Patents

Literature

65results about How to "Improve cycle retention" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium ion battery cathode material and preparation method thereof

ActiveCN105449197AEasy to prepareEasy to operateCell electrodesSecondary cellsThermal expansionCobalt

The invention provides a lithium ion battery cathode material and a preparation method thereof. The method comprises: taking a lithium source, a cobalt source and a compound with doped elements as raw materials, respectively preparing two kinds of bulk phase doped lithium cobalt oxide precursors of median grain diameters (namely D50 grain diameters), carrying out surface doped treatment to the two kinds of lithium cobalt oxide semi-finished products, finally mixing the two kinds of lithium cobalt oxide semi-finished products, carrying out surface coating, and finally preparing the high voltage and high density lithium ion battery cathode material. The prepared lithium ion battery cathode material is featured by good electrical property, specifically high capacity, high cycle retention rate, low thermal expansion coefficient and high compaction density.

Owner:北京盟固利新材料科技有限公司

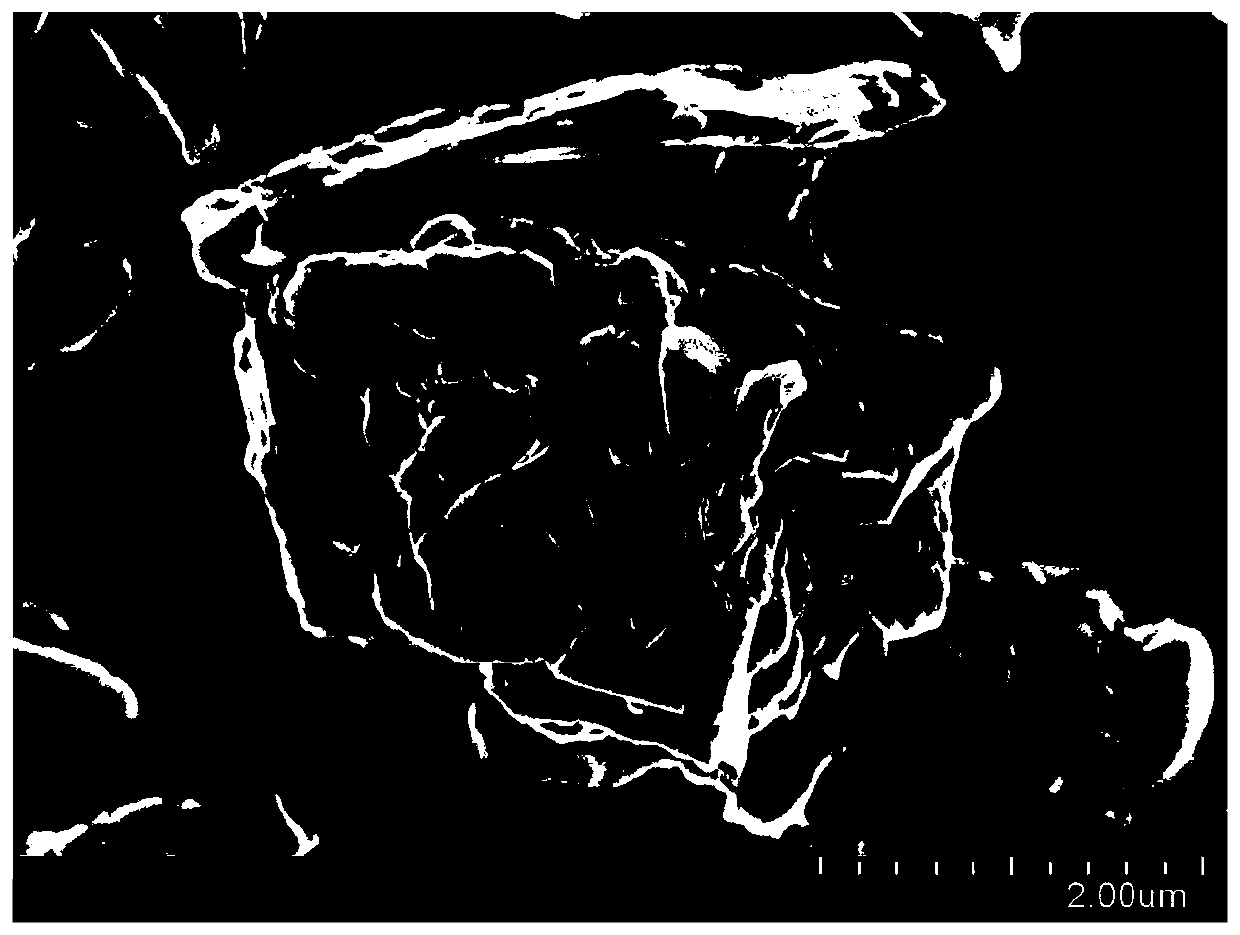

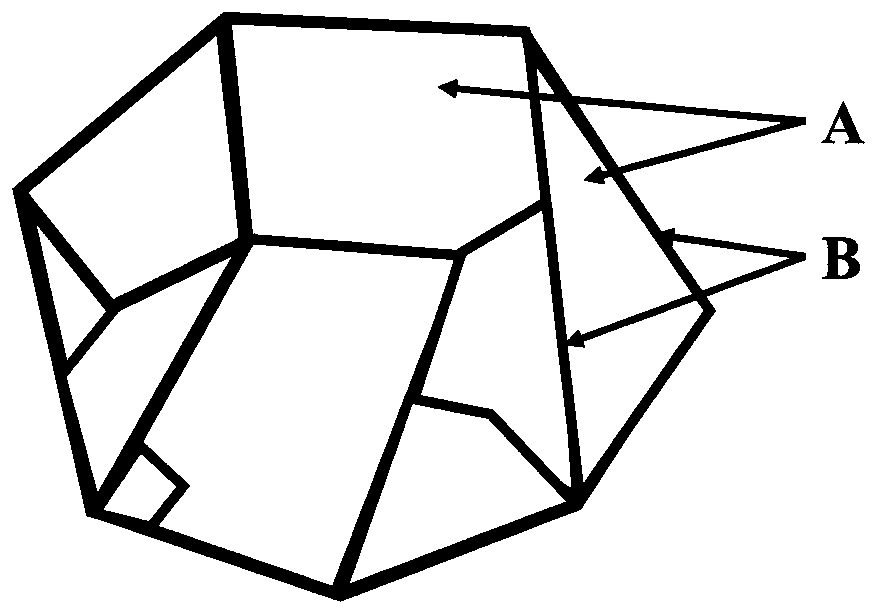

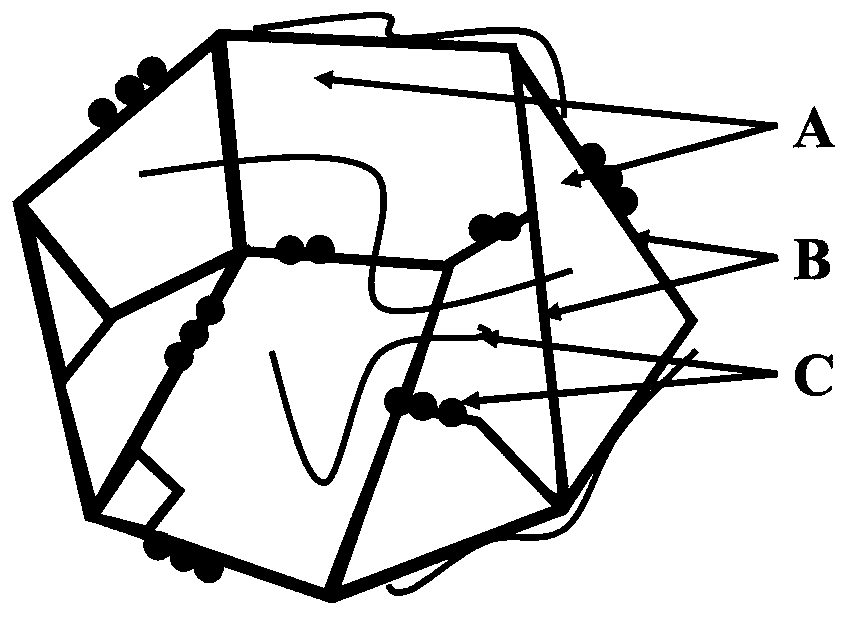

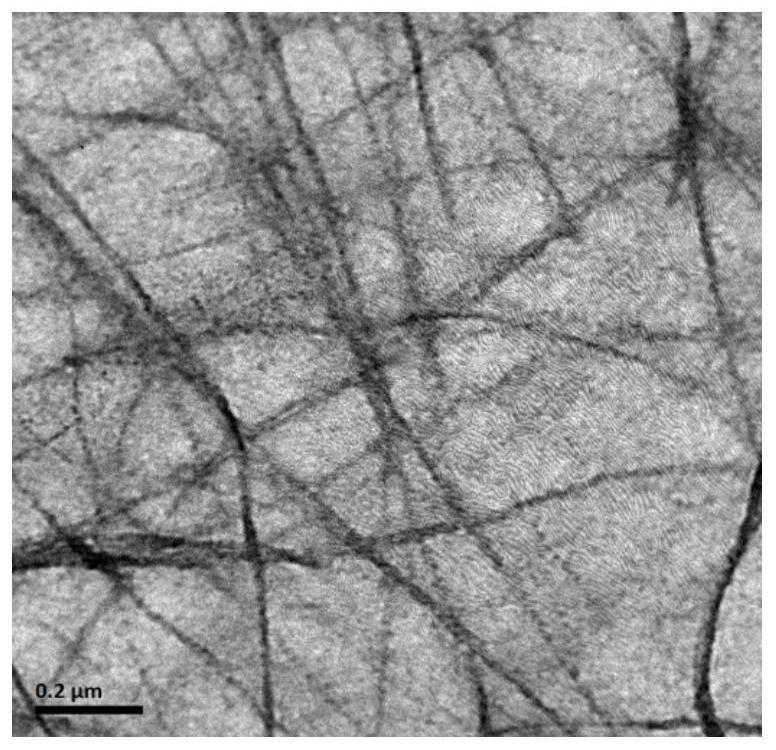

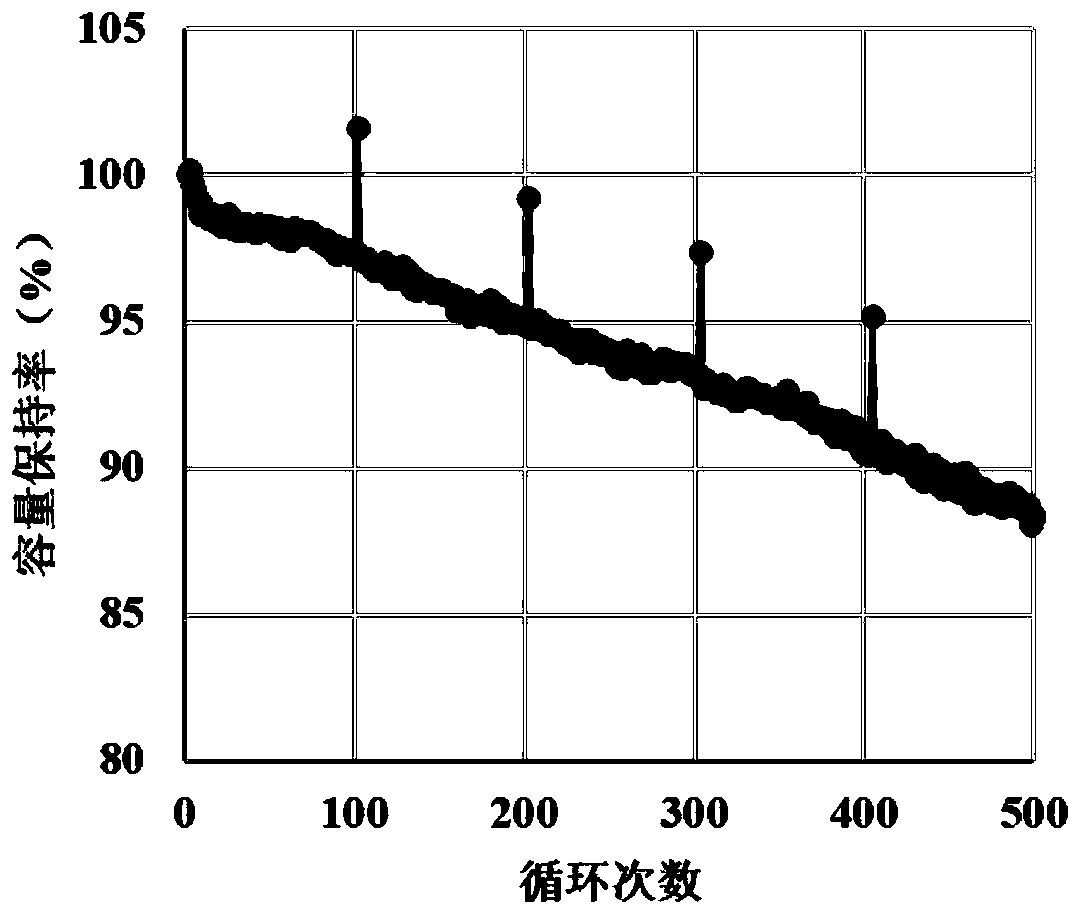

Positive electrode active material for secondary battery and magnesium secondary battery using the same

InactiveUS20120164537A1High cycle retention rateHigh energy densityNon-aqueous electrolyte accumulatorsPositive electrodesCobalt oxideManganese oxide

In a positive electrode active material for a magnesium secondary battery and a magnesium secondary battery using it, there is contained a powder particle containing a crystal phase having a structure formed with aggregation of a plurality of crystallites, and amorphous phases formed between the crystallites themselves; the amorphous phases contain at least one kind of a metal oxide selected from a vanadium oxide, an iron oxide, a manganese oxide, a nickel oxide and a cobalt oxide; and the crystal phase and the amorphous phases use the positive electrode active material enabling to store and release magnesium ions.

Owner:HITACHI LTD

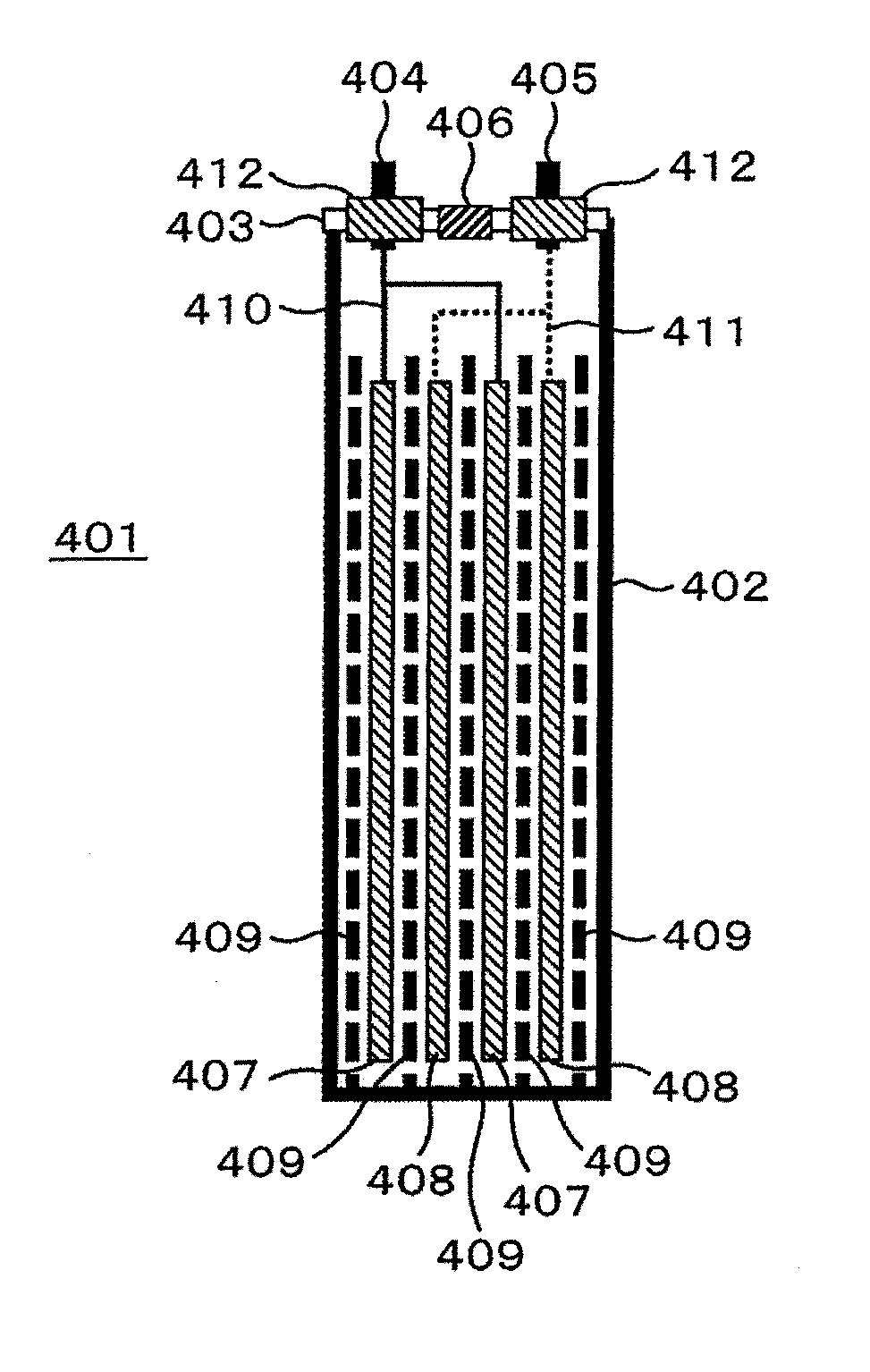

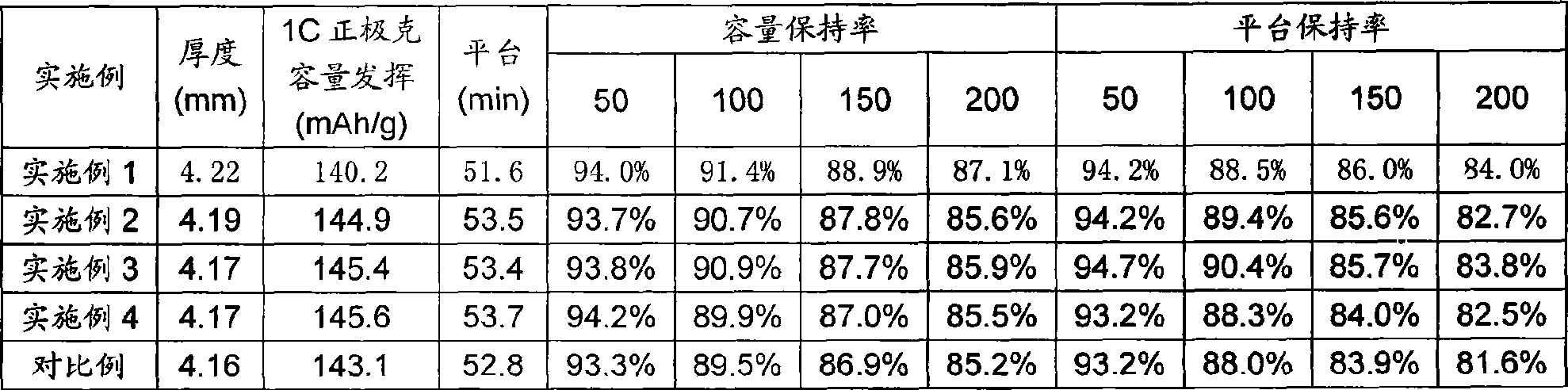

Liquid injection process for core of lithium ionic cell

InactiveCN101399328AImprove performanceImproved gram capacity playFinal product manufactureSecondary cellsVacuum pumpingGram

The invention relates to a liquid injection process of an electric core of a lithium-ion battery, the liquid injection process comprises: (S1) when in liquid injection of the electric core of the lithium-ion battery, 70-90 percent of the total amount of pre-determined electrolyte is firstly injected for being placed for 14-20 hours; (S2) the pre-charging is carried out on the electric core, the charging condition is that the charging is carried out for 210-1200 minutes at 0.06-0.2C; (S3) the residual electrolyte is injected in the electric core after the completion of the pre-charging under the vacuum pumping condition, and the sealing is carried out for the preparation. The process can improve the performance of the electric core, improve the gram capacity exertion of positive electrode material and improve the capacity of the electric core and the cycle retention rate of a platform; the electrolyte is saved, the production cost of the electric core is reduced, the environmental air is improved, and the service life of a device is prolonged.

Owner:SHENZHEN BAK BATTERY CO LTD

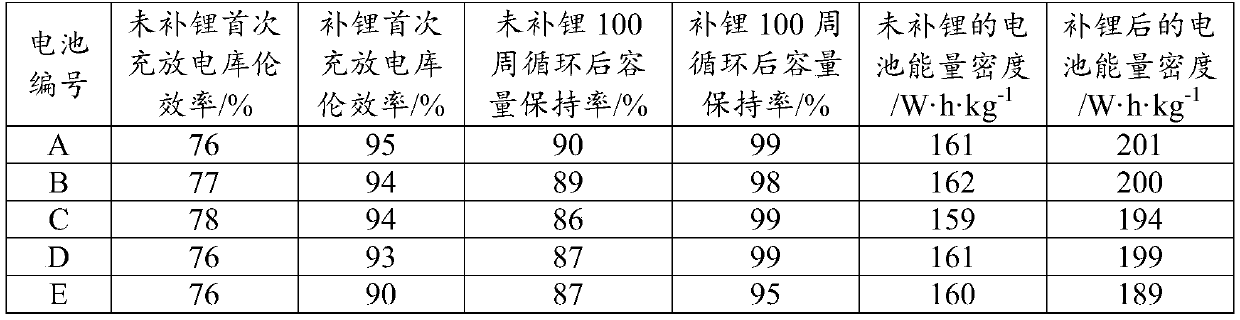

Silicon-containing high-energy-density lithium ion battery

ActiveCN109713367AEnhanced complexationEnergy barrier increaseFinal product manufactureSecondary cells servicing/maintenanceSolubilityHigh energy

The invention relates to a silicon-containing lithium ion battery with high energy density. The lithium ion battery comprises a positive electrode, a silicon-containing negative electrode, a fluorine-containing electrolyte, a diaphragm, electrode lugs and a packaging material. The silicon-containing negative electrode takes a silicon-based material as a whole or a part of electrochemical active substances. The electrolyte contains lithium salt, a non-aqueous organic solvent capable of dissolving the lithium salt, an SEI film-forming additive and hydrofluoroether. The solubility of the lithiumsalt in the non-aqueous organic solvent capable of dissolving the lithium salt is higher than 2 mol / L. The solubility of the lithium salt in the hydrofluoroether is lower than 0.3 mol / L, wherein the non-aqueous organic solvent capable of dissolving the lithium salt is mutually dissolved with the hydrofluoroether, the non-aqueous organic solvent capable of dissolving the lithium salt and the liquidSEI film-forming additive are mutually dissolved, so the solid SEI film-forming additive can be dissolved. The silicon-containing lithium ion battery has the advantages of high energy density, long cycle life, good rate capability, high safety performance, difficulty in expansion and deformation and the like.

Owner:BERZELIUS (NANJING) CO LTD +1

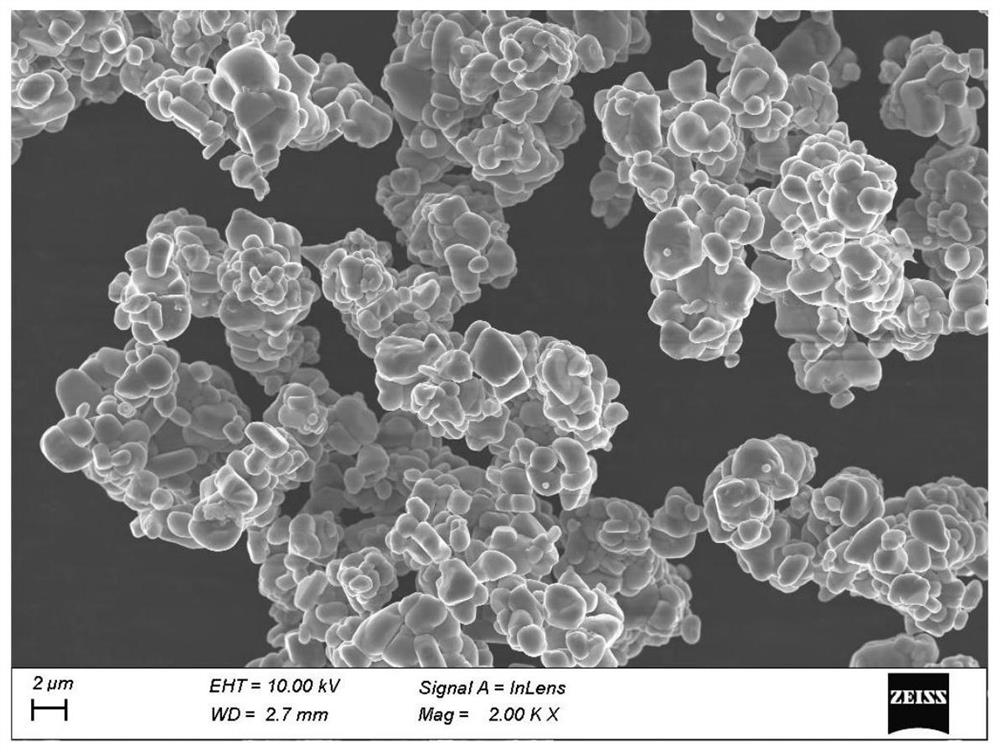

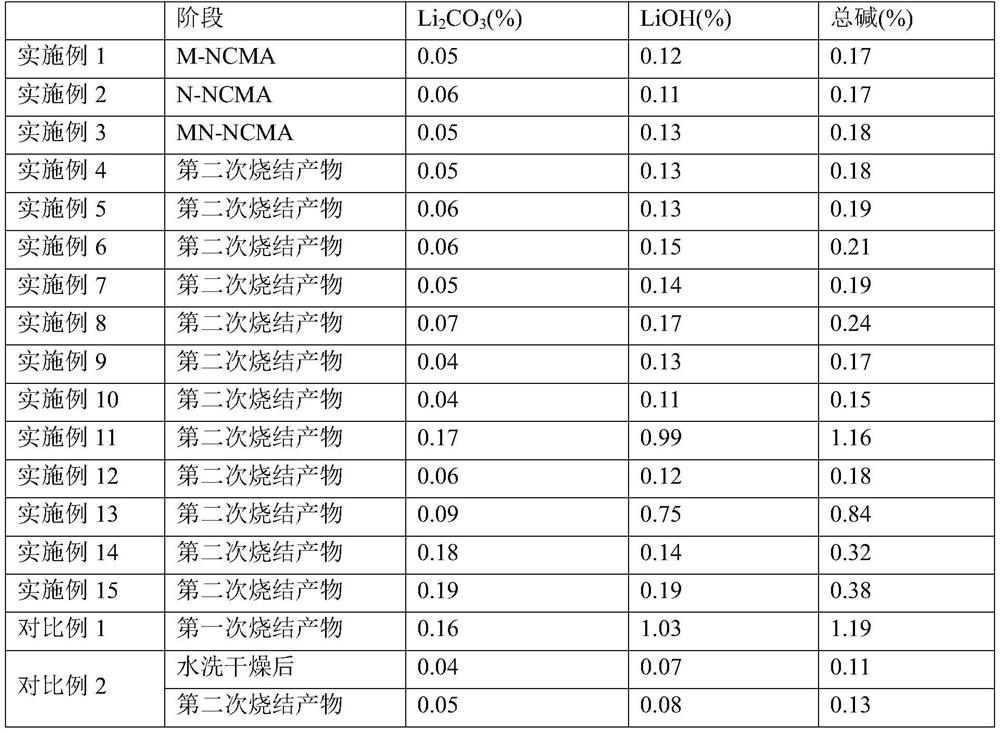

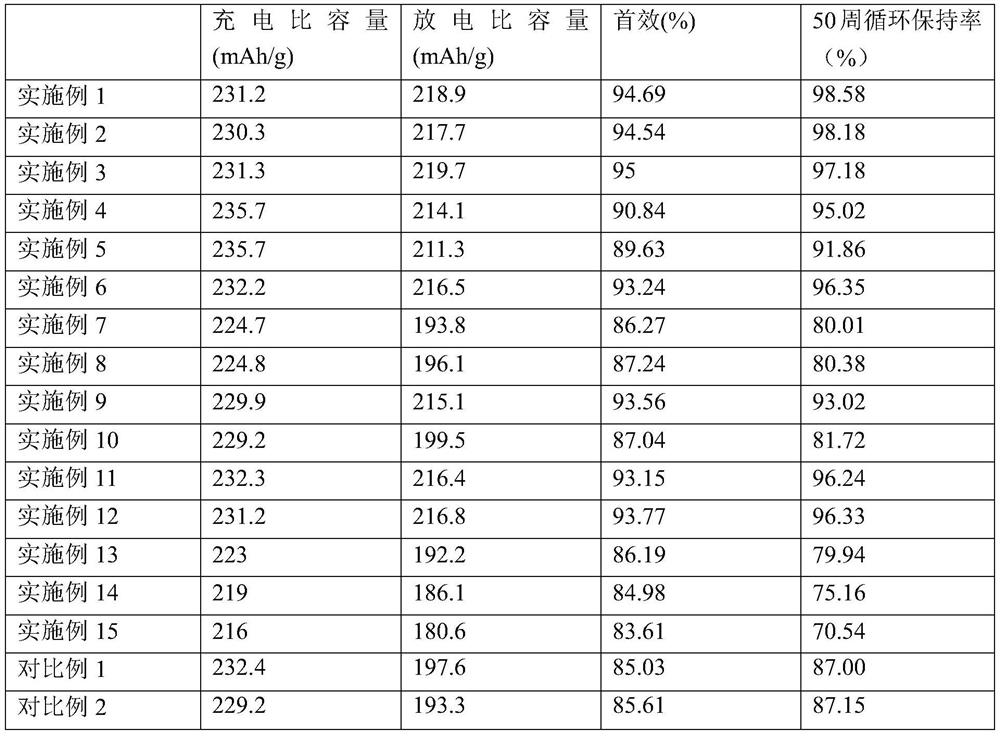

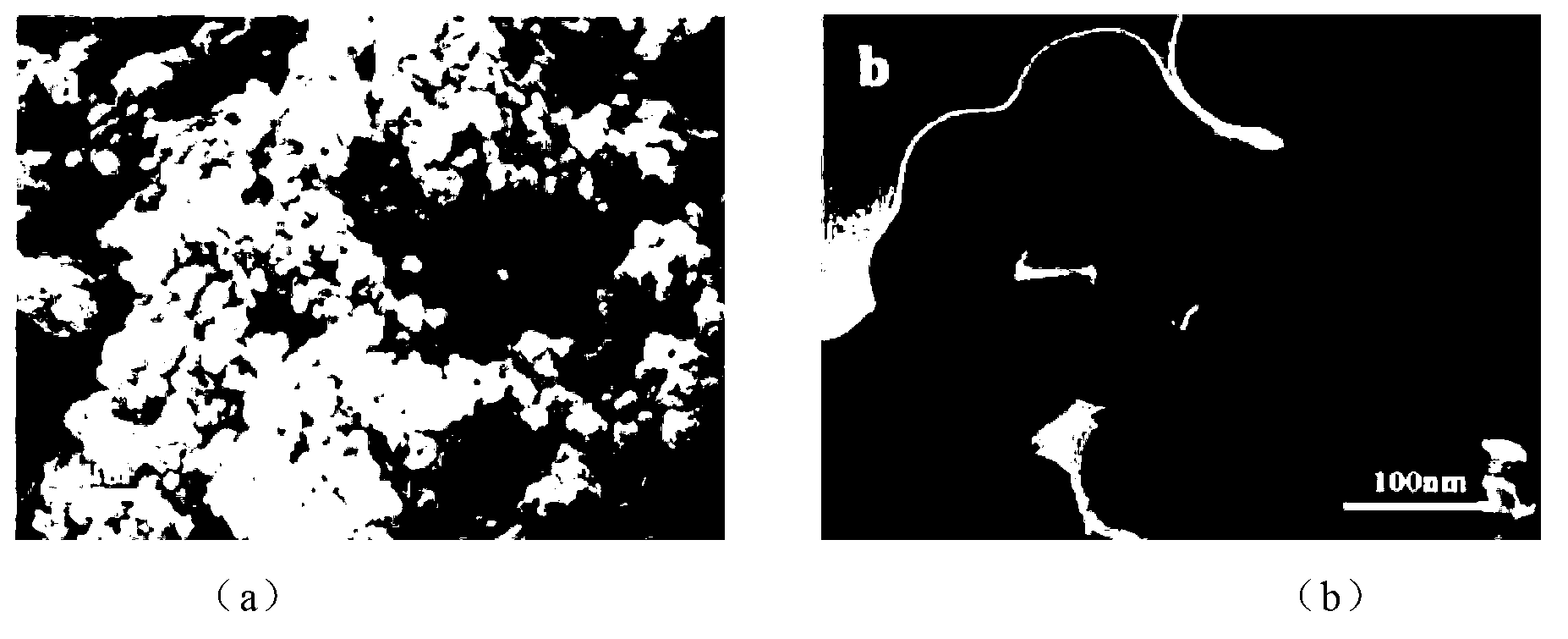

Positive electrode material, preparation method thereof and lithium ion battery

PendingCN111628157ALess side effectsExtend your lifeSecondary cellsPositive electrodesElectrolytic agentSingle crystal

The invention provides a positive electrode material, a preparation method thereof and a lithium ion battery. The preparation method comprises the following steps: carrying out first sintering treatment on a lithium source material and a positive electrode precursor material to obtain a first sintered product; and coating the surface of the first sintering product with a coating agent, and then carrying out second sintering treatment to obtain the positive electrode material, the coating agent being a nickel source material and / or a manganese source material. A specific coating agent is selected, a secondary sintering process (namely primary sintering, primary coating and secondary sintering) is combined to synthesize the single crystal-like positive electrode material, and the single crystal-like positive electrode material is formed by aggregating a plurality of primary particles of a single crystal-like positive electrode material with similar morphology. By adopting the preparationmethod, the synthesis process can be simplified, the energy consumption can be reduced, the yield can be improved, the washing process can be canceled, the residual lithium can be reduced, the circulating capacity is not lost, the side reaction between electrolyte and the inside of particles is reduced, the circulating retention rate is improved, and the service life of the battery is prolonged.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

Anode material for lithium secondary battery, manufacturing method of the same, lithium secondary battery anode using the same, and lithium secondary battery

ActiveCN1989637AExcellent battery characteristicsImprove immersionSecondary cellsNegative electrodesHigh current densityMetal particle

Disclosed is a negative electrode material which can be produced by a simple process and enables to obtain a lithium secondary battery which is excellent in various battery characteristics, namely a lithium secondary battery having high electrode plate strength, good immersibility, small initial irreversible capacity, excellent charge / discharge characteristics at high current density and high cycle retention rate. Specifically disclosed is a negative electrode material wherein two or more different polymer materials are respectively adhered to different positions of a particle (A) which is selected from the group consisting of carbon material particles, metal particles and metal oxide particles.

Owner:MITSUBISHI RAYON CO LTD

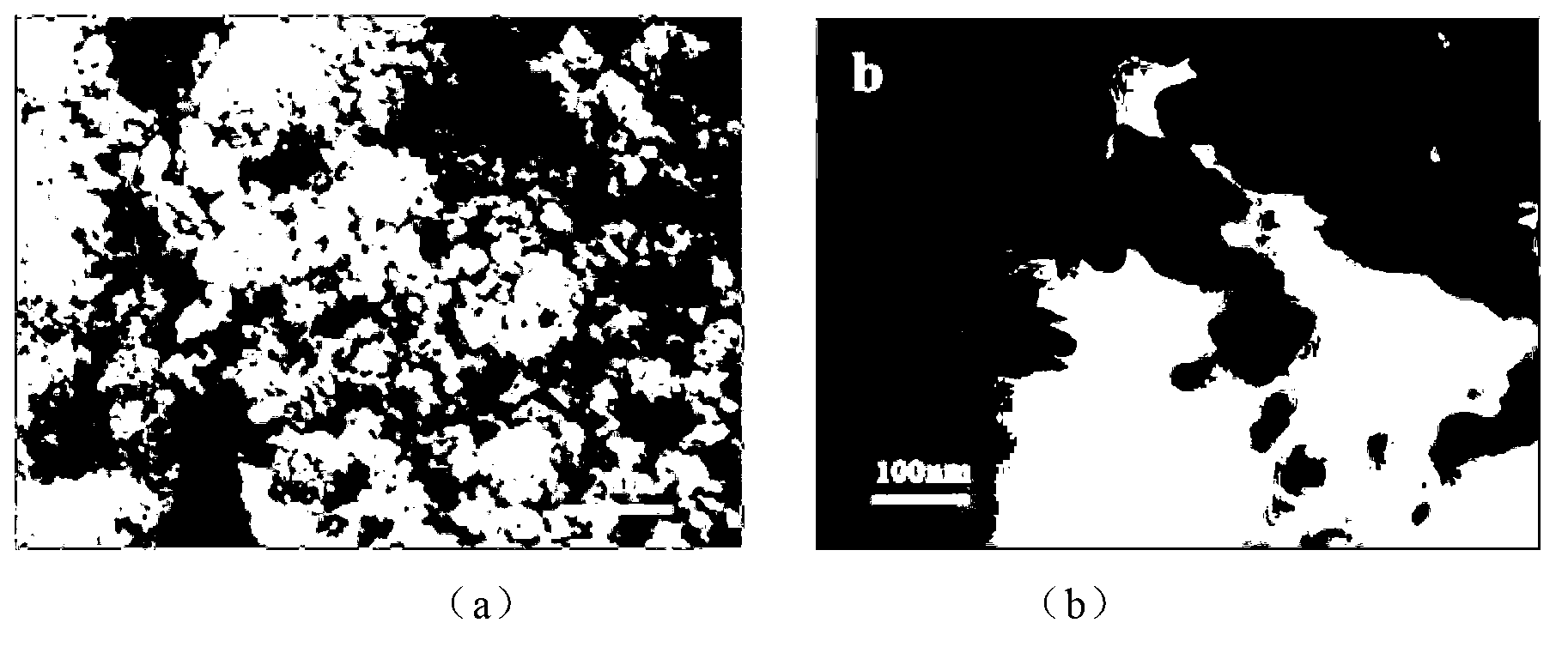

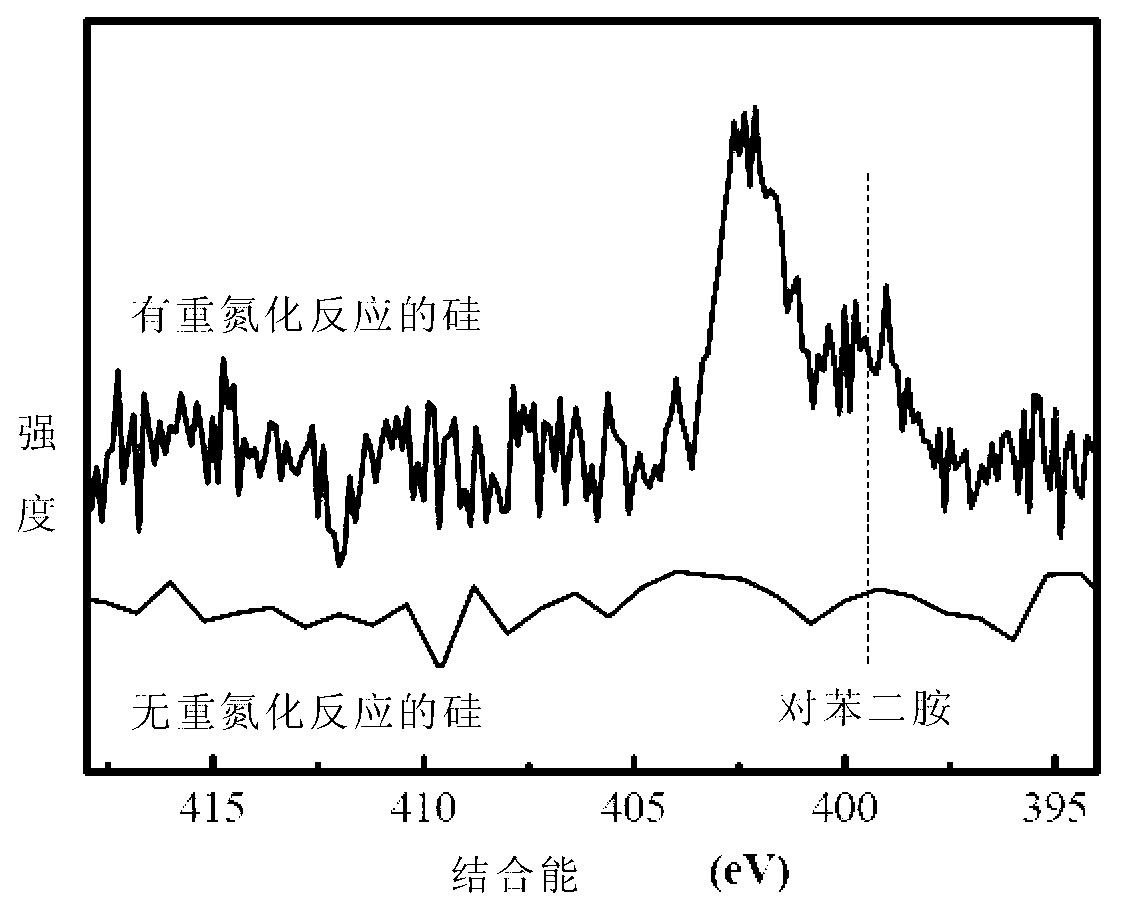

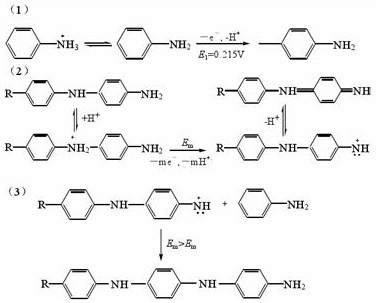

Silicon-based composite material, preparation method and application thereof

The invention provides a silicon-based composite material, a preparation method and an application thereof. The silicon-based composite material comprises nanometer silicon particles and polyaniline cladding layers cladded on surface of the nanometer silicon particles, and Si-C covalent bonds are formed between the nanometer silicon particles and the polyaniline coating layers. The preparation method of the silicon-based composite material comprises carrying out a diazotization reaction of P-phenylenediamine (H2N-Ar-NH2) in the presence of nitrite under an acidic condition to generate diazonium salts; adding the nanometer silicon particles into a solution of a complete diazotization reaction for a replacement reaction to obtain nanometer silicon precursors with aniline monomers connected to the surfaces of the nanometer silicon particles through the Si-C covalent bonds; adding the nanometer silicon precursors into a microemulsion mixed from an oil phase and a water phase, adjusting a pH value of the solution, adding the aniline monomers; and adding an initiator enabling polymerization of the aniline into the microemulsion for an aniline polymerization reaction, thereby obtaining the silicon-based composite material with polyaniline-cladded nanometer silicon particles. The silicon-based composite material provided by the invention can improve a cladding effect.

Owner:DONGGUAN AMPEREX TECH +1

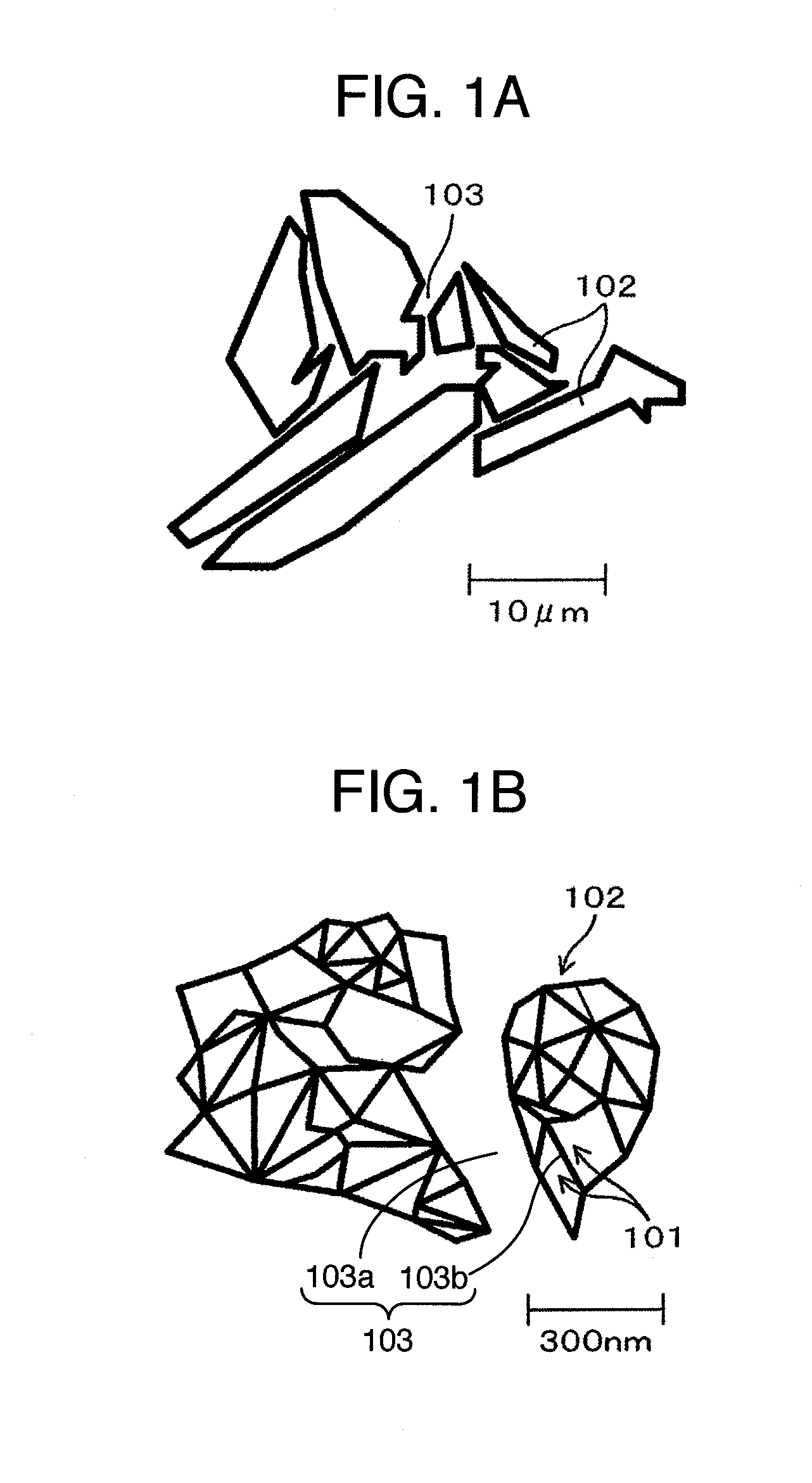

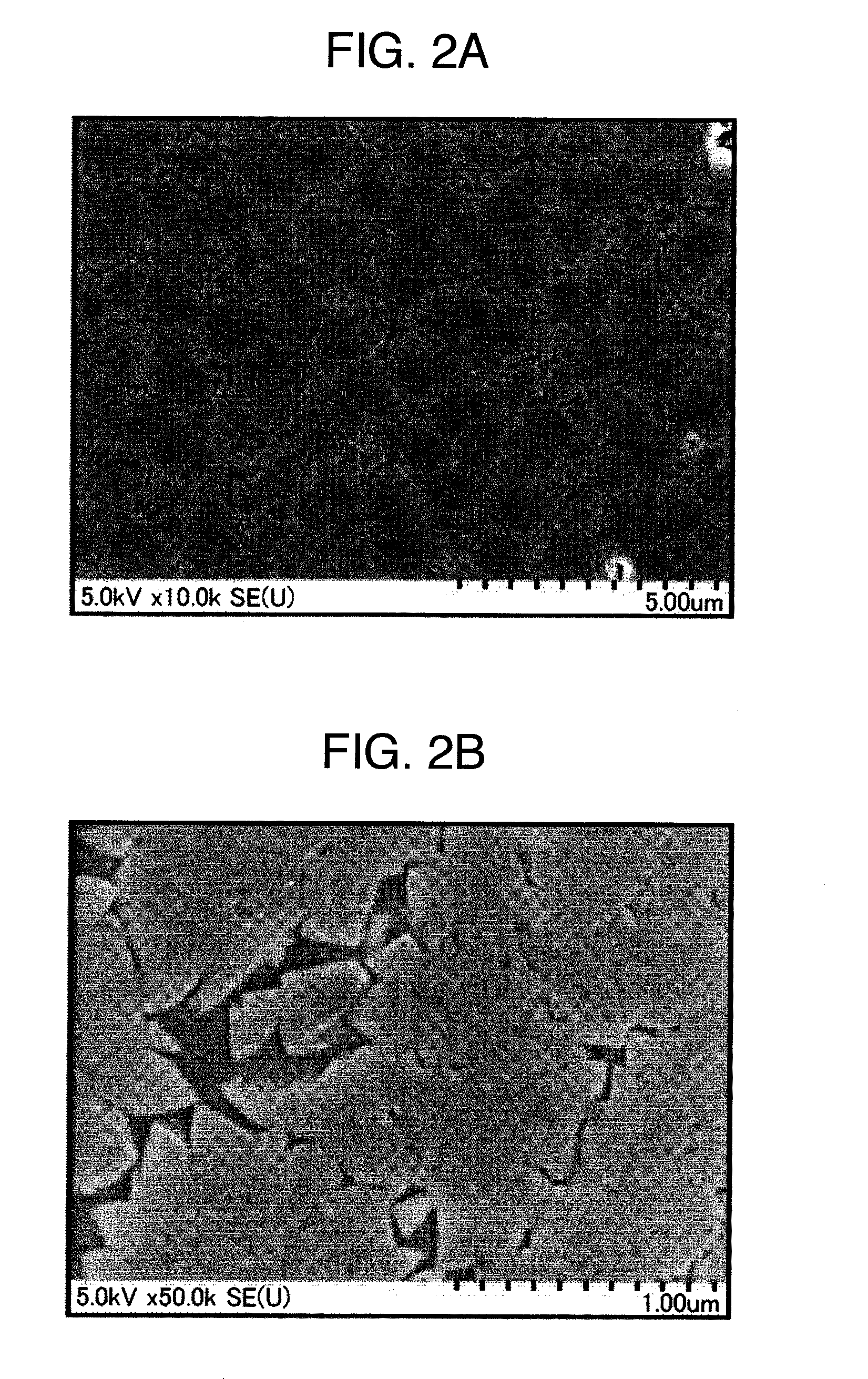

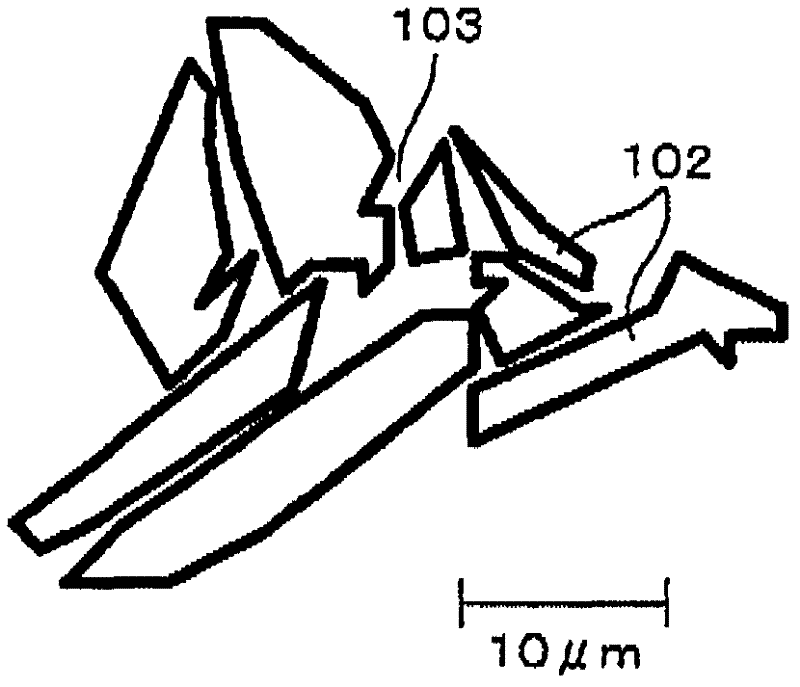

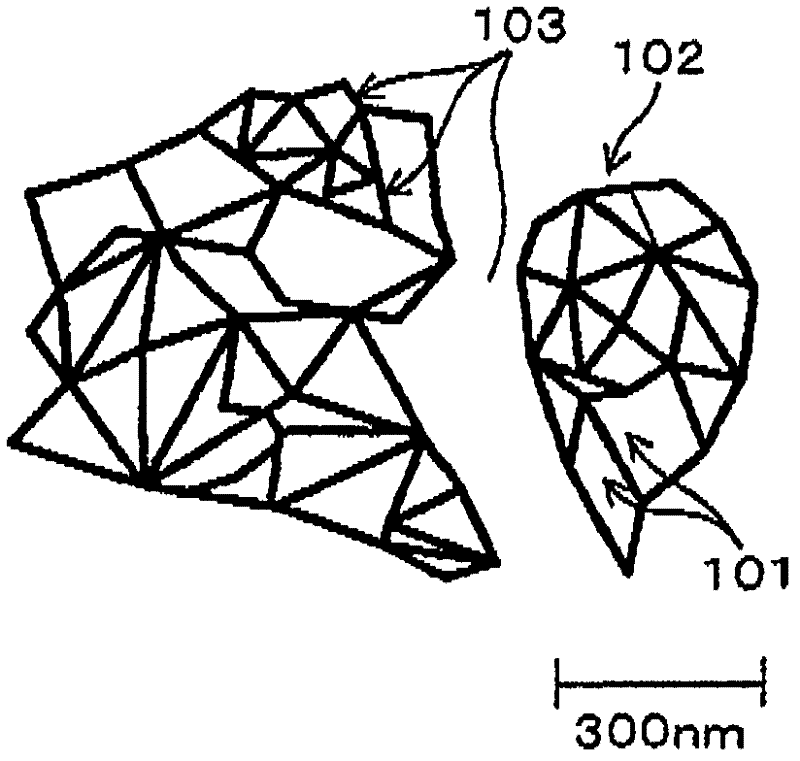

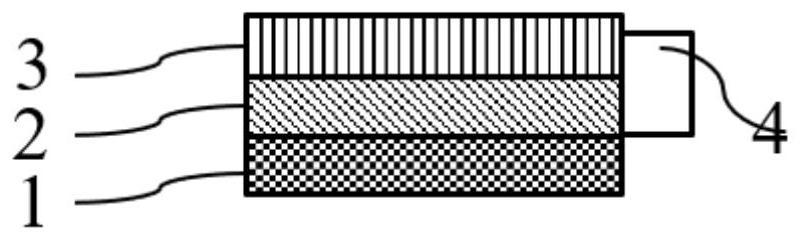

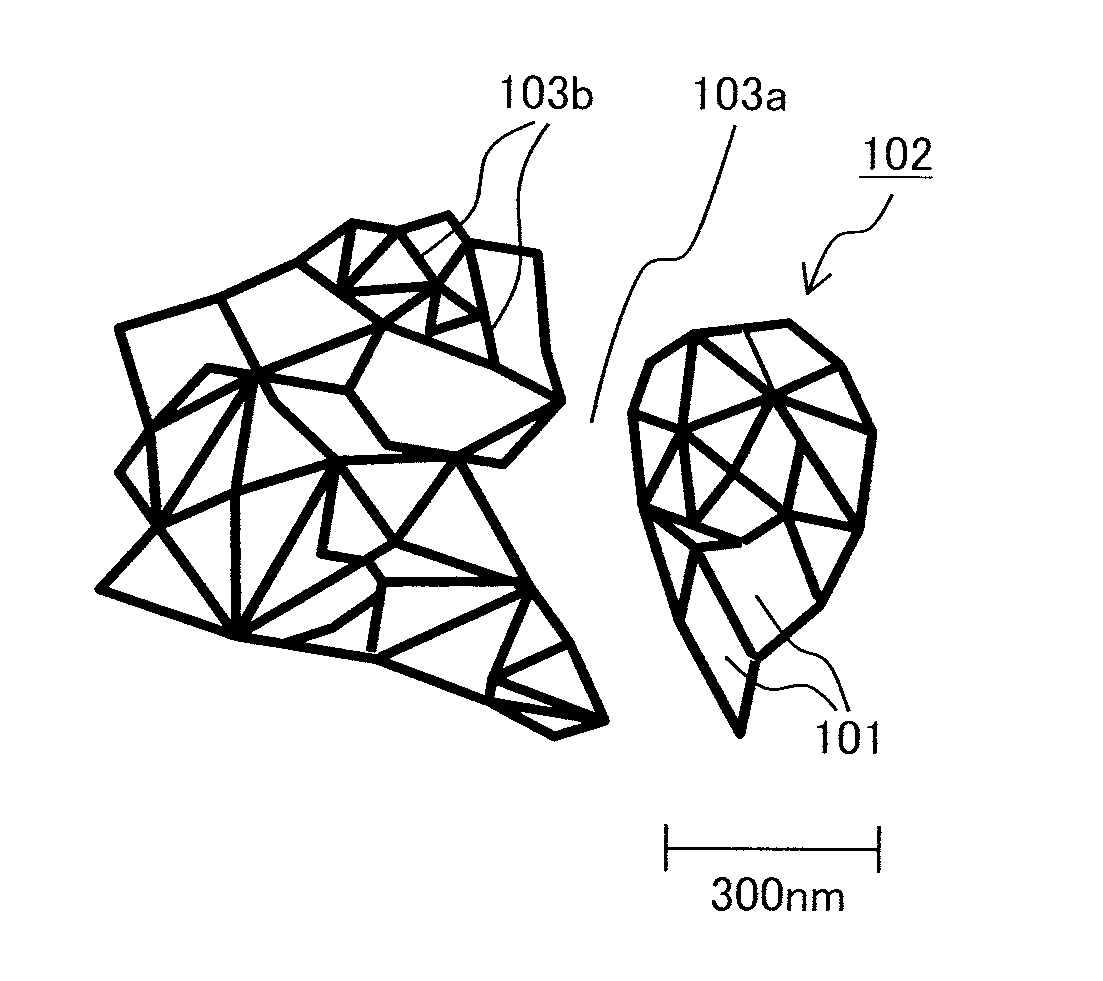

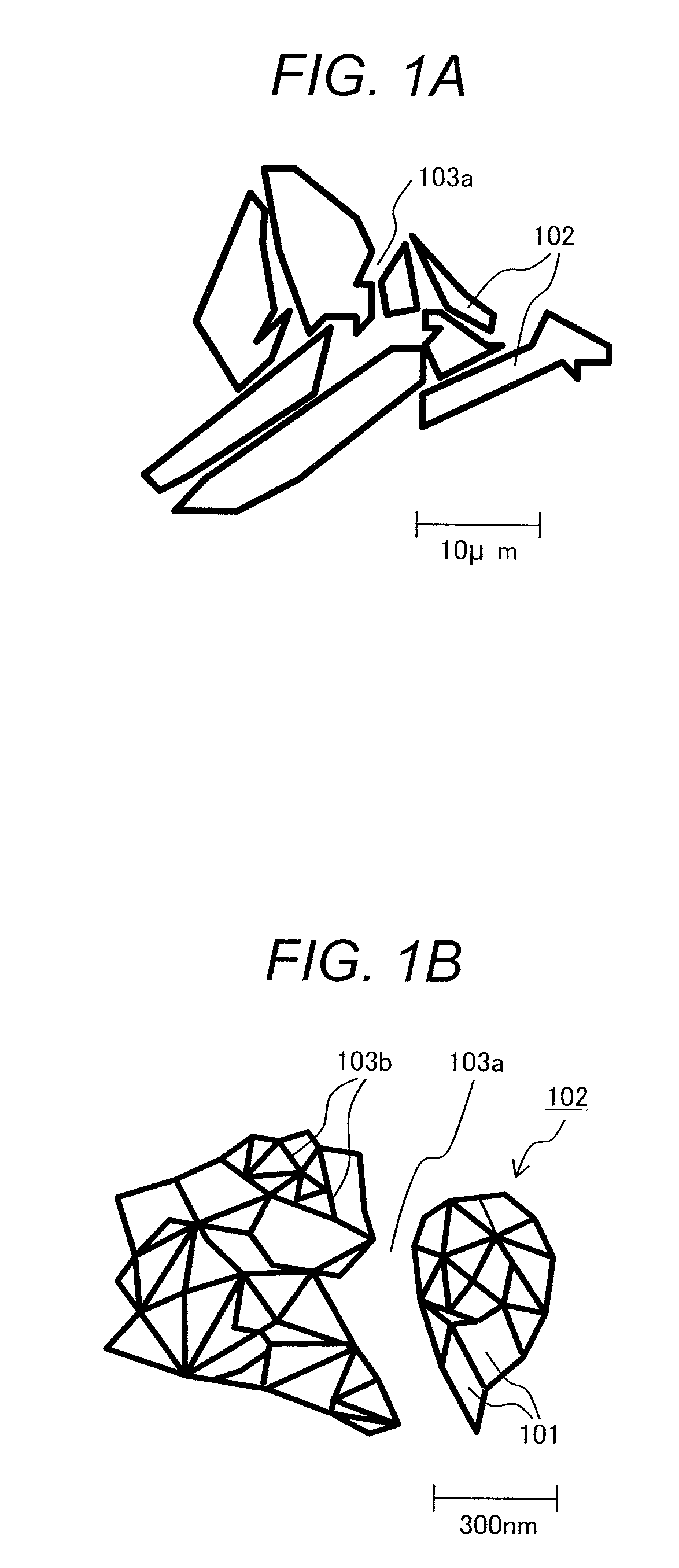

Positive electrode active material for secondary battery and magnesium secondary battery using the same

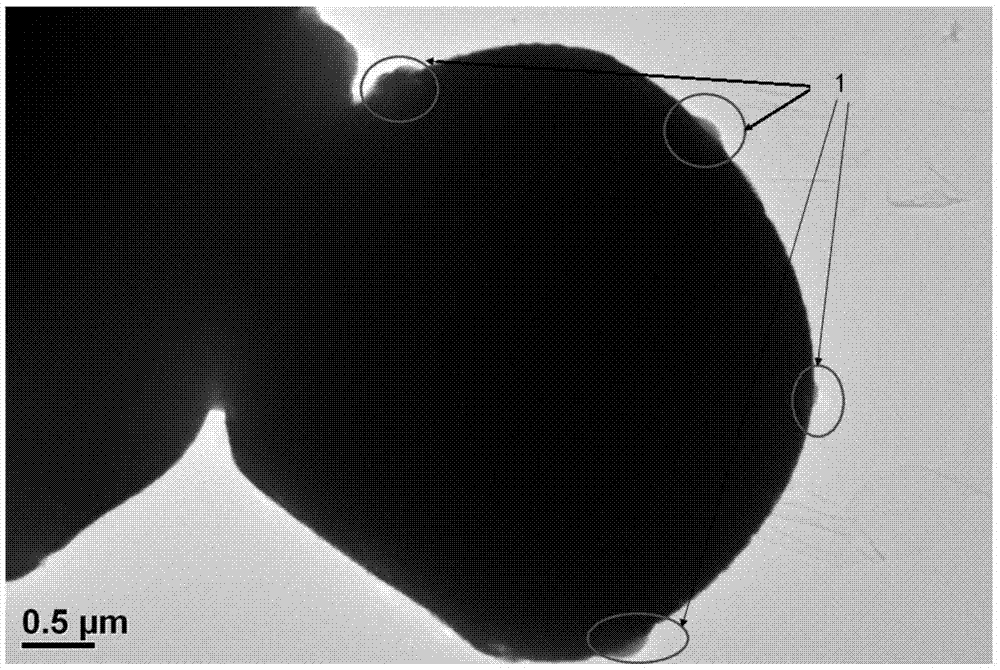

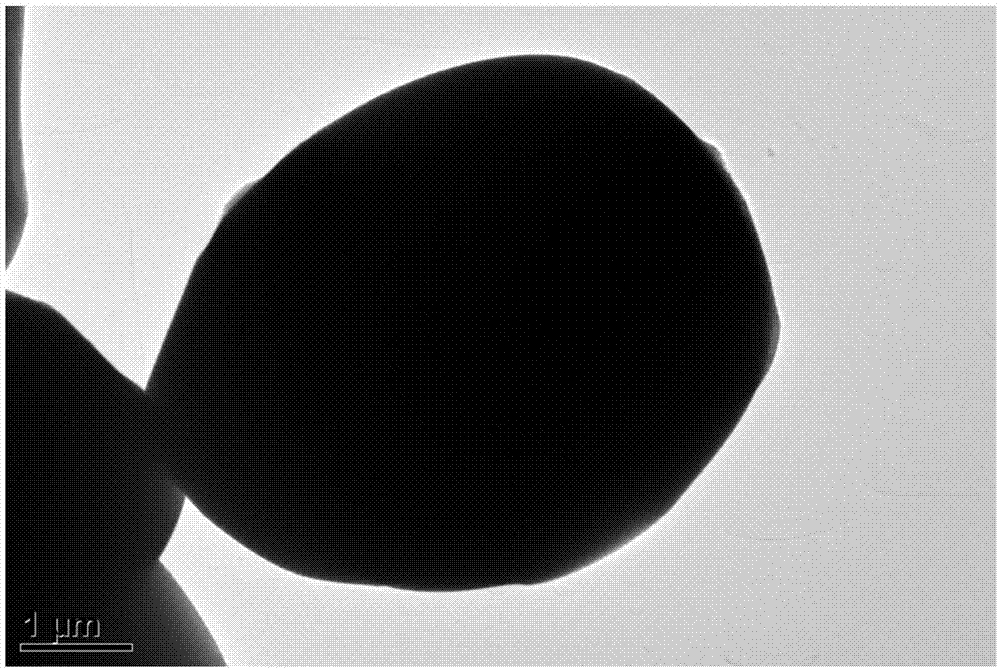

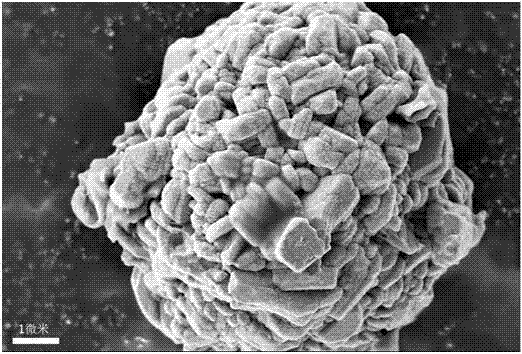

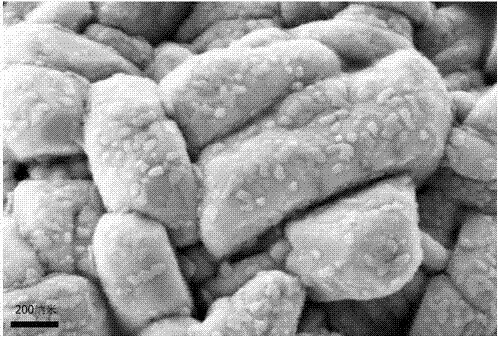

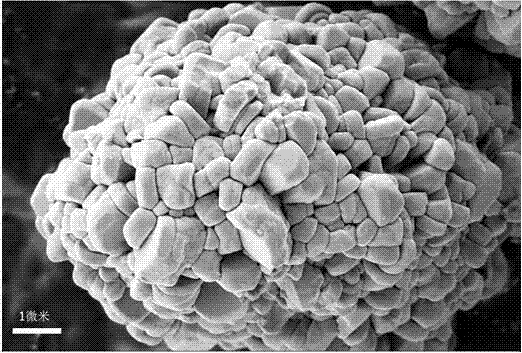

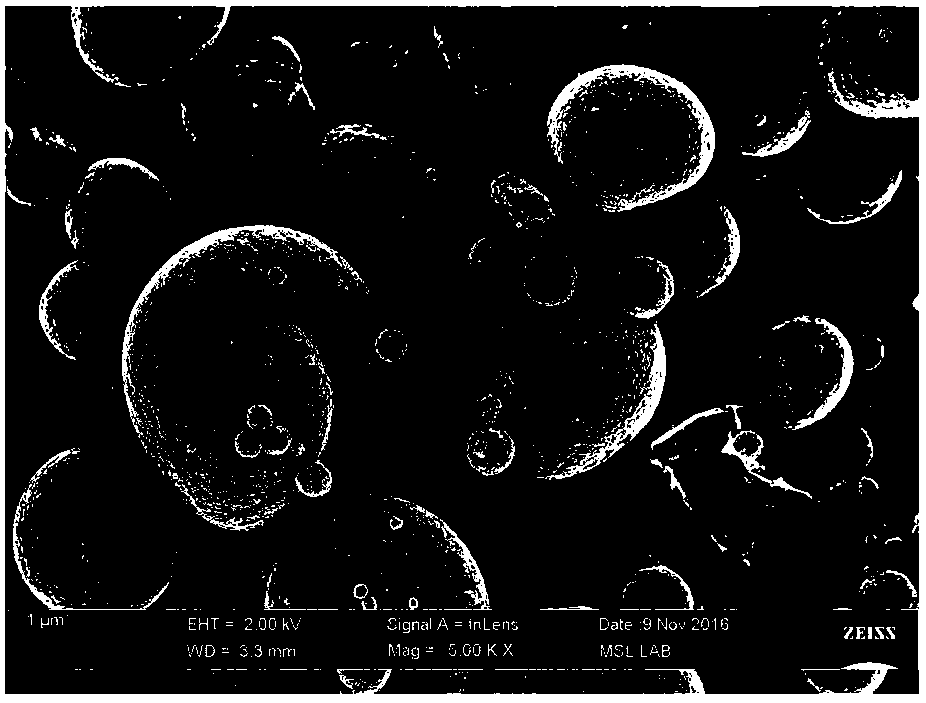

InactiveCN102544467AIncrease energy densityLarge capacityNon-aqueous electrolyte accumulatorsPositive electrodesElectrical batteryCharge discharge

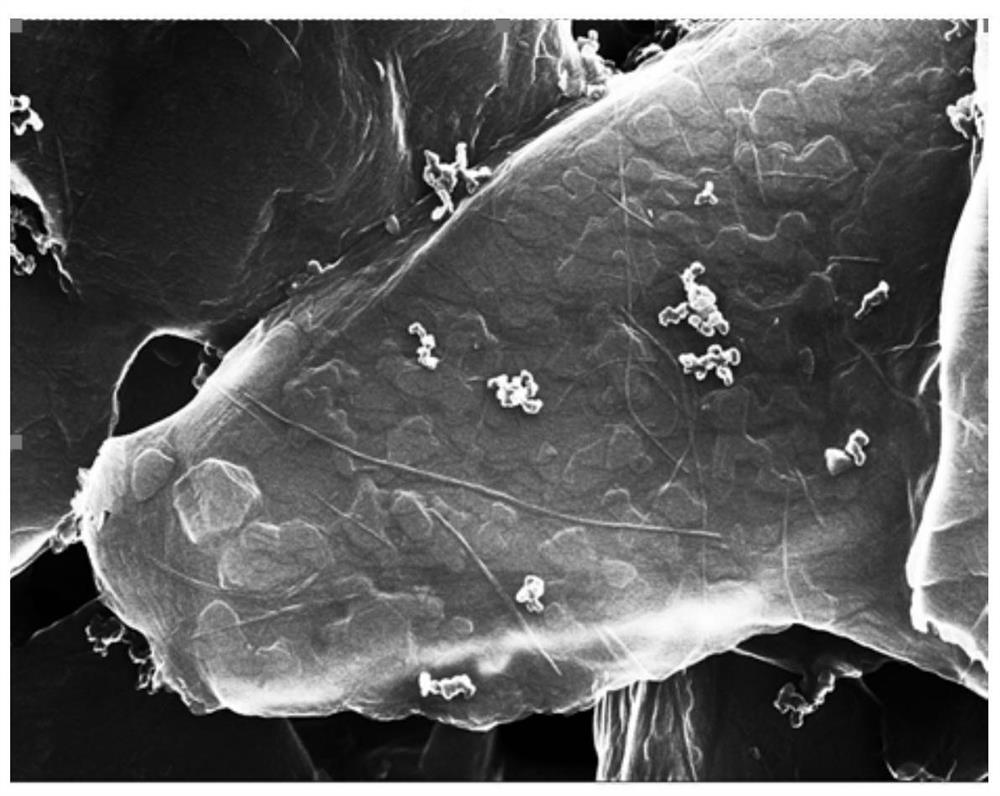

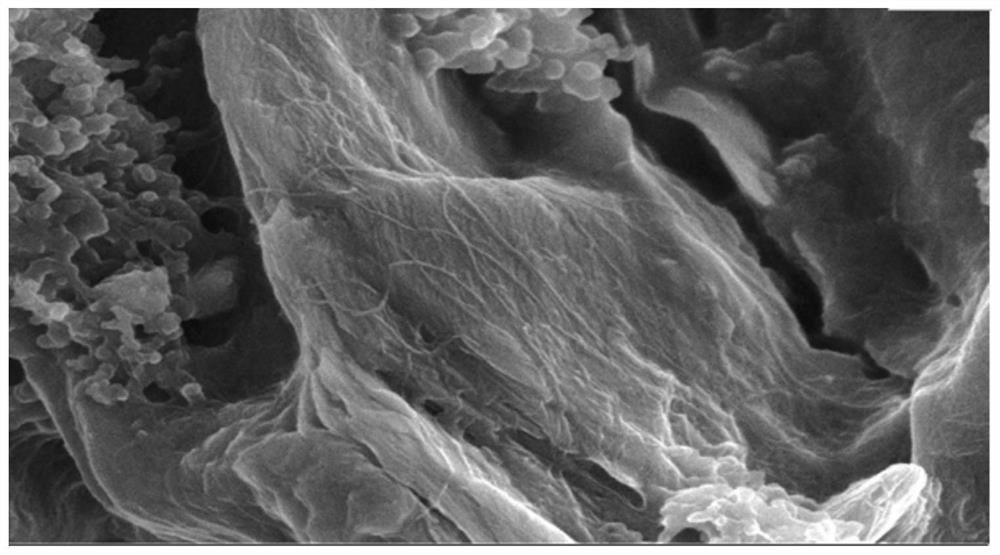

The invention provides a positive electrode active material for a secondary battery and a magnesium secondary battery using the same. Specifically, the invention provides a positive electrode active material for the magnesium secondary battery having high charge-discharge cycle retention rate and high capacity, and a magnesium secondary battery using the same. The positive electrode active material for a secondary battery contains a powder particle containing a crystal phase having a structure formed with aggregation of a plurality of crystallites (101) and amorphous phases (103a, 103b) formed between the crystallites (101) themselves. The amorphous phases (103a, 103b) contain at least one kind of a metal oxide selected from a vanadium oxide, an iron oxide, a manganese oxide, a nickel oxide and a cobalt oxide; and the crystal phase and the amorphous phases (103a, 103b) use the positive electrode active material enabling to store and release magnesium ions.

Owner:HITACHI LTD

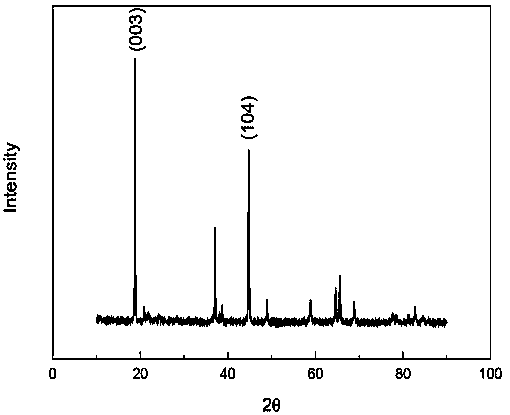

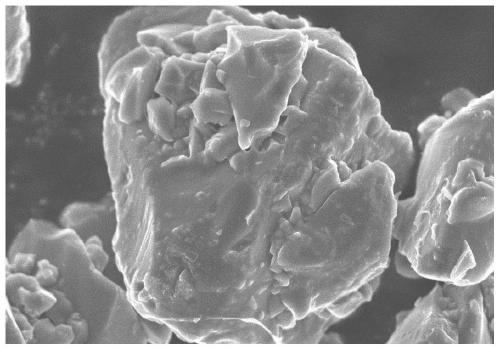

Surface coating type ternary positive electrode material and preparation method thereof

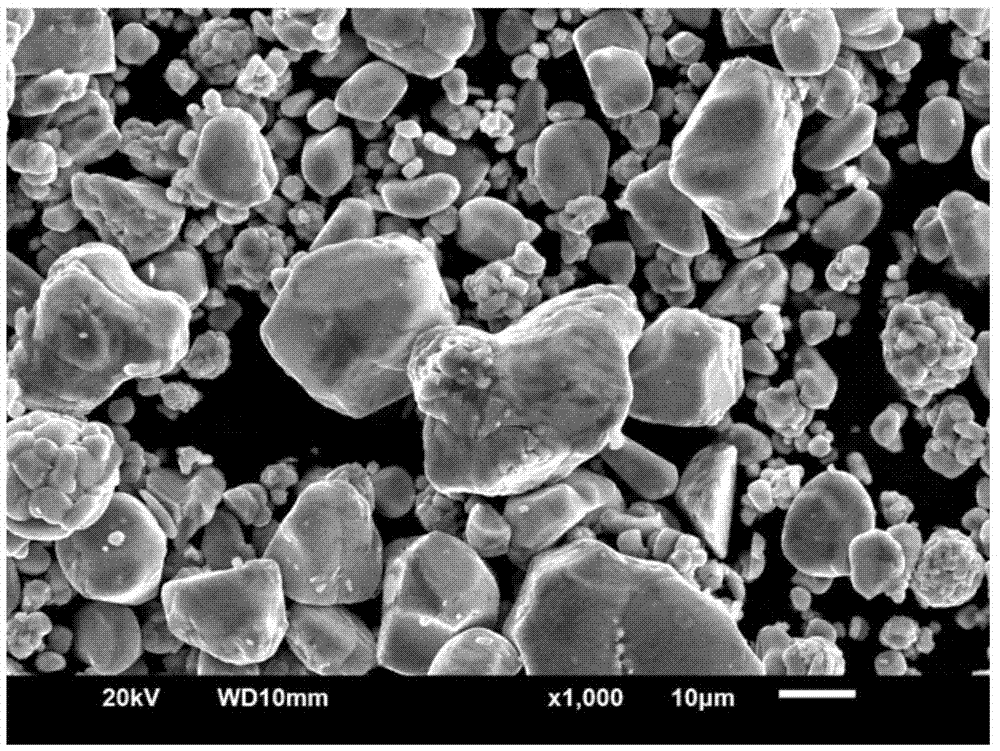

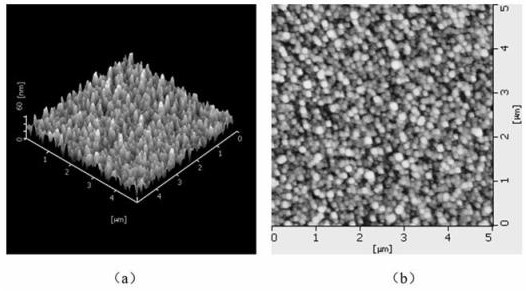

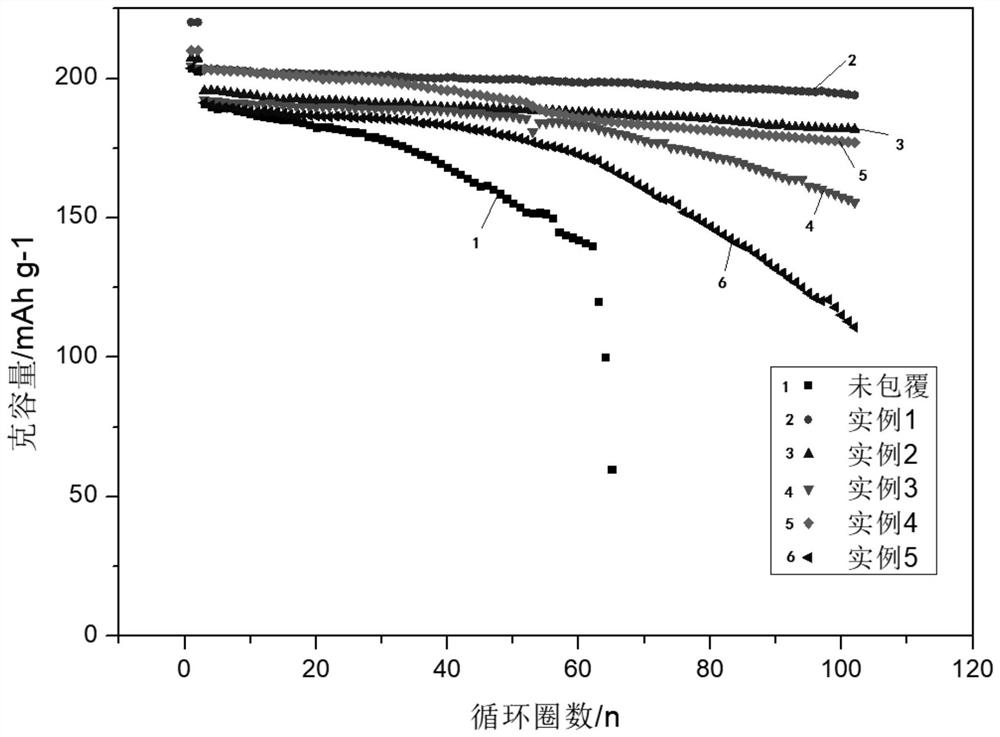

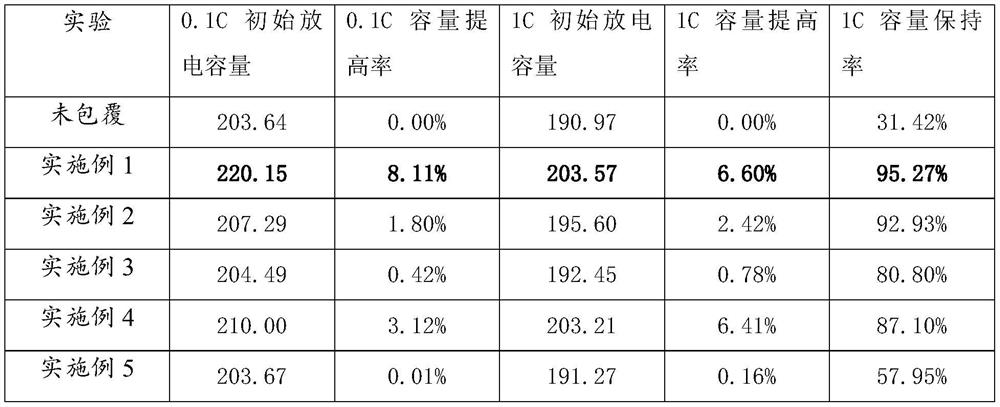

ActiveCN106941162AImprove cycle retentionImprove Interface StabilityMaterial nanotechnologyCell electrodesAlkalinityNanoparticle

The invention discloses a surface coating type ternary positive electrode material and a preparation method thereof, and belongs to the technical field of positive electrode materials of lithium ion batteries. The surface coating type ternary positive electrode material includes particles having the molecular formula of LiNi[x]Co[1-x-y]Mn[y]O[2], and the surface of the LiNi[x]Co[1-x-y]Mn[y]O[2] particles is covered with Li2MTiO4 nanoparticles, wherein M is at least one of metal elements of Ni, Co and Mn. A basic crystal phase structure of LiNi[x]Co[1-x-y]Mn[y]O[2] is not damaged, only the surface is coated with the new-phase nanoparticles, the surface protection is formed, and the stability of the interface of the surface of the positive electrode material and an electrolyte solution is increased, so the material circulation maintaining rate is further improved, and the electrochemical performance is enhanced. The surface alkalinity of the positive electrode material is lowered, the hygroscopic property is suppressed, and the processing performance is improved.

Owner:SHANDONG YUHUANG NEW ENERGY TECH

Silica particles for electrode material and preparation method and application of silica particles

PendingCN110718685AIncrease the scope of applicationSmall specific surface areaNegative electrodesSilicon oxidesSilicon oxygenSilicon particle

The present invention relates to silica particles for an electrode material, and the silica particles are characterized in that the silica particles comprise silicon monoxide particles having a general formula SiOx; and a carbon layer, wherein the silicon monoxide particles are bonded by the carbon layer, and the silicon monoxide particles bonded by the carbon layer are coated by the carbon layer.The silica particles are compact, narrow in particle size distribution and small in specific surface area, and have the advantages of high capacity, high coulombic efficiency, low expansion, high cycle retention rate and the like.

Owner:AMPRIUS NANJING CO LTD

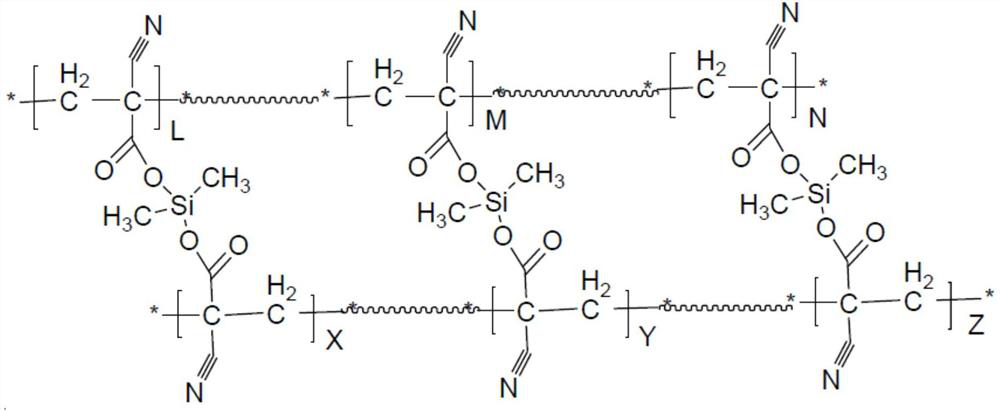

Water-based conductive binder for lithium ion battery and preparation method of water-based conductive binder

PendingCN113078317AImprove conductivityHigh peel strengthCell electrodesSecondary cellsElectrically conductiveLithium electrode

The invention relates to a water-based conductive binder for a lithium ion battery and a preparation method of the water-based conductive binder, and the water-based conductive binder comprises the following components in parts by weight: 10-30 parts of a basic binder, 90-120 parts of a functional binder, 2-10 parts of an intrinsic conductive polymer, 2-20 parts of modified carbon nanotubes, 1000 parts of deionized water and 0.7-4.1 parts of an auxiliary agent. The preparation method is simple, the steps are easy to operate, the prepared water-based conductive adhesive has relatively high conductivity, a pole piece of the water-based conductive adhesive is high in peel strength, good in adhesive force and low in dosage, lithium ions can be easily embedded / embedded out, the performance of an active material is fully played, the internal resistance value of a battery is smaller, the gram capacity of a positive electrode is better played, and in a cycle, the capacity loss is less, and the cycle retention rate is higher.

Owner:无锡零一未来新材料技术研究院有限公司

Preparation method of porosity controllable graphene modified silicon-carbon composite material

ActiveCN109873136AGood flexibilityImprove conductivityMaterial nanotechnologyCell electrodesPorosityCarbon composites

The invention discloses a preparation method of a porosity controllable graphene modified silicon-carbon composite material. The preparation method comprises the following specific manufacturing steps: step one, preparing a pre-dispersed coarse silica powder sizing agent: firstly adding a dispersing agent and an addition agent into a solvent, stirring for complete dissolution, then adding high-purity metal silica powder with the particle diameter of 1 to 10 microns, and then stirring for uniform dispersion to obtain the coarse silica powder sizing agent; step two, preparing a nano-scale silicon sizing agent: adding the coarse silica powder sizing agent obtained in the step one into a dispersion tank, introducing protective gas into the dispersion tank, and adding a ball-milling medium intoa ball-milling tank according to the ratio of a grinding medium to a material being (200 to 20): 1; step three, preparing a nanometer silica powder; step four, preparing a graphene modified nanometersilicon composite sizing agent; and step five, preparing the graphene modified silicon-carbon composite material used for an energy storage material. The graphene modified nanometer silicon preparedby the method is controllable in porosity, and has the advantages of high mechanical strength, low specific surface area, high conductivity, high initial efficiency and high circulation retention rate.

Owner:SUPERCDONGGUAN TECH +1

Negative pole sheet for lithium ion battery and preparation method of negative electrode sheet

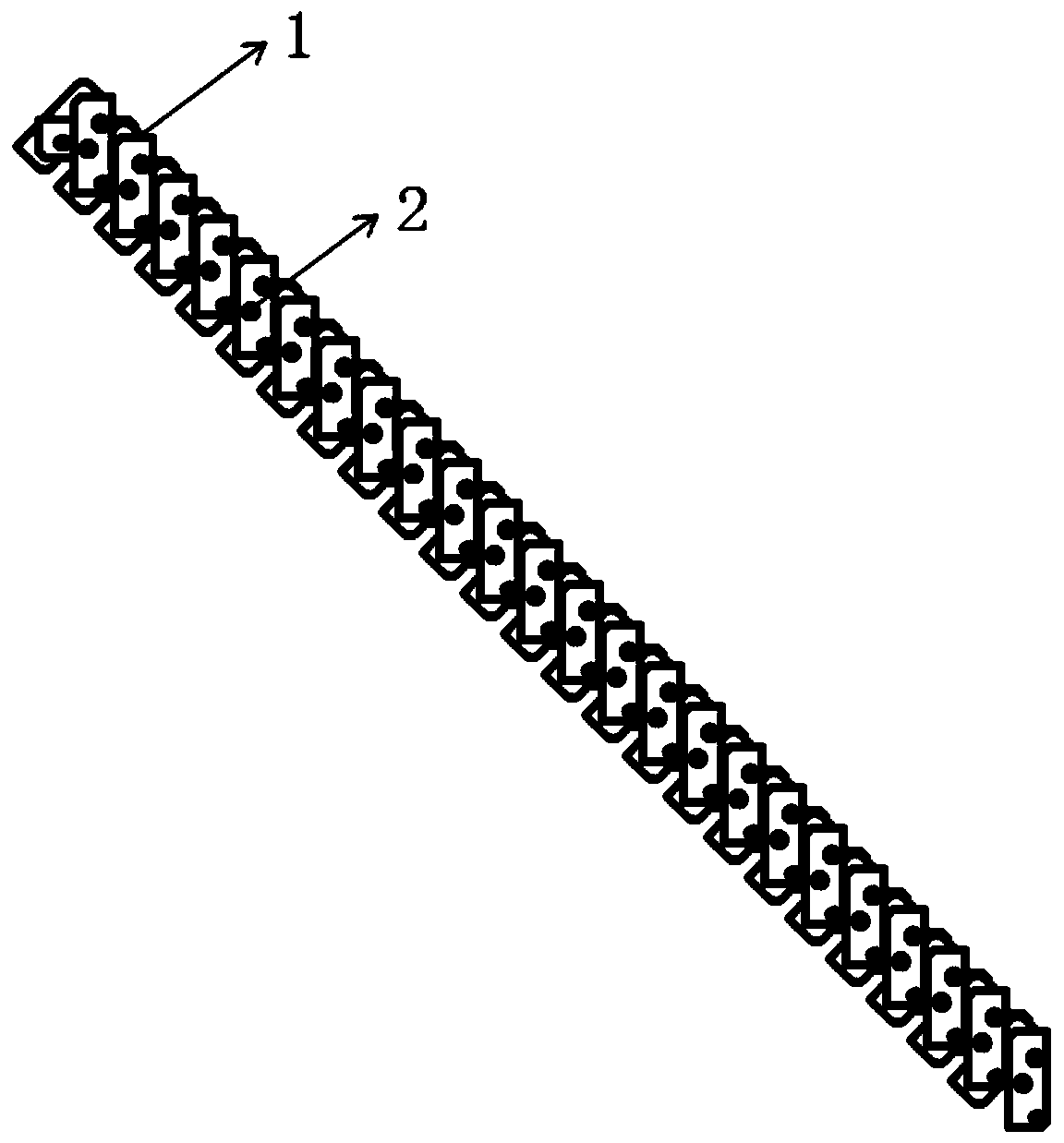

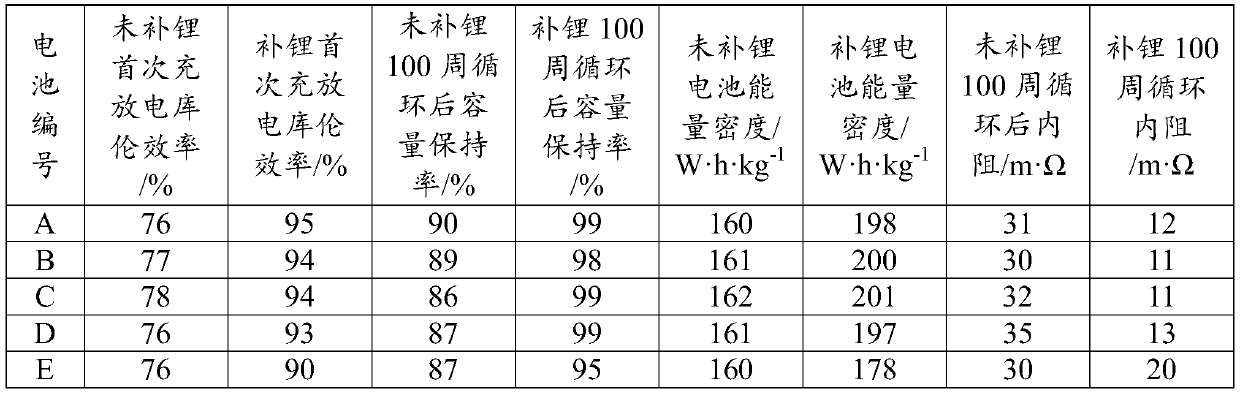

InactiveCN110729452AGuaranteed long cycle performanceImprove performanceElectrode carriers/collectorsSecondary cellsMetallic lithiumCarbon layer

The invention discloses a negative pole sheet for a lithium ion battery. The negative pole sheet comprises a current collector and a lithium-supplemented material sprayed on the current collector; thelithium-supplemented material comprises spun fibrous graphene and metal lithium uniformly distributed in the graphene and on the surface of the graphene; and the metal lithium distributed on the surface of the graphene is also coated with a carbon layer. According to the negative pole sheet for the lithium ion battery of the invention, an electrostatic spinning technology is adopted to directly spin graphene fibers on the negative pole sheet to supplement lithium; the obtained negative pole composite lithium-supplemented pole sheet of the lithium ion battery is stable in performance; the degree of bonding between the lithium-supplemented material and the pole sheet is high; safety performance is excellent; uniform lithium supplementation can be realized; the fibrous graphene is adopted, so that most of lithium is coated with the fibers; lithium supplementation can be continuously realized in the circulation process of the battery, so that the circulation retention rate of the batteryis improved; the first efficiency and energy density of the lithium ion battery are effectively improved; and the long circulation performance of the lithium ion battery is ensured.

Owner:SHANDONG YUHUANG NEW ENERGY TECH

A method for preparing nano-and micro-scale core-shell ternary cathode materials by low temperature self-propagation method

InactiveCN109167039AReduce generationShorten the production cycleCell electrodesSecondary cellsCapacity lossLithium-ion battery

The invention belongs to the technical field of preparation of cathode materials for lithium ion batteries, in particular to a core-shell ternary cathode material mLi [NibCocMnd] O2. NLi1 + e [NifCogMnh] 1 prepared by a low-temperature self-propagation method. EO2 (m+n=1, ne=a, mb+n (1-E) f=x (1-A), mc+n (1-E) g=y (1-A), md+n (1-E) h=z (1-A), 0.1 < = b <= 0. 5, 0.6 <= f <= 0. 9, 0 <= e <= 0. 4).At first, a high-nickel or lithium-rich core is prepare, and then a core-shell structure ternary cathode material is prepared as that core, and finally, the nano-and micro-scale core-shell ternary cathode material is obtain by high-temperature calcination. If the multilayer core-shell structure material is prepared, the shell is prepared repeatedly according to the actual design ratio. With the high stability ternary cathode material of low nickel as the shell, the core of high nickel or lithium-rich system which has many defects but high capacity is coated. Through the design of the structureand batch preparation, the obtained material will play a better role in the high capacity of the core and the stability of the shell. The preparation method is simple, rapid, low energy consumption,and does not need additional doping coating to increase the cost of capacity loss and other problems, so it is a practical and industrialized application method.

Owner:SHANDONG UNIV OF TECH

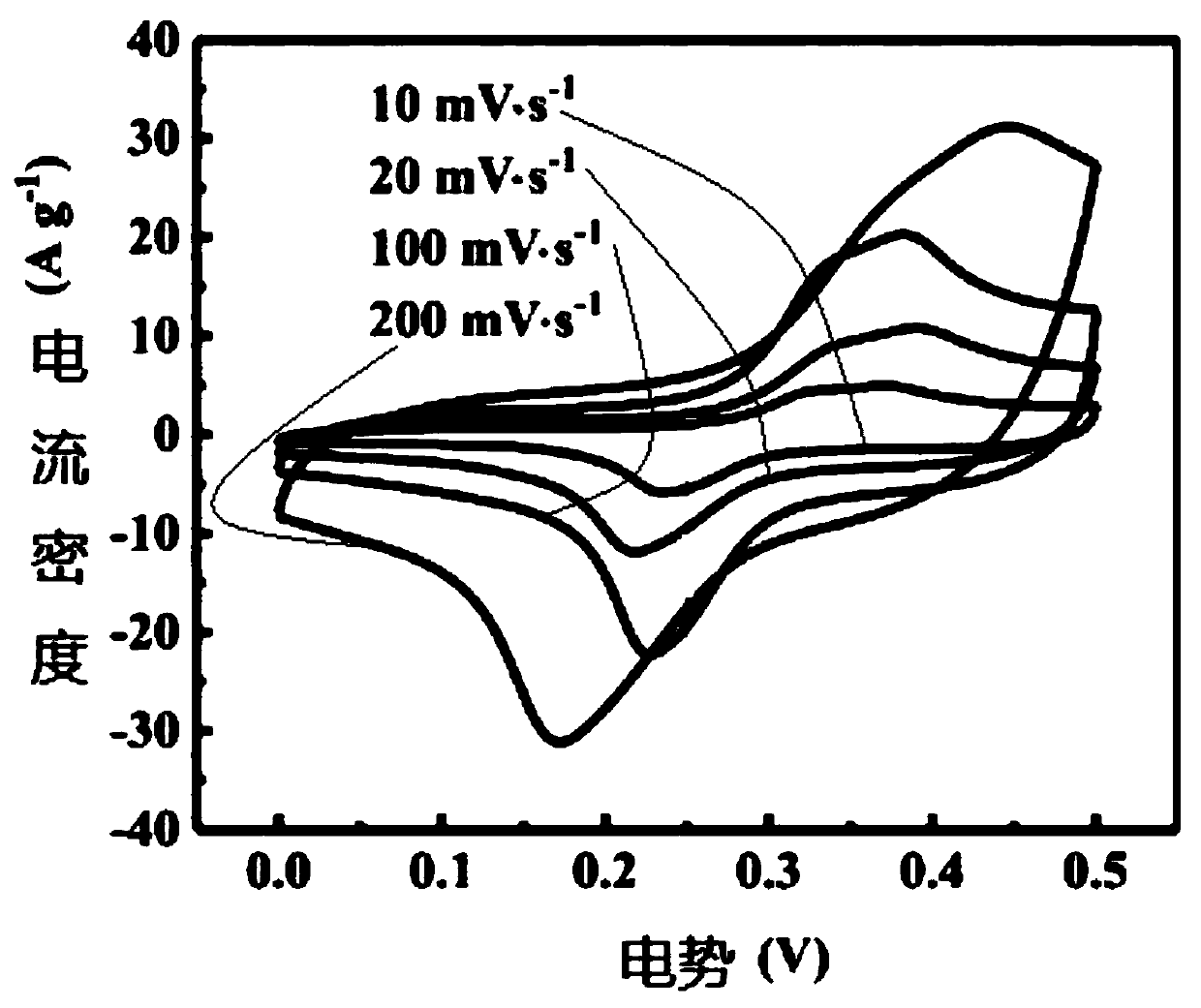

Electrode material, preparation method of electrode material and supercapacitor

InactiveCN110033956AExcellent supercapacitor performanceImprove cycle stabilityHybrid capacitor electrodesCapacitanceMetal-organic framework

The invention discloses an electrode material, a preparation method of the electrode material and a supercapacitor; a substrate comprises a metal organic framework and a carbon nanotube formed on themetal organic framework; and the substrate is subjected to selenization treatment, so that the substrate can obtain an effect of keeping the morphology of a precursor, and therefore the electrode material has excellent super-capacitance performance and high cycling stability, and excellent cycling retention rate can be kept continuously during cyclic utilization of the electrode.

Owner:宁波正锂新能源科技有限公司 +1

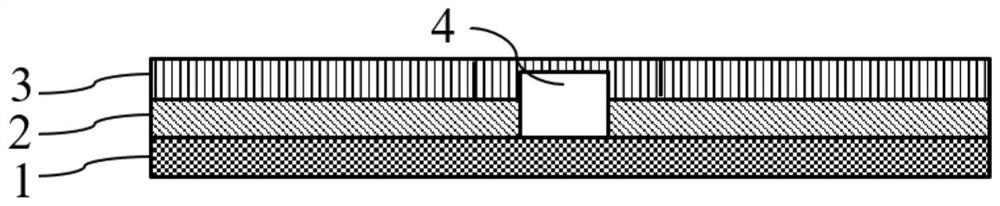

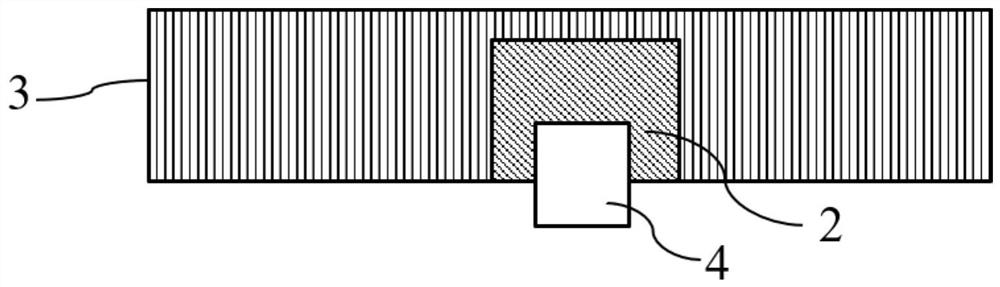

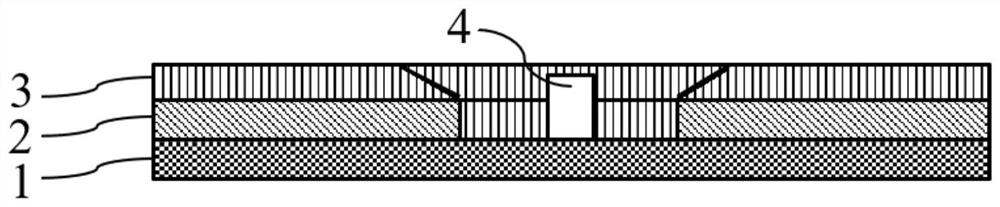

Pole piece and lithium ion battery

ActiveCN112802992AImprove charging riskImprove cycle retentionElectrode carriers/collectorsSecondary cellsPhysicsEngineering

The invention provides a pole piece and a lithium ion battery. The pole piece comprises a current collector, a first active layer and a second active layer, wherein the first active layer and the second active layer are sequentially stacked on the surface of the current collector; the first active layer is provided with a first groove, the second active layer is provided with a second groove, and the vertical projection of the second groove on the current collector covers the vertical projection of the first groove on the current collector; and the tab is arranged at the first groove and is electrically connected with the current collector. According to the pole piece provided by the invention, the charging risk of the tab connection position is effectively improved, and the cycle retention rate of the lithium ion battery is improved under the condition of keeping high-rate charging.

Owner:ZHUHAI COSMX BATTERY CO LTD

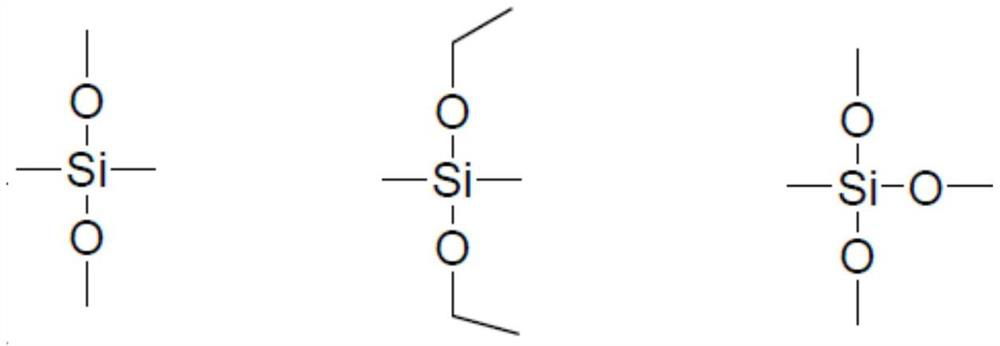

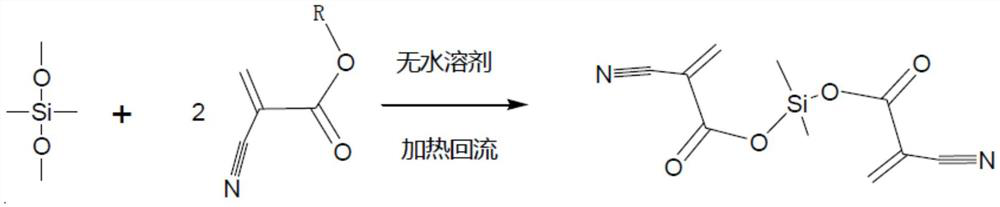

Metal lithium battery negative electrode, preparation method thereof and lithium secondary battery

ActiveCN112635766AEasy to crossGrowth inhibitionSecondary cellsNegative electrodesMetallic lithiumElectrolytic agent

The invention provides a metal lithium battery negative electrode, a preparation method thereof and a lithium secondary battery. The negative electrode provided by the invention can improve the cycle performance of the battery under the condition of high capacity density. A specific silane coupling agent and cyanoacrylate are subjected to transesterification to form a transesterification product, the surface of a negative electrode foil is coated with the transesterification product, and after coating, an anionic polymerization reaction is initiated by Li or a small amount of water in air, so that the transesterification product forms a spatial cross-linked network polymer; the cross-linked network polymer coating can effectively promote lithium ion penetration and induce lithium ions to deposit on the surface of the negative electrode foil, has good compatibility with the negative electrode foil, and can inhibit growth of lithium dendrites; the cross-linked network polymer coating is insoluble in electrolyte, so that side reaction between the electrolyte and metal lithium can be well inhibited; the cycle performance of the battery can be effectively improved through the effects in multiple aspects.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Negative electrode composite lithium-supplemented material for lithium ion battery and preparation method thereof

PendingCN110729459AImprove cycle retentionStable performanceMaterial nanotechnologyCarbon fibresMetallic lithiumLithium electrode

The invention discloses a negative electrode composite lithium-supplemented material for a lithium ion battery. The lithium supplemented-material comprises a compound comprising graphene and metal lithium, the mass ratio of the graphene and metal lithium being 1:(0.7-3.5); the graphene is a spun fibrous carrier; the metal lithium is uniformly distributed in the carrier and on the surface of the carrier; and the metal lithium distributed on the surface of the carrier is coated with a carbon layer. According to the lithium-supplemented material of the invention, an electrostatic spinning technology is adopted to realize the lithium supplementation of the negative electrode material; the fibrous graphene is used as the carrier, so that most of lithium is coated with the fibers; and the lithium supplementation can be continuously realized during the cycle process of the battery so as to improve the cycle retention rate of the battery. The obtained negative electrode composite lithium-supplemented material for the lithium ion battery has stable performance and high safety. With the negative electrode composite lithium-supplemented material for the lithium ion battery, uniform lithium supplementation is realized, the first efficiency and energy density of the lithium ion battery can be improved, and the long cycle performance of the lithium ion battery can be ensured.

Owner:SHANDONG YUHUANG NEW ENERGY TECH

Negative electrode active material for battery and preparation method thereof

ActiveCN111162269ALower pHDoes not affect rheological propertiesMaterial nanotechnologyCell electrodesElectrical batterySilicon oxygen

The invention relates to a negative electrode active material for a battery. The negative electrode active material comprises the negative electrode active material particles, and the negative electrode active material particles contain a silica compound and comprise a lithium element, the doped metal M1 and the doped metal M2, wherein the metal M1 comprises one or more of titanium, magnesium, zirconium, zinc, aluminum, yttrium and calcium, the metal M1 comprises one or more of copper, nickel, iron, manganese, cobalt and chromium, the metal M2 comprises one or more of copper, nickel, iron, manganese, cobalt and chromium, and the metal M1 and the metal M2 account for 0.01-25 wt%, preferably 0.05-15 wt%, more preferably 0.1-10 wt% and more preferably 0.1-5 wt% of the content of the negativeelectrode active material. The battery prepared from the negative electrode active material has the advantages of high capacity, high coulombic efficiency, long cycle life and high water resistance.

Owner:BERZELIUS (NANJING) CO LTD +1

Positive electrode active material

InactiveUS8951436B2Improve cycle retentionIncrease battery capacityMaterial nanotechnologyConductive materialLithiumAmorphous phase

Owner:HITACHI LTD

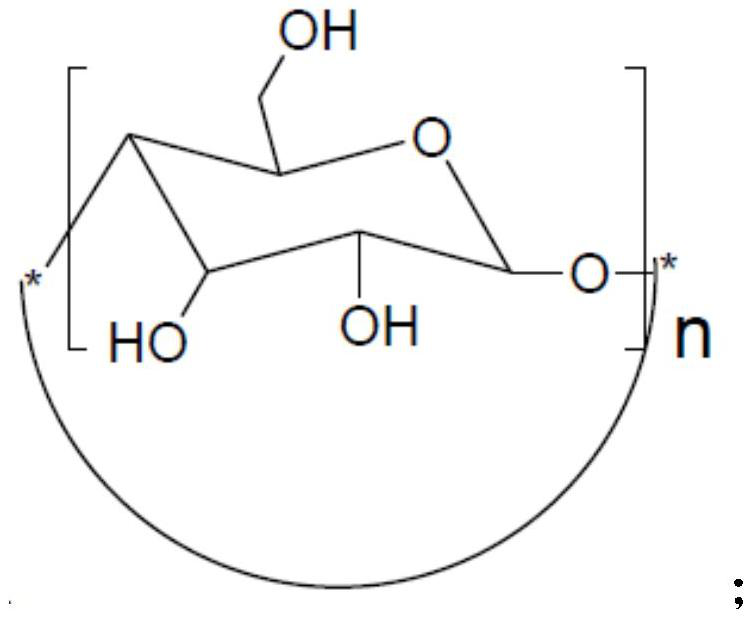

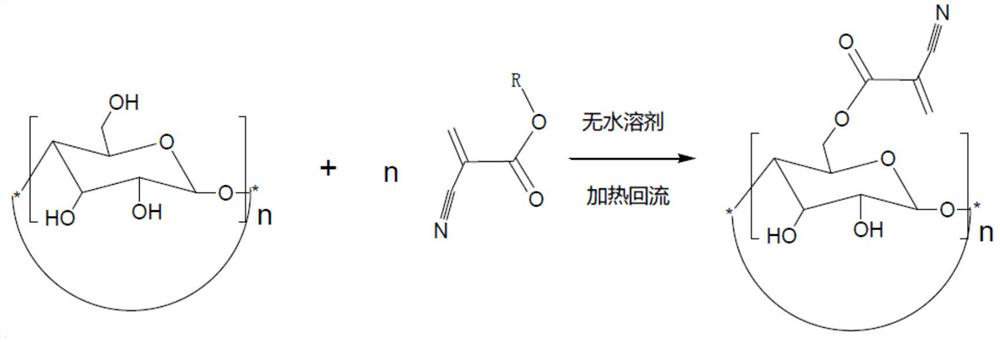

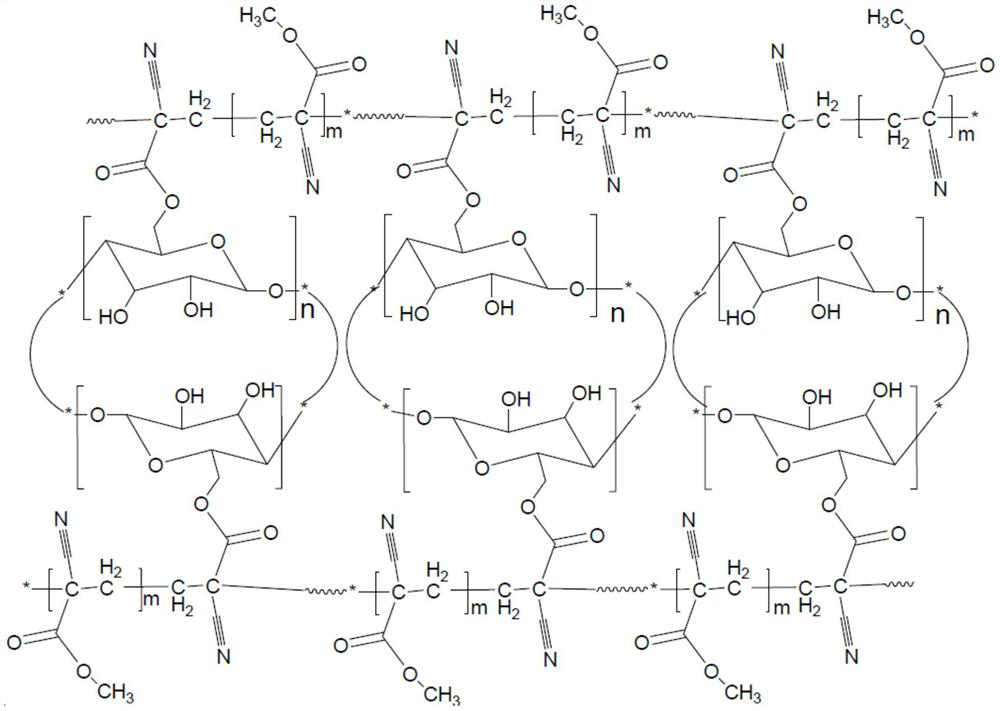

Metal lithium battery negative electrode, preparation method thereof and lithium secondary battery

ActiveCN112635765AFacilitate lithium ion crossingGood compatibilitySecondary cellsNegative electrodesCompatibilizationLithium battery

The invention provides a metal lithium battery negative electrode, a preparation method thereof and a lithium secondary battery. The negative electrode provided by the invention can improve the cycle performance of the battery under the condition of high capacity density. Cyclodextrin substances and cyanoacrylate are subjected to transesterification to form a transesterification product, the surface of a negative electrode foil is coated with the transesterification product, and after coating, an anionic polymerization reaction is initiated by Li or a small amount of water in air, so that the transesterification product forms a spatial cross-linked network polymer; the cross-linked network polymer coating can effectively promote lithium ion penetration and induce lithium ions to deposit on the surface of the negative electrode foil, has good compatibility with the negative electrode foil, and can inhibit growth of lithium dendrites; the cross-linked network polymer coating is insoluble in electrolyte, so that side reaction between the electrolyte and metal lithium can be well inhibited; the cycle performance of the battery can be effectively improved through the effects in multiple aspects.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

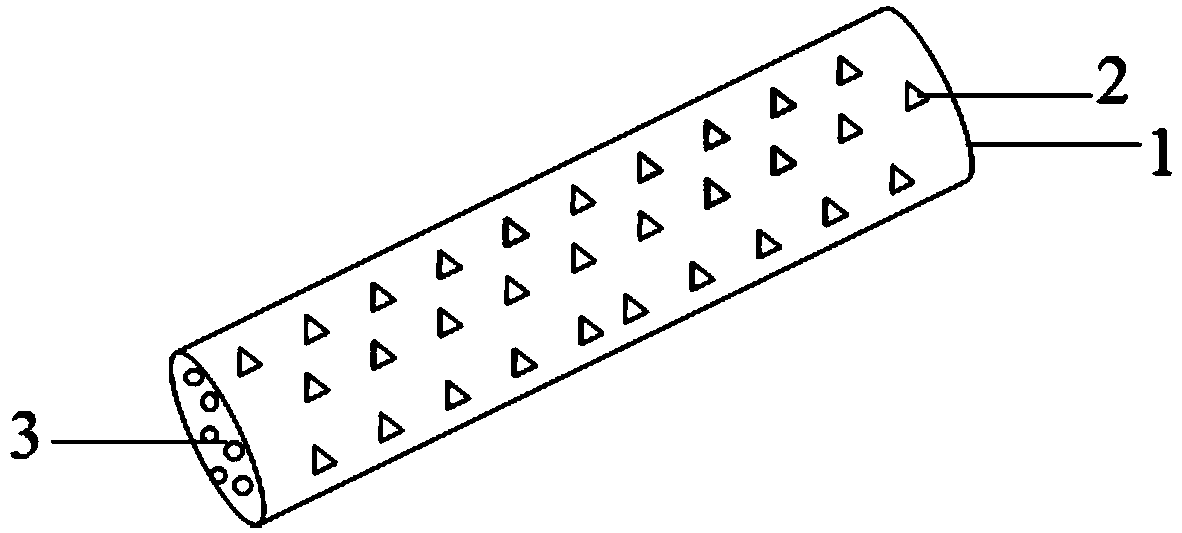

Lithium-sulfur battery positive electrode material and preparation method thereof

The invention provides a lithium-sulfur battery positive electrode material. The lithium-sulfur battery positive electrode material comprises a matrix layer, a polymer layer and a core layer, whereinthe polymer layer wraps the matrix layer, and the core layer is arranged in the matrix layer. The invention also provides a preparation method of the lithium-sulfur battery positive electrode material. In the lithium-sulfur battery positive electrode material provided by the invention, the conductive polymer layer wraps the matrix layer, and the matrix layer is filled with the core layer; meanwhile, by a physical limitation effect of a one-dimensional pipeline of the matrix layer and an absorption effect of a chemical constituent, the problems that the battery capacity and cycle retention ratecan be relatively low and the integral electrochemical performance is low by a shuttle effect of intermediate product polysulfide ions generated during the charging and discharging process of a sulfur positive electrode of a lithium-sulfur battery are solved; and the matrix layer is a halloysite layer, the shuttling of the polysulfide ions can be prevented from two aspects of physical limitationand chemical absorption, the halloysite is used as natural mineral at a low cost, the cost of the position electrode also can be reduced by using the halloysite as a matrix, and promotion and application are facilitated.

Owner:CENT SOUTH UNIV

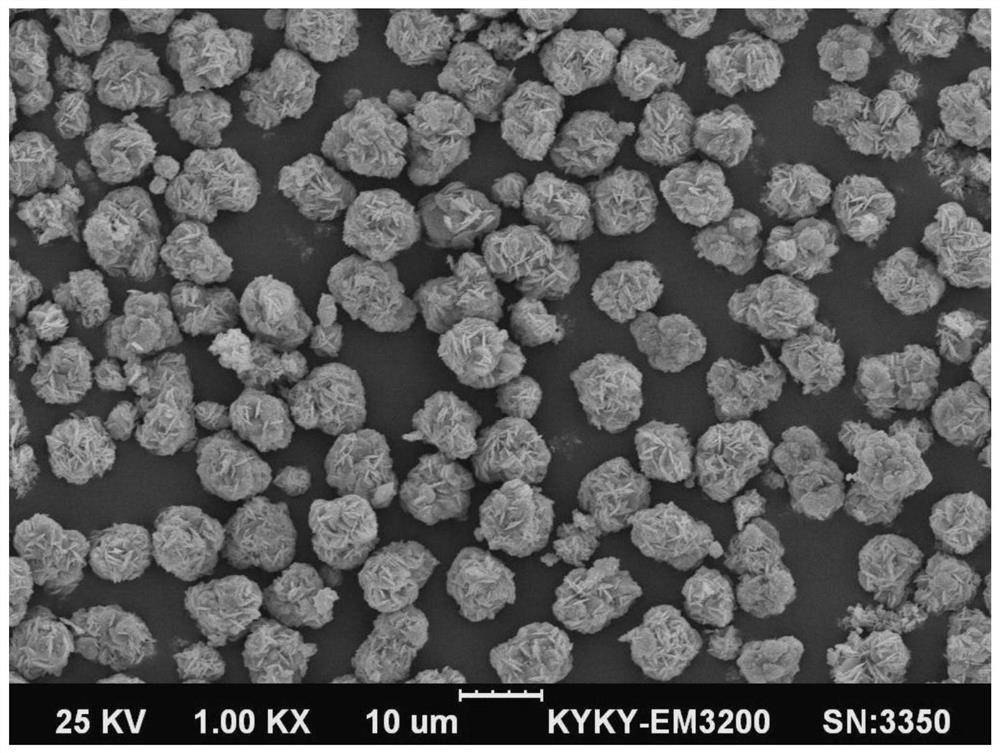

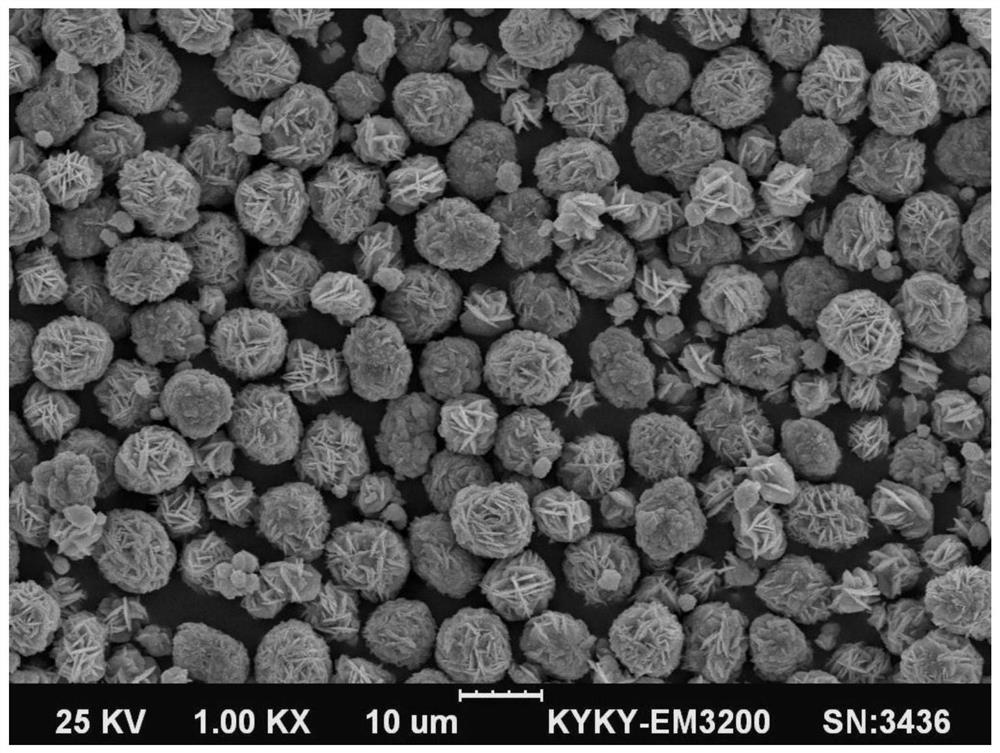

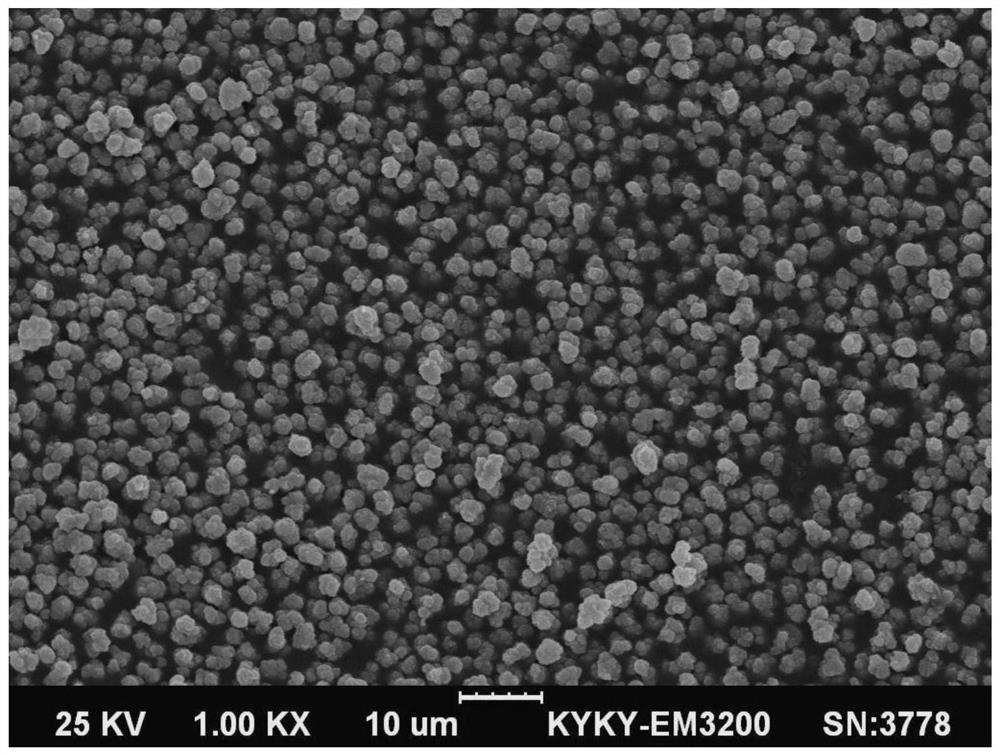

A kind of preparation method of aluminum-magnesium-nickel-manganese spherical cobalt tetroxide

ActiveCN110534719BAvoid it happening againAvoid gatheringCell electrodesElectrical batteryCobalt(II,III) oxide

The invention belongs to the technical field of preparing precursor of battery positive electrode material, in particular to a preparation method of doped cobalt tetroxide, and provides a preparationmethod of aluminum-magnesium-nickel-manganese doped spherical cobalt tetroxide. Cobalt liquid containing doped elements is prepared, EDTA is used as a complexing agent and synthesis is performed at acertain pH and temperature. Meanwhile, the doped elements are uniformly and fully precipitated, and finally the high-density spherical cobalt hydroxide with uniform doping is obtained and the doped cobalt tetroxide is obtained through centrifugation and calcination. The aluminum-magnesium-nickel-manganese doped spherical cobalt tetroxide prepared by the method has uniform particle size, good compactness, complete precipitation and uniform distribution of doped elements and stable and controllable process.

Owner:취저우화여우코발트뉴머터리얼컴퍼니리미티드 +1

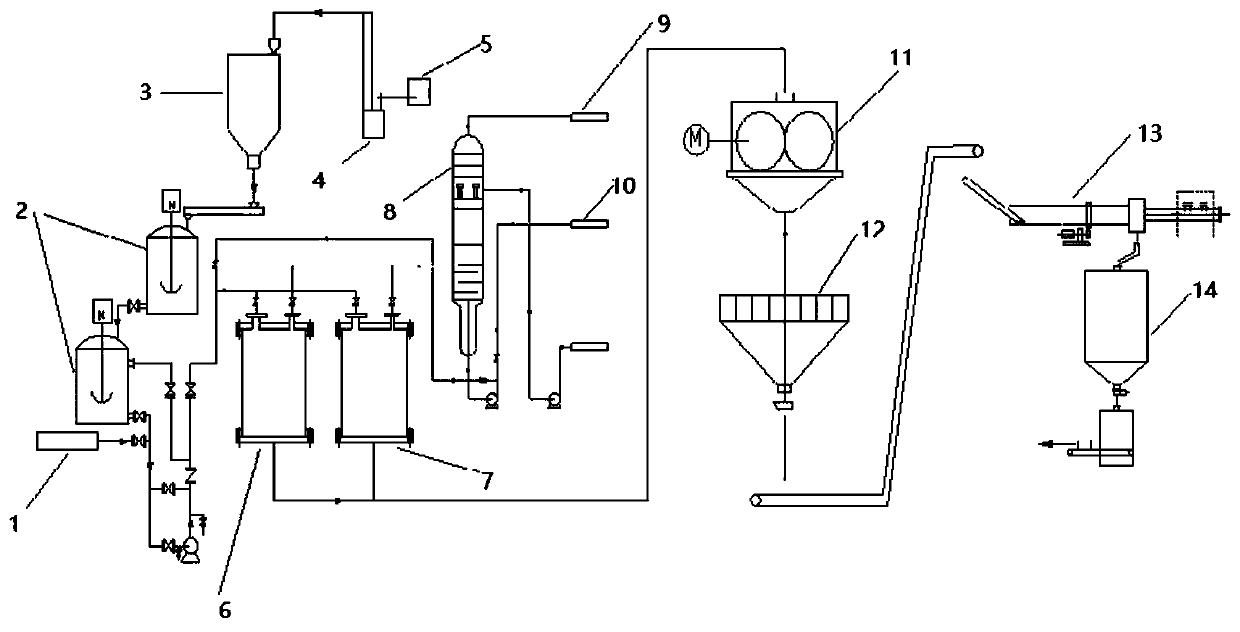

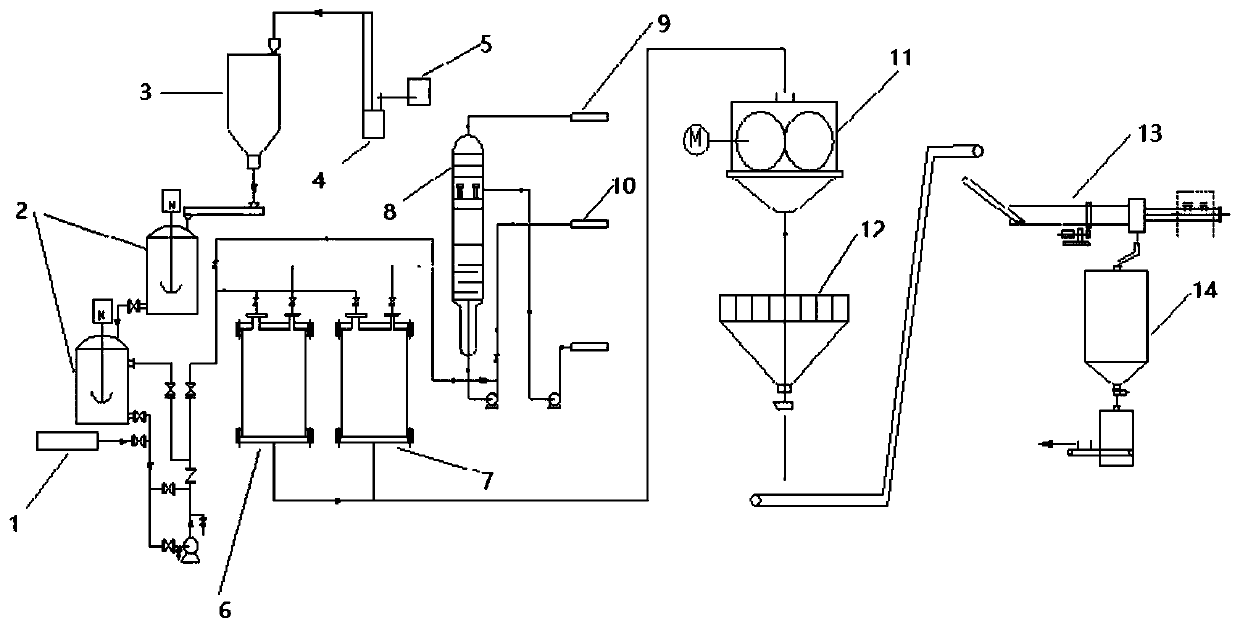

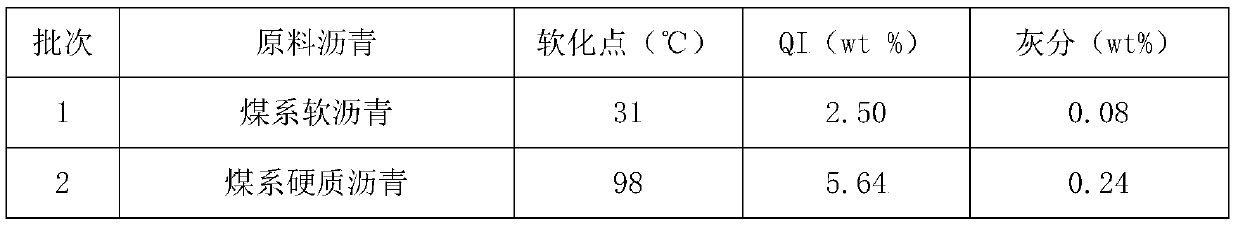

Quick-charging negative electrode material production process and device

PendingCN111171851AStable material structureIncrease capacityCell electrodesHydrocarbon distillationMelting tankElectrical battery

The invention discloses a quick-charging negative electrode material production process and device. The device comprises a bucket elevator, a stock bin, a melting tank, a pressurizing tower, a distillation tower, a crusher, a screening machine and a high-temperature carbonization furnace, wherein the bucket elevator is connected with the stock bin, the stock bin feeds materials to the melting tankthrough the screw feeder, the melting tank is connected with the pressurizing tower, a light phase extraction opening of the pressurizing tower is connected with the distillation tower, a coke outletof the pressurizing tower feeds materials to the crusher, the crusher feeds materials to the screening machine, and the screening machine feeds materials to the high-temperature carbonization furnace. According to the invention, different asphalt raw materials are coarsely crushed or directly melted, then enter the pressurizing tower for coking and are crushed and screened after coke discharging,and then the treated raw materials enter the high-temperature carbonization furnace for carbonization to obtain the negative electrode material with excellent electrochemical performance and stable material structure. The high-capacity quick-charging negative electrode material prepared by the invention is high in battery safety performance, high in capacity, good in rate capability, excellent incycle performance and outstanding in anti-attenuation capability, and is an excellent raw material for lithium ion and sodium ion batteries and quick-charging battery equipment.

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD

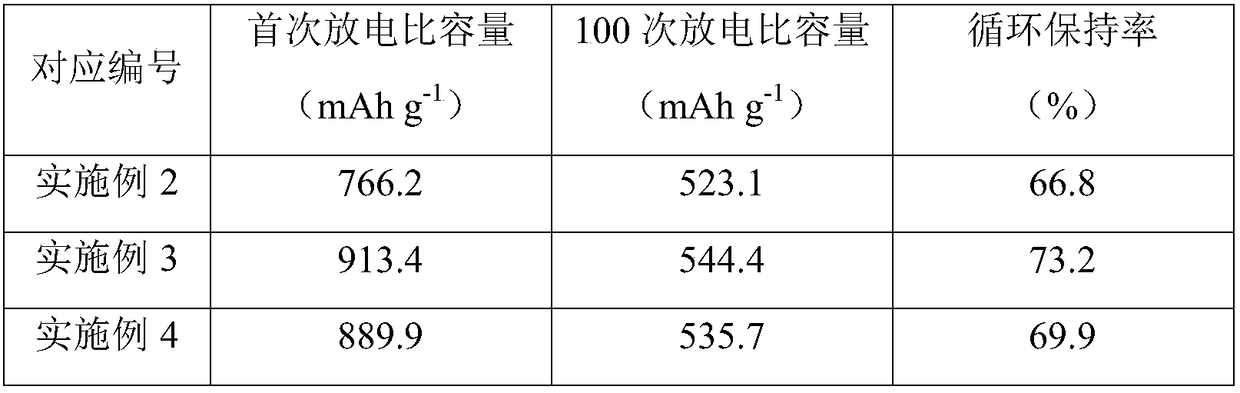

Battery cathode and preparation method thereof

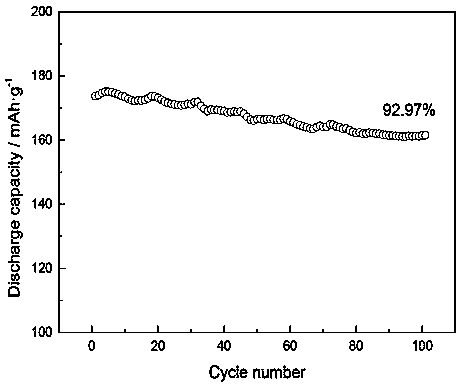

InactiveCN109461922ALow costInhibit shuttleElectrode collector coatingLi-accumulatorsChemical compositionAdhesive

The invention provides a battery cathode. The battery cathode comprises aluminum foil, an electrode layer, an adhesive and a conductive agent; the electrode layer is coated on a surface of the aluminum foil, the electrode layer comprises a matrix layer, a polymer layer cladding the matrix layer, and a core layer located in the matrix layer. Through the battery cathode provided by the invention, aconductive polymer layer coated on the outside of the matrix layer of the electrode layer, the core layer is filled in the matrix layer, a physical limit effect of the one-dimension pipeline and an absorption effect of the chemical component of the matrix layer are utilized at the same time, the problems that the battery specific capacity and cycling retention rate are low and the entire electrochemical performance is low due to the shuttle effect of the intermediate product polysulfur ion generated in the lithium-sulfur battery sulfur cathode charging / discharging process in the prior art canbe solved. The first discharging specific capacity of the battery cathode prepared by adopting the method provided by the invention under the 0.1C multiplying power is 913.4mAh g-1, and the cycling retention rate reaches up to 73.2% after cycling for 100 times.

Owner:长沙瑞联材料科技有限公司

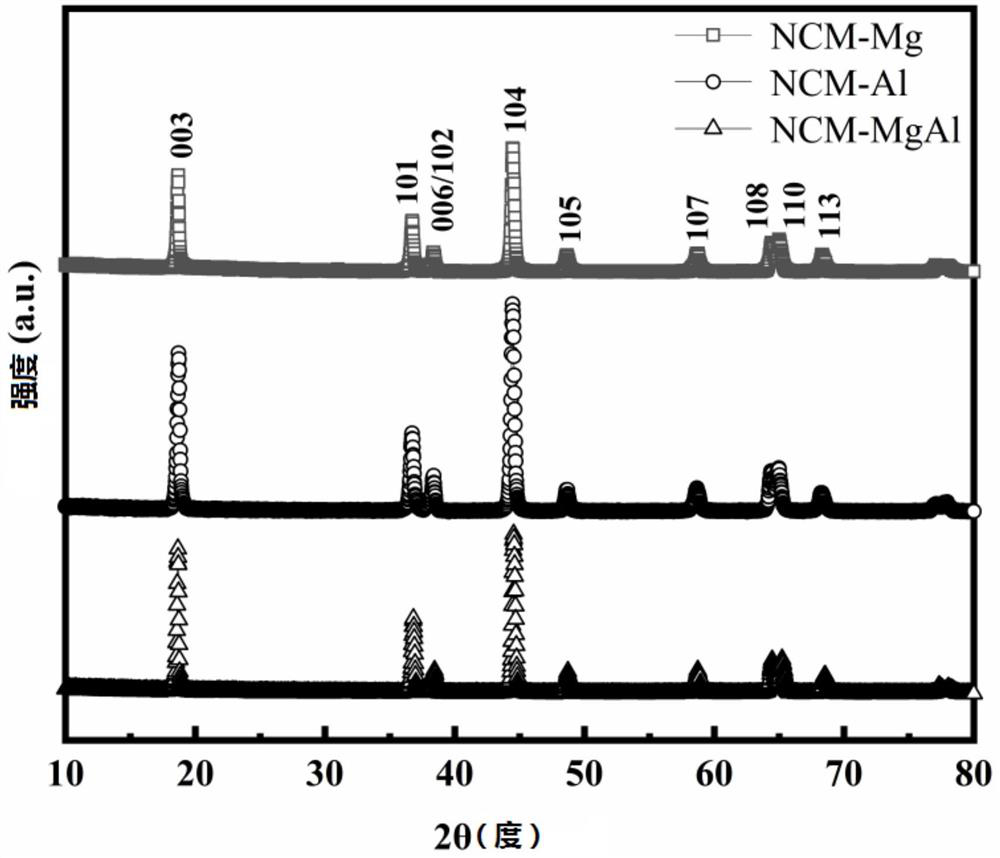

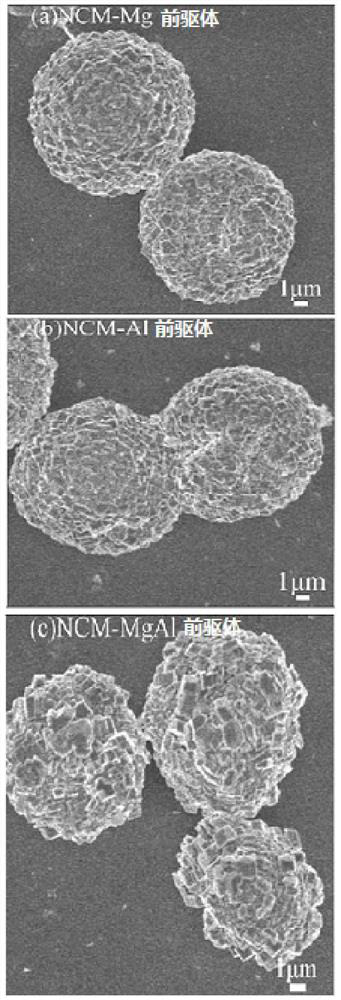

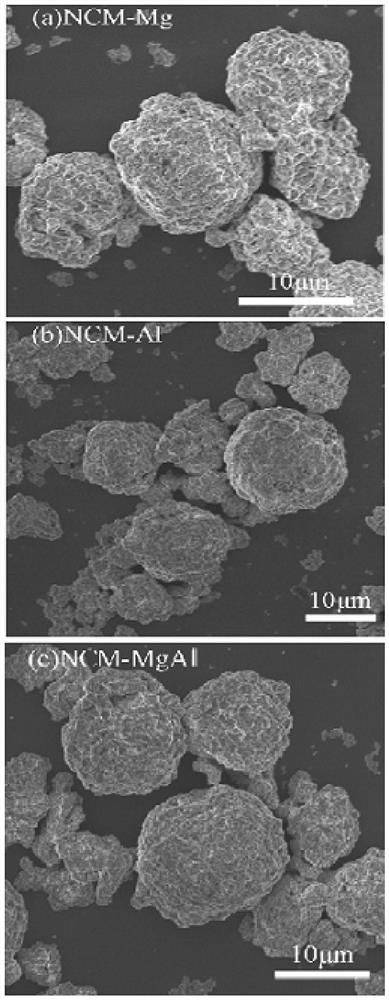

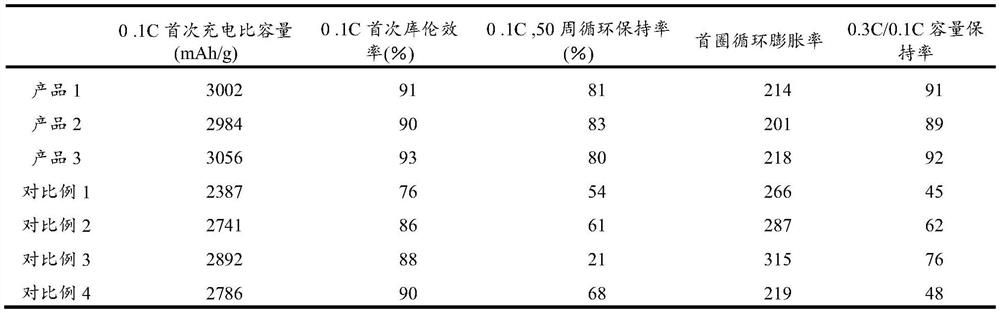

Metal-doped modified ternary positive electrode material and preparation method thereof

PendingCN114212834AImprove thermal stabilityImprove cycle lifeSecondary cellsPositive electrodesAluminum IonPhysical chemistry

The invention belongs to the technical field of batteries, and discloses a metal-doped modified ternary positive electrode material and a preparation method thereof. The chemical formula of the ternary positive electrode material is LiNi < 0.6 > Co < 2-x > Mn < 0.2 > M < x > O < 2 >, x is more than 0 and less than 0.1, and M is at least one of Al and Mg. According to the metal-doped modified ternary positive electrode material provided by the invention, by doping the aluminum ions and / or magnesium ions, the structure phase change can be inhibited, the lithium-nickel mixed arrangement can be reduced, the thermal stability of the material can be improved, the cycle life can be prolonged, and the rate capability can be improved.

Owner:SHANTOU UNIV

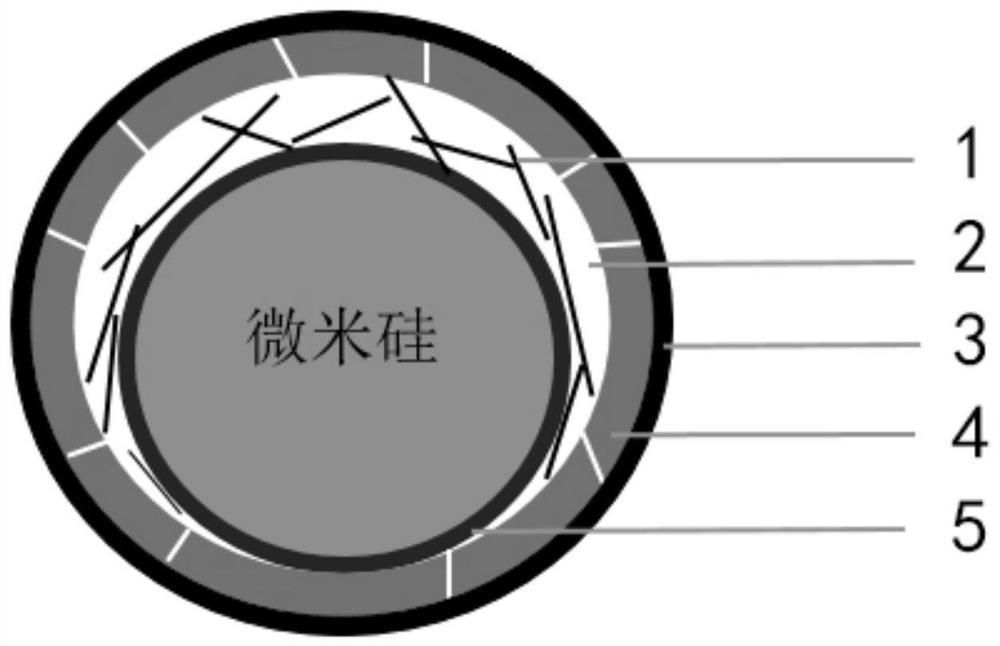

Micron silicon composite material and preparation method and application thereof

ActiveCN114267839AIntegrity guaranteedImprove cycle stabilityCell electrodesSecondary cellsCarbon coatingLithium-ion battery

The invention provides a micron silicon composite material as well as a preparation method and application thereof, and belongs to the technical field of lithium ion batteries. The micron silicon composite material is of a core-shell structure and sequentially comprises micron silicon, a first coating layer, a cavity layer, a second coating layer and a third coating layer from inside to outside, the first coating layer and the second coating layer are carbon coating layers, the third coating layer is a compact carbon coating layer, a cavity layer is arranged between the second coating layer and the third coating layer, and a conductive agent is contained in the cavity layer. According to the micron silicon composite material, a volume expansion space is reserved for embedding lithium into silicon, so that the carbon coating layer is prevented from being broken due to the volume expansion of lithium when the silicon is embedded, the integrity of the composite material is maintained, and the cycling stability of the micron silicon composite material is improved. The invention further discloses a preparation method and application of the composite material, the preparation method is simple and easy to implement, and the prepared negative electrode is good in electrochemical performance.

Owner:BEIJING WELION NEW ENERGY TECH CO LTD

Negative plate and lithium ion battery

ActiveCN112820852AImprove charging riskImprove cycle retentionSecondary cellsNon-aqueous electrolyte accumulator electrodesStructural engineeringLithium-ion battery

The invention provides a negative plate and a lithium ion battery. On the first aspect, the invention provides the negative electrode plate, the negative electrode plate comprises a current collector, a first active layer and a second active layer, the first active layer is arranged on the surface of the current collector and is provided with a first groove, and the second active layer is divided into a first part arranged in the first groove and a second part arranged on the surface, far away from the current collector, of the first active layer; the first part is provided with a second groove, a tab is arranged in the second groove and is electrically connected with the current collector, and the thickness of the first part of the second active layer is smaller than the total thickness of the first active layer and the second part of the second active layer. According to the negative plate provided by the invention, by reducing the thickness of the active layer around the tab, the charging risk of the tab connection position is effectively improved, and the cycle retention rate of the lithium ion battery is improved under the condition of maintaining high-rate charging.

Owner:ZHUHAI COSMX BATTERY CO LTD

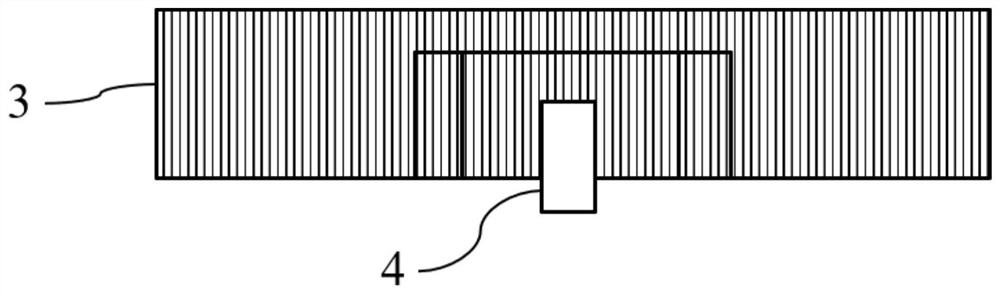

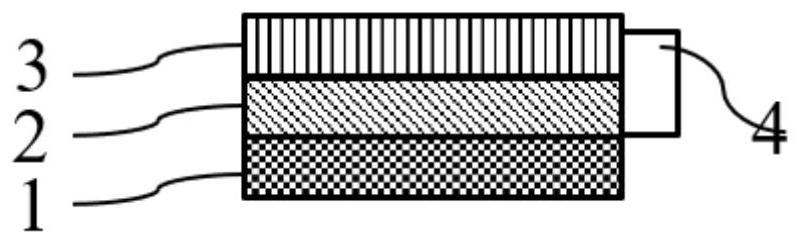

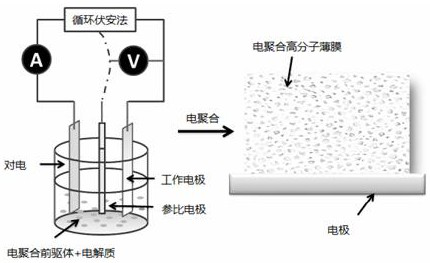

Positive pole piece modified by polymer film and preparation method of positive pole piece

PendingCN114220944AImprove spatial connectivityImprove conductivityElectrode manufacturing processesSecondary cellsSolid state electrolyteElectrolytic agent

The invention provides a positive pole piece modified by an electro-polymerization polymer film and a preparation method of an all-solid-state battery of the positive pole piece. The surface of the positive pole piece is modified with a layer of electro-polymerization polymer film by adopting an electro-polymerization method, the electro-polymerization polymer film prepared by the method is internally doped with electrolyte, the ionic conductivity is high, and the polymer film has a certain respiration effect, so that stress generated when a positive pole material is in contact with solid electrolyte can be relieved, and an interface is stable; and the advantages of the organic liquid electrolyte and the solid electrolyte are integrated, and the cycle performance of the solid-state battery prepared by the method is excellent.

Owner:TIANJIN B&M SCI & TECH

Cathode material coated with co-embedded film, preparation method and lithium ion battery

ActiveCN114156478AIncrease capacityImprove cycle performanceSecondary cellsPositive electrodesElectrical conductorInterface impedance

According to the positive electrode material coated with the co-embedded thin film, the preparation method and the lithium ion battery, the co-embedded thin film is deposited on the surface of the positive electrode material through an atomic layer deposition method, so that the positive electrode material coated with the co-embedded thin film is obtained. The co-embedded thin film comprises an amorphous oxide layer of phosphorus and an amorphous oxide layer of titanium. By adopting the atomic layer deposition method, the precise regulation and control of the element content and proportion can be realized, the cost is low, the coating period is short, and the PO bond in the obtained co-embedded film with the specific element proportion and content can prevent the material structure collapse caused by material deoxidation; and the amorphous oxide layer of phosphorus and residual lithium of the positive electrode material can form fast ion conductor lithium phosphate, so that the interface impedance is reduced. The amorphous oxide layer of titanium has the effect of blocking electrolyte erosion. Therefore, the positive electrode material coated with the co-embedded film and the lithium ion battery assembled by the positive electrode material have relatively high capacity and cycle performance.

Owner:XIAMEN YUNMAO TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com