Electrode plate and manufacturing method thereof, and electrochemical device

An electrode pole piece and manufacturing method technology, applied in electrode manufacturing, electrochemical generator, electrode current collector coating, etc., can solve problems such as unsatisfactory effect, reduce the risk of lithium precipitation, prolong service life, and improve power performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

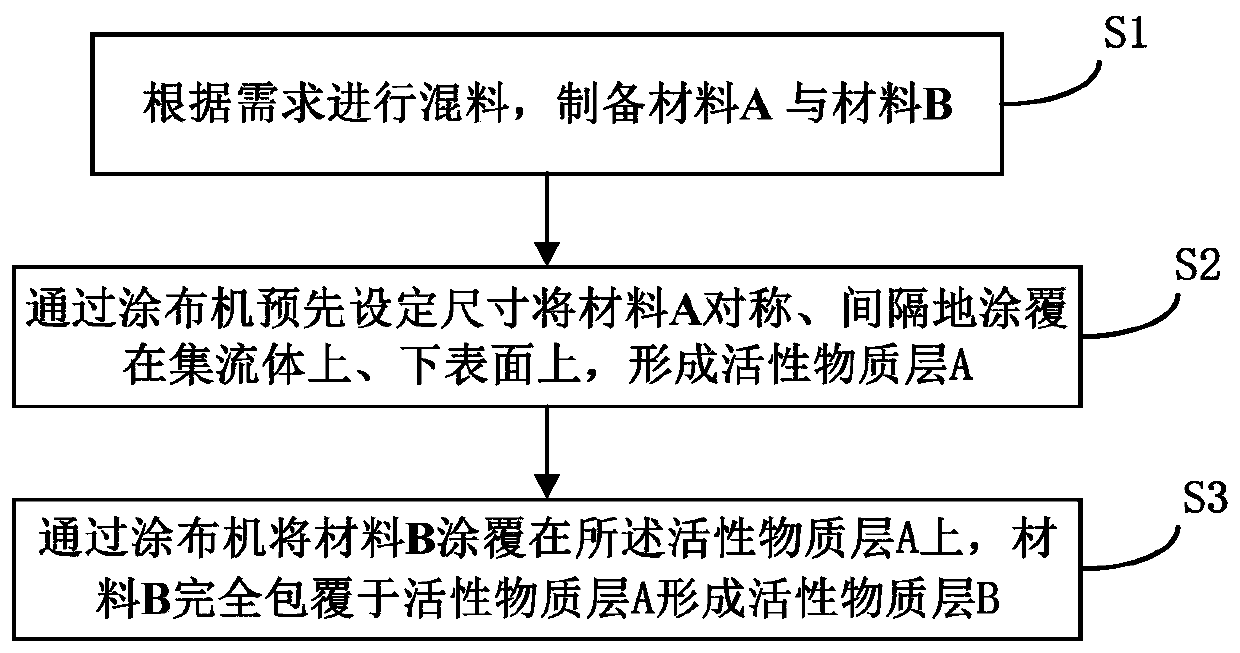

[0032] By changing the traditional coating method, the present invention coats two materials with different properties on the current collector in layers, so that the surface layer has the ability to quickly deintercalate lithium ions, reduce the risk of lithium precipitation on the surface of the pole piece, and improve the safety performance of the battery , extending the battery life, but also improve the power performance of the battery. The present invention will be described in detail below with reference to the specific embodiments and the accompanying drawings, but the embodiments in the application documents should not be construed as limitations on the application documents.

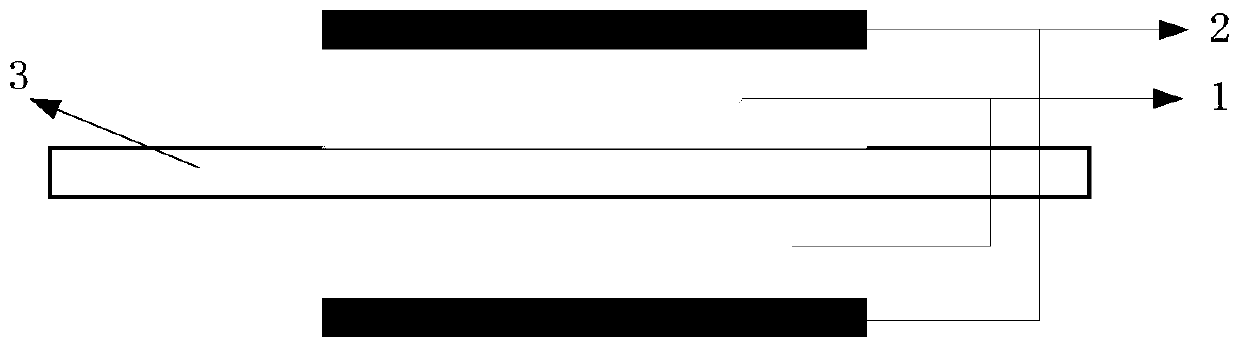

[0033] like Figure 1-2 As shown, the present invention provides an electrode pole piece, including a current collector, which plays the role of transferring electrons; in this embodiment, the current collector is preferably selected from copper foil and tin foil with excellent electrical condu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com