Cutting method for steel for use in machine structure

一种机械结构、切削方法的技术,应用在用于车床的刀具、金属加工机械零件、车削设备等方向,达到工具寿命优良的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

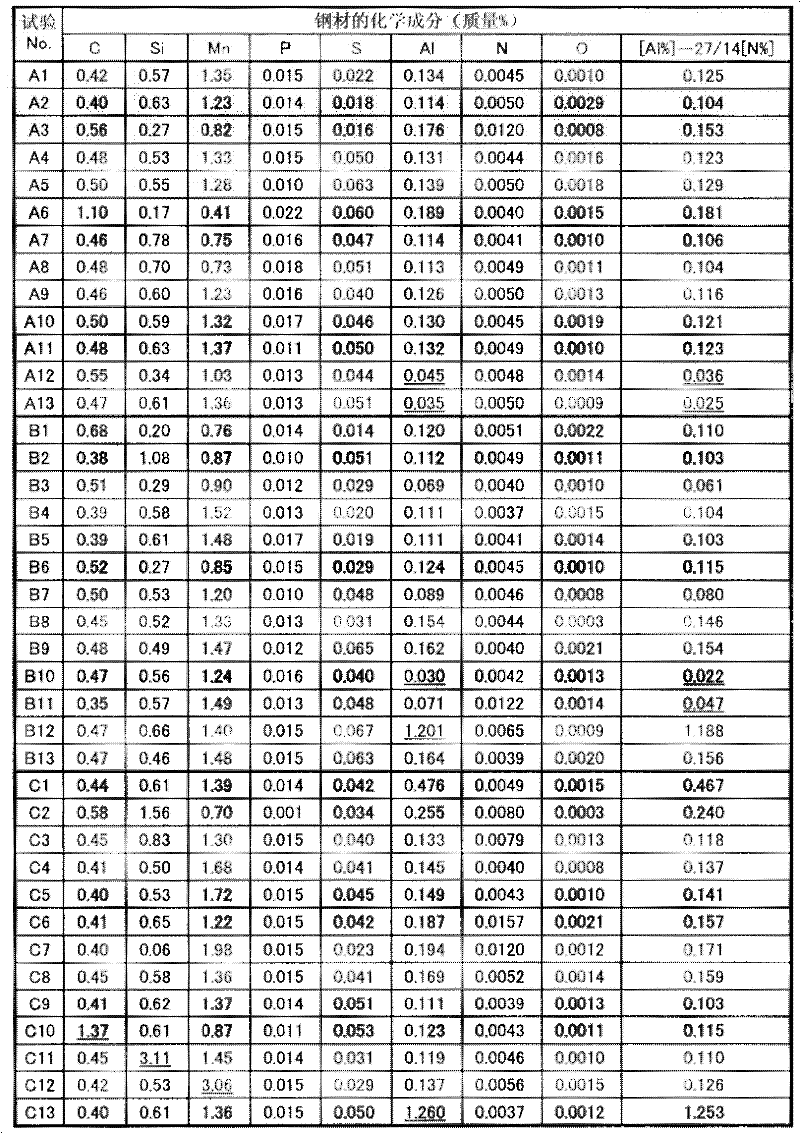

[0144] Next, examples will be given to specifically describe the effects of the present invention.

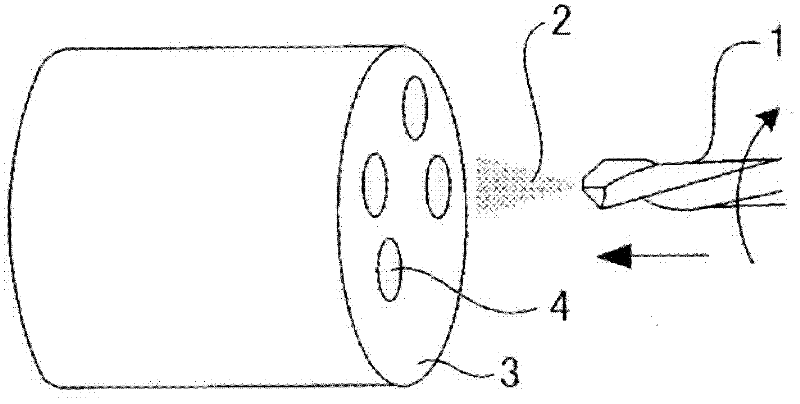

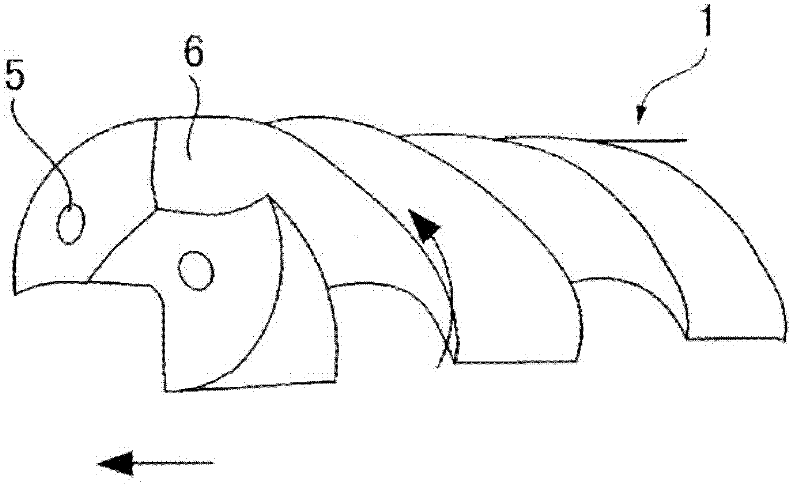

[0145] In this example, 150 kg of steel having the compositions shown in Tables 1 to 5 were smelted in a vacuum melting furnace, and then the obtained steel was forged into a cylindrical shape with a diameter of 50 mm at a temperature of 1250° C. , performing a homogenization treatment of heating at 1300° C. for 2 hours and then air cooling, and then performing a heat treatment of heating at 1200° C. for 1 hour and then air cooling. Then, a test piece for tool life evaluation with a diameter of 48 mm and a length of 105 mm was cut out from the obtained steel material, and the test piece was used for a test (test Nos. A1 to E12).

[0146] Table 1

[0147]

[0148] * Table 2 shows other elements.

[0149] * In Test Nos. A1 to C12, Sb, Sn, Zn, B, Te, Se, Bi, Pb, Li, Na, K, Ba, and Sr were not added to the steel as other elements.

[0150] * Underlines in the table indicat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| composition ratio | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com