Thick electrode structure of lithium ion battery

A lithium-ion battery and electrode structure technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, structural parts, etc., can solve the problem of uneven distribution of conductive agents and pores, difficulty in infiltration of thick electrode electrolytes, and changes in the tortuosity of pole pieces. It can improve the rate and cycle performance, facilitate capacity development, and reduce EIS.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

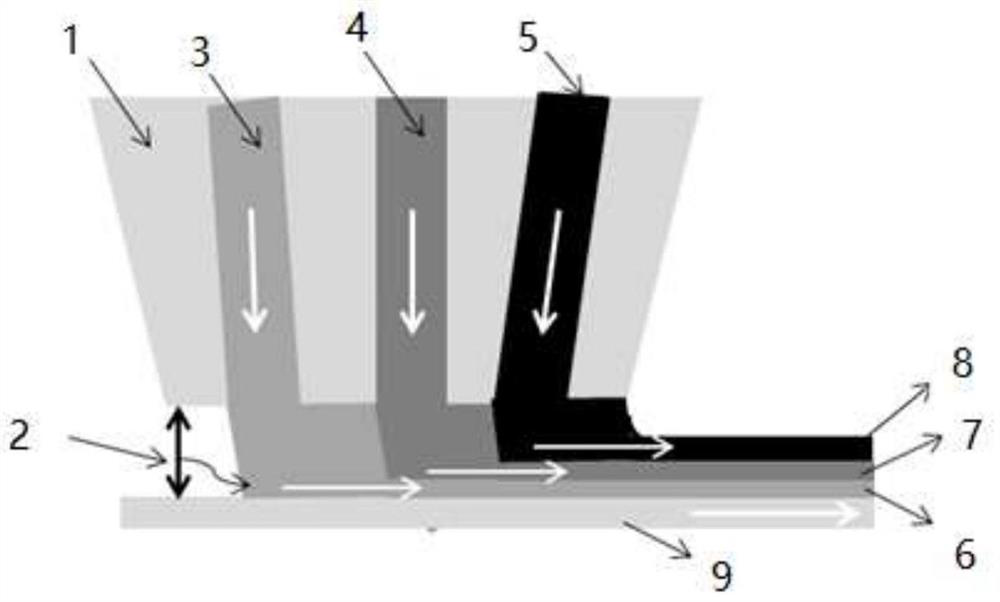

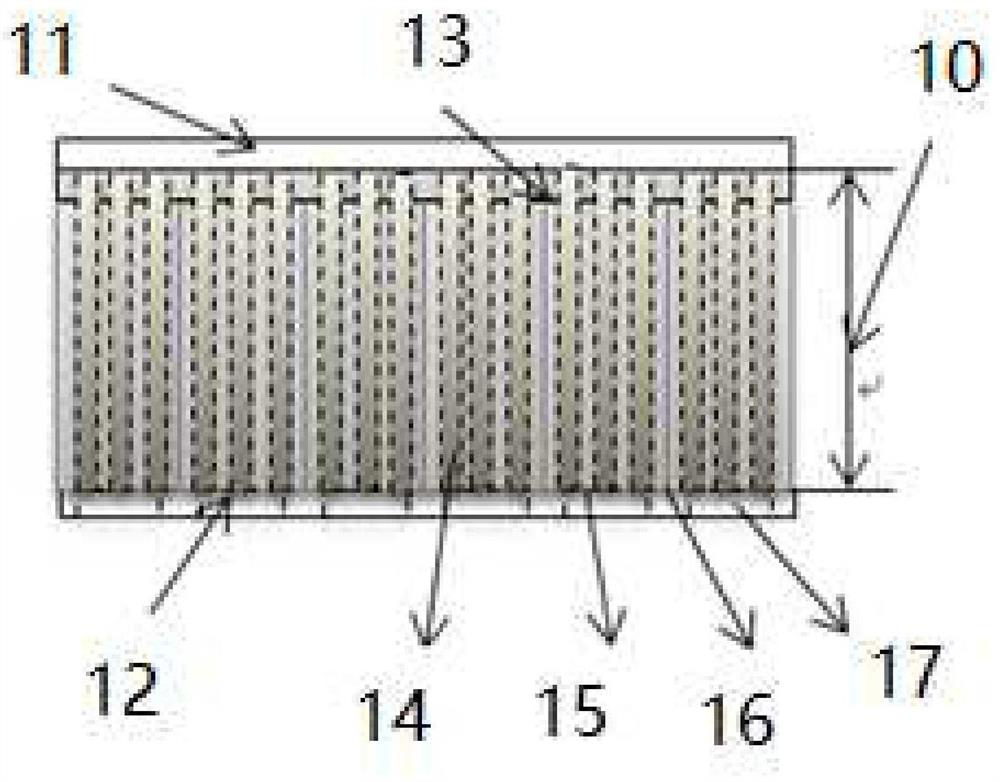

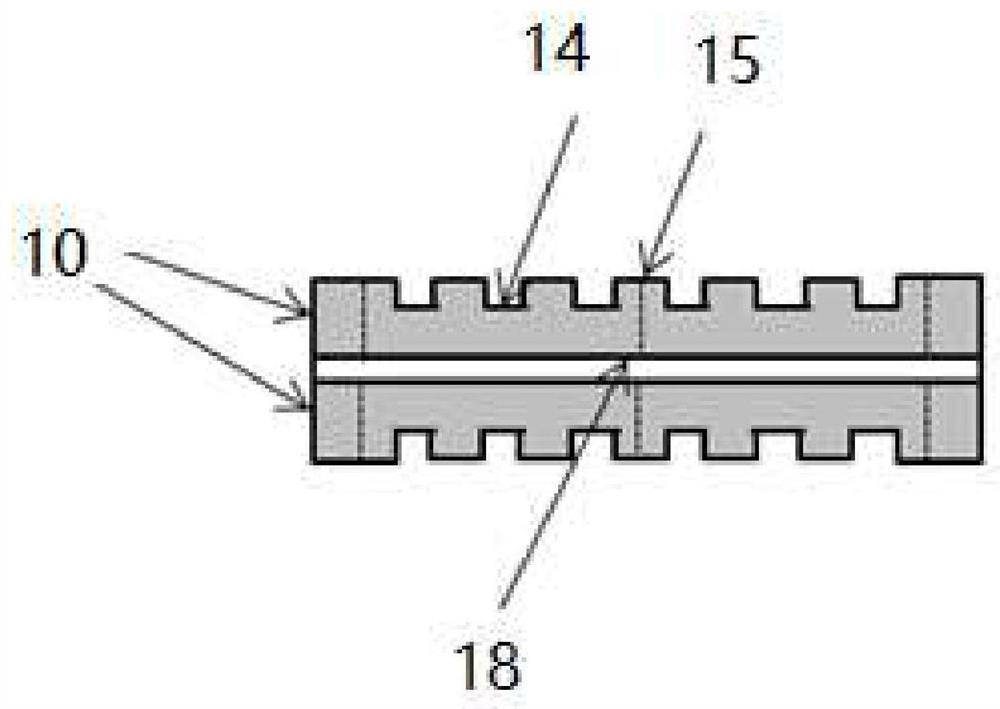

[0042] The negative electrode current collector 9 (the copper foil thickness is 8 um) is rolled, and the strip is formed, and the coating machine die 1 lip and the negative electrode current collector 9 are formed between the coating machine dielectric 9. The gap 2 (about 200um) between the mouth and the current body, three different components of the negative slurry from three cavities: No. 1 coating machine die cavity 3, No. 2 coating machine die cavity 4, three Number coater die cavity 5 lip extruded, the gap 2 between the coated machine dielectric slurry, the three-layer wet coating, three-stage porosity and The wet coating of the pore structure facilitates the infiltration of the electrolyte from the surface of the dressing layer 10 to the direction fluid 18, and improves the adhesion between the dressing layer 10 and the current collector 18, thereby improving the magnification and cycle performance of the thick electrode battery. Reduced lithium lithium risks under high-mag...

Embodiment 2

[0047] The negative electrode current collector 9 (the copper foil thickness is 8 um) is rolled, and the strip is formed, and the coating machine die 1 lip and the negative electrode current collector 9 are formed between the coating machine dielectric 9. The gap 2 (about 200um) between the mouth and the current body, three different components of the negative slurry from three cavities: No. 1 coating machine die cavity 3, No. 2 coating machine die cavity 4, three Number coater die cavity 5 lip extruded, the gap 2 between the coated machine dielectric slurry, the three-layer wet coating, three-stage porosity and The wet coating of the pore structure facilitates the infiltration of the electrolyte from the surface of the dressing layer 10 to the direction fluid 18, and improves the adhesion between the dressing layer 10 and the current collector 18, thereby improving the magnification and cycle performance of the thick electrode battery. Reduced lithium lithium risks under high-mag...

Embodiment 3

[0052] 9 the negative electrode collector (copper foil having a thickness of 8um) on the volume, threading, extruded backing roll coater, a die coater so that the lip 1 and the negative electrode collector is formed between the coater die lip 9 between the port and the collector slit (about 200um), three kinds of negative electrode slurry different components from three cavities: One coating machine body 3 of the die cavity, the die coater II cavities 4, three No. coater die cavity after extrusion lip 5, the gap between the coater die lip 2 and the current collector, to achieve three-wet coating, the porosity of three different components of the slurry and the negative electrode the wet coating pore structure facilitates infiltration of the electrolyte layer 10 from the surface of the dressing to the direction of the current collector 18, 10 and the dressing layer improves adhesion of the current collector 18, thereby improving the rate and cycle characteristics of the thick elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com