Patents

Literature

301results about How to "Good plastic effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

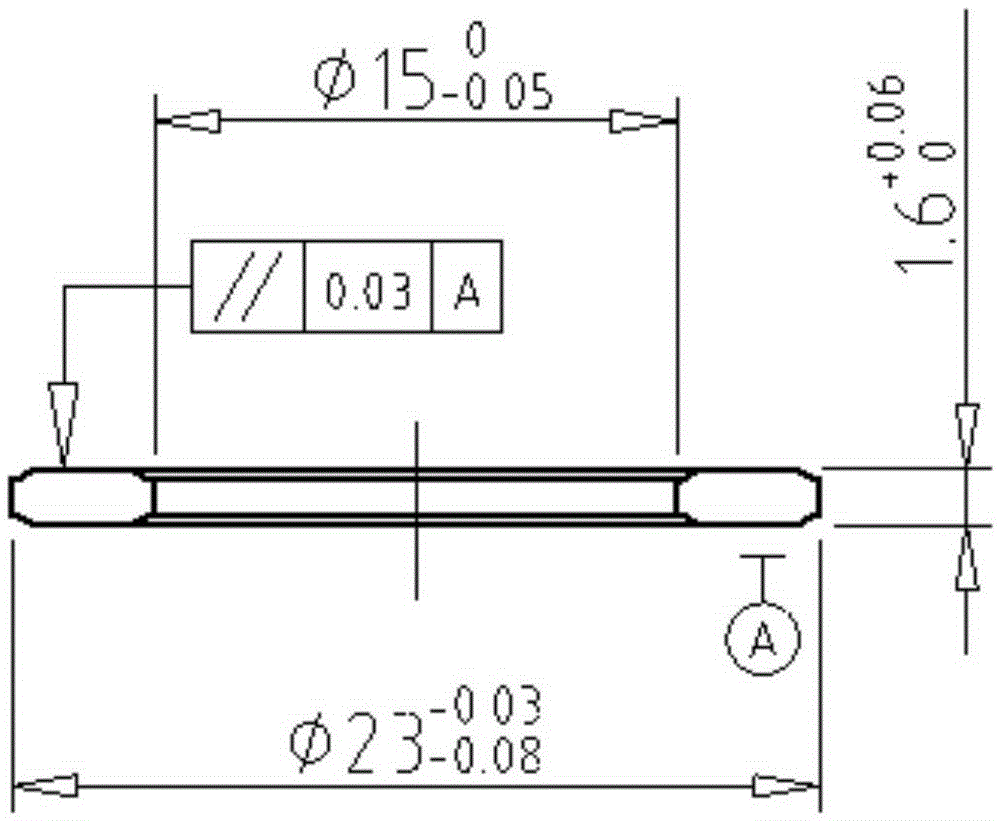

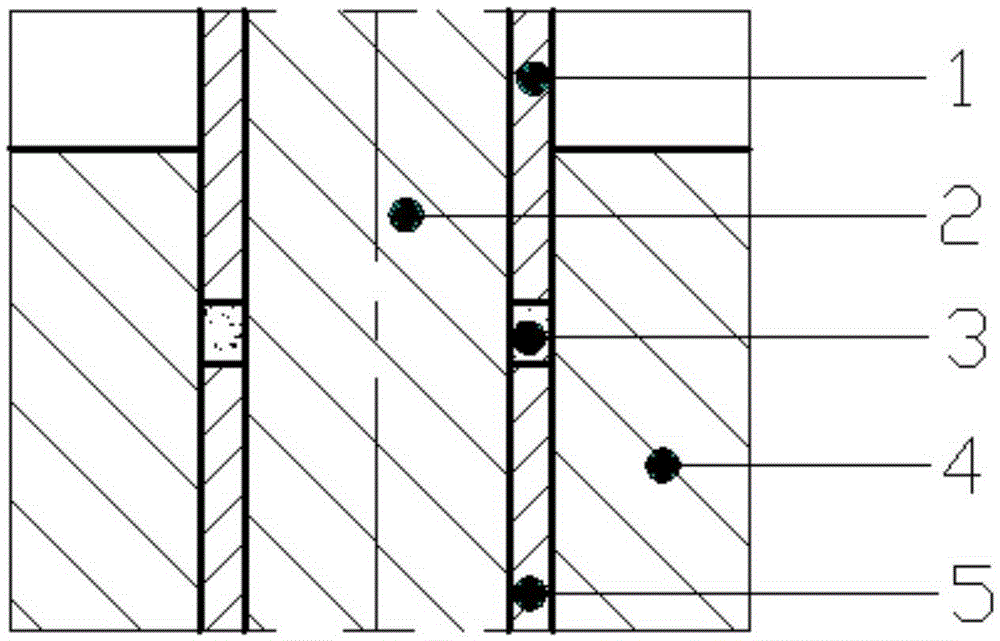

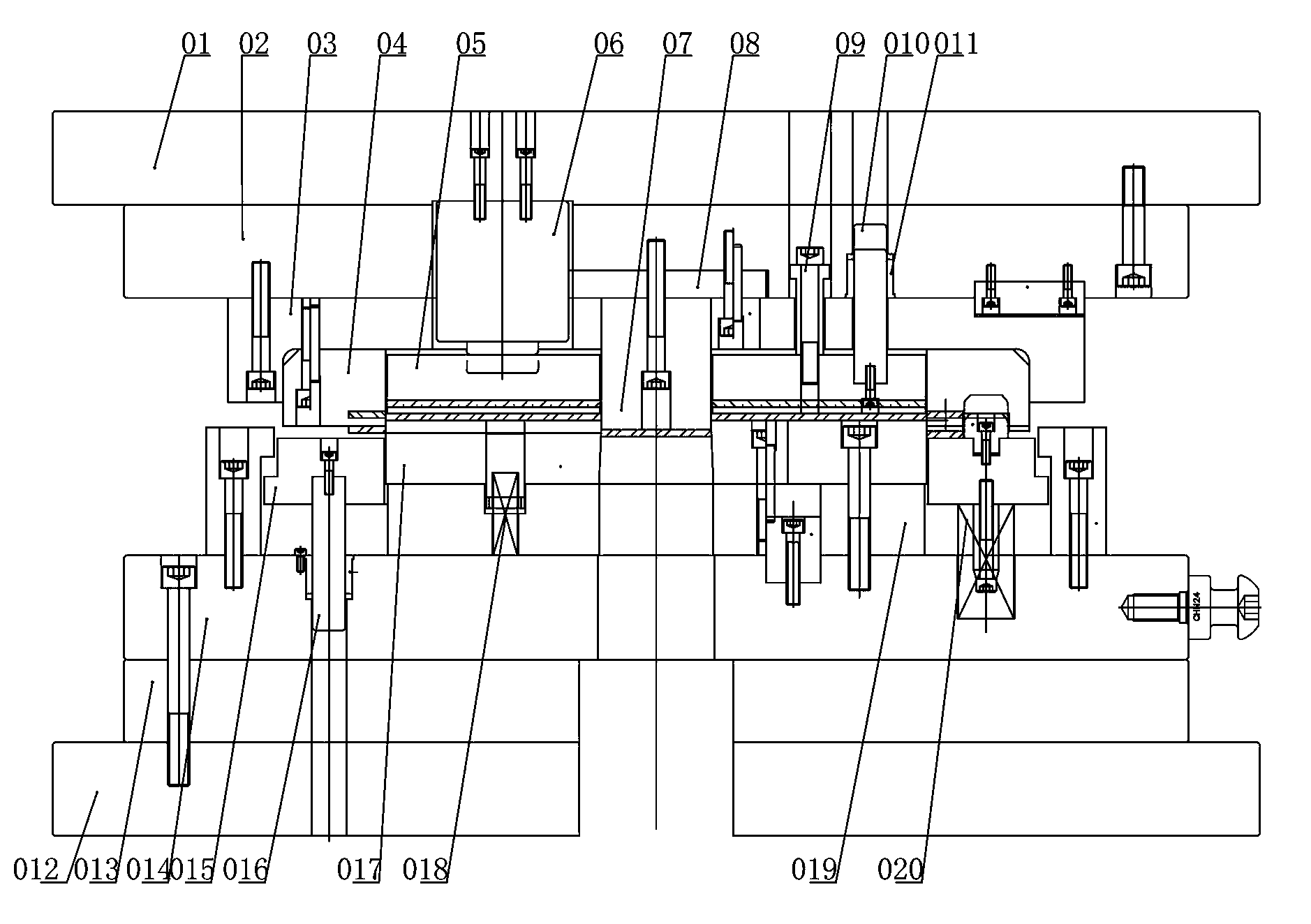

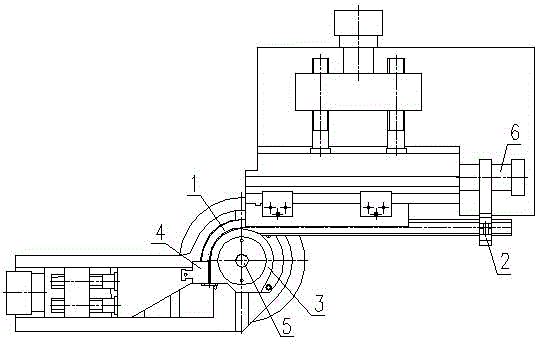

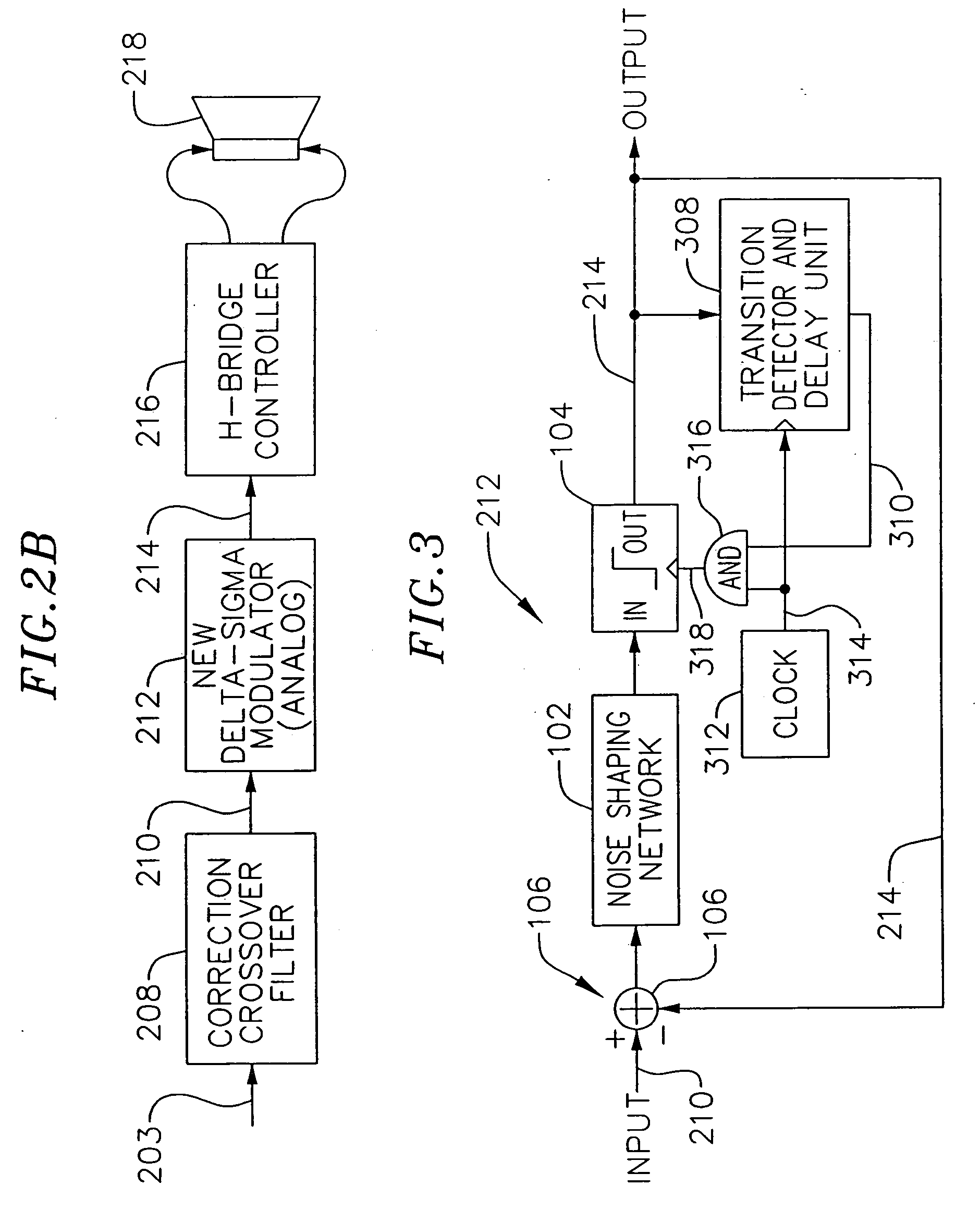

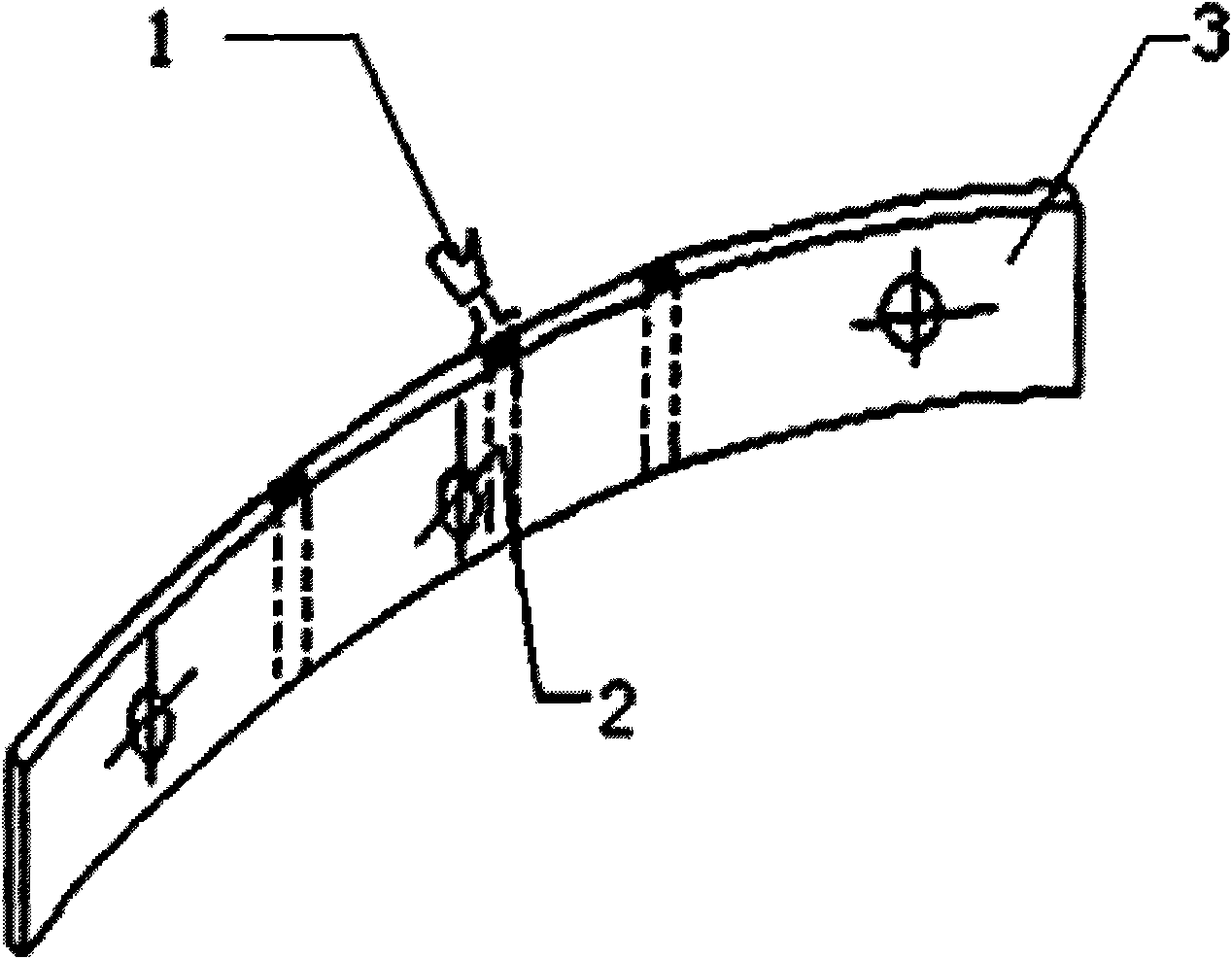

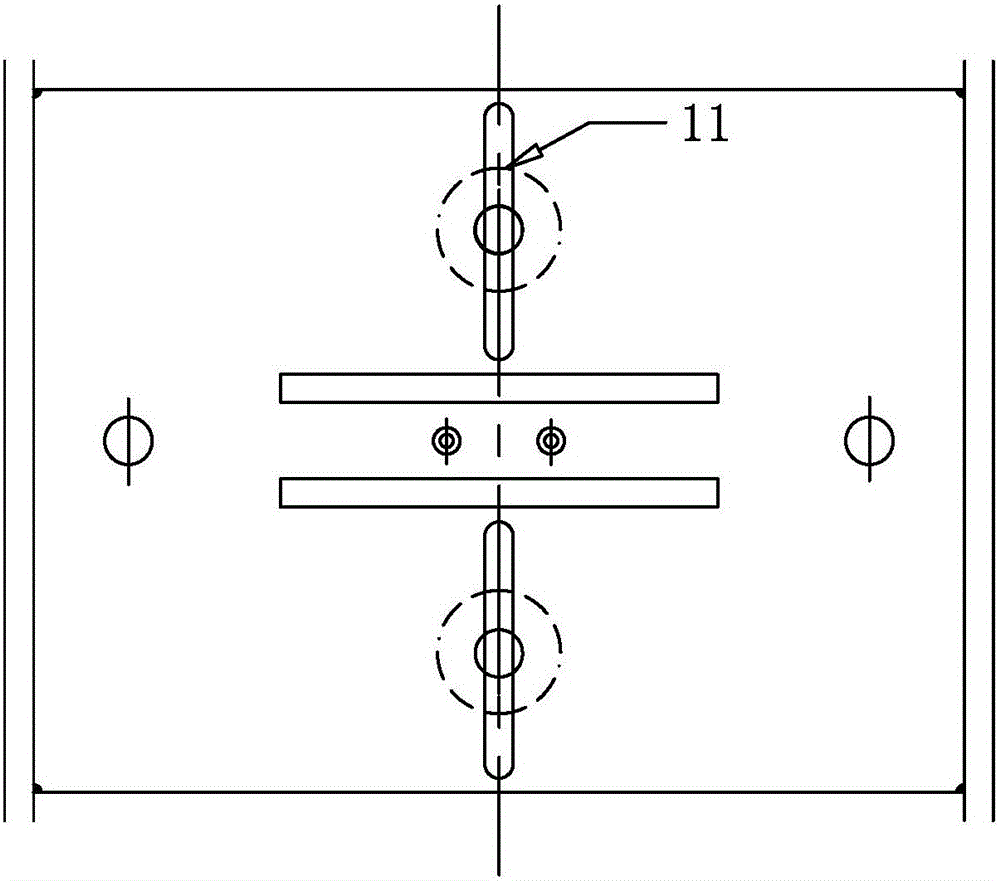

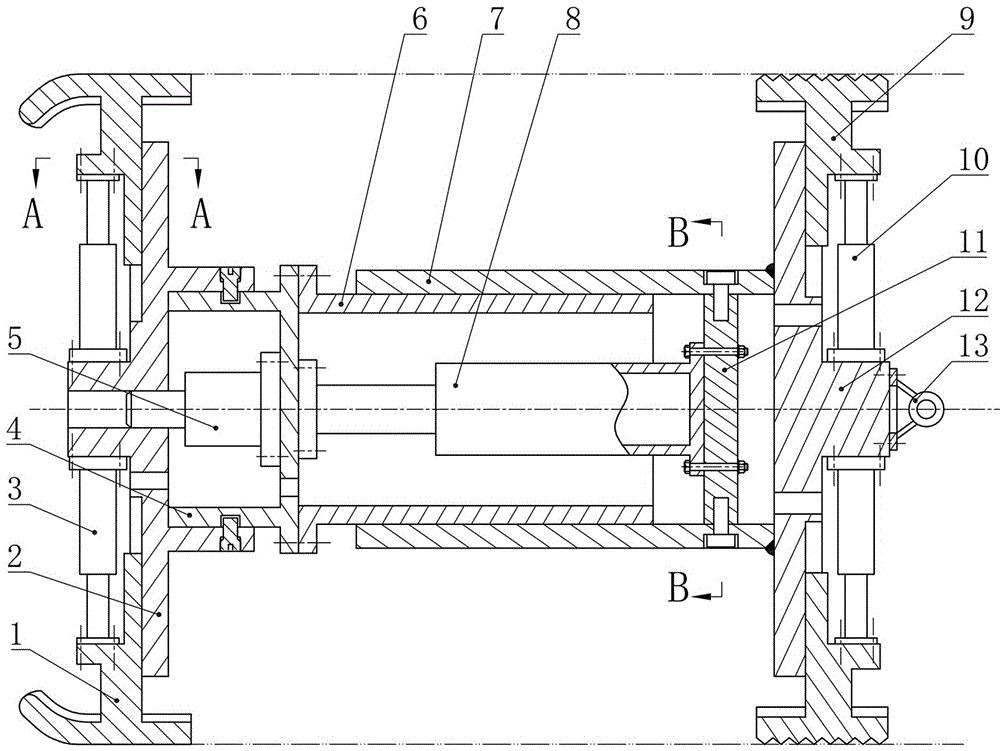

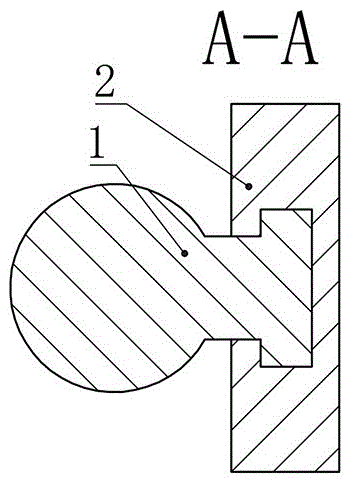

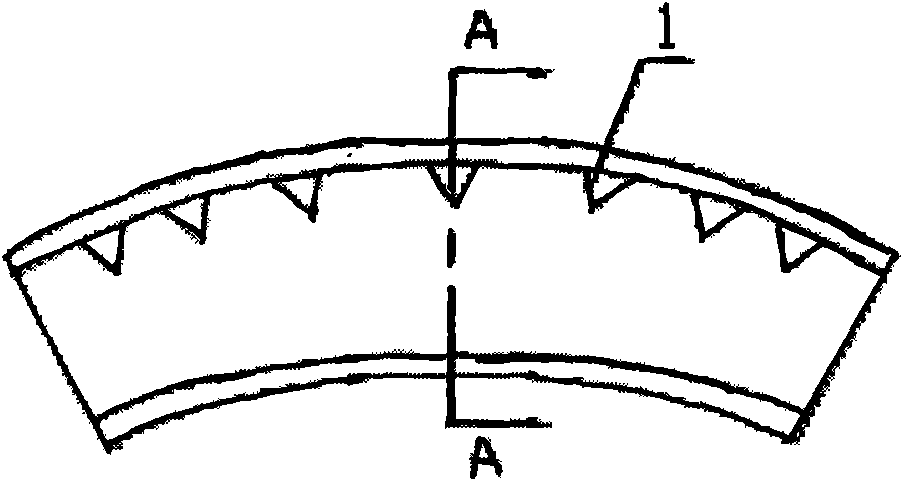

Shaping mechanism for powder metallurgy spacer products

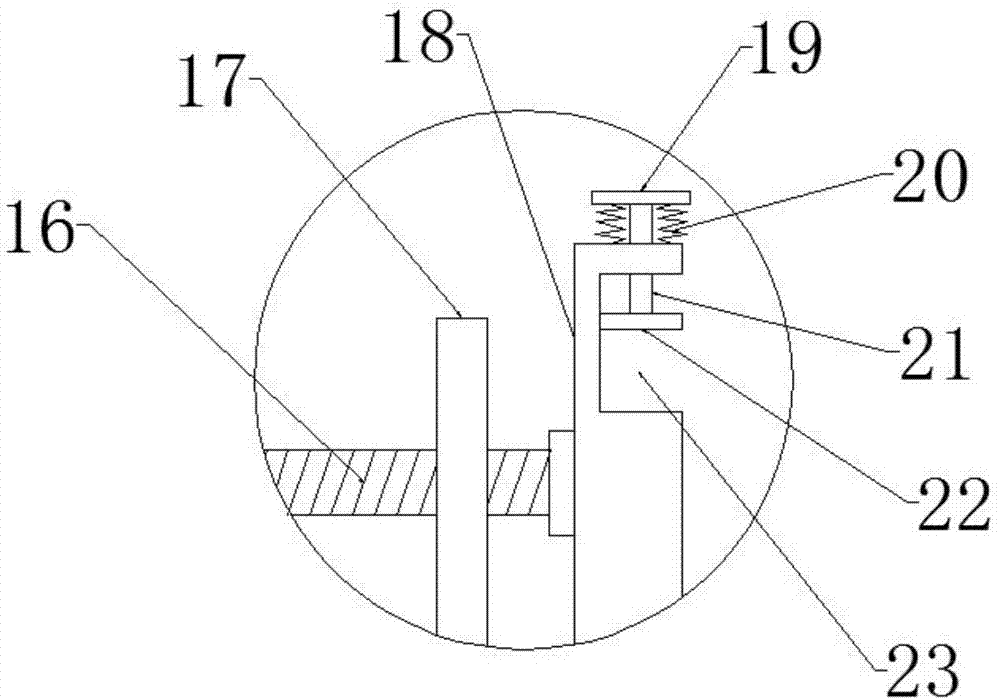

The invention discloses a shaping mechanism for powder metallurgy spacer products. The shaping mechanism for the powder metallurgy spacer products comprises an upper punch. An upper punch hanging block is connected to the upper punch. A floating punch is movably connected to the upper punch hanging block and has a degree of freedom of movement relative to the upper punch hanging block. A cushion block used for storing the products to be shaped is arranged below the floating punch. Height check blocks are arranged on the edges of the cushion block and are higher than the cushion block. According to the shaping mechanism, the parallelism of the shaped products depends on the machining precision of the cushion block and the check blocks, the problem that when a mechanical press is used for shaping, the parallelism tolerance of the products cannot be controlled and is instable is solved, and the shaping capacity is greatly improved; the influence of the precision of the press on the parallelism tolerance of the products is eliminated, the requirement for purchasing a high-precision press is avoided, and the cost is reduced; in addition, multiple products to be shaped can be placed on the cushion block during one-time shaping, so that the shaping efficiency is greatly improved, and the defect that a hydraulic machine acts slowly is overcome.

Owner:常熟市华德粉末冶金有限公司

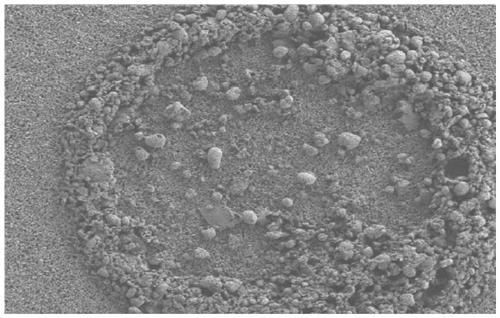

Graphite spheroidization method and production system thereby

The invention discloses a graphite spheroidization method and a production system thereby. The method comprises the following three steps of: (1) ultra-fine pulverizing, namely pulverizing graphite to a proper granularity by utilizing an ultra-fine high-energy pulverizer; (2) reshaping treatment, namely performing reshaping treatment on the pulverized graphite by utilizing a batch-type or continuous reshaping system consisting of one or more special reshaping devices and a micro-nano particle reshaping cladding system; and (3) ultra-fine multilevel classification, namely performing high-precision multilevel series classification on the graphite subjected to reshaping treatment by utilizing an ultra-fin multilevel classification system, so as to obtain narrow granular spherical graphite with the D50 of 3-35mu m. The method and the system haves the following advantages: the product spheroidization effect is good, the tap density is large, the yield of finished products is high, a favorable reshaping effect can be achieved for artificial graphite which is difficult to reshape, the preparation period is short, the processing equipment is compact, and the method is safe and environmentally-friendly.

Owner:WUHU ZHEXIN NEW ENERGY

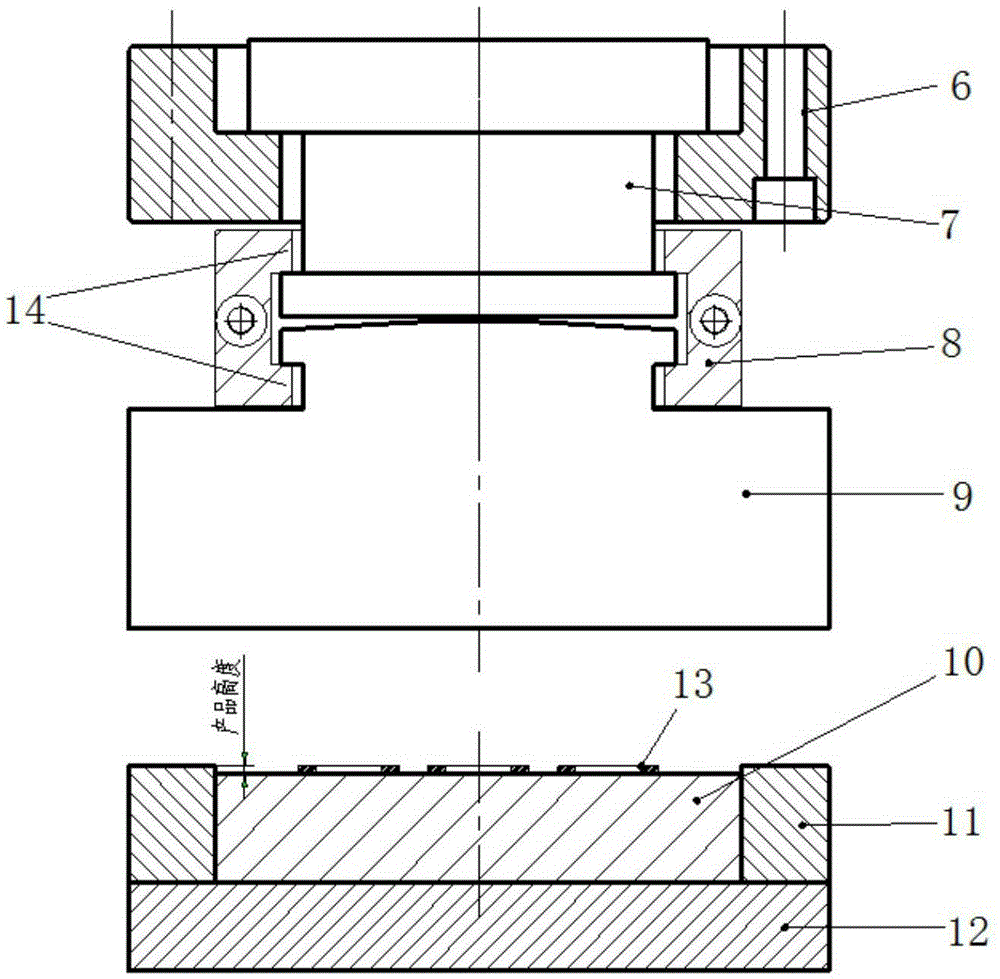

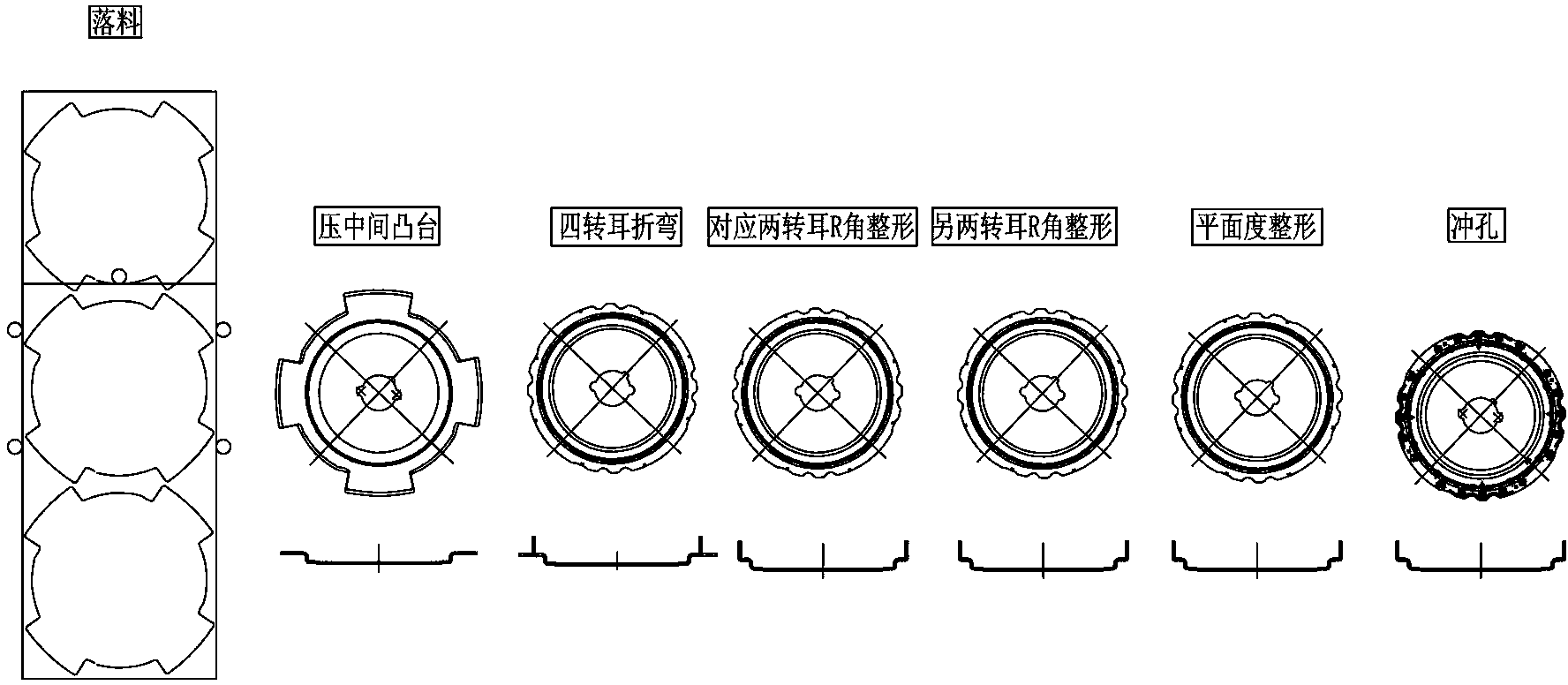

Clutch cap forming process and forming equipment thereof

The invention discloses a clutch cap forming process. The clutch cap forming process is characterized by including the following steps of (a) blanking, (b) pressing a middle boss, (c) bending four rotating lugs, (d) angle R shaping of two corresponding rotating lugs, (e) angle R shaping of the other two rotating lugs, (f) shaping flatness, and (g) punching. The invention further discloses clutch cap forming equipment which comprises a blanking die, a stretching die, a bending die, a first shaping die, a second shaping die and a punching die. According to the clutch cap forming process and the forming equipment thereof, the mode that pulling is carried out first and then folding is carried out is adopted, the thickness of a clutch can reach 6.35 mm, and the obtained bearing force of the clutch can reach 100000 newtons; meanwhile, a bending mode with an angle R is adopted, the probability that materials break during bending is reduced, and the bending success rate reaches 99.3%; angle R shaping of the rotating lugs is carried out twice, the angle R is eliminated, an assembling hole is convenient to form, and the best shaping effect is achieved; a flatness shaping procedure is arranged, accuracy of the formed hole is guaranteed, and meanwhile, a cap of the clutch and the clutch are accurately assembled.

Owner:RAINBOW METAL TECH

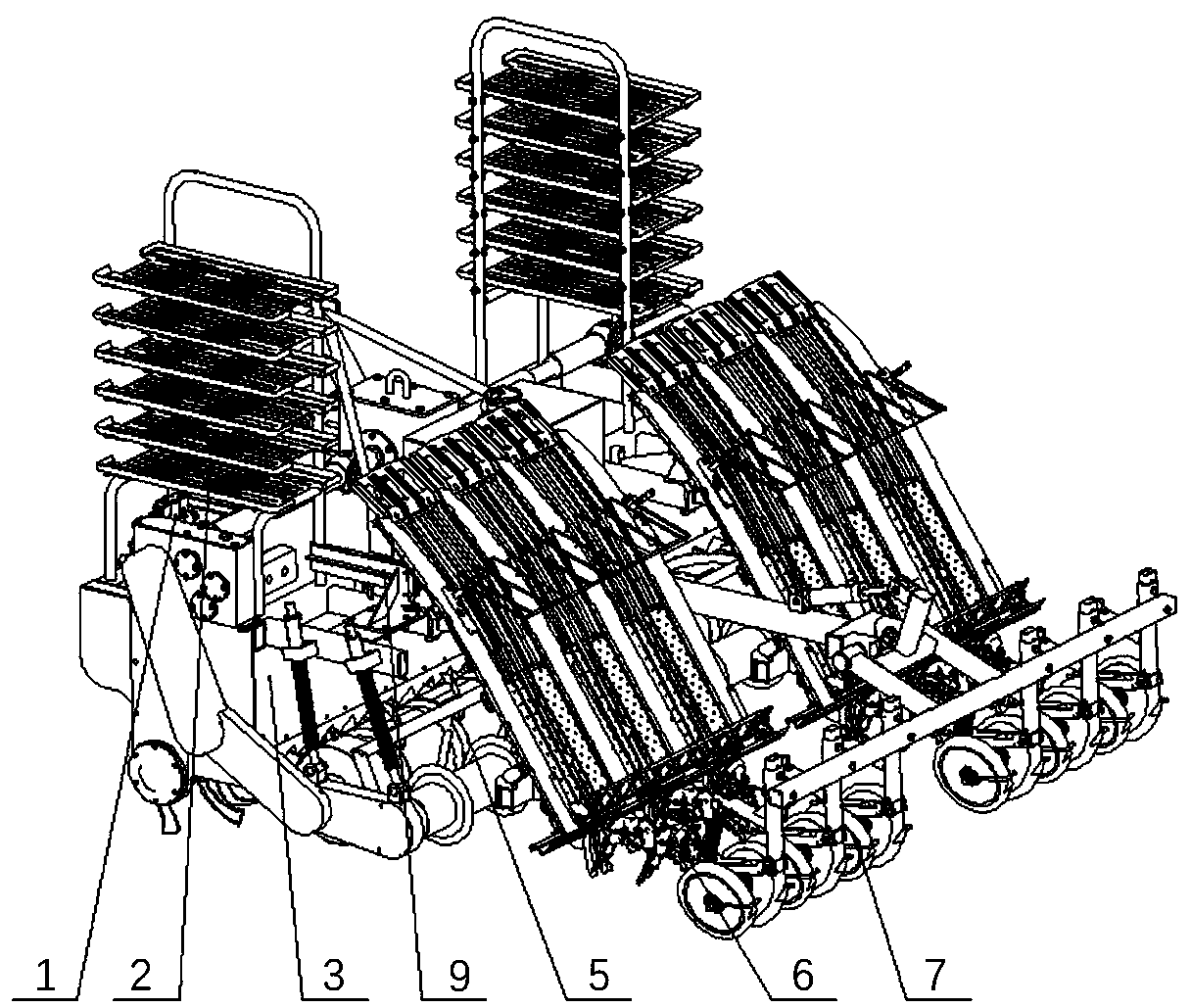

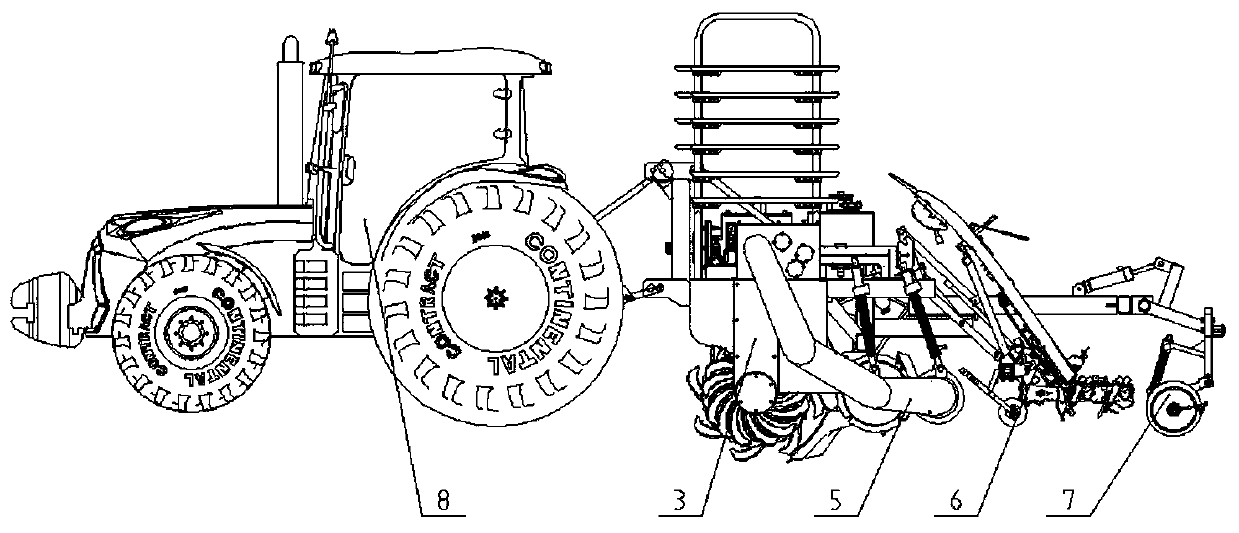

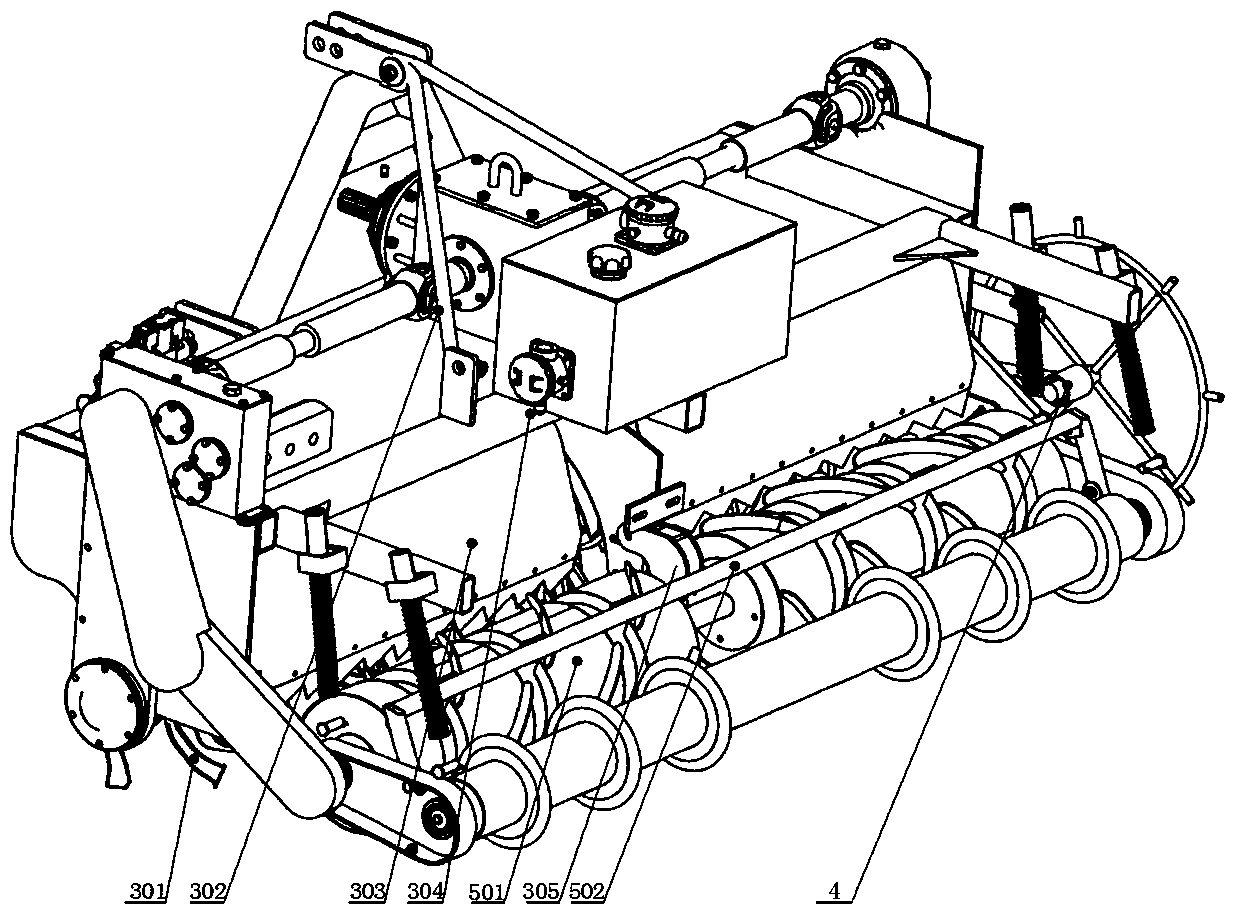

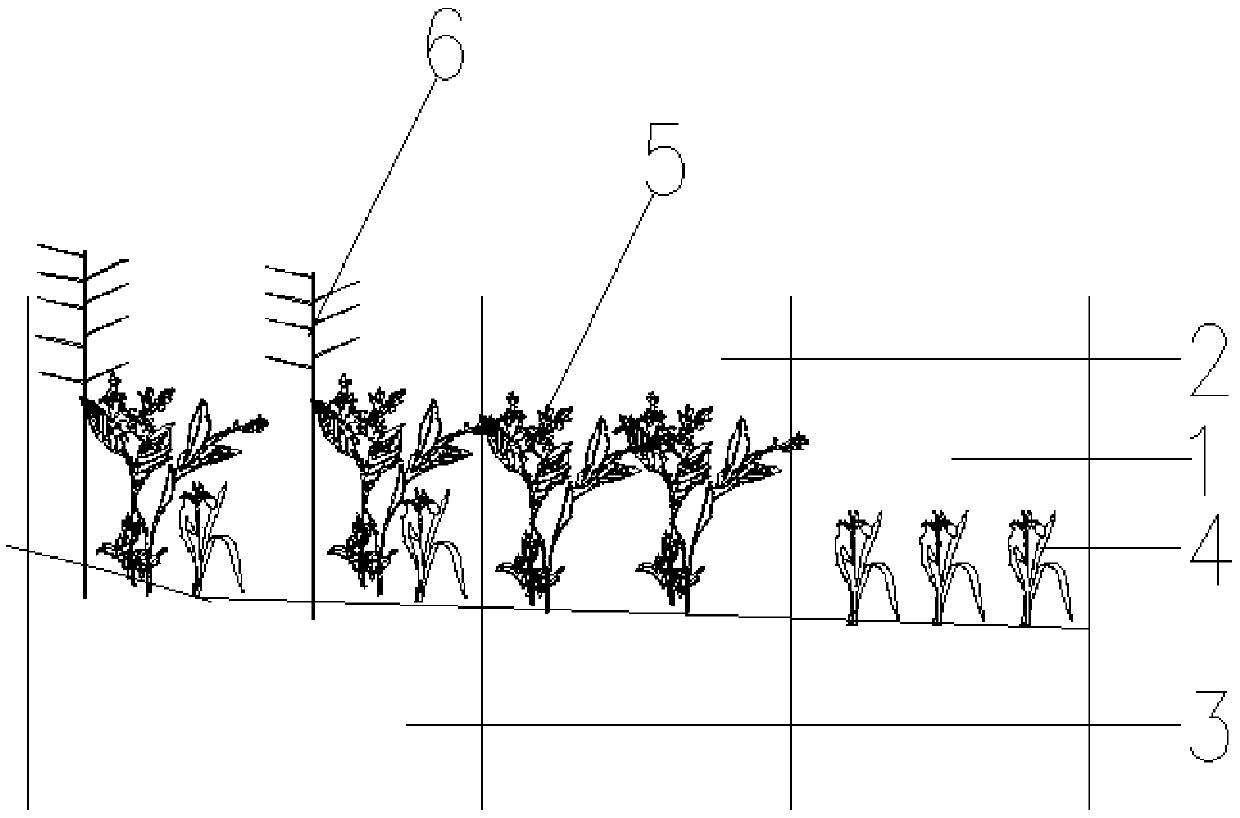

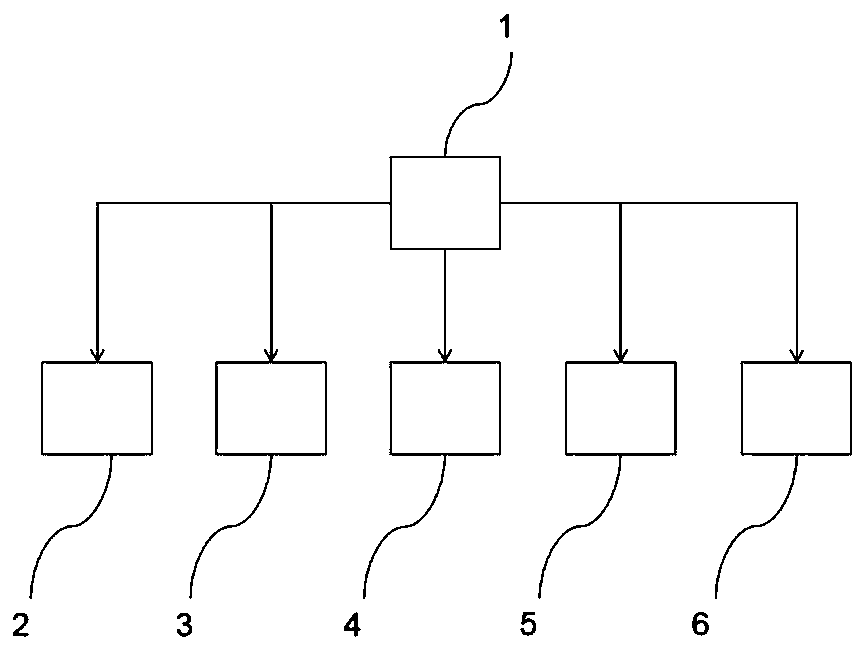

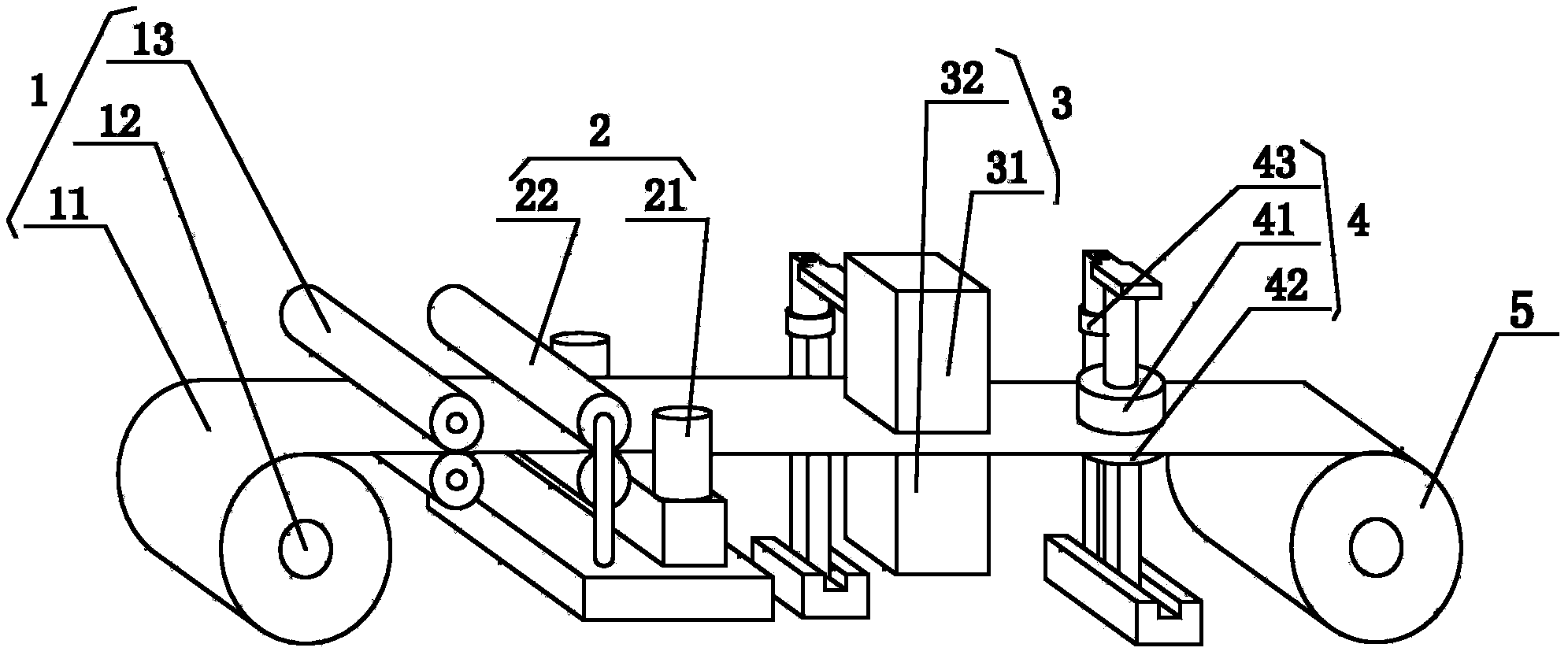

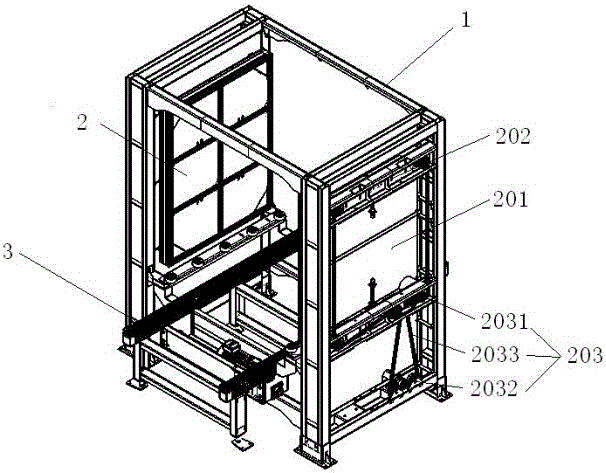

Fully automatic transplanting combined machine

PendingCN110278729AGood plastic effectNot easy claySpadesTilling equipmentsControl systemAgricultural engineering

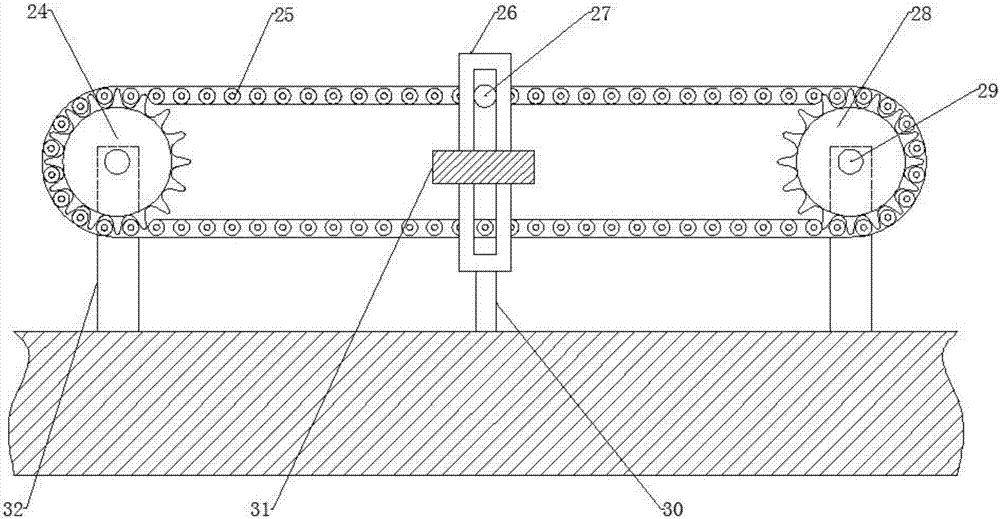

The invention provides a fully automatic transplanting combined machine. The machine includes traction equipment, operation equipment and a control system. The operation equipment is installed on a main machine frame and towed behind the traction equipment. The machine is characterized in that the operation equipment includes a rotary tillage ditching system, a micro soil preparation narrow-ditch formation system, a transplanting system and a soil covering and pressing system. The transplanting system includes more than one transplanting units. The combined machine can perform ordered rotary tillage stubble cleaning on an untilled land, bed surface leveling, ditch formation, narrow slit formation, transplanting, soil covering and compacting at a time, the soil condition required by high-speed transplanting of blanket seedlings of crops such as rapeseed is met, soil is not easily attached onto working parts for tillage and soil preparation, the transplanting quality can still be guaranteed under the condition of high-speed transplanting, structure configuration is reasonable, production, manufacturing, management and maintenance are easy, and the machine is suitable for application and popularization.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

Manufacture process of thin-wall U-shaped bend pipe with small bending radius

ActiveCN104438433AGood plastic effectReduce distortionShaping toolsExtrusion diesPipe fittingEngineering

The invention discloses a manufacture process of a thin-wall U-shaped bend pipe with small bending radius. The manufacture process comprises the following steps: (A) filling sands: filling sands into a pipe fitting fully and closing two ends; (B) prebending: assembling the pipe fitting on a top-upsetting pipe-bending machine: clamping one end of the pipe fitting by a top-upsetting clamp, fixing the other end of the pipe fitting by a pipe bending mold and a clamping block, driving the pipe bending mold to rotate by a main shaft, applying axial pushing force to the top-upsetting clamp by an oil cylinder, and enabling the pipe fitting to be bent to have the preset bending radius R1; (C) hot extrusion: heating the pipe fitting to preset temperature, placing the pipe fitting into an extrusion mold to be extruded to have the bending radius R0, then placing into a forming mold with a U-shaped cavity, extruding the pipe fitting to enter a cavity formed by an upper mold piece and a lower mold piece through mold closing, thereby realizing forming, wherein the final bending radius of the pipe fitting is R0, and R0<R1; D) removing end covers at two ends of the pipe fitting and the sands in the pipe. According to the manufacture process, the deformation of the bend pipe can be reduced, the ball-through diameter requirement can be met, the rate of finished product is high, the working procedures are less, the processing operation is simple, the cycle is short and the production cost is low.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

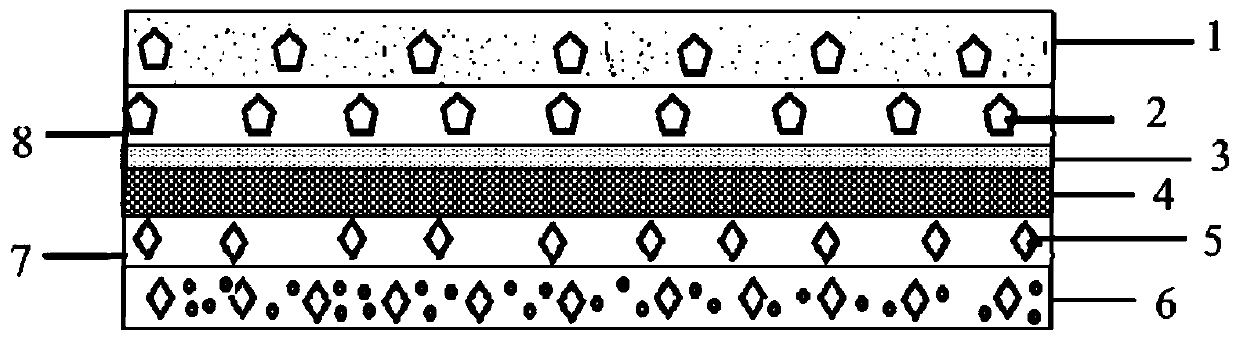

Water-based high-viscosity glued diaphragm, preparation method thereof, and application of diaphragm in battery

PendingCN111129406AImprove adhesionEasy to packCell component detailsPhysical chemistryPolymer chemistry

The invention relates to a water-based high-viscosity glued diaphragm, a preparation method thereof and an application of the diaphragm in a battery. The water-based high-viscosity glued diaphragm comprises a base membrane, and a positive polymer layer and a negative polymer layer which are respectively arranged at two sides of the base membrane, wherein a positive ceramic layer is arranged between the base membrane and the positive polymer layer, and / or a negative ceramic layer is arranged between the base membrane and the negative polymer layer; a binder in the positive polymer layer and a battery positive electrode piece is the same type of binder, and a binder in the negative polymer layer and a battery negative electrode piece is the same type of binder. The diaphragm disclosed by theinvention has the characteristics of small coating amount of coatings on two sides, light and thin coatings, high cohesiveness and the like, so the shaping effect of a battery cell is optimal, and module boxing is facilitated; meanwhile, a module limiting effect is achieved. Moreover, the risk of hole blockage of the diaphragm is low, so the internal resistance of the battery cell is stable and controllable, the lithium precipitation risk is reduced, and the cycle life and safety performance of the battery cell are ensured.

Owner:HUBEI JINQUAN NEW MATERIALS CO LTD

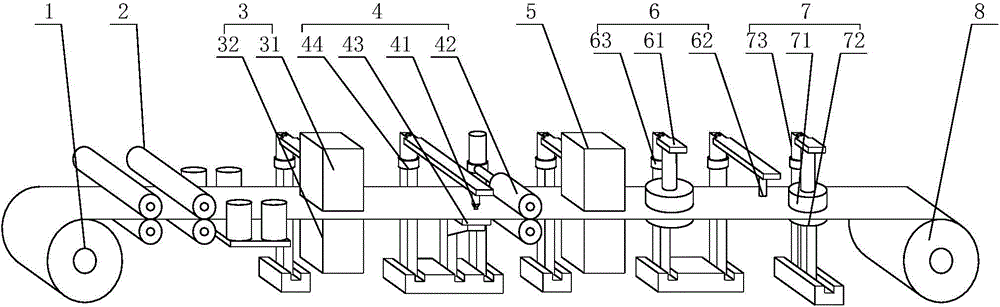

Automatic control method for surface defect shaping of strip steel

ActiveCN104368602AImprove flatnessFine shaping of tiny shape defectsMeasuring devicesMetal rolling arrangementsAutomatic controlStrip steel

The invention discloses an automatic control method for surface defect shaping of strip steel. The automatic control method for surface defect shaping of the strip steel comprises the steps of feeding, rough rolling, detecting, material supplementing, polishing, washing, knocking and winding, wherein rough rolling is conducted on the planar strip steel, the surface of the planar strip steel is detected, the defect type is judged according to a detection signal, and at least one of material supplementing, polishing and knocking is conducted on the portion, with a shape defect, of the surface of the strip steel according to the defect type and the position. According to the automatic control method for surface defect shaping of the strip steel, the defect on the surface of the strip steel can be detected automatically, the defect type is judged according to the detection signal, at least one of material supplementing, polishing and knocking is adopted for conducting corresponding shaping on different shape defects on the surface of the planar strip steel according to the defect type, in this way, fine shaping of tiny shape defects on the surface of the strip steel is achieved, working efficiency is high, the shaping effect is good, secondary damage is avoided during shaping, and the smoothness of the surface of the shaped strip steel is high.

Owner:浙江新景和纺织科技有限公司

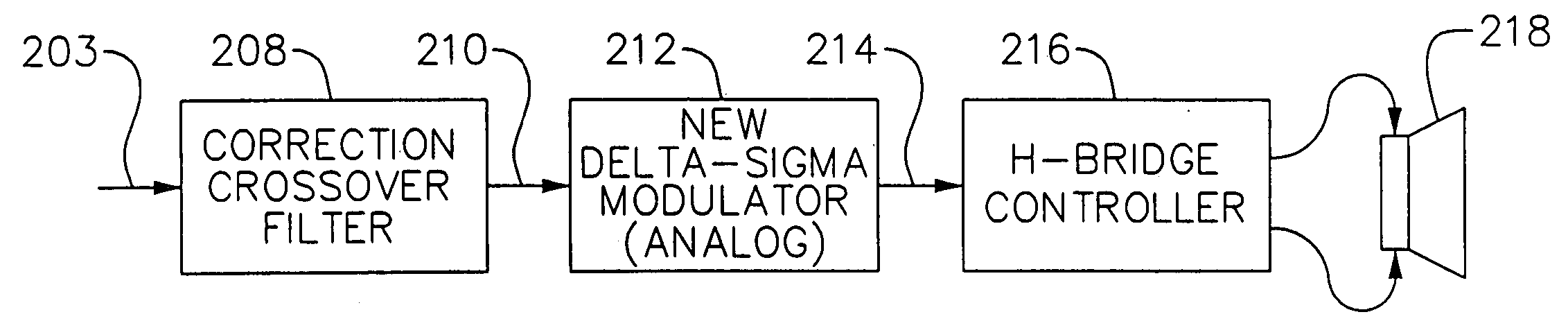

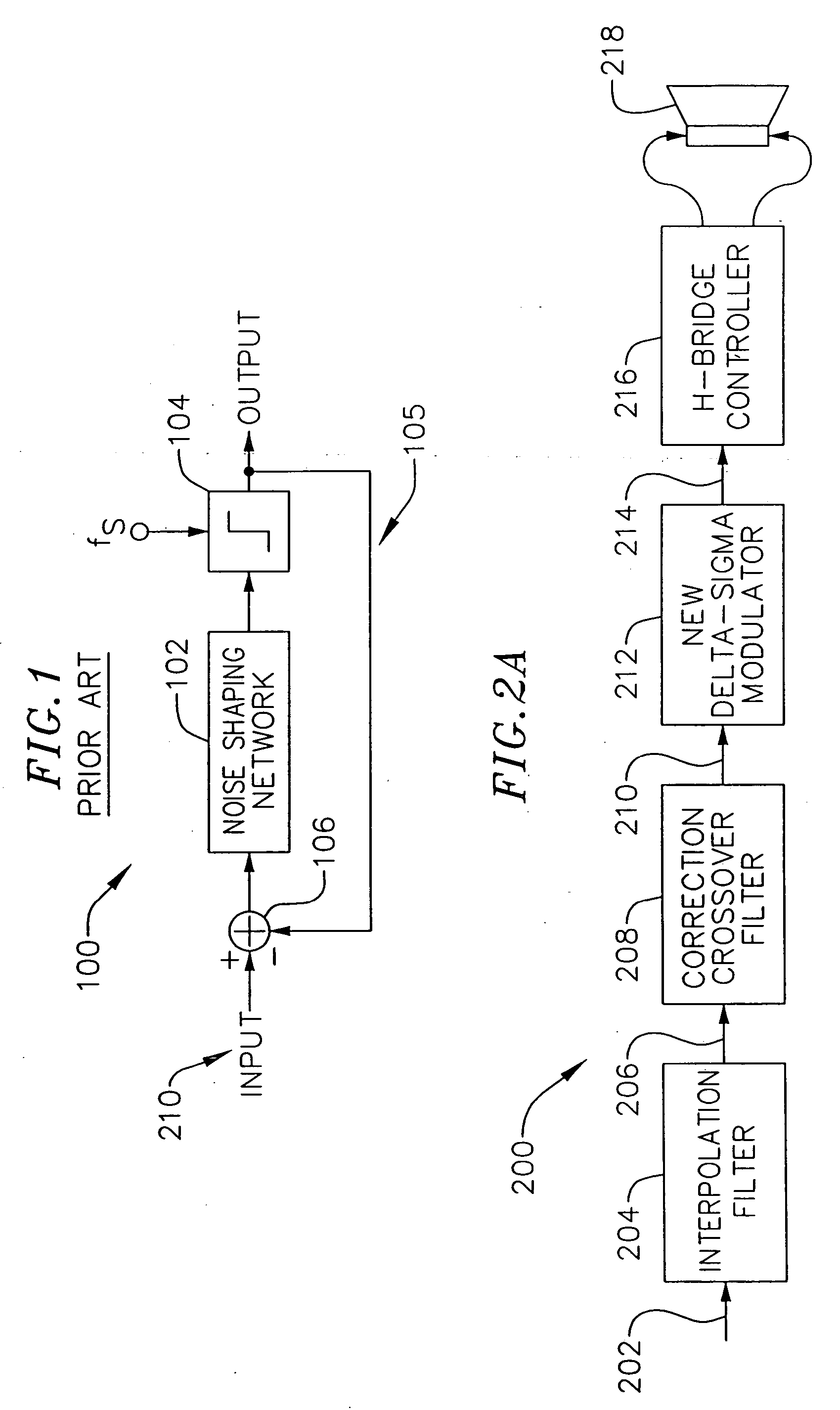

Method and apparatus for efficient mixed signal processing in a digital amplifier

InactiveUS20050030093A1High power accurate representationAggressive noise-shapingDelta modulationDc amplifiers with modulator-demodulatorNoise shapingEngineering

A system and method of creating a highly efficient digital amplifier which can take either analog or digital inputs, and produce a high power accurate representation of the input to drive speakers or other low impedance load is described. The system employs a transition detector and delay unit which allows the comparator of the signal modulator to ignore its inputs for a pre-determined number of subsequent clock cycles once an output transition has been detected. Through the use of faster clocks and variable clock cycle skips upon the comparator's output transition, finer resolution of the feedback's clock period for noise-shaping purposes is achieved. Finer resolution of the clock period allows the present invention to employ a more aggressive noise-shaping than previously possible. In another aspect of the invention; additional delta-sigma modulator noise suppression is obtained by using the common bridge implementation of the power output stage with the improvement of configuring the bridge to create a 3-state condition instead of the conventional 2 states. By controlling the two halves of the bridge independently of one another, an output with 3 states makes for improved noise shaping performance.

Owner:AVAGO TECH WIRELESS IP SINGAPORE PTE

Double-faced efficient reshaping device for building decorative board

The invention discloses a double-sided high-efficiency shaping device for building decorative boards, which includes a base, a top plate, a pressing device and a movement mechanism. A working table is arranged above the base, and pressing devices are arranged on both sides of the upper part of the working table. There is a lower shaping knife between the pressing devices on both sides of the workbench, a second threaded rod is arranged in the middle of the upper part of the top plate, and an inverted U-shaped plate is spirally connected to the outside of the second threaded rod. The shaping knife is fixedly connected, and the right side of the workbench is equipped with a movement mechanism. The present invention is equipped with a pressing device to press the decorative plate, and the pressing is reliable. It is provided with a second threaded rod, an inverted U-shaped plate, an upper shaping knife and a lower The shaping knife can adapt to different thicknesses of decorative panels, and can perform double-sided shaping, which improves work efficiency. It is equipped with a movement mechanism to drive the worktable to move left and right, and the upper and lower shaping knives can repeatedly shape the upper and lower surfaces of the decorative panels. , The plastic effect is better, the labor load of the workers is reduced, and the work efficiency is improved.

Owner:吴秀女

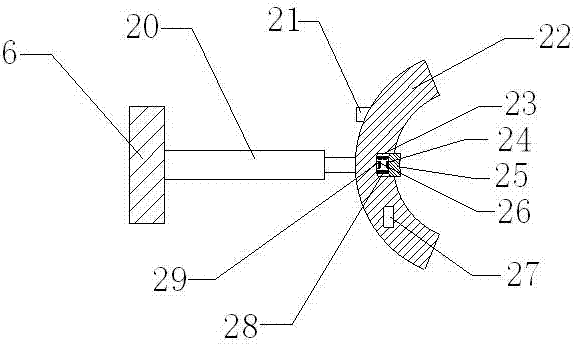

Beam shaping of linear laser diode array and coupling system

InactiveCN101017306ASimple structureEasy to processCoupling light guidesNon-linear opticsMicro columnEm coupling

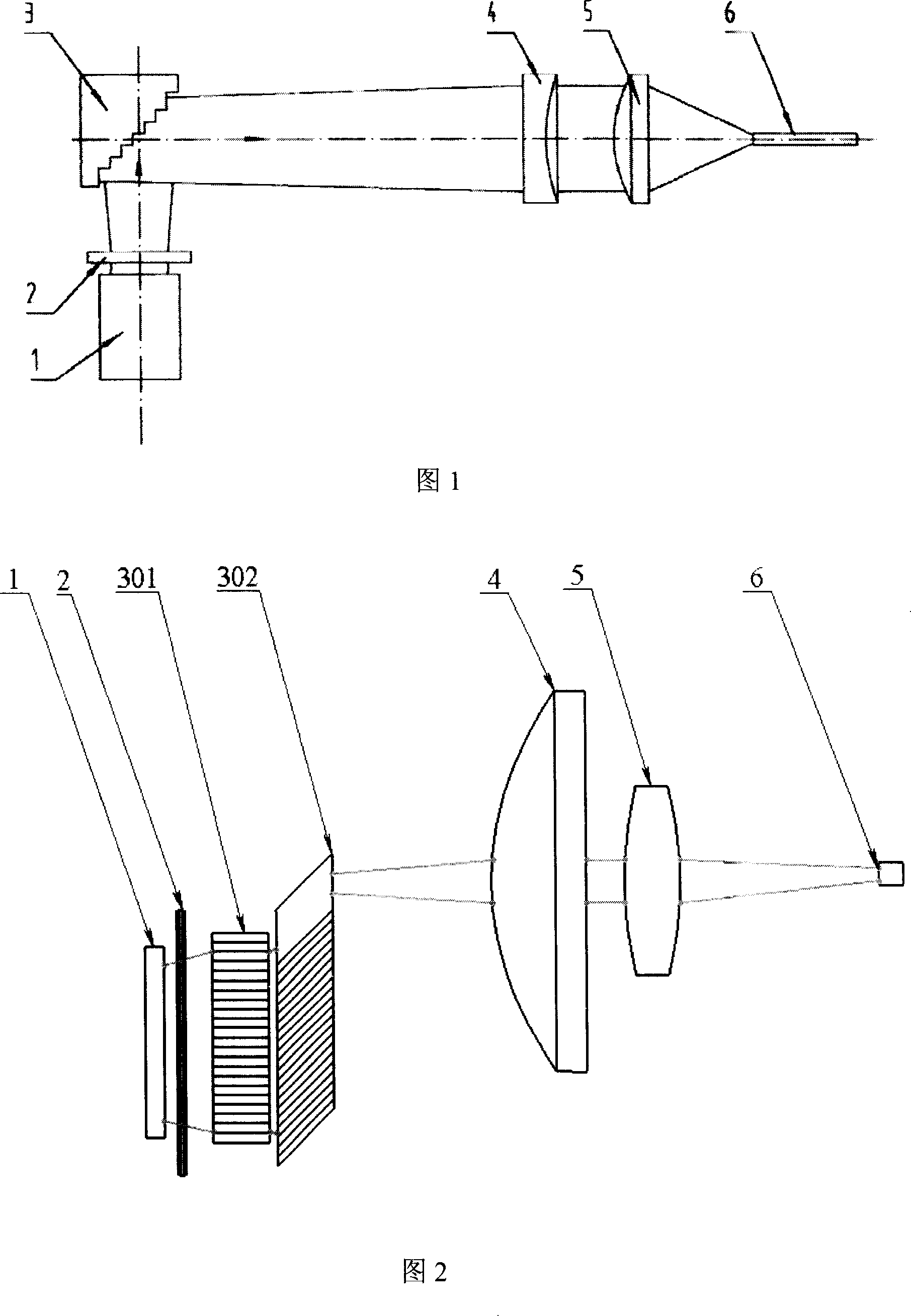

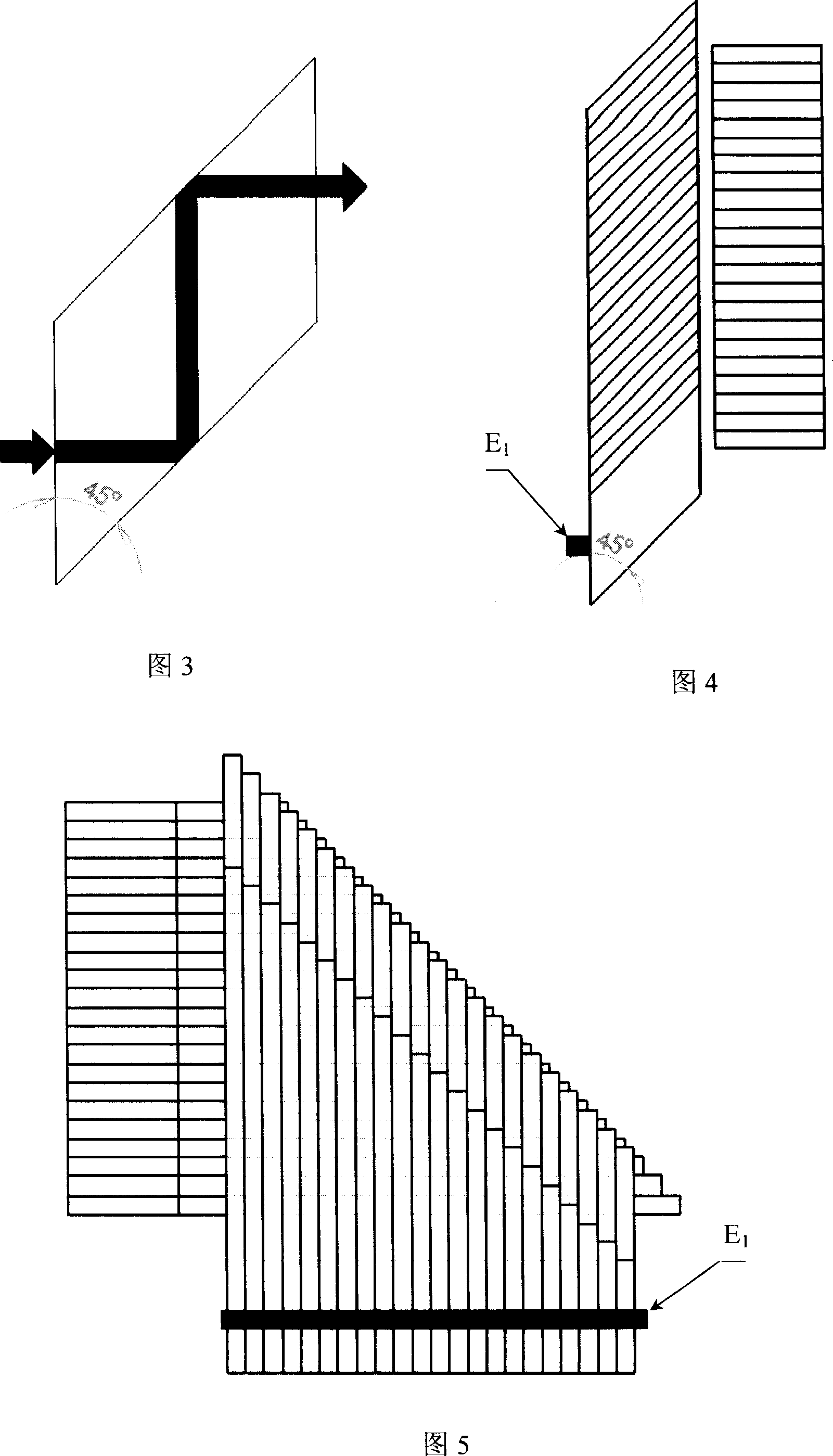

This invention relates to one line laser diode tube array beam rectangle shaping and its couple system, which comprises beams forward direction orderly through micro column lens, parallel micro slice stack shaping device; axis symmetric non-sphere lens and column; the said axis symmetric non-sphere lens and column lens to overlap the beam focus point. This invention relates to line large power light diode array beam couple merge energy transmission fiber for fix laser pump couple.

Owner:徐州奕创光电科技有限公司

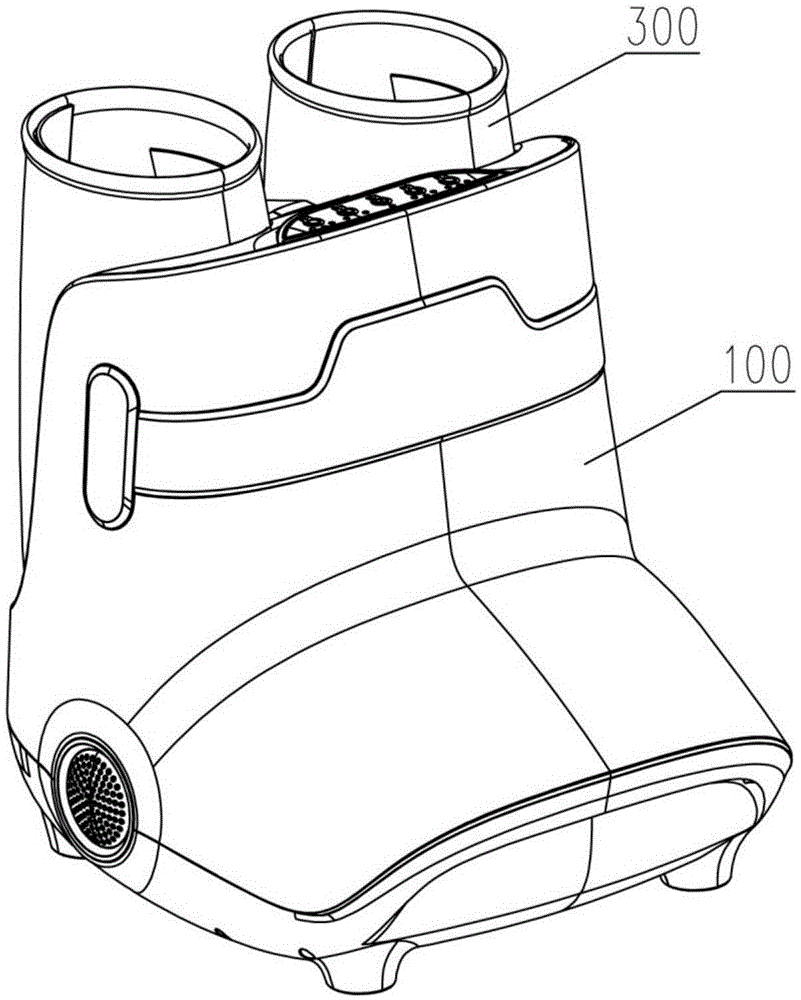

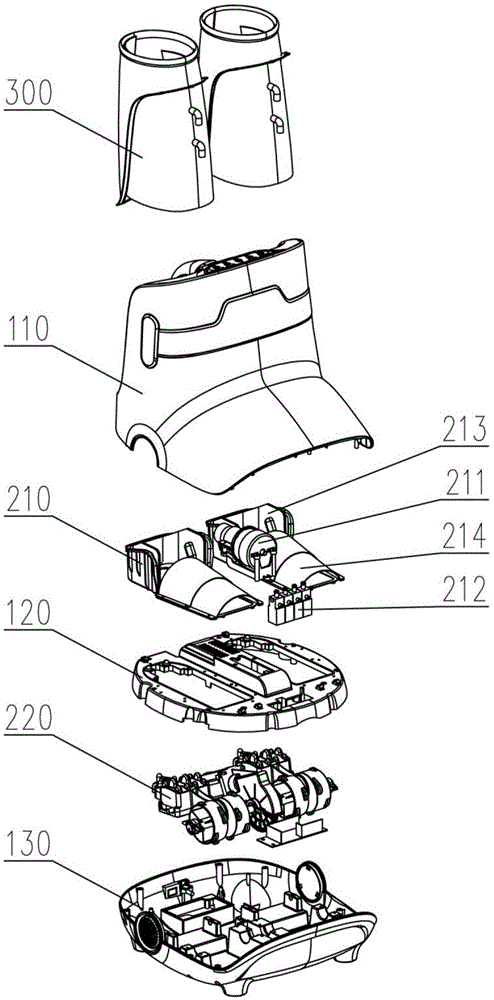

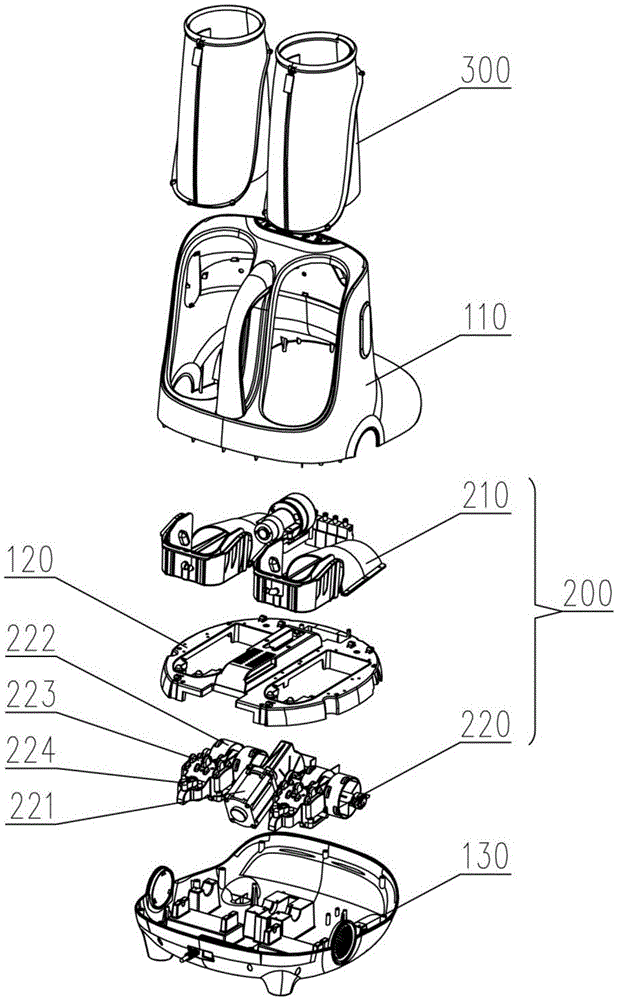

Foot massager

ActiveCN105456009AGood plastic effectBeautiful shapePneumatic massageDevices for pressing relfex pointsEngineeringMechanical engineering

The invention relates to a foot massager. The foot massager comprises a housing, a massaging mechanism disposed inside the housing, and cloth sleeves arranged on the housing. Feet and / or legs are put in the cloth sleeves, and are massaged through the massaging mechanism. The housing is provided with insertion holes through which the feed and / or legs can be put in the housing. A rubber pad is sewn on each cloth sleeve, and a steel wire ring matching the outline of the corresponding insertion hole is arranged between the cloth sleeve and the rubber pad. Multiple fastening screws are arranged on the peripheries of the insertion holes, and are used for fixing the rubber pads to the housing. According to the invention, the cloth sleeves and the housing can be firmly connected, and are easy to assemble. Furthermore, the invention also provides a cloth sleeve structure through which a better foot massaging effect can be obtained.

Owner:닝버풀조이일렉트로닉테크놀로지컴퍼니리미티드

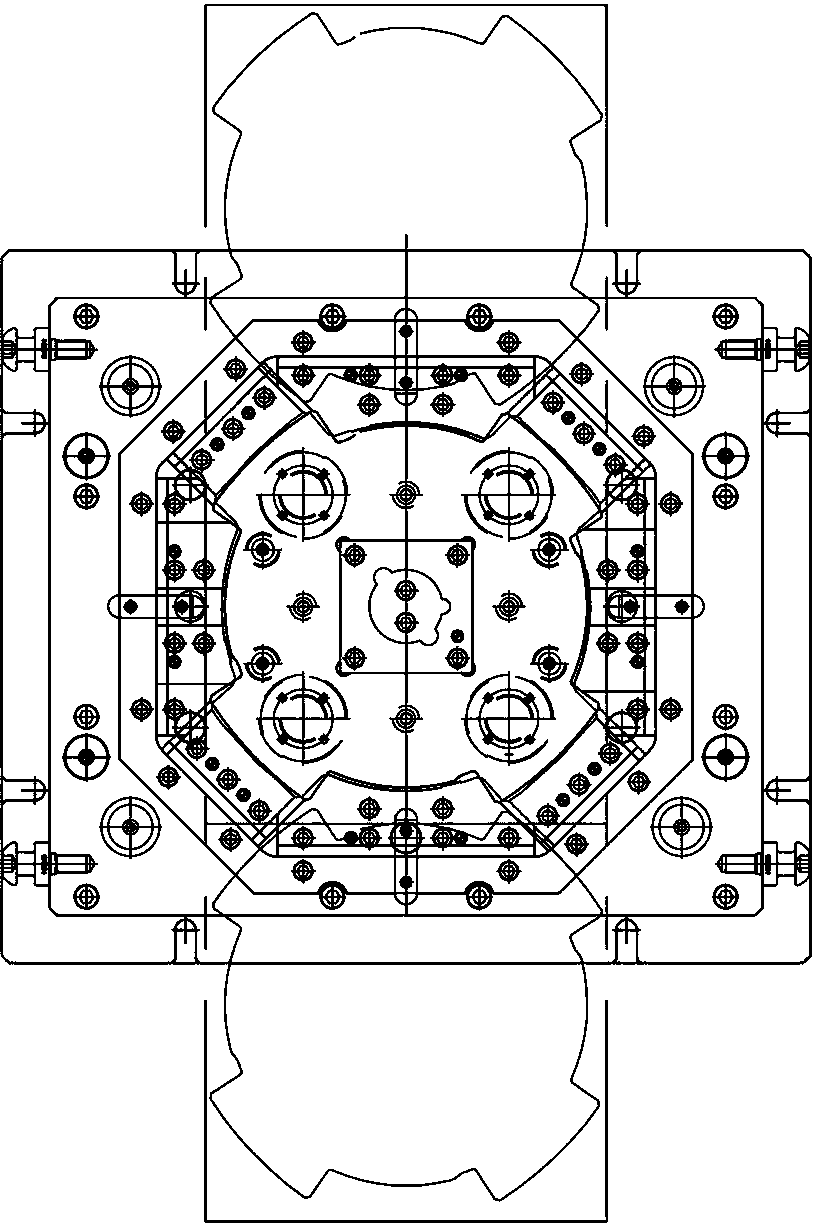

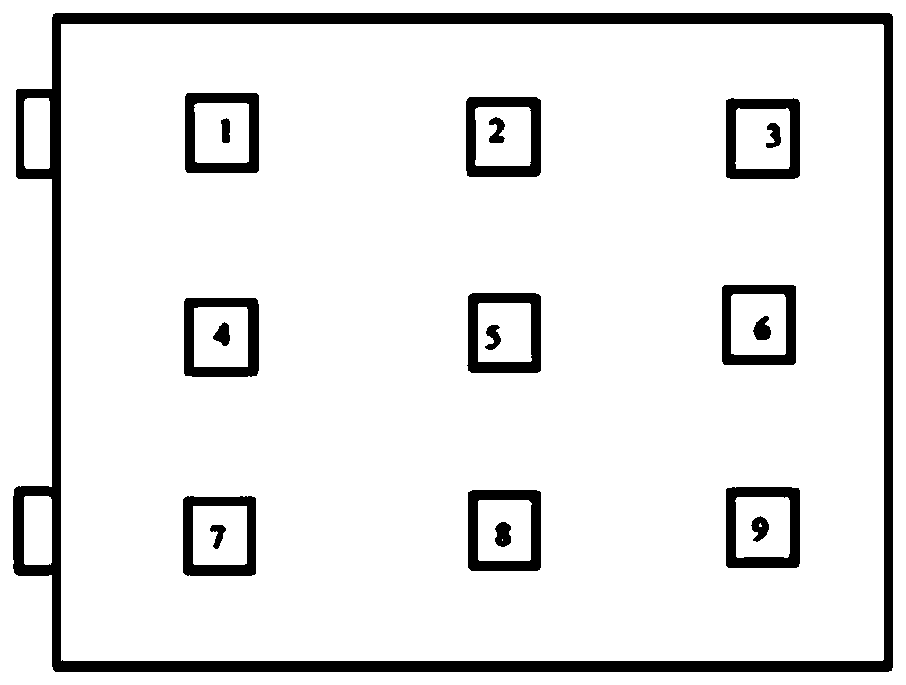

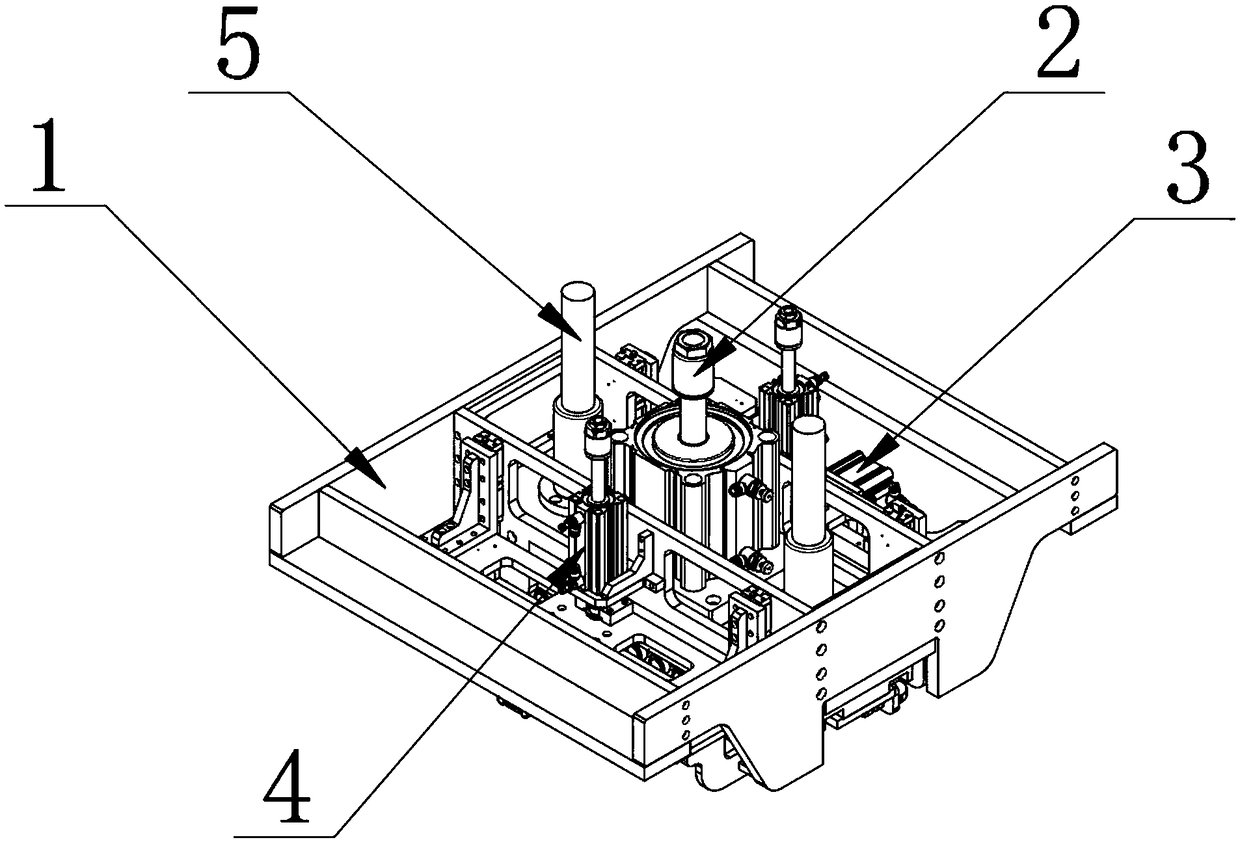

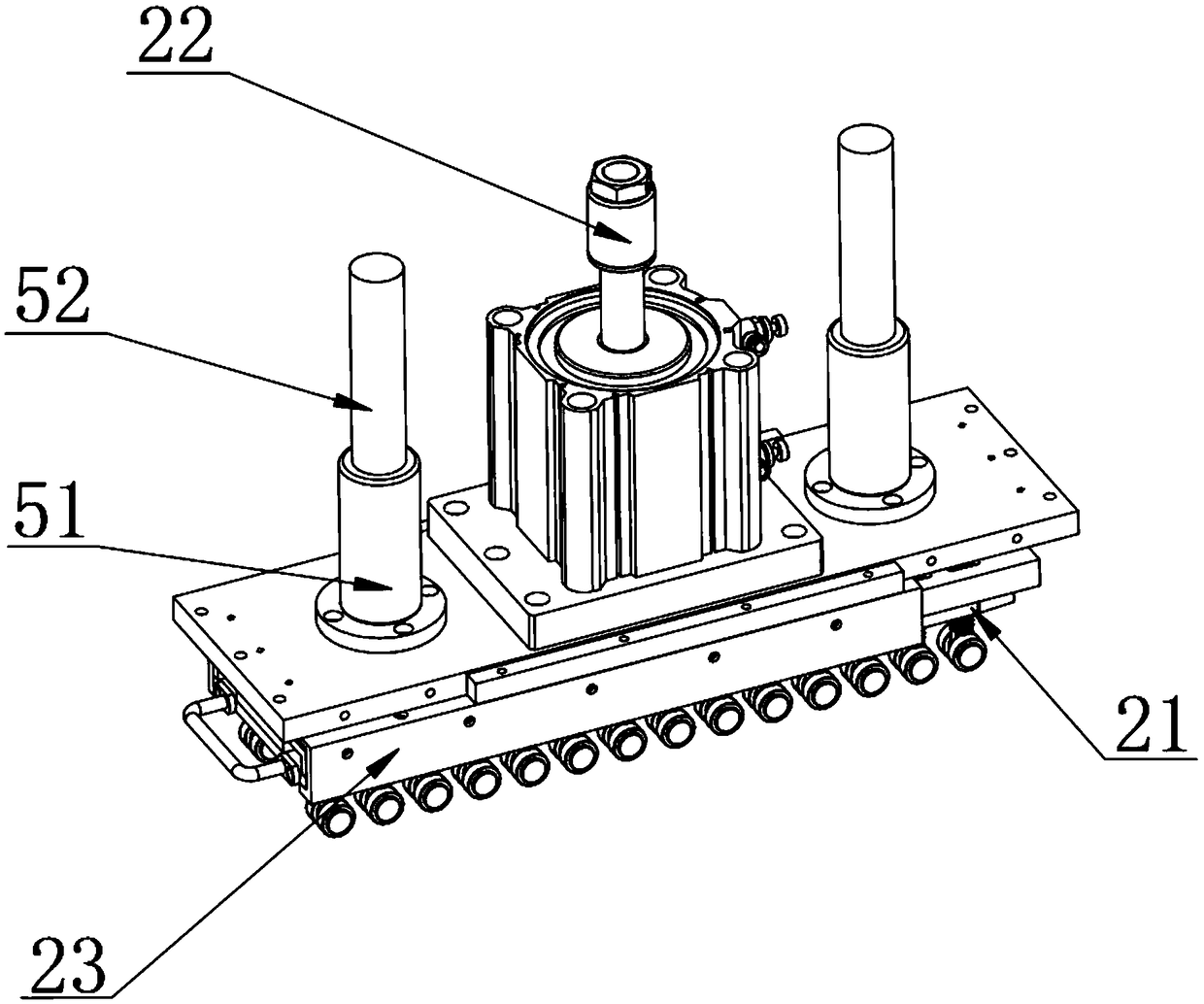

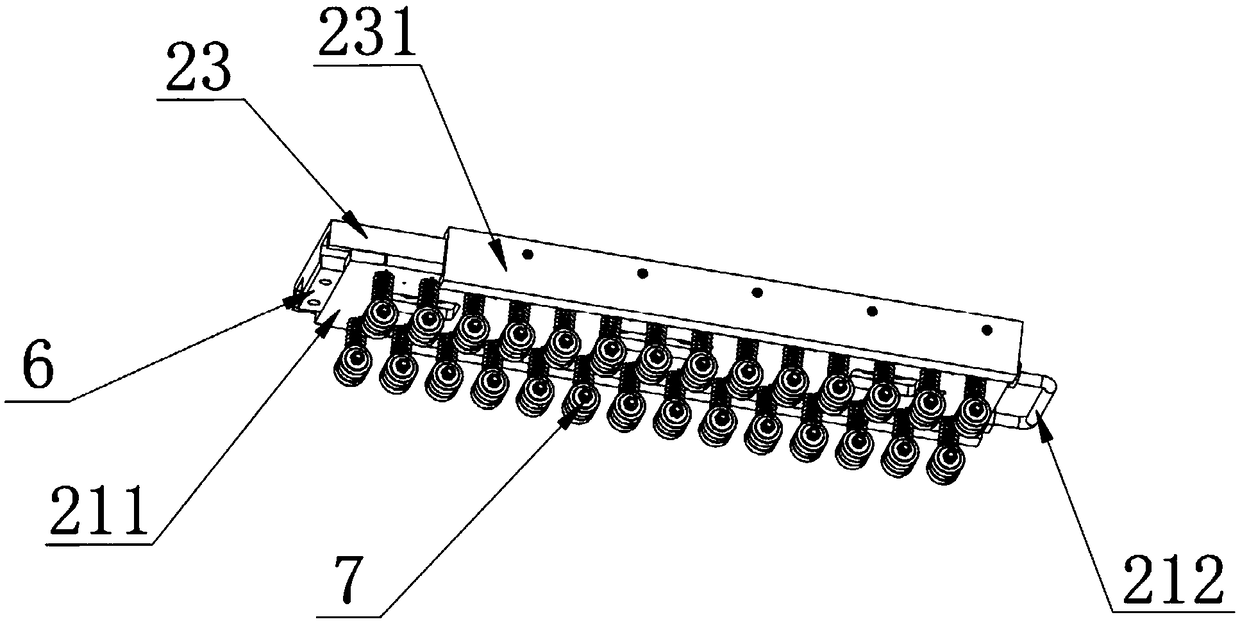

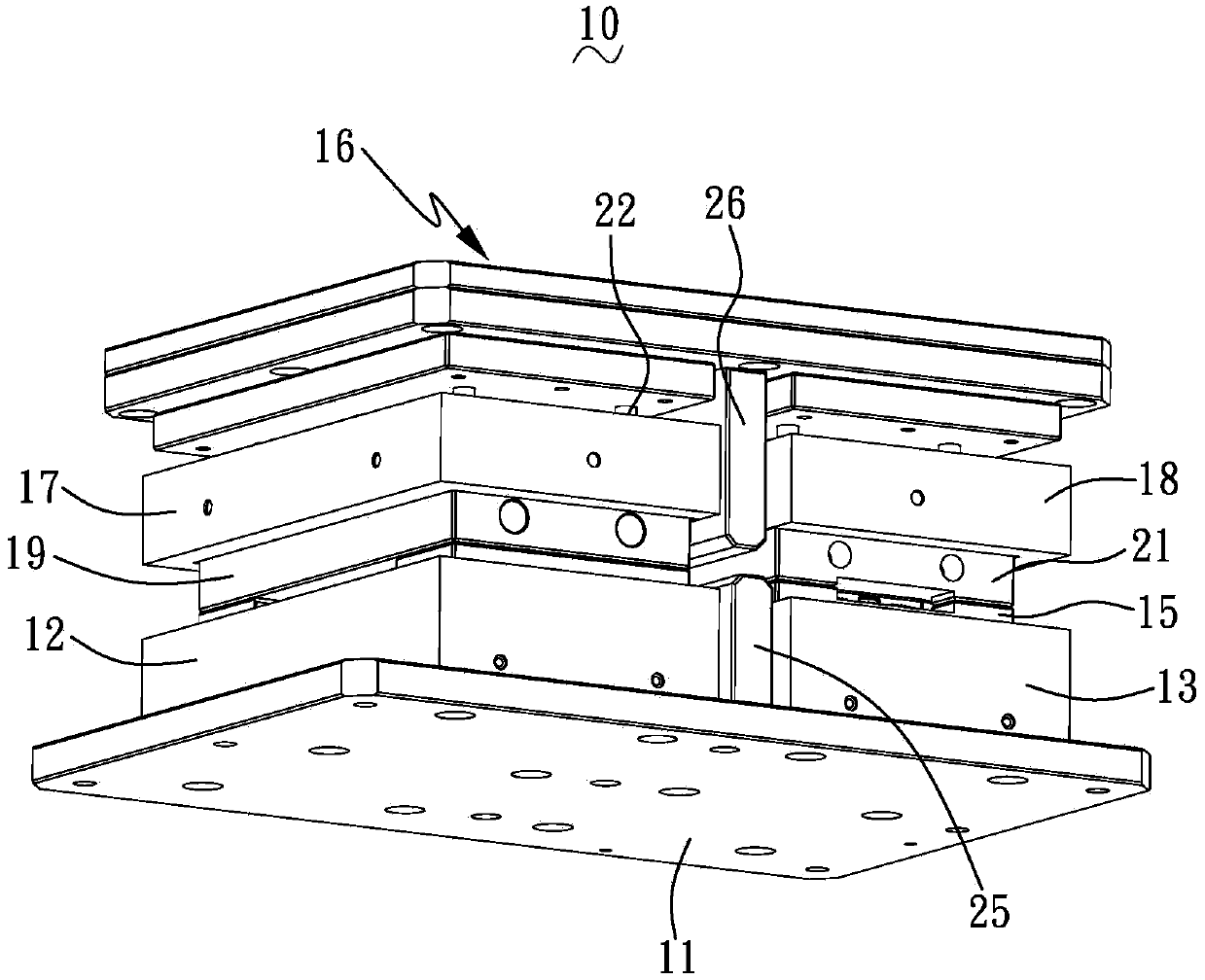

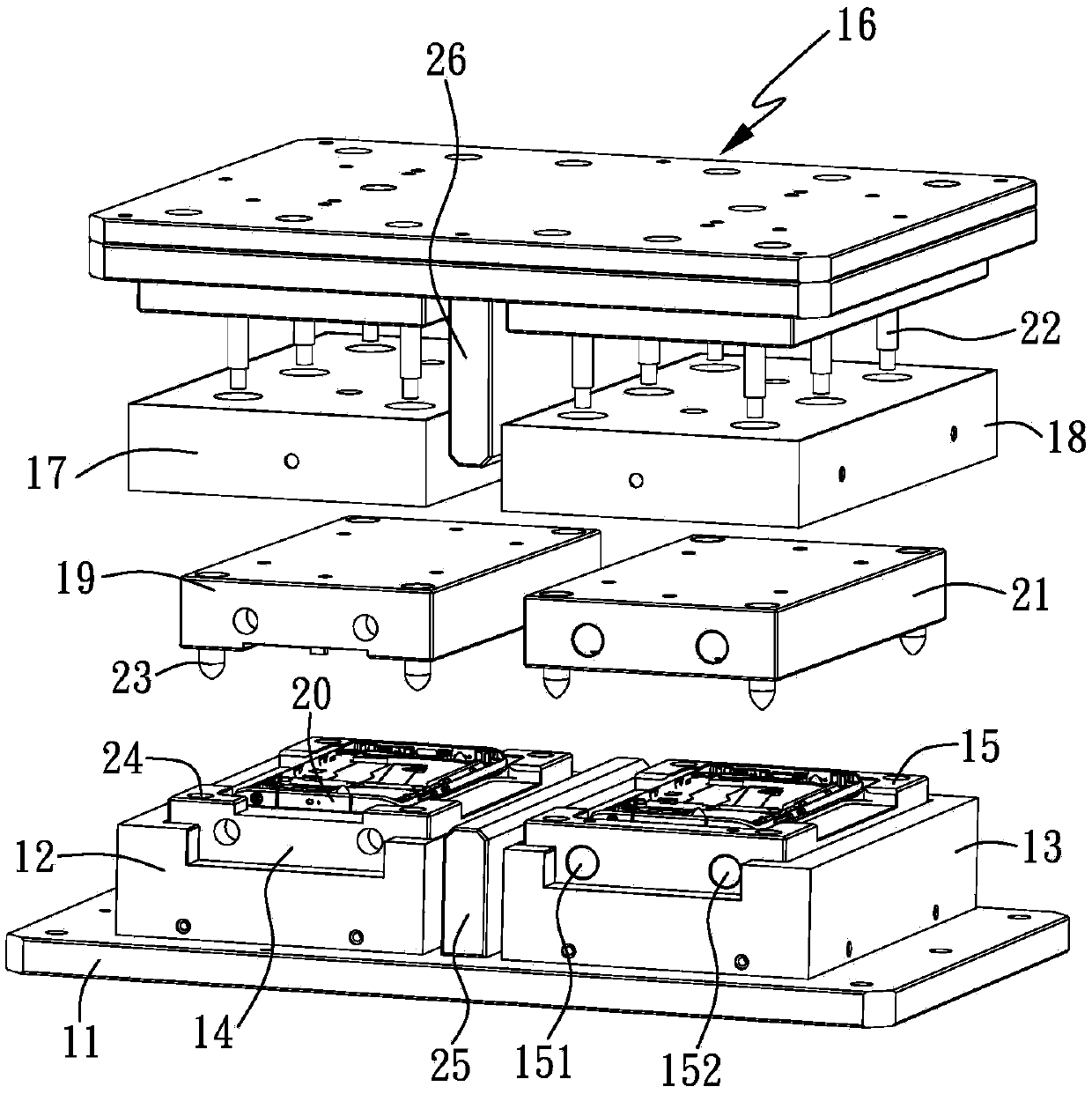

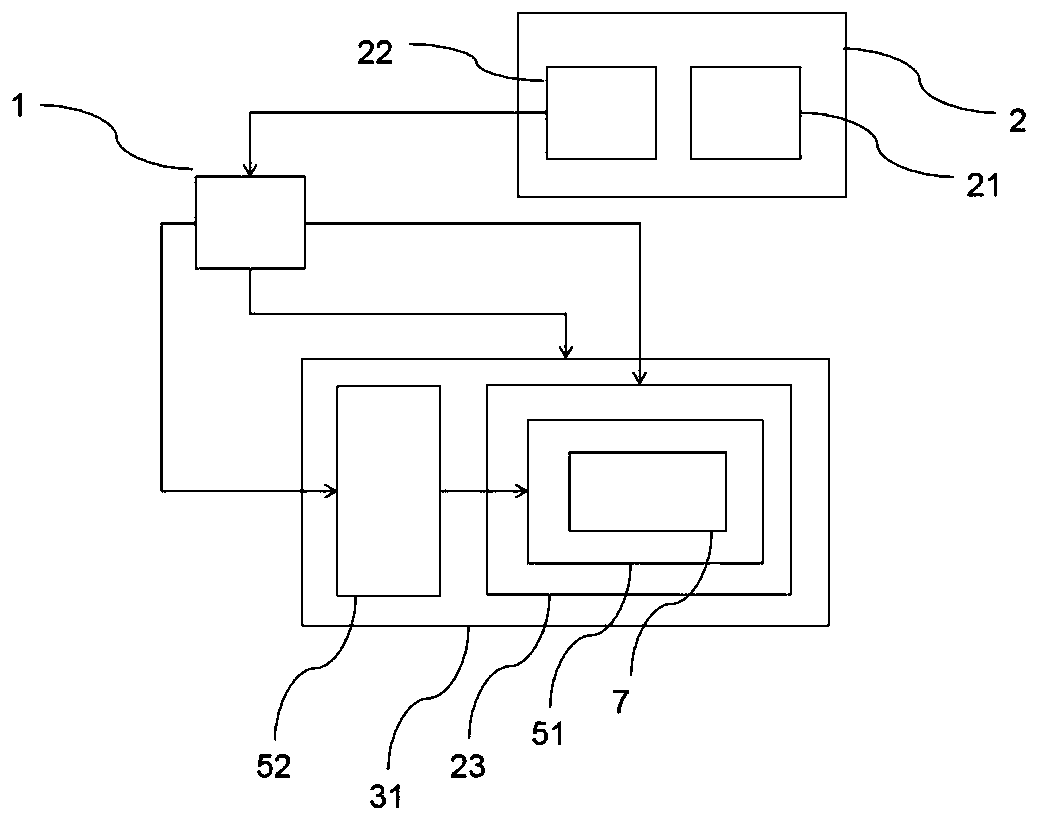

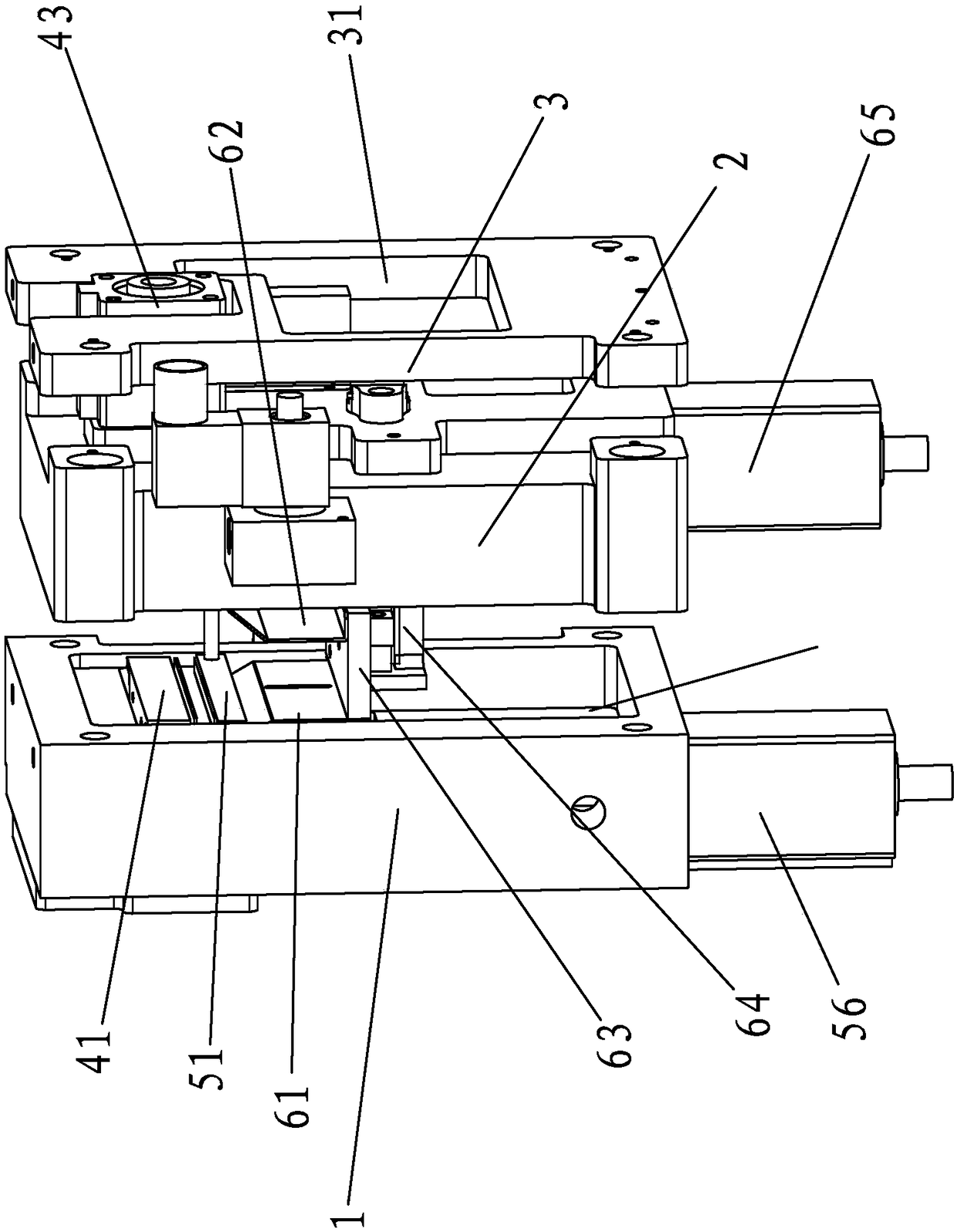

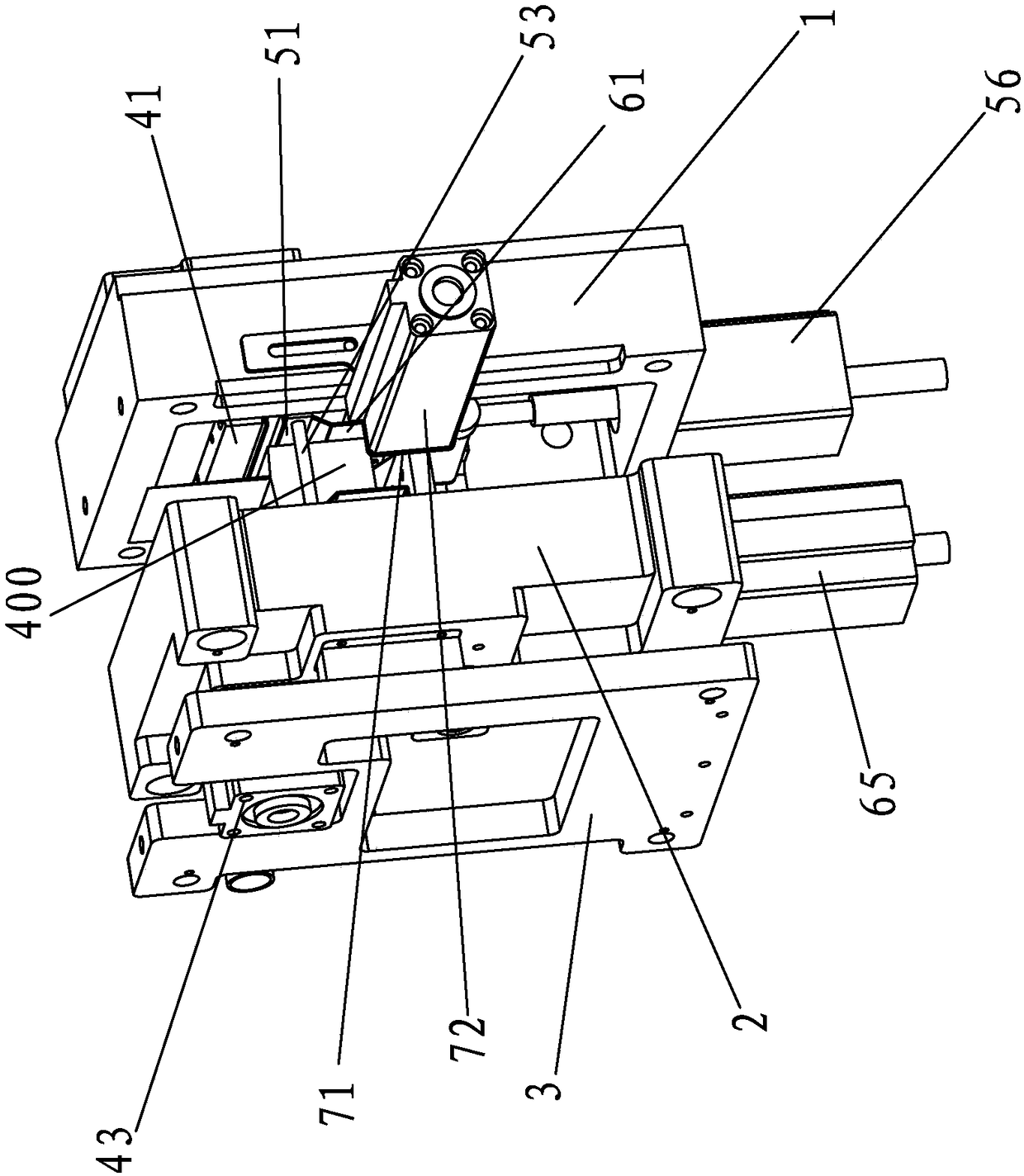

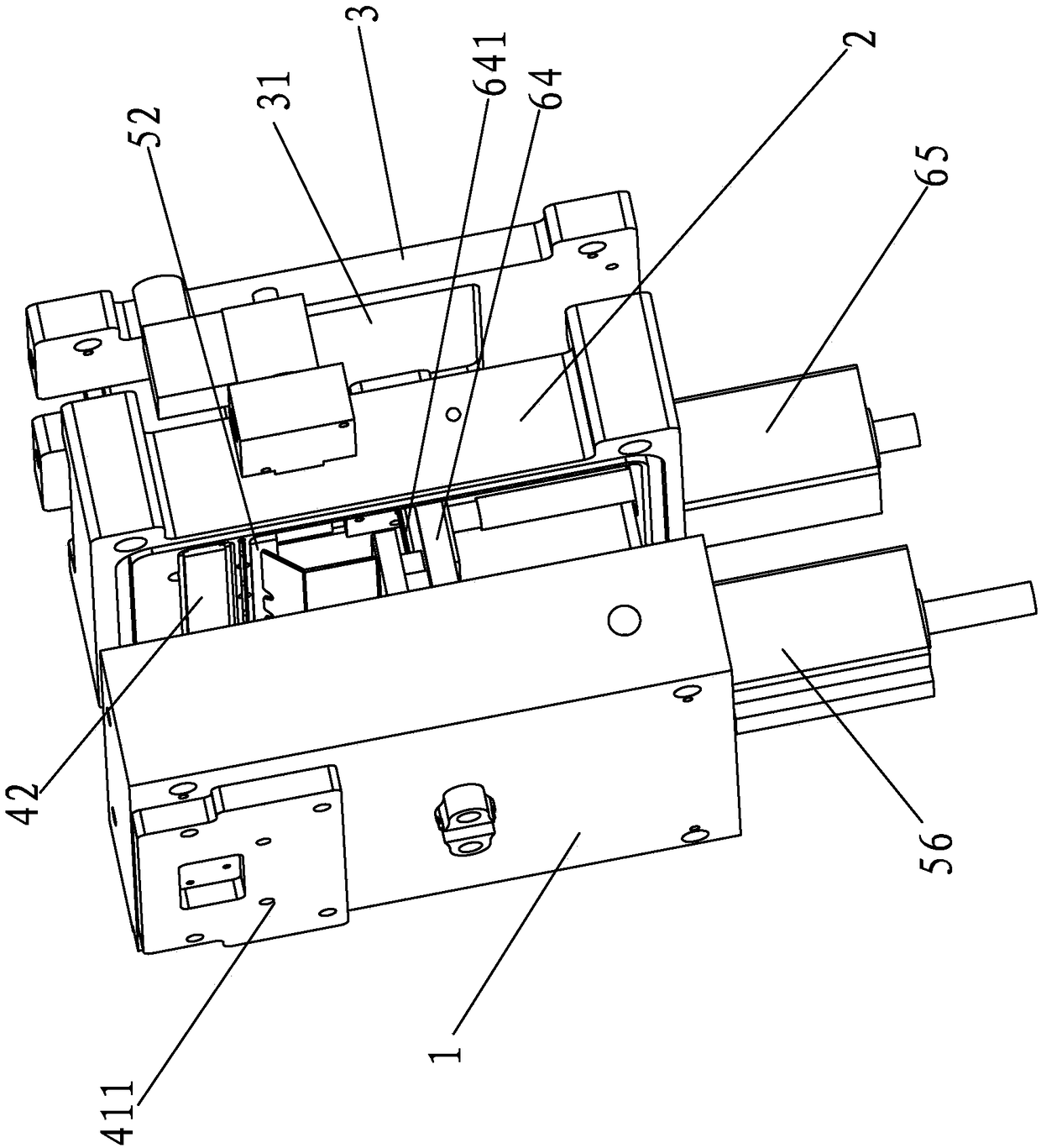

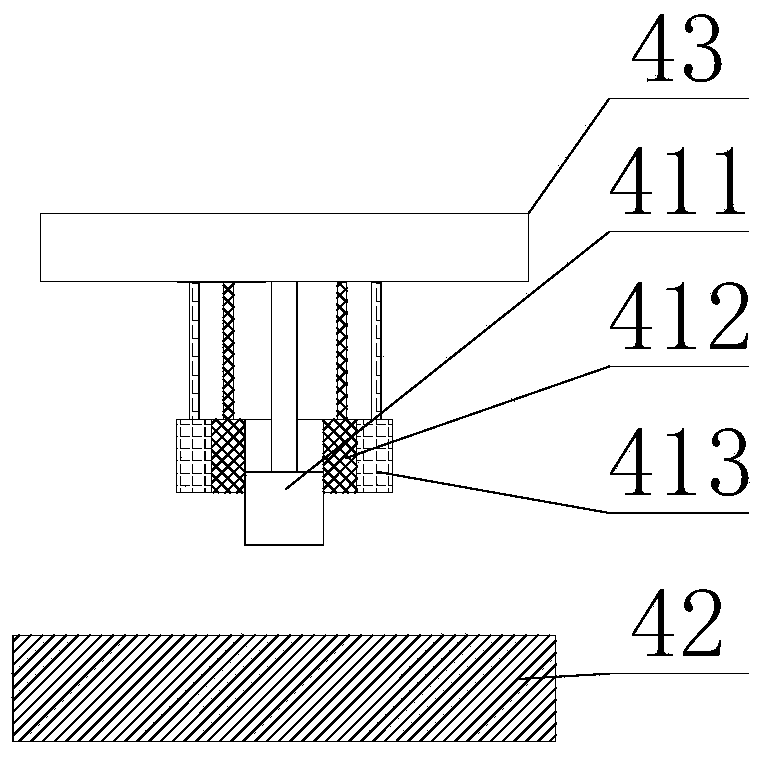

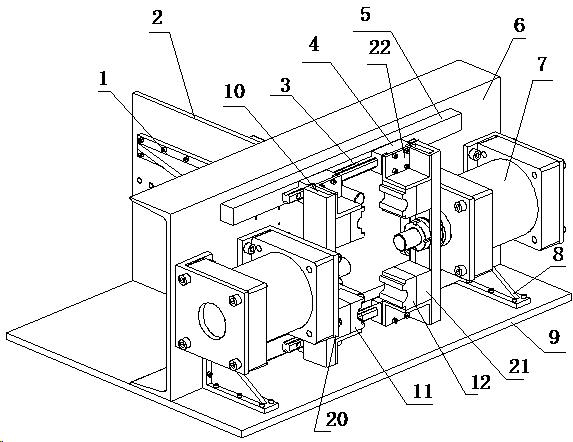

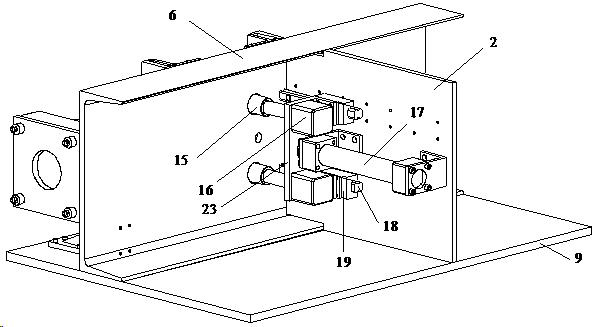

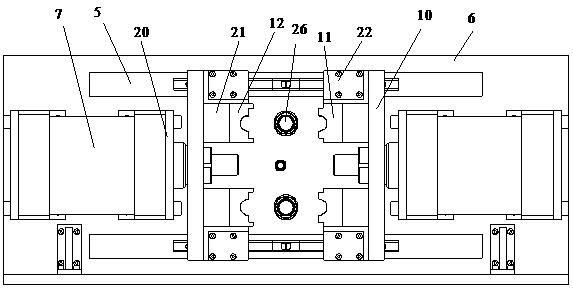

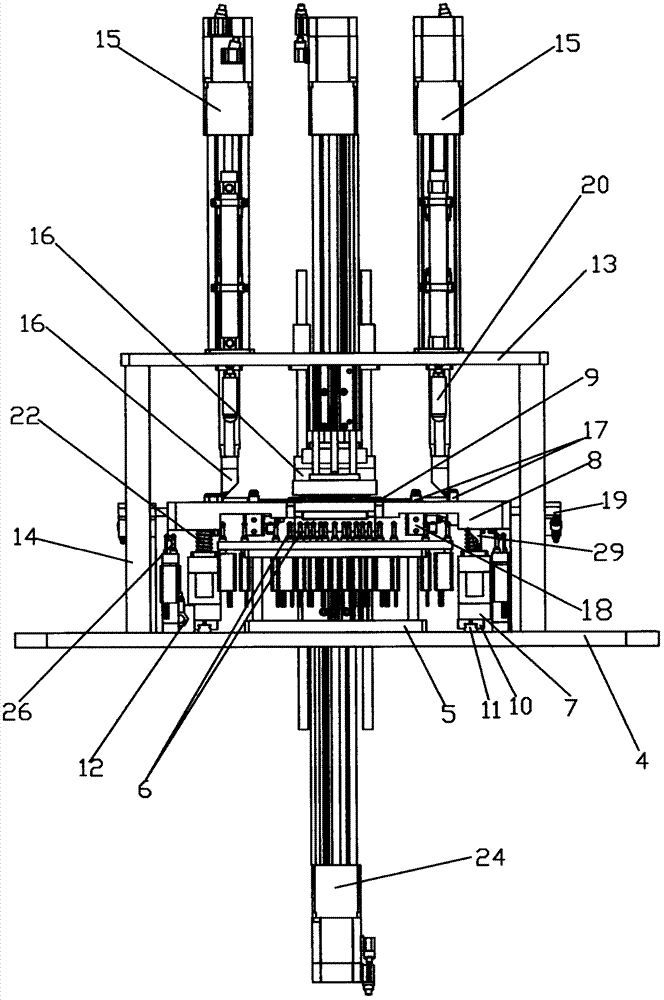

A shaping and pressing device of a power battery

ActiveCN109088088AAvoid mutual interferenceImprove the effect of compression plastic surgeryFinal product manufactureSecondary cells manufacturePower batteryEngineering

The invention belongs to the field of power battery production, in particular to a shaping and pressing device of a power battery. The shaping and pressing device comprises a frame main body, a heightshaping mechanism, a width shaping mechanism, and a lifting mechanism for driving the width shaping mechanism to perform lifting and lowering motion. The height shaping mechanism comprises a detachable lower pressing plate assembly; the height and side shaping of the battery module can be completed through the cooperation of the height shaping mechanism and the width shaping mechanism, and the shaping of the battery module in a certain height and width range can be compatible; the height of the width shaping mechanism is adjusted by the lifting mechanism, which can be used for preventing theinterference between the width shaping mechanism and the lower pressing plate assembly during shaping work, and the width shaping mechanism can be positioned in the middle of the battery module to improve the effect of pressing and shaping. By setting the lower pressing plate assembly as detachable mounting and replacing different lower pressing plate assemblies according to different battery modules, the shaping effect and the versatility of the device can be improved.

Owner:深圳市大族锂电智能装备有限公司

Hot-pressing sizing device

The invention relates to a hot-pressing sizing device. The hot-pressing sizing device comprises a base, a first heat insulation piece, a second heat insulation piece, a heating lower die, a cooling lower die, a pressing base, a third heat insulation piece, a fourth heat insulation piece, a heating upper die, a cooling upper die, a plurality of guiding columns and buffer springs, wherein the heating lower die and the cooling lower die are arranged in the first heat insulation piece and the second heat insulation piece in an inlaid mode respectively; the heating upper die is arranged in the third heat insulation piece in an inlaid mode; the cooling upper die is arranged in the fourth heat insulation piece in an inlaid mode; the multiple guiding columns are fixed to the pressing base and sleeved with the buffer springs. Heating rods are arranged in the heating lower die and / or the heating upper die. The cooling lower die and / or the cooling upper die are provided with water inlets, water outlets and pipelines which are communicated with the water inlets and the water outlets. A cell phone middle frame is clamped between the heating lower die and the heating upper die, the cell phone middle frame is deformed at a preset high temperature through the heating rods, and the flatness is restored. Then the cell phone middle frame which is affected at the preset high temperature is taken out and clamped between the cooling lower die and the cooling upper die, and the cell phone middle frame can be cooled and sized rapidly by pouring circulating water flow. According to the hot-pressing sizing device, the sizing effect is good, and the production cost is reduced.

Owner:GUANGDONG TIANJI IND INTELLIGENT SYST CO LTD +1

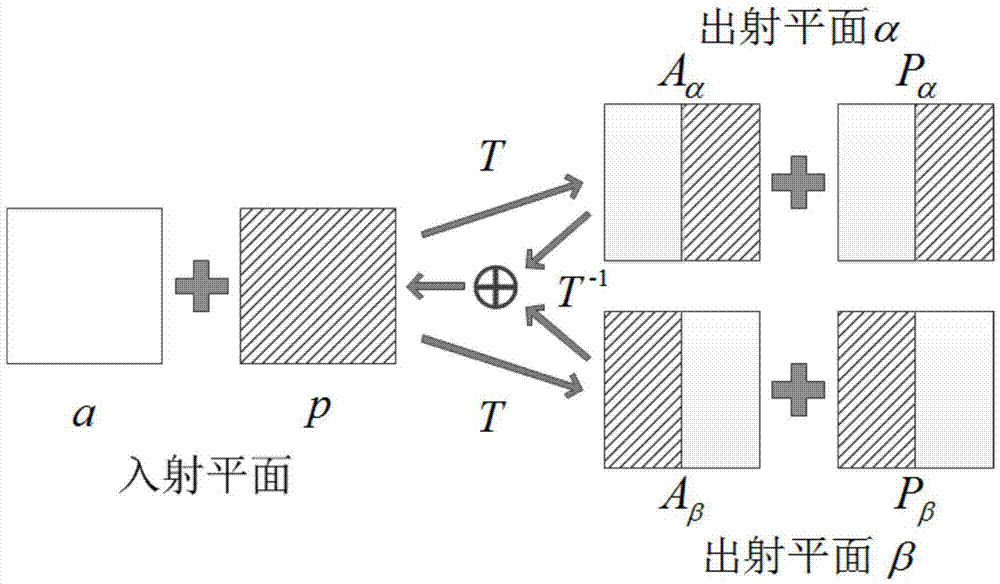

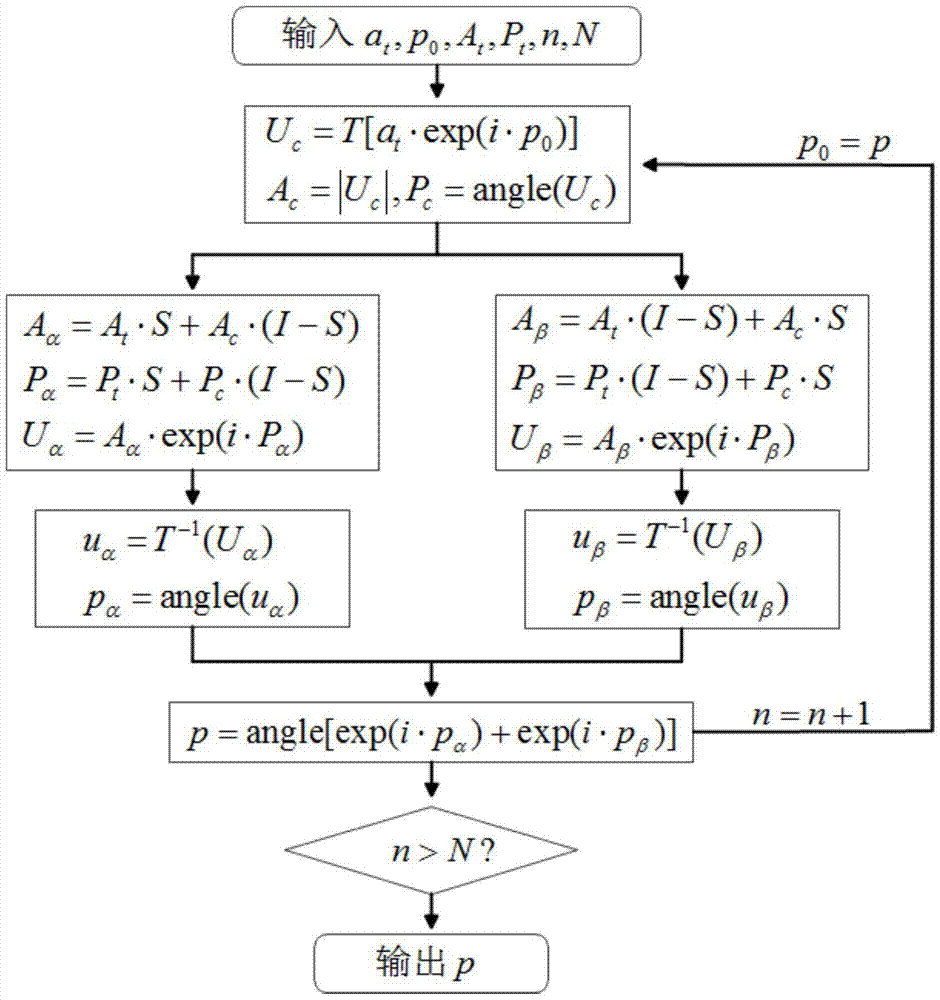

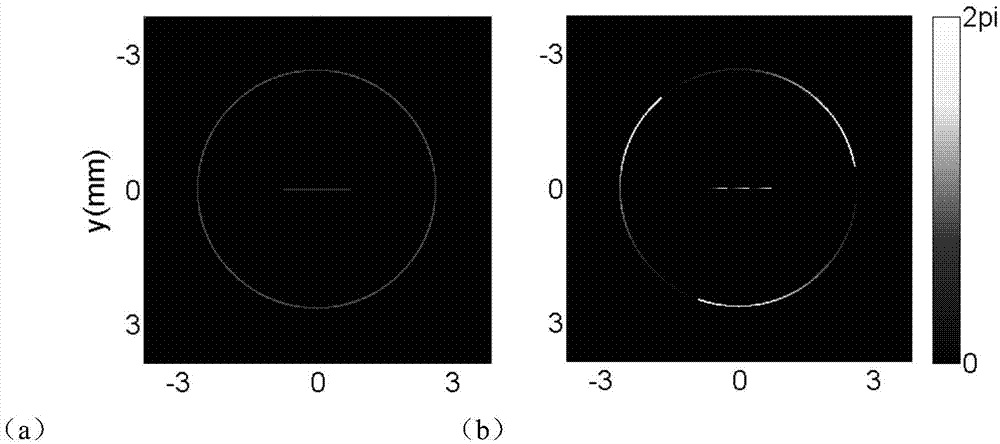

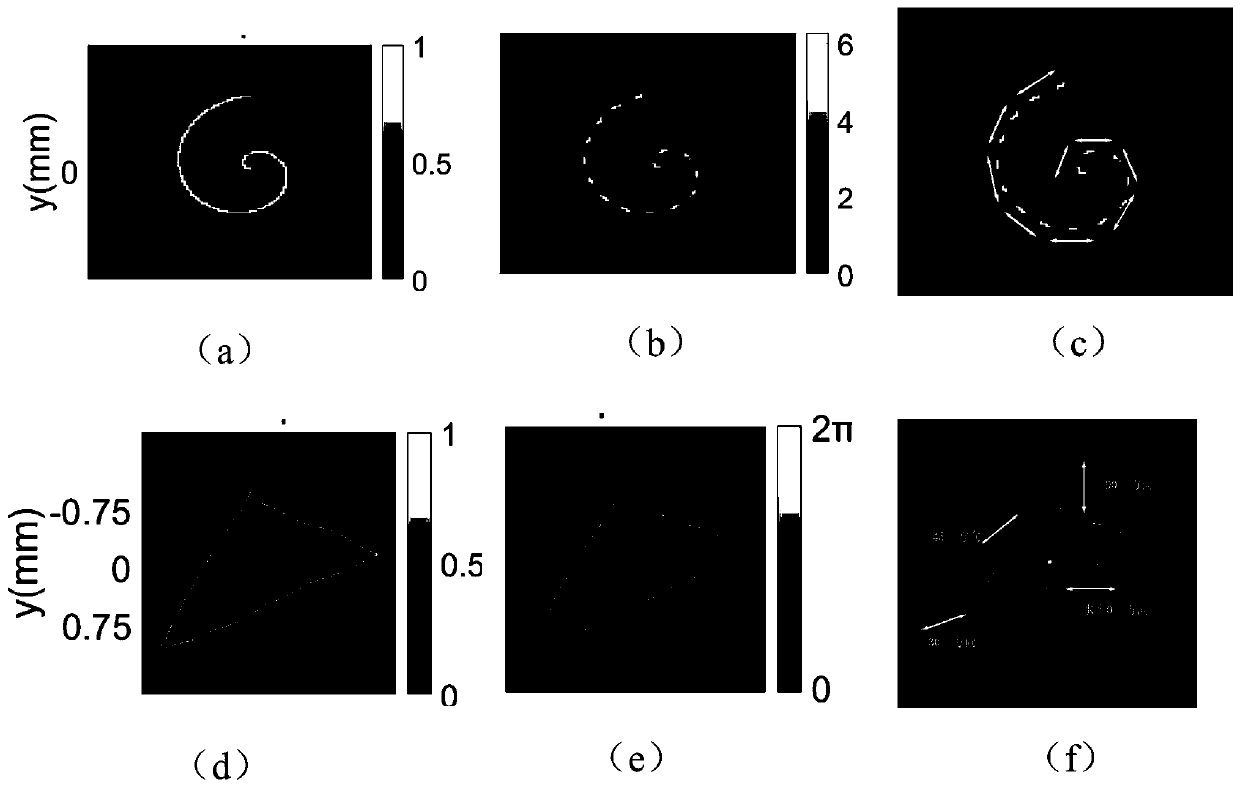

Iterative algorithm for performing shaping on amplitude and phase of light beam simultaneously

InactiveCN104777612AGood plastic effectGuaranteed convergenceOptical elementsClassical mechanicsLight beam

The invention discloses an iterative algorithm for performing shaping on the amplitude and phase of a light beam simultaneously. An input plane and two output planes are utilized to perform shaping on the light beam; free zones distributed for constraint conditions and values of the input plane serve as the amplitude and phase of the incident light respectively; the two output planes (alpha and beta) are overlapped completely, and the amplitude and phase of the target light beam are both divided into two parts to serve as constraint conditions of the amplitudes and phases of the two output planes respectively; amplitude constraint and phase constraint are performed on each output plane simultaneously, constrained zones of the two output planes are complementary, and therefore the amplitude and phase of the outgoing beam are completely constrained. The constrained zones of the output planes of the algorithm are equal to the free zones in area, so that iterative convergence is guaranteed. In this way, shaping of the target beam of amplitude and phase in any shape is achieved, operation is simple, the computation speed is high, and the shaping effect is good.

Owner:CENT SOUTH UNIV

Flame shaping method for side bending deformation of transformer core clamping piece

InactiveCN101570815ASolve the problem of side bending deformationGood plastic effectTransformerUpper limb

The invention relates to a flame shaping method for the side bending deformation of a transformer core clamping piece. The method in particular is as follows: for the side bending deformation of a splicing core clamping piece, a. when the side bending deformation is towards the non-core side of a web, an upper limb and a lower limb of the clamping piece are respectively heated by a method of triangular heating zone; and b. when the side bending deformation is towards the core side of the web, the upper limb and the lower limb of the clamping piece are respectively heated by the method of triangular heating zone, and simultaneously the web of the clamping piece is vertically and linearly heated. The invention has the positive effects of better solving the problem of side bending deformation of the transformer core clamping piece after welding and having good shaping effect; and the method is simple and easy.

Owner:BAODING TIANWEI GRP CO LTD

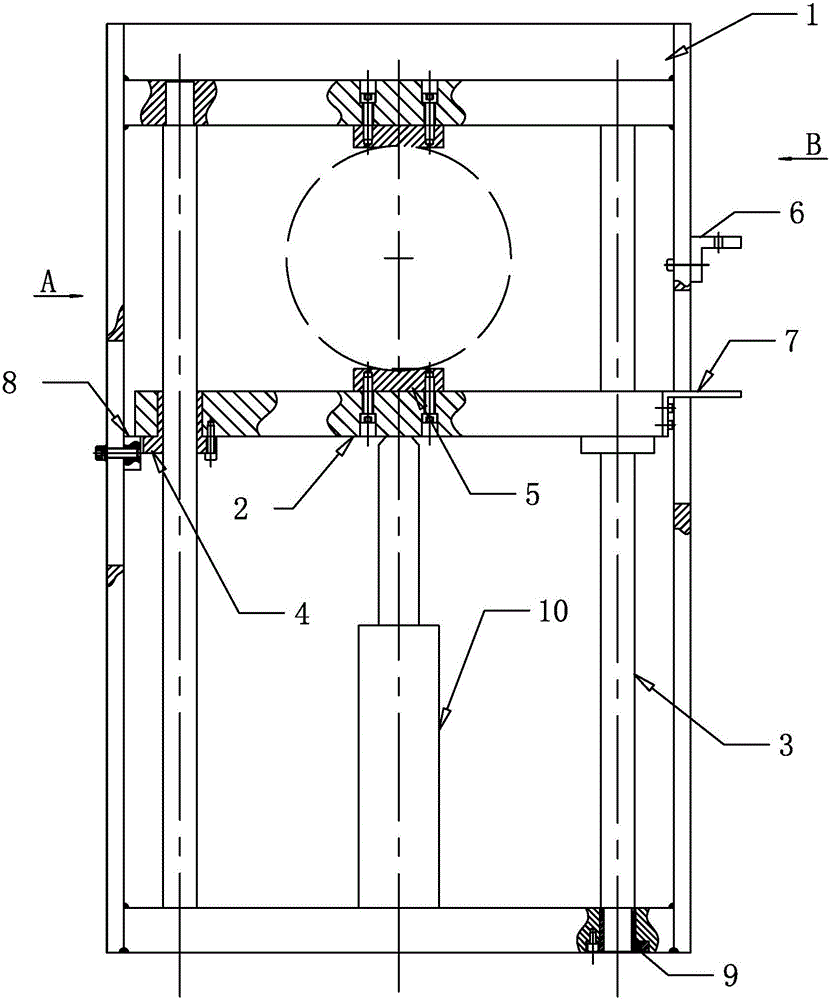

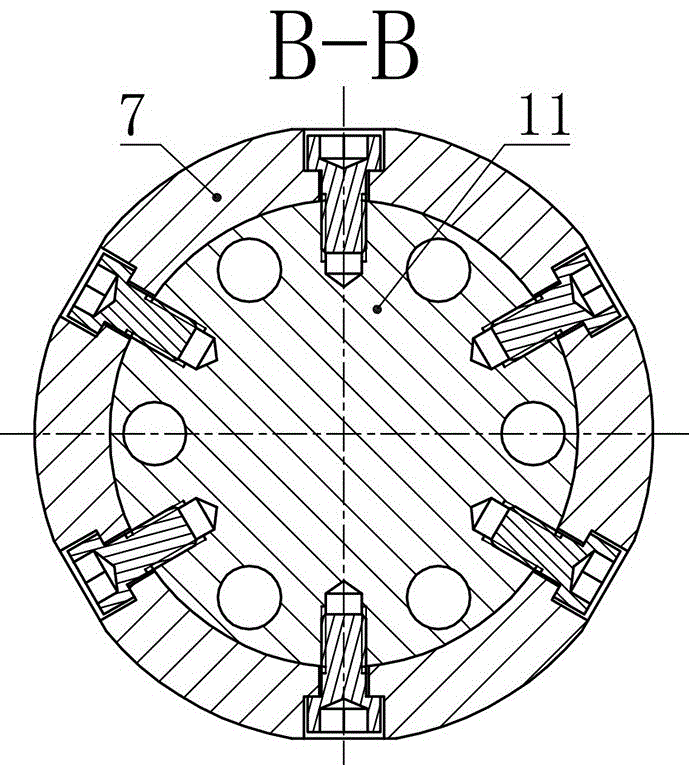

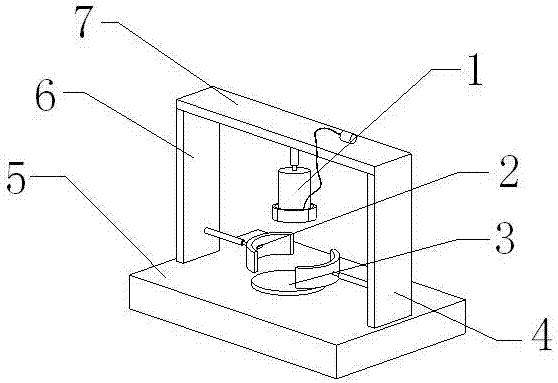

Bearing ring shaping device and method

ActiveCN105945096ATo achieve the purpose of plastic surgeryEasy to operateMetal-working apparatusEngineeringQuenching

The invention relates to a shaping device and method, and particularly relates to a bearing ring shaping device and method. The bearing ring shaping device and method aim at solving the problem that a molding pressing technology or a mold control deformation technology is difficult to realize in a quenching process of a bearing ring which is complicated in structure and changes greatly in wall thickness. The bearing ring shaping device comprises a main body frame, a lifting cross beam, two guide columns, two guide sleeves, two fixing cushion blocks, an instrument pedestal, a positioning table, a limited block, a jack and two adjustable vertical columns, wherein the two guide columns are vertically arranged in the main body frame side by side; the upper ends of the two guide columns are fixedly connected to the main body frame; and the lifting cross beam is horizontally arranged in the main body frame. The bearing ring shaping device and method belong to the field of bearing manufacturing.

Owner:AVIC HARBIN BEARING

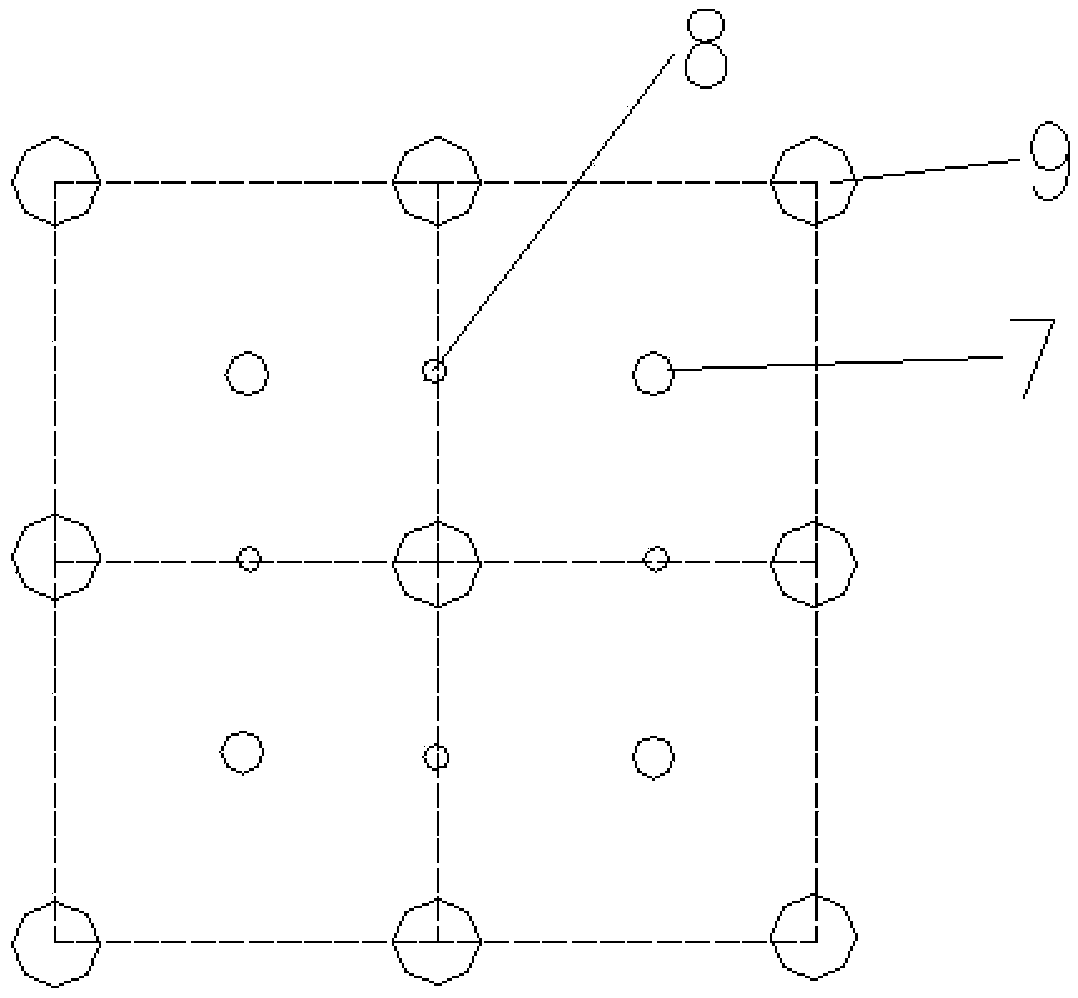

Construction method of amphibious plant community with water body purification function

ActiveCN105502666AGrowth inhibitionGood plastic effectSustainable biological treatmentBiological water/sewage treatmentBiological propertyPlant community

The invention discloses a construction method of an amphibious plant community with a water body purification function. The construction method comprises the following steps: dividing planting regions on a land-lake ecotone in a manner of being parallel to a river way; selecting amphibious plants, which have a good purification effect and a high survival rate, are amphibious and have a good landscape effect, and planting the amphibious plants into the planting regions to construct a plant community, wherein the amphibious plants are selected from more than three of bamboo reeds, iris wilsonii, cyperus altrnlifolius, reeds, cannas and lythrum salicaria; managing the plants according to growth conditions of the plants. Properties of absorbing pollutants of the plants are combined with biological properties of the different plants, and an attractive landscape is created at the same time; an amphibious plant community system is constructed by using ecological niches of the different plants, so that the effect of purifying a water body is improved; meanwhile, withered plants are harvested and external pollutants are not introduced, so that rotted plants are prevented from entering the water body, and furthermore, the content of the pollutants in the water body is reduced.

Owner:北京东方利禾景观设计有限公司

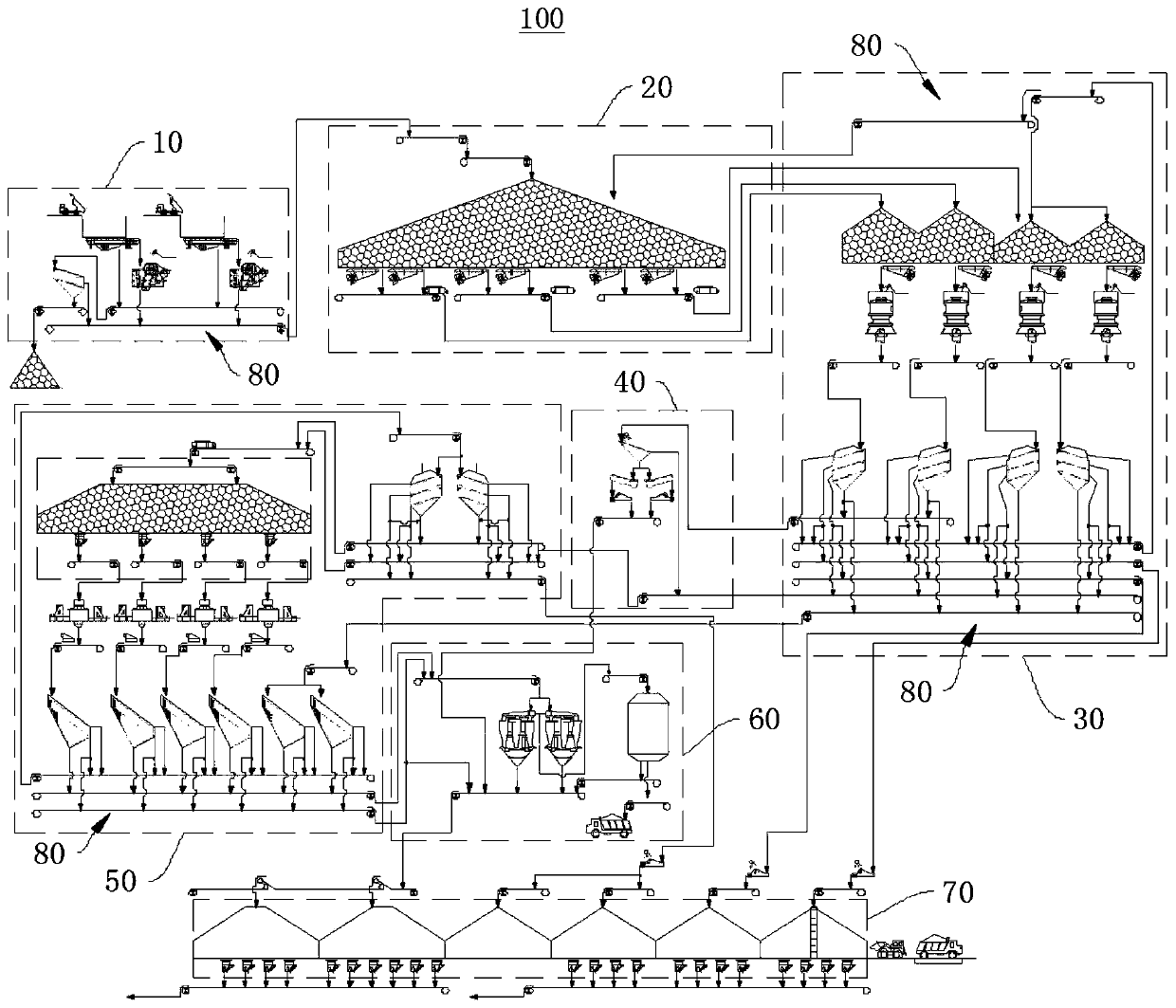

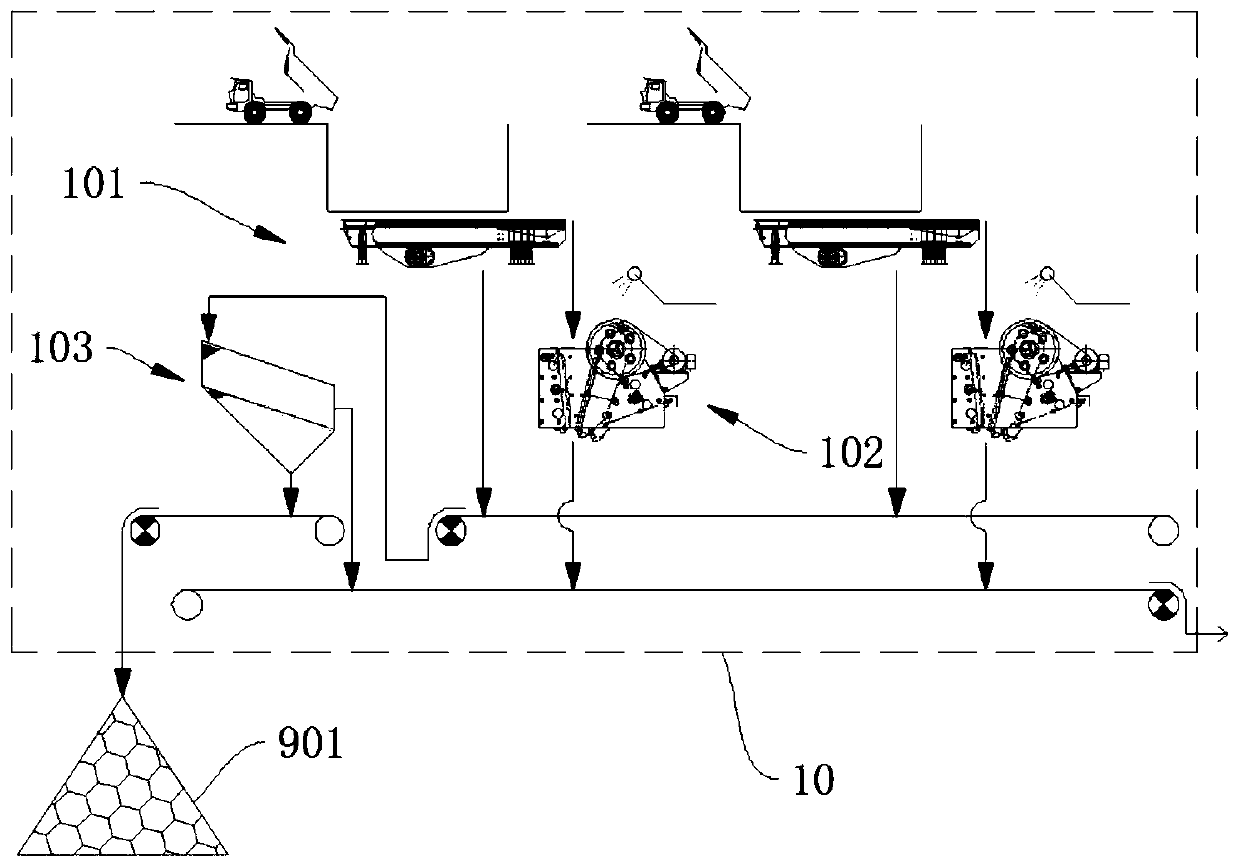

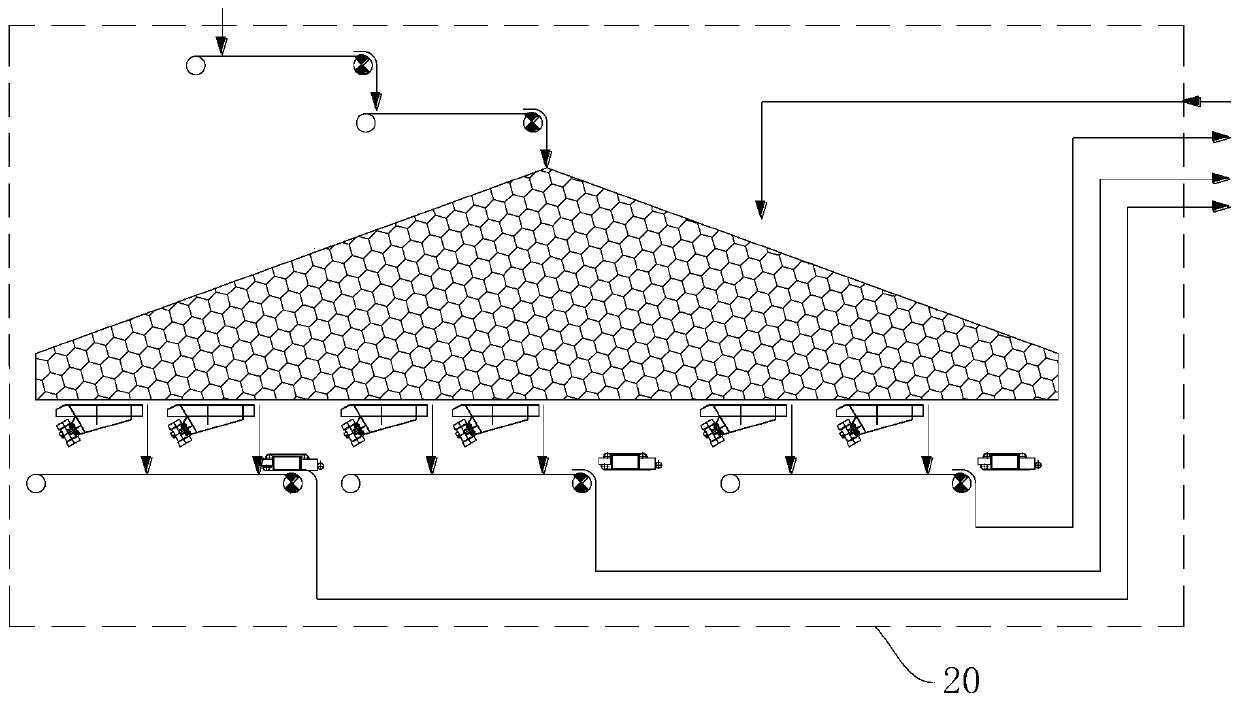

Processing technology and system for producing concrete aggregate by using complex material source

InactiveCN111302686AIncrease profitContinuous gradationSolid waste managementGrain treatmentsProcess engineeringComplex materials

The invention discloses a processing technology and system for producing concrete aggregate by using a complex material source, and relates to the technical field of concrete aggregate production. Theprocess comprises the following steps: coarsely crushing excavated materials to form coarse crushed materials; intermediately crushing the coarse crushed materials to form intermediate crushed materials, screening the intermediate crushed materials, conveying the intermediate crushed materials of which the particle sizes meet a second particle size region to a finished product bin, and mixing theintermediate crushed materials of which the particle sizes meet a first particle size region with the coarse crushed materials; and finely crushing the coarse crushed materials and the intermediate crushed materials to form fine crushed materials, screening the fine crushed materials, mixing the fine crushed materials of which the particle sizes meet a first particle size interval with the coarsecrushed materials again for fine crushing, and conveying the fine crushed materials of which the particle sizes meet a second particle size interval to a finished product bin, wherein the first particle size interval is larger than the second particle size interval. According to the processing technology and system for producing concrete aggregate by utilizing a complex material source, the concrete aggregate can be produced by utilizing a complex excavated material source, and the processing technology and system have the characteristics of good aggregate shaping effect, continuous gradationof the produced finished aggregate and high material source utilization rate.

Owner:华电西藏能源有限公司 +1

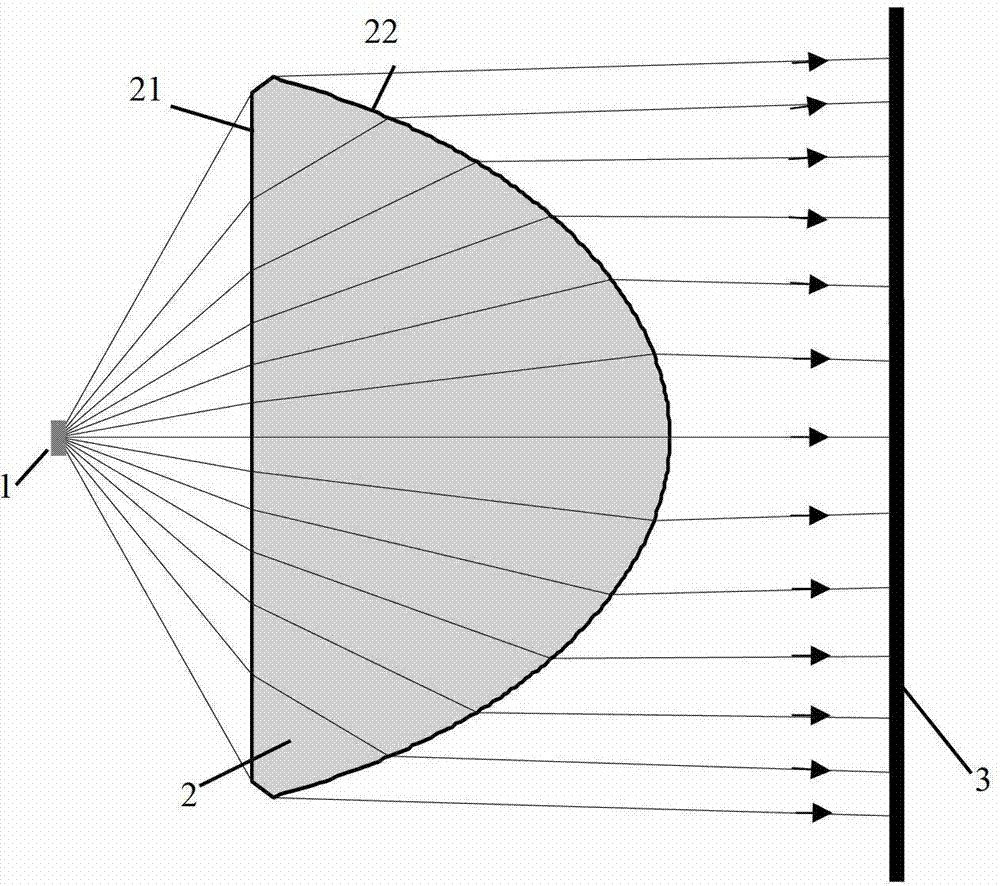

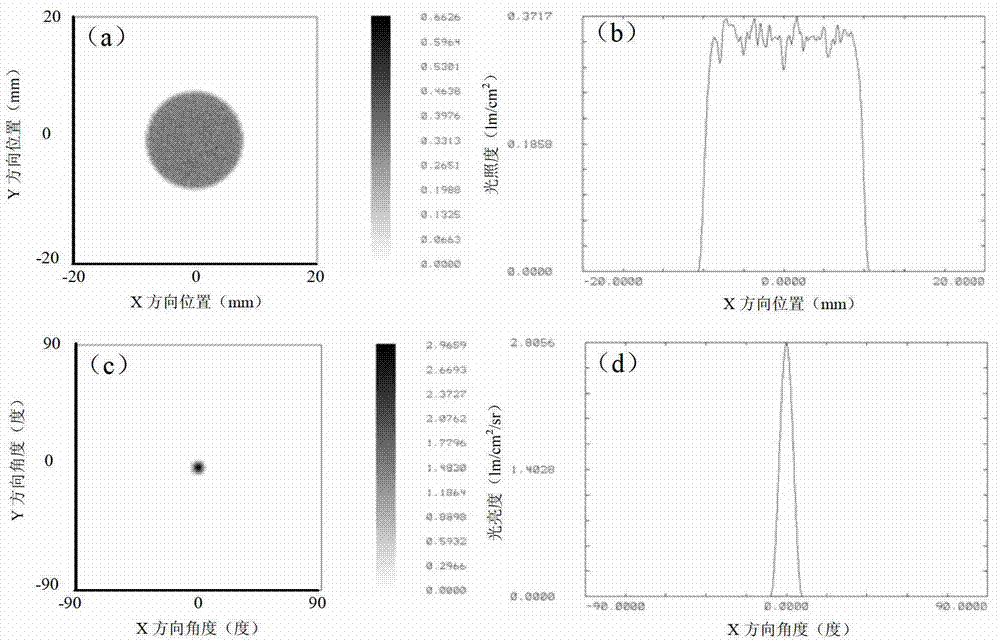

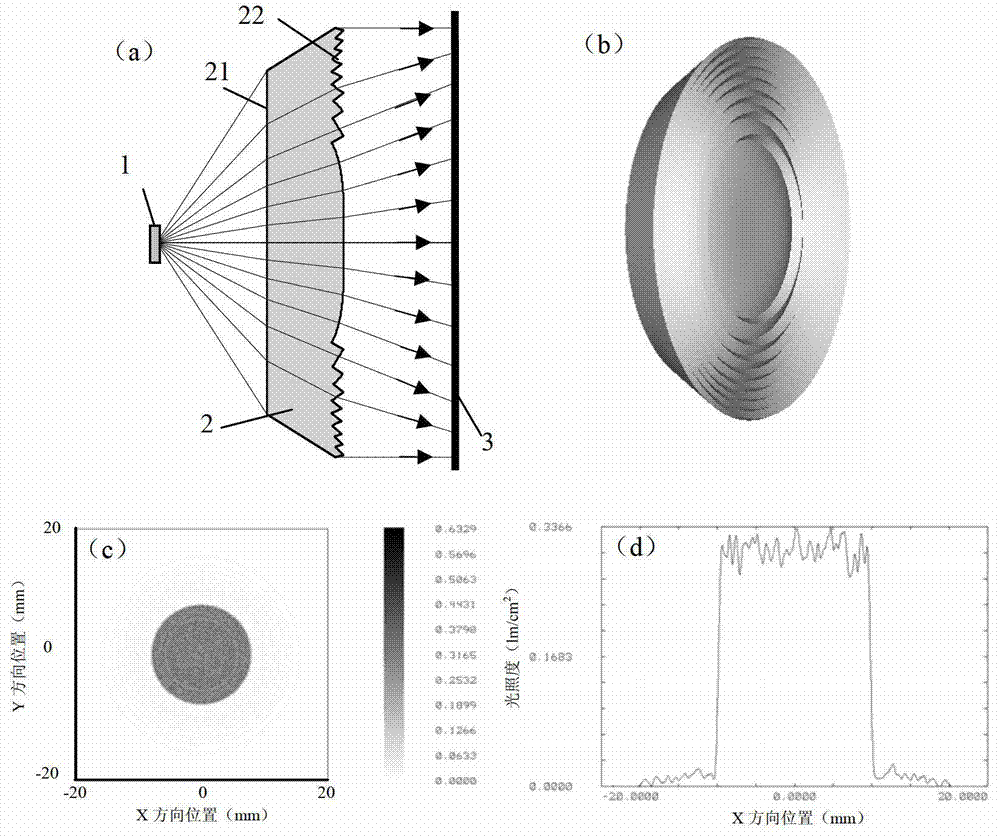

Single-free-form-surface thick lens with short-distance uniform light effect and array thereof

InactiveCN103116197AGood plastic effectHomogenization distance shortenedLensRefractorsLight sourceEffect light

The invention provides a single-free-form-surface thick lens with short-distance uniform light effect and an array thereof, and relates to the technical field of secondary optical elements of light sources such as cold cathode fluorescence lamps and LEDs. One surface of the lens is an optionally set curved surface while the other surface of the lens is a free-form surface. In a second optical element, front surfaces and rear surfaces of the lens and the array thereof refract light to control a travelling direction of the light, and thicknesses of the lens and the array determine offset of the light in a radial direction of the lens, so that after emitted light of light sources such as a cold cathode fluorescence lamp and an LED passes the lens, energy on a test surface is specific in spatial distribution, and angle of divergence of reshaped light beams can be partially controlled. The lens and the array thereof can reshape the emitted light of the light sources such as the cold cathode fluorescence lamp and the LED to obtain the light beams excellent in directivity and uniformity. By applying the lens and the array to the fields of backlights of side-disturbance-free uniform lighting and liquid crystal display and the like, lighting effect can be improved remarkably, and uniform light distance is shortened.

Owner:UNIV OF SCI & TECH OF CHINA

Radial stretching type concave pipe maintenance device

InactiveCN106287104AGreat driving forceBig shaping forcePigs/molesHydraulic motorPetroleum engineering

The invention relates to a radial stretching type concave pipe maintenance device used for reshaping repair construction of instable pipelines, locally deformed pipelines and deformed barrels. Through the technical scheme, an outer barrel is arranged outside an inner barrel, the inner barrel is arranged on a substrate, the substrate is sleeved in a front end cover, a hydraulic motor is arranged on the substrate, a first T-shaped groove is formed in the radial direction of the front end cover, reshapers are arranged in the radial direction of the front end cover, front oil cylinders are arranged between the front end cover and the reshapers, a second T-shaped groove is formed in the radial direction of a rear end cover, slips arranged in the radial direction of the rear end cover, rear oil cylinders are arranged between the rear end cover and the slips, one end of a middle oil cylinder is arranged at the central position of the substrate, and the other end of the middle oil cylinder is fixed in the outer barrel through a mounting plate. The slips and the reshapers are driven by the independent oil cylinders, the radial stretching distance can be adjusted independently, the rebounding of deformed parts of a pipeline can be taken into account in the reshaping process, and the reshaping effect is good.

Owner:SOUTHWEST PETROLEUM UNIV

Device for repairing defects of flexible OLED display device

PendingCN111571003AHigh positioning accuracyImprove repair efficiencySolid-state devicesLaser beam welding apparatusDisplay deviceControl cell

The invention relates to a device for repairing defects of a flexible OLED display device. The device comprises a display panel alignment mechanism, a movement mechanism, a laser repairing mechanism,an OLED lighting mechanism and a control mechanism, the display panel alignment mechanism is provided with a UVW console used for adjusting an alignment angle; the OLED lighting mechanism is providedwith a lighting control unit and an air suction needle pressing unit used for adsorbing and fixing a to-be-repaired workpiece to, the lighting control unit is electrically connected with the air suction needle pressing unit, and the air suction needle pressing unit is fixed to the UVW console; the movement mechanism is provided with a displacement table movement unit and a gantry movement unit, the laser repairing mechanism is arranged on a gantry movement unit, and the UVW console is arranged on the displacement table movement unit. A placing position and angle of the to-be-repaired workpieceare accurately controlled through the movement mechanism and the display panel alignment mechanism, the defect positioning and repairing precision of the to-be-repaired workpiece is better, defects can be completely repaired, and the repairing efficiency and the repairing quality are improved.

Owner:BEIJING C&W TECH DEV

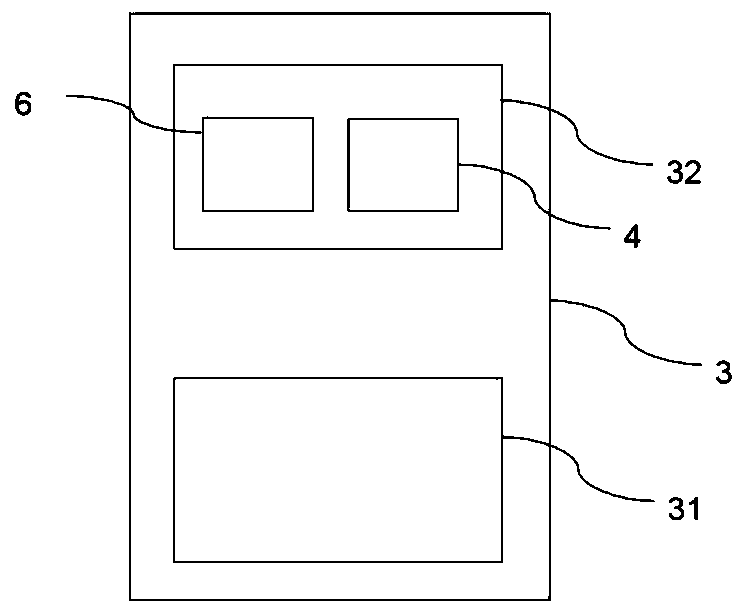

Packaging mechanism for tea packaging machine

PendingCN108327974AReduce air volumeSave production spacePackaging under vacuum/special atmosphereBlack teaEngineering

The invention discloses a packaging mechanism for a tea packaging machine. The packaging mechanism for the tea packaging machine comprises a fixed mold base, a movable mold base subjected to mold closing opposite to the fixed mold base, an upper hot sealing mechanism performing hot pressing sealing on tea packaging bags, an upper shaping mechanism providing lower pressure for the tea packaging bags, and a lower shaping mechanism providing upper pressure for the tea packaging bags; the fixed mold base and the movable mold base are each concavely provided with a vacuum cavity with a vacuum gas hole; the upper hot sealing mechanism comprises a fixed heating strip and a movable clamping strip; the upper shaping mechanism comprises a first shaping block and a second shaping block which can movedownwards synchronously; the lower shaping mechanism is provided with a left side plate, a right side plate and a shaping cavity; the lower shaping mechanism is located below the upper shaping mechanism and is between the fixed mold base and the movable mold base; and the fixed mold base is fixedly provided with a push-out mechanism for pushing the tea packaging bags out. Compared with the priorart, the packaging mechanism for the tea packaging machine can be used for packaging green tea and black tea, diverse in packaging function and achieves dual purposes, and the producing cost and the spaced occupied by the machine are greatly saved for tea merchants.

Owner:安溪县钱盛自动化设备有限公司

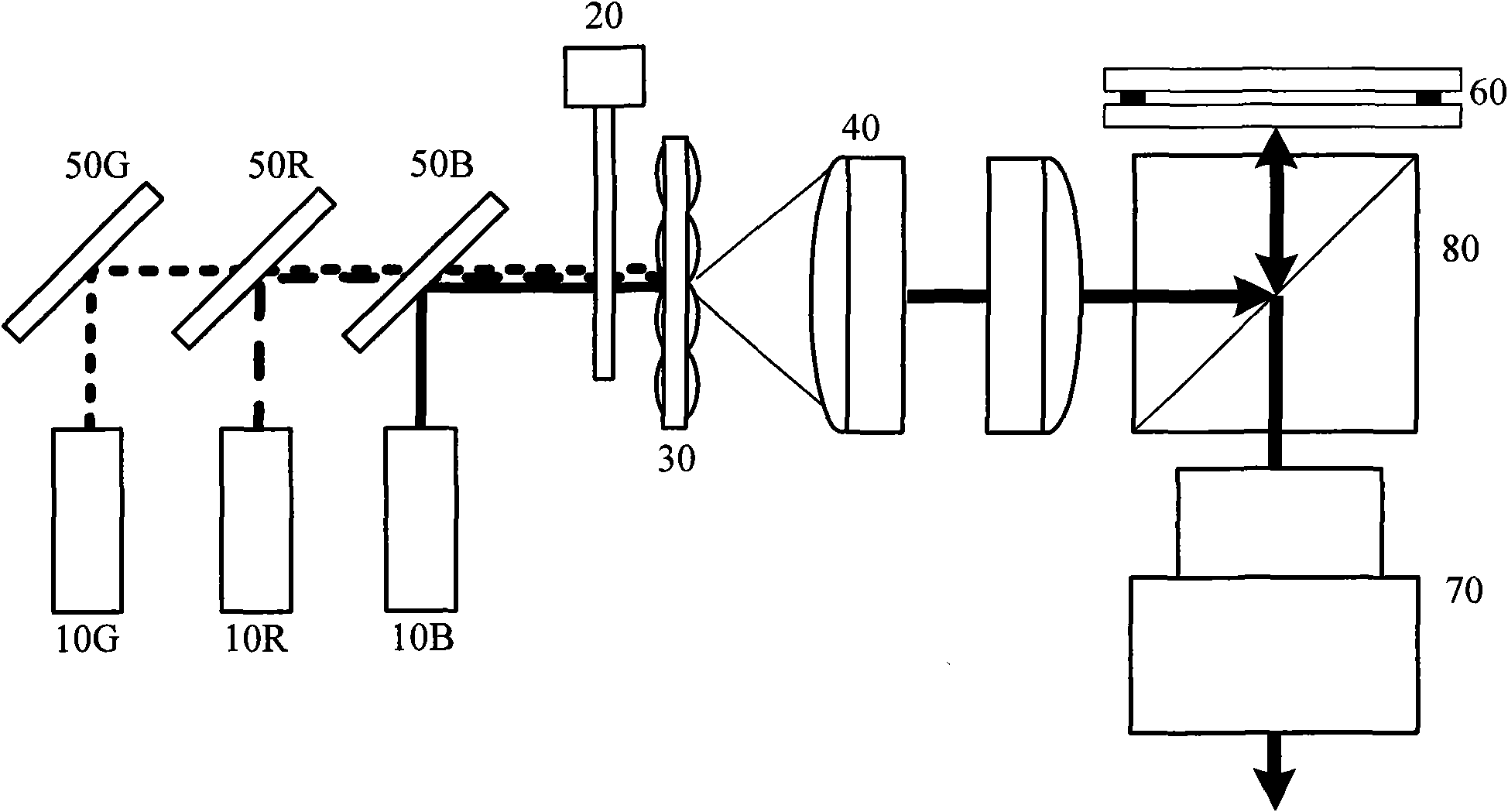

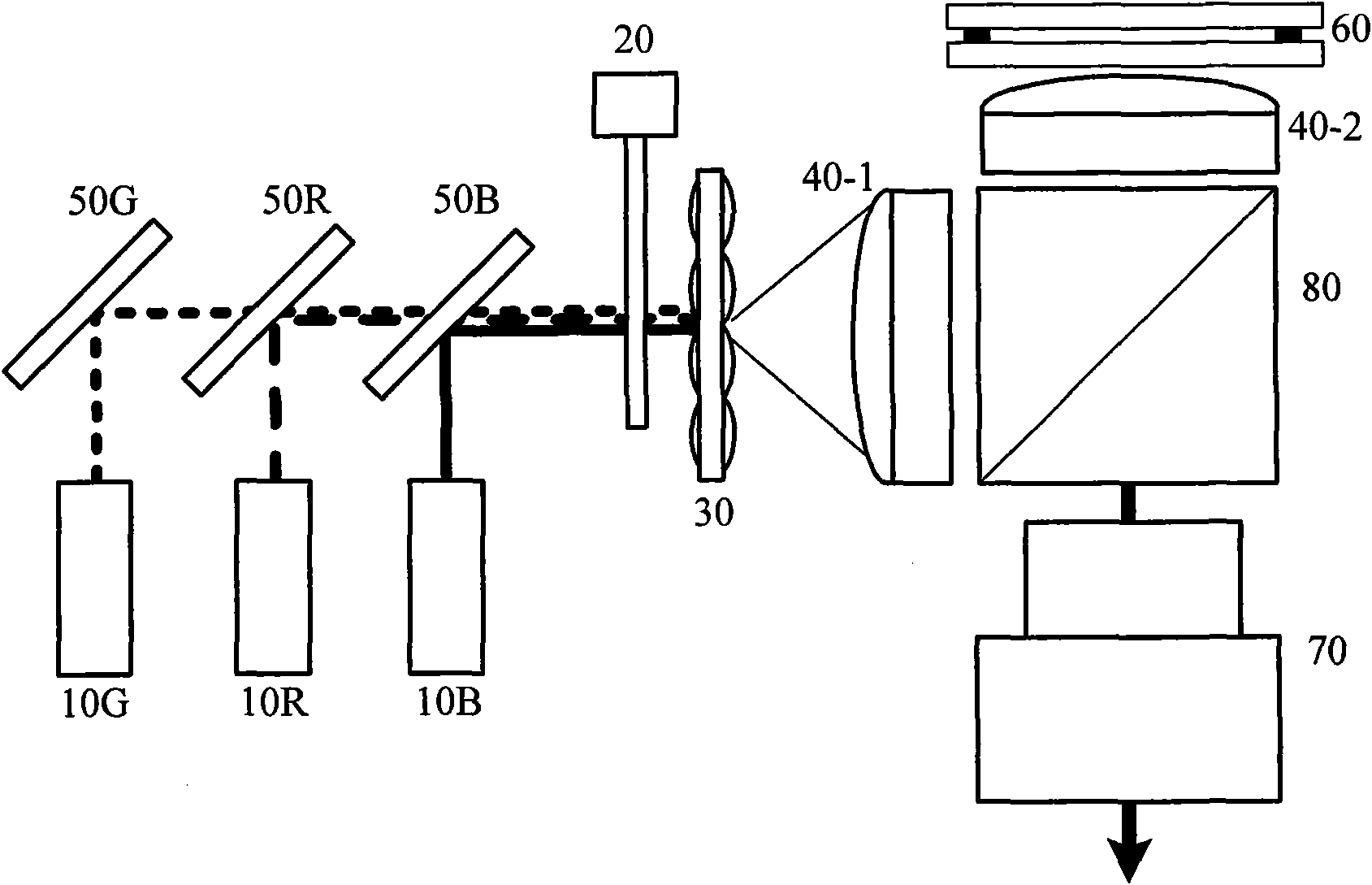

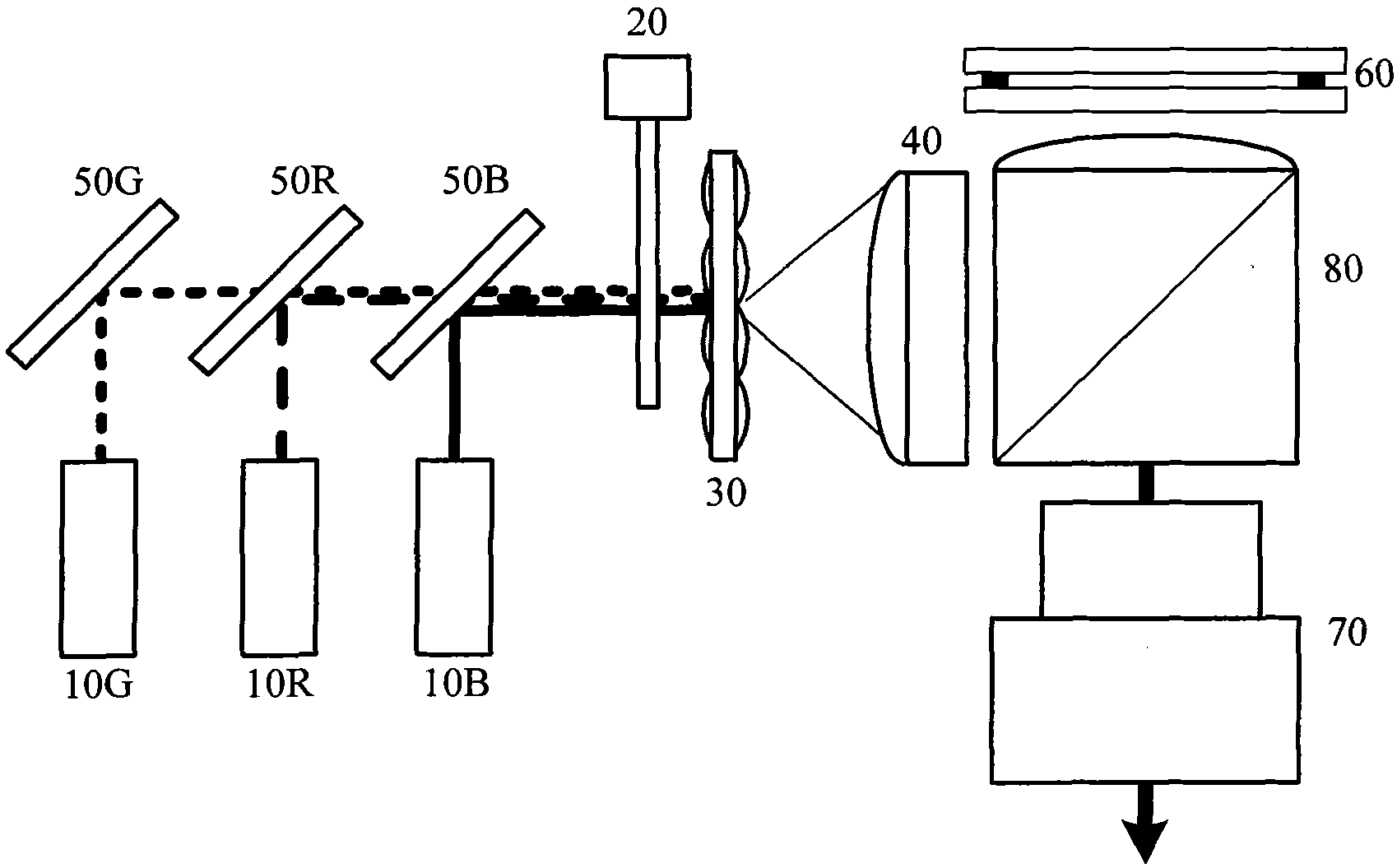

Reflection-type optical engine

InactiveCN101825830AReduce volumeSave spaceProjectorsLighting device detailsBeam splitterOptical polarization

The invention refers to a portable micro-projector, and discloses a reflection-type optical engine. In the invention, a polarizing beam splitter is placed with a spacing distance necessarily kept between two objective lenses for sharing space, thereby maintaining the spacing distance required between the two objective lenses and saving the space so as to reduce the volume of the optical engine. Furthermore, one or more lenses of the objective lenses can be integrally formed with the polarizing beam splitter so as to improve the precision of the optical engine assembly. Through integral formation of the optical element between the polarizing beam splitter and the optical modulator with the polarizing beam splitter, the liquid crystal optical valve can be arranged closer to the polarizing beam splitter.

Owner:SHANGHAI SANXIN TECH DEV

Small special electrical machine stator shaping device

InactiveCN107370304AThe problem of poor shaping effect due to synchronous expansionGood plastic effectManufacturing stator/rotor bodiesStatorEngineering

The invention provides a stator shaping device for a micro-special motor, which includes an air pump, a limiting plate, a shaping plate, a rubber balloon, an annular groove, an alarm bell, a contact piece 1, a front plate, a contact piece 2 and a battery. Set on the lower side of the circular side of the cylinder, the rubber balloon is assembled in the annular groove, the limiting plate is assembled in the hollow cavity, the shaping plate is arranged outside the cylinder, and the air pump is assembled on the upper end surface of the upper plate , this design achieves the purpose of synchronous expansion and shaping in the present invention, the alarm bell is assembled on the arc-shaped outer surface of the arc-shaped splint, the first contact piece is installed at the middle position of the left end surface of the front plate, and the second contact piece is assembled on the insulating On the right end of the plate, the storage battery is arranged in the arc-shaped splint. This design increases the early warning function of the present invention for clamping the stator in place. The present invention is easy to use, simple to operate, good in stability and high in reliability.

Owner:ZHONGSHAN HUAMEITE ELECTRICAL APPLIANCE MFG

Strip steel surface deformation shaping apparatus

ActiveCN104289520AImprove flatnessImprove work efficiencyMeasuring devicesMetal rolling arrangementsStrip steelMaterials science

The invention discloses a strip steel surface deformation shaping apparatus. The strip steel surface deformation shaping apparatus comprises a feeder, a limiter, a detector, a fine shaper and a winder, wherein the limiter is used for limiting a plane strip steel in the feeding process; next, the detector is used for detecting the deformation of the upper and lower surfaces of the plane strip steel; next, a second driving mechanism is used for performing vibrating impact shaping by selecting a shaping component corresponding to a defect in size according to a detection signal. The strip steel surface deformation shaping apparatus is capable of detecting the concavo-convex deformation defects on the surface of the strip steel and performing vibrating and knocking shaping on the concavo-convex deformation by selecting the shaping component according to the detection signal, and thus realizing fine shaping on the tiny concavo-convex deformation defects on the surface of the strip steel; besides, the apparatus is high in working efficiency and good in shaping effect; no secondary damage is caused in the shaping process and the shaped strip steel is high in surface flatness.

Owner:浙江新景和纺织科技有限公司

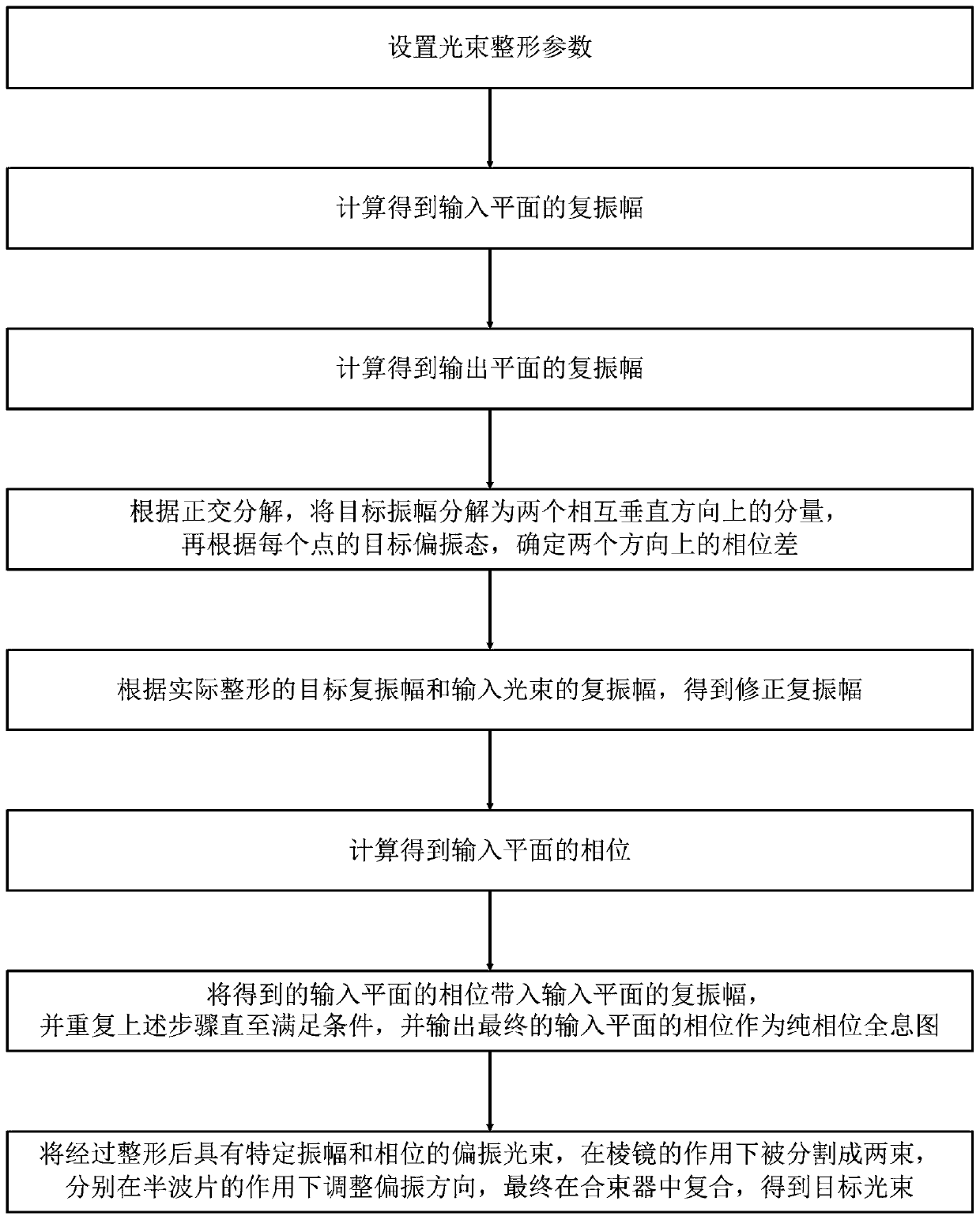

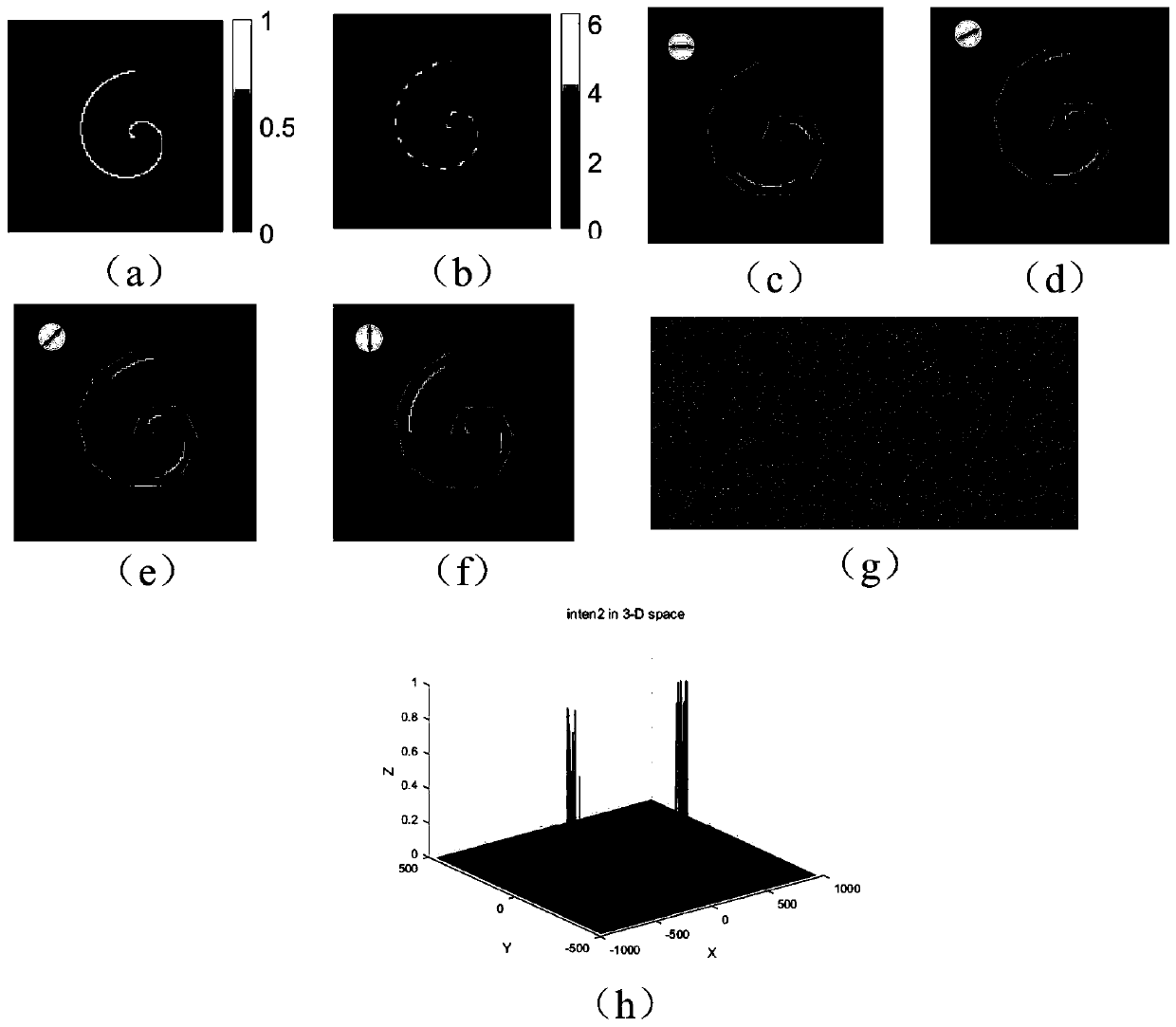

Shaping algorithm used for amplitude, phase and polarization of any light beam, and light path thereof

InactiveCN110119028AAmplitude controlAchieve shapingOptical elementsComplex amplitudeSpatial light modulator

The invention discloses a shaping algorithm used for the amplitude, the phase and the polarization of any light beam. The algorithm comprises the following steps that: setting a light beam shaping parameter; carrying out calculation to obtain the complex amplitude of an input plane and the complex amplitude of an output plane; decomposing target amplitude into components in two mutually vertical directions, and determining a phase difference in two directions; obtaining corrected complex amplitude and the input plane; outputting the phase of the final input plane as a pure phase hologram; andobtaining a target light beam. By use of the algorithm, the amplitude, the phase and the polarization state of any point in the light field can be controlled, and the light beam shaping of any shape,phase distribution and polarization state can be realized. Meanwhile, the pure phase hologram is obtained so as to be conveniently realized by a spatial light modulator or a manufactured diffracted light component and phase sheet, and the shaping of the amplitude and the phase of the light beam can be finished. The method is quick, has a good shaping effect, is suitable for light paths, and has asimple equipment instrument. Meanwhile, the light path provided by the invention has the advantages of being simple in arrangement and calibration.

Owner:CENT SOUTH UNIV

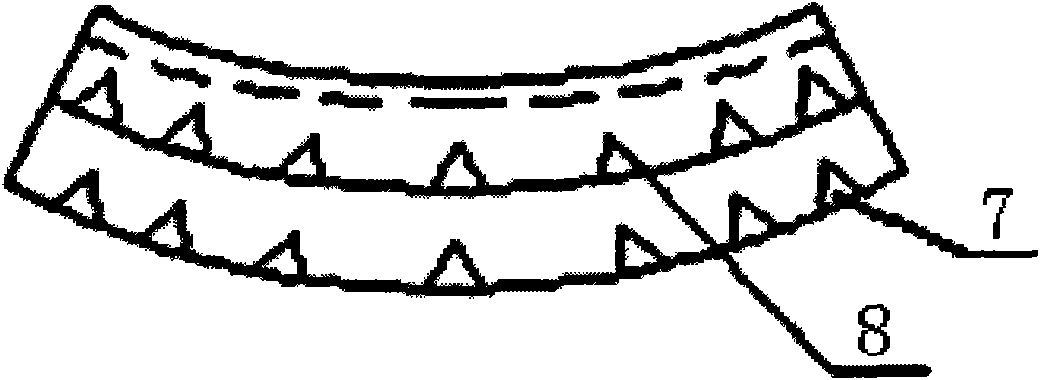

Flame shaping method for vertical bending deformation of transformer core clamping piece

InactiveCN101570814ASolve the problem of vertical bending deformationGood plastic effectTransformerEngineering

The invention relates to a flame shaping method for a vertical bending deformation of a transformer core clamping piece, which is applicable to the deformation of the transformer core clamping piece after welding. A heating method of triangular heating zone is used on a web of a splicing core clamping piece, namely to frame-heat a row of triangular heating zones at the upwarp of the web; the vertexes of the triangular heating zones are downward; the height of the vertex of the triangular heating zones is smaller than or equal to half height of the web; and the triangular heating zones are intensively heated to 700-800 DEG C, namely that the heated zones of the web are dull red. If the shaping requirements can not be satisfied by heating once, repetitive heating is to be carried out, and the repetitive heating areas are staggered from the former areas. The invention has the beneficial effects of better solving the problem of vertical bending deformation of the transformer core clamping piece and having good shaping effect; and the method is simple and easy.

Owner:BAODING TIANWEI GRP CO LTD

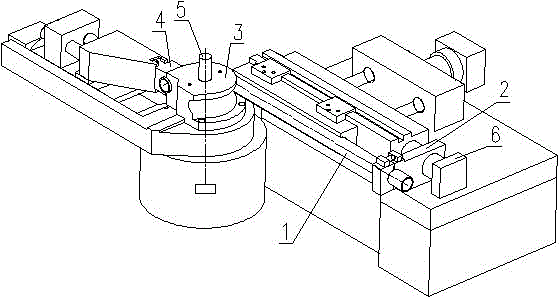

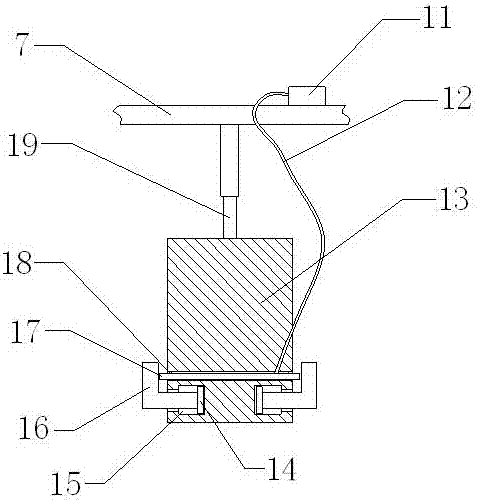

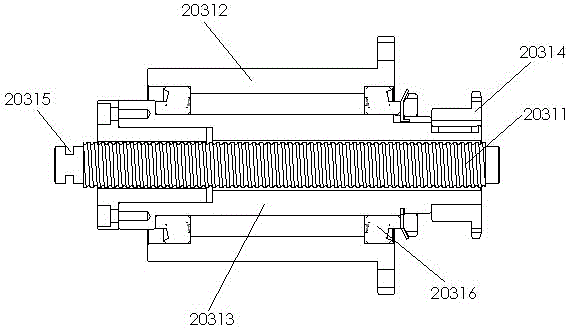

Coreless motor coil accurate reshaping machine

InactiveCN102684402AGood plastic effectMeet the finishing process requirementsManufacturing dynamo-electric machinesElectric machineMotive power

The invention relates to a coreless motor coil accurate reshaping machine, which comprises a bottom plate, a clamping mechanism and a telescopic mechanism, wherein the clamping mechanism and the telescopic mechanism are perpendicularly arranged on the bottom plate; the clamping mechanism comprises a clamping supporting plate which is fixed on the bottom plate, a propulsion supporting plate which is arranged on the clamping supporting plate, a clamping mold which is arranged on the propulsion supporting plate, and a power cylinder which drives the propulsion supporting plate to operate; the telescopic mechanism comprises a telescopic mechanism supporting plate, a telescopic propulsion plate and a propulsion cylinder which drives the telescopic propulsion plate to operate; and at least one core shaft rotary mechanism is arranged on the telescopic propulsion plate. The coreless motor coil accurate reshaping machine has the advantages that different surfaces of a coreless motor coil can be uniformly clamped and stressed, a reshaping effect of the coil is improved, a plurality of coreless motor coils can be accurately reshaped, the coreless motor coil accurate reshaping machine is high in working efficiency, high in degree of automation and high in positioning accuracy, requirements for accurate reshaping procedures in the manufacturing process of the coreless motor coils with different diameters and of different shapes can be met, and the compatibility of the coil accurate reshaping machine is improved.

Owner:KUSN KUKE AUTOMATION TECH

Package shaping machine

The invention, which belongs to the field of the packaging machinery, provides a package shaping machine comprising a rack. Shaping units for carrying out pushing and shaping on at least one side of a package box body are arranged on the rack; and the shaping units are arranged in pairs at opposite directions and the target displacement directions of the opposite shaping units are opposite. According to the invention, while packages are shaped, the relative positions of the packages on the conveying track are corrected, thereby providing a unified and normalized package transport state for a next procedure of the packages.

Owner:HUZHOU NANXUN DEAO MACHINERY EQUIP

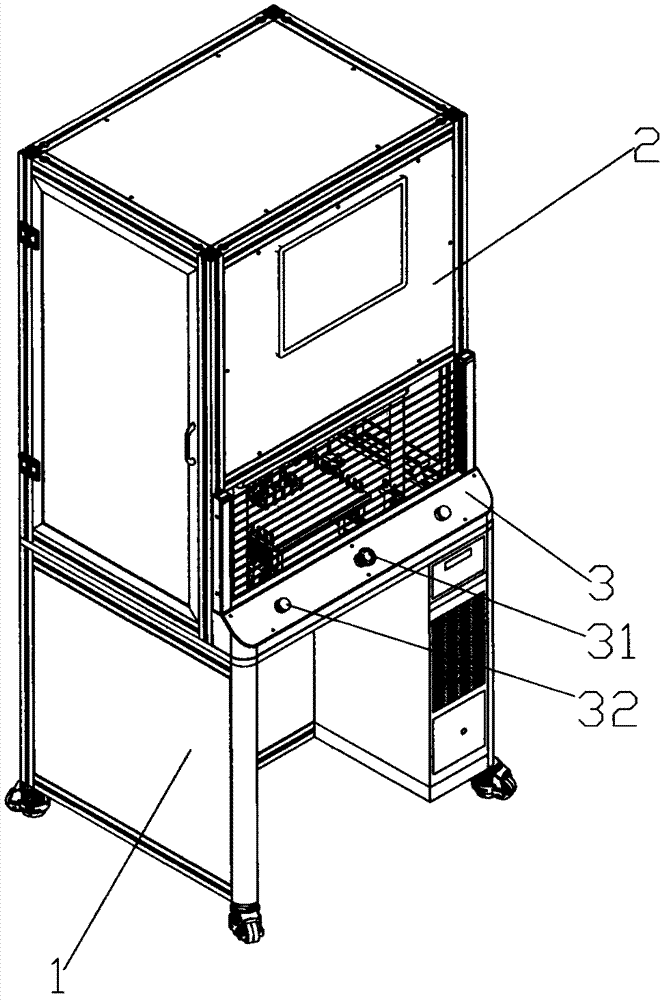

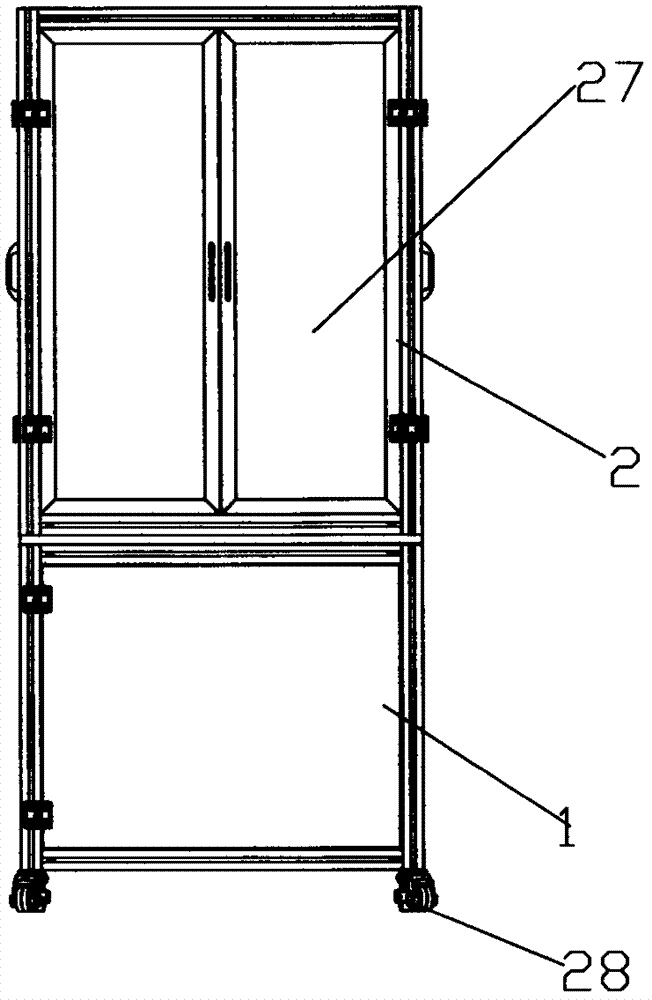

Thin-part flatness shaper

InactiveCN104742387AImprove detection accuracyEasy to fixMeasurement devicesEmergency Stop SwitchEngineering

The invention discloses a thin-part flatness shaper which comprises a rack. A protecting frame and a control box are arranged on the rack, the protecting frame is provided with a door body, the control box is provided with an emergency stop switch and a start switch, and a flatness detection shaping device is arranged in the protecting frame and comprises a testing mechanism, a thin-part clamping mechanism and a thin-part shaping mechanism which are arranged on a base; the testing mechanism comprises a testing pedestal and a flatness detection probe; the thin-part clamping mechanism comprises a thin-part clamping pedestal and a thin-part clamping plate, the thin-part clamping plate is provided with a clamping cavity, a thin-part is arranged in the clamping cavity, the base is provided with a power mechanism, and due to the power mechanism, the thin-part clamping mechanism can move forwards and backwards by virtue of a slide rail and a slide block cooperating with each other; and the thin-part shaping mechanism comprises a shaping fixed plate and a shaping assembly, and the shaping assembly comprises a shaping cylinder and a shaping press head. The thin-part flatness shaper is simple in structure, the precision and efficiency of detection on thin-part flatness are relatively high, and the shaping effect on thin-part flatness is relatively good.

Owner:SUZHOU KANGHONG INTELLIGENT EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com