Patents

Literature

66results about How to "High energy density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biofuel Processing System

InactiveUS20080280338A1High energy densityImprove conversion efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsProcess engineeringBiological process

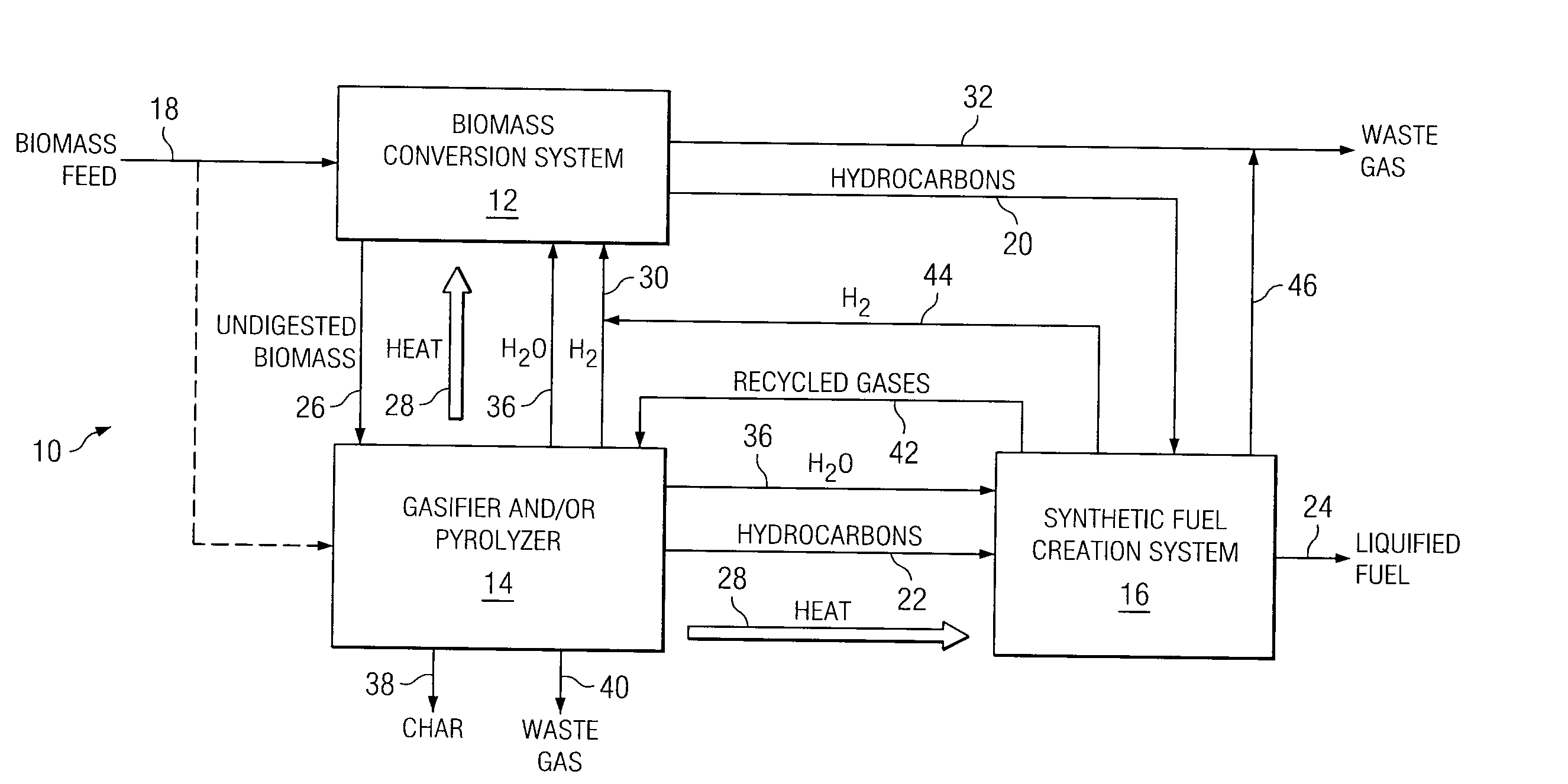

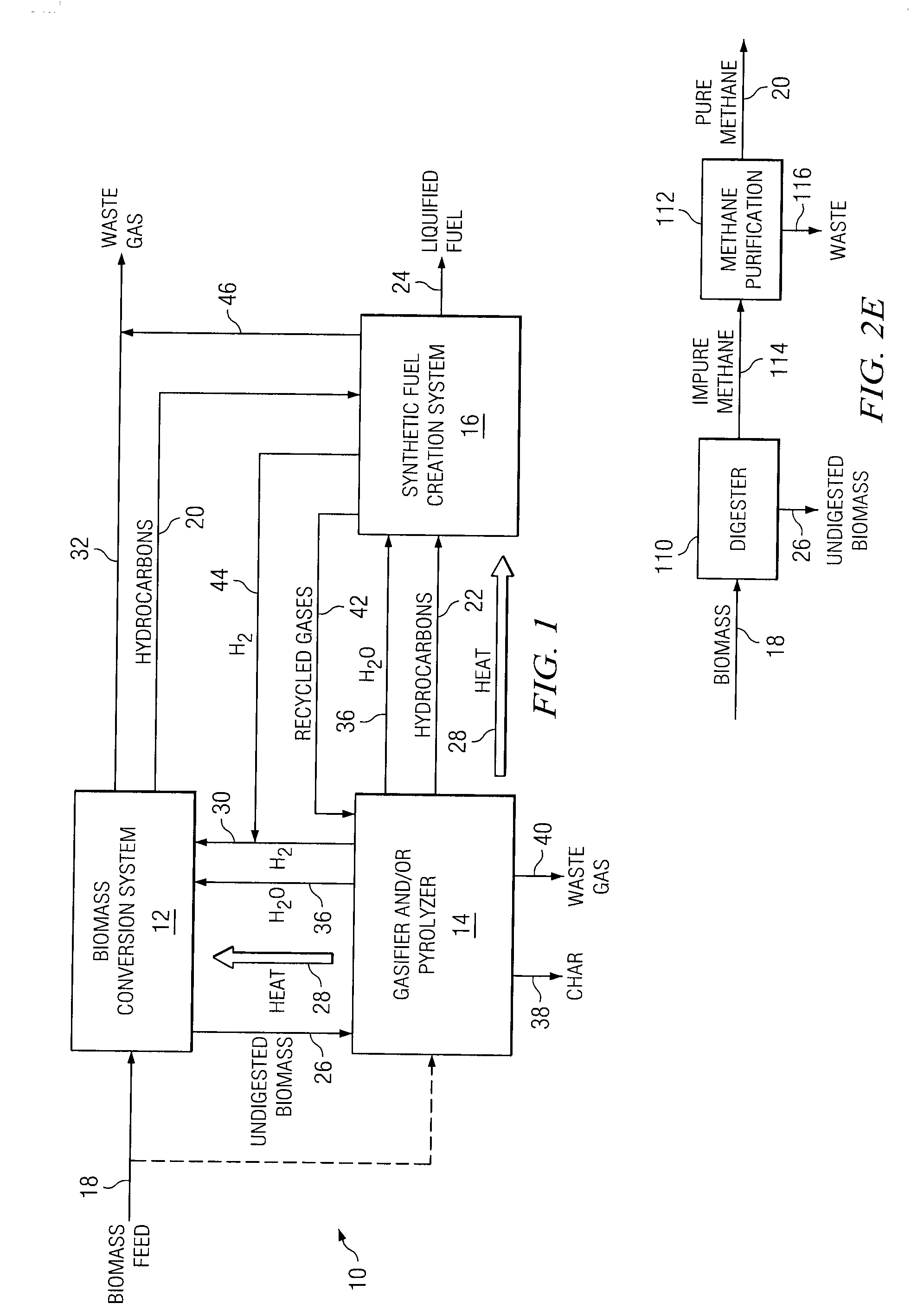

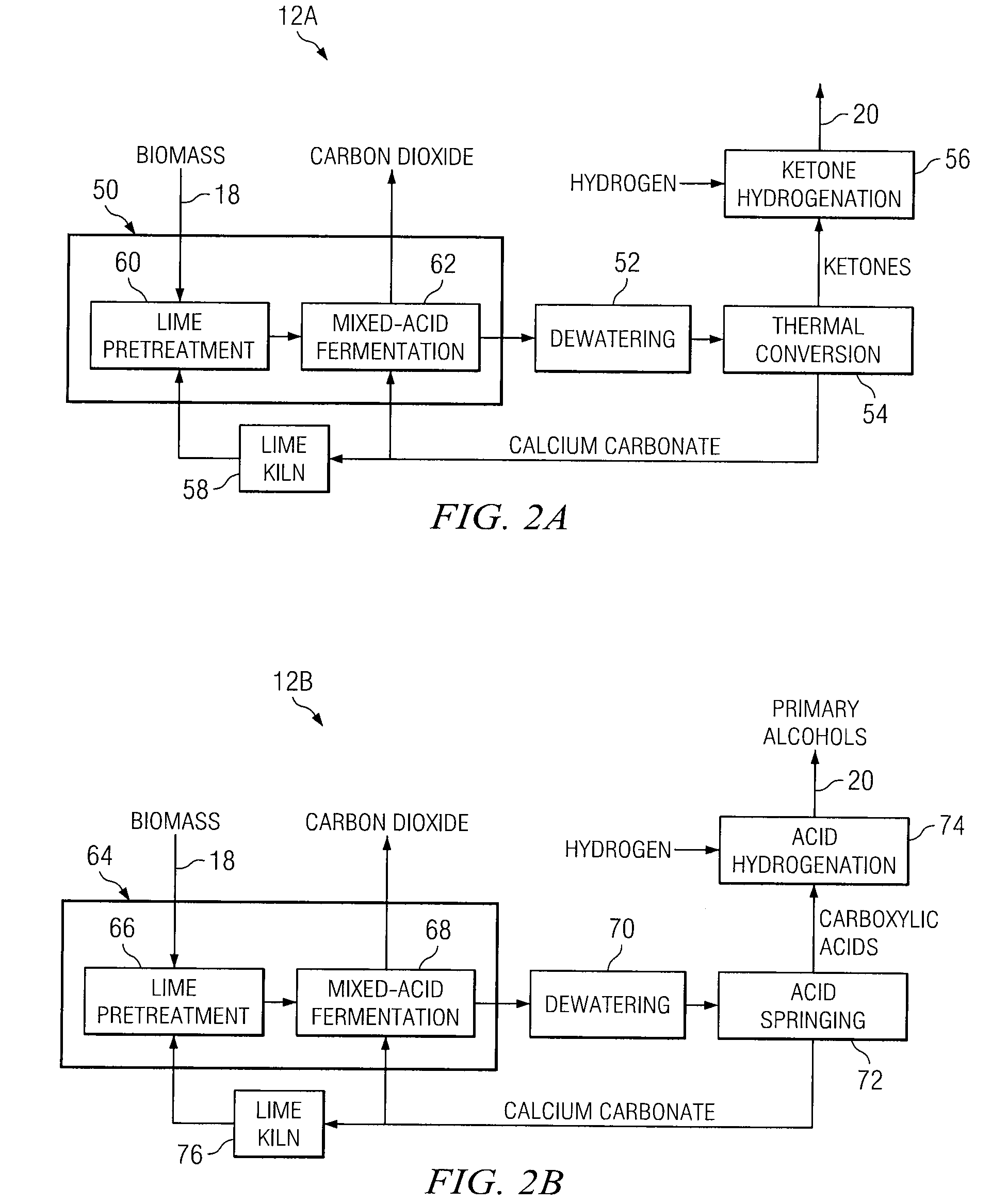

According to one embodiment, a biofuel processing system includes a biomass conversion system, a gasification reactor and / or a pyrolysis reactor, and a synthetic fuel creation system. The biomass conversion system uses a biological process to create a low-molecular-weight hydrocarbon stream from a biomass. The reactor generates heat and hydrogen using fresh biomass or undigested biomass from the biomass conversion system in which a portion of the heat is used by the biomass conversion system. The synthetic fuel creation system converts the low-molecular-weight hydrocarbon stream from the biomass conversion system and / or the reactor to liquefied fuel using another portion of heat from the reactor.

Owner:TEXAS A&M UNIVERSITY

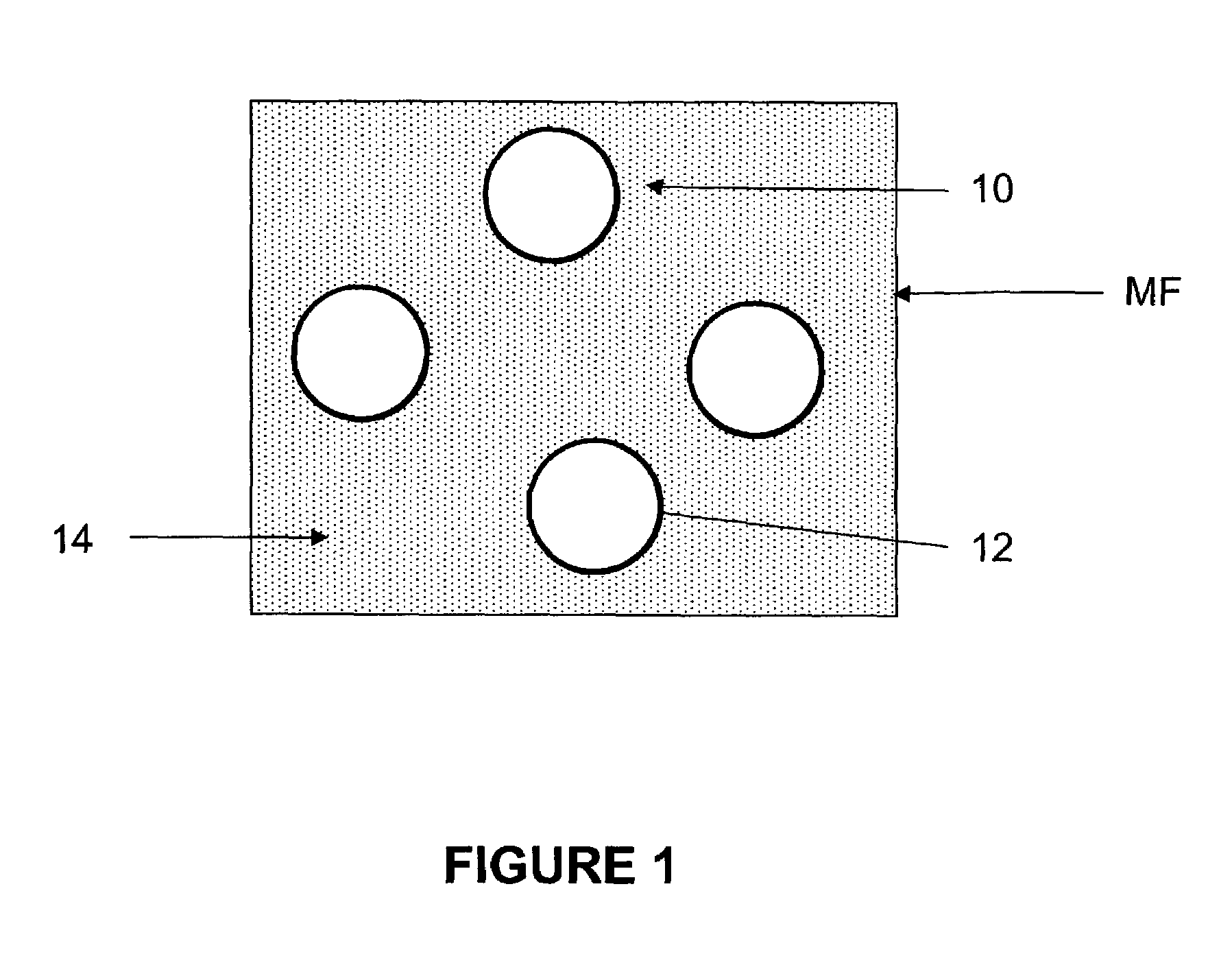

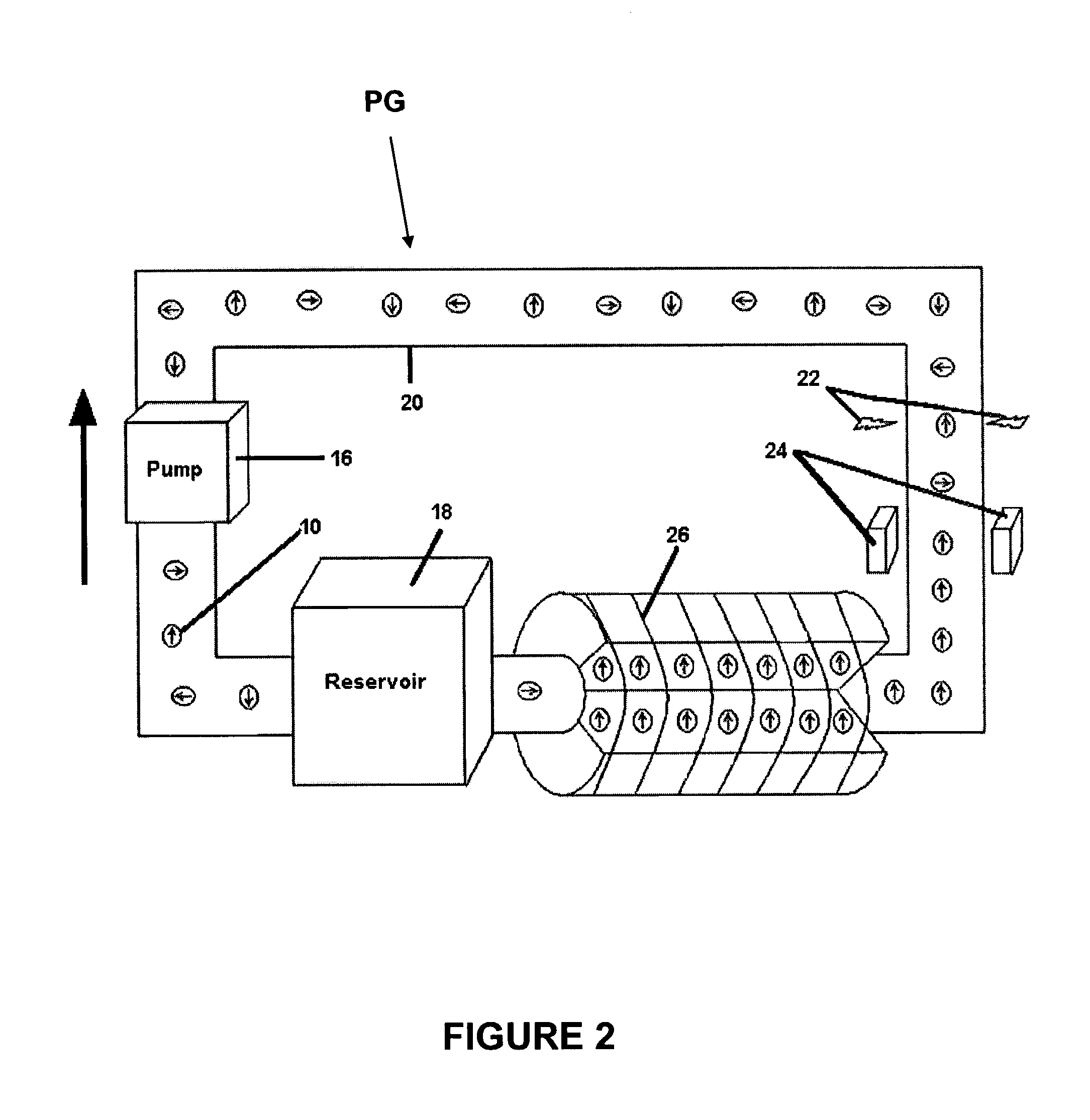

Magnetic fluid power generator device and method for generating power

ActiveUS6982501B1High energy densityIncrease reliabilityNanomagnetismElectric discharge tubesMagnetic fluxMagnetohydrodynamic generator

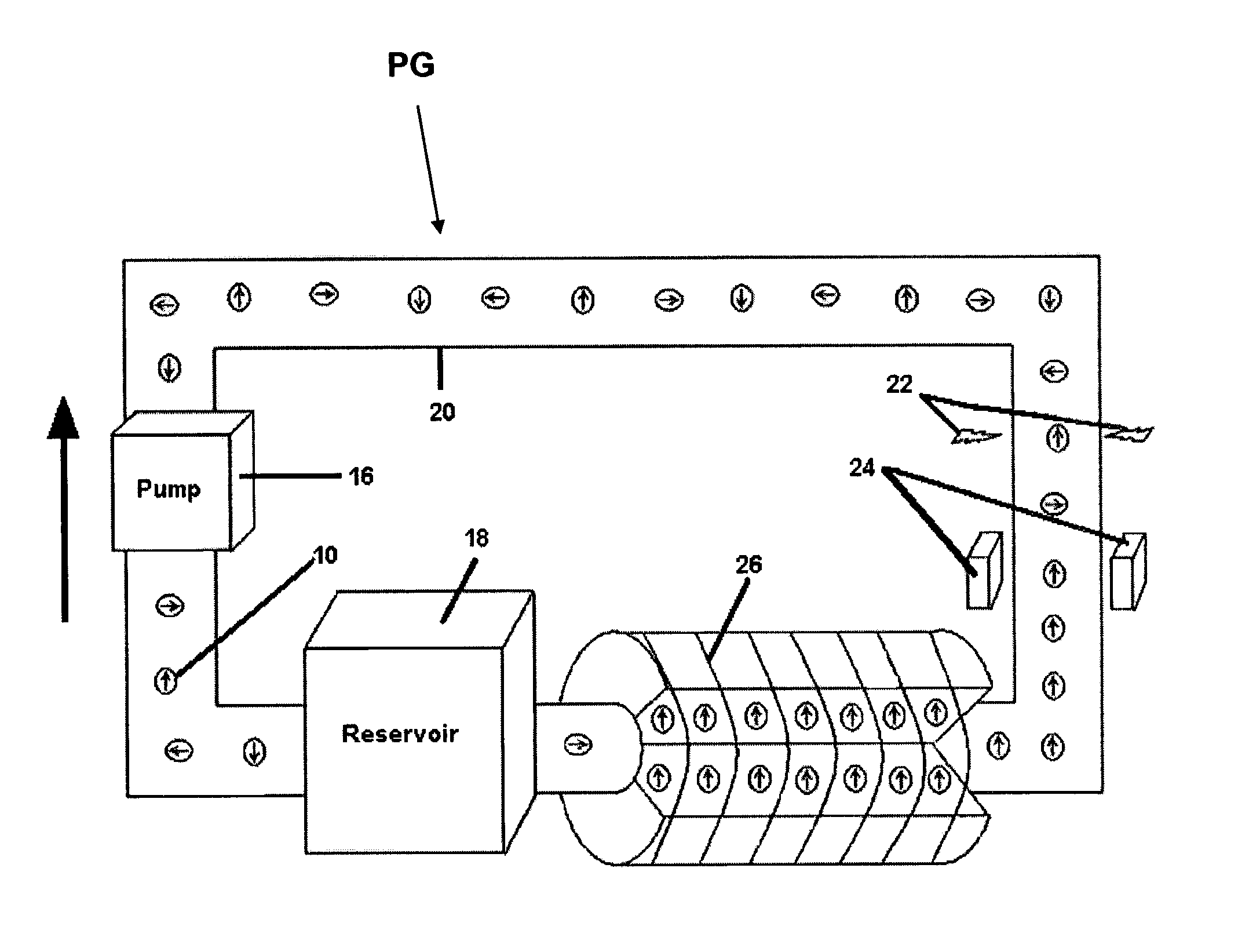

A device for generating power includes a fluid including magnetic particles. A source magnetizes the fluid thereby inducing rotations in the magnetic particles for creating a magnetic flux. The rotations of the magnetic particles induce an electromagnetic force in a coil associated with the fluid.

Owner:MATERIALS MODIFICATION INC

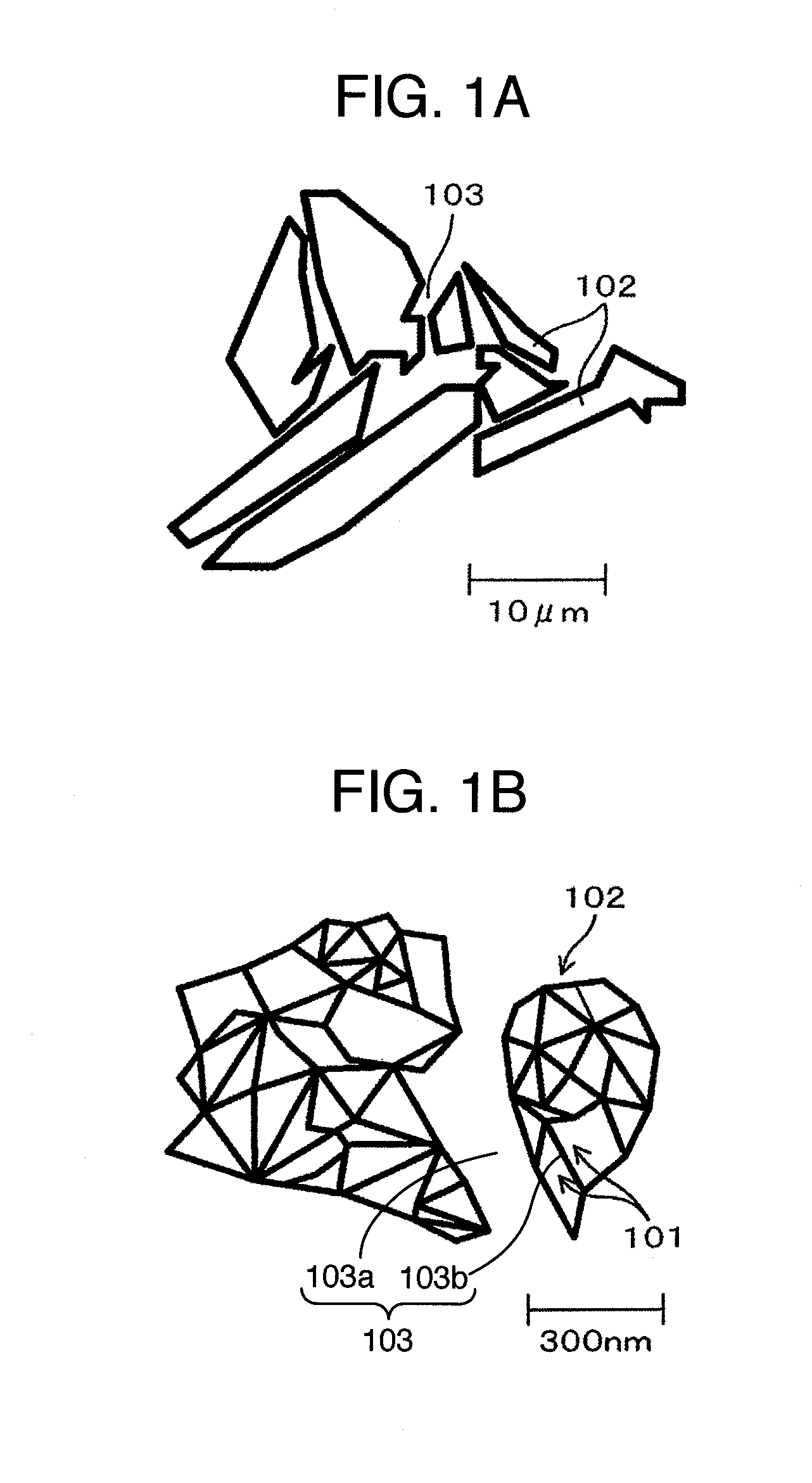

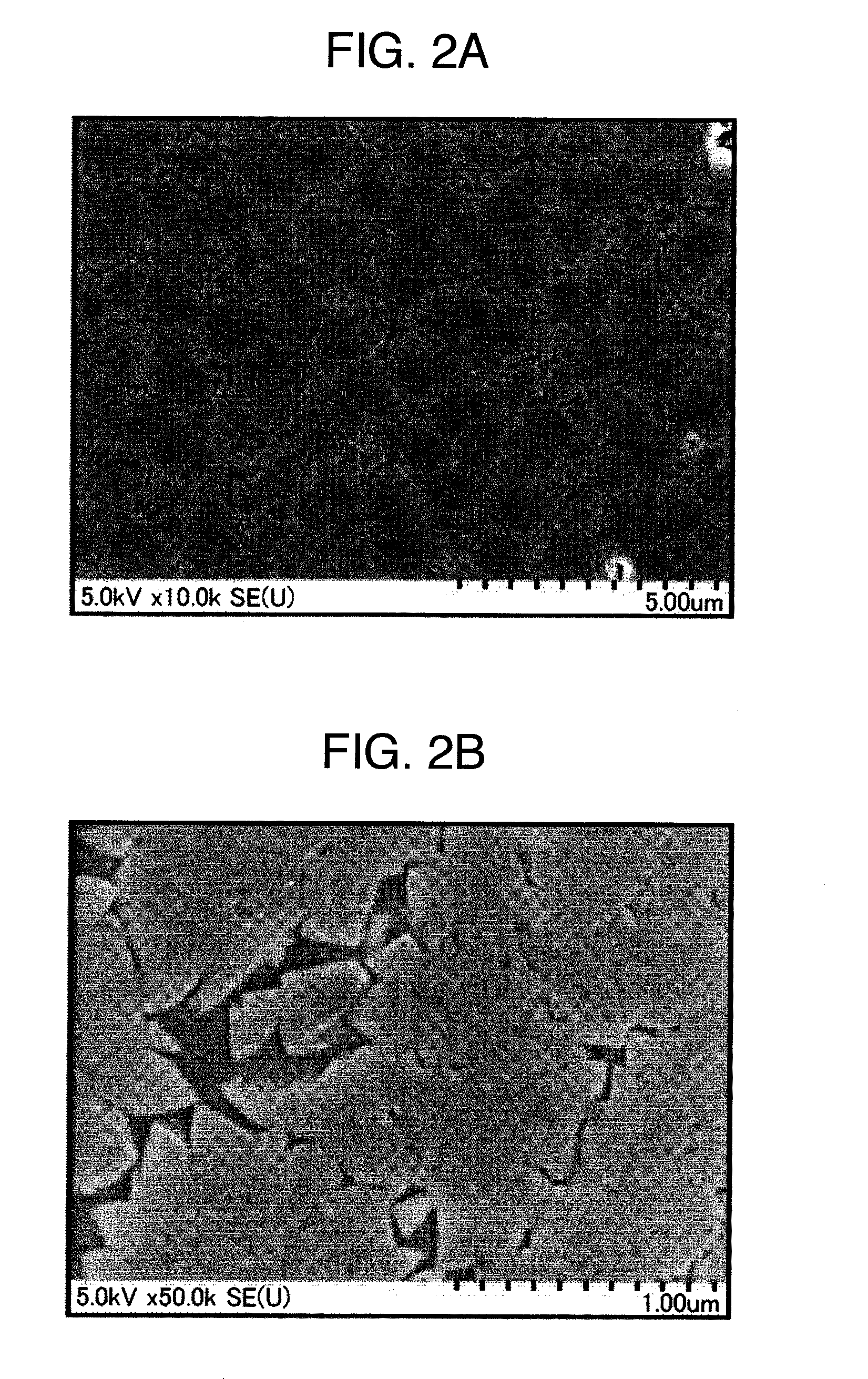

Non-Aqueous Electrolyte Secondary Battery and Method for Producing Negative Electrode Therefor

InactiveUS20080113271A1High energy densityExcellent characteristicCeramic shaping apparatusNon-aqueous electrolyte accumulator electrodesElectrical batteryNon aqueous electrolytes

A non-aqueous electrolyte secondary battery of the present invention includes a pelletized negative electrode. An active material for the negative electrode includes a first phase mainly composed of Si and a second phase containing a silicide of a transition metal. At least one of the first and second phases is amorphous or low-crystalline. The mean particle size (D50) is 0.50 to 20 μm, and the 10% diameter (D10) and 90% diameter (D90) in a volume cumulative particle size distribution are respectively 0.10 to 5.0 μm and 5.0 to 80 μm. The battery is improved in density and current collecting properties of the negative electrode, has a high capacity, and has an excellent cycle life.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

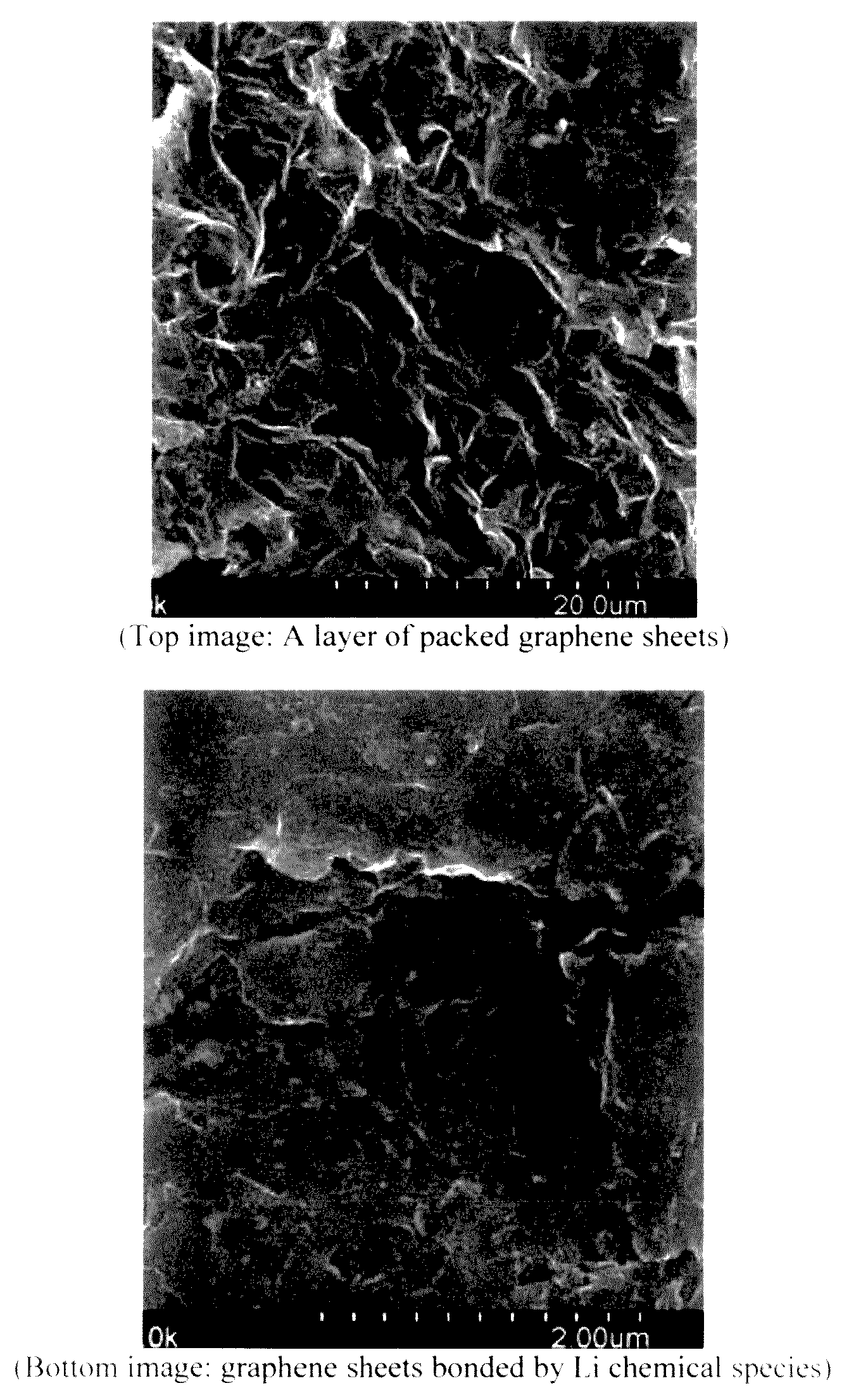

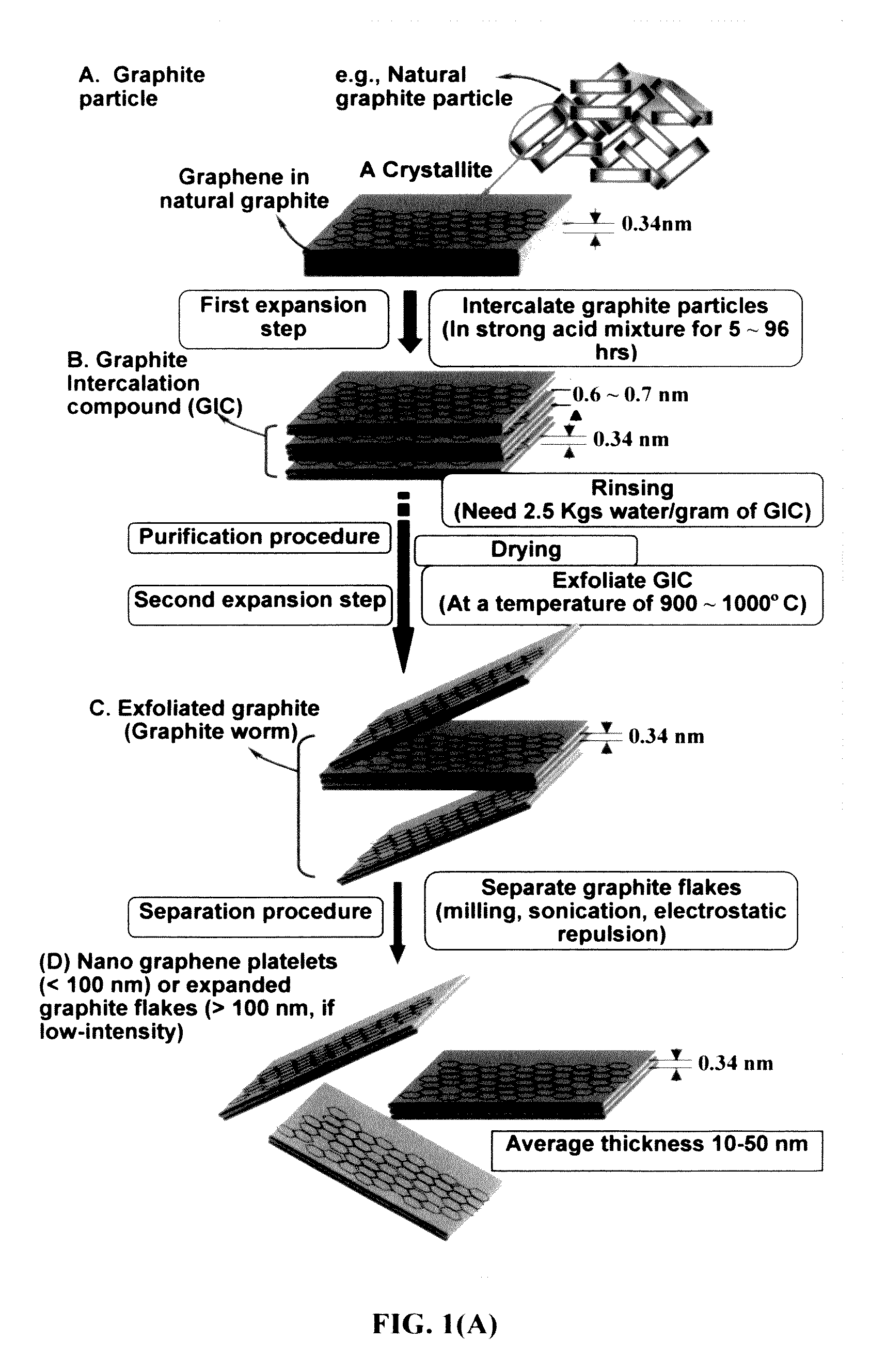

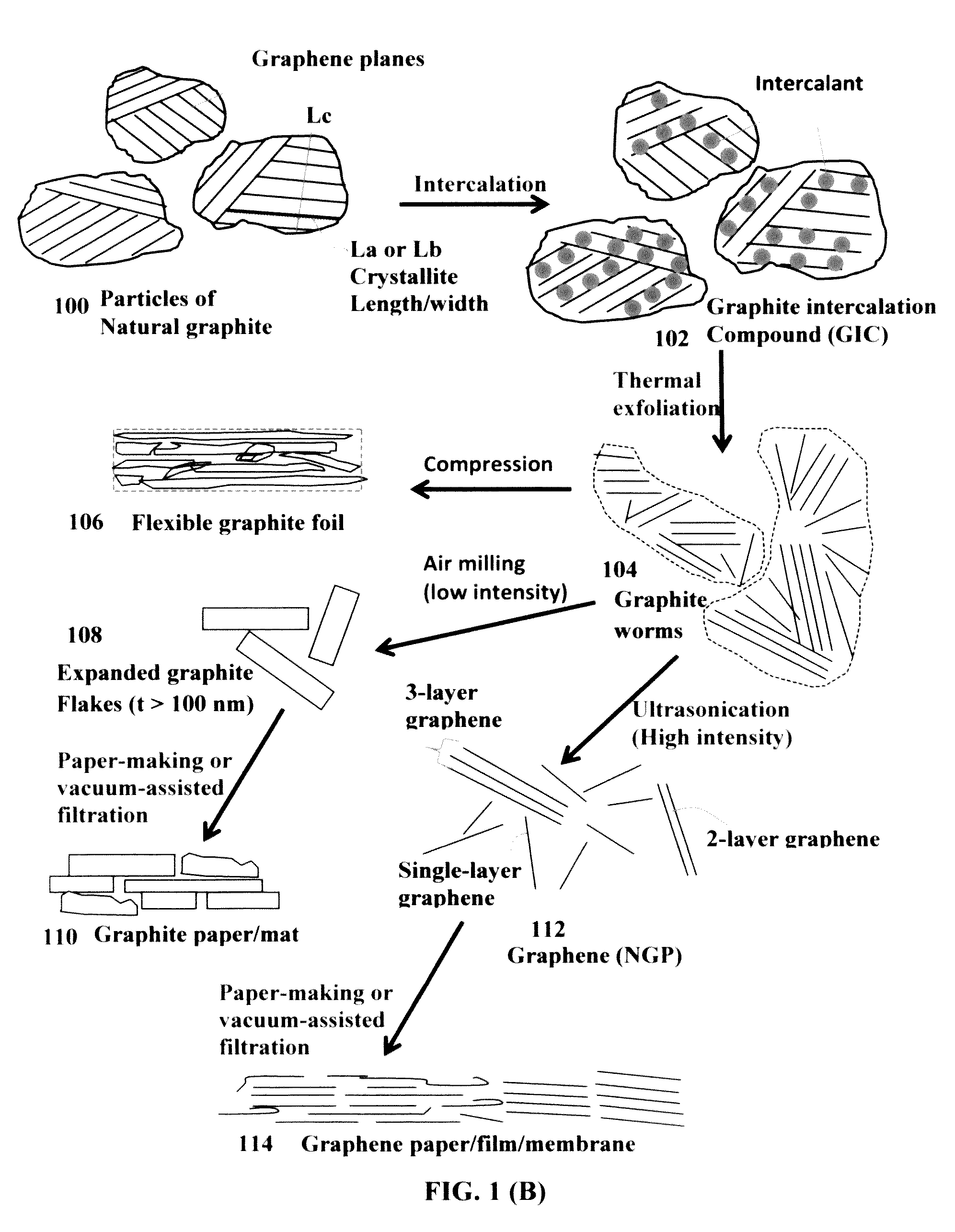

Dendrite-Intercepting layer for alkali metal secondary battery

ActiveUS20160301075A1High energy densityLow material costElectrode manufacturing processesNegative electrodesElectrochemical decompositionLithium

A dendrite penetration-resistant layer for a rechargeable alkali metal battery, comprising multiple graphene sheets or platelets or exfoliated graphite flakes that are chemically bonded by a lithium- or sodium-containing species to form an integral layer that prevents dendrite penetration through the integral layer, wherein the lithium-containing species is selected from Li2CO3, Li2O, Li2C2O4, LiOH, LiX, ROCO2Li, HCOLi, ROLi, (ROCO2Li)2, (CH2OCO2Li)2, Li2S, LixSOy, Na2CO3, Na2O, Na2C2O4, NaOH, NaiX, ROCO2Na, HCONa, RONa, (ROCO2Na)2, (CH2OCO2Na)2, Na2S, NaxSOy, or a combination thereof, wherein X=F, Cl, I, or Br, R=a hydrocarbon group, x=0-1, y=1-4. Also provided is a process for producing a dendrite penetration-resistant layer based on the principle of electrochemical decomposition of an electrolyte in the presence of multiple graphene sheets.

Owner:GLOBAL GRAPHENE GRP INC

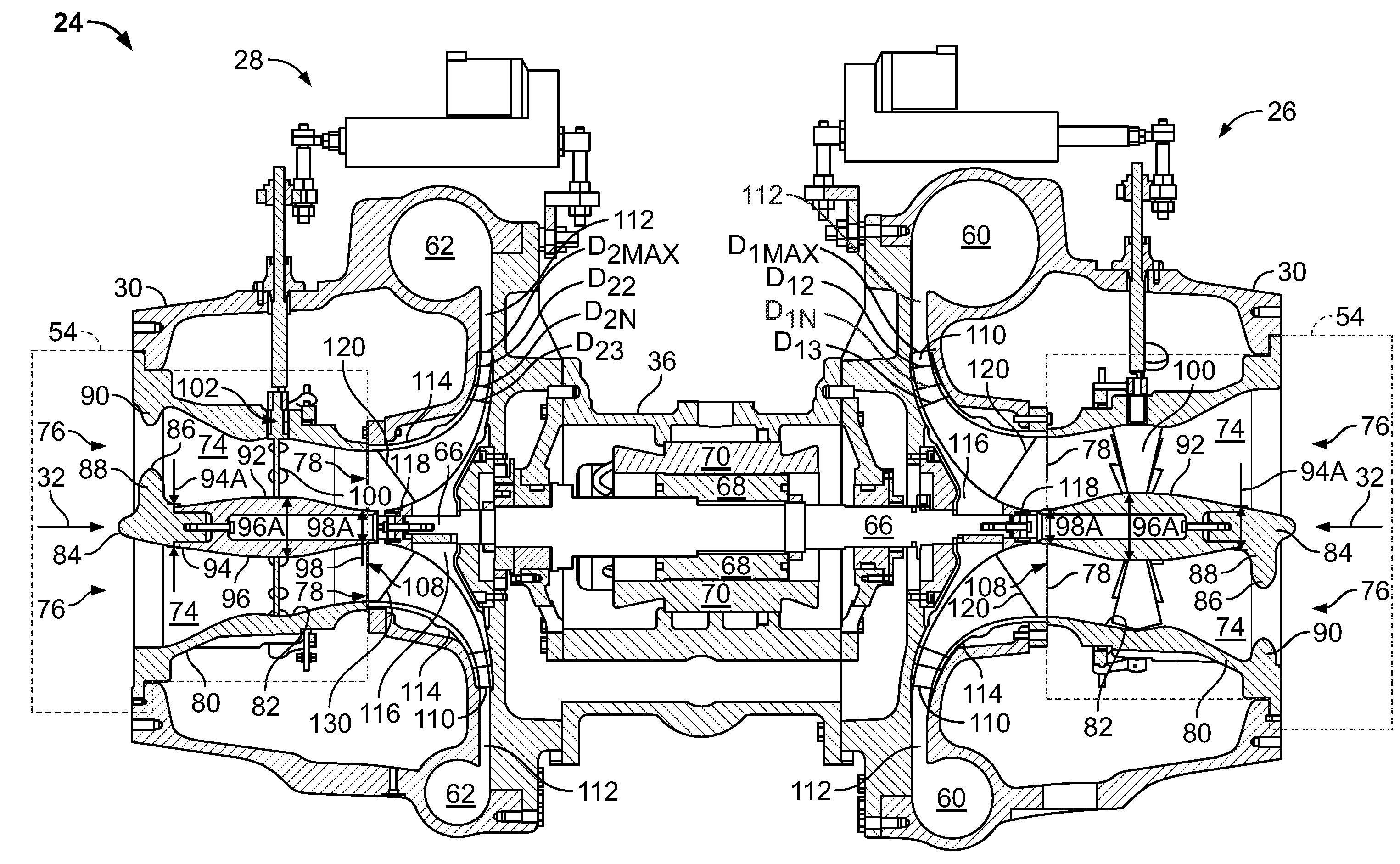

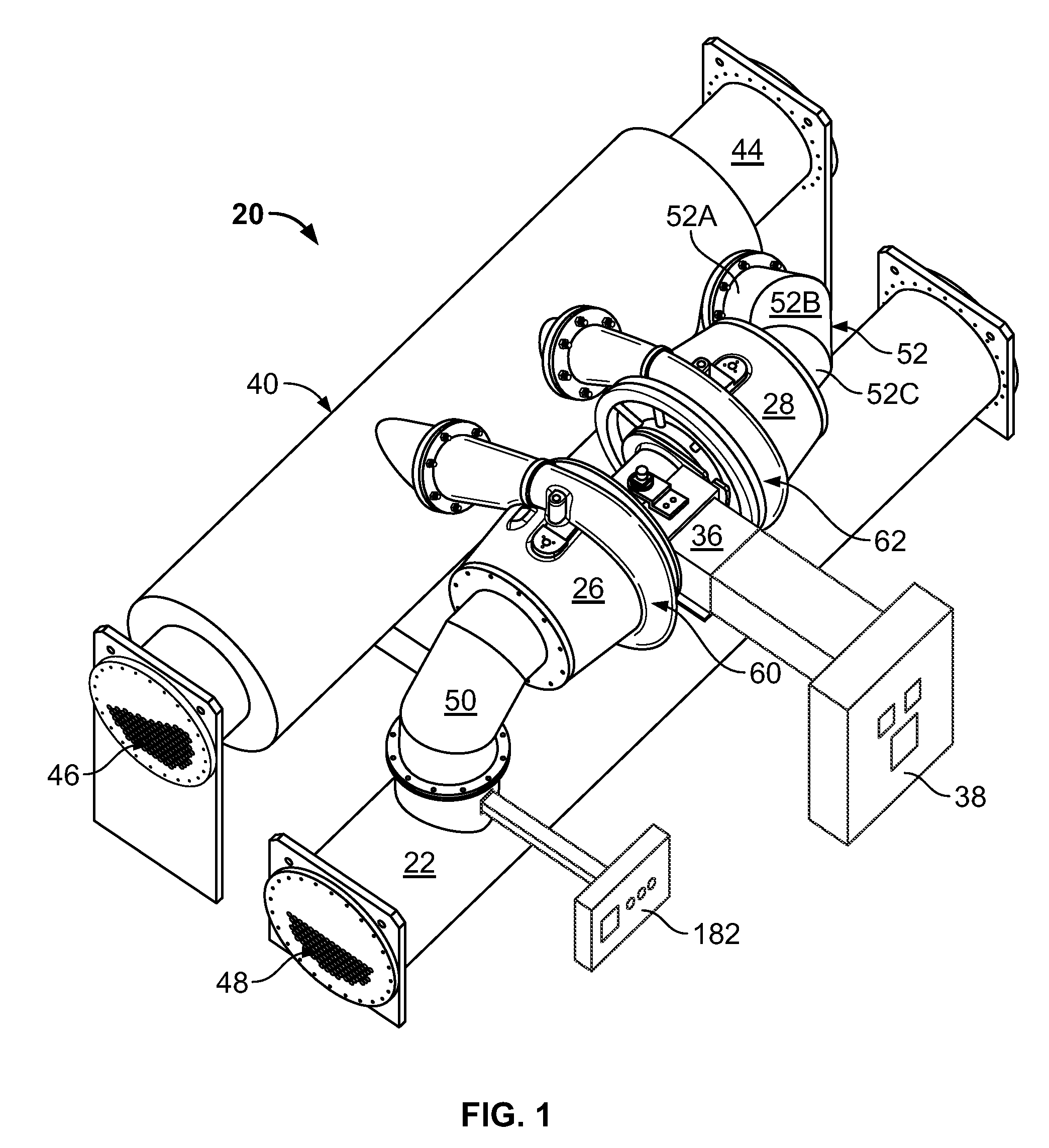

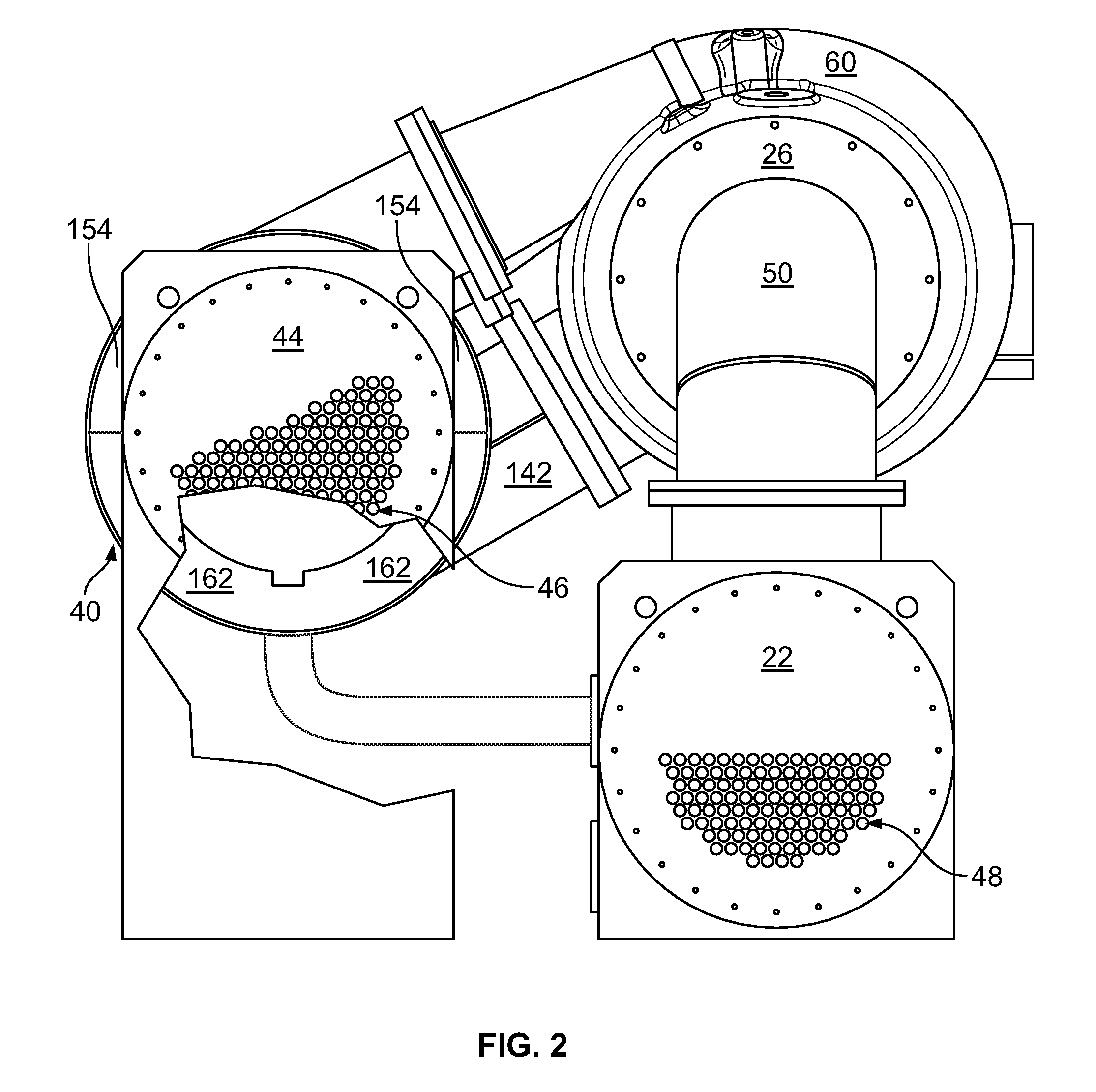

Centrifugal compressor assembly and method

ActiveUS20090205360A1High energy densityImprove performancePump componentsRotary non-positive displacement pumpsConstant angleHigh energy

A centrifugal compressor assembly for compressing refrigerant in a 250-ton capacity or larger chiller system comprising a motor, preferably a compact, high energy density motor or permanent magnet motor, for driving a shaft at a range of sustained operating speeds under the control of a variable speed drive. Another embodiment of the centrifugal compressor assembly comprises a mixed flow impeller and a vaneless diffuser sized such that a final stage compressor operates with an optimal specific speed range for targeted combinations of head and capacity, while a non-final stage compressor operates above the optimum specific speed of the final stage compressor. Another embodiment of the centrifugal compressor assembly comprises an integrated inlet flow conditioning assembly comprising a flow conditioning nose, a plurality of inlet guide vanes and a flow conditioning body that positions inlet guide vanes to condition flow of refrigerant into an impeller to achieve a target approximately constant angle swirl distribution with minimal guide vane turning.

Owner:TRANE INT INC

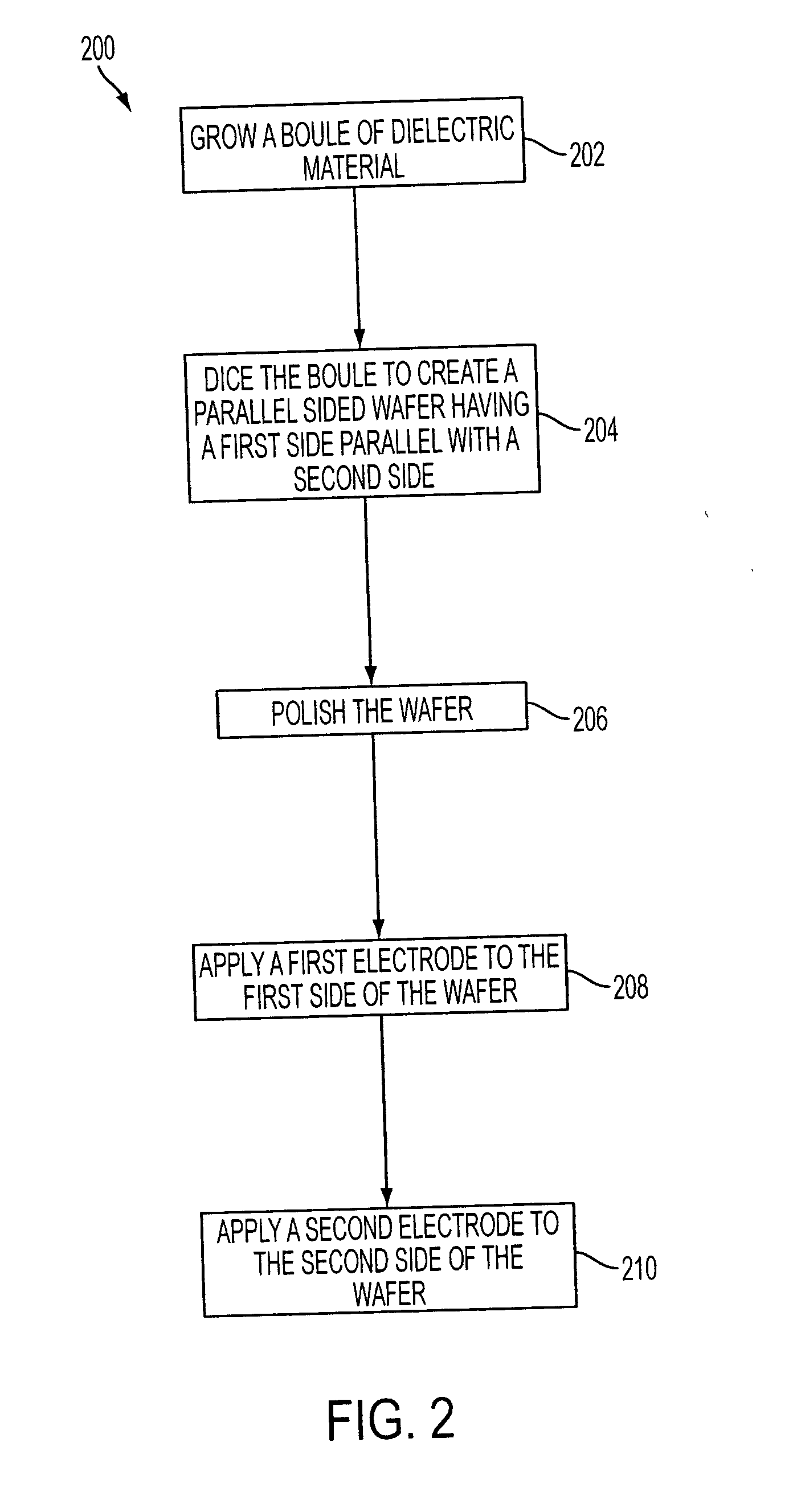

Small volume thin film and high energy density crystal capacitors

InactiveUS20070121274A1High energy densitySmall and lightMultiple fixed capacitorsThin/thick film capacitorParallel plateHigh energy

Embodiments of the invention provide parallel plate capacitors comprising a bulk single crystal or single crystal film dielectric material disposed between the parallel plates and capacitors comprising one or more bulk single crystal or single crystal film dielectrics each disposed between two electrodes. Energy storage devices incorporating these capacitors also are disclosed.

Owner:NORTHROP GRUMMAN SYST CORP

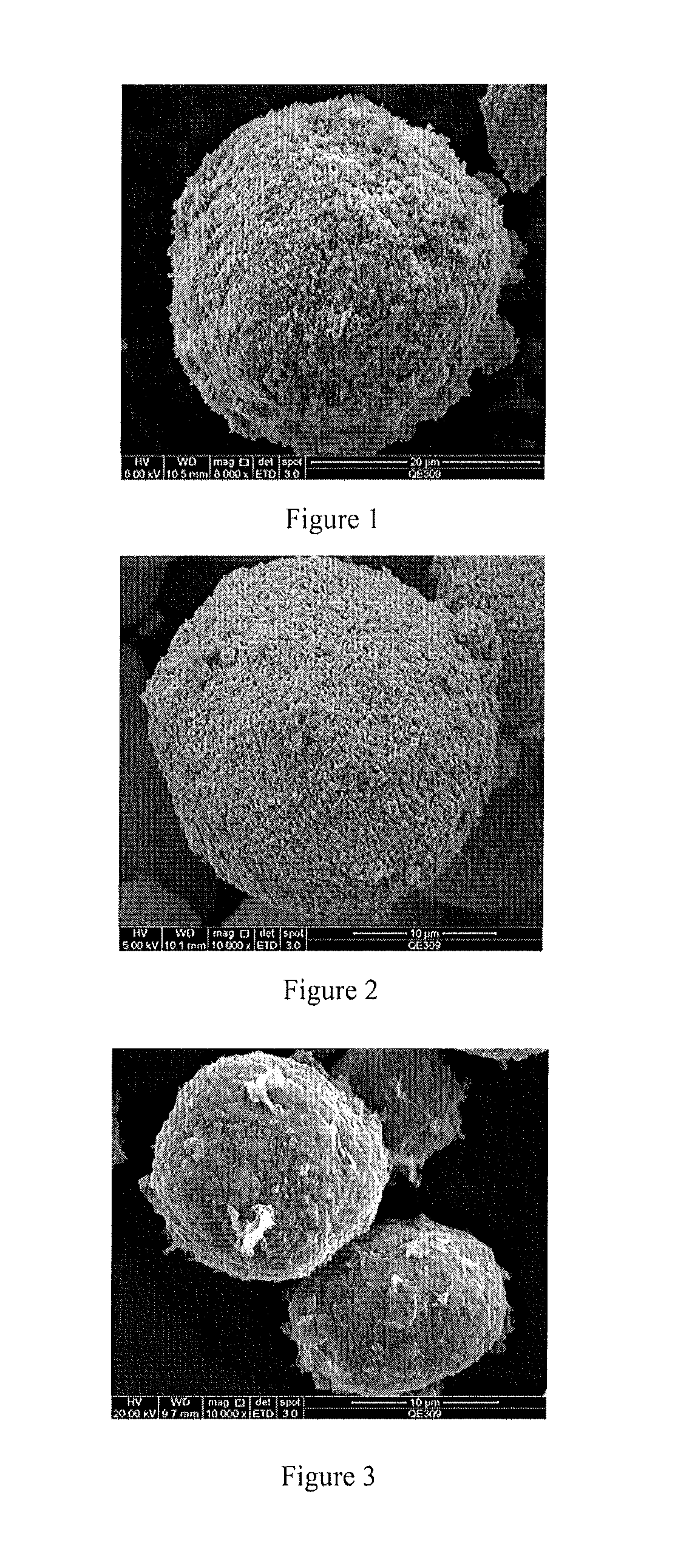

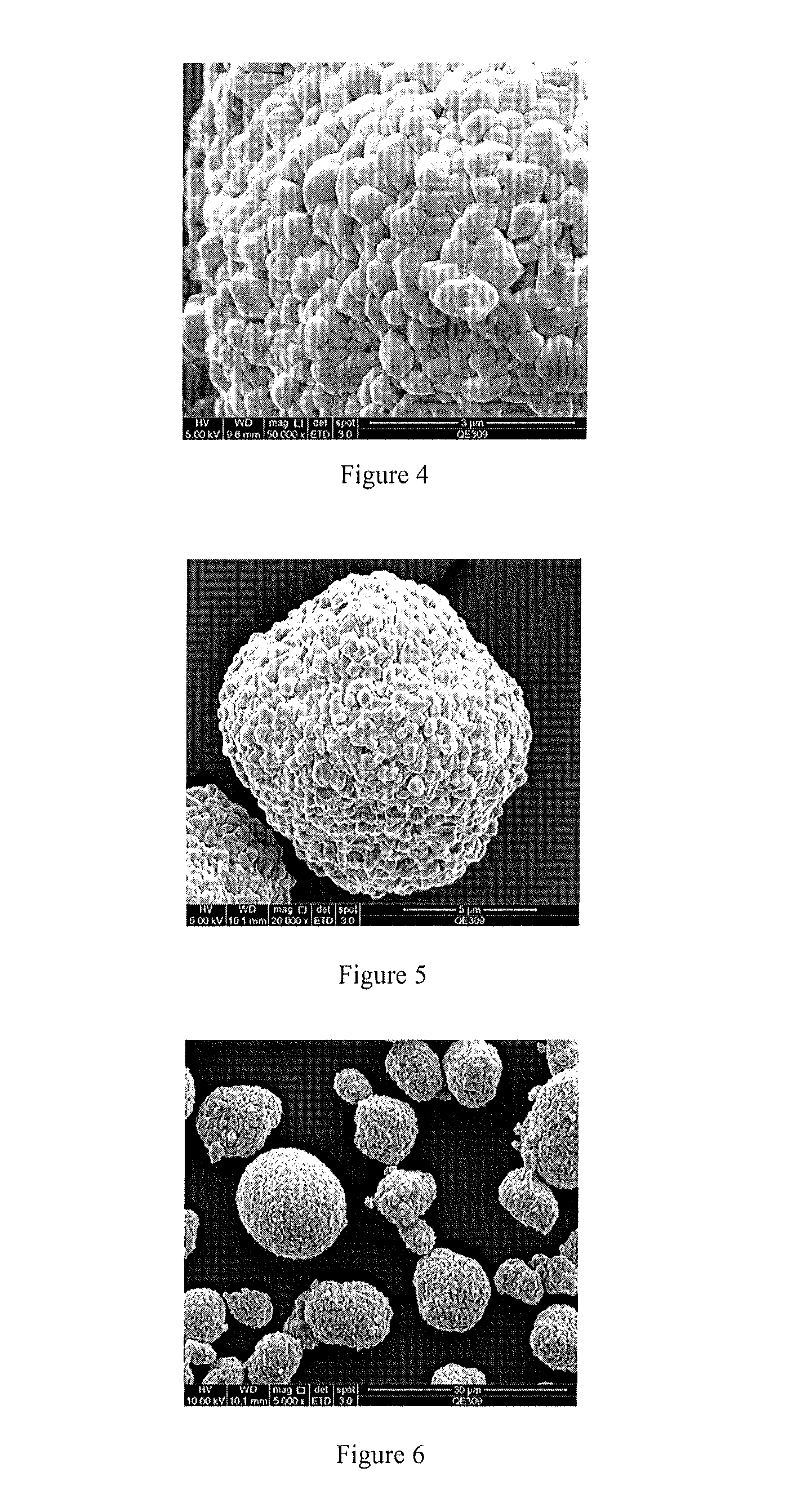

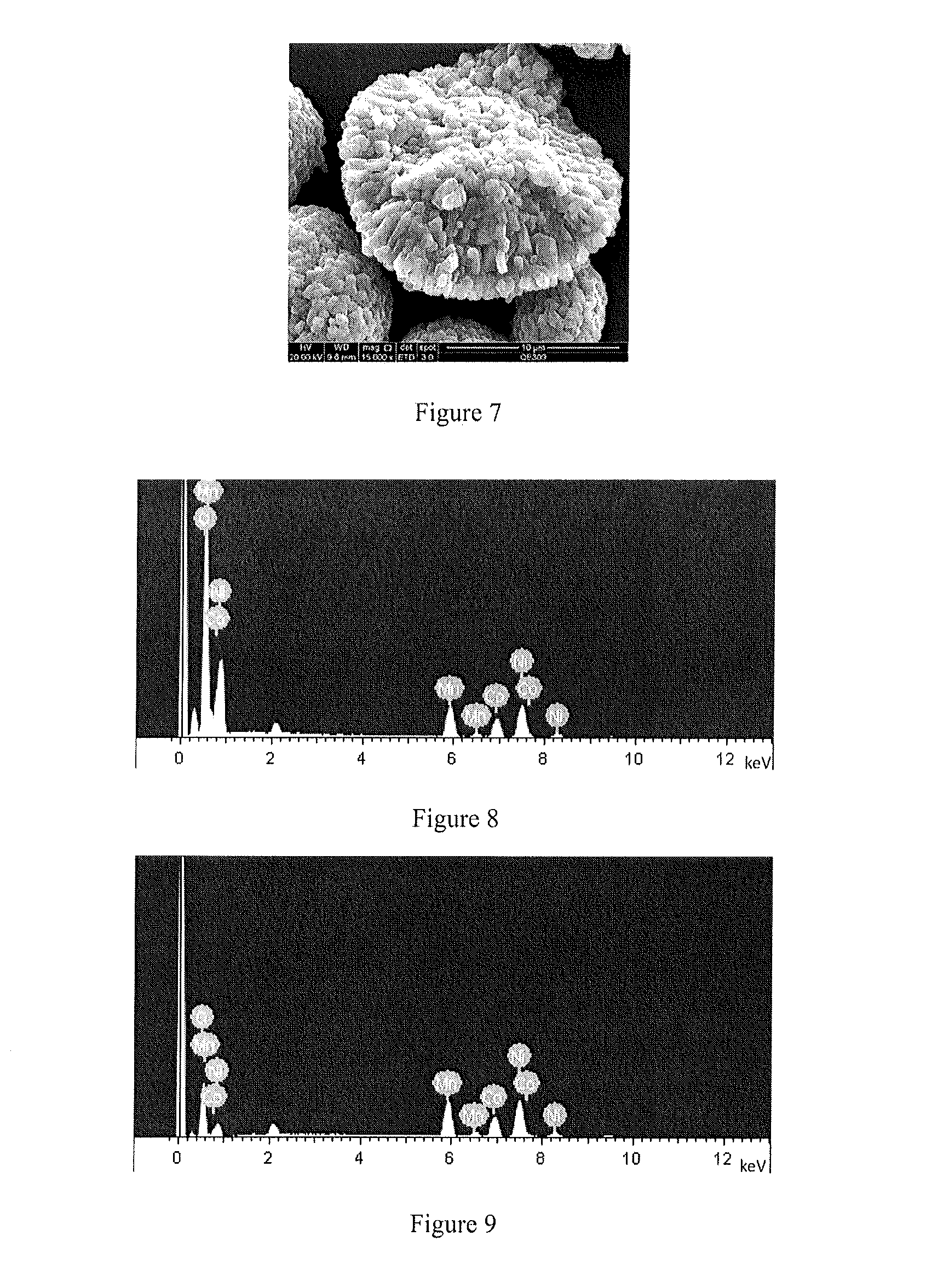

Oxide cathode material for lithium ion battery having high energy density and preparation process thereof

InactiveUS20150104708A1High energy densityUniform shellSecondary cellsPositive electrodesHigh energyEnergy density

Provided are a high energy density oxide anode material for lithium ion battery, preparation process and use thereof. Said anode material includes a main part of the anode material and a covering layer. Said main part includes a shell and a core inside the shell. The material of said core is Li1+x[Ni1−y−zCoyMnz]O2 wherein −0.1≦x≦0.2, 0≦y≦0.5, 0≦z≦0.5 and 0≦y+z≦0.7. The material of said shell is Li1+a[Co1−bXb]O2, wherein −0.1≦a≦0.2, 0≦b≦0.5, and X is selected from Al, Mg, Cu, Zr, Ti, Cr, V, Fe, Mn, Ni, or combination thereof. Otherwise, The material of said main part is a mixture of Li1+x[Ni1−y−zCoyMnz]O2 and LiCoO2, wherein −0.1≦x≦0.2, 0≦y≦0.5, 0<z≦0.5 and 0≦y+z≦0.7. The material of said covering layer is selected from Al2O3, ZrO2, MgO, SiO2, ZnO2, TiO2, Y2O3, LiAlO2, or combination thereof. Said anode material has the advantages of high capacity, good cycle performance, low surface activity, high voltage resistance and fine safety. The preparation process is simple, and is suitable for large-scale production.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +1

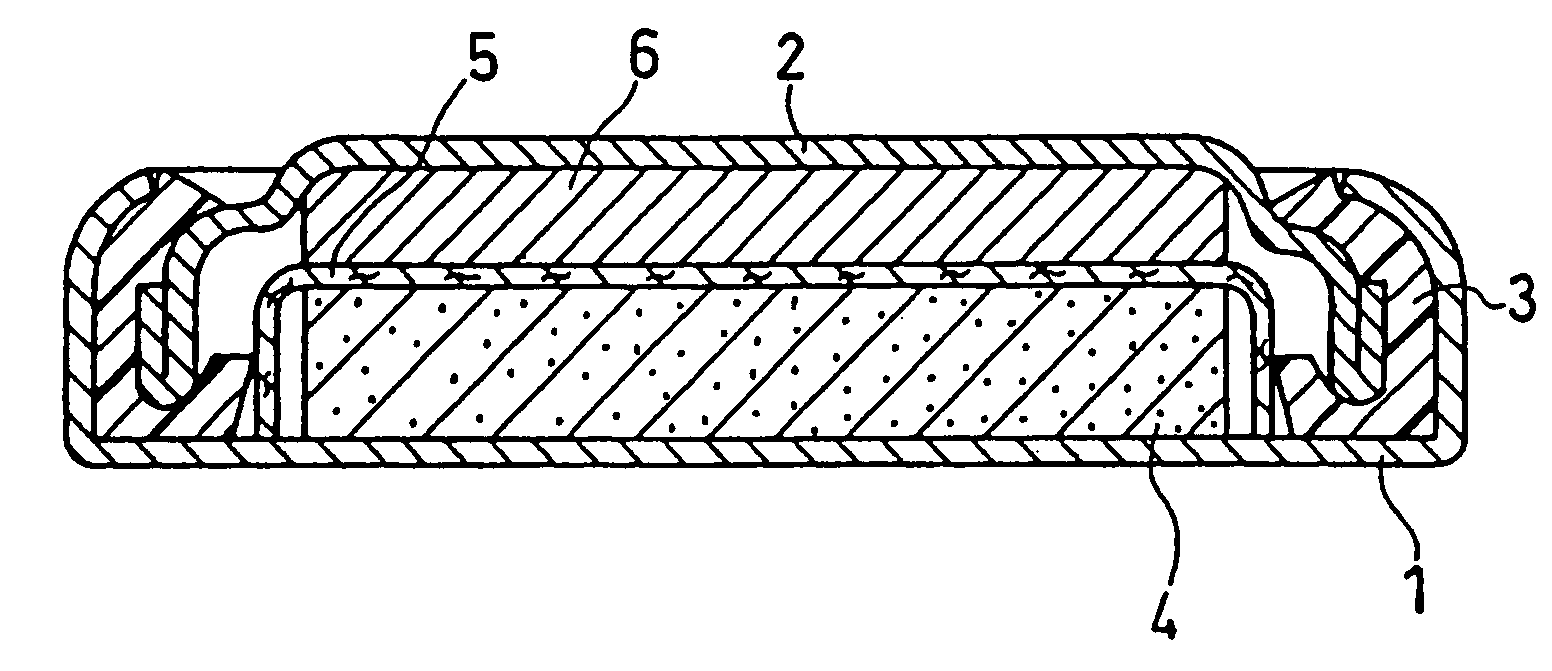

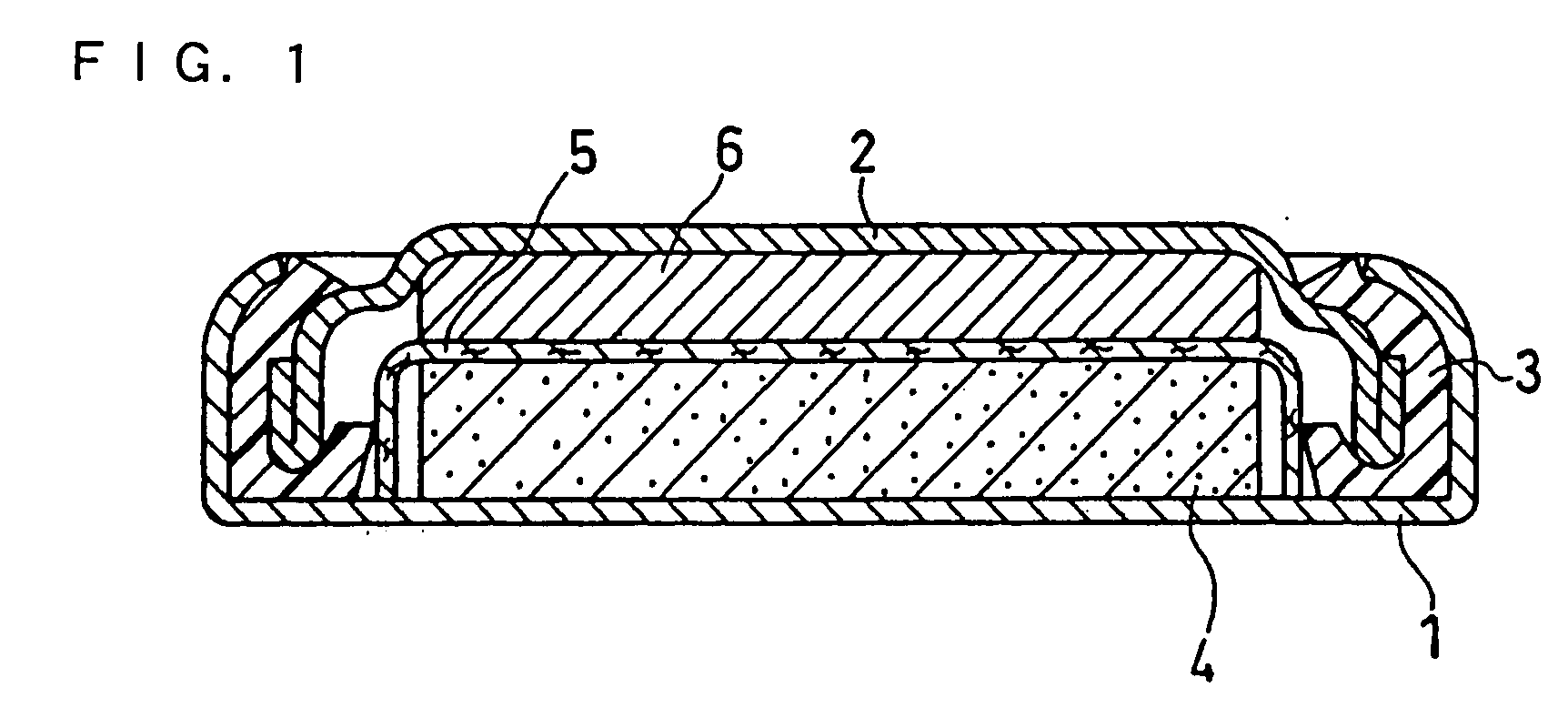

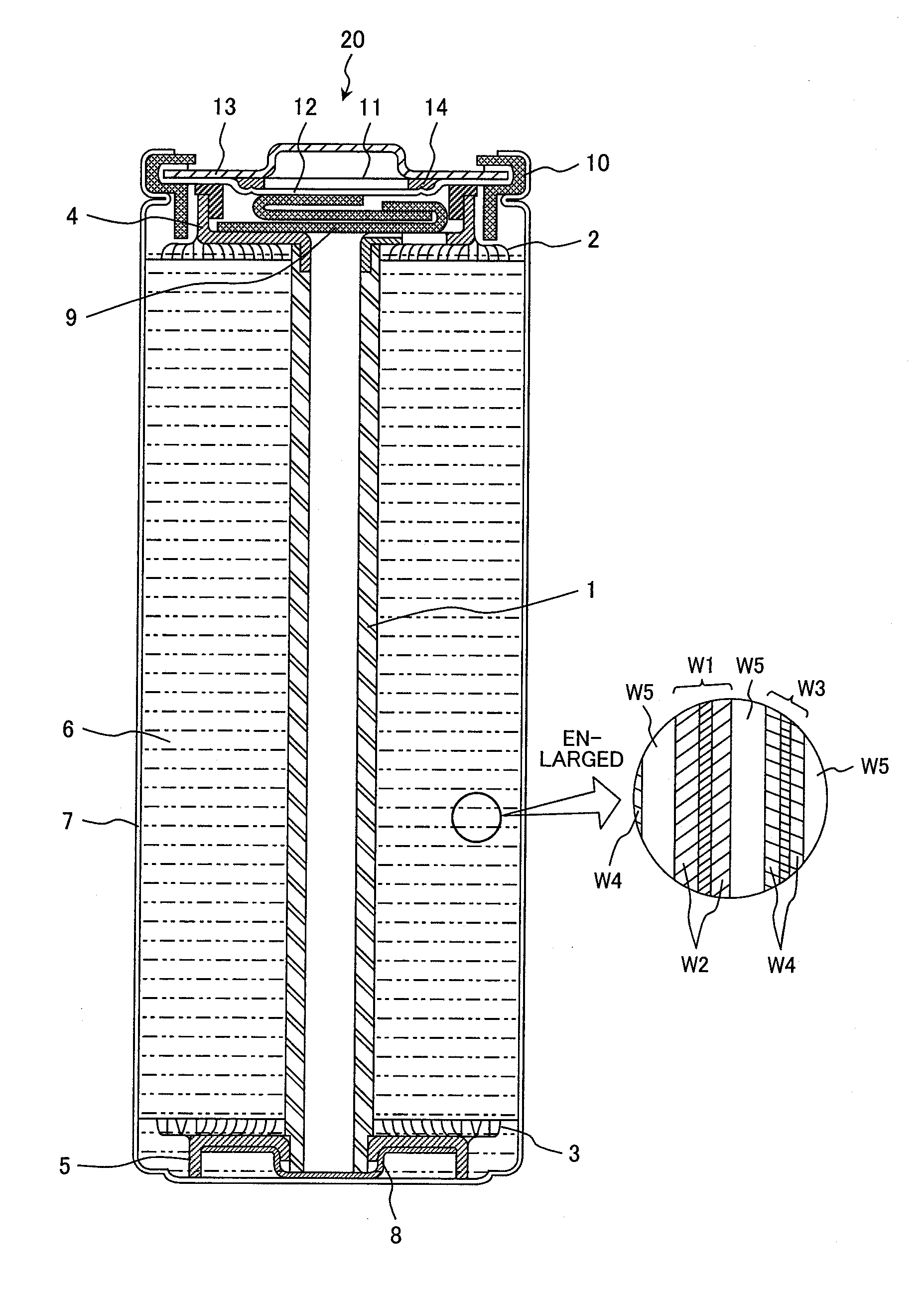

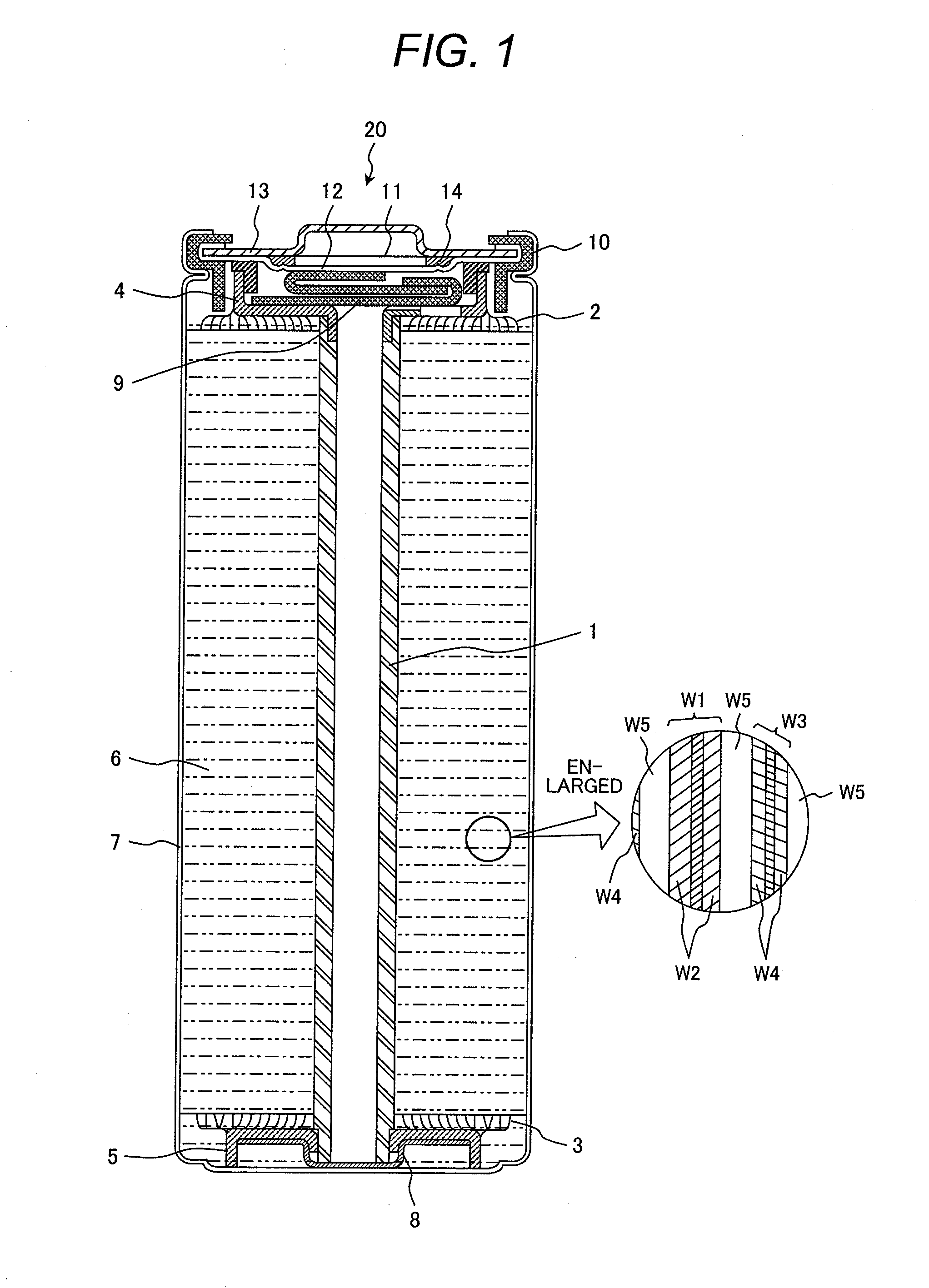

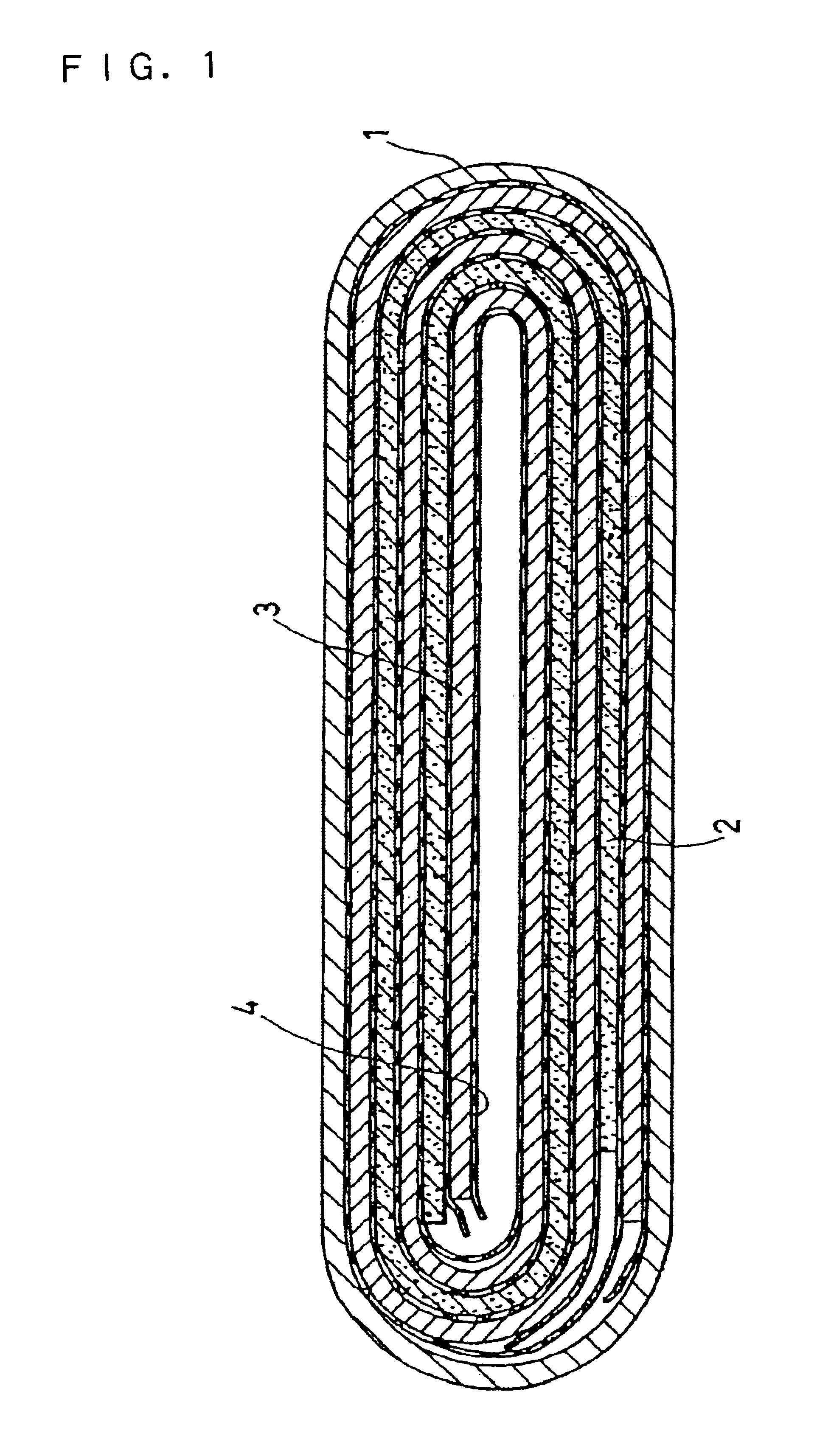

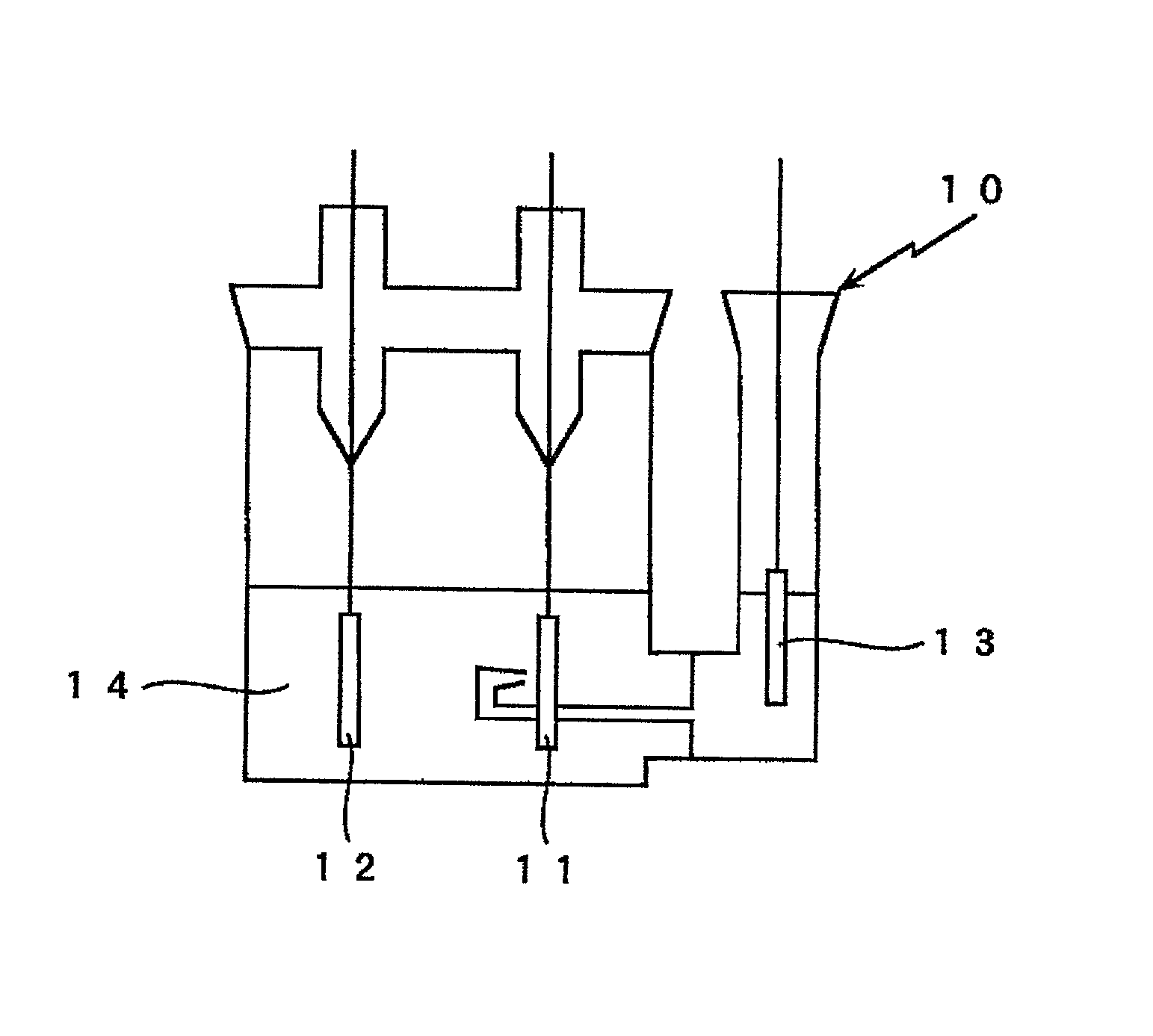

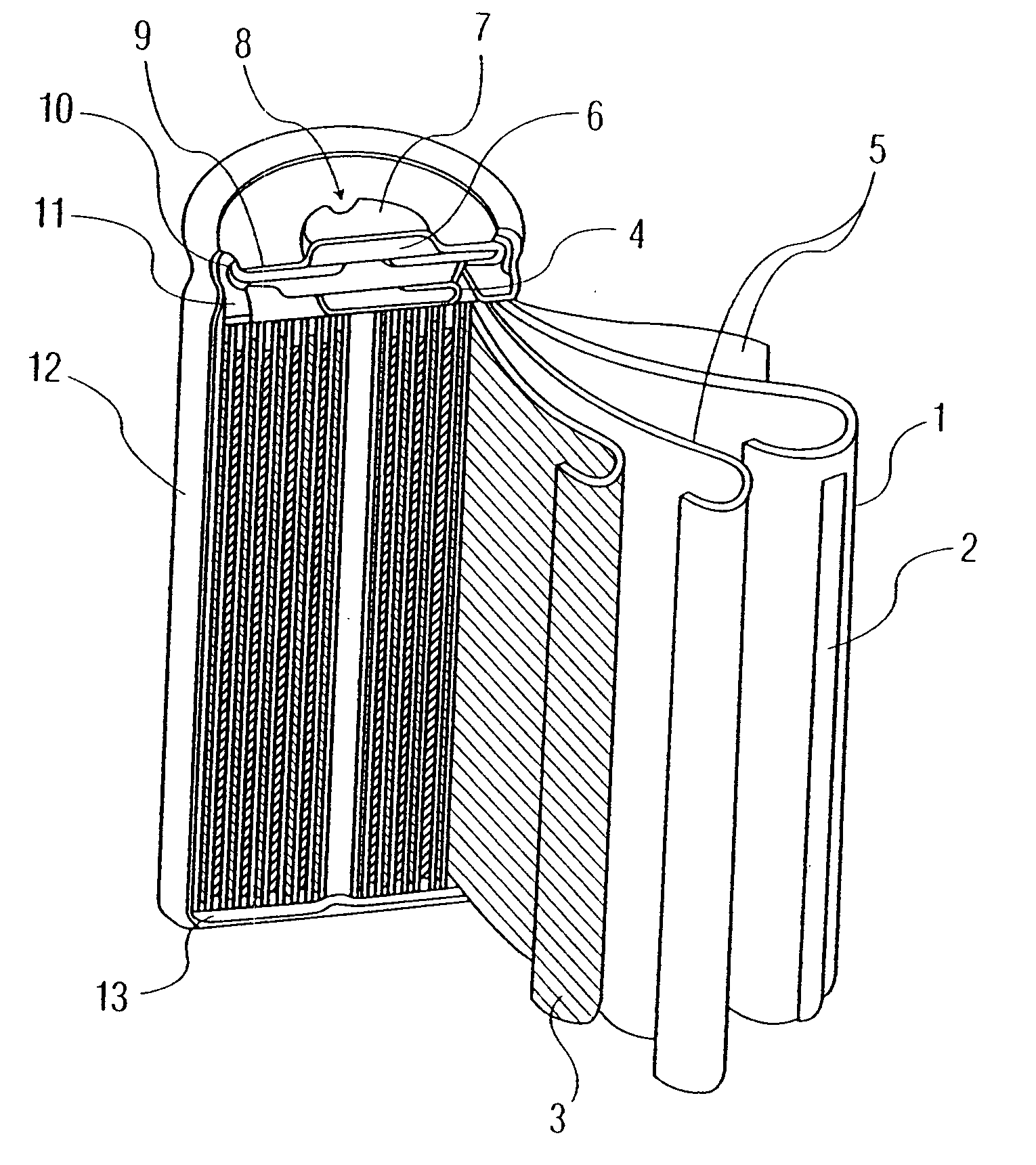

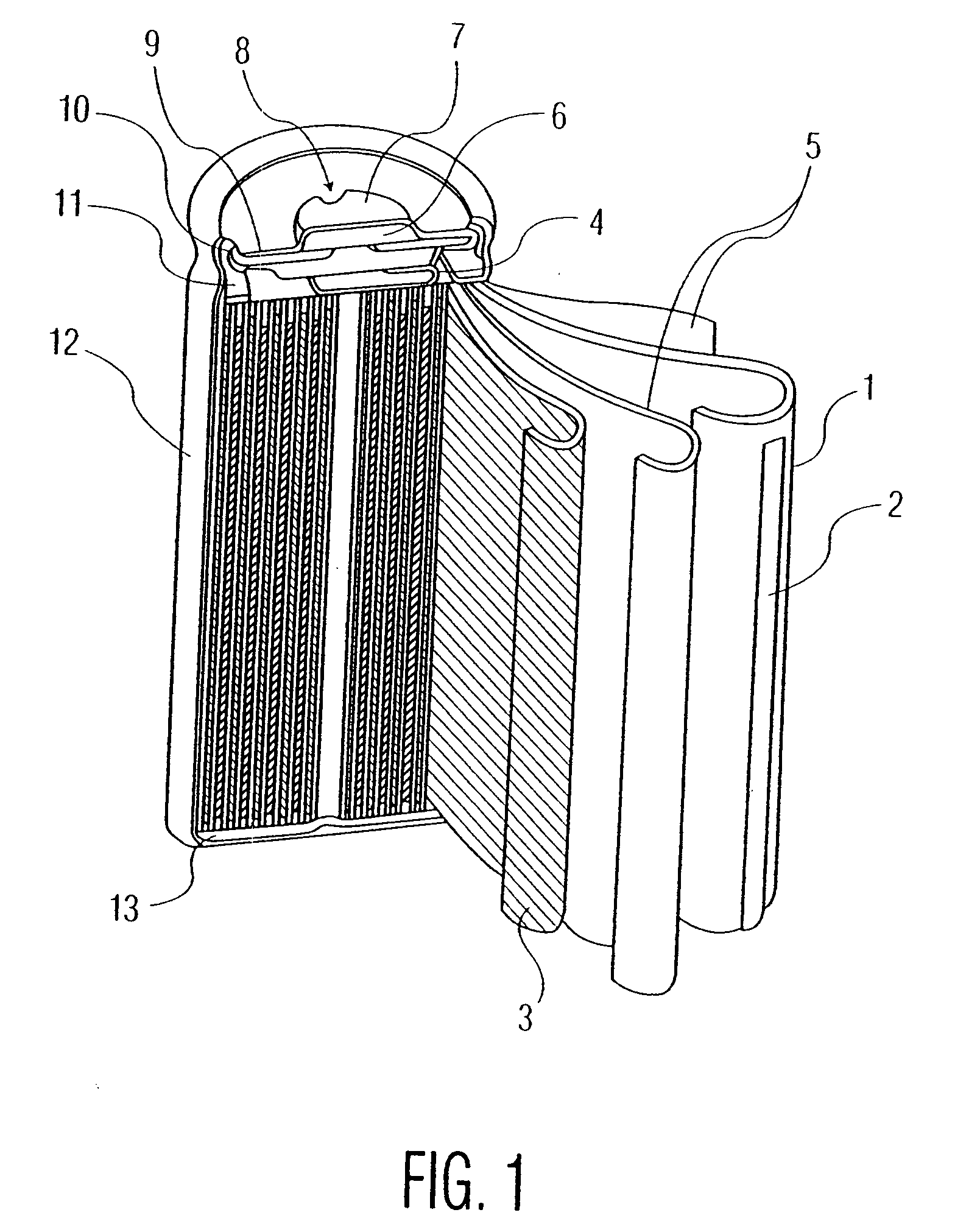

Nonaqueous electrolyte secondary battery

InactiveUS20120009452A1High energy densityIncrease resistanceSecondary cellsNon-aqueous electrolyte accumulator electrodesCopper foilEnergy density

Disclosed is a nonaqueous electrolyte secondary battery wherein the energy density is improved by increasing the range of depth of discharge to be used. Specifically disclosed is a lithium ion secondary battery 20 wherein an electrode group 6 is contained within a battery case 7. The electrode group 6 is formed by winding a positive electrode plate W1 and a negative electrode plate W3 with a separator W5 interposed therebetween. The positive electrode plate W1 has positive-electrode mixture layers W2 which are formed on both surfaces of an aluminum foil and contain a positive-electrode active material. The positive-electrode active material contains lithium iron phosphate as a principal component. The negative electrode plate W3 has negative-electrode mixture layers W4 which are formed on both surfaces of a rolled copper foil and contain a negative-electrode active material. The negative-electrode active material contains a mixture of a graphite material as a principal component and an amorphous carbon material as a secondary component. The positive electrode plate W1 has a positive-electrode initial charge / discharge efficiency of e1, the negative electrode plate W3 has a negative-electrode initial charge / discharge efficiency of e2, and e1 and e2 satisfy the relation of formula e2=e1−x (10≦x≦20). This avoids usage of the high resistance region of the positive electrode plate W1.

Owner:HITACHI AUTOMOTIVE SYST LTD

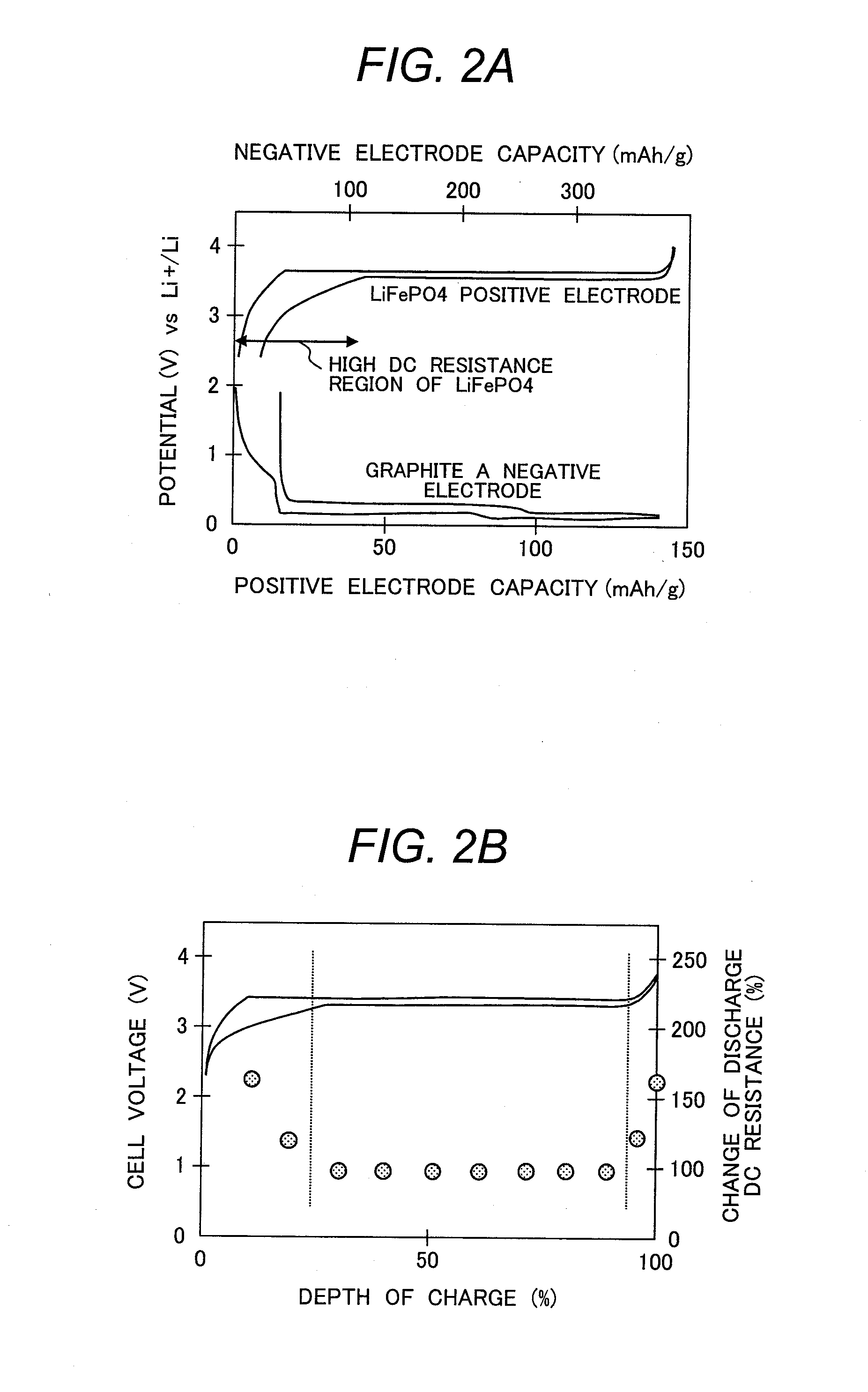

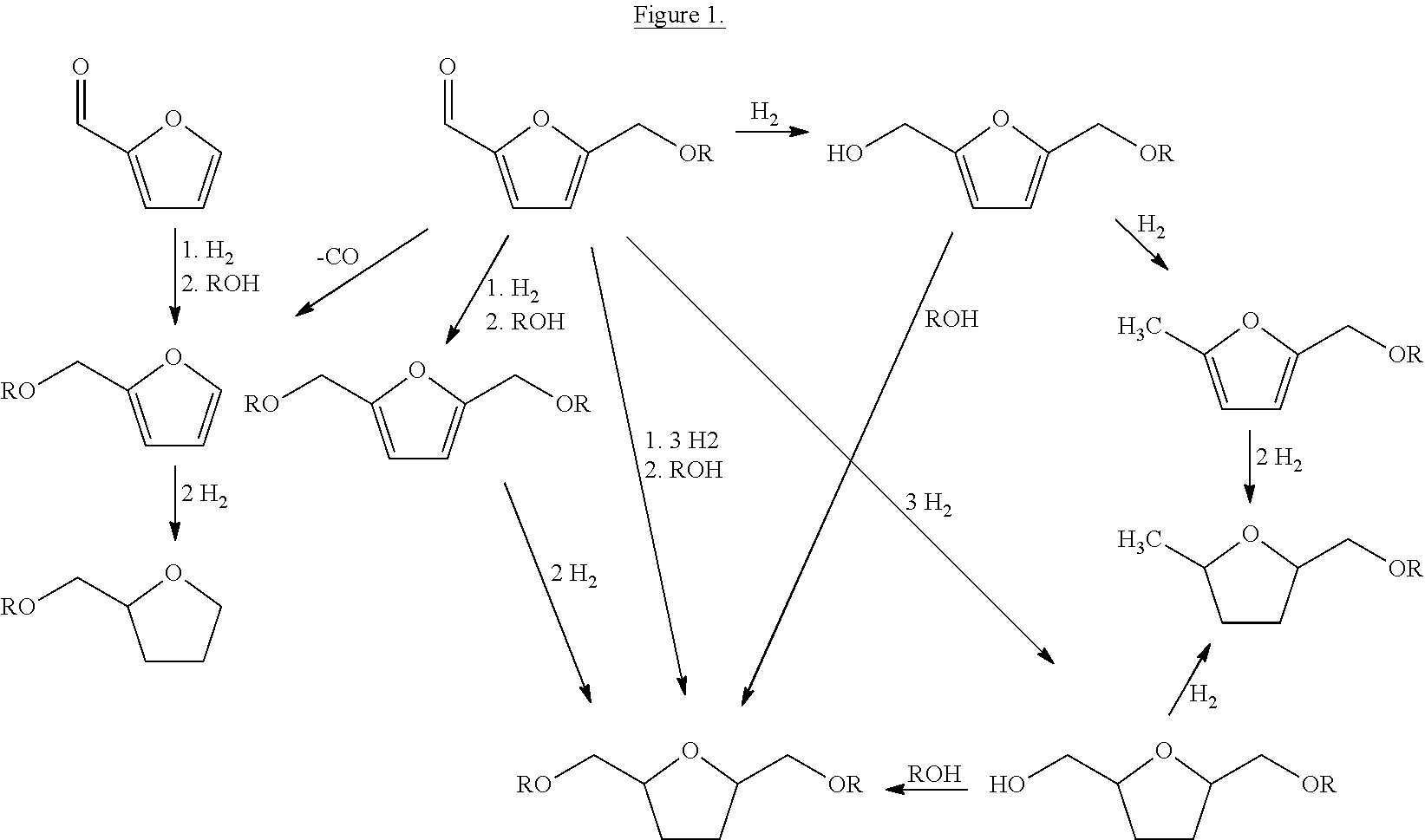

Fuel composition

InactiveUS20110107659A1High in unsaturationHigh energy densityOrganic chemistryEfficient propulsion technologiesFuranEther

The invention provides a fuel composition comprising a ring-hydrogenated alkyl furfuryl ether of the general formula (I): (I) R″-TF-CH2-O—R wherein TF represents a 2,5-disubstituted tetrahydrofuran ring, wherein each R independently represents a hydrocarbyl group having from 1 to 20 carbon atoms and wherein each R″ independently represents a methyl group, a hydroxymethyl group, the product of an aldol condensation reaction or an alkoxymethyl group of the general formula (II): (II) —CH2-O—R′ wherein each R′ independently represents a hydrocarbyl group having from 1 to 20 carbon atoms. The invention also provides novel and useful ring-hydrogenated alkoxymethyltetrahydrofuran ethers of the general formula (I) above. Moreover, these ring-hydrogenated alkoxymethyltetrahydrofuran ethers disclosed herein have never been used as fuel component, and therefore the use of these ethers has also been claimed as an invention. A further embodiment of the current invention is the process for preparing these components. Finally, the use of a 5-(alkoxymethyl)furfural, and / or a 2,5-bis(alkoxymethyl)furan as hydrogen storage molecules, in particular for fuel purposes is claimed as a further embodiment of the current invention.

Owner:FURANIX TECH BV

Composite electrode for lithium ion capacitor

ActiveUS20140293507A1High energy densityHigh power densityHybrid capacitor electrodesElectrolytic capacitor manufactureActivated carbonActive carbon

A lithium-ion capacitor includes a cathode, an anode, and a porous separator positioned between the cathode and the anode. The cathode is formed using activated carbon, and the anode is formed from a composite material that includes lithium titanium oxide and a carbon material such as hard carbon or graphite.

Owner:CORNING INC

Positive electrode active material for secondary battery and magnesium secondary battery using the same

InactiveUS20120164537A1High cycle retention rateHigh energy densityNon-aqueous electrolyte accumulatorsPositive electrodesCobalt oxideManganese oxide

In a positive electrode active material for a magnesium secondary battery and a magnesium secondary battery using it, there is contained a powder particle containing a crystal phase having a structure formed with aggregation of a plurality of crystallites, and amorphous phases formed between the crystallites themselves; the amorphous phases contain at least one kind of a metal oxide selected from a vanadium oxide, an iron oxide, a manganese oxide, a nickel oxide and a cobalt oxide; and the crystal phase and the amorphous phases use the positive electrode active material enabling to store and release magnesium ions.

Owner:HITACHI LTD

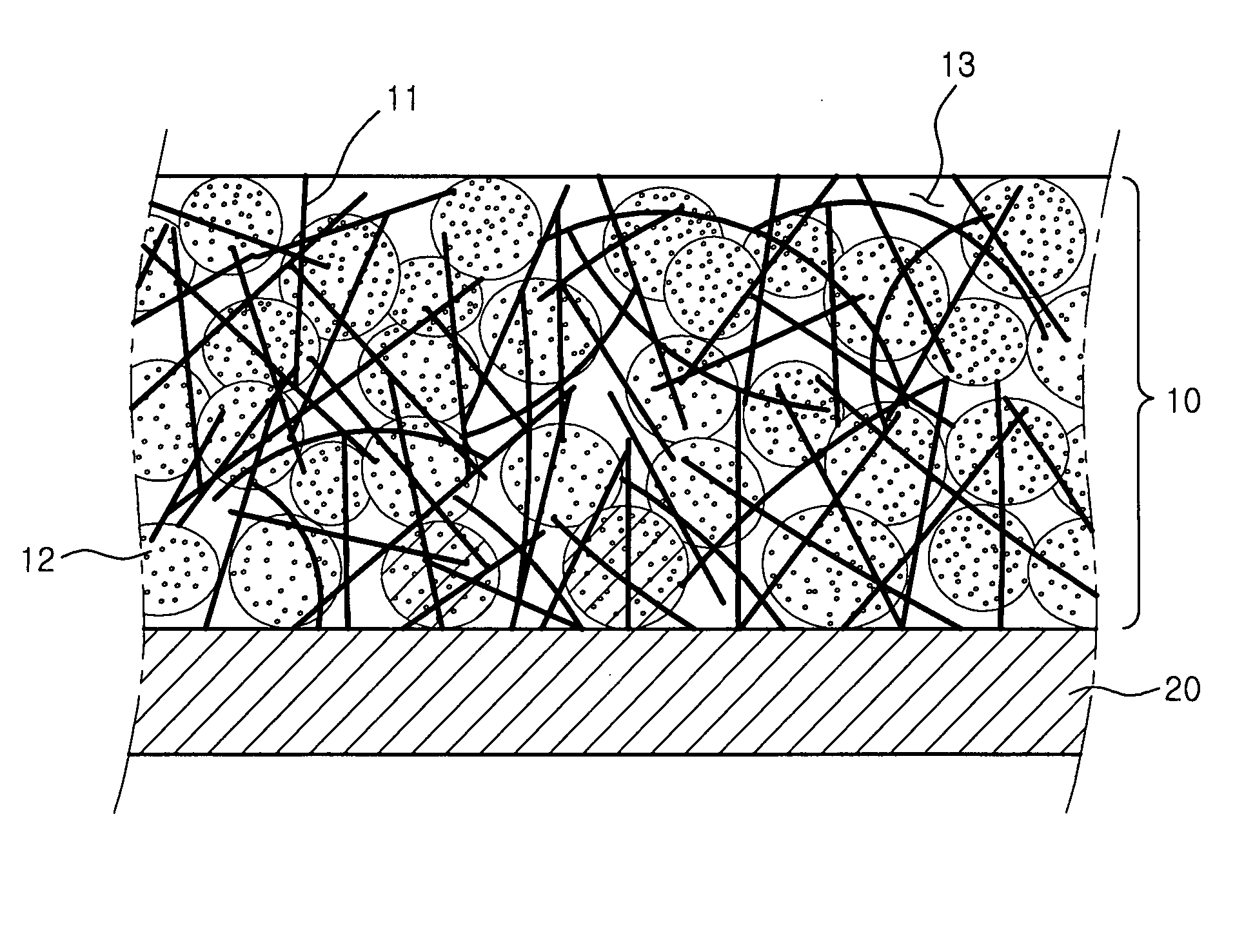

Polarizable electrode for capacitor and electric double layer capacitor having the same

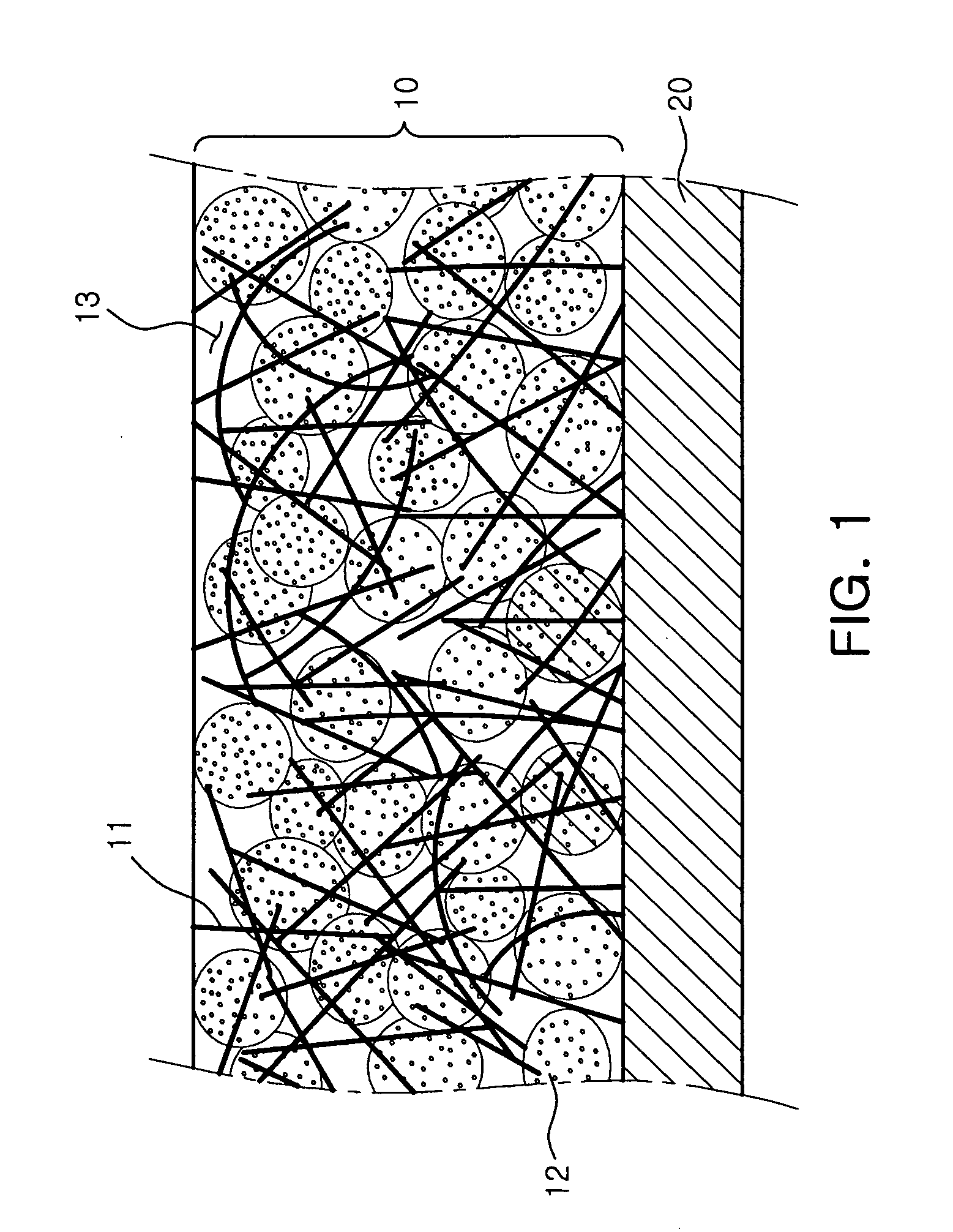

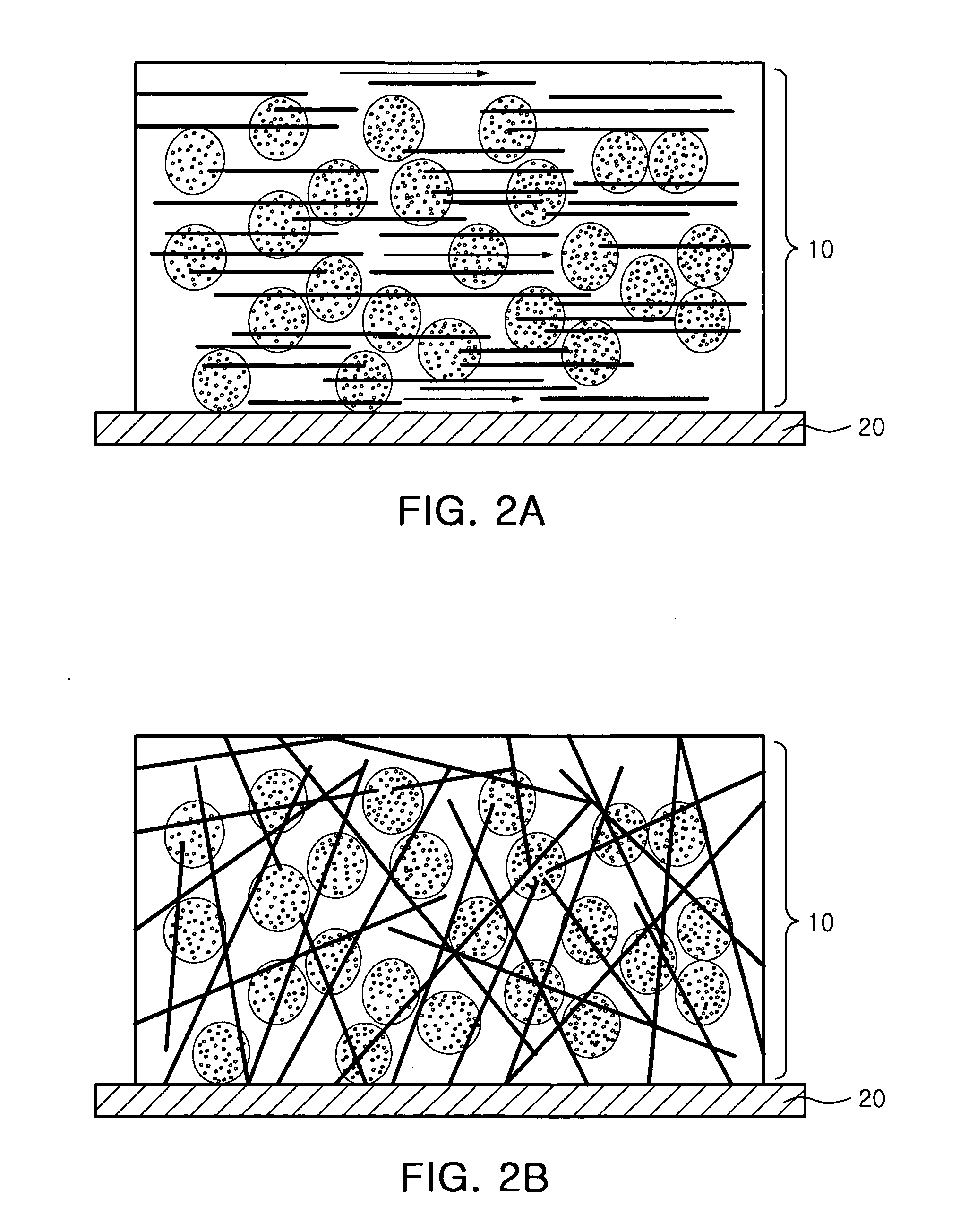

InactiveUS20110013344A1High power outputHigh energy densityElectrolytic capacitorsHybrid capacitor electrodesIonCarbon nanotube

There is provided a polarizable electrode for a capacitor and an electric double layer capacitor having the same. The polarizable electrode is a gel-state mixture including carbon nanotubes (CNTs) forming a network structure, porous carbon materials dispersed between the CNTs, and ionic liquids allowing the CNTs and the porous carbon materials to be dispersed. The polarizable electrode secures an electrical connection path between an electrode and a collector and prevents separation between the porous carbon materials and the ionic liquids using the network structure formed by the CNTs. Accordingly, the electric double layer capacitor having the polarizable electrode has low contact resistance between the electrode and the collector and has low possibility of polarization occurrence between the electrode and an electrolyte, resulting in high capacitance and high energy efficiency due to low equivalent series resistance.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

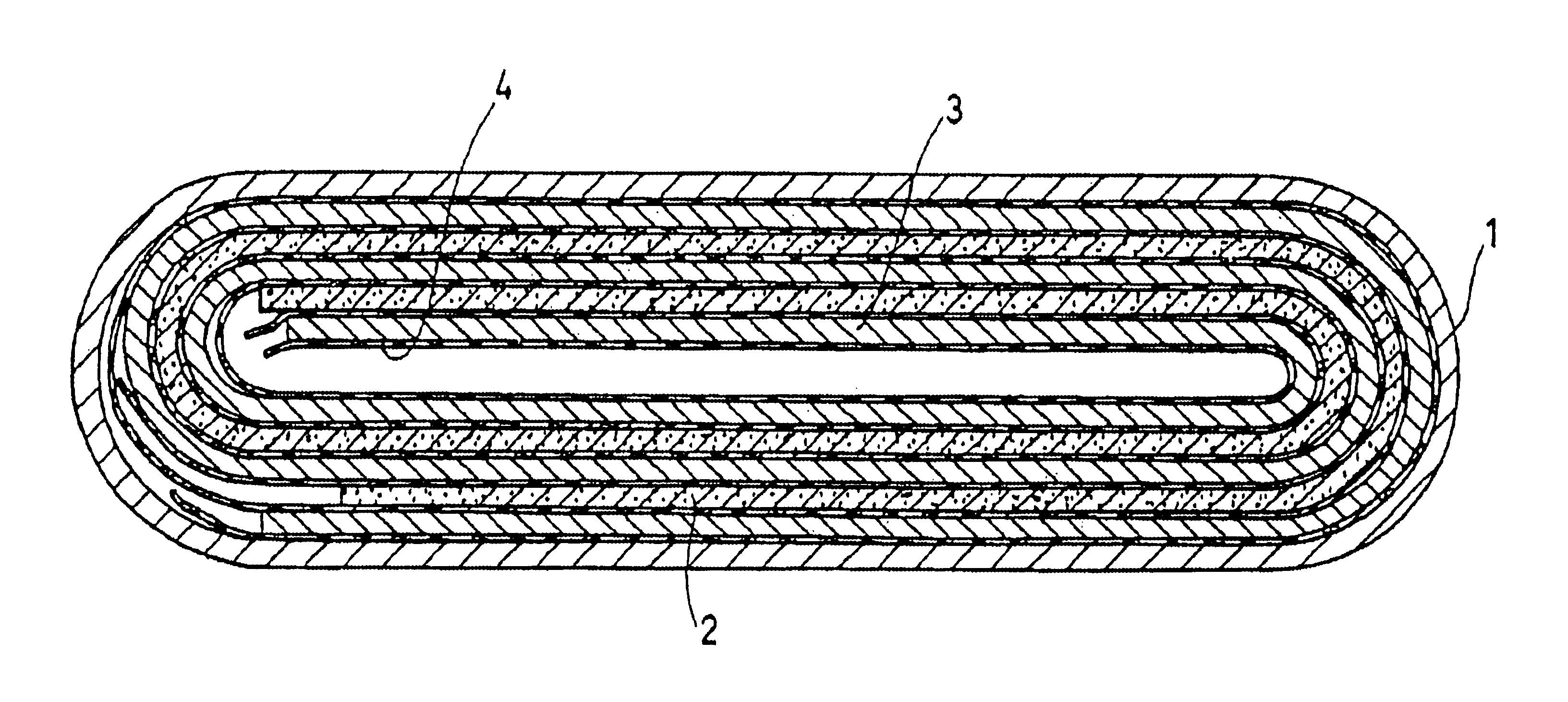

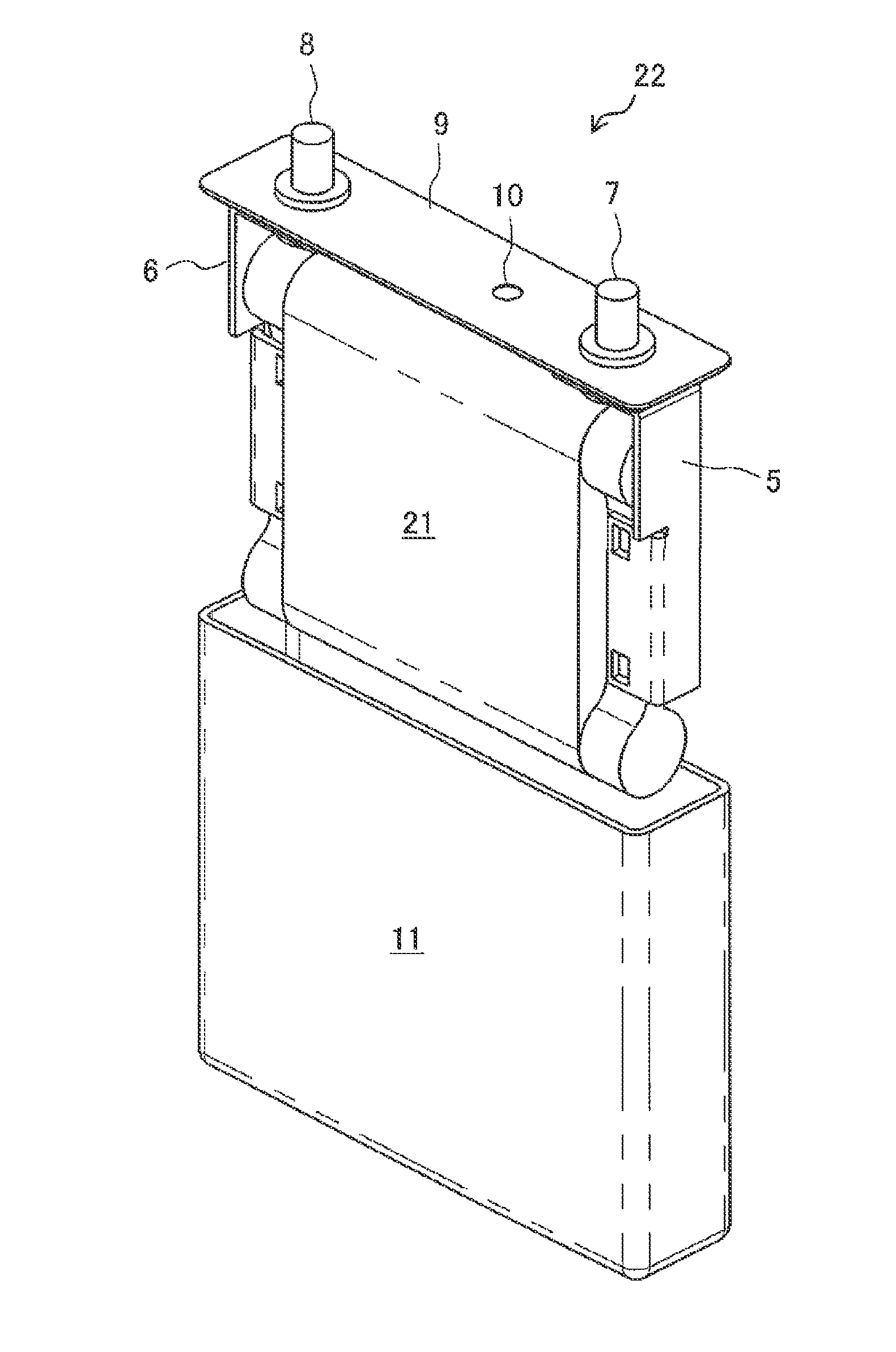

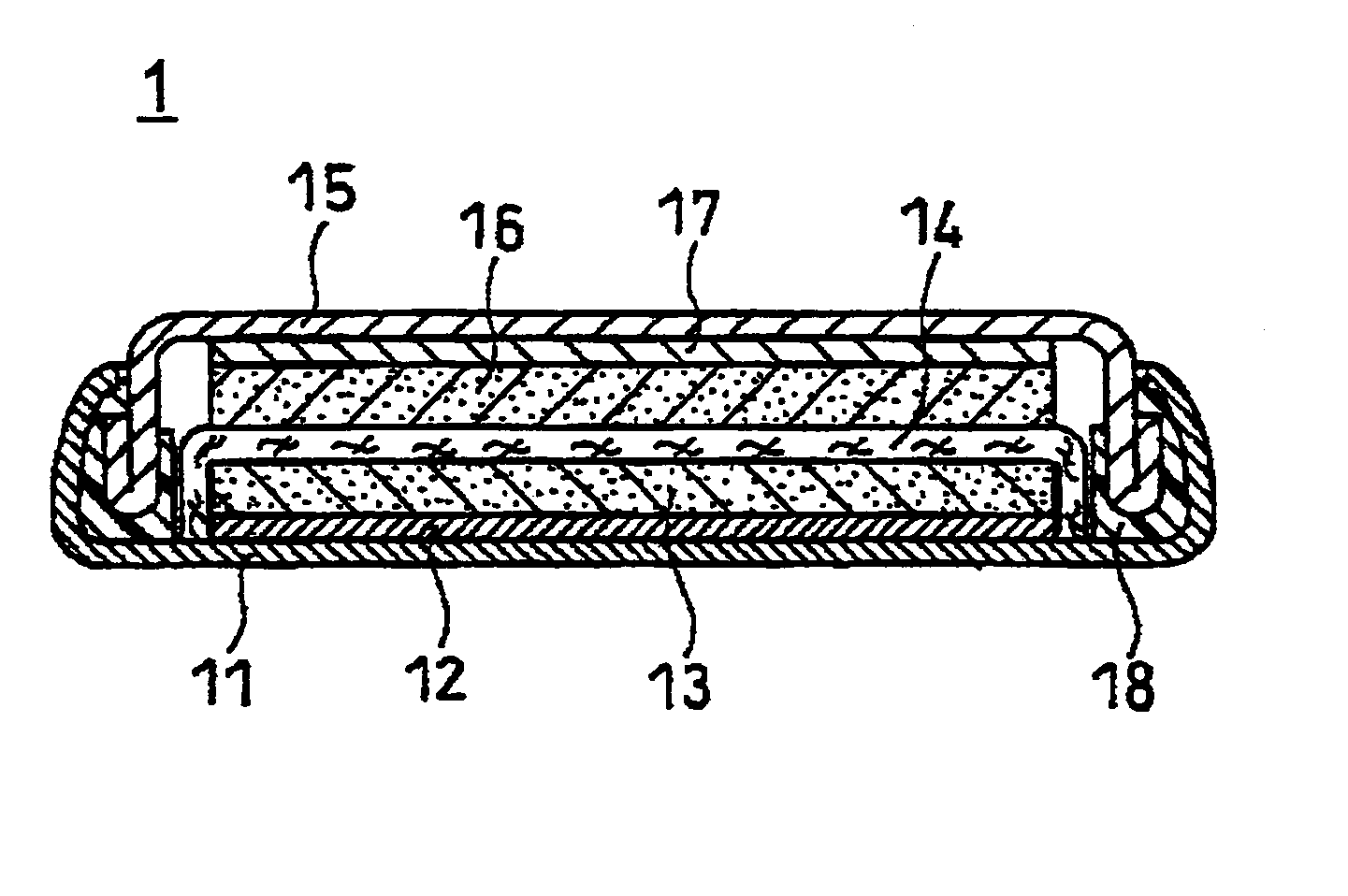

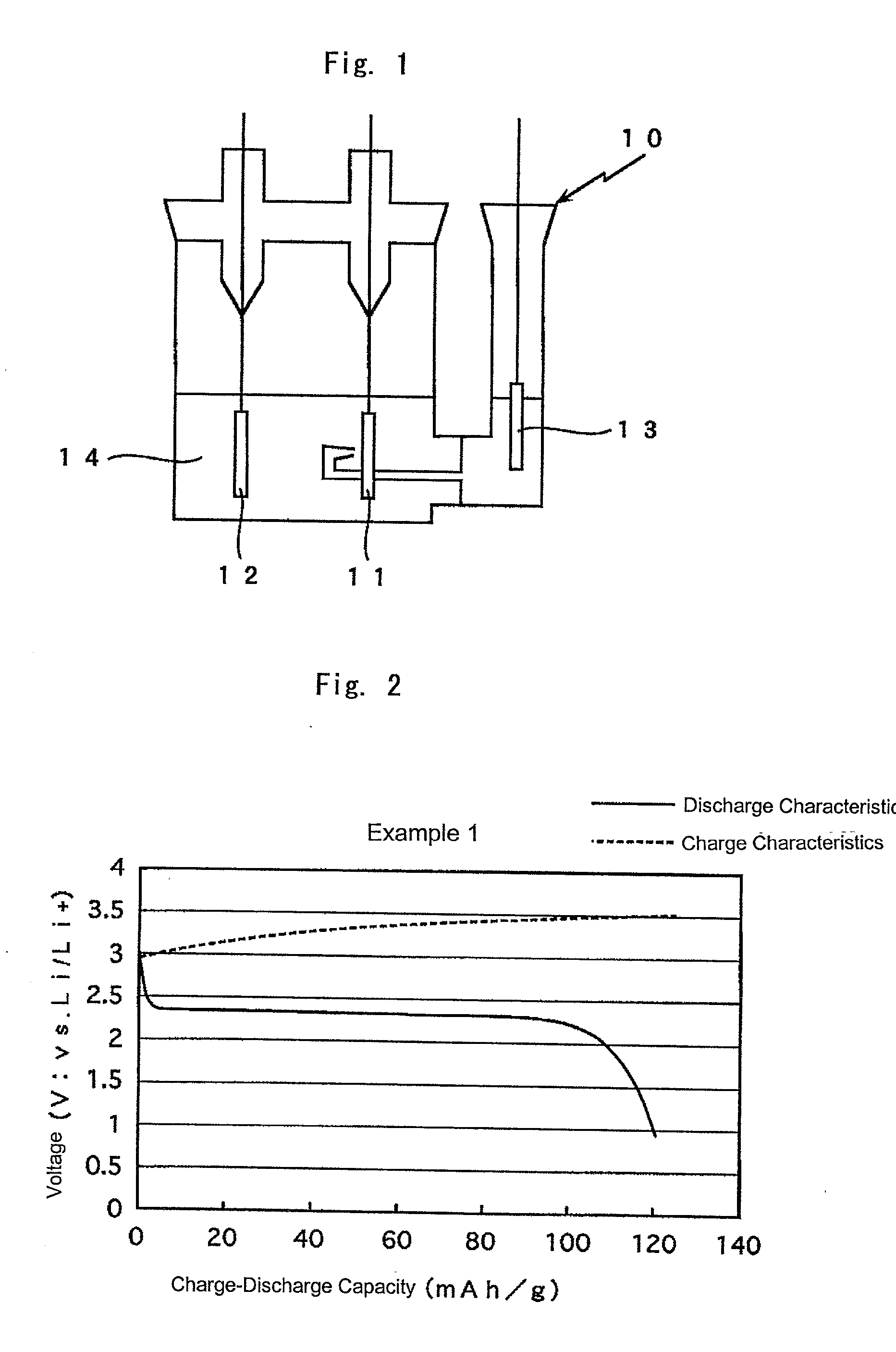

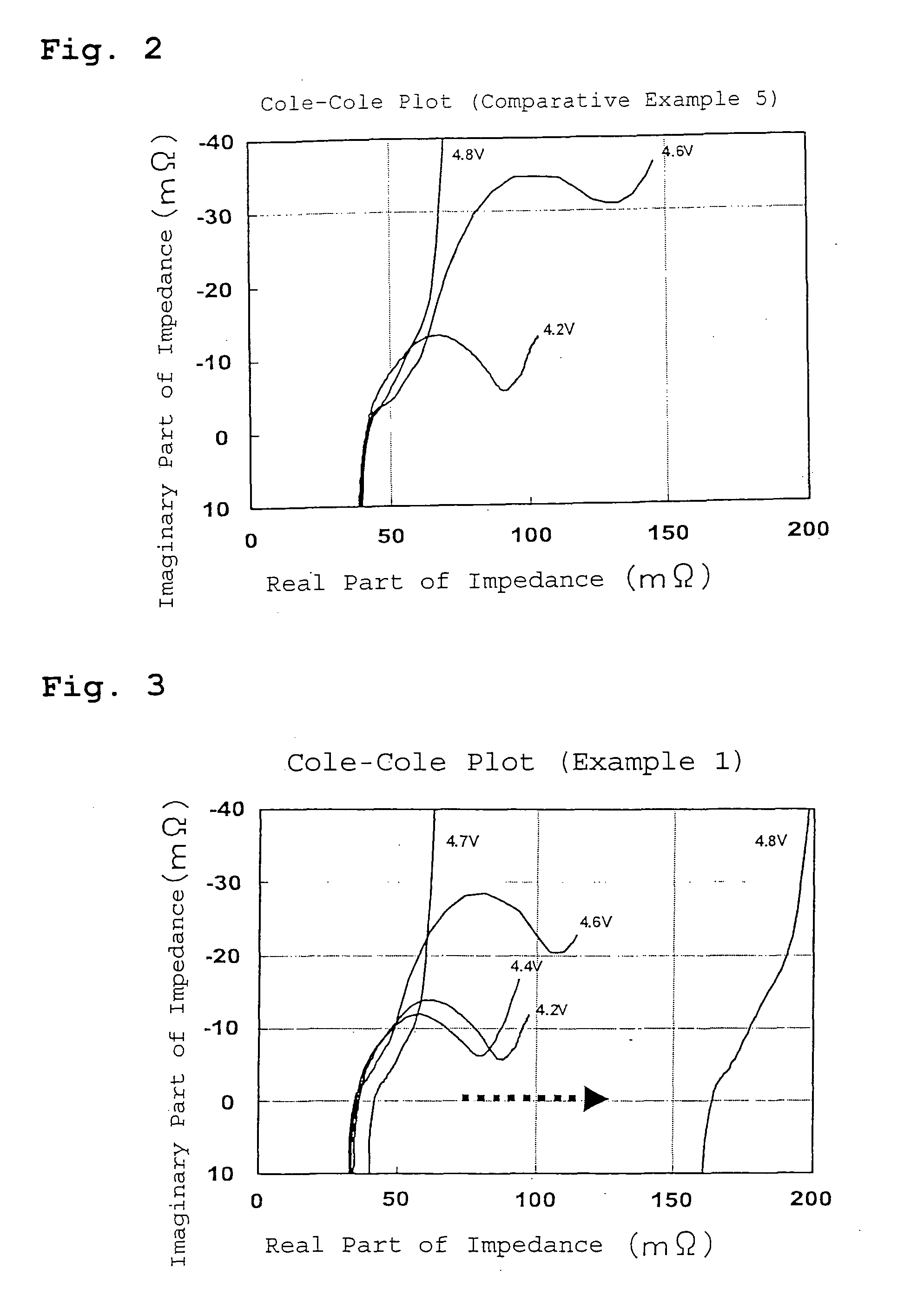

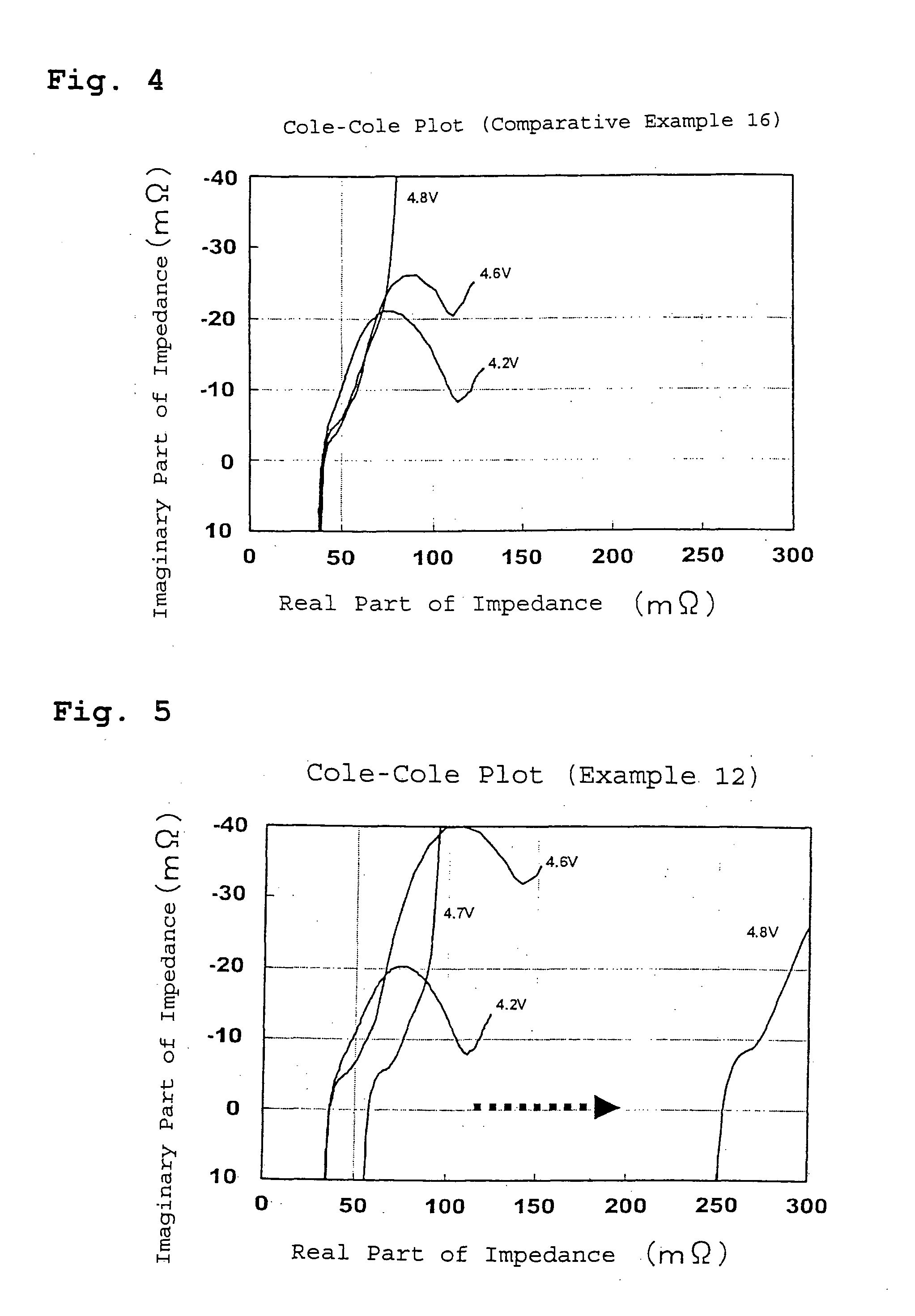

Non-aqueous electrolyte secondary battery and positive electrode for the same

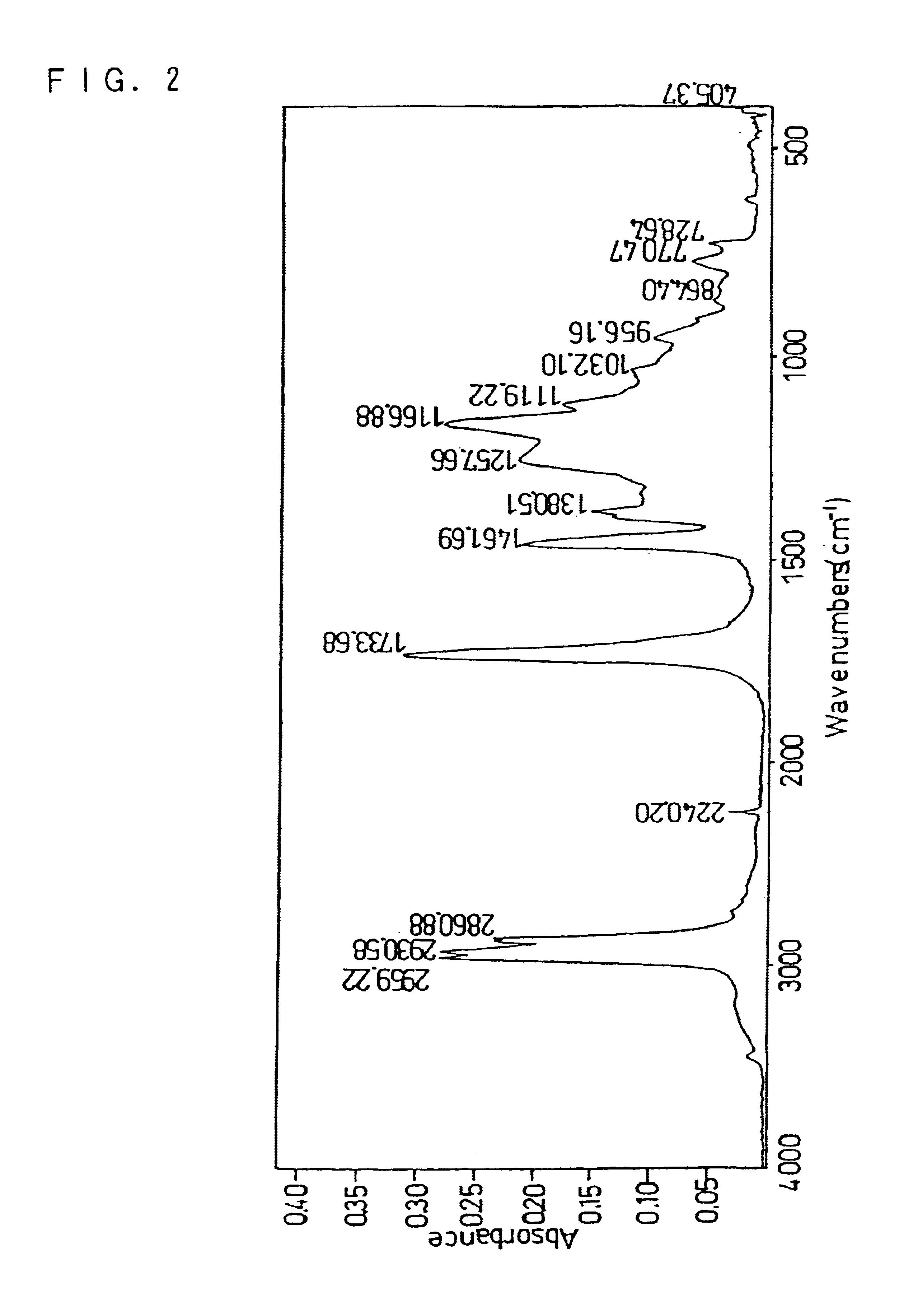

InactiveUS6869724B2Long lifeHigh energy densityFinal product manufactureActive material electrodesHigh energyEnergy density

A non-aqueous electrolyte secondary battery comprises: a positive electrode sheet comprising a positive electrode mixture containing a lithium-containing transition metal oxide as an active material and a particulate binder; a negative electrode sheet comprising a negative electrode mixture containing a carbon material; a separator interposed between the positive electrode sheet and the negative electrode sheet; and a non-aqueous electrolyte containing a lithium salt, wherein the positive electrode sheet and the negative electrode sheet are wound with the separator interposed therebetween to form an electrode assembly, and the positive electrode mixture has an active material density of 3.0 to 4.0 g / ml. The battery has a long life, high energy density and high output.

Owner:GK BRIDGE 1

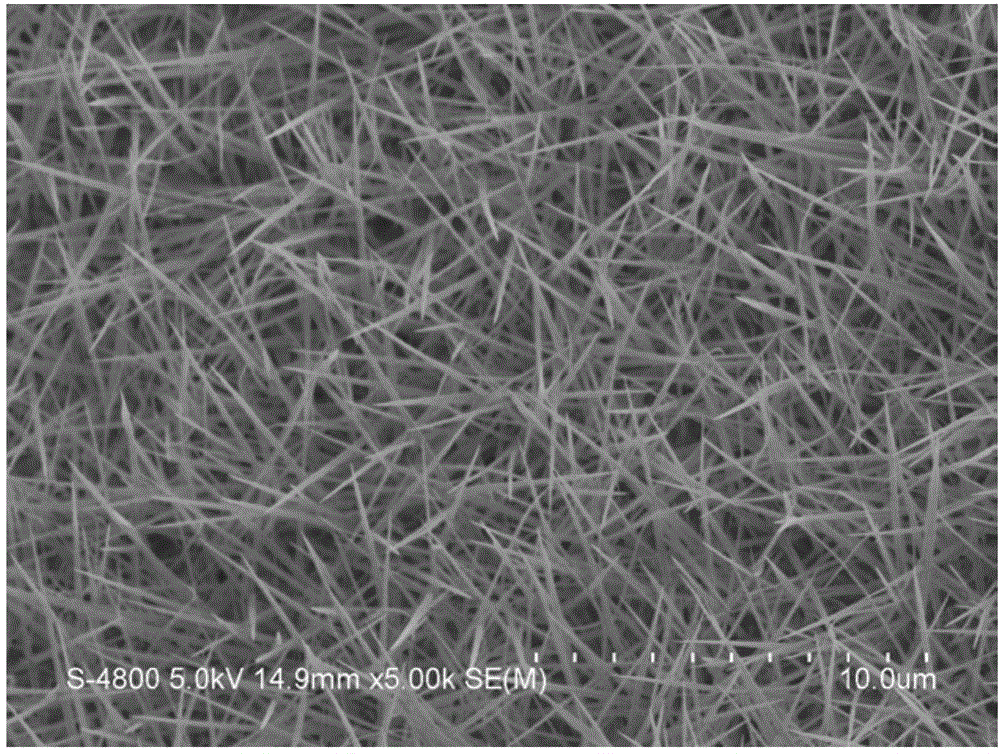

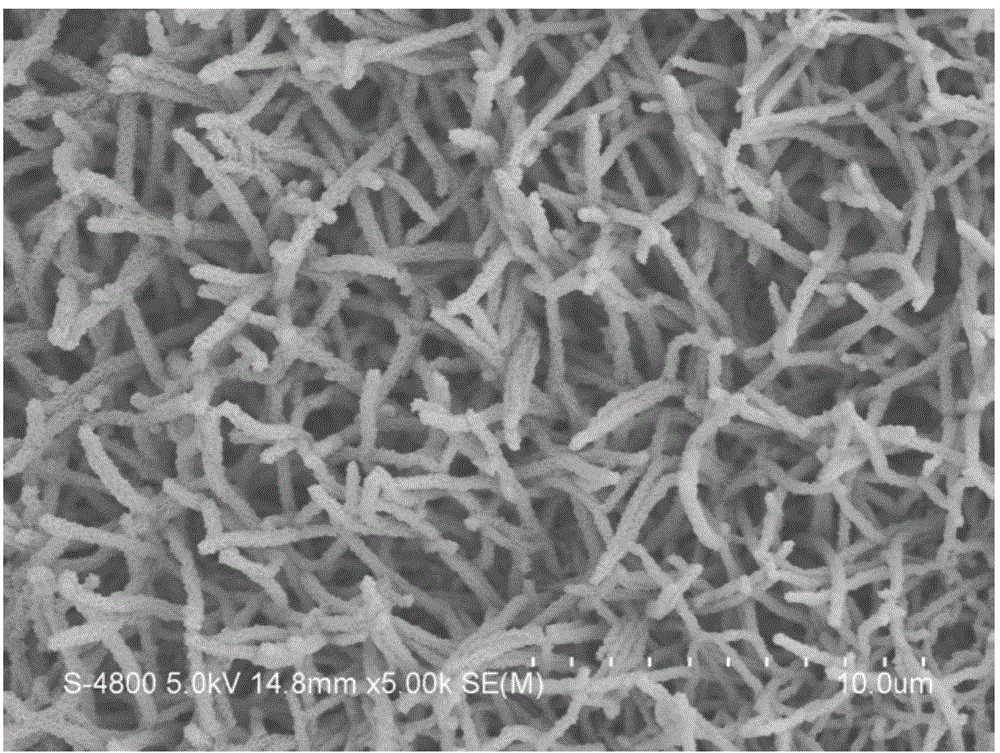

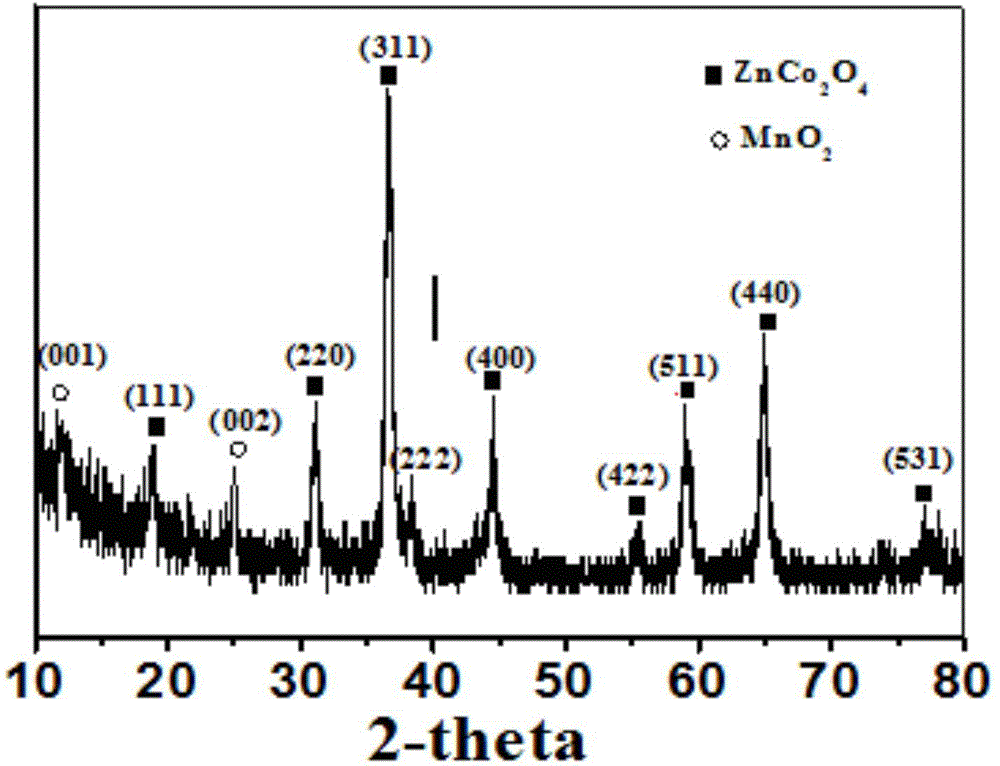

ZnCo2O4@MnO core-shell heterostructure nanotube array material, and preparation method and application thereof

InactiveCN104465117AHigh purityGood dispersionHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceDispersity

The invention provides a preparation method and application of a ZnCo2O4@MnO core-shell heterostructure nanotube array material. According to the prepared product, a ZnCo2O4 nanowire serves as a framework and is wrapped with a MnO nanofilm material, and the product grows vertically, is arranged orderly and has a regular three-dimensional heterostructure. Compared with the prior art, the product prepared through the preparation method is high in purity, good in dispersity, good and controllable in crystalline form, low in production cost and good in reproducibility. The prepared tubular ZnCo2O4@MnO core-shell heterostructure nanotube array grows on nickel foam, can serve as an electrode material of a super capacitor directly, has long-term circulatory stability, large specific capacitance and high energy density and power density, and has great commercial value.

Owner:ANHUI NORMAL UNIV

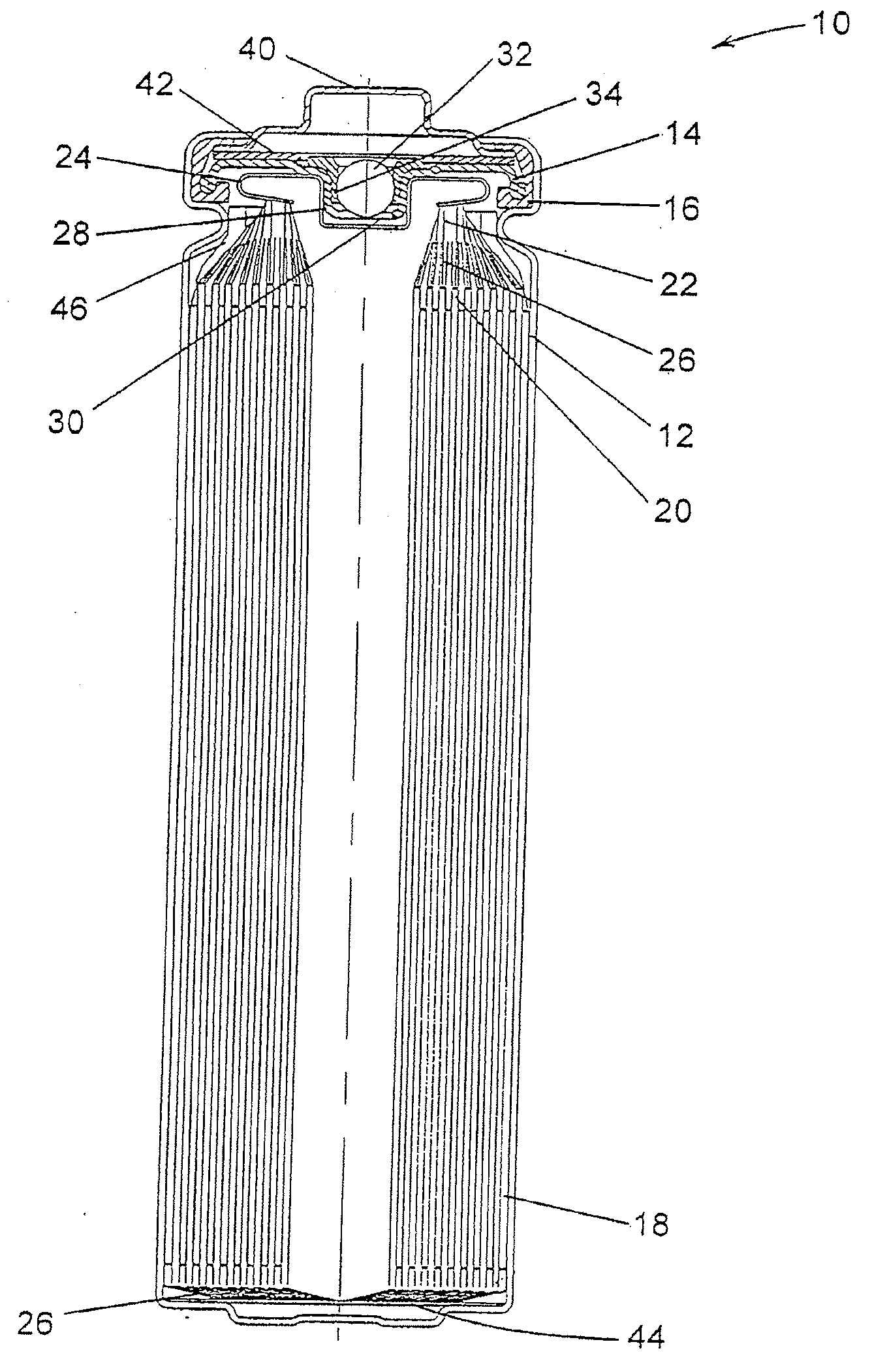

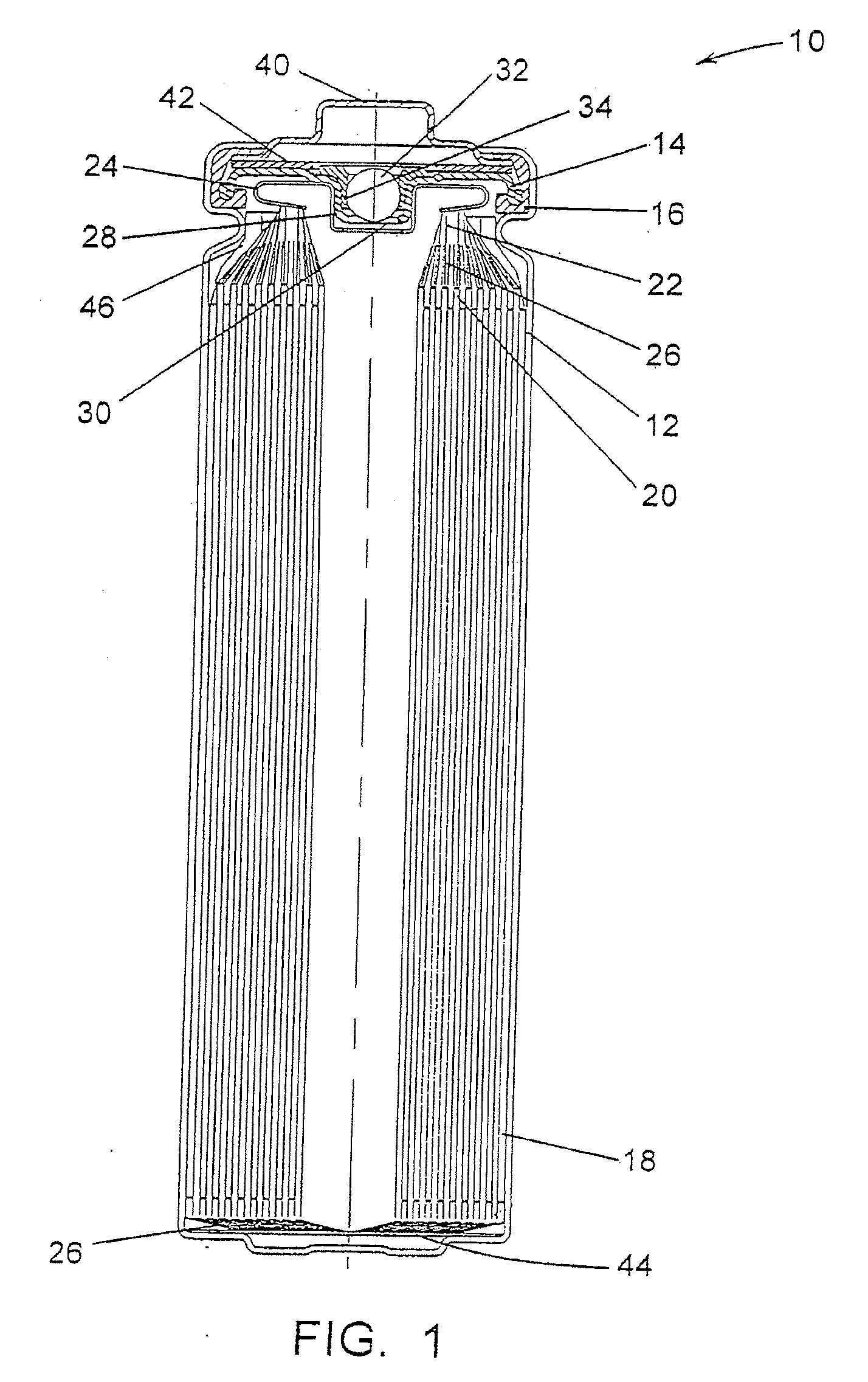

High Discharge Capacity Lithium Battery

ActiveUS20100151303A1Increase discharge capacityHigh energy densityOrganic electrolyte cellsPrimary cell electrodesHigh rateJet mill

A lithium / iron disulfide electrochemical battery cell with a high discharge capacity. The cell has a lithium negative electrode, an iron disulfide positive electrode and a nonaqueous electrolyte. The iron disulfide of the positive electrode has a controlled average particle size range which allows the electrochemical cells to exhibit desired properties in both low and high rate applications. In various embodiments, the iron disulfide particles are wet milled, preferably utilizing a media mill or milled utilizing a non-mechanical mill such as a jet mill, which reduces the iron disulfide particles to a desired average particle size range for incorporation into the positive electrode.

Owner:ENERGIZER BRANDS

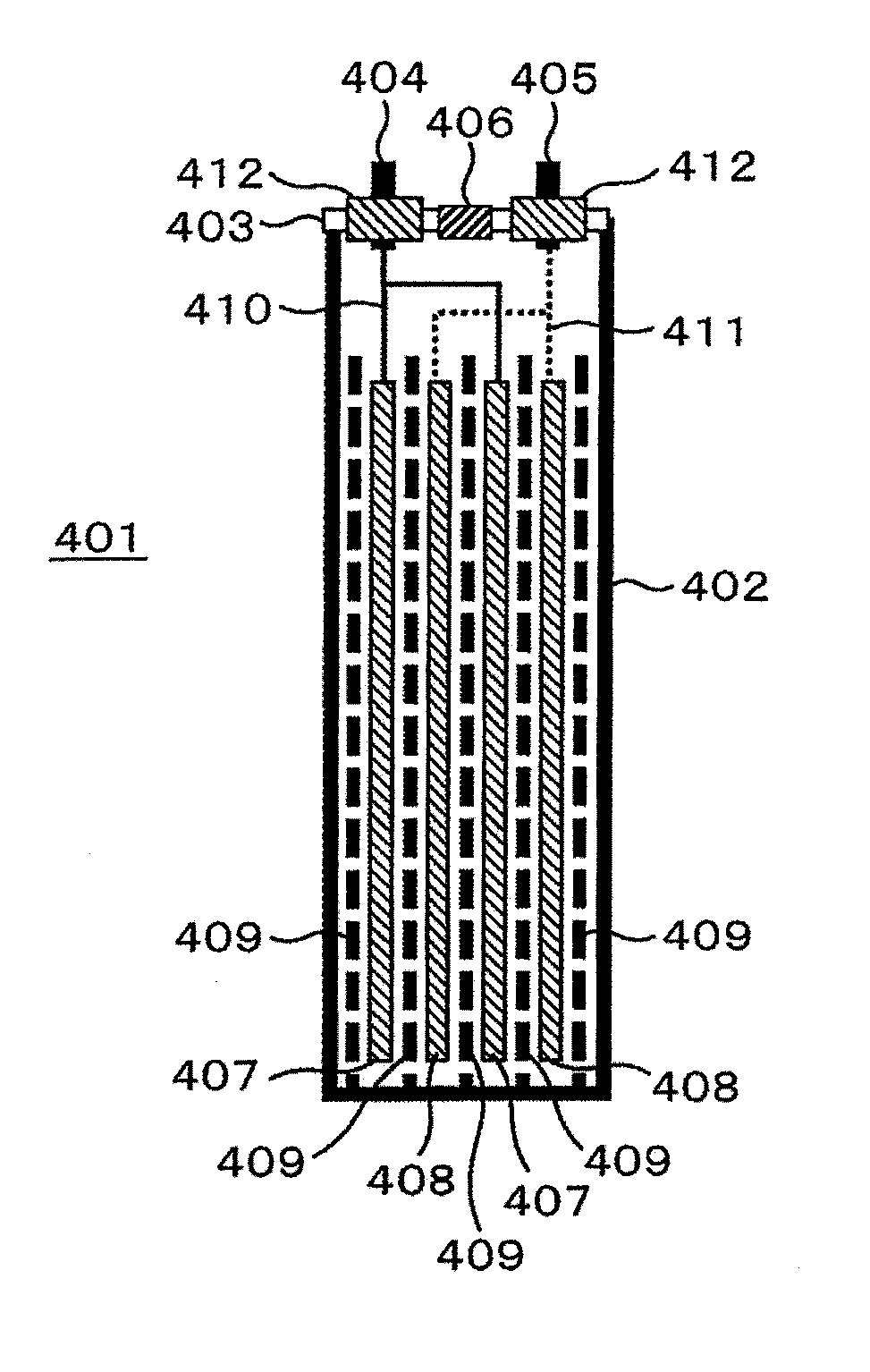

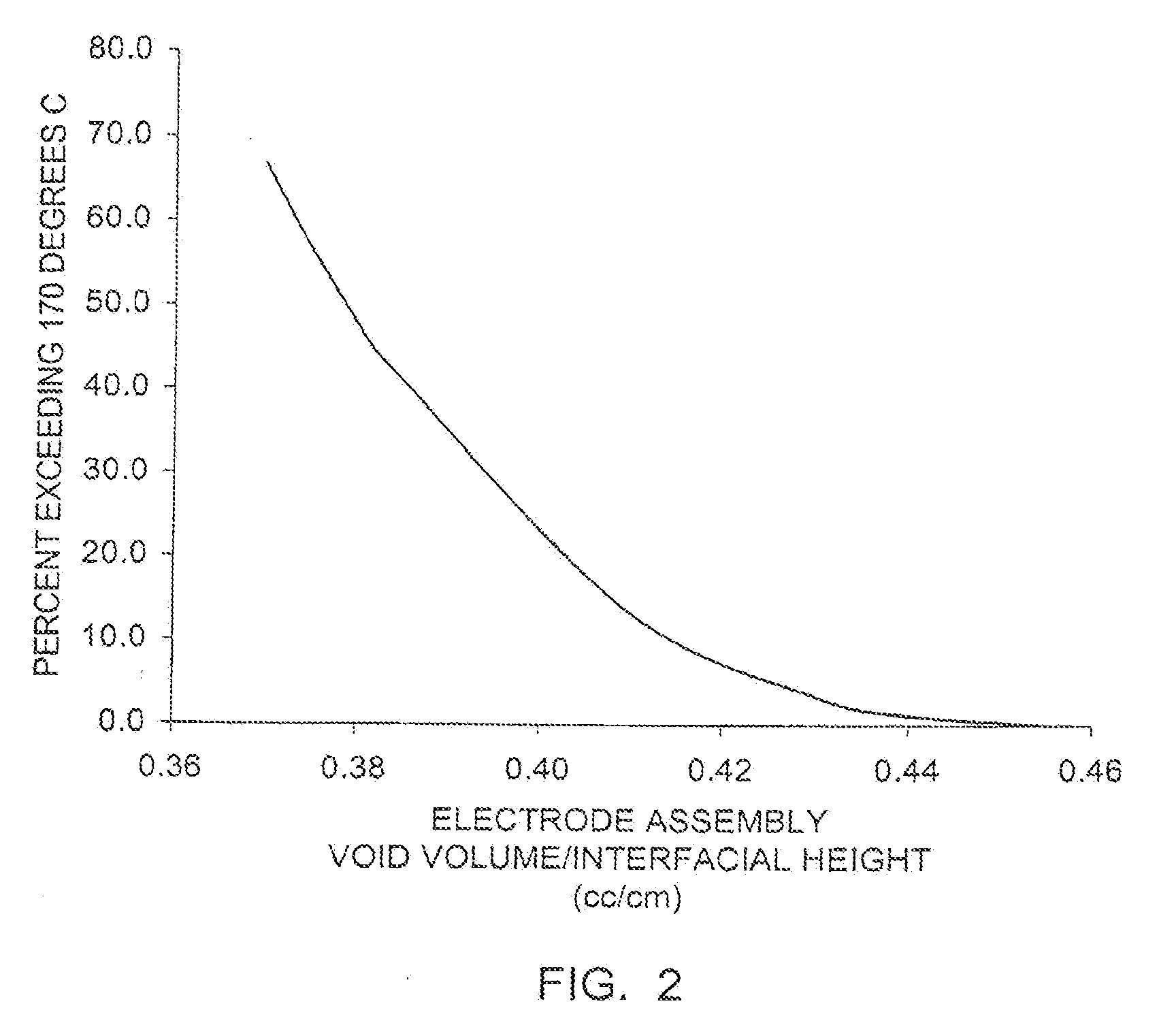

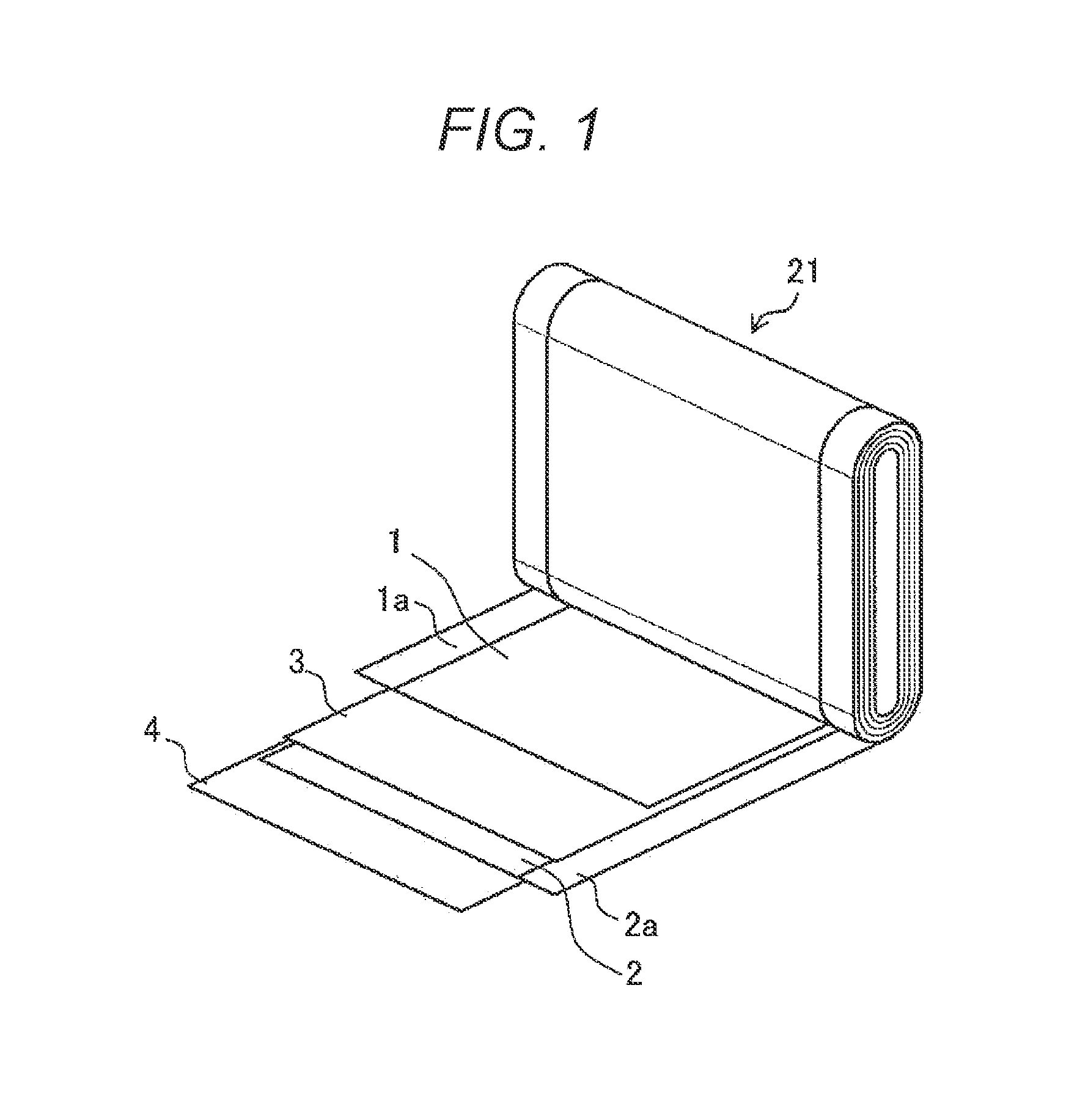

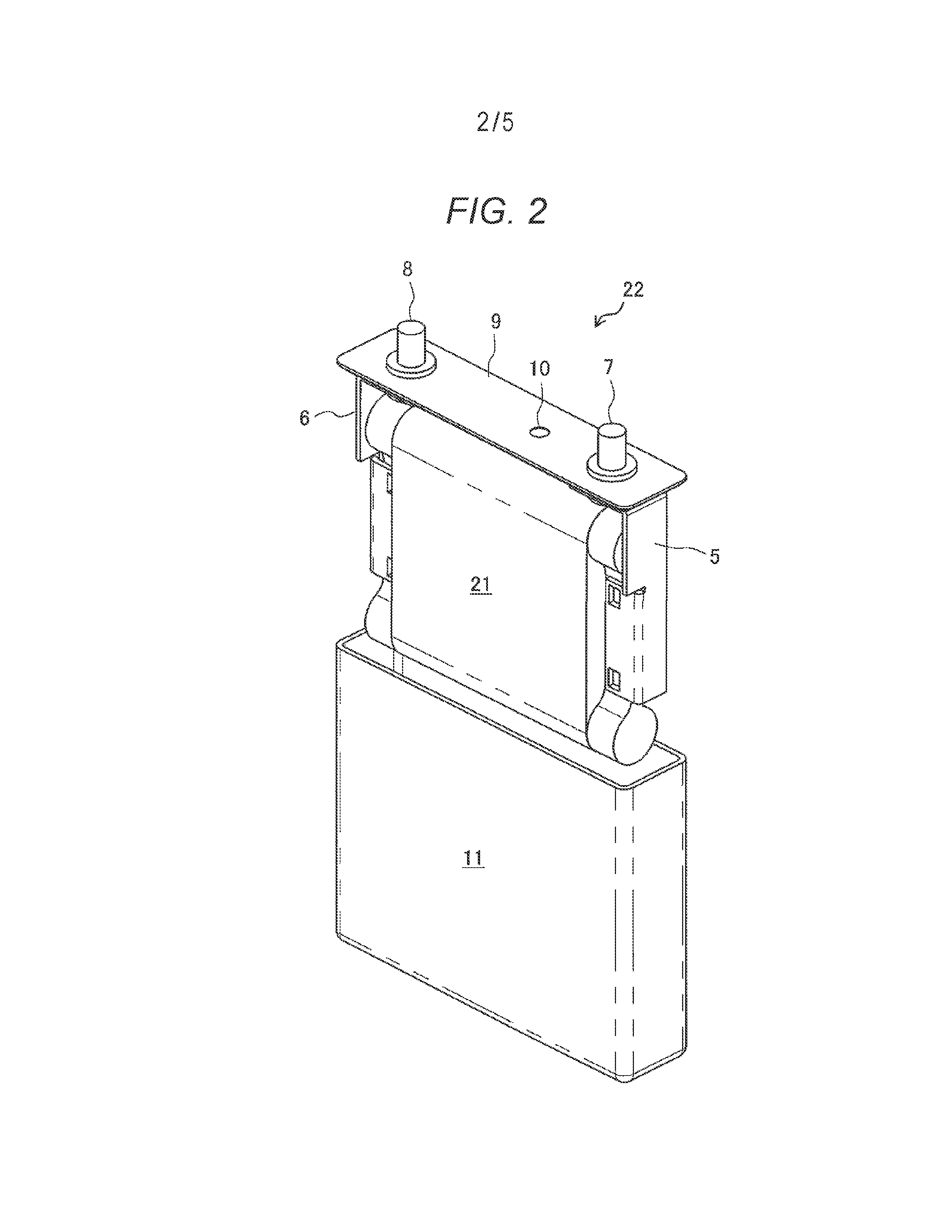

Lithium ion secondary battery

InactiveUS20160104919A1High energy densityIncrease in internal pressureFinal product manufactureJackets/cases materialsBinding forceInternal pressure

A lithium ion secondary battery is provided that suppresses an increase of an internal pressure of a battery caused by gases generated therein so as to suppress battery swelling which is linked to a variation of a thickness of the battery and an increase of a binding force of the battery, and is trouble-free in manufacturing as an on-vehicle battery module, so that a high reliability is provided. The lithium ion secondary battery includes a clathrate compound in a battery container, and the clathrate compound is one or more types of compounds selected from a group consisting of cyclodextrins, calixarenes, and crown ethers. With this configuration, CO gas, CO2 gas, and H2 gas in the battery container are absorbed, and the battery swelling caused by the gases is suppressed.

Owner:HITACHI AUTOMOTIVE SYST LTD

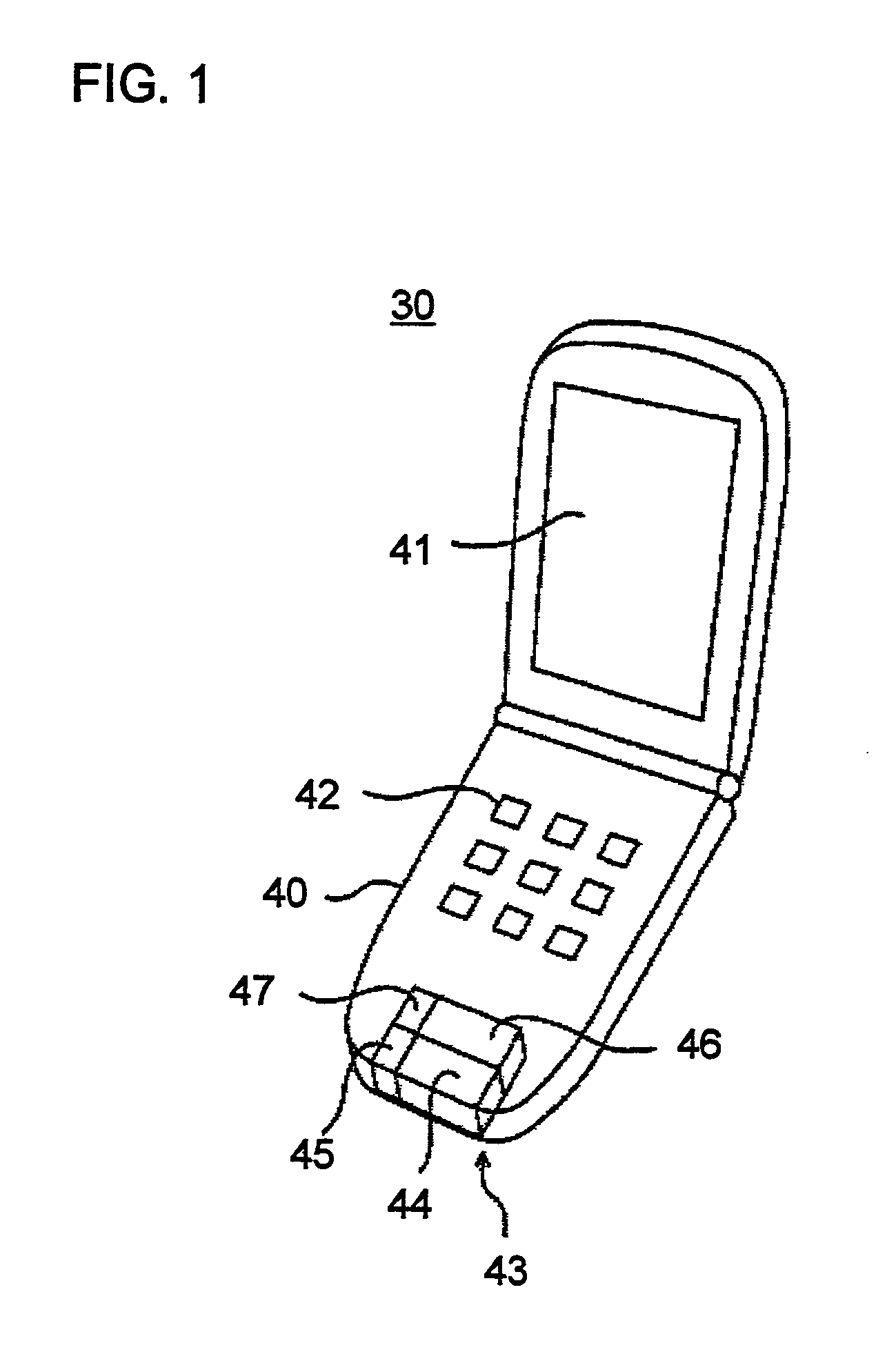

Electrode active material for power storage device and power storage device, and electronic equipment and transportation equipment

InactiveUS20110143197A1High energy densityHigh outputAlkaline accumulatorsOrganic chemistryKetonePower storage

An electrode active material for a power storage device of the invention includes an organic compound having, in the molecule, a plurality of electrode reaction sites and a linker site. The electrode reaction sites are residues of a 9,10-phenanthrenequinone compound that contributes to an electrochemical redox reaction. The linker site is disposed between the plurality of electrode reaction sites, does not contain any ketone group, and does not contribute to the electrochemical redox reaction. The electrode active material for a power storage device of the present invention is inhibited from being dissolved in an electrolyte and has a high energy density. By using the electrode active material, it is possible to obtain a power storage device having a high energy density and excellent charge / discharge cycle characteristics.

Owner:PANASONIC CORP

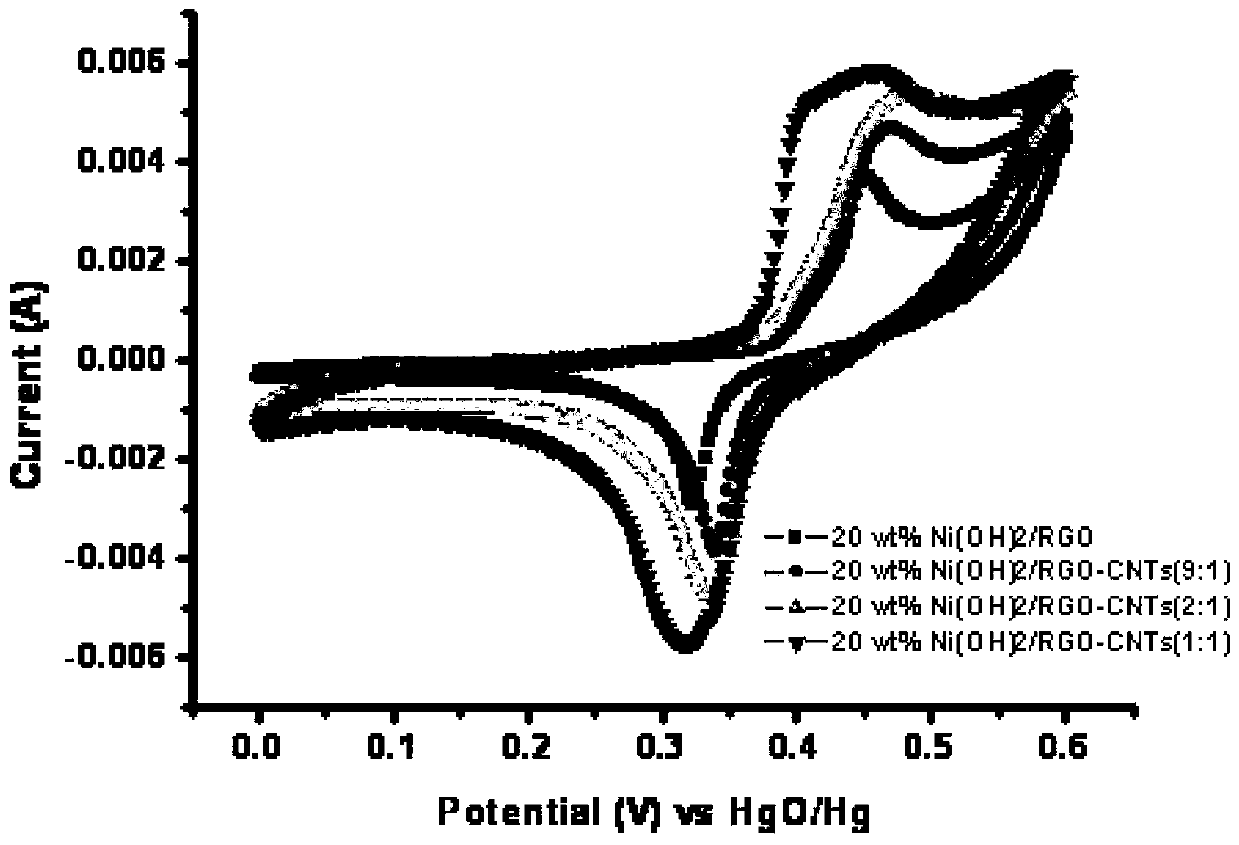

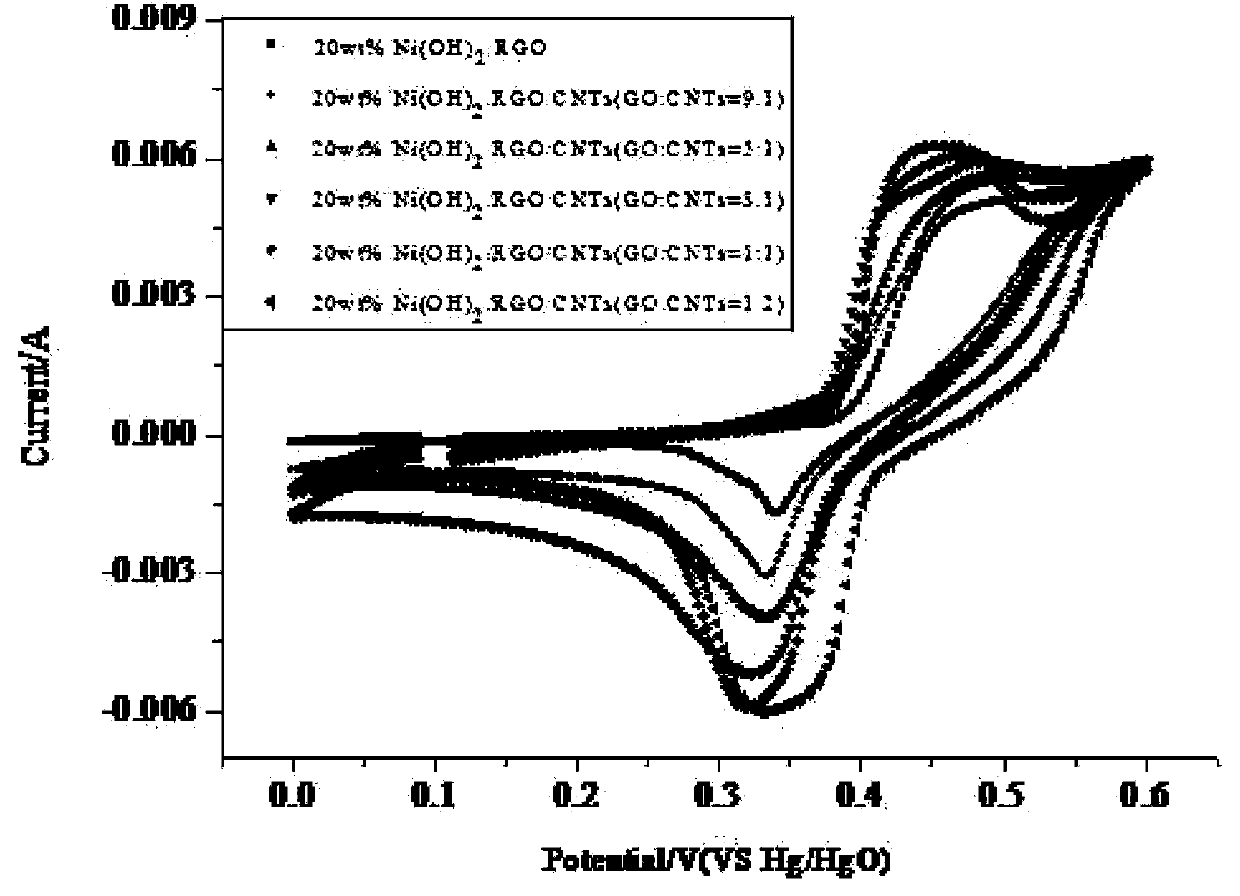

Super-capacitor electrode material and preparation method thereof

InactiveCN103390509ASmall particle sizeEasy to removeHybrid capacitor electrodesHybrid/EDL manufactureMicrowave methodNickel oxide hydroxide

The invention relates to a super-capacitor electrode material and a preparation method thereof. A conventional commercial super-capacitor product still has lower energy density, but the greatest defect of low energy density of the super-capacitor is hopeful to be overcome and the energy density of a carbon nano tube / nickelous hydroxide / graphene composite material can be greatly improved if a carbon nano tube / nickelous hydroxide / graphene composite material with reasonable structure and composition can be manufactured due to the fact that nickelous hydroxide has a large pseudocapacitance value and good reversibility, graphene has a large specific surface area and excellent electrical conductivity, the nickelous hydroxide and the graphene are stacked in a layered manner and can generate an synergistic effect, and a small quantity of conductive carbon nano tubes are doped. The super-capacitor electrode material is a carbon nano tube / nickelous hydroxide / graphene composite prepared with a microwave method. According to the super-capacitor electrode material, micromolecular non-toxic and harmless ethylene glycol is adopted as a reaction medium, microwave heating is adopted to promote fast completion of a reaction, the reaction is finished in one pot, and the prepared composite has a large specific capacity and a large energy density.

Owner:SOUTHWEST PETROLEUM UNIV

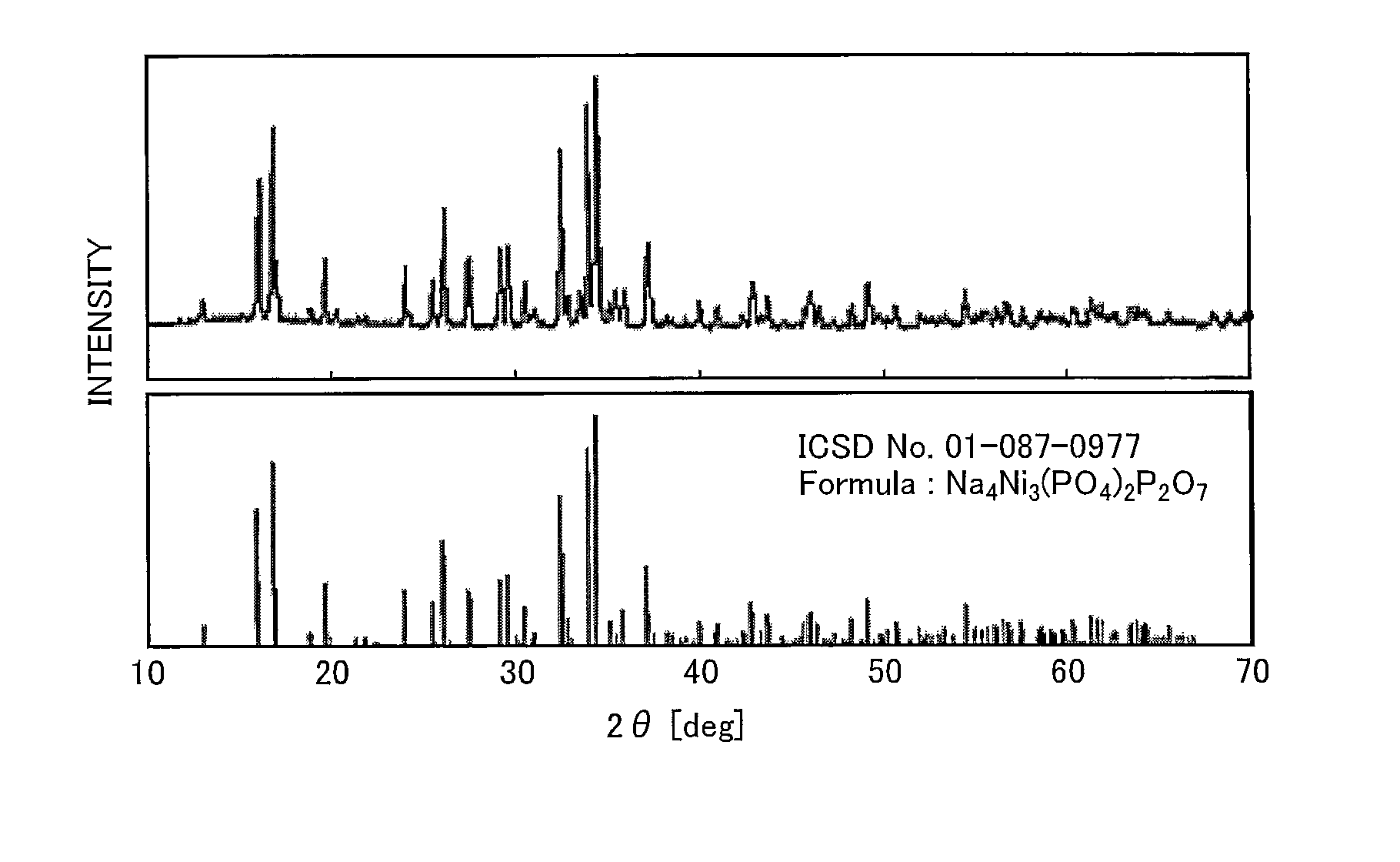

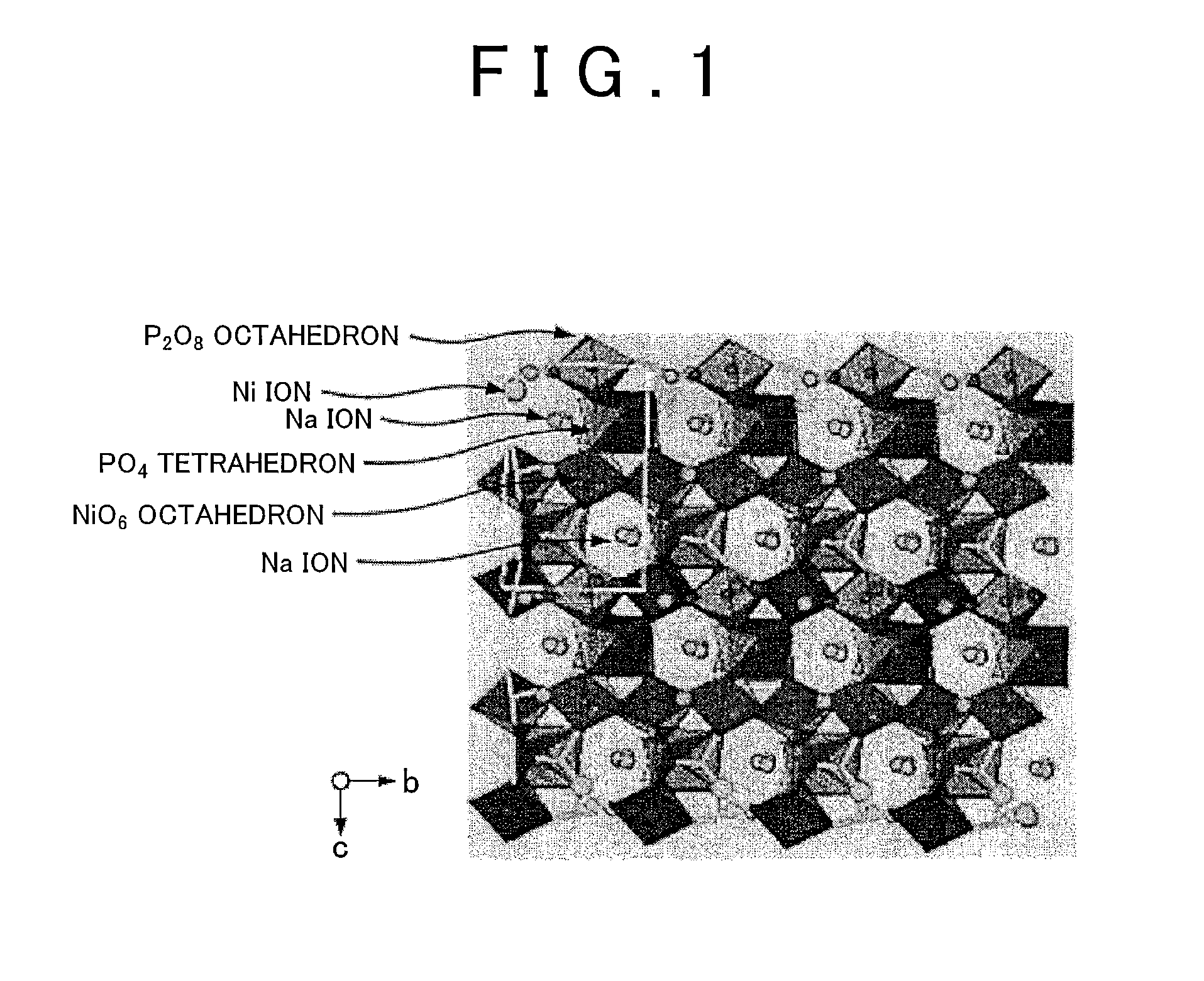

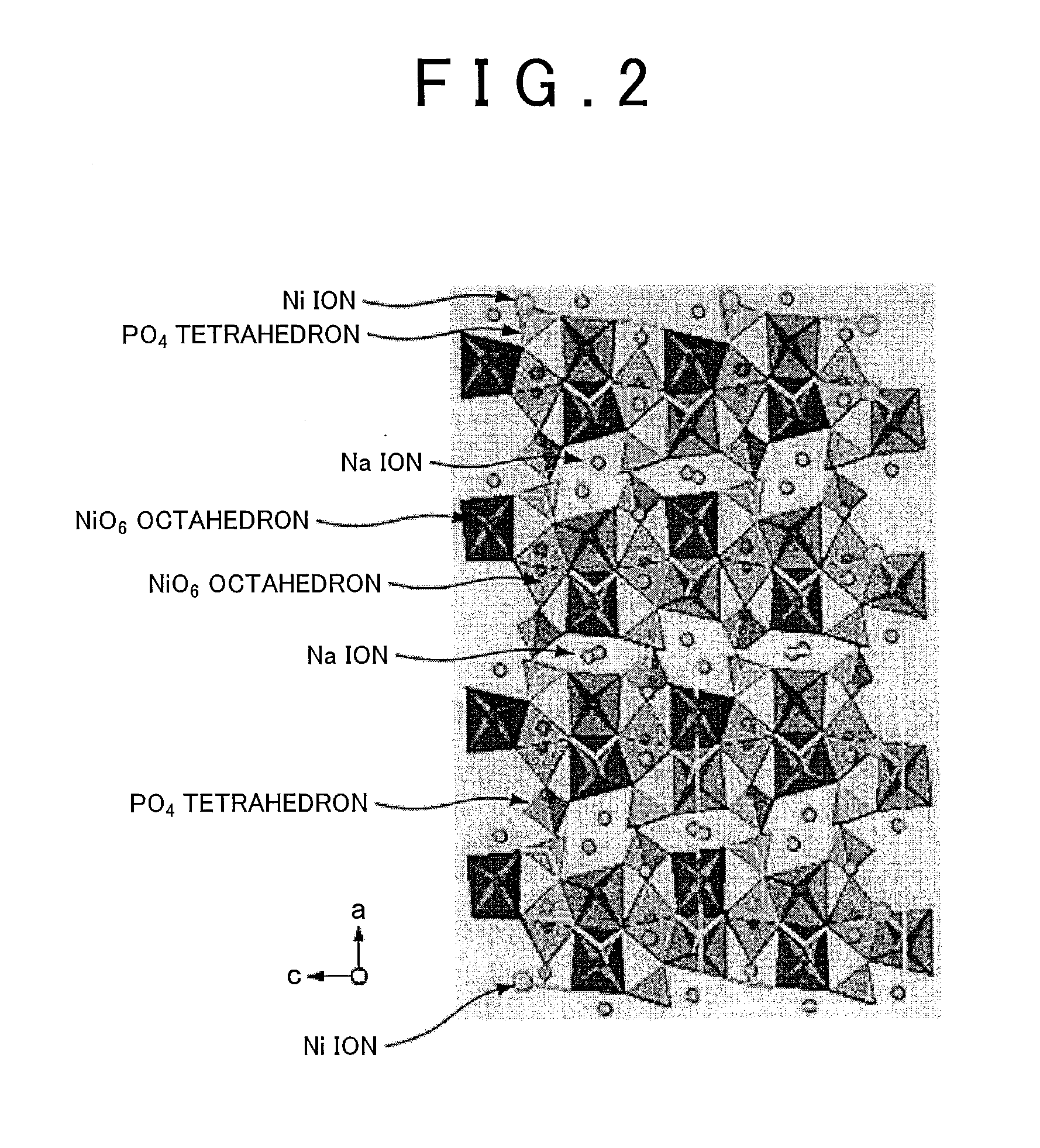

Positive electrode active material for sodium battery, and method of producing the same

ActiveUS20140197358A1High energy densityWork at highPhosphatesElectrode thermal treatmentChemistryTungsten

The invention provides a positive electrode active material for sodium batteries which has a high working potential and can be charged and discharged at a high potential. The invention also provides a method of producing such a positive electrode active material, with this positive electrode active material for sodium batteries being represented by general formula (1) below:NaxMy(AO4)z(P2O7)w (1)(wherein M is at least one selected from the group consisting of titanium, vanadium, chromium, manganese, iron, cobalt, nickel, copper and zinc; A is at least one selected from the group consisting of aluminum, silicon, phosphorus, sulfur, titanium, vanadium and tungsten; x satisfies the condition 4≧x≧2; y satisfies the condition 4≧y≧1, z satisfies the condition 4≧z≧0; w satisfies the condition 1≧w≧0; and one or both of z and w is 1 or more).

Owner:TOYOTA JIDOSHA KK

Electrode active material and lithium secondary battery

InactiveUS20020009639A1Light weightHigh energy densityPhysical/chemical process catalystsNon-aqueous electrolyte accumulatorsActivated carbonActive carbon

The present invention provides an improved electrode material for a lithium secondary battery to provide a lithium secondary battery that is light in weight and has high energy density. Sulfur and a catalyst material such as active carbon, and the like, that reduces activation energy of an addition reaction of lithium to sulfur and allows the reaction to occur at not greater than 60 ° C., are included in the electrode material.

Owner:SANYO ELECTRIC CO LTD

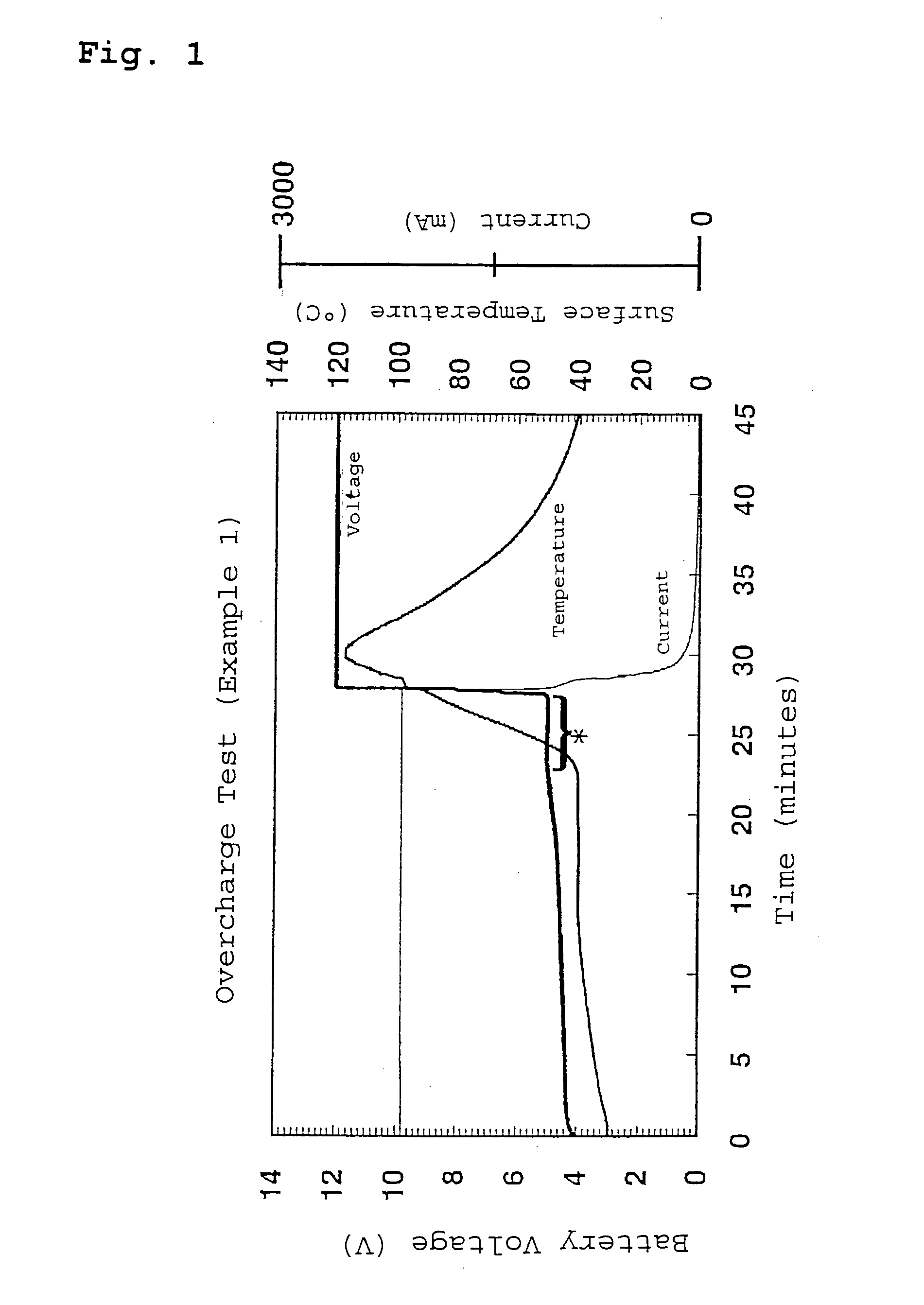

Lithium secondary battery

InactiveUS20040038130A1High energy densitySufficient securityCell electrodesOrganic electrolyte cellsChemistryDecomposition potential

A lithium secondary battery including a positive electrode which is capable of occluding and releasing lithium, a negative electrode which is capable of occluding and releasing lithium, a separator between the positive electrode and the negative electrode, and a nonaqueous electrolyte comprising a nonaqueous solvent and a wettability improving agent. The nonaqueous solvent does not substantially wet the separator, and the wettability improving agent is dissolved in the nonaqueous solvent, improves the wettability of the nonaqueous solvent to the separator, and has an oxidative decomposition potential in a range of 4.5 V to 6.2 V.

Owner:SANYO ELECTRIC CO LTD

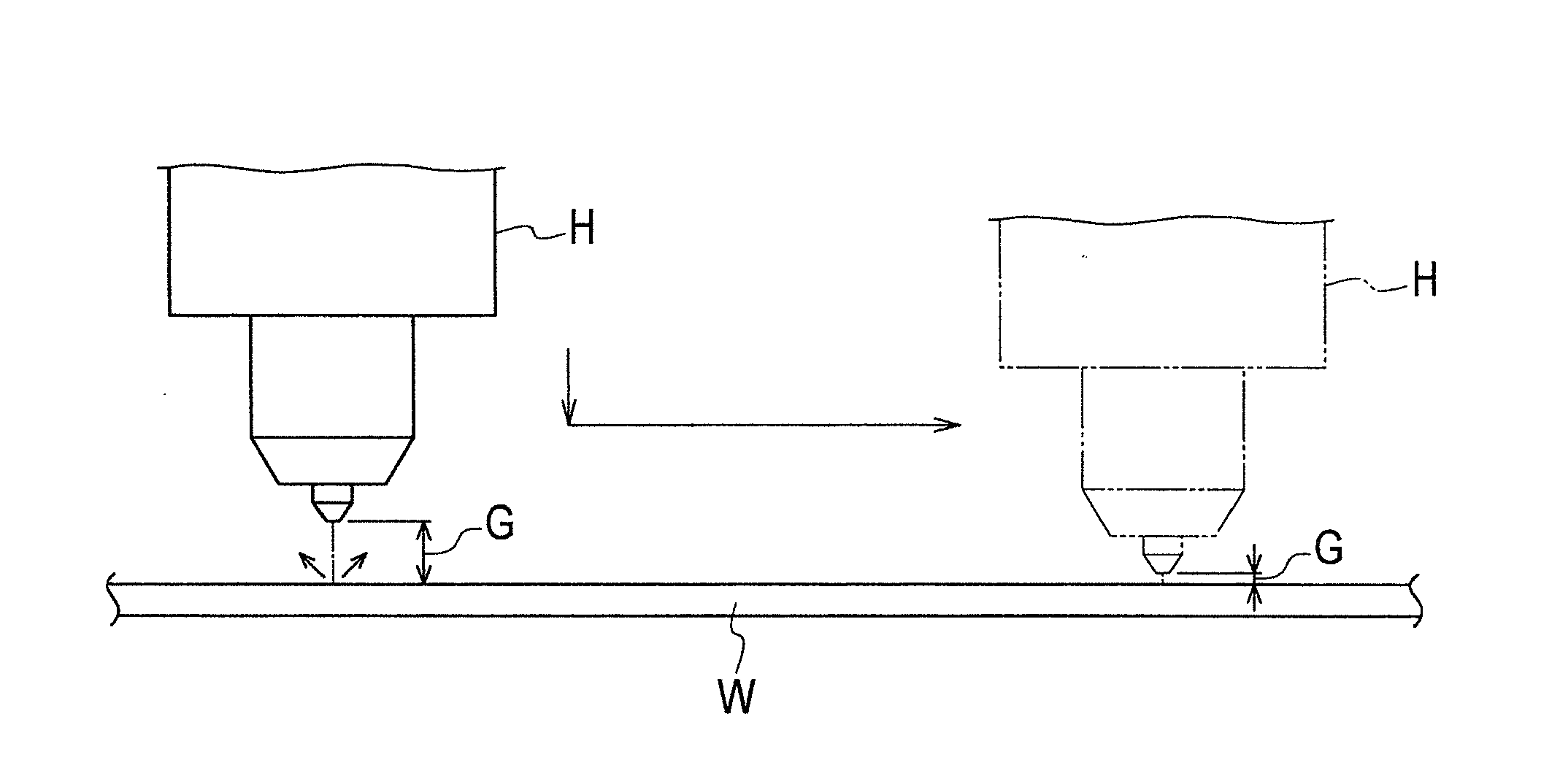

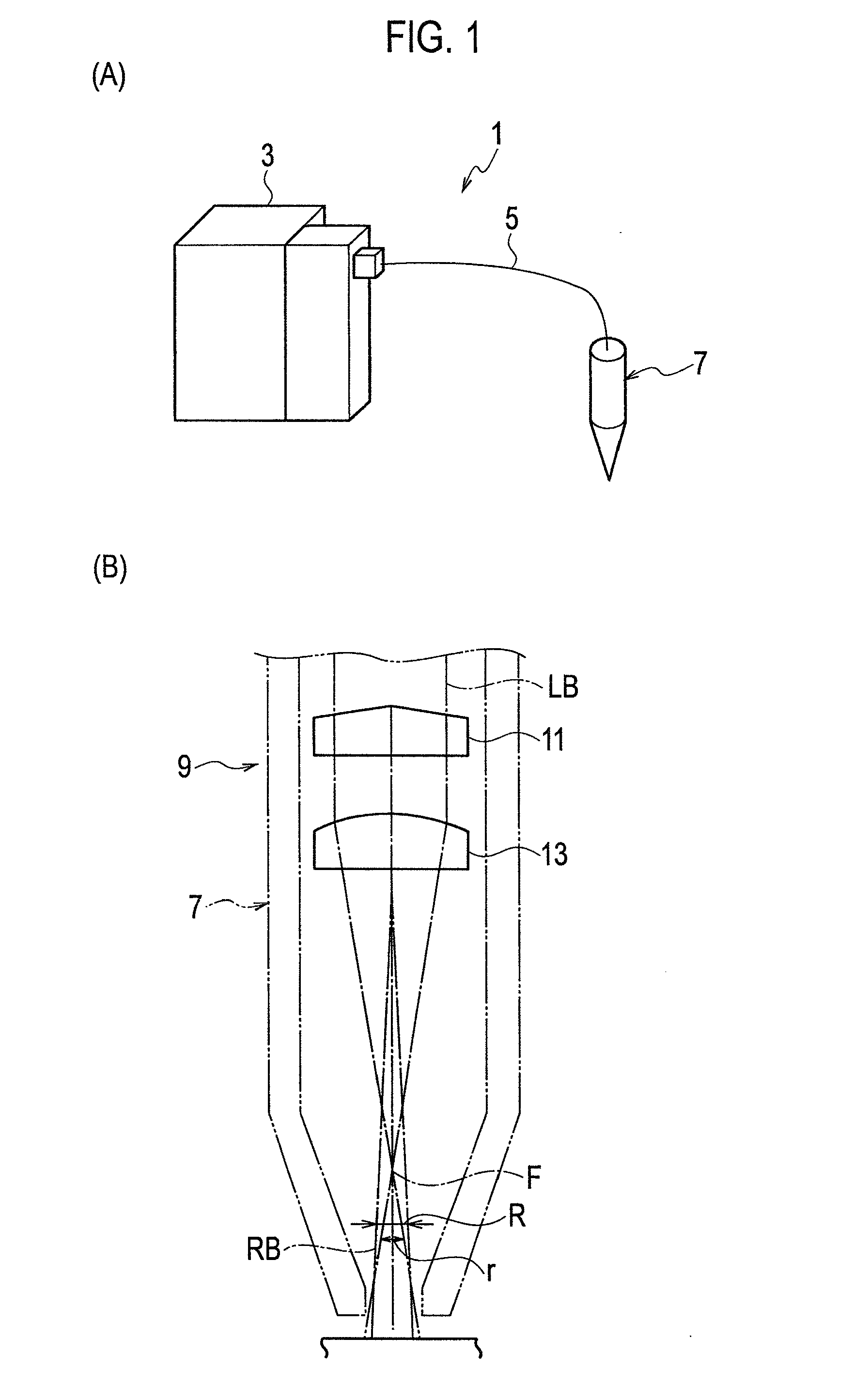

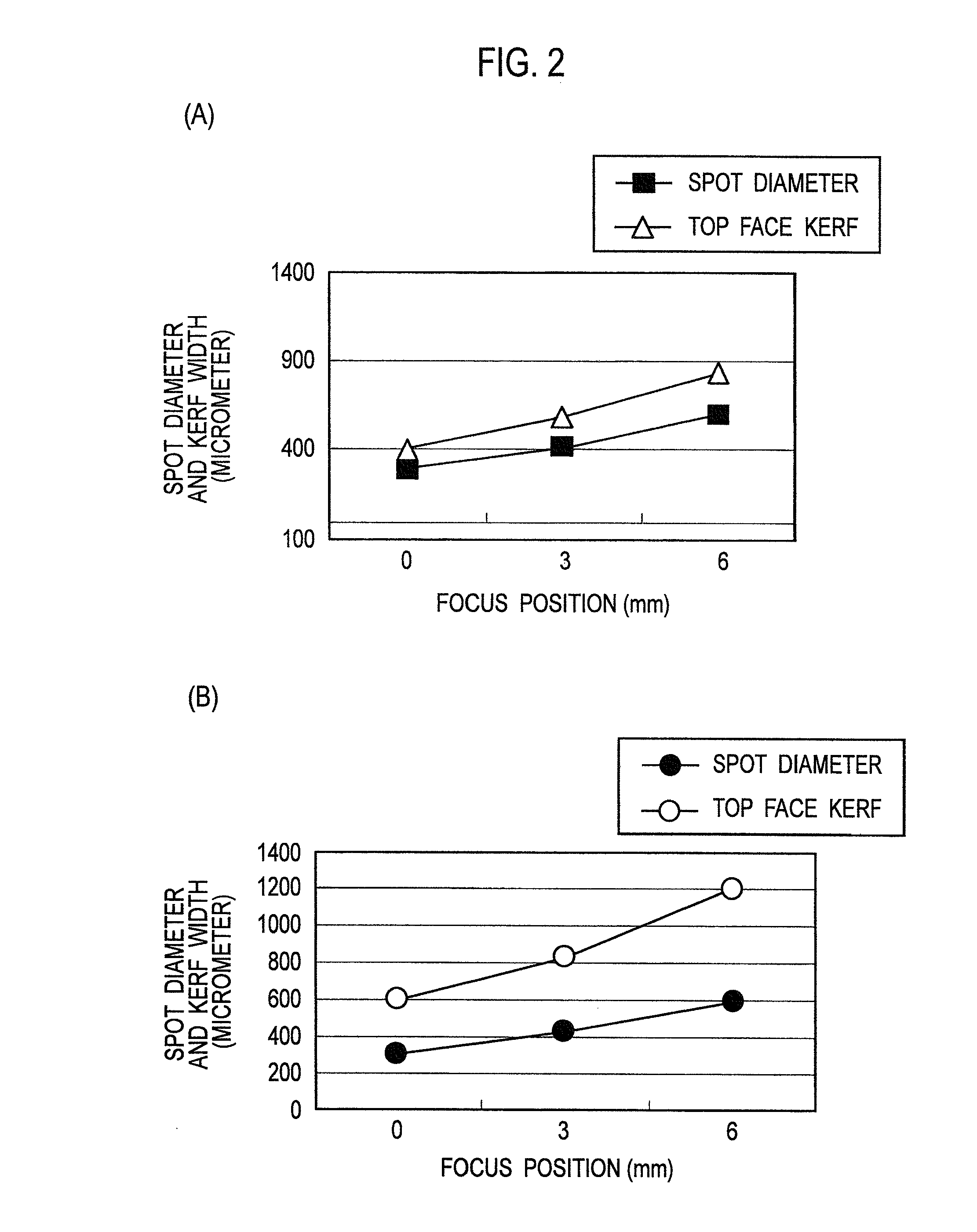

Laser cutting method and apparatus

ActiveUS20140339207A1High optical energy absorptionHigh energy densityLaser beam welding apparatusOptical elementsDiameter ratioMicrometer

A laser cutting method and a laser cutting apparatus cut a metallic work with a laser beam of a one-micrometer waveband. The method and apparatus carry out the laser cutting of the work with a ring beam RB passed through a focus position of a condenser lens 13 and having inner and outer diameters that tend to expand. The outer diameter of the ring beam is in a range of 300 μm (micrometers) to 600 μm, an inner diameter ratio of the same is in a range of 30% to 70%, and a focal depth of the condenser lens is in a range of 2 mm to 5 mm.

Owner:AMADA CO LTD

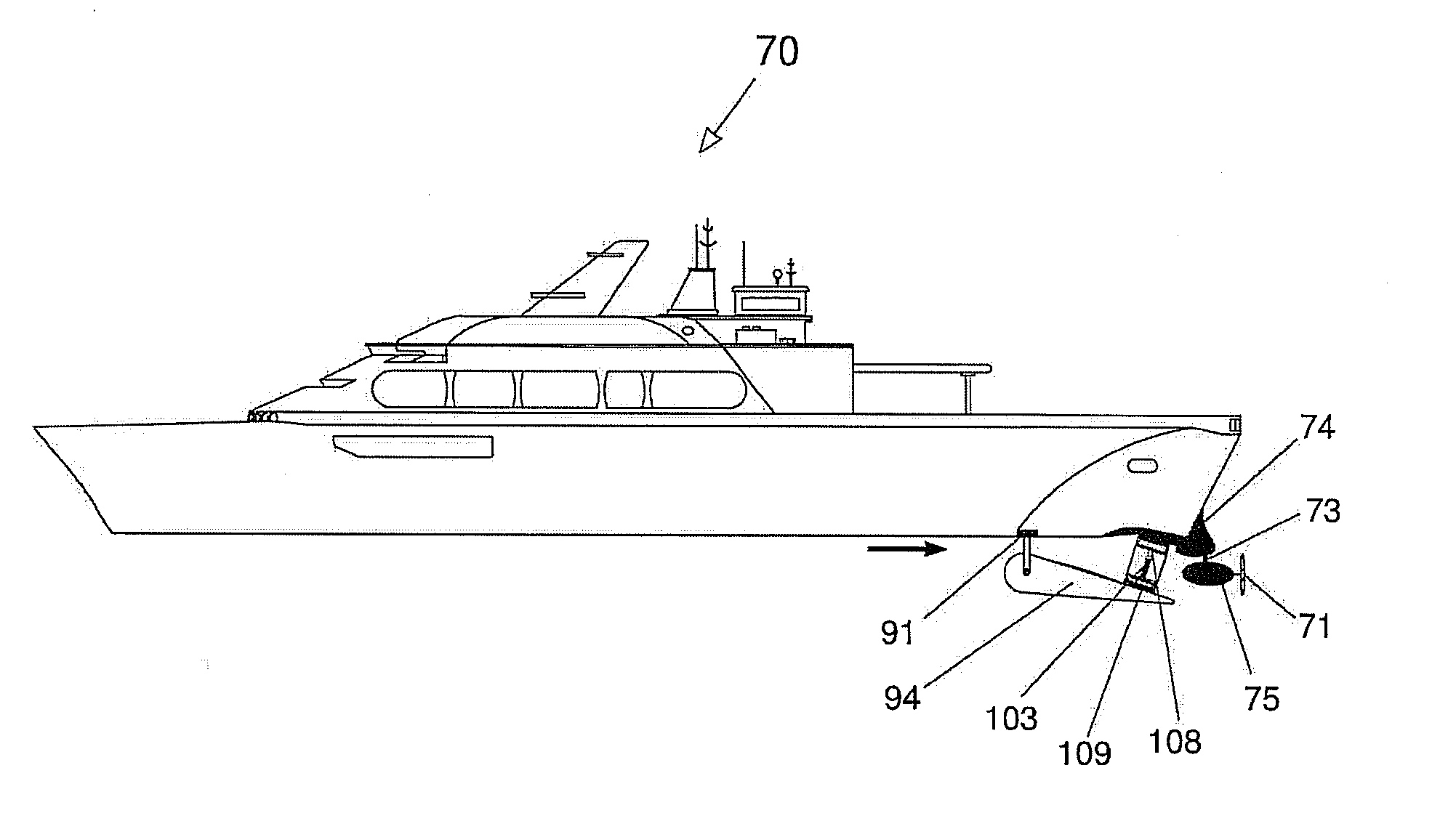

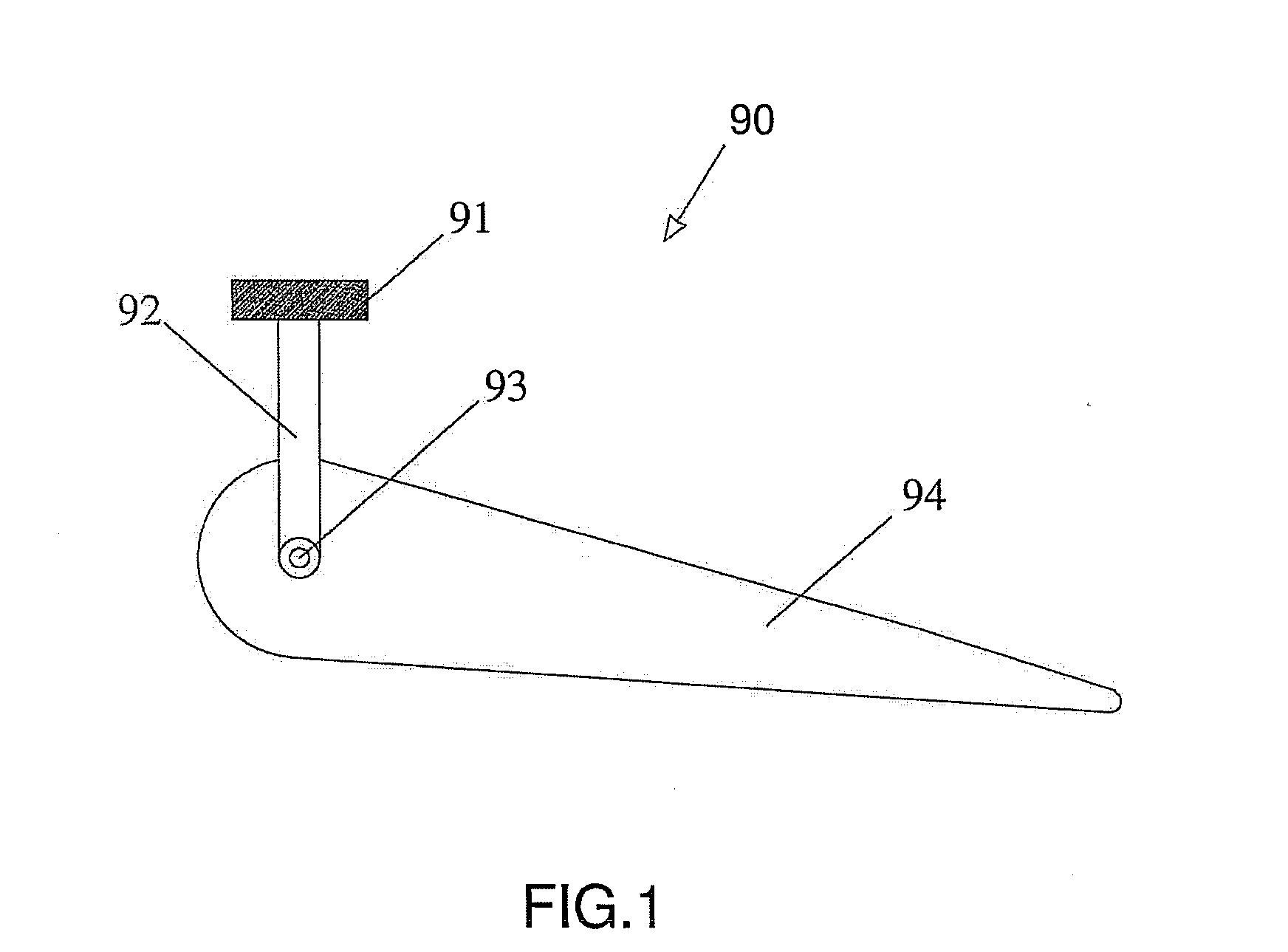

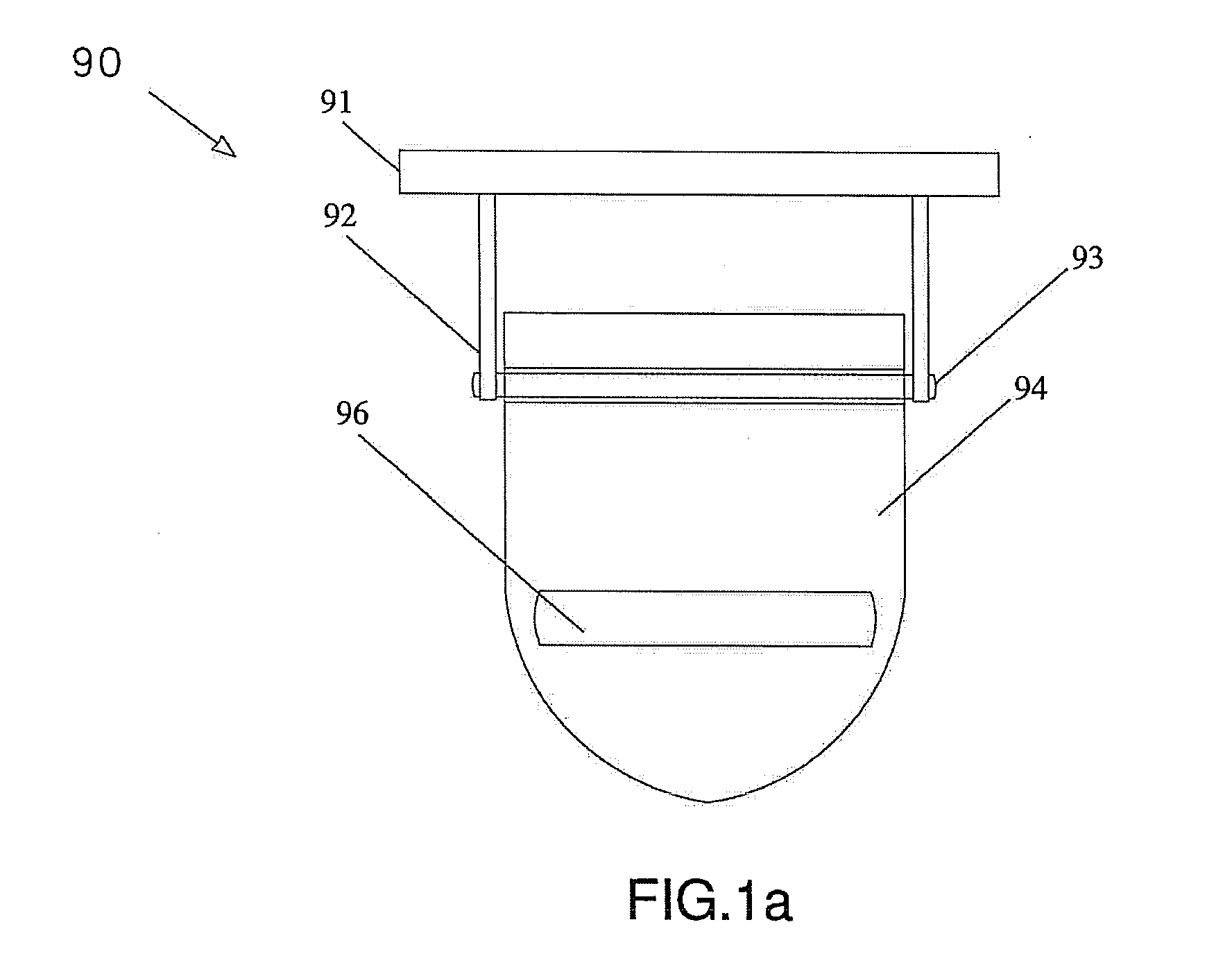

Dielectric elastomer powered boat and electricity generator and associated method

InactiveUS20150214862A1High energy densityIncrease energy densityPropellersPump componentsElectric generatorTransformer

A system is disclosed in which ocean wave power compresses smart electro-active polymers (EAP) material. Dielectric elastomers (DE) convert ocean wave power pressure into electrical current. Advantageously, DE has a very high power density and elasticity. The resultant electrical power is directly used to operate an electric motor of a boat screw propeller or stored in a lithium-ion battery for any other use. The mechanical work produced by the movement of ocean waves can also be transformed into electrical current via a crank shaft and a dynamo using very strong magnets or neodymium magnets that are made of a combination of neodymium, iron, and boron (NdFeB). An underwater and above water screw propeller propagates the boat at high speed across the ocean. Electrical power produced on board during port parking or unused energy is connected to a transformer or supplied for recharging electrical vehicles or port lighting.

Owner:DAKHIL FAROUK

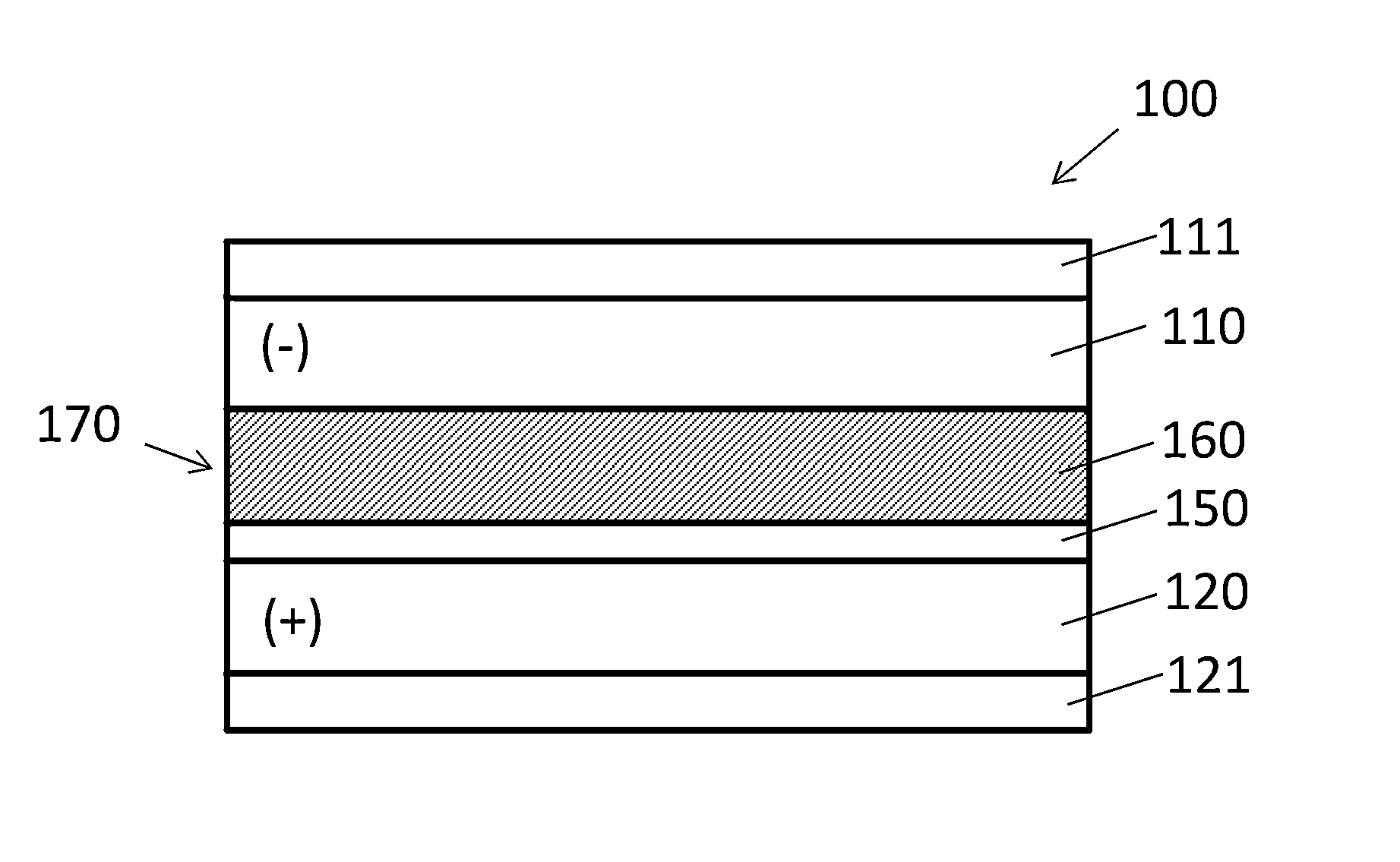

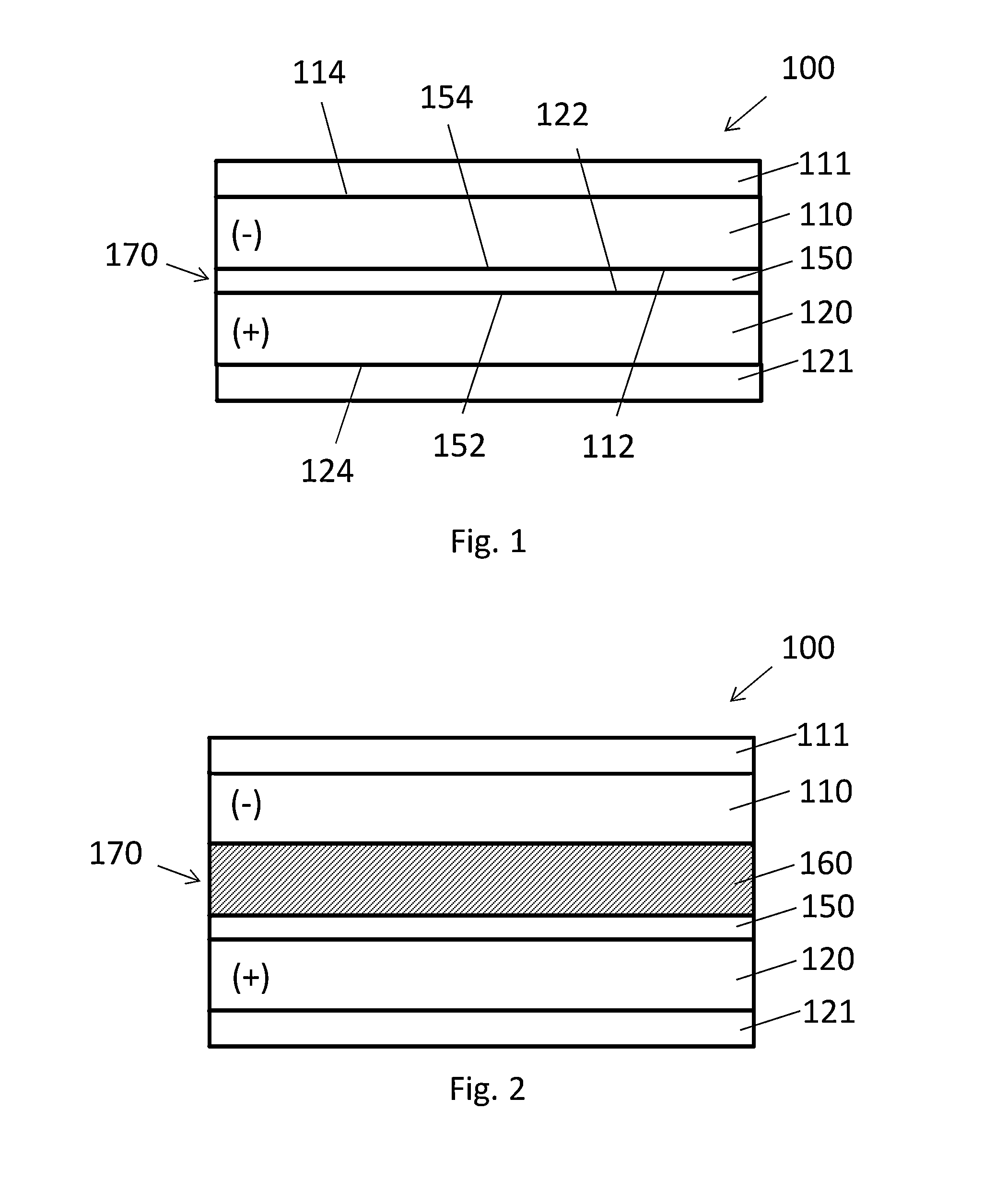

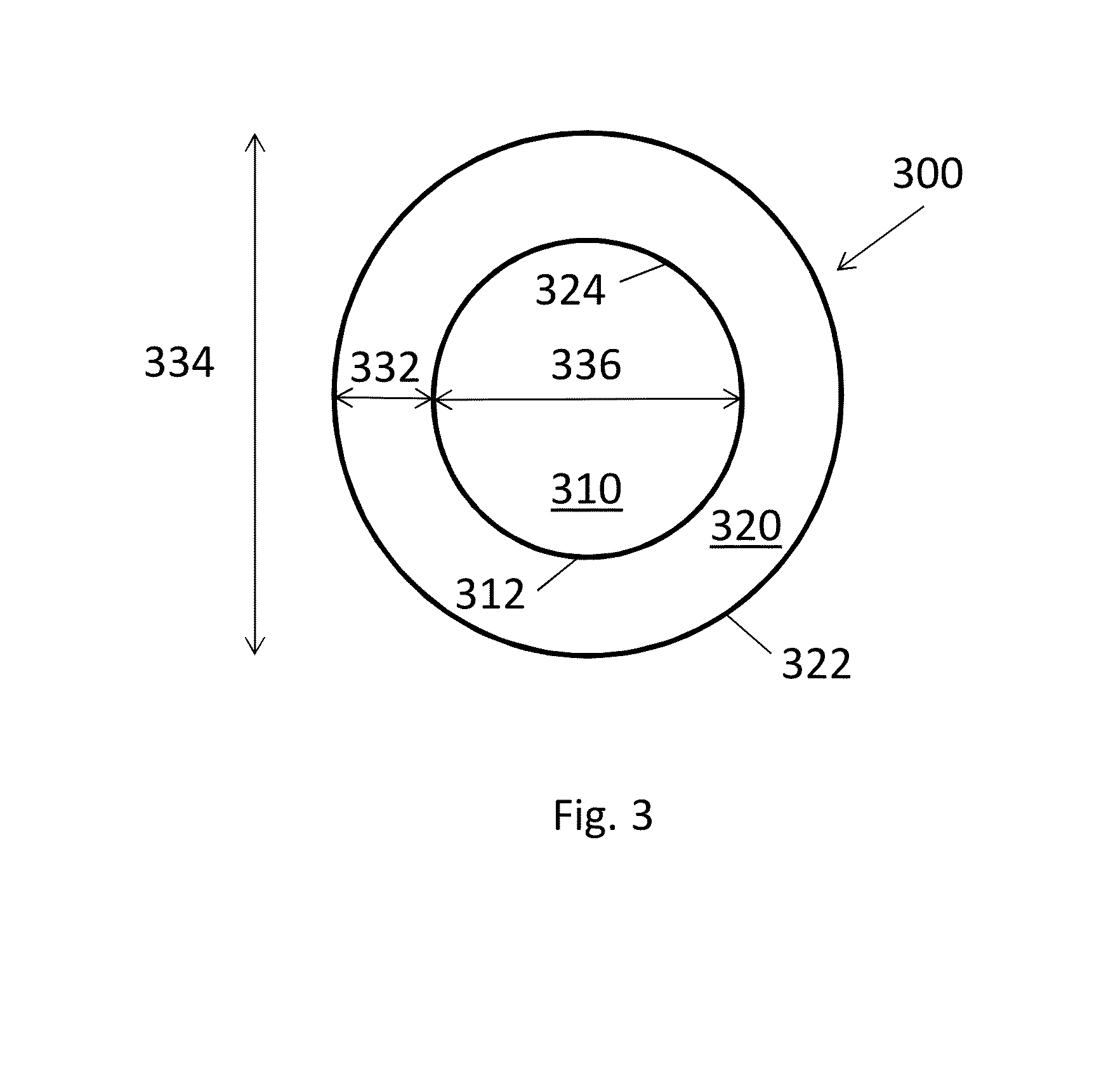

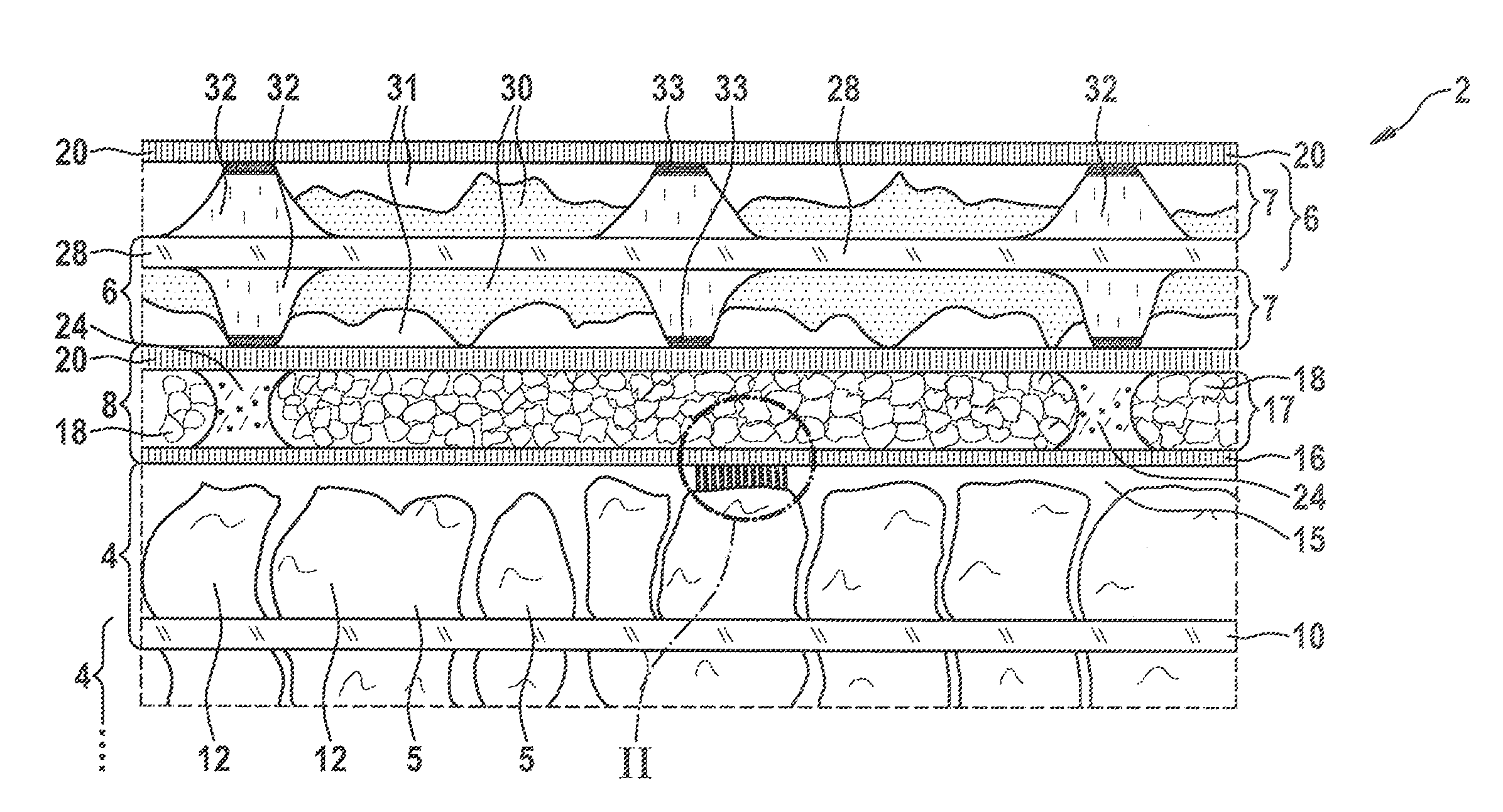

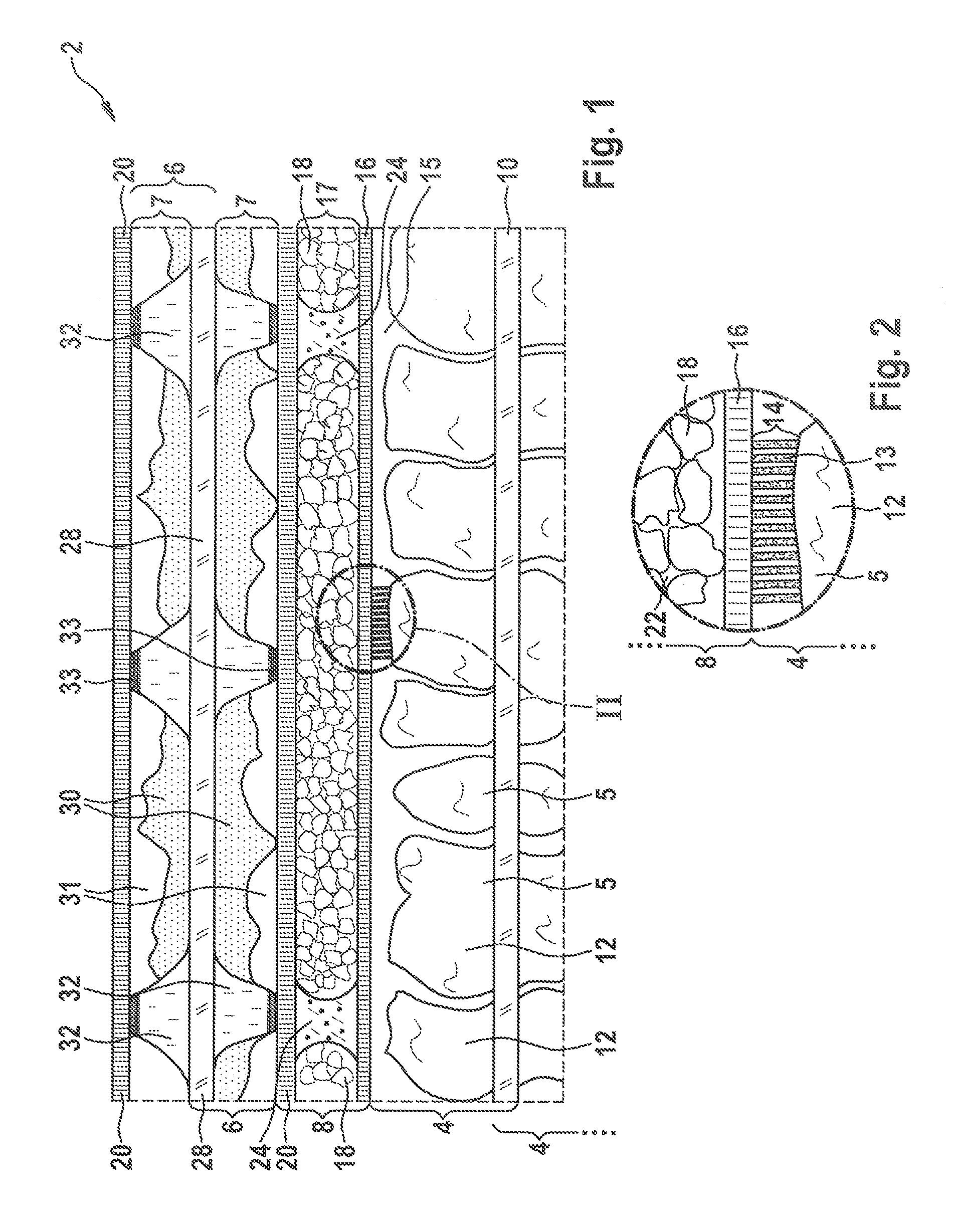

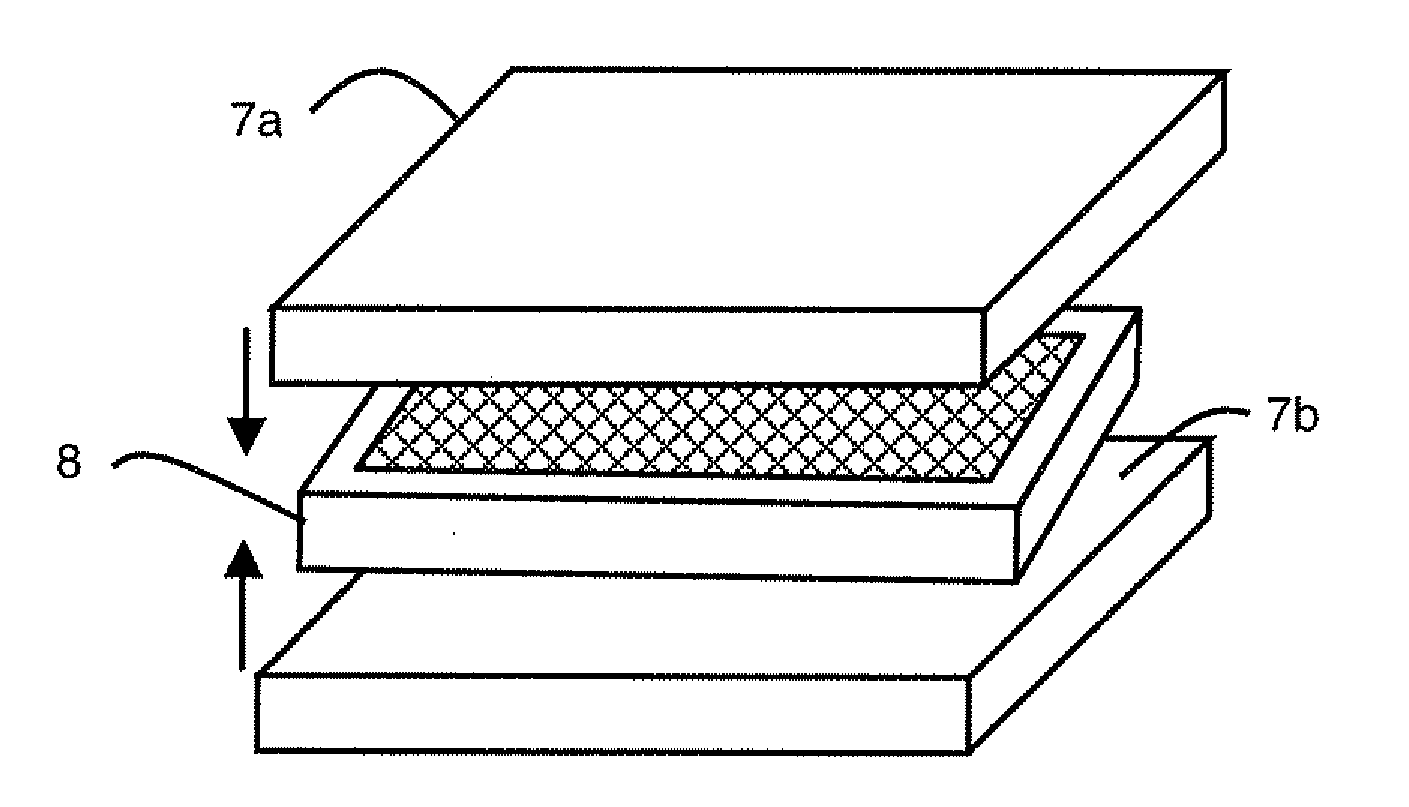

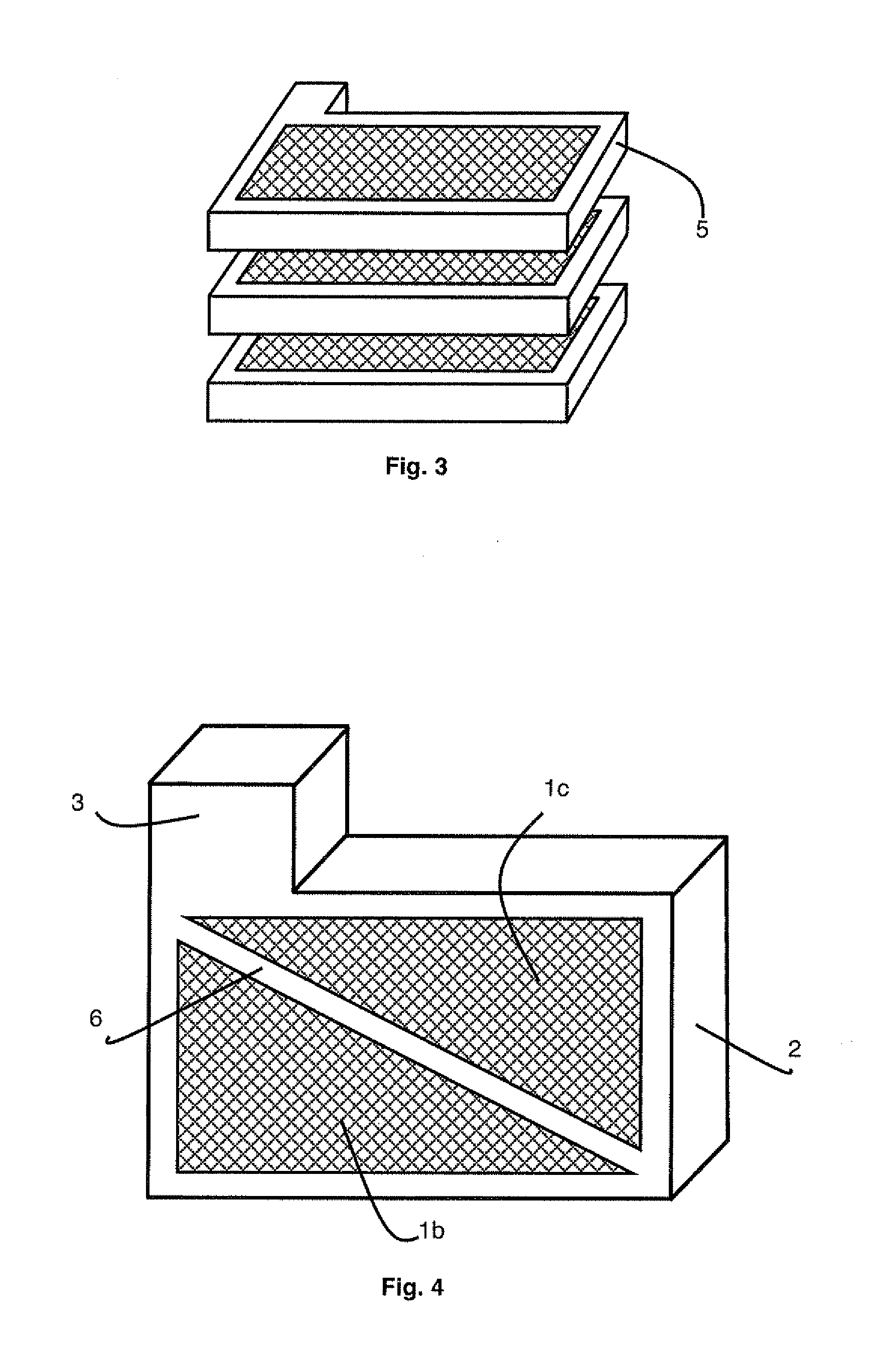

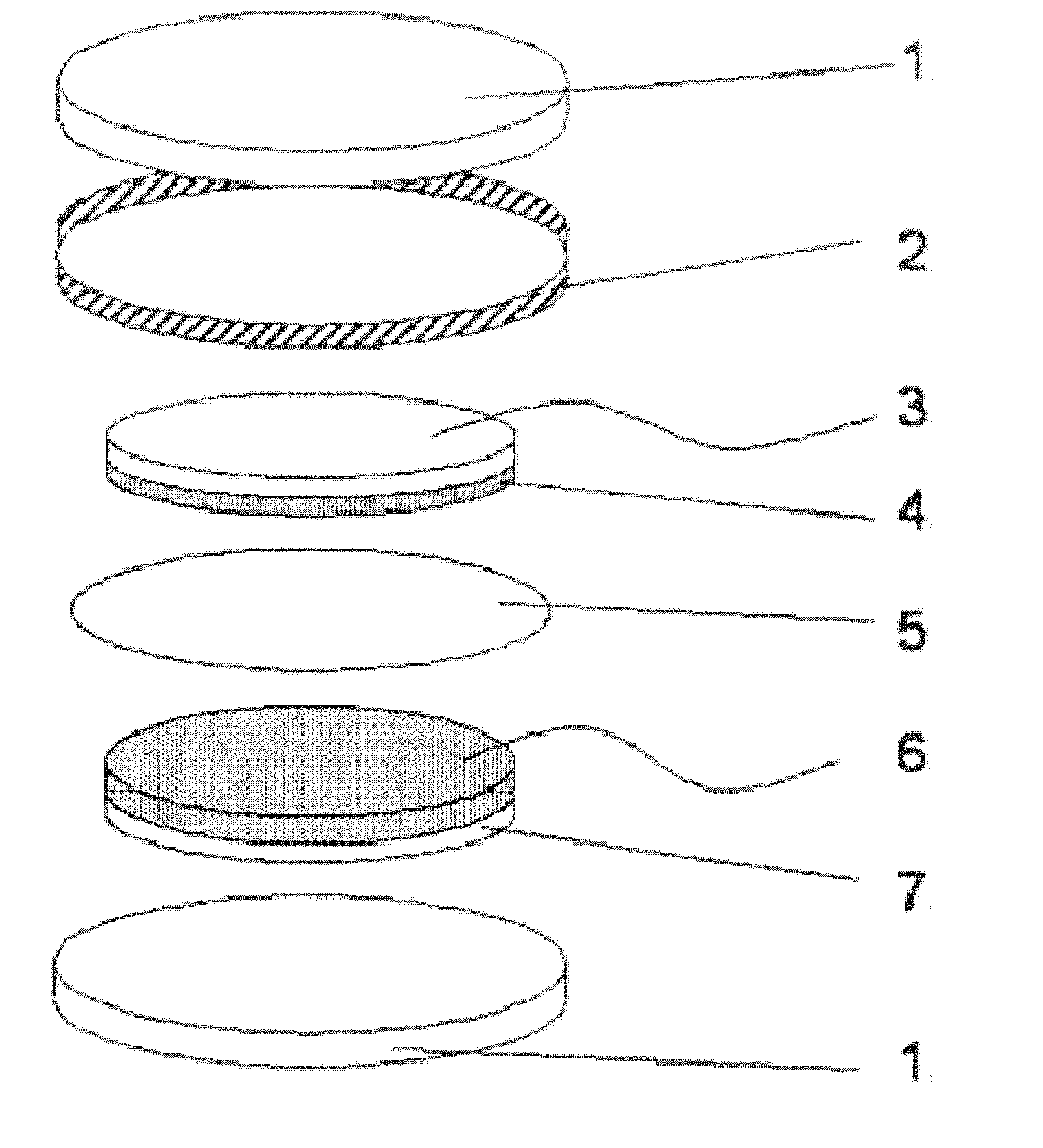

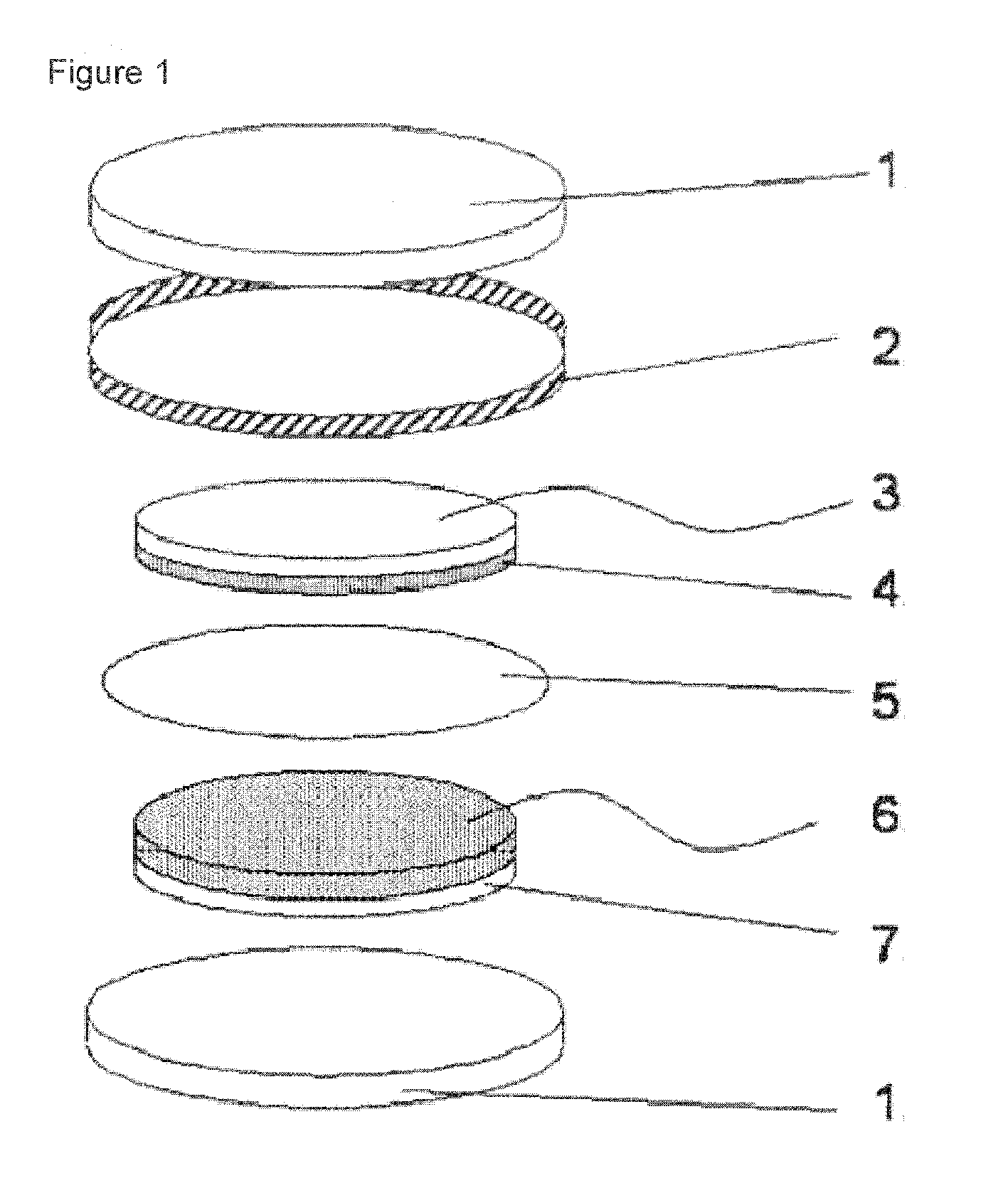

Separator and galvanic cell providing robust separation of anode and cathode

ActiveUS20160111701A1Prevent be damageHigh energy densityLi-accumulatorsCell component detailsAnodePolymer

A separator having a first polymer diaphragm and a second polymer diaphragm and a layer between the first polymer diaphragm and the second polymer diaphragm including particles featuring low elasticity, the first polymer diaphragm and the second polymer diaphragm being interconnected, which may be periodically, by first support elements. In addition, a galvanic cell and a battery having such a separator are provided.

Owner:ROBERT BOSCH GMBH

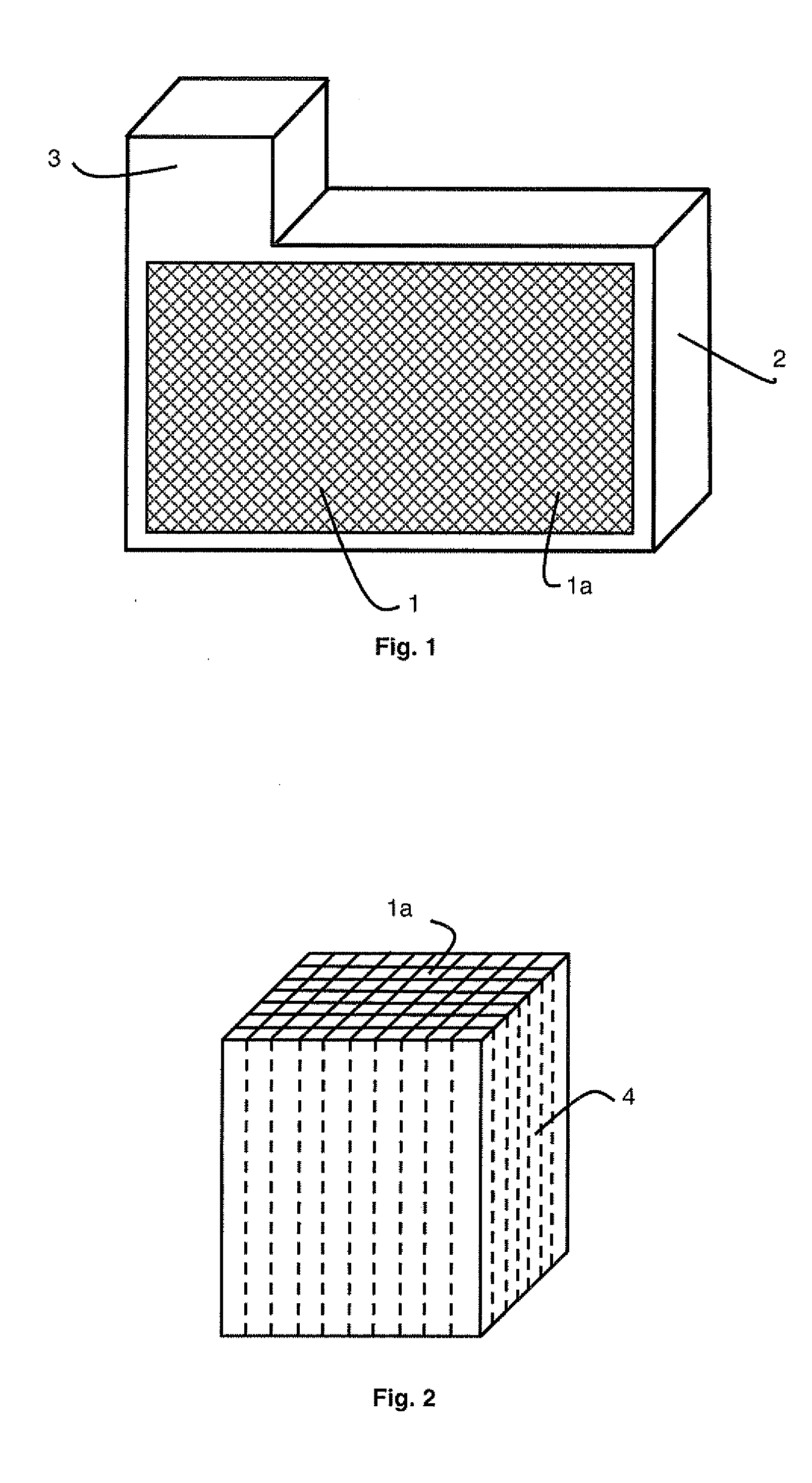

Acid-lead battery electrode comprising a network of pores passing therethrough, and production method

InactiveUS20120003543A1Easy to produceHigh energy densityElectrochemical processing of electrodesFinal product manufactureEngineeringBattery electrode

A structure including a network of parallel, homogeneous pores extending through the structure, and an outer frame around the lateral faces of the structure. The structure and the frame are made of carbon. The electrode is covered by a layer based on lead. The pores are filled with an active material based on lead.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

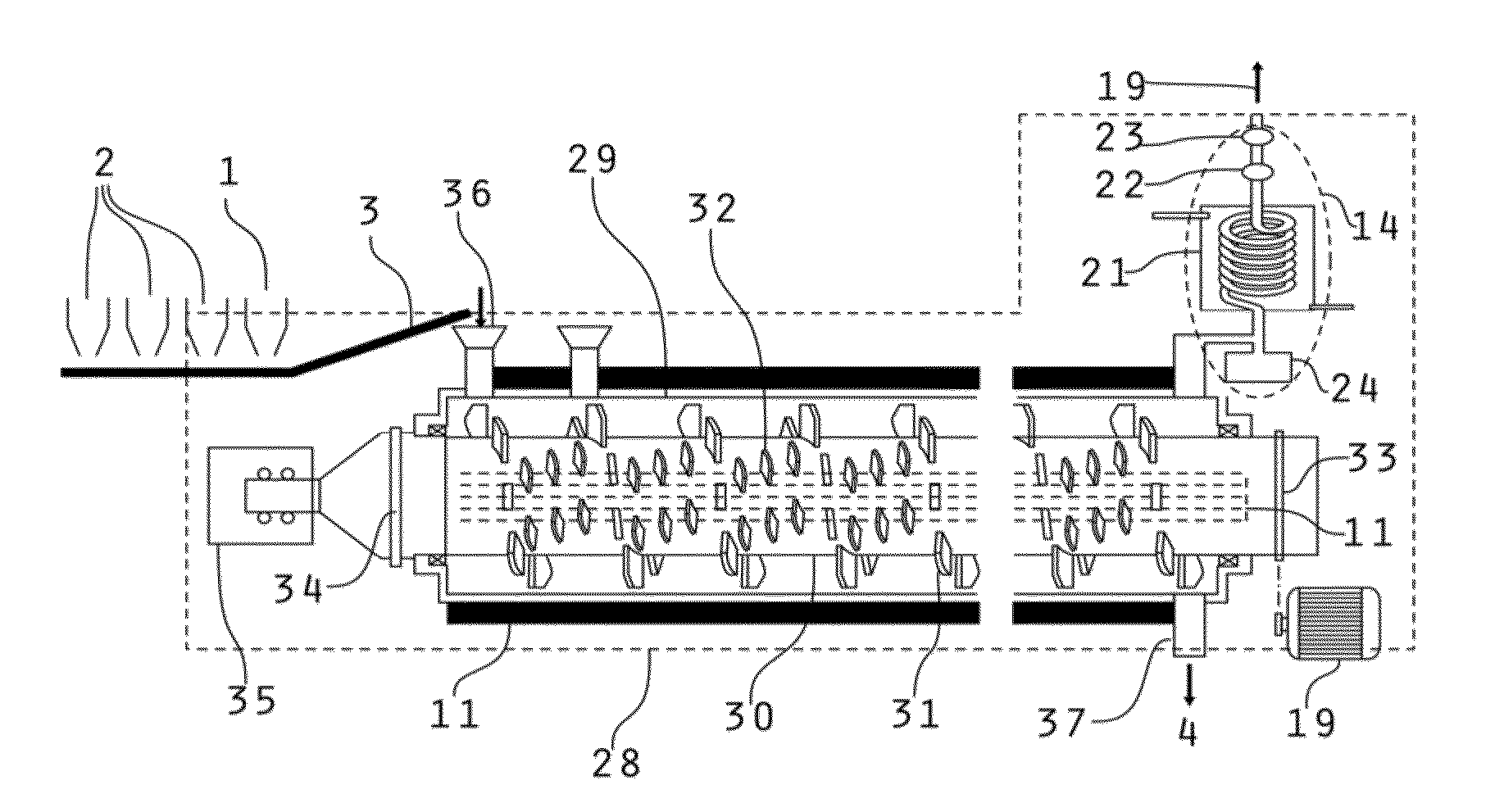

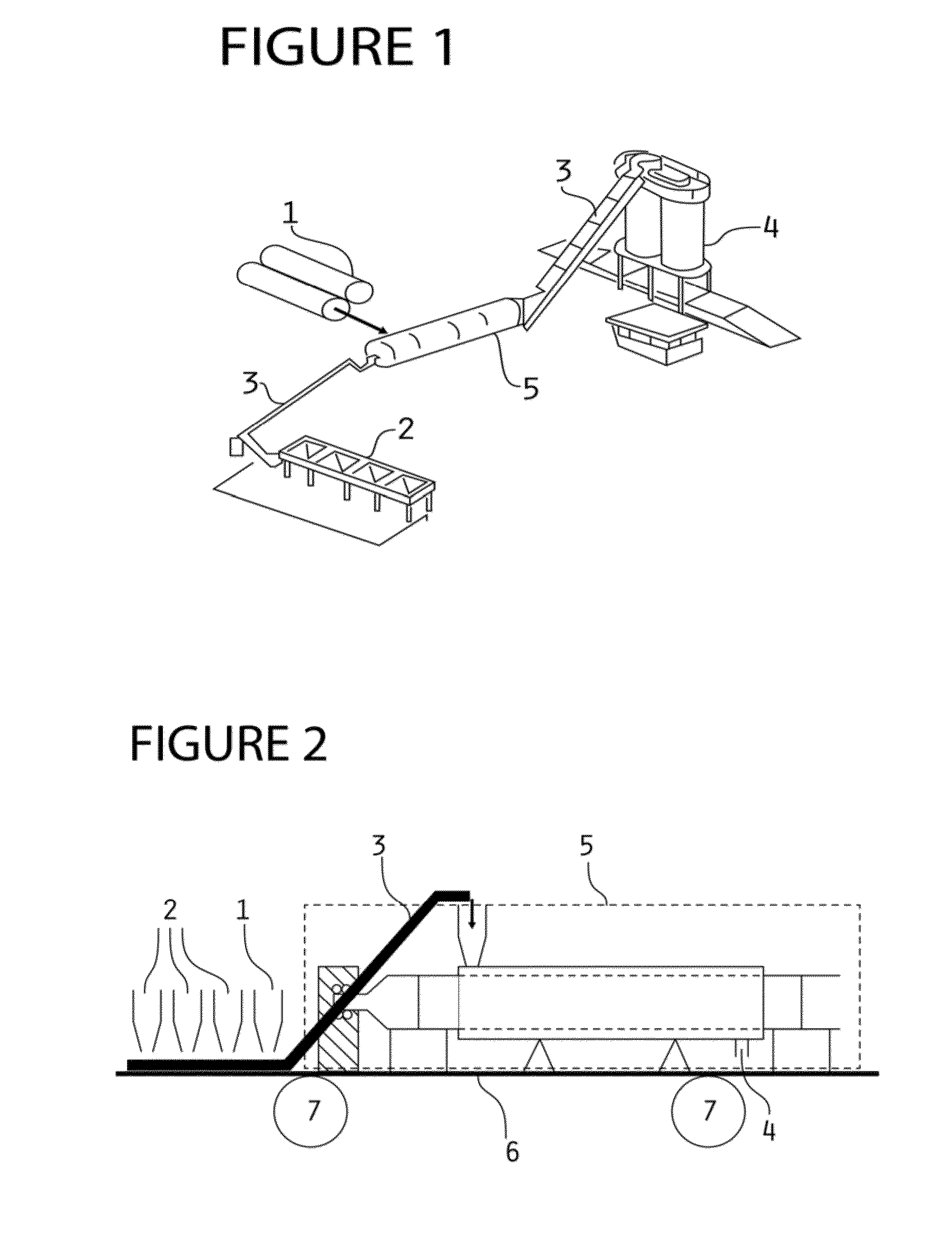

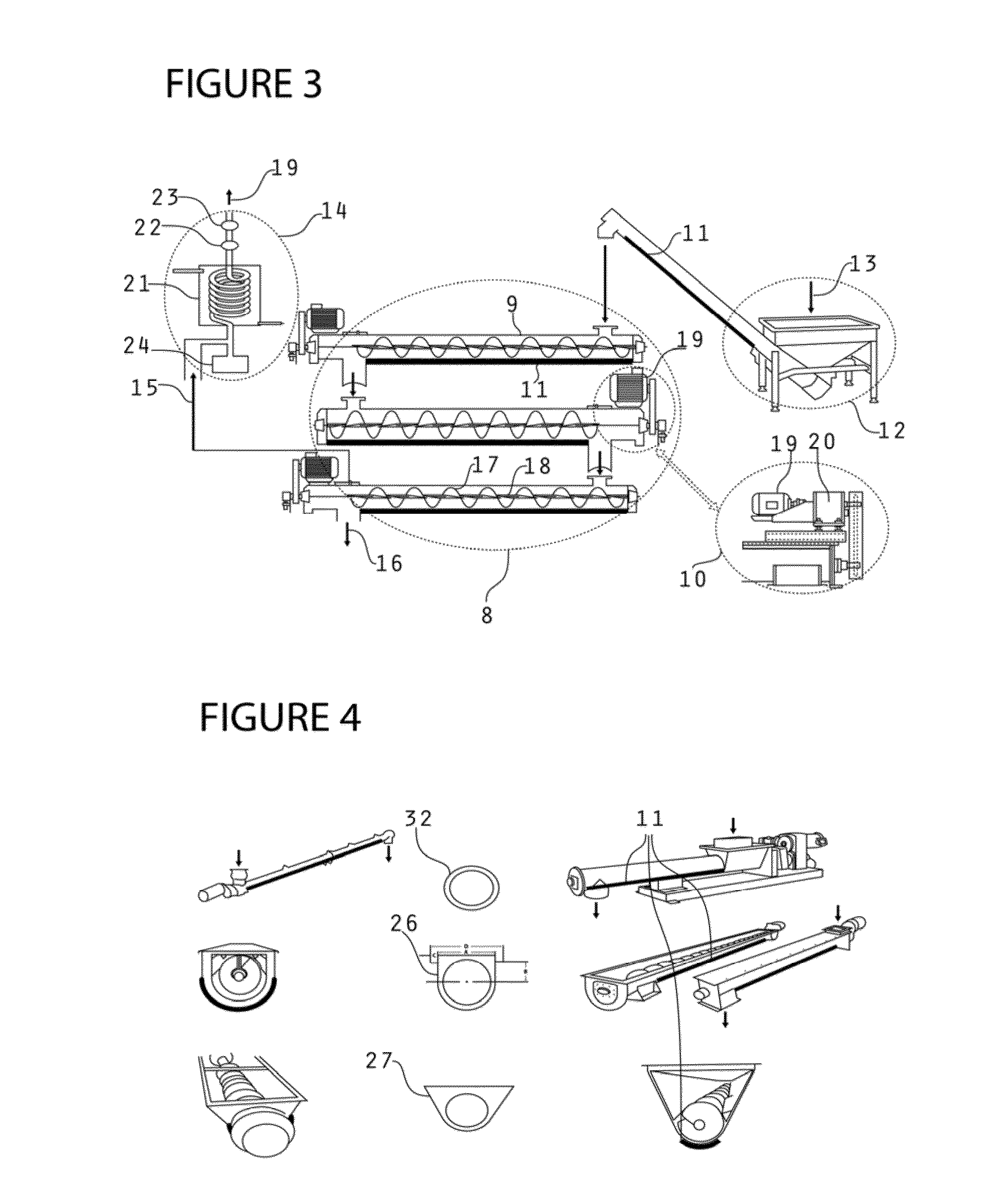

Hot (or warm) mix asphalt plants capability of producing up to 100 percent rap (or ars) recycled asphalt mixes

ActiveUS20160199799A1Reduce air pollutionHigh energy densityRotating receptacle mixersTransportation and packagingOil burnerMaterial transfer

A hot mix asphalt (HMA) or warm mix asphalt (WMA) plant features material transfer by shear action of segmented screws and directional flights standing on an inner drum. Indirect convective material heating is initiated by a heating source located inside of the inner drum. Material mixing, heating, melting, and uniform coating, all take place as a single simultaneous process. As the result of processing, regular HMA (or WMA) or up to 100% RAP (or ARS) recycled HMA (or WMA) can be produced. Many heat sources, such as a conventional oil burner and the surface combustion burner, may also be utilized in the plant. The plant may be combined with paving units for an integrated, mobile paving system.

Owner:HUH JUNG DO

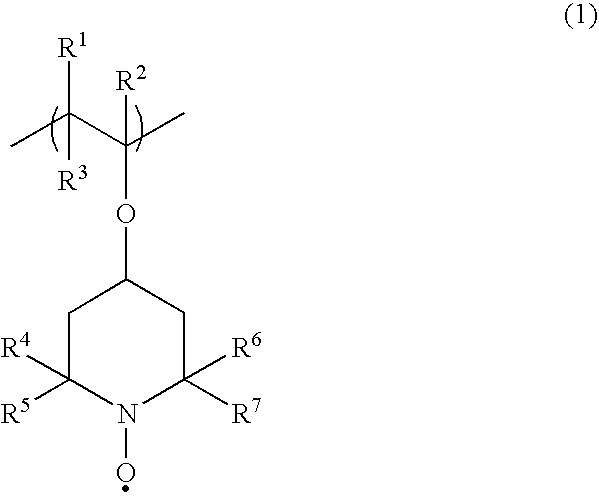

Polyradical compound-conductive material composite, method for producing the same, and battery using the same

ActiveUS20100009256A1High capacity densityHigh energy densityNon-aqueous electrolyte accumulator electrodesCell component detailsDecompositionHigh energy

Disclosed is a composite body of an electrode active material and a conductivity-imparting agent, which has high capacity density and enables to take out a large current. Also disclosed are a method for producing such a composite body, and a battery having high energy density and a large output power. Specifically, a polyradical compound as an electrode active material and a conductive material are heated and mixed at a temperature not less than the softening temperature but less than the decomposition temperature of the polyradical compound, thereby for forming a composite body of the polyradical compound and the conductive material. By producing an electrode using such a composite body, there can be obtained a novel battery having high energy density and large output power.

Owner:NEC CORP

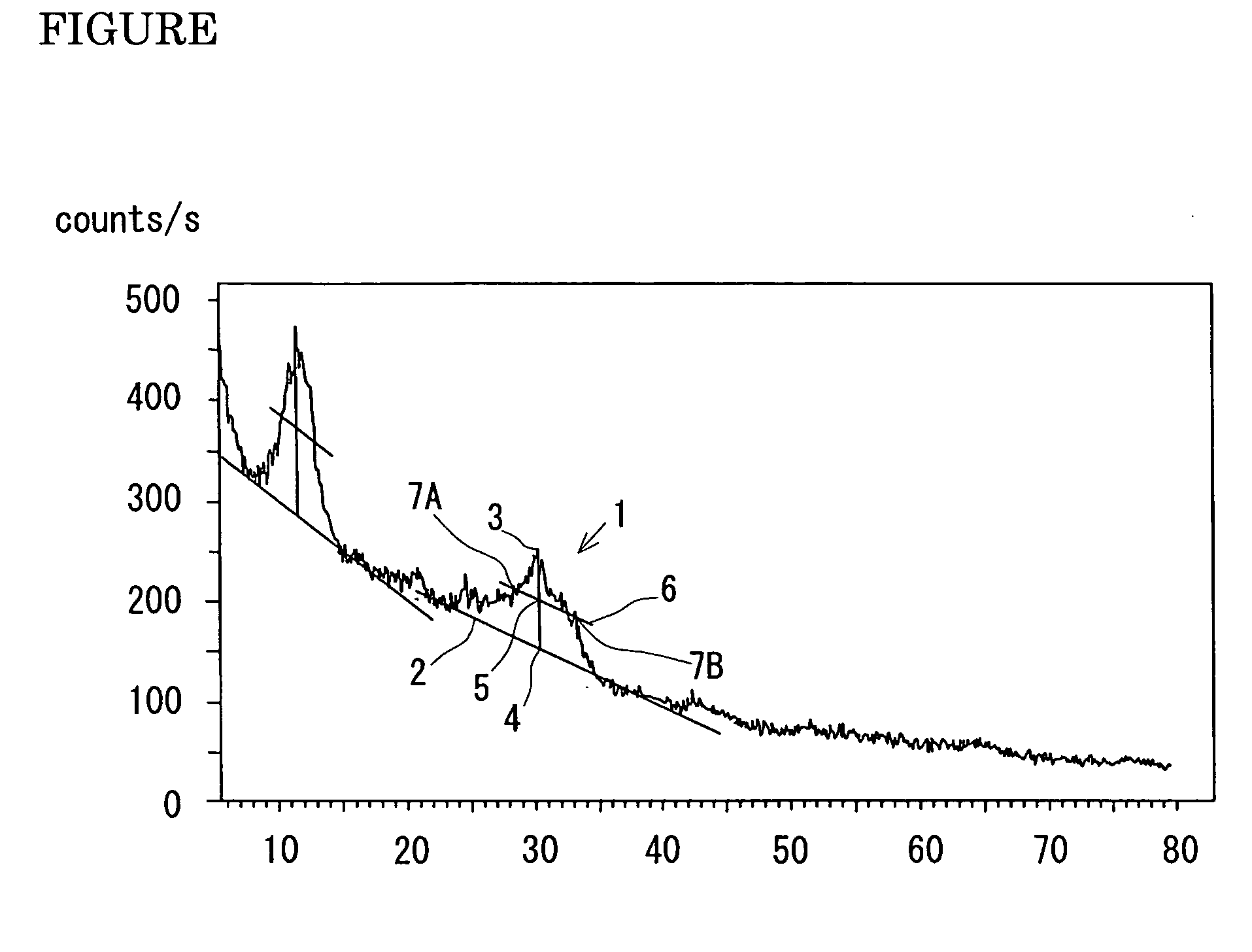

Lithium secondary battery anode member and method for manufacturing the same

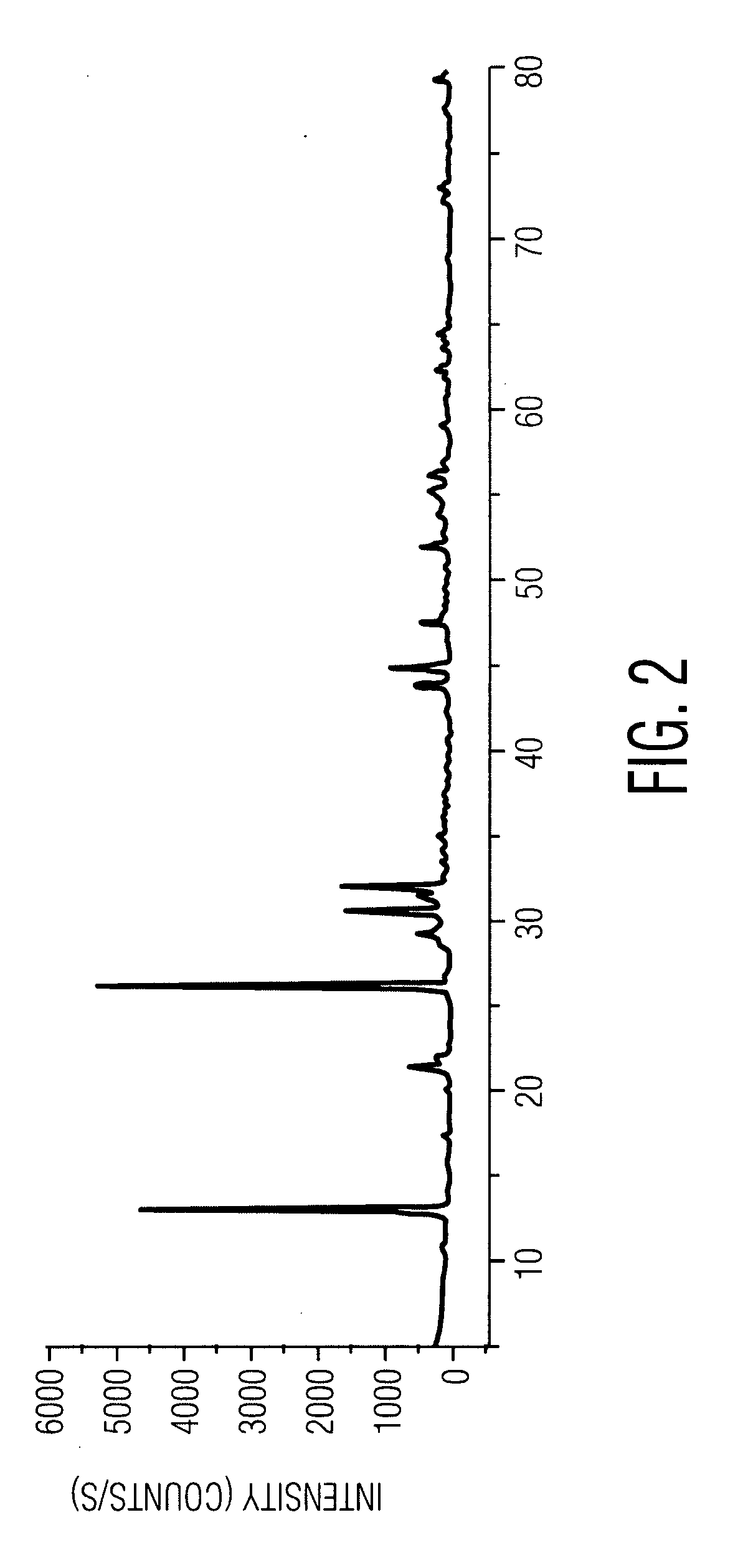

InactiveUS20060292449A1High energy densityExcellent charge-discharge cycling propertyElectrode manufacturing processesFinal product manufactureRadiationMetal

A lithium secondary battery anode member of the present invention includes a solid electrolyte film formed on a lithium metal film and is capable of suppressing reduction of the solid electrolyte film over a long period of time. In the lithium secondary battery anode member, the lithium metal film and the solid electrolyte film are laminated on a substrate, the solid electrolyte film contains the composition xLi.yP.zS.wO wherein x, y, z, and w satisfy the relations, 0.2≦x≦0.45, 0.1≦y≦0.2, 0.35≦z≦0.6, and 0.03≦w≦0.13, respectively, (x+y+z+w=1), and the main peaks of an X-ray diffraction pattern of the solid electrolyte film measured by a film method using Cu Kα radiation are at 2θ of about 11° and 30° and each have a half width of 10° or less.

Owner:SUMITOMO ELECTRIC IND LTD

Electrode active material for non-aqueous secondary batteries

InactiveUS20100112444A1Prolonging electrode lifeHigh energy densityElectrode manufacturing processesNon-aqueous electrolyte accumulatorsCurrent collectorLithium

An electrode for non-aqueous secondary batteries that is capable of intercalating and de-intercalating an alkali metal, such as lithium, and a non-aqueous secondary battery comprising the electrode are disclosed. The electrode comprises an electrode current collector, and, on the electrode current collector, an electrode active material. The electrode active material has the overall composition: SiaMbPc, in which 0<a<1, 0≦b<1, 0<c<1, and a+b+c=1; and M is selected from the group consisting of Mn, Co, Ni, Sn, Fe, and mixtures thereof. Depending on the redox potential of the other electrode in the battery, the electrode may be either a positive electrode (cathode) or a negative electrode (anode).

Owner:PANASONIC CORP

Lithium ion capacitor

ActiveUS20140002960A1Low internal resistanceHigh energy densityHybrid capacitor electrolytesLiquid electrolytic capacitorsPhysicsTotal thickness

Provided is a lithium ion capacitor having a low internal resistance, a high energy density, and a high capacity retention rate.The lithium ion capacitor includes a positive electrode having a positive electrode active material layer formed on a roughened positive electrode current collector, a negative electrode having a negative electrode active material layer containing graphite-based particles formed on a negative electrode current collector, and an electrolytic solution containing a solution of a lithium salt in an aprotic organic solvent, wherein the total thickness of the positive electrode active material layer is 50 μm to 140 μm, and the ratio of mass of the positive electrode active material layer to the sum of the mass of the positive electrode active material layer and that of the negative electrode active material layer is 0.4 to 0.5.

Owner:MUSASHI ENERGY SOLUTIONS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com