Flexible shaft grinding head system of large-lead ball nut grinding and grinding method for machining nut

A technology of ball nut and large lead, which is applied in the direction of metal processing equipment, grinding/polishing equipment, grinding machines, etc., can solve the problems of grinding process and equipment that are not ideal enough, and achieve high grinding wheel repair efficiency and high grinding process efficiency. The effect of simple process and simple system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

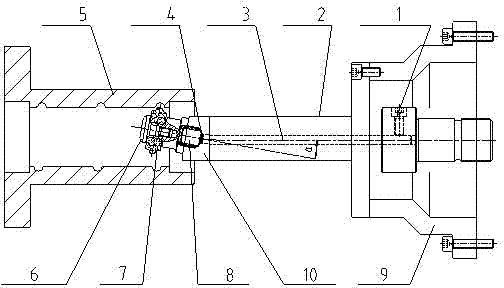

[0026] In this example, see figure 1 and figure 2 , a flexible shaft grinding head system for large-lead ball nut grinding, mainly including a mechanical flexible shaft 3, a small front shaft 8, a flexible shaft joint 4, a support block 10, a grinding rod sleeve 2, and the power of the mechanical flexible shaft 3 The output end and the front small shaft 8 are connected and assembled through the flexible shaft joint 4, the driven end of the mechanical flexible shaft 3 is coaxially fixedly connected with the electric spindle connection shaft head 1, and the front small shaft 8 is movably nested and installed on the support in a rotational connection. In the inner hole of the block 10, the mechanical flexible shaft 3 is movably nested and installed in the inner cavity of the grinding rod bushing 2 in a rotating connection mode, and the connecting support block 10 is tightly connected with the nested grinding rod bushing 2. 9 Fix the nested grinding rod sleeve 2 on the grinding ...

Embodiment 2

[0036] This embodiment is basically the same as Embodiment 1, especially in that:

[0037] In this embodiment, the front small shaft 8 is movably nested in the inner hole of the support block 10 through bearings, and the mechanical flexible shaft 3 is movably nested in the inner cavity of the grinding shaft sleeve 2 through bearings to form a rotating connection pair respectively. When the rotating parts are made to move relative to each other, the friction coefficient in the power transmission process is reduced and the central position of the shaft is kept fixed, so as to improve the working stability and service life of the flexible shaft grinding head system of this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com