Patents

Literature

229results about How to "Improve shaping efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

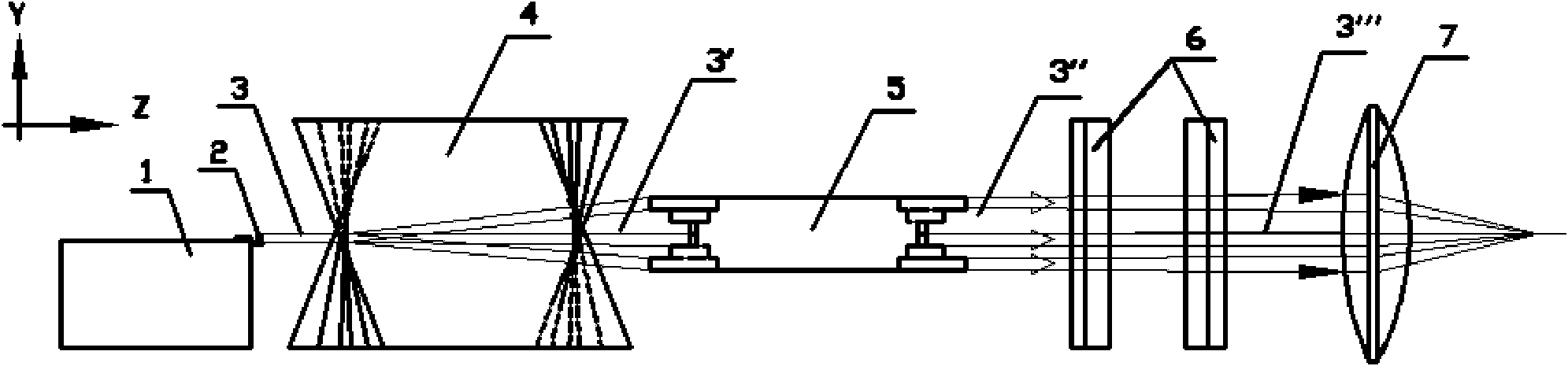

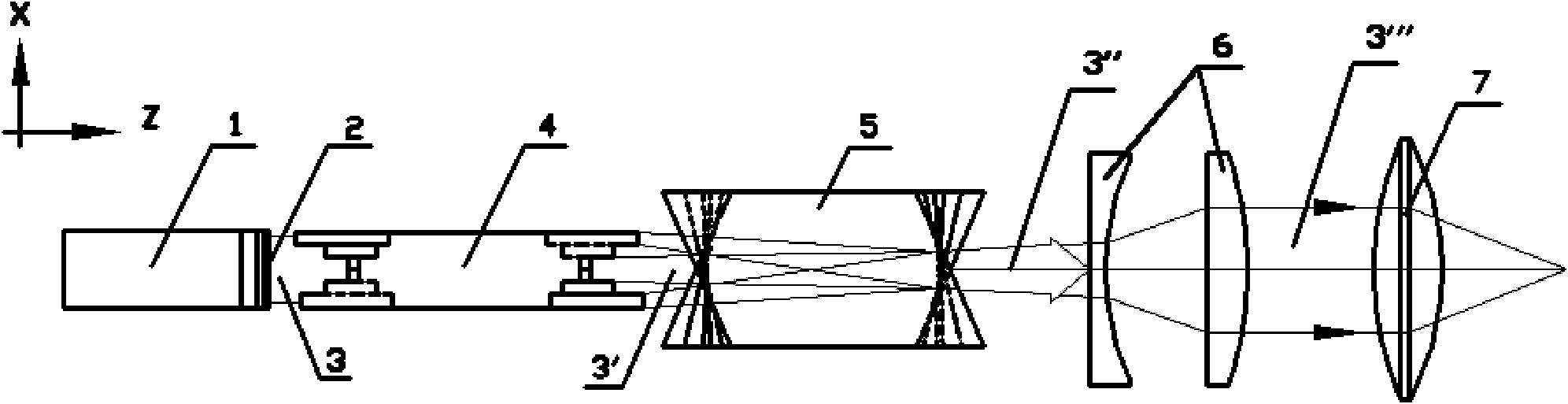

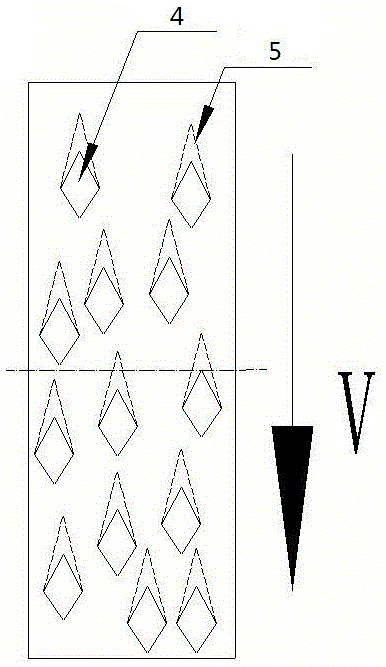

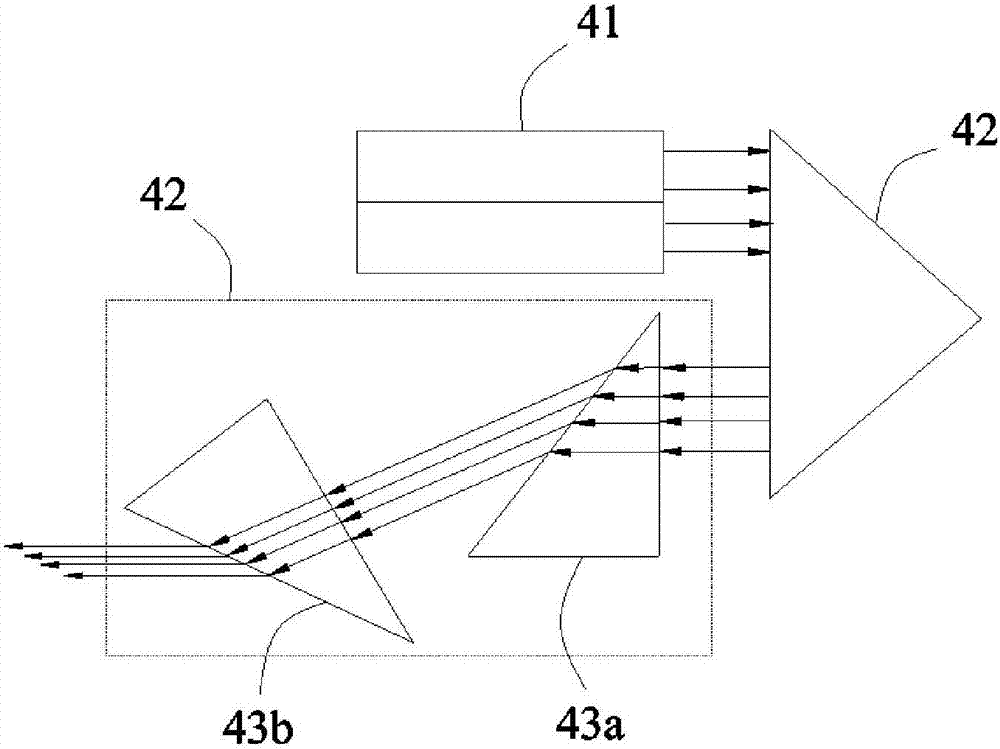

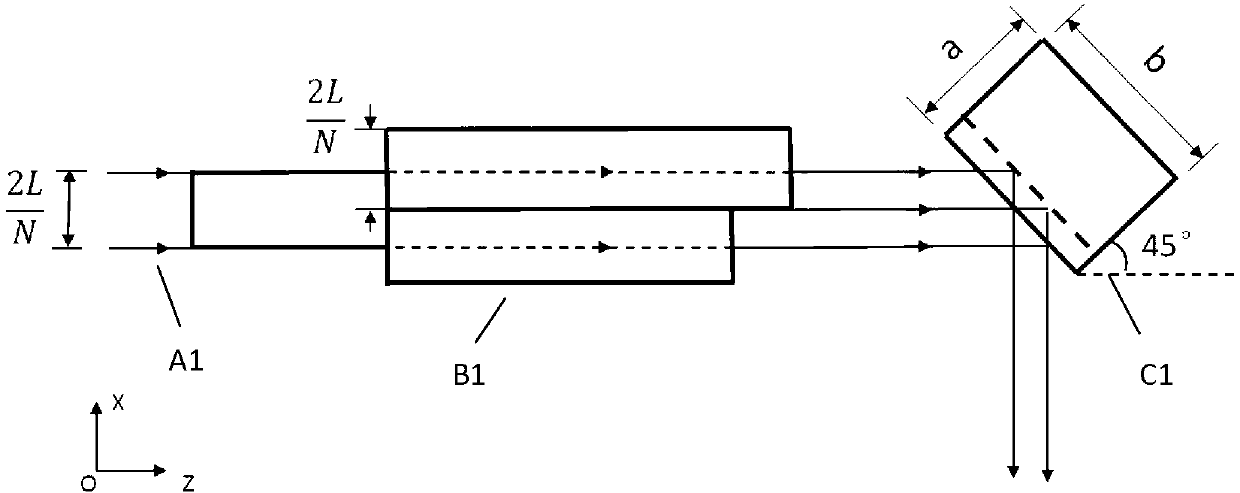

Semiconductor laser array fast and slow axis beam rearrangement device and manufacturing method

The invention discloses a semiconductor laser array fast-slow axis beam rearrangement device and a manufacturing method, and belongs to the field of laser technology application. By using the principle that the light produces different offsets after passing through parallel flat plates of the same thickness in different incident angles, an optical shaping element 4 and an optical shaping element 5 provided with a plurality of small surfaces are increased in the laser light path transmission process. The device can realize homogenization of fast and slow axis beam quality; by changing the conventional mode of waveguide transmission by means of a thin sheet, the loss of optical power is further reduced, and the shaping efficiency is improved; the device is particularly suitable for high-power semiconductor laser beam shaping; and meanwhile, the device has the advantages of more compact structure, no accumulated error, convenience in installation and adjustment and the like.

Owner:SHANXI FEIHONG LASER TECH

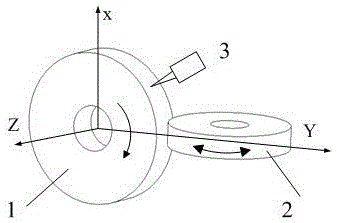

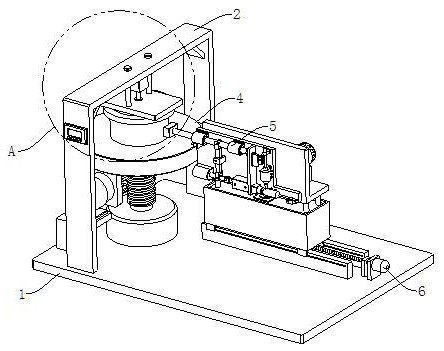

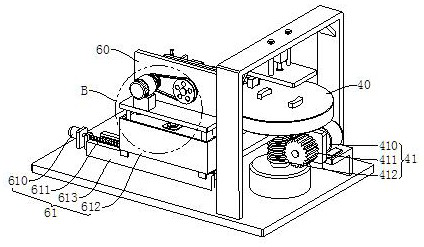

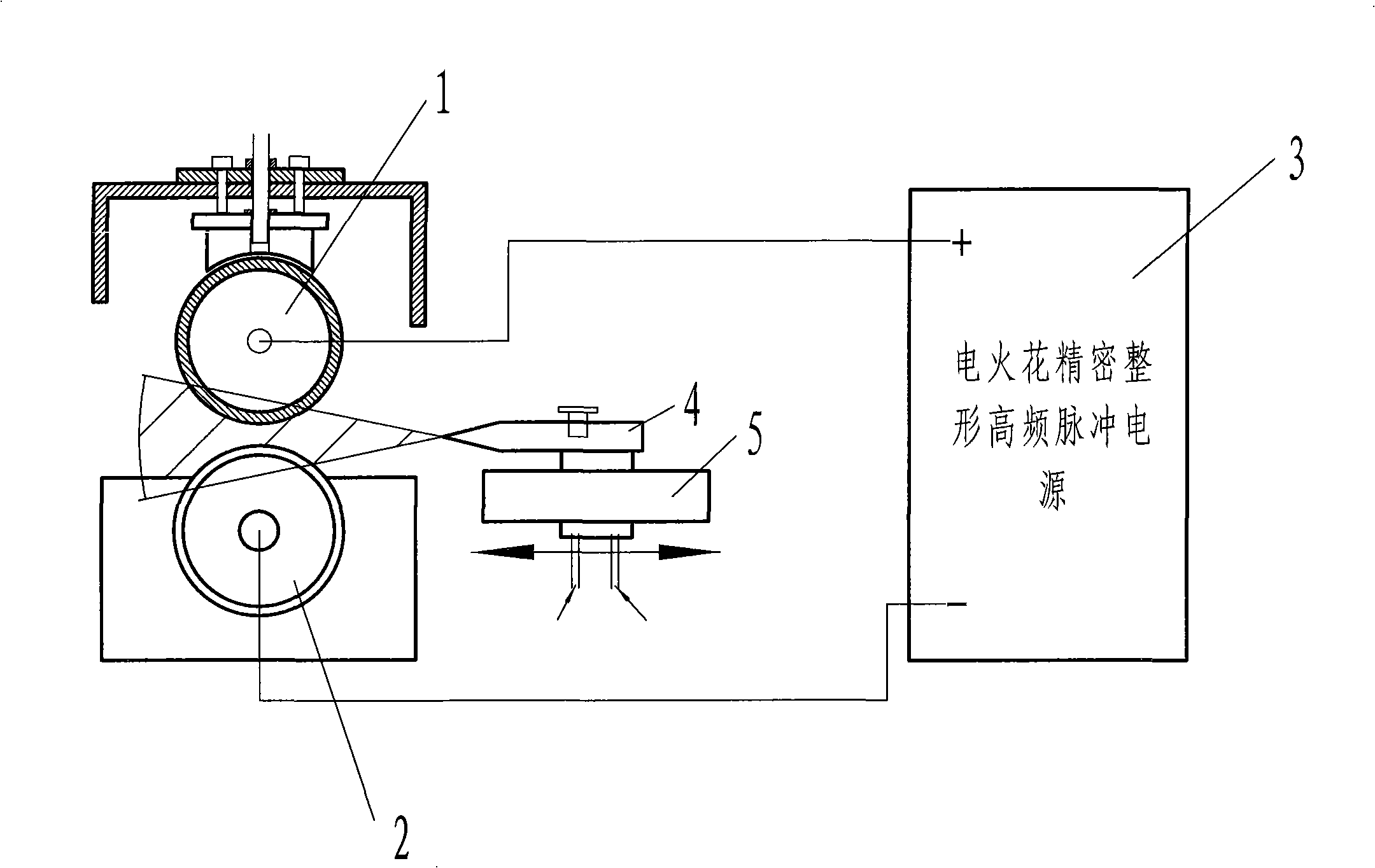

Quick and efficient shaping method of super-abrasive grinding wheel

ActiveCN105081977AGood removal effectFast and efficient shapingAbrasive surface conditioning devicesTime domainLow speed

The invention discloses a quick and efficient shaping method of a super-abrasive grinding wheel. The quick and efficient shaping method specifically comprises the steps that a trimming wheel driver is mounted on a grinding machine; a spindle of the grinding machine is arranged to be perpendicular to a spindle of the trimming wheel driver; a to-be-trimmed grinding wheel is mounted on the spindle of the grinding machine; a trimming wheel is mounted on the trimming wheel driver; axes of the to-be-trimmed grinding wheel and the trimming wheel are arranged in a crossed manner, to allow the directions of linear speeds of the to-be-trimmed grinding wheel and the trimming wheel to be mutually perpendicular; a motor of the spindle of the grinding machine and a motor of the trimming wheel driver are connected with frequency converters of the grinding machine and the trimming wheel driver respectively; and the frequency converters are connected with a PLC (Programmable Logic Controller). In addition, time domain control of rotating speeds of the to-be-trimmed grinding wheel and the trimming wheel has periodicity; periods of the to-be-trimmed grinding wheel and the trimming wheel are identical; a phase difference between the to-be-trimmed grinding wheel and the trimming wheel is 180 degrees; and when the super-abrasive grinding wheel grinds and shapes, a high speed of the to-be-trimmed grinding wheel is matched with a low speed of the trimming wheel, and a low speed of the to-be-trimmed grinding wheel is matched with a high speed of the trimming wheel. Compared with the traditional grinding method having the defect that a grinding wheel shaped by traditional grinding method has single trimmed comet tails, the shaping efficiency of the super-abrasive grinding wheel can be increased by times, the consumption of the trimming wheel is reduced, and energy conservation and environment protection are facilitated.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

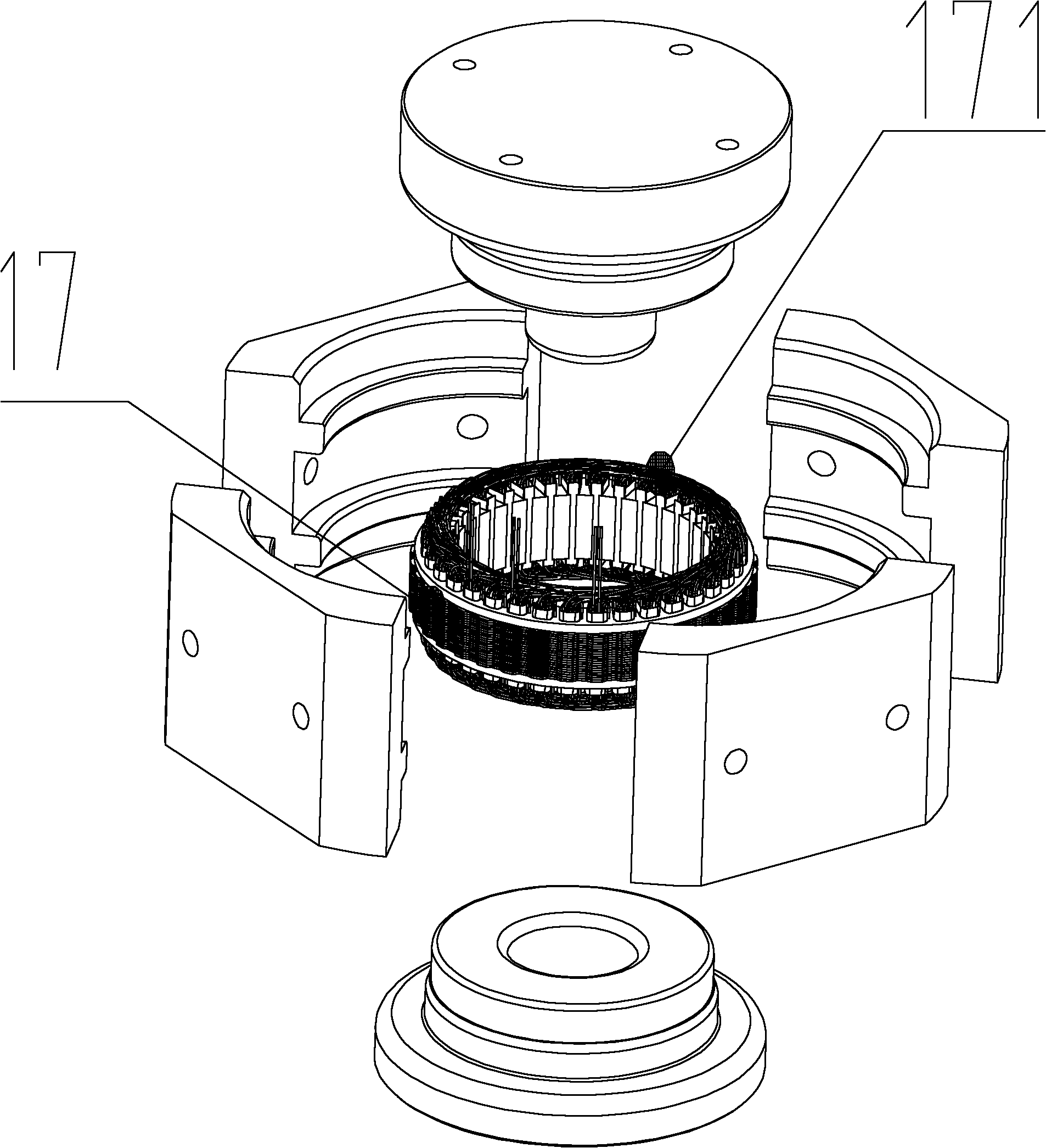

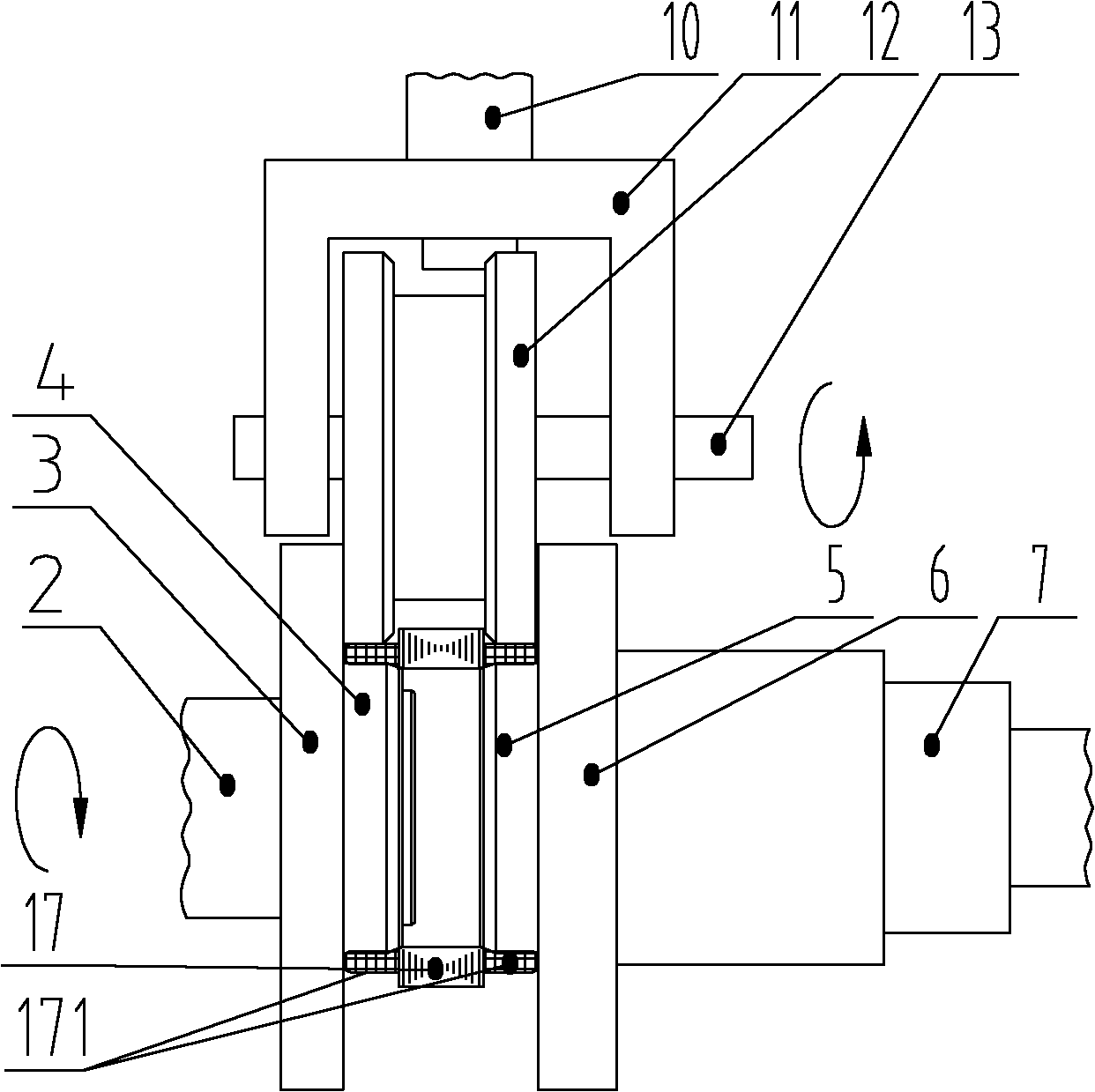

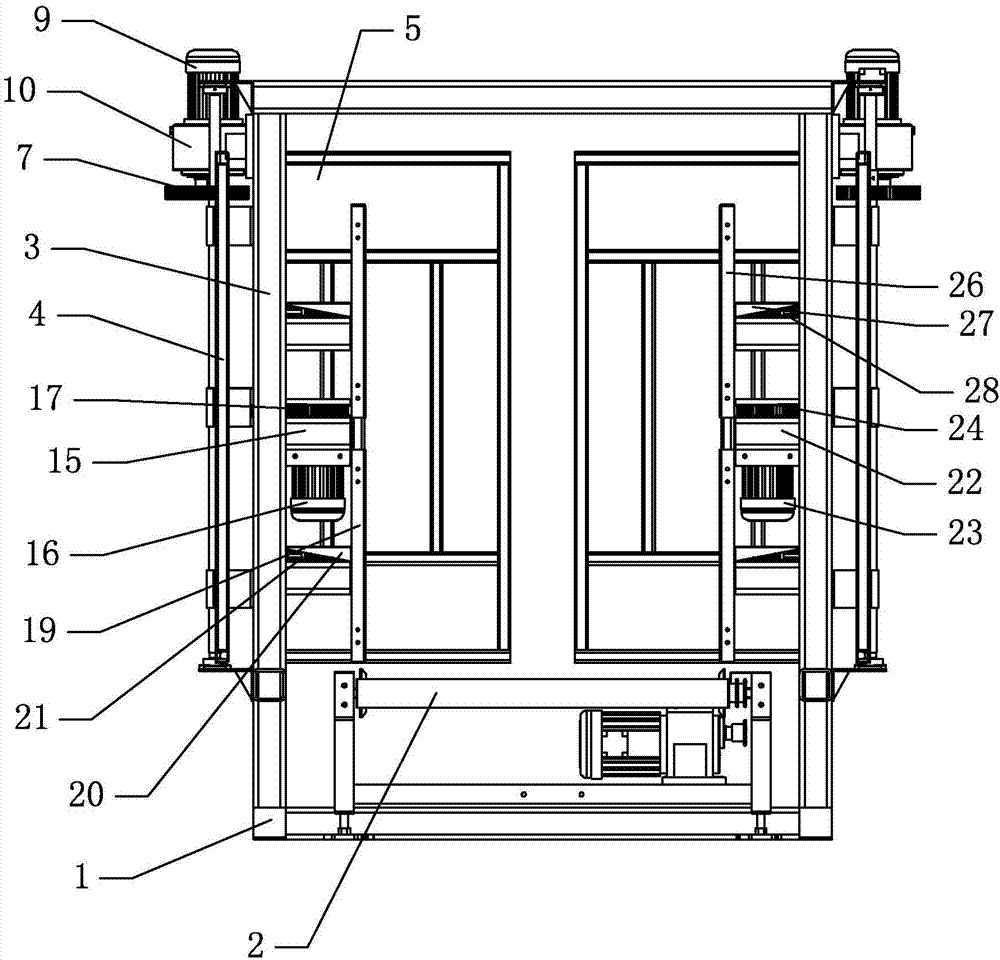

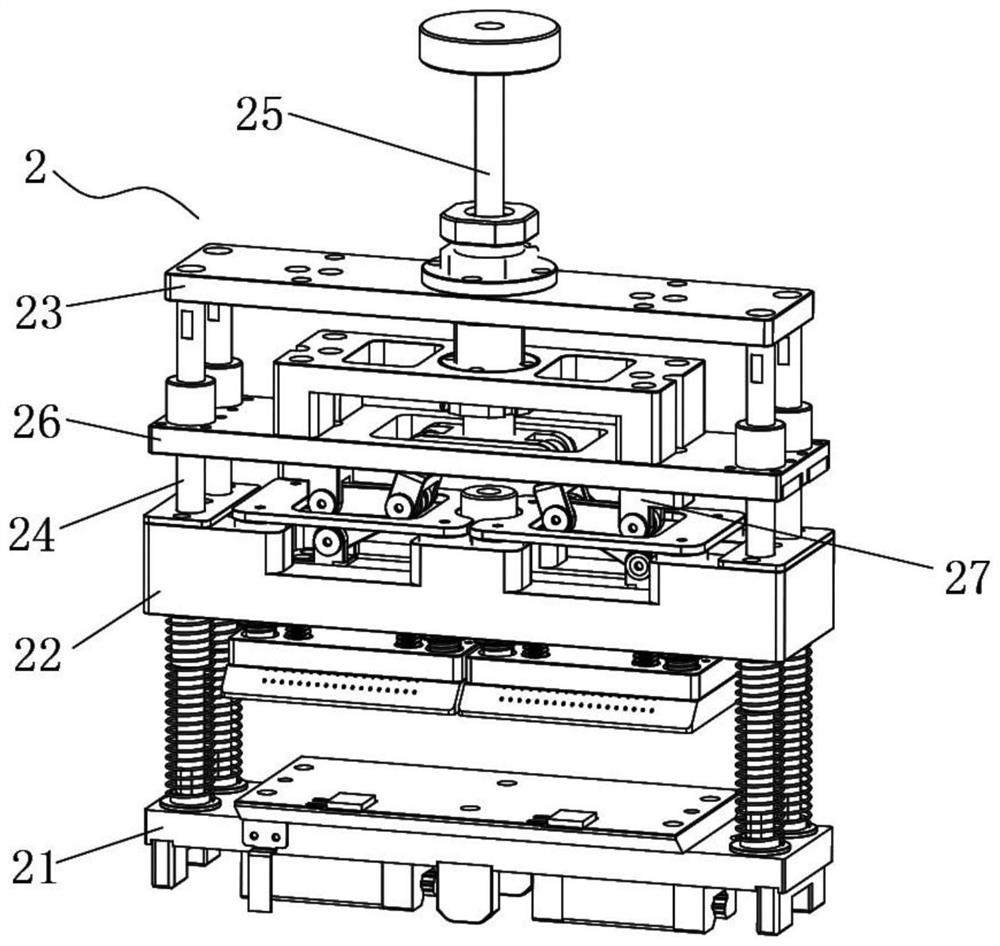

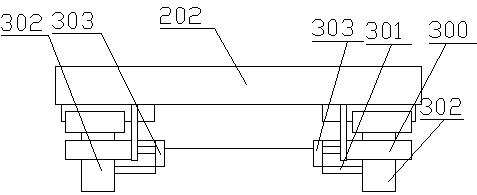

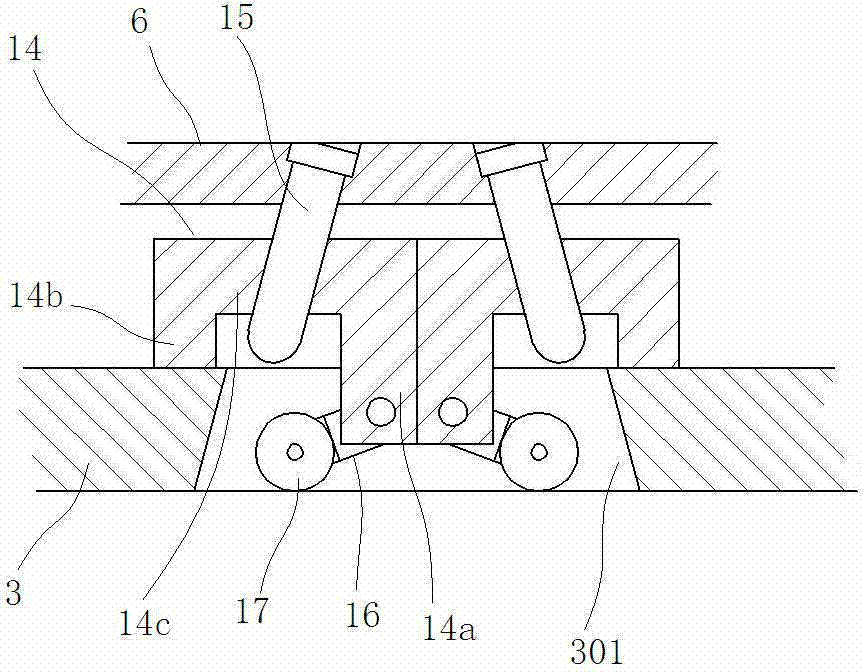

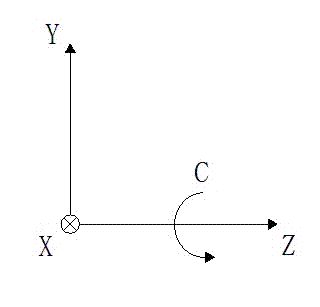

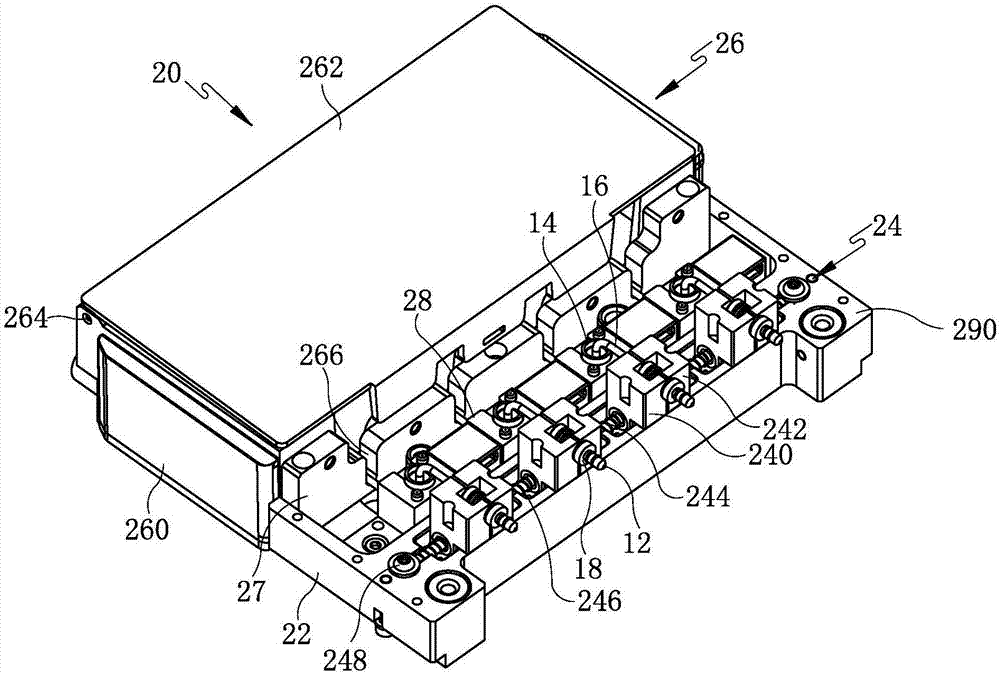

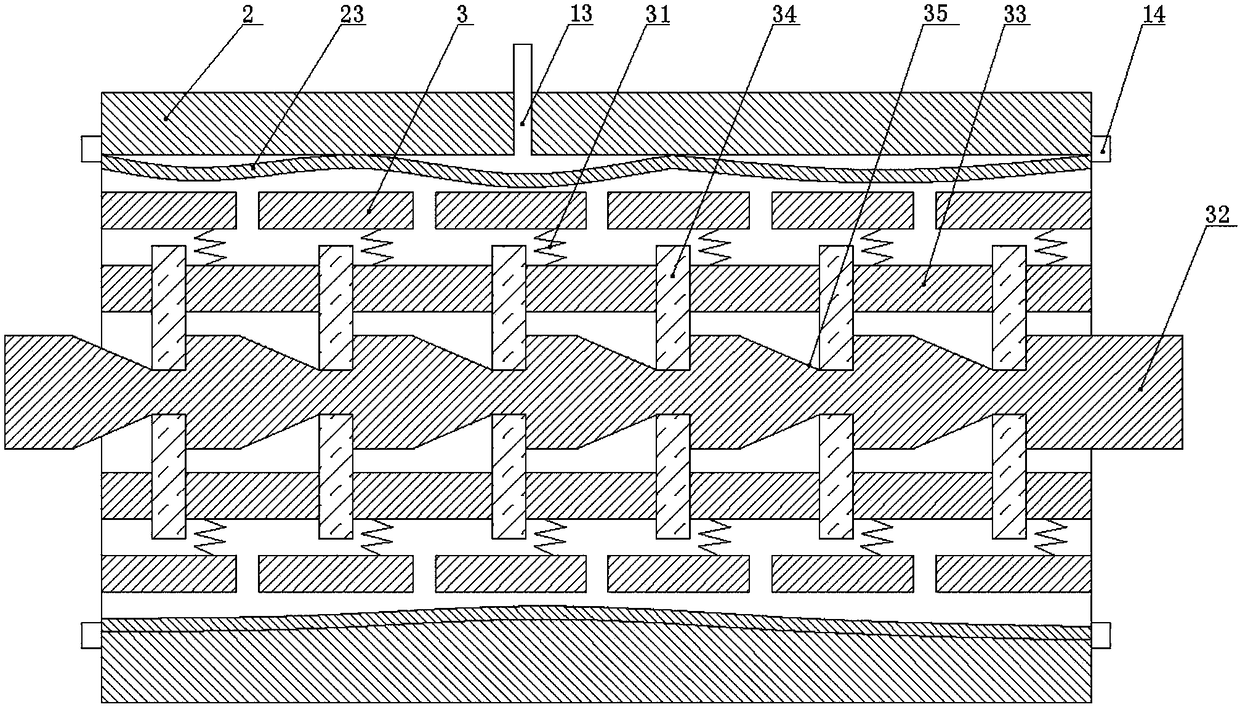

Motor stator coil reshaping method and device

ActiveCN101877519ABeautiful appearanceClosely arrangedManufacturing dynamo-electric machinesDrive shaftStator coil

The invention relates to a motor stator coil reshaping device which comprises a reshaping clamp, a driving mechanism, a transverse motion mechanism and a longitudinal motion mechanism, wherein the reshaping clamp comprises a left flange, a rolling wheel, a right flange, a fixed mandrel and a roller assembly; the right flange is fixed to the moving member of the transverse motion mechanism; the fixed mandrel is fixed on one side of the axial line of the right flange; the left flange is connected with the driving shaft of the driving mechanism; the rolling wheel is fixed on one side of the axial line of the left flange; the rolling wheel and the fixed mandrel are arranged on the same axial line; the left flange is over against the right flange; the roller assembly is fixed on the moving member of the longitudinal motion mechanism; and the roller is over against a position between the left flange and the right hand flange. Conductors in the reshaped coil are compact, can not easily loosen, and have the advantages of favorable dimensional uniformity and small degree of roundness. The invention increases the percent of pass of stator reshaping, and maximally reduces the slippage between the roller and the coil, thereby reducing the damage of the roller on the insulating layer of the coil. The invention has the advantages of simple reshaping operation, high reshaping efficiency and good product quality.

Owner:NINGBO YUNSHENG +2

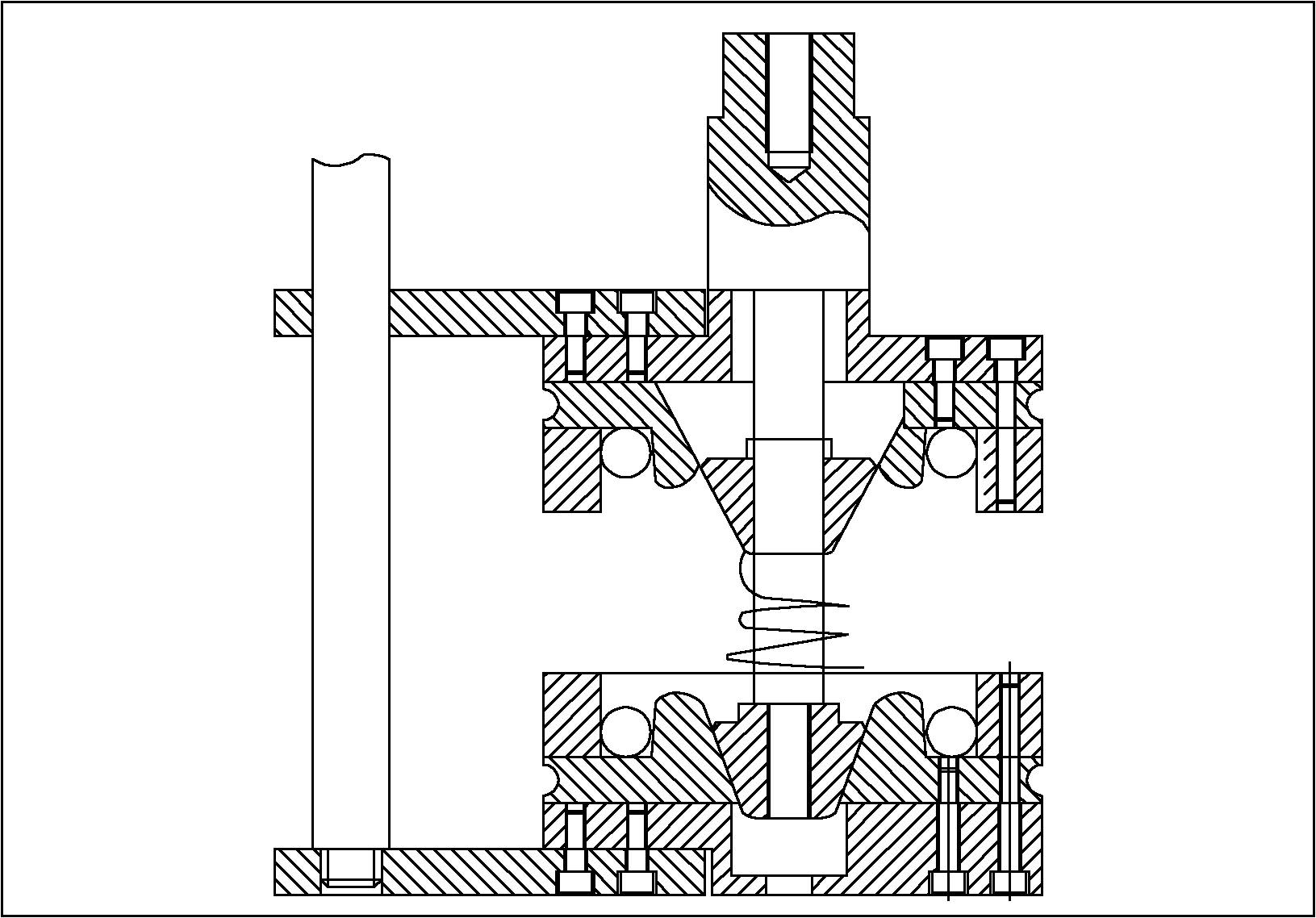

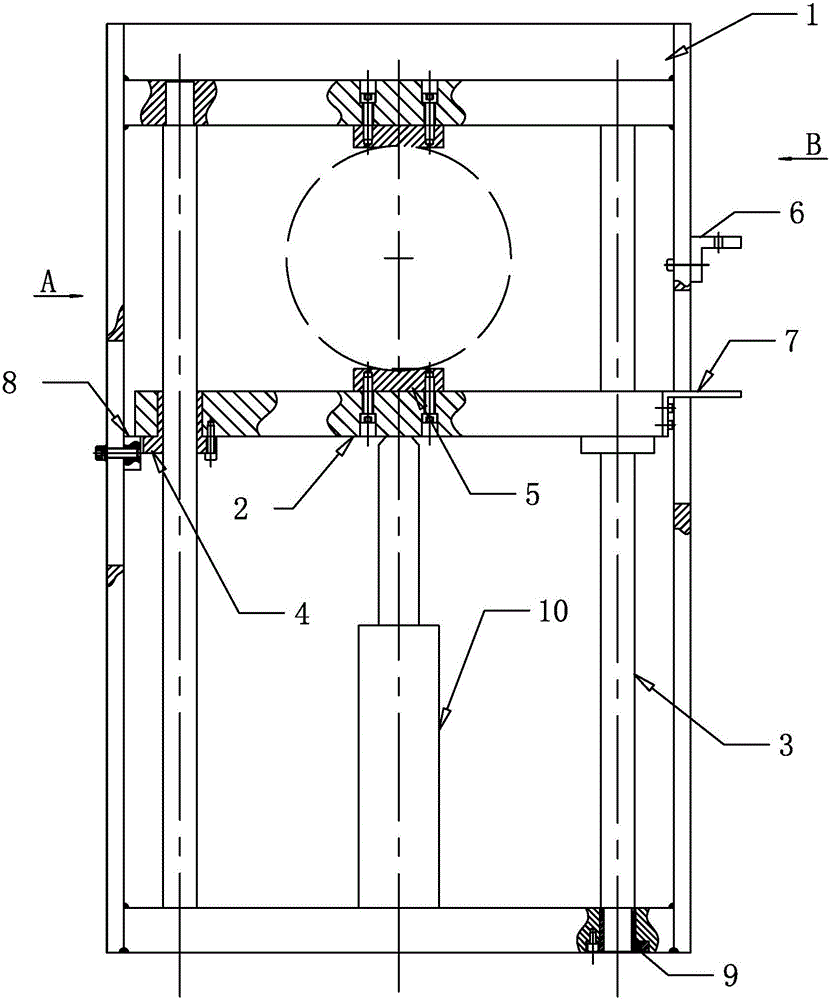

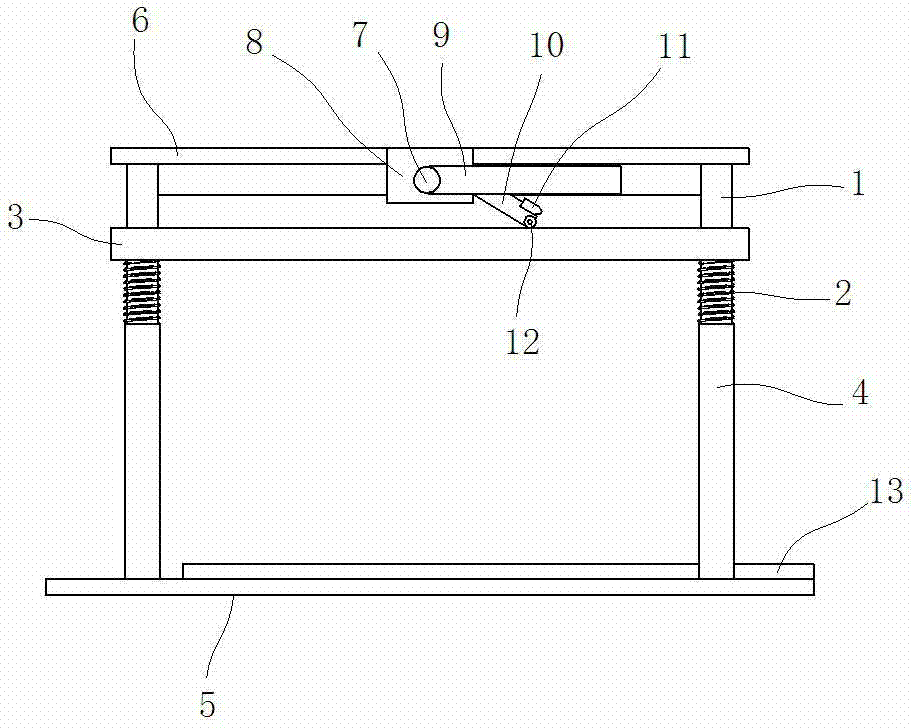

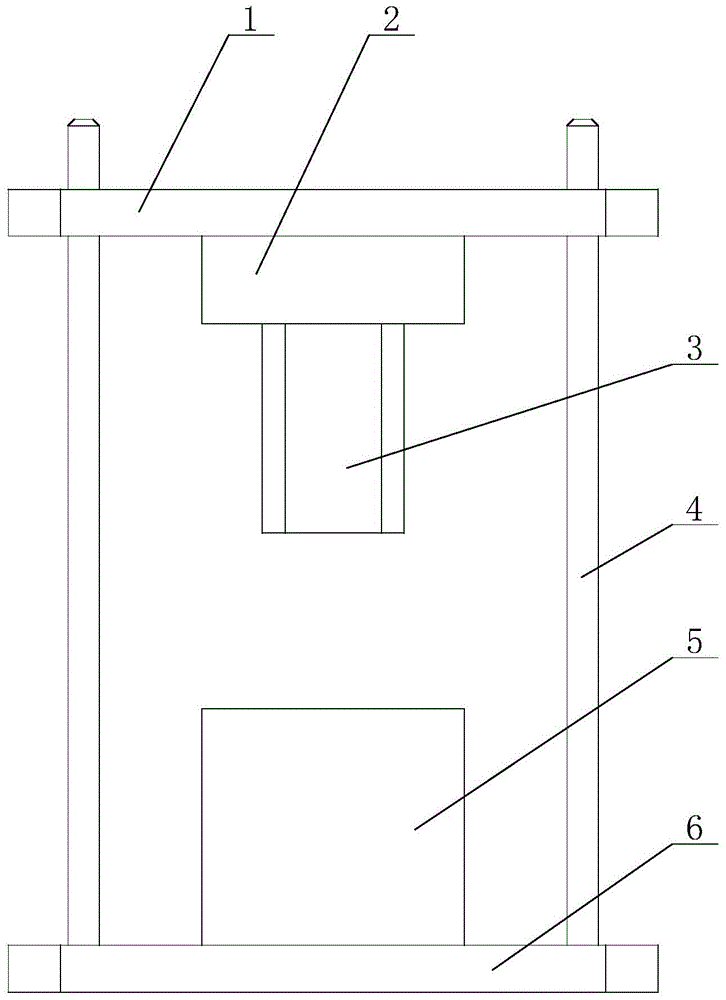

Bearing ring shaping device and method

ActiveCN105945096ATo achieve the purpose of plastic surgeryEasy to operateMetal-working apparatusEngineeringQuenching

The invention relates to a shaping device and method, and particularly relates to a bearing ring shaping device and method. The bearing ring shaping device and method aim at solving the problem that a molding pressing technology or a mold control deformation technology is difficult to realize in a quenching process of a bearing ring which is complicated in structure and changes greatly in wall thickness. The bearing ring shaping device comprises a main body frame, a lifting cross beam, two guide columns, two guide sleeves, two fixing cushion blocks, an instrument pedestal, a positioning table, a limited block, a jack and two adjustable vertical columns, wherein the two guide columns are vertically arranged in the main body frame side by side; the upper ends of the two guide columns are fixedly connected to the main body frame; and the lifting cross beam is horizontally arranged in the main body frame. The bearing ring shaping device and method belong to the field of bearing manufacturing.

Owner:AVIC HARBIN BEARING

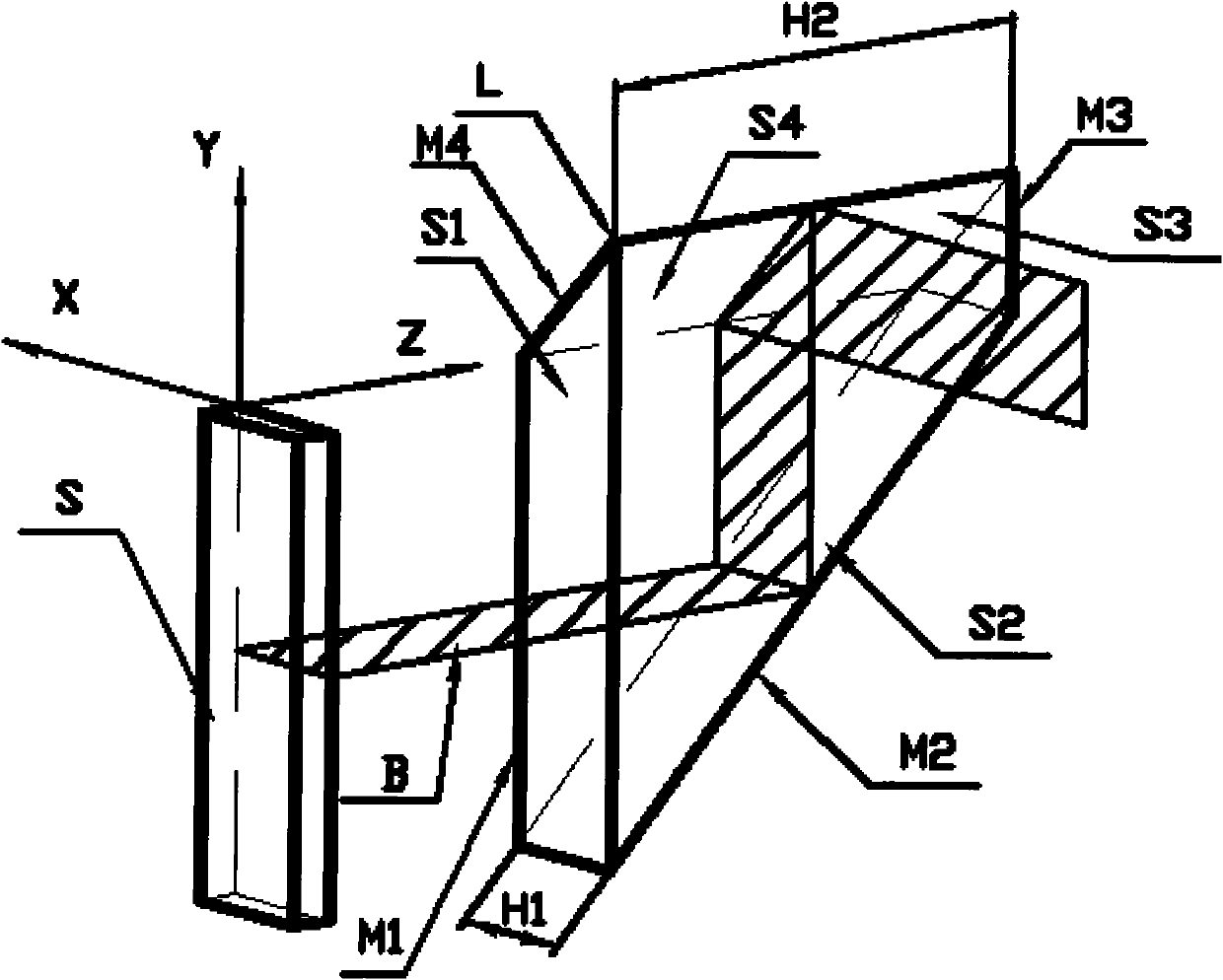

A light beam shaping apparatus

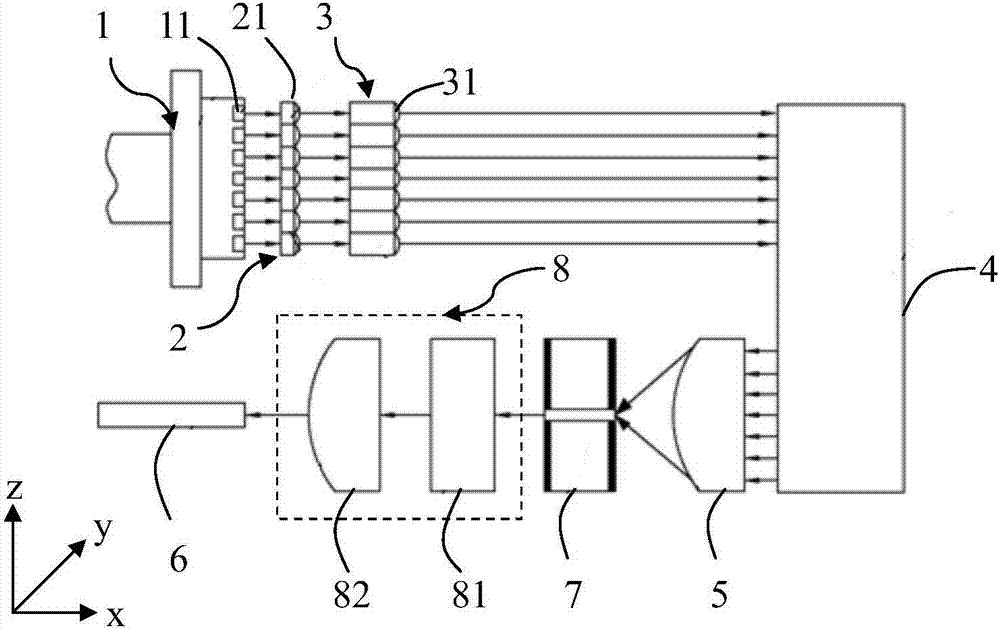

The present invention provides a light beam shaping device comprising a light source and a first lens array, a second lens array, a light beam shaper, a light beam focusing device and a first optical fiber which are sequentially remote from the light source and disposed on an outgoing light path of the light source; the light source comprises a plurality of semiconductor lasers arranged in arrays; the first lens array comprises a plurality of first lenses arranged in arrays; the first lenses are aligned with the semiconductor lasers in a one-to-one corresponding mode; the second lens comprises a plurality of second lenses arranged in arrays; the second lenses are corresponding to the first lenses in a one-to-one mode; the light source is located in a front focal plane of the first lens array; and a back focal plane of the first lens array coincides with the front focal plane of the second lens array. The first lens array collimates the light of the light source in the direction of the fast axis, and the second lens array collimates the light of the light source in the slow axis direction. By collimating the light of the light source in the slow axis direction, loss on sides surfaces due to divergence in the slow axis direction is reduced, thereby raising the shaping efficiency.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

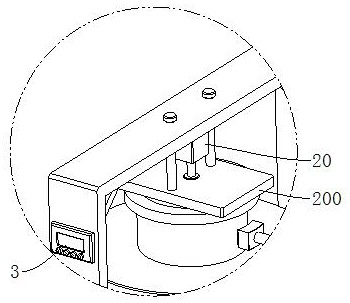

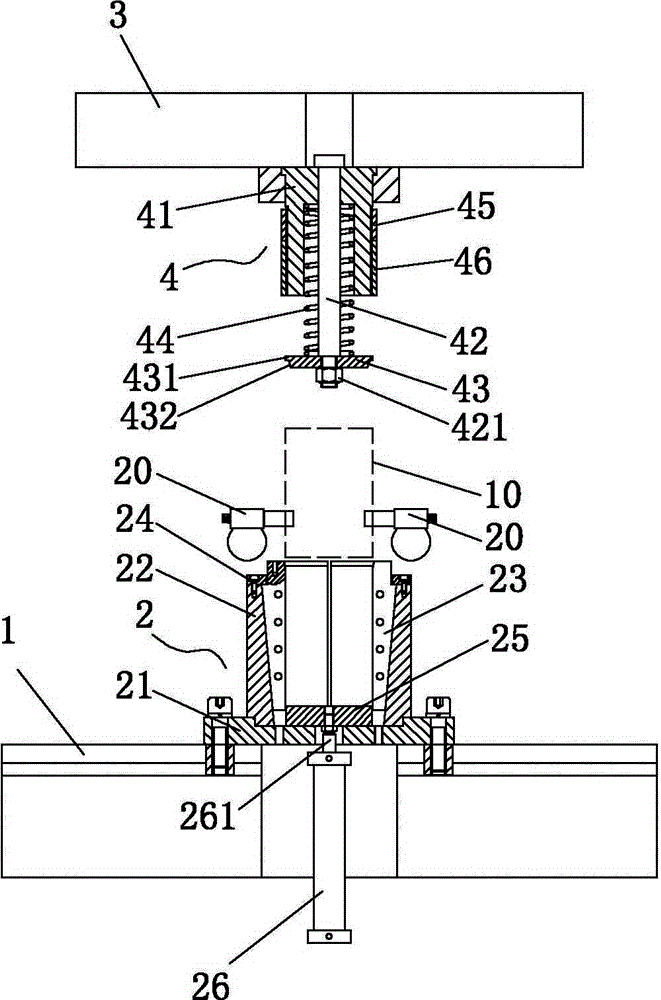

Shaping device for cylindrical flange plate after forging and working method

InactiveCN112171176AImprove efficiencyImprove qualityMetal working apparatusManufacturing engineeringFlange

The invention relates to the field of flange plate forging, in particular relates to to a shaping device for a cylindrical flange plate after forging and a working method. The shaping device comprisesa base, a supporting frame, a controller, a rotating mechanism, a repairing mechanism and a position adjusting mechanism, wherein the rotating mechanism comprises a machining table and a rotating component; the position adjusting mechanism is arranged at the top of the base so as to support the repairing mechanism to adjust the position, and the position adjusting mechanism comprises a lifting plate, a sliding component and a jacking component; the repairing mechanism comprises a bearing plate, a hammer head, a spray head, a material receiving pipe, a pushing component and a discharging component; and the rotating component, the sliding component, the jacking component, the pushing component and the discharging component are electrically connected with the controller. According to the shaping device for the cylindrical flange plate after forging and the working method, various defects on the outer wall of the flange plate can be detected in time and repaired in time, and meanwhile, most of repairing modes are automatic; and meanwhile, frequent contact of workers is not needed in the repairing process, and thus potential safety hazards are small.

Owner:含山县龙顺机械配件厂

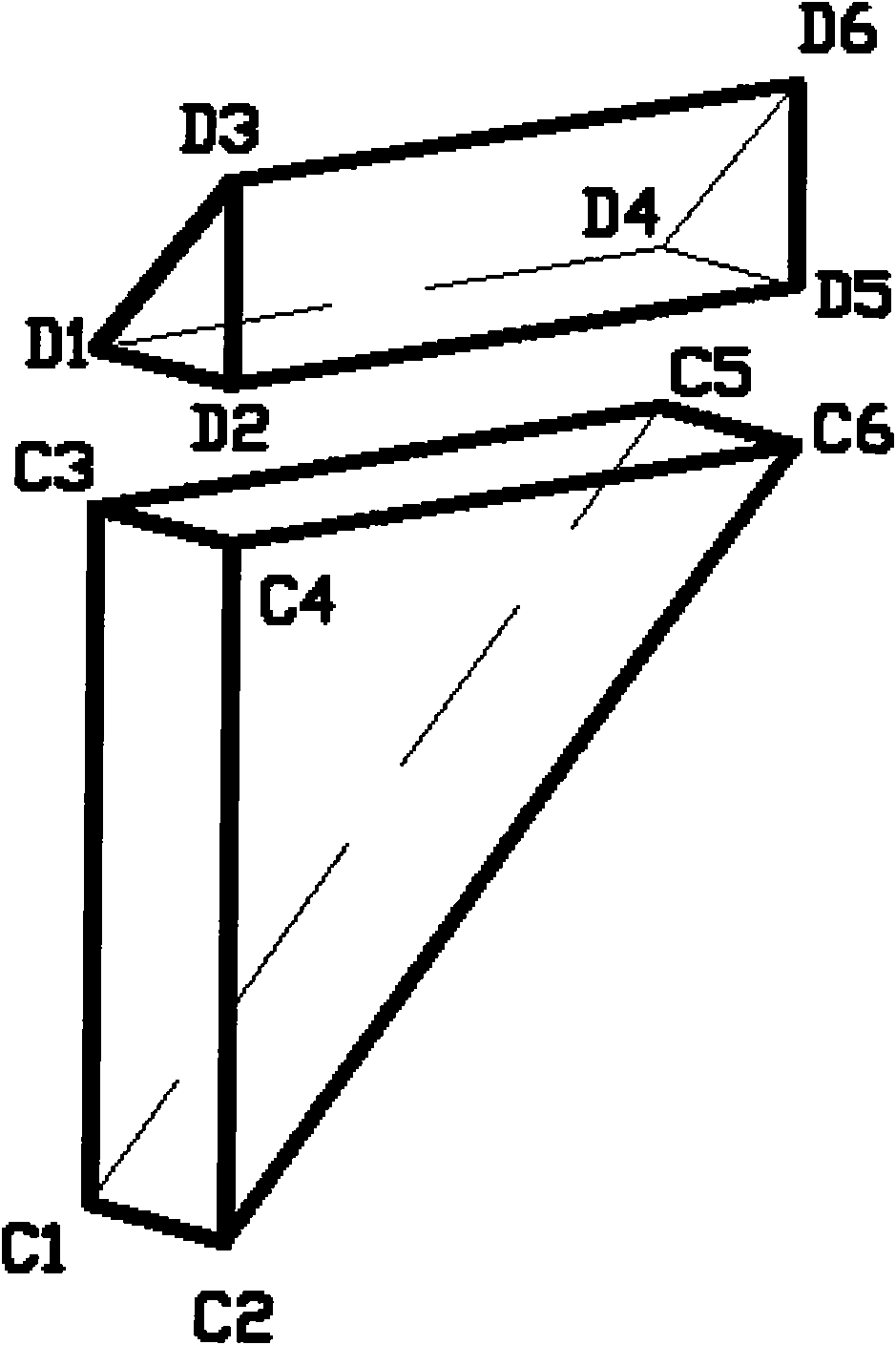

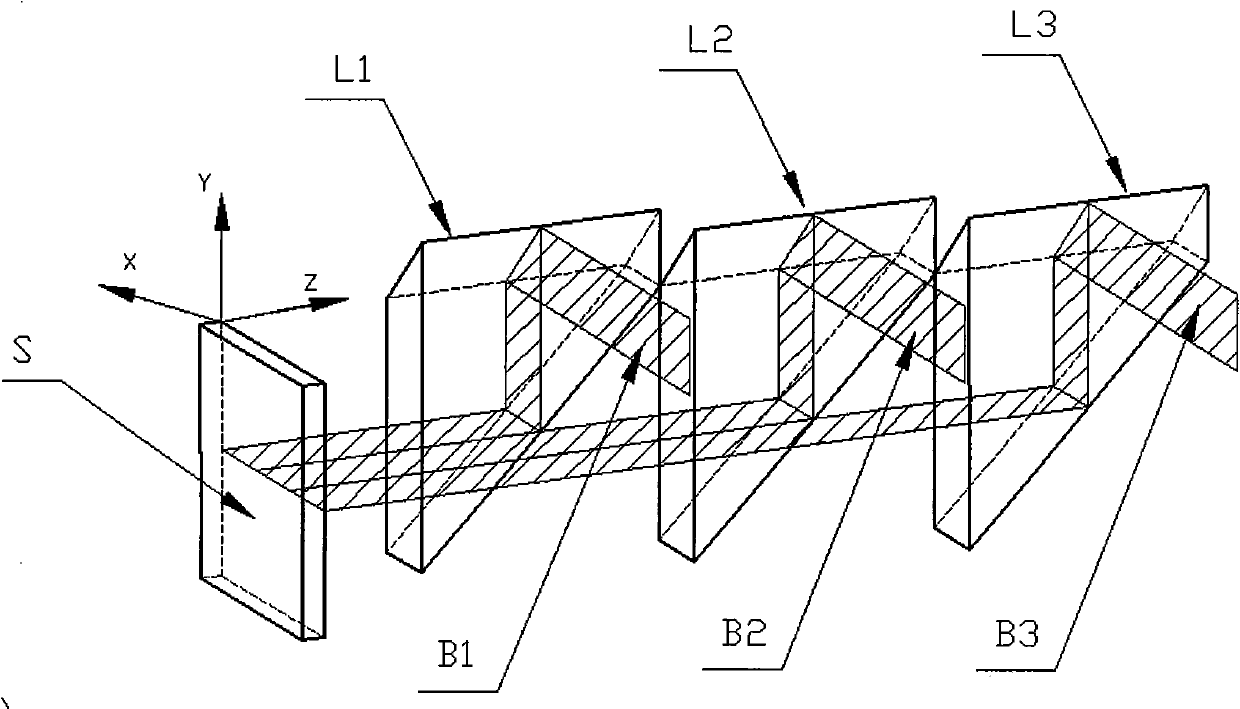

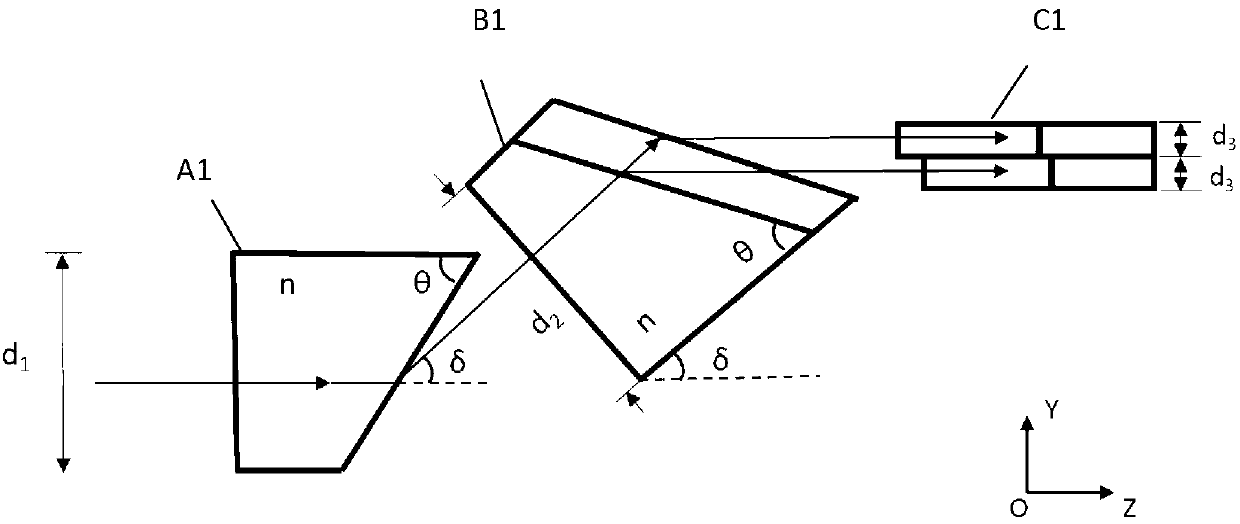

High-power semiconductor laser array fast and slow axis beam quality homogenization device

InactiveCN102004320AImprove efficiencyImprove shaping efficiencyOptical elementsLaser technologyLaser array

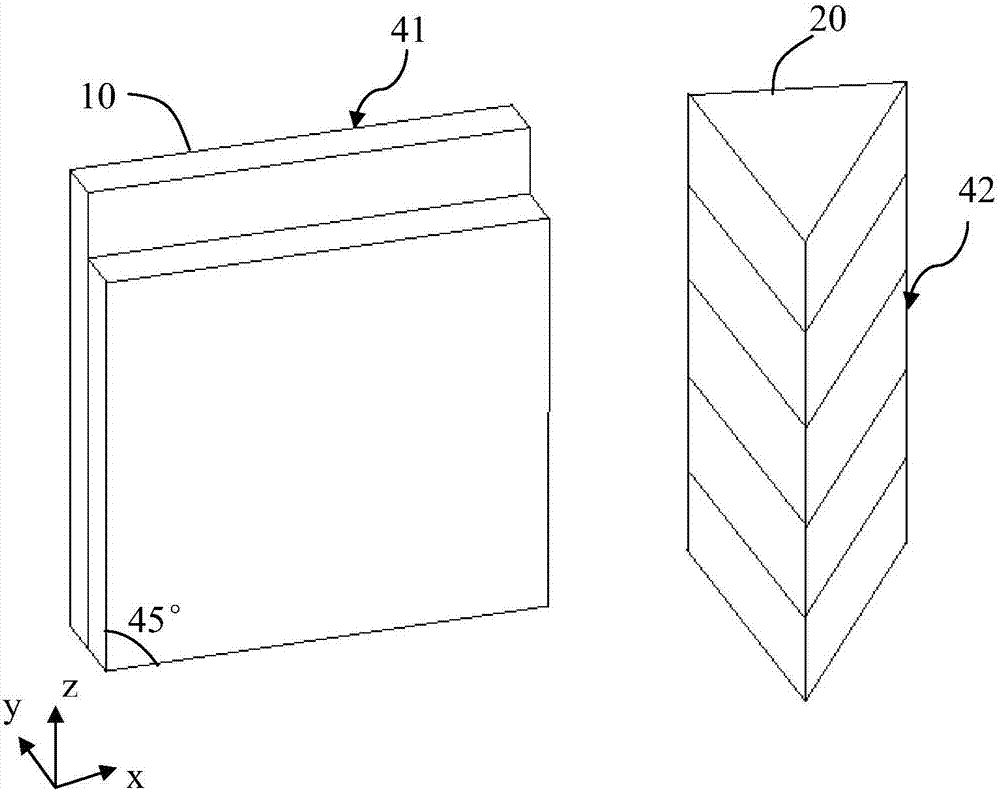

The invention relates to a high-power semiconductor laser array shaping device, and belongs to the field of application of laser technology. The device comprises a group of improved isosceles right-angle prisms, wherein the improved isosceles right-angle prisms in the prism group have identical size and structure and are arranged at different positions; all prisms are parallelly arranged along the direction of a slow axis of a semiconductor laser array in a ladder-like distribution mode and staggered at certain intervals front and back; the slow axis of the laser array is subjected to beam cutting by first surfaces of all the prisms staggered at certain intervals front and back, and beams pass through second surfaces which form an angle of 45degrees with the first surfaces to be subjected to total reflection; and the beams subjected to total reflection meet third surfaces which form an angle of 45 degrees with both the first surfaces and the second surfaces to be subjected to total reflection again, so that the effect of cutting and rearranging the beams is achieved. The device has high efficiency, is particularly suitable for high-power semiconductor laser beam shaping, has the advantages of low cost and the like, and is convenient to install and adjust.

Owner:BEIJING UNIV OF TECH

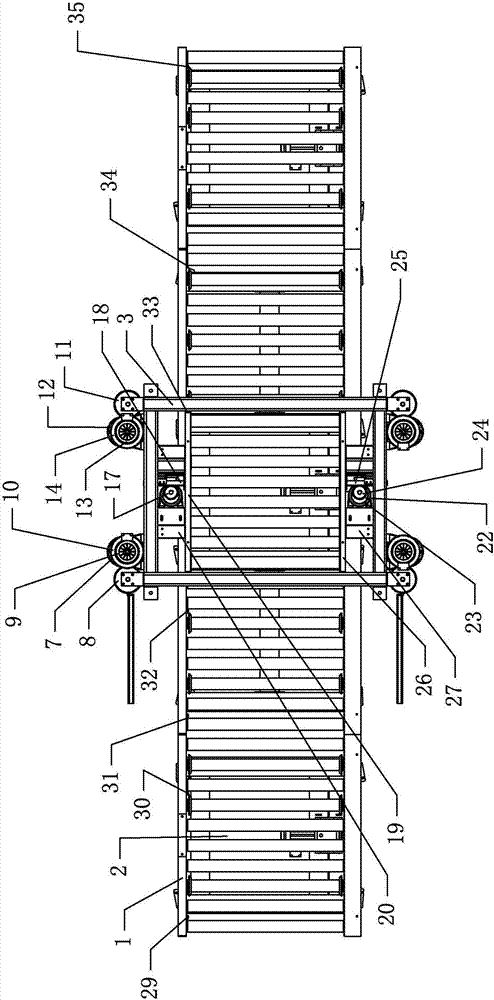

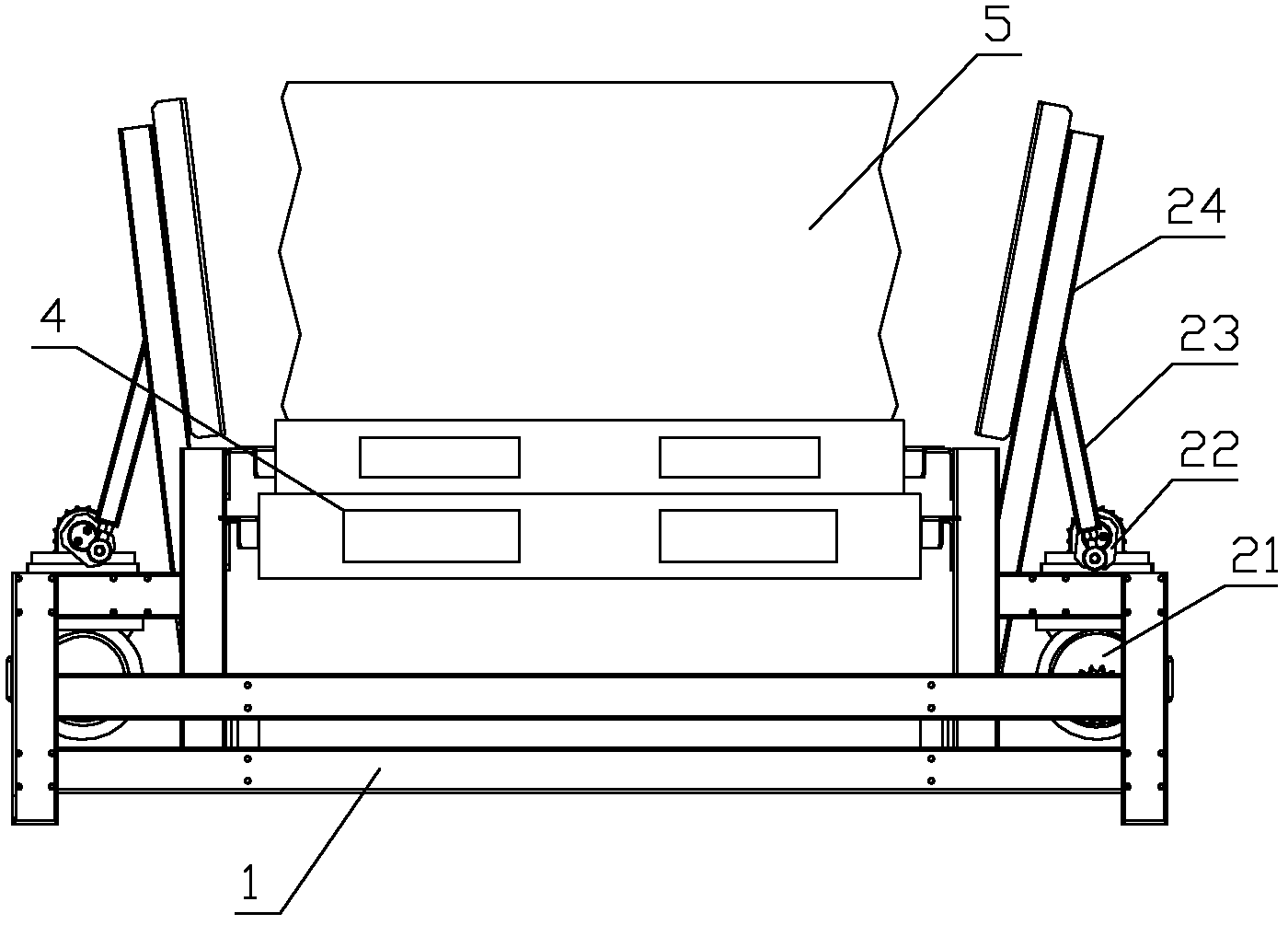

Automatic online four-side shaping machine for tray goods

InactiveCN106995123AEasy to shapeTo achieve the purpose of plastic surgeryControl devices for conveyorsHigh densityEngineering

An automatic online four-side shaping machine for tray goods comprises a rack and conveying rollers arranged on the rack, wherein a framework is arranged in the middle of the rack in a covering manner, the four corners of the framework are separately provided with a rotating shaft vertically arranged, a door plate is separately arranged on each rotating shaft, the two door plates located at the front end of the advancing direction of the framework form a front door, and the two door plates located at the rear end of the advancing direction of the framework form a rear door. The front sides and the rear sides of the goods on trays can be conveniently shaped, and the left sides and the right sides of the goods on the trays can be conveniently shaped, so that a purpose of shaping the four sides of the goods on the trays is achieved, the shaping efficiency is high, and the online continuous four-side shaping of the conveyed tray goods can be carried out. Problems, such as the material tilting and scattering of the tray goods in the conveying process and appearance out-of-tolerance, are solved, and the warehousing efficiency and safety of a high-density tray warehouse are ensured. The automatic online four-side shaping machine is particularly suitable for the before-warehousing shaping of an AGV intelligent unmanned warehouse.

Owner:山东银方信息技术有限公司

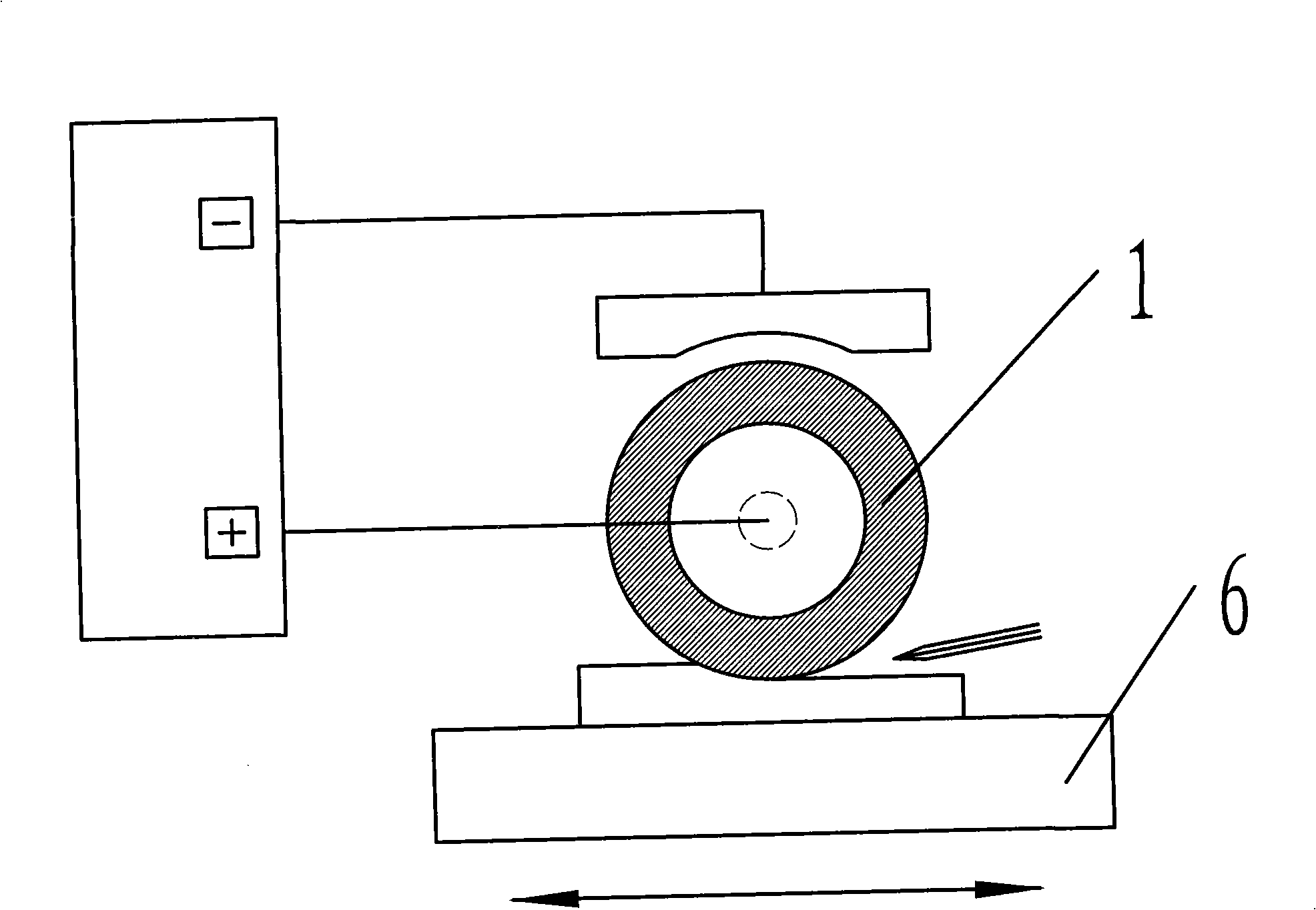

Method for processing complex surface knife tool

InactiveCN101298122AFully sharpenedInhibit excessive electrolysisAbrasive surface conditioning devicesEngineeringAlloy

The invention provides a processing method of a cutter with complex profile, comprising the steps as follows: (1) a dressing electrode is designed according to the structure and size requirement of the cutter to be processed, the design theory of the cutter and the processing principle of the profile modeling method; (2) the profile of a grinding wheel is dressed by the dressing electrode; (3) the dressing electrode is grinded and processed by the grinding wheel with profile dressed; and (4) no-pressure rolling grinding and impact polishing of the surface of the workpiece which is online electrolyzed, dressed and grinded are carried out to gain the hard alloy cutter. The invention provides the processing method for the cutter with complex profile, which has high dressing efficiency and low cost.

Owner:ZHEJIANG UNIV OF TECH

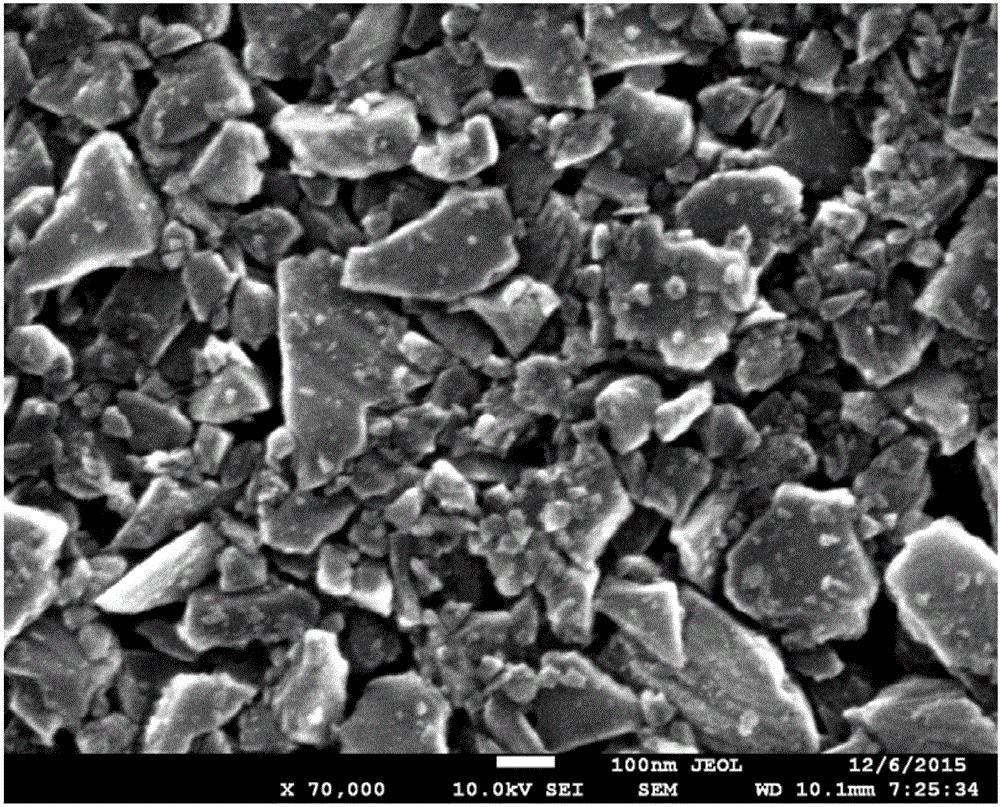

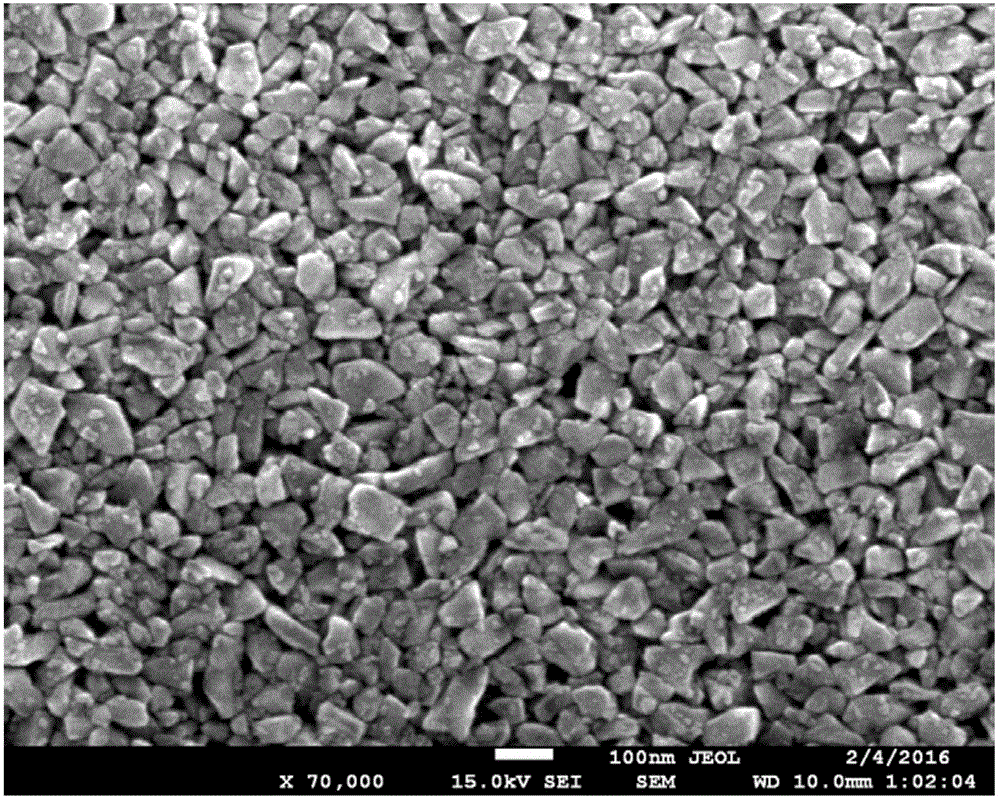

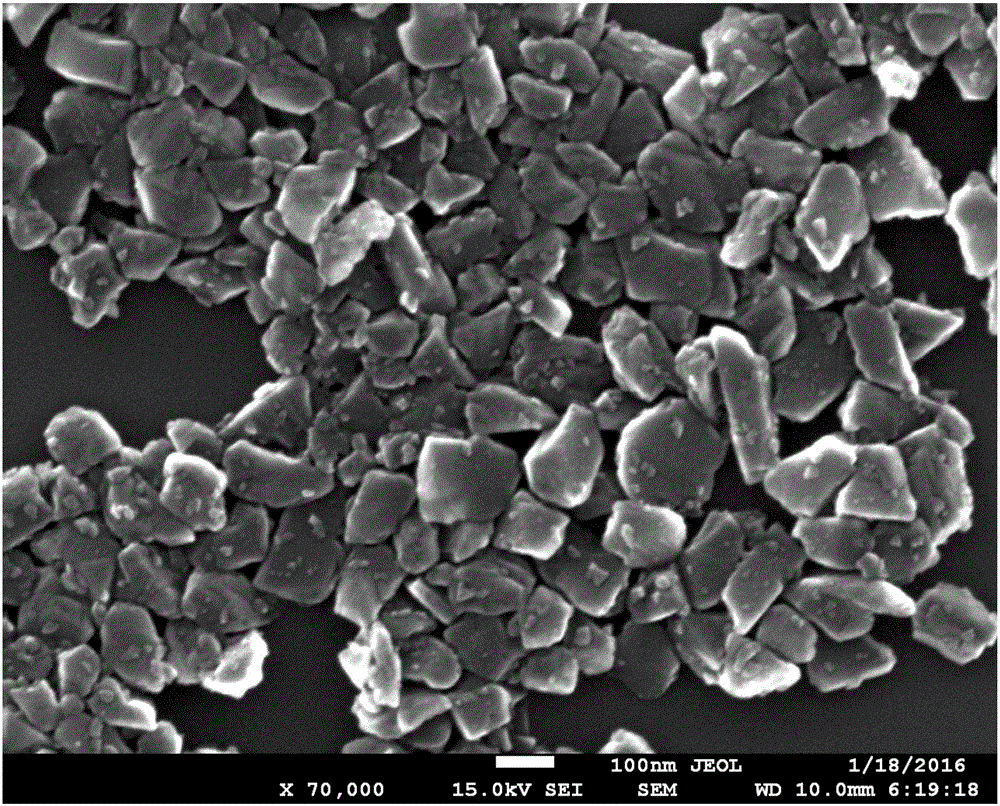

Preparation method of nanoscale diamond micropowder narrow in particle size distribution

ActiveCN106829954AHigh strengthHigh particle size concentrationEdge grinding machinesPolishing machinesSteel ballSlurry

The invention relates to a preparation method of nanoscale diamond micropowder narrow in particle size distribution. The preparation method includes: 1), mixing diamond micropowder with median particle size below 0.3um with water to obtain raw material slurry; 2), adding ultra-hard abrasive particles serving as a grinding medium into the raw material slurry for grinding and shaping, and filtering to obtain shaped slurry, wherein particle size of the grinding medium is larger than that of the diamond micropowder in the step 1); 3), grading the shaped slurry obtained in the step 2) to obtain the nanoscale diamond micropowder. The ultra-hard abrasive particles thicker than the diamond micropowder in particle size and used as the grinding medium and are high in strength, the grinding medium is more effective in friction, collision and shearing when compared with steel balls undergoing contact and collision shaping only on contact points, so that shaping efficiency is improved, and obtaining of nanoscale diamond micropowder products which are regular in shape and high in particle size concentration is facilitated.

Owner:HENAN UNION ABRASIVES

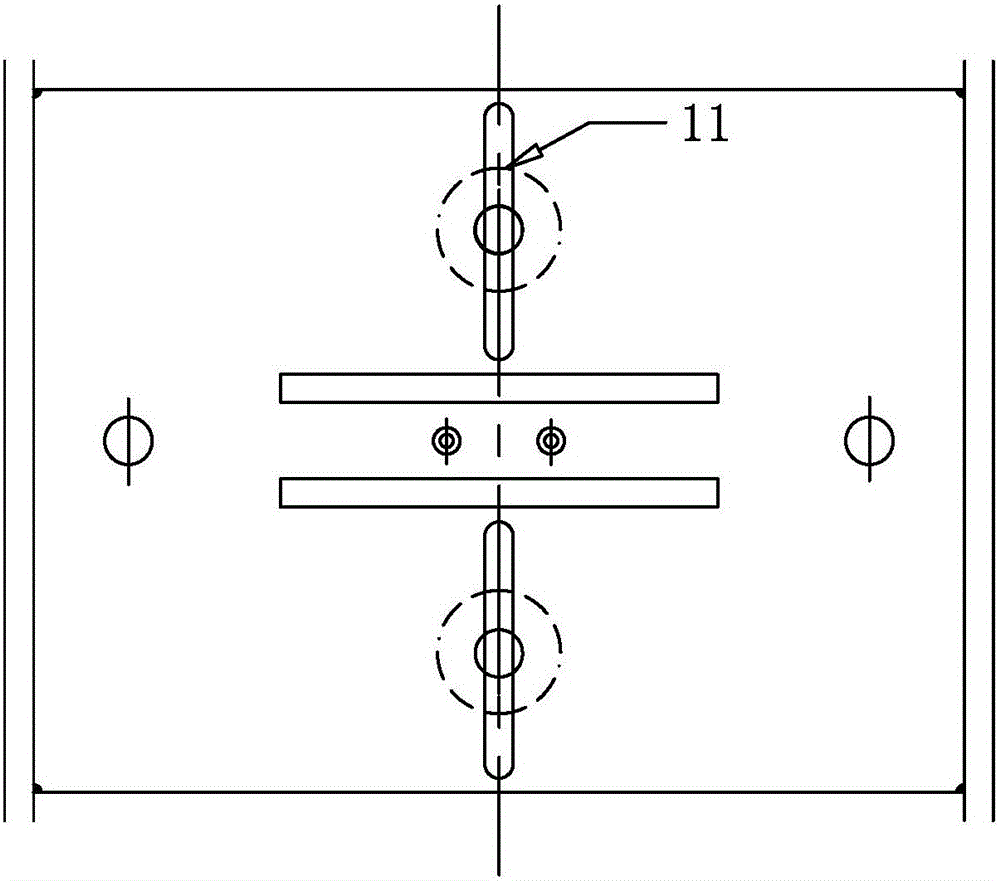

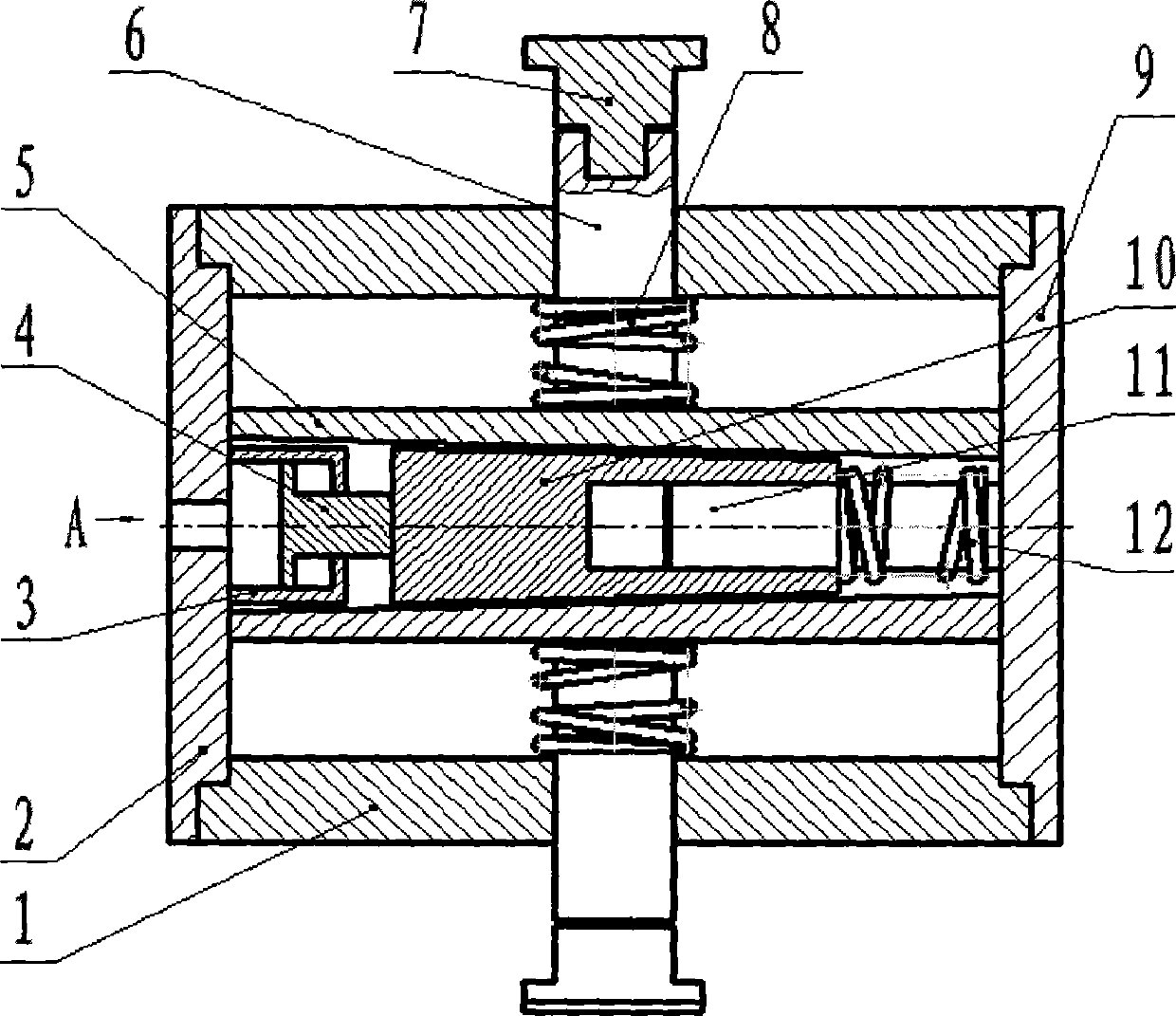

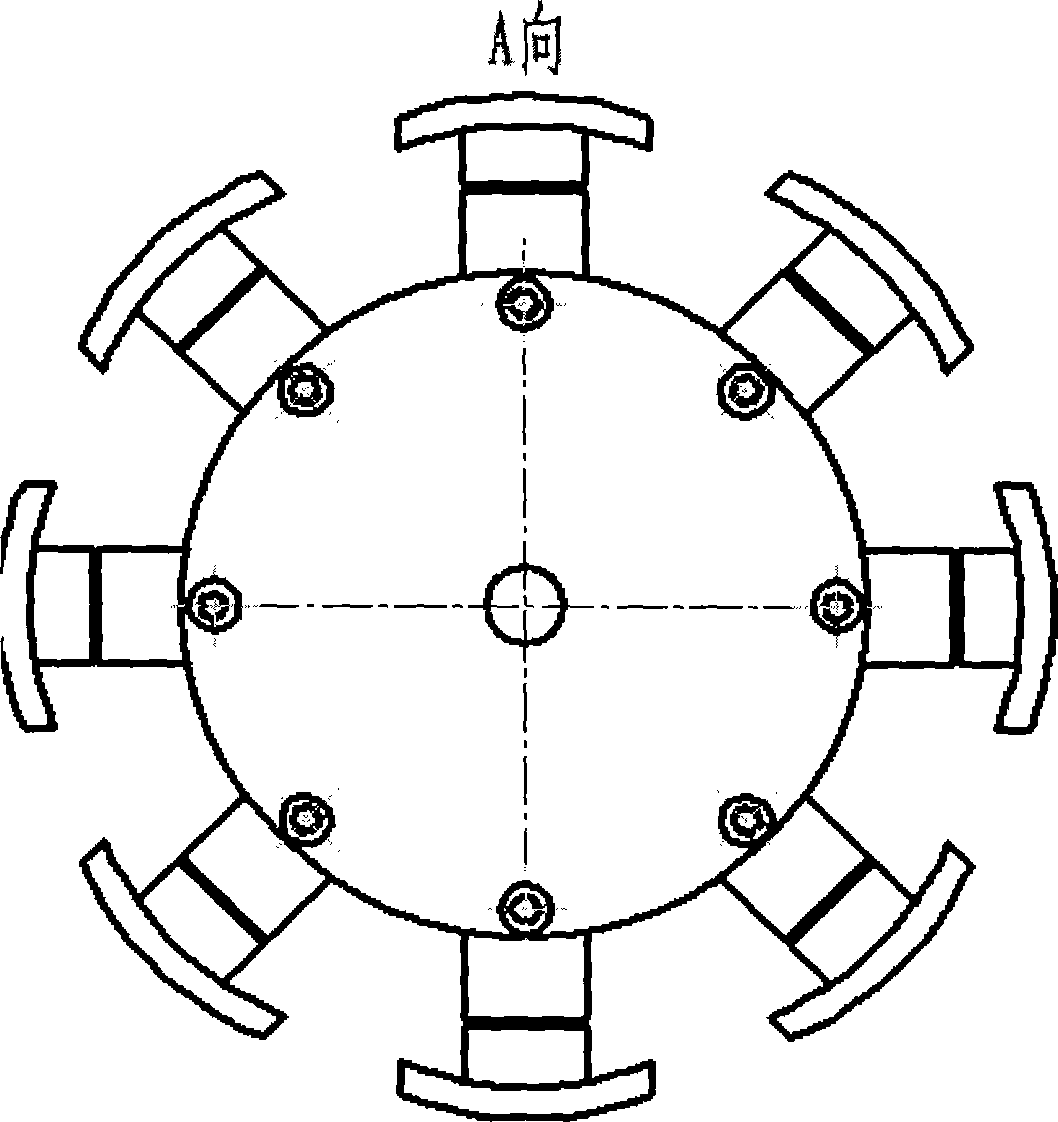

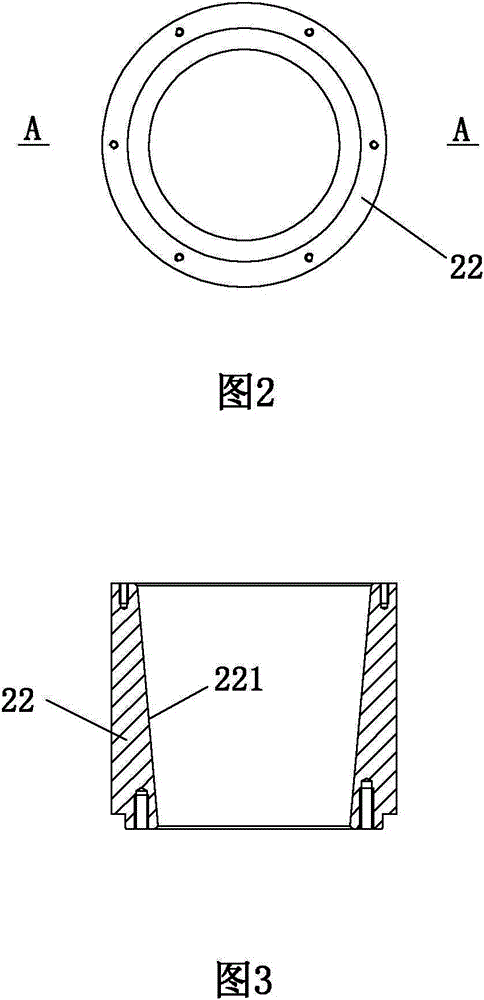

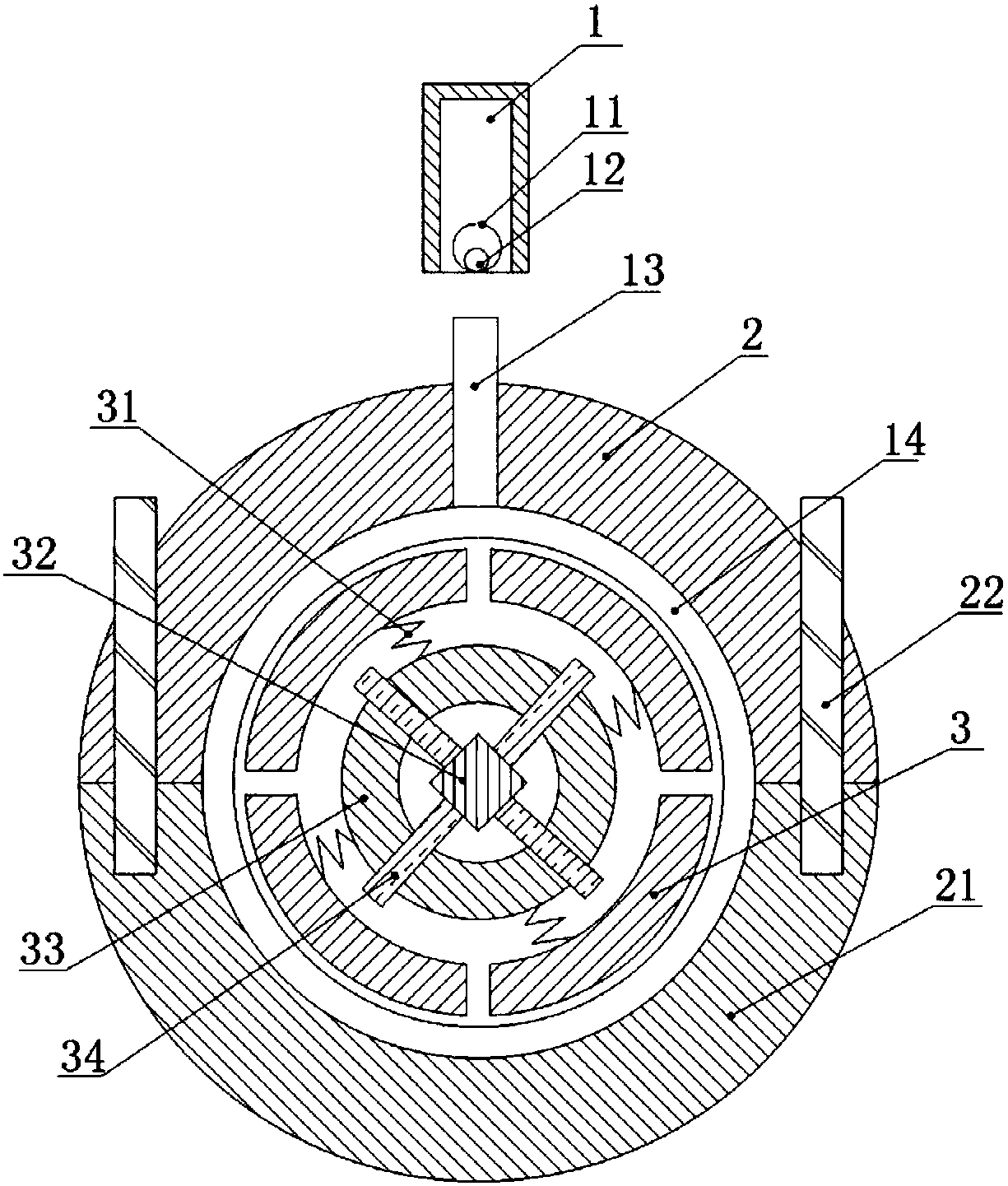

Synchronous circle shaping device for cylindrical work-piece

The invention relates to a synchronous circle shaping device for a cylindrical work-piece and belongs to the field of work-piece shaping. The synchronous circle shaping device for the cylindrical work-piece comprises a supporting cylinder, a left end cover, an air cylinder body, a piston, an expansion body, a supporting rod, supporting heads, a radial reset spring, a right end cover, an expansion rod, a guide rod and an axial reset spring. An air compressing device is used for inflating the air cylinder body so that the piston can drive the expansion rod to move right together. The expansion rod pushes all separated parts of the expansion body to synchronously expand outwards in the radial direction through matched conical surfaces among inner holes of combined parts of the expansion body. The arc surfaces of all the supporting heads connected to the outer ends of all the separated parts of the expansion body are used for synchronously shaping the inner wall of the cylindrical work-piece to be shaped. According to the circle shaping device, synchronous perfect circle shaping is carried out on the thin-wall cylindrical work-piece, the shaping efficiency is high, the shaping quality is good, and the synchronous circle shaping device has high application and popularization value.

Owner:JINXI IND GRP

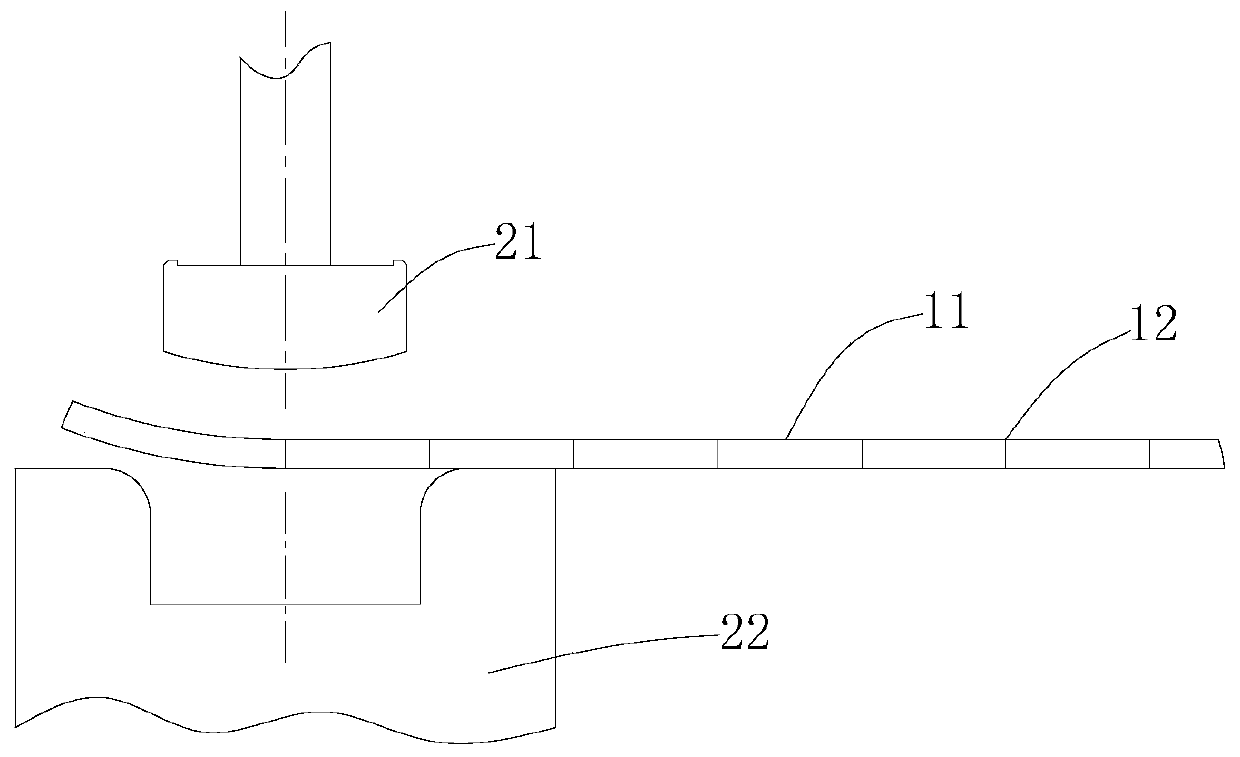

JCO steel pipe forming shape-adjusting process

ActiveCN110102607AImprove molding efficiencyHigh geometric accuracyMetal working apparatusSheet steelMaterials science

The invention provides a JCO steel pipe forming shape-adjusting process, and belongs to the technical field of steel pipe manufacturing. The process comprises the steps of determining pressing pass numbers; calculating the theoretical reduction amount and the theoretical chord height of each pass, wherein the theoretical chord height is the chord height corresponding to the measuring chord, and the measuring chord is the chord corresponding to the inner arc molded through pressing; and pressing a steel plate, after each-pass pressing, measuring the actual chord height corresponding to the theoretical chord height, and according to the difference value between the actual chord height and the theoretical chord height, adjusting the theoretical reduction amount until pressing of all passes can be finished. According to the JCO steel pipe forming shape-adjusting process, the geometric dimensioning precision of a pipe formed through the JCO process is improved, and the shape-adjusting efficiency is improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

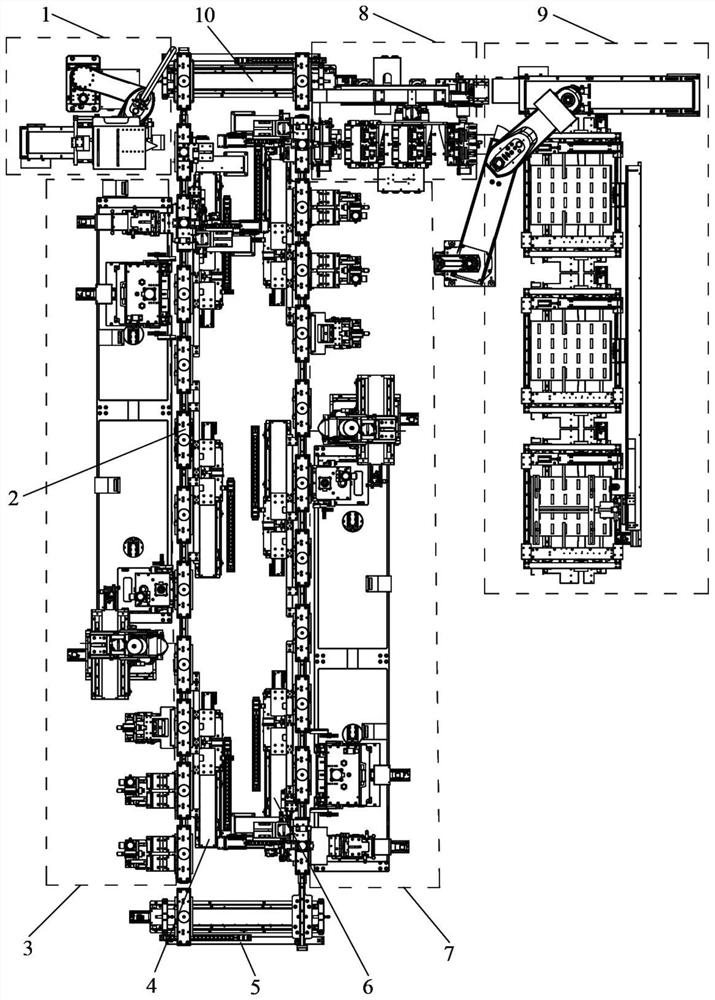

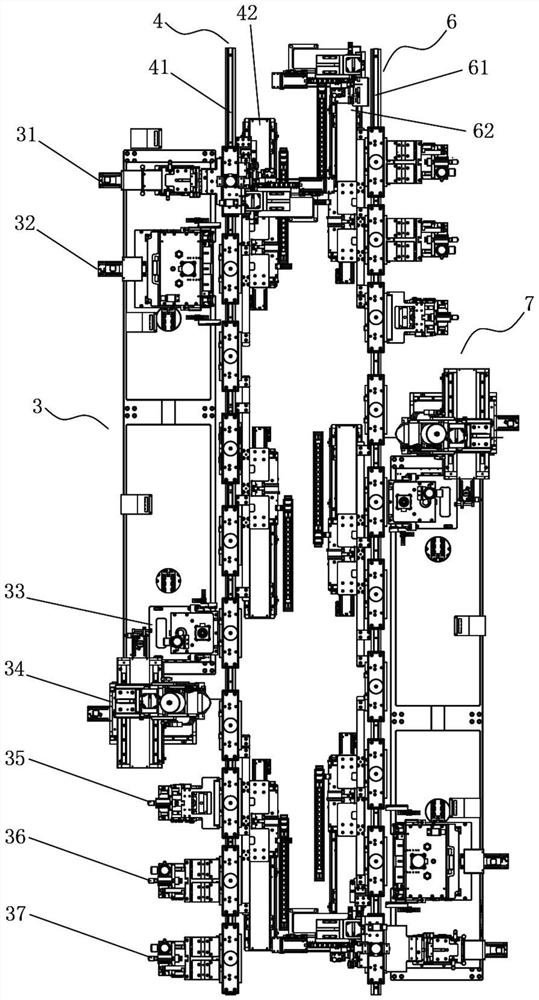

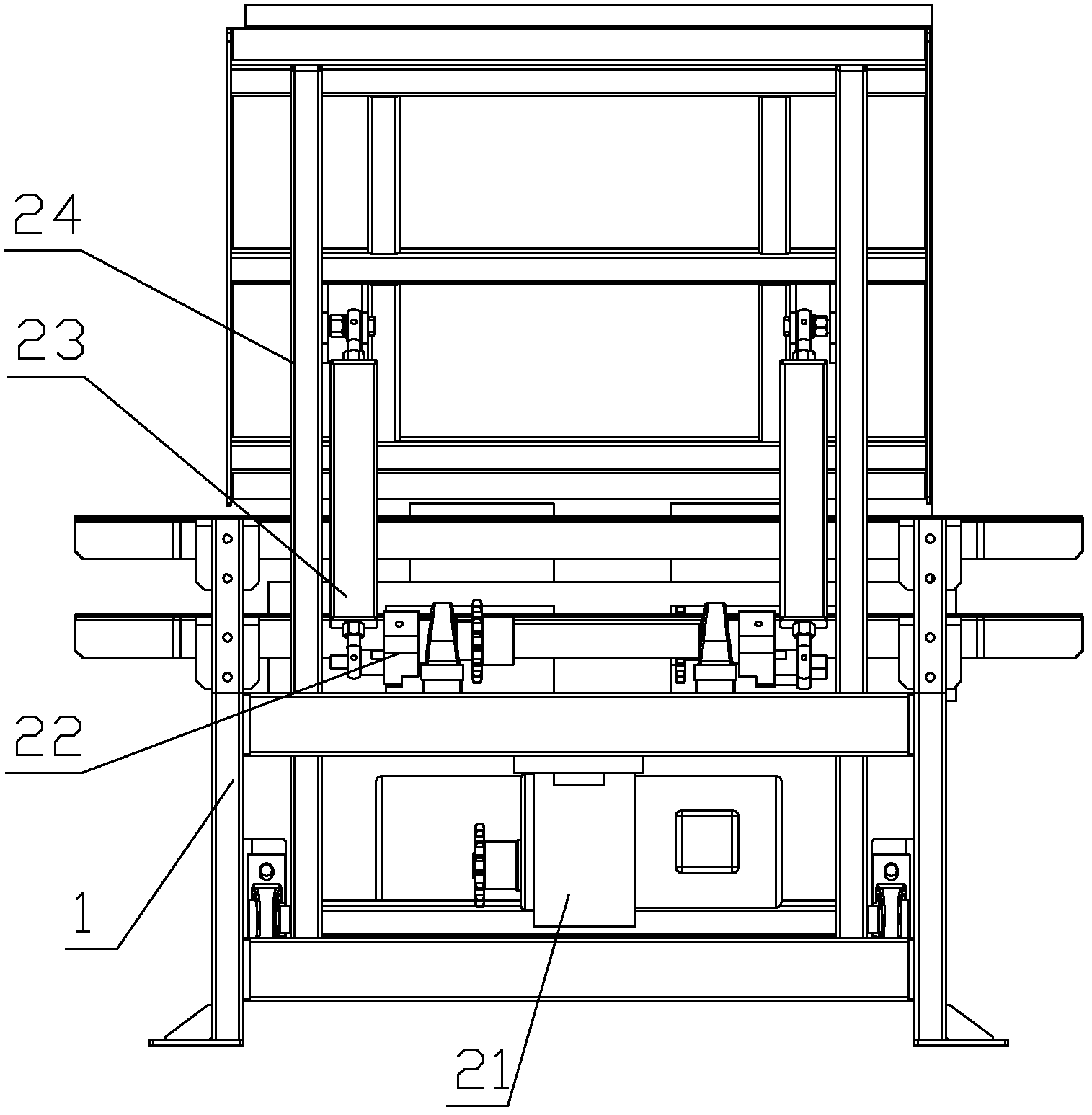

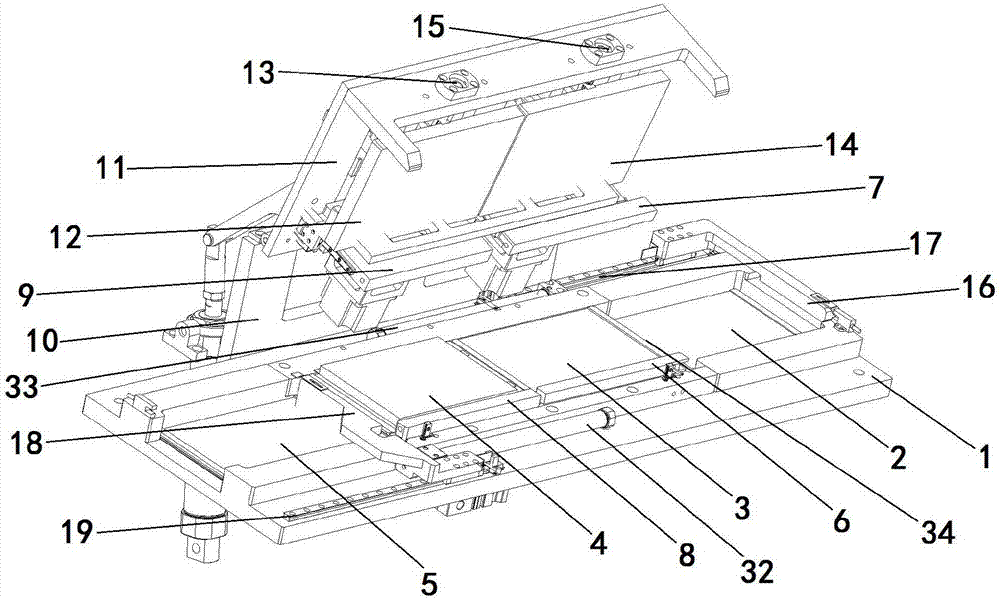

Lithium battery shaping equipment

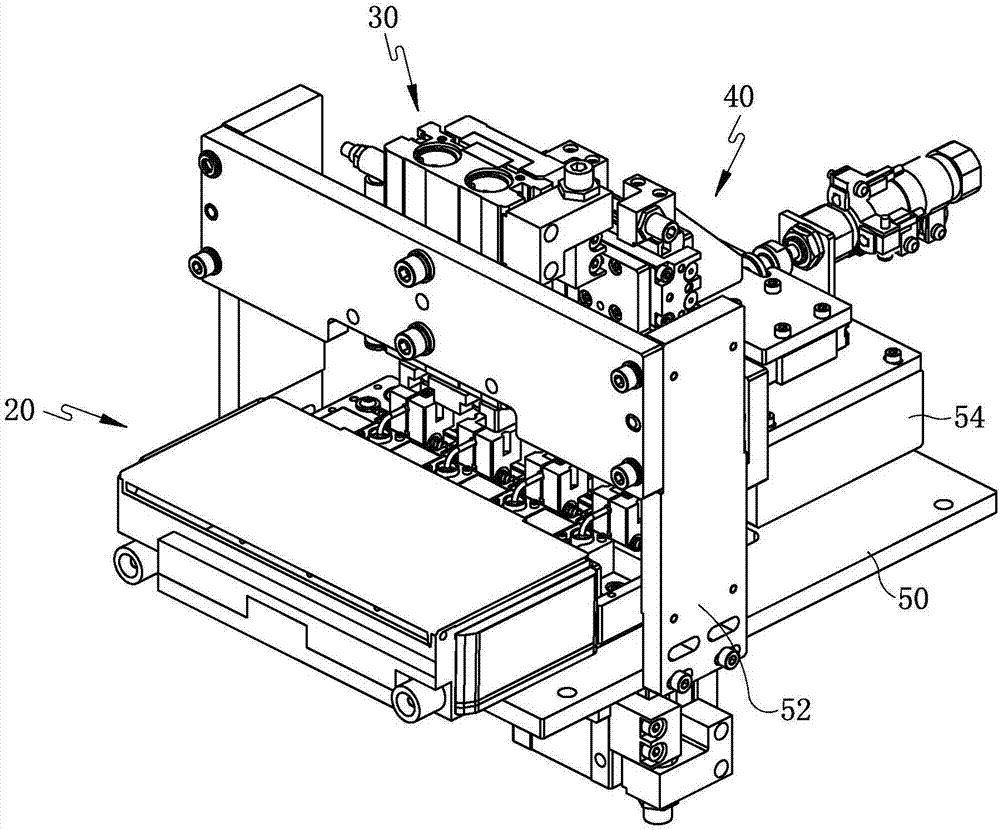

ActiveCN111786027AImprove shaping efficiencyQuality assuranceAssembling battery machinesFinal product manufactureEngineeringTransfer mechanism

The invention provides lithium battery shaping equipment. The lithium battery shaping equipment comprises a feeding mechanism, a left shaping mechanism, a right shaping mechanism, a left conveying mechanism, a right conveying mechanism, a front clamp transfer mechanism, a rear clamp transfer mechanism, a fine shaping mechanism, a discharging mechanism and a plurality of battery cell clamps, wherein the left conveying mechanism and the right conveying mechanism are distributed in parallel left and right; the front clamp transfer mechanism is connected to the front ends of the left conveying mechanism and the right conveying mechanism, the rear clamp transfer mechanism is connected to the rear ends of the left conveying mechanism and the right conveying mechanism, and the battery cell clampsare circularly conveyed on the left conveying mechanism, the rear clamp transfer mechanism, the right conveying mechanism and the front clamp transfer mechanism. The feeding mechanism and the left shaping mechanism are arranged on the left side of the left conveying mechanism from front to back. The full-automatic battery cell shaping machine has the beneficial effects that the automation of eachshaping process of a battery cell is realized, the production efficiency is improved, and the production stability can be ensured.

Owner:东莞市爱康智能技术有限公司

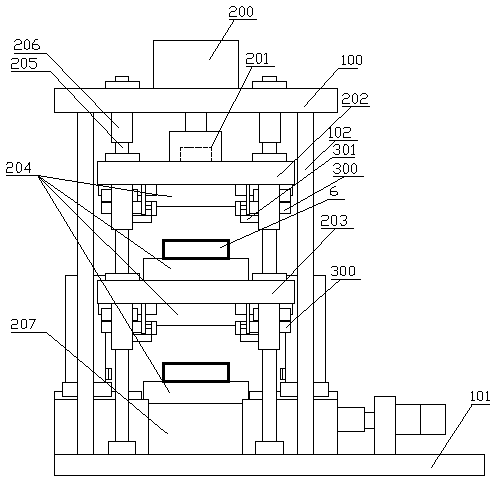

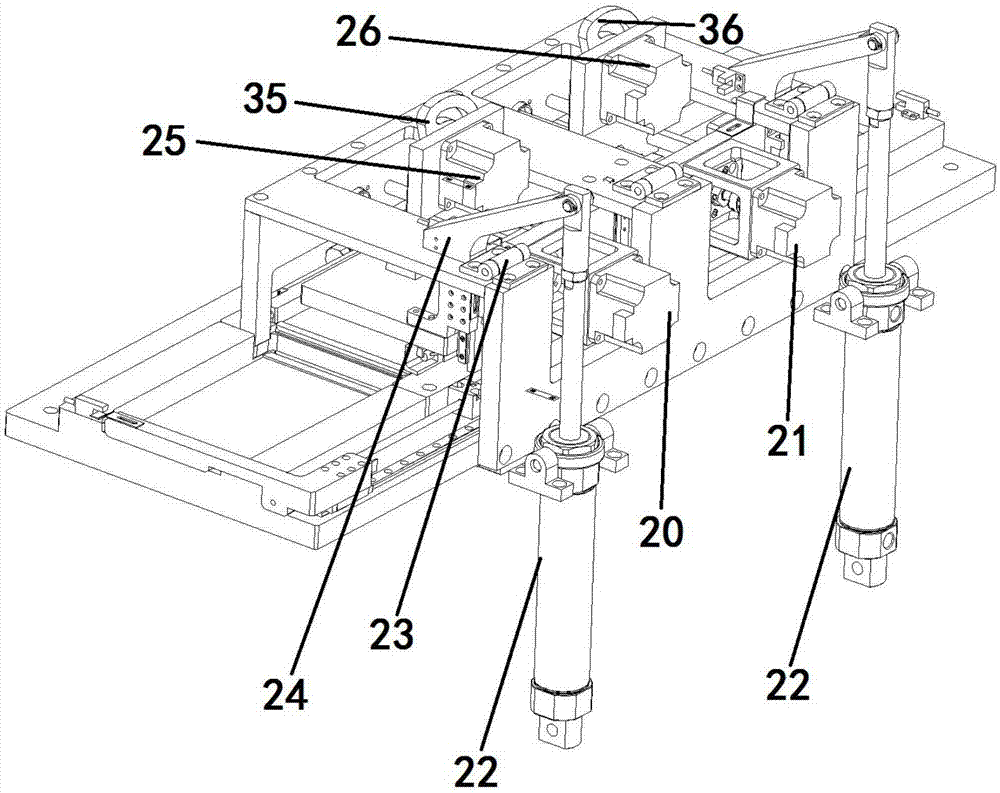

Shaping mechanism and shaping method

PendingCN107623144ASimple structureLow costFinal product manufactureElectrolyte accumulators manufacturePressure.driveMobile end

The invention discloses a shaping mechanism and a shaping method. The shaping mechanism comprises a rack, a main pressure mechanism and a connecting rod mechanism, wherein the main pressure mechanismmainly comprises a main pressure drive device, a first pressure plate, a second pressure plate and a first support plate, wherein a first shaping space is arranged between the first pressure plate andthe second pressure plate; a second shaping space is arranged between the second pressure plate and the first support plate; a mobile end of the main pressure drive device is connected to the first pressure plate; and when the main pressure drive device acts, the connecting rod mechanism achieves linkage of the first pressure plate and the second pressure plate. According to the shaping mechanism, the target of shaping (hot pressing) two shaped objects (battery cores) once is achieved through the connecting rod mechanism, the shaping mechanism is compact in structure, ingenious in design, high inefficiency and low in cost. According to the shaping method, the shaping efficiency is high and the shaped objects are good in shaping quality.

Owner:WUXI LEAD INTELLIGENT EQUIP CO LTD

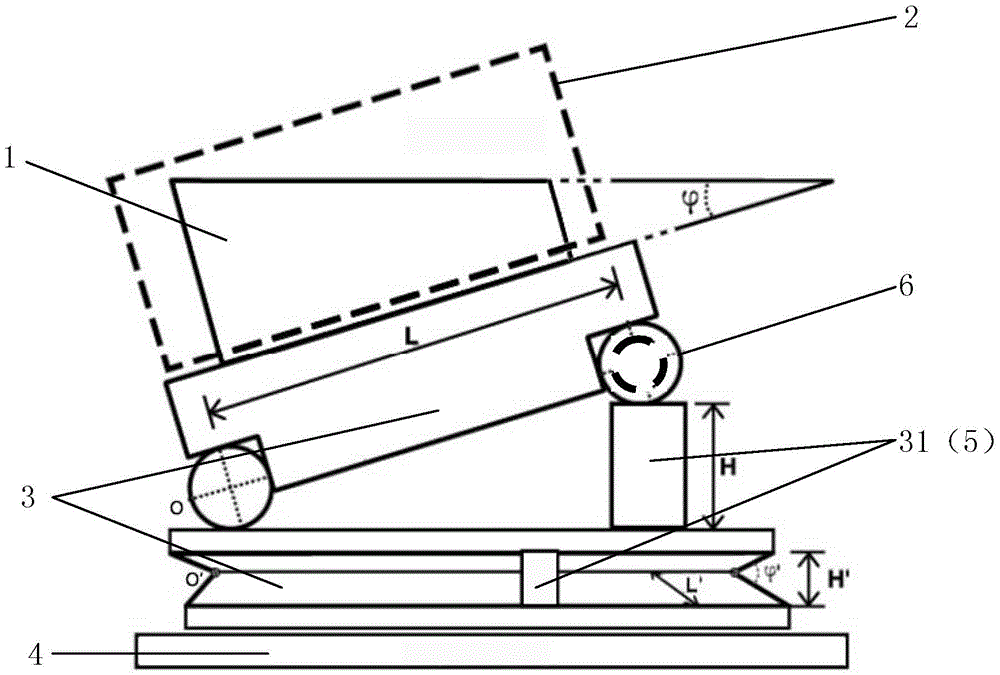

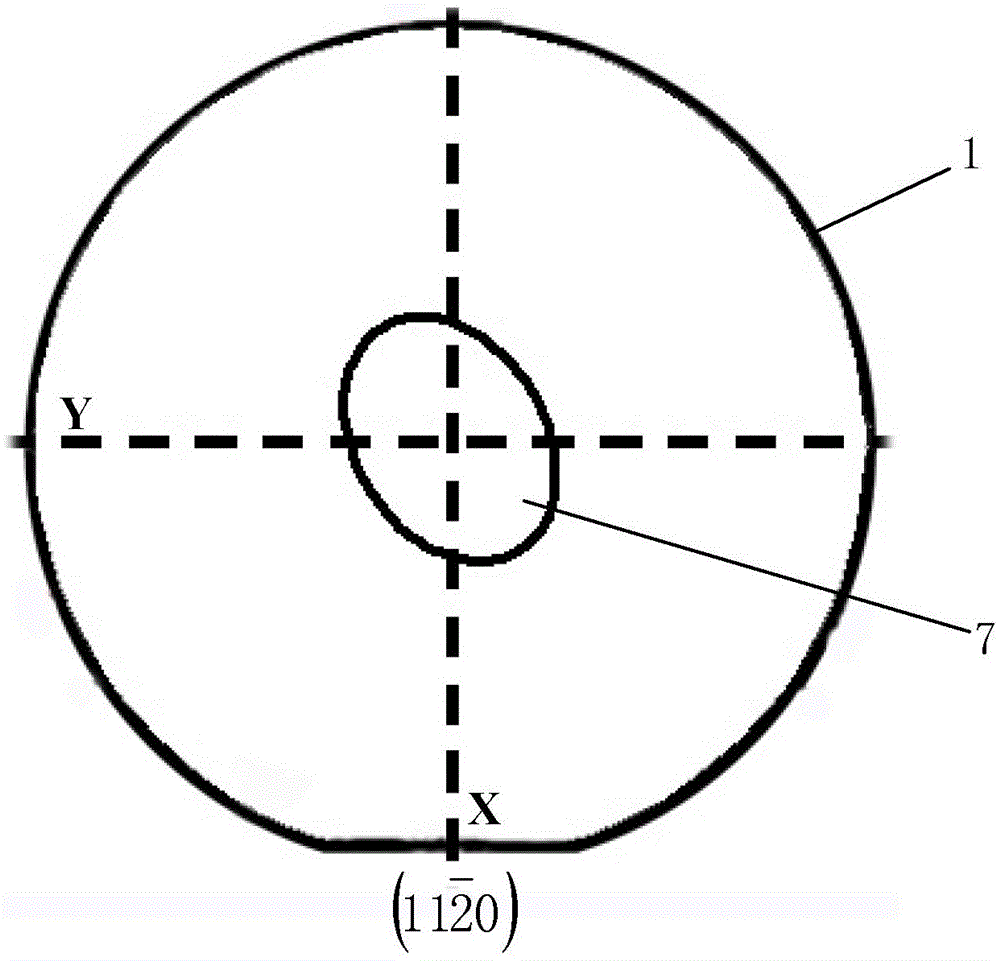

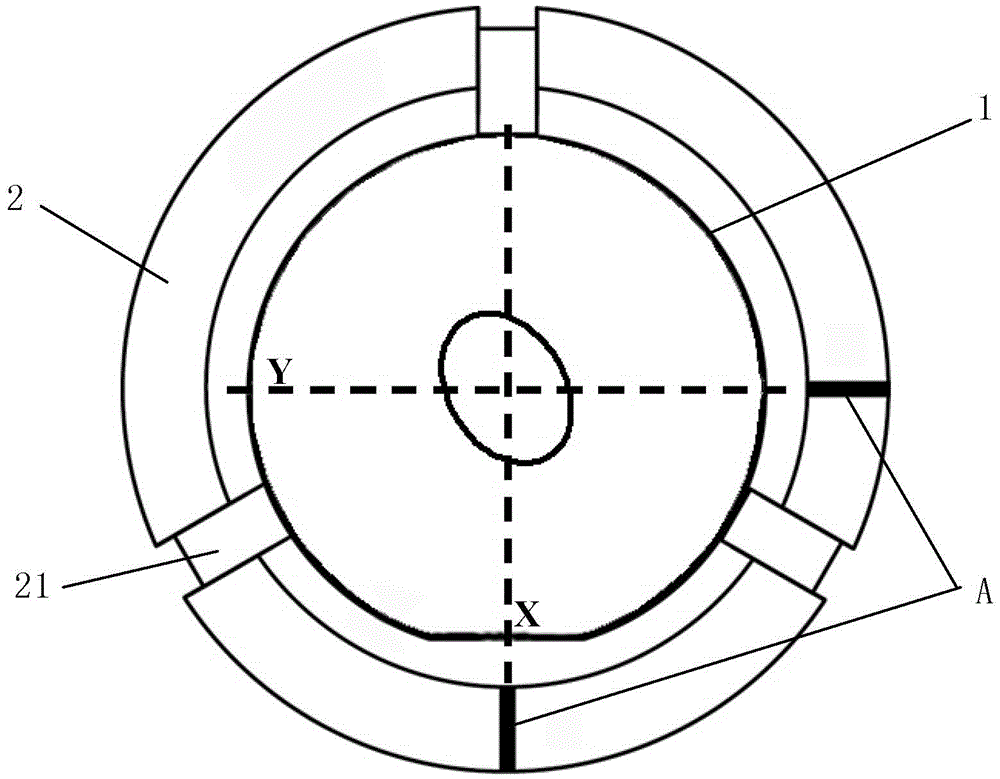

Device and method for silicon carbide crystal deflection shaping

InactiveCN105479280AImprove production rateReduce the probability of crackingGrinding work supportsPlane surface grinding machinesIngotMaterials science

The invention provides a device and method for silicon carbide crystal deflection shaping. The device comprises a clamp for clamping a crystal ingot, a deflection adjusting module for adjusting the deflection direction and a substrate attached to a milling bed; and the deflection adjusting module is a dual-sine module. By means of the device and method, it can be guaranteed that silicon carbide crystal deflection crystal faces are molded in a one-time orientation manner, the repeated correction process during conventional deflection shaping is avoided, the shaping efficiency is effectively improved, and the device is simple in operation and higher in accuracy.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

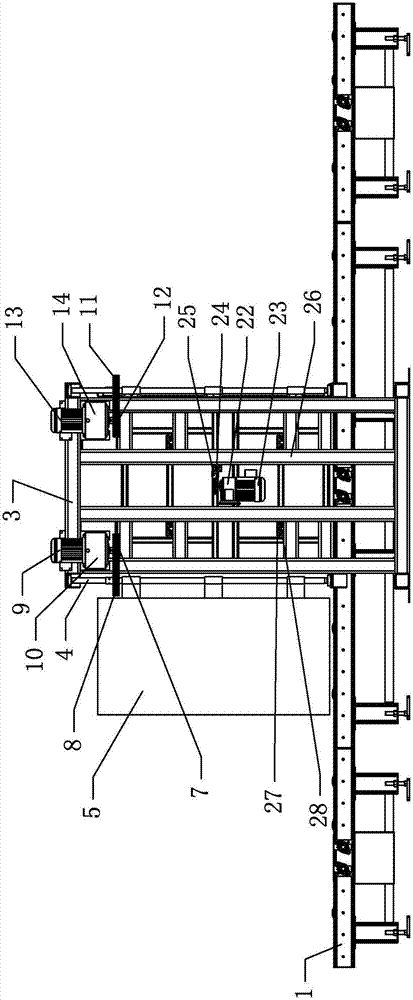

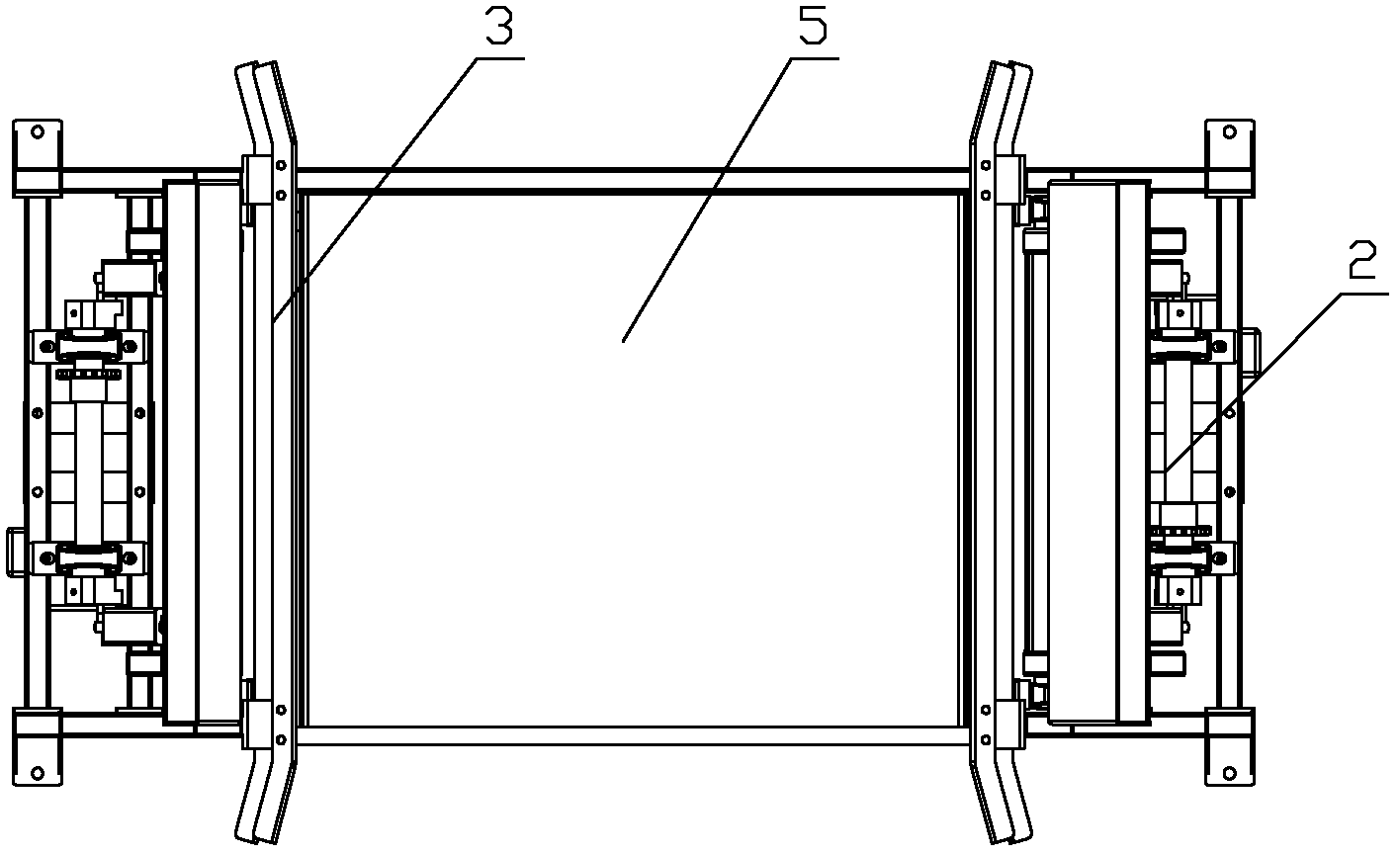

On-line automatic reshaping machine for palletized goods

ActiveCN102249081ASolve looseSolve the tiltControl devices for conveyorsMechanical engineeringLinkage concept

The invention discloses an on-line automatic reshaping machine for palletized goods, and the on-line automatic reshaping machine provided by the invention comprises a conveyor, wherein the palletized goods are carried on the conveying plane of the conveyor; reshaping devices which are used for clamping and reshaping the palletized goods are arranged on the left and right sides of the conveying plane of the conveyor; each of the reshaping devices comprises clamping plates arranged on the left or right side of the conveying plane of the conveyor; the bottoms of the clamping plates are rotatablyconnected to a frame of the conveyor; at least one support arm is rotatably connected to the middle parts of the clamping plates; the lower end of the support arm is rotatably connected to a crank arm; and the linkage of the crank arm and the support arm is used for driving the clamping plates to clamp and reshape the palletized goods. The structure is simple and the reshaping efficiency is high.In the on-line automatic reshaping machine for the palletized goods, the reshaping devices which are used for clamping and reshaping the palletized goods are arranged on the left and right sides of the conveying plane of the conveyor, thereby reshaping the goods in a conveying process and solving the problems easily occurred in a tray conveying process that the goods are loose and bias and have inferior outlines. Besides, the on-line automatic reshaping machine has the advantages of high reshaping efficiency, safety and reliability.

Owner:浙江德能物流装备科技有限公司

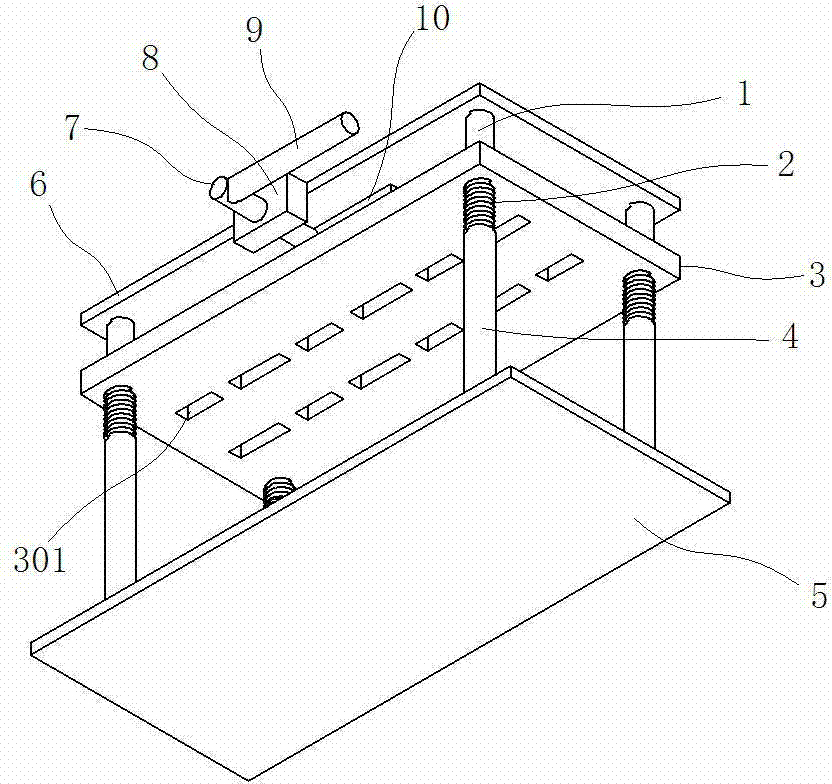

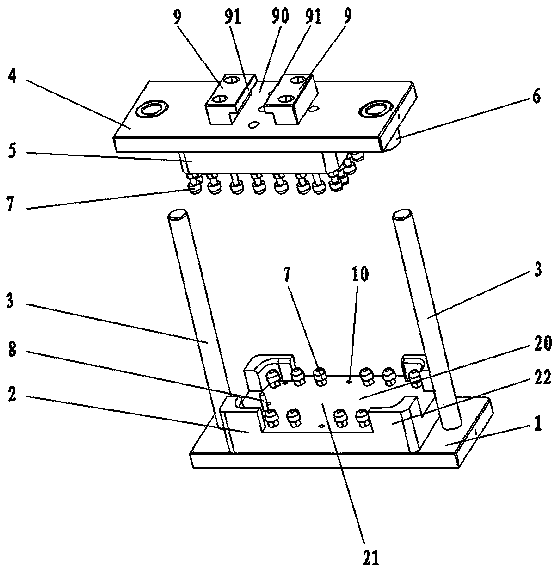

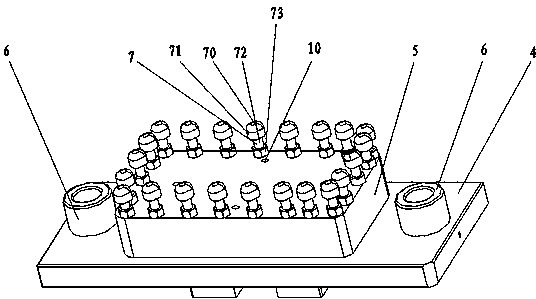

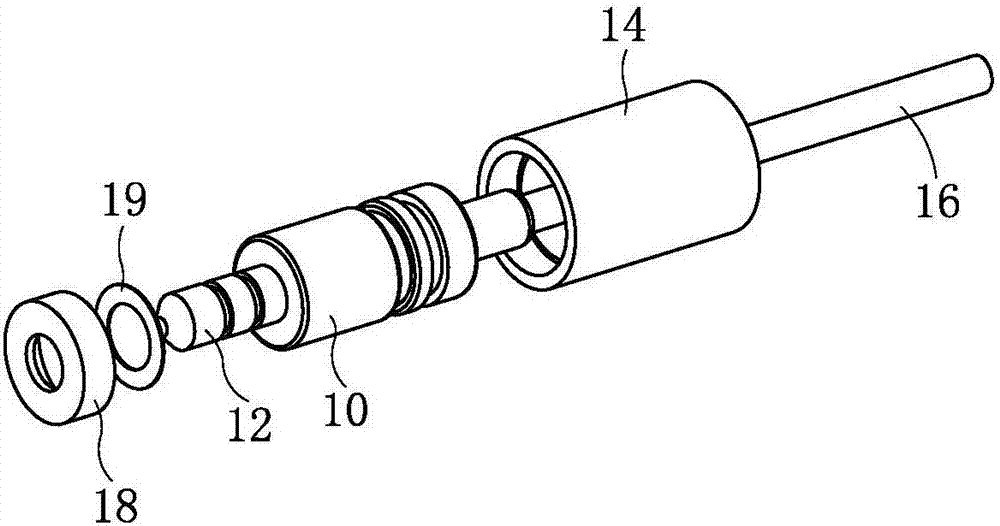

Shaping device for electrode lug of side negative plate

The invention discloses a shaping device for an electrode lug of a side negative plate. The shaping device comprises a bottom plate. The bottom plate is provided with a plurality of locating columns. The locating columns are provided with guide rods and a shaping die plate capable of moving vertically along the guide rods. A panel is fixed to the tops of the guide rods. A starting mechanism capable of enabling the shaping die plate to be pressed is arranged below the panel. The portions, between the shaping die plate and the locating columns, of the guide rods are sleeved with return springs. The shaping die plate is provided with a plurality of rectangular shaping holes. The inner walls of the shaping holes are inclined towards the centers of the shaping holes from bottom to top. Rolling mechanisms acting on the inner side of the electrode lug through pressing wheels are arranged in the shaping holes. According to the shaping device for the electrode lug of the side negative plate, the shaping strength and angle on shaping of the electrode lug of the side negative plate are uniform, and the potential quality hazard of the short circuit due to the fact that the electrode lug is made manually can be effectively avoided.

Owner:ANHUI YONGHENG STORAGE BATTERY

Battery shaping mechanism

PendingCN107331899AImprove shaping efficiencyFinal product manufactureElectrolyte accumulators manufactureElectrical batteryLithium battery

The embodiment of the invention discloses a battery shaping mechanism. The mechanism is used for solving the technical problem that existing lithium battery shaping equipment can not simultaneously shape skirts on the two sides of a lithium battery. The battery shaping mechanism includes a worktable; a feeding station, a hot-pressing station, a cold-pressing station and a discharge station are sequentially arranged on the worktable, and a to-be-shaped battery is conveyed from the feeding station, then the hot-pressing station and the cold-pressing station to the discharge station in sequence; when the battery is conveyed to the hot-pressing station, a first heating block fixed on the hot-pressing station and a second heating block movable on the hot-pressing station are cooperated for simultaneously heating the skirts on the two sides of the lithium battery; when the battery is conveyed to the cold-pressing station, a shaping block fixed on the cold-pressing station and a liner plate movable on the cold-pressing station are cooperated for simultaneously cooling the skirts on the two sides of the lithium battery. The shaping mechanism can be used for simultaneously heating and cooling the skirts on the two sides of the lithium battery, and the battery shaping efficiency is largely improved.

Owner:DONGGUAN ALI AUTOMATION CO LTD

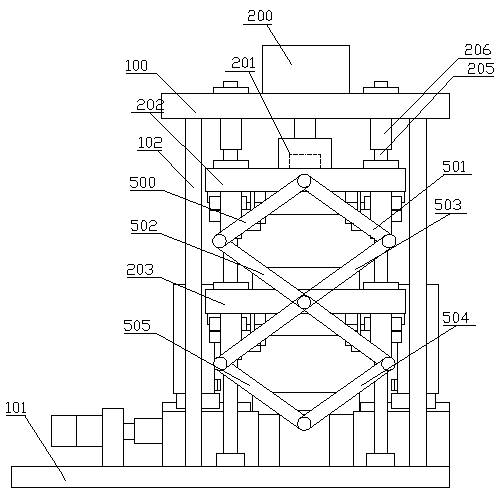

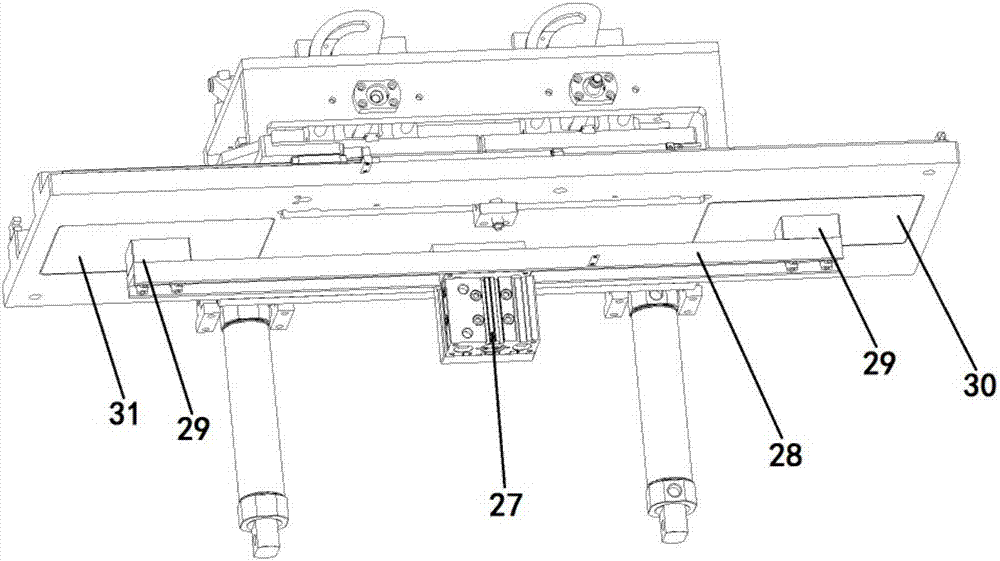

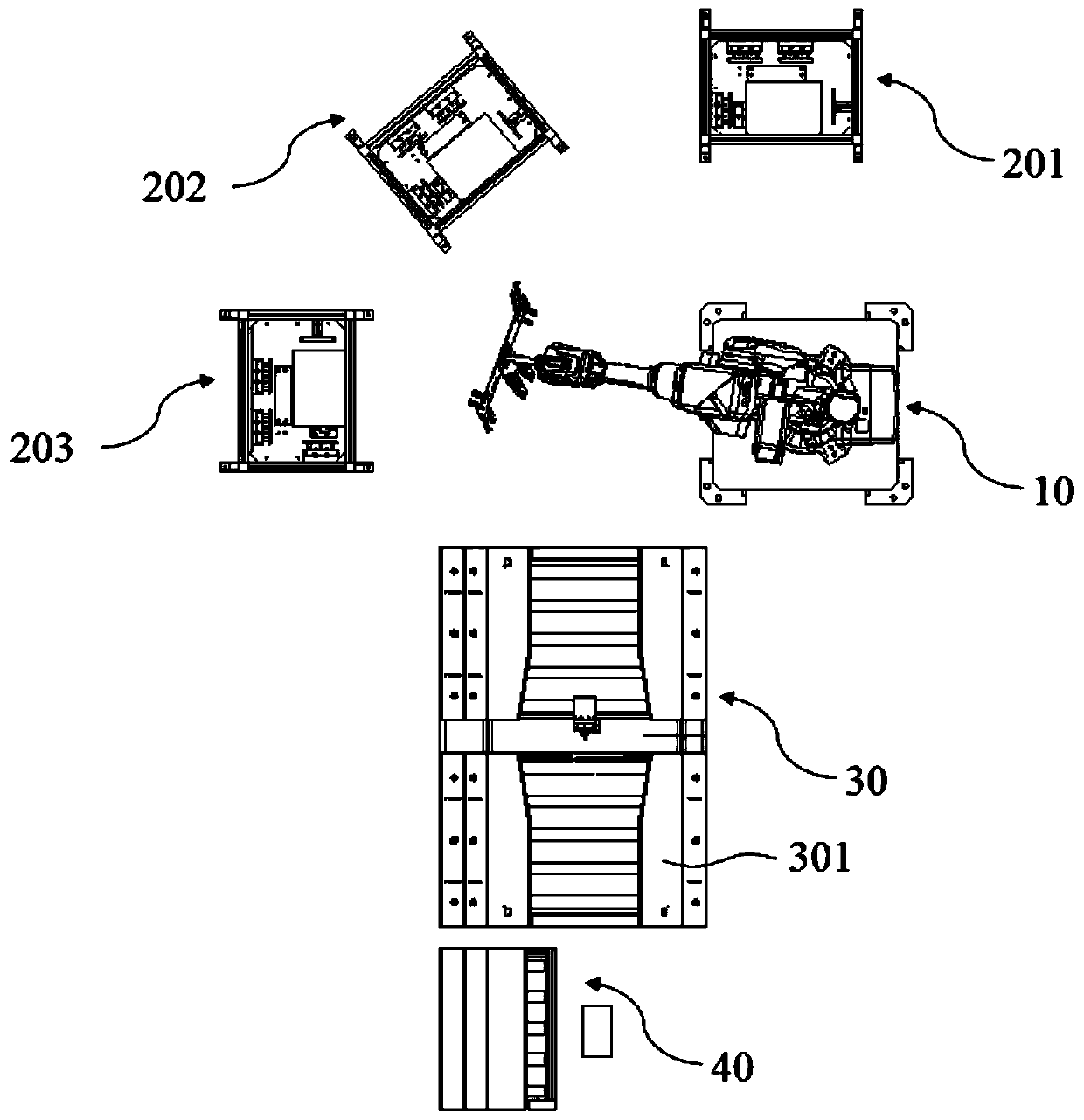

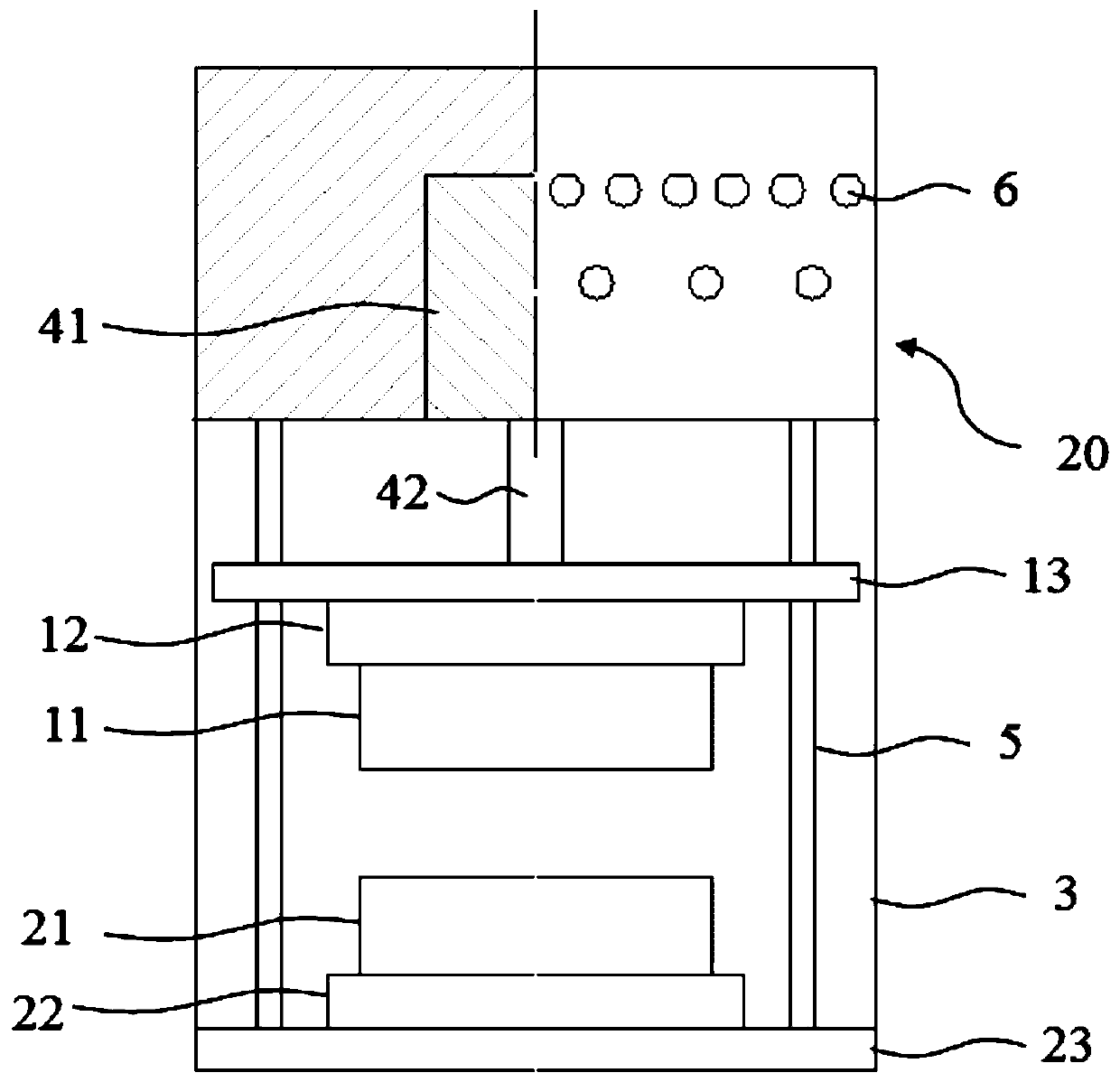

Thermal shaping system and thermal shaping method

The invention relates to a thermal shaping system and a thermal shaping method. The thermal shaping system comprises a mechanical arm, at least one thermal shaping device and a cooling device, whereinthe mechanical arm is used for taking and placing workpieces, at least one thermal shaping device is sequentially arranged around the mechanical arm clockwise or counterclockwise, each thermal shaping device comprises an upper die and a lower die which are oppositely arranged up and down, the upper dies and the lower dies are matched to form cavities so as to press-fit and shape to-be- shaped workpieces placed in the cavities, each thermal shaping device further comprises a heating mechanism connected with the upper die and / or the lower die, each heating mechanism can heat the upper die and / or the lower die to a preset temperature to carried out thermal shape on the workpiece pressed on the cavity, and the cooling device is used for cooling and forming at least one workpiece shaped by theat least one thermal shaping device through the cooling device. According to the thermal shaping system and the thermal shaping method, the mechanical deformation and the hot pressing deformation arecombined, so that the shaping efficiency and the shaping effect of the product can be improved, the product yield can be improved, and the jig cost and the labor cost can be reduced.

Owner:HEFEI LCFC INFORMATION TECH

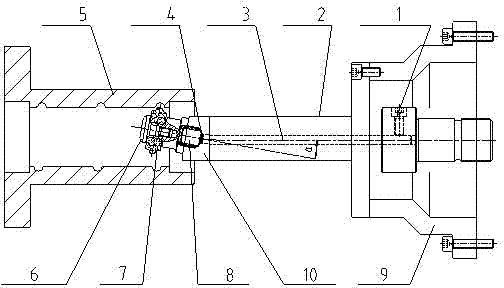

Flexible shaft grinding head system of large-lead ball nut grinding and grinding method for machining nut

InactiveCN103170888AEnables long distance grindingWith cardan driveGrinding machinesGrinding wheelScrew thread

The invention discloses a flexible shaft grinding head system of large-lead ball nut grinding, and further discloses a grinding method for machining a nut. According to the flexible shaft grinding head system of large-lead ball nut grinding, a power output end of a mechanical flexible shaft is connected and assembled with a front end small shaft through a flexible shaft connector, a driven end of the mechanical flexible shaft is coaxially and fixedly connected with a motorized shaft connection shaft head, an axis of rotation of a grinding wheel is coaxially arranged with the front end small shaft, the grinding wheel is fixed on the front end small shaft of the grinding wheel through a compression screw of the grinding wheel, and a connection angle alpha of the axis of rotation of the grinding wheel and an axis of the mechanical flexible shaft is in accordance with an angle of a thread lead angle of the nut to be grinded for grinding and machining the nut to be grinded. The flexible shaft grinding head system is constructed due to the adoption of a combined shaft with shaft end couple vector directions randomly adjustable, so that the connection angle of the axis of rotation of the grinding wheel and a grinding rod axis accords with different lead angles, and interference of a grinding wheel grinding rod and a nut inner ring is avoided. The flexible shaft grinding head system of large-lead ball nut grinding and the grinding method for machining the nut are applicable to long-distance grinding and machining of large-lead nut inner rolling passages.

Owner:SHANGHAI UNIV

Reshaping mechanism for cylinderical workpiece mounted to pressing machine

The invention discloses a reshaping mechanism for a cylinderical workpiece mounted to a pressing machine. The reshaping mechanism comprises a female die component and a male die component, the female die component comprises a base and an outer sleeve fixed to the upper portion of the base, an axial inverted conical through hole matching with an inner sleeve with the outer surface in the shape of an inverted cone is processed in the middle of the outer sleeve, an axial cylindrical through hole is processed in the middle of the inner sleeve, and a stripping plate is mounted on the lower portion of the axial through hole in the middle of the inner sleeve. The inner sleeve is axially cut into four equant components, a plurality of corresponding holes are processed among the side end faces of the equant components, and compression springs are mounted among the corresponding holes. The male die component comprises a fixed sleeve fixed with a slider of the pressing machine, a push rod capable of moving up and down is mounted in the middle of the fixed sleeve, a pressing plate is fixed at the lower end of the push rod, a pressure spring is mounted on the push rod between the pressing plate and the fixed sleeve, the pressing plate moves downwards along with the slider to press the workpiece into the inner sleeve, and the fixed sleeve moves downwards along with the slider to enable the inner sleeve to move downwards. The reshaping mechanism can well protect the appearance of the workpiece and a reshaping female die and is high in reshaping efficiency.

Owner:厦门锻压机床有限公司

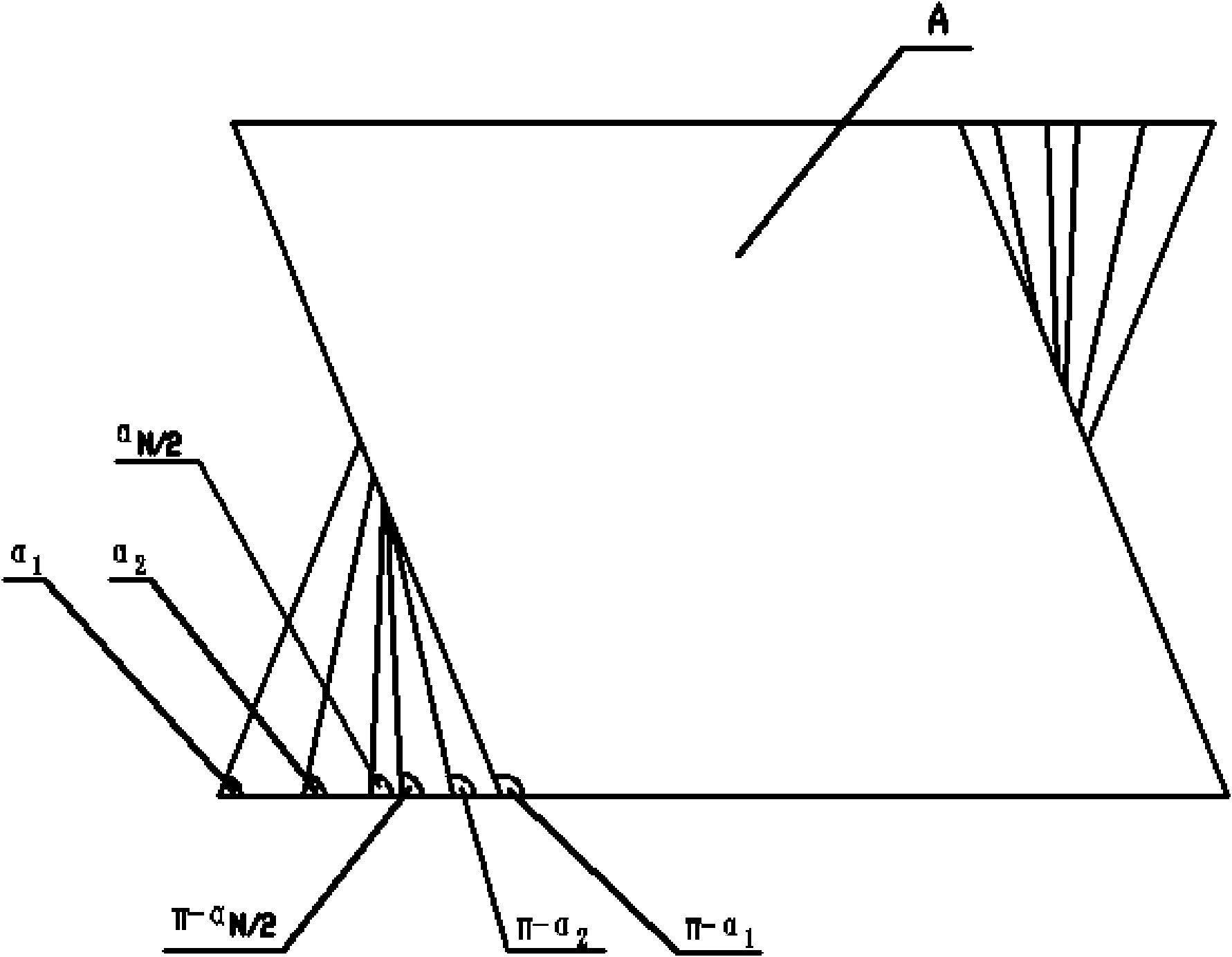

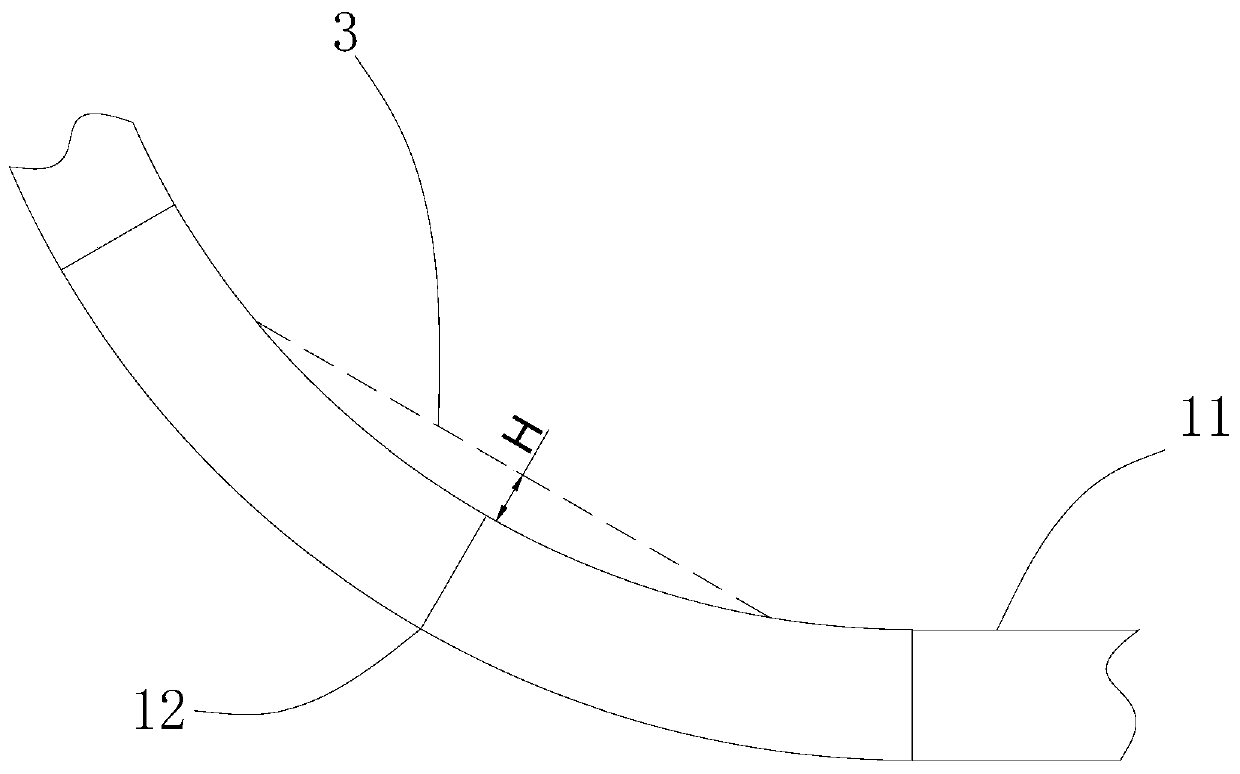

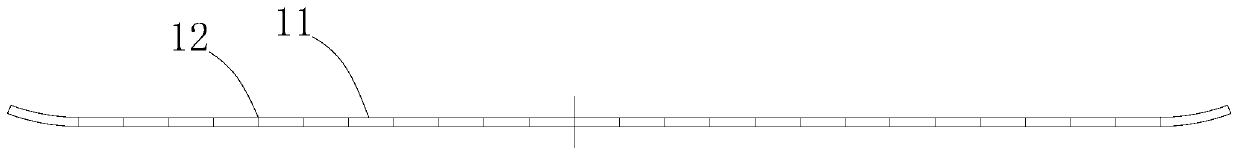

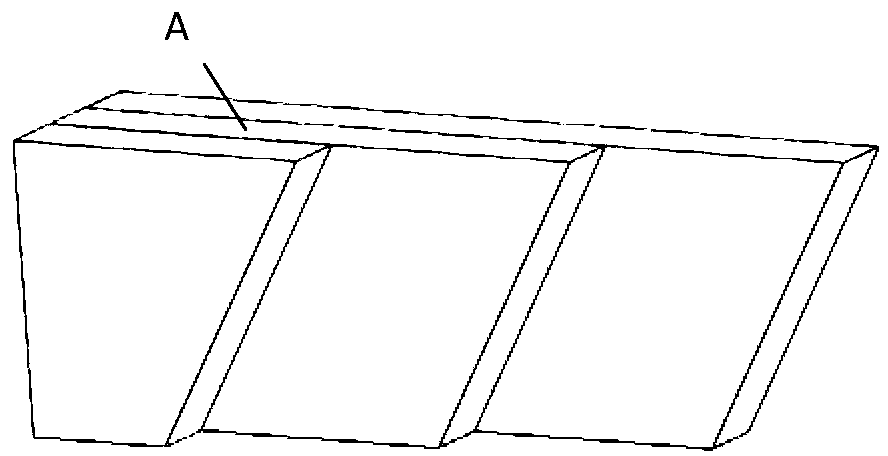

Refracting high-power semiconductor laser array beam shaping device

The invention provides a refracting high-power semiconductor laser array beam shaping device. While a beam is shaped, the thickness size of each block of step glass in a shaping element can be doubled, the error accumulation can be reduce by half, the processing difficulty is greatly reduced, the precision is improved, the loss is reduced, meanwhile, the width of a laser beam in the direction of a quick axis is compressed, the focal distance of a focusing lens is reduced, and a system is more compact. When a plurality of bars and a laminated array optical fiber are coupled and cutting number is relatively large, the advantages of the element can be better embodied.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Laser trimming device and method for superhard abrasive forming grinding wheel

ActiveCN112571282AReduce jumpingImprove sharpening efficiencyAbrasive surface conditioning devicesLaser beam welding apparatusAcoustic emissionLaser scanning

The invention discloses a laser trimming device and method for a superhard abrasive forming grinding wheel. The device is sequentially provided with a reflection lens clamp, a reflection lens base, ahorizontal displacement adjusting table, a vertical displacement adjusting frame and a fixed support along the laser beam emitting direction; and is provided with a constant-angle rotating knob, a displacement lead screw and acoustic emission equipment. The device is a three-degree-of-freedom reflecting lens carrying device which can move in the x direction, the y direction and the z direction androtate around the axis; and a reflecting lens is regulated and controlled to reflect an emergent laser beam at a nearly vertical angle, so that laser energy acts in the horizontal direction and the vertical direction at the same time, and the shaping efficiency is improved by times. A method for coating a laser cross section by the lens clamp is designed, and a modification method for increasingthe laser scanning times in an odd number is provided, so that high modification efficiency and good grinding wheel outline appearance are ensured, and high speed and energy conservation are realized;and a model for sharpening a scanning track of a laser beam on the surface of the grinding wheel is established, and a method for controlling the optimal scanning times and performing layered laser scanning sharpening is provided, so that the effects that abrasive particles are excellent in edging and high in percent of pass are achieved.

Owner:HUNAN UNIV OF SCI & TECH

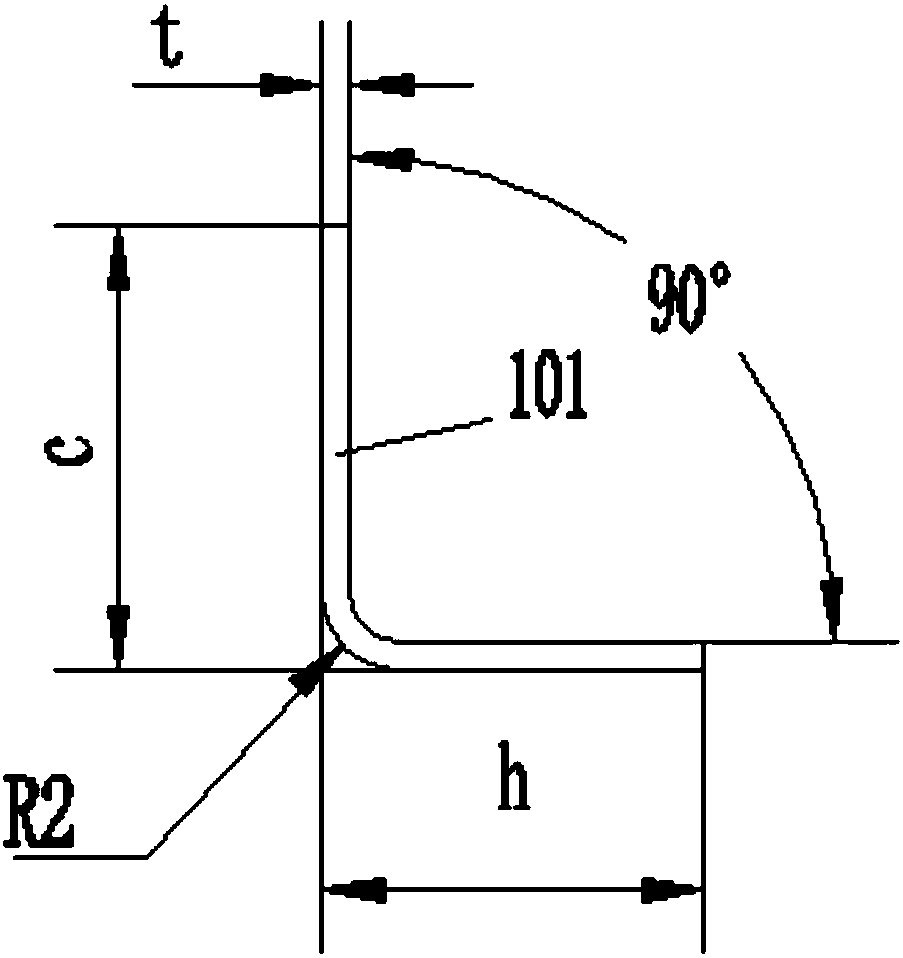

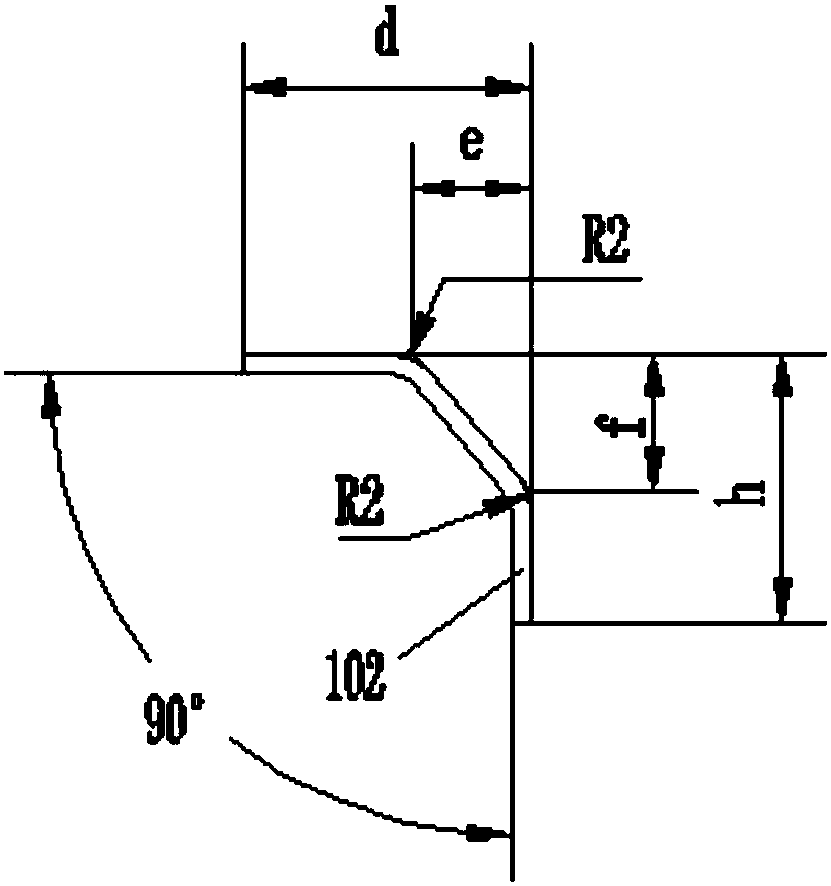

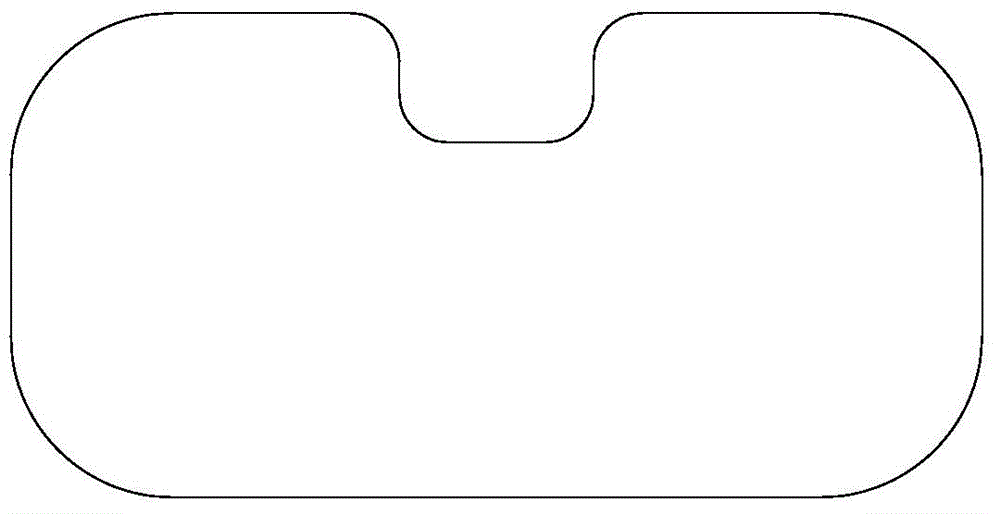

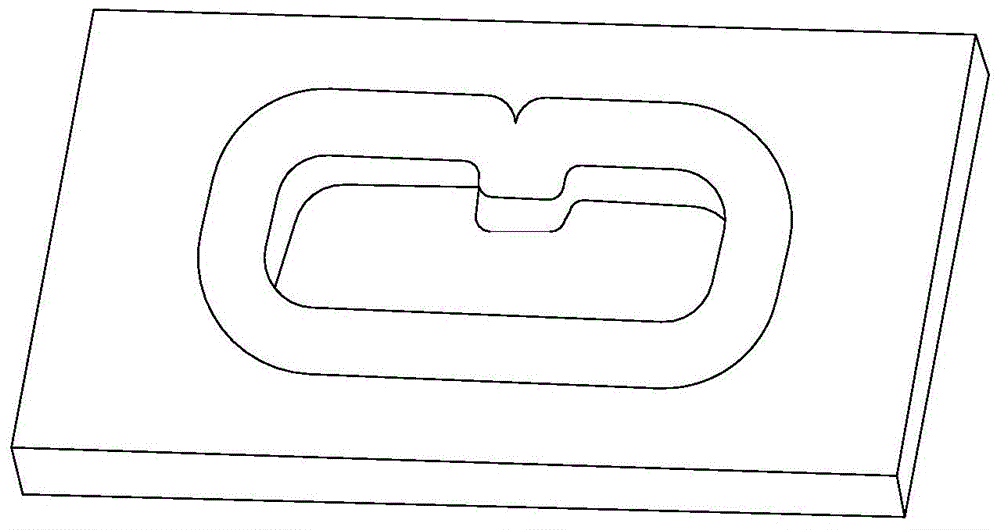

Reshaping die of urban rail vehicle door corner part

InactiveCN108568474AGap stabilityEliminate defects of poor flatnessShaping toolsVehicle componentsEngineeringUrban rail

The invention provides a reshaping die of a door corner part. The reshaping die is used for reshaping an urban rail vehicle door corner part. The reshaping die of the door corner part comprises a lower die plate, an upper die plate, a guide column, a guide sleeve, a convex die, a concave die, a fixed wedge block, a sliding wedge block, a side compressing block and a door corner, wherein a groove is formed in the lower die plate and can reshape the door corner part arranged at a door corner, the plane of the fixed wedge block is in contact with the side compressing block when the door corner part reshaping die is closed and the fixed wedge block goes down, the oblique plane is in contact with the sliding wedge block, and the side compressing block is fixed, so that the fixed wedge block pushes the sliding wedge block to slide towards the concave die and clamp the door corner. Compared with the prior art, the door corner part reshaping die effectively overcomes the two defects of poor planeness and large 90-degree angle resilience occurred in door corner stamping formation, the defect problem which cannot be solved by adopting a traditional door corner reshaping method is eliminated,the product quality and precision of door corners can be effectively improved, and accordingly the forming precision of like members is remarkably improved.

Owner:JILIN UNIV

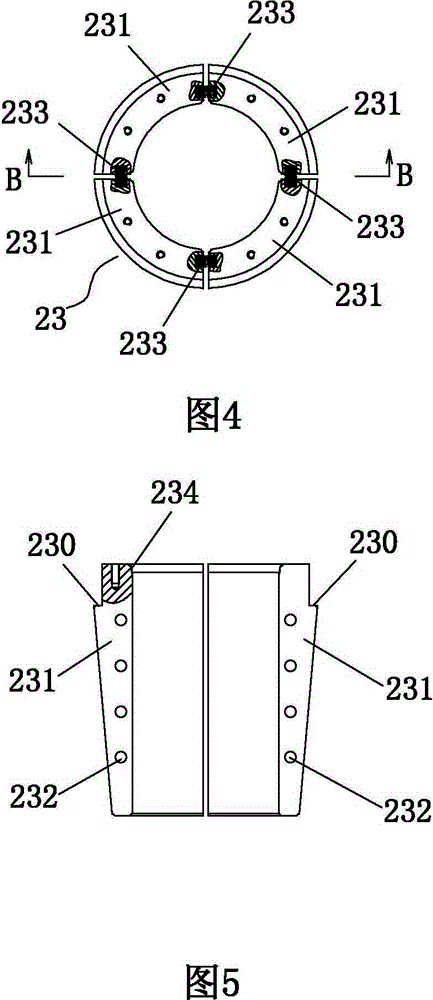

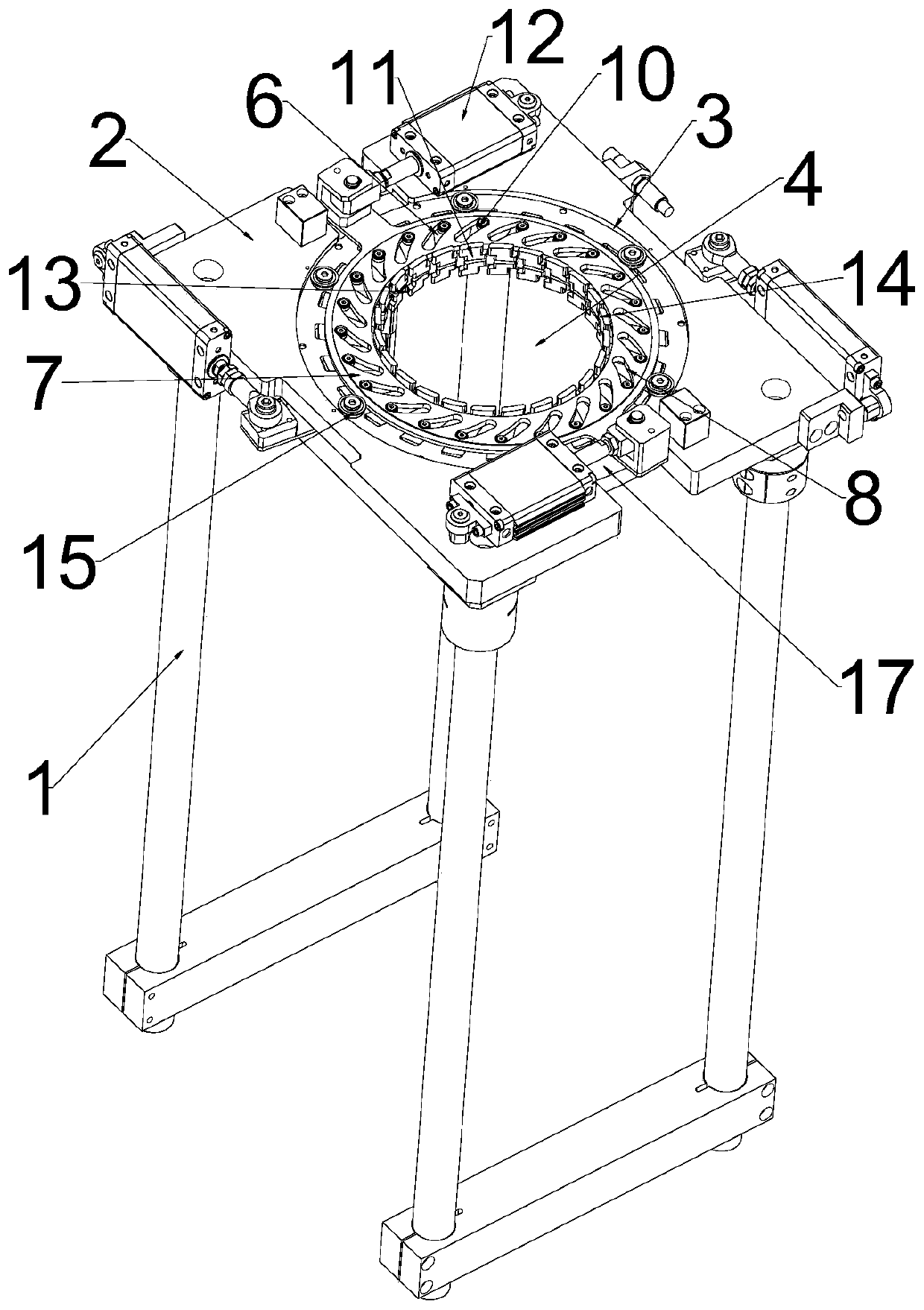

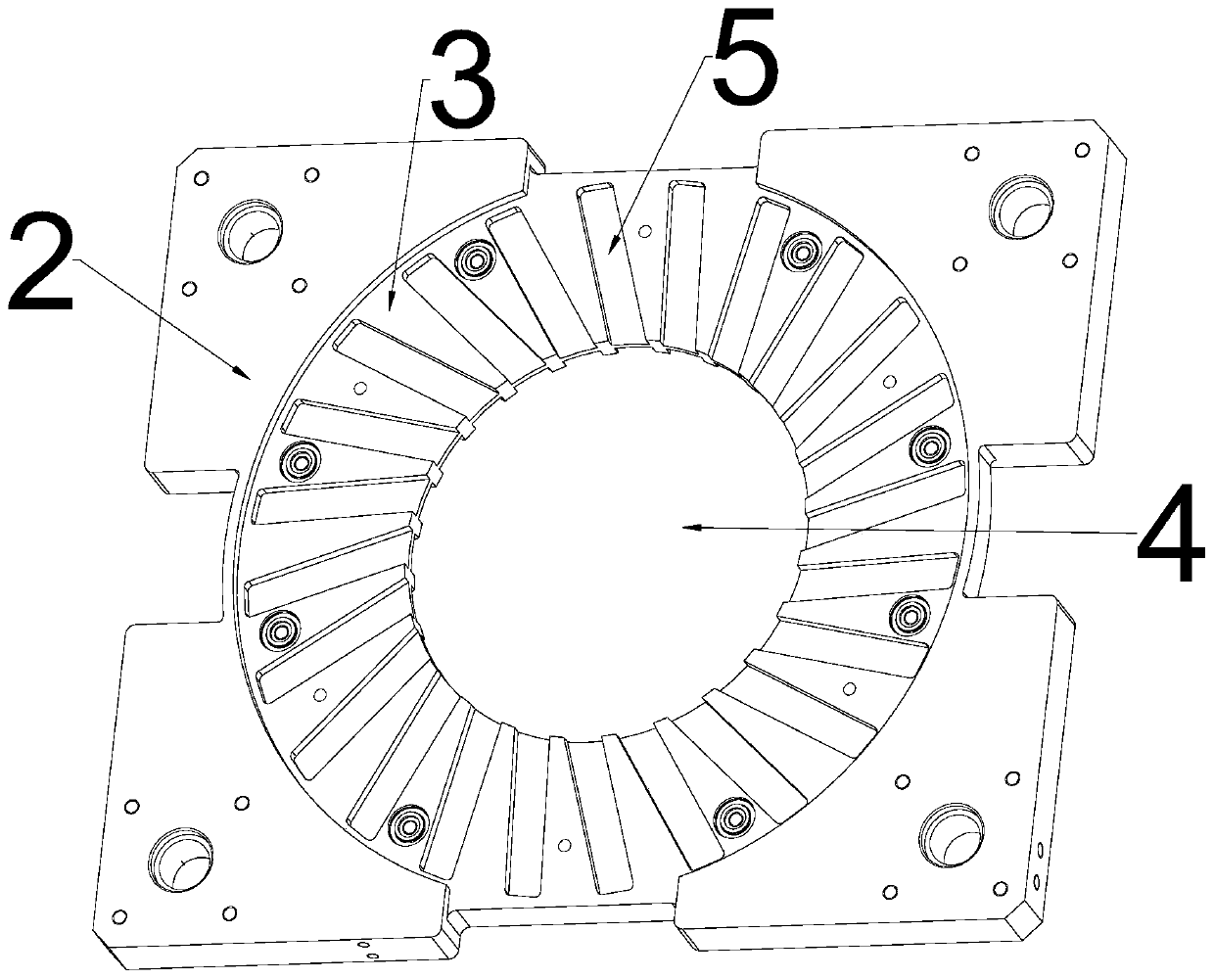

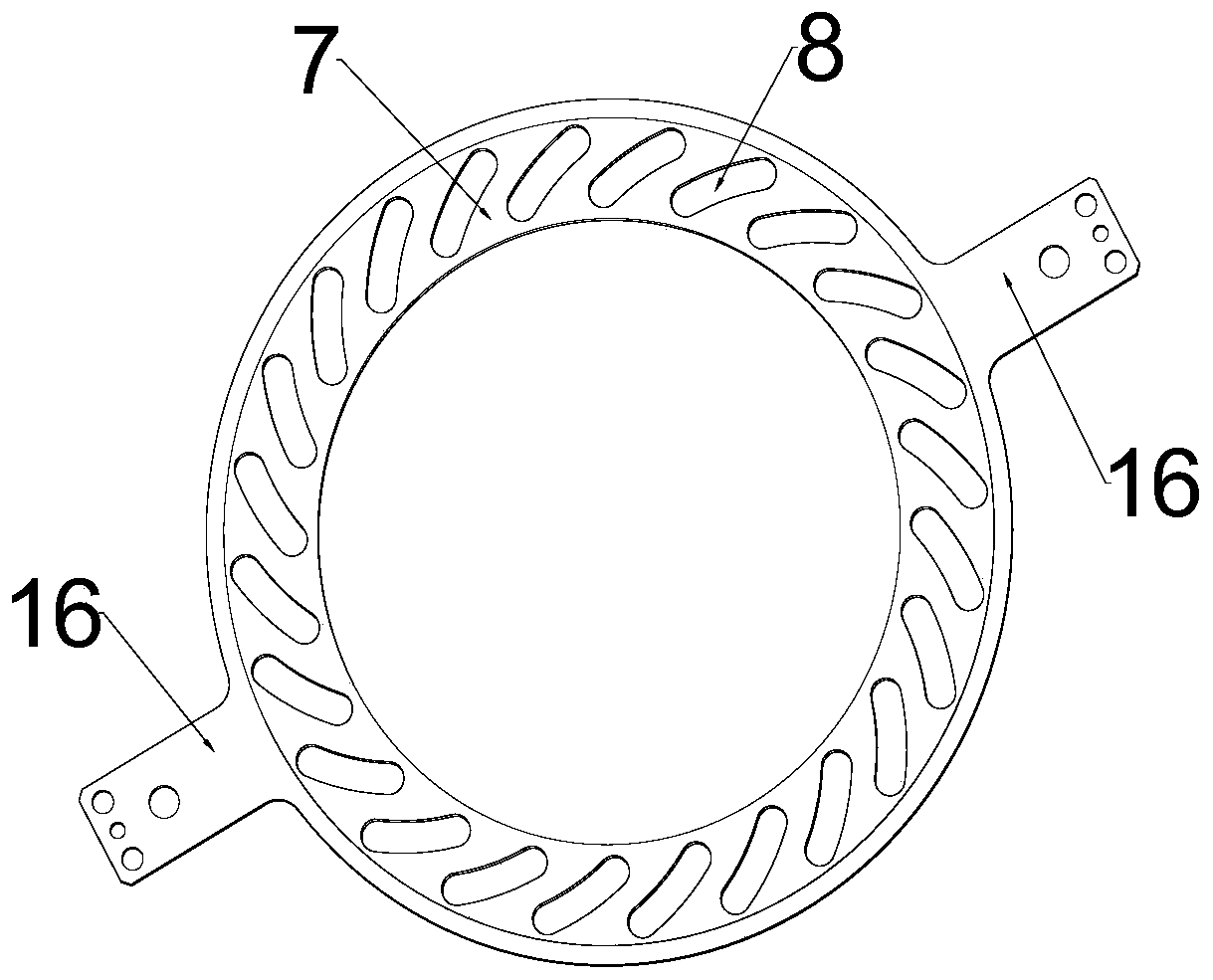

External shaping device of motor winding group

PendingCN110445325AMeet assembly requirementsQuality assuranceManufacturing dynamo-electric machinesElectric machineEngineering

The invention discloses an external shaping device of a motor winding group. The external shaping device comprises an organic rack and a bottom plate, wherein a shaping mechanism is arranged on an upper surface of the bottom plate, the shaping mechanism comprises a round groove, the round groove is formed in the upper surface of the bottom plate, a round through is formed in a middle part of the round groove, a plurality of linear sliding grooves are arranged in the round groove, sliding blocks are arranged in the linear sliding grooves, an annular groove disc is arranged in the round groove,the sliding block is clamped between the annular groove disc and the linear sliding groove, a plurality of arc grooves are formed in the annular groove disc, a push block is connected with one end ofeach sliding block, an upper surfaces of the upper end of each sliding block is connected with a bearing, the bearing is rotatably embedded into the corresponding arc groove, an inner arc surface is arranged at an inner side of each push block, the inner arc surfaces of the push blocks can encircle to form a round shape, and the annular groove disc is driven to rotate by an air cylinder. By the external shaping device of the motor winding group, external shaping is performed on the motor winding group, the motor assembly quality is ensured, the winding group shaping efficiency and mechanical and automatic degree of motor production are improved, and labor cost is reduced.

Owner:JULI AUTOMATION EQUIP ZHEJIANG CO LTD

Digital product shell shaping fixture

The invention discloses a digital product shell shaping fixture, comprising a lower die base plate, a guide rod fixed on the lower die base, an upper die base plate, and a guide sleeve fixed on the upper die base plate. The fixture is characterized in that the lower die base plate is provided with a lower press plate, the lower press plate is provided with a fixed groove, and the basal plane of the fixed groove is provided with a plurality of press heads; correspondingly, the upper die base plate is provided with an upper press plate, the upper press plate is provided with a plurality of press heads, and the upper die base plate is also provided with a fixed block. The invention realizes transformation of digital product shell shaping from traditional manual shaping to mechanical automatic shaping, improves the production efficiency, greatly enhances the product shaping quality and saves product production cost, and is suitable for popularization and application in the field of digital products manufacturing.

Owner:GUANGDONG GREEN PRECISION COMPONENTS CO LTD

Locating and shaping device

ActiveCN107008773AImprove consistencyAchieve shapingMetal-working feeding devicesPositioning devicesEngineering

The invention discloses a locating and shaping device and relates to the technical field of product shaping equipment. The locating and shaping device comprises an attraction locating device and a shaping device. The attraction locating device comprises an attraction locating assembly capable of longitudinally moving. The attraction locating assembly comprises multiple clamping blocks capable of transversely moving. The clamping blocks can provide transverse clamping force for products. The shaping device comprises an upper shaping device body and a lower shaping device body, wherein the upper shaping device body and the lower shaping device are oppositely arranged on the upper side and the lower side of an installation base plate correspondingly. The portion, corresponding to the shaping device, of the installation base plate is provided with a vertically-through hole. The upper shaping device body and the lower shaping device body each comprise a shaping plate capable of moving up and down. Each shaping plate is provided with shaping grooves adaptable to the structure of components to be shaped. The locating and shaping device can achieve accurate locating of the product, the shaped product components are good in consistency, the shaping efficiency is high, the yield of the products can be improved, automatic product is facilitated, and the production cost of an enterprise is reduced.

Owner:GOERTEK INC

Pipefitting flaring round shaping machine

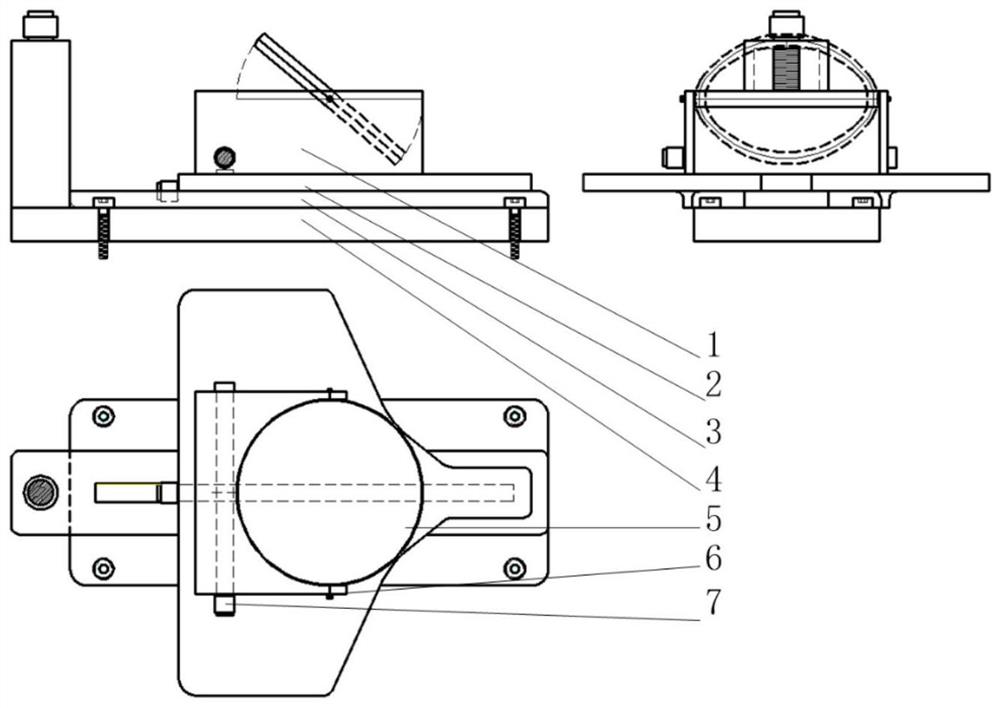

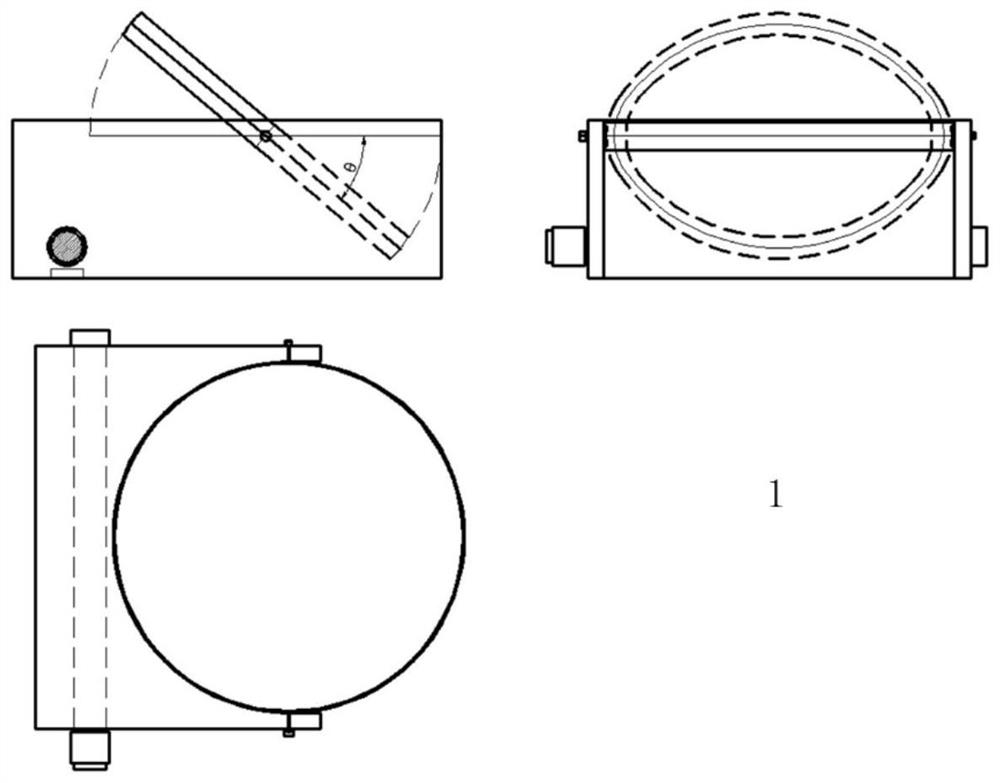

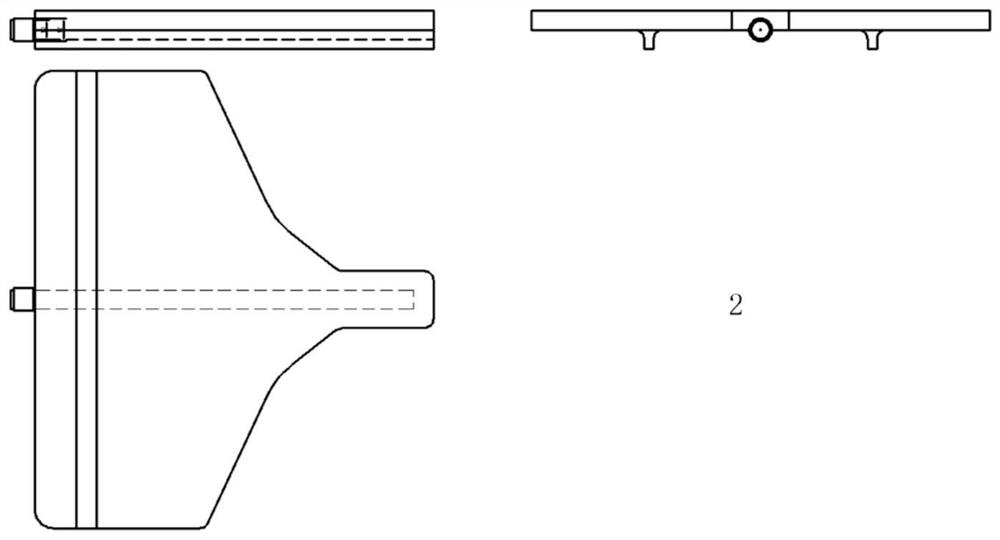

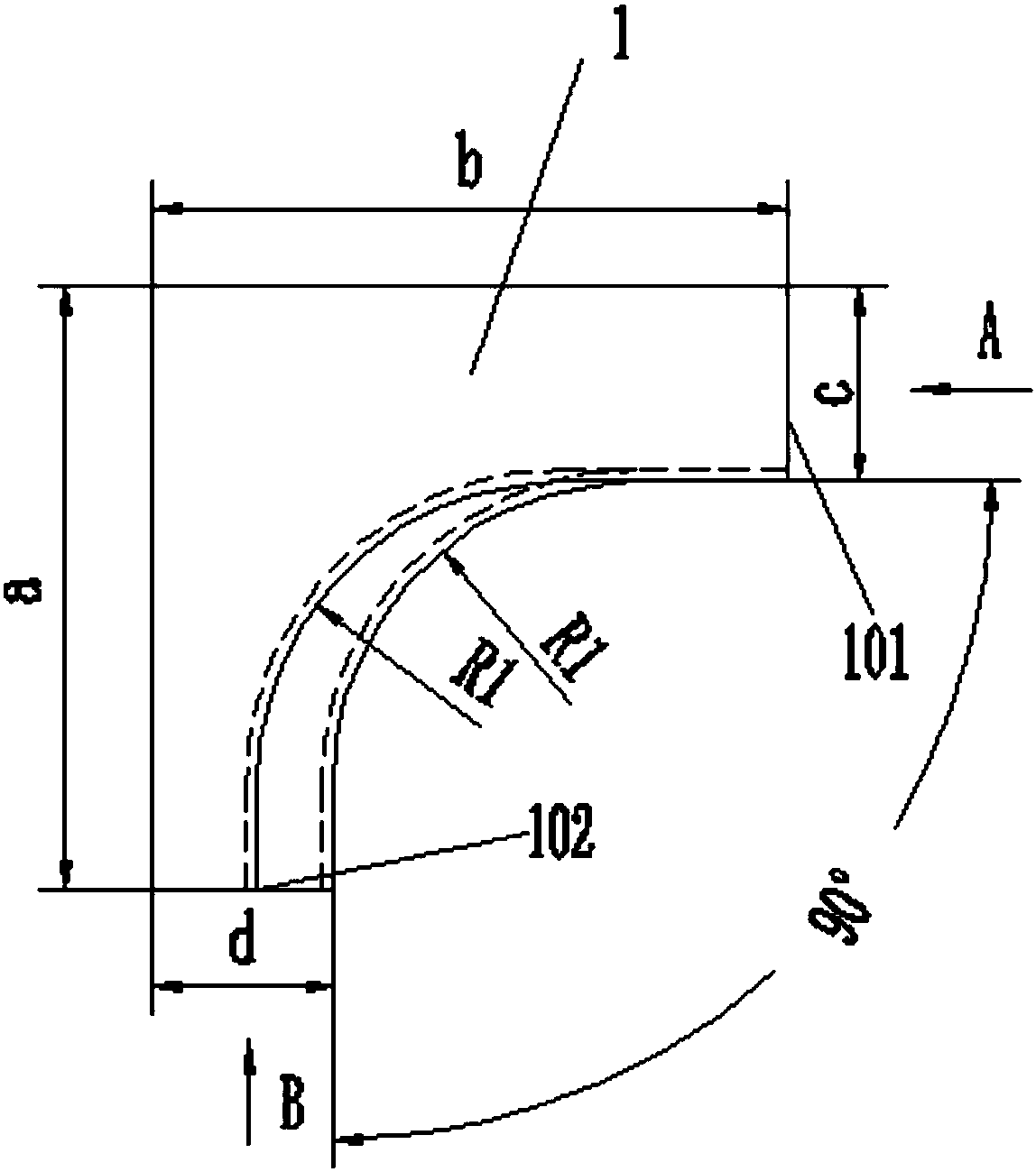

InactiveCN106475480ASolve the technical problems of caliber depression plastic surgeryHigh shape accuracyPipe fittingEngineering

A pipefitting flaring round shaping machine is composed of an arc support 1, a core shaft 2, an oil cylinder 3, a housing 4, a spring 5 and a manual reversing valve 6; a pull rod of the oil cylinder 3 shrinks to drive the core shaft 2 to descend, the conical face of the core shaft 2 compresses the inner conical face of the arc support 1, the arc support 1 is expanded outwards, the inner wall of a pipefitting pipe opening formed in the arc support in a sleeving manner is gradually and tightly attached to the outer round face of a pipe support, and therefore pipe opening expansion and round shaping are achieved; after a pipe opening is expanded, the pipe opening is molded through pressing, the pipe opening shape precision is greatly improved, the shaping quality is stable, operation is easy, the shaping efficiency is high, the machine is suitable for meeting the shaping needs of pipe fittings of multiple specifications, and the technical problem of steel plate pipefitting opening diameter sinking and shaping is solved.

Owner:东台市远洋不锈钢制造有限公司

Pipe fitting shaping device

ActiveCN108526254AGood plastic effectImprove shaping efficiencyMetal-working feeding devicesPositioning devicesEngineeringMachining

The invention relates to the technical field of pipe fitting machining, in particular to a pipe fitting shaping device. The pipe fitting shaping device comprises a fixing mechanism. The fixing mechanism comprises a lower fixing plate and an upper fixing plate arranged on the upper portion of the lower fixing plate. The upper fixing plate and the lower fixing plate are detachably connected. A firstclamping groove is formed in the top of the lower fixing plate in a sunken mode. A second clamping groove is formed in the bottom of the upper fixing plate in a sunken mode. The first clamping grooveand the second clamping groove can be in buckle fit to form a channel used for storing a pipe fitting. A square shaft is slidably arranged in the channel. A fixed barrel is arranged outside of the square shaft in a sleeving mode. A plurality of jacking plates are arranged on the outer side of the fixed barrel. Springs are connected between the jacking plates and the fixed barrel. Jacking rods arearranged between the jacking plates and the square shaft. A plurality of grooves are formed in the square shaft. The grooves and the surface of the square shaft are in smooth connection. One ends ofthe jacking rods are slidably connected into the grooves. The other ends of the jacking rods penetrate through the fixed barrel and can abut against the jacking plates. According to the pipe fitting shaping device, overall shaping of the pipe fitting can be achieved at a time, and meanwhile, the shaping degree of the pipe fitting is controlled.

Owner:宁波隆锐机械制造有限公司

Sectional material dressing die

The invention discloses a sectional material dressing die. The sectional material dressing die comprises an upper die plate, a lower die plate and guide posts arranged between the upper die plate and the lower die plate. The lower end of the upper die plate is connected with a fixing plate. An upper pressing head is connected with the lower end of the fixing plate. A concave die body is connected with the upper end of the lower die plate. The sectional material dressing die is characterized in that a die core is arranged in the concave die; a plurality of cutting tools are evenly distributed in the vertical direction of the die core at intervals; the cutting tools are provided with tool edges matched with the contours of workpieces; the anterior angle of the cutting tools is 15-25 degrees, and the relief angle of the cutting tools is 0.5-1.5 degrees. According to the sectional material dressing die, the multiple cutting tools are evenly distributed in the vertical direction of the die core of the concave die at intervals, and thus layered cutting of the workpieces can be conducted without adopting multiple pairs of dies and the cost is reduced. In addition, the dressing efficiency is improved, and dressing can be completed at a time. Dressed section materials are good in surface smoothness, high in size precision, less in product vertical flash and high in product qualified rate.

Owner:过冬

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com