Micron silicon composite material and preparation method and application thereof

A silicon composite material and coating technology, which is applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of poor performance, unreasonable preparation process of micro-silicon composite materials, and high cost of nano-scale production, so as to improve the electrical conductivity. efficiency, good isolation effect, and the effect of improving cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

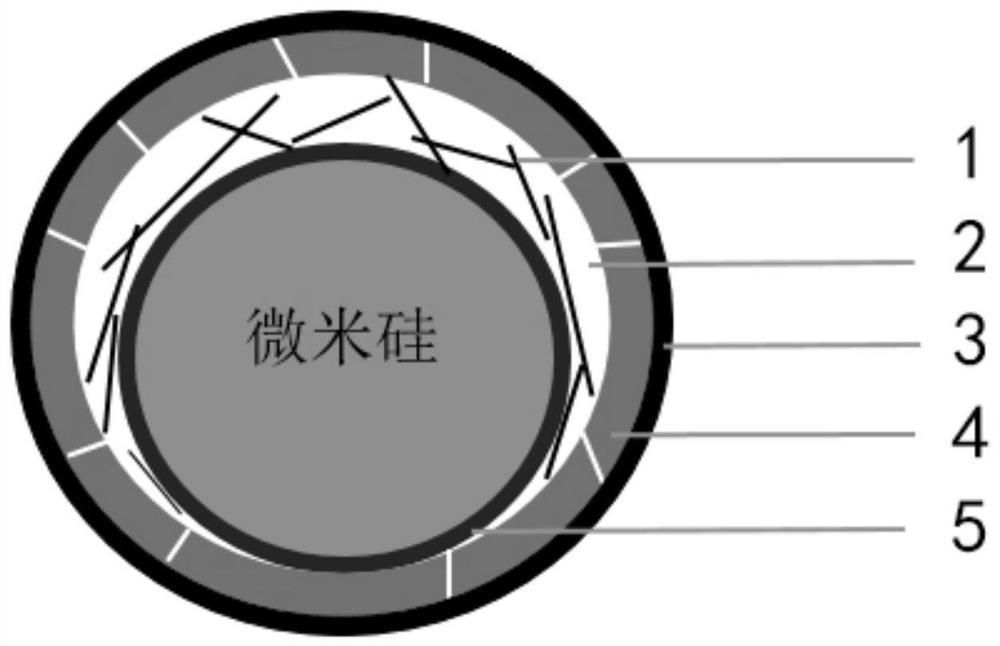

[0062] A micro-silicon composite material, which is a core-shell structure, and the core-shell structure is sequentially composed of micro-silicon, a first cladding layer 5, a cavity layer 2, a second cladding layer 4 and a third cladding layer from the inside to the outside 3.

[0063] Both the first coating layer 5 and the second coating layer 4 are carbon coating layers, the third coating layer 3 is a dense carbon coating layer, and the cavity layer 2 contains a conductive agent 1 .

[0064] The cavity layer reserves space for volume expansion for silicon intercalation of lithium, avoids the cracking of the carbon coating layer due to volume expansion of lithium during silicon intercalation, and maintains the integrity of the composite material. The first cladding layer provides good electrical conductivity and insulation effect for the composite material. The conductive agent maintains the close connection between the micron silicon and the second and third carbon coating...

Embodiment 2

[0072] A method for preparing a micron-silicon composite material, comprising the steps of:

[0073] (1) Carbon-coat micron-silicon by using a solid-phase method or a liquid-phase method to obtain sample 1 comprising the first coating layer and micron-silicon.

[0074] When the solid-phase method is adopted, the carbon coating layer is formed by uniformly mixing micron silicon and solid carbon source materials; the solid carbon source includes any one or a combination of pitch and phenolic resin.

[0075] When the liquid-phase method is adopted, the micro-silicon is added to the solvent, and the liquid-phase coating material is added for in-situ polymerization, separated and dried. The liquid phase coating material includes polyphenolic resin, polydopamine, tannic acid, PVA any one or a combination of at least two, and the mass ratio of the liquid phase coating material to micron silicon is (0.02~0.2):1 , such as 0.02:1, 0.1:1, 0.2:1, etc. The solvent is water or a mixed sol...

Embodiment 3

[0088] A lithium battery negative electrode, comprising a negative electrode slurry, the negative electrode slurry is made by dissolving a negative electrode active material, a conductive agent and a binder in deionized water, and the negative electrode active material is as described in Example 1 or Example 2 The micro-silicon composite material or the mixed material of the micro-silicon composite material and carbon, the negative electrode slurry is coated on the copper foil, and the negative electrode is obtained after drying; the solid content of the slurry is 5%.

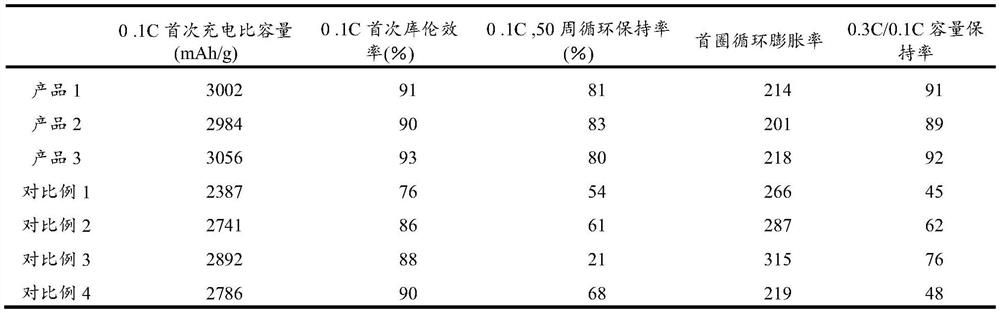

[0089] Experimental group 1

[0090] A method for preparing a micro-silicon composite material, comprising the following steps:

[0091] S1. Take 20g of micro-silicon with a particle size of 2μm and add it to 200ml of buffer solution with a pH value of 8-9. After stirring evenly, add 1g of dopamine. After stirring for a period of time, separate and dry to form a polydopamine coating layer to obtain sample 1.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com