Patents

Literature

31results about How to "Reduce the risk of lithium analysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

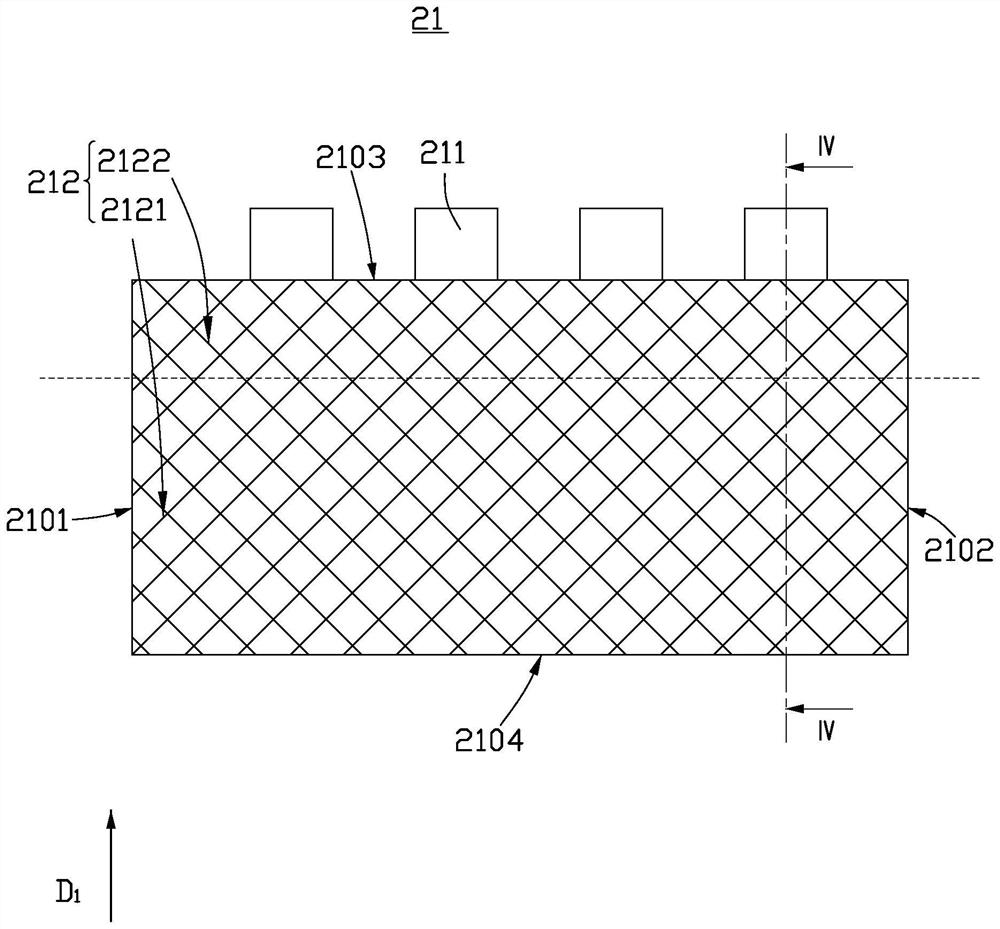

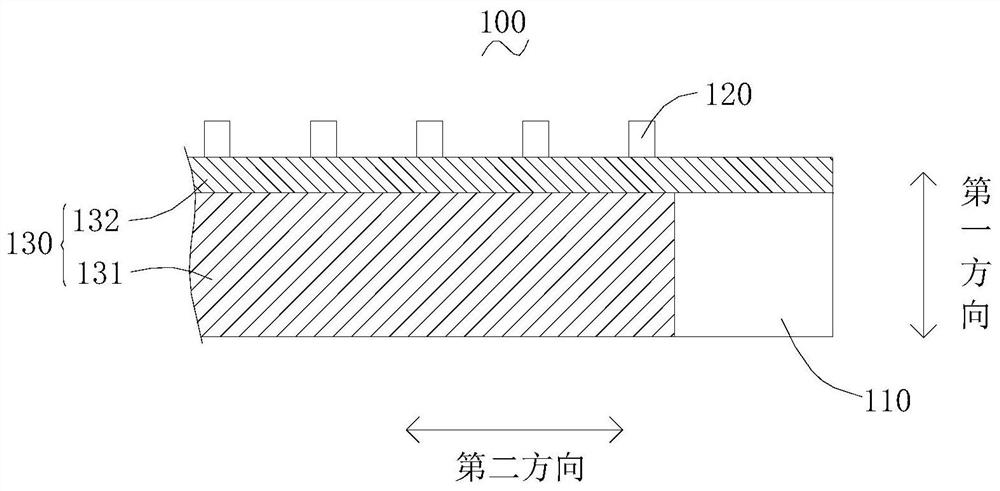

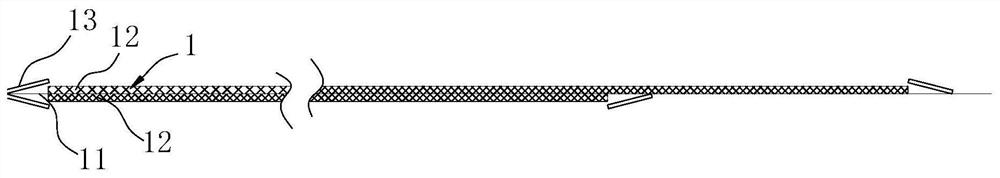

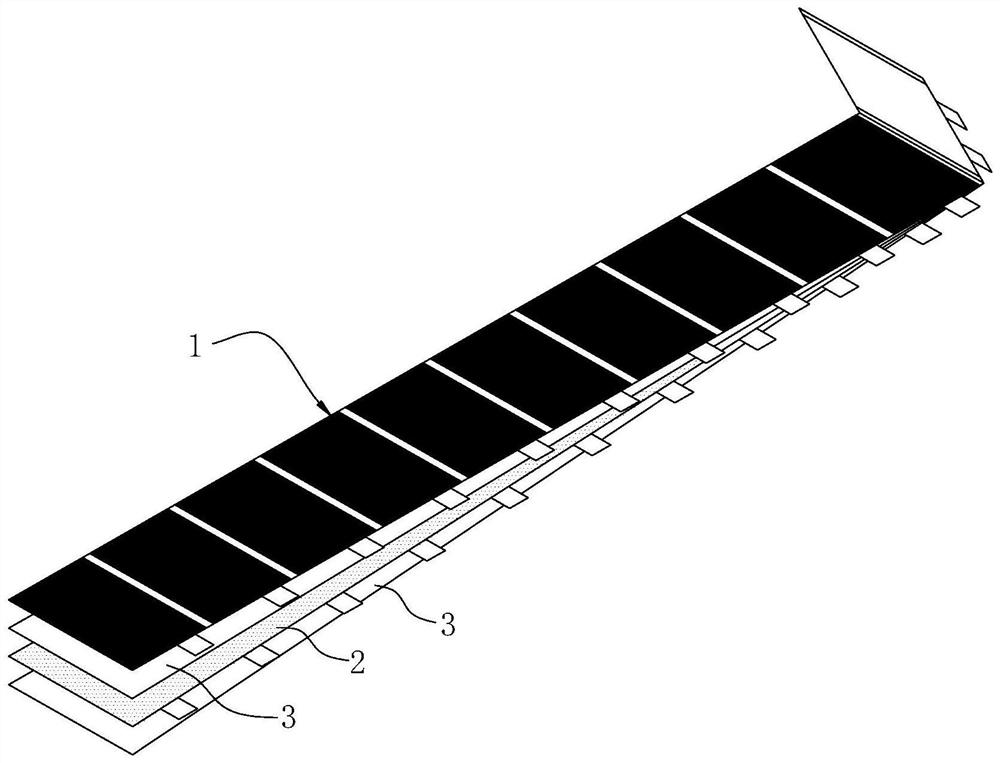

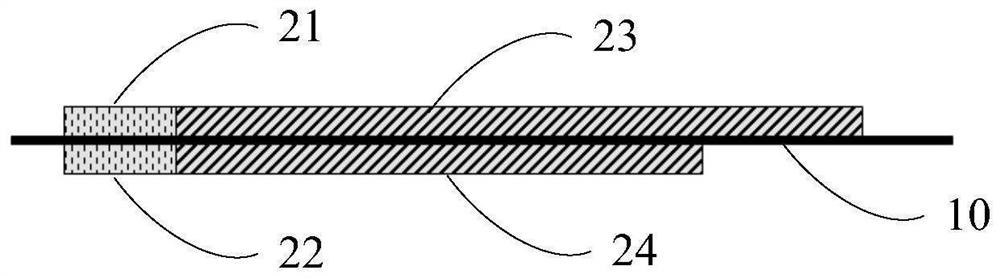

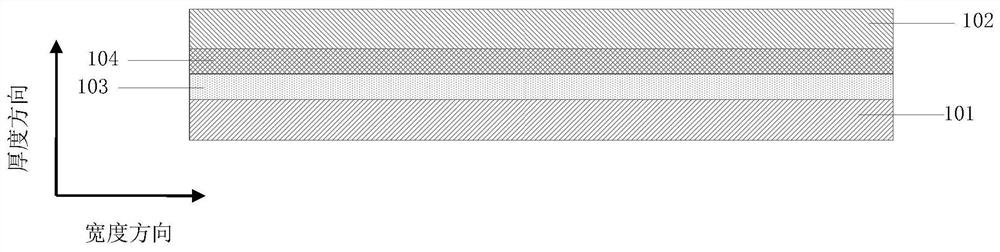

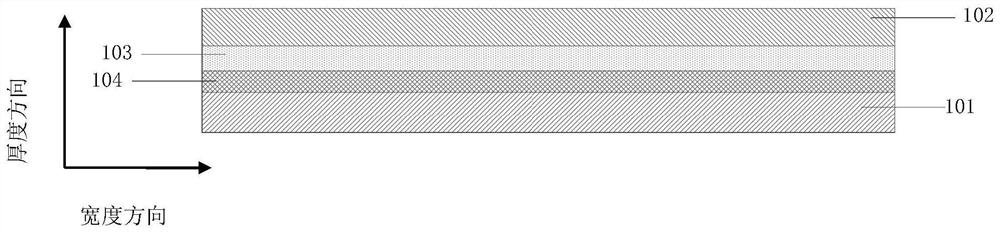

Electrode plate and manufacturing method thereof, and electrochemical device

InactiveCN110534701AReduce the risk of lithium analysisImprove securitySecondary cellsNegative electrodesPower performanceCurrent collector

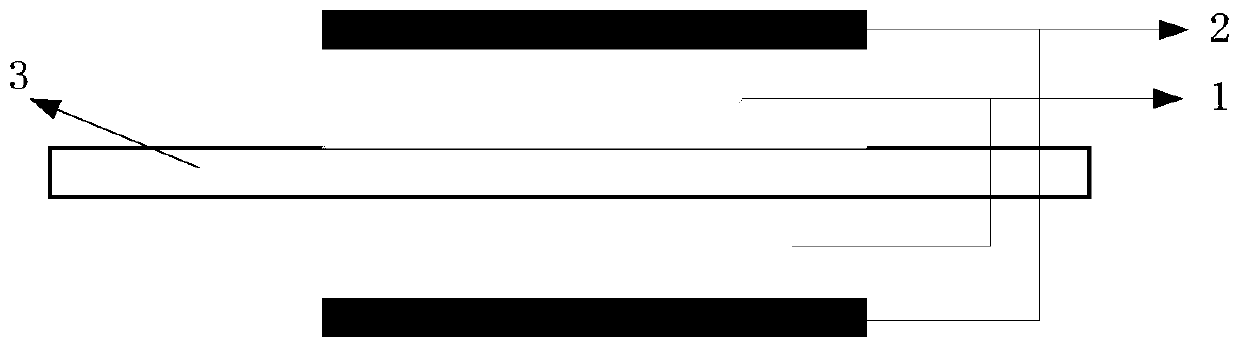

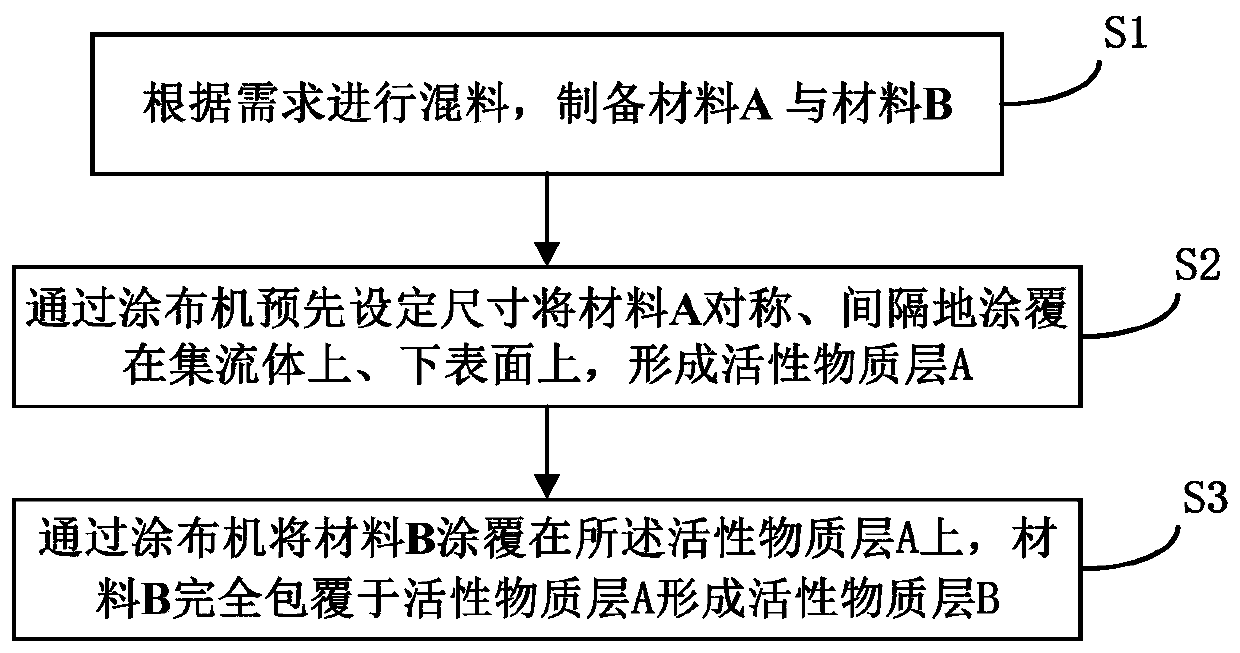

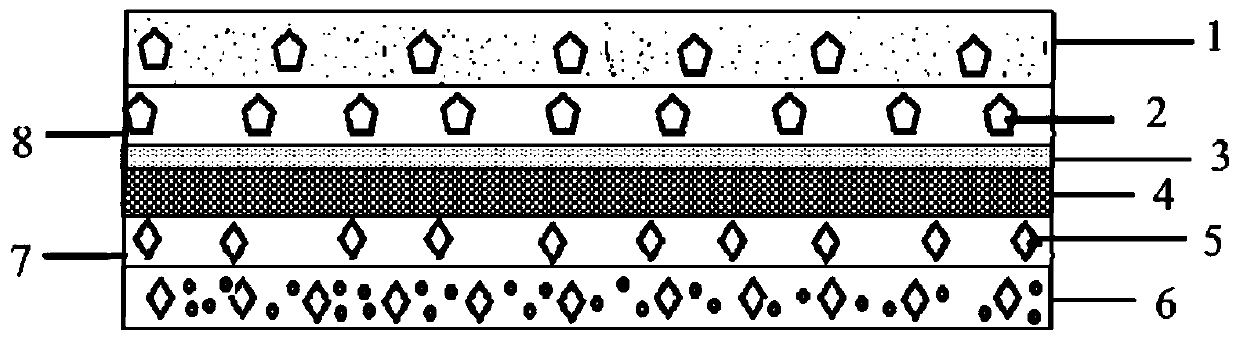

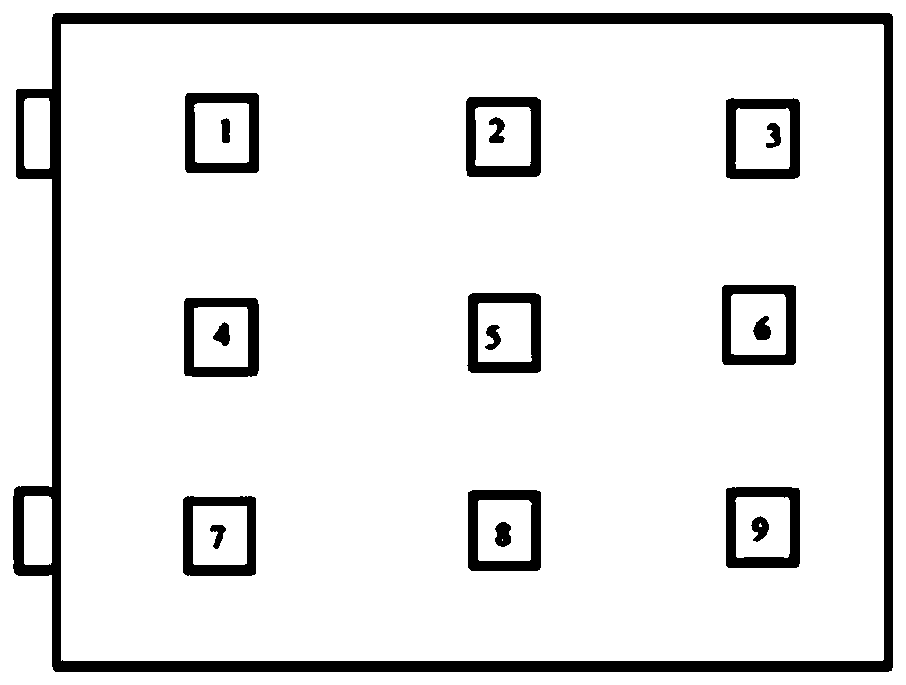

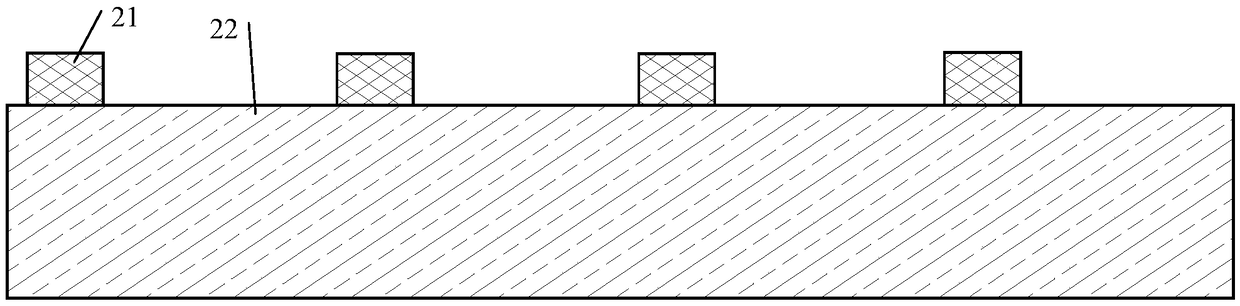

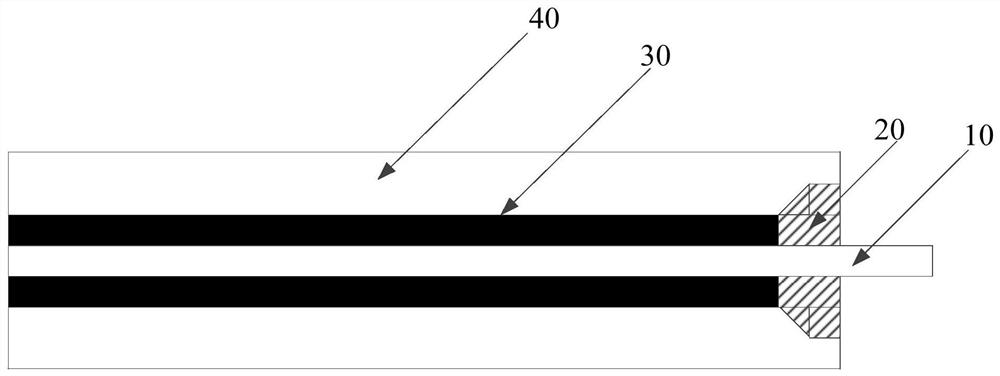

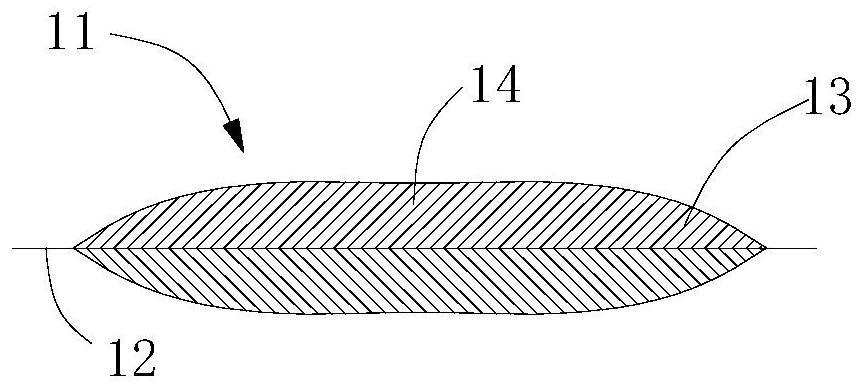

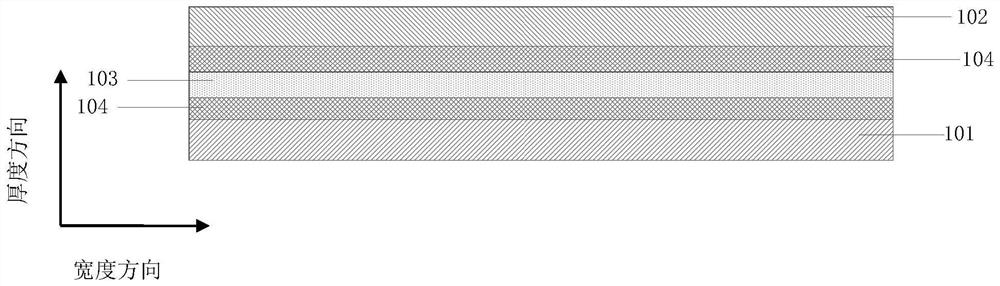

The invention discloses an electrode plate and a manufacturing method thereof, and an electrochemical device. The electrode plate comprises a current collector and further comprises active substance layers symmetrically arranged on the upper surface and the lower surface of the current collector respectively, and second active material layers respectively arranged on the first active material layers; and the current collector at the edges of the second active material layers forms a tab. By changing a traditional coating mode, two materials with different properties are coated on the current collector in a layered manner, so that the surface layer of the current collector has the capability of quickly removing and embedding lithium ions, the risk of lithium precipitation on the surface ofa pole piece is reduced, the safety performance of the battery is improved, the service life of the battery is prolonged, and the power performance of the battery is also improved.

Owner:RISESUN MENGGULI NEW ENERGY SCIENCE & TECHNOLOGY CO LTD

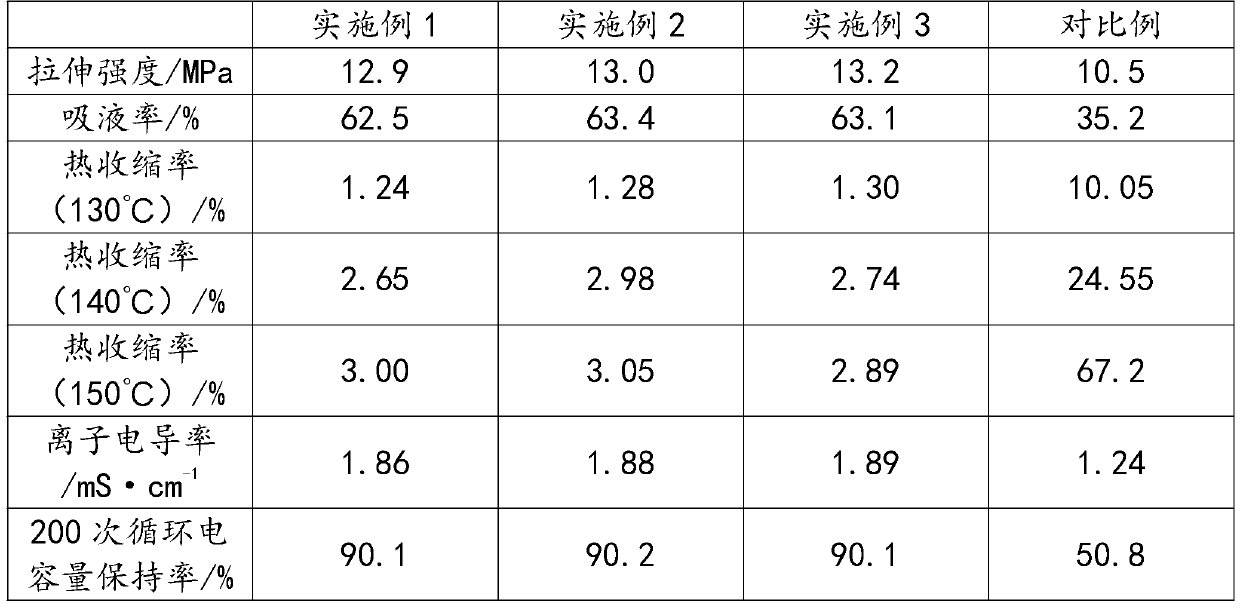

Water-based high-viscosity glued diaphragm, preparation method thereof, and application of diaphragm in battery

PendingCN111129406AImprove adhesionEasy to packCell component detailsPhysical chemistryPolymer chemistry

The invention relates to a water-based high-viscosity glued diaphragm, a preparation method thereof and an application of the diaphragm in a battery. The water-based high-viscosity glued diaphragm comprises a base membrane, and a positive polymer layer and a negative polymer layer which are respectively arranged at two sides of the base membrane, wherein a positive ceramic layer is arranged between the base membrane and the positive polymer layer, and / or a negative ceramic layer is arranged between the base membrane and the negative polymer layer; a binder in the positive polymer layer and a battery positive electrode piece is the same type of binder, and a binder in the negative polymer layer and a battery negative electrode piece is the same type of binder. The diaphragm disclosed by theinvention has the characteristics of small coating amount of coatings on two sides, light and thin coatings, high cohesiveness and the like, so the shaping effect of a battery cell is optimal, and module boxing is facilitated; meanwhile, a module limiting effect is achieved. Moreover, the risk of hole blockage of the diaphragm is low, so the internal resistance of the battery cell is stable and controllable, the lithium precipitation risk is reduced, and the cycle life and safety performance of the battery cell are ensured.

Owner:HUBEI JINQUAN NEW MATERIALS CO LTD

Charging method and device

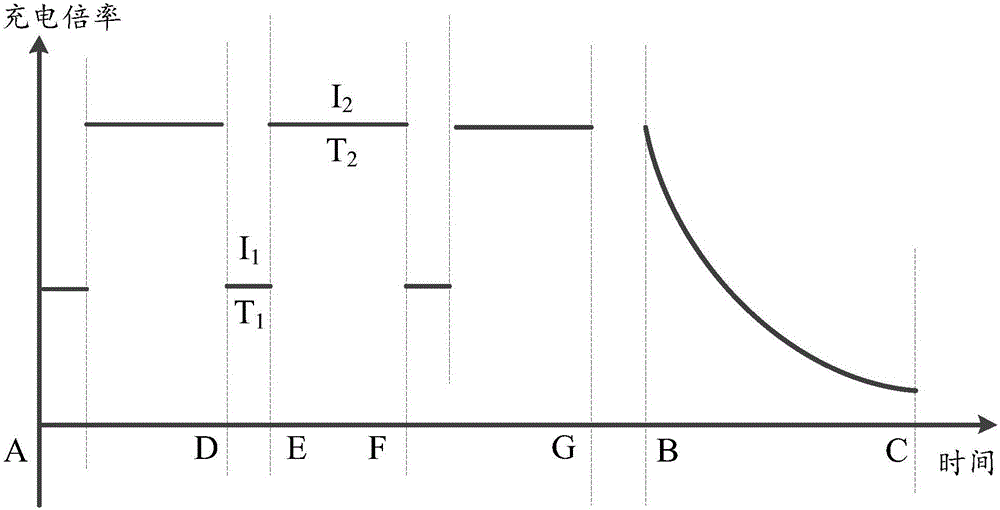

InactiveCN106654425AFast chargingReduce polarizationSecondary cells charging/dischargingElectrical batteryEngineering

The embodiment of the invention provides a charging method and device. For one thing, the charging process comprises a first charging stage and a second charging stage when a battery is charged in the embodiment; the first charging stage comprises at least two charging sub-stages; the battery is successively subjected to first constant current charging and second constant current charging in each charging sub-stage; and then the battery is subjected to constant voltage charging until the current of the battery reaches to a stop current in the second charging stage. Therefore, the technical scheme provided by the embodiment can solve the problems that the existing charging mode may result in accumulation of battery polarization and the battery has relatively big potential safety hazards along with the improvement of the charging speed.

Owner:NINGDE AMPEREX TECH

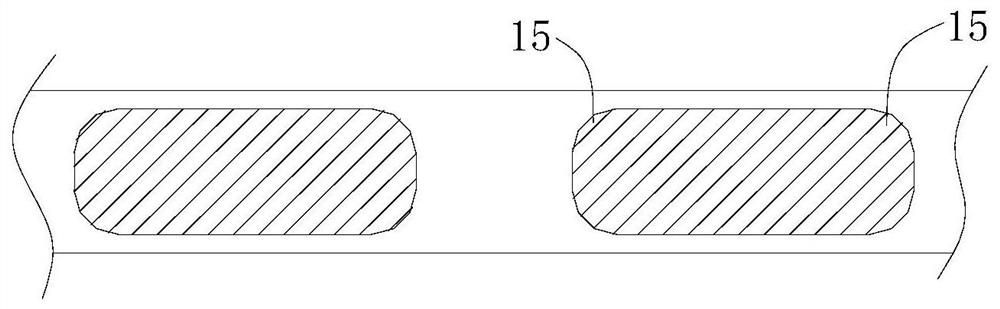

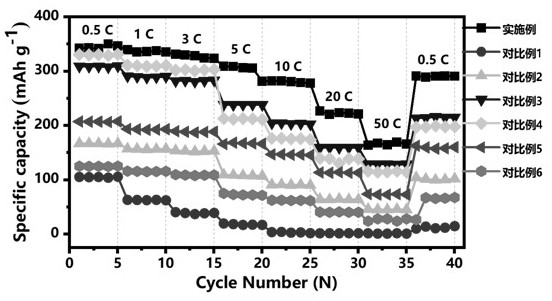

Lithium ion battery negative electrode capable of improving high-voltage cycle performance and preparation method thereof

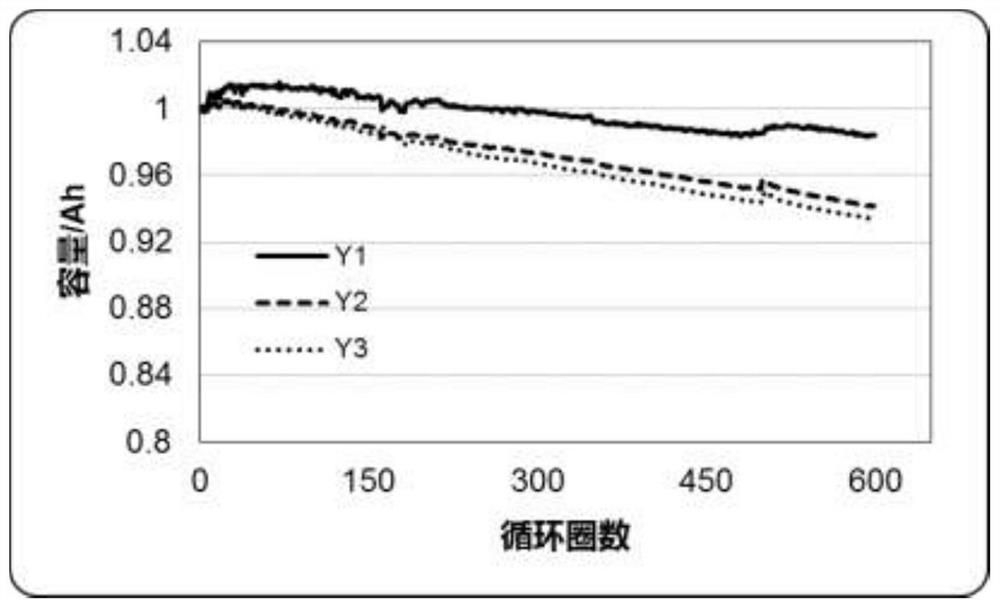

ActiveCN110323409AImprove cycle performanceImprove polarization effectSecondary cellsElectrode collector coatingHigh voltage batteryPole piece

The invention discloses a lithium ion battery negative electrode for improving high-voltage cycle performance and a preparation method thereof, and belongs to the technical field of lithium ion batteries. The specific scheme is that the negative electrode comprises a negative electrode current collector and a negative electrode coating; the negative electrode coating comprises a long paste coatinglayer and a short paste coating layer; one surface of the negative electrode current collector is coated with the long paste coating layer in a spaced mode, and the other surface of the negative electrode current collector is coated with the short paste coating layer in a spaced mode; and the negative electrode paste of the long paste coating layer and the negative electrode paste of the short paste coating layer are different. According to the invention, through employing two coating processes, the two sides of the negative current collector are respectively coated with different types of negative slurry to control the liquid absorption performance and the dynamic performance of a long paste coating layer and a short paste coating layer of a negative pole piece of the high-voltage battery; and particularly, the polarization effect between the long paste coating layer and the negative electrode current collector is improved, so that the cycle performance of the high-voltage battery isimproved, and the lithium precipitation risk of the negative electrode single paste coating layer is reduced.

Owner:ZHUHAI COSMX BATTERY CO LTD

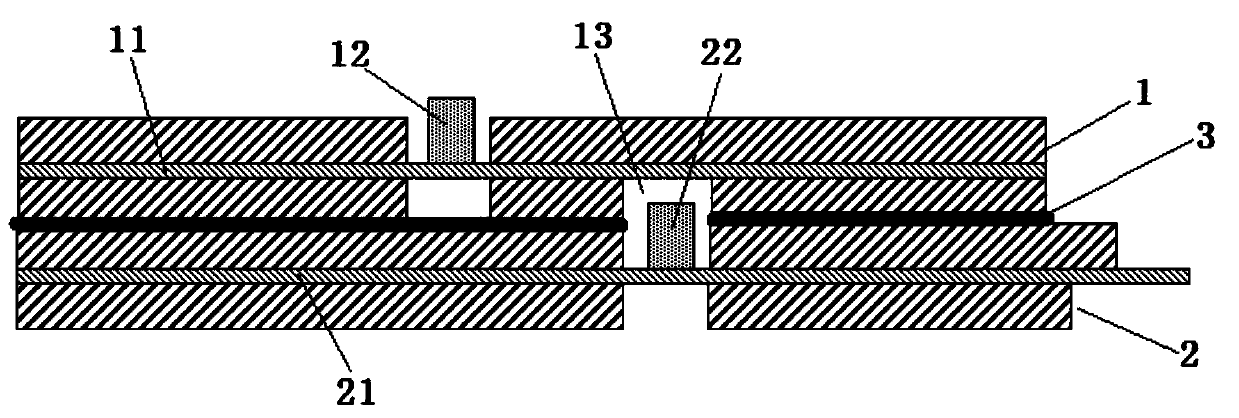

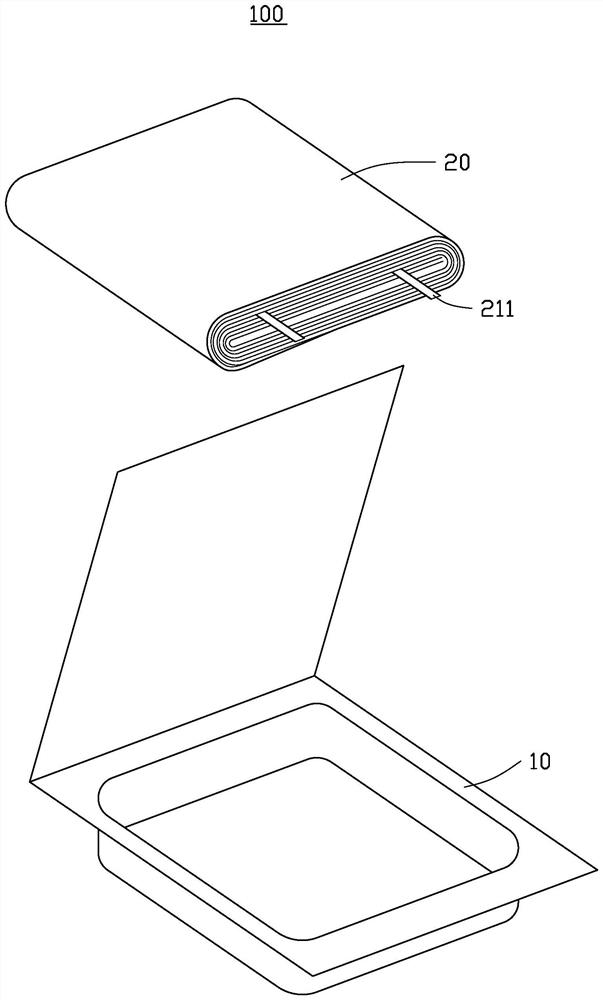

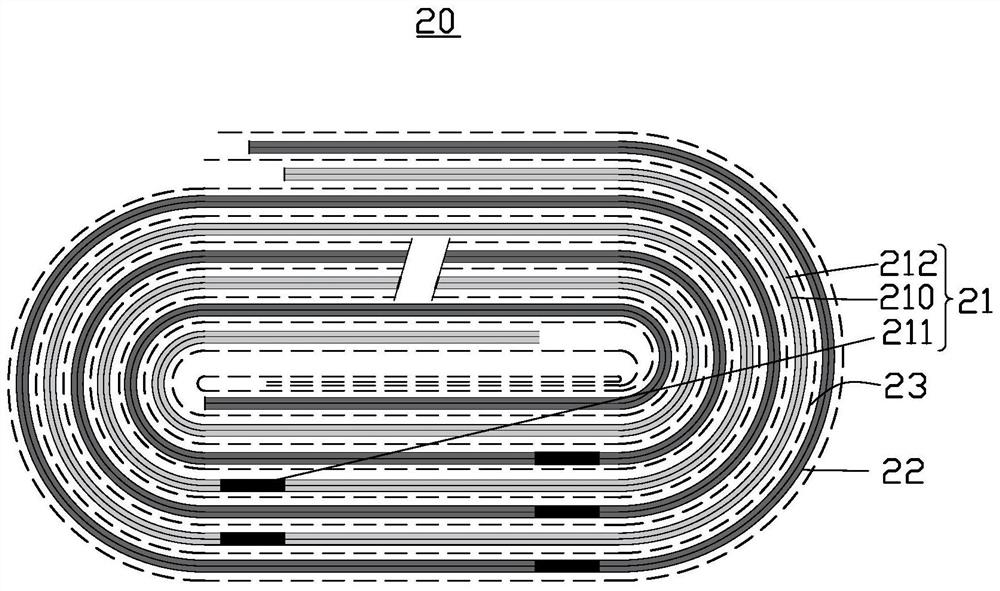

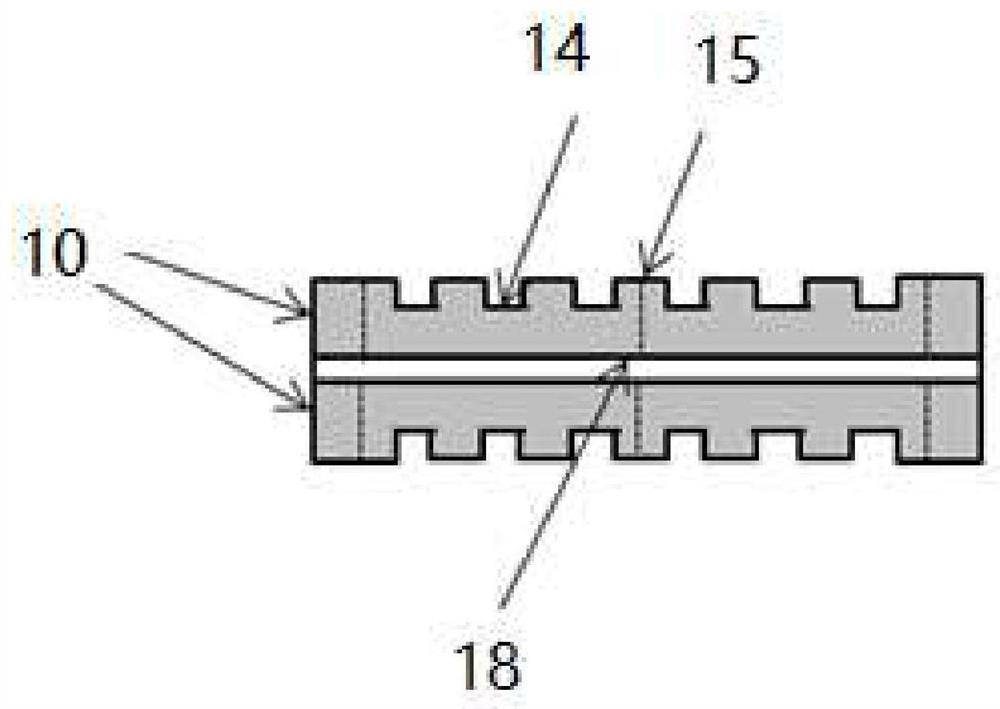

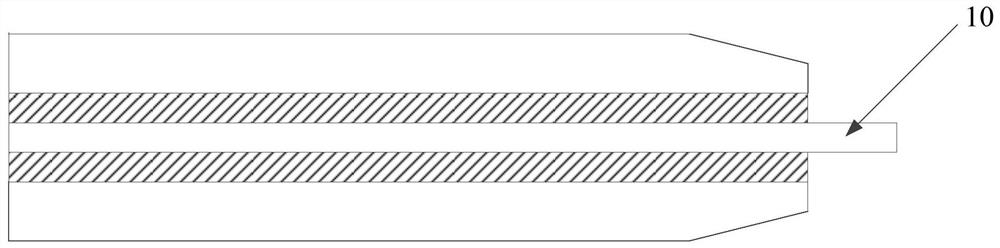

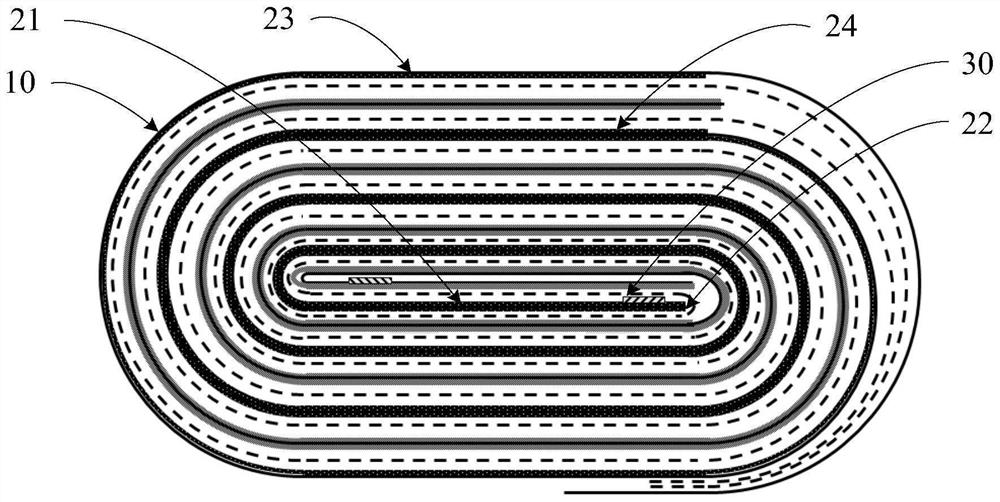

Lithium ion battery intermediate tab roll core

InactiveCN110148777AThere is no risk of lithium analysisLarge specific surface areaFinal product manufactureSecondary cellsLithium electrodeEngineering

The invention discloses a lithium ion battery intermediate tab roll core. The lithium ion battery intermediate tab roll core comprises an intermediate tab cathode plate, an intermediate tab anode plate and a diaphragm, two blank sections are arranged in the middle of a cathode material layer, a cathode tab is fixed at one blank section, the intermediate tab anode plate comprises an anode materiallayer, an anode tab is fixed at the blank section, and the intermediate tab cathode plate, the intermediate tab anode plate and the diaphragm are spirally wound and adhered together; and the anode material layer of the intermediate tab anode plate is wound and adhered with the cathode material layer of the intermediate tab cathode plate in a gapless manner through the diaphragm. According to the invention, the anode material layer of the intermediate tab anode plate is wound and attached to the cathode material layer of the intermediate tab cathode plate in a gapless manner through the diaphragm, namely the anode tab and the cathode material layer are avoided, the surface of the cathode material layer of the intermediate tab cathode plate, which faces the anode tab, is provided with a corresponding groove, and the anode tab is partially accommodated in the groove of the cathode material layer, so that the lithium separation risk caused by no anode at the welding position is avoided.

Owner:合肥众禾动力新能源科技有限公司

Electrode assembly and electrochemical device

PendingCN113826240AImprove undervoltage problemReduce the risk of Lithium analysis problemsFinal product manufactureNon-aqueous electrolyte accumulator electrodesChemistryComposite material

The invention provides an electrode assembly. The electrode assembly comprises a positive plate, a negative plate, an isolating membrane and a positive tab, the positive plate comprises a positive current collector and a positive active material layer arranged on the surface of the positive current collector, the negative plate comprises a negative current collector and a negative active material layer arranged on the surface of the negative current collector, and the isolating membrane is arranged between the positive plate and the negative plate. A first groove is formed in the positive electrode active material layer, and one end of the positive electrode tab is arranged in the first groove and is electrically connected with the positive electrode current collector. The negative active material layer is provided with a second groove, the second groove corresponds to the first groove, the second groove extends to the negative current collector along the thickness direction of the electrode assembly, and first protection glue is arranged in the second groove, so that the thickness consistency of the groove and the pole piece main body area is ensured; the under-voltage problem at the tab position is improved, and the short-circuit risk is reduced. The invention further provides an electrochemical device with the electrode assembly.

Owner:NINGDE AMPEREX TECH

Negative prelithiated electrode and preparation method thereof

InactiveCN112038577AReduce the risk of oxidationImprove first-time efficiencySecondary cellsElectrode collector coatingOrganic solventElectrical polarity

The invention discloses a negative prelithiated electrode. The negative prelithiated electrode comprises a metal current collector, and an active substance layer, a lithium supplementing layer and a functional polymer film protection layer which sequentially coat the surface of the metal current collector, wherein a functional polymer is a polymer containing a lithium-philic polar functional group. The invention discloses a preparation method of the negative prelithiated electrode. The preparation methodcomprises the following steps: S1, coating the surface of the metal current collector withthe active substance, and carrying out prelithiation treatment to obtain an intermediate electrode; and S2, mixing and stirring the functional polymer and an organic solvent for 6-10h, conducting standing for 12-24h, uniformly coating the surface of the intermediate electrode with a formed supernatant, and performing vacuum drying at 45-85 DEG C to obtain the negative prelithiated electrode. The risk that the lithium supplementing layer of the prelithiated electrode is oxidized can be effectively reduced, and the initial efficiency, the energy density, the cycling stability and the safety performance of a lithium ion battery are improved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Negative plate, battery and preparation method of negative plate

PendingCN113097428AIncrease energy densityEasy to moveSecondary cellsNon-aqueous electrolyte accumulator electrodesIonic diffusionElectrical battery

The invention provides a negative electrode plate, a battery and a preparation method of the negative electrode plate. The negative electrode plate comprises a negative current collector, a negative tab, a first coating and a second coating, wherein the edge of the second coating is closer to the negative tab compared with the edge of the first coating; and the median diameter D50 of an active material contained in the second coating is smaller than the median diameter D50 of an active material contained in the first coating, so the negative paste closer to the negative electrode tab is the active material with a relatively small particle size, better ion diffusion dynamic performance can be presented, and the risk of lithium precipitation in a charging process is reduced.

Owner:ZHUHAI COSMX BATTERY CO LTD

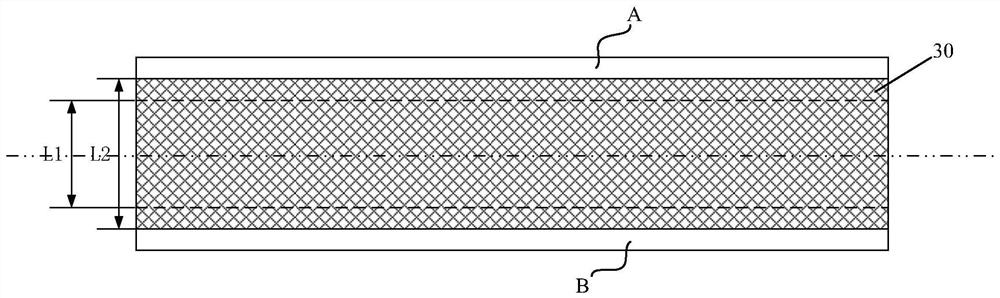

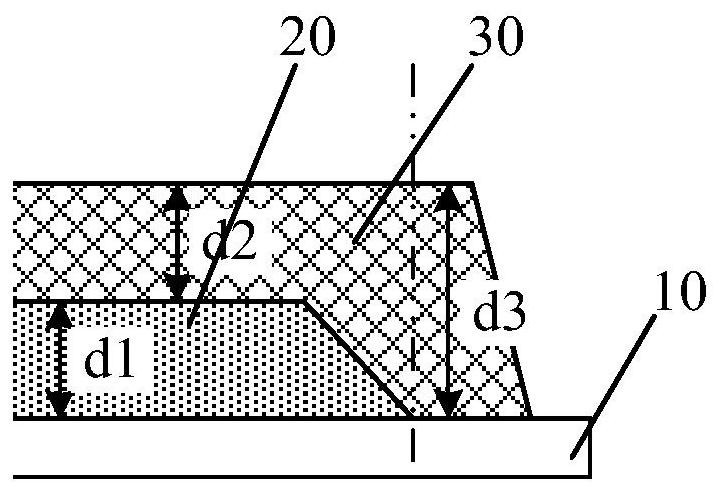

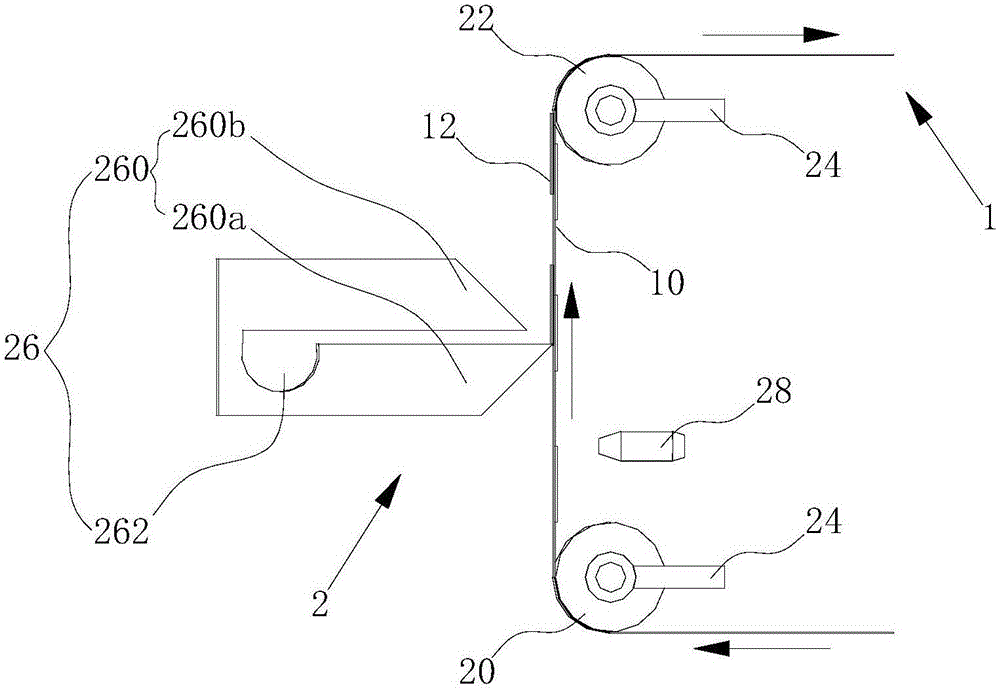

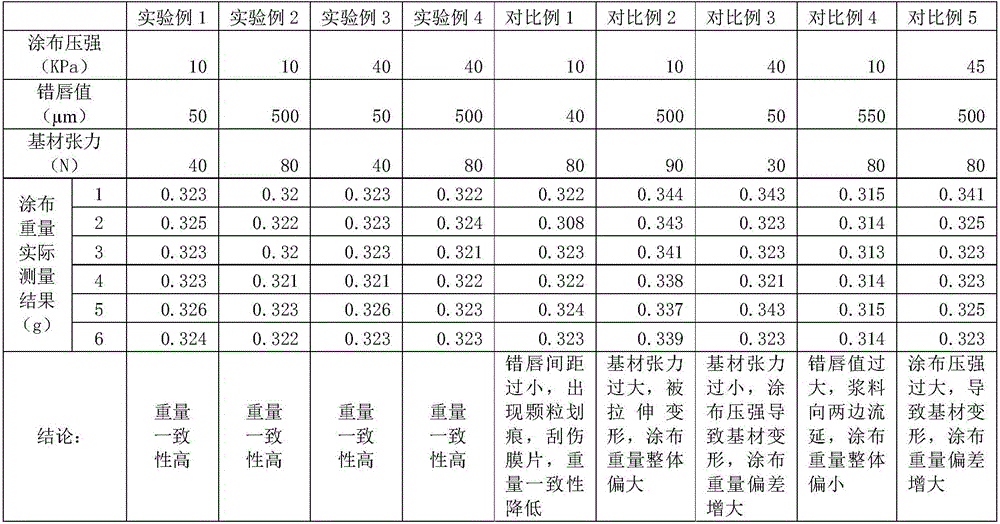

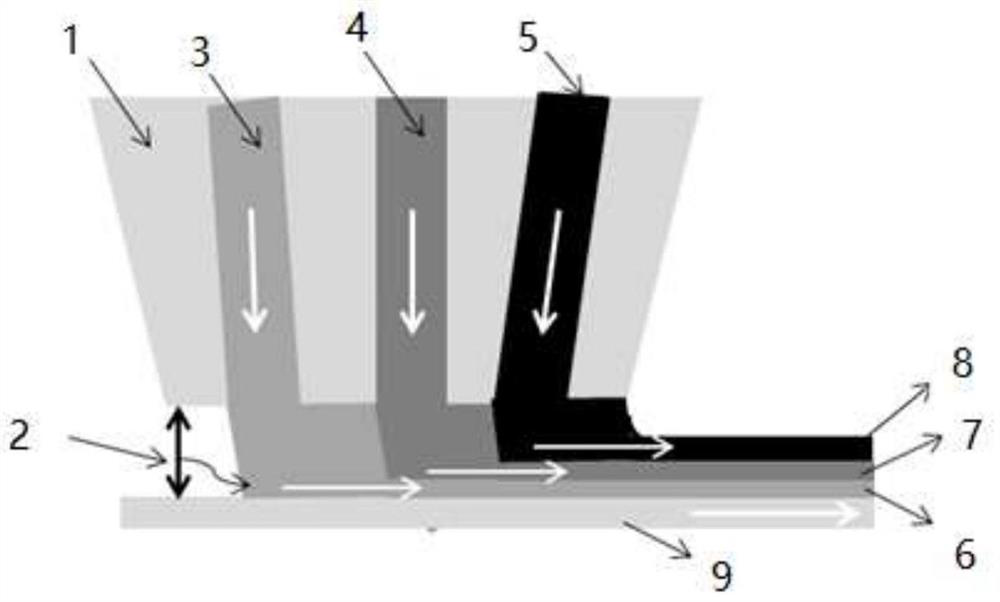

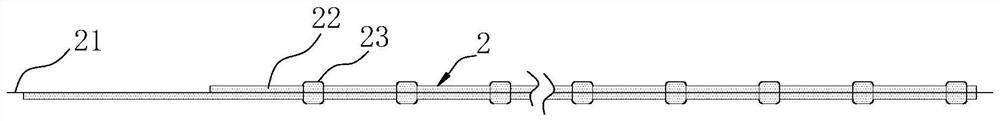

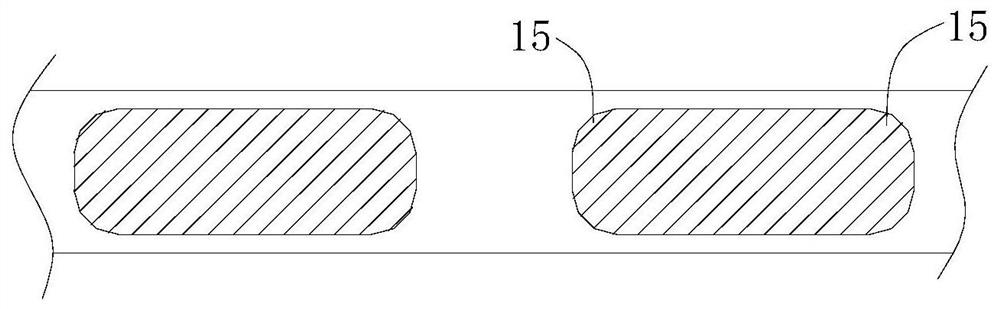

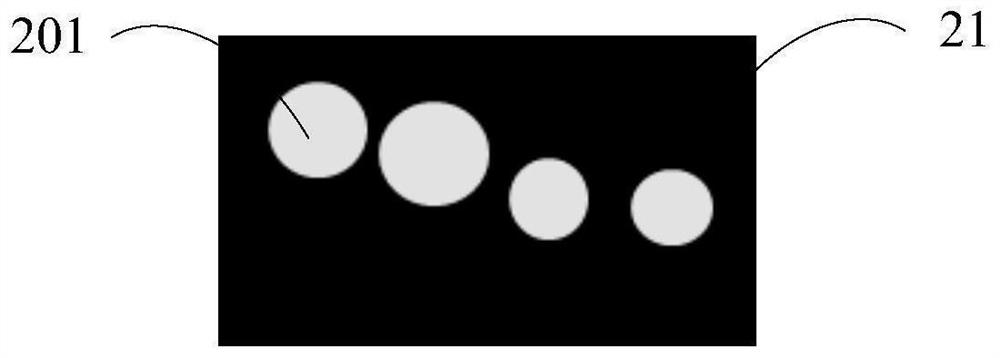

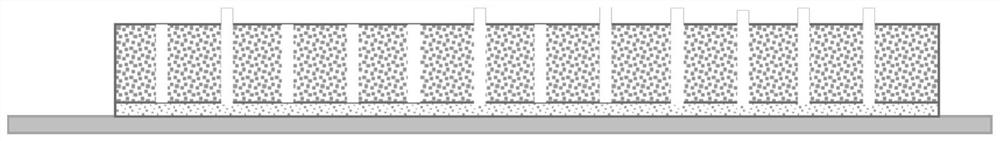

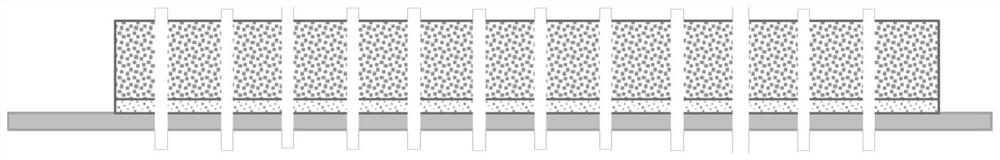

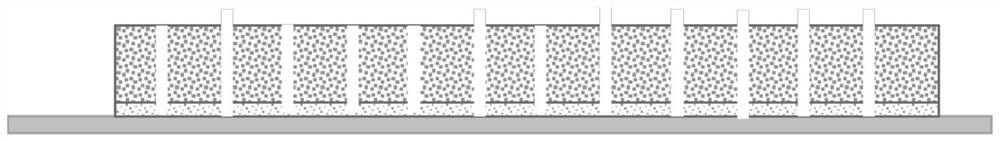

Double-dislocation coating method and device

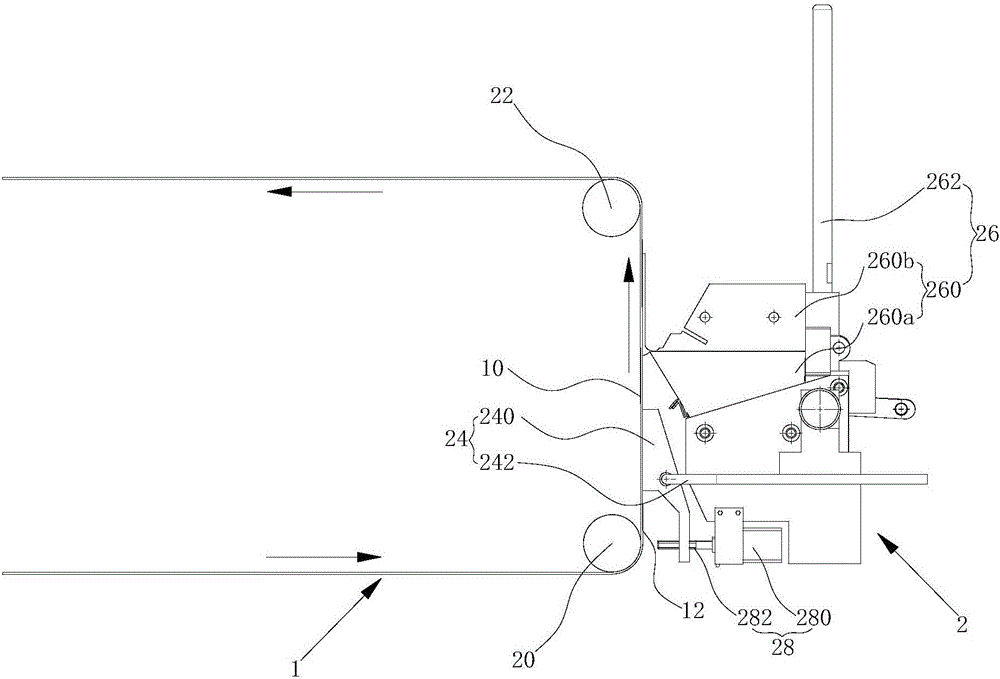

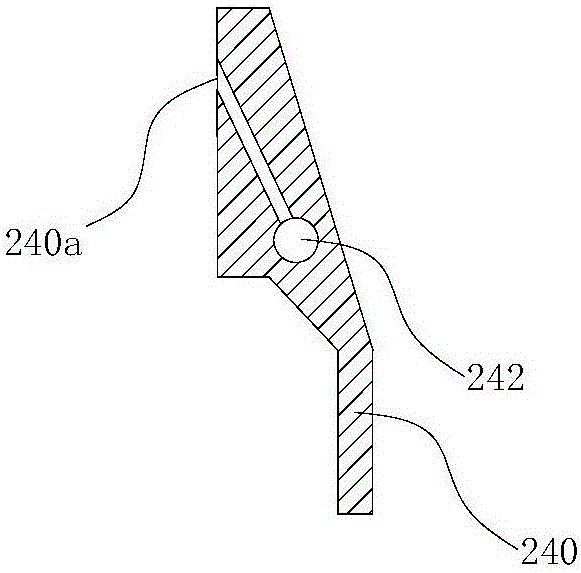

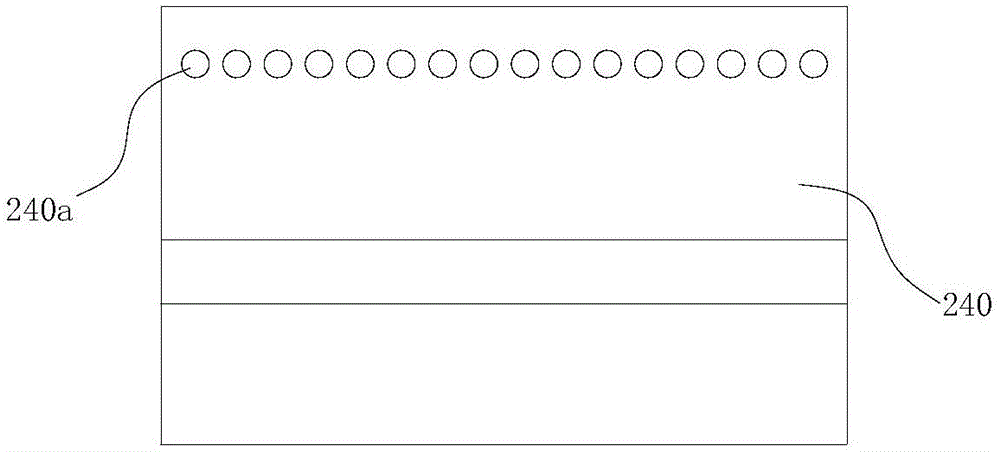

InactiveCN106733393AUniform coating thicknessUniform weightLiquid surface applicatorsCoatingsDislocationEnergy storage

The invention relates to the field of energy storage devices, in particular to a double-dislocation coating method and a device. The method comprises the following steps: after a substrate is tensioned and conveyed to a coating position, a gap between the substrate and a dislocation lip mold head is changed to bond a surface to be coated with the dislocation lip mold head; the surface to be coated is coated by a kiss coating mode; and after the coating reaches a preset length, the gap between the substrate and the dislocation lip mold head is changed to deviate the surface to be coated from the dislocation lip mold head. The device comprises a first roller, a second roller, a moving module and a kiss coating module; the kiss coating module includes the dislocation lip mold head; the dislocation lip mold head is positioned between the first roller and the second roller in the conveying direction, and is towards the surface to be coated; and the moving module is connected with at least one of the first roller, the second roller and the kiss coating module, can drive the first roller, the second roller or the dislocation lip mold head to change the gap between the substrate and the dislocation lip mold head, and bonds / deviates the surface to be coated with / from the dislocation lip mold head. The double-dislocation coating method and device can guarantee uniform coating weight.

Owner:NINGDE AMPEREX TECH

Electrochemical device and electronic device

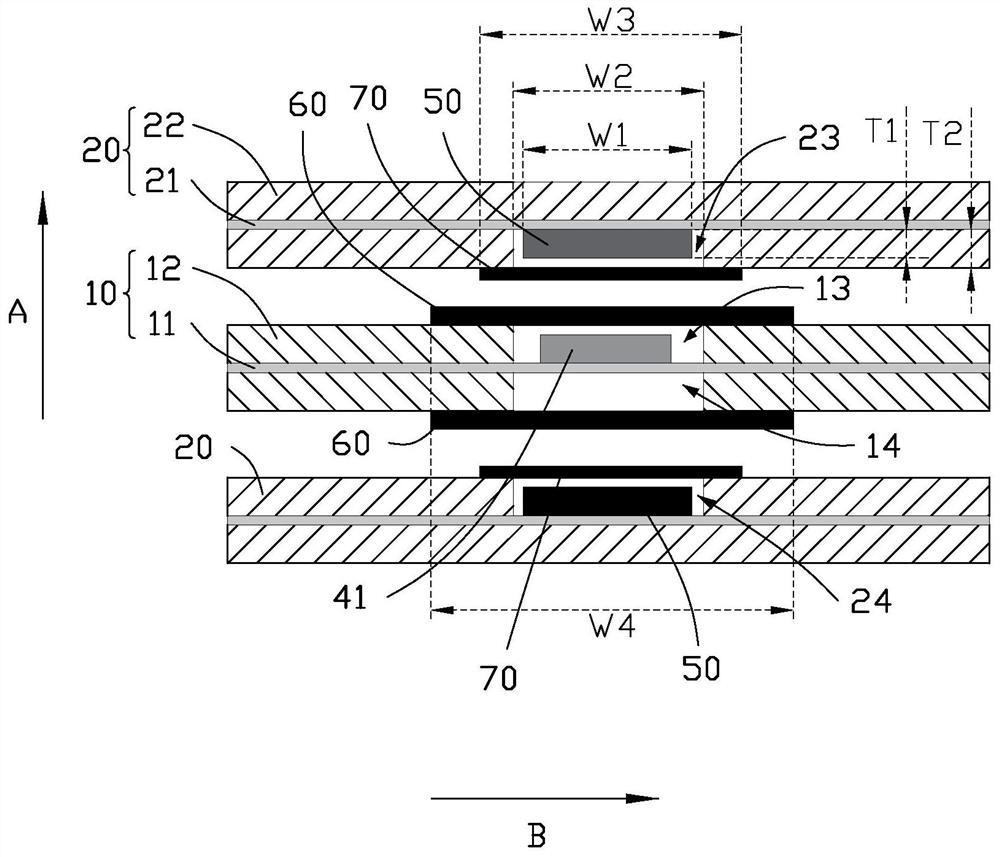

ActiveCN113659105ALower internal resistanceIncrease charge and discharge rateSecondary cellsNon-aqueous electrolyte accumulator electrodesEngineeringPole piece

The invention provides an electrochemical device which comprises an electrode assembly composed of a first pole piece, a second pole piece and a diaphragm arranged between the first pole piece and the second pole piece, the first pole piece comprises a current collector, a tab and an active substance layer, the active substance layer is composed of a main body area and an edge area, the width of the edge area and the width of the main body area are w1 and w2 respectively, and w1 / w2 is larger than 0 and smaller than or equal to 5%, the thicknesses of the edge area and the main body area are t1 and t2 respectively, t1 and t2 satisfy the relation equation that and 95% < = t1 / t2 < = 100%. The edge area with the parameters is beneficial to improving the energy density of the electrochemical device, reducing the lithium precipitation risk and improving the safety of the electrochemical device. In addition, the invention also provides an electronic device.

Owner:NINGDE AMPEREX TECH

Square coiled battery pole piece as well as preparation method and square soft package battery thereof

InactiveCN108735973AImprove consistencyImprove securityElectrode rolling/calenderingFinal product manufacturePunchingSlurry coating

The invention discloses a square coiled battery pole piece as well as a preparation method and a square soft package battery thereof. The preparation method comprises the following steps: coating, namely carrying out double-faced intermittent coating on a current collector by adopting battery slurry, so as to form more than two of slurry coating areas which are sequentially distributed at intervals in the length direction of the current collector, and reserving a blank area uncoated with the battery slurry at the tail part of each slurry coating area, wherein coating areal density of any slurry coating area is 90-160g / m<2>; and rolling and punching, namely after the double-faced intermittent coating is completed, carrying out rolling and punching treatment on the current collector coated with more than two slurry coating areas, thus the required square coiled battery pole piece is obtained. The scheme of the invention can overcome the defects of large polarization effect, poor batteryperformance and poor use security and realizes the beneficial effects of small polarization effect, good battery performance and good use security.

Owner:YINLONG ENERGY CO LTD

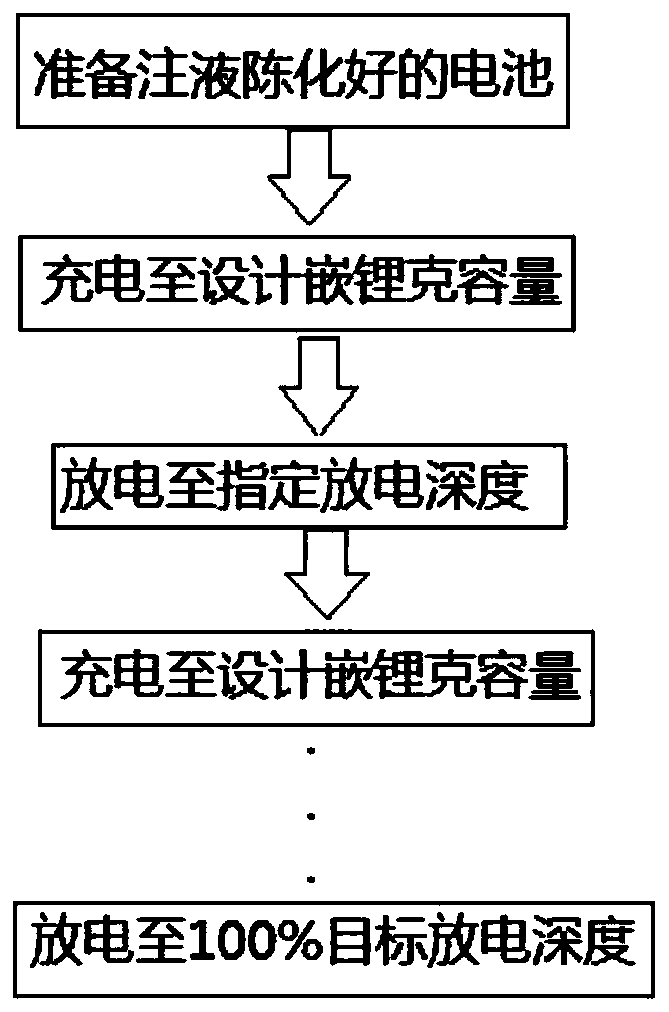

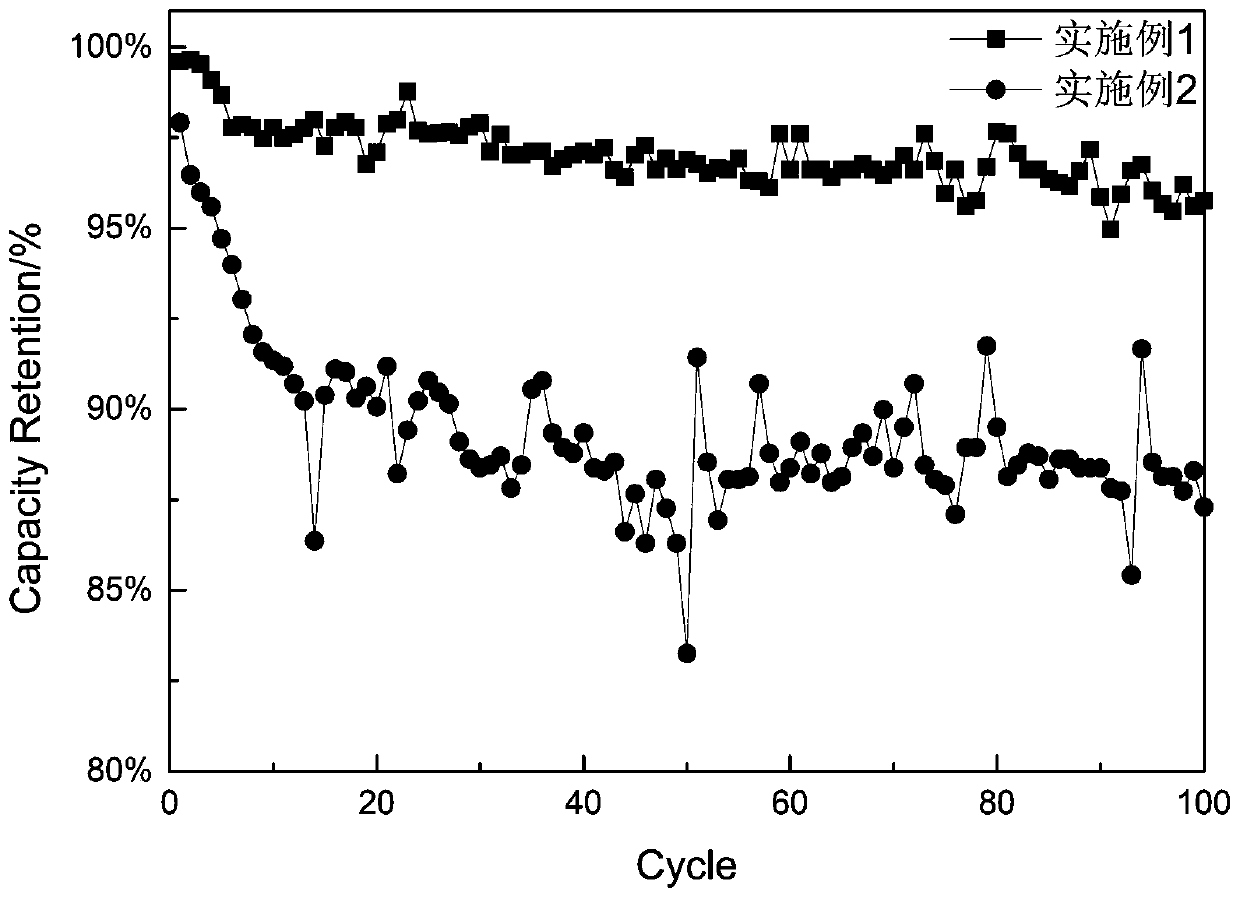

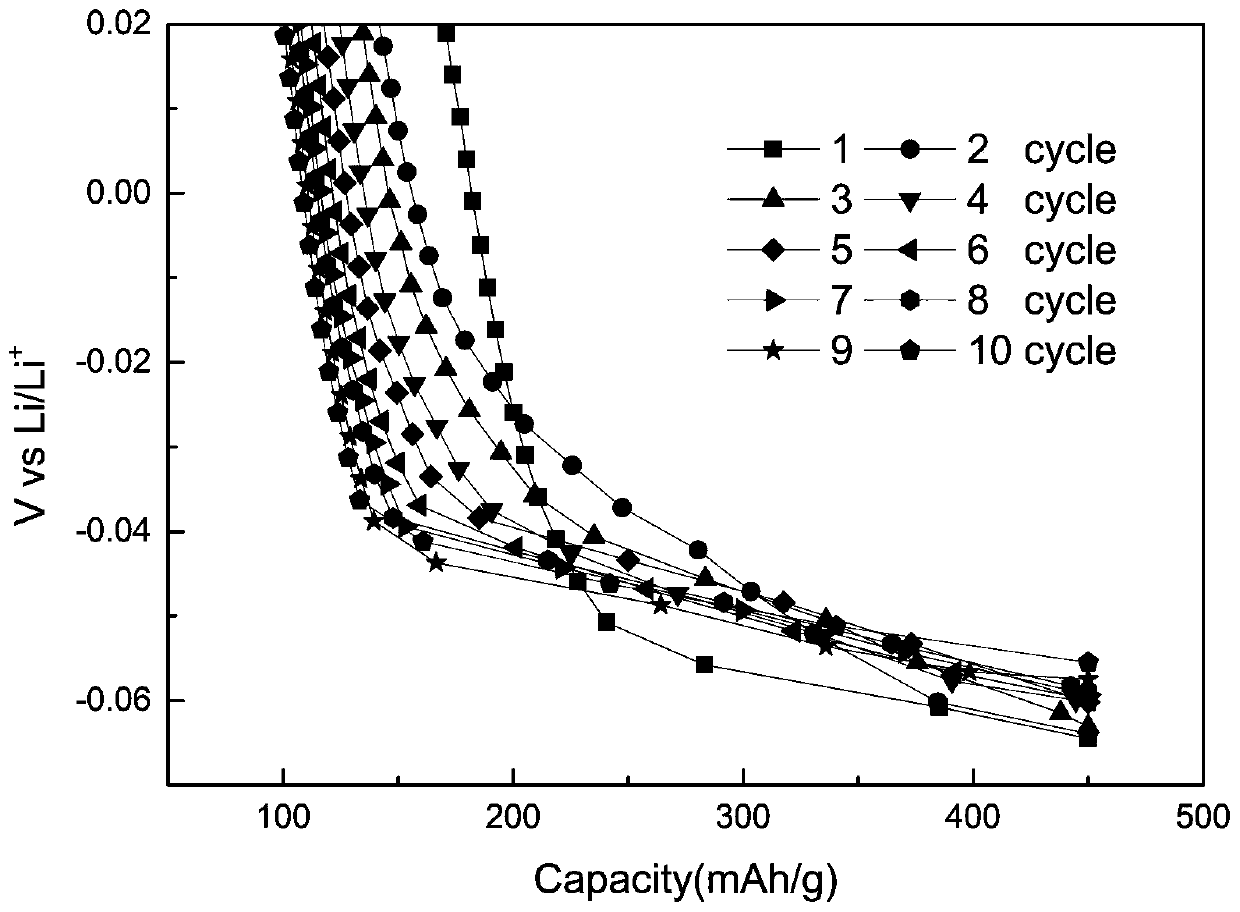

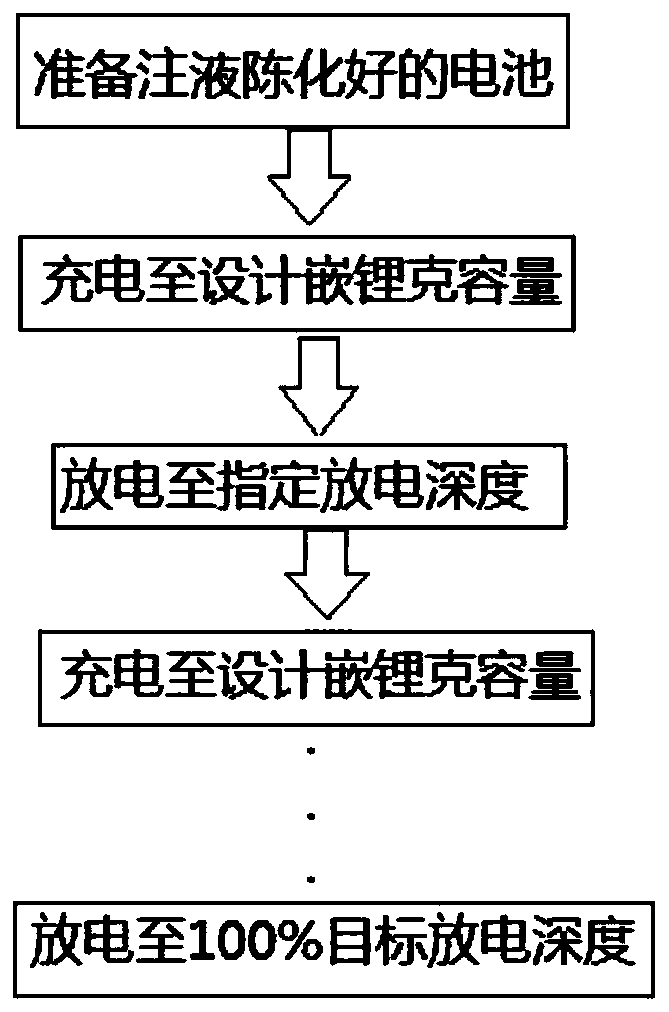

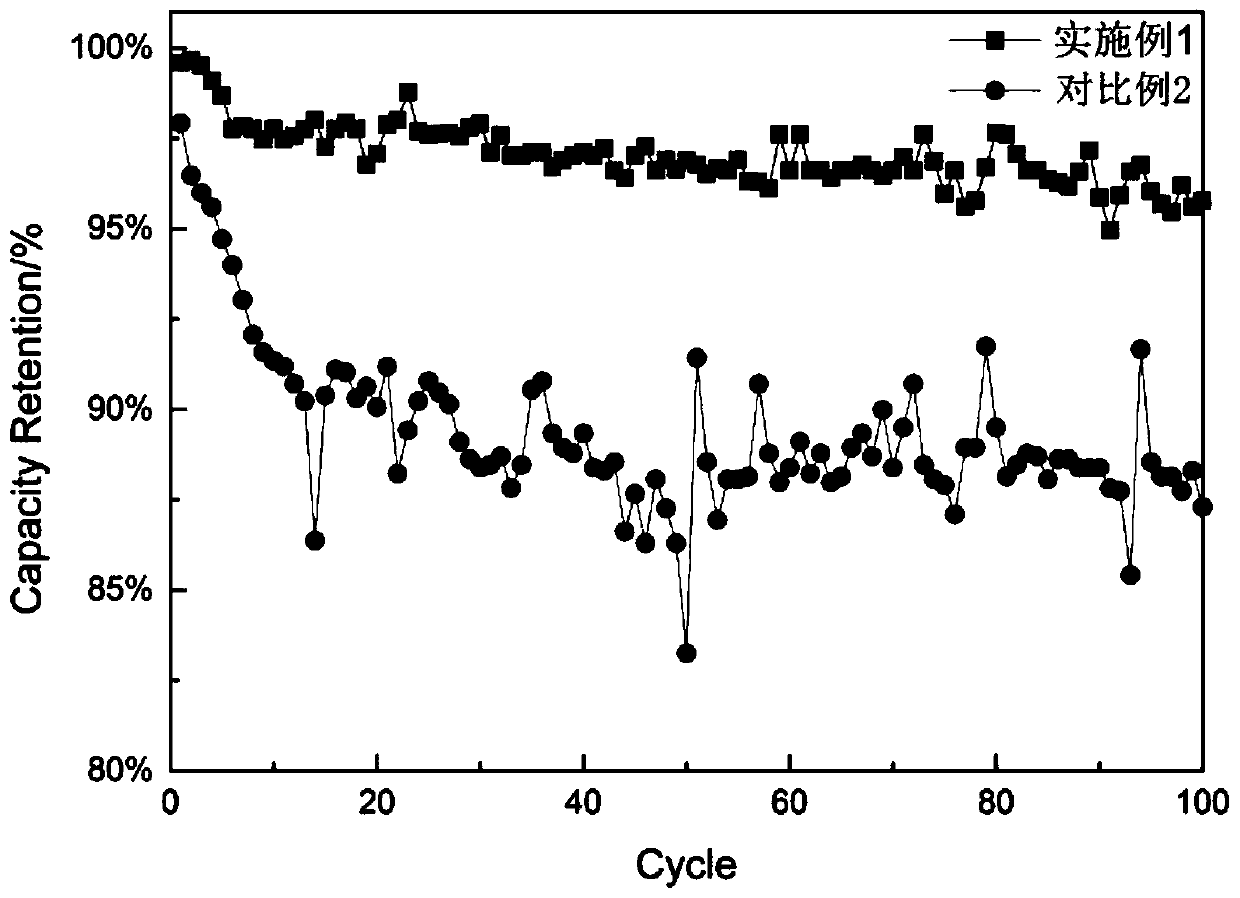

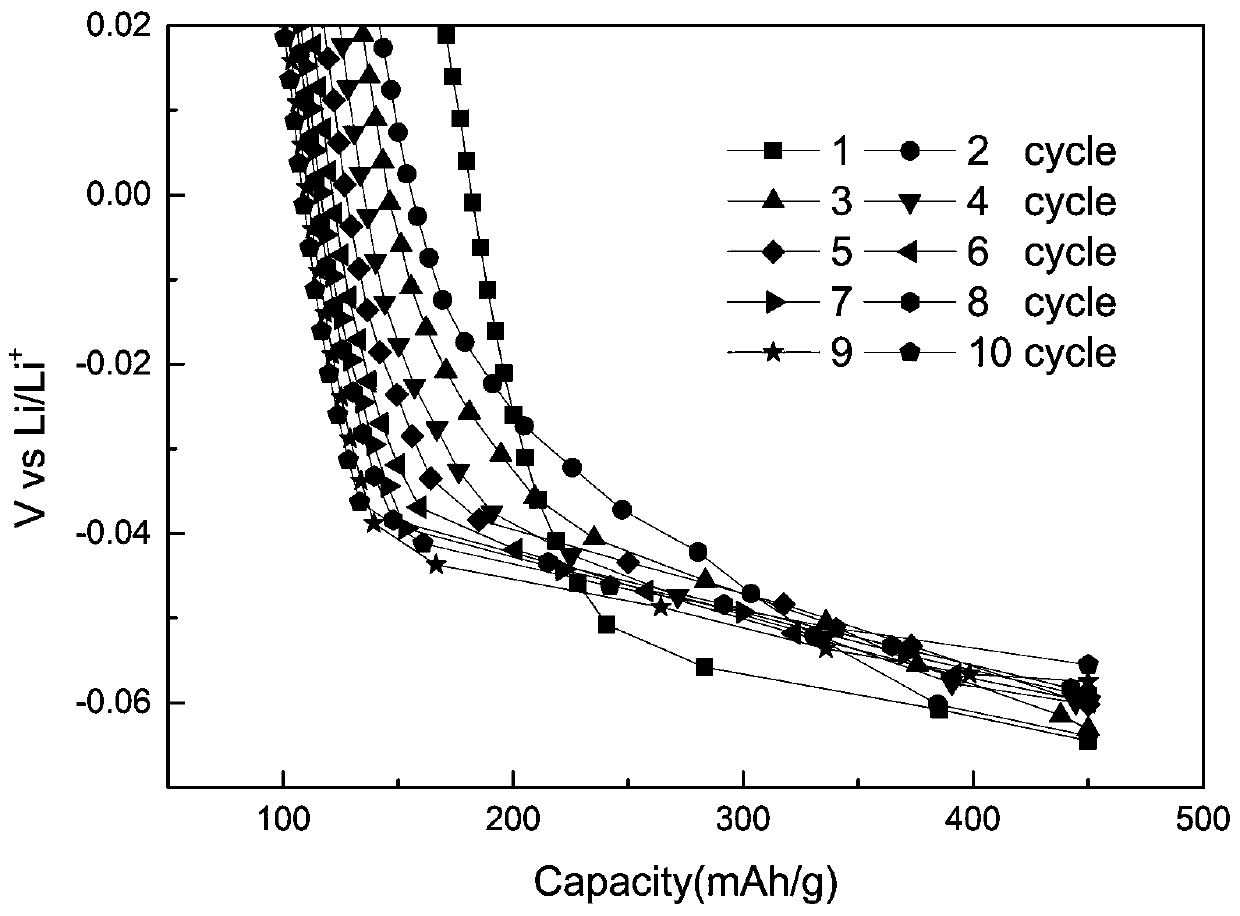

Method for forming hard carbon anode material lithium ion battery

ActiveCN109713386AImprove cycle stabilityGuarantee the safety of useFinal product manufactureSecondary cells charging/dischargingCyclic processGram

The invention provides a method for forming a hard carbon anode material lithium ion battery, and belongs to the technical field of battery formation. The formation method of the present invention isto carry out a formation treatment on a liquid-filled and aged battery. The formation treatment comprises performing charging to designed lithium-intercalated capacity per gram-discharging process N times until the discharge depth reaches 100% of a target discharge depth, wherein the designed lithium-intercalated capacity per gram is 350-700 mAh / g, the target discharge depth is 100% of the designed lithium-intercalated capacity per gram, the depth of the first discharge is 10 to 90% of the target discharge depth, and the depth of the Nth discharge is increased by 1 to 20% of the target discharge depth compared with the depth of the (N-1)th discharge, wherein the N >=2, and N is an integer. The method eliminates the irreversible lithium in a cycle process by controlling the target dischargedepth and the depth of each discharge, improves the lithium-intercalated platform of the hard carbon anode material, reduces the risk of lithium deposition, and improves the cycle stability of the hard carbon anode material lithium ion battery.

Owner:上海飞鸿创联新能源发展有限公司

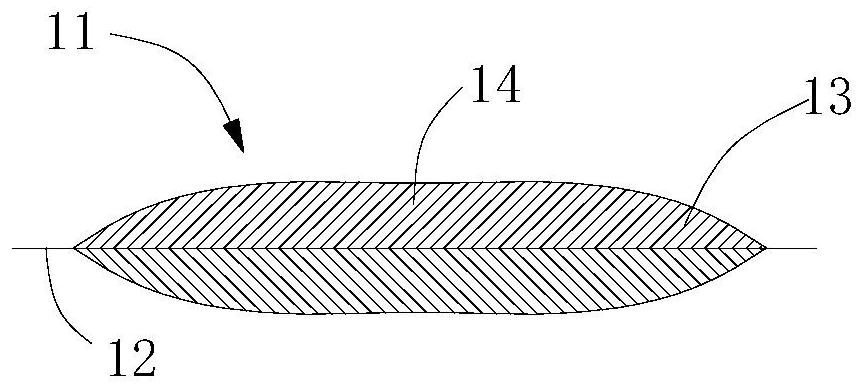

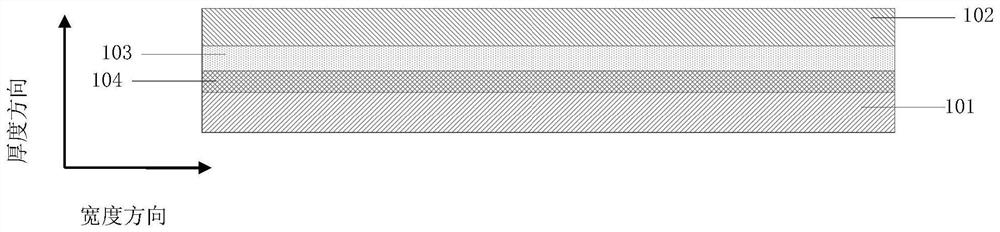

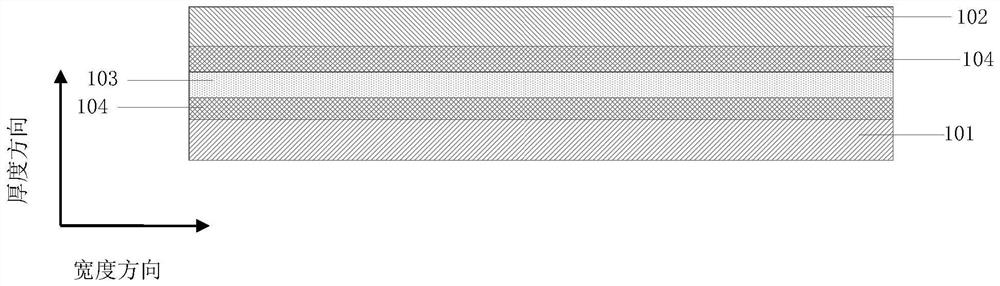

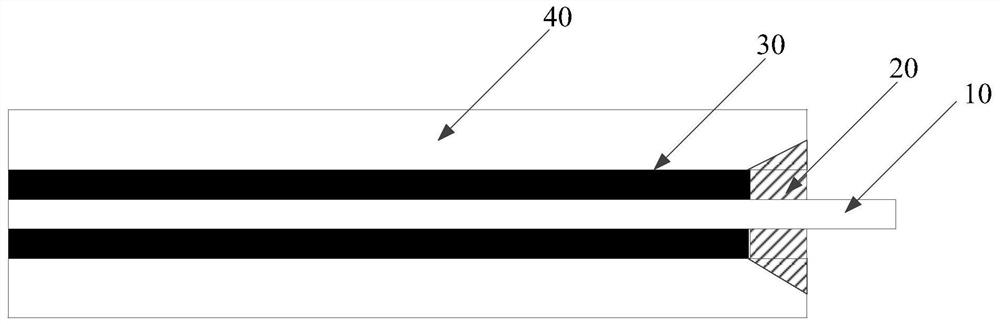

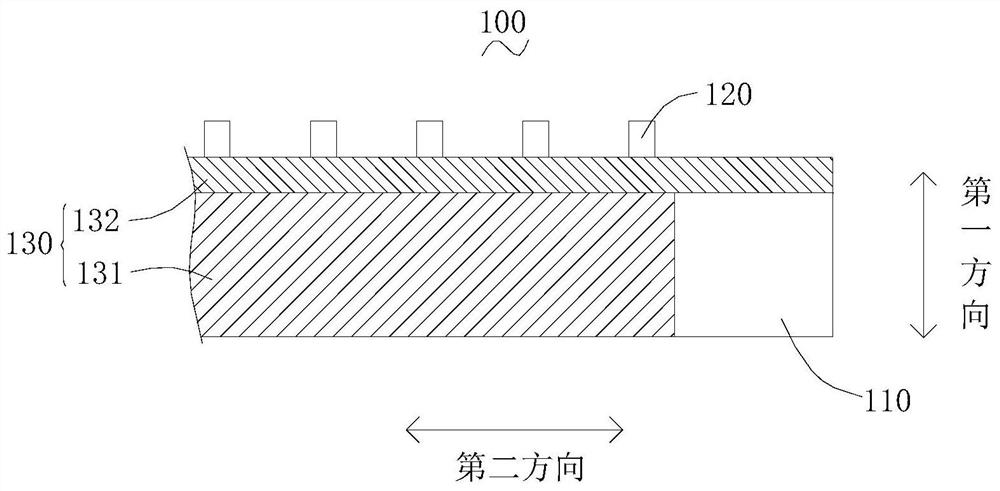

Electrochemical device and electronic device

ActiveCN113675372AIncrease energy densityReduce riskFinal product manufactureNegative electrodesComposite materialElectrical connection

A disclosed electrochemical device comprises a winding type battery cell and a shell for containing the battery cell, the battery cell comprises a first pole piece, a second pole piece and a diagram which are arranged in a stacked mode. The first pole piece comprises a current collector with a first surface facing the interior of the battery cell and a second surface deviating from the interior of the battery cell; a tab which is electrically connected with the current collector and extends out of the current collector; and a first active material layer which is arranged on the first surface of the current collector, The first active material layer comprises a main body coating and an edge coating; in the first direction, the edge coating is located at the side, facing the tab, of the main body coating and is adjacent to or partially overlapped with the main body coating; and in the second direction, the main body coating and the edge coating extend in a strip shape, and the length of the edge coating is larger than that of the main body coating. The electrochemical device is high in energy density and relatively high in electrical property.

Owner:NINGDE AMPEREX TECH

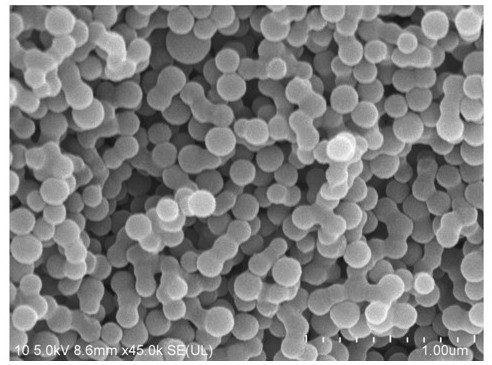

Preparation method and application of lithium battery negative plate

ActiveCN114759164AImprove conductivityBig spaceNegative electrodesSecondary cellsCurrent collectorHigh conductivity

The preparation method specifically comprises the following steps: uniformly mixing a core-shell structure magnetic nano template which takes polyaniline as a shell and Fe3O4 as a core with a negative electrode material, a binder, a conductive agent and a solvent water to prepare negative electrode slurry, coating the surface of a current collector with the negative electrode slurry, and drying to obtain the lithium battery negative electrode plate. The preparation method comprises the following steps: preparing a thick electrode from magnetic nano Fe3O4, directionally assembling the magnetic nano Fe3O4 on the surface of a current collector by loading a magnetic field, recycling the magnetic nano Fe3O4 in the thick electrode through microwave heating and a magnetic recycling device, and constructing a three-dimensional network channel with high conductivity in the thick electrode to effectively improve the conductivity of the electrode, shorten ion and electron migration paths and improve the conductivity of the electrode. A multi-dimensional open permeation channel is provided, the wettability of an electrolyte is enhanced, the electrode tortuosity is reduced, the gradient porosity is generated, a molecular-level channel beneficial to lithium ion transportation is formed, and high-speed conduction of lithium ions is promoted.

Owner:新乡市中天新能源科技股份有限公司

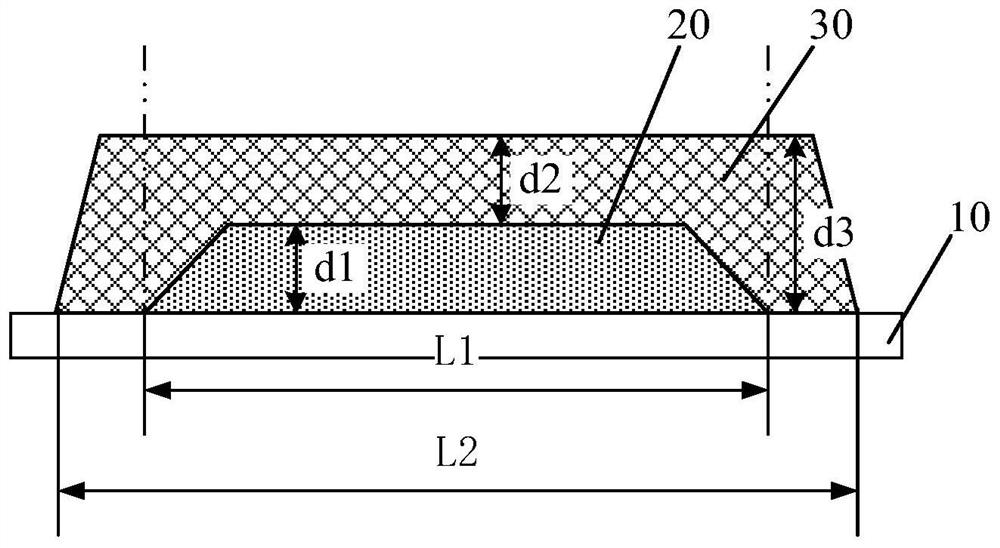

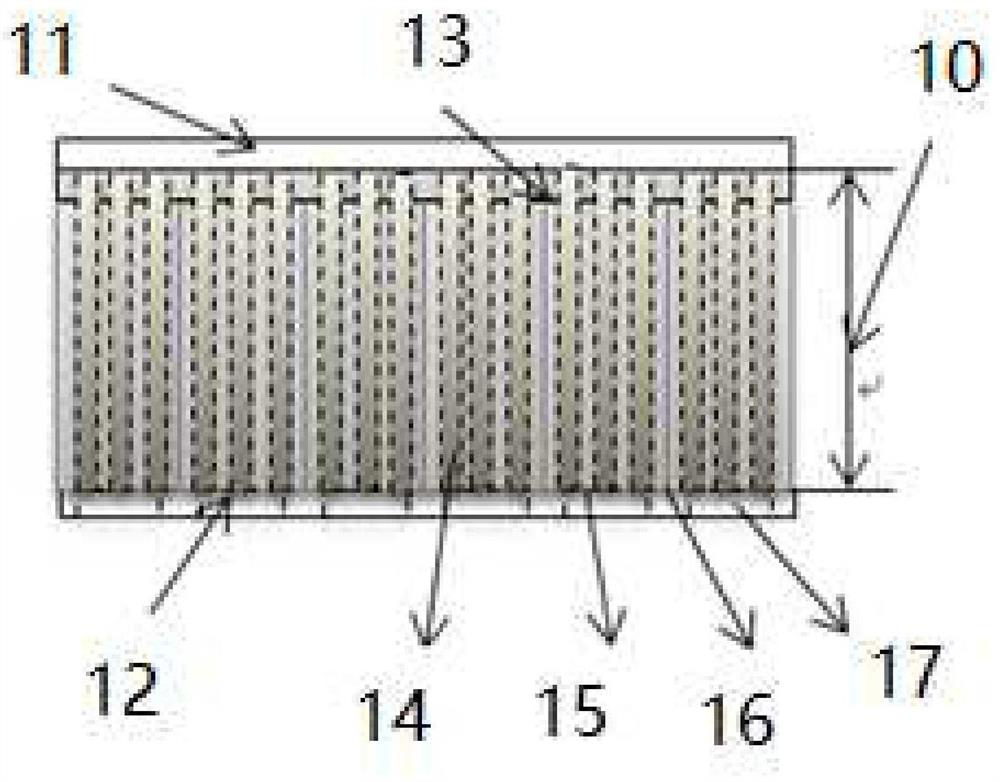

Thick electrode structure of lithium ion battery

PendingCN113745450AStructural advantageAdvantages of thick electrode structureElectrode carriers/collectorsSecondary cellsLithium-ion batteryBattery cell

The invention provides a thick electrode structure of a lithium ion battery. The thick electrode structure comprises a coating machine die head, and a gap between a coating die head lip and a current collector is formed between the coating machine die head and a negative current collector; the coating machine die head is provided with a plurality of coating machine die head cavities, and the cavities are not communicated with one another; negative electrode slurry with different components is extruded from a slit of the coating machine die head lip, so that negative electrode slurry with different components can be formed, the current collector is wet-coated with the negative electrode slurry with different components at the same time; two sides of a dressing layer of a rolled electrode roll are respectively provided with a non-tab side blank space and a tab side blank space, and electrode thickness direction grooves are arranged along an electrode thickness direction; groove gaps are formed between the electrode thickness direction grooves, and the electrode thickness direction grooves are formed in the surface of each electrode piece. According to the thick electrode structure of the lithium ion battery, the infiltration of electrolyte from the surface of the dressing layer to the current collector is facilitated, the binding power between the dressing layer and the current collector and the rate and cycle performance of the thick electrode battery are improved, and the lithium precipitation risk under high-rate charge and discharge is reduced.

Owner:TIANJIN ENERGIES

Electrochemical device and electronic device

ActiveCN113078287AImprove cycle performanceImprove securityNon-aqueous electrolyte accumulator electrodesSecondary cells servicing/maintenancePhysical chemistryEngineering

The invention provides an electrochemical device and an electronic device. The electrochemical device comprises a positive pole piece, a negative pole piece and an isolating membrane arranged between the positive pole piece and the negative pole piece. The electrochemical device satisfies at least one of the following conditions (a)-(d): (a) a protective coating layer is provided on the surface of at least one side of the separator, the protective coating layer including a blocking agent; (b) the isolating membrane comprises a blocking agent; (c) the negative pole piece comprises a negative active material layer, and a protective coating is arranged on the surface of the negative active material layer; (d) the negative electrode active material layer comprises core-shell structure particles, the shells of the core-shell structure particles comprise at least one of an inorganic material or a polymer, and the cores of the core-shell structure particles comprise the blocking agent. The blocking agent comprises at least one of red phosphorus, sulfur, iodine or selenium. According to the embodiment of the invention, the lithium precipitation risk can be reduced, and the cycle performance and safety performance of the electrochemical device are improved.

Owner:NINGDE AMPEREX TECH

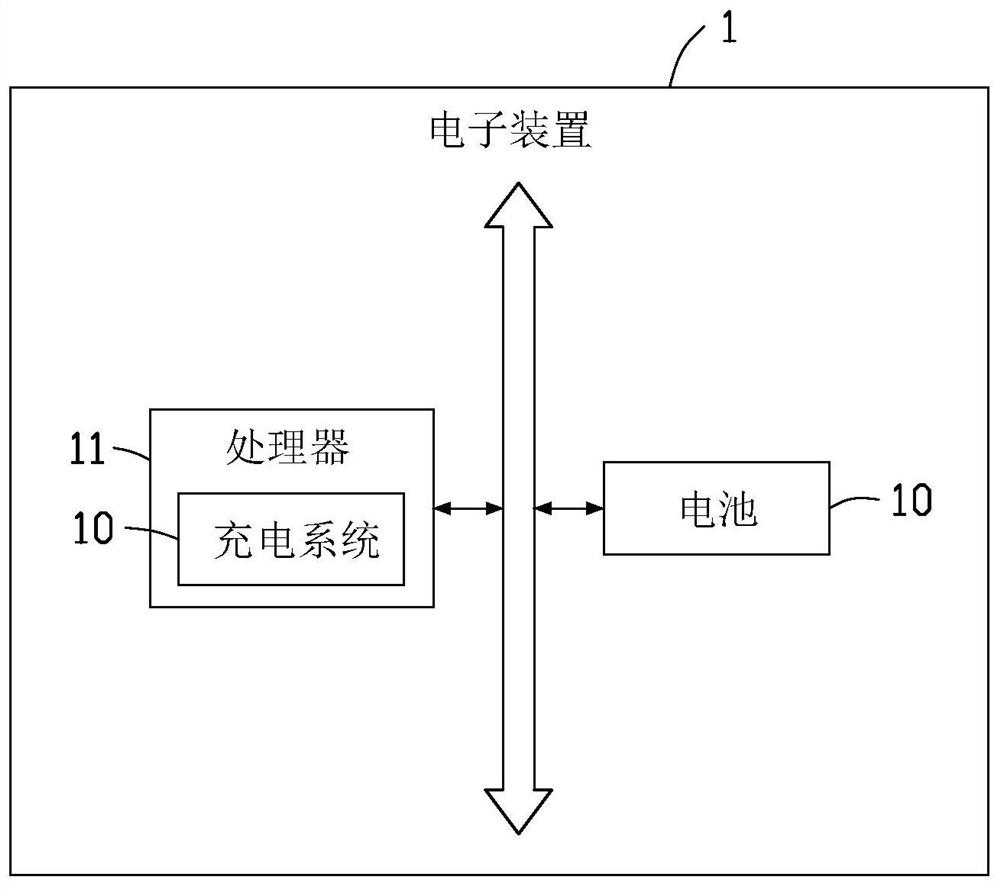

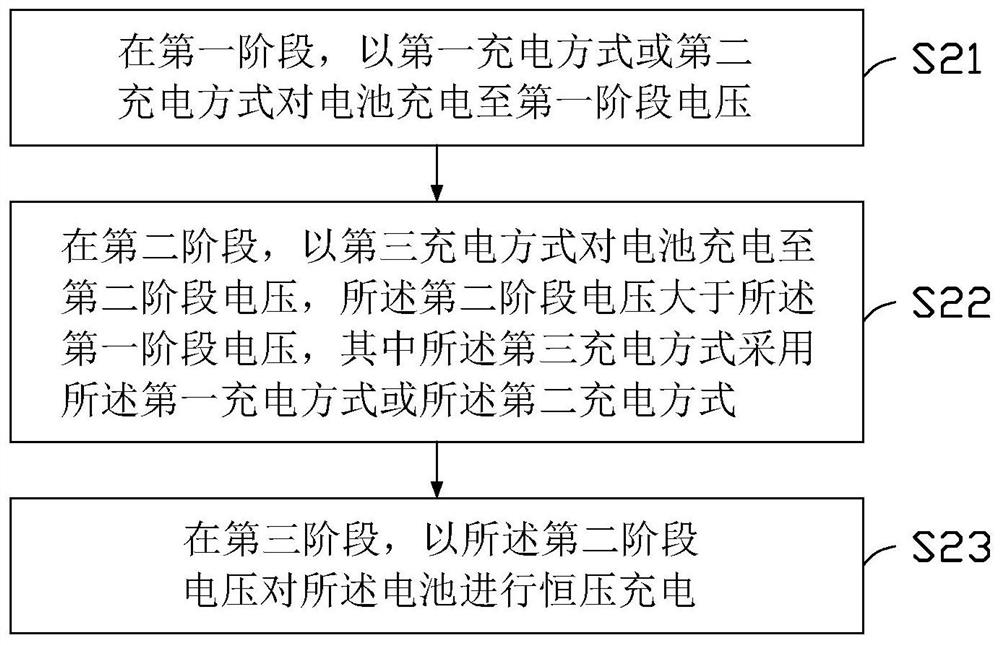

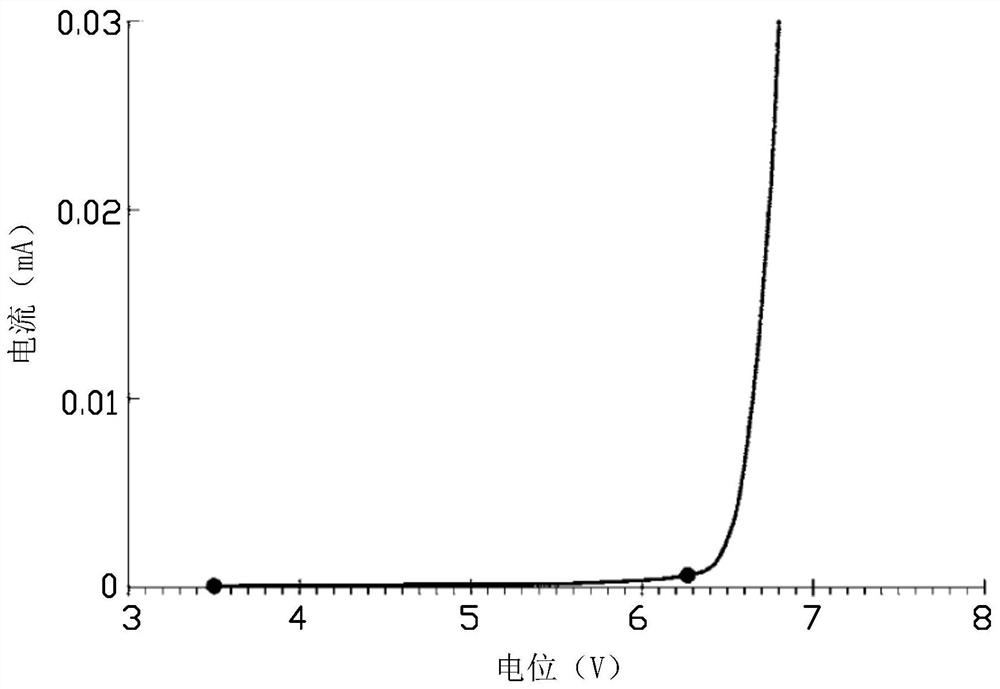

Charging method, electronic device and storage medium

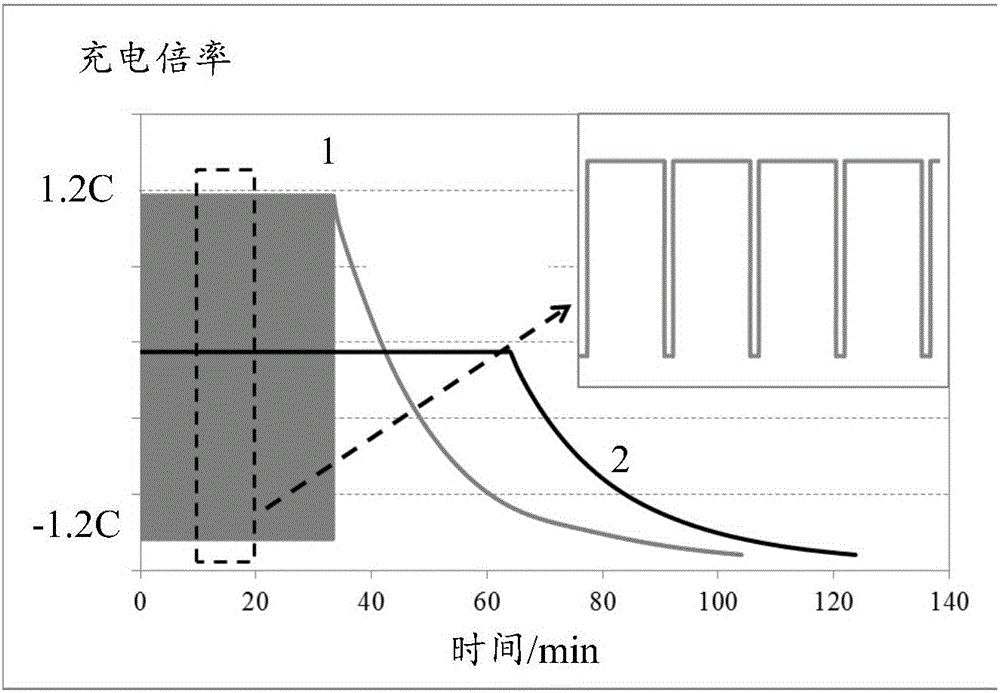

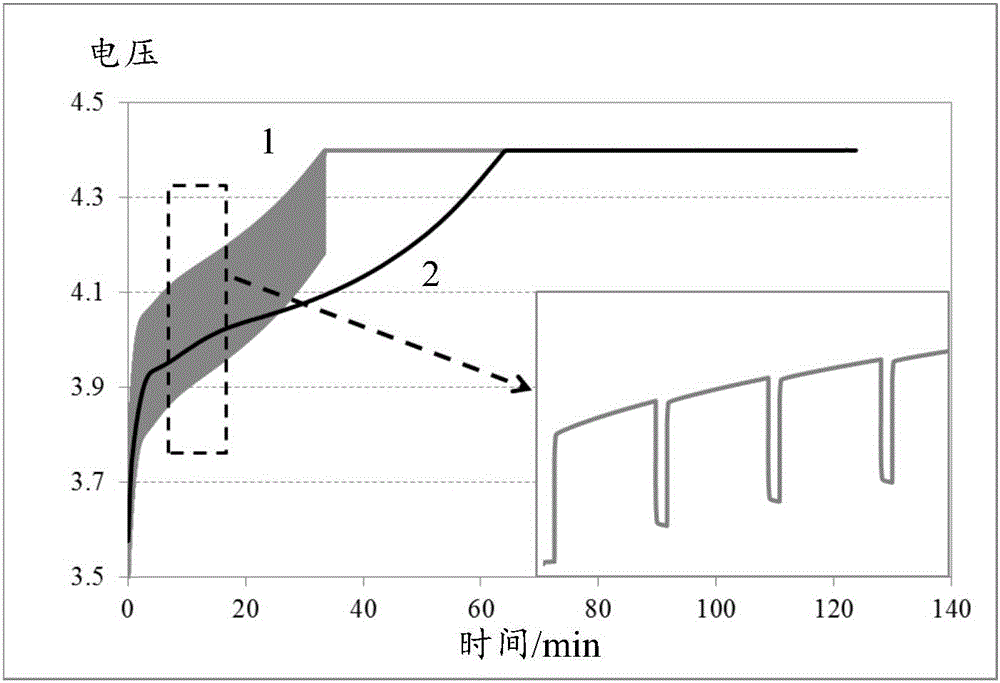

PendingCN113316878AShorten charging timeFast chargingSecondary cells charging/dischargingElectric powerElectrical batteryComputational physics

The invention provides a battery charging method, which comprises the following steps: in a first stage, charging a battery to a first stage voltage in a first charging mode or a second charging mode; and in the second stage, chaging the battery to a second-stage voltage in a third charging mode, wherein the second-stage voltage is larger than the first-stage voltage, and the third charging mode adopts the first charging mode or the second charging mode. The invention further provides an electronic device and a storage medium. According to the charging method provided by the invention, the charging speed of the battery in the charging process can be improved, and the total charging time is shortened.

Owner:NINGDE AMPEREX TECH

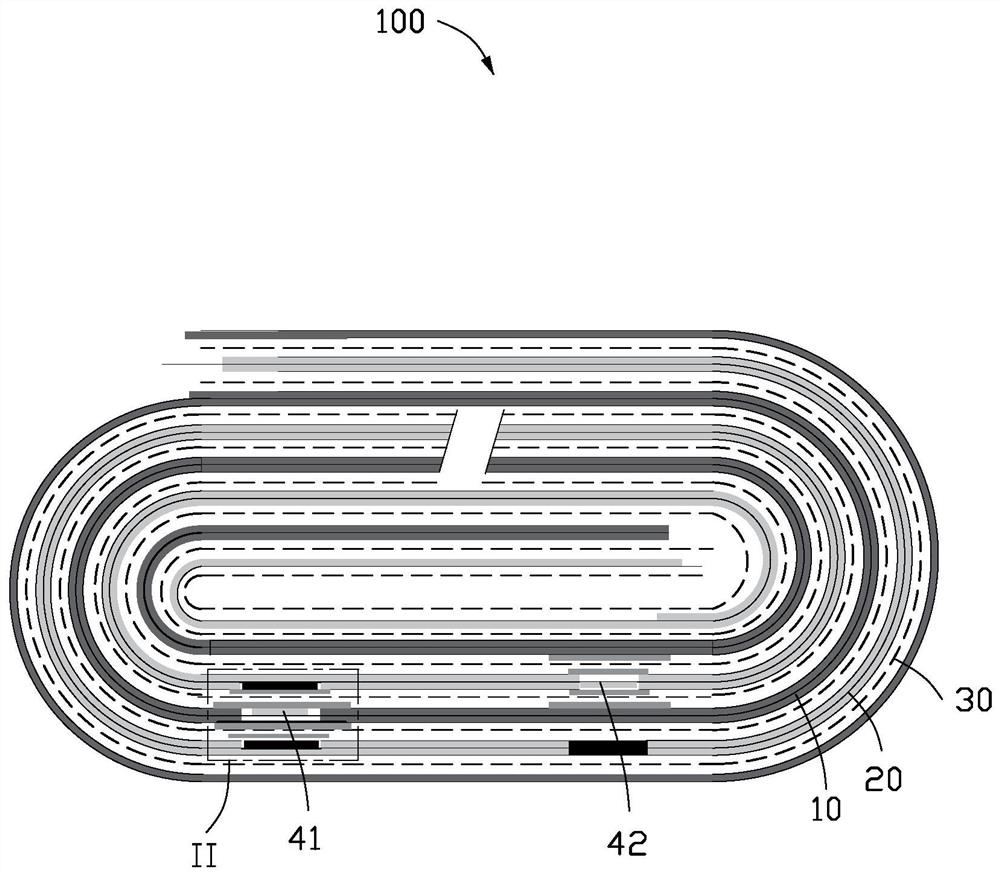

Manufacturing method of battery roll core and battery roll core

ActiveCN113381080AGuaranteed performanceEnsure safetyFinal product manufactureNon-aqueous electrolyte accumulator electrodesElectrical batteryEngineering

The invention discloses a manufacturing method of a battery roll core and a battery roll core. The manufacturing method of the battery roll core comprises the following steps that: step S10, a negative electrode current collector, a positive electrode current collector and at least two diaphragms are provided, the negative electrode current collector is coated with negative electrode slurry, the negative electrode slurry forms at least two convex parts on at least one side surface of the negative electrode current collector, and two adjacent convex parts are distributed at intervals along the extension direction of the negative electrode current collector, so that a negative electrode plate can be obtained, the positive electrode current collector is coated with positive electrode slurry, so that a positive electrode plate can be obtained; and step S20, the positive electrode plate, the diaphragm, the negative electrode plate and the diaphragm are overlapped, the first end of the positive electrode plate is wound, so that a flat roll core can be formed, and the convex parts cover the arc-shaped structure surface of the roll core on the negative electrode plate. According to the manufacturing method of the battery roll core and the battery roll core, more lithium embedding space can be provided for the negative electrode plate, so that the risk of lithium precipitation of the battery roll core is reduced.

Owner:APOWER ELECTRONICS CO LTD

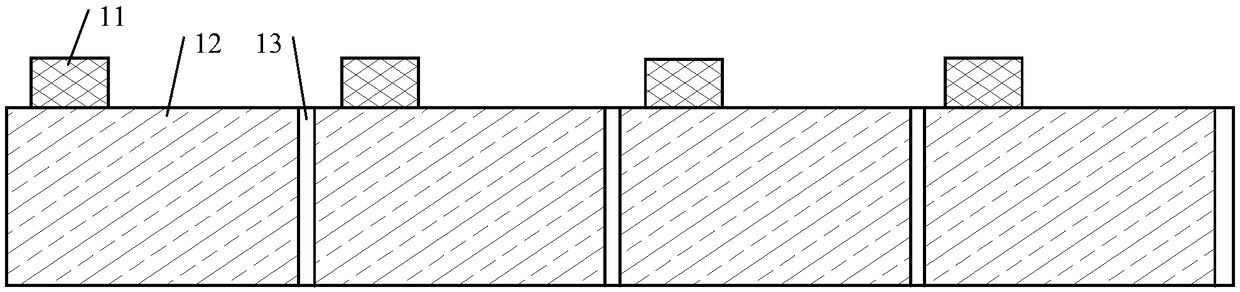

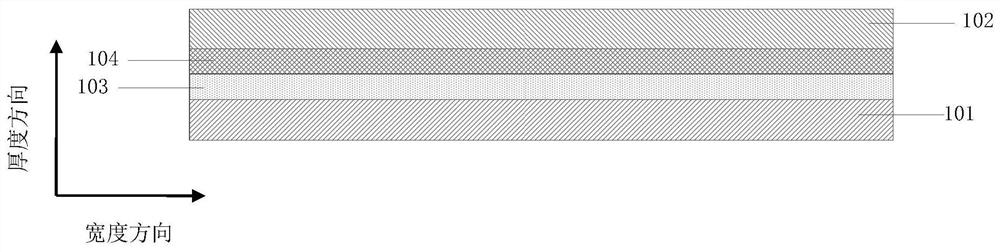

Negative plate and lithium ion battery

PendingCN113178543AReduce the risk of lithium analysisImprove securityNegative electrodesNon-aqueous electrolyte accumulator electrodesCurrent collectorLithium electrode

The invention provides a negative plate and a lithium ion battery. The negative plate comprises a current collector, a first coating, a second coating and a third coating. One side of the current collector is provided with a tab, at least one surface of the current collector is provided with a first coating area and a second coating area, and the first coating area is arranged close to the tab; the first coating covers the first coating area, the second coating covers the second coating area, and the thickness of the first coating is larger than that of the second coating; and third coatings are arranged on one surface, far away from the current collector, of the first coating and one surface, far away from the current collector, of the second coating. According to the embodiment of the invention, the thickness fluctuation of the bottom coating is eliminated by increasing the thickness of the bottom coating located in the edge area of the surface of the current collector, so that the thickness of the bottom coating is stable, the lithium precipitation risk of the negative plate caused by the interface difference existing in the contact area of the negative plate and the diaphragm is reduced, and the safety of the battery is improved.

Owner:ZHUHAI COSMX BATTERY CO LTD

Double-dislocation coating method and device

InactiveCN106423774AUniform thicknessUniform weightLiquid surface applicatorsCoatingsCoated surfaceEngineering

The invention relates to the field of coating processing, in particular to a double-dislocation coating method and device. The method comprises the following steps of: in a substrate tightening conveying process, adopting a negative-pressure source to fit and adsorb a to-be-coated surface; after conveying a substrate to a coating position, moving a negative-pressure source, and enabling the to-be-coated surface to fit to a dislocation lip mould head; adopting a kiss-coating mode to coat the to-be-coated surface; and after coating to predetermined length, moving the negative-pressure source, and enabling the to-be-coated surface to separate from the dislocation lip mould head. The device comprises a first roller, a second roller, a negative-pressure assembly, a moving assembly and a kiss-coating assembly, wherein the first roller and the second roller are arranged in parallel at intervals; the negative-pressure assembly comprises an absorption head which is positioned between the first roller and the second roller in the conveying direction; the kiss-coating assembly comprises the dislocation lip mould head which is positioned between the absorption head and the second roller in the conveying direction, and faces towards the to-be-coated surface; and the moving assembly is connected with the negative-pressure assembly, and can drive the absorption head to move. The double-dislocation coating method and device can guarantee uniform coating weight.

Owner:NINGDE AMPEREX TECH

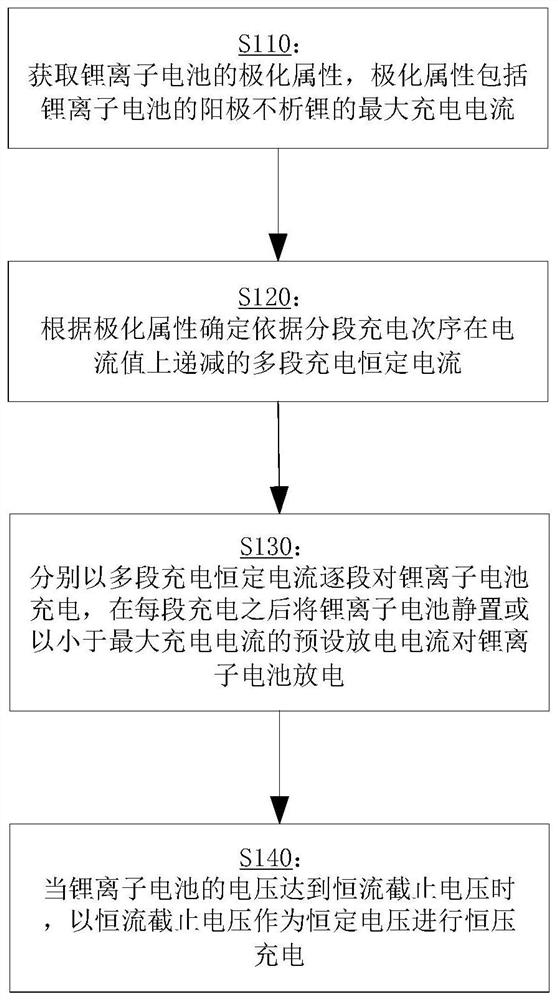

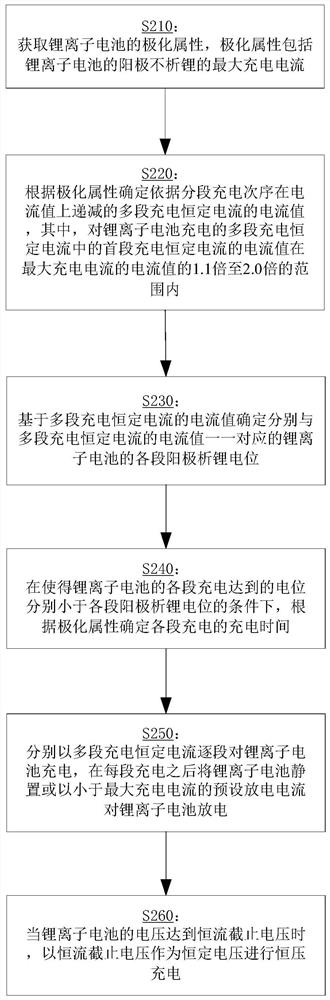

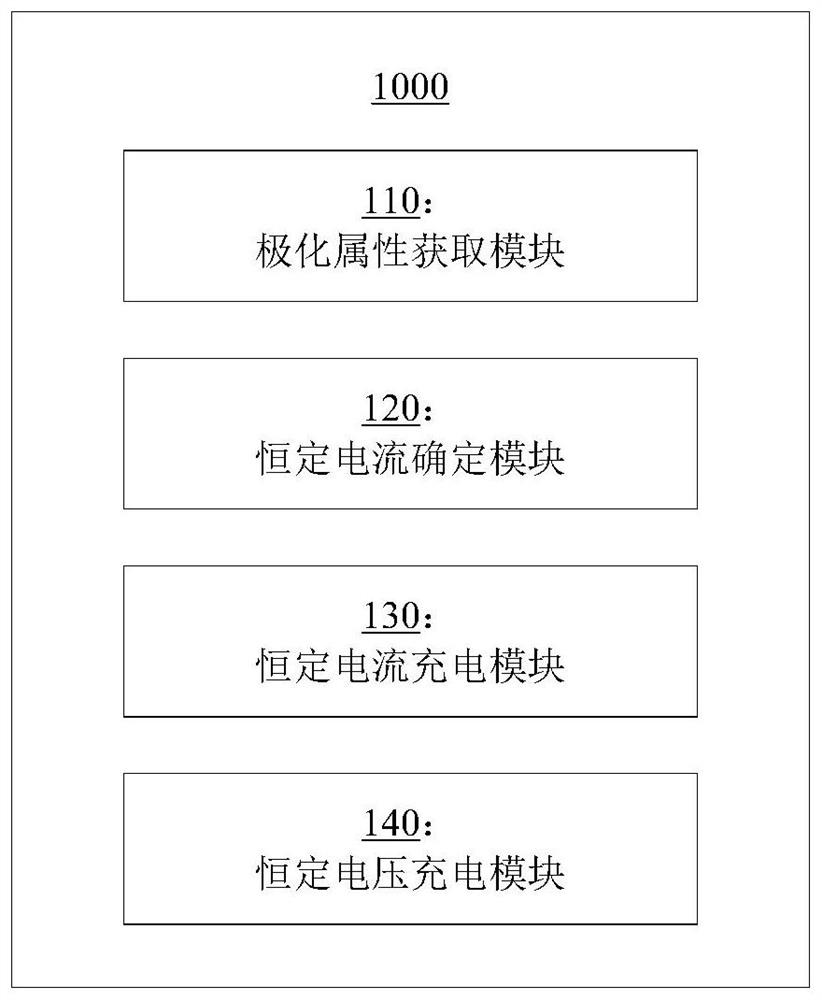

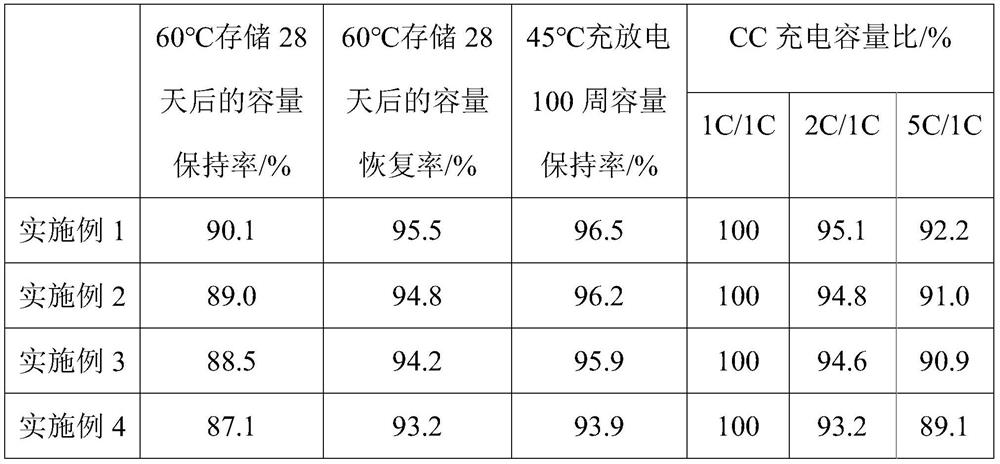

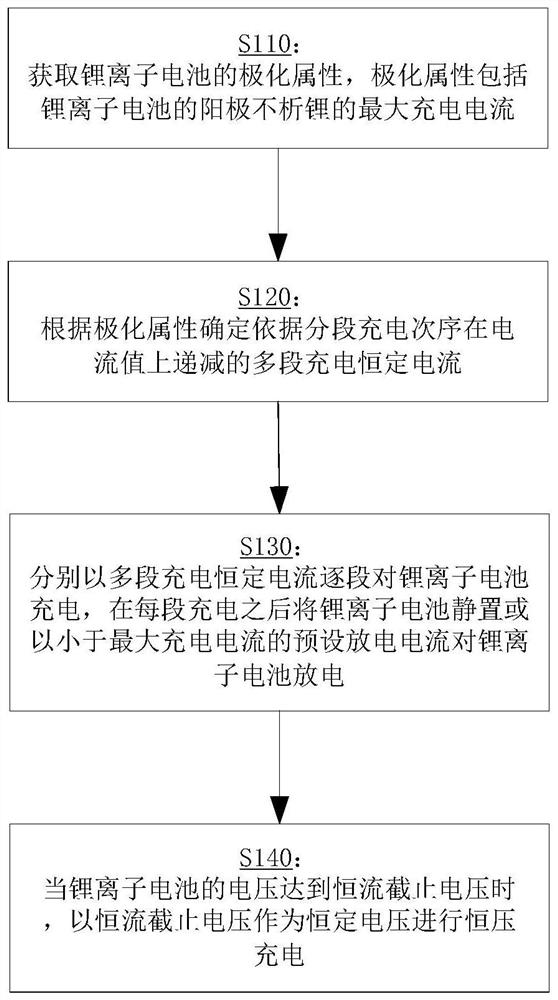

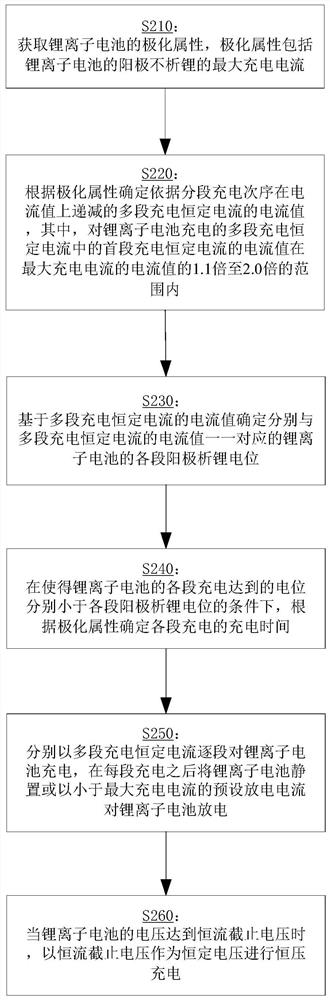

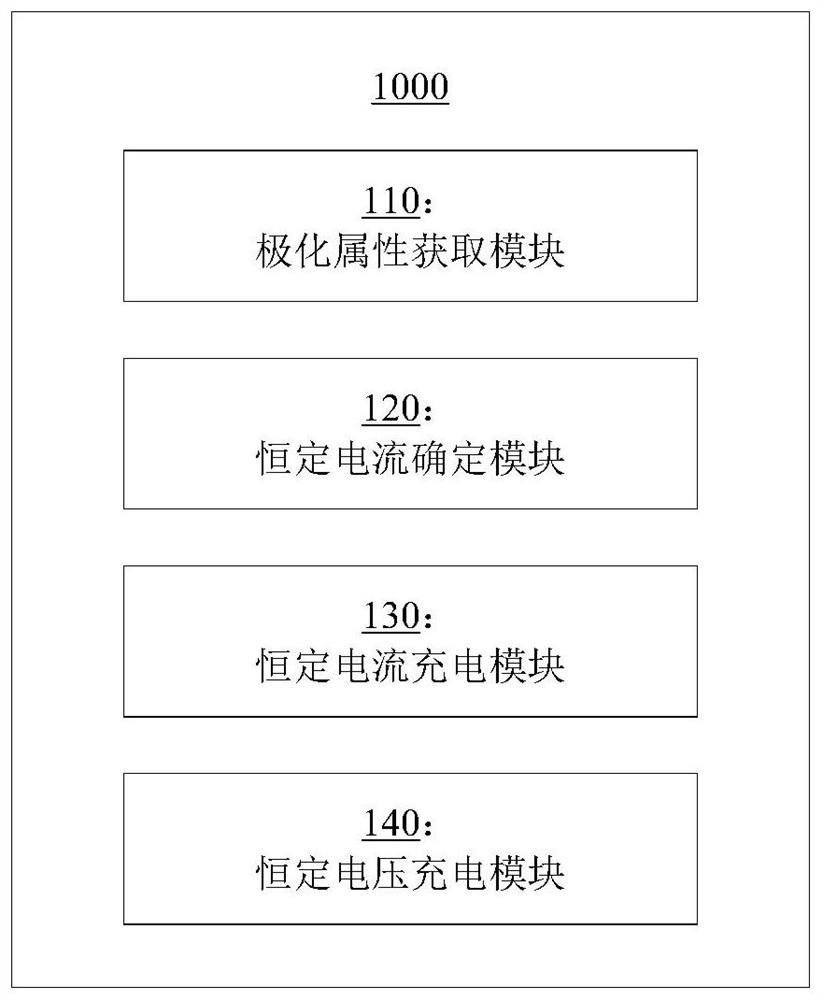

Charging method of lithium ion battery and charging device of lithium ion battery

ActiveCN112448050AReduce full charge timeReduce polarizationBatteries circuit arrangementsSecondary cells charging/dischargingEngineeringLithium-ion battery

The invention relates to a charging method of a lithium ion battery and a charging device of the lithium ion battery. The charging method of the lithium ion battery comprises the following steps: acquiring a polarization attribute of the lithium ion battery, wherein the polarization attribute comprises a maximum charging current of an anode of the lithium ion battery without separating out lithium; determining a plurality of sections of charging constant currents which are decreased progressively on the current value according to the sectional charging sequence according to the polarization attribute; respectively charging the lithium ion battery section by section by multiple sections of charging constant currents, and standing the lithium ion battery after each section of charging or discharging the lithium ion battery by a preset discharging current smaller than the maximum charging current; and when the voltage of the lithium ion battery reaches the constant-current cut-off voltage, taking the constant-current cut-off voltage as the constant voltage to carry out constant-voltage charging. According to the embodiments of the invention, the polarization of the battery is effectively reduced, so that the full-charge charging time of the lithium ion battery is reduced.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

Silicon-carbon negative electrode material with artificial SEI film and preparation method and application of silicon-carbon negative electrode material

ActiveCN113851613AReduce irreversible capacityImprove the first Coulombic efficiencyElectrode carriers/collectorsNegative electrodesVinyl etherElectrical battery

The invention provides a silicon-carbon negative electrode material with an artificial SEI film and a preparation method and application of the silicon-carbon negative electrode material, and the preparation method comprises the following steps: mixing a perfluoromethyl vinyl ether / maleic anhydride / 2-vinyl-1H-benzimidazole copolymer and a silicon-carbon negative electrode material to obtain a mixed solution, and drying the mixed solution to obtain the silicon-carbon negative electrode material with the artificial SEI film, wherein the perfluoromethyl vinyl ether / maleic anhydride / 2-vinyl-1H-benzimidazole copolymer is an artificial SEI film coated on the surface of the silicon-carbon negative electrode material. The copolymer plays a role of an artificial SEI film, has a good lithium ion transmission mechanism, and can reduce the risk of lithium separation, effectively reduce the irreversible capacity of the lithium ion battery and improve the first coulombic efficiency of the lithium ion battery; and the artificial SEI film has high thermal stability, and can greatly improve the stability of high-temperature storage and high-temperature circulation of the silicon negative electrode material.

Owner:EVE ENERGY CO LTD

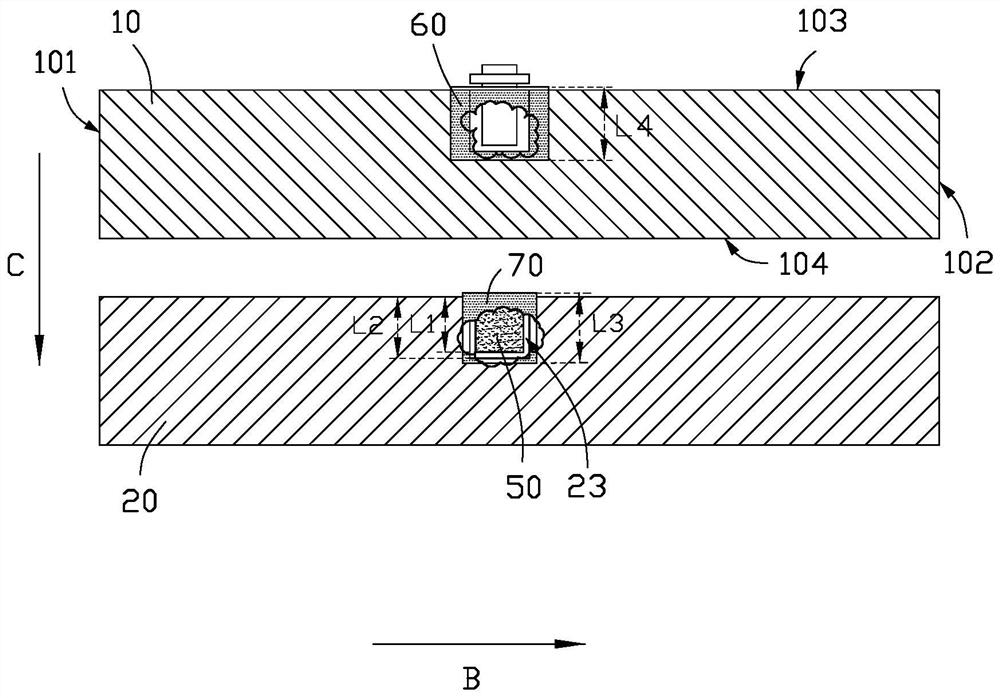

Electrochemical devices and electronic devices

ActiveCN113675372BIncreasing the thicknessReduce cornerFinal product manufactureSecondary cellsBand shapeHigh energy

The electrochemical device disclosed in the present application includes a wound battery cell and a casing for accommodating the battery cell. The battery cell includes a first pole piece, a second pole piece, and a film arranged in layers. The first pole piece includes a current collector, and the current collector It includes a first surface facing the inside of the battery core and a second surface facing away from the inside of the battery core; the tab is electrically connected to the current collector and protrudes from the current collector; the first active material layer is arranged on the first surface of the current collector; An active material layer includes a main coating and an edge coating. Along the first direction, the edge coating is located on the side of the main coating facing the tab, and is adjacent to or partially overlapped with the main coating; along the second direction , the main coating and the edge coating extend in a band shape, and the length of the edge coating is longer than that of the main coating; the electrochemical device has high energy density and good electrical performance.

Owner:NINGDE AMPEREX TECH

A kind of formation method of hard carbon negative electrode material lithium ion battery

ActiveCN109713386BImprove cycle stabilityGuarantee the safety of useFinal product manufactureSecondary cells charging/dischargingPhysical chemistryLithium-ion battery

The invention provides a method for forming a hard carbon negative electrode material lithium ion battery, belonging to the technical field of battery formation. The formation method of the present invention is to perform formation treatment on the battery that has been aged by liquid injection; the process of the formation treatment includes: charging to the designed lithium intercalation gram capacity-discharging process N times until the discharge depth reaches 100% of the target discharge depth; The designed lithium intercalation gram capacity is 350-700mAh / g, the target discharge depth is 100% of the designed lithium intercalation gram capacity; the depth of the first discharge is 10-90% of the target discharge depth, and the depth of the Nth discharge is compared to The depth of the N-1th discharge is increased by 1 to 20% of the target discharge depth; N≥2, where N is an integer. The present invention eliminates irreversible lithium in the cycle process by controlling the target discharge depth and each discharge depth, improves the lithium intercalation platform of the hard carbon negative electrode material, reduces the risk of lithium analysis, and improves the cycle stability of the hard carbon negative electrode material lithium ion battery .

Owner:上海飞鸿创联新能源发展有限公司

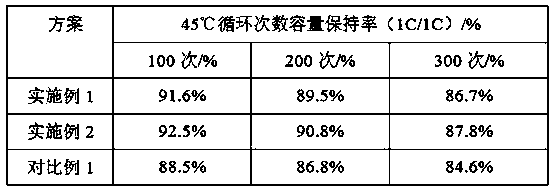

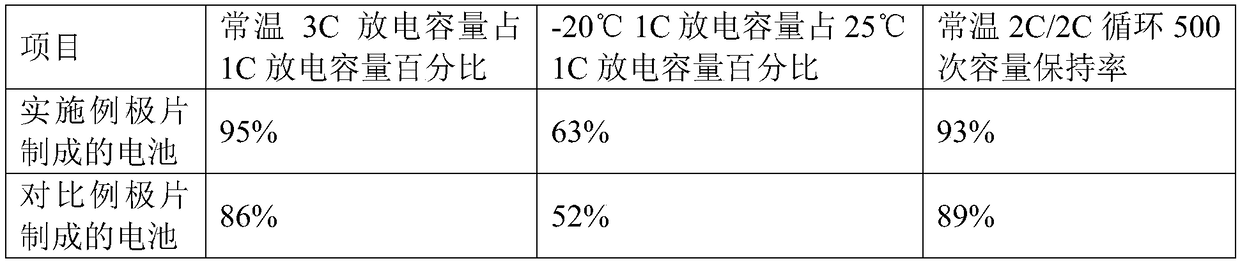

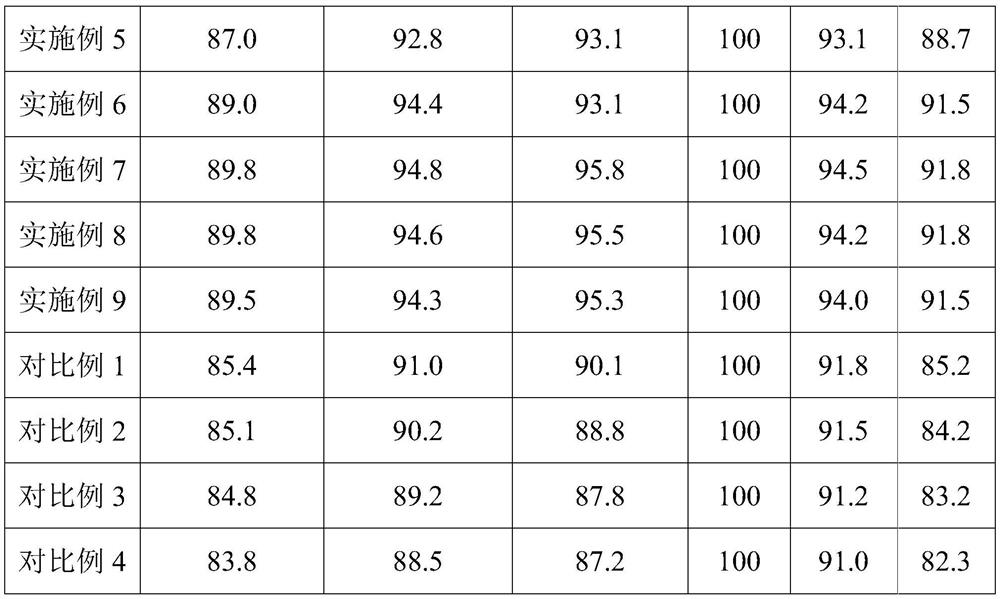

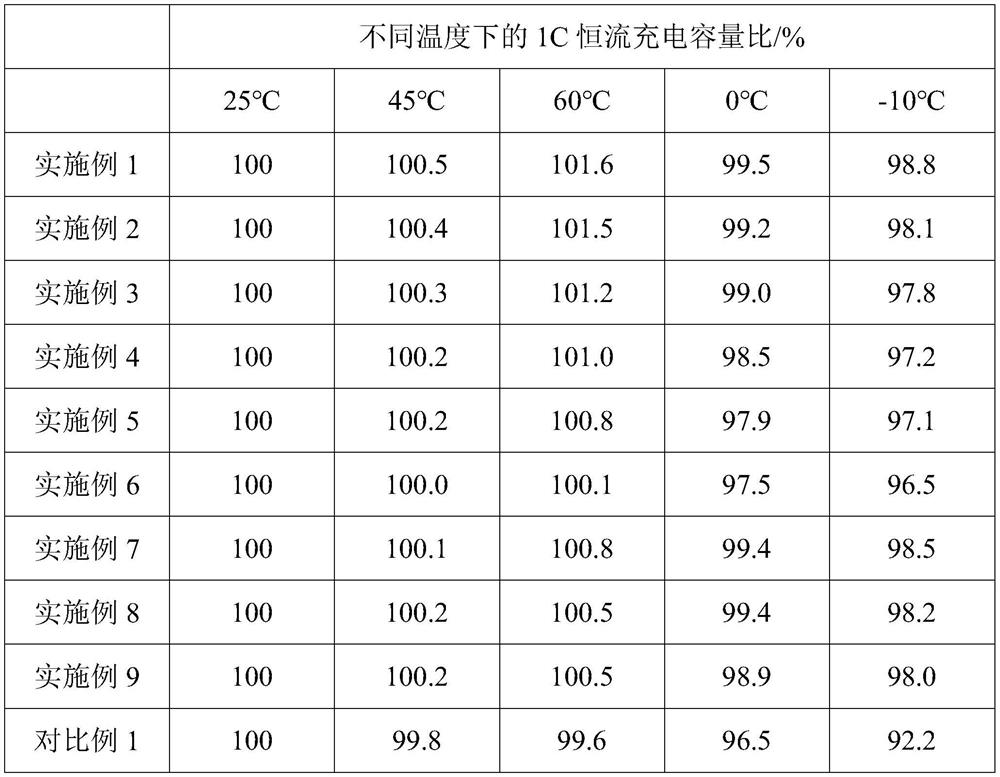

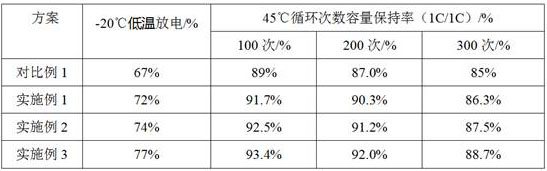

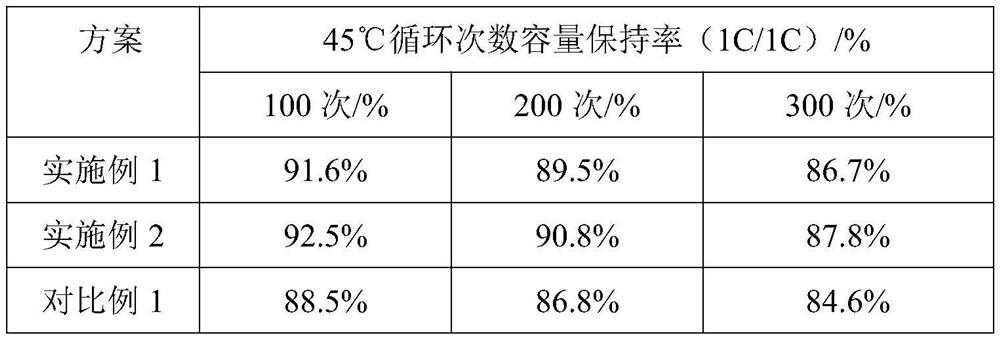

A preparation method of a lithium-ion battery with improved high-voltage low-temperature discharge and cycle performance

ActiveCN109888175BEvenly dispersedReduce compacted densityElectrode manufacturing processesSecondary cellsPhysical chemistryHigh voltage battery

Owner:ZHUHAI COSMX BATTERY CO LTD

Battery and electronic equipment

PendingCN113991189AIncrease the cathode capacity ratioReduce the risk of lithium analysisFinal product manufactureElectrode carriers/collectorsCurrent collectorEngineering

The invention provides a battery which comprises a positive plate and a negative plate. The positive plate and the negative plate are wound to form a roll core structure, the positive plate comprises a current collector, a first positive smear, a second positive smear, a third positive smear and a fourth positive smear, the first positive smear is adjacent to the third positive smear, and the first positive smear and the third positive smear are coated on the first surface of the current collector; the second positive smear is adjacent to the fourth positive smear, the second positive smear and the fourth positive smear are coated on the second surface of the current collector, and the first surface of the current collector is opposite to the second surface of the current collector; the first positive smear corresponds to the second positive smear; and the first positive smear and the second positive smear are provided with a plurality of holes. According to the embodiment of the invention, the plurality of holes are formed to reduce the content of the positive active material, so that the capacity ratio of the positive electrode to the negative electrode is improved, and the risk of lithium separation of the lithium ion battery is reduced.

Owner:ZHUHAI COSMX BATTERY CO LTD

Negative plate and battery comprising same

PendingCN114512670AImproved magnification performanceIncrease energy densitySecondary cellsNegative electrodesEngineeringBattery cell

The invention provides a negative plate and a battery comprising the negative plate. The negative plate comprises a negative current collector, an electrolyte supplementing layer and a negative active material layer, the electrolyte supplementing layer is positioned on the surface of one side or two sides of the negative electrode current collector, and the negative electrode active material layer is positioned on the surface of the electrolyte supplementing layer; the negative electrode active material layer is provided with a first orientation hole. By using the negative plate, the rate capability and the energy density of the battery can be improved at the same time, and the lithium separation risk is reduced, the utilization rate of the electrode plate is improved and the energy density is improved by constructing an orientation hole rapid ion channel on the surface of the electrode plate.

Owner:ZHUHAI COSMX BATTERY CO LTD

Lithium-ion battery charging method and lithium-ion battery charging device

ActiveCN112448050BReduce full charge timeReduce polarizationBatteries circuit arrangementsSecondary cells charging/dischargingLithium-ion batteryMaterials science

The disclosure relates to a charging method for a lithium ion battery and a charging device for the lithium ion battery. The charging method of lithium-ion battery comprises: obtaining the polarization property of lithium-ion battery, and polarization property comprises the anode of lithium-ion battery and does not analyze the maximum charging current of lithium; According to the polarization property, it is determined that according to the stepwise charging sequence, the current value decreases progressively. Multi-stage charging constant current; charge the lithium-ion battery step by step with multi-stage charging constant current, and after each stage of charging, let the lithium-ion battery stand still or discharge the lithium-ion battery at a preset discharge current that is less than the maximum charging current; when the lithium-ion When the voltage of the battery reaches the constant current cutoff voltage, constant voltage charging is performed with the constant current cutoff voltage as a constant voltage. Various embodiments of the present disclosure effectively reduce the polarization of the battery, thereby reducing the full charge time of the lithium-ion battery.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

Electrochemical and electronic devices

ActiveCN113078287BImprove cycle performanceImprove securityNon-aqueous electrolyte accumulator electrodesSecondary cells servicing/maintenanceEngineeringIsolation membrane

The present application provides electrochemical devices and electronic devices. The electrochemical device includes a positive pole piece, a negative pole piece, and a separator disposed between the positive pole piece and the negative pole piece. The electrochemical device satisfies at least one of the following conditions (a)-(d): (a) a protective coating is provided on the surface of at least one side of the isolation membrane, and the protective coating includes a blocking agent; (b) the isolation membrane Including a blocking agent; (c) the negative electrode pole piece includes a negative electrode active material layer, and the surface of the negative electrode active material layer is provided with a protective coating; (d) the negative electrode active material layer includes core-shell structure particles, and the outer shell of the core-shell structure particles includes At least one of inorganic materials or polymers, and the core of the core-shell structured particle includes the blocking agent. The blocking agent includes at least one of red phosphorus, sulfur, iodine, or selenium. The embodiments of the present application can reduce the risk of lithium precipitation and improve the cycle performance and safety performance of the electrochemical device.

Owner:NINGDE AMPEREX TECH

A lithium-ion battery negative electrode with improved high-voltage cycle performance and preparation method thereof

ActiveCN110323409BImprove cycle performanceImprove polarization effectSecondary cellsElectrode collector coatingElectrical batteryMaterials science

The invention discloses a lithium ion battery negative electrode for improving high-voltage cycle performance and a preparation method thereof, and belongs to the technical field of lithium ion batteries. The specific scheme is that the negative electrode comprises a negative electrode current collector and a negative electrode coating; the negative electrode coating comprises a long paste coatinglayer and a short paste coating layer; one surface of the negative electrode current collector is coated with the long paste coating layer in a spaced mode, and the other surface of the negative electrode current collector is coated with the short paste coating layer in a spaced mode; and the negative electrode paste of the long paste coating layer and the negative electrode paste of the short paste coating layer are different. According to the invention, through employing two coating processes, the two sides of the negative current collector are respectively coated with different types of negative slurry to control the liquid absorption performance and the dynamic performance of a long paste coating layer and a short paste coating layer of a negative pole piece of the high-voltage battery; and particularly, the polarization effect between the long paste coating layer and the negative electrode current collector is improved, so that the cycle performance of the high-voltage battery isimproved, and the lithium precipitation risk of the negative electrode single paste coating layer is reduced.

Owner:ZHUHAI COSMX BATTERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com