Laser power meter and method for calibrating sampling coefficient of large optical system based on laser power meter

A laser power meter and optical sampling technology, applied in the field of laser parameter detection devices, can solve problems such as inability to apply to industrial field installation and testing, inability to perform long-distance transmission, and incompetent structure, and achieve reliable and stable data transmission process and state monitoring. Smart and efficient, compact effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

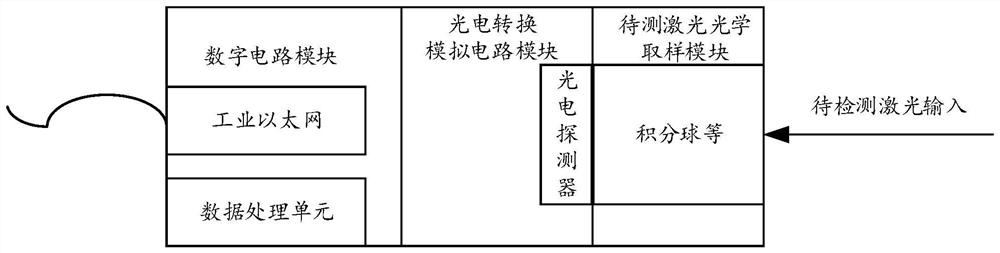

[0075] The principle block diagram of the laser power meter in this embodiment is as follows figure 1 As shown, it mainly consists of three parts: the laser optical sampling module to be tested, the photoelectric conversion analog circuit module and the digital circuit module.

[0076] The laser optical sampling module to be tested in this embodiment includes a beam pre-processing optical element, and the beam pre-processing optical element includes a reflective filter and an integrating sphere with a large attenuation ratio and high-power laser resistance. The reflective filter is installed at the light entrance of the integrating sphere. The laser to be detected is first incident on the surface of the reflective filter. The reflective filter is used as the first stage of sampling attenuation to attenuate the incident signal with a large magnification. The main reason why this embodiment chooses the reflective filter instead of the absorbing filter is that the absorbing filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com