Negative plate and battery comprising same

A technology of negative electrode sheet and negative electrode, which is applied in the field of negative electrode sheet and batteries including the negative electrode sheet, can solve the problems of low utilization rate of negative electrode sheet, etc., achieve the goal of improving rate performance and energy density, improving concentration polarization, and improving utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

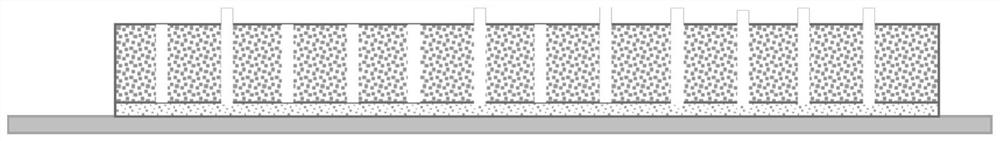

Image

Examples

Embodiment 1

[0084] Mix 80wt% garnet-type solid electrolyte LLZO, 5wt% conductive carbon black and 15wt% polyvinylidene fluoride, add N-methylpyrrolidone to stir and disperse to form a slurry, that is, electrolyte supplement layer slurry.

[0085] The graphite that particle diameter Dv50 is 15 μ m prepares negative electrode slurry as negative electrode active material: according to negative electrode active material 96.8%, conductive agent (conductive carbon black) 1.2%, binder (styrene-butadiene rubber) 2% mass ratio and water Mixing and stirring to prepare negative electrode active material layer slurry, the viscosity of the slurry is 2000-5000 mPa·s, and the solid content is 40%-50%.

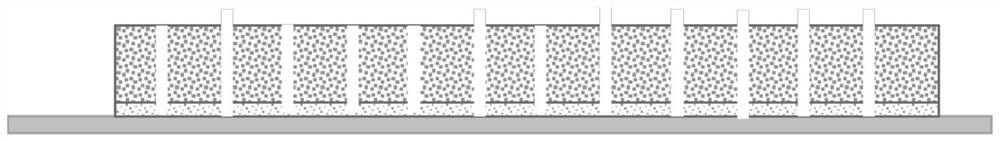

[0086] The electrolyte replenishment layer slurry and the negative electrode active material layer slurry are coated on the negative electrode current collector using a double-layer coating device, wherein the electrolyte replenishment layer is coated on the negative electrode current collector, and the n...

Embodiment 2~3

[0090] Other operations were the same as in Example 1, except that the thickness H of the negative electrode active material layer and the radius R of the first alignment hole after drying and rolling were different, as shown in Table 1 for details.

Embodiment 4

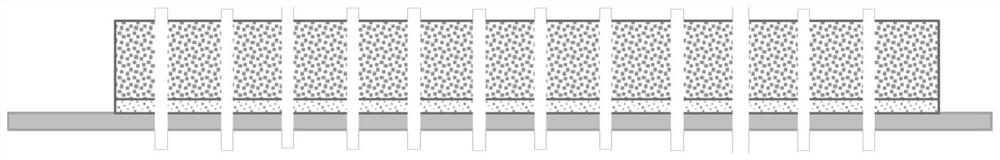

[0092] The other operations are the same as in Example 1, the difference is that the first orientation hole with a radius R of 25 μm is constructed on the negative electrode active material layer, and the first orientation hole with a radius R of 25 μm is constructed on the electrolyte replenishment layer by using the method of arranging the nail plate in an array and rolling. The second orientation hole, the third orientation hole with a radius L of 25 μm is constructed on the negative electrode current collector, the specific structure is as follows figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com