Micro electro mechanical system (MEMS) process-based micro atomic cavity device air tightness package and method

An atomic cavity and airtight technology, which is applied in the process of producing decorative surface effects, electric solid devices, semiconductor devices, etc., can solve the frequency stability drift of micro atomic clocks, shorten the life of micro atomic clocks, and change the composition of buffer gas, etc. problem, to achieve the effect of low power consumption, convenient design, and improved air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In this embodiment, the miniature atomic clock adopts the hermetic packaging structure of the present invention, the material of the buffer chamber is glass, the atmosphere in the buffer chamber is alkali metal vapor and buffer gas similar to the atomic chamber, and the glass processing technology adopts the melting process. Its production process is as follows:

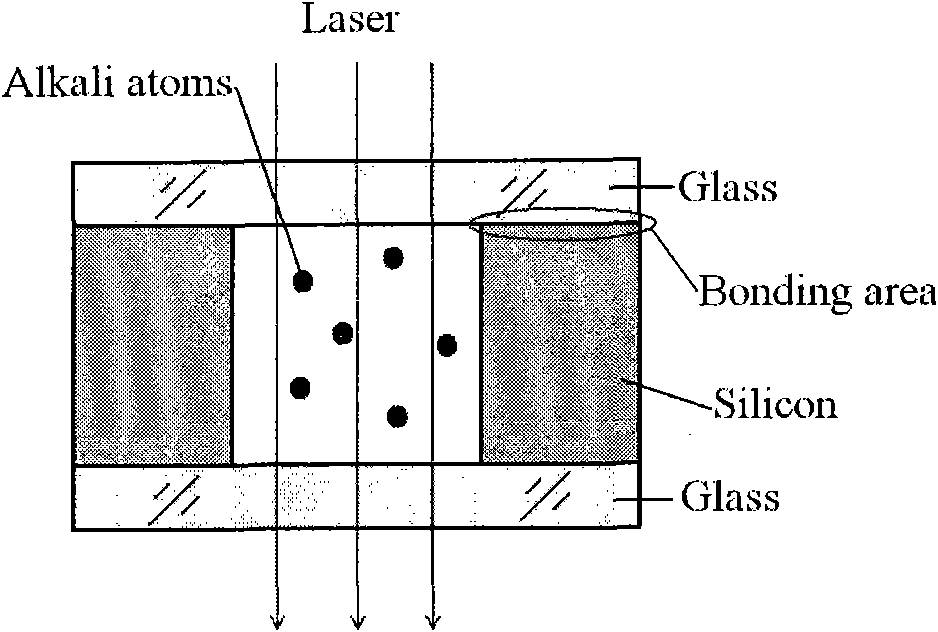

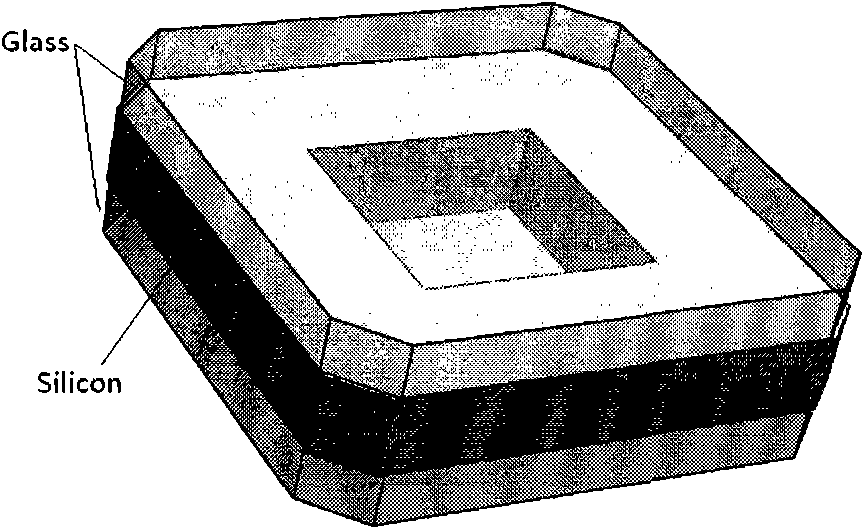

[0029] (1) The atomic cavity is fabricated by MEMS technology. The shape of the atomic cavity can be cuboid or cylinder, or other shapes, and the size is between 1-5mm. In this example, a 2×2mm square hole is first etched on a thick silicon wafer (thickness 0.5-2mm) and bonded with Pyrex glass (thickness about 0.5mm), and the cavity is filled with alkali metal vapor and mixed buffer gas , and then the other side of the silicon wafer is bonded to the Pyrex glass for the second time, and finally the MEMS atomic cavity is separated by dicing. Such as Figure 1b shown.

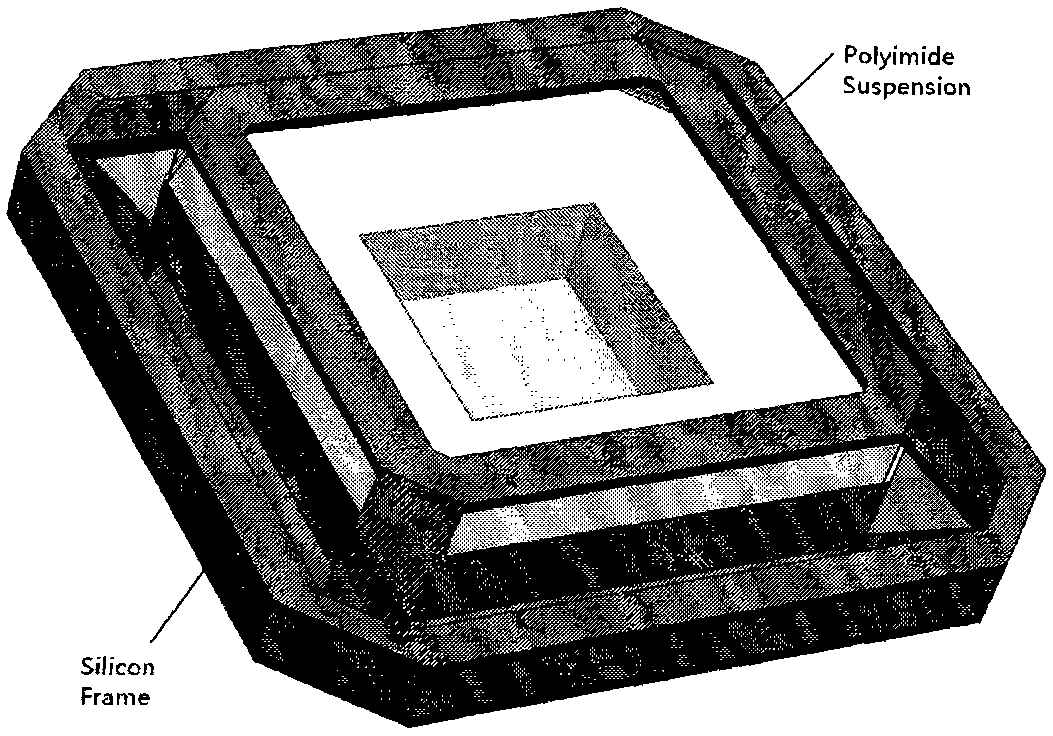

[0030] (2) Fabrication of a miniature a...

Embodiment 2

[0038] In this embodiment, the miniature atomic clock adopts the hermetic packaging structure of the present invention, the material of the buffer cavity is made of Kovar metal shell, the inside of the buffer cavity is evacuated, and the metal shell is sealed by a parallel sealing welding process. Its production process is as follows:

[0039] Steps (1), (2) and (3) are the same as (1), (2) and (3) in Example 1.

[0040] (4) Preparation before parallel sealing welding. The shape of the buffer cavity of the Kovar metal shell to be welded is a cuboid, and the base is equipped with lead pins that meet the sealing requirements, such as Figure 5 As shown, the length and width of the cuboid range from 10 to 20 mm, and the height is 5 mm. Suspend the atomic clock chip with peripheral circuits in the base of the metal tube shell, and at the same time stick volume-type zirconium getter on the wall of the base to clean oxides, dirt, oil and other impurities on the surface of the devi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com