Floor beam structure applied to vehicle

A floor beam and floor technology, applied in the field of vehicles, can solve problems such as squeezed battery installation space, weak floor strength, battery fire, etc., to achieve the effects of improving battery life, dispersing impact force, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

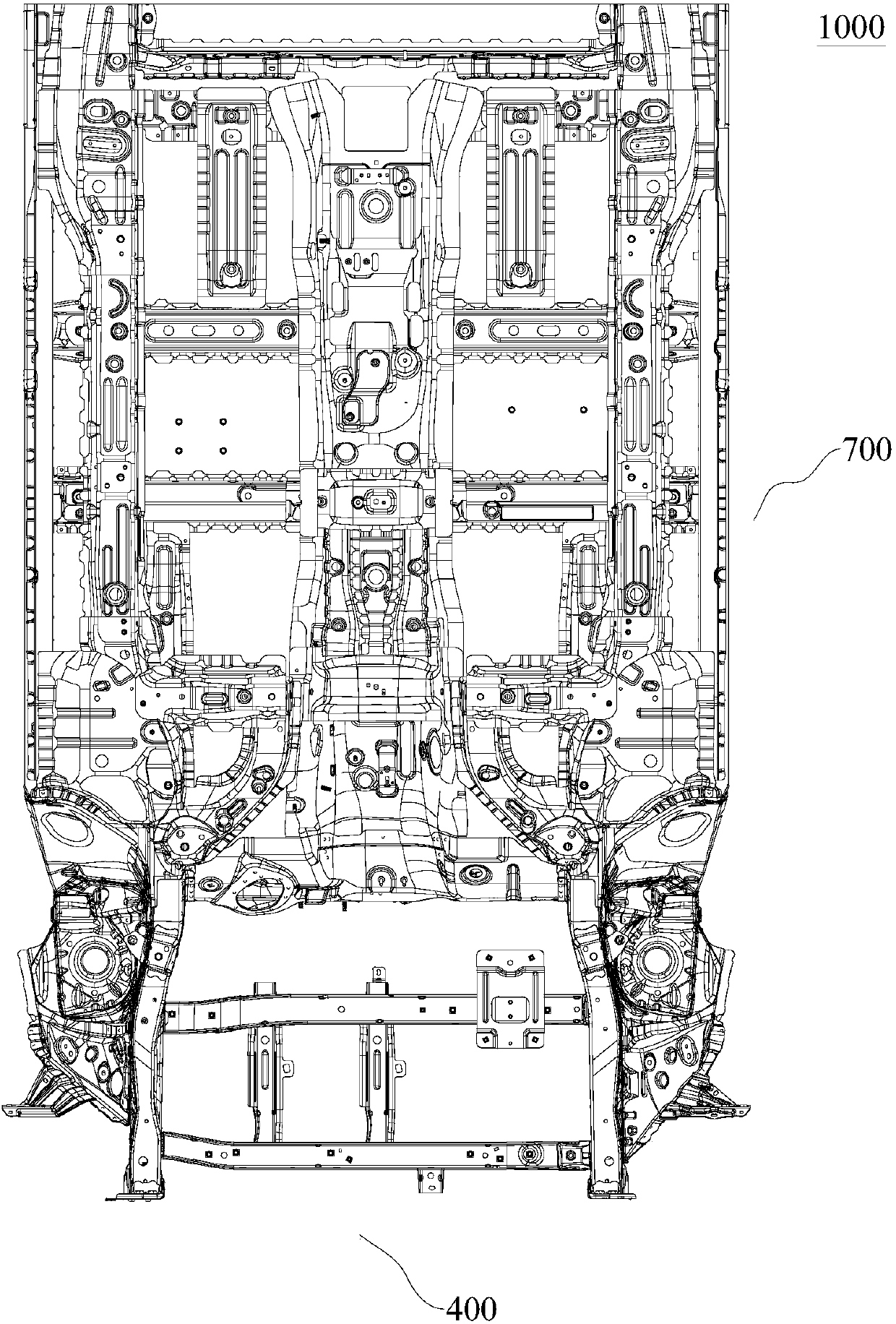

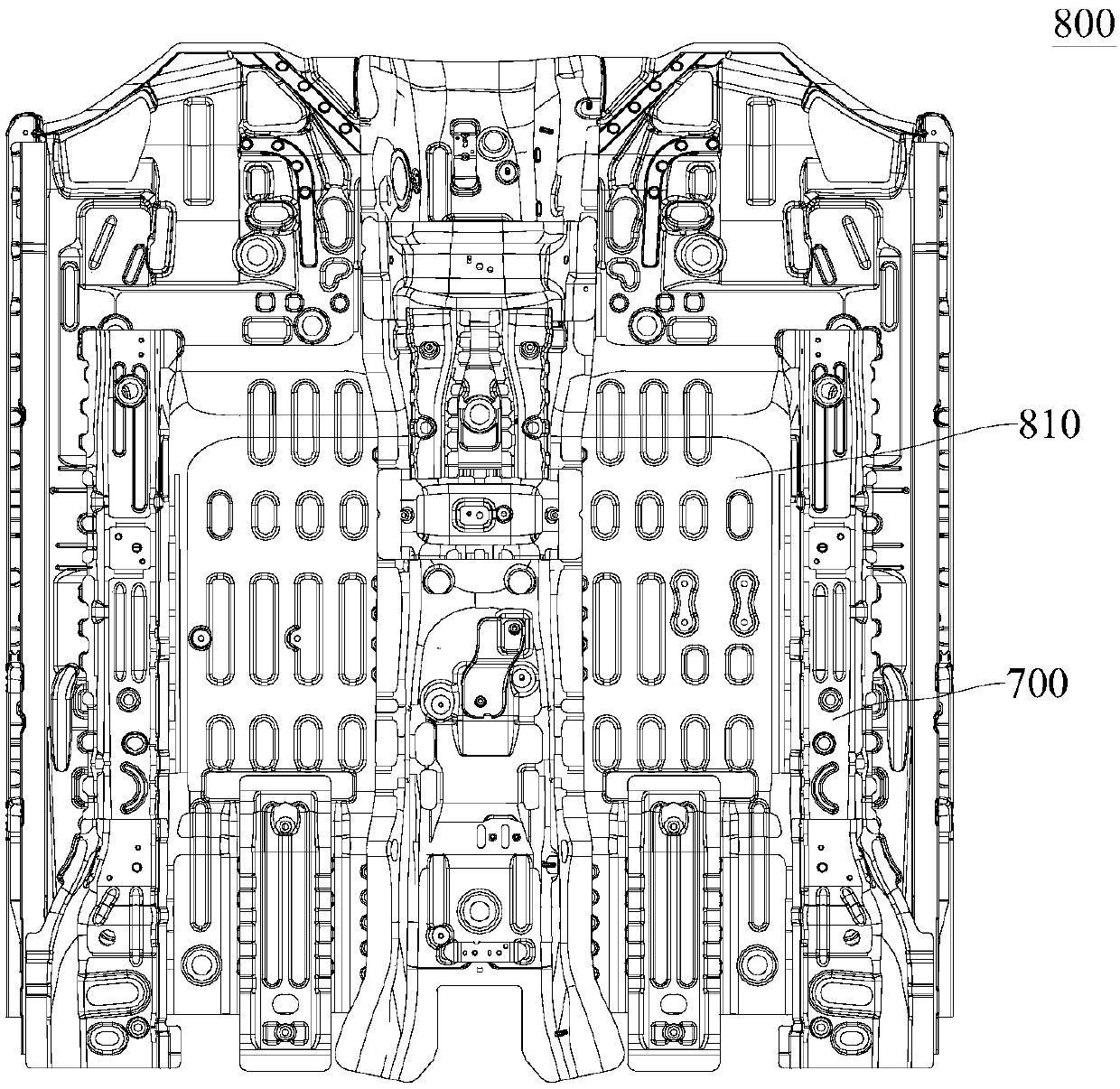

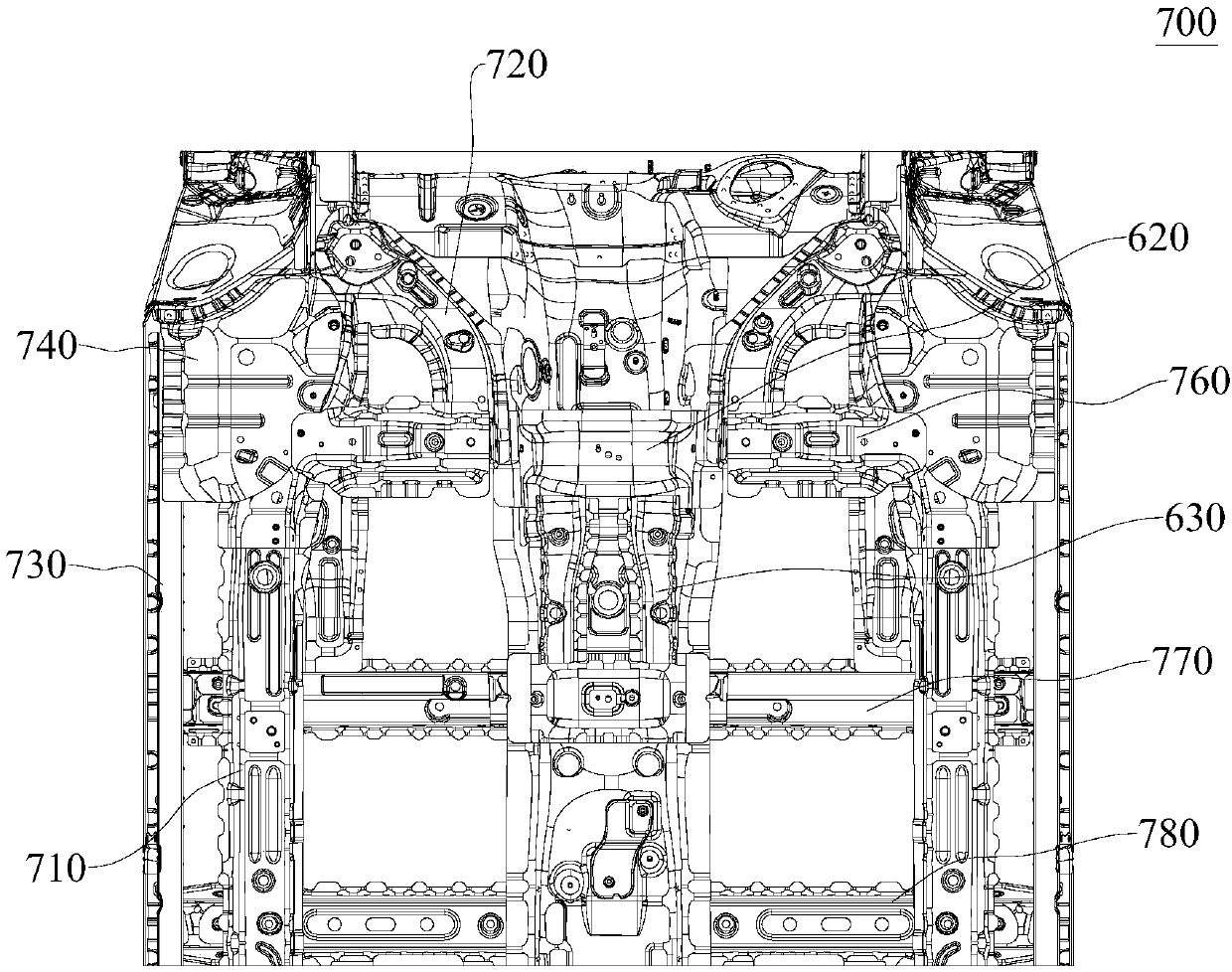

[0056] Combine below Figure 1 to Figure 23The floor assembly 1000 for a vehicle according to the embodiment of the present invention will be described in detail.

[0057] Such as Figure 1 to Figure 3 As shown, the floor assembly 1000 for a vehicle according to the embodiment of the present invention may include a power assembly 900 and a floor assembly 800 , wherein the power assembly 900 further includes a cabin installation frame structure 400 and a plurality of functional modules.

[0058] Such as Figure 9-Figure 12 As shown, the cabin installation frame structure 400 includes a crossbeam 410 and a plurality of connecting longitudinal beams 420, the crossbeam 410 includes a front crossbeam 411 and a longitudinal crossbeam 410, the front crossbeam 411 and the rear crossbeam 412 are spaced apart from f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com