Patents

Literature

36results about How to "Low material cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dendrite-Intercepting layer for alkali metal secondary battery

ActiveUS20160301075A1High energy densityLow material costElectrode manufacturing processesNegative electrodesElectrochemical decompositionLithium

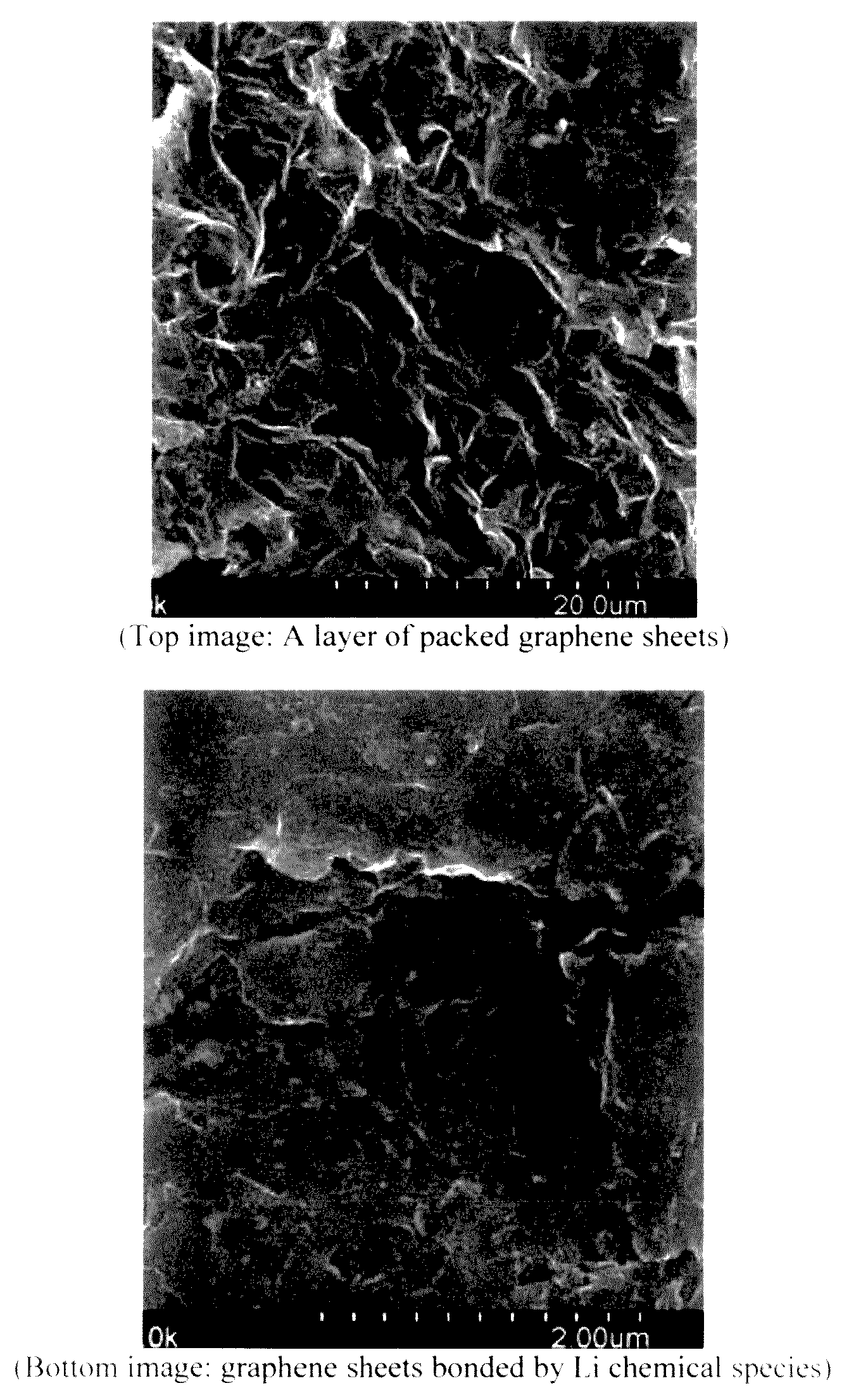

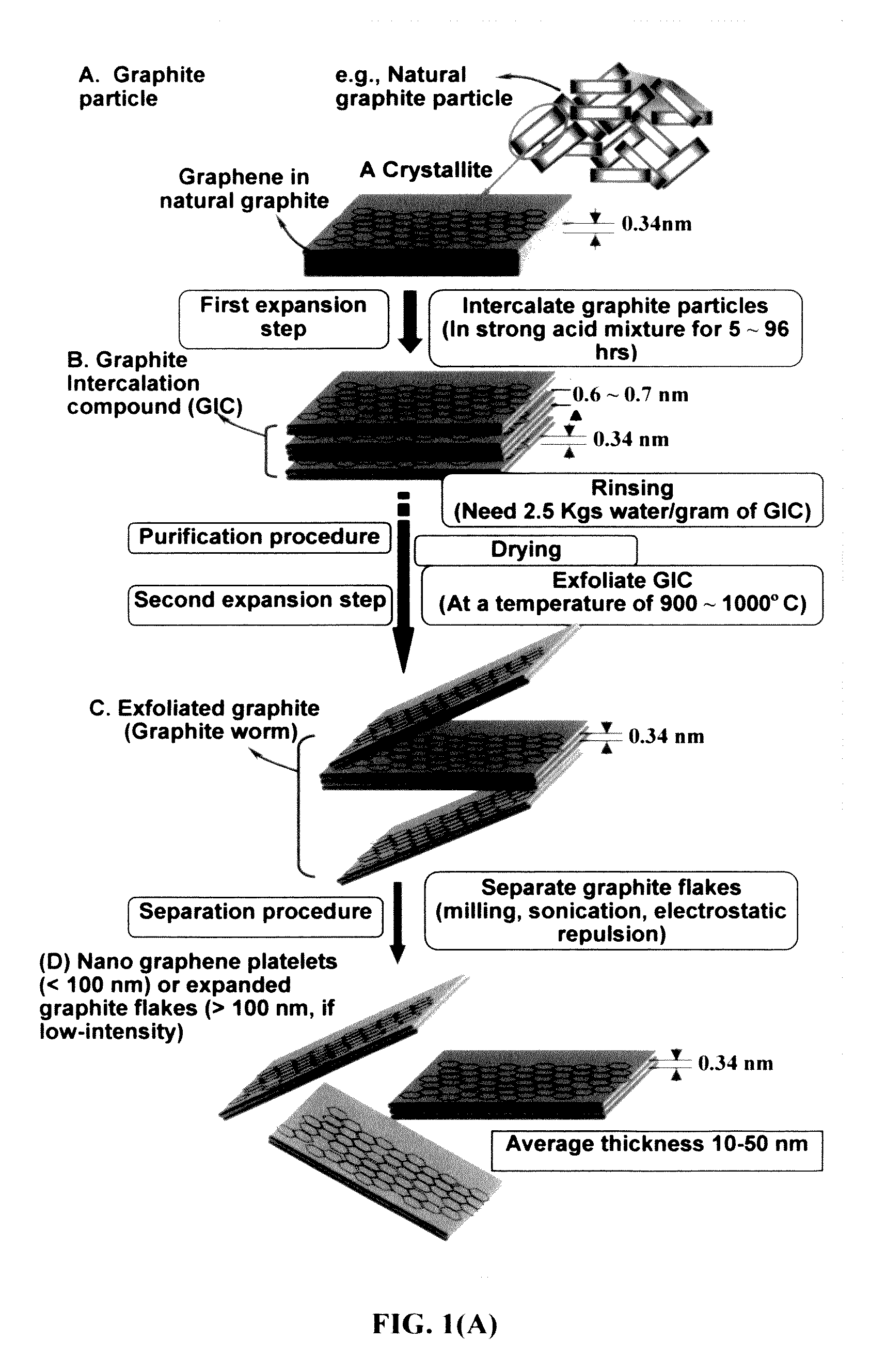

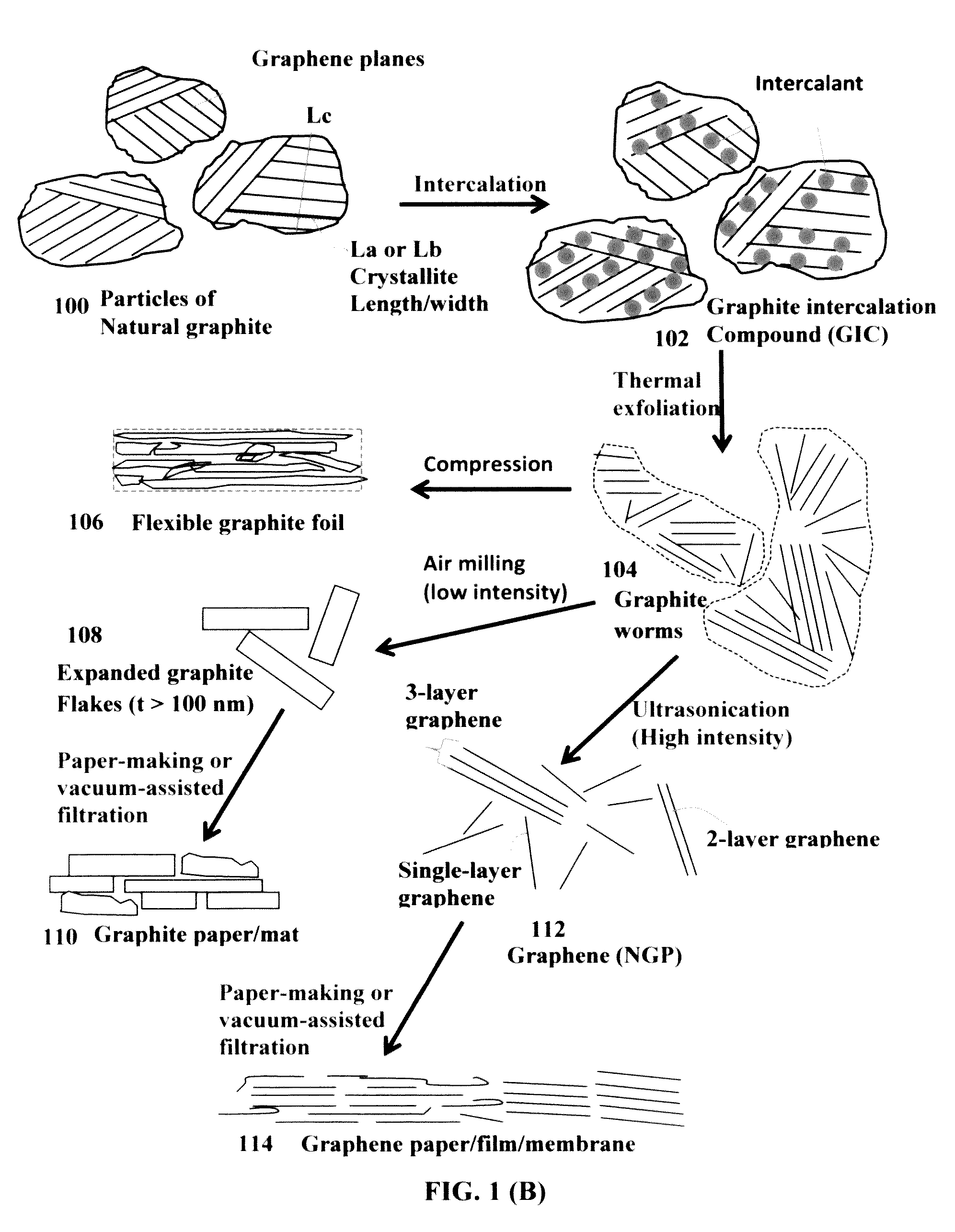

A dendrite penetration-resistant layer for a rechargeable alkali metal battery, comprising multiple graphene sheets or platelets or exfoliated graphite flakes that are chemically bonded by a lithium- or sodium-containing species to form an integral layer that prevents dendrite penetration through the integral layer, wherein the lithium-containing species is selected from Li2CO3, Li2O, Li2C2O4, LiOH, LiX, ROCO2Li, HCOLi, ROLi, (ROCO2Li)2, (CH2OCO2Li)2, Li2S, LixSOy, Na2CO3, Na2O, Na2C2O4, NaOH, NaiX, ROCO2Na, HCONa, RONa, (ROCO2Na)2, (CH2OCO2Na)2, Na2S, NaxSOy, or a combination thereof, wherein X=F, Cl, I, or Br, R=a hydrocarbon group, x=0-1, y=1-4. Also provided is a process for producing a dendrite penetration-resistant layer based on the principle of electrochemical decomposition of an electrolyte in the presence of multiple graphene sheets.

Owner:GLOBAL GRAPHENE GRP INC

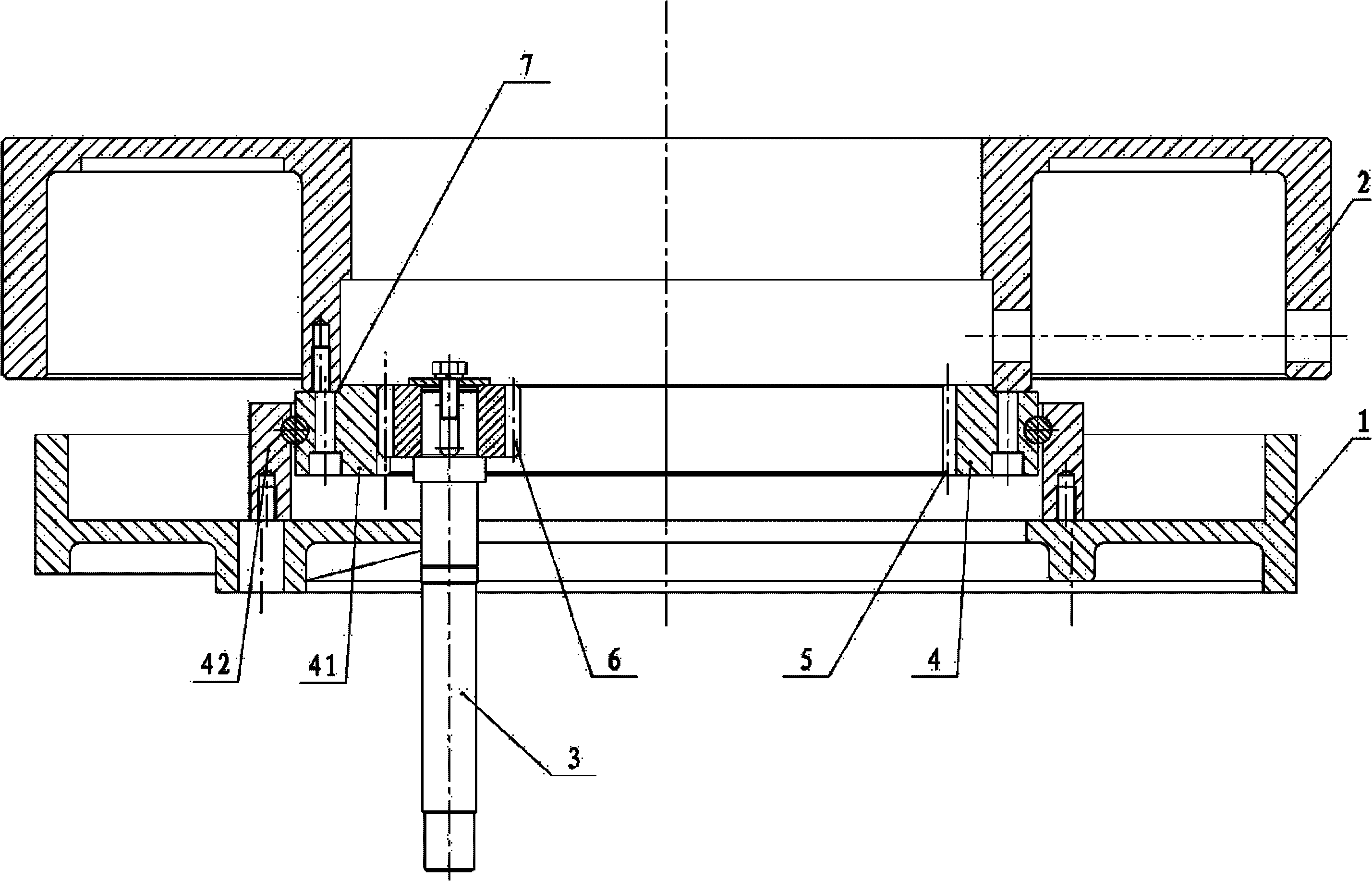

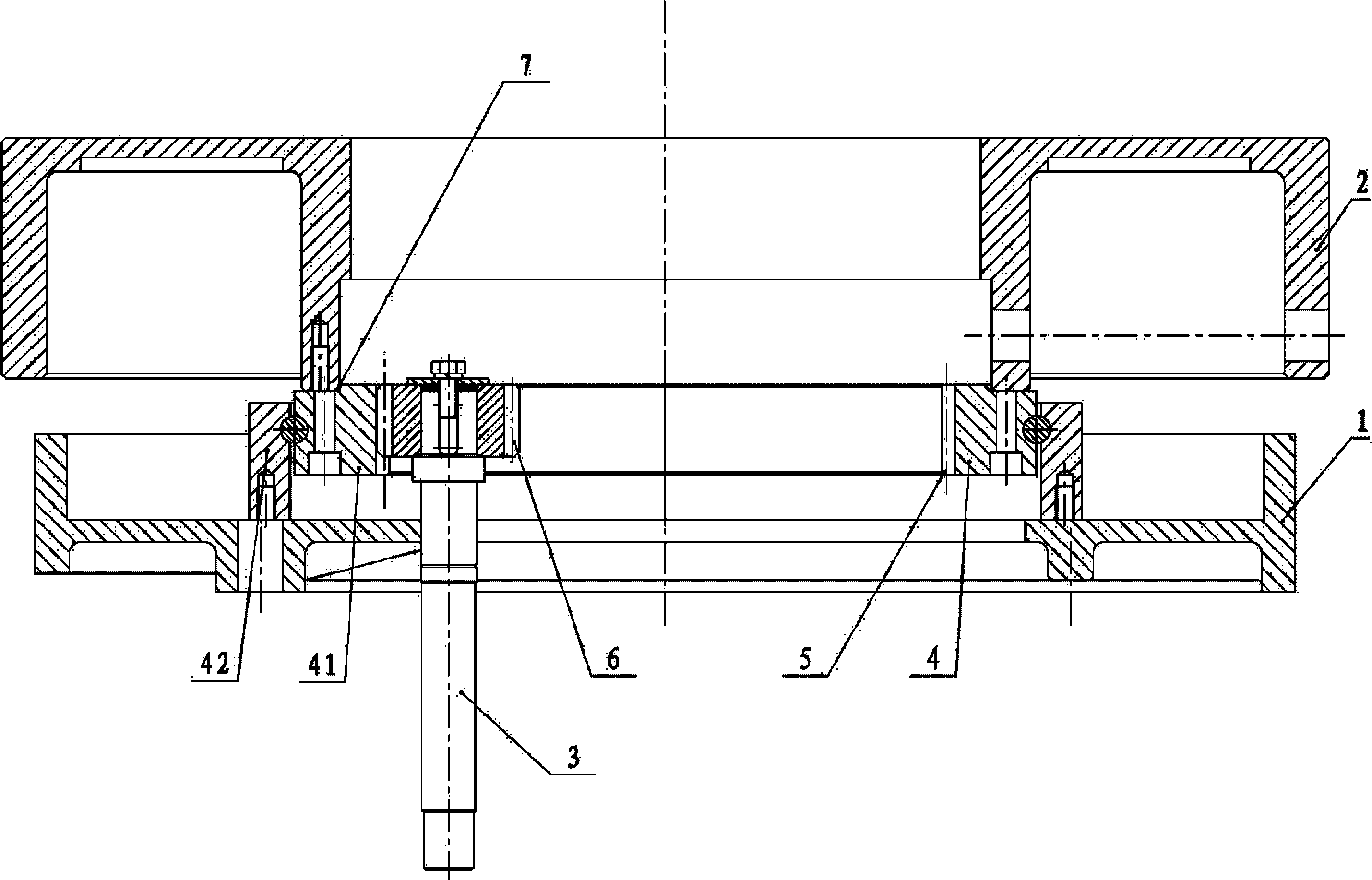

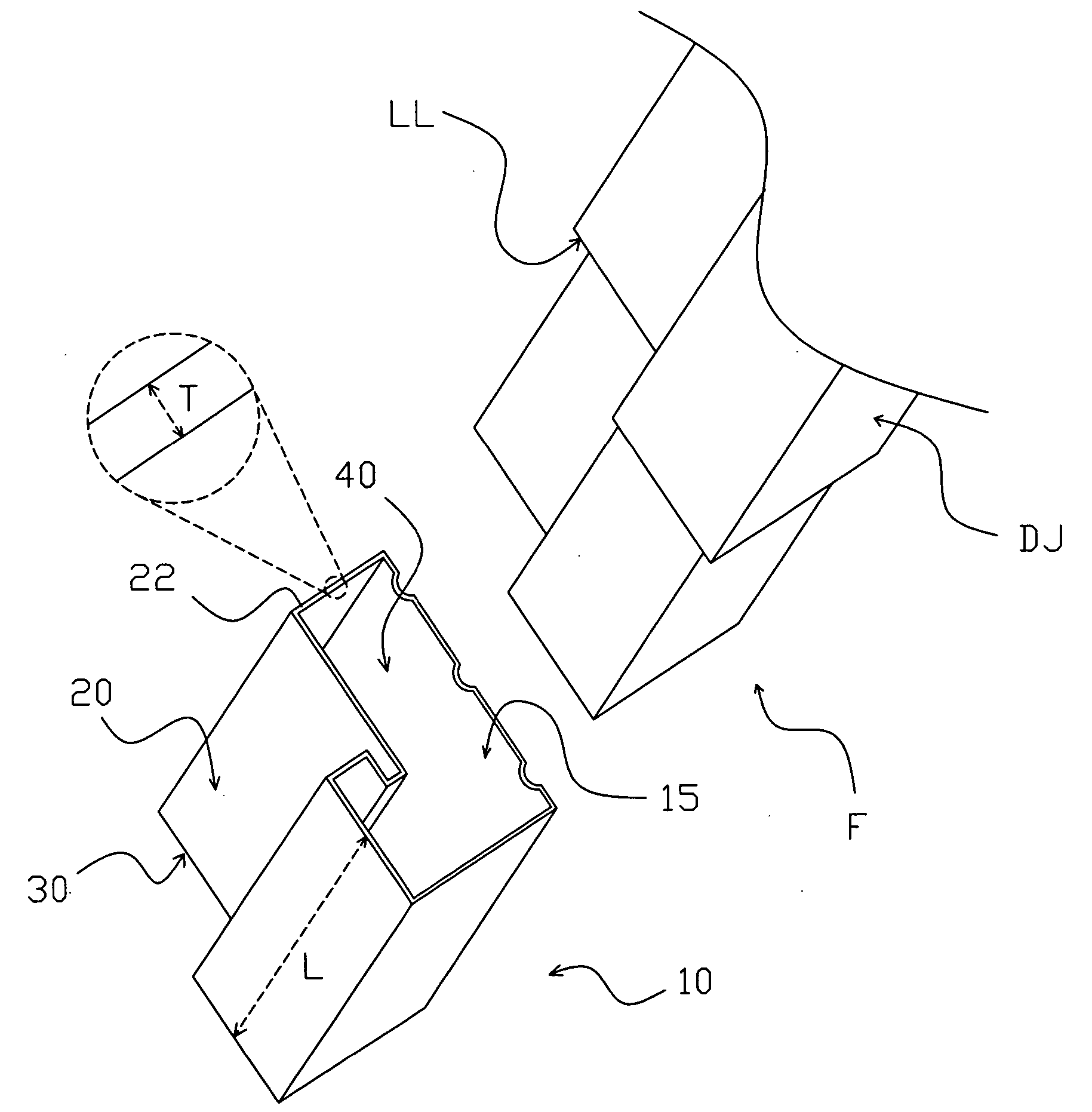

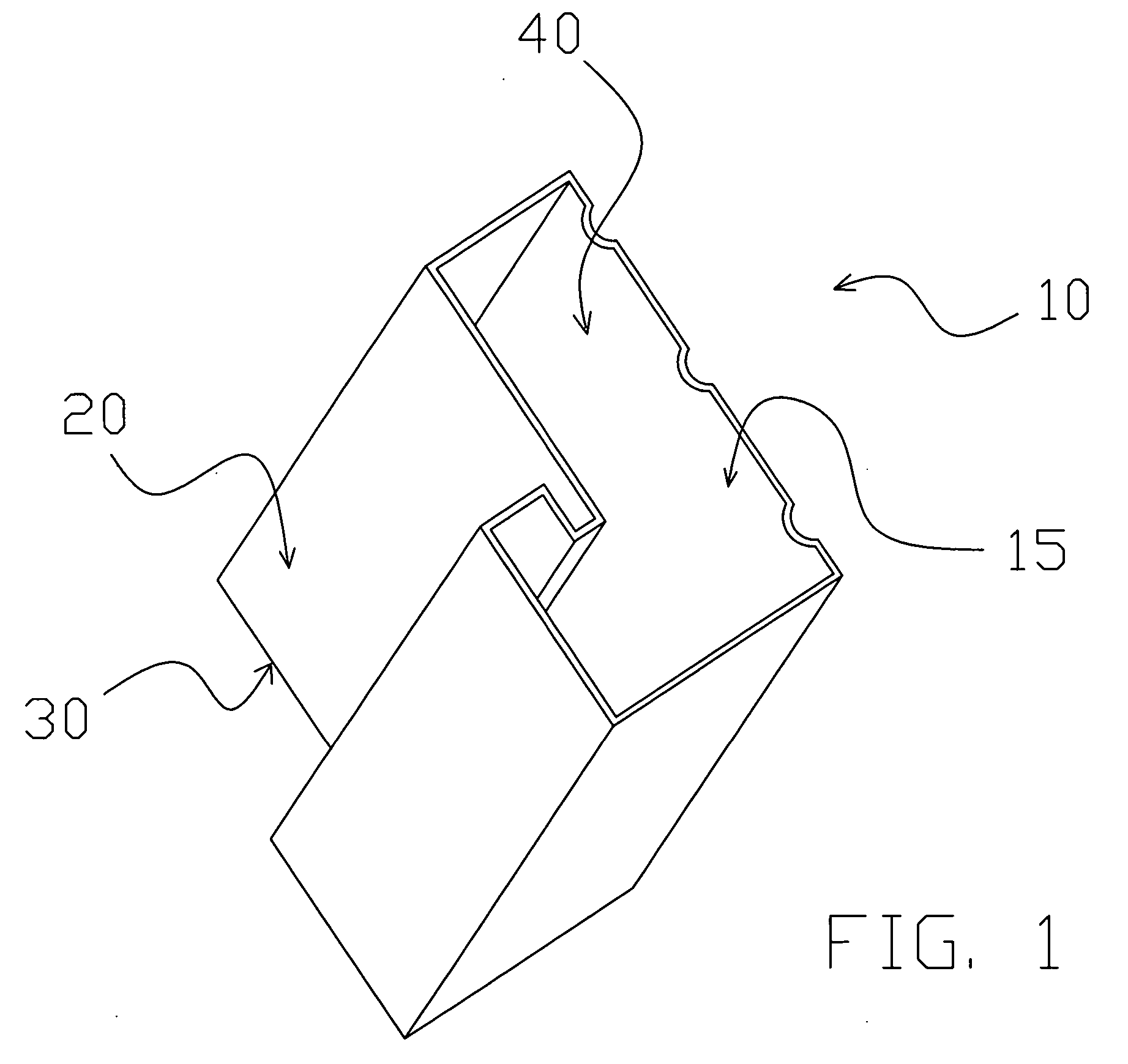

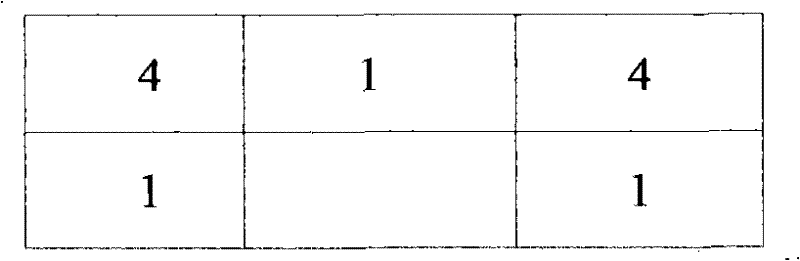

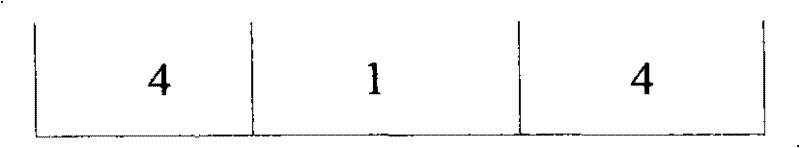

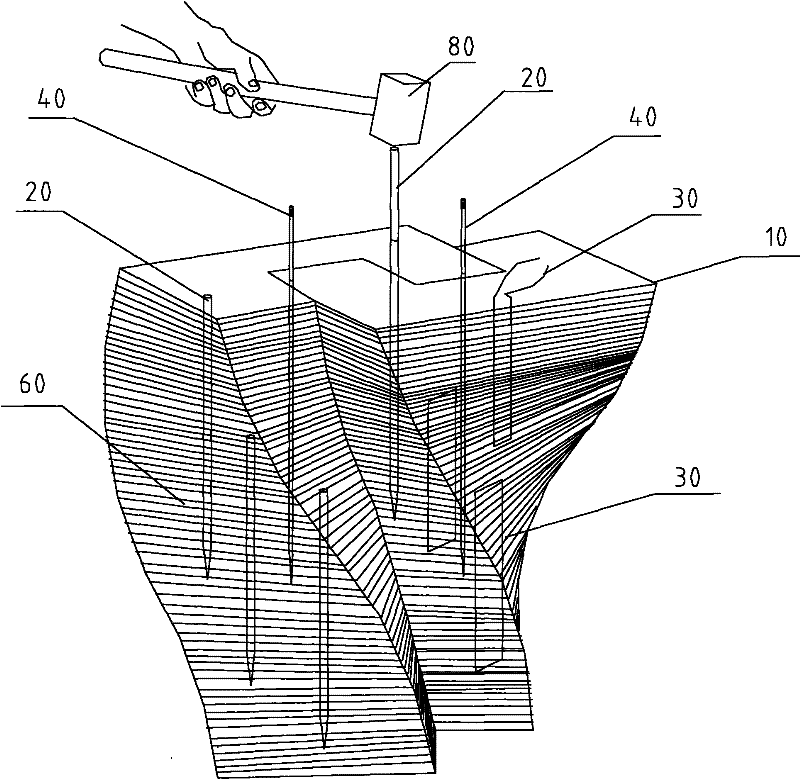

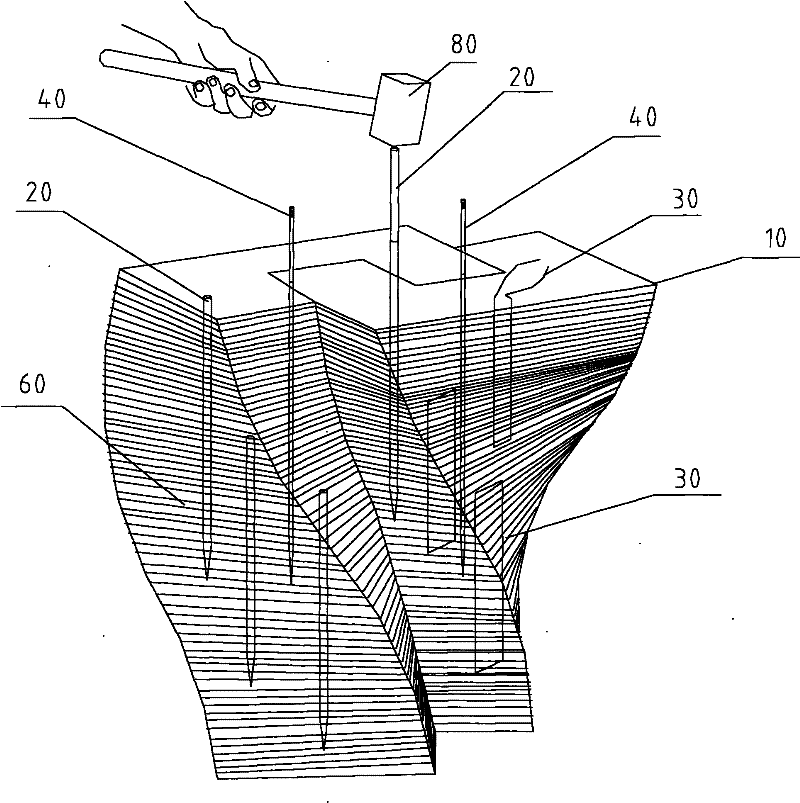

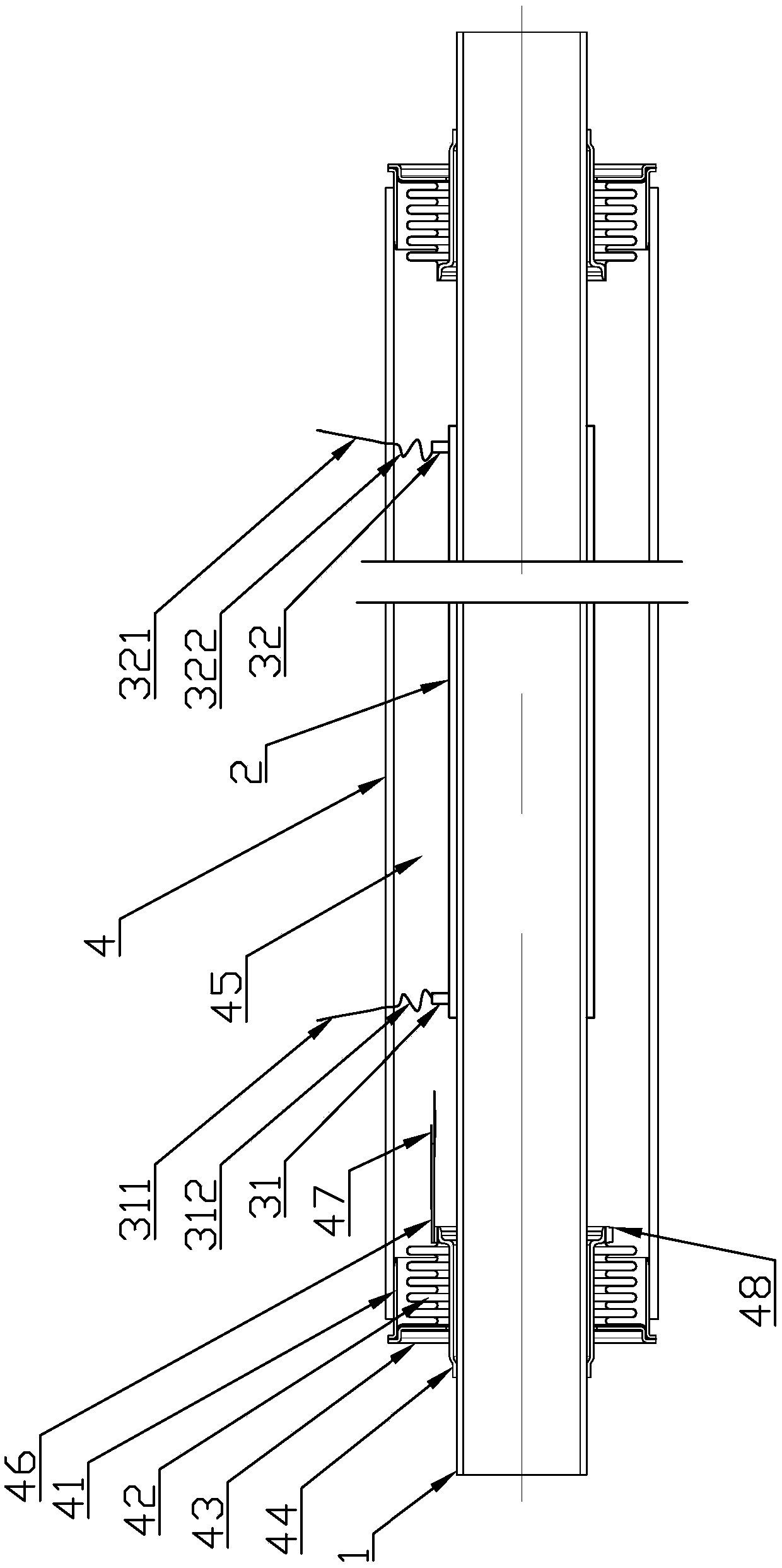

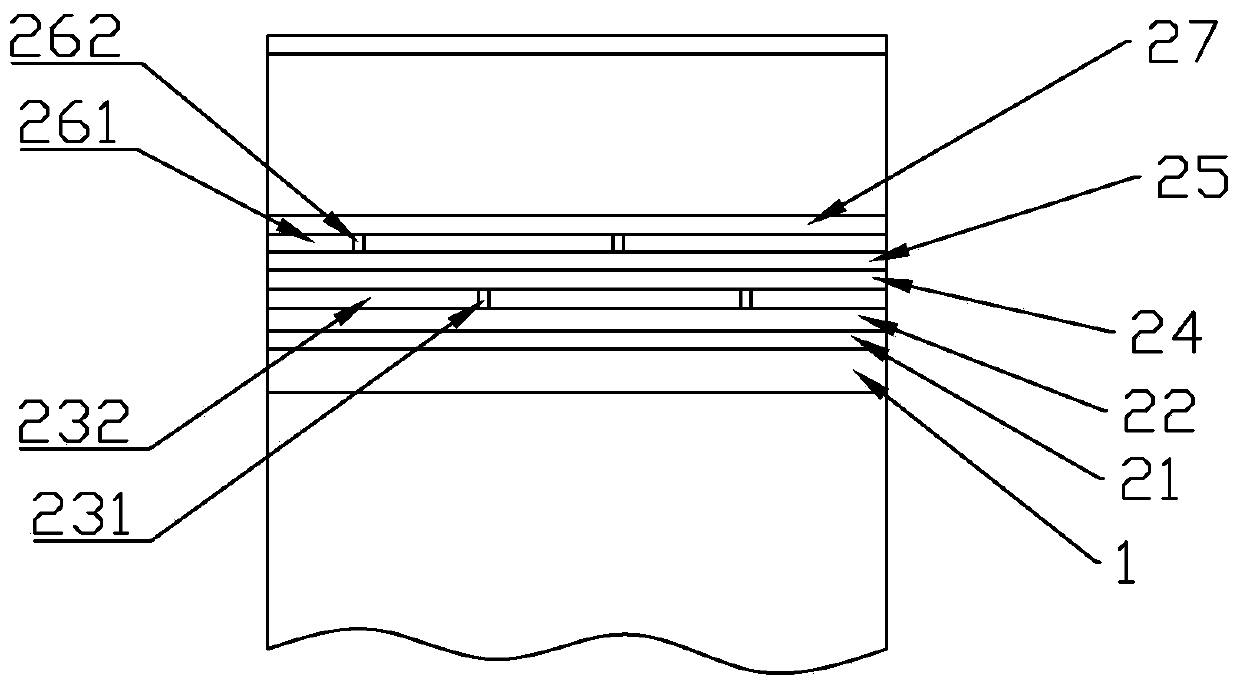

Method for improving optical element additional surface shape caused by force of gravity, and clamping system thereof

InactiveCN102591013AReduce residual stressImprove additional shapeMountingsFinite element analysis softwareEngineering

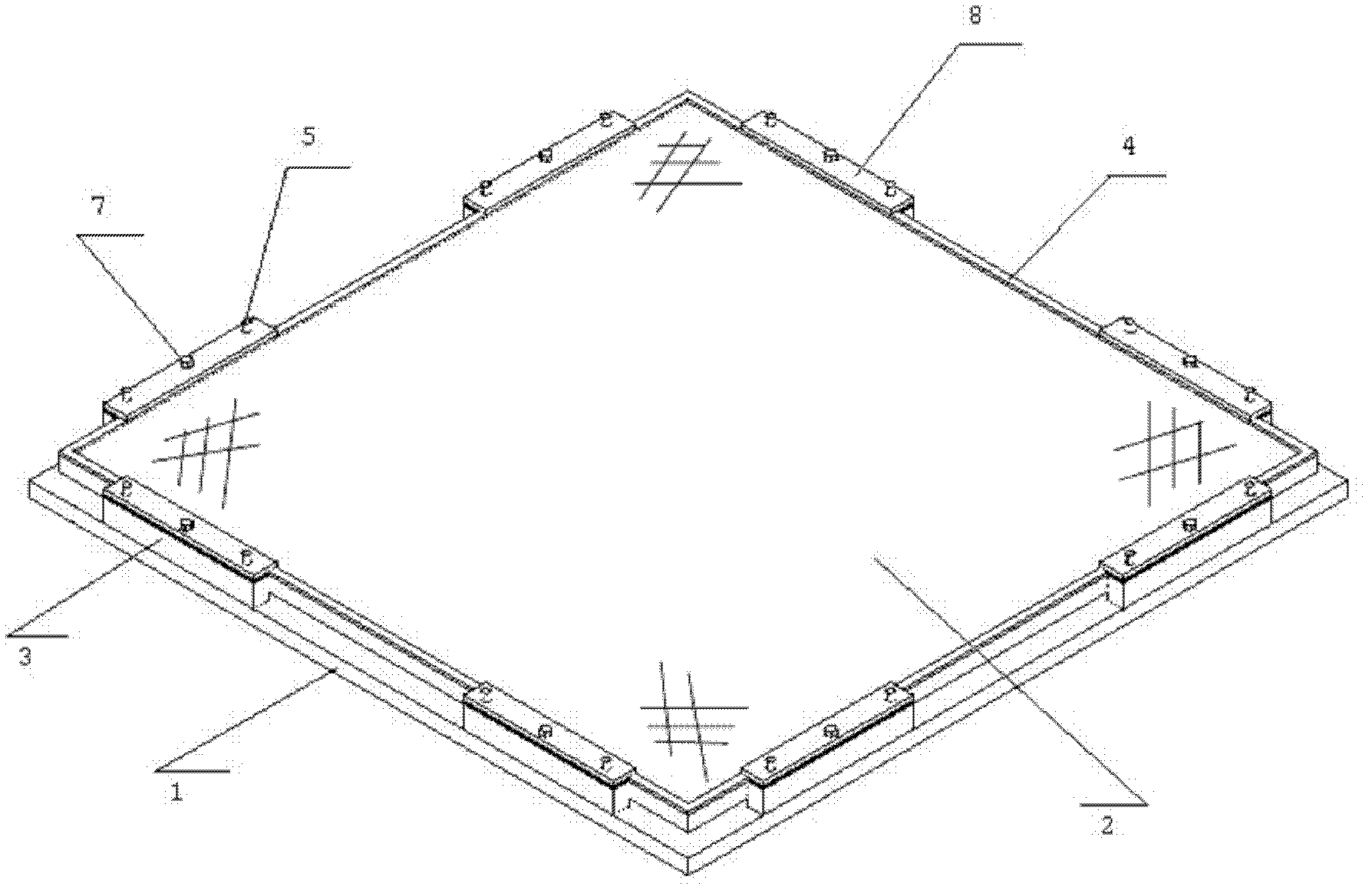

The invention relates to a method for improving an optical element additional surface shape caused by force of gravity, and a clamping system thereof. The method utilizes the lever principle, and aims at a heavy-calibre ultrathin transmission-type optical element under the condition of effective clear aperture. Through the clamping system provided by the invention, finite-element analysis software is adopted to carry out modeling simulation and determine lengths, widths and positions of a support strip and a pressure strip as well as force applied onto the pressure strip in the clamping system when the optical element is placed to be balanced at different work gestures and has the minimum additional surface shape change. Through changing the force applied onto the pressure strip, the optical element in the clamping system can have the balanced state at different work gestures, so as to achieve the purpose of improving the optical element additional surface shape caused by force of gravity. The clamping system for realizing the method includes a base, the support strip, a baffle plate, the pressure strip, the optical element, as well as an external wrench and a heavy-calibre interferometer. The method and the clamping system provided by the invention can improve the additional surface shape of the heavy-calibre ultrathin transmission-type optical element caused by force of gravity.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS +1

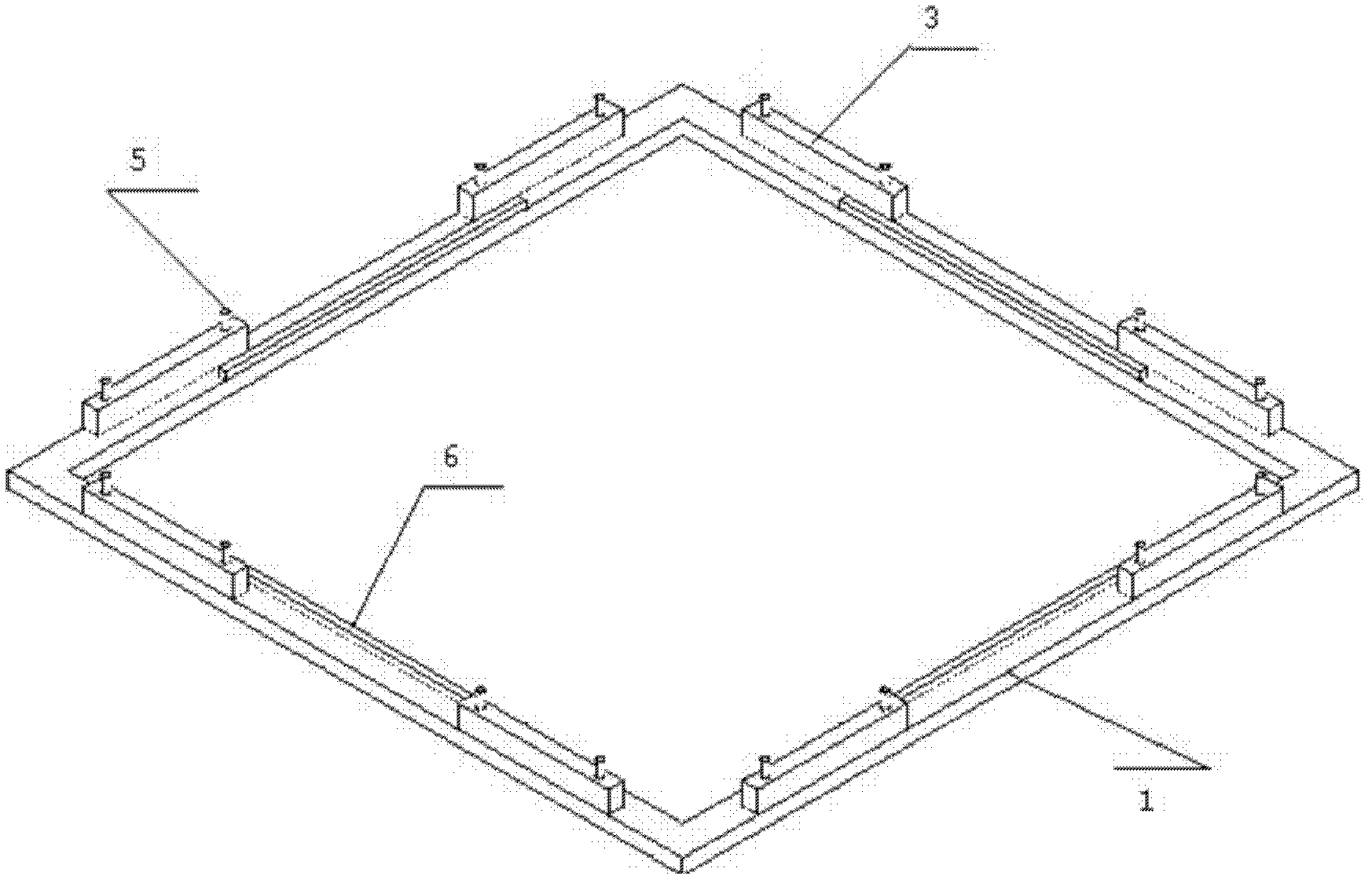

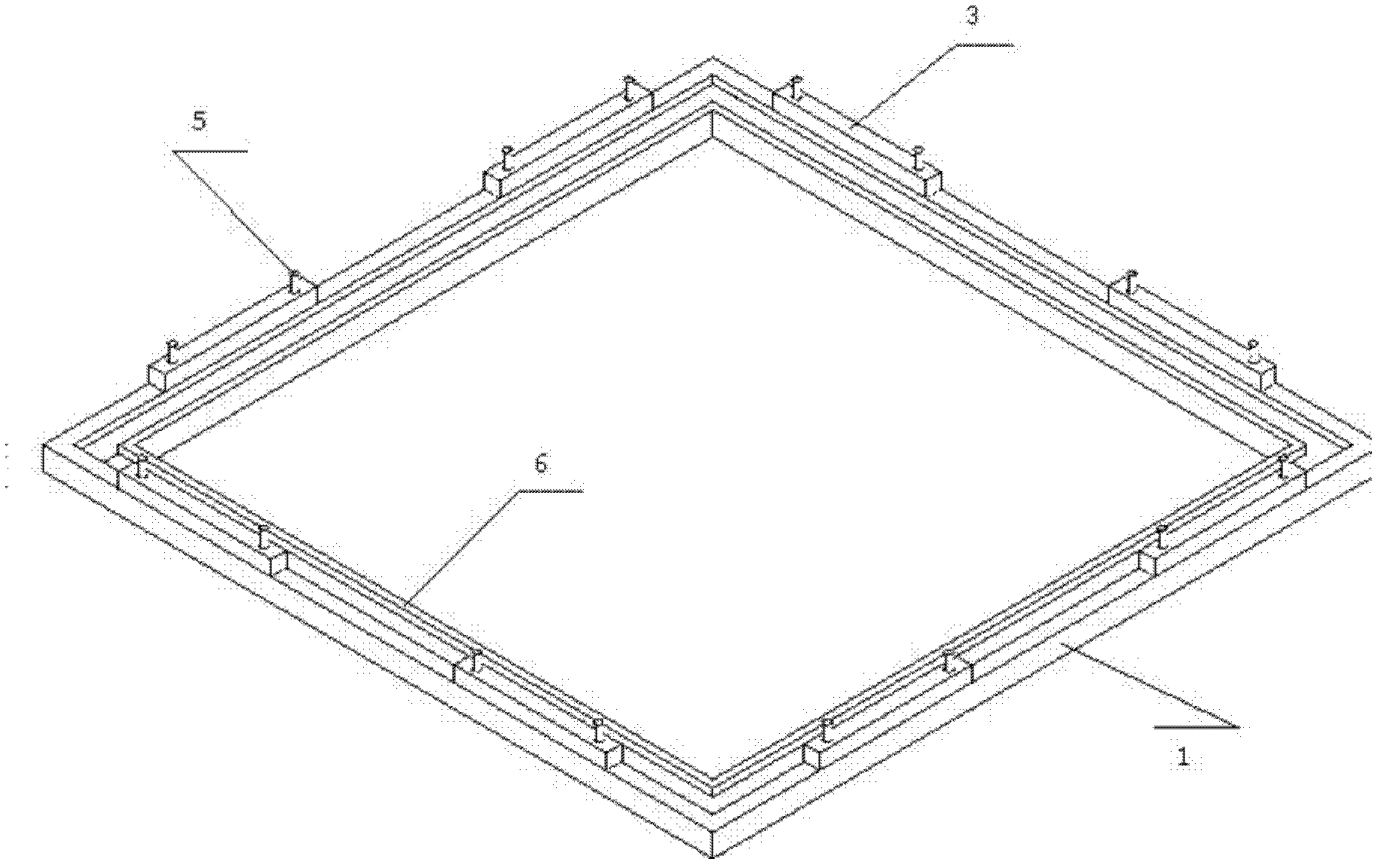

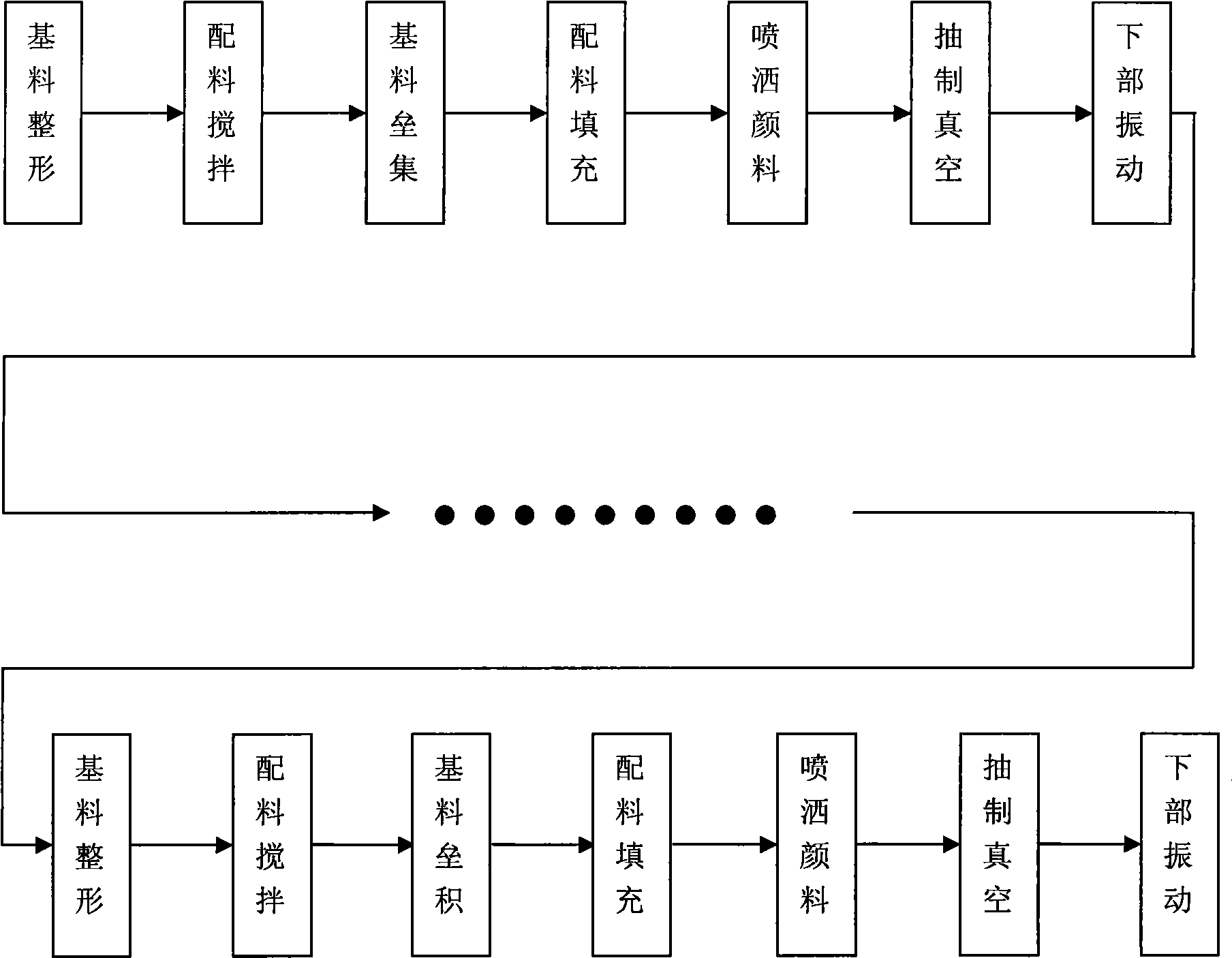

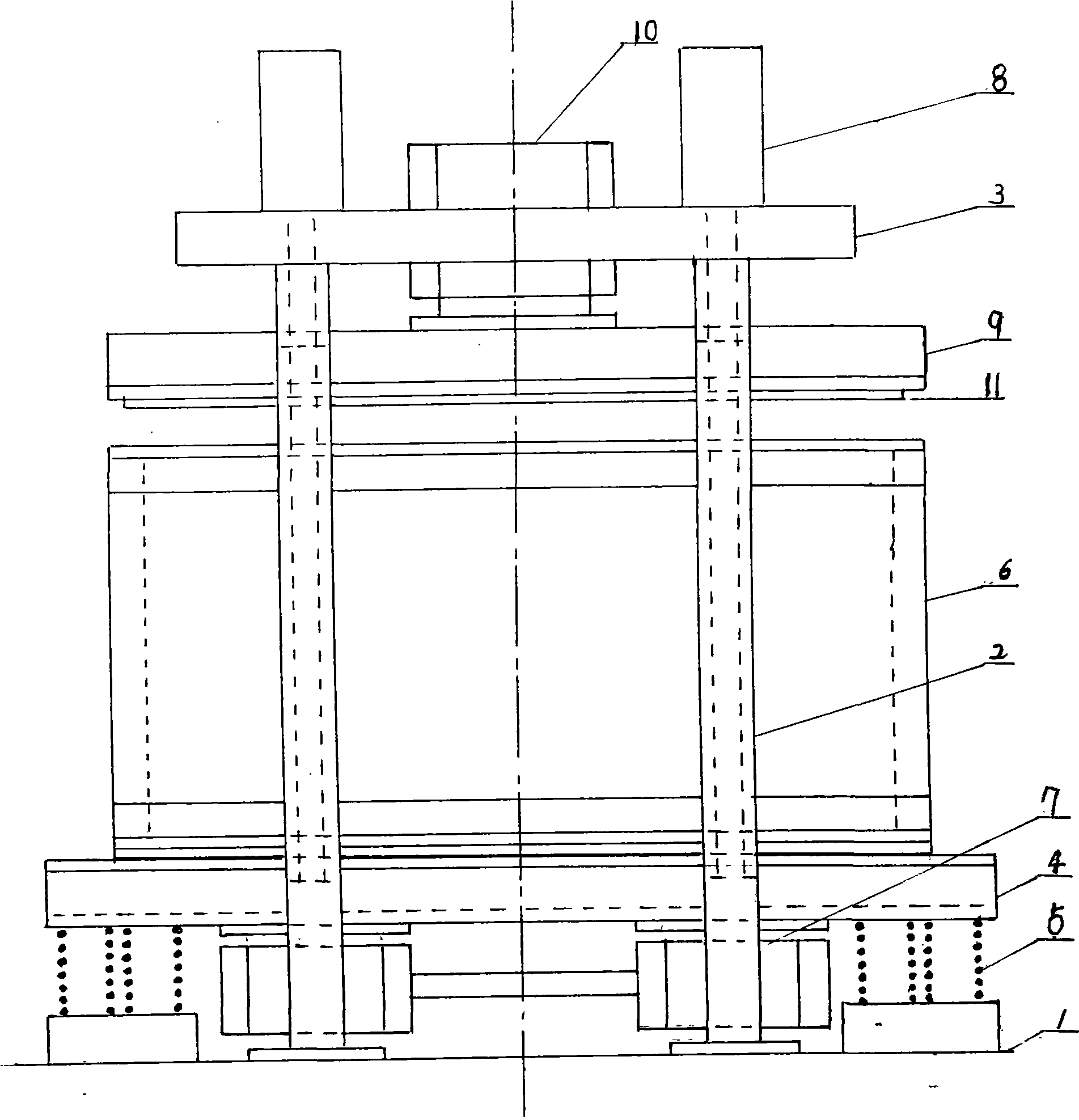

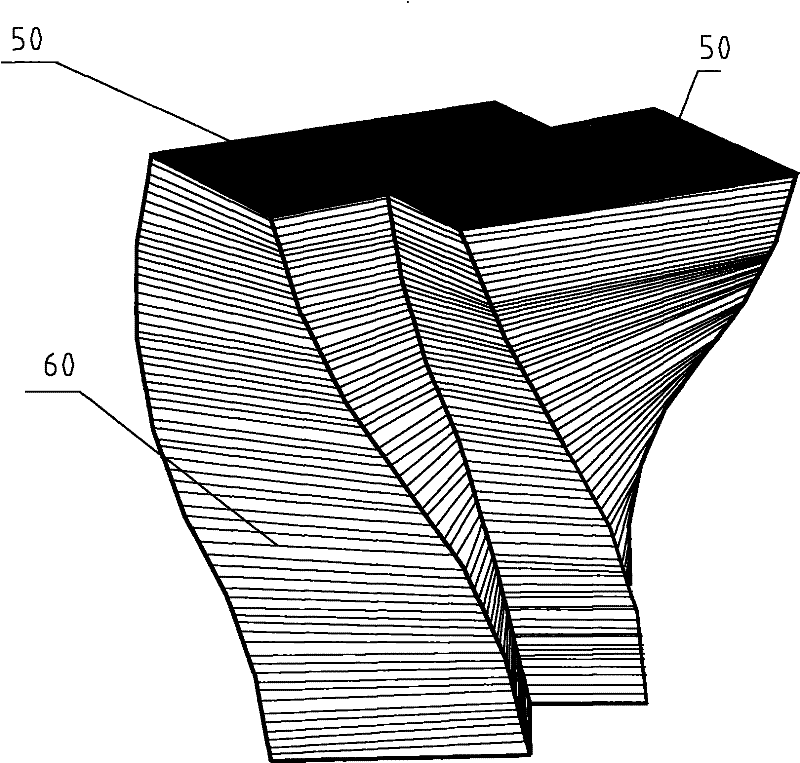

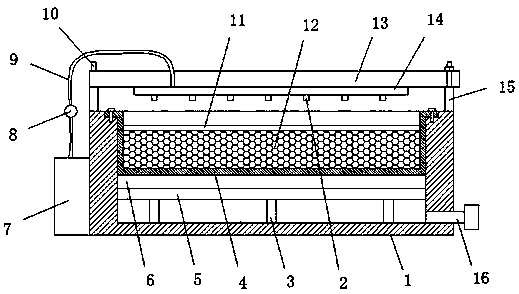

Method for synthesizing stone by layered vibration and moulding vibration device

ActiveCN101486217AImprove compactnessReduce manufacturing costMixing operation control apparatusCeramic shaping apparatusVacuum pumpingMachining process

The invention belongs to the field of artificial synthetic stone for building materials, and in particular relates to a method for producing synthetic stone by layered vibration and a molding vibration device for solving the problems of the prior artificial synthetic stone production process and equipment. The method comprises the following synthetic steps: firstly, a base material and an ingredient are alternately distributed in a mold box layer by layer, the ingredient is paved on the base material, and the base material and the ingredient vibrate under vacuum pumping to complete a first layer; secondly, a second layer is machined according to the first step, and the first step is repeated continuously to complete the molding of quarry stone; and finally, the machining process is completed by sawing, grinding and cutting. The device comprises a base plate, an upright post and a supporting frame; the upper part of the supporting frame is provided with a vibrating table; a buffering spring is arranged between the vibrating table and the soleplate; the upper part of the vibrating table is provided with a mold box; the lower part of the vibrating table is provided with a vibrator; the periphery of the supporting frame is provided with an oil cylinder; the bottom end of a piston of the oil cylinder is hung with a vacuum cover; and a vacuum pump is arranged on the vacuum cover. The process is advanced; the particle diameter of the raw material is not limited; a product has high-grade texture and artistic quality; and the device has a simple structure and low construction cost.

Owner:STATE GRID CORP OF CHINA +1

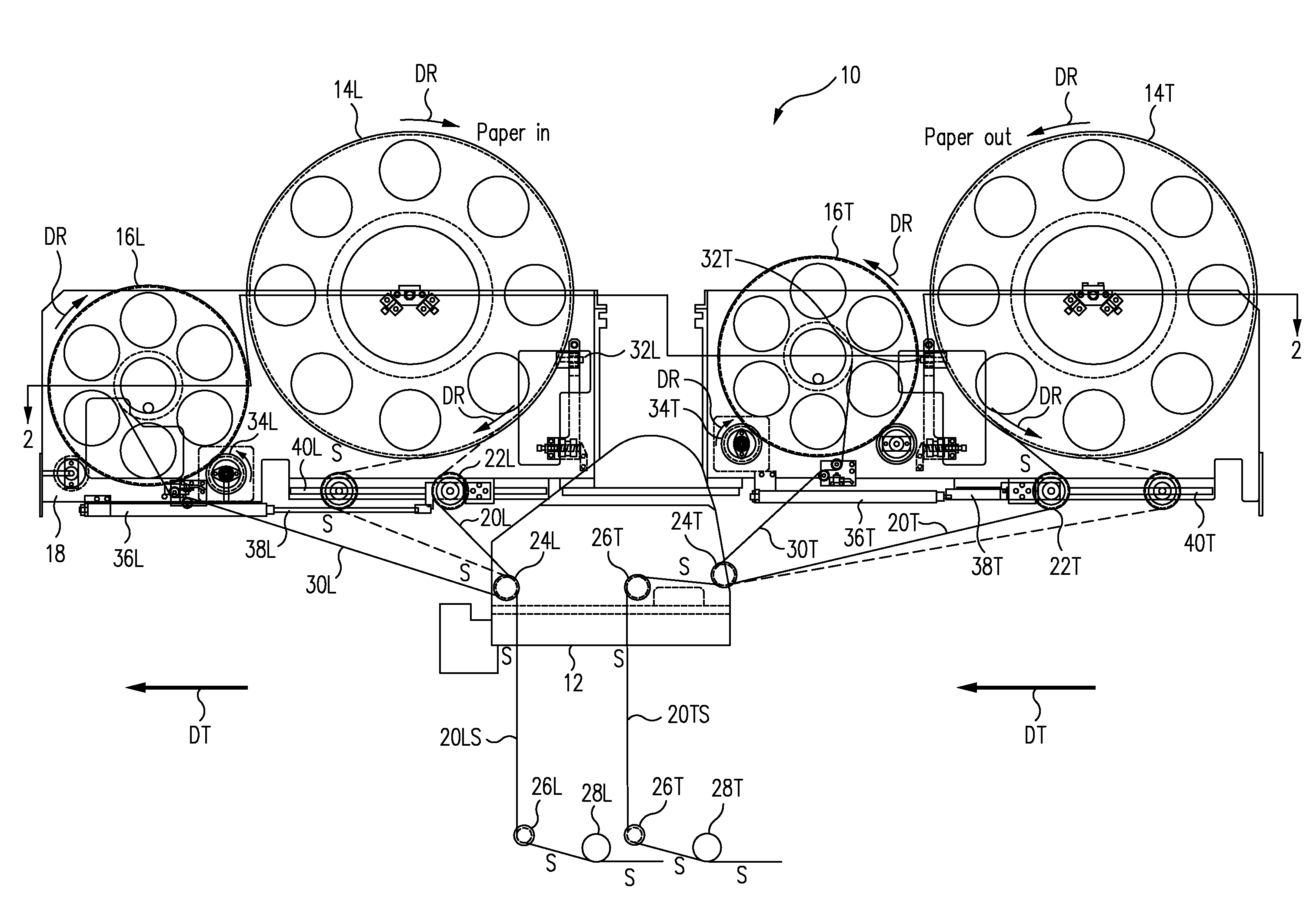

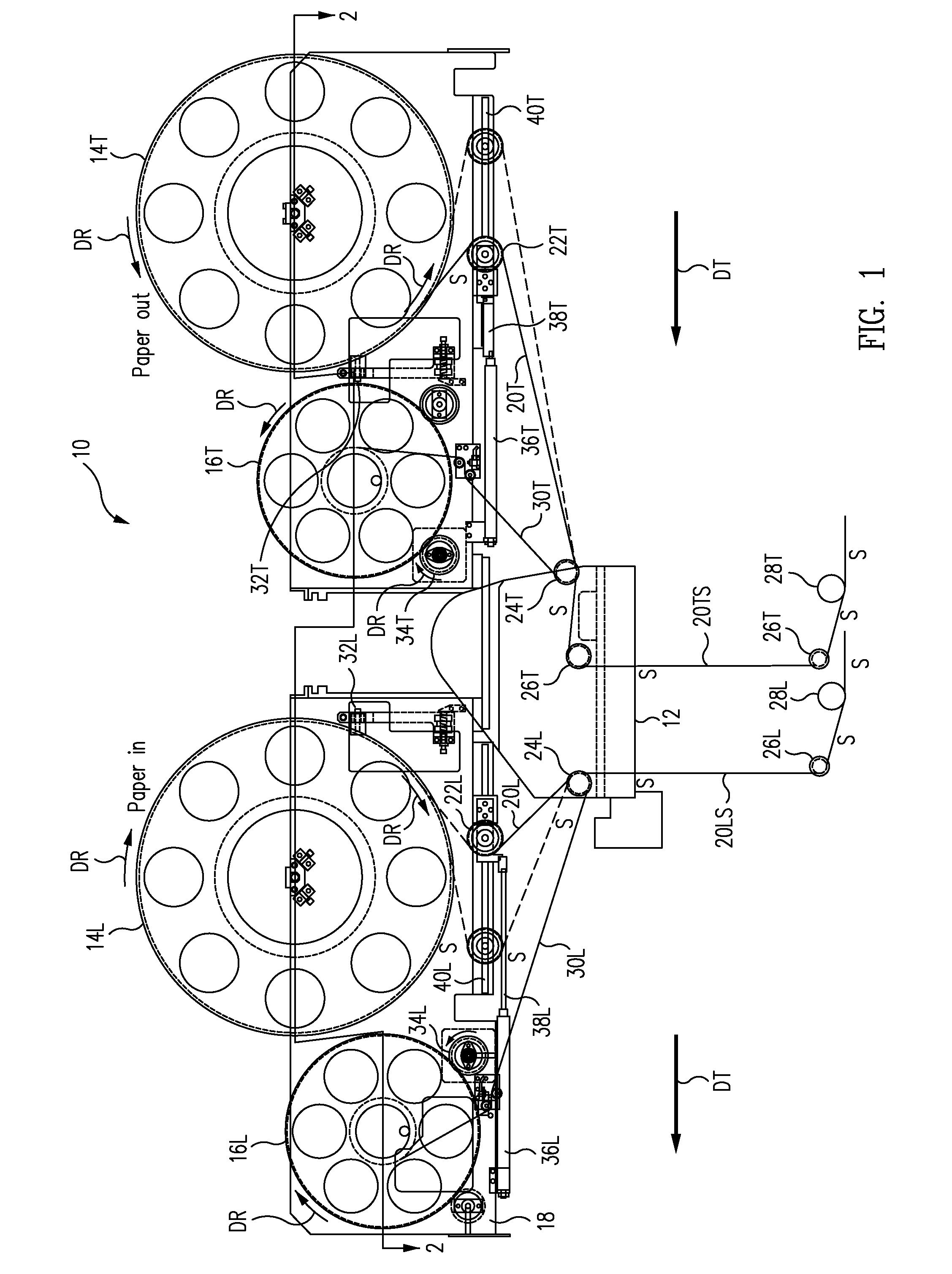

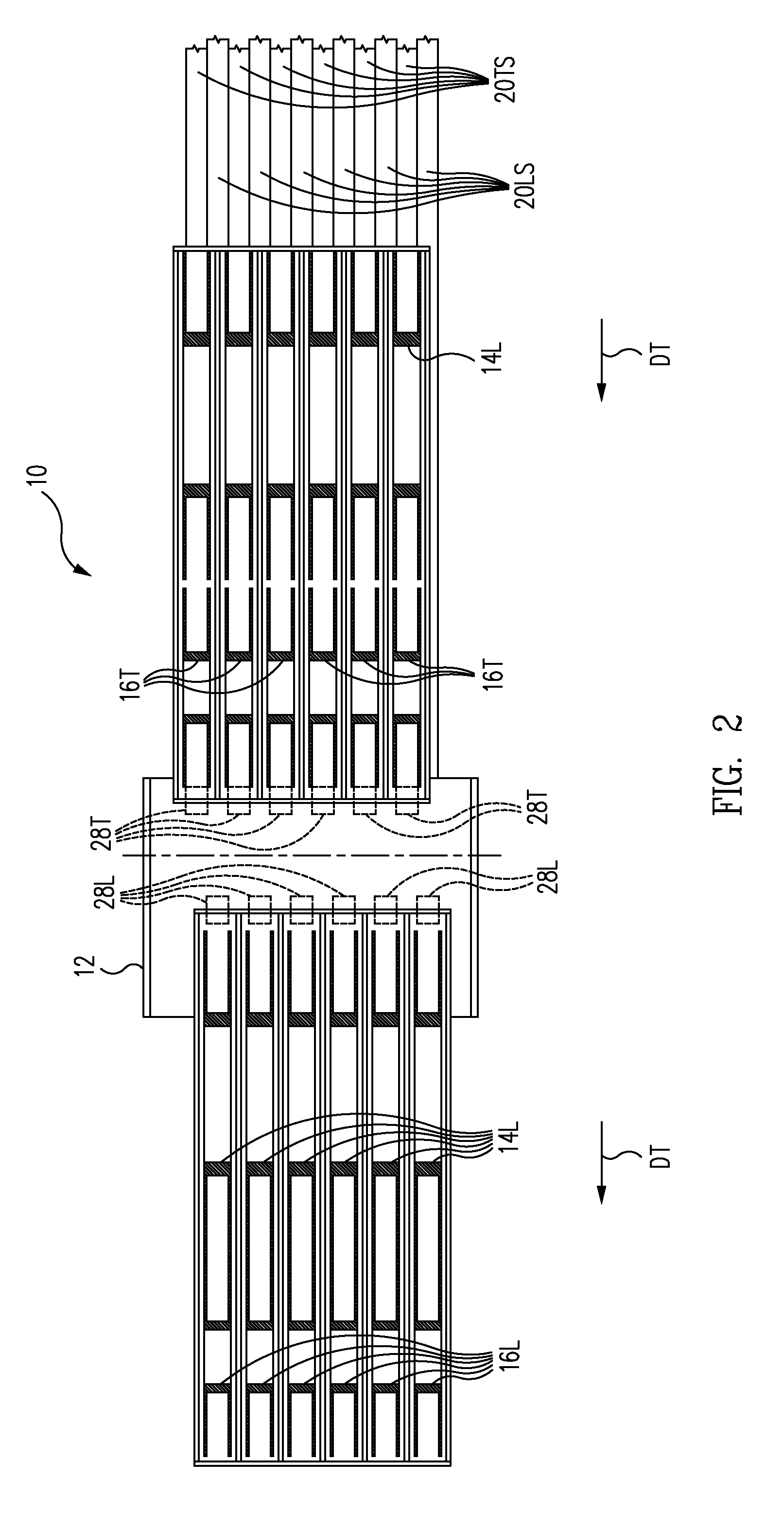

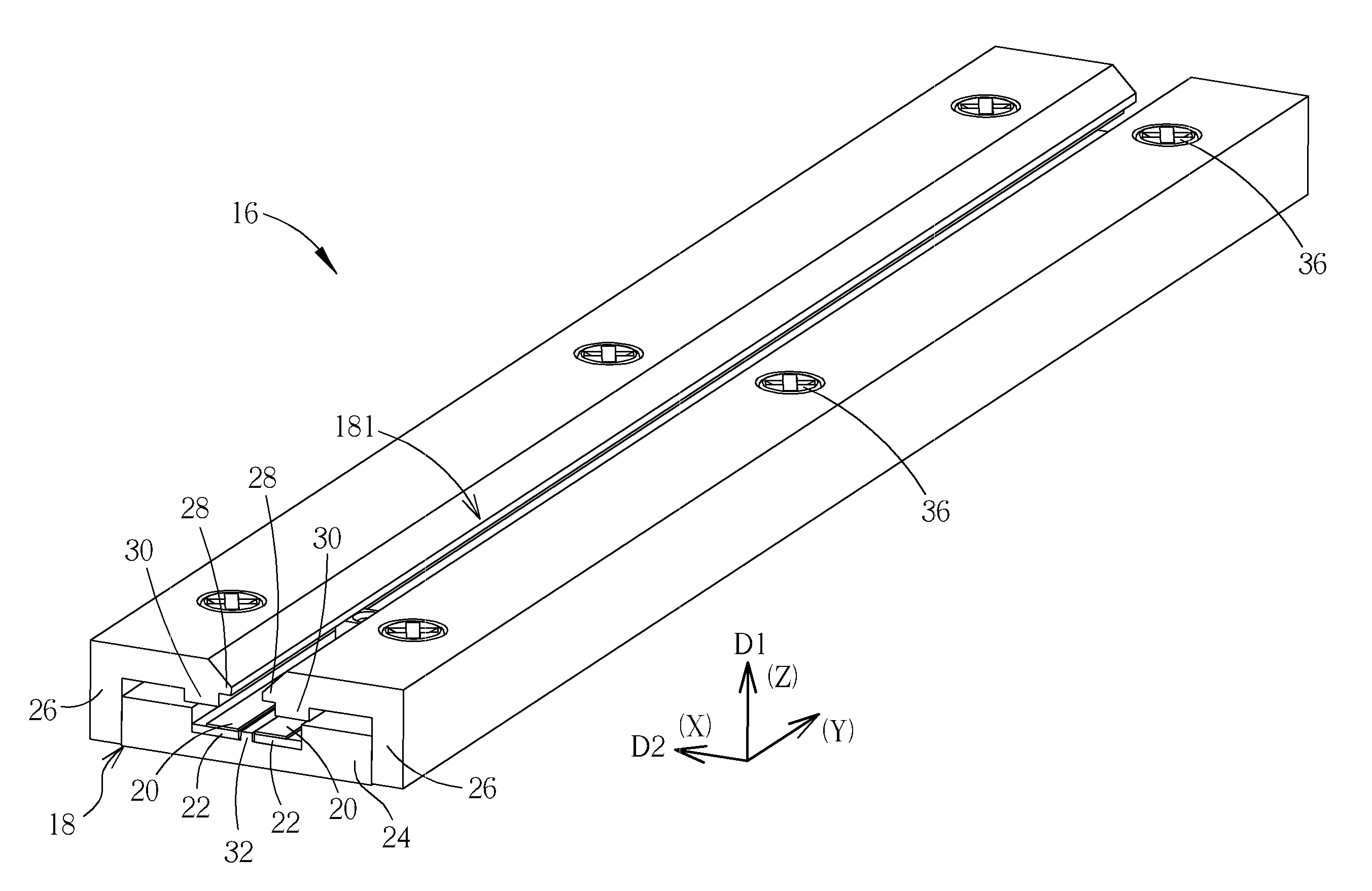

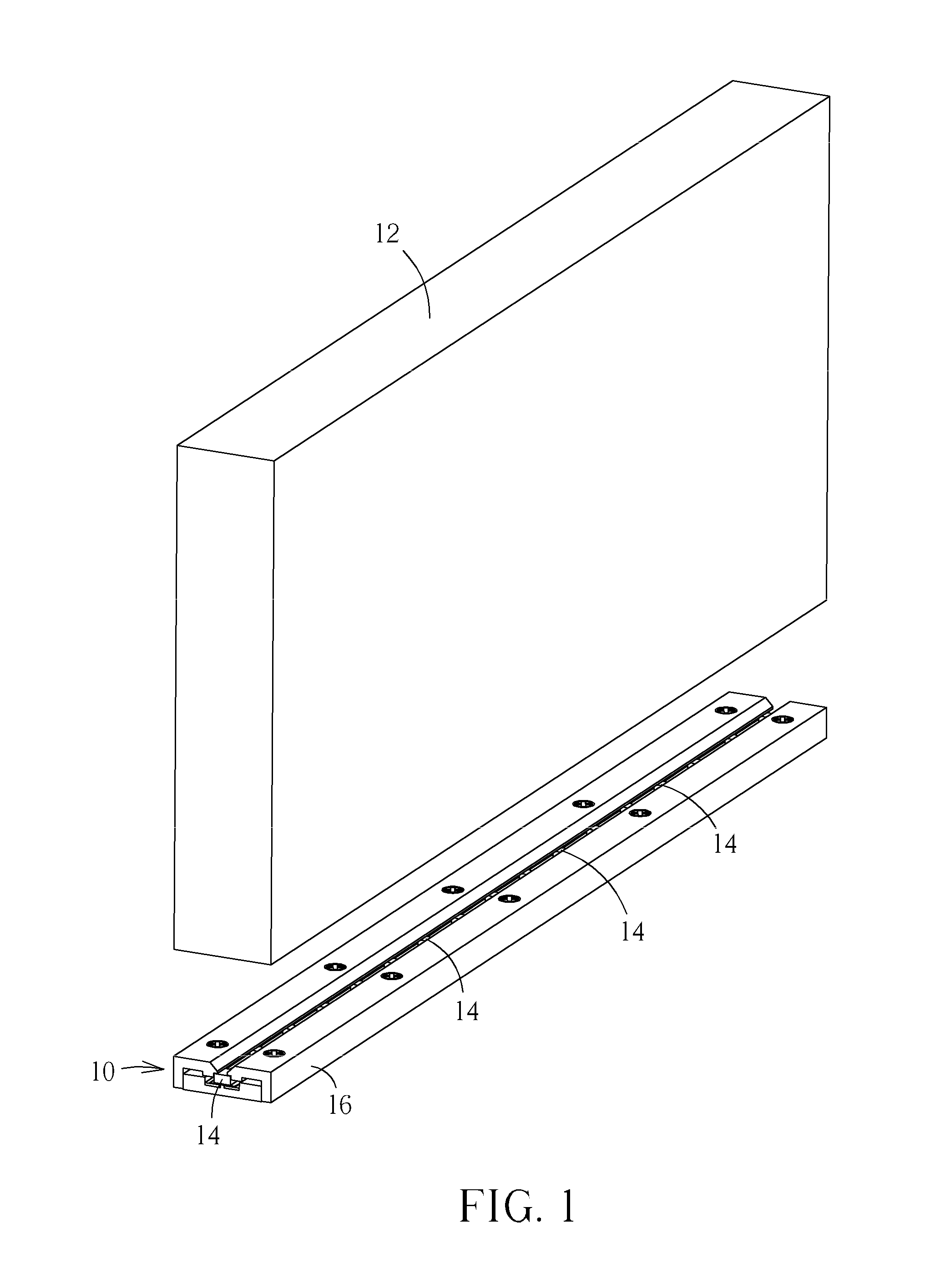

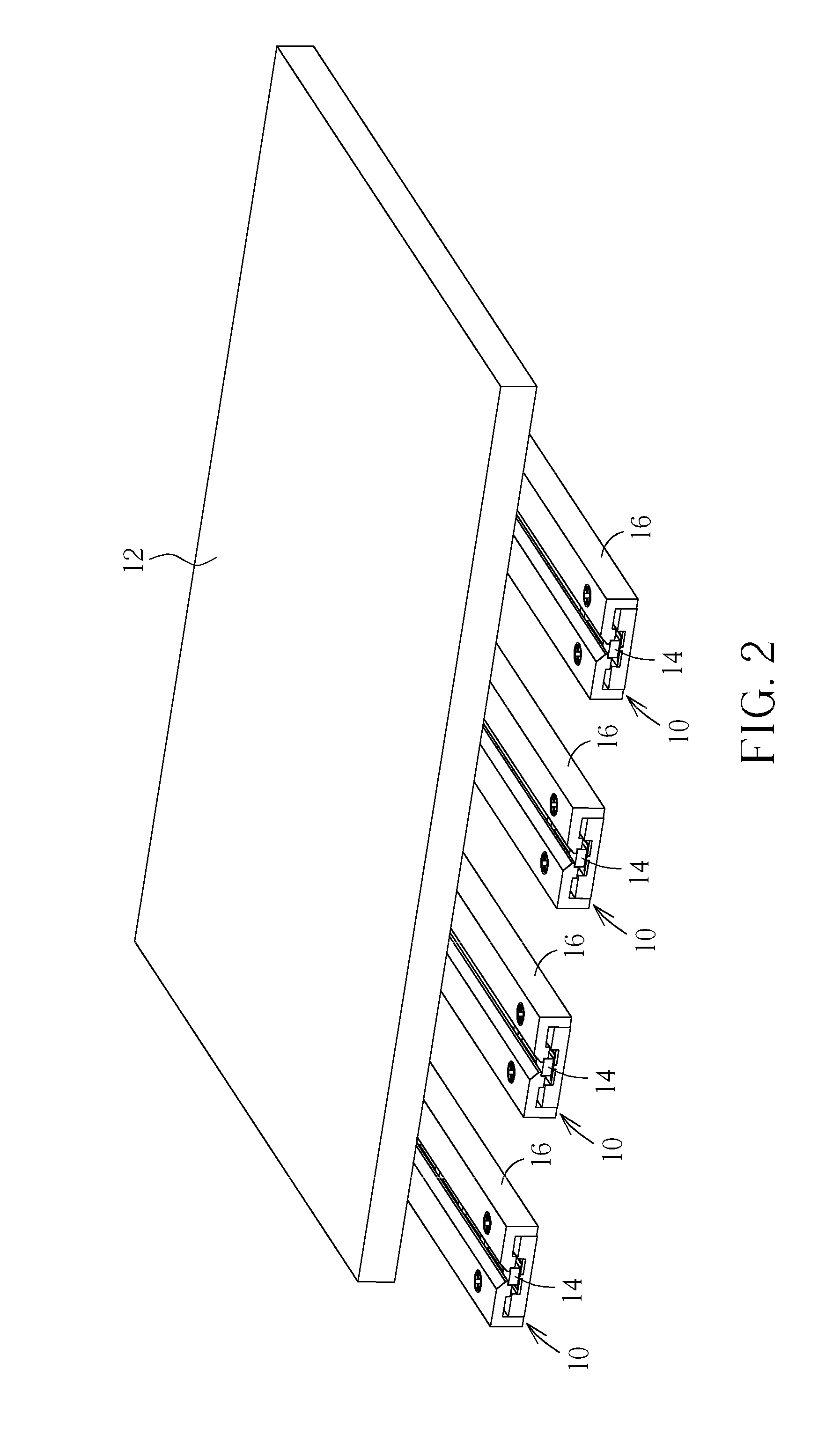

Graphite Tape Supply and Backing Paper Take-Up Apparatus

ActiveUS20110114265A1High laminating rateLow material costControlling laminationFilament handlingPaper sheetEngineering

An apparatus for supplying one or more strands of a relatively wide tape to a high-speed graphite tape laminating machine may include a tape supply reel and a backing paper take-up reel rotatably mounted on the machine, a dancer roller mounted on the machine for lateral movement thereon, and a mechanism for actively controlling the rotation of the tape supply and backing paper take-up reels and the lateral movement of the dancer roller relative to the support frame such that the respective tensions in the tapes are maintained substantially constant during both an on-the-fly tape add operation and an on-the-fly tape cut operation of the laminating machine.

Owner:THE BOEING CO

Light bar structure and light source device

ActiveUS20130021791A1Low material costHeat dissipate efficiency and optical efficiency be not decreasePoint-like light sourceLighting support devicesElectricityLight source

Owner:WISTRON CORP

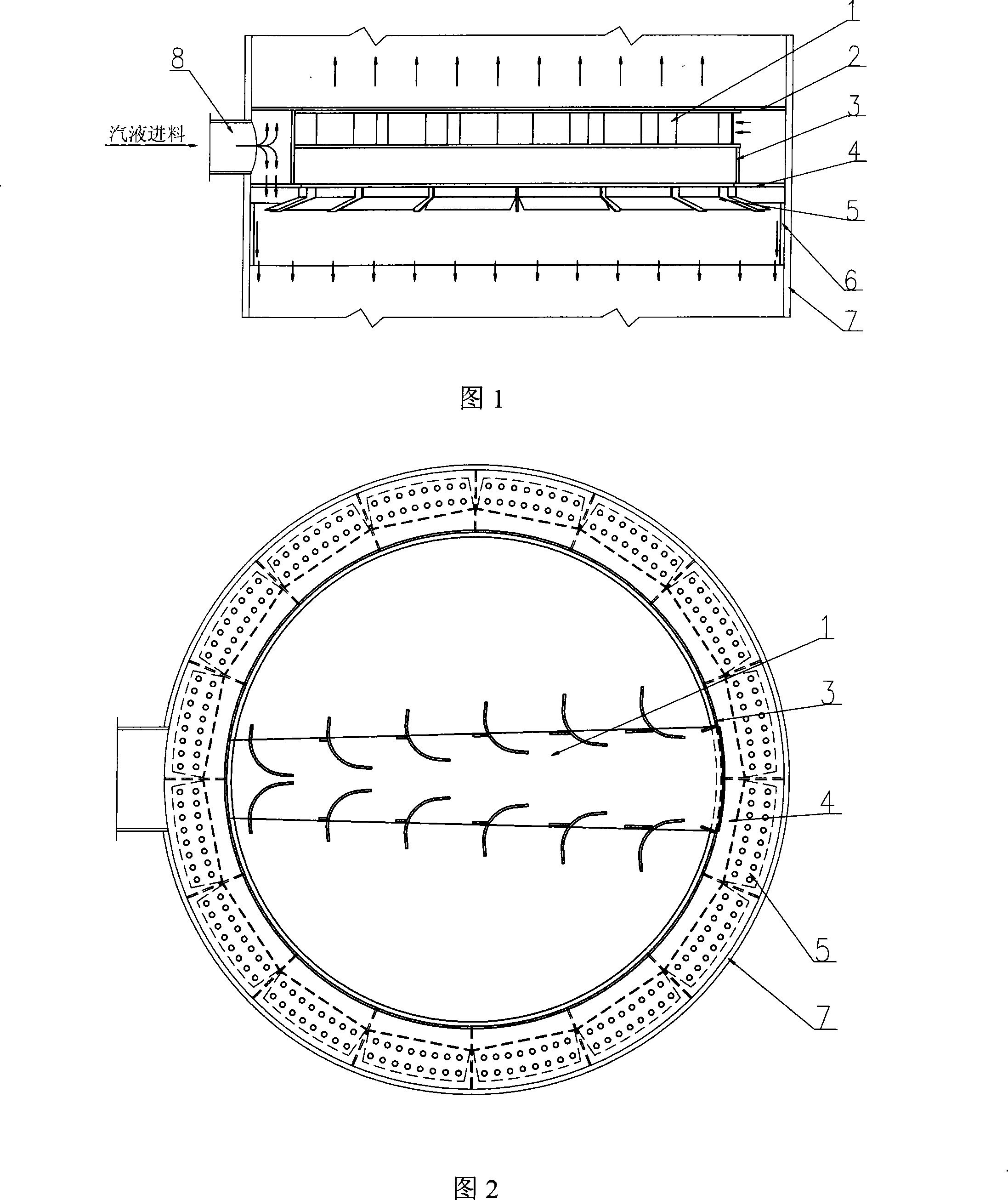

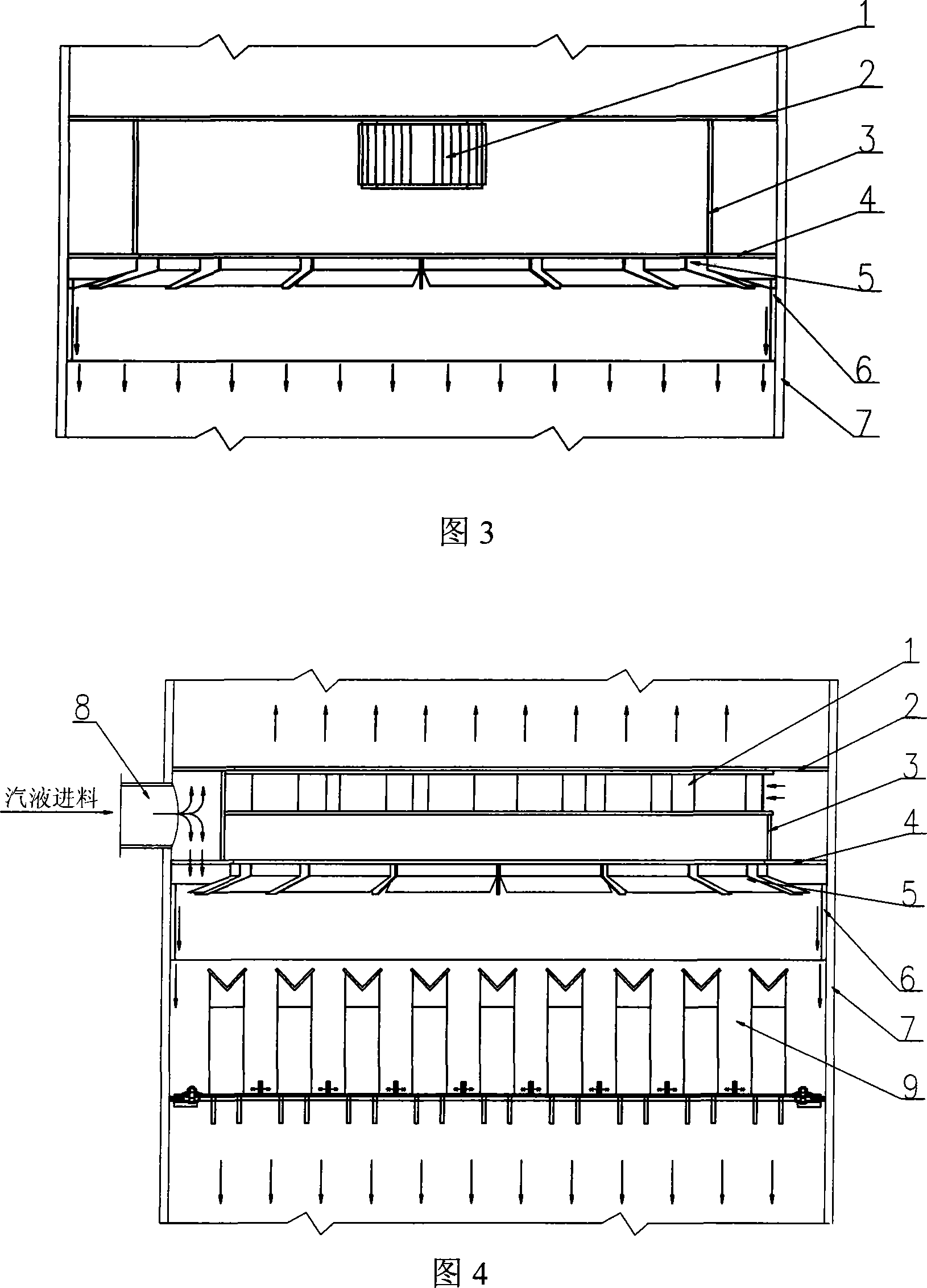

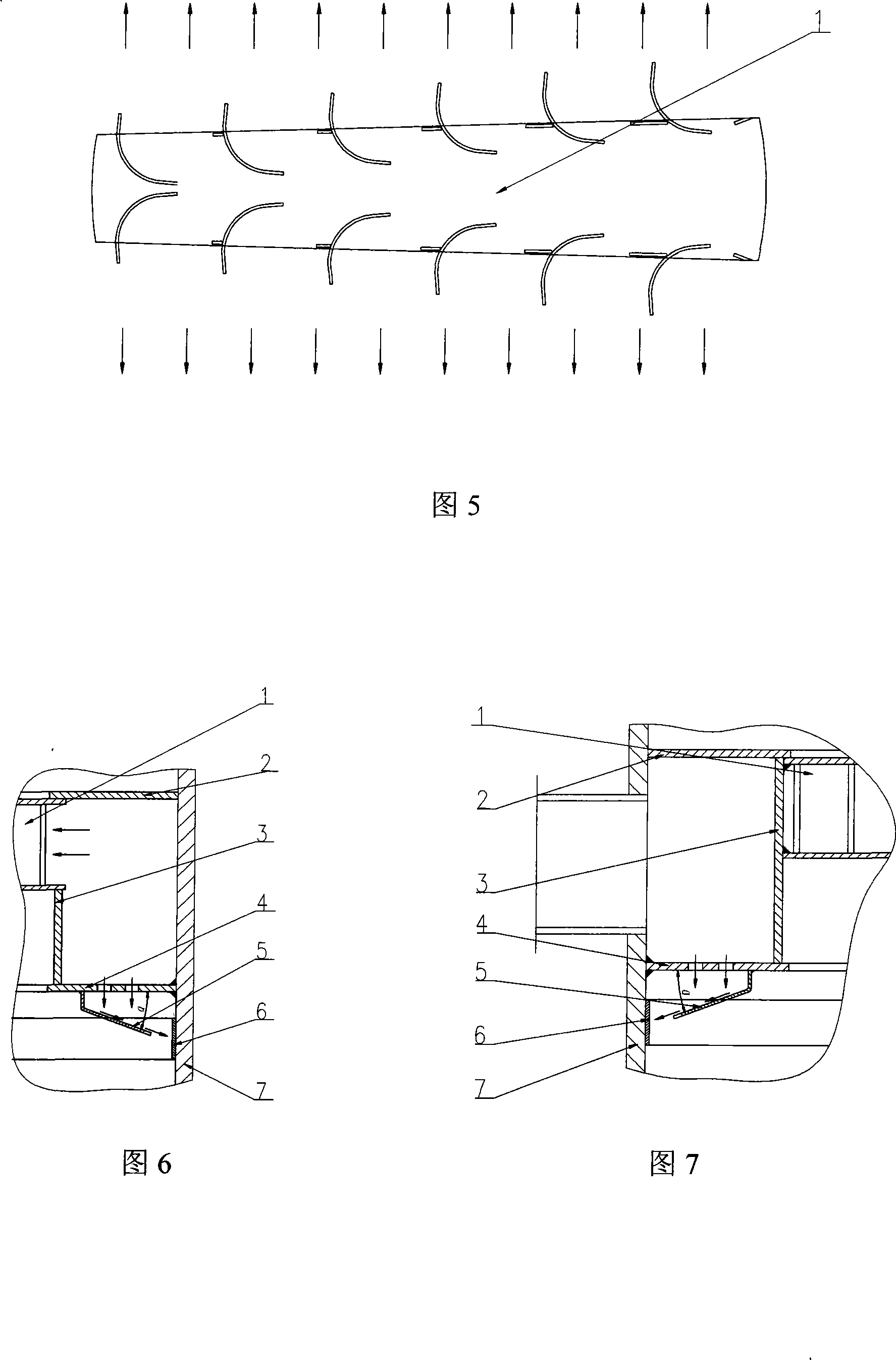

Liquid preliminary distribution device with gas distribution function

InactiveCN101239248AEasy to makeLow material costDispersed particle separationExtractive distillationProduct gasEngineering

The present invention provides a liquid pre-distributor having gas distributing function. The ring material gas-liquid phase separating room is formed by the combination of an adding an air seal ring 2, a liquid collector 3 and a liquid collecting base ring 4 by utilizing of the evenly distribution of the symmetrically two-dimensional guide two rows blade gas distributor. The upper of the room is set with a square or circle hole as an outlet after separation of the gas and liquid, air entering in the symmetrically two-dimensional guide two rows blade gas distributor, enters the top filling layer after being evenly distributed, and liquid flows to the lower gas-liquid distributor by the guide hole on the bottom of the liquid collecting base of the separating room. The invention has a lower towering space, economic equipment investment, lower mounting requirement, wide operation range, strong applicability. The distributor is used in two-phase feeding or flashing feeding device of the filling tower of each specification under the course of gas-liquid mass transfer, separating, heat transfer operation in the industrial production.

Owner:TIANJIN UNIV

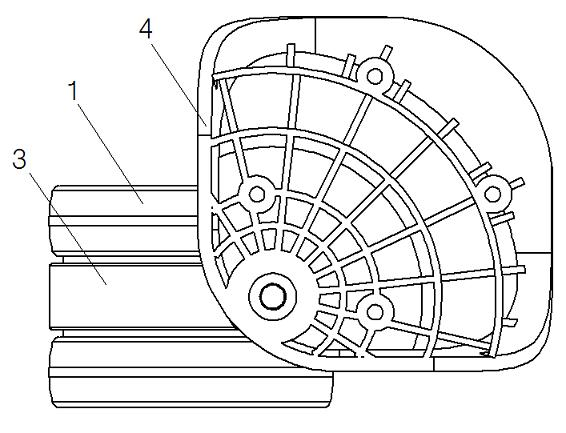

Rotary supporting device for pharmaceutical machine

InactiveCN101839387ASimple structureLow material costBearing componentsStands/trestlesEngineeringMechanical engineering

The invention discloses a rotary supporting device for a pharmaceutical machine. The rotary supporting device comprises a base and a turn plate, wherein the turn plate is arranged on the base; a rolling bearing is arranged between the turn plate and the base and comprises an inner ring and an outer ring; and one of the base and the turn plate is fixedly connected with the inner ring, and the other of the base and the turn plate is fixedly connected with the outer ring. The rotary supporting device for the pharmaceutical machine has the advantages of simple and compact structure, convenient assembly, low cost, stable running and long service life.

Owner:TRUKING TECH LTD

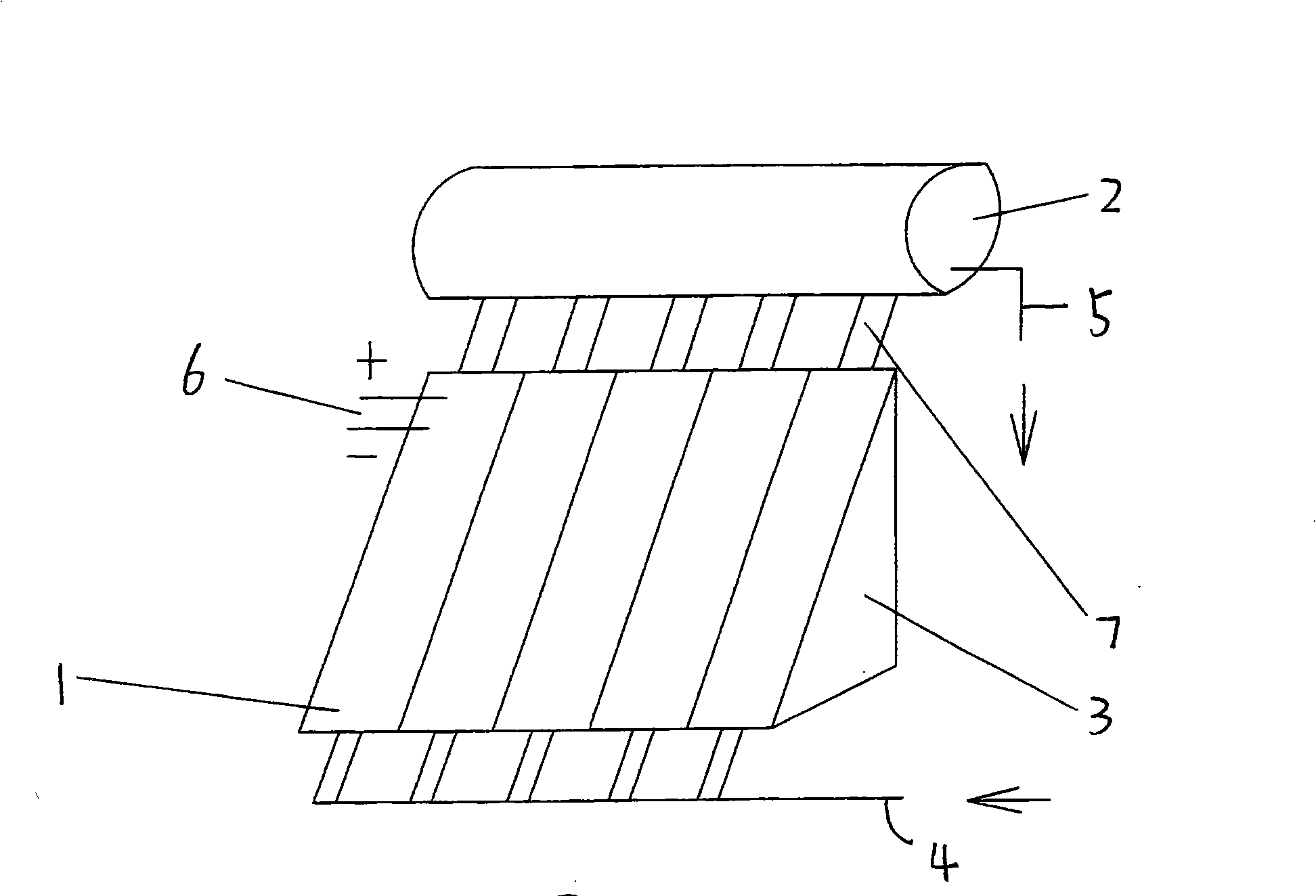

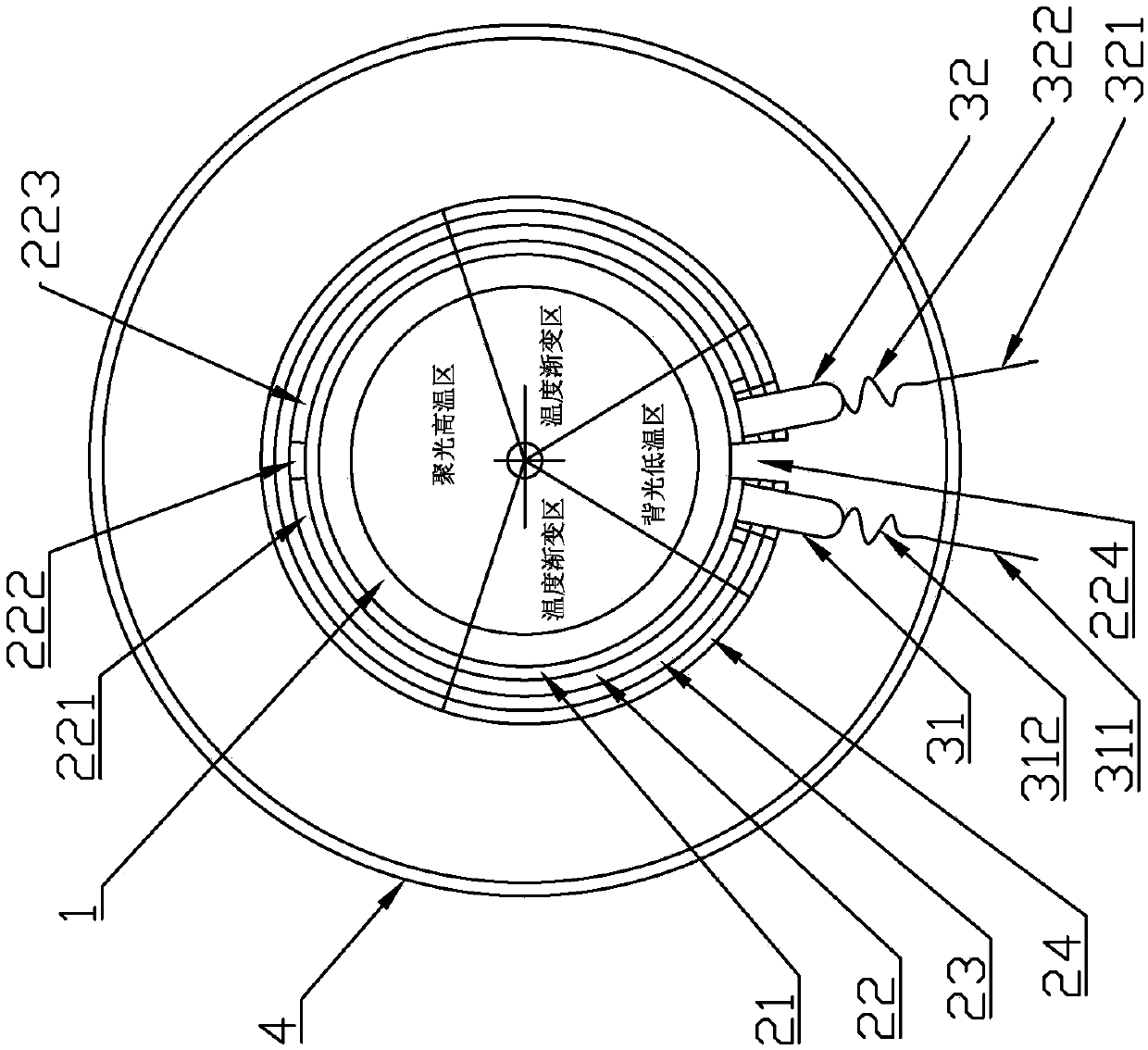

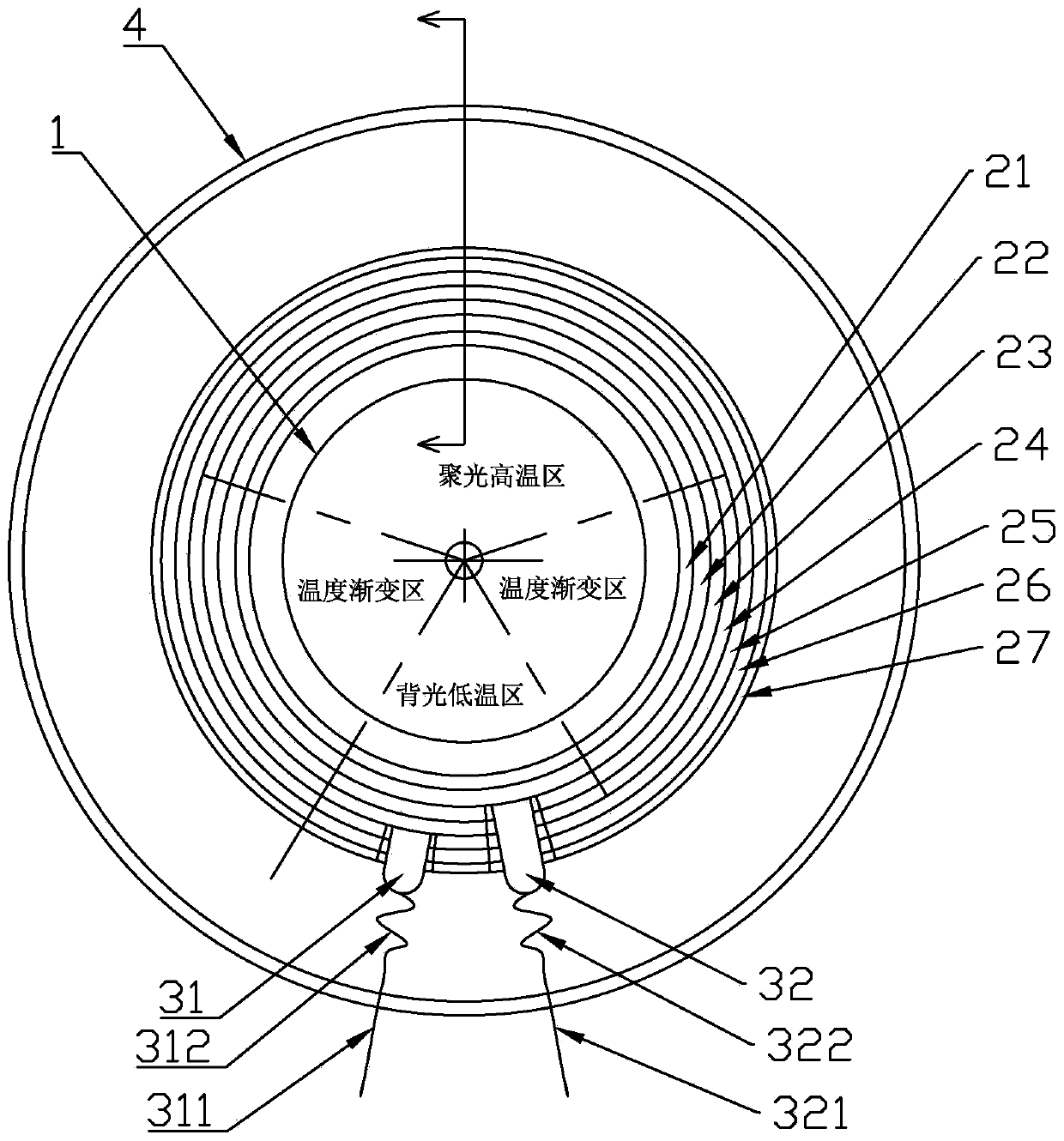

Light-gathering solar thermal electric combined supply device

InactiveCN101312331AReduce material manufacturing costsLow material costSolar heating energySolar heat devicesWater pipeEngineering

The invention discloses a condenser type solar energy co-generation device, which comprises a condenser type co-generator, an insulation water tank, a supporting bracket, an cold water inlet, a hot water outlet and a power supply output interface, wherein the condenser type co-generator is arranged below the insulation water tank, a water outlet of a heat exchange water pipe in the co-generator is communicated with an inner chamber of the insulation water tank, the condenser type co-generator and the insulation water tank are arranged on the supporting bracket, the cold water inlet is communicated with a water inlet of the heat exchange water pipe arranged in the co-generator, the hot water outlet is communicated with the inner chamber of the insulation water tank and is arranged at the lower portion of the insulation water tank, then the cold water inlet, the heat exchange water pipe of the condenser type co-generator, the insulation water tank and the hot water outlet form a water channel, and after a solar cell in the condenser type co-generator are mutually connected, an output end of the solar cell is connected with the power supply output interface. The condenser type solar energy co-generation device not only can efficiently generate power, but also can supply heat, and simultaneously, the consumed material cost is low and the occupation space is small.

Owner:KUSN TAIDELONG MACHINERY

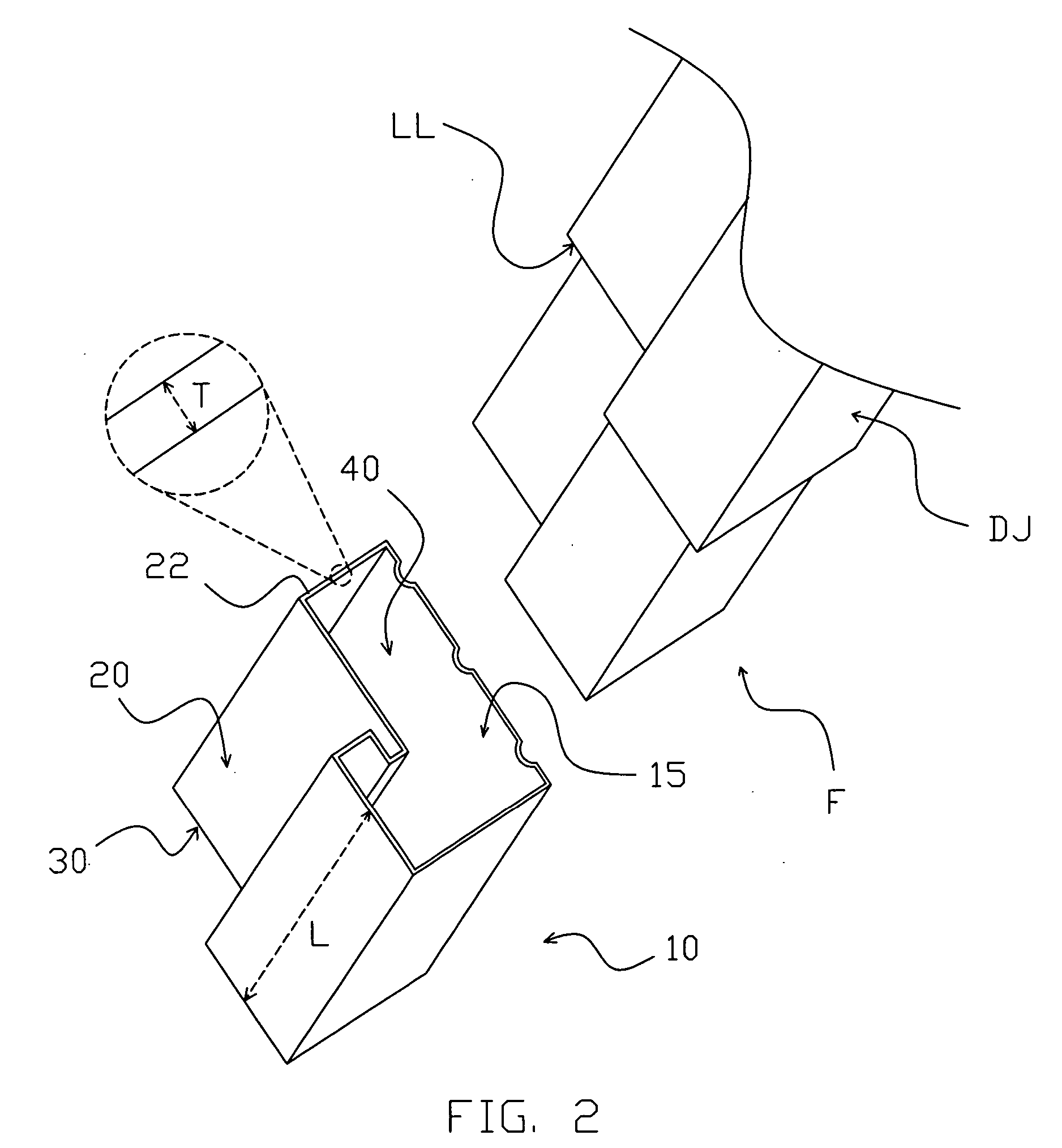

Doorjamb end cap and method of installation therefor

InactiveUS20050126089A1Low material costInstalled with relative easeRoofingFrame fasteningEngineeringExtrusion

A doorjamb end cap and method of installation therefor, wherein application of the present invention to wooden doorjambs permits the enclosed or encased portion thereof to effectively resist or avoid the onset of rot therein, and wherein the present invention is effectuated without expensive extrusion processes and / or thermoplastic melt and adhesive applications.

Owner:EVERMARK LLC

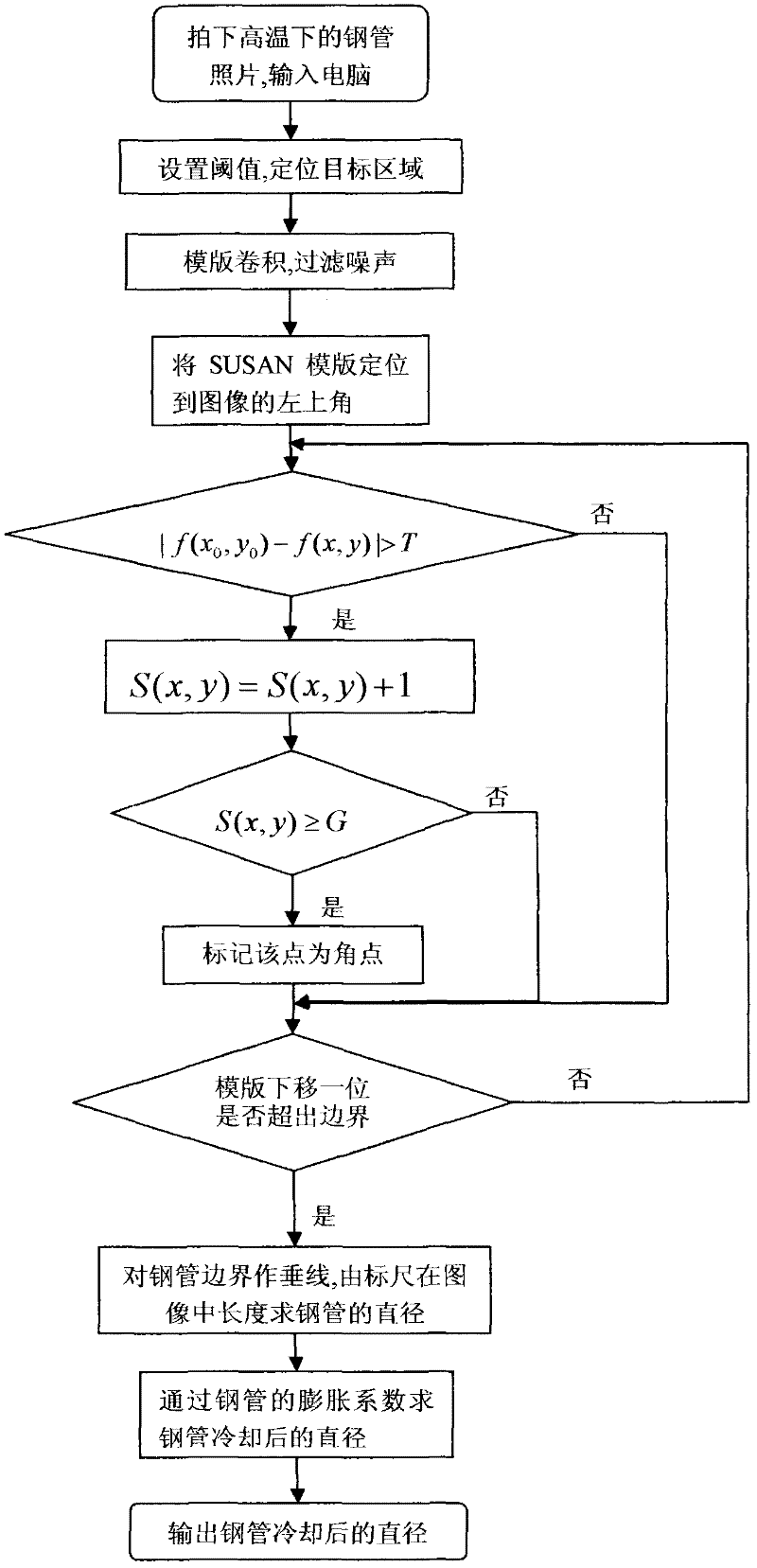

Method for measuring diameter of high-temperature steel pipe by using image recognition technology

The invention discloses a method for measuring the diameter of a high-temperature steel pipe by using an image recognition technology. The method comprises the following steps of: placing a metric scale on the same plane where the steel pipe is located, carrying out image pick-up on the steel pipe by adopting a high-definition camera, obtaining a pixel point ratio of the metric scale to the steel pipe after the image processing carried out by a computer, obtaining the diameter of the steel pipe, and finally calculating to obtain the accurate diameter of the cooled steel pipe by using the scaling coefficient of the cooled steel pipe. The method for measuring the diameter of the high-temperature steel pipe by using the image recognition technology has the characteristics that: the cost is saved and the efficiency is increased.

Owner:TAIYUAN UNIV OF TECH

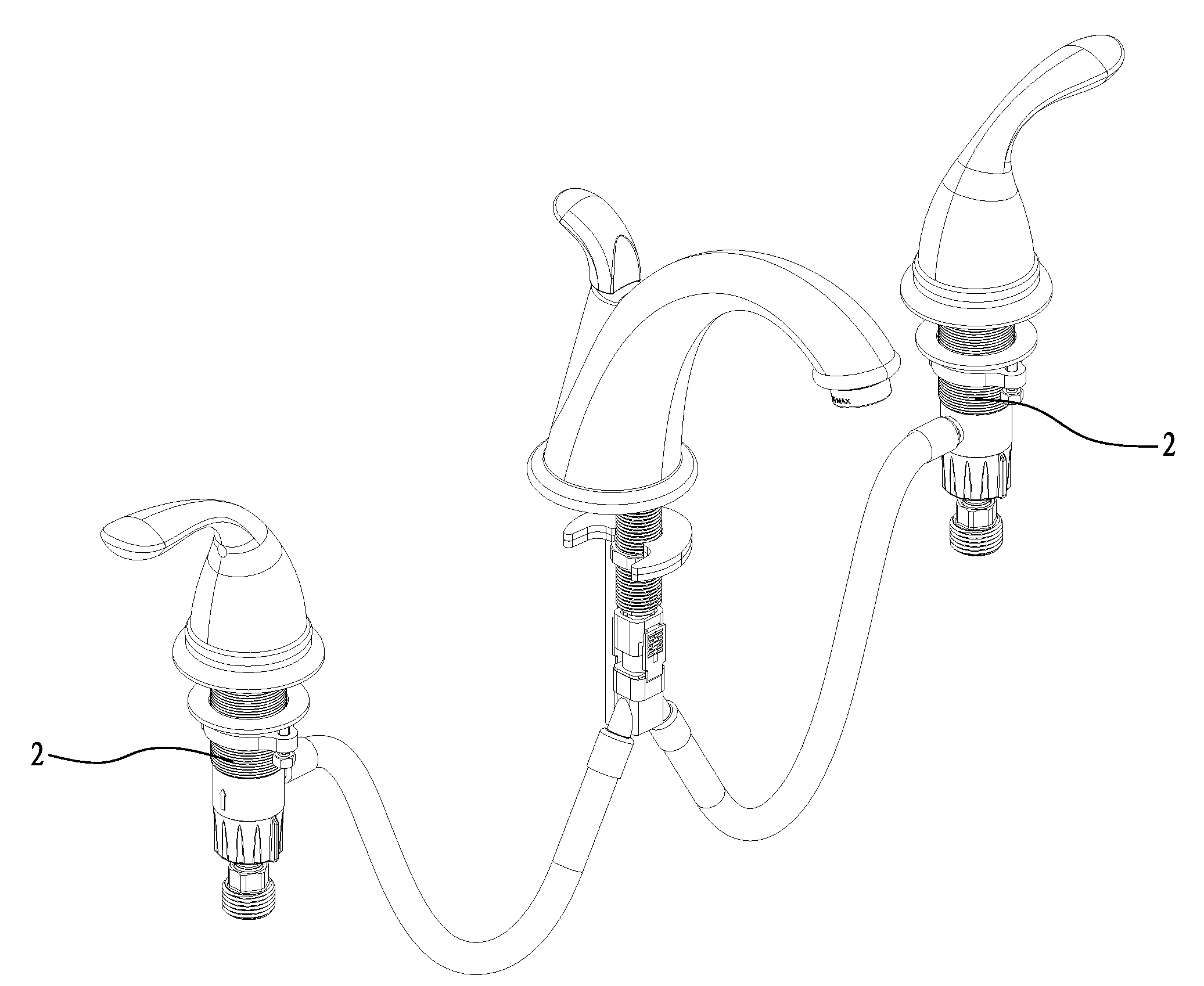

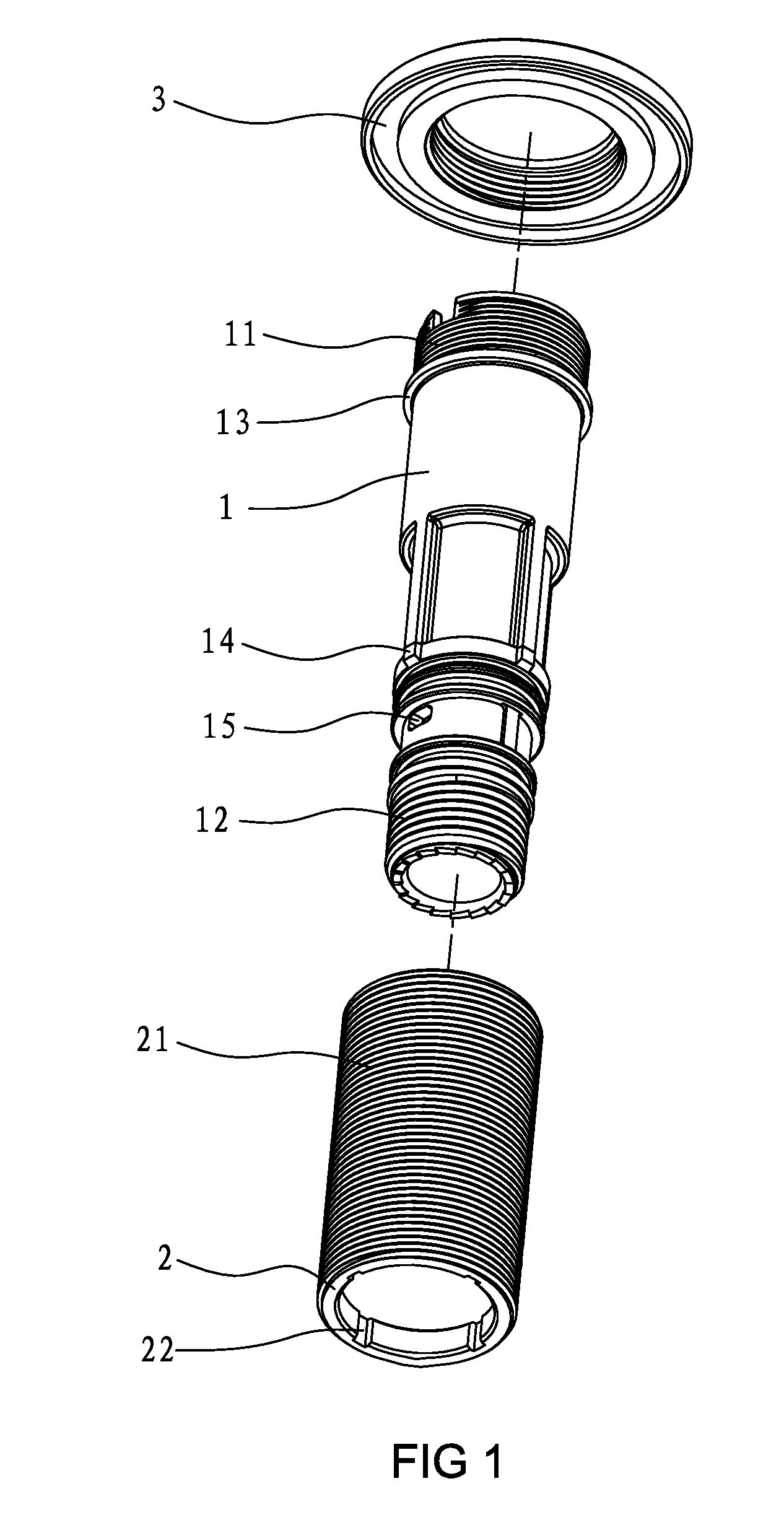

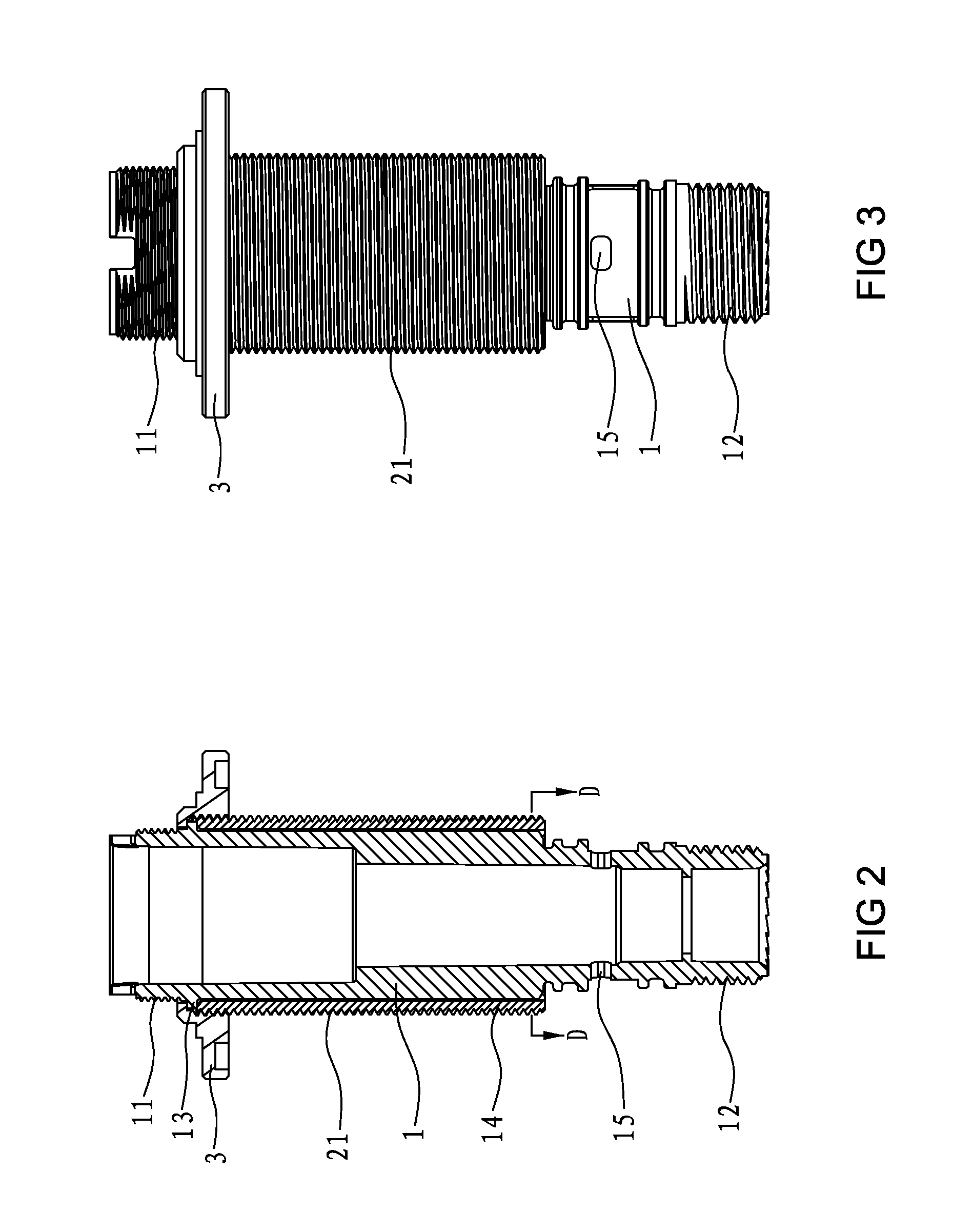

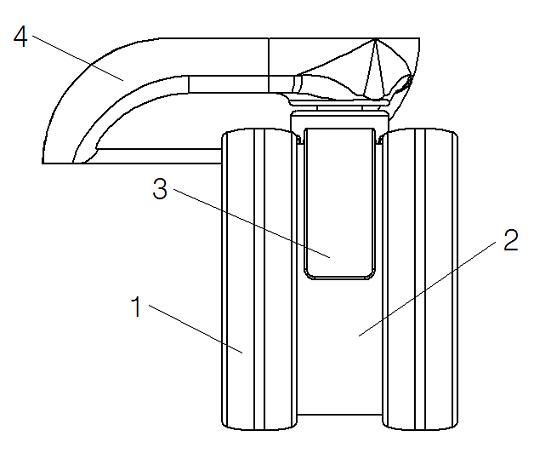

Split-Type Valve Seat For A Faucet

InactiveUS20110061753A1Light weightLow material costMultiple way valvesThin material handlingEngineeringFlange

The inventive valve seat for a faucet includes a one-piece plastic valve seat body, a metal cover and a flange. The metal cover is set outside the valve seat body and is fixed to the valve seat body by the flange. The valve seat is environmentally friendly, and of light weight and low materials cost. Since the metal cover has high strength and is combined with a plastic valve seat body, it can bear the substantial forces imposed upon the valve seat.

Owner:XIAMEN LOTA INT CO LTD

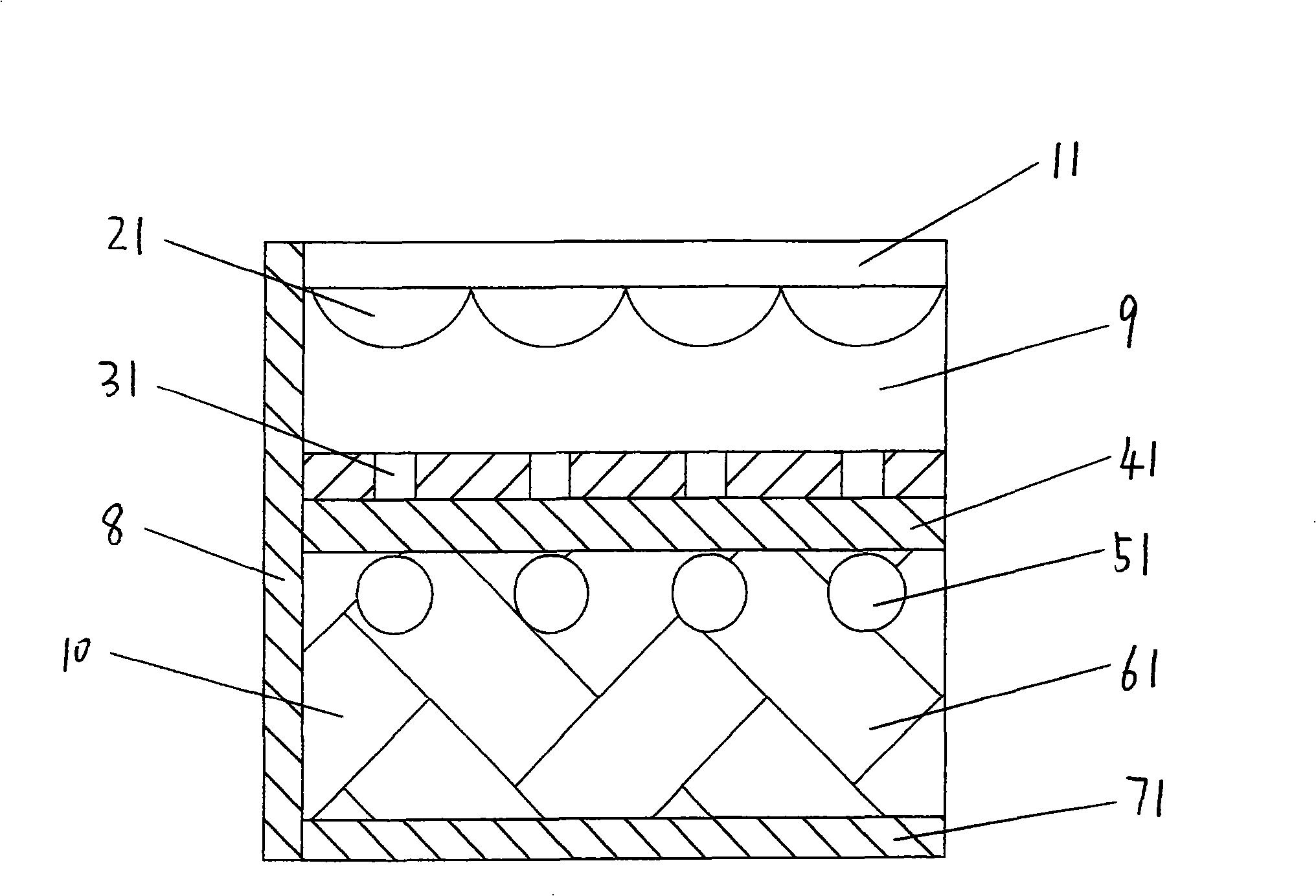

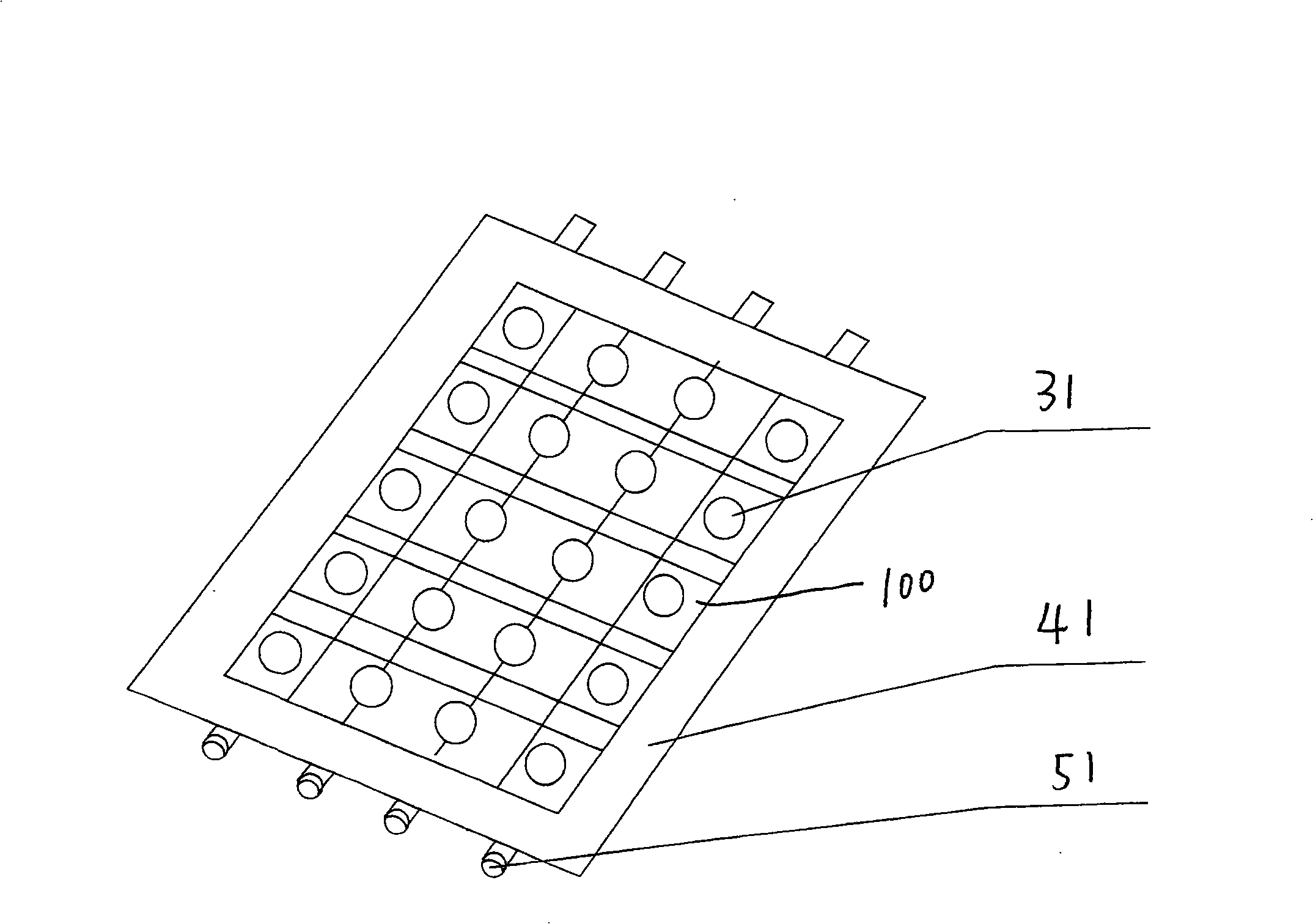

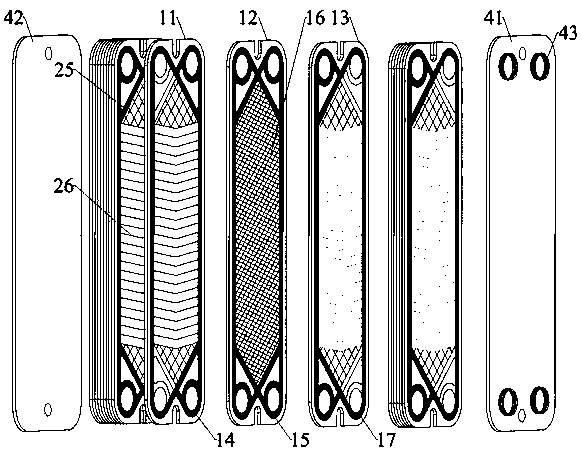

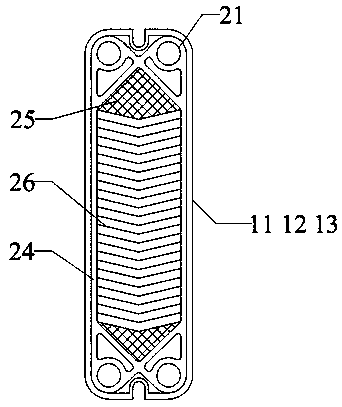

Unintermittent phase change energy storage and heat exchange system

PendingCN109186297AFlexible and reasonable allocationCompact structureHeat storage plantsStationary plate conduit assembliesEngineeringPhase change

The invention discloses an unintermittent phase change energy storage and heat exchange system. The system comprises a plurality of phase change energy storage and heat exchange units. Each phase change energy storage and heat exchange unit comprises a first heat exchange plate, a second heat exchange plate, a third heat exchange plate, two semi-closed sealing rings, a totally-closed sealing ringand a phase change material. The three heat exchange plates are arranged at intervals, and the four corners of each heat exchange plate are provided with through holes. The first semi-closed sealing ring is arranged between the first heat exchange plate and the second heat exchange plate, so that the upper and lower through holes on one side communicate directly, and the upper and lower through holes on the other side communicate with an enclosed space. The totally-closed sealing ring is arranged between the second heat exchange plate and the third heat exchange plate, so that the through holes at the four corners directly communicate, and a totally-closed space is formed between the second heat exchange plate and the third heat exchange plate. The phase change material is arranged in thetotally-closed space. The second semi-closed sealing ring is reversely arranged on the other side of the third heat exchange plate. The three heat exchange plates constitute a cold fluid channel and ahot fluid channel through the semi-closed sealing rings and the totally-closed sealing ring. The unintermittent phase change energy storage and heat exchange system increases the heat exchange coefficient and realizes fast response to heat storage and release so that energy can be distributed flexibly and reasonably.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

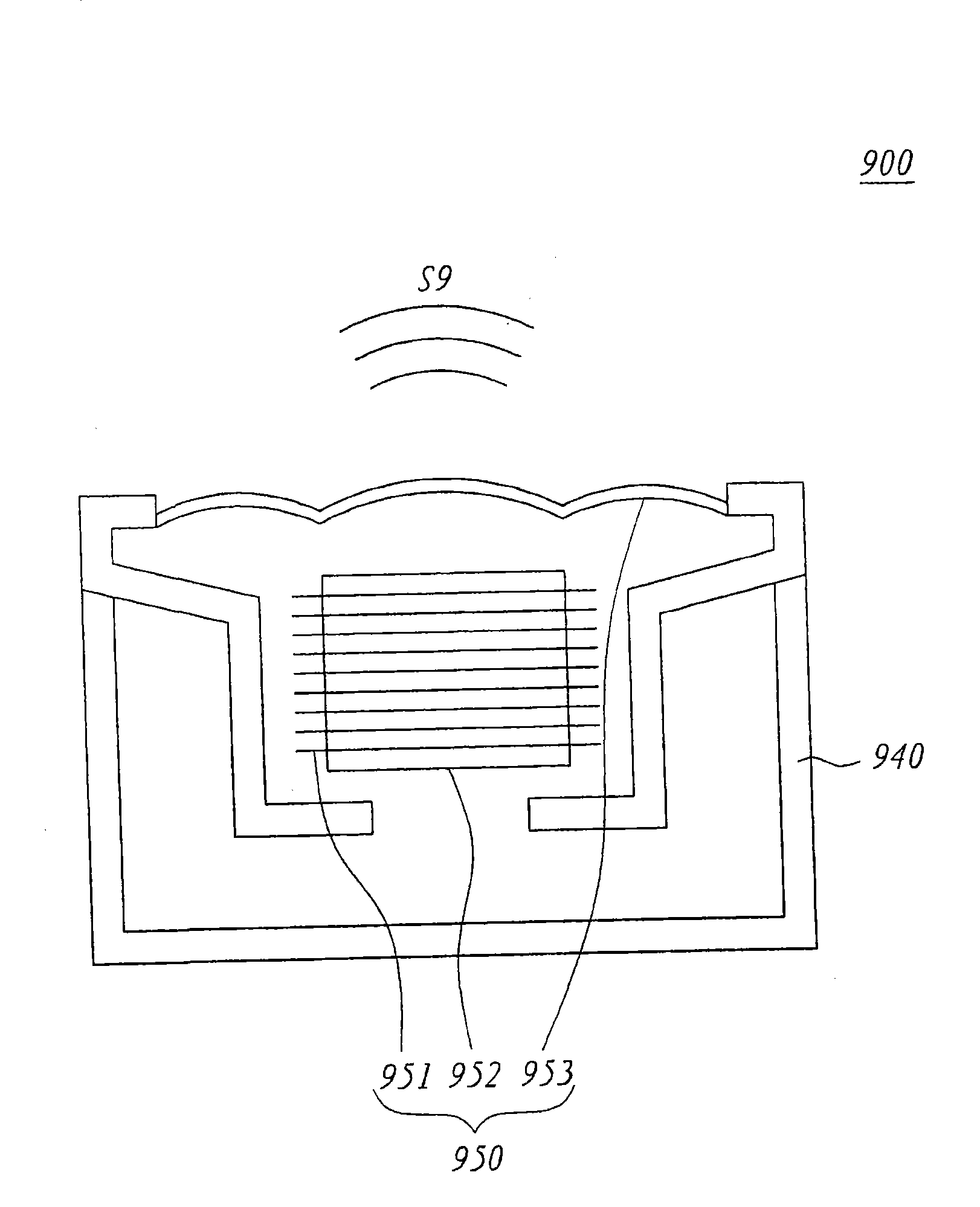

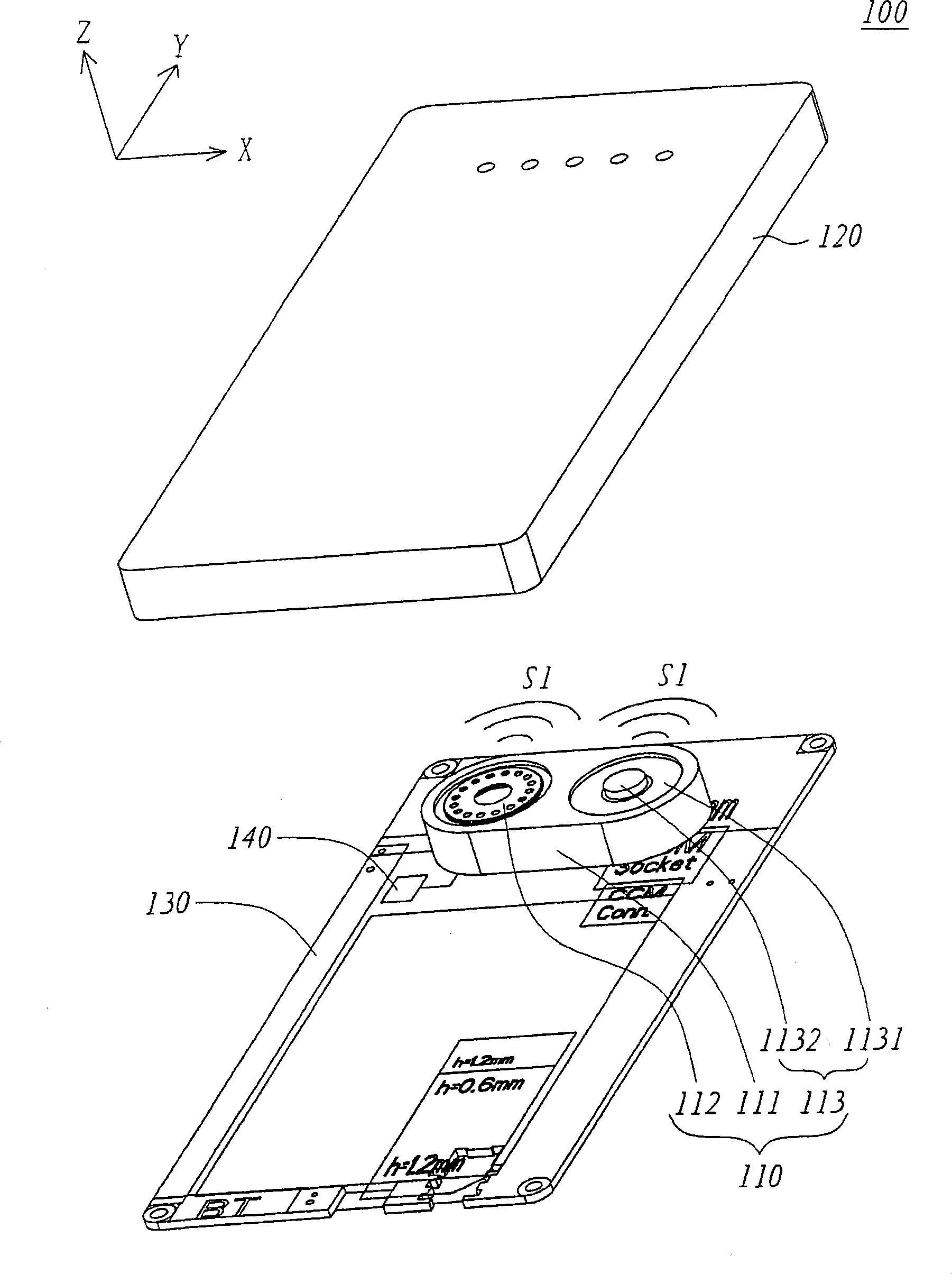

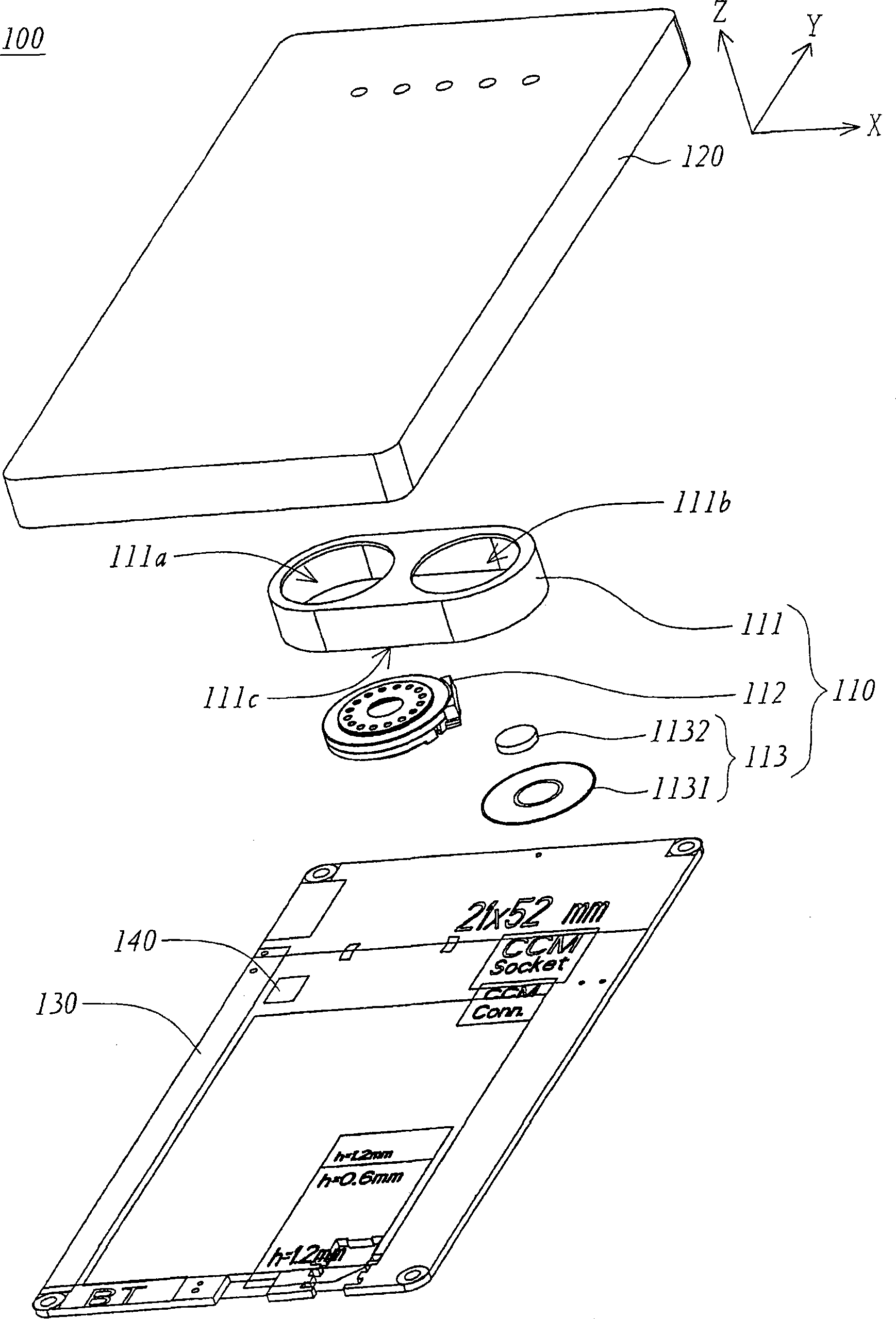

Loudspeaker mechanism and electronic device applying the same

InactiveCN101453678AReinforce the audio signalTroubleshoot poor bassFrequency/directions obtaining arrangementsResonanceEngineering

The invention provides a loudspeaker mechanism and an electric device using the same. The loudspeaking mechanism comprises a speaker, a loudspeaker element and a sound compensation element, wherein the loudspeaker element is arranged on the surface of the speaker; the loudspeaker element is used to send a sound signal; the sound compensation element is arranged on the surface of the speaker; the sound compensation element comprises a resonant membrane and a weight-increasing element; the resonant membrane and the sound signal are resonated in the range of resonant frequency so as to compensate the sound strength of the sound signal in the range of resonant frequency; the weight-increasing element is adhered to the surface of the resonant membrane; and the weight of the weight-increasing element is related to the range of resonant frequency.

Owner:ASUSTEK COMPUTER INC

Method for manufacturing corrugated cardboard sculpture

InactiveCN102173267AUnique texture effectStrong sense of volumeOrnamental structuresCardboardEngineering

The invention discloses a method for manufacturing a corrugated cardboard sculpture, which comprises the following steps: design: drawing the appearance and structure drafts of the sculpture; material selection: selecting abandoned corrugated cardboards for backing cases or finished corrugated cardboard products; blanking: cutting the corrugated cardboards into required shapes; tacking: combiningthe corrugated cardboards in an overlying mode, tacking the inner parts of the corrugated cardboards by flax threads and nailing bamboo nails into the corrugated cardboards; coating: coating a mixture of talcum powder and acetic acid resins on the surface of the sculpture; sheltering: carrying out sheltering on the surface of the sculpture according to the color distribution situations; and coloring: carrying out spray-paint coloring on all color parts, then over-coating the whole sculpture by using varnishes. The method disclosed by the invention has the beneficial effects that because the corrugated cardboard is a recognized green environmental protection material, in the method, the waste corrugated cardboard is reused, therefore, the method has environmental protection value: a uniquetextural effect and a subtle light change can be formed on the manufactured sculpture, therefore, the sculpture is clear in color, can satisfy the artistic ideal of people on the interior public space of the modern building, and has artistic value; the method is simple and reasonable, and low in cost, and can be formed directly by using a dry method without using a frame, therefore, the method isbeneficial for promotion and application and has economic value.

Owner:NORTHEAST DIANLI UNIVERSITY

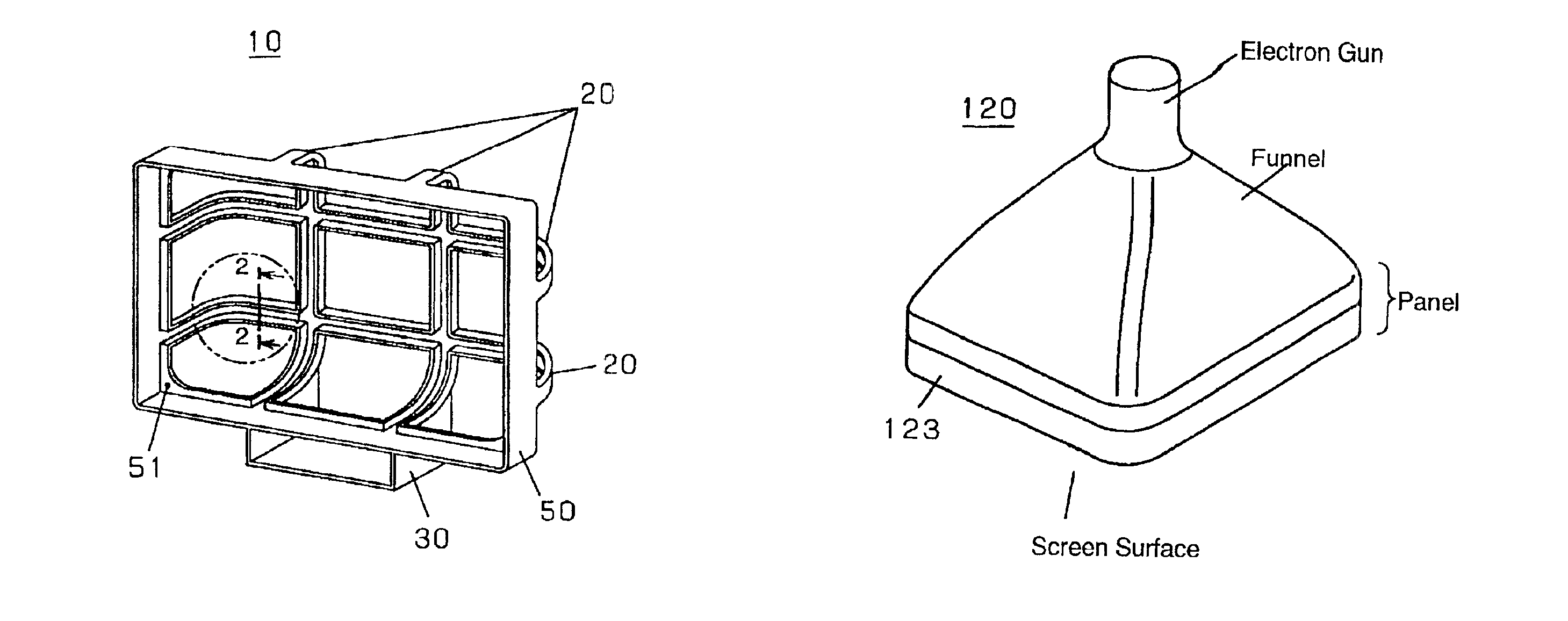

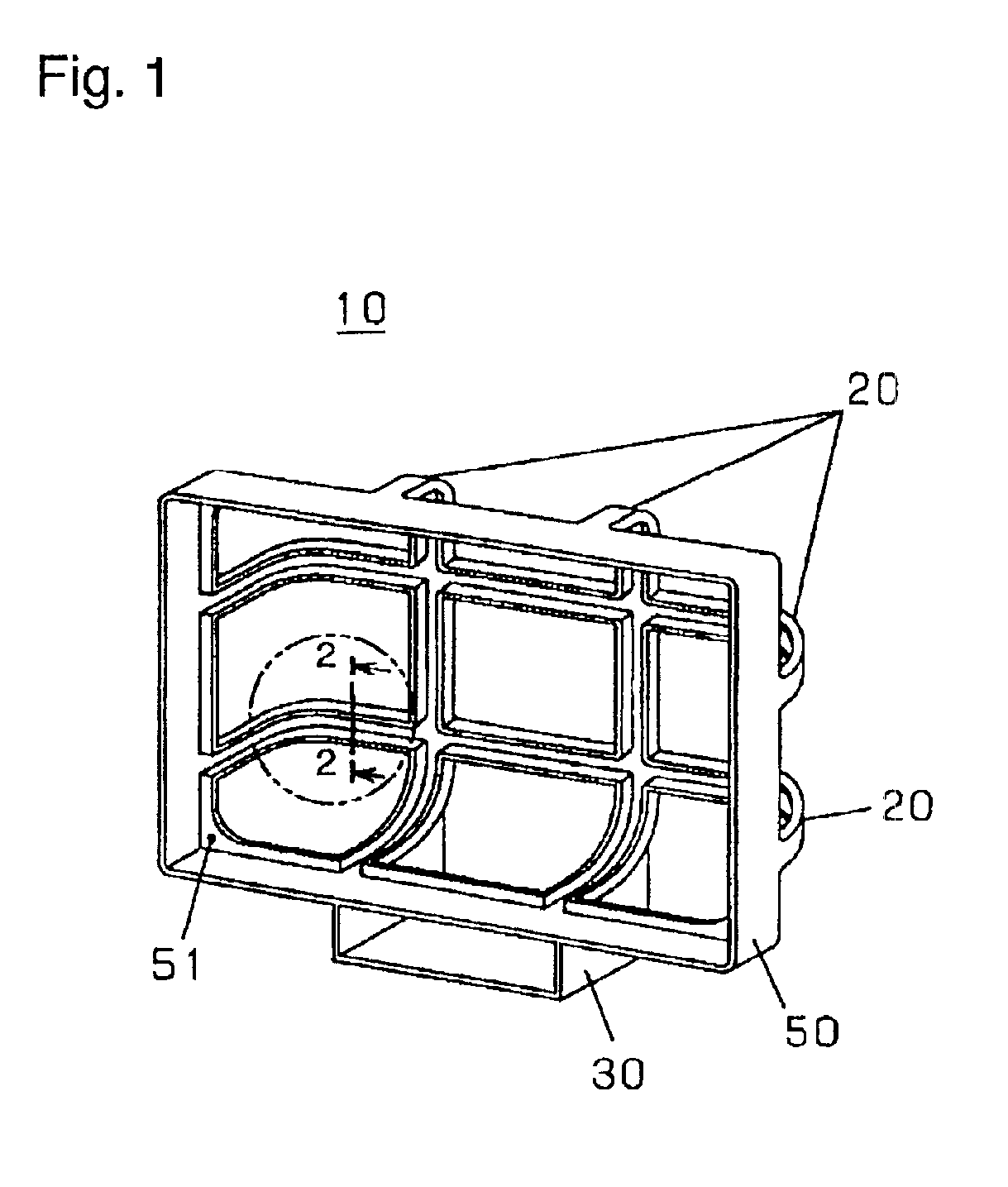

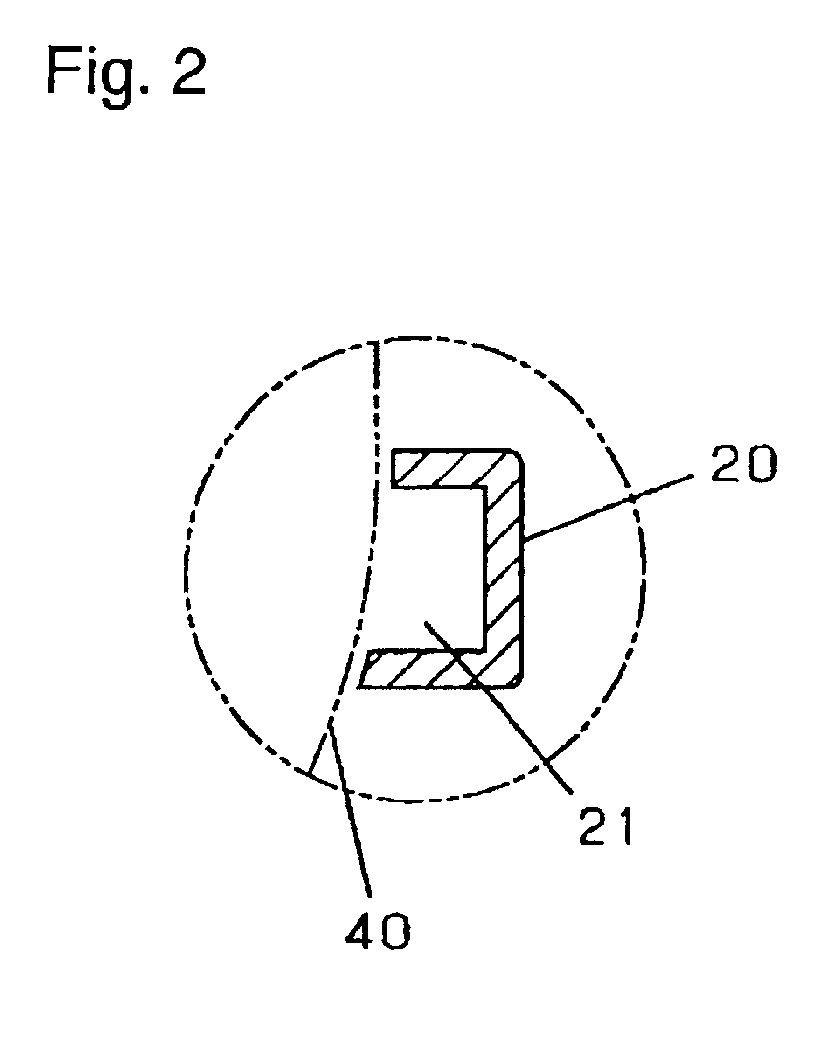

Video appliance, holding device, and manufacturing method of holding device

InactiveUS6930731B2Reduce wall thicknessLow material costWorkpiece holdersTelevision system detailsCathode Ray Tube DisplayMechanical engineering

A cathode-ray tube (CRT) holding device holds a CRT from the rear side by a rib section having a shape similar to that of a funnel of the CRT and extending in plural directions. The rib section has a section having shaped in a recessed groove, and a degaussing coil is disposed in the groove. The CRT holding device has a low cost and a raised recycling rate. Without increasing the number of parts, the degaussing coil can be mounted.

Owner:PANASONIC CORP

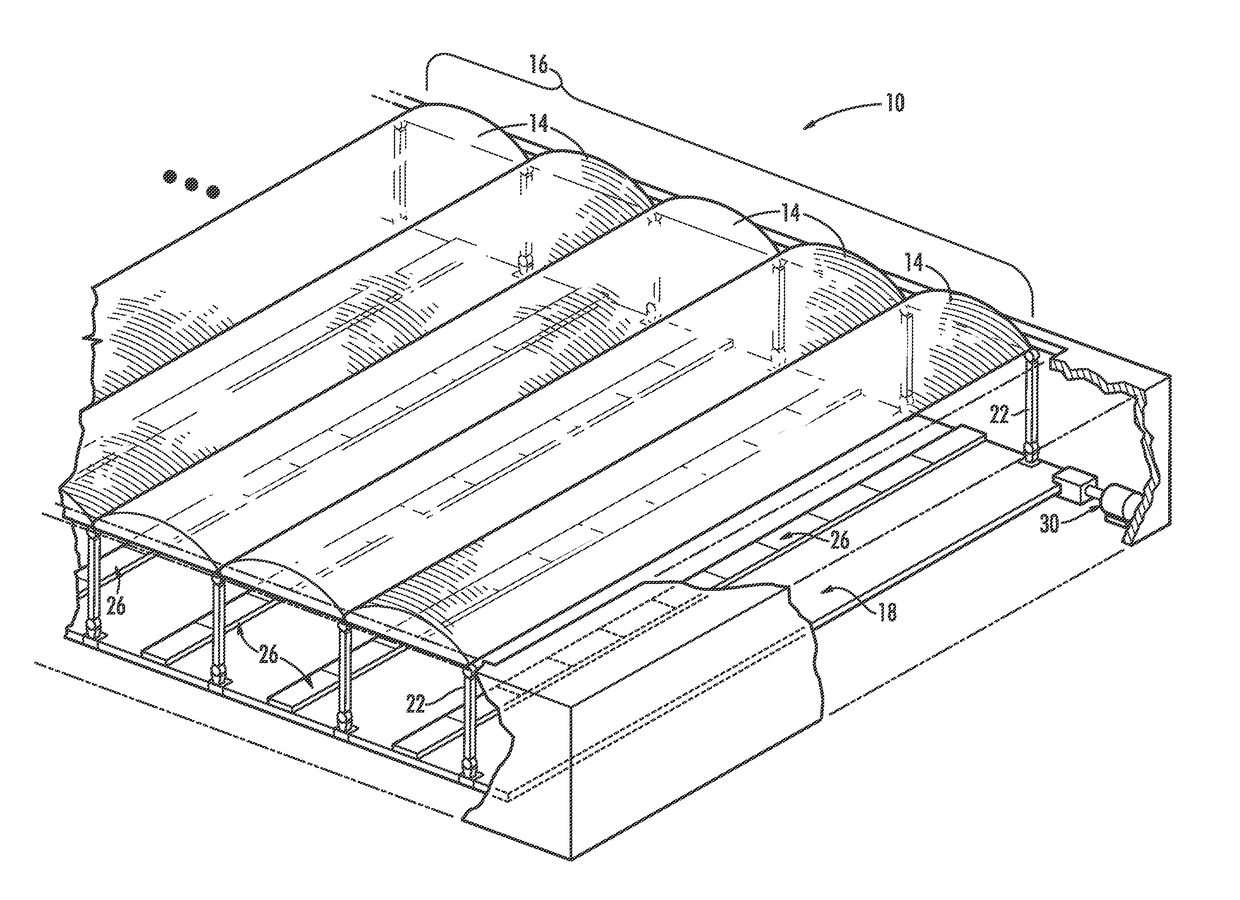

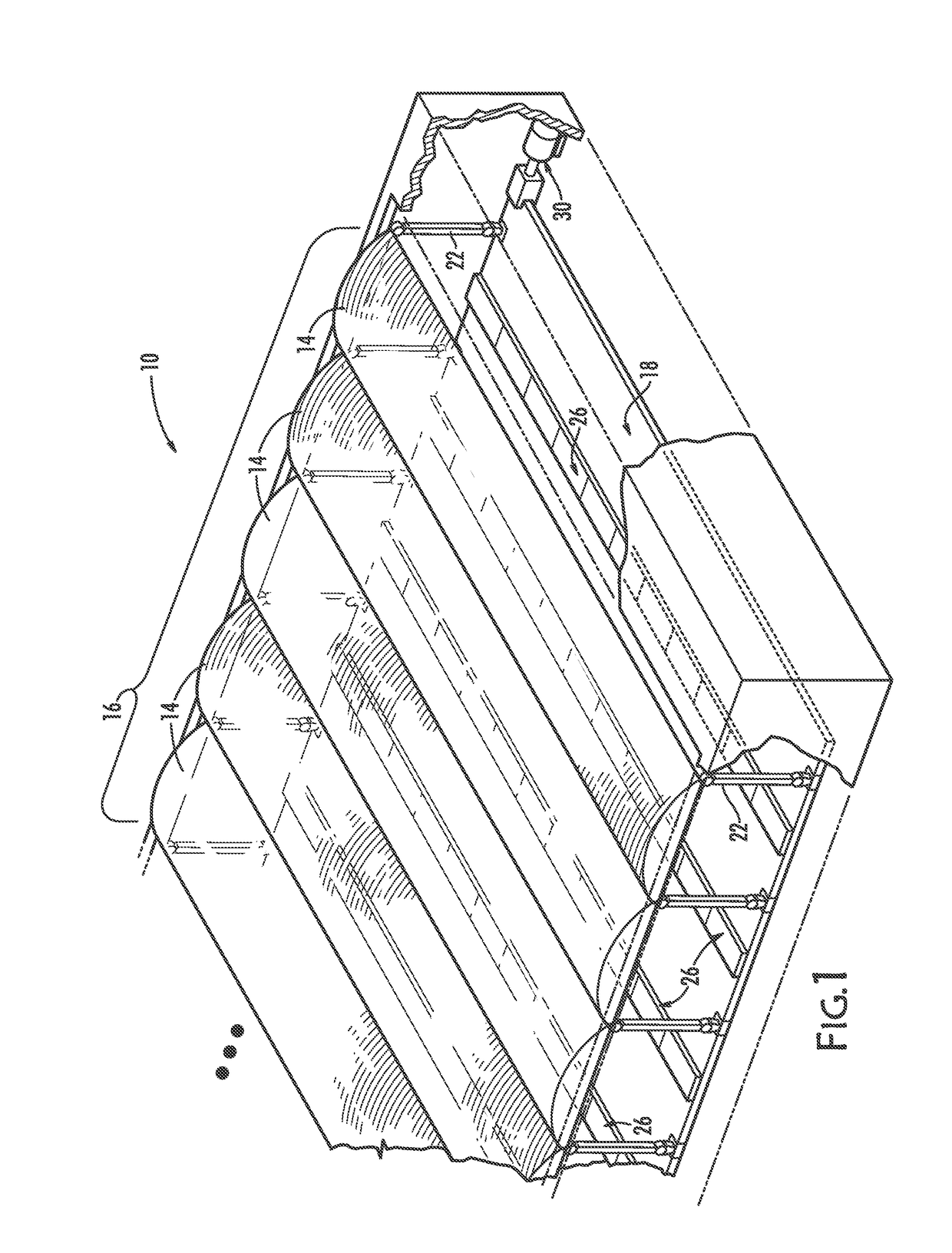

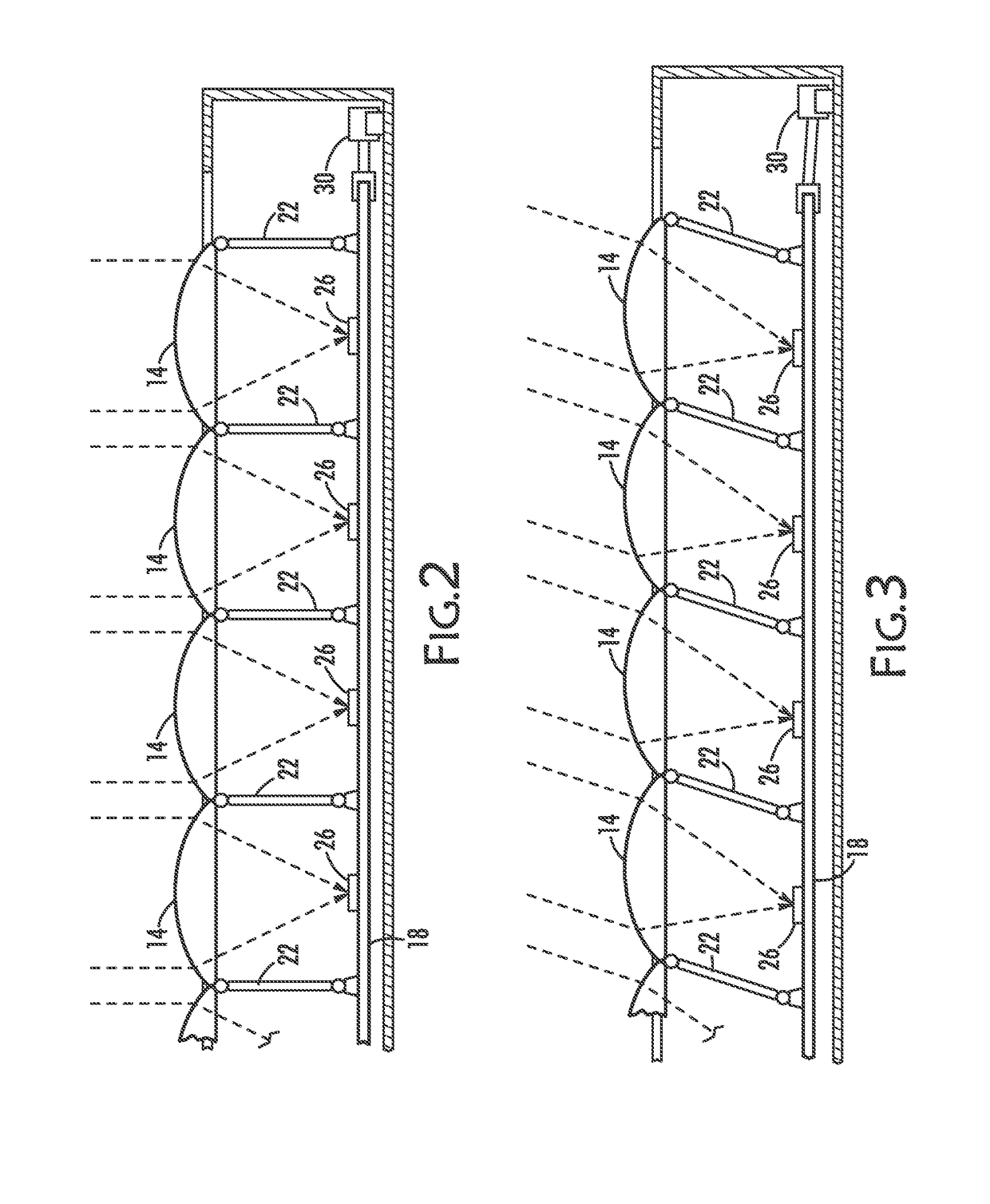

Rigidly mounted tracking solar panel and method

InactiveUS20170104444A1Conversion efficiency be highLow material costPhotovoltaic supportsSolar heating energyElectricitySunlight

A rigidly mountable solar panel includes lenses supported above a movable panel to focus sunlight onto photovoltaic material carried on the movable panel. Flexible supports space the movable panel at the focal points of the lenses, and a servo-mechanism enables movement of the movable panel to adjust position as the focal point moves with the sun. A light detector on the movable panel, sensing movement of the focal point signals the servo-mechanism to adjust the position of the movable panel automatically, thereby tracking the sun's movement. Concentrating sunlight on photovoltaic material selected to have higher conversion efficiency increases output. Segmenting the photovoltaic material so the output of the segments can be combined in a series-parallel relationship and using mirrors on the ends of the movable panel to reflect sunlight onto the segments allows electricity that is generated by the photovoltaic material to be more uniform during daylight.

Owner:THE BOEING CO

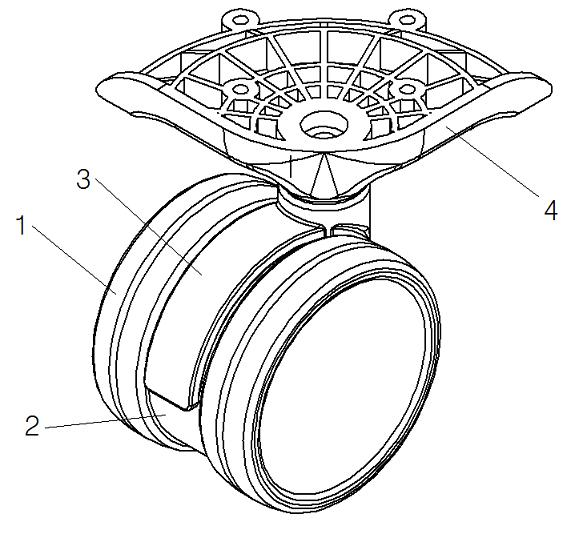

Hollow caster

InactiveCN101954838AExcellent structural strengthExcellent structural bearing capacityCastorsEngineeringCaster

The invention discloses a hollow caster, which relates to the technical field of casters and aims to solve the technical problem of reduction in weight and manufacturing cost. The caster comprises an axle, a rolling bearing and annular belting leather, wherein the inner ring of the rolling bearing is fixedly connected with the axle. The hollow caster is characterized in that: the axle is a hollow hard round tube; and the belting leather is coaxially sleeved on the outer ring of the rolling bearing. The hollow caster provided by the invention has light weight and low manufacturing cost.

Owner:SHANGHAI CONWOOD INT CO LTD

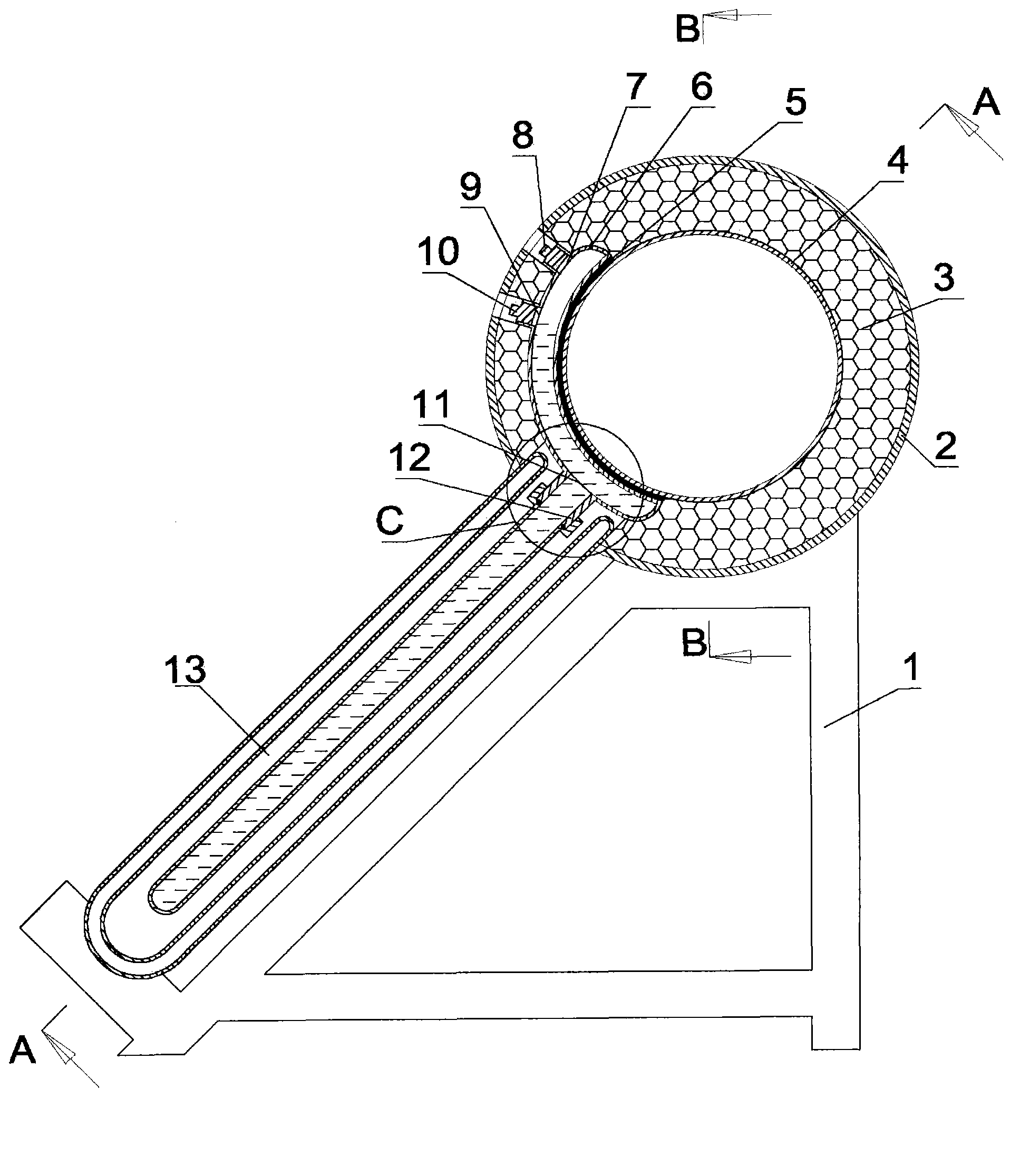

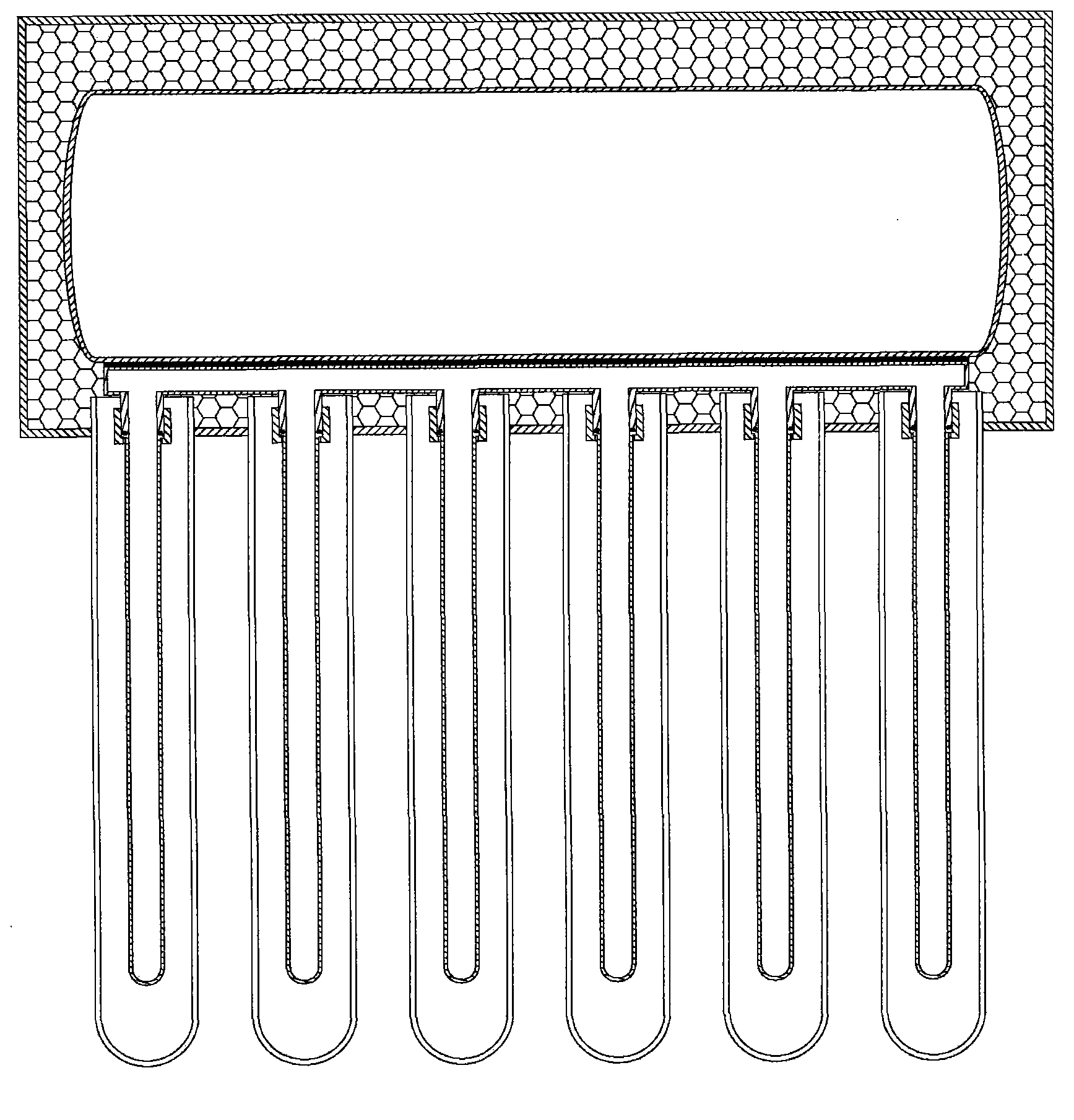

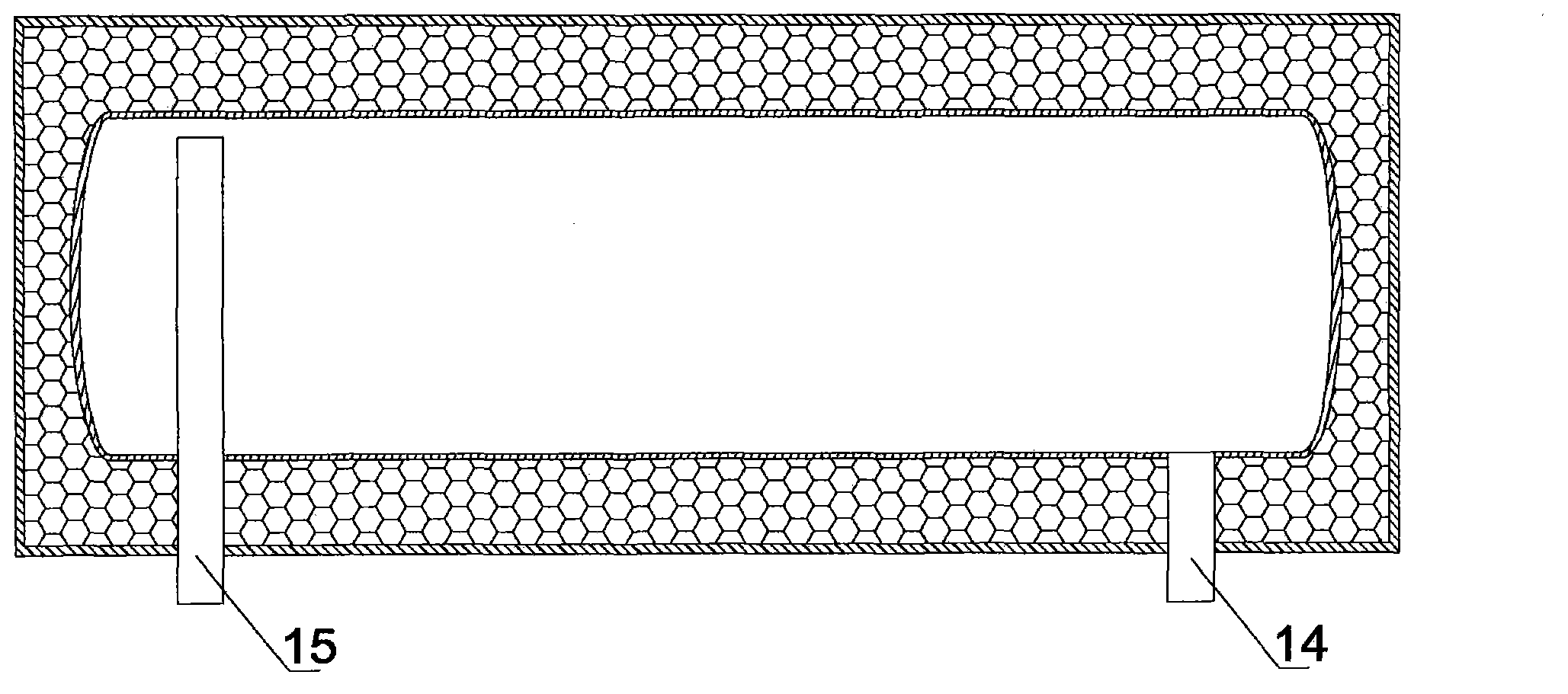

Double-pressure-bearing solar water heater

InactiveCN102798233AGuaranteed Thermal PerformanceLow material costSolar heating energySolar heat devicesSolar waterEngineering

The invention discloses an integral double-pressure-bearing solar water heater which comprises a support, a water tank shell, a thermal insulating layer, a heat exchange jacket, a heat-conducting interfacial packing layer and an inner heat storage container, wherein a short heat-exchange working medium circulating tube used for connecting a pressure-bearing solar vacuum heat collecting tube is arranged on the heat exchange jacket, the heat exchange jacket is provided with a heat-exchange working medium filling port and a heat-exchange working medium overflow port, and the heat-exchange working medium circulating tube communicates the pressure-bearing solar vacuum heat collecting tube and an cavity of the heat exchange jacket. A cold water inlet tube and a hot water outlet tube are connected on the inner heat storage container. The heat exchange jacket is tightly attached too the inner heat storage container through the heat-conducting interfacial packing layer. Heat collection and heat storage of the integral double-pressure-bearing solar water heater provided by the invention respectively and independently operate in a closed type, use water is used by bearing pressure, the use water can not be polluted due to the seepage of a heat exchange working medium, the use water is sanitary, and the system is safe and reliable. The entire system has reasonable structural design, low cost, high cost performance and long service life.

Owner:孙传玲

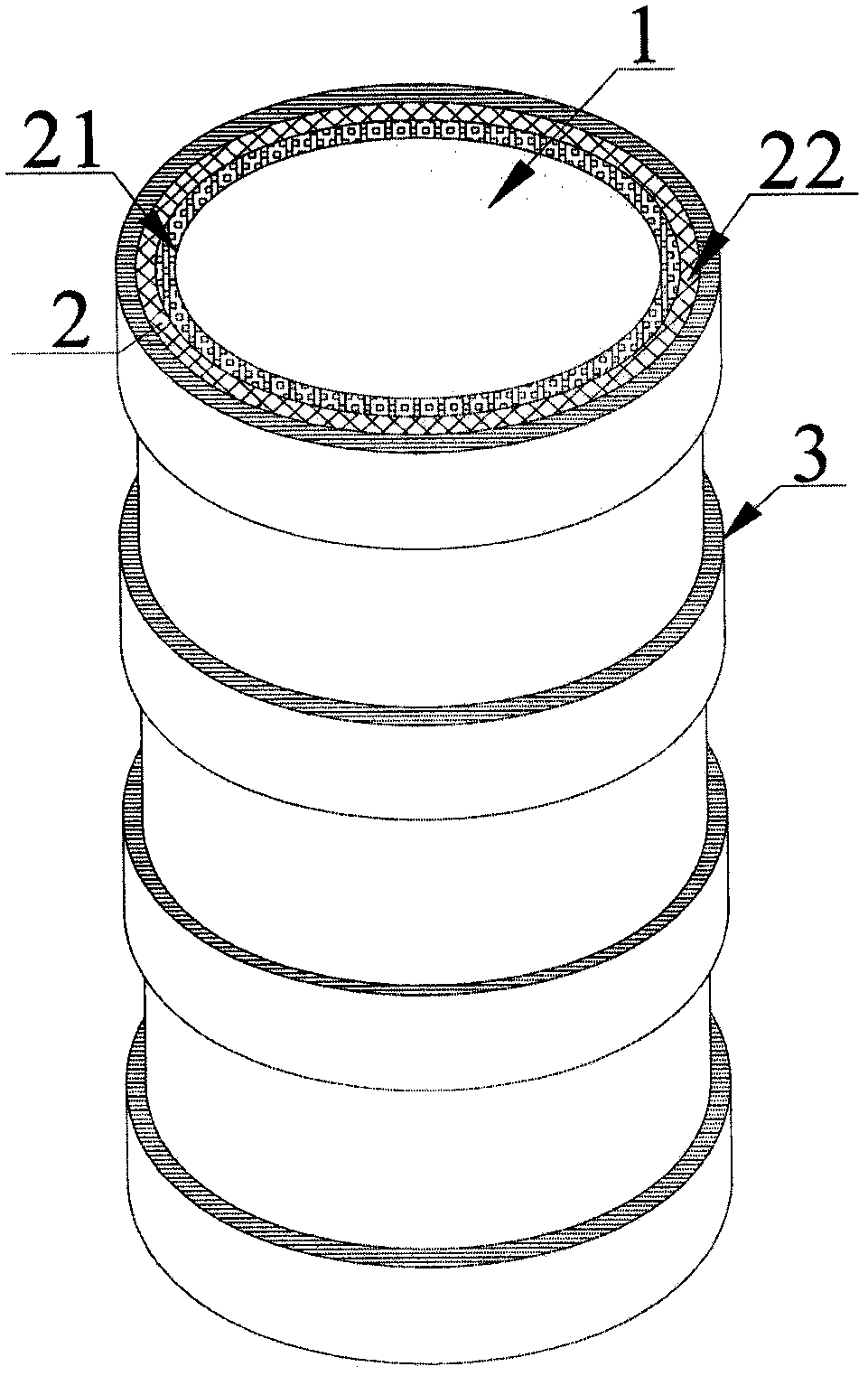

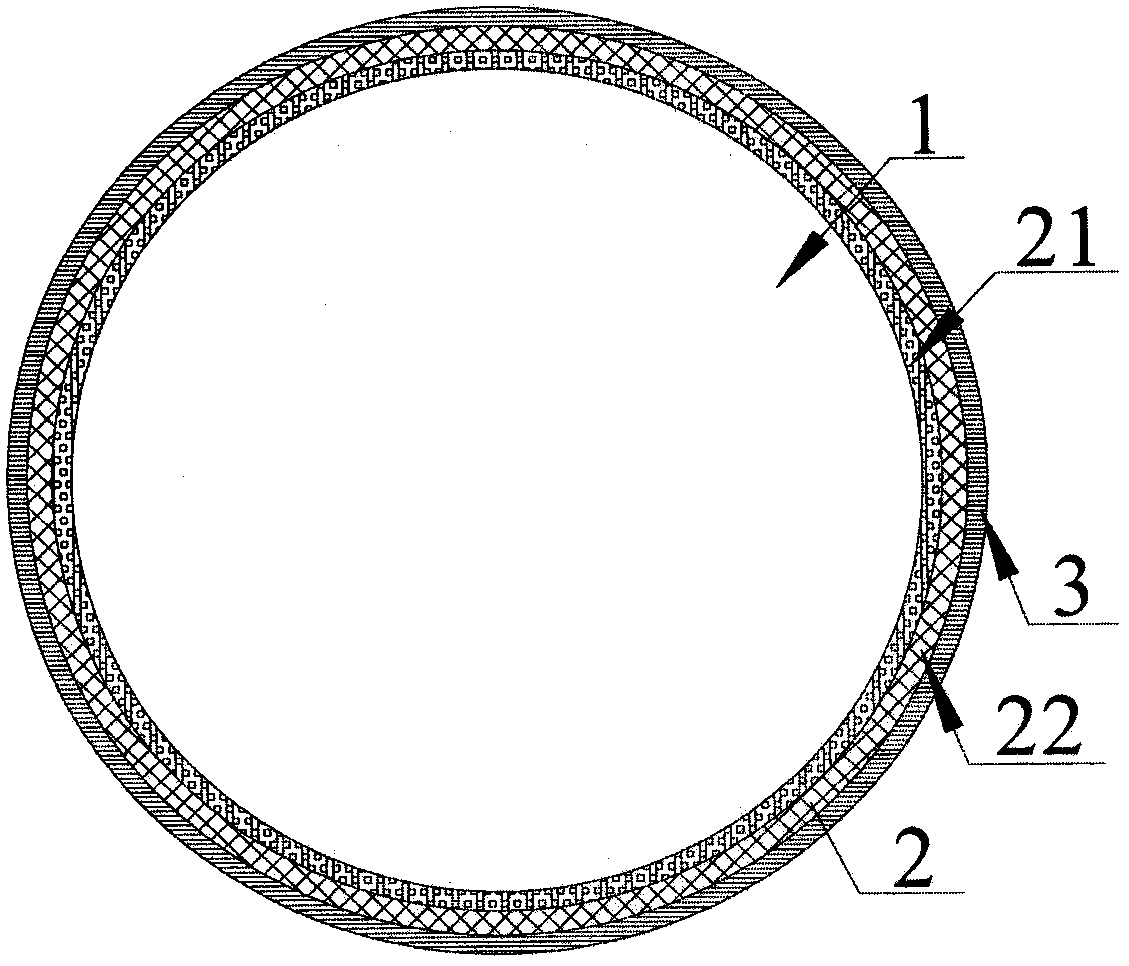

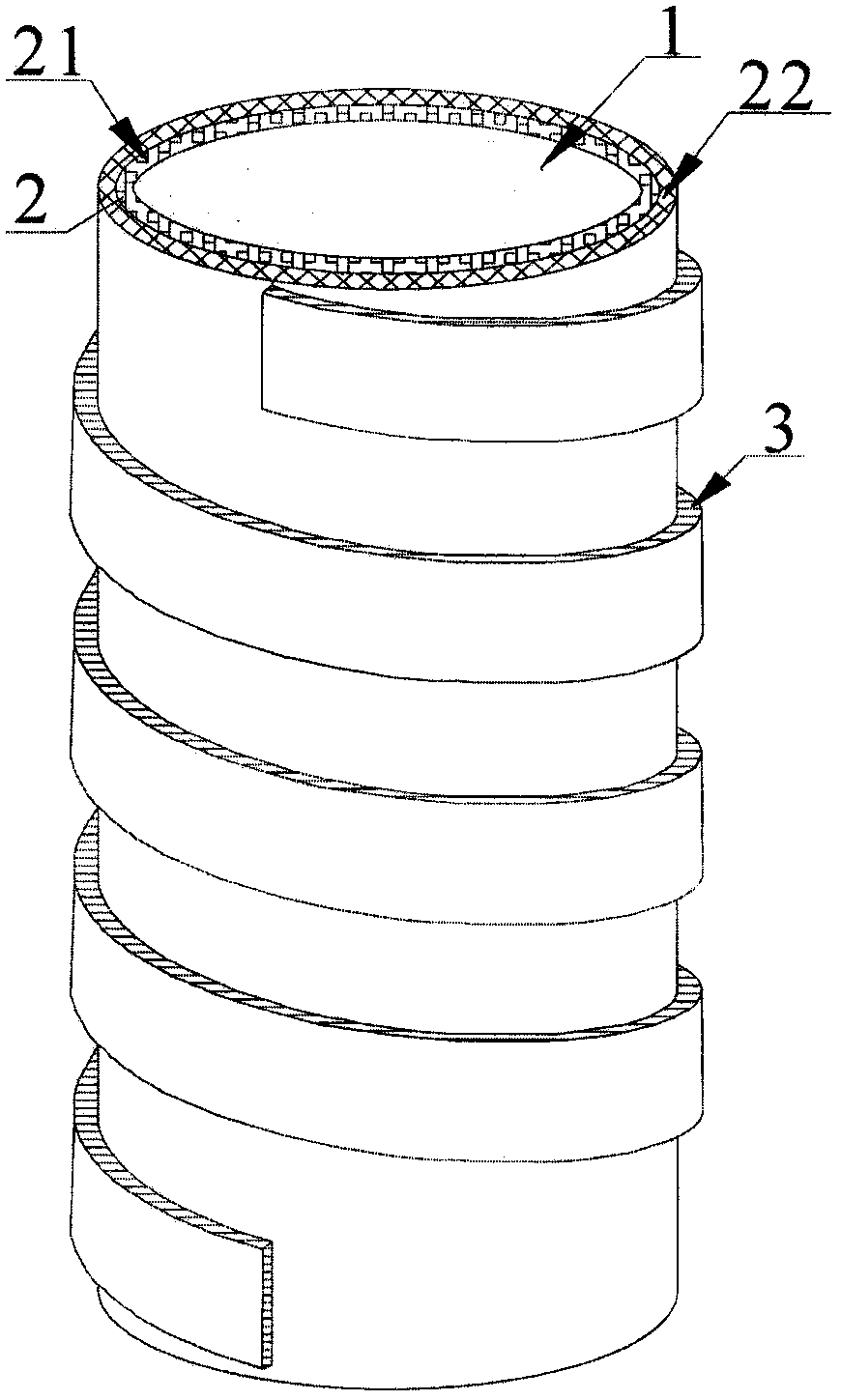

Light filled core bamboo tube structure

PendingCN109184081ABamboo consumption is smallLow material costStrutsBridge structural detailsPhysicsFiber orientation

The invention relates to a light filled core bamboo tube structure. The light filled core bamboo tube structure comprises a light filled core (1), a bamboo tube (2) and reinforced bamboo belts (3), wherein a cavity of the bamboo tube (2) is provided with the light filled core (1), the bamboo tube (2) is formed by mutually compounding a longitudinal bamboo band (21) and a bamboo coiled material (22); and the reinforced bamboo belts (3) are adhered to the outer wall of the outer wall of the bamboo coiled material (22) in a spiral or loop type internal winding manner so as to form included anglesof (-45)-(45) degrees or 0 degree with the direction of the cross section with the bamboo tube (2). According to the light filled core bamboo tube structure, a lateral support force is provided for the tube wall of the bamboo tube from side to outside by the light filled core, so that the inward local buckling of the bamboo tube is prevented or delayed, and the bearing force of the bamboo tube isgreatly increased; and the annular constraint force is provided for the light filled core by the bamboo tube, so that the stressed bearing capacity of the light filled core is improved, and the transverse deformation of the light filled core is reduced. The light filled core bamboo tube structure is suitable for components such as piles, columns, piers and beams in newly built structures.

Owner:NANJING FORESTRY UNIV

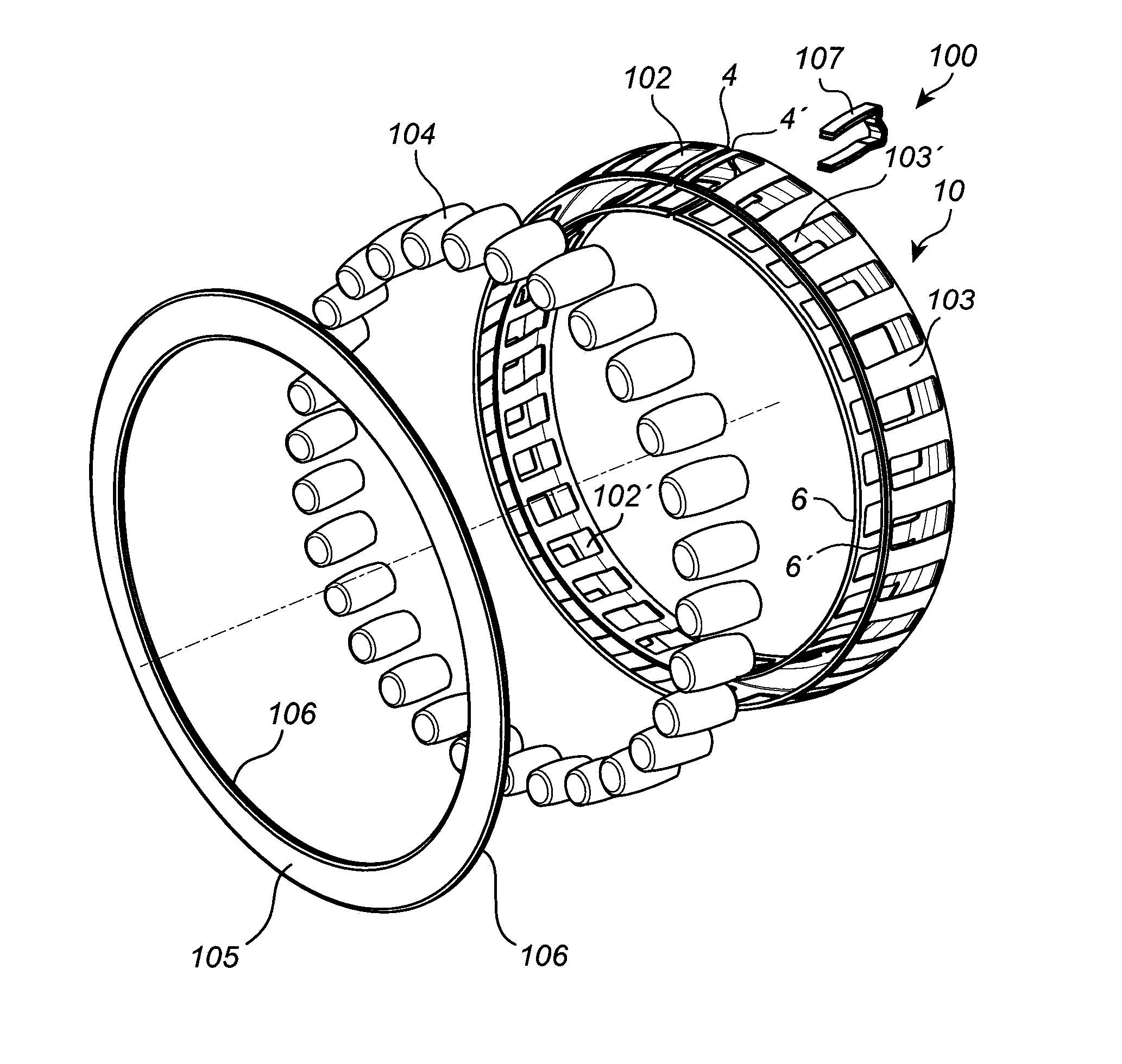

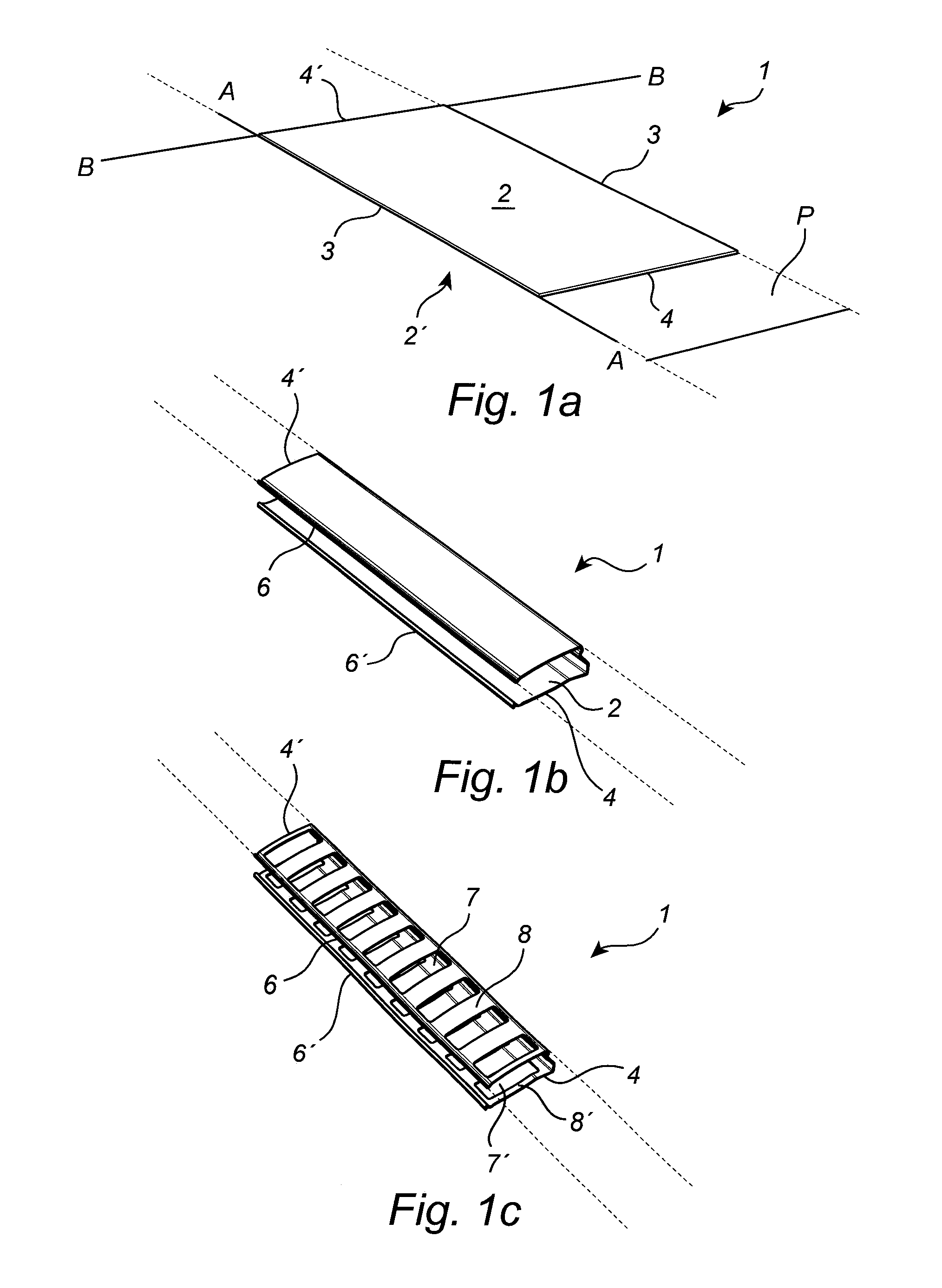

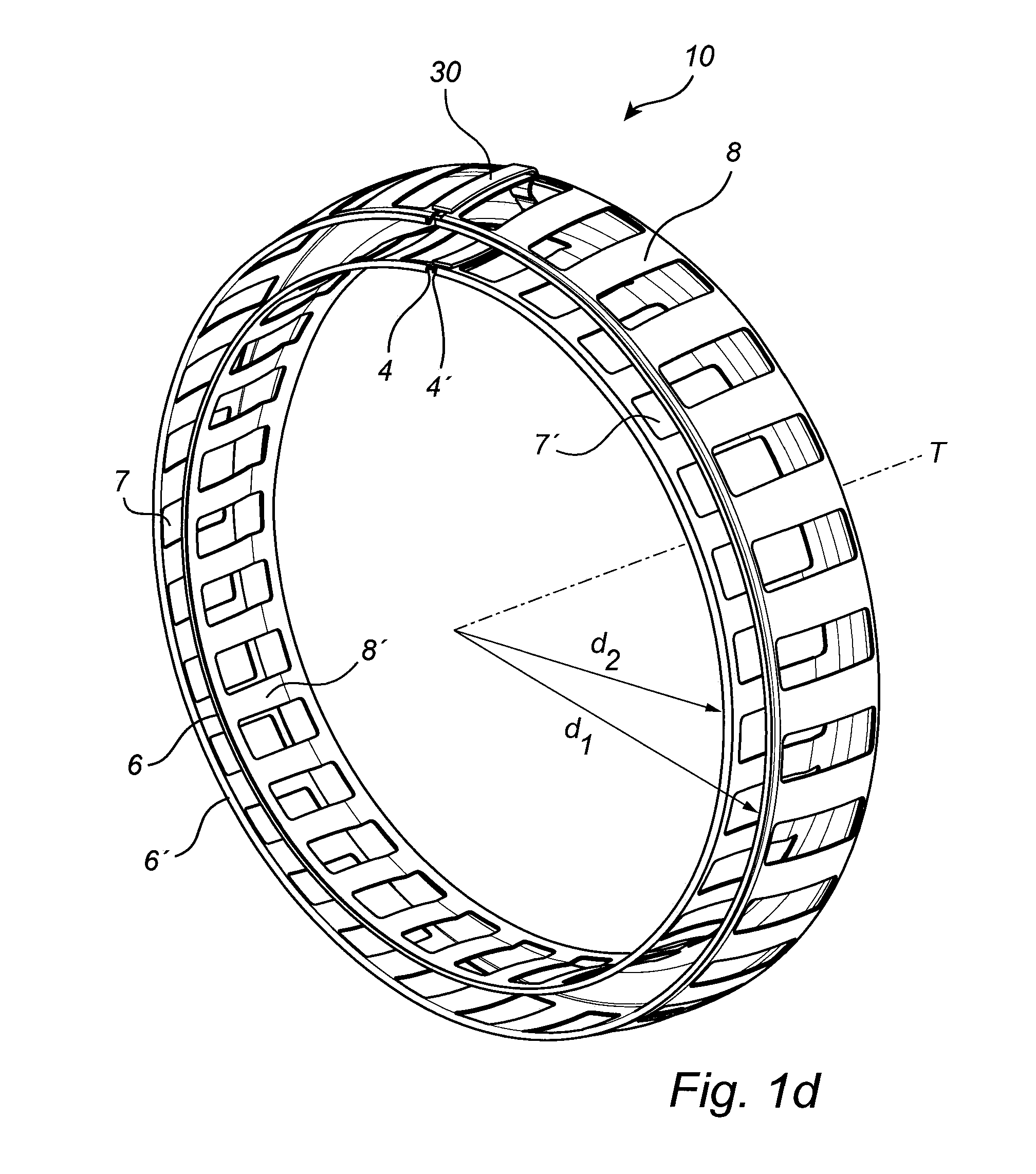

Cage for a bearing assembly and manufacturing method

ActiveUS20160040717A1Improve manufacturingLow material costRoller bearingsMetal-working apparatusEngineeringMechanical engineering

A method for producing an annular-shaped cage for a rolling bearing assembly. The method comprises steps of: (a) providing a workpiece contained in a plane having a first side and a second side; (b) forming an annular-shaped cage from the workpiece, the annular-shaped cage having a U-shaped cross section such that portions of the first side of the workpiece face each other; and (c) forming a plurality of windows in the workpiece for receiving and positioning a set of rolling elements.

Owner:AB SKF

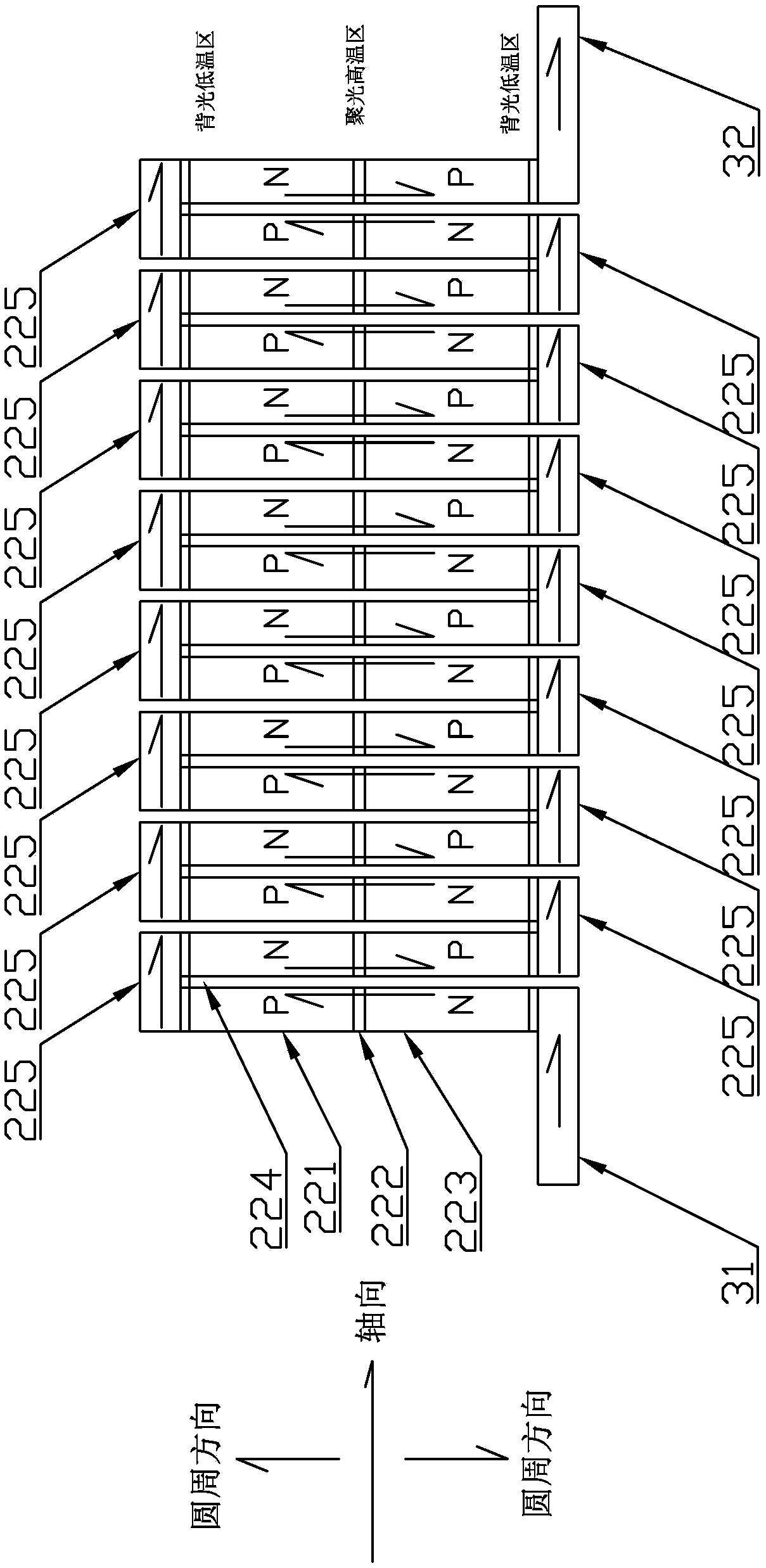

Thin film thermoelectric power generation and selective absorption coating coupled solar collector tube

PendingCN109654745AStructural advantageEasy to processSolar heating energySolar heat collector detailsTwo temperatureTemperature difference

The invention provides a thin film thermoelectric power generation and selective absorption coating coupled solar collector tube. The solar collector tube comprises a metal tube and a cover glass tube; the outer wall of the metal tube is successively provided with a first insulating layer, a PN junction layer, a second insulating layer and a selective absorption coating; the PN junction layer is connected with an extraction electrode; the two ends of the cover glass tube are each fused with a Kovar metal sleeve; the Kovar metal sleeves form a vacuum sandwich by forming a sealed connection withthe outer wall of the metal tube through a corrugated tube assembly; a wire connected with the extraction electrode forms a zigzag section in the vacuum sandwich; the tail of the zigzag section is led out of the cover glass tube through direct sealing or through a transition material. The solar collector tube especially applies to a trough solar collector tube which can make the temperature difference between the two temperature zones reach 10-50 DEG C. Therefore, the natural temperature difference of the trough solar collector tube can be fully utilized to realize thermoelectric power generation, and there is no need to actively dissipate heat in the low temperature zone.

Owner:河北道荣新能源科技有限公司

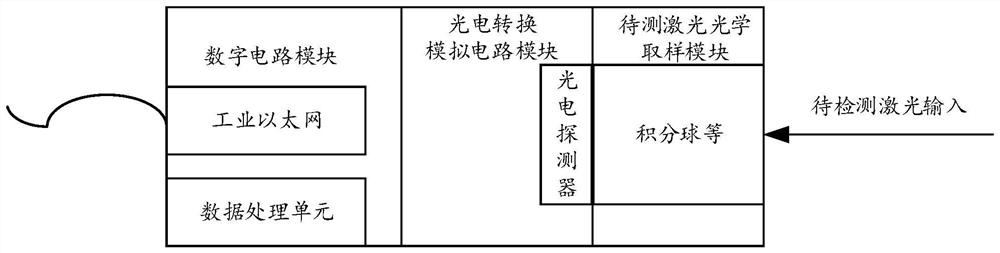

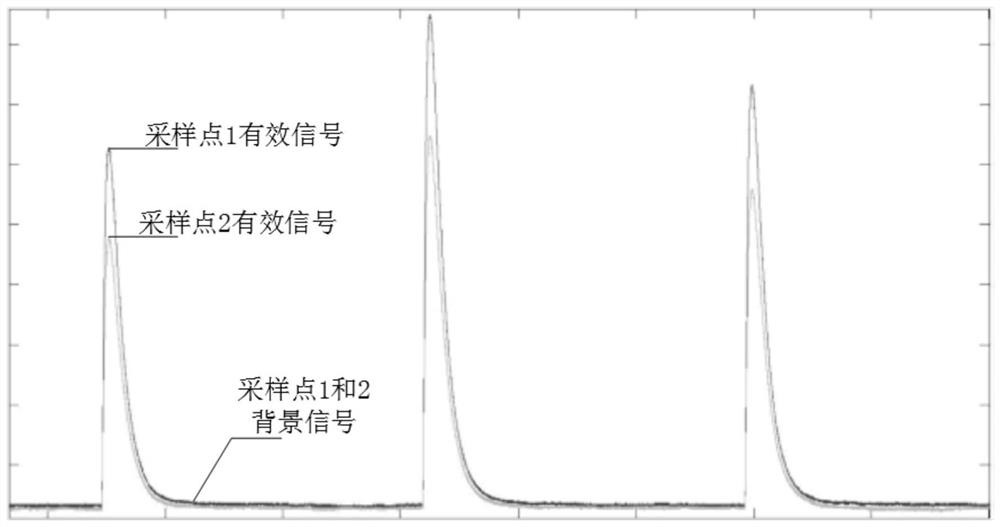

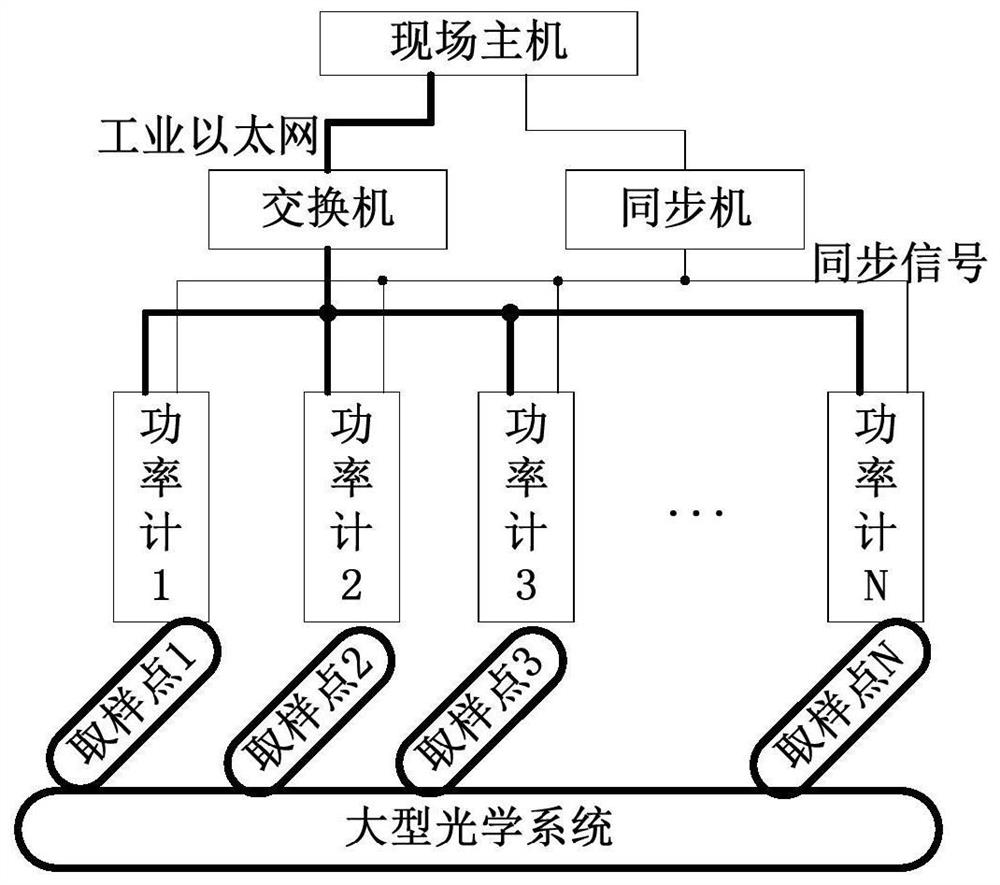

Laser power meter and method for calibrating sampling coefficient of large optical system based on laser power meter

ActiveCN114397013AEasy to installEasy to debugPhotometry using electric radiation detectorsOptical power meterEngineering

The invention relates to a laser parameter detection device, in particular to a laser power meter and a method for calibrating a sampling coefficient of a large optical system based on the laser power meter. The problems that when an existing laser power meter is applied to large optical system sampling coefficient calibration in an industrial field, the structure is not compact, installation and testing in the industrial field cannot be achieved, long-distance transmission cannot be achieved, and the calibration cost is high are solved. The laser power meter comprises a to-be-measured laser optical sampling module, a photoelectric conversion analog circuit module and a digital circuit module which are directly connected in sequence; the device is of an integrated design, is compact in structure, is easy to integrate, facilitates the installation, debugging and maintenance of an industrial field, and can be applied to the calibration of a large-scale optical system sampling coefficient. In the calibration process, the influence of background light is deducted, the interference of background stray light on sampling coefficient measurement is weakened, and the whole calculation method is simple, convenient to realize online and short in processing time. And meanwhile, due to synchronous sampling, the interference of light source fluctuation on sampling coefficient measurement can be reduced.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

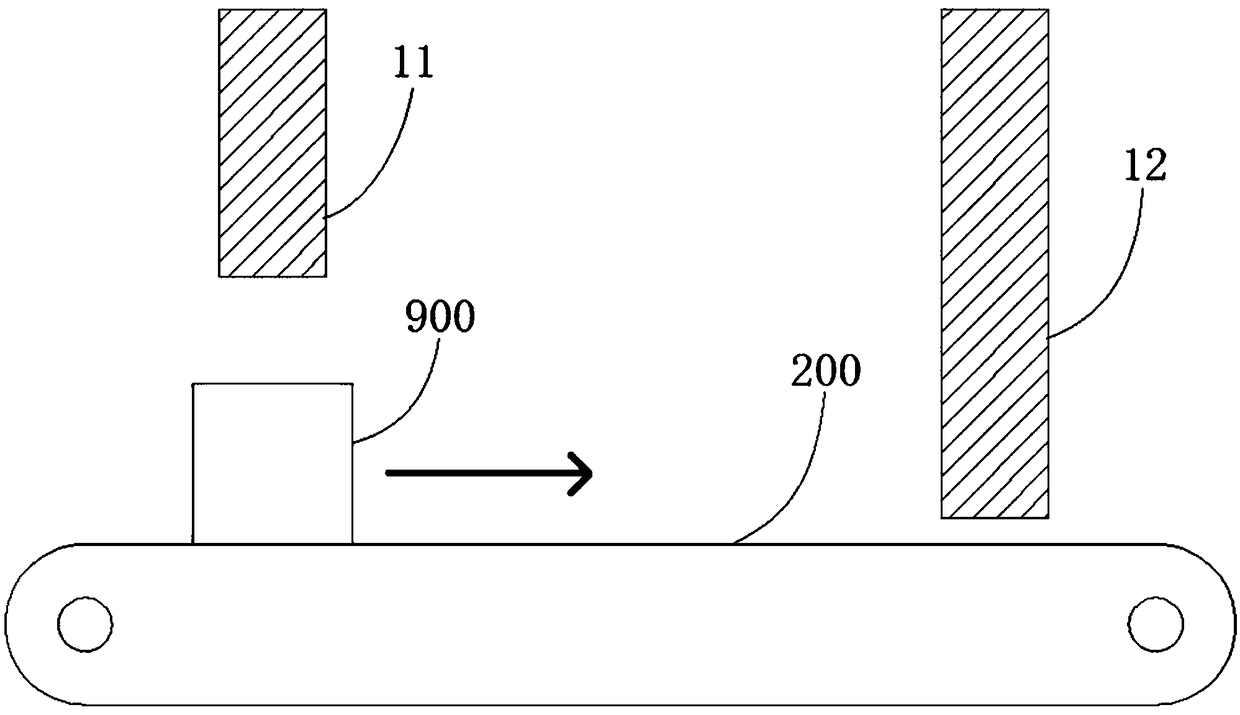

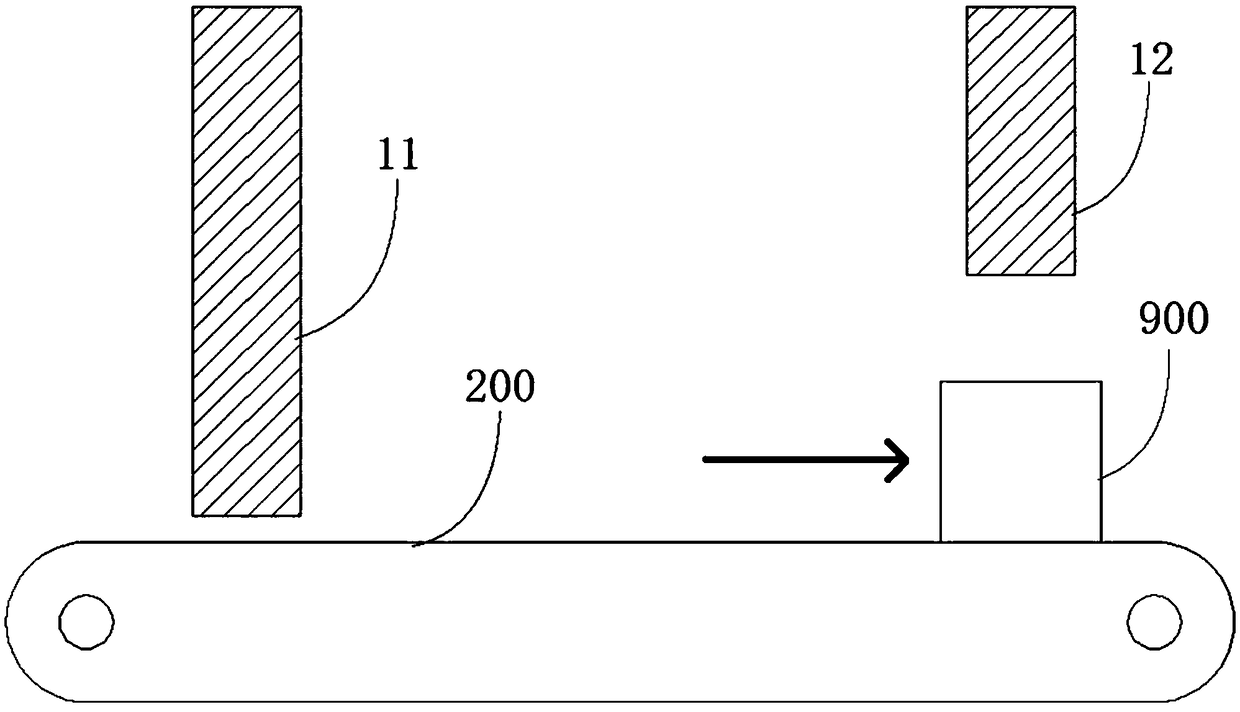

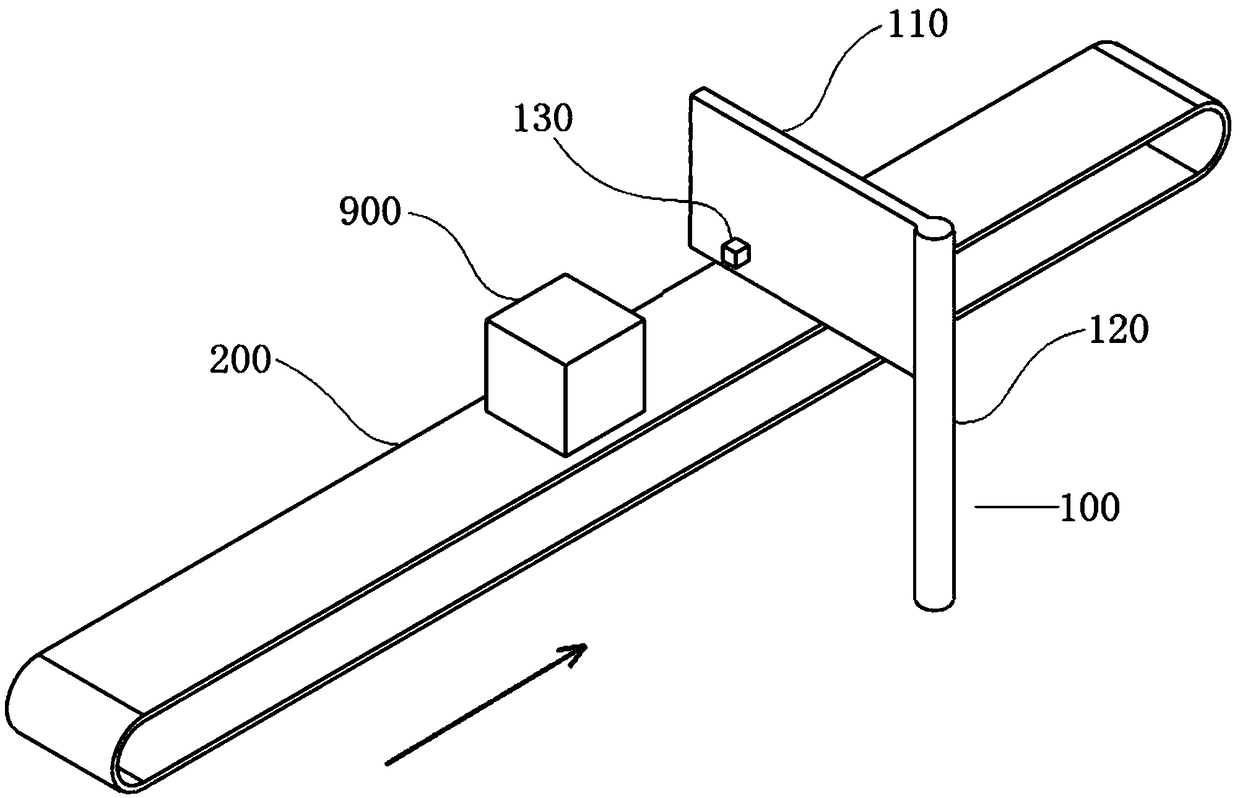

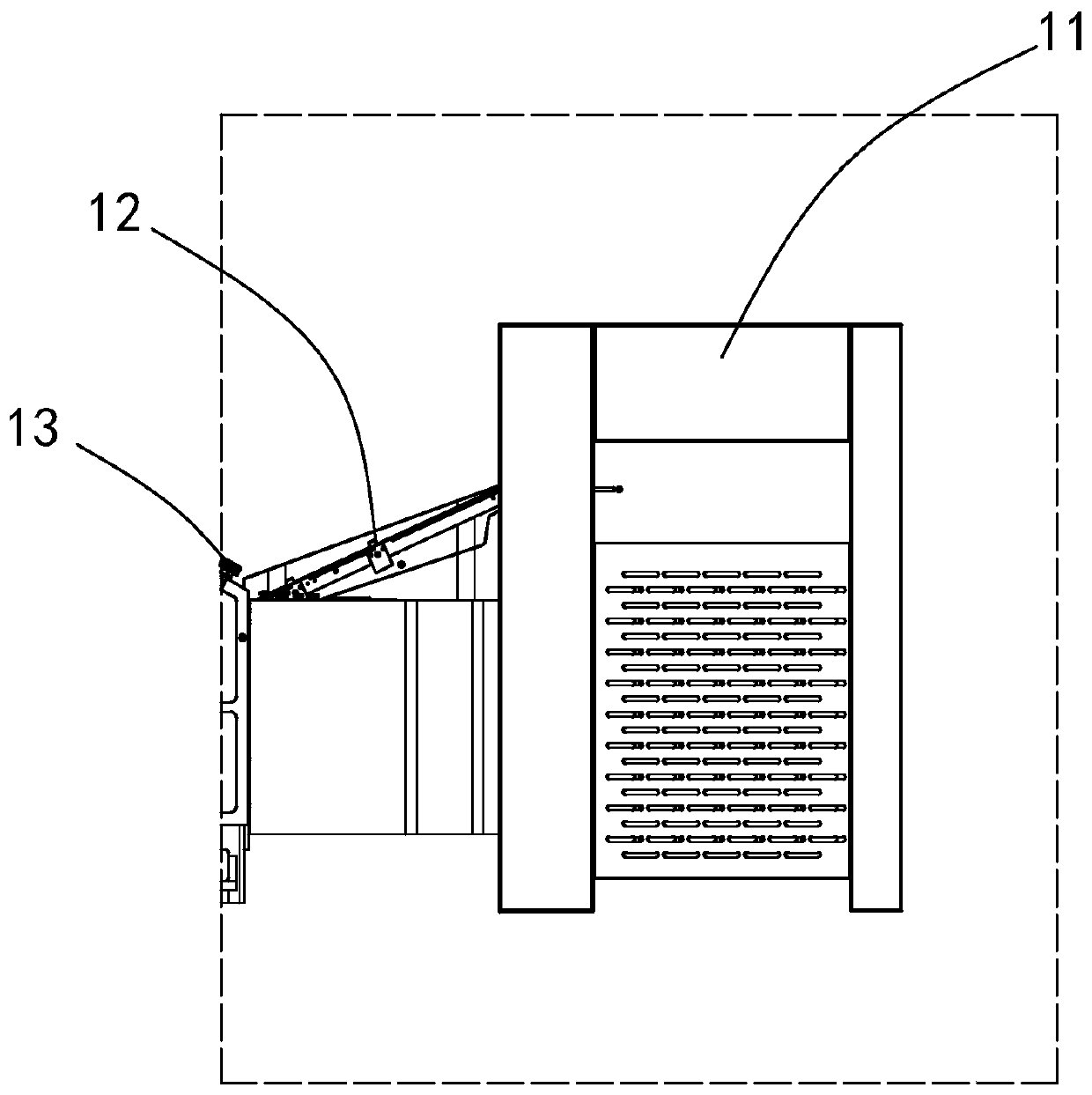

Rotating goods stopping device, goods conveying control system and method

The invention provides a rotating goods blocking device, and a goods conveying control system and method, wherein the system comprises a rotating mechanism arranged at one side of a conveying mechanism and a baffle structure arranged on a moving track of the goods and being passed through by the conveying mechanism, the rotating mechanism drives a rotating door to block / release the goods on one ormore conveying mechanisms, only one actuator is required to control the rotating door to automatically rotate so as to simultaneously control the goods conveying of the plurality of conveying mechanisms, compared with four actuator used in a prior system, the materials and cost are saved, the baffle structure is arranged at the outer side of the rotating mechanism, and is used for matching the rotating mechanism to form an isolation belt which divides the conveying mechanism into an outer side end and an inner side end, so that a goods storage center can be separated from an external area, and non-related personnel can be prevented from entering.

Owner:SHENZHEN DORABOT ROBOTICS CO LTD

Germination accelerating device for planting paddy rice

PendingCN108566797AGood insulation effectLow material costGerminating apparatusGerminationWater pipe

The invention discloses a germination accelerating device for planting paddy rice. The germination accelerating device comprises a germination accelerating box, wherein supporting columns are fixed atthe bottom in the germination accelerating box; a placement plate is mounted at the top ends of the supporting columns; the placement plate comprises a framework and a metal net; the metal net is arranged in the framework; a straw layer is paved at the top of the placement plate; a first woven bag is fixed in the germination accelerating box through a screw and is located above the straw layer; rice seeds are placed in the first woven bag; a second woven bag is paved above the rice seeds; a first fixed column and a second fixed column are mounted at the top of the germination accelerating box; a rotary arm rotatably sleeves the first fixed column; a notch is formed in a side edge of the rotary arm; the second fixed column is located in the notch; a water tank is mounted at a side edge ofthe germination accelerating box; an outlet of the water tank is communicated with a water pipe. The germination accelerating device can be used for sufficiently dispersing and uniformly blending therice seeds, a condition that the water is lost due to local stuffiness is avoided and the germination accelerating efficiency is high.

Owner:贵州贵米农业科技有限公司

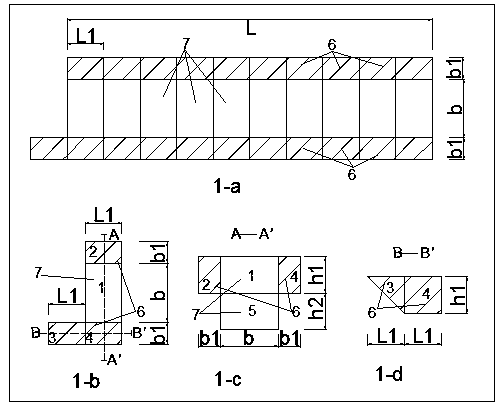

Construction method of dark modified soil anti-sliding retaining wall

ActiveCN109610502ALow material costReduce construction costsArtificial islandsUnderwater structuresResidual soilsRetaining wall

The invention discloses a construction method of a dark modified soil anti-sliding retaining wall. A sectional excavation method (L1) is combined with partitioned and layered (h1, h2) excavation method, a main excavation method (7) is combined with an auxiliary excavation (6) method, and a construction method combining on-site mixing and compaction rapid construction with timely temporary supportis used for constructing. Compared with similar methods, the construction method has the advantages such as high construction speed, stable tank walls, easy control over construction quality and low engineering cost, and is especially suitable for deep landslide treatment in high liquid limit residual soil above a argillaceous sandstone and carbonaceous shale residual soil road cut slope soil-rockinterface.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

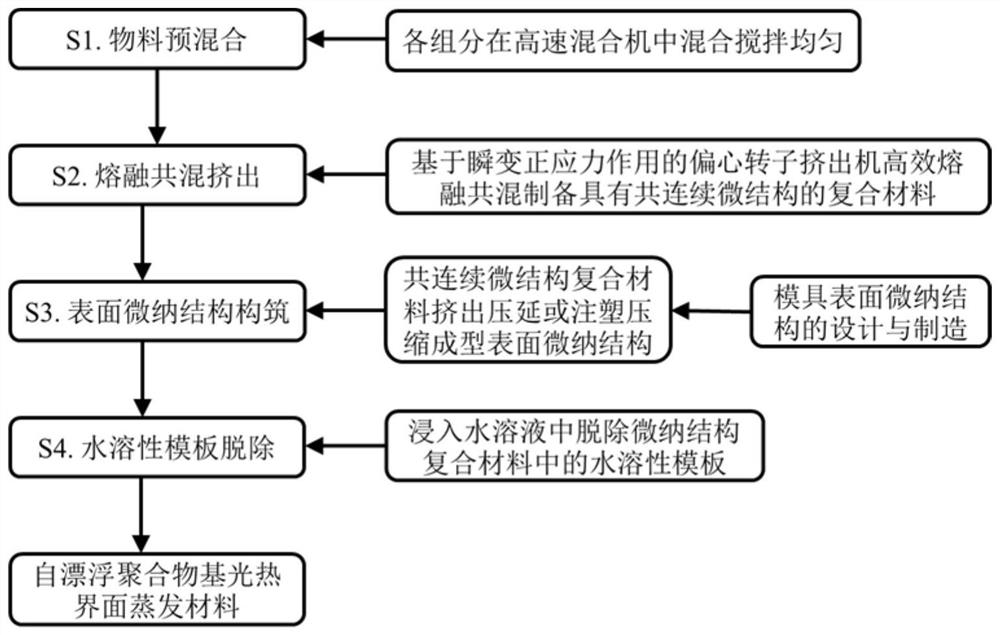

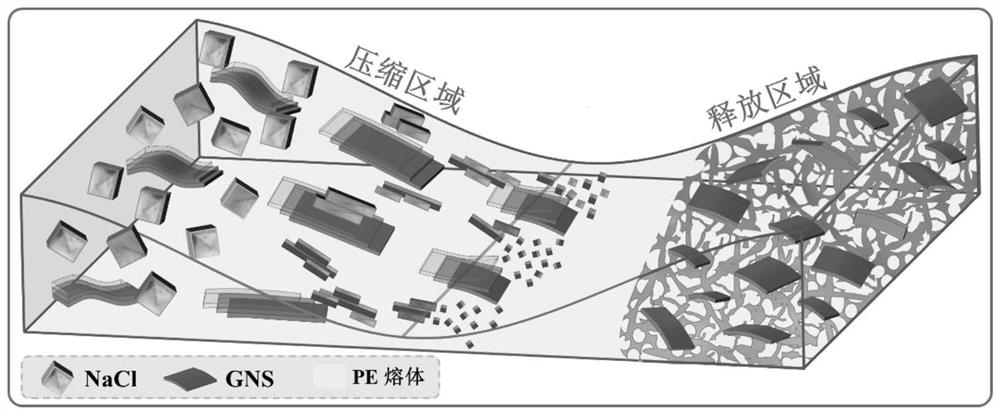

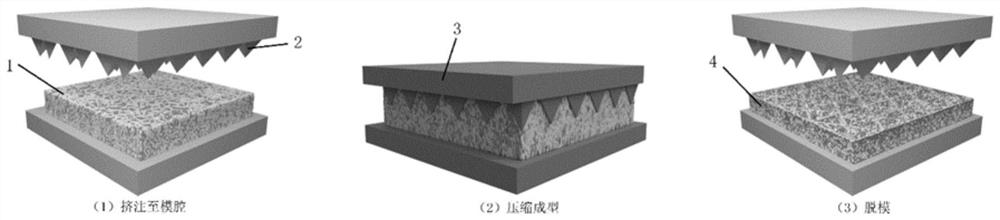

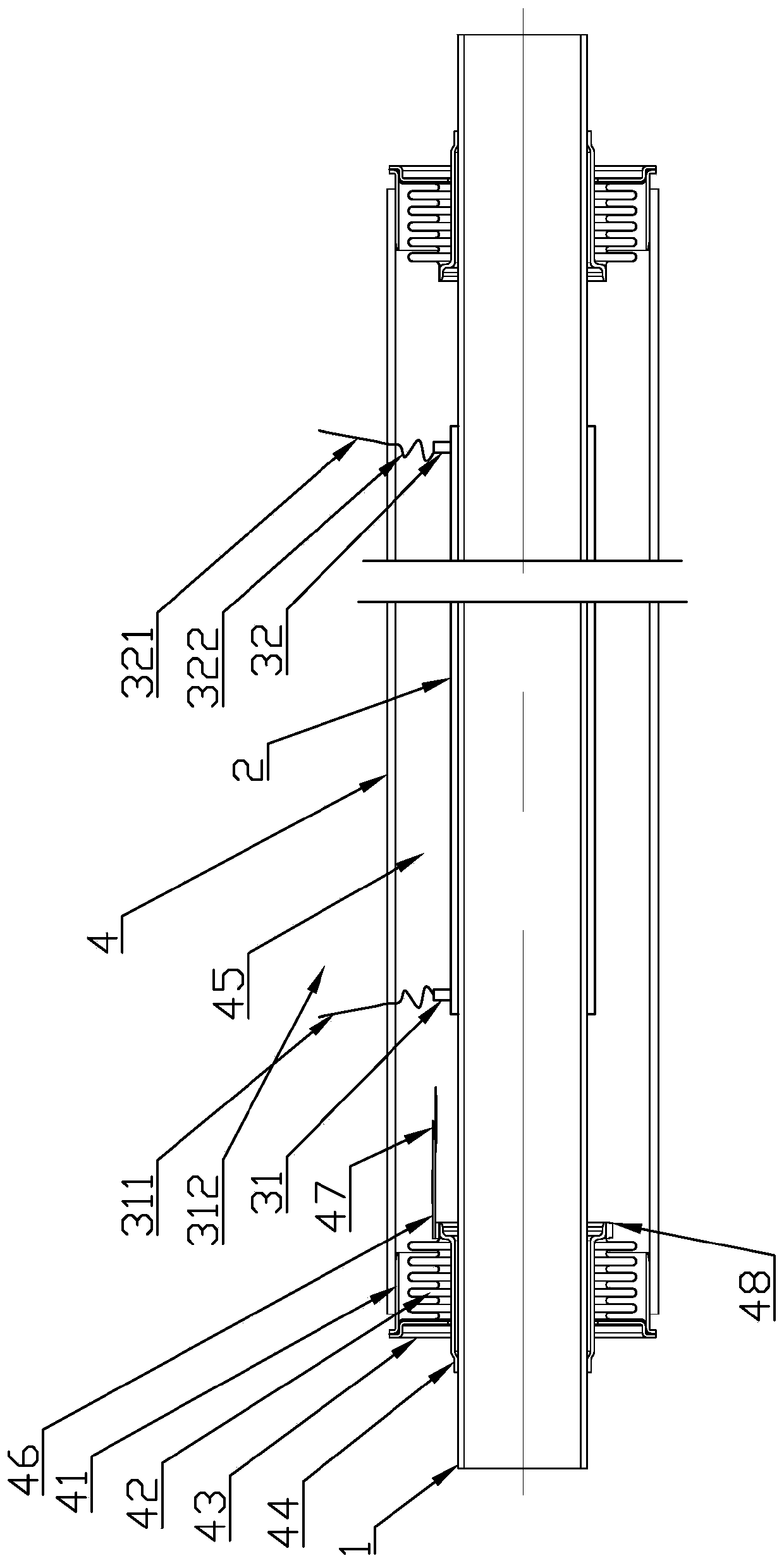

Preparation method and application of photo-thermal interface evaporation material under transient normal stress action

ActiveCN114316407AHigh porosityImprove light-to-heat conversion efficiencyGeneral water supply conservationSeawater treatmentPhysical chemistryPolymer chemistry

The invention belongs to the technical field of solar interface evaporation, and particularly relates to a preparation method and application of a photo-thermal interface evaporation material with a transient normal stress effect. The preparation method comprises the following steps: (1) uniformly mixing a polymer matrix, a water-soluble template and a photo-thermal functional filler to obtain a multi-phase system, and carrying out volume periodic compression and release on the multi-phase system to form a composite material with a co-continuous microstructure; (2) loading a modified nano material on the surface of the composite material with the co-continuous microstructure; and (3) immersing the composite material loaded with the modified nano material into water to remove the water-soluble template. According to the method, large-scale, continuous and green preparation of the self-floating polymer-based photo-thermal interface evaporation material can be achieved, the forming processing technology is simple, the material and production cost is low, large-scale application and popularization can be achieved, and the wide market prospect is achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

Solar energy heat collecting tube with film photovoltaic power generation coupling selective absorption coating

PendingCN109855312AReduce structural complexityReduce processing costsSolar heating energyEnergy industryProduction lineMetal

The invention provides a solar energy heat collecting tube with a film photovoltaic power generation coupling selective absorption coating. The solar energy heat collecting tube comprises a metal tubeand a hood glass tube which sleeves outside of the metal tube, wherein a film photovoltaic power generation coupling selective absorption coating structure is formed in the outer wall of the metal tube, and extraction electrodes are connected to an inner side electrode coating belt and an outer side electrode coating belt; kovar metal sleeves are respectively in sealing connection with two ends of the hood glass tube, and are in tight connection with the outer wall of the metal tube through corrugated tube assemblies; a vacuum interlayer is formed between each hood glass tube and the metal tube; a bending section is formed by a conducting wire connected with each extraction electrode in the vacuum interlayer; and the tail end of each bending section is led outside the hood glass tube through direct leading or through transition materials. According to the solar energy heat collecting tube disclosed by the invention, a film photovoltaic power generation coupling selective absorption coating production line is perfectly merged to a conventional glass metal sealing solar energy heat collecting tube production line, so that the cost is reduced.

Owner:河北道荣新能源科技有限公司

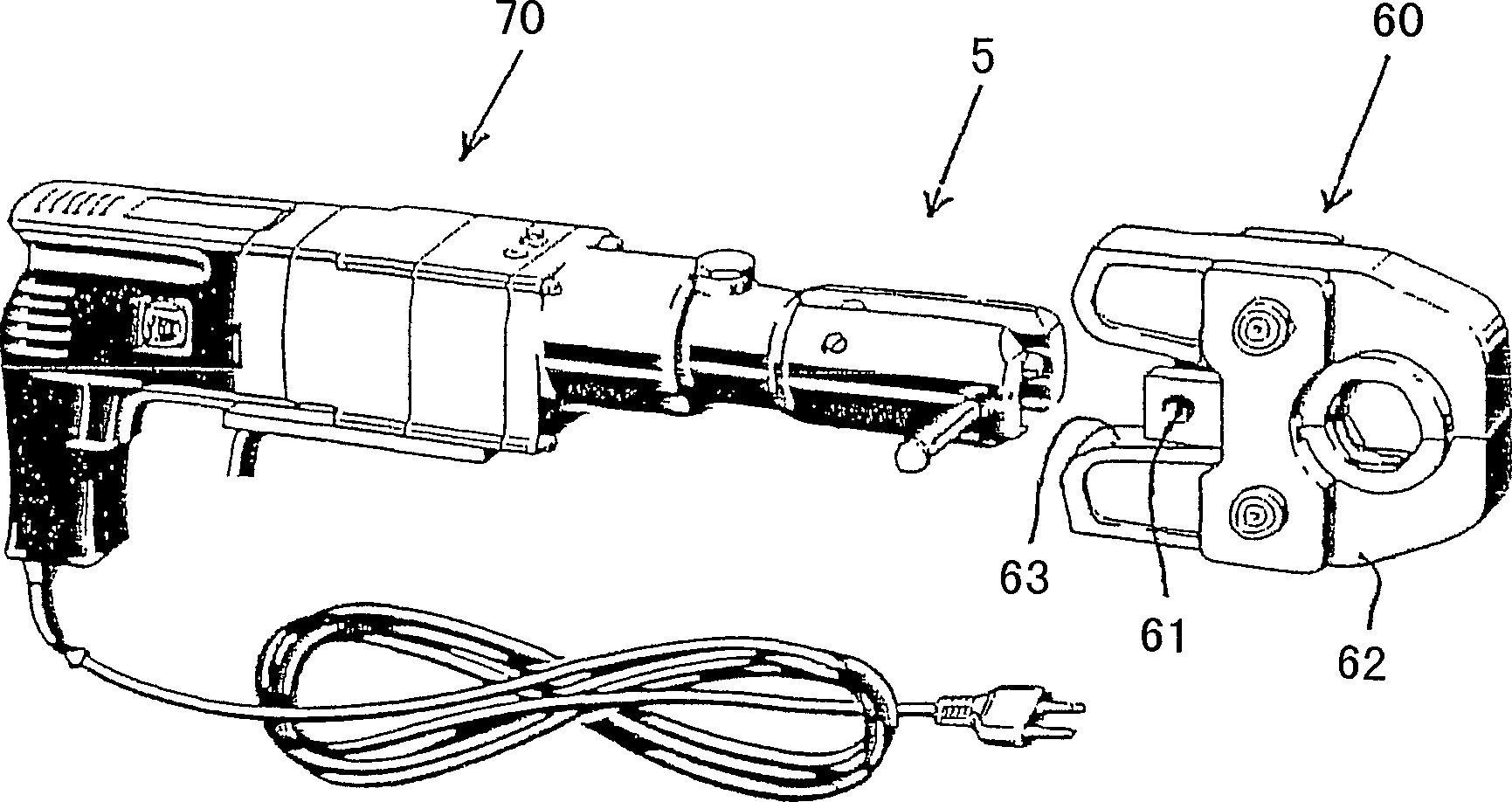

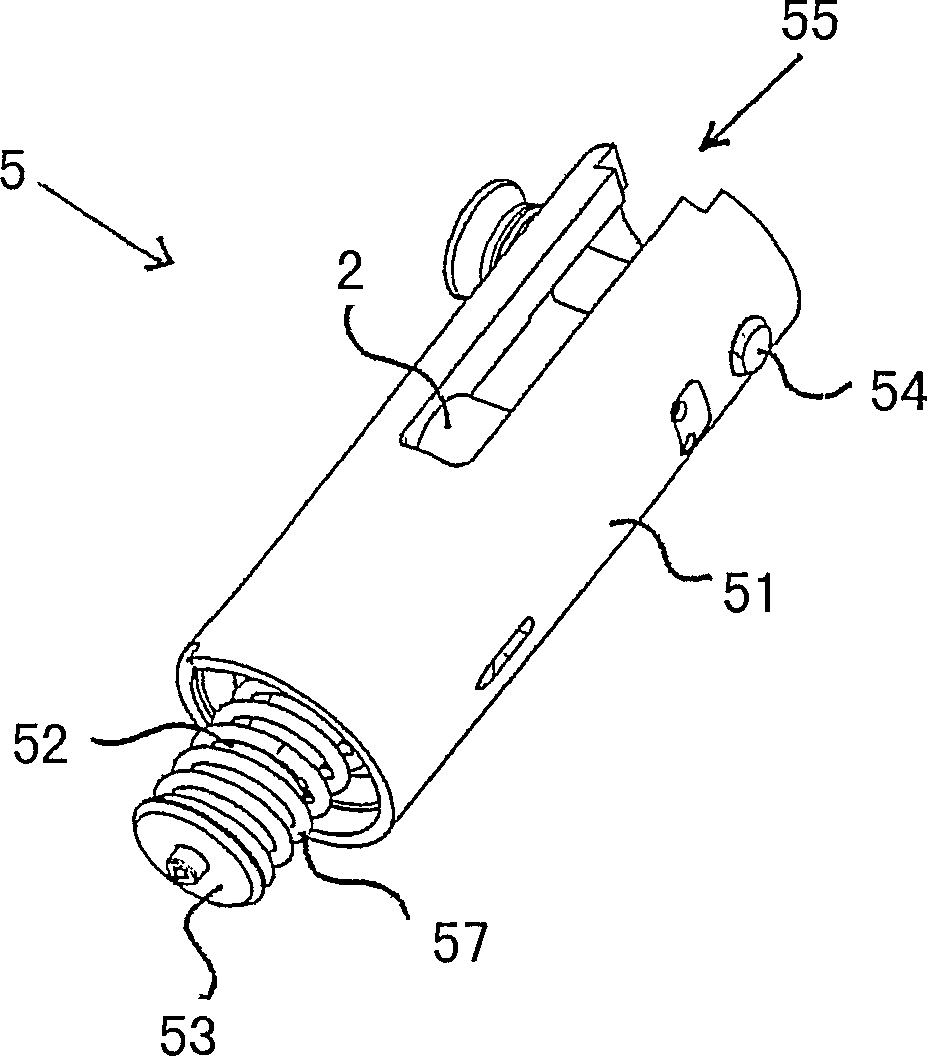

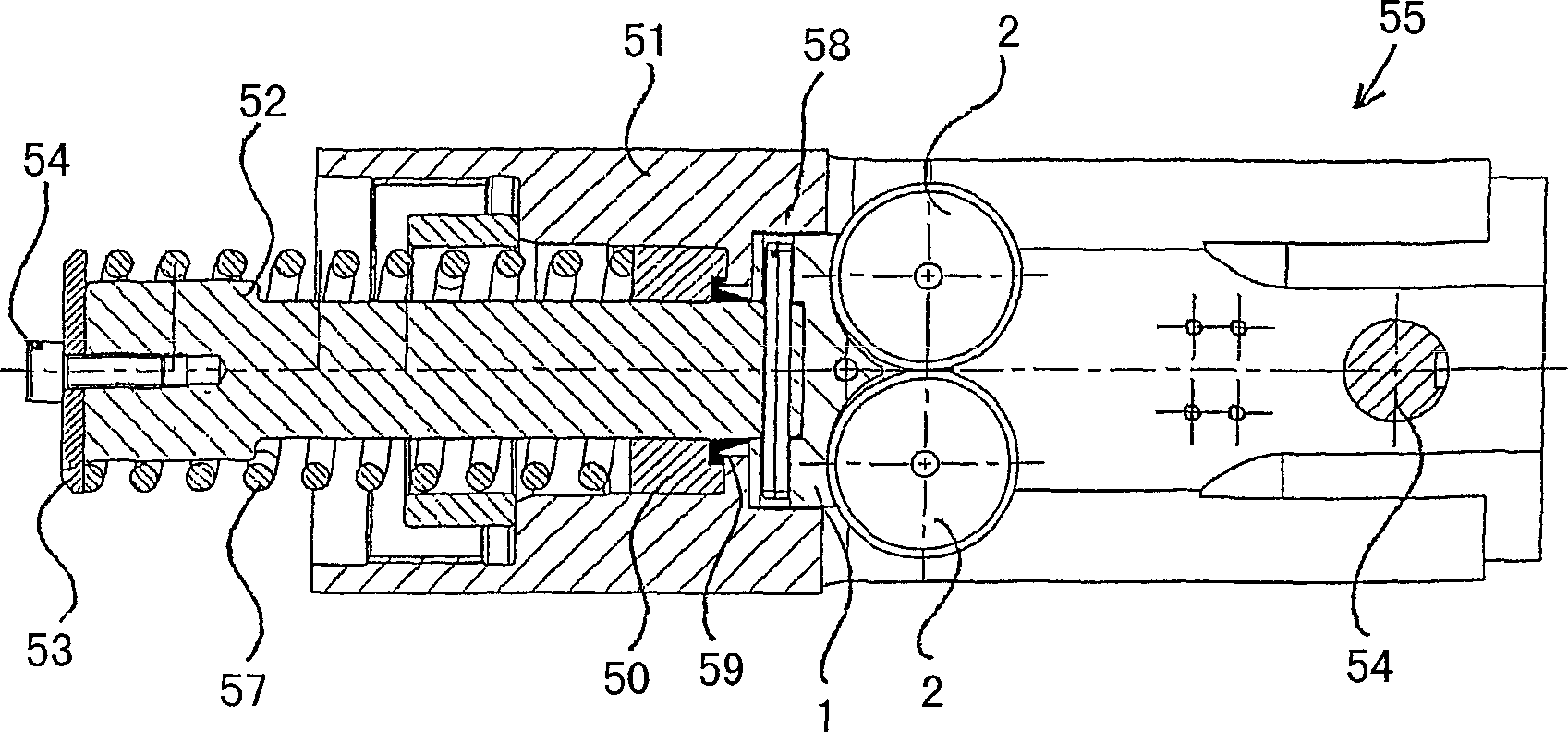

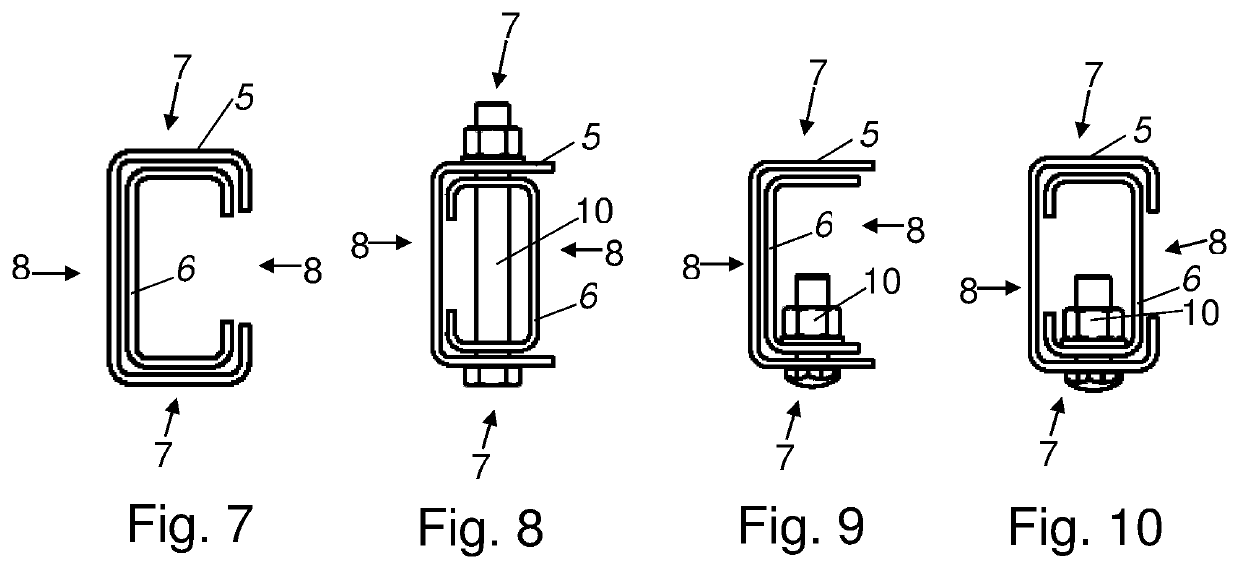

Roll holding unit

InactiveCN1882424ALow material costLow production costMetal-working hand toolsMechanical engineeringPlain bearing

The invention relates to a roll holding unit for a press tool. Said roll holding unit comprises a bearing block (1) and at least one lateral fixing metal plate (3) which is arranged on the block and securely fixes two rolls (2) in a rotatable manner. The bearing block (1) for each roll (2, 2') is provided with a plain bearing surface (11, 12), the form of said surface corresponding to the rolling surface and thus the outer diameter of the roll (2, 2').

Owner:VON ARX AG

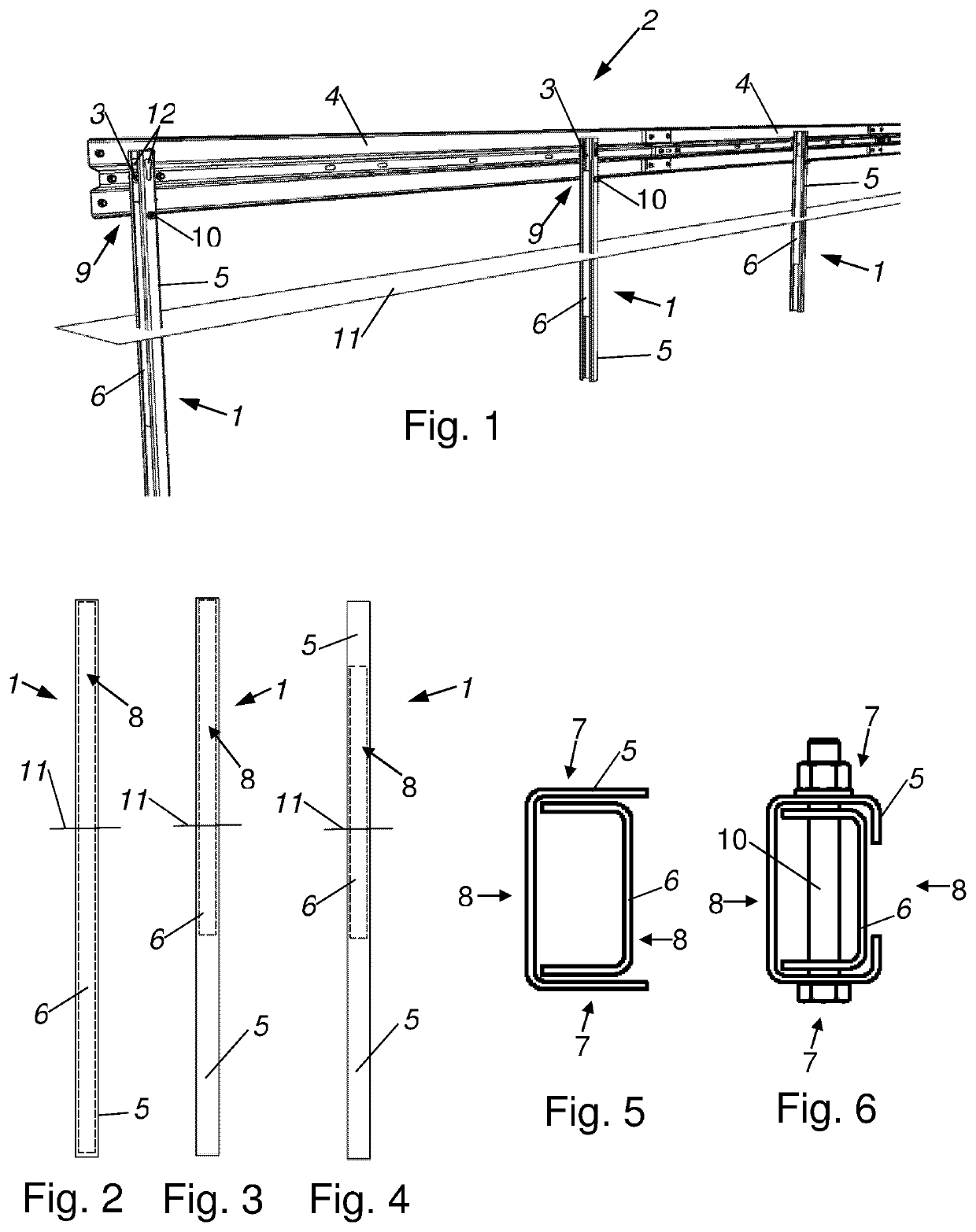

Vertical member for a vehicle restraint system

ActiveUS20210246619A1Increase resistanceLow material costRoadway safety arrangementsPhysicsEngineering

Disclosed is a vertical member for a vehicle restraint system, said vertical member being intended for attaching a guard rail of the vehicle restraint system. The vertical member includes a profiled support and a reinforcing support within the profiled support, and the longitudinal axis of the reinforcing support runs substantially parallel to the longitudinal axis of the profiled support.

Owner:DELTA BLOC INT GMBH

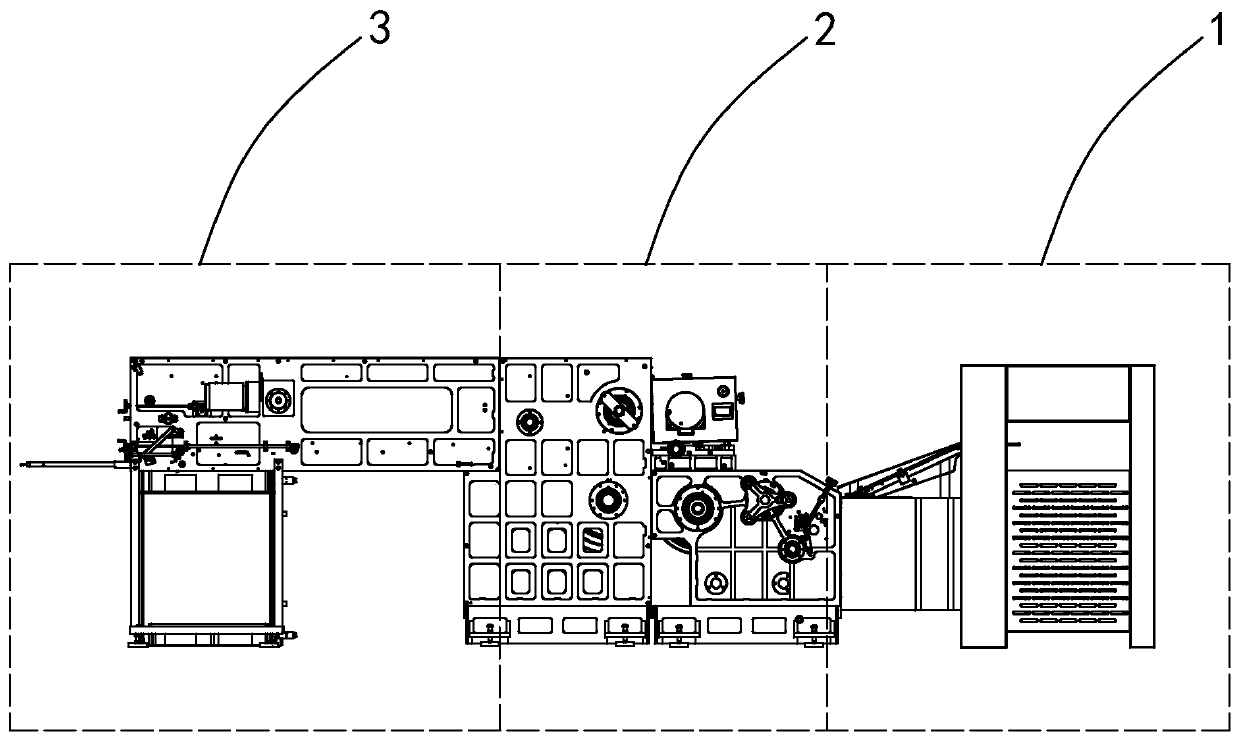

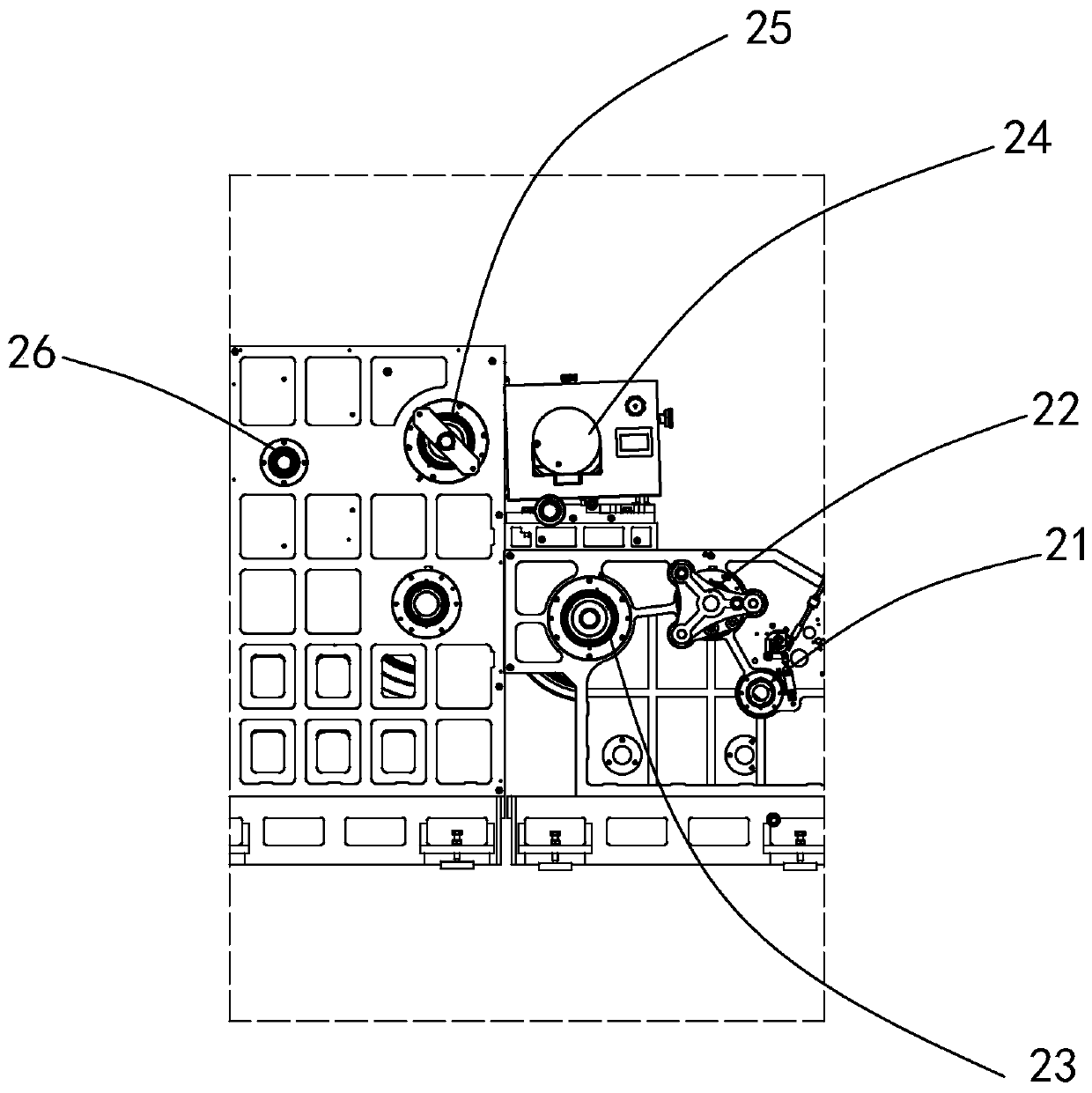

Silk-screen printing system and printing method thereof

PendingCN110181930ALess consumption of printing materialsReduce in quantityScreen printersOther printing apparatusScreen printingBarrel Shaped

The invention discloses a silk-screen printing system. The silk-screen printing system comprises a paper supply part, a main body part and a paper collection part, wherein the paper supply part, the main body part and the paper collection part are sequentially arranged from an initial station to an ending station. The main body part comprises a paper delivery cylinder, a paper conveying cylinder,an impression cylinder and a paper collection cylinder. The input end of the paper delivery cylinder is connected with the output end of the paper supply part, and the output end of the paper deliverycylinder is connected with the input end of the paper conveying cylinder. The output end of the paper conveying cylinder is connected with the input end of the impression cylinder, and the output endof the impression cylinder is connected with the input end of the paper collection cylinder. The output end of the paper collection cylinder is connected with the input end of the paper collection part. The paper conveying cylinder comprises a double-diameter paper conveying cylinder and a small-diameter paper conveying cylinder. The paper delivery cylinder and the small-diameter paper conveyingcylinder are arranged at the right side and the left side of the double-diameter paper conveying cylinder correspondingly. The impression cylinder is arranged above the small-diameter paper conveyingcylinder. The paper collection cylinder is arranged at the left side of the impression cylinder. Based on the technical characteristic that a plane printing substrate is rolled into a barrel-shaped printing substrate in the printing process, the requirement of the special printing effect is met; printing materials are supplied continuously; and the materials are connected closely, and the flatnessis good.

Owner:VOORUN AUTOMATION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com