Patents

Literature

67results about How to "Structural advantage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

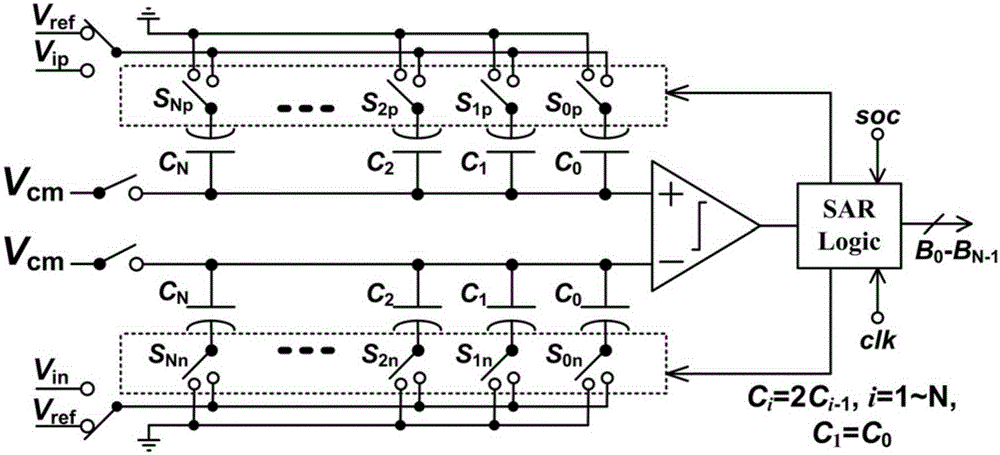

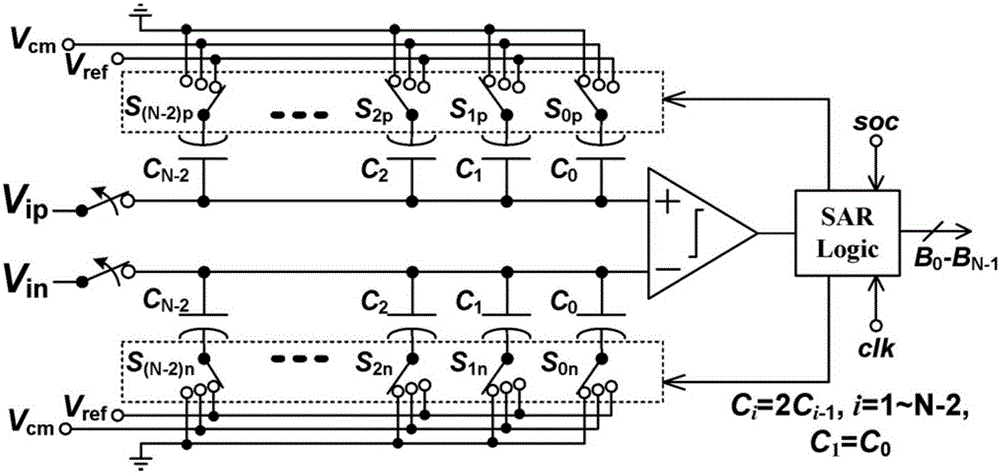

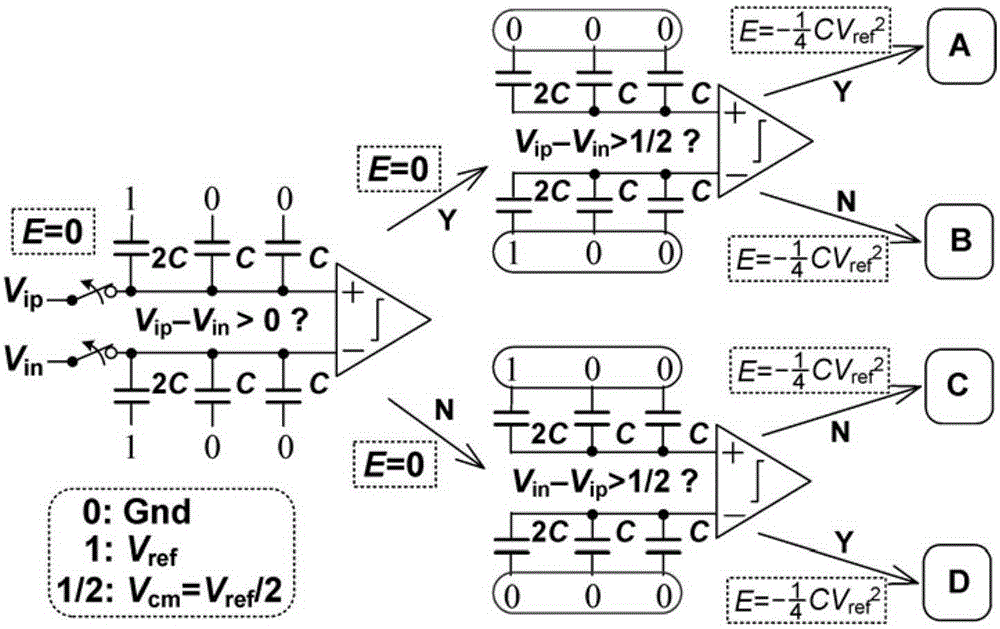

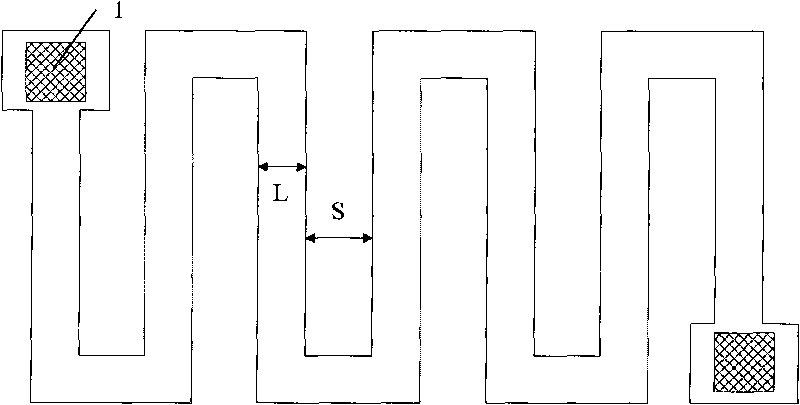

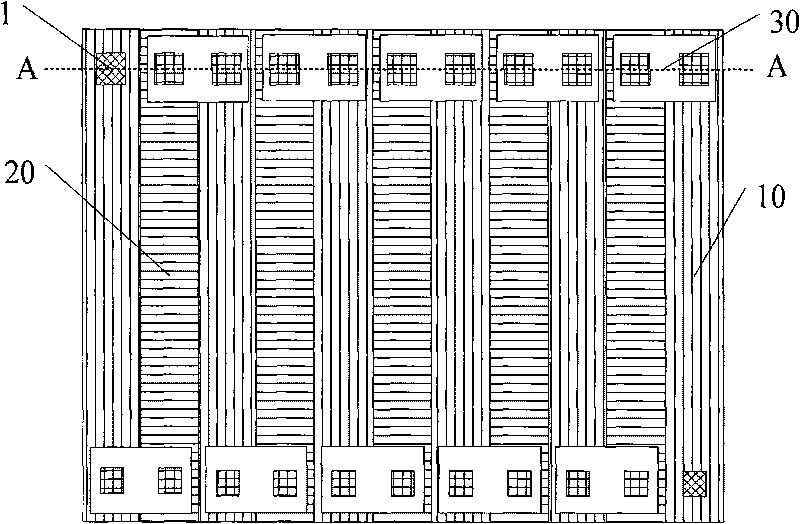

Successive approximation ADC ultra-low power consumption capacitor array and logic control method thereof

ActiveCN105187065AStructural advantageAnalogue/digital conversionElectric signal transmission systemsUltra low powerEngineering

The invention discloses a successive approximation ADC ultra-low power consumption capacitor array and a logic control method thereof and belongs to the successive approximation ADC ultra-low power consumption design technical field. The successive approximation ADC ultra-low power consumption capacitor array includes a binary capacitor array, a switch array and references (Vref, Vcm=Vref / 2 and Gnd=0); the logic control method is a novel logic control method. According to the method, capacitor upper polar plate sampling, switch control time sequence initialization, parasitic capacitance power consumption reduction and capacitor monotonic switching are used in combination. The average energy consumption of the capacitor array is only 1.2% of a traditional charge redistribution structure. The capacitor array has advantages of simple structure, low power consumption, small size and so on. When the capacitor array and the logic control method thereof of the invention are applied to successive approximation ADC, power consumption can be significantly reduced. Under the same conversion accuracy, the size of the capacitor array of the invention can be decreased, so that improvement of A / D conversion rate can be benefitted.

Owner:XIAN UNIV OF POSTS & TELECOMM

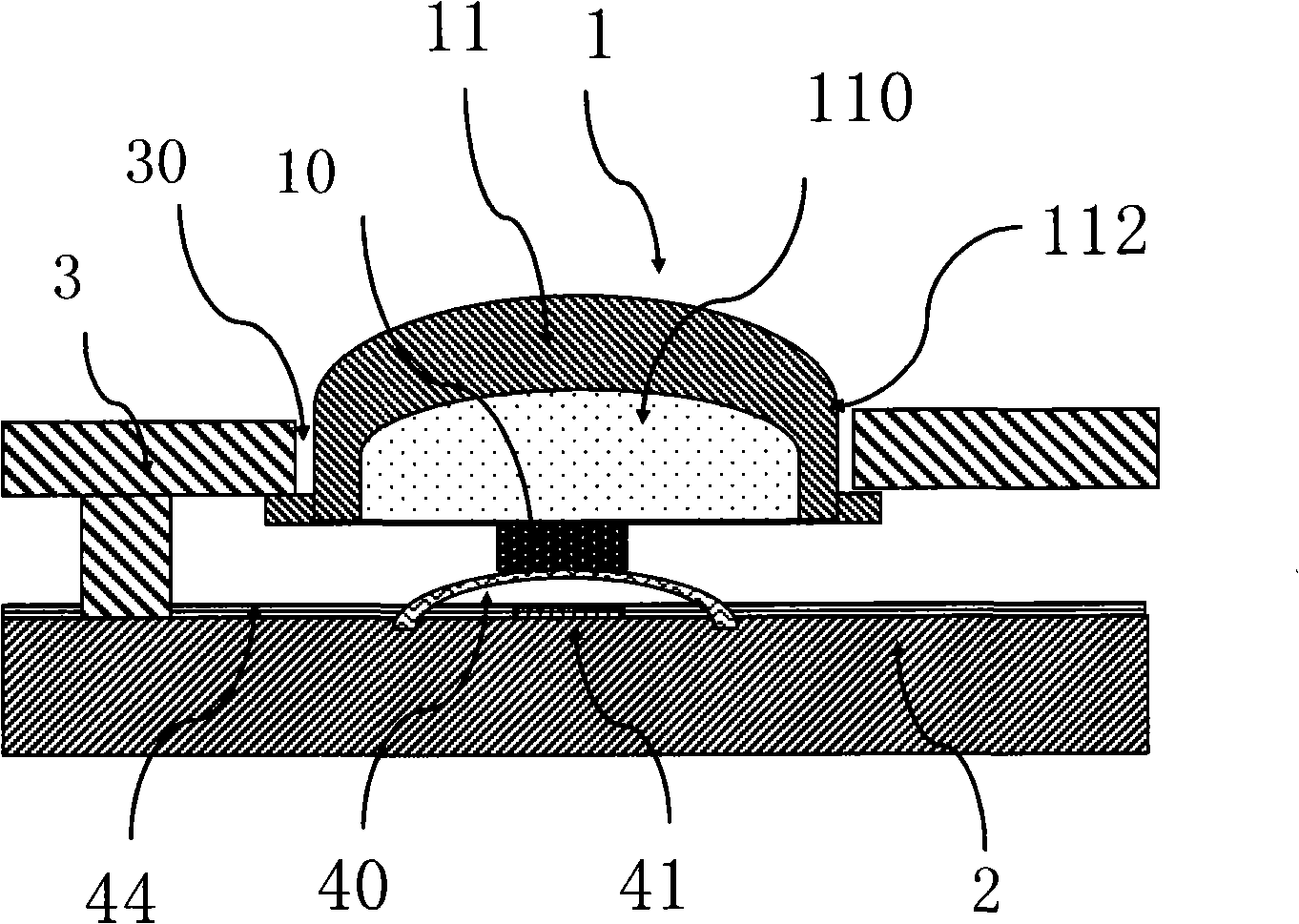

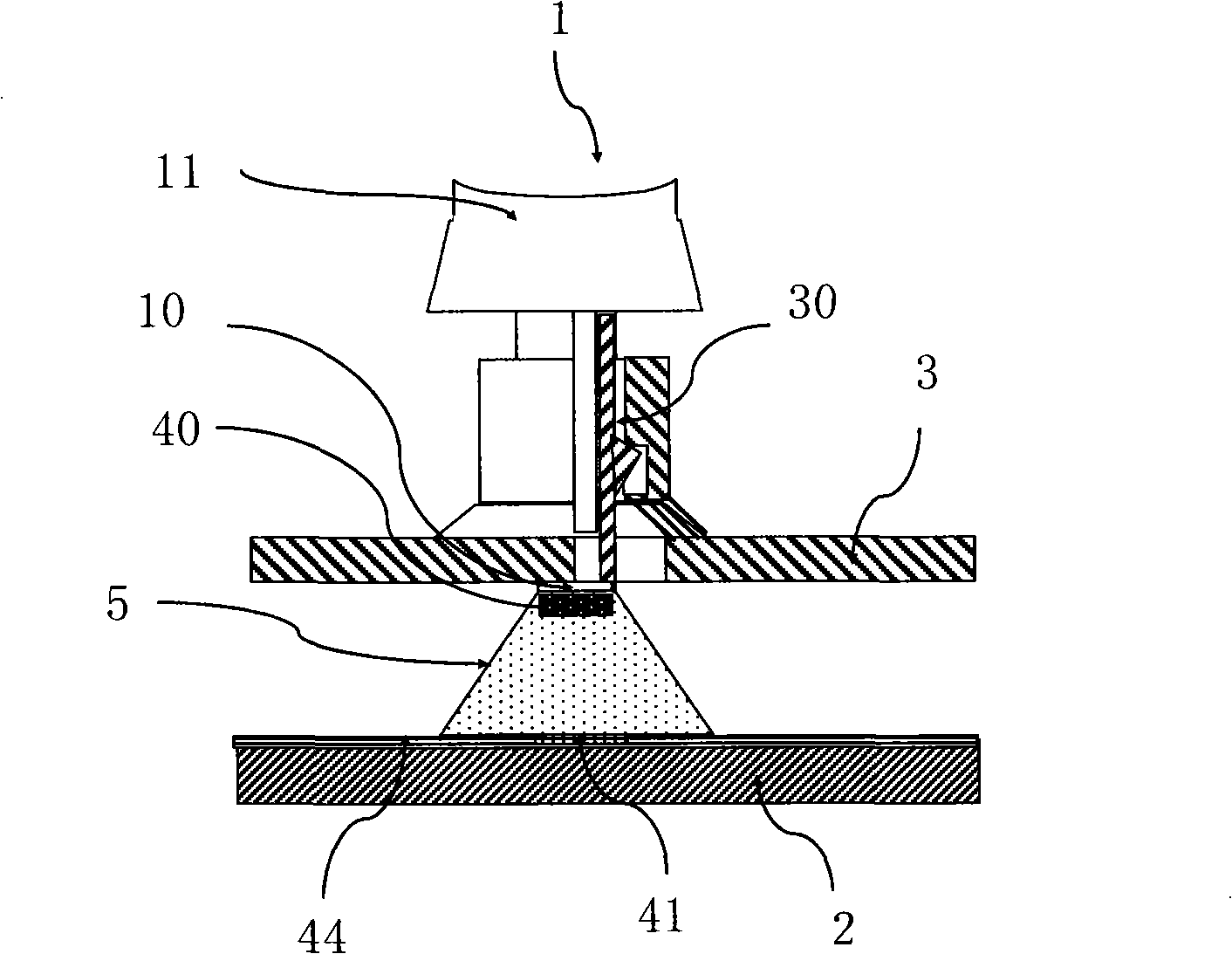

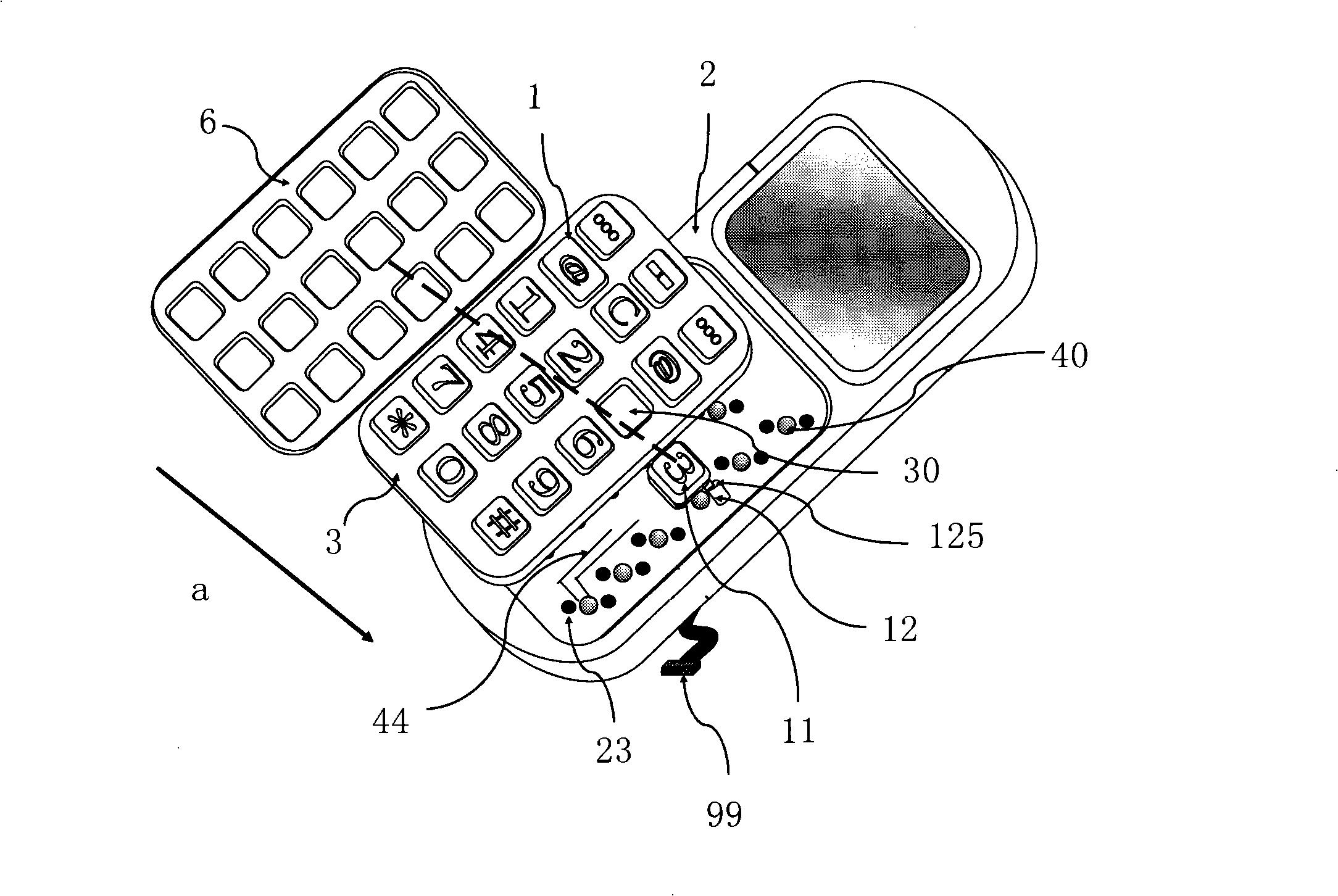

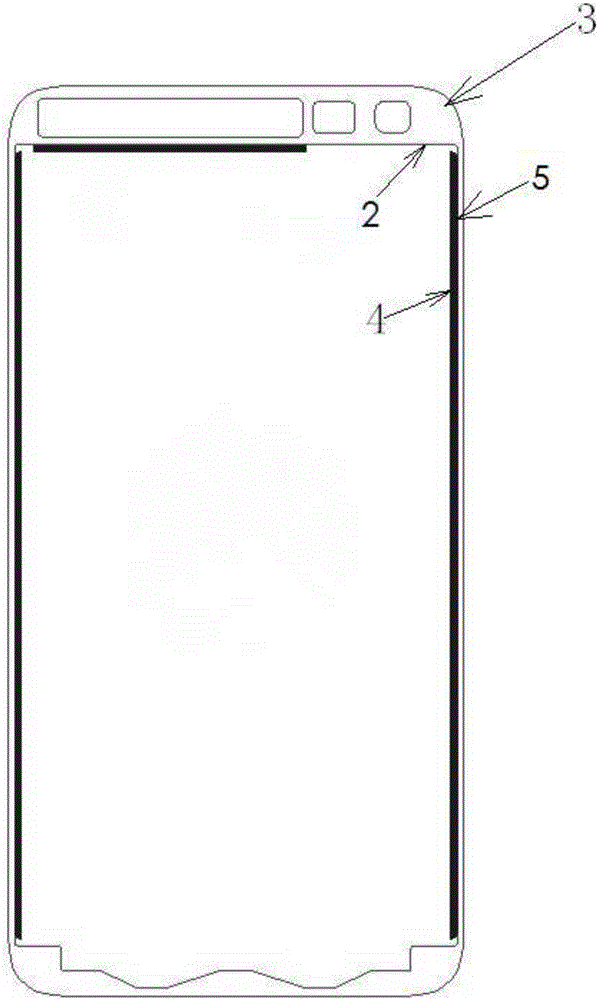

Button switch having guiding device and construction thereof

InactiveCN101335142AStructural advantageDoes not affect functionElectric switchesWhole bodyTouch switch

The invention discloses a press key provided with a guiding device, which is installed on a shell body with a curved surface (including a plane) while the shell body is provided with switch contact points and circuits. A springing device is further arranged and a front cover is integrated with the shell body as a whole body if the front cover is available. The press key with the structure of the invention has simple structure, low cost, convenient and high-efficiency installation, portable operation, and stability and durability, and provides waterproof and dustproof functions for circuits in equipment, and has ultra-thin press key with a comparatively large stroke. Furthermore, the press key of the invention does not occupy the resources of a PCB board in the equipment, can be installed on the shell boy with the curved surface (including the plane) in low cost, and is applicable to the press keys and touch switches of electronic equipment with large, middle and small strokes.

Owner:王光达

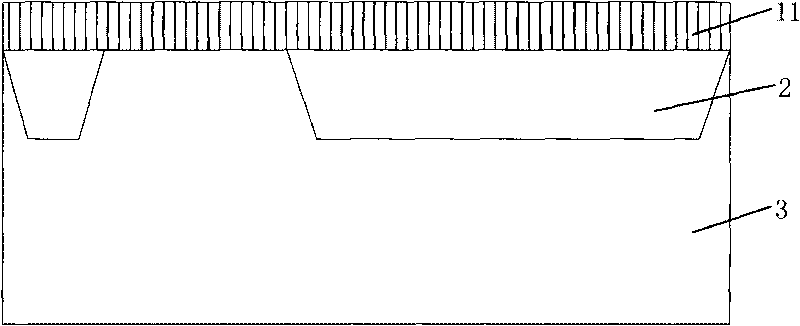

Polycrystalline silicon electric resistance and manufacturing method thereof

ActiveCN101740639ASmall footprintLow costSolid-state devicesSemiconductor/solid-state device manufacturingInsulation layerSilicon oxide

The invention discloses a polycrystalline silicon electric resistance, comprising two layers of polycrystalline silicon which are arranged from top to bottom, an insulation layer is arranged between the two layers of polycrystalline silicon; the two layers of polycrystalline silicon are connected with a first layer of metal wire through contact holes. The insulation layer is silicon oxide or silicon nitride or the combination of silicon oxide and silicon nitride. In the invention, the two layers of polycrystalline silicon are adopted to change a plane polycrystalline silicon electric resistance into a two-layered up-and-down three-dimensional structure, a layer of insulation layer is used for segregating the two layers of polycrystalline silicon; in addition, the two layers of polycrystalline silicon are connected with the first layer of metal wire through the contact holes, so that 50% of chip-occupied area can be saved and the cost can be greatly reduced; moreover the structure enjoys more advantages when being applied to manufacture large polycrystalline silicon electric resistance. The invention also discloses a manufacturing method of the polycrystalline silicon electric resistance.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

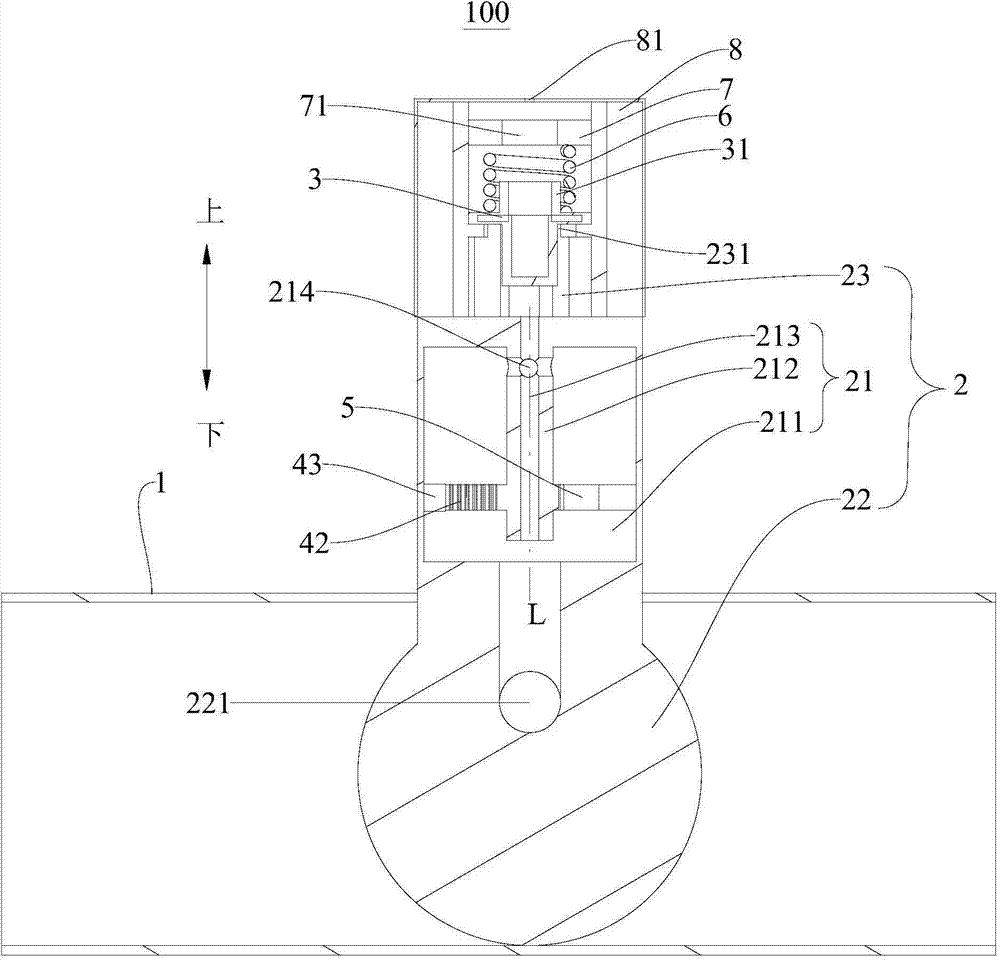

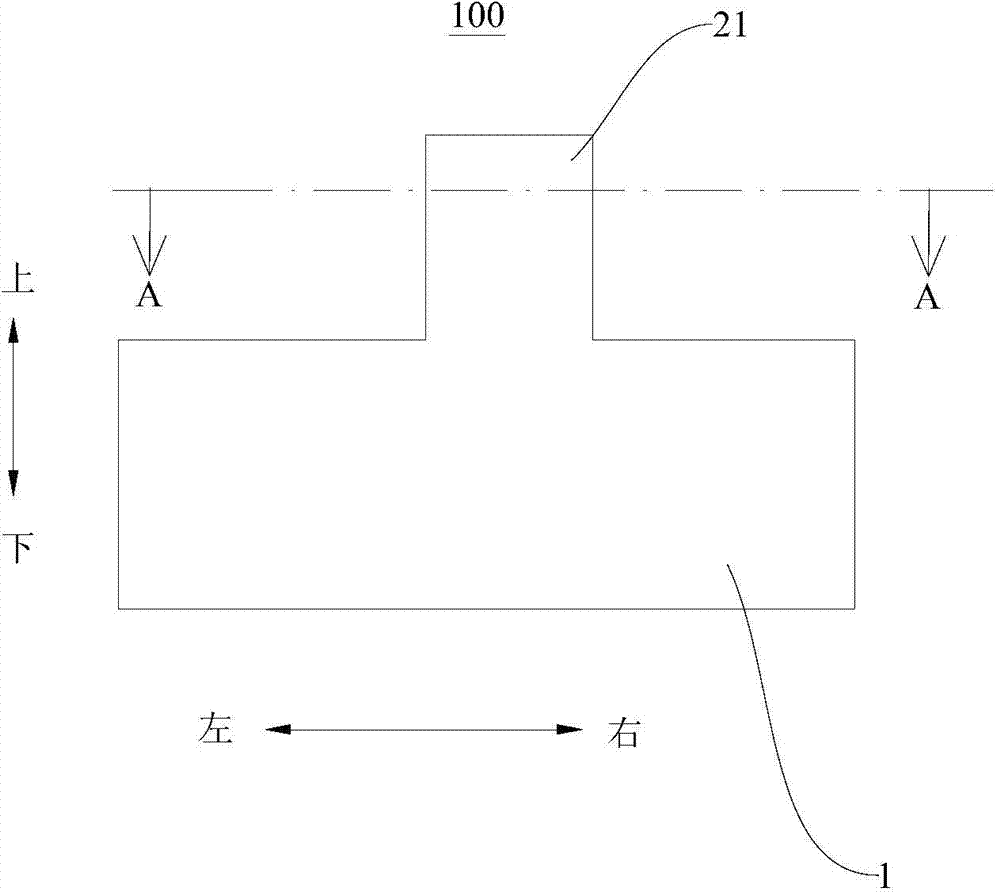

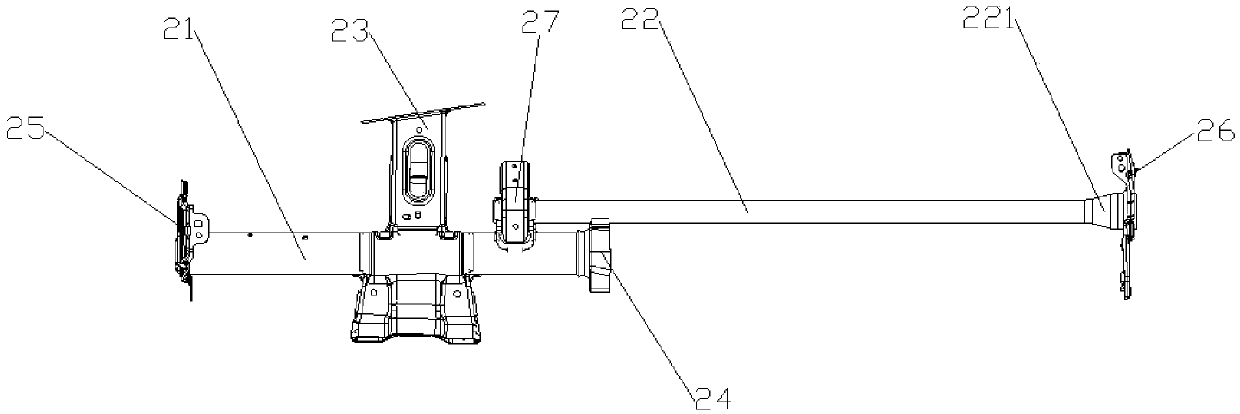

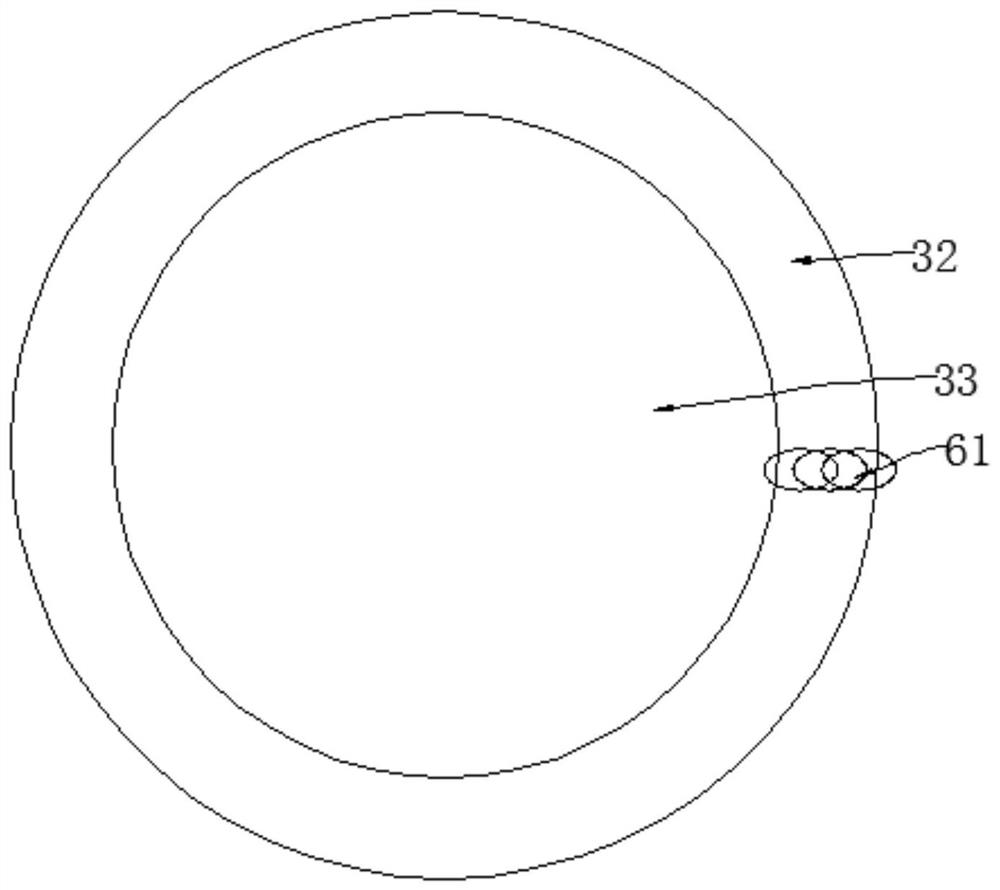

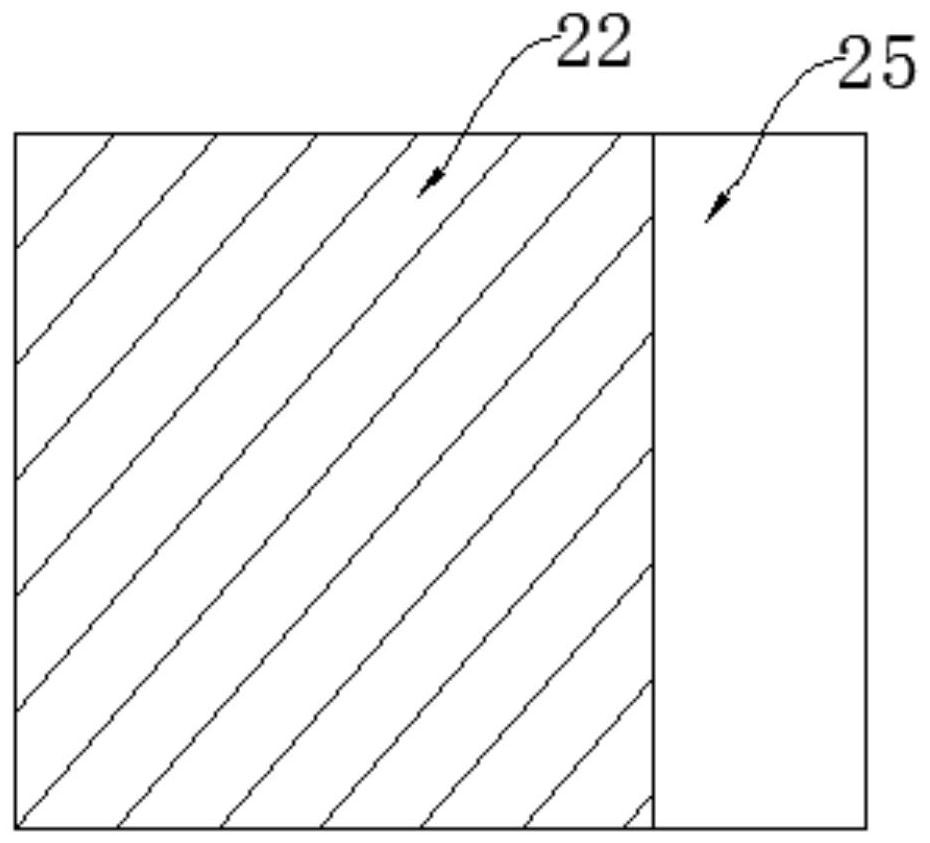

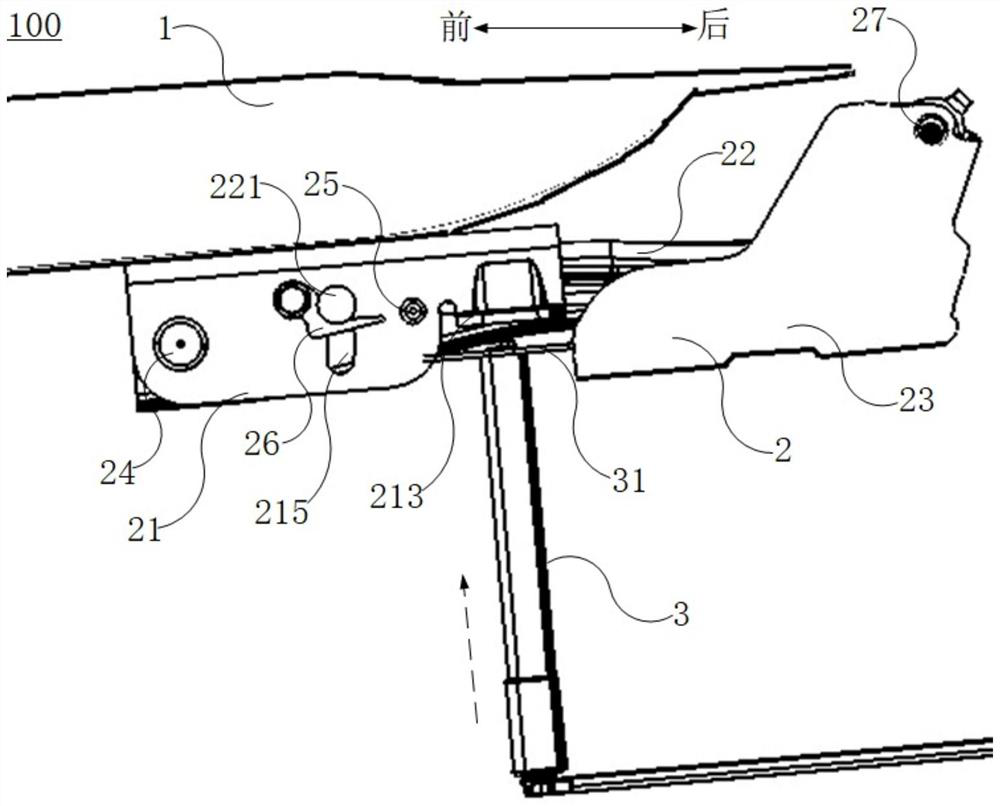

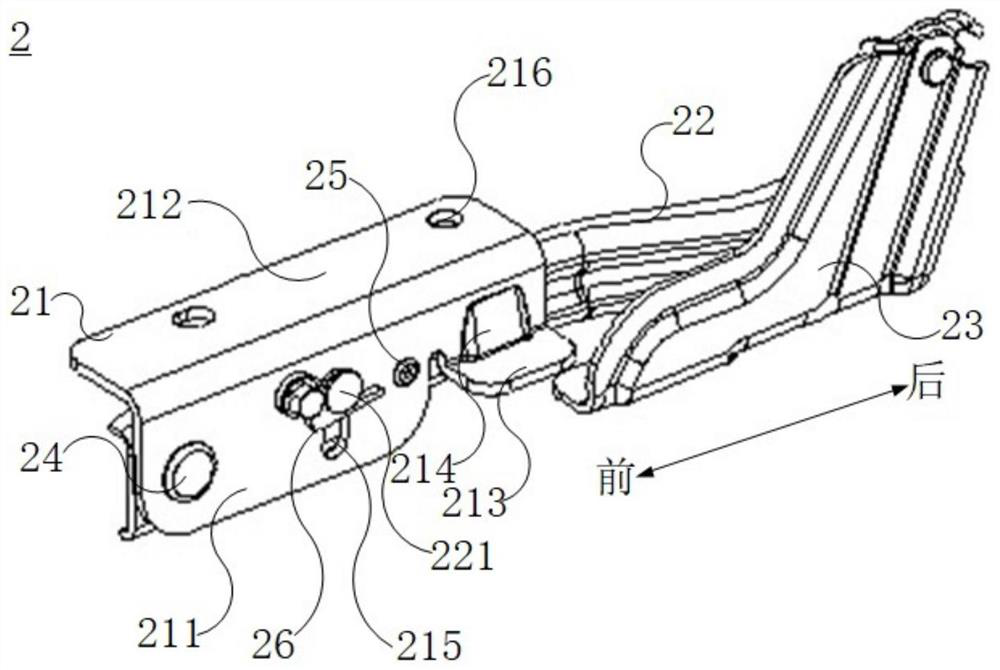

Water valve structure for automobile and automobile with same

InactiveCN104500826AStructural advantageRealize automatic adjustmentAir-treating devicesOperating means/releasing devices for valvesExhaust valveEngineering

The invention provides a water valve structure for an automobile and the automobile with the same. The water valve structure comprises a water tube, a water valve, exhaust valve blocks and a driving component, wherein the water valve penetrates through the water tube and can rotate relative to the water tube; the water valve comprise a body part and a valve block part; the valve block part is at least partially positioned inside the water tube; the body part is at least partially positioned outside the water tube; a cavity, which is internally communicated with the water tube, is defined inside the body part; the body part is internally provided with a rotating shaft part which is fixed with the body part; a shaft hole, which is communicated with the cavity, is formed inside the rotating shaft part; a water-gas separation cavity is also formed in the end, relatively far away from the valve block part, of the body part; the water-gas separation cavity is communicated with the shaft hole; exhaust holes are formed in the water-gas separation cavity; the exhaust valve blocks can be used for opening or closing the exhaust holes; the driving component is arranged to drive the rotating shaft part to rotate around the axis of the rotating shaft part. By adopting the water valve structure for the automobile, functions of automatically adjusting the liquid flow and automatically exhausting gases are achieved simultaneously.

Owner:TIANJIN BOXIN AUTOMOBILE PARTS

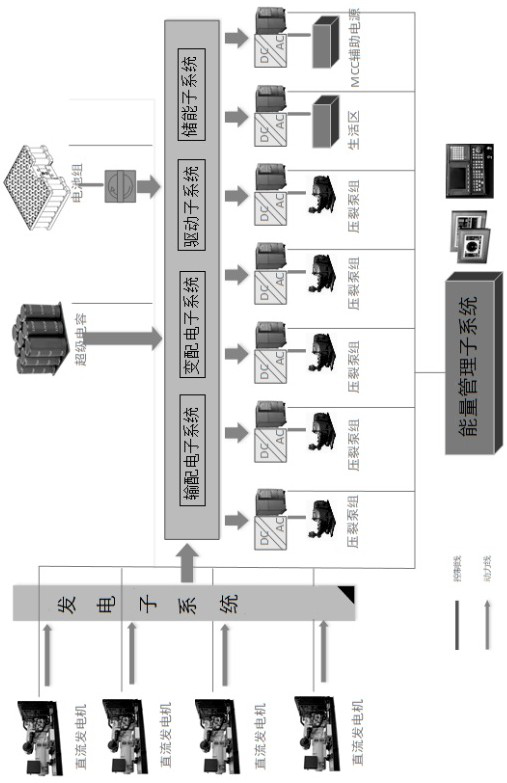

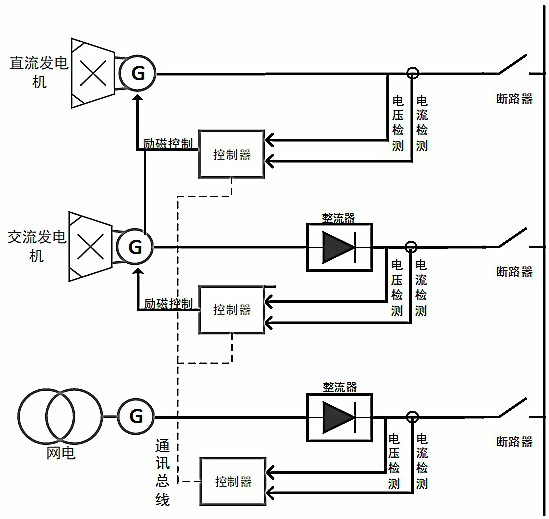

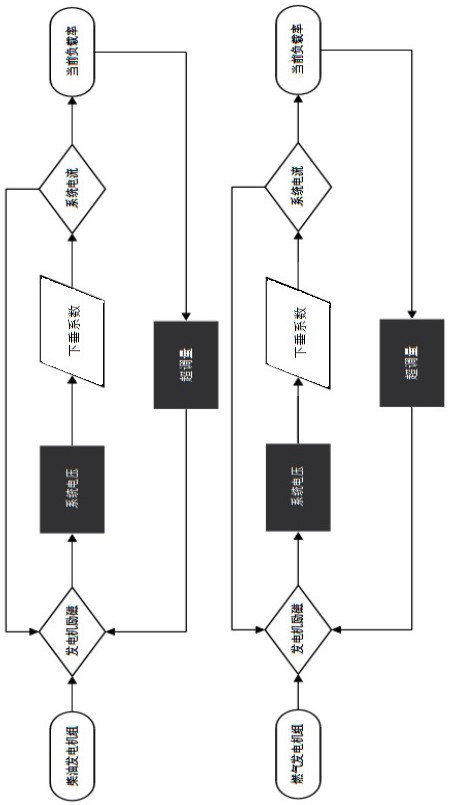

Petroleum fracturing direct-current transmission power system

InactiveCN112993965ARealize comprehensive utilizationChange frequencyBatteries circuit arrangementsLoad balancing in dc networkDC - Direct currentThermodynamics

The invention provides a petroleum fracturing direct-current transmission power system. The system comprises a power generation subsystem, a power transmission and distribution subsystem, a power transformation and distribution subsystem, a driving subsystem, an energy storage subsystem and an energy management subsystem; a power generation system and a driving system which are mutually independent in traditional electric fracturing are combined into a whole, and is unified as direct-current voltage in the form of electric energy; the direct current is transmitted to the driving end of each electric device through a bus; a driving device supplies power to the device through an inverter or a switch; and therefore, comprehensive utilization of energy of a whole well site is achieved.

Owner:山东汉德自动化控制设备有限公司

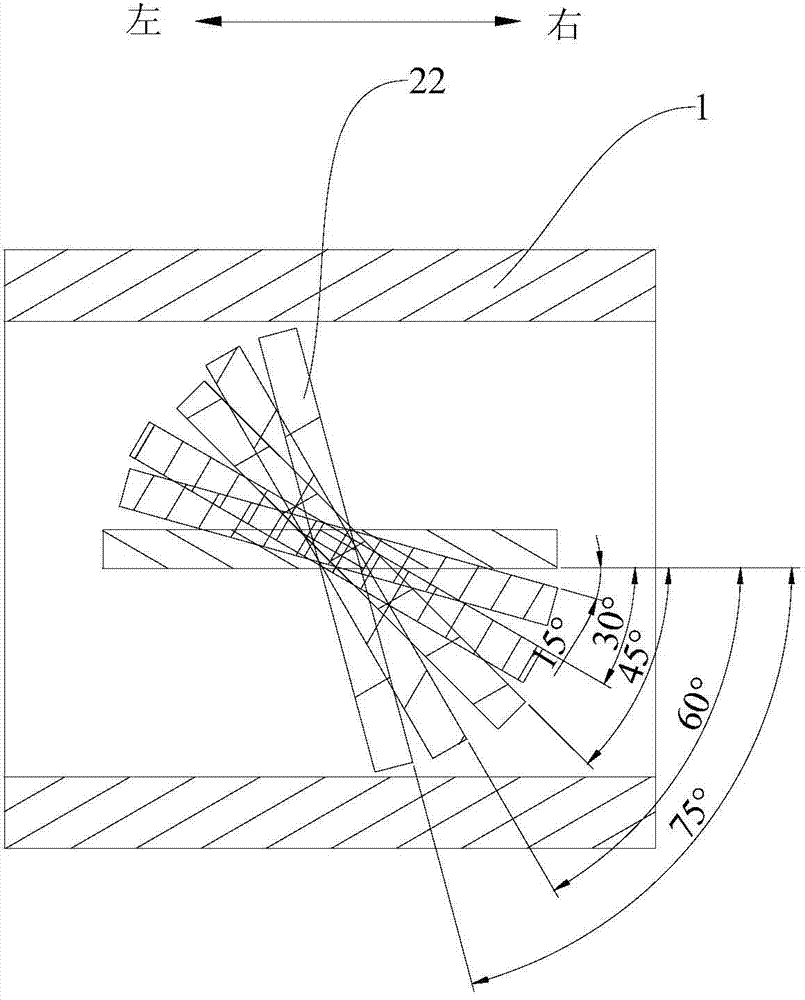

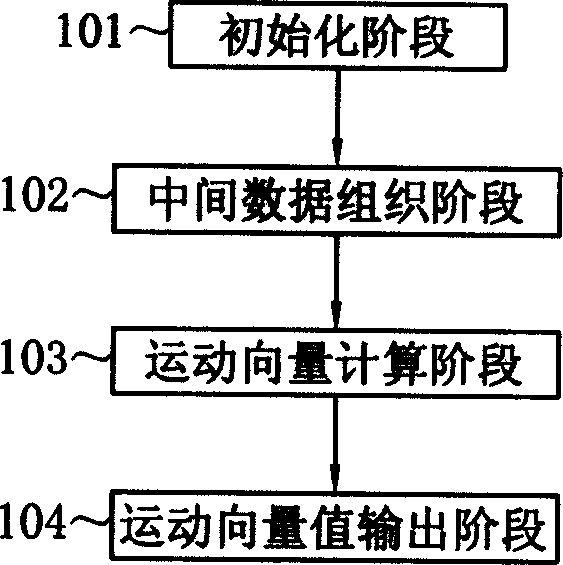

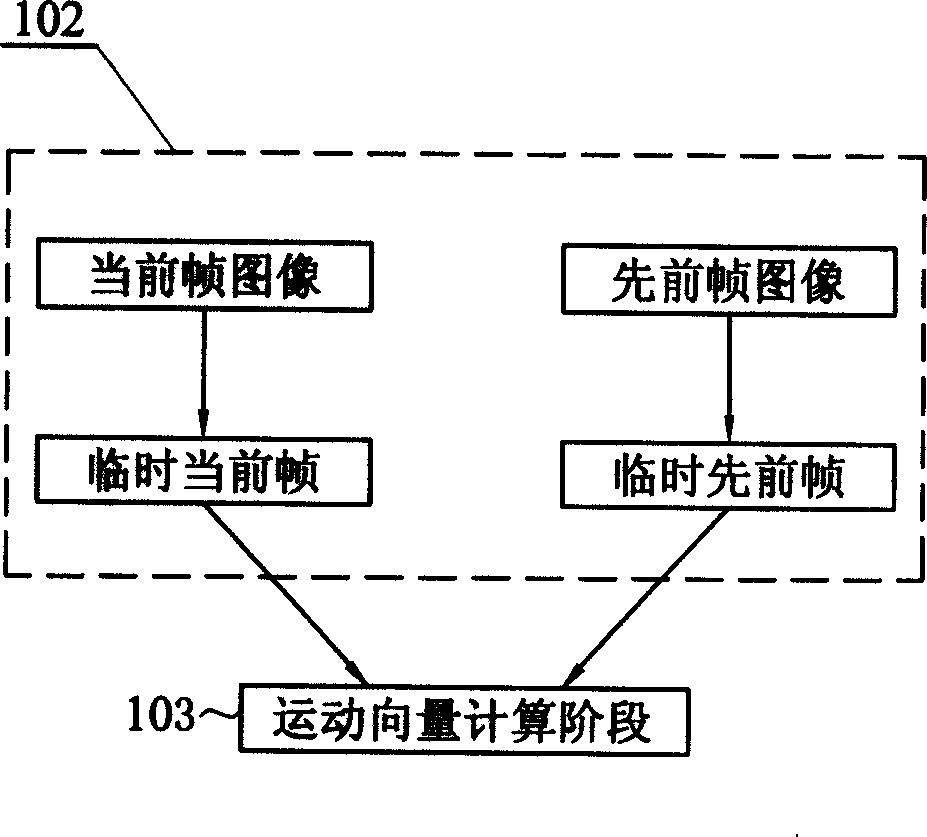

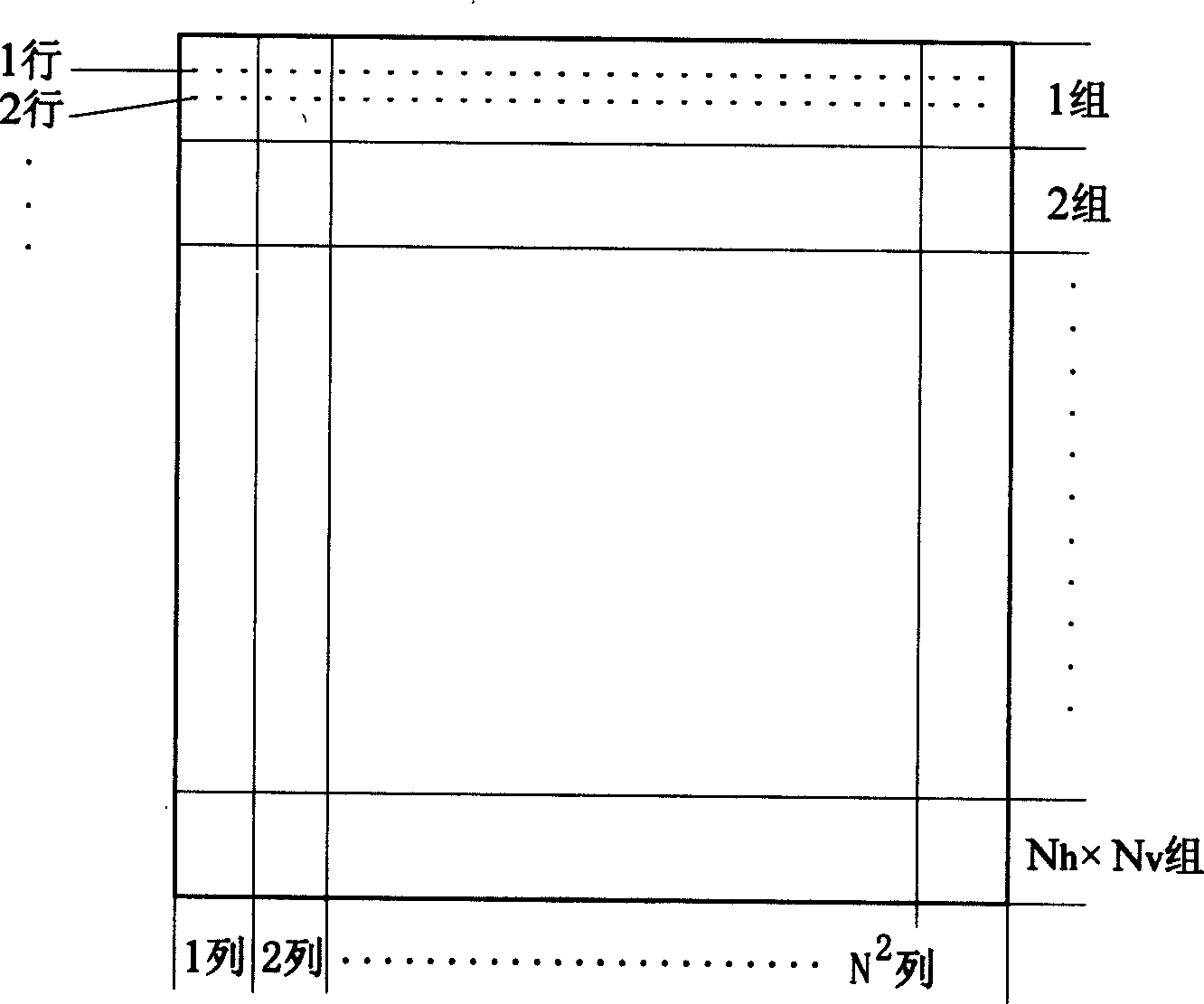

Motion estimating method and motion estimating circuit using the method

InactiveCN1599461AStructural advantageSimple structureTelevision systemsDigital video signal modificationCircuit complexityData stream

This invention discloses a motion evaluation method and a circuit based on FSBM algorithm including: 1. initializing stage: inputting pixel data, 2, intermediate data organization stage, 3, motion vector computing stage, 4, the motion vector value output stage. It's favourable to circuit comparison, discrimination and motion vector output and reducing the circuit complexity utilizing the input data stream described by the said algorithm to compute MAD. The circuit images the said two-way algorithm to a pulsation array structure, and projects 1 to PE array, the last frame data have two sets of input buses y1 and y2 which transmit the data to PE unit by the multipath selector unit. The current reference block data in the current frame are put in RA set in PE.

Owner:HARBIN INST OF TECH

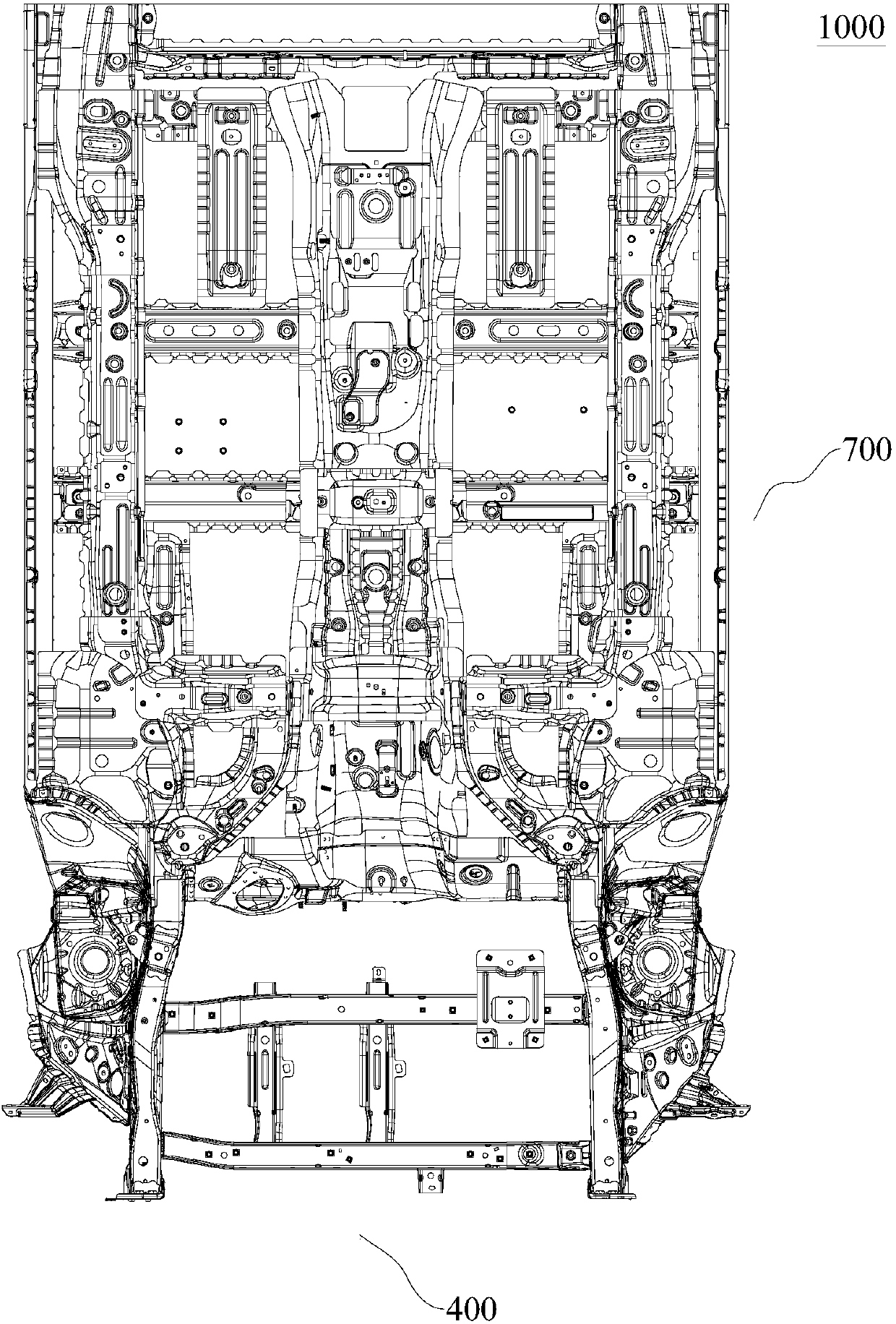

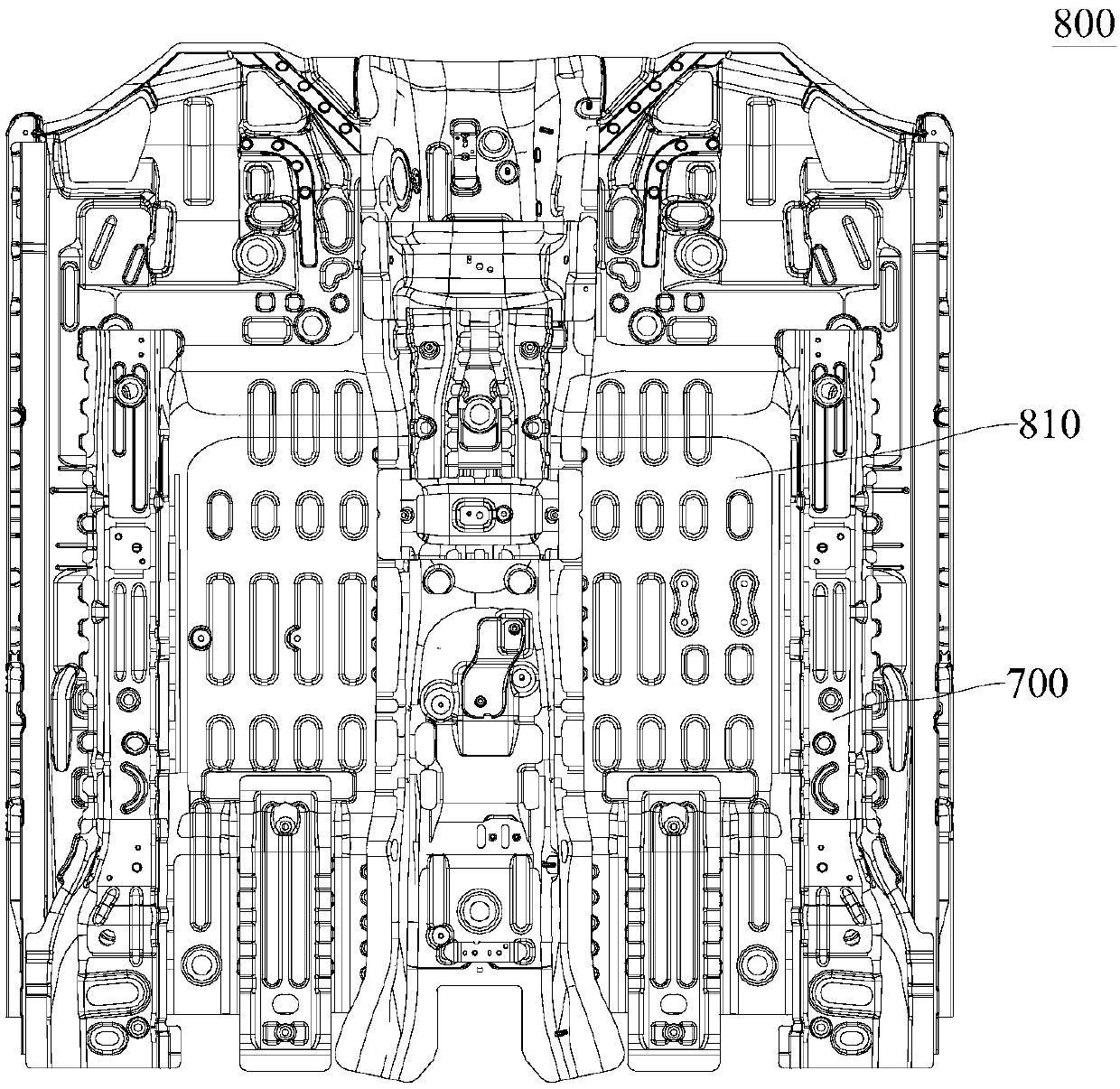

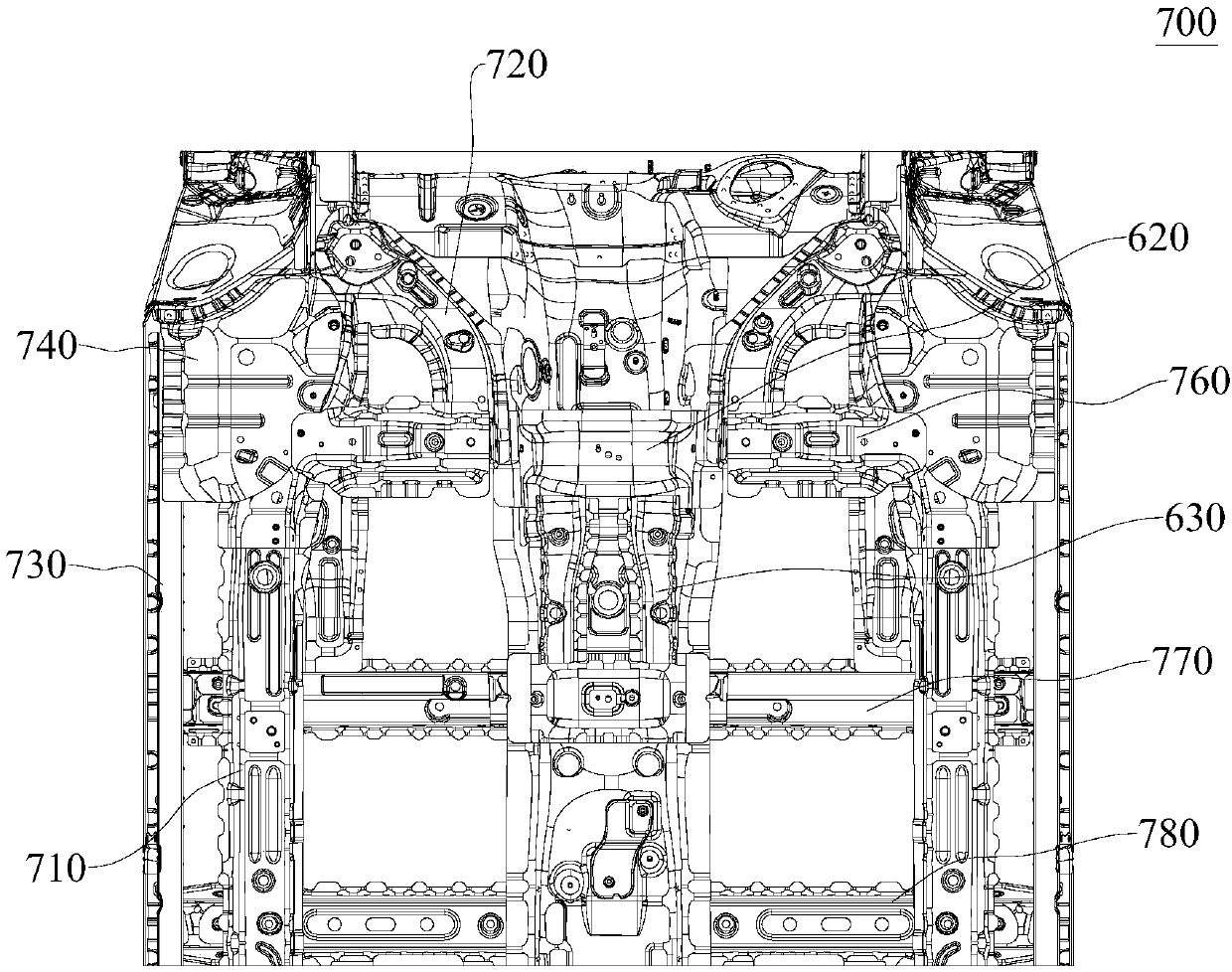

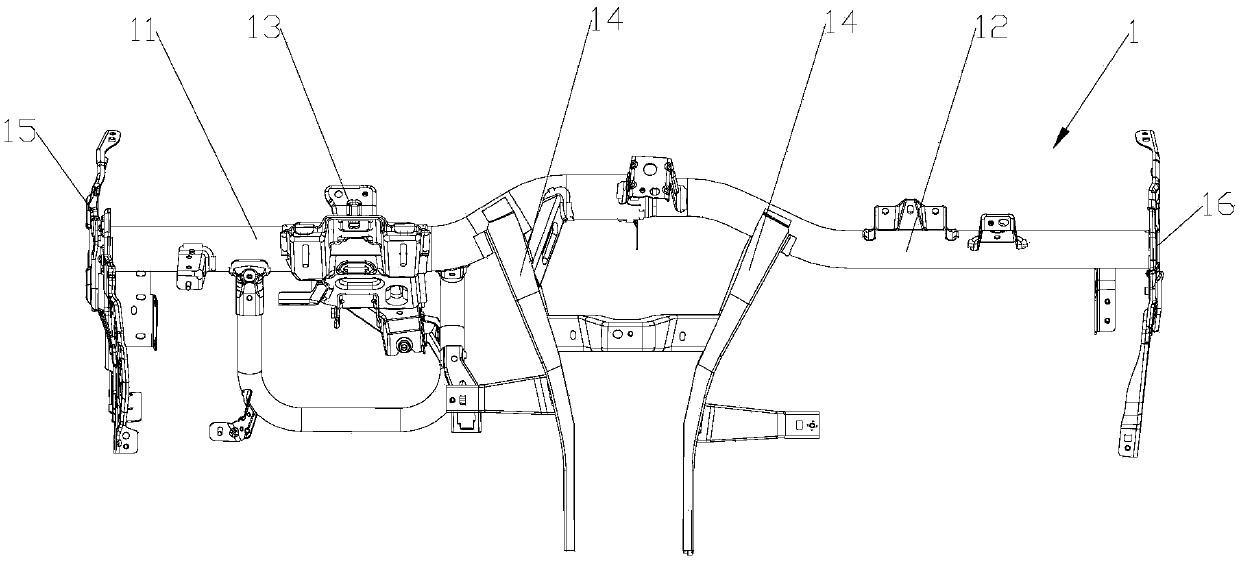

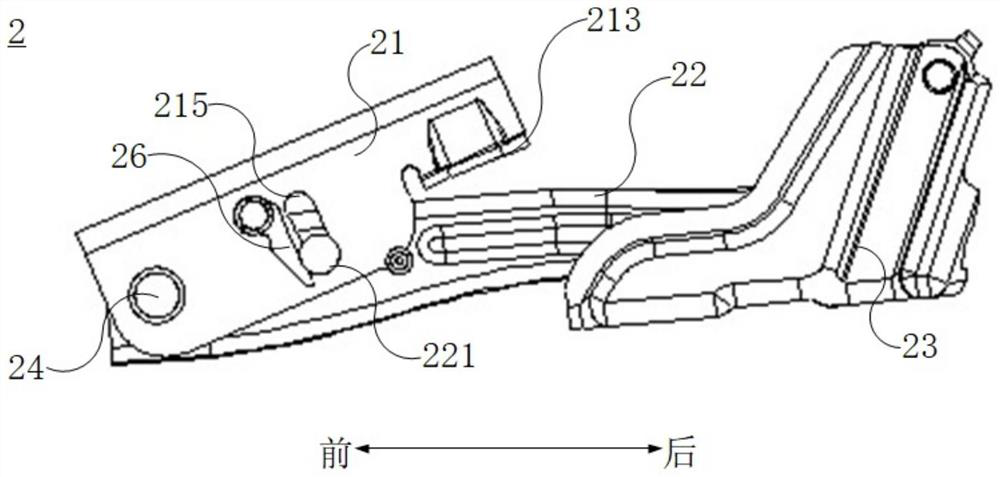

Floor beam structure applied to vehicle

ActiveCN107554621AStructural advantageHigh strengthSuperstructure subunitsTransmission channelStructural engineering

The invention provides a floor beam structure applied to a vehicle. The structure comprises a middle channel, underfloor longitudinal beams, floor cross beams and inclined connecting beams, wherein the underfloor longitudinal beams are located on the left side and the right side of the middle channel; the floor cross beams are disposed on the left side and the right side of the middle channel, thefloor cross beam on each side is connected to the underfloor longitudinal beam on the same side and the middle channel; and the inclined connecting beams are connected to the left side and the rightside of the middle channel, and the front end of the inclined connecting beam on each side is connected to the underfloor longitudinal beam on the same side, and the rear end is connected to the floorcross beam on the same side and the middle channel. The floor beam structure applied to the vehicle provided by the invention has more force transmission channels, so serious deformation of a floor generated when the vehicle suffers impact can be avoided.

Owner:GREAT WALL MOTOR CO LTD

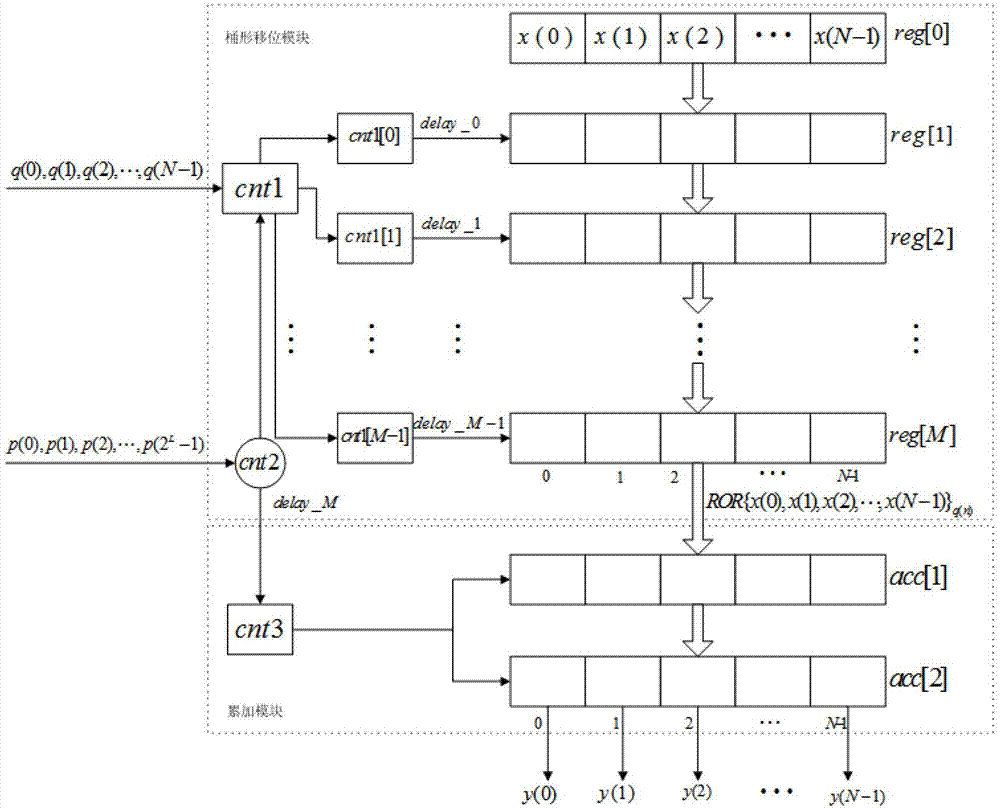

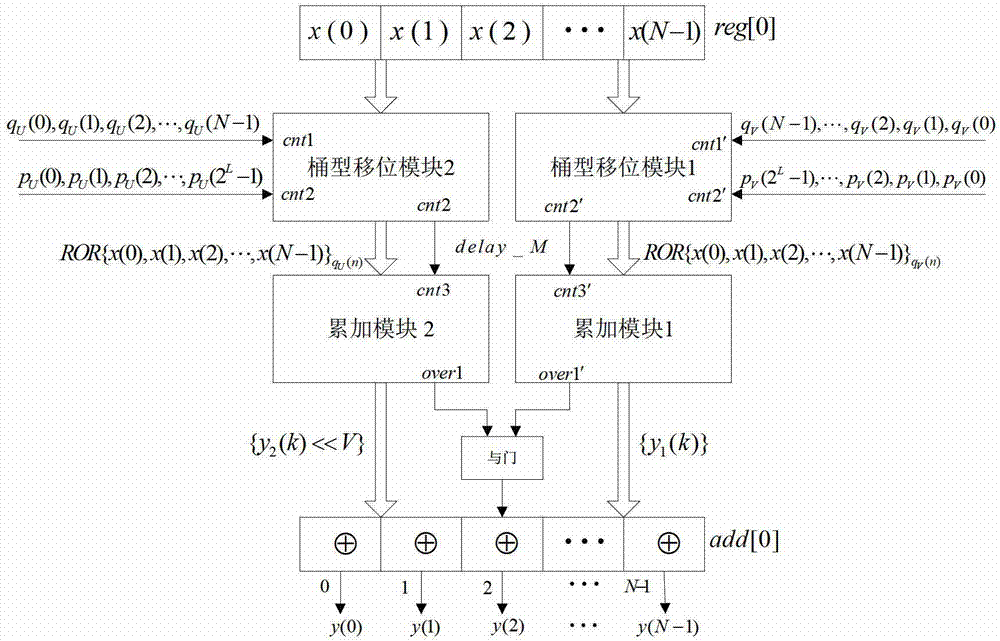

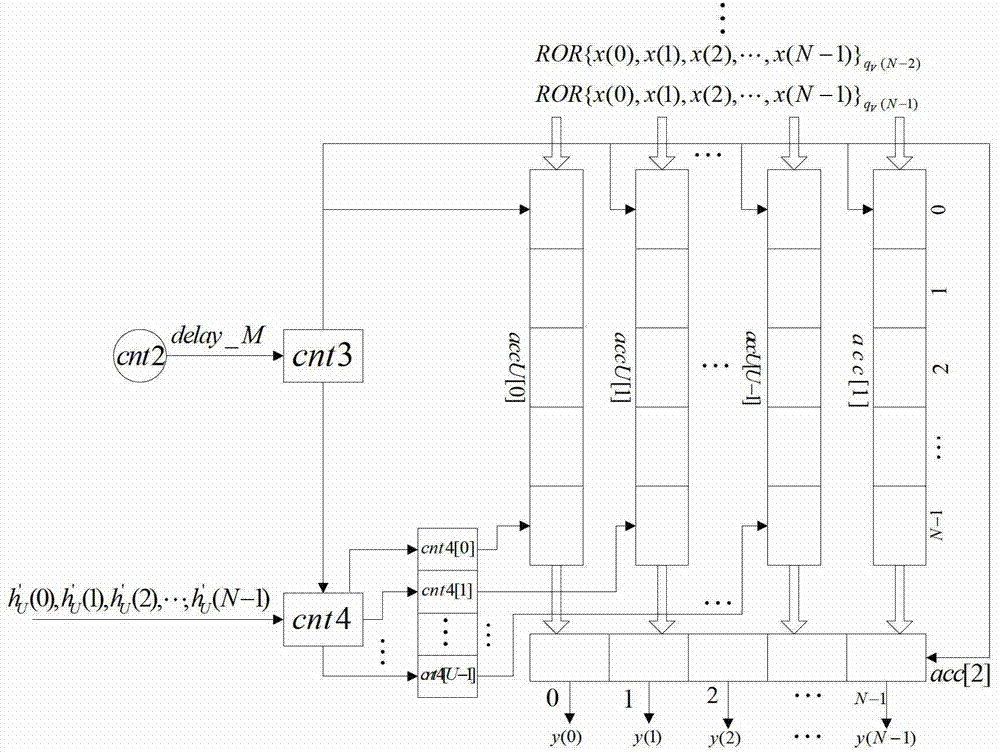

First moment-based convolver

InactiveCN103049716ASimple structureReduce power consumptionComputing operations for addition/subtractionMass storageDigital signal processing

The invention discloses a first moment-based convolver, and belongs to the field of processing a digital signal. A convolution kernel sequence data value and a sequence number are counted in advance and are used as a control signal of the subsequent calculation; the cyclic convolution calculation is converted into the operation containing little displacement and add operation; and a high-efficiency digital signal convolution calculator which is simple in structure and is suitable for any length and data distribution range can be designed. In the convolution calculation, the introduction of trigonometric function and complex number calculation is avoided, and the calculation precision is improved; the requirements of the existing rapid convolver on a multiplier or large capacity storage resources can be conquered; the limit on the length when the convolution is calculated is eliminated; and the hardware resource occupancy is reduced, the power consumption is reduced, and higher calculation speed can be kept.

Owner:HUAZHONG UNIV OF SCI & TECH

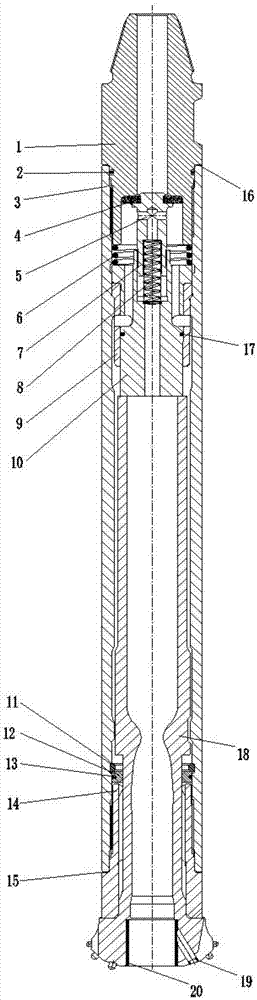

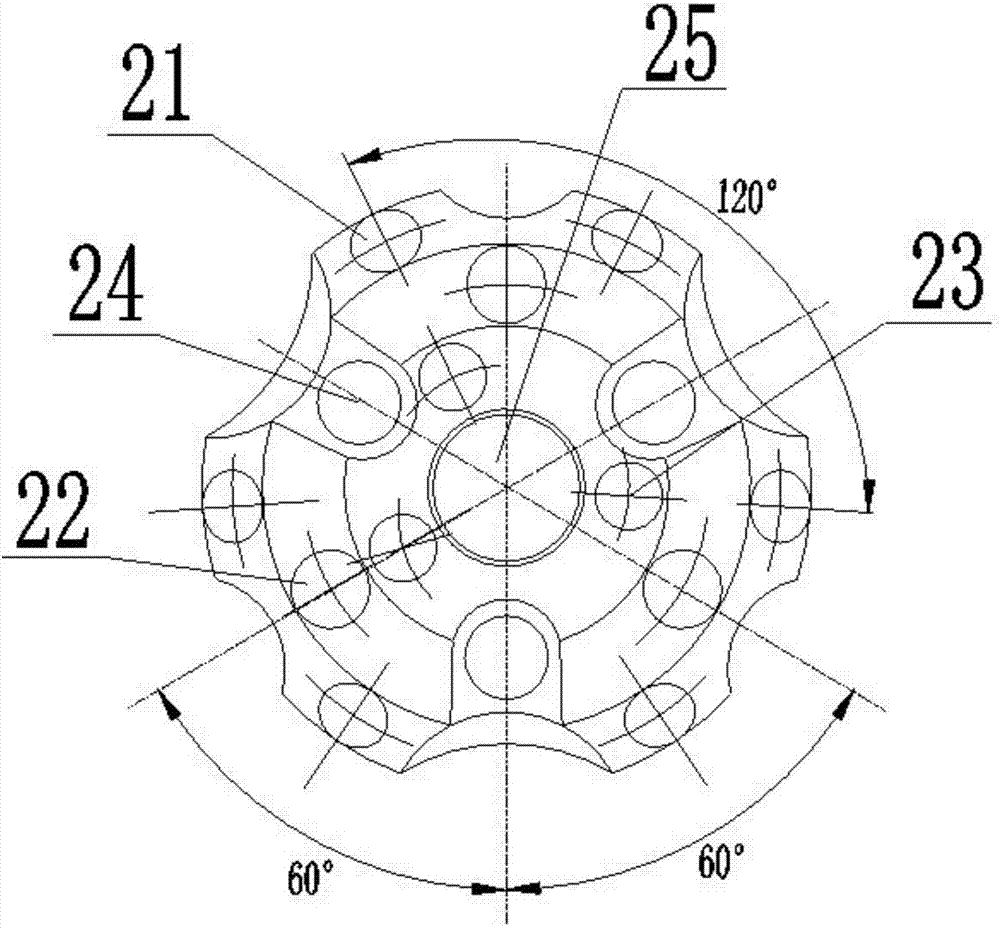

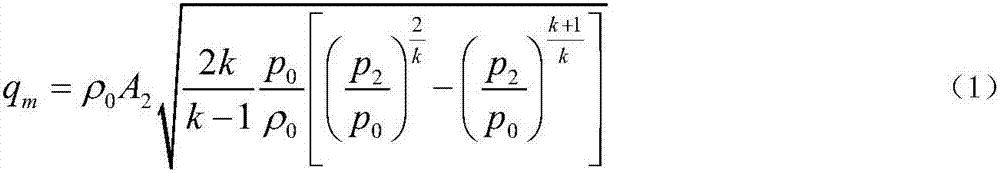

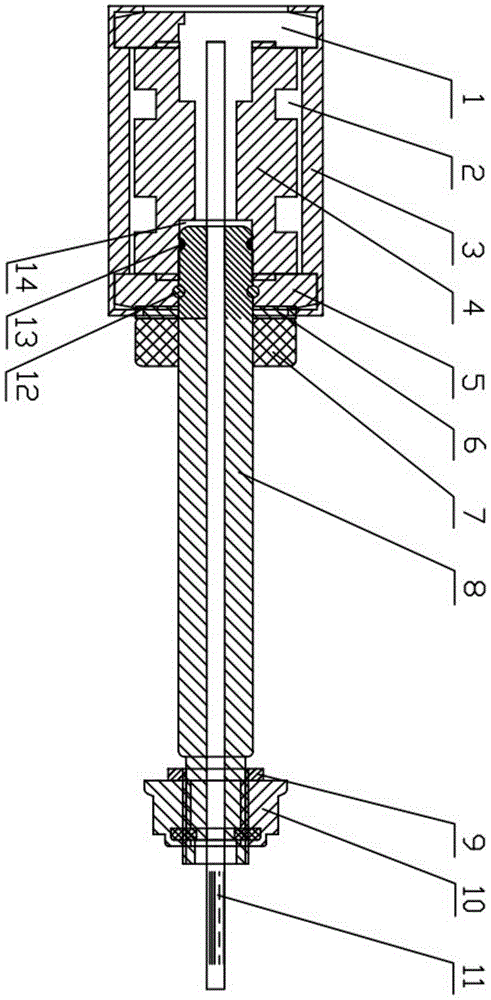

Novel geo-thermal drilling impactor

ActiveCN107461148AImprove cooling effectReduce the temperatureDrill bitsConstructionsAlloyHigh pressure

The invention discloses a novel geo-thermal drilling impactor, which consists of a back connector, an outer casing pipe, an alloy head, an air passage hole, a spring, a check valve body, a gas distribution seat, an air cylinder, a sealing ring, a Lafarol drill bit body, a spray nozzle and alloy teeth. In a geo-thermal well drilling process, high-temperature and high-pressure gas flow passes through an impactor inner hole air passage; high-speed gas enters a piston and an inner hole of the Lafarol drill bit body; power gas pushes the drill bit body to rotate and to do axial reciprocating movement; according to the Lafarol pipeline principle, when the gas reaches an outlet of the impactor, the temperature is fast lowered to a value below 50 DEG C; the drill bit is cooled in time; in the rebounding process of the impactor, the gas pushes a check valve, so that the alloy head rebounds; the air passage is closed; the spring device absorbs the impact power of the impactor in the reciprocating movement process, so that the integral movement of the impactor is stable; and erosion alloy is added in the position of the spray nozzle, and the gas erosion at an outlet of the air passage of the drill bit body is reduced. Compared with the existing power buffer device, the novel geo-thermal drilling impactor has the advantages that the structure is simpler; the assembly is easier; and the implementation performance is better.

Owner:SOUTHWEST PETROLEUM UNIV

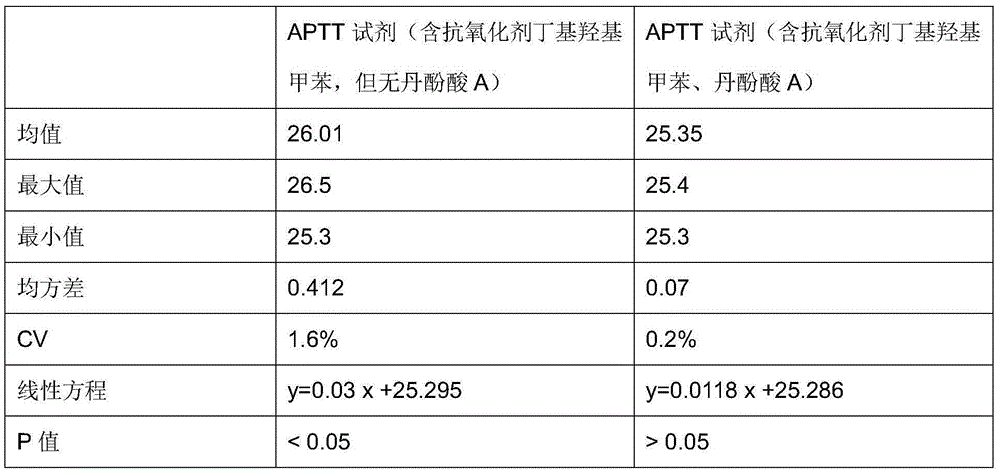

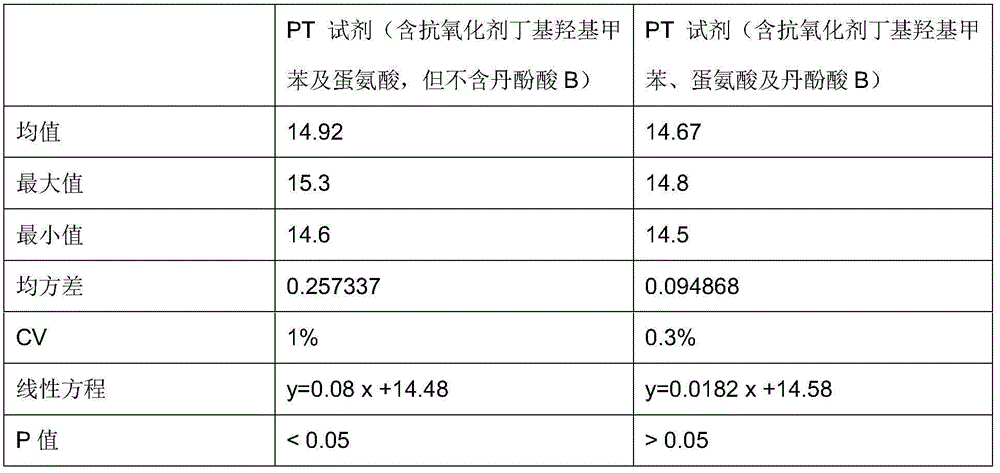

Antioxidant for coagulative reagent

ActiveCN104991079AStructural advantageStrong chelation abilityBiological testingSalvianolic acid BButylated hydroxytoluene

The invention relates to an antioxidant for a coagulative reagent. The antioxidant is salvianolic acid or rosmarinic acid, and the salvianolic acid comprises salvianolic acid A, salvianolic acid B and salvianolic acid C. The coagulative reagent comprises an APTT reagent, a PT reagent, a TT reagent, an FIB reagent and an AT-III reagent. The concentration of the salvianolic acid or rosmarinic acid in the APTT reagent is 0.5-15mM; the concentration of the salvianolic acid or rosmarinic acid in the PT reagent is 0.05-5mM; and the concentration of the salvianolic acid or rosmarinic acid in the TT reagent is 0.01-2mM. The salvianolic acid or rosmarinic acid can reduce destroys or damages of harmful metal ions and free radicals to tissue factors or thrombin in raw materials or in the process, and greatly improves the oxidation resistance of the coagulative reagent. The antioxidant can be added to other general antioxidants, such as butylated hydroxytoluene or butylated hydroxyanisole, ascorbic acid, glycine and methionine, and the antioxidants are commonly used to further improve the stability of the coagulative reagent.

Owner:QINGDAO GUGAO BIOTECH CO LTD

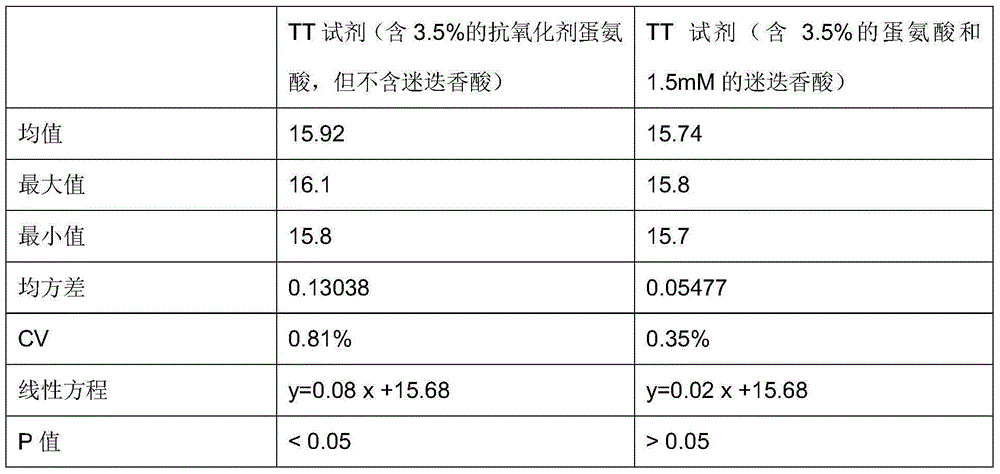

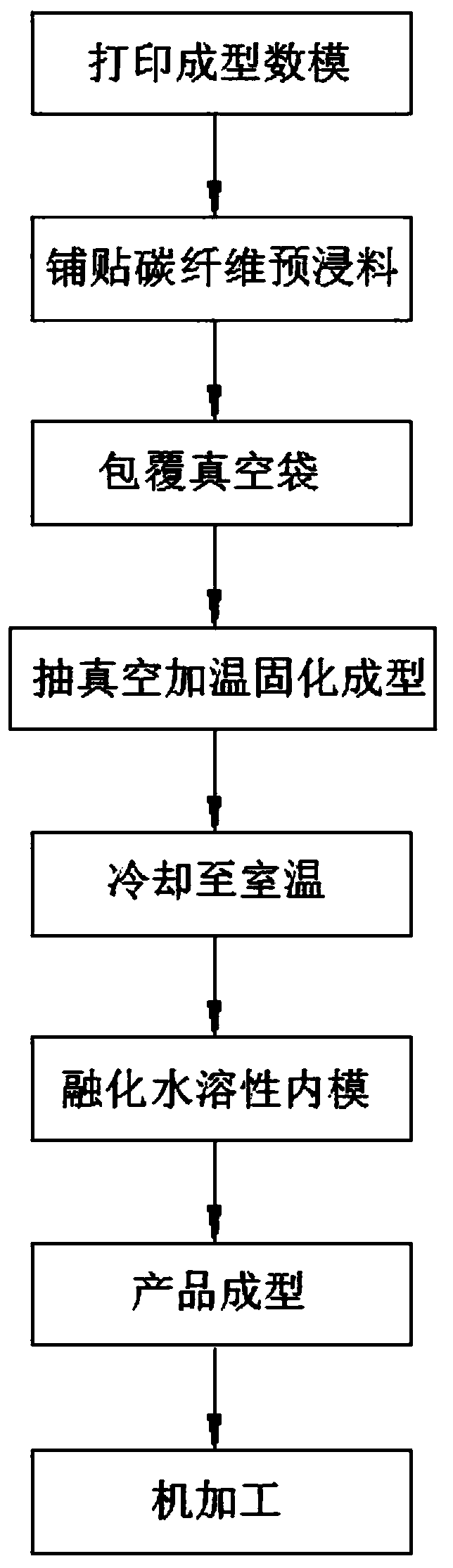

Forming method, structure and forming mold of 3D printing technology assisted carbon fiber component

The invention discloses a forming method, structure and forming mold of a 3D printing technology assisted carbon fiber component, and belongs to the technical field of carbon fiber component forming processes. The forming method of the 3D printing technology assisted carbon fiber component comprises the following steps that a water soluble material is adopted, a digital mold is printed and formedthrough the 3D printing technology, carbon fiber prepreg is paved, a vacuum bag is adopted for coating, vacuumizing and heating curing are carried out for curing, cooling is carried out to room temperature, a water soluble inner mold is molten, products are formed, and machining is achieved. The problems that in the prior art, a metal mold needs to consider the demolding angle, the demolding effect of products is poor, products of complex structures cannot be formed, cost is high, and the production period is long are solved. The water soluble inner mold is adopted to be molten, low-temperature curing forming is achieved, no mold made of metal needs to be put in, products of complex products can be formed, the water soluble inner mold is formed through additive manufacturing, the filling rate can be selected during manufacturing, an environment-friendly material capable of being naturally degraded is adopted, and the production cost can be greatly reduced.

Owner:TIANJIN ISTAR-SPACE TECH CO LTD

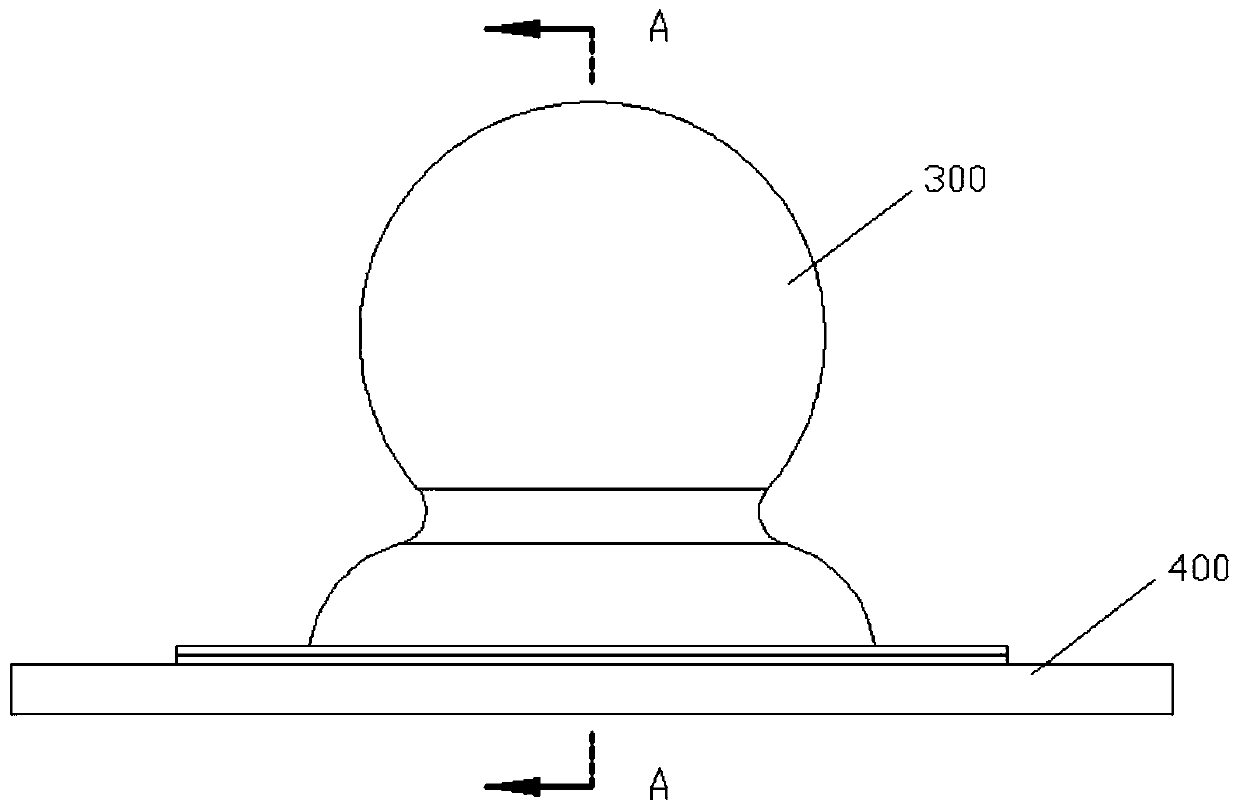

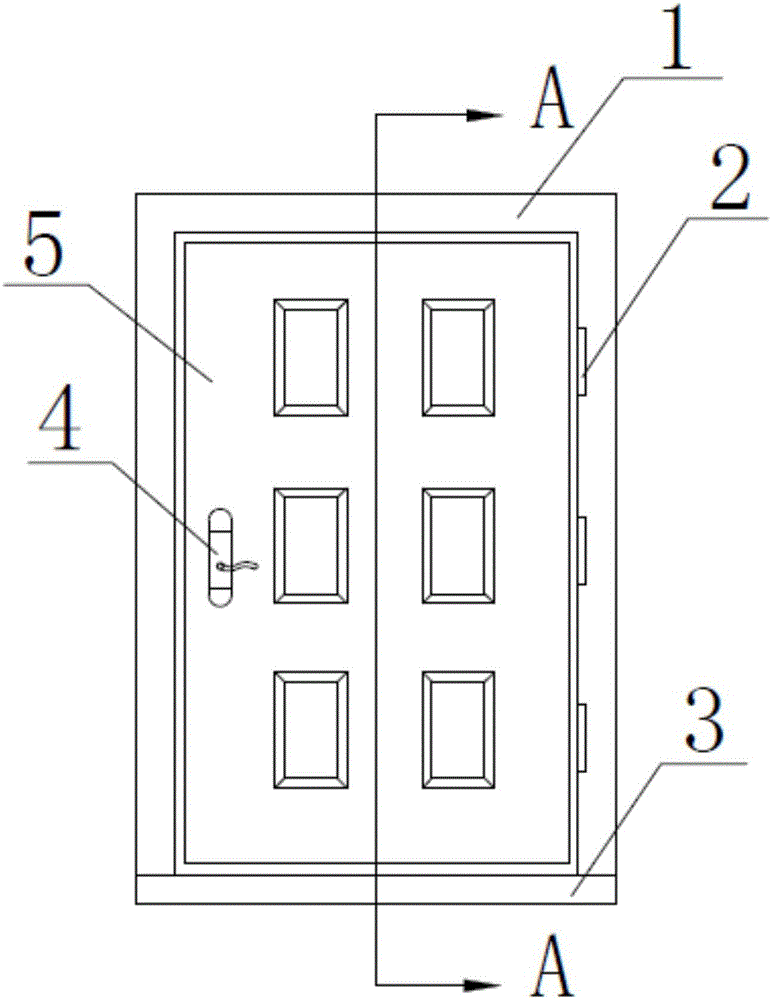

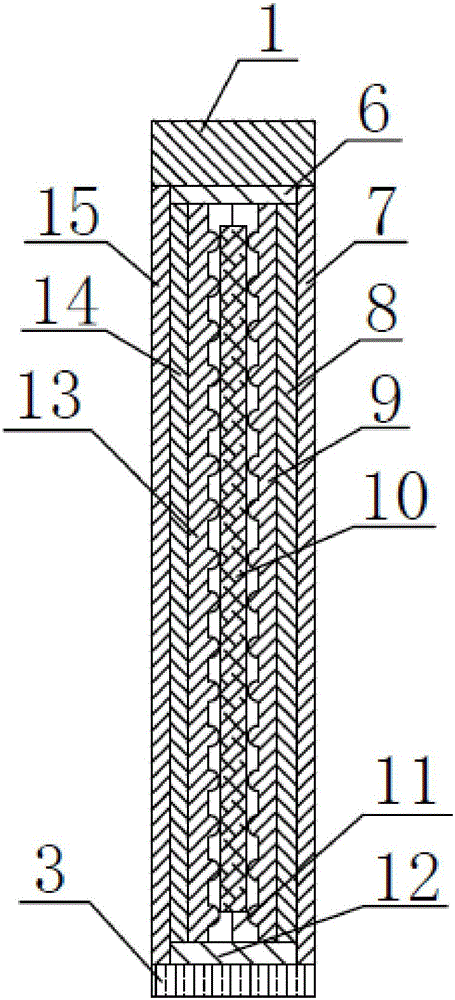

Sound-and-fire proof door leaf structure

InactiveCN106246079AImprove sound insulationStructural advantageFireproof doorsNoise insulation doors/windowsKeelElectrical and Electronics engineering

The invention provides a sound-and-fire proof door leaf structure. The sound-and-fire proof door leaf structure comprises a door frame and a door sheet, wherein the door sheet is connected to the door frame through a hinge; the door sheet is provided with a door lock; the door sheet comprises a first door sheet and a second door sheet; the first door sheet is connected to a first frame; the second door sheet is connected to a second door frame; a first keel is arranged on the tops of the first door frame and the second door frame; a second keel is arranged at the bottoms of the first frame and the second frame; the first frame is provided with a first sound-absorbing plate; the second frame is provided with a second sound-absorbing plate; a sealed cavity is formed between the first sound-absorbing plate and the second sound-absorbing plate; the sealed cavity is in a vacuum state; the sealed cavity is suspended on the first keel; the second keel is provided with an elastic support for connecting the sealed cavity. The sound-and-fire proof door leaf structure is characterized in that a sound-insulating material and a vacuum sealed cavity are arranged between the two layers of door sheets, so that transmission of sound is effectively blocked.

Owner:天津华夏防火设备有限公司

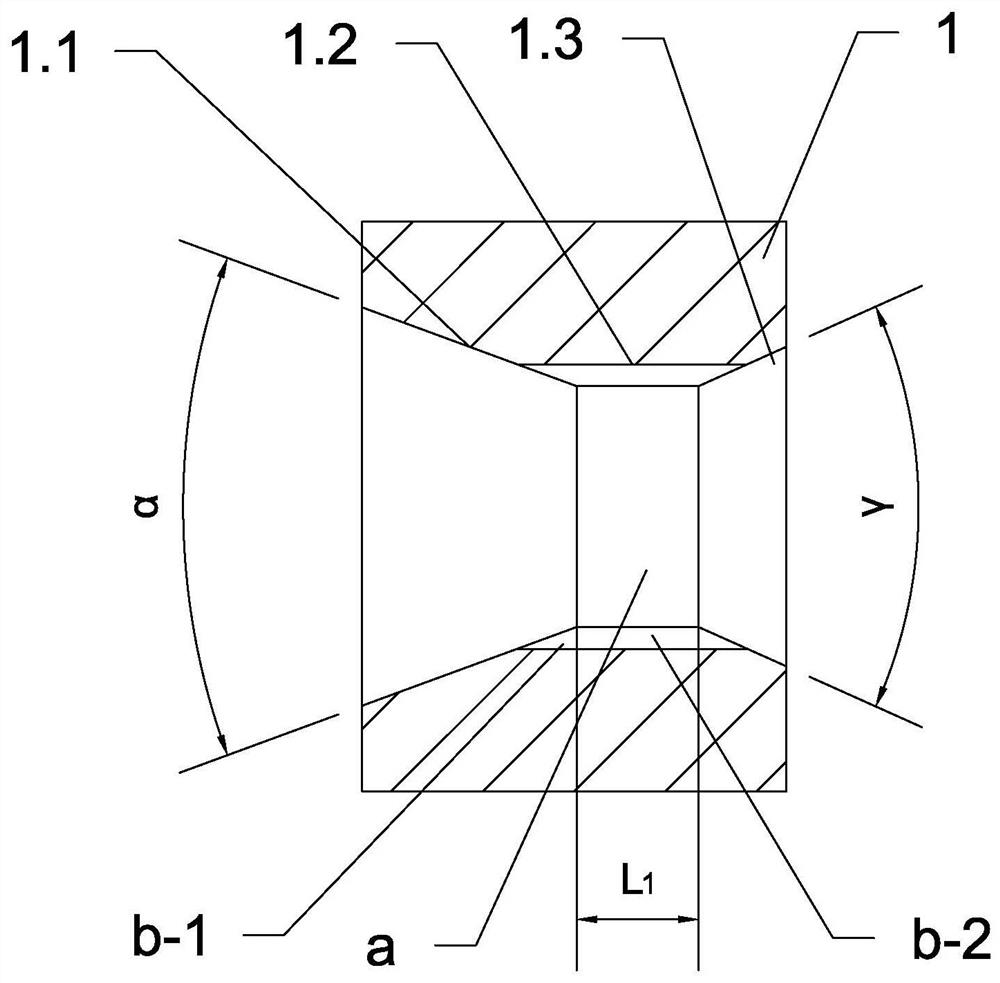

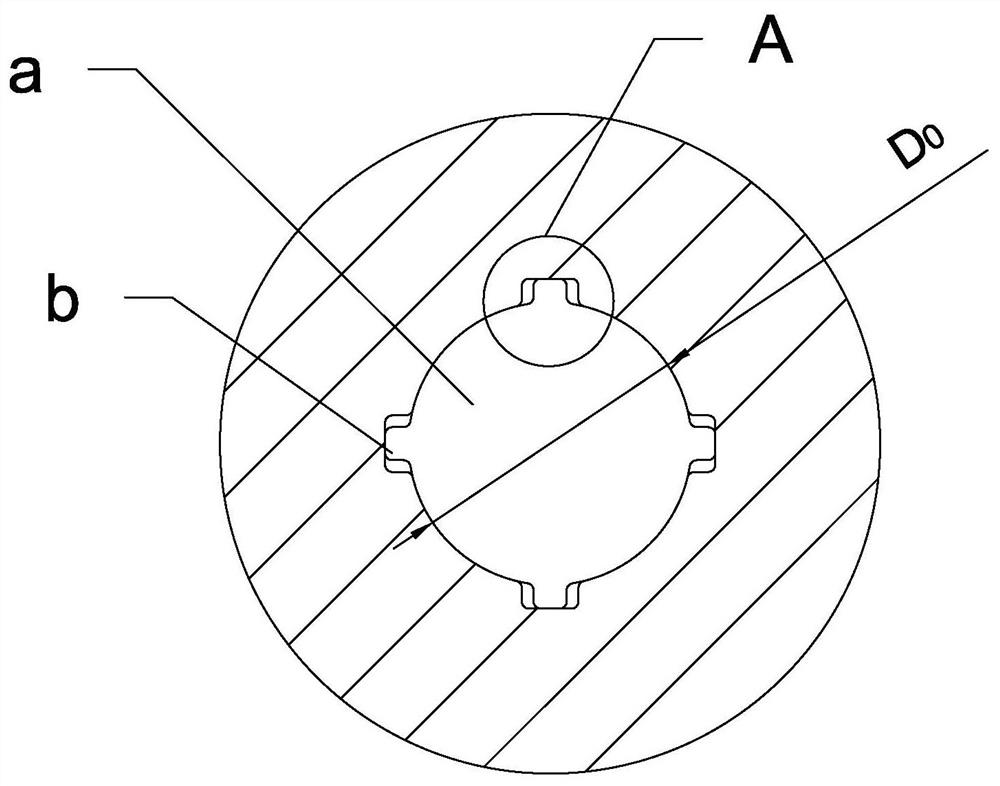

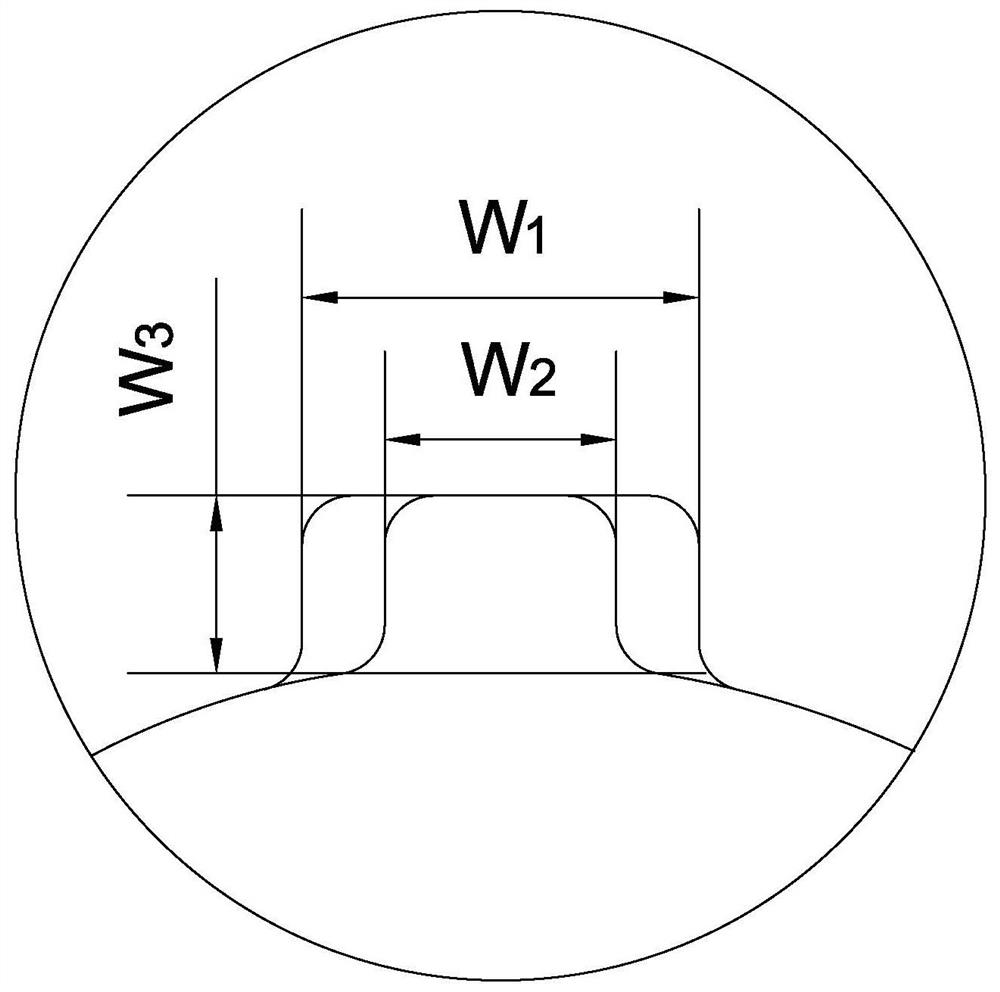

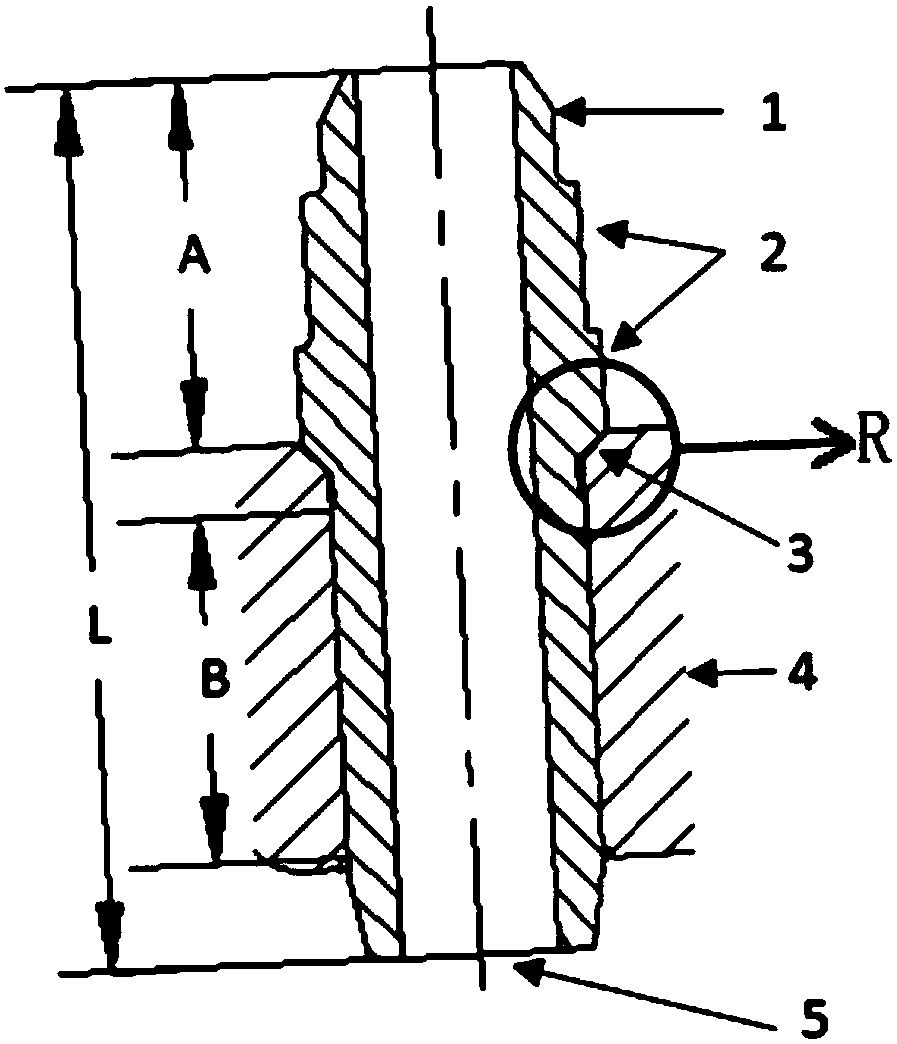

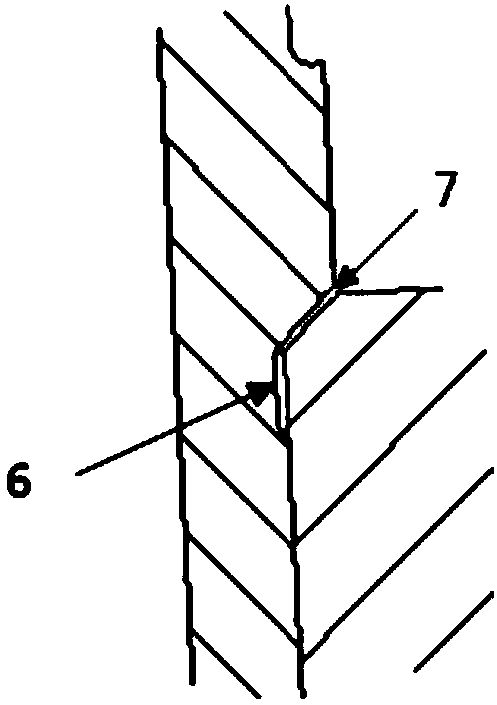

Cold-drawing die of ribbed cladding pipe, production process and finished pipe thereof

InactiveCN111842517AStructural advantageSimple structureWire straightening devicesDrawing diesSolution treatmentSolid structure

The invention relates to the field of machining and manufacturing of special-shaped section stainless steel precise seamless pipes, and particularly relates to a cold-drawing die of a ribbed claddingpipe, a production process and a finished pipe thereof. The cold-drawing die comprises a cold-drawing outer die for molding the outer contour of a pipe, and a cold-drawing core head for limiting the inner diameter of the pipe, wherein an internal molding cavity of the cold-drawing outer die comprises an inlet section, a molding section and an outlet section arranged in sequence; the inlet sectionand the outlet section are both circular table grooves; the molding section comprises an outer diameter molding hole, and at least one section of rib groove formed in the outer periphery of the outerdiameter molding hole; and the cold-drawing core head is a solid structure, and comprises a fixed inner diameter section, a circular table section and a back cylinder section arranged in sequence. Theprocess comprises the steps of preparation of machined pipes, cold-drawing pretreatment, cold-drawing molding, pipe cutting cleaning, solution treatment and straightening. The die is simple in structure and low in production cost; and the used process is high in production efficiency, excellent in surface quality, high in size precision and excellent in comprehensive performance.

Owner:ZHEJIANG JIULI HI TECH METALS

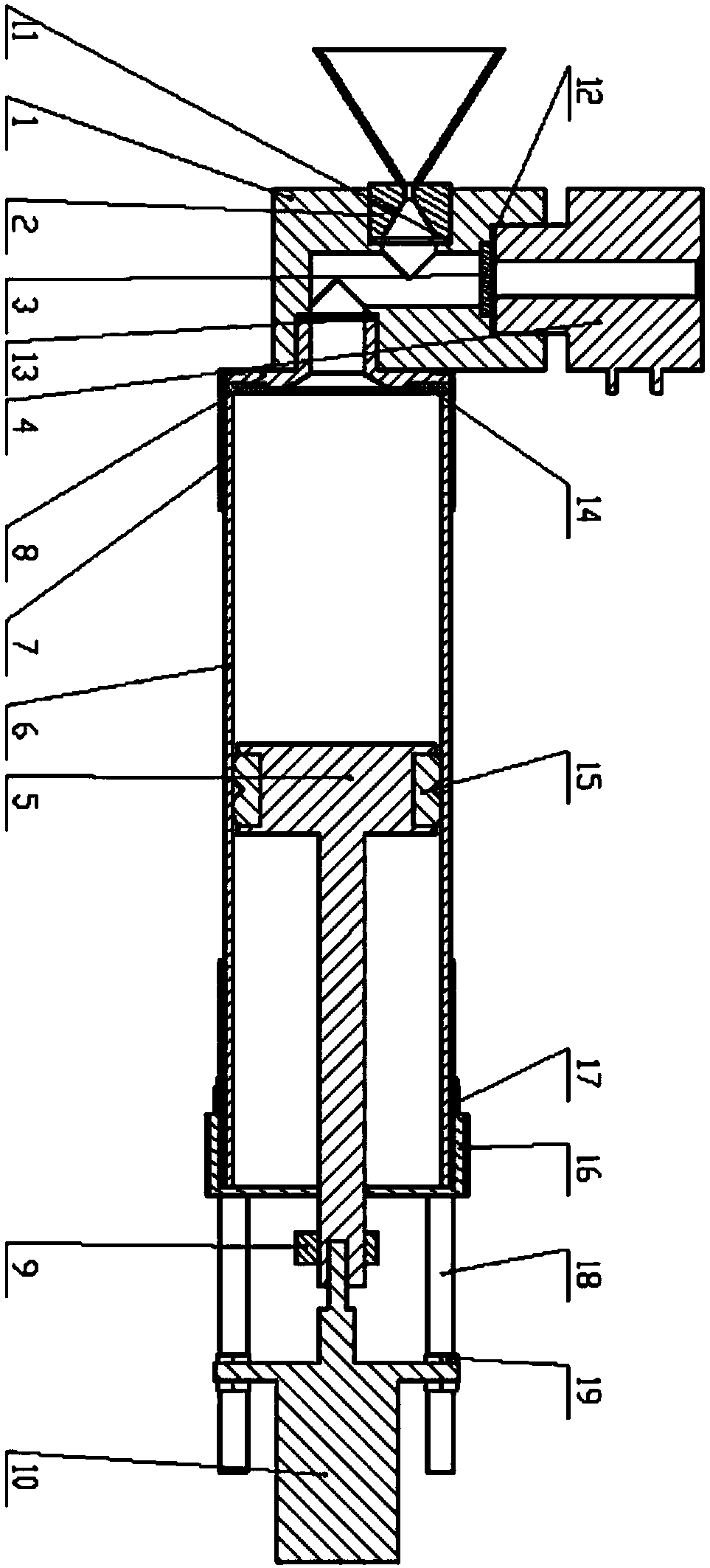

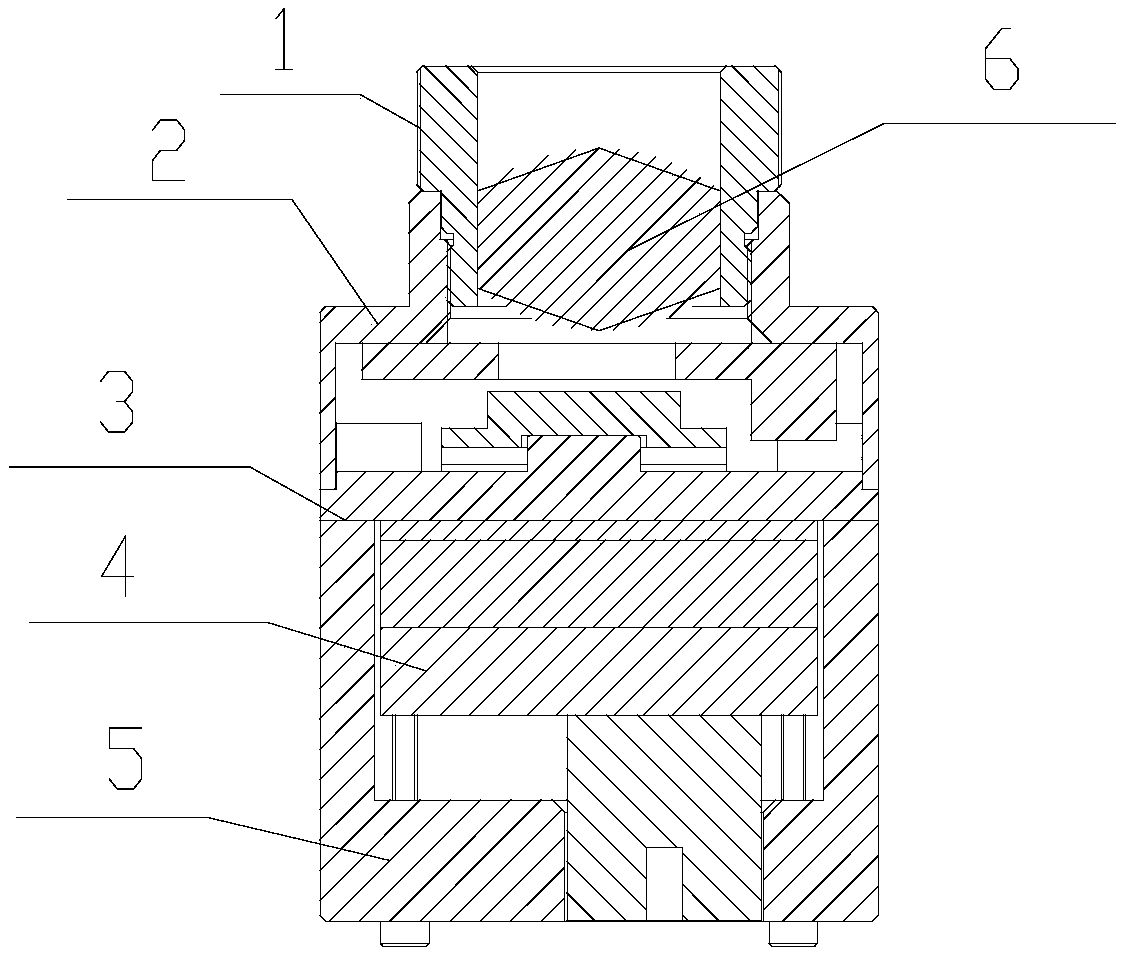

Piston structure of magnetorheological damper

InactiveCN104948647AReduce vibrationReduce recoilSpringsNon-rotating vibration suppressionControl systemControllability

The invention discloses a piston structure of a magnetorheological damper. The piston structure of the magnetorheological damper substantially comprises a piston rod and a piston assembly, wherein a piston rod fixed cavity is arranged on the rear end of the piston assembly, the piston rod is detachably connected with the piston assembly after being inserted into the piston rod fixed cavity, the piston assembly comprises a piston body and a coil protective shell, a coil is wound on the piston body, the coil protective shell is sleeved on the outer side of the piston body, a coil is connected with a control system which is arranged outside a damper through a signal wire, a fixed mechanism is arranged on the rear end of the piston rod, and the piston structure is fixed in the damper through the fixed mechanism. The piston structure can not generate sport wear and damage in the damper, can prolong the whole service lie of the piston structure of the magnetorheological damper. A magnetic field of the coil changes flow characteristics of magnetorheological damping liquid, enables the magnetorheological damping liquid to generate damping force with rapid reaction and strong controllability, and can adjust the damping force in stepless.

Owner:WUHU XINGZHONG IMPORT & EXPORT

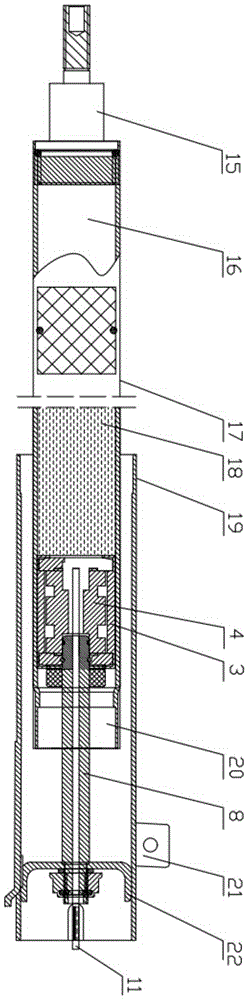

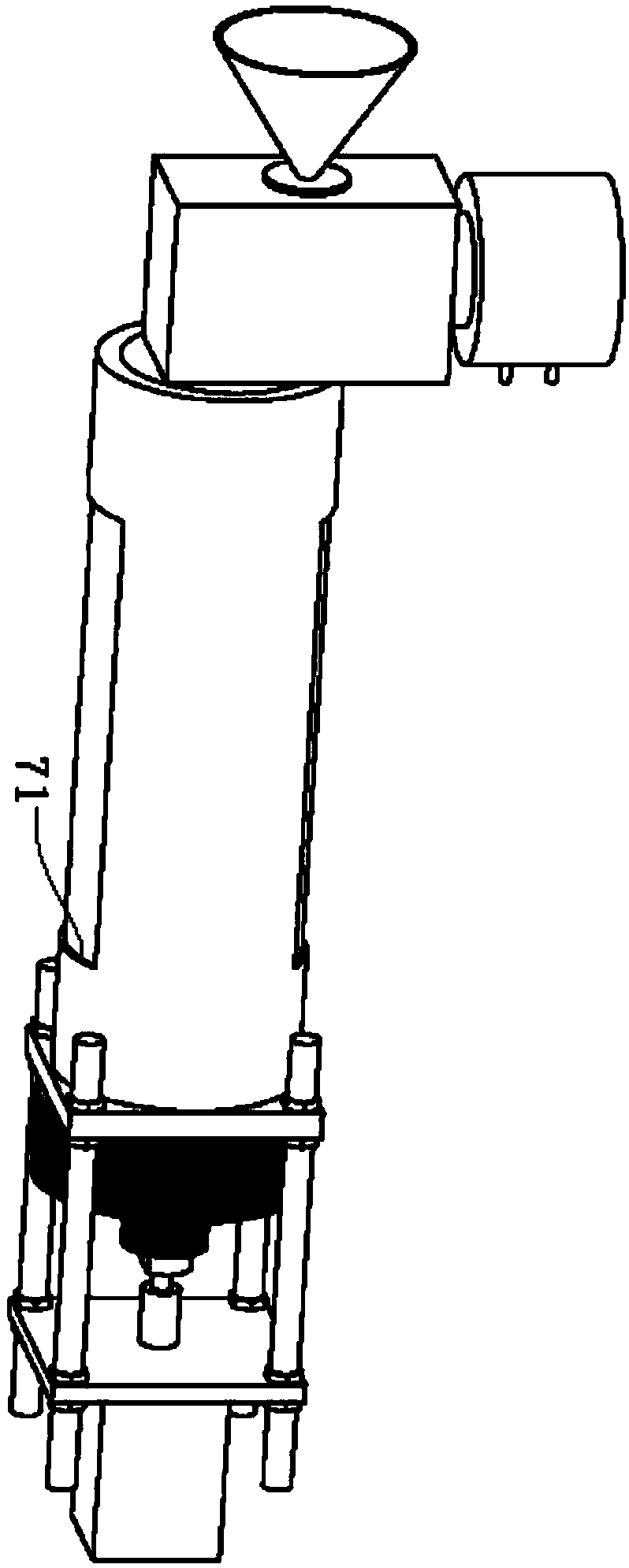

Piston-driven charge structure of the laser-chemical combined propeller

ActiveCN109131943AStructural advantageSimple structureCosmonautic propulsion system apparatusCombustion chamberSatellite attitude control

The invention provides a piston-driven charge structure of a laser-chemical combined propeller. A metal protective shell is sleeved on the charge tube; a fastening head is arranged at one end of the charge tube and is threadably connected with a metal protective shell; the adapter is arranged at the other end of the charge tube; one end of the piston rod is arranged in the charge tube, and the other end protrudes out of the charge tube through the fastening head; the paste propellant is placed in the charge tube; the transmission shaft of the stepping motor is connected with one end of the piston rod protruding out of the charge tube; the three-channel combustion chamber is connected with the adapter; the semiconductor laser is connected with a three-channel combustion chamber, and a glasslens is arranged between the semiconductor laser and the three-channel combustion chamber; the nozzle is connected with a three-channel combustion chamber. The piston-driven charge structure of the laser-chemical combined propellant of the invention is small in volume and light in weight, the paste propellant enters a combustion chamber under the pressure of the piston, the paste propellant combustion is controlled to generate thrust under the laser irradiation, and the thrust adjustment range is in the order of micro-ox to ox, so as to meet the power requirements of micro satellite attitudecontrol and orbit change.

Owner:SHANGHAI XINLI POWER EQUIP RES INST

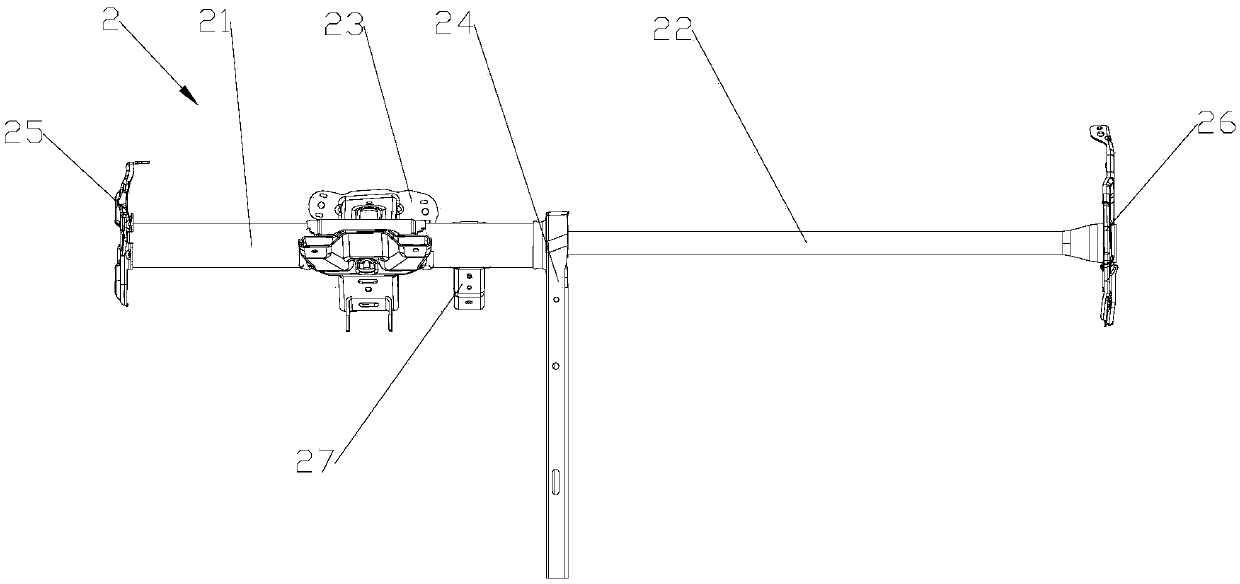

Beam structure and cross car beam assembly

InactiveCN110733577AStructural advantageIncrease stiffnessSuperstructure subunitsStructural engineeringMechanical engineering

The invention relates to the field of vehicle body structures, and provides a beam structure and a cross car beam assembly. The beam structure comprises a first beam body and a second beam body whichare sequentially arranged, wherein the tail end of the first beam body and the head end of the second beam body are staggered and connected through a connector. According to the beam structure disclosed by the invention, the tail end of the first beam body and the head end of the second beam body are staggered and connected through the connector, so that the adjustment of the position of the second beam body relative to the first beam body can be more flexible. In addition, bent beam bodies and expansion and contraction beam bodies are avoided or reduced so as to enable the whole beam structure to be designed in a flat and straight manner, and eliminate the reduction in structural stiffness and strength caused by a bent structure. Moreover, the anti-torsion stiffness of the whole beam structure can be improved by avoiding a same axis, and the overall stiffness of the beam structure is improved.

Owner:GREAT WALL MOTOR CO LTD

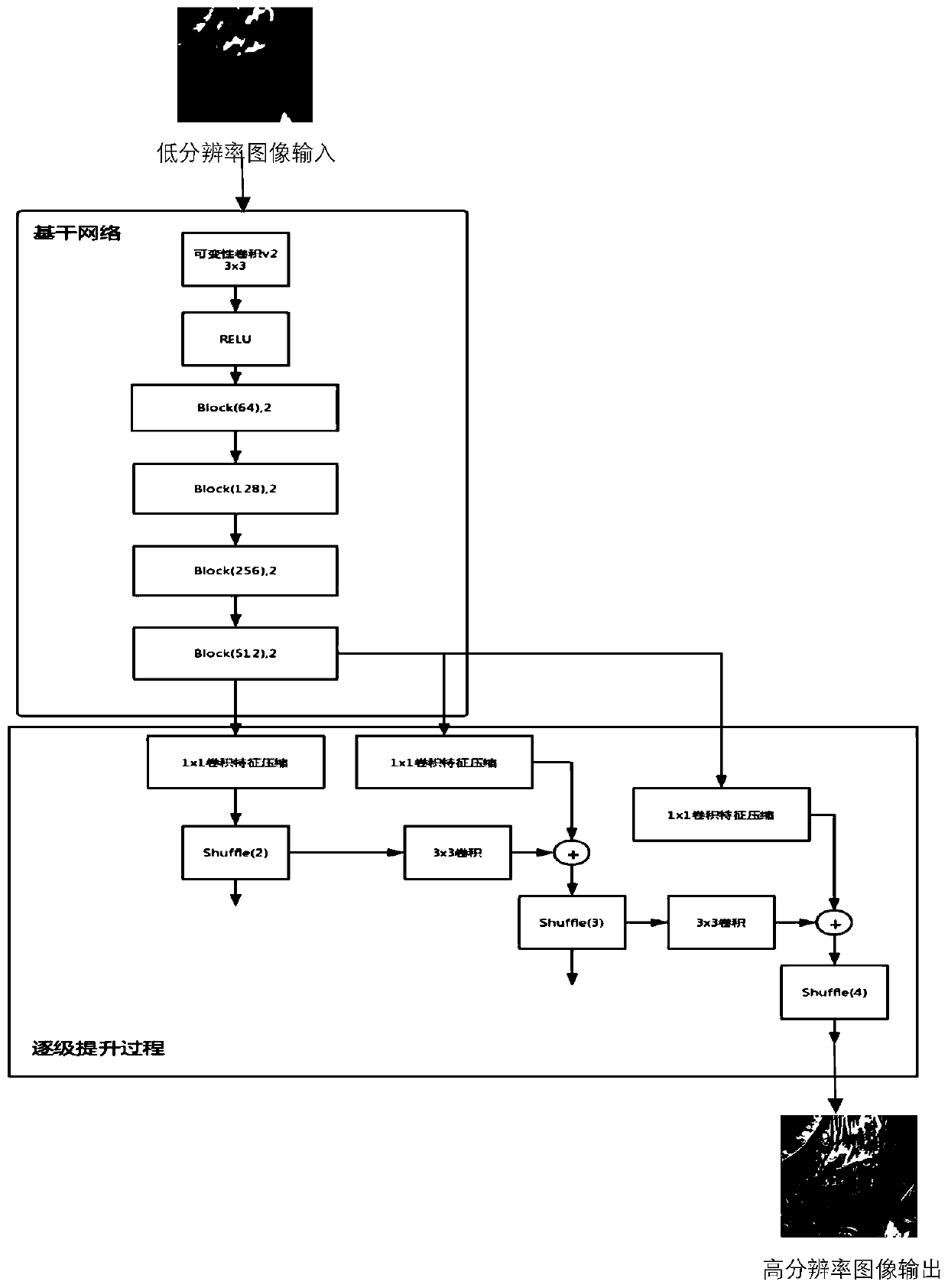

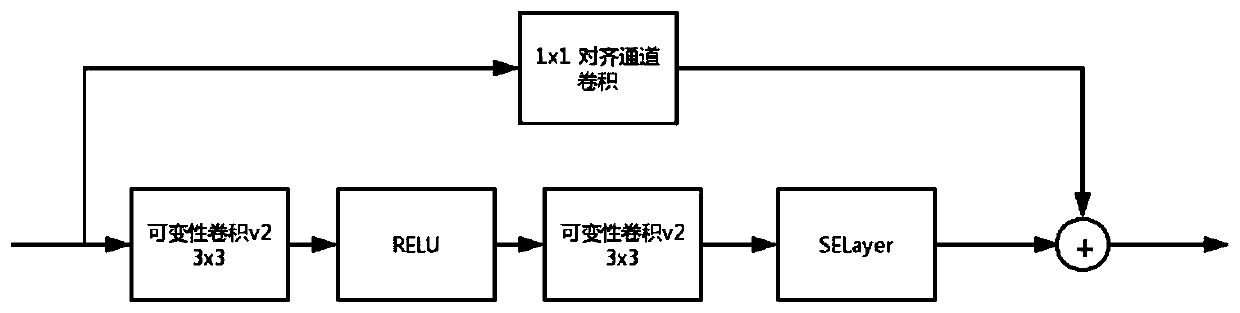

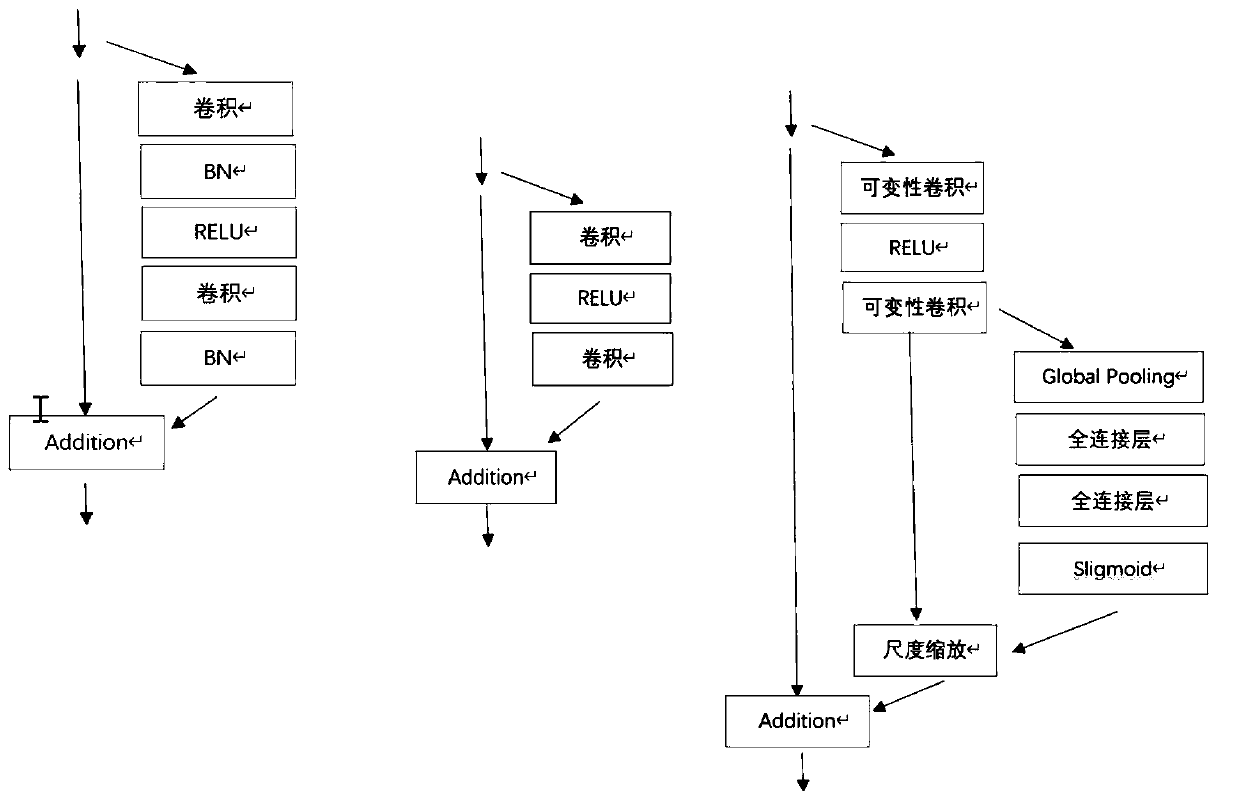

Resolution-by-resolution improved image super-resolution restoration method based on an attention mechanism

PendingCN111461978AStructural advantageReduce training difficultyImage enhancementImage analysisFeature DimensionData set

The invention discloses a resolution-by-resolution improved image super-resolution restoration method based on an attention mechanism, which is mainly based on a resolution-by-resolution improved super-resolution restoration network of a double attention mechanism, and improves the feature extraction capability of a model by introducing a convolution module of a feature dimension attention mechanism and a spatial dimension attention mechanism. Furthermore, related ideas of a resolution-by-resolution improvement network in the field of adversarial neural networks are used for reference, the network learning difficulty is simplified, and super-resolution restoration of resolution-by-resolution improvement is realized. Finally, the algorithm performance is tested through a DIV2K data set, andexperimental results show that the method can improve the input low-resolution image resolution by resolution, the same network can improve the resolution by 2-4 times at the same time, and the PSNRvalue of the reconstructed image is significantly superior to that of a current mainstream algorithm.

Owner:BEIJING UNIV OF TECH

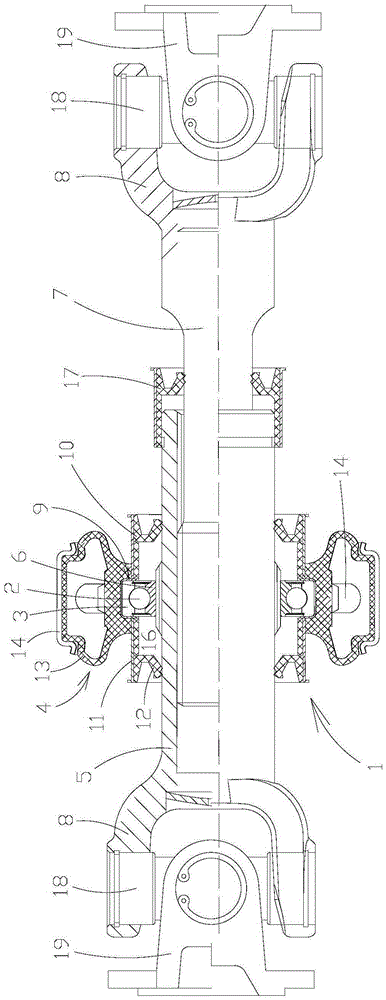

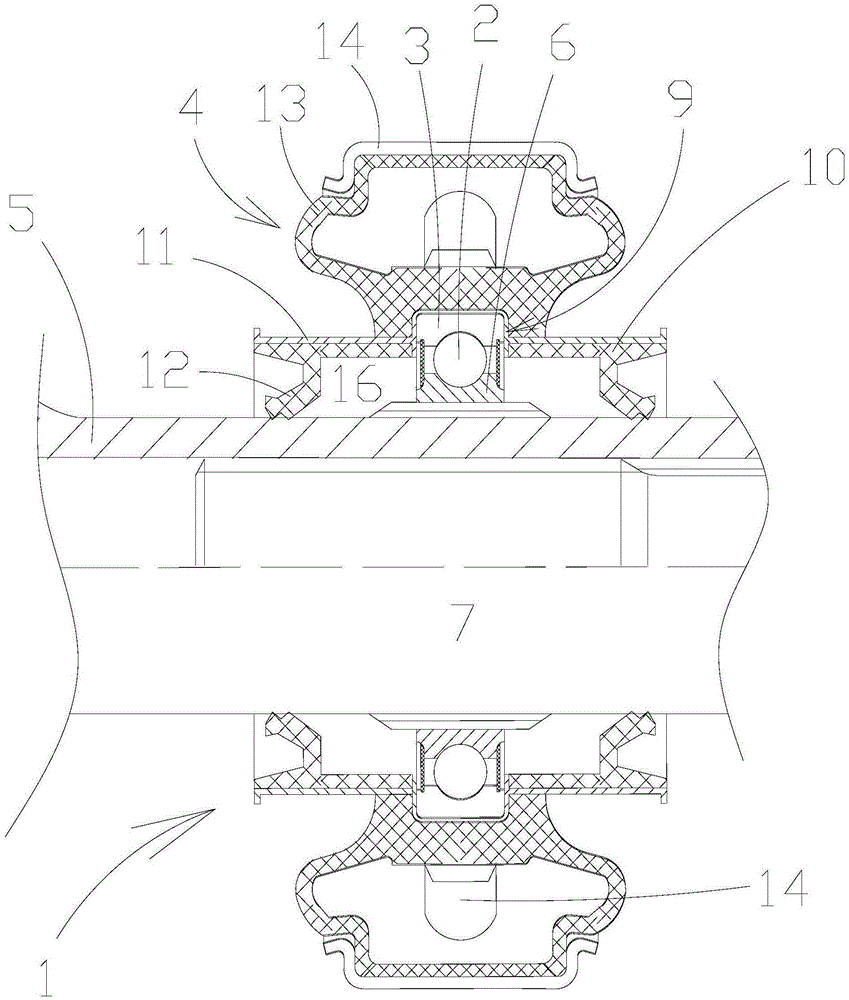

Transmission shaft structure and transmission shaft

ActiveCN106812811AStructural advantageReduce or solve vibration and noise problems such as unbalanced rotationYielding couplingBearing unit rigid supportDrive shaftEnergy absorption

The invention relates to the technical field of vehicle driving shafts, and provides a transmission shaft structure. The transmission shaft structure comprises a bearing, a spline sleeve and a spline shaft, wherein a vibration reducing support device is arranged on an outer ring of the bearing, and can be fixedly supported on a vehicle body; the spline sleeve is assembled in the inner ring of the bearing through a spline structure; and the spline shaft is assembled in the spline sleeve through a key slot structure, and can axially extend. The transmission shaft structure prominently reduces or solves such vibration noise problems as unbalanced rotation caused by nonuniform mass distribution of the transmission shaft, is excellent in energy absorption and vibration isolation effects, and improves the NVH performance of a transmission system.

Owner:GREAT WALL MOTOR CO LTD

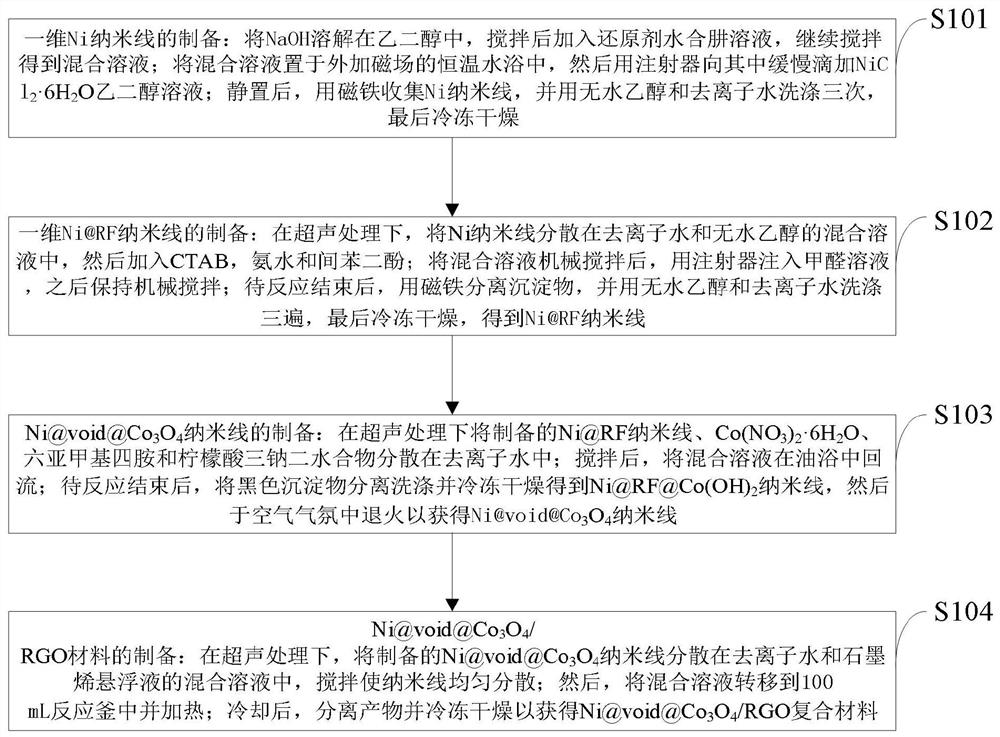

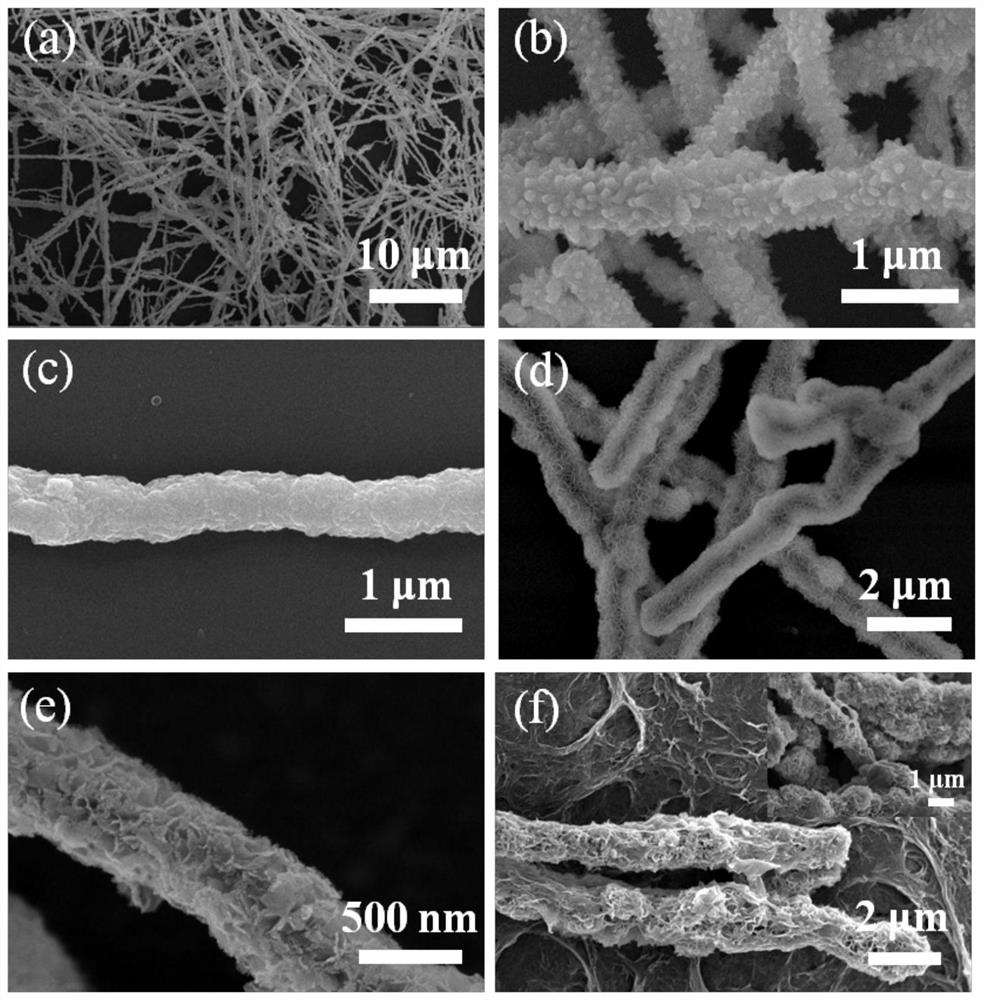

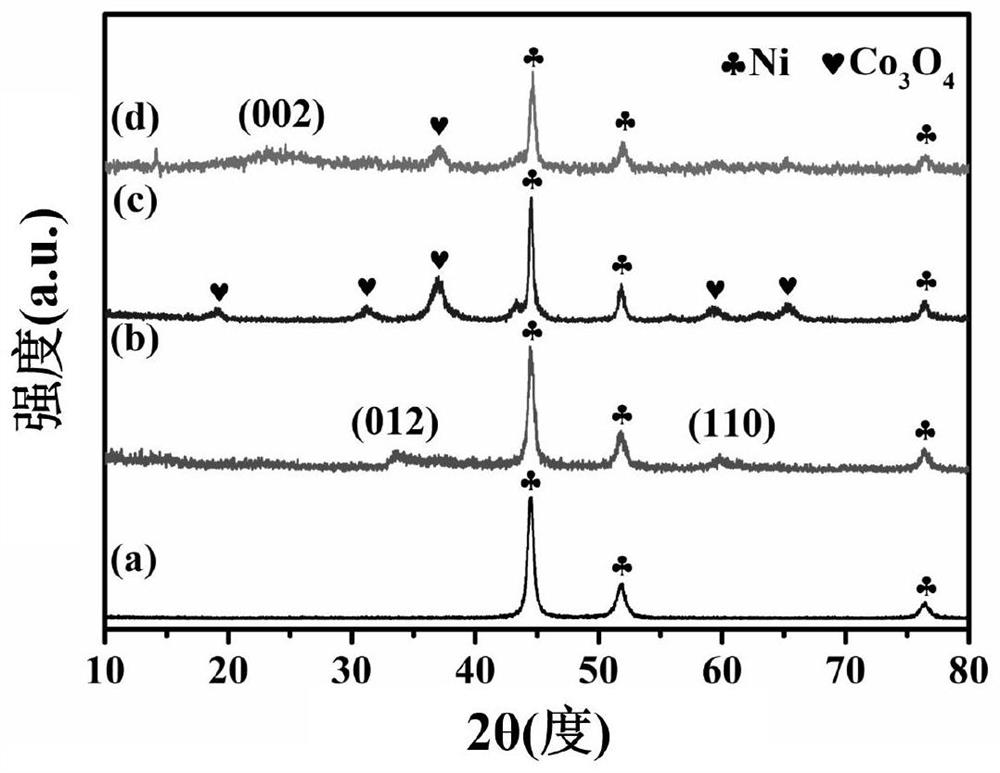

One-dimensional olk-shell Ni@void@Co3O4@RGO wave-absorbing agent and preparation method thereof

PendingCN113068385AImprove performanceLow densityMagnetic/electric field screeningNanowireDielectric loss

The invention belongs to the technical field of wave absorbing agents, and discloses a one-dimensional olk-shell Ni@void@Co3O4@RGO wave absorbing agent, a preparation method and application thereof, preparation of a one-dimensional Ni nanowire, preparation of a one-dimensional Ni@phenolic aldehyde (Ni@RF) nanowire and preparation of a Ni@void@Co3O4 nanowire. The one-dimensional Ni nanowire is prepared through a chemical reduction method, the one-dimensional Ni nanowire is coated with a phenolic resin layer and a Co(OH)2 nanosheet layer, the one-dimensional Ni nanowire is calcined in air to obtain a one-dimensional Ni@void@Co3O4 nanowire, the one-dimensional Ni@void@Co3O4 nanowire is compounded with reduced graphene to obtain the final composite wave-absorbing agent, and the composite wave-absorbing agent is novel in structure and excellent in performance. The wave-absorbing agent prepared by the method is excellent in performance and has a good application prospect. In the Ni@void@Co3O4 nanowire with the layered structure, the magnetic Ni nanowire in the Ni@void@Co3O4 nanowire is used for generating active magnetic loss, and the flower-shaped Co3O4 nanosheet and the RGO nanosheet support dielectric loss.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

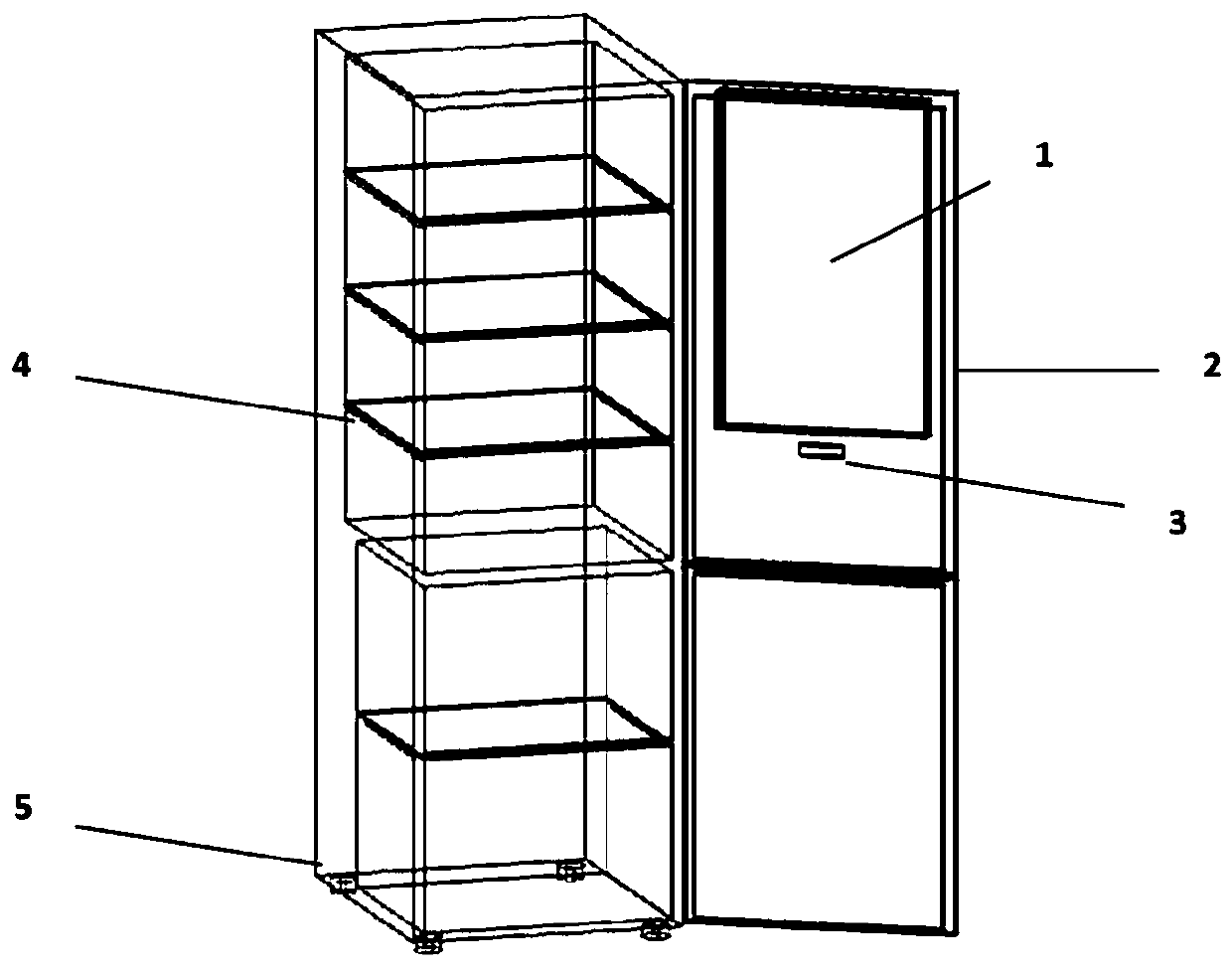

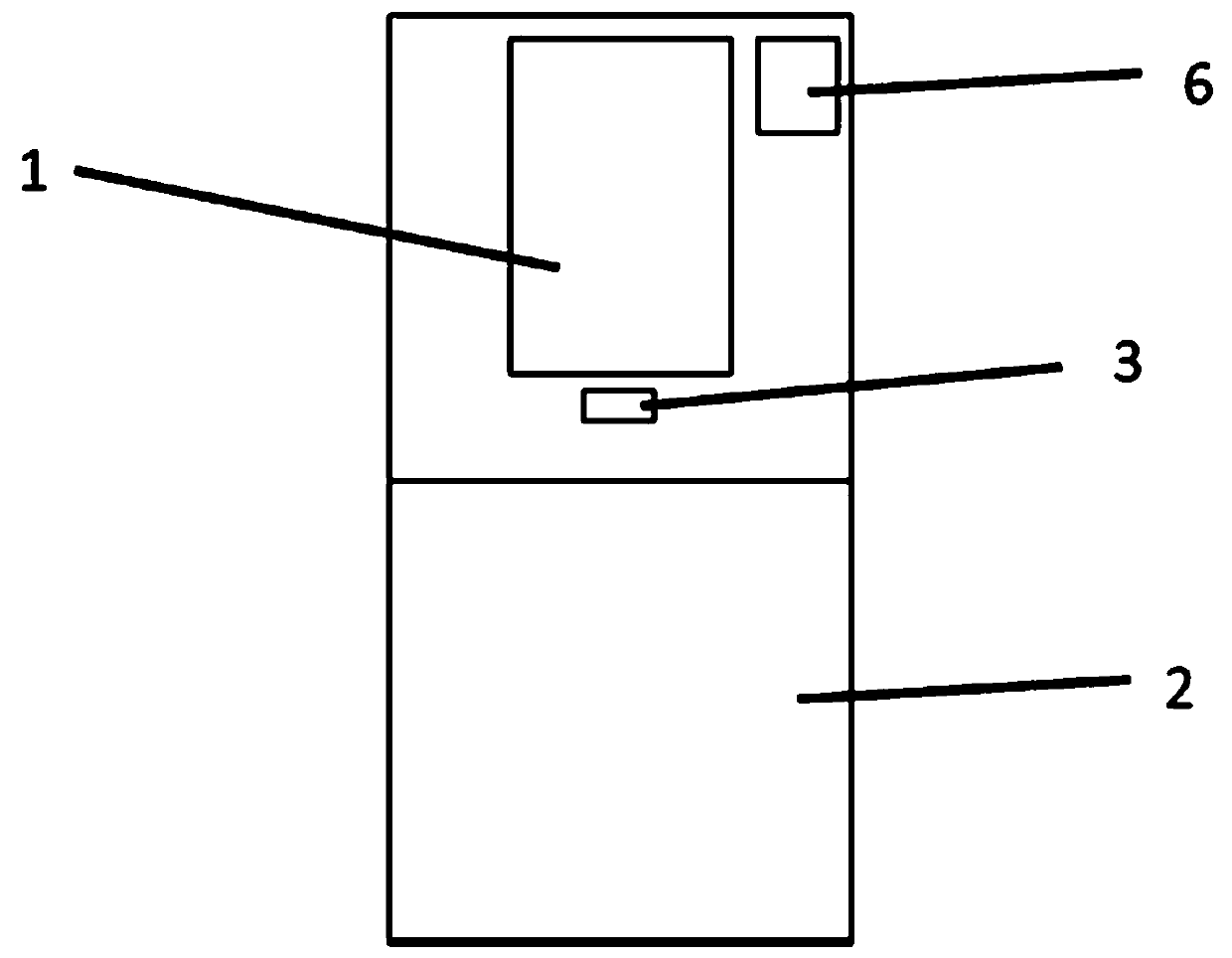

Intelligent refrigerator with shelf life reminding function

InactiveCN110595134AReduce food safety issuesMonitor temperature at any timeLighting and heating apparatusDomestic refrigeratorsLiquid-crystal displayFood safety

The invention discloses an intelligent refrigerator with a shelf life reminding function. The intelligent refrigerator comprises a liquid crystal display screen, a refrigerator door, a bar code scanner, partition plates and a temperature and humidity sensor; and the intelligent refrigerator is characterized in that the liquid crystal display screen is located on the refrigerator door, a acquisition module, a screen display module, a central processor, a clock module, a power supply module, the temperature and humidity sensor, the acquisition module, the screen display module, the central processor, the clock module, the power supply module, a bar code identification module and the temperature and humidity sensor are arranged on the main body of the intelligent refrigerator, and the temperature and humidity sensor is located on one partition plate in a refrigerator body. According to the intelligent refrigerator, the problem that a user is prone to forget the shelf life of the food in the refrigerator can be effectively solved, the user can be reminded to eat the food in the refrigerator in time, and meanwhile, the temperature and humidity sensor can help the user to monitor the temperature and the humidity in the refrigerator at any time. Through utilizing the function of judging the shelf life of the food, the possibility of the food safety problem caused by eating food whichexceeds the shelf life can be greatly reduced.

Owner:SHANGHAI OCEAN UNIV

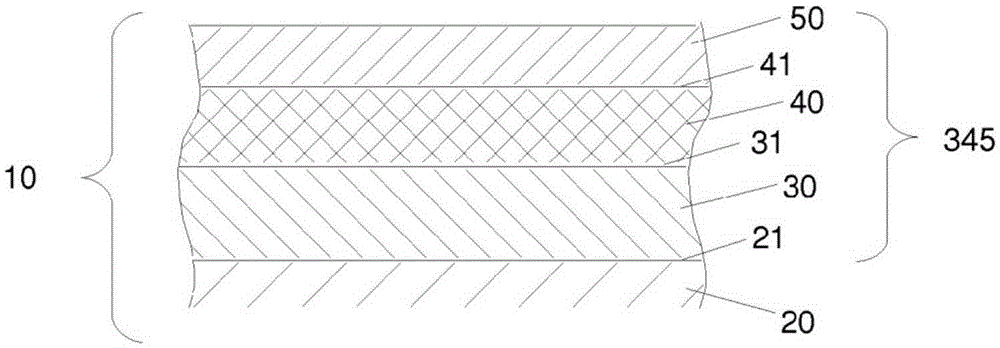

Aircraft structure with solar energy capture capacity

InactiveCN105392701AStructural advantagePower installationsPower plant arrangements/mountingNacelleFuselage

The invention relates to an aircraft structure (10), in particular the fuselage, nacelles or wings, comprising, over all or part of an outer surface (21) that may undergo lightning impacts, a layer of flexible polymer (30), a photovoltaic film (40) and a protective layer (50) protecting said photovoltaic film. This aircraft structure primarily has a solar energy capture capacity making it possible to meet the needs of an aircraft as well as an ability to protect against the effects of lightning.

Owner:EUROPEAN AERONAUTIC DEFENCE & SPACE CO EADS FRANCE +1

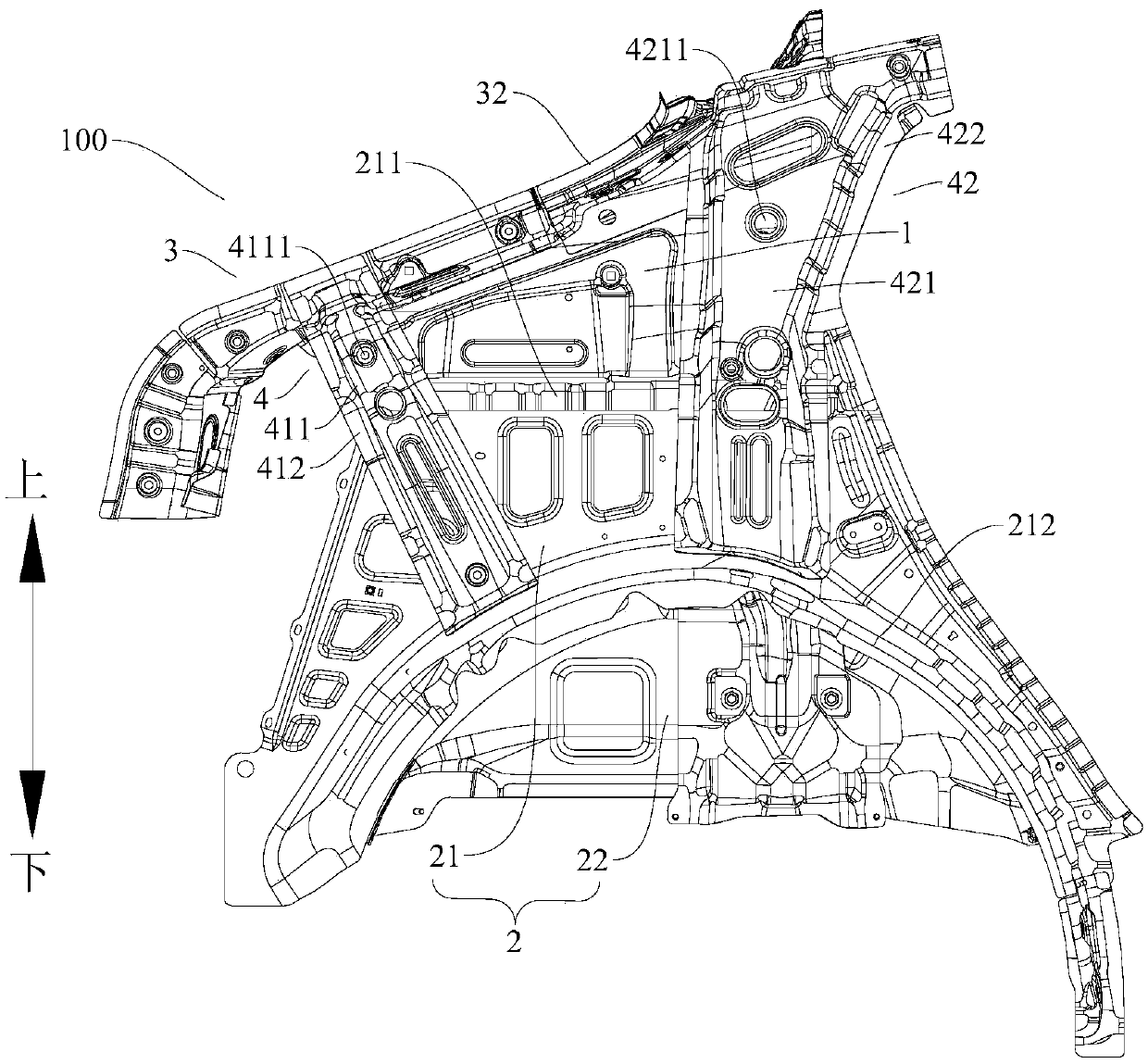

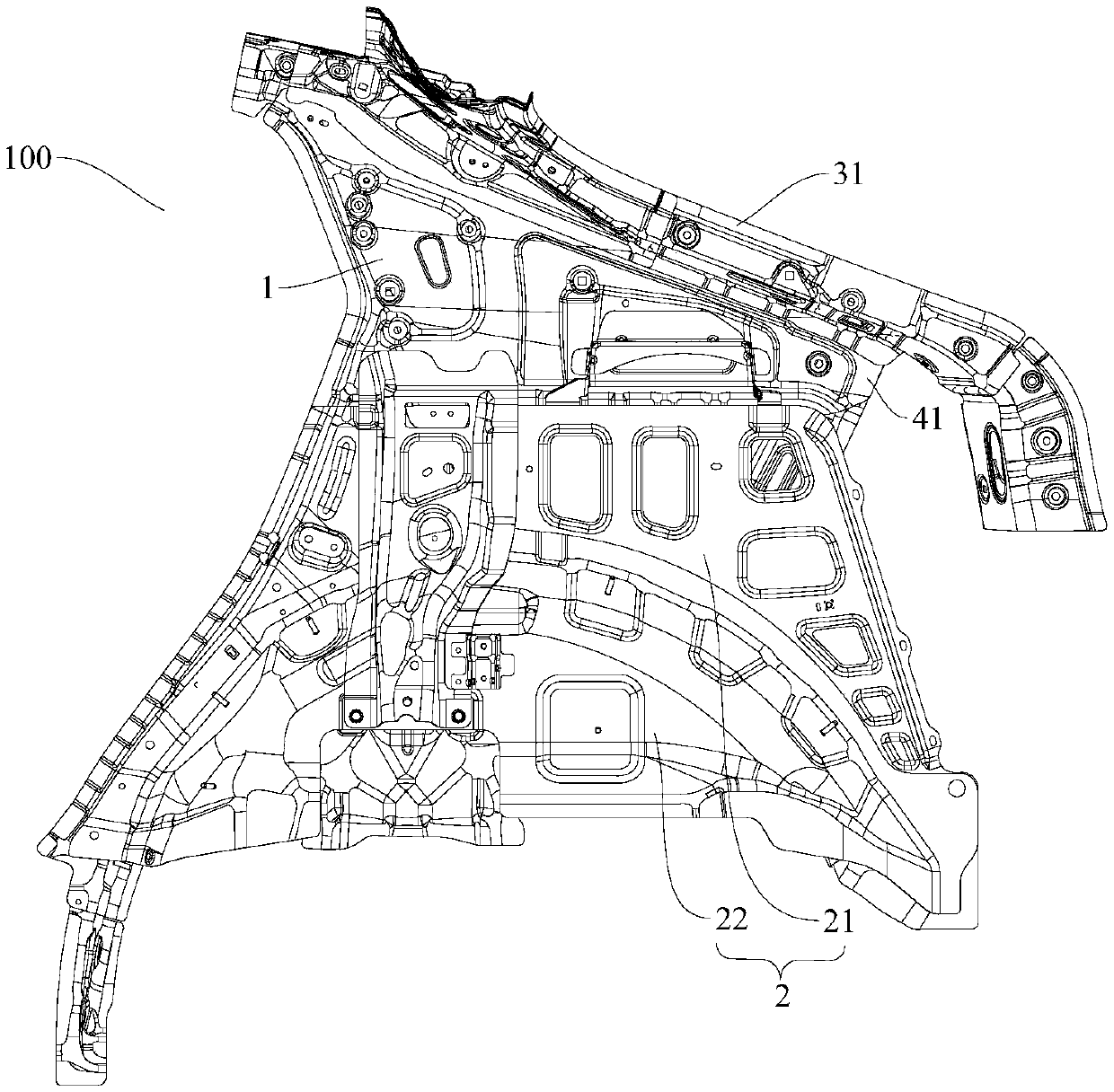

Side wall inner plate rear section assembly structure and vehicle with same

ActiveCN111098926AStructural advantageAvoid affecting workSuperstructure subunitsStructural engineeringAssembly structure

The invention provides a side wall inner plate rear section assembly structure and a vehicle with the side wall inner plate rear section assembly structure. The side wall inner plate rear section assembly structure comprises a C column inner plate and a C column reinforcing plate, wherein the C column inner plate is connected with a rear wheel cover assembly, the C column reinforcing plate is fixed to an outer side of the C column inner plate, the C column reinforcing plate is connected between a D column and the rear wheel cover assembly, and an annular reinforcing structure is formed betweenthe C column reinforcing plate and the D column and between the C column reinforcing plate and the rear wheel cover assembly. The side wall inner plate rear section assembly structure is advantaged in that the assembly force transmission effect from a lower portion of a vehicle body to an upper portion of the vehicle body can be effectively improved, the number of manufactured parts is small, thewhole vehicle mass can be reduced, and welding precision can be improved.

Owner:GREAT WALL MOTOR CO LTD

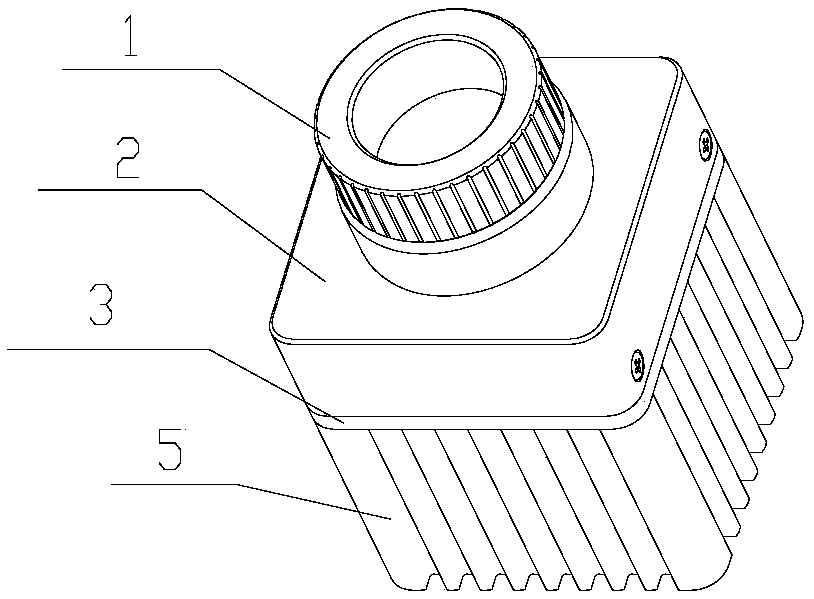

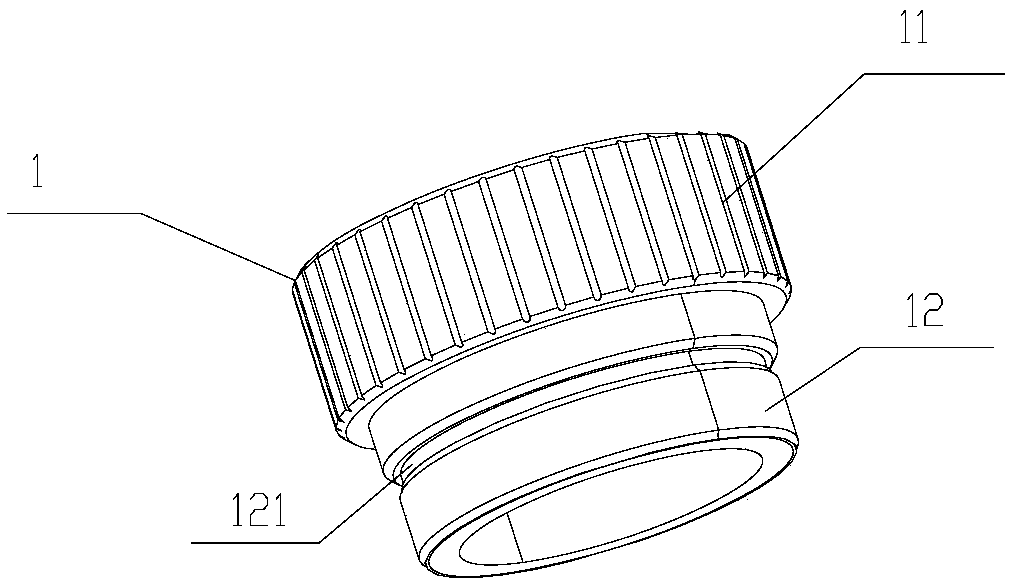

Heat dissipation type machine core shell structure

PendingCN109462972AStructural advantageCompact structureMountingsCooling/ventilation/heating modificationsCamera lensSoftware engineering

The invention provides a heat dissipation type machine core shell structure. The heat dissipation type machine core shell structure comprises a camera lens, an upper shell, a heat dissipation plate, aheating assembly and a lower shell; the upper side of the lower shell is fixedly connected to the heat dissipation plate; the heating assembly is fixedly arranged at the interior of the lower shell;a machine core circuit is integrated at the interior of the heating assembly; the top part of the heating assembly is in contact connection with the bottom of the heat dissipation plate; the upper shell is arranged above the heat dissipation plate; the upper side of the upper shell is in threaded connection with the camera lens; and a lens is installed at the interior of the camera lens. The heatdissipation type machine core shell structure is compact in structure, reasonable in design, simple to assemble and operate, and is strong in universality.

Owner:HARGLO APPLIED LASER TECH INST CO LTD

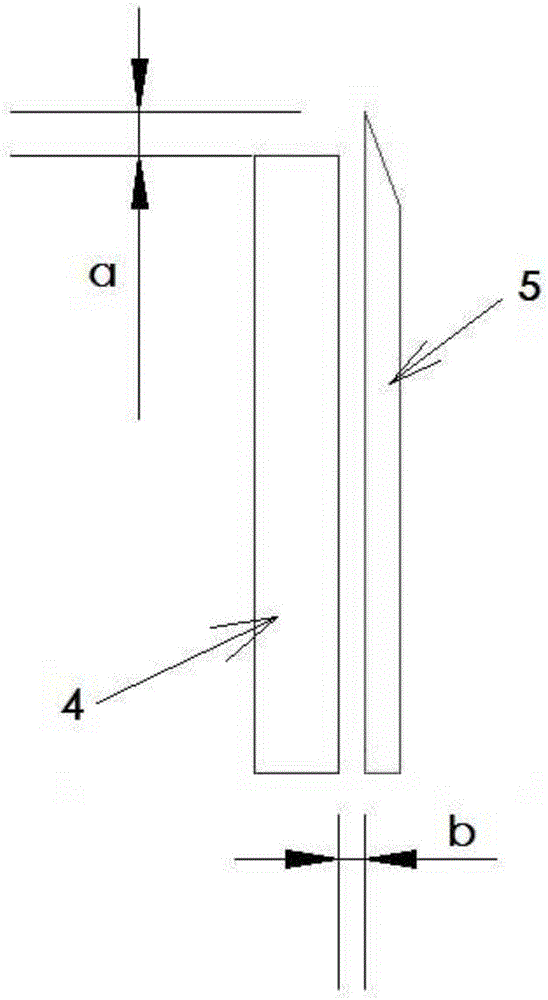

Die-cutting machining die structure

The invention provides a die-cutting machining die structure. A narrow-edge double-faced adhesive tape is attached to the lower bottom surface of a product; the product is attached to a die-cutting machining die; a stop strip is arranged along the side, which is required to be cut, of a frame of the die-cutting machining die; the stop strip and the inside position of the narrow-edge double-faced adhesive tape are positioned in the same horizontal line; the distance between the stop strip and the inside of the narrow-edge double-faced adhesive tape is 0.03 to 0.05 mm; the height of the stop strip is 0.03 to 0.05 mm lower than that of a cutting edge of the die. Due to the adoption of the technical scheme, the current common die structure of the die-cutting machining die structure provided by the invention is redesigned on the basis of not changing a material, and the same linear stop strip is added to the position which is 0.03 to 0.05 mm away from the narrow-edge double-faced adhesive tape, so that the product quality problems of glue overflowing and transformation after the narrow-edge double-faced adhesive tape is die-cut and stamped are avoided.

Owner:TIANJIN RIJIN TECH

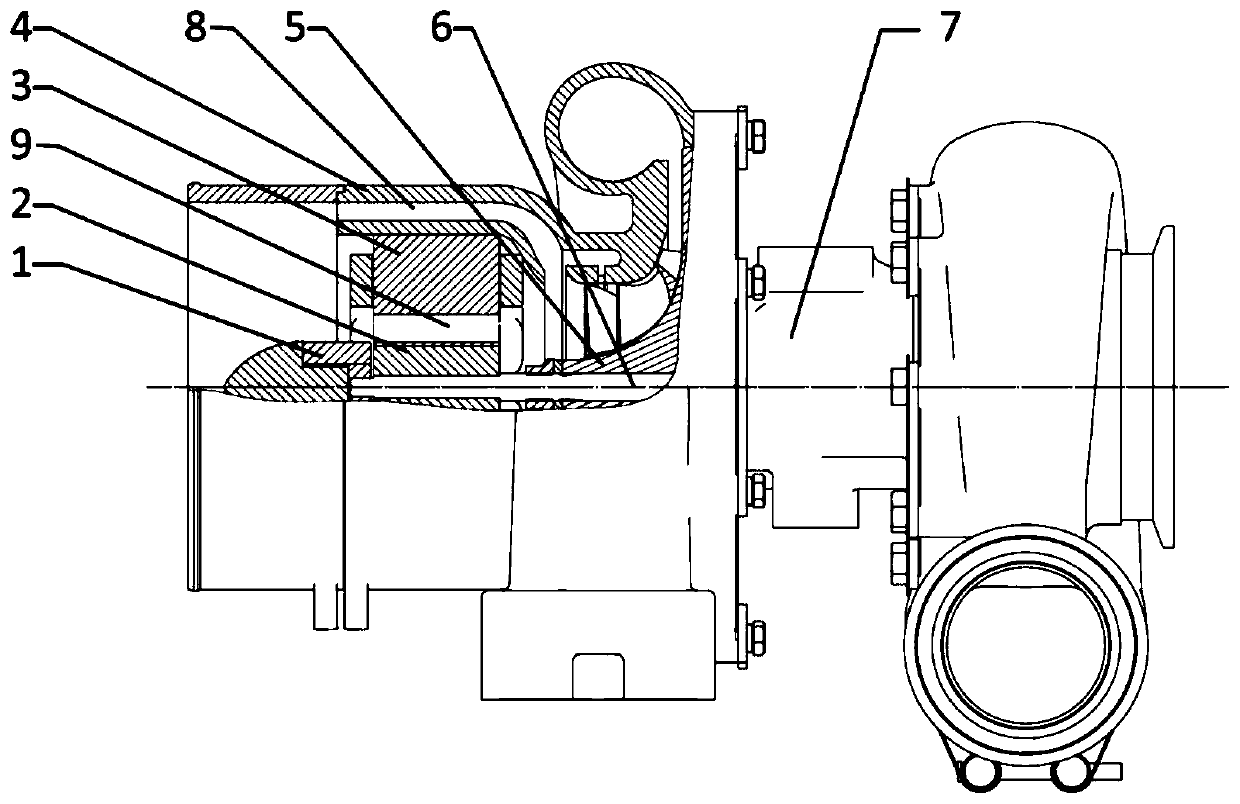

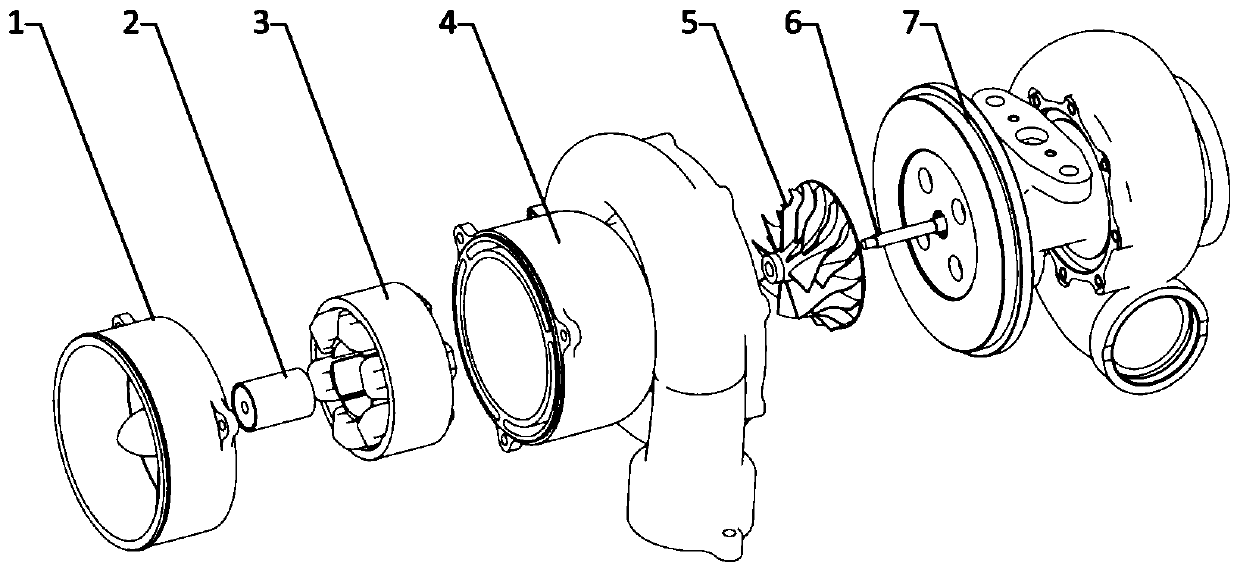

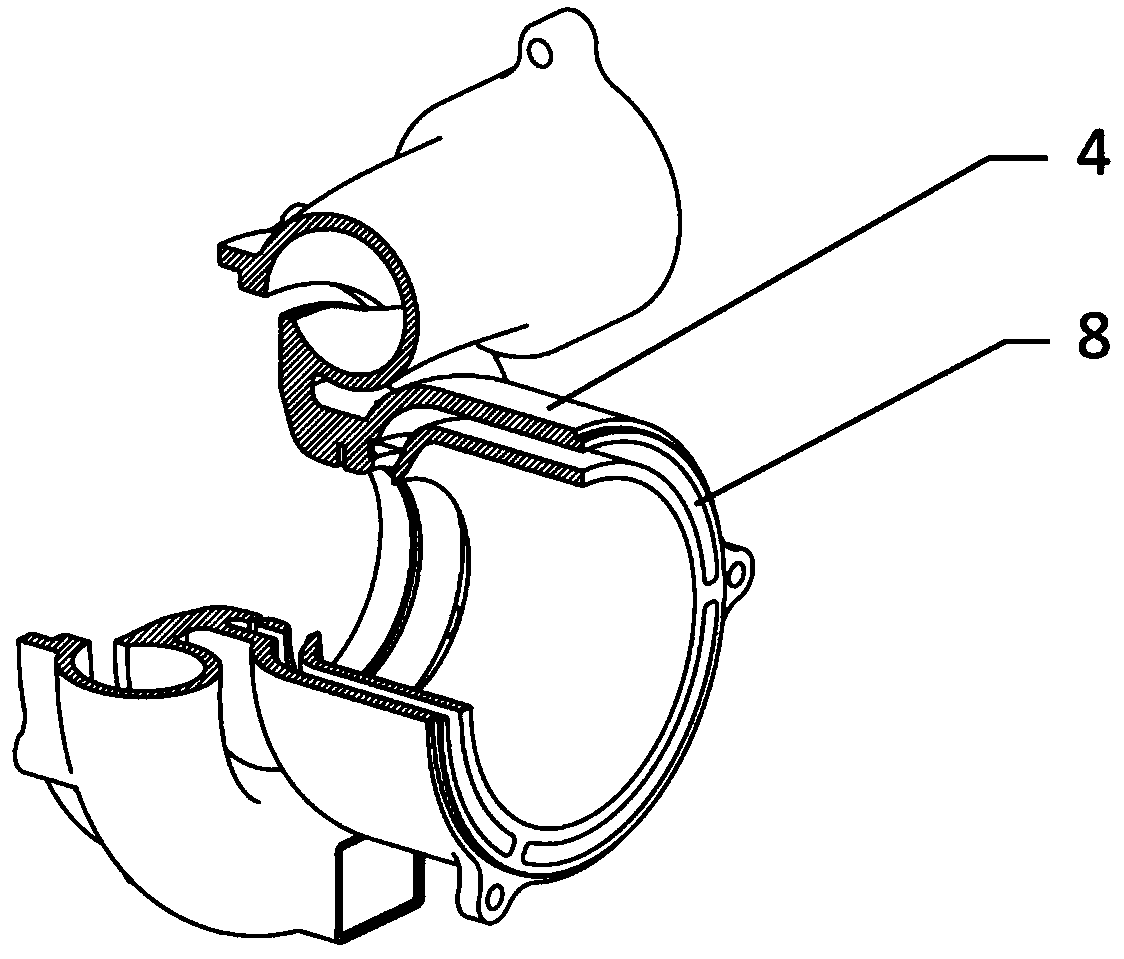

Electric auxiliary supercharger structure based on duct-air gap air intake

InactiveCN110985199AStructural advantageHigh working reliabilityCombustion enginesEngine componentsInterference fitTurbocharger

The invention provides an electric auxiliary turbocharger structure based on duct-air gap air intake. The structure mainly comprises a bearing seat, a motor with a large air gap, an air compressor volute with a duct, an air compressor impeller, an intermediate body and a turbine, the motor is mainly composed of a stator and a rotor, the bearing seat is connected with an inlet section of the air compressor volute, the front end of the motor rotor is provided with a bearing and matched with the bearing seat, the rear end of the motor rotor is coaxially connected with a rotating shaft of the turbocharger, and the motor stator is in interference fit with the inner wall of the inlet section of the air compressor volute. The motor is mounted in front of an inlet of an air compressor; the air inlet requirement of the air compressor is met through the duct and the air gap, the motor is far away from a turbine heat source, the heat dissipation condition is improved, the working reliability of the motor is improved, in addition, the motor can be additionally arranged on a traditional turbocharger only by changing the air compressor volute and a turbine rotating shaft, and the electric auxiliary turbocharger is formed. Airflow flowing through the duct and the air gap further solves the heat dissipation problem of the motor.

Owner:CHINA NORTH ENGINE INST TIANJIN

Novel valve guide pipe structure

InactiveCN108412571AStructural advantageImprove reliabilityMachines/enginesLift valveEngineeringHigh power density

The invention provides a novel valve guide pipe structure. The novel valve guide pipe structure comprises a valve guide pipe body, the middle of the valve guide pipe body is provided with a guide pipehole, the middle of the outer side of the valve guide pipe body is provided with an assembling rabbet, the position, on the upper side of the assembling rabbet, of the outer side of the valve guide pipe body is circumferentially provided with a plurality of stepped bosses, and the assembling rabbet is provided with a groove inwards in the circumferential direction. The novel valve guide pipe structure has the beneficial effects of being suitable for an air cylinder cover compact in structure, high in reliability and capable of being popularized to other high power density engine air cylindercovers.

Owner:CHINA NORTH ENGINE INST TIANJIN

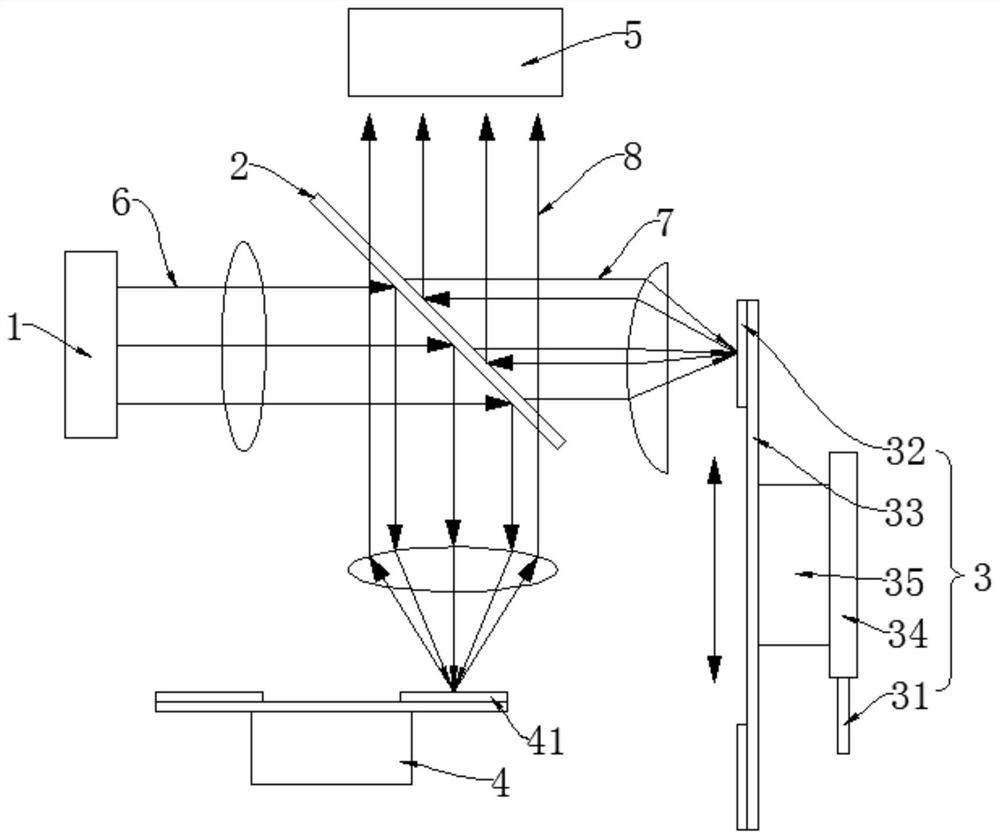

Laser light source structure, projection optical system, and color temperature adjusting method of system

ActiveCN112631054AStructural advantageColor temperature adjustableProjectorsMountingsProjection opticsLight beam

The invention provides a laser light source structure, a projection optical system, and a color temperature adjusting method of the system. The laser light source structure comprises a light source shell, and an excitation light source, a light splitting and combining element, a wavelength conversion device, a blue light reversing device and an optical machine which are arranged in the light source shell; and at least one of the light splitting and combining element, the wavelength conversion device and the blue light reversing device is of a position-adjustable structure, so that the energy ratio of the excited light beam to the reversing exciting light beam is adjustable during light combination. The ratio of the exciting light beam guided to the wavelength conversion device to the exciting light beam guided to the blue light reversing device is adjustable, so that the ratio of the generated excited light beam to the reversing exciting light beam is adjustable, namely, the energy ratio of the excited light beam for light combination to the reversing exciting light beam is adjustable, therefore, the color temperature of the light source is adjustable.

Owner:WUXI SEEMILE LASER DISPLAY TECH

Engine hood structure and vehicle with same

ActiveCN111845953AStructural advantageSimple structurePedestrian/occupant safety arrangementSuperstructure subunitsRotational axisEngineering

The invention discloses an engine hood structure and a vehicle with the same. The engine hood structure comprises an engine hood body, a hinge mechanism and a jacking device. The rear portion of the engine hood body is rotatably fixed to a vehicle body of a vehicle through the hinge mechanism. The hinge mechanism comprises a first support and a second support. The first support is connected with the engine hood body; the second support is rotatably connected with a vehicle body, the first support and the second support are connected with a rotating shaft and a positioning pin, the jacking device is suitable for pushing the first support upwards so that the rear portion of the engine hood body can rotate upwards relative to the second support along with the first support and damage the positioning pin, and the first support is provided with an abutting and pressing plate. According to the engine hood structure, when a pedestrian directly collides with a vehicle or is about to directly collide with the vehicle, the jacking device can jack the first support so that the rear portion of the engine hood body can tilt upwards, pedestrian safety can be protected, and meanwhile the engine hood structure is simple in structure and convenient to arrange.

Owner:GREAT WALL MOTOR CO LTD

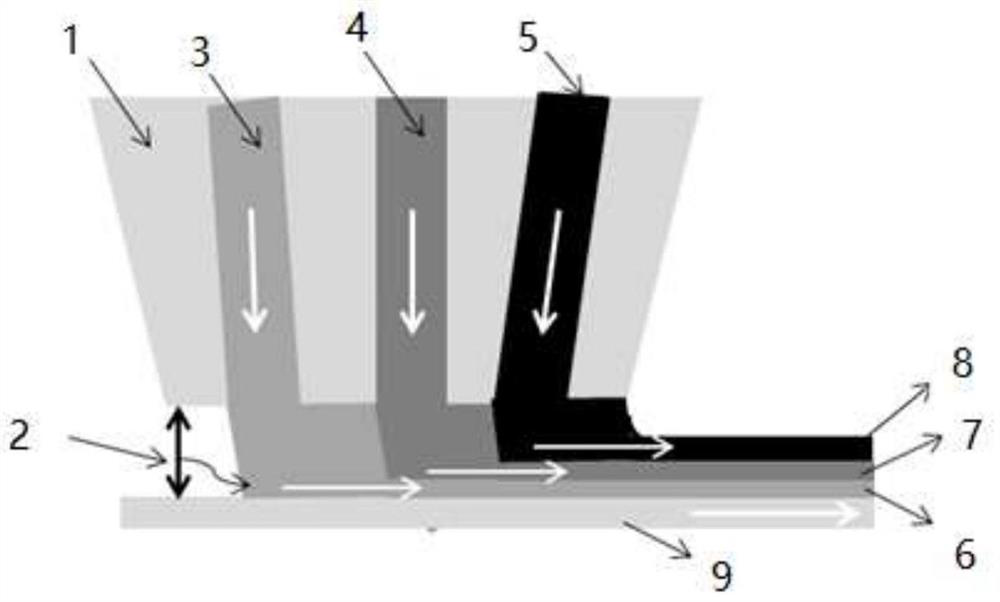

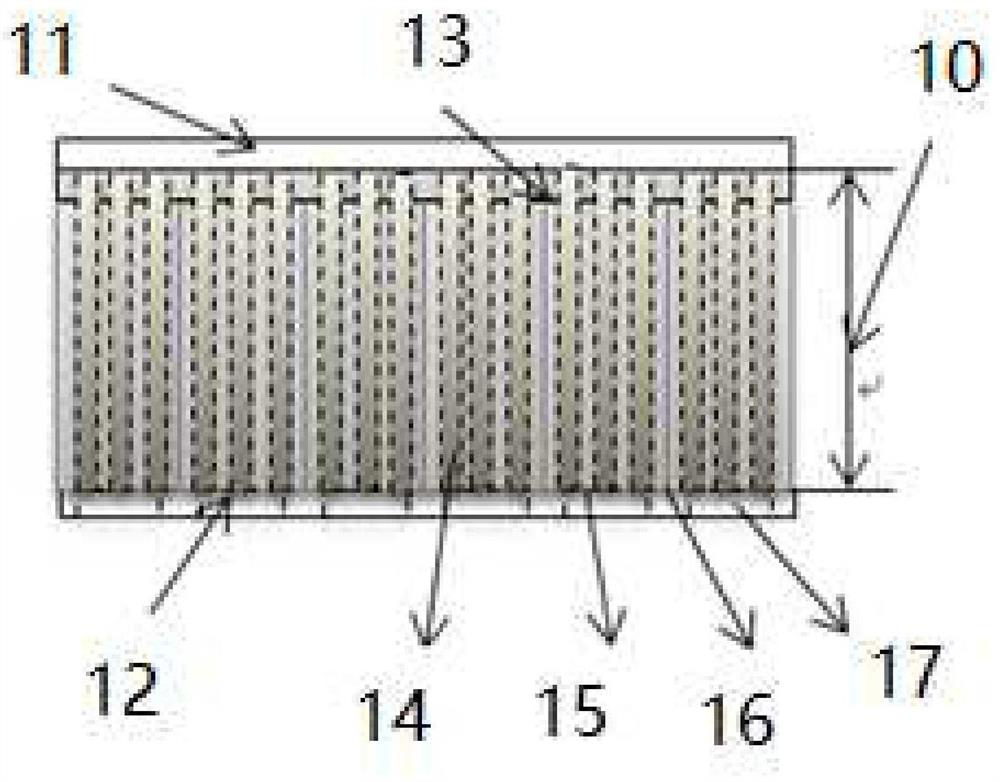

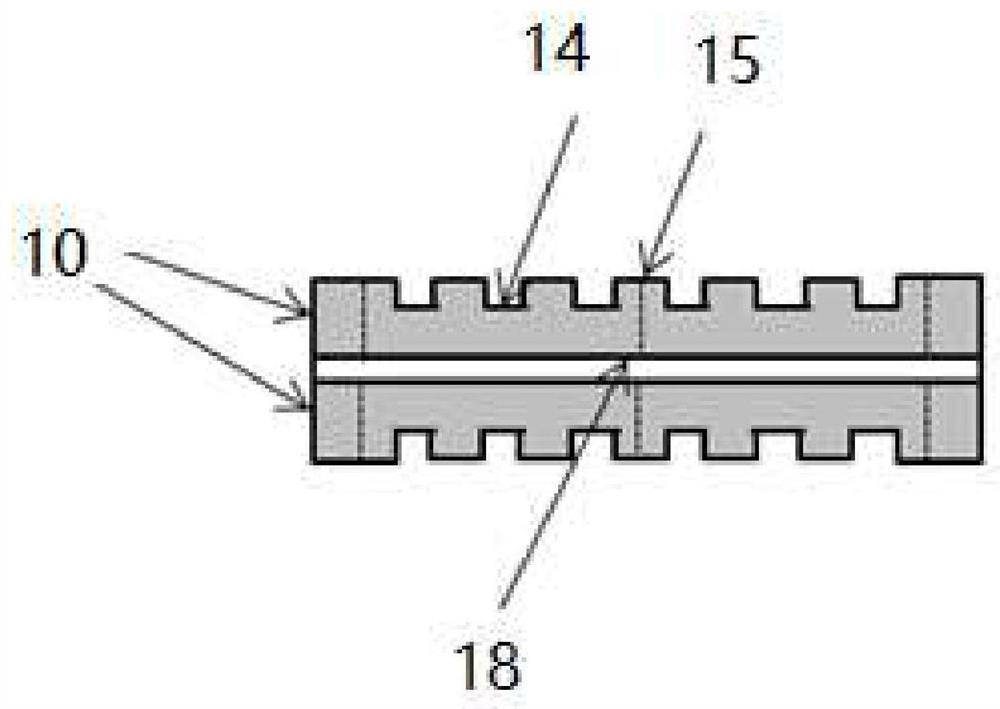

Thick electrode structure of lithium ion battery

PendingCN113745450AStructural advantageAdvantages of thick electrode structureElectrode carriers/collectorsSecondary cellsLithium-ion batteryBattery cell

The invention provides a thick electrode structure of a lithium ion battery. The thick electrode structure comprises a coating machine die head, and a gap between a coating die head lip and a current collector is formed between the coating machine die head and a negative current collector; the coating machine die head is provided with a plurality of coating machine die head cavities, and the cavities are not communicated with one another; negative electrode slurry with different components is extruded from a slit of the coating machine die head lip, so that negative electrode slurry with different components can be formed, the current collector is wet-coated with the negative electrode slurry with different components at the same time; two sides of a dressing layer of a rolled electrode roll are respectively provided with a non-tab side blank space and a tab side blank space, and electrode thickness direction grooves are arranged along an electrode thickness direction; groove gaps are formed between the electrode thickness direction grooves, and the electrode thickness direction grooves are formed in the surface of each electrode piece. According to the thick electrode structure of the lithium ion battery, the infiltration of electrolyte from the surface of the dressing layer to the current collector is facilitated, the binding power between the dressing layer and the current collector and the rate and cycle performance of the thick electrode battery are improved, and the lithium precipitation risk under high-rate charge and discharge is reduced.

Owner:TIANJIN ENERGIES

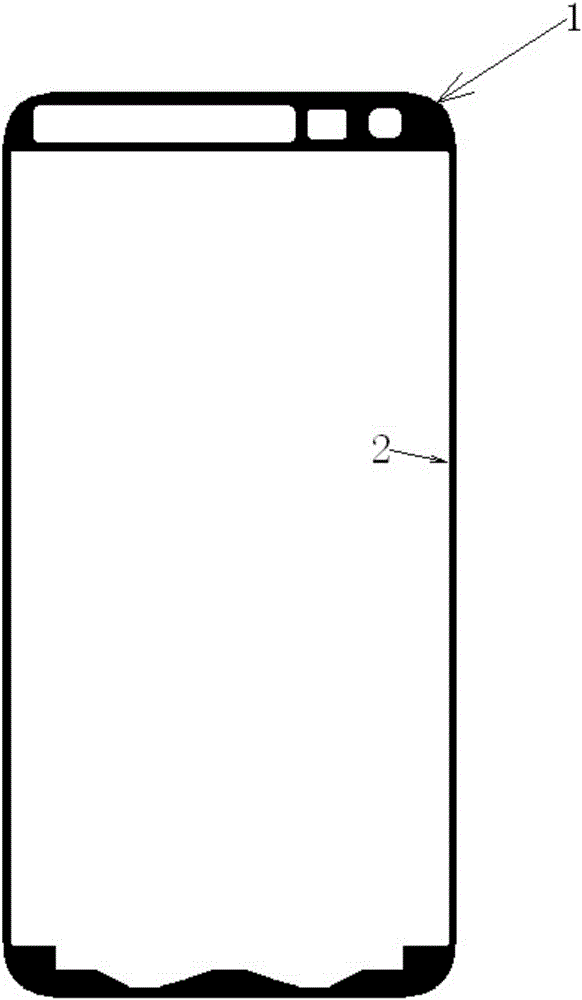

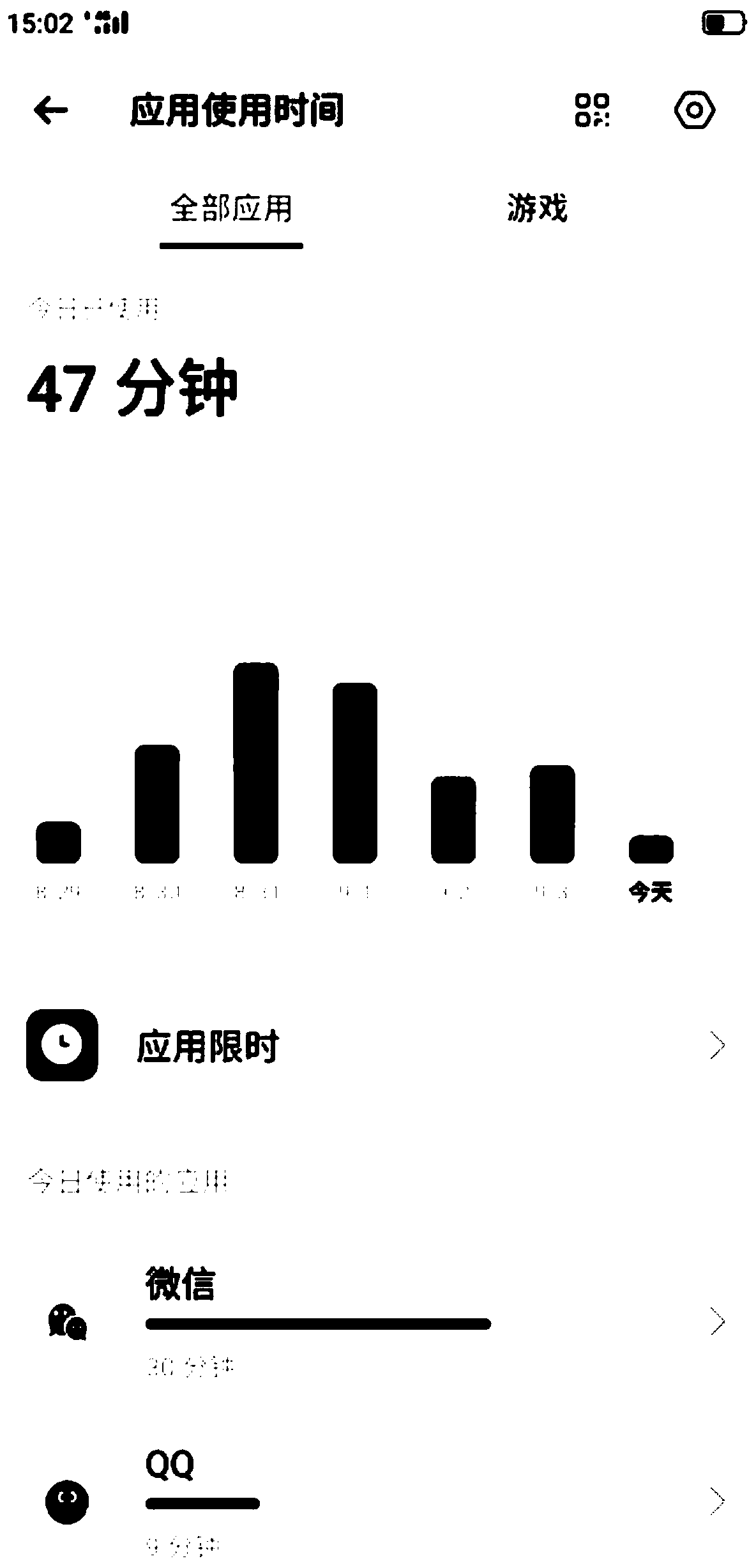

Application use time segment statistics method and terminal

PendingCN110618913AGuaranteed accuracyImprove accuracyDatabase updatingHardware monitoringTime informationTime segment

The invention discloses an application use time segment statistics method and a terminal, which are used for providing detailed use conditions of various applications on a mobile terminal and improving the perception experience of a user on application use. The method comprises the steps that the state of an application is monitored in real time through a monitoring program; when it is monitored that the state of the application jumps to the foreground from the background, the current system moment serves as the starting moment of using the application; in the process that the application is in the foreground, the use time information of the application in a database is periodically updated, and the use time information comprises the use date, the use time in a set time period and the total use time; and when it is monitored that the state of the application skips from the foreground to the background, the current system moment serves as an end moment of using the application, and theuse time information of the application in a database is updated.

Owner:QINGDAO HISENSE MOBILE COMM TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com