Positive pole piece modified by polymer film and preparation method of positive pole piece

A technology of polymer film and positive pole piece, which is applied in the field of all-solid-state batteries, can solve the problems of poor interface contact effect, high material grain boundary impedance, and high interface impedance, so as to prevent particle shedding, reduce interface polarization, and reduce interface impedance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

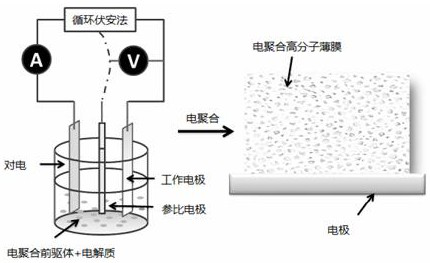

[0033] A method for preparing a positive electrode sheet modified by a polymer film, comprising the steps of:

[0034] 1) Mix 15-18 g of positive electrode material, 0.1-0.5 g of binder, and 0.1-0.5 g of conductive agent together, perform high-speed stirring and homogenization, filter the uniformly dispersed slurry and apply it to the electrode collector, and then Drying and cold pressing to obtain the primary pole piece, after the primary pole piece is cleaned by ultrasonic waves, the working electrode is obtained;

[0035] 2) Mix 0.1~3 g polymer monomer, 0.2~2.0 mol / L tetrabutylammonium hexafluorophosphate (TBAPF 6 ) 1~10mL, 0.01~2g lithium hexafluorophosphate, and 0.01~2 g electrolyte are added to the organic solvent, stirred evenly to form a mixed solution, and then added to the electrolytic cell, which is protected by an inert gas;

[0036]3) Ultrasonic pre-clean the working electrode obtained in step 1), one of gold, platinum, lead and titanium is used as the counter el...

Embodiment 1

[0052] A kind of preparation of the electropolymerization thin film modified positive pole piece, comprises following preparation steps:

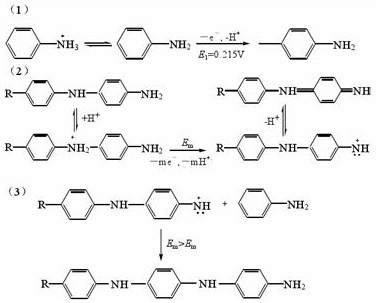

[0053] 1) The high nickel LiNi 0.9 co 0.06 mn 0.04 Positive electrode material 16 g, binder PVDF: 0.33 g, conductive agent Super P: 0.25 g, high-speed stirring and homogenization for 5 min, the uniformly dispersed slurry was filtered and coated on the current collector, and then dried and cooled. Press to obtain a fresh positive pole piece, after ultrasonic cleaning for 1 min, it was used as a working electrode;

[0054] 2) Mix 10 ml 0.5 mg / mL aniline, 5 mL 1.0 mol / L tetrabutylammonium hexafluorophosphate (TBAPF 6 ), 0.01g lithium hexafluorophosphate, 0.01 g ammonium perchlorate were added to the volume ratio of acetonitrile and dichloromethane of 2:3, after stirring evenly, the mixture was added to the electrolytic cell, and high-purity N was introduced into the electrolytic cell 2 Protect;

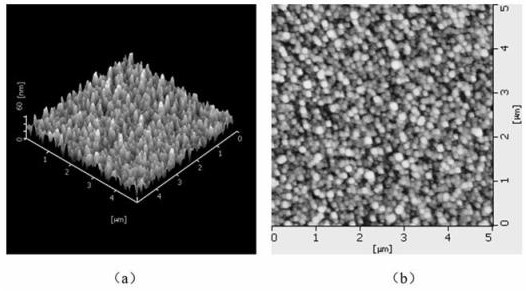

[0055] 3) The positive electrode sheet (2×...

Embodiment 2

[0061] A kind of preparation of the electropolymerization thin film modified positive pole piece, comprises following preparation steps:

[0062] 1) The high nickel LiNi 0.9 co 0.06 mn 0.04 Positive electrode material 16 g, binder PVDF: 0.33 g, conductive agent Super P: 0.25 g, high-speed stirring and homogenization for 5 min, the uniformly dispersed slurry was filtered and coated on the current collector, and then dried and cooled. Press to obtain a fresh positive pole piece, after ultrasonic cleaning for 1 min, it was used as a working electrode;

[0063] 2) Mix 10 ml 0.5 mg / mL aniline, 5 mL 1.0 mol / L tetrabutylammonium hexafluorophosphate (TBAPF 6 ) 0.01g of lithium hexafluorophosphate, 0.01g was added to the volume ratio of acetonitrile and dichloromethane of 2:3, after stirring evenly, the mixed solution was added to the electrolytic cell, and high-purity N was introduced into the electrolytic cell 2 Protect;

[0064] 3) The positive electrode sheet (2×2 cm) whose su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com