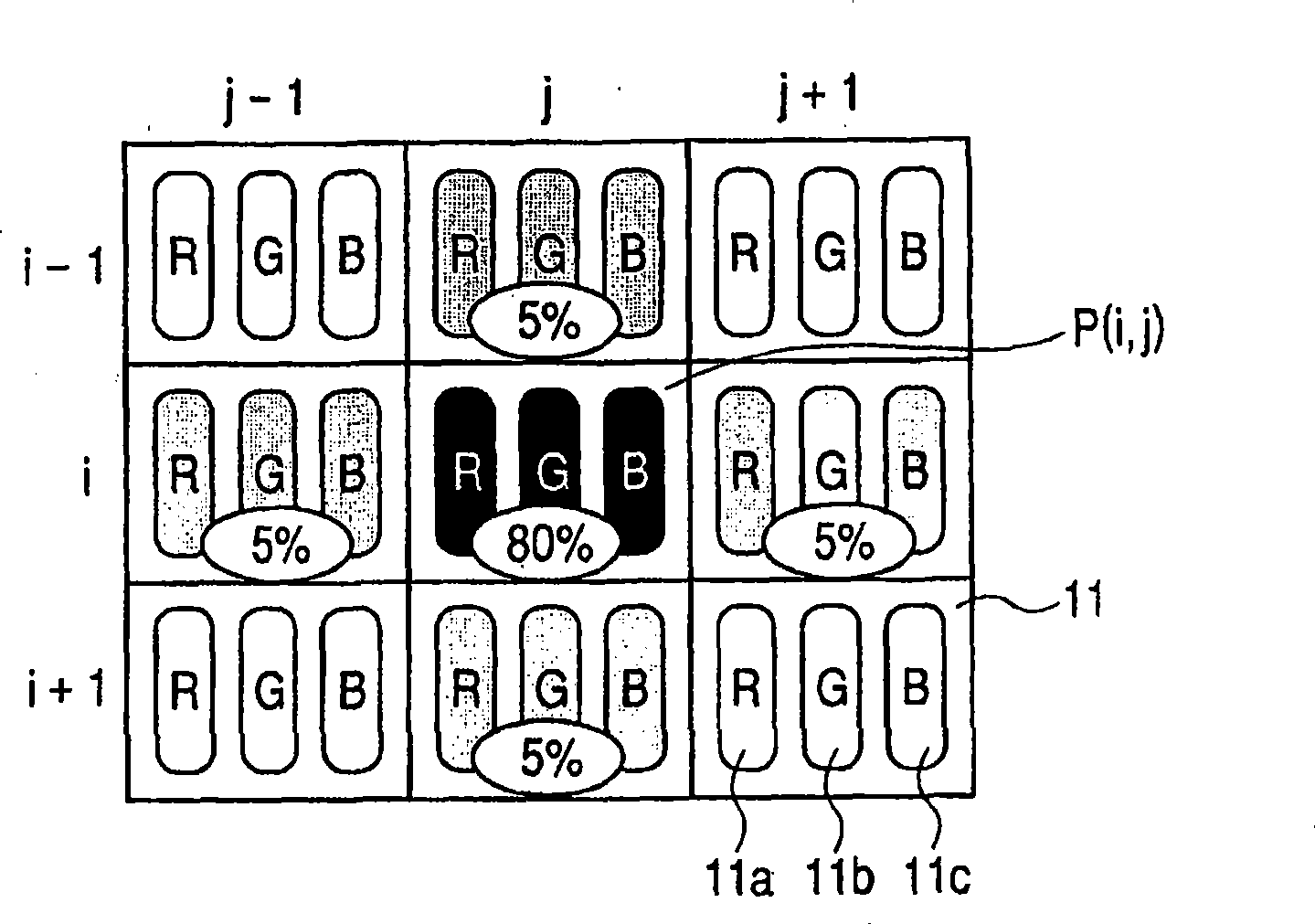

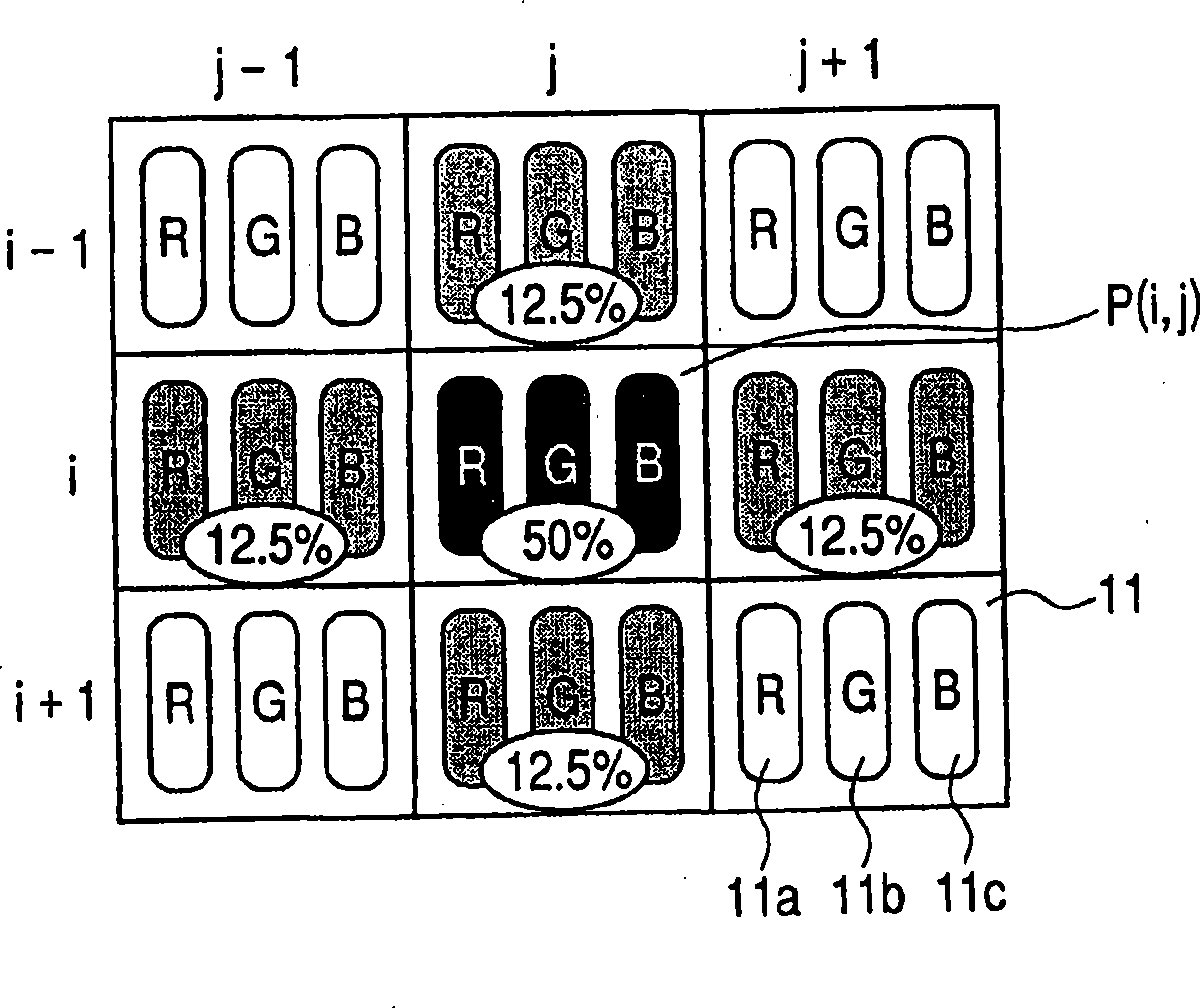

Display method of emission display apparatus

InactiveCN101373575ASuppress image stickingImprove overall lifespanCathode-ray tube indicatorsTime changesImage resolution

Sticking of a Pixel is suppressed to improve the life of a display panel. In an emission display apparatus with a display panel in which a plurality of pixels each having at least one subpixel (11a, 11b, 11c) are disposed. A first display method of emitting light with only a pixel P(I,j) serving as an emission center and a second display method of allocating luminance of the pixel P(i,j) serving as an emission center to nearby pixels surrounding the pixel are combined in a controllable manner. A high-resolution mode with a high ratio of the first display method and a long-life mode with a high ratio of the second display method are switched therebetween depending on a spatial change or time change of image input data, an emission time, a degradation rate, a temperature, an emission luminance, and a display time.

Owner:CANON KK

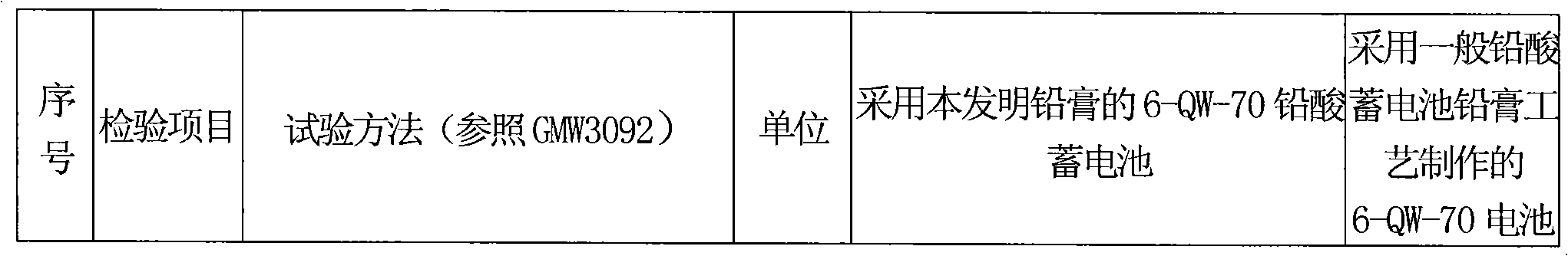

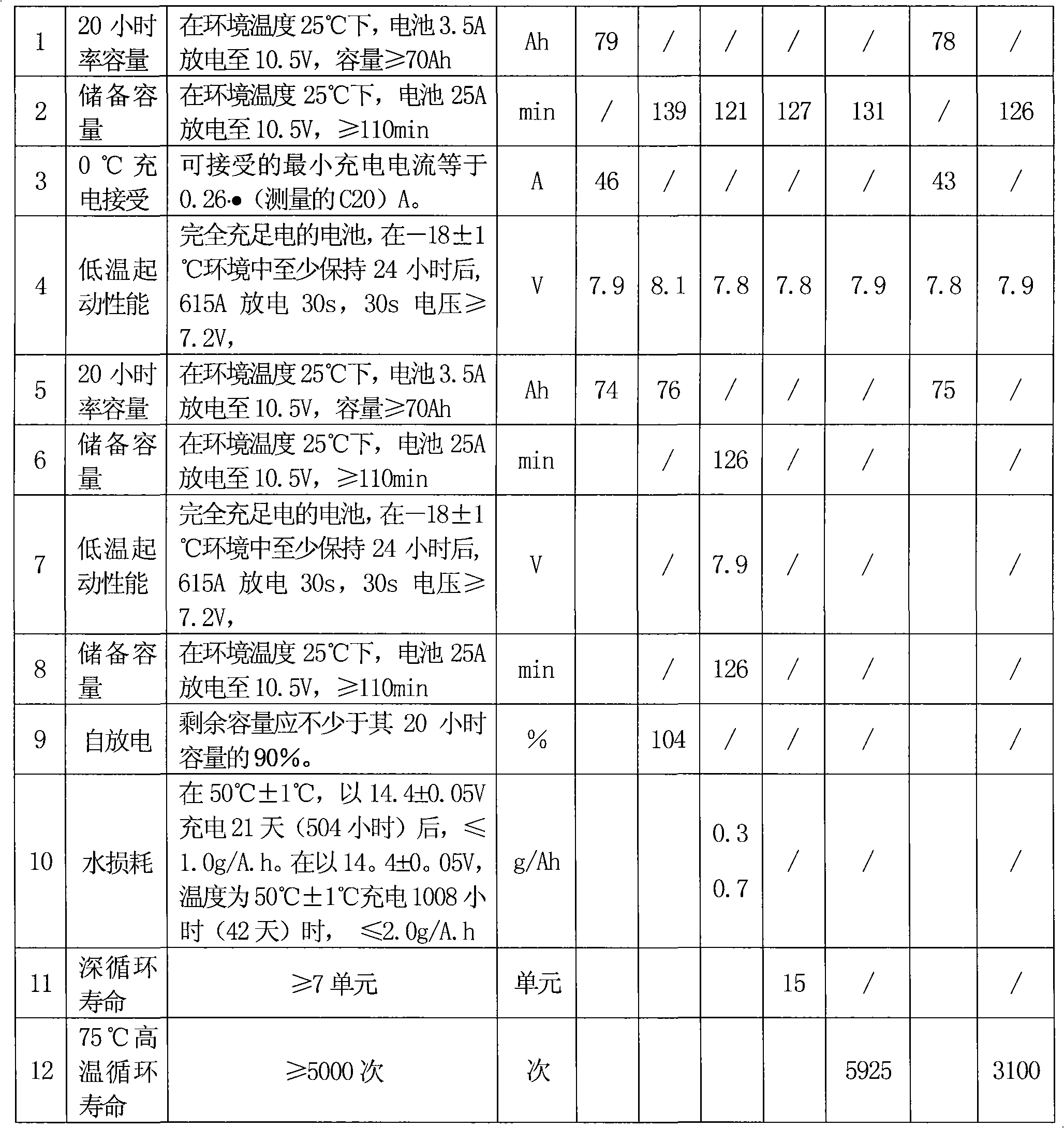

High-temperature lead-acid accumulator cathode diachylon and preparation method

ActiveCN101330140AExcellent high temperature life performanceImproved high temperature life performanceLead-acid accumulator electrodesFiberSodium lignosulfonate

The invention relates to vehicle used high-temperature lead acid battery negative pole lead plaster and a preparation method thereof, belongs to the storage battery technical field and is used for improving the high-temperature service life and the low-temperature starting capacity of the storage battery. The technical proposal is as follows: the lead plaster solid raw material comprises the following materials by the weight unit: 100 units of lead powder, 0.01 to 0.5 units of sodium lignosulfonate, 0.01 to 0.8 units of high-temperature sodium lignosulfonate, 0.01 to 1.0 unit of graphite powder, 0.03 to 0.08 units of fibre, 0.3 to 1.2 units of barium sulfate, 0.2 to 1.0 units of humic acid and 0.1 to 0.4 units of black carbon. The materials, such as the high-temperature sodium lignosulfonate and the graphite powder are added to the compounding recipe of the negative pole lead plaster, thereby the performance of the negative pole active materials is effectively improved at the high temperature by matching with the reasonable compounding recipe ratios of the added materials, the contraction is reduced, thereby the high-temperature service life and the low-temperature starting capacity of the storage battery are enhanced, particularly the high-temperature service life can be above 90 percent higher than the storage battery prepared based on a common compounding recipe.

Owner:FENGFAN

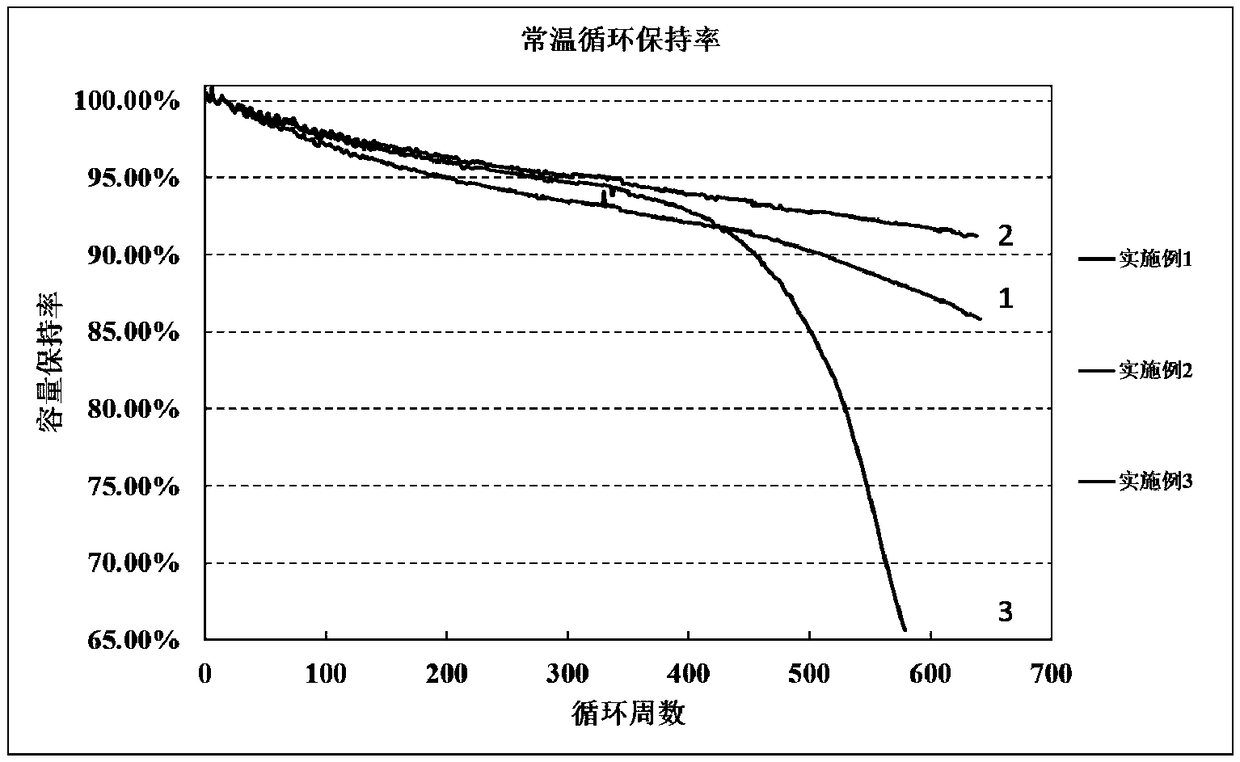

A wetting method for high-capacity high-pressure negative electrode lithium ion battery

InactiveCN109065826AImprove the ability to absorb electrolyteKeep securityFinal product manufactureSecondary cells charging/dischargingCharge dischargeHigh pressure

The invention relates to the field of preparation of lithium ion batteries, in particular to a wetting method of a high-capacity high-pressure negative electrode lithium ion battery. On the basis of high temperature wetting, Vacuum injection, high temperature shelving, pre-forming, high temperature shelving, secondary injection sealing and continuous forming are adopted in six phases to fully soakthe high-capacity high-pressure negative electrode. Firstly, the advantages of high-efficiency high-temperature soaking are retained, and two high-temperature shelves are used before and after the high-temperature soaking, which reduces the soaking time and waiting time and saves the time cost. 2, that pre-forming and the continuous for processes are added to enhance the adsorption capacity of the high-capacity high-pressure solid negative electrode to the electrolyte, and the phenomenon of lithium precipitation in the charge-discharge process is avoided; The cycle life of high-capacity high-pressure lithium ion battery is prolonged.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

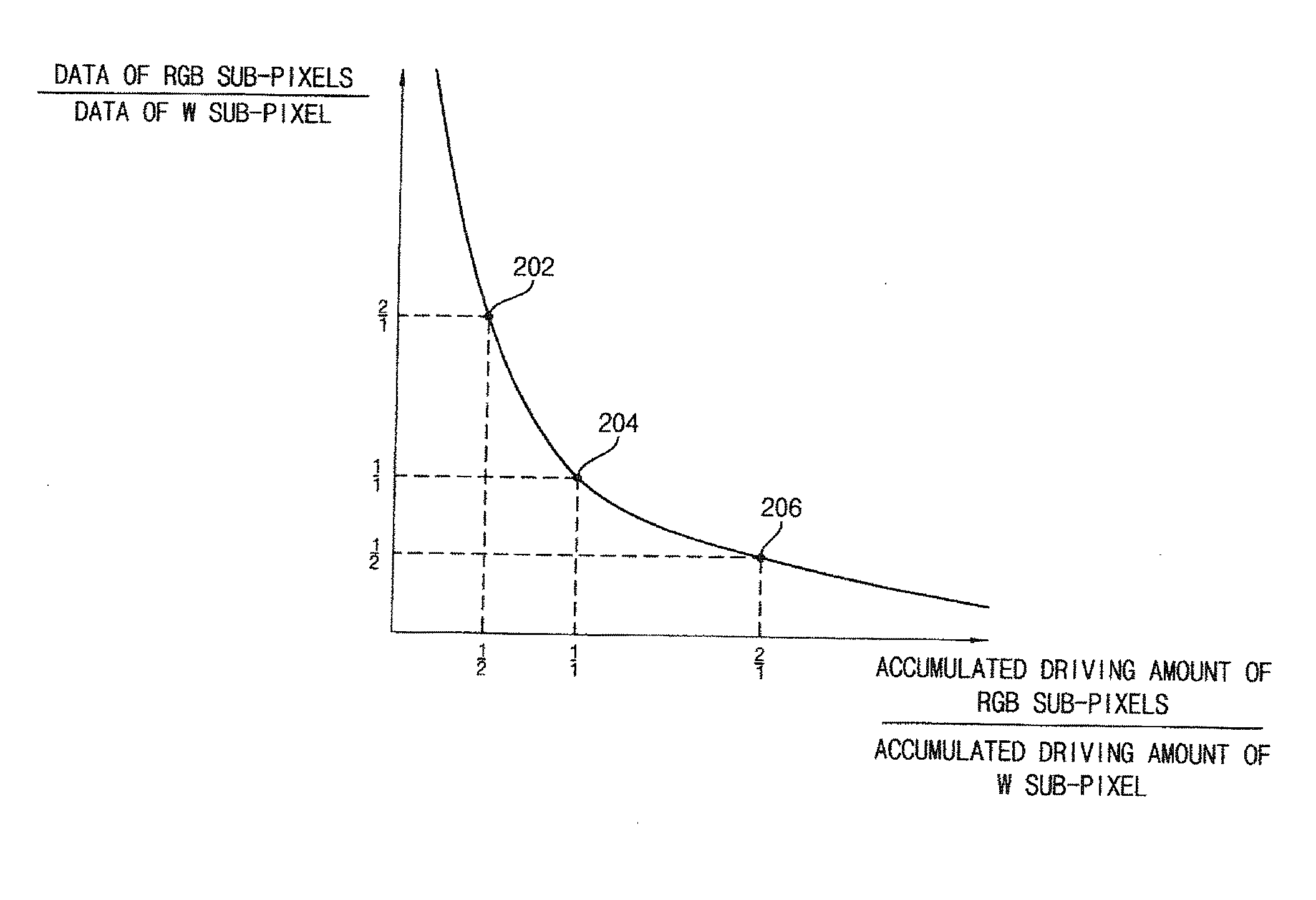

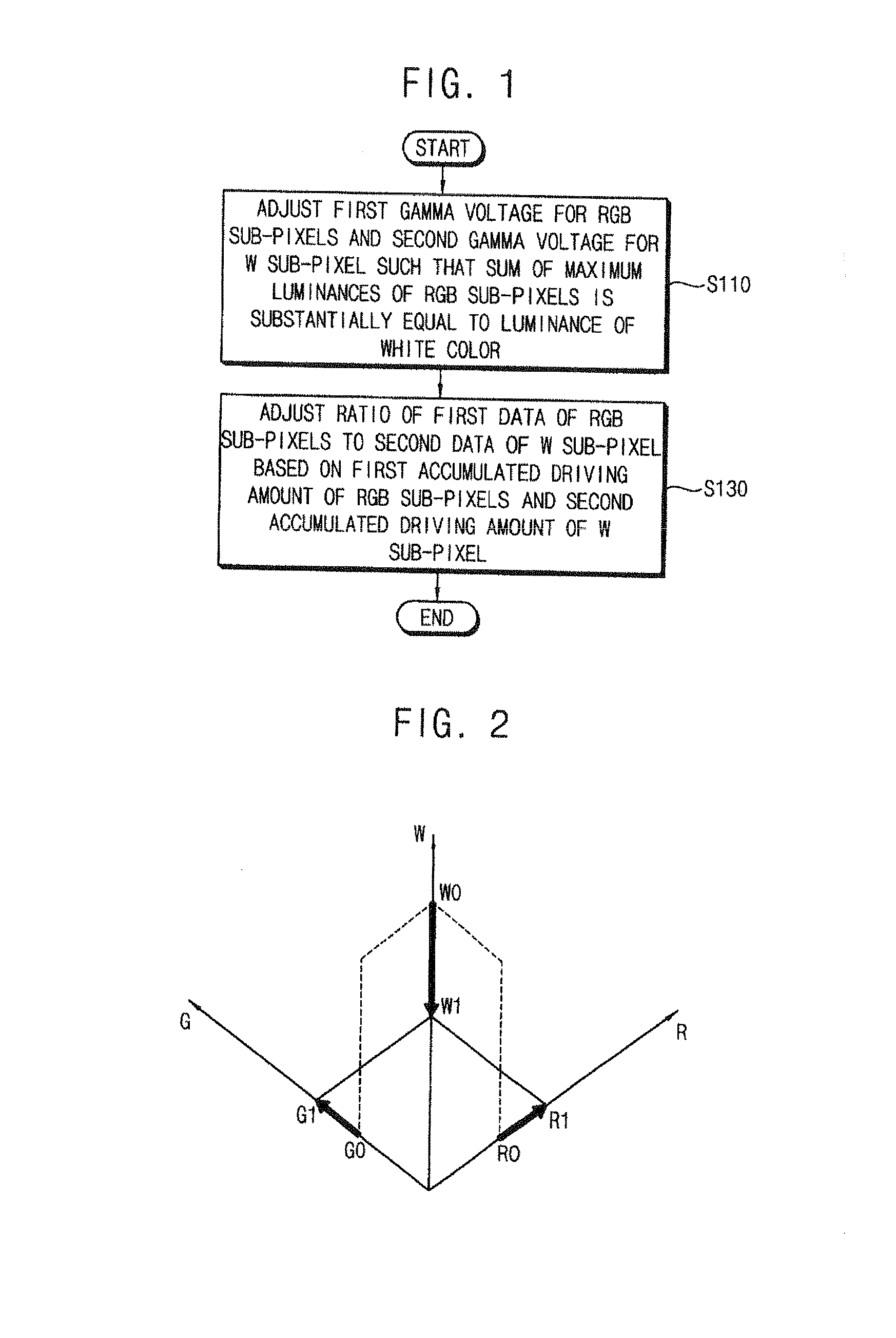

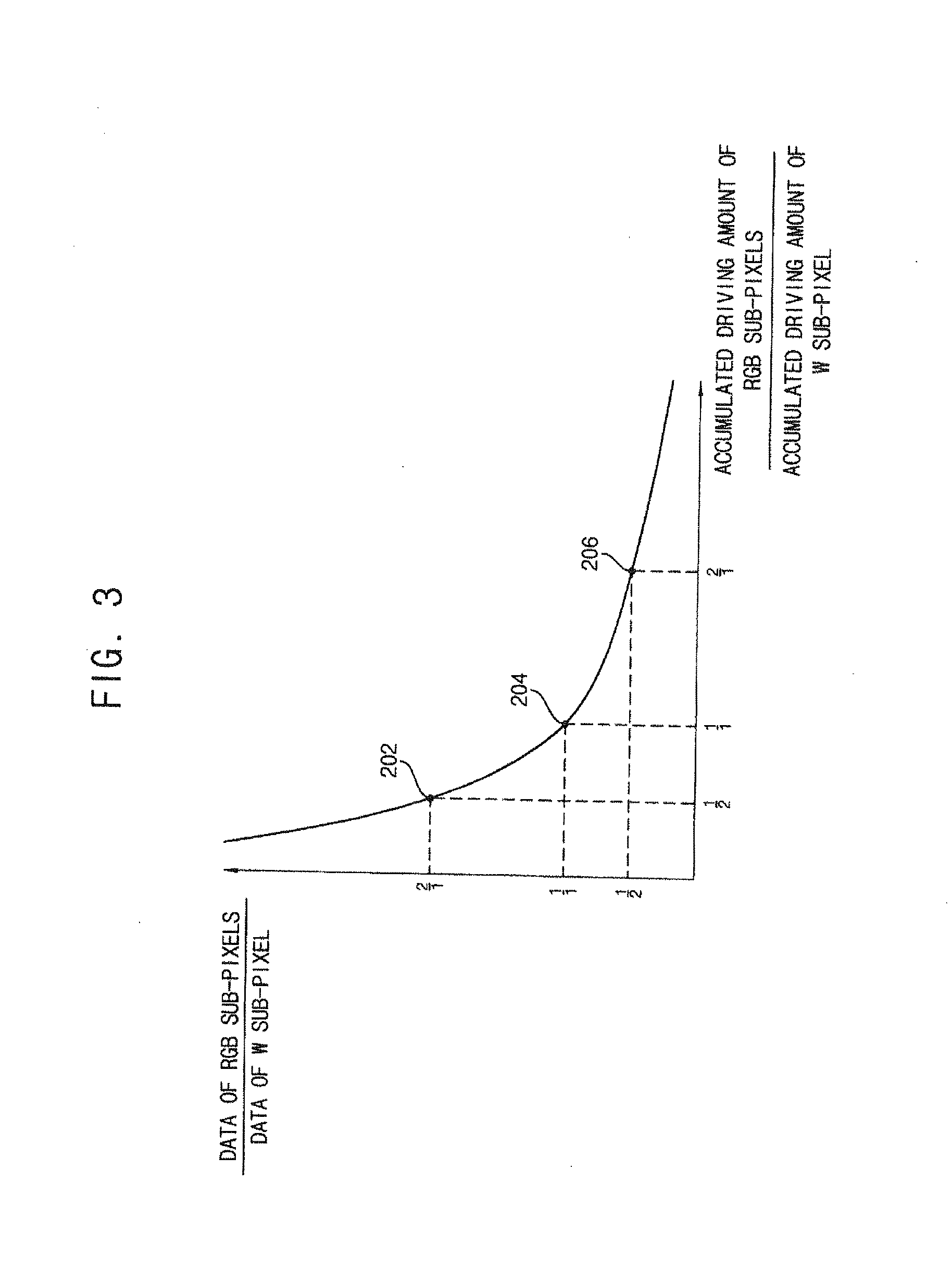

Method of operating an organic light emitting display device, and organic light emitting display device

ActiveUS20140085170A1Avoid comparisonImprove overall lifespanCathode-ray tube indicatorsDisplay deviceOptoelectronics

A method of operating an organic light emitting display device including a red sub-pixel, a green sub-pixel, a blue sub-pixel and a white sub-pixel, wherein a first gamma voltage for the red, green and blue sub-pixels and a second gamma voltage for the white pixel are adjusted such that a sum of maximum luminances of the red, green and blue sub-pixels is substantially equal to a luminance of a white color displayed by the organic light emitting display device. With respect to a white portion of input data, a ratio of first data of the red, green and blue sub-pixels to second data of the white sub-pixel is adjusted based on a first accumulated driving amount of the red, green and blue sub-pixels and a second accumulated driving amount of the white sub-pixel.

Owner:SAMSUNG DISPLAY CO LTD

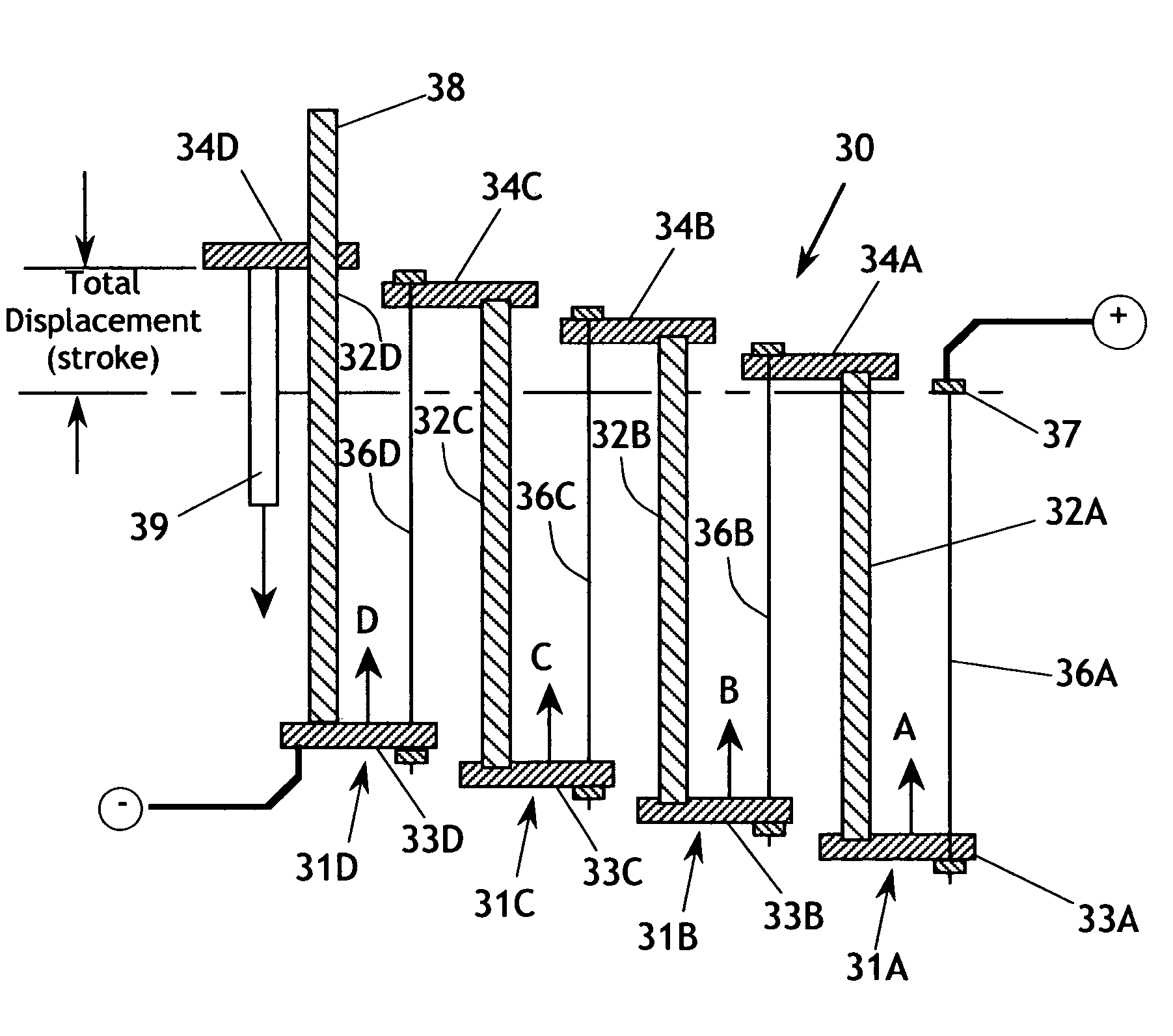

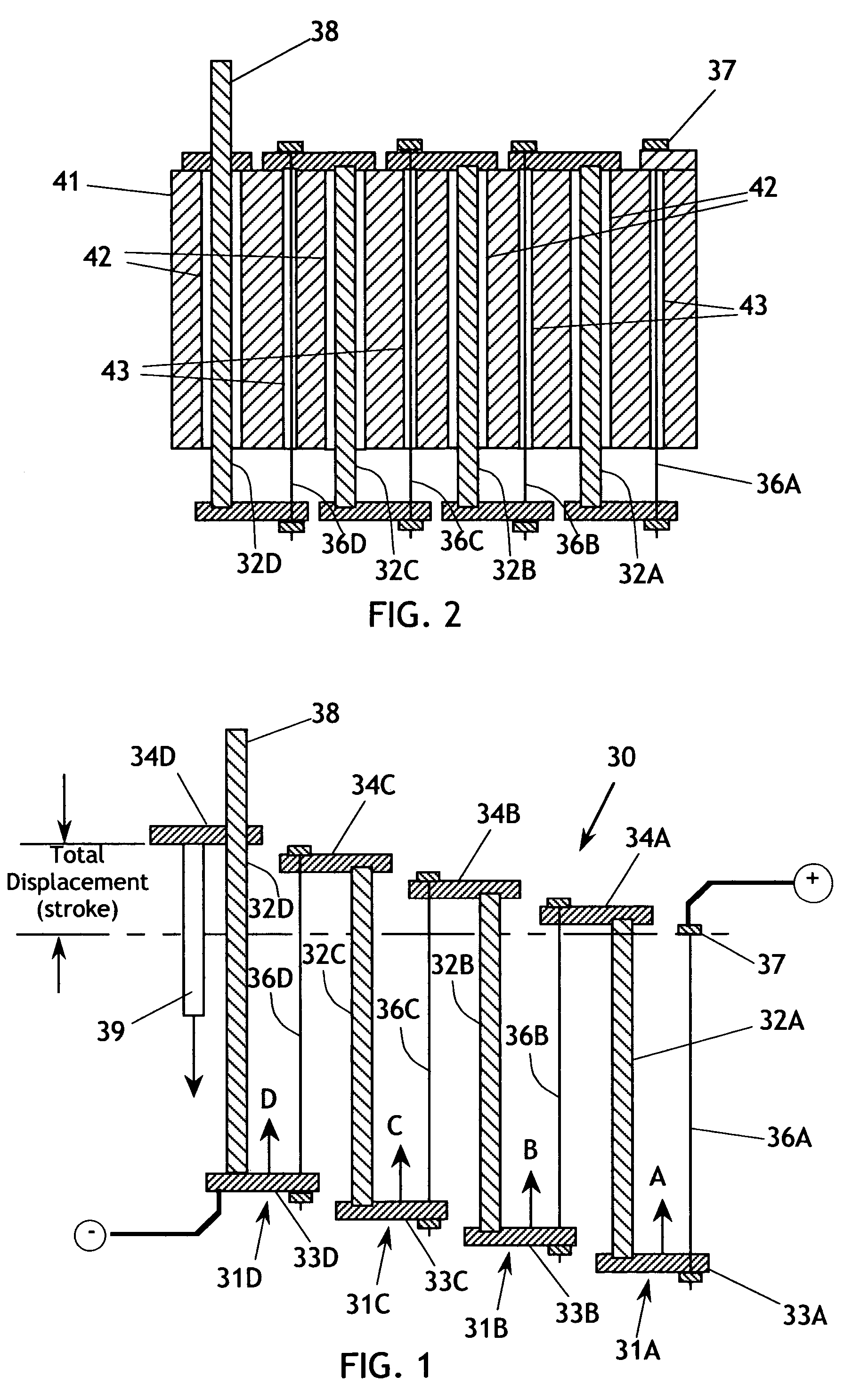

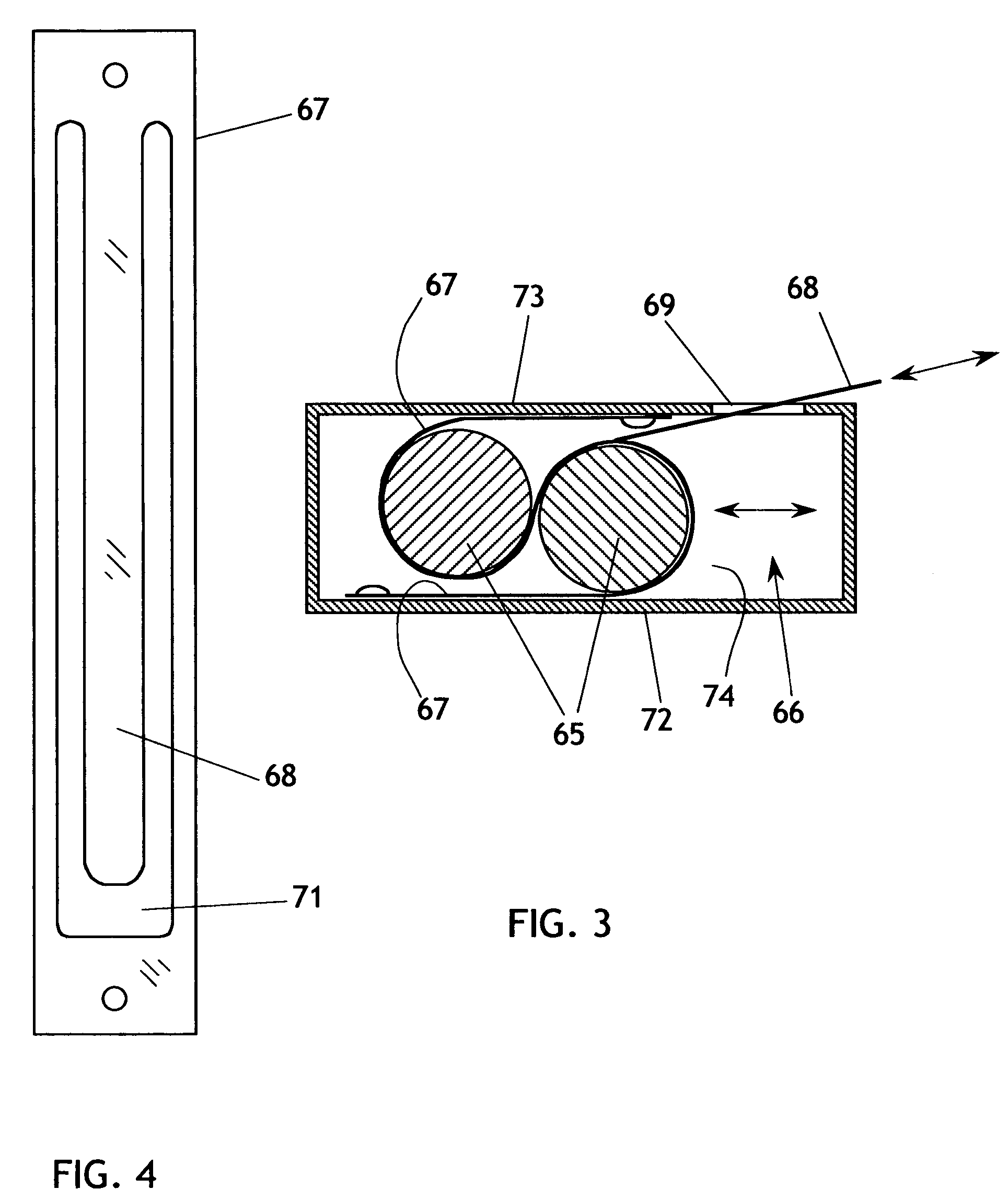

Shape memory alloy actuators

InactiveUS7256518B2Expand the scope ofShorter and powerful strokeMechanical power devicesPropulsion systemsEngineeringLinear actuator

Owner:PERIHELIAN

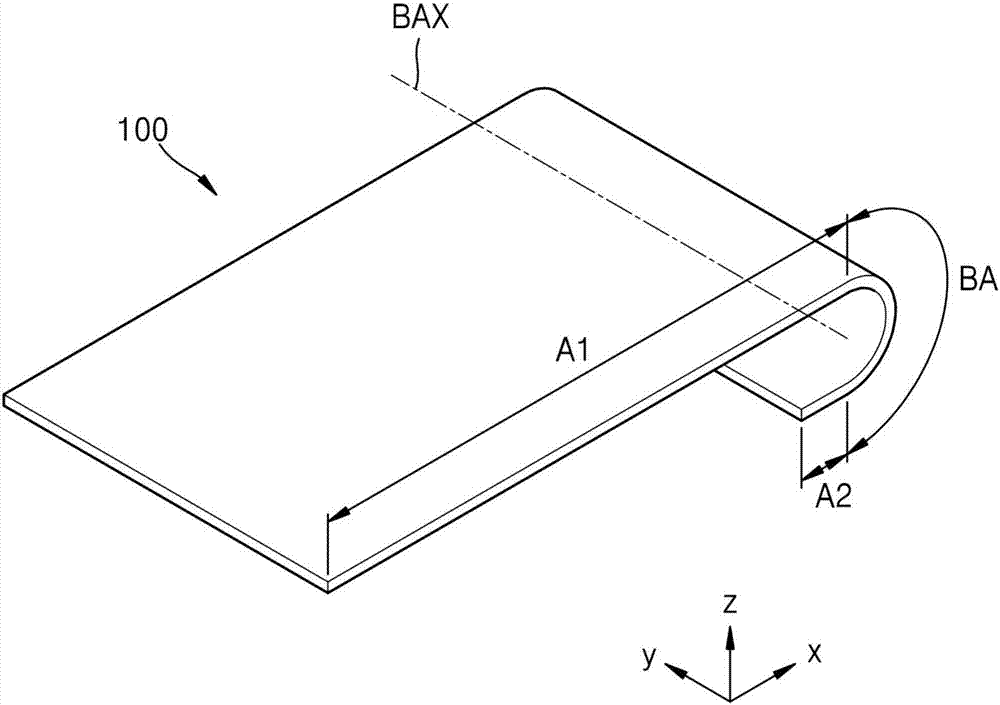

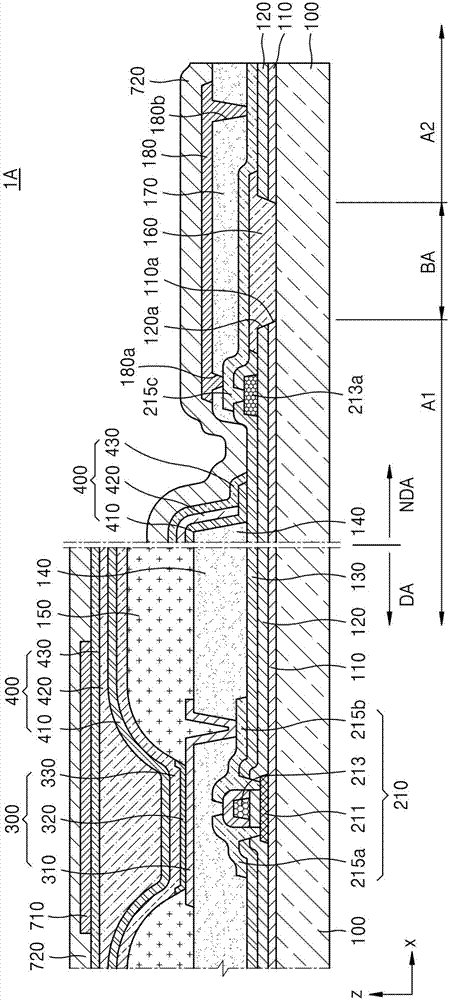

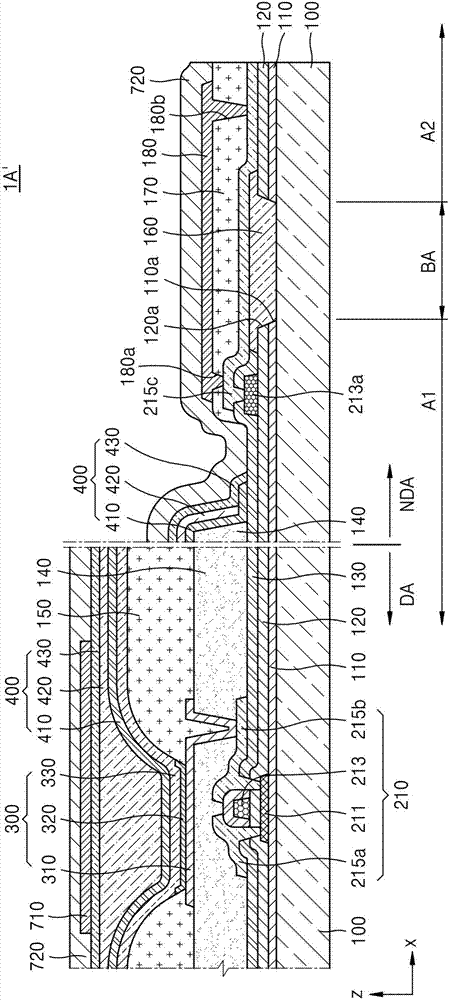

Display apparatus

ActiveCN107230680AImprove overall lifespanReduce minimizeFinal product manufactureSolid-state devicesDisplay deviceEngineering

A display device includes a substrate including a bending area located between a first region and a second region, and bent around a bending axis extending in a first direction, a first conductive layer above the substrate, and extending from the first region to the second region through the bending area, a second conductive layer above the first conductive layer, and extending from the first region to the second region through the bending area, and an organic insulating layer between the first conductive layer and the second conductive layer.

Owner:SAMSUNG DISPLAY CO LTD

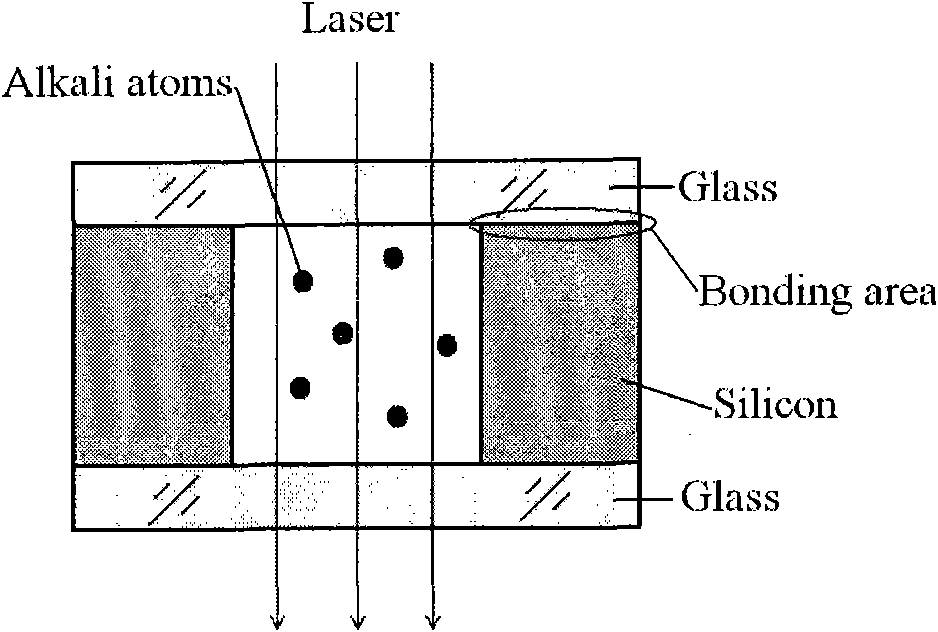

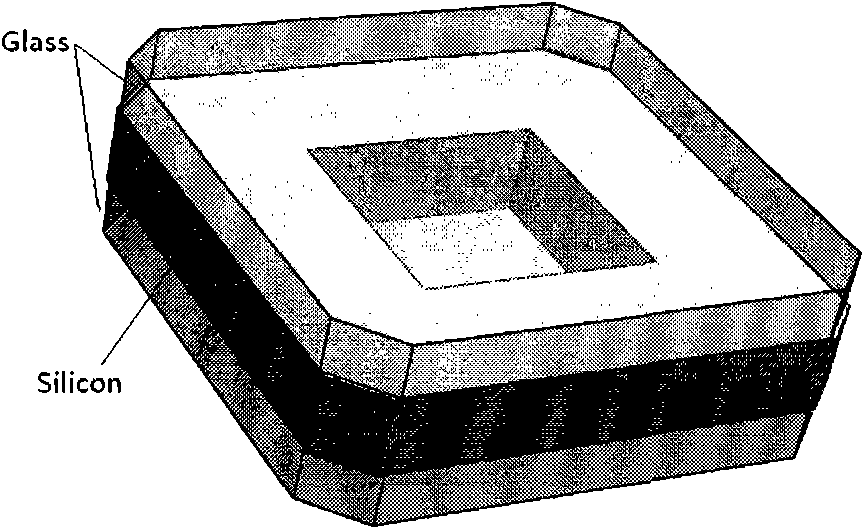

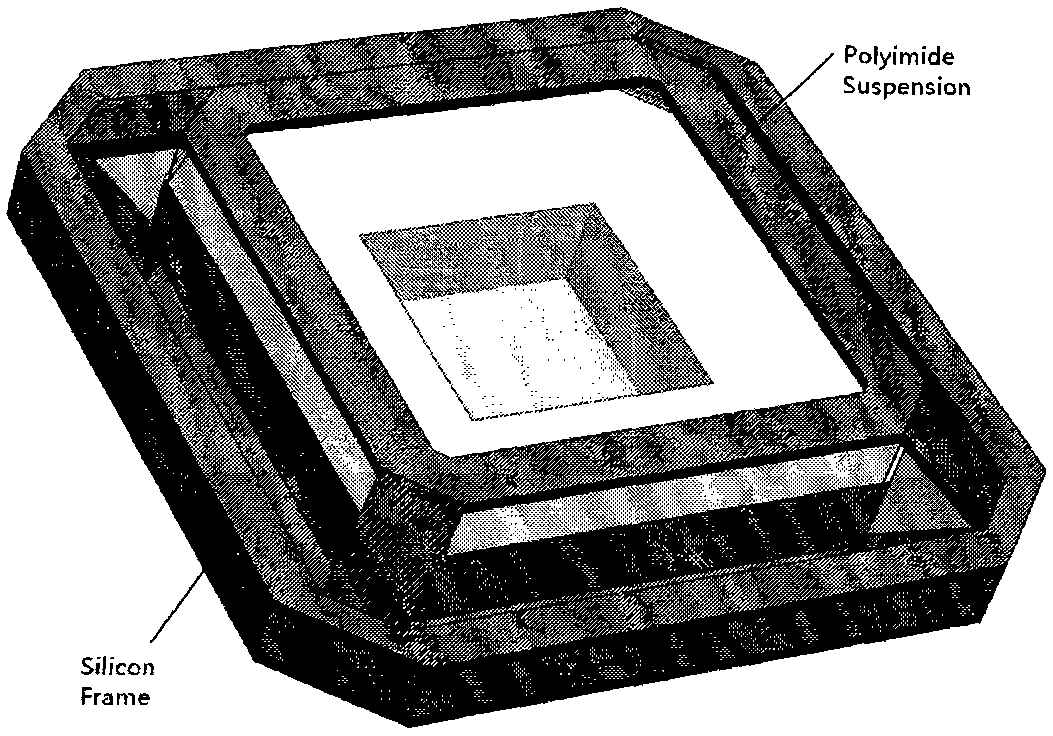

Micro electro mechanical system (MEMS) process-based micro atomic cavity device air tightness package and method

InactiveCN102205941ASimple structural designSimple processDecorative surface effectsSolid-state devicesGyroscopeEngineering

The invention relates to a micro electro mechanical system (MEMS) manufacturing process-based micro atomic cavity air tightness package structure and a method. The structure and the method are characterized in that: a micro atomic cavity which is manufactured by the MEMS process is arranged in a glass or metal seal buffer cavity through a supporting structure, and the air tightness of the micro atomic cavity is improved, so that the service life of devices such as a micro atomic clock and the like based on the micro atomic cavity is prolonged, and the stability of the devices is improved. The structure and the method have a key point that: in the glass or metal buffer cavity structure, the inside of the buffer cavity is vacuumized or filled with buffer gas of which the components and the pressure are approximate to those of gas in the micro atomic cavity, and a leading wire of the micro atomic cavity passes through the buffer cavity to realize air tightness lead. By the package structure and the method, the leakage rate of the micro atomic cavity and outside can be effectively reduced, and the technical problem of short service life of micro atomic cavity devices is solved. The air tightness package structure is particularly suitable for the micro atomic cavity devices such as micro atomic clocks, micro atom magnetometers, micro atom gyroscopes and the like with low power consumption and small volumes.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

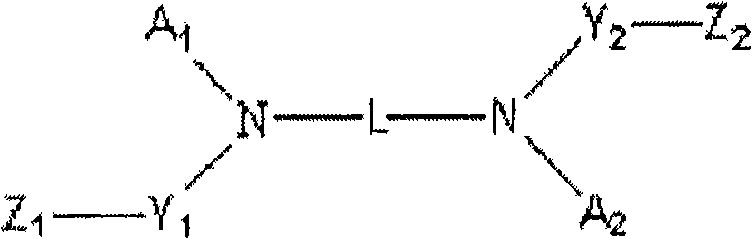

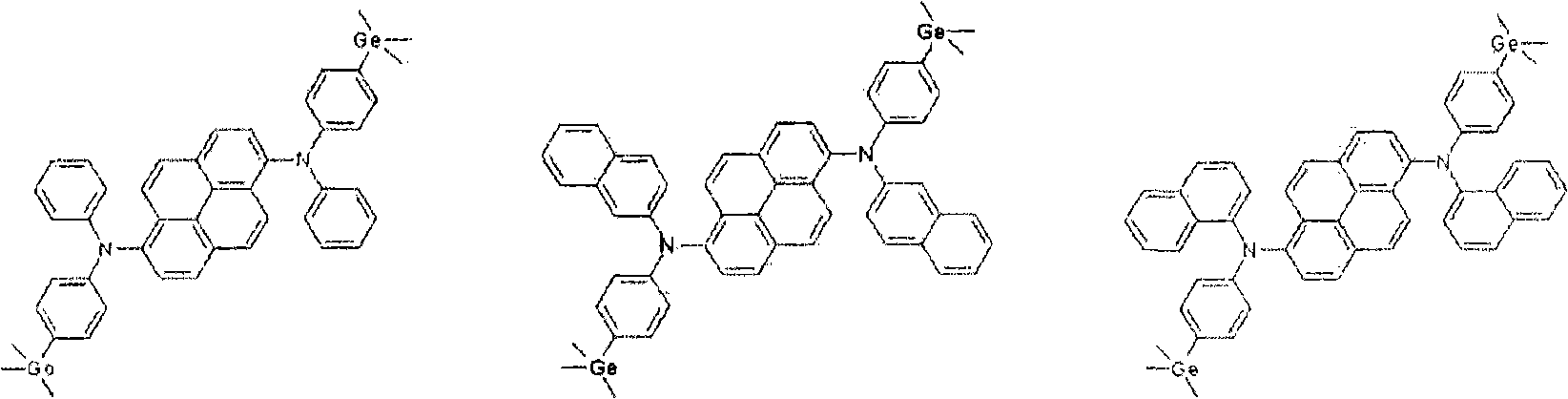

New diamine derivatives, preparation method thereof and organic electronic device using the same

ActiveCN101405255AImprove efficiencyIncrease the driving voltageGermanium organic compoundsDomestic articlesDopantElectron hole

The present invention relates to a novel diamine derivative, a method for preparation thereof, and an organic electronic device using the same. The diamine derivative according to the present invention can serve as a hole injecting, hole transporting, electron injecting, electron transporting, or light emitting material in an organic electronic device including an organic light emitting device. Particularly, it can be used as a light emitting material as used alone, and also serve as a light emitting host, or a light emitting dopant, in particular, a blue light emitting dopant. The organic electronic device according to the present invention exhibits excellent characteristics in terms of efficiency, drive voltage, life time, and stability.

Owner:LG CHEM LTD

Novel materials for organic electroluminescent devices

ActiveCN101490208AHigh purityEasy to purifyOrganic chemistryOrganic compound preparationDopantHost material

The present invention relates to compounds according to formulas (1) to (8) and to the use thereof in organic electroluminescent devices, in particular in blue-emitting devices. The compounds according to formulas (1) to (8) are used as host material or as a dopant in the emitting layer, or in a hole transport layer or electron transport layer.

Owner:MERCK PATENT GMBH

Compound for an organic photoelectric device, and organic photoelectric device comprising same

InactiveCN102597158AImprove overall lifespanImprove efficiencyElectroluminescent light sourcesSolid-state devicesPhotochemistryChemical formula

The present invention relates to a compound for an organic photoelectric device and to an organic photoelectric device comprising same. The compound for an organic photoelectric device is expressed in chemical formula 1, wherein the definitions of Ar1 to Ar4 and R1 to R4 are the same as those specified in the description. An organic photoelectric device having superior thermal / electrochemical stability and efficiency and an extended lifespan can be provided using the above-described compound for an organic photoelectric device.

Owner:CHEIL IND INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com