Battery cathode and preparation method thereof

A battery positive electrode and electrode layer technology, applied in the direction of electrode manufacturing, battery electrodes, non-aqueous electrolyte battery electrodes, etc., can solve the problem of low Coulombic efficiency, failure to properly solve the shuttle effect of lithium polysulfide intermediate products, irreversible loss of effective substances, etc. problems, to achieve the effect of facilitating popularization and application, inhibiting the shuttle of polysulfide ions, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

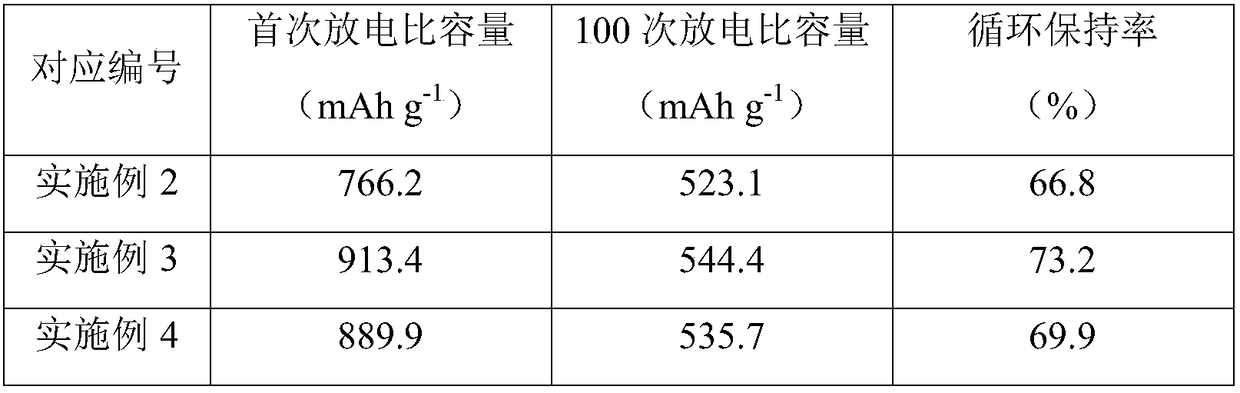

Examples

Embodiment 1

[0035] A positive electrode of a battery, comprising an aluminum foil, an electrode layer, a binder and a conductive agent, the electrode layer being coated on the surface of the aluminum foil, the electrode layer comprising a matrix layer, a polymer layer covering the matrix layer, and The core layer located in the base layer.

[0036] Wherein, the conductive agent is conductive carbon black, the binder is PVDF / NMP, the matrix layer is halloysite, and the polymer is polypyrrole (PPy), polyaniline (PANI) and poly-3, One of 4-ethylenedioxythiophene (PEDOT), the core layer is a sulfur element layer.

Embodiment 2

[0038] A method for preparing a positive electrode of a battery, the steps comprising:

[0039] (1) After the base layer is leached with acid and heat-treated, the base layer is dispersed in a solvent, and polymer monomers and oxidants are added to the solvent to polymerize to obtain a semi-finished product;

[0040] (2) loading the core layer into the semi-finished product obtained in step (1) to obtain an electrode layer material;

[0041] (3) Grinding the electrode layer material and conductive agent obtained in step (2) evenly according to the mass ratio of 7:2, adding a binder, and stirring at room temperature for 24 hours to prepare a slurry;

[0042] (4) Coating the slurry obtained in step (3) on the aluminum foil, drying and slicing to obtain the positive electrode of the battery.

[0043] The acid described in step (1) is a kind of in hydrochloric acid, sulfuric acid and oxalic acid, and the mass fraction of described hydrochloric acid is 30%, and the temperature of ...

Embodiment 3

[0046] A method for preparing a positive electrode of a battery, the steps comprising:

[0047] (1) After the base layer is leached with acid and heat-treated, the base layer is dispersed in a solvent, and polymer monomers and oxidants are added to the solvent to polymerize to obtain a semi-finished product;

[0048] (2) loading the core layer into the semi-finished product obtained in step (1) to obtain an electrode layer material;

[0049] (3) Grinding the electrode layer material and conductive agent obtained in step (2) evenly according to the mass ratio of 7:2, adding a binder, and stirring at room temperature for 24 hours to prepare a slurry;

[0050] (4) Coating the slurry obtained in step (3) on the aluminum foil, drying and slicing to obtain the positive electrode of the battery.

[0051] Wherein, the acid described in the step (1) is one of hydrochloric acid, sulfuric acid and oxalic acid, and the mass fraction of the hydrochloric acid is 40%. , the extraction temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com