Knee joint endoprosthesis

A technology for knee joints and prostheses, applied in the directions of knee joints, elbow joints, joint implants, etc., can solve the problems of affecting the movement stability of knee joint prostheses and shortening the life of tibial pads, so as to ensure movement stability. sex, improve overall life expectancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

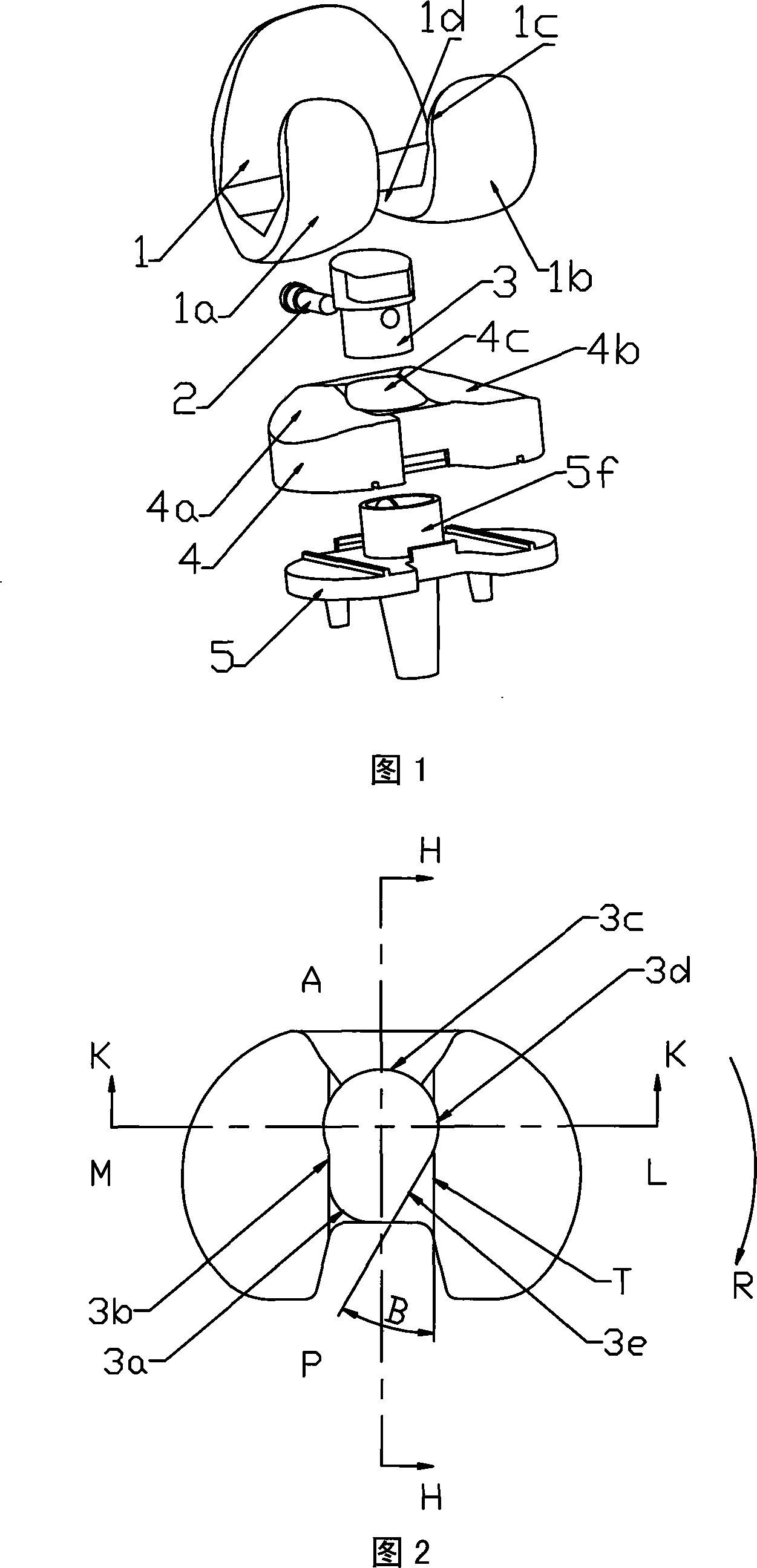

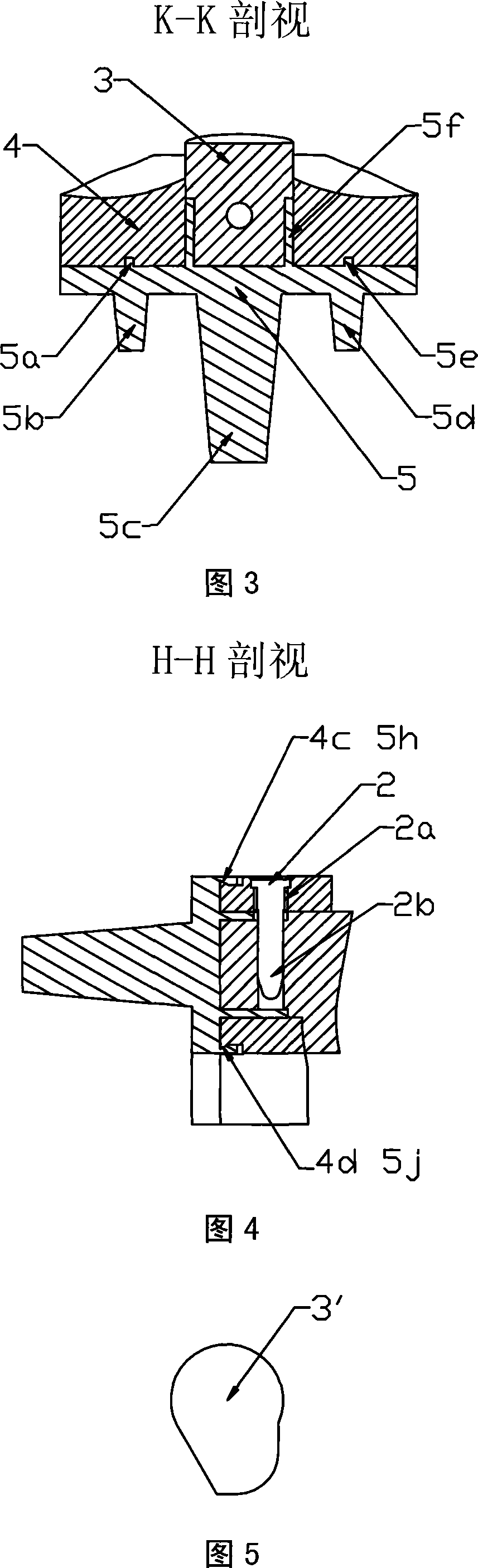

[0024] In Fig. 1, Fig. 2, Fig. 3 and Fig. 4, the femoral prosthesis 1 is made of cobalt-chromium-molybdenum alloy material, connected with the distal end of the femur through femoral mounting stems or screws, and has inner condyle 1a and outer condyle 1b . The tibial bearing 5 is made of cobalt-chromium-molybdenum alloy material, and is connected with the proximal end of the tibia through the tibial mounting stem 5c and the fixing columns 5b, 5d, wherein the tibial mounting stem 5c is pressed into the tibial medullary cavity to play a major role of fixation, fixing Columns 5b and 5d are pressed into the cut surface of the proximal tibia to prevent rotation and assist fixation. The tibial liner 4 is made of ultra-high molecular weight polyethylene material, is located between the femoral prosthesis 1 and the tibial bearing 5, has the inner bone condyle 4a and the outer bone condyle 4b, and passes along the tibial bearing A-P direction (anterior-posterior direction) The protrus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com