Liquid injection process for core of lithium ionic cell

A technology of lithium-ion batteries and lithium batteries, which is applied in secondary batteries, battery pack parts, circuits, etc., can solve problems such as adverse effects of battery performance, waste of electrolyte, and environmental pollution, so as to save electrolyte and improve usage Longevity and the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

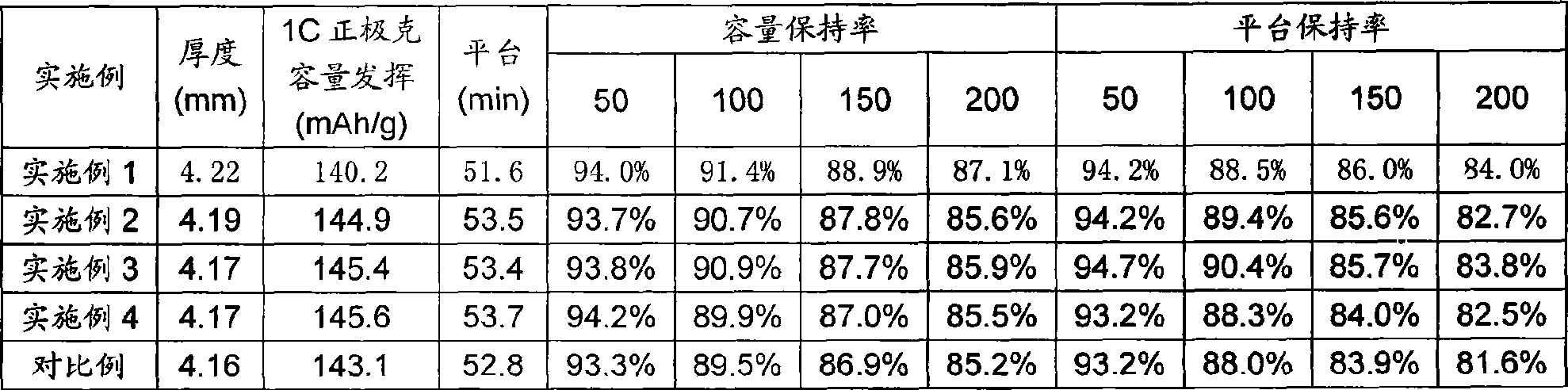

Embodiment 1

[0017] Inject lithium-ion battery cells, first inject 60% of the total electrolyte required according to the predetermined process requirements, and then let it stand for 16 hours, then put cotton and rubber plugs on the cells, and put the cells on the pre-charging cabinet , pre-charging (0.1C charging for 390 minutes), the battery cell is put into the cabinet, and then the liquid is injected twice under vacuum conditions (replenishment such as the remaining electrolyte), and finally transferred to the sealing process.

[0018] The positive electrode is lithium cobalt oxide, the negative electrode is graphite, the cell model is 423048A2, the nominal capacity is 650mAh, and the compaction density of the positive electrode sheet is 3.82g / cm 3 , the compacted density of the negative electrode sheet is 1.59g / cm 3 (The compacted densities of the positive and negative electrodes are all within the range of normal use values). The gram capacity performance of the positive electrode ...

Embodiment 2

[0020] Inject the lithium-ion battery cells, inject 70% of the total electrolyte required according to the predetermined process requirements for the first time, and then let it stand for 16 hours, then put cotton and rubber plugs on the cells, and put the cells on the pre-charging cabinet , pre-charging (0.1C charging for 390 minutes), the battery cell is put into the cabinet, and then the liquid is injected twice under vacuum conditions (replenishment such as the remaining electrolyte), and finally transferred to the sealing process.

[0021] The positive electrode is lithium cobalt oxide, the negative electrode is graphite, the cell model is 423048A2, the nominal capacity is 650mAh, and the compaction density of the positive electrode sheet is 3.82g / cm 3 , the compacted density of the negative electrode sheet is 1.59g / cm 3 (The compacted densities of the positive and negative electrodes are all within the range of normal use values). The gram capacity performance of the po...

Embodiment 3

[0023] Inject the lithium-ion battery cells, first inject 80% of the total electrolyte required according to the predetermined process requirements, and then let it stand for 16 hours, then put cotton and rubber plugs on the cells, and put the cells on the pre-charging cabinet , pre-charging (0.1C charging for 390 minutes), the battery cell is put into the cabinet, and then the liquid is injected twice under vacuum conditions (replenishment such as the remaining electrolyte), and finally transferred to the sealing process.

[0024] The positive electrode uses lithium cobalt oxide, the negative electrode uses graphite, the cell model is 423048A2, the nominal capacity is 65CmAh, and the compaction density of the positive electrode sheet is 3.82g / cm 3 , the compacted density of the negative electrode sheet is 1.59g / cm 3 (The compacted densities of the positive and negative electrodes are all within the range of normal use values). The gram capacity performance of the positive el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com