A shaping and pressing device of a power battery

A compression device and power battery technology, applied in the direction of secondary batteries, secondary battery manufacturing, circuits, etc., can solve the problems of complex structure, high cost, poor versatility, etc., to improve the effect of plastic surgery, improve the effect of compression plastic surgery Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Now in conjunction with the accompanying drawings, the preferred embodiments of the present invention will be described in detail.

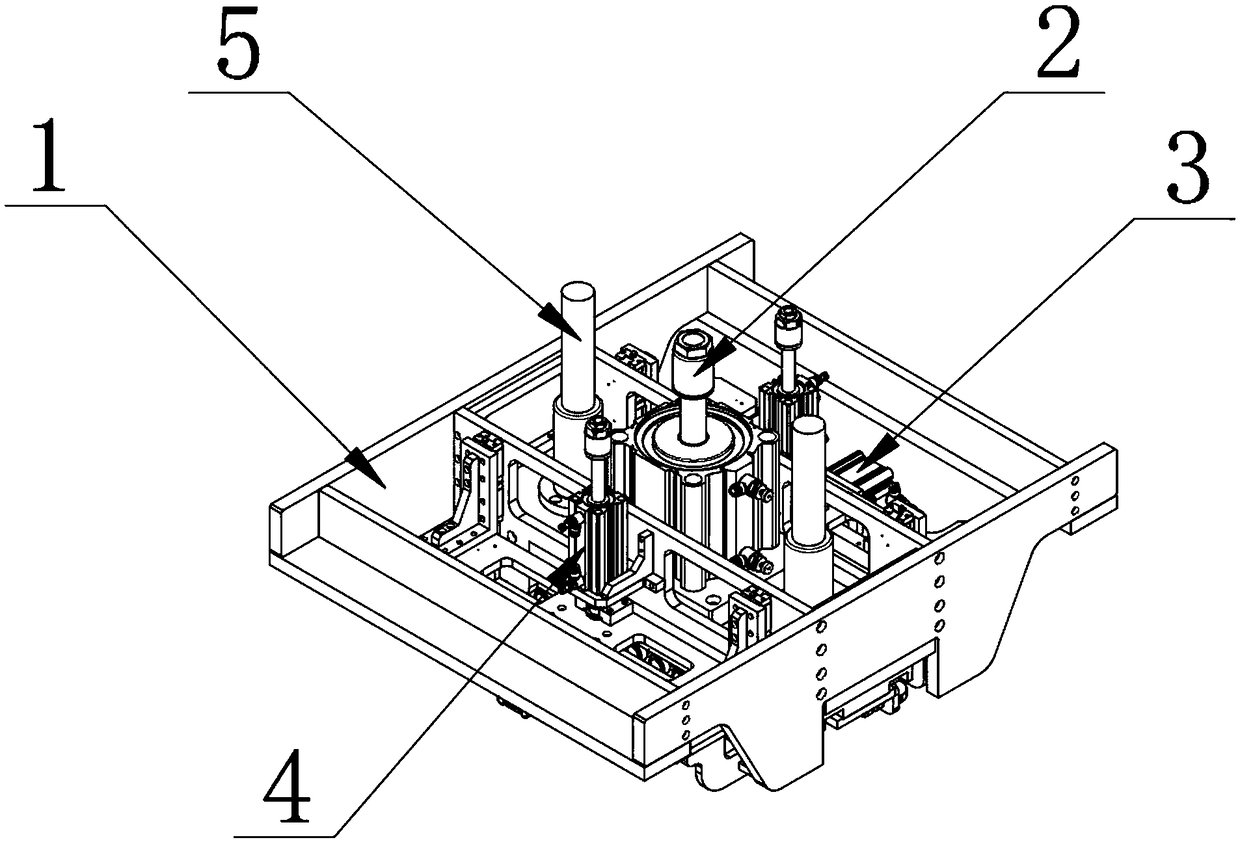

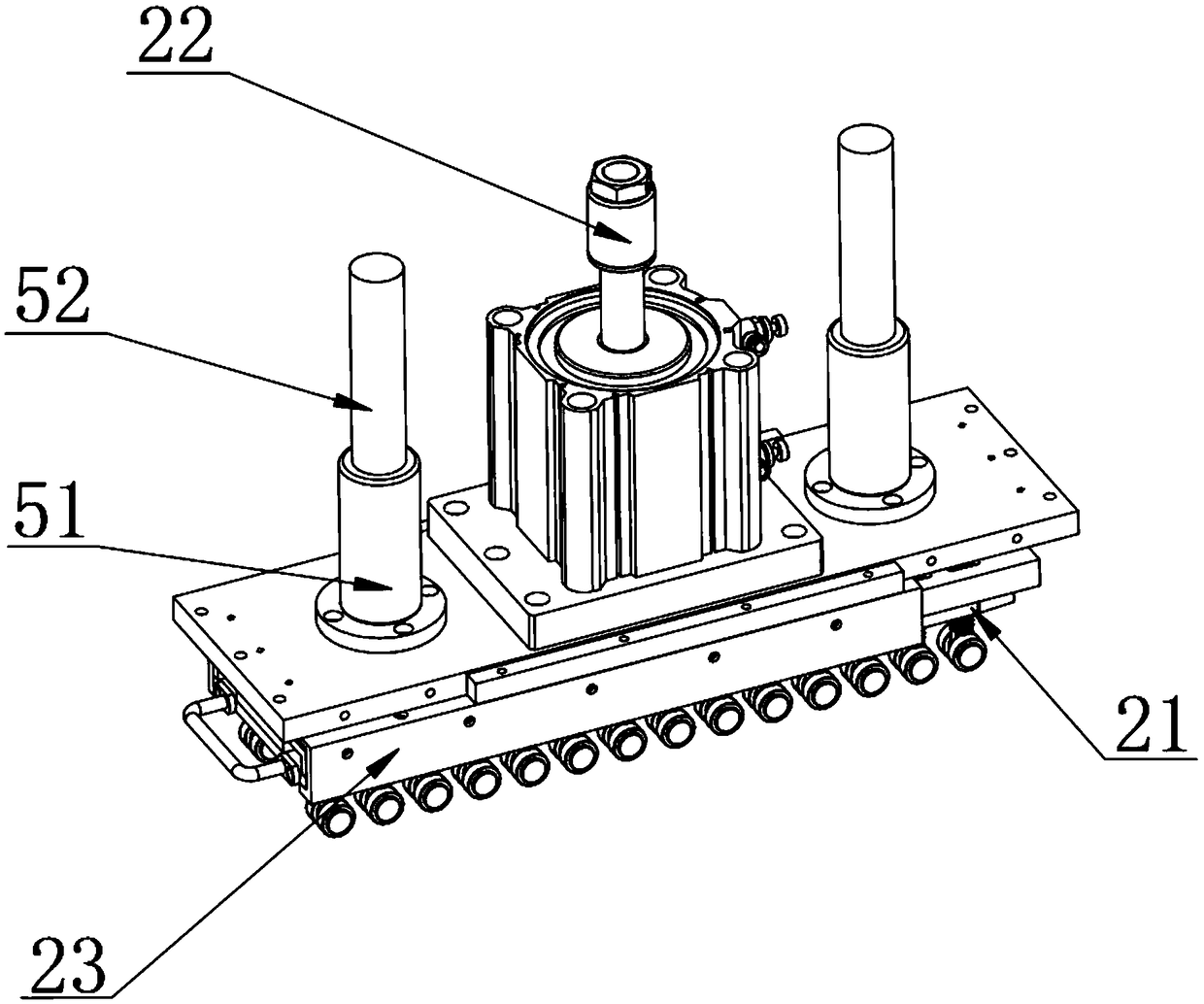

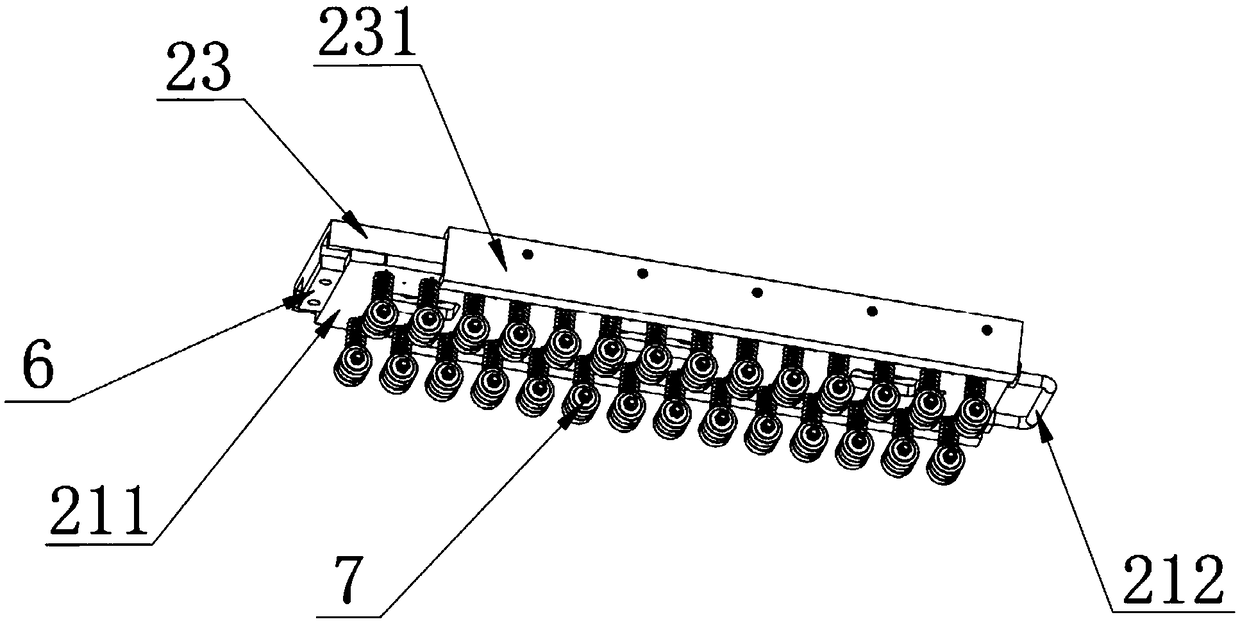

[0024] Such as figure 1 , figure 2 As shown, a power battery shaping and pressing device of this embodiment includes a frame body 1, a height shaping mechanism 2 arranged on the frame body 1, a width shaping mechanism 3 arranged on both sides of the height shaping mechanism 2, and a width shaping mechanism 3. The lifting mechanism 4 connected to the mechanism 3, the height shaping mechanism 2 includes a detachable lower pressing plate assembly 21 for pressing the battery module, the lifting mechanism 4 is used to drive the width shaping mechanism 3 to lift to avoid the lower pressing plate assembly 21 . The lifting mechanism 4 is arranged on the frame main body 1 , and the width shaping mechanism 3 is arranged at the lower part of the lifting mechanism 4 and moves up and down with the lifting mechanism 4 . Through the cooperation of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com