Novel numerically controlled special-shaped glass edge grinding machine

A special-shaped glass and edging machine technology, which is applied to machine tools suitable for grinding workpiece edges, parts of grinding machine tools, grinding machines, etc., can solve problems such as difficult edging, low processing efficiency, and limited functions, and achieve consistent performance, improve smoothness, and simplify the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

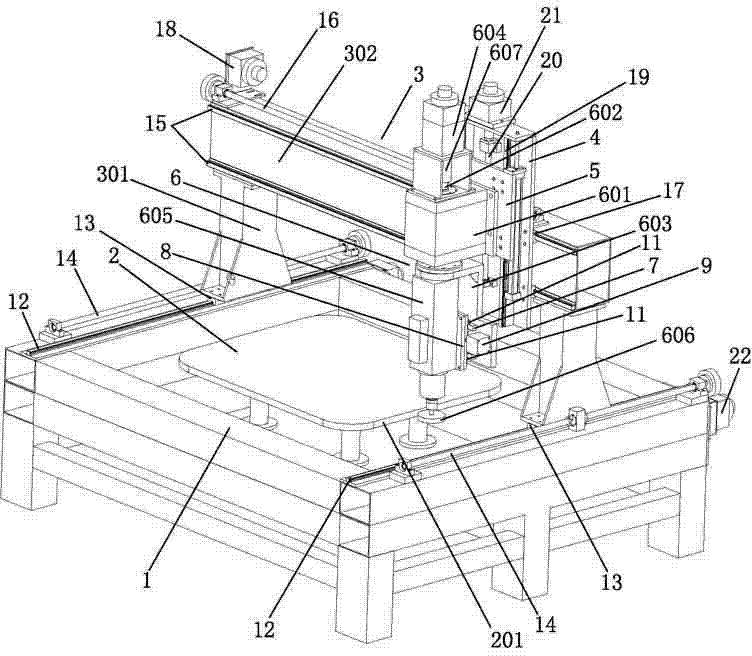

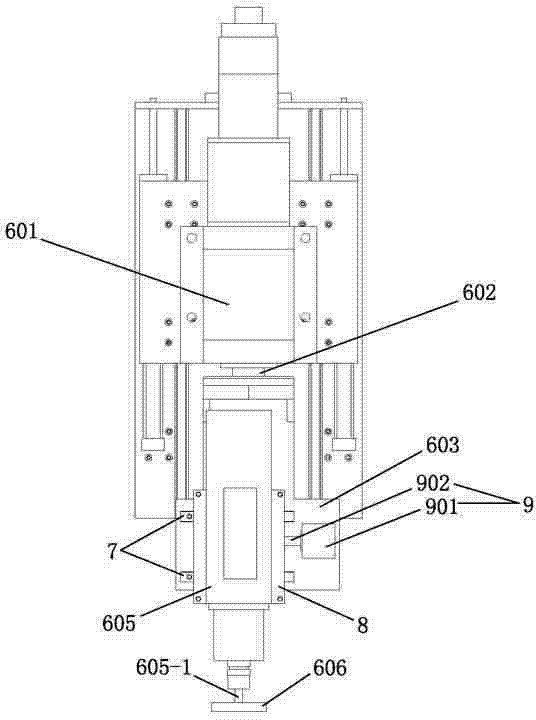

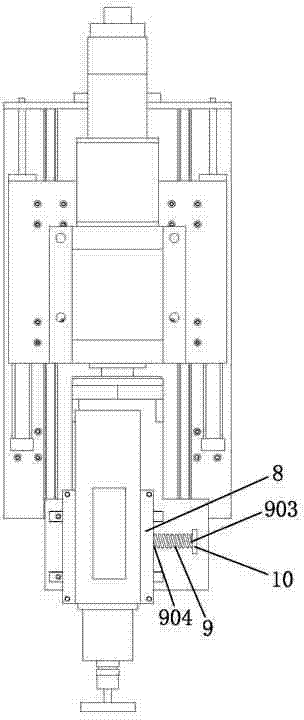

[0020] The first embodiment: as Figure 1 to Figure 2 As shown, a new CNC special-shaped glass edging machine includes a frame 1, and a glass workpiece 2 is adsorbed on the frame 1. A gantry 3 sliding along the Y-axis is installed on the frame 1. The X-axis slide plate 4 that slides on the X-axis, the Z-axis slide plate 5 that slides up and down along the Z-axis is installed on the X-axis slide plate 4, and the Z-axis slide plate 5 is equipped with a spindle mechanism 6, which is characterized in that the spindle mechanism 6 includes a swing angle Main shaft sleeve 601, swing angle main shaft 602, swing angle turret 603, swing angle servo motor 604, grinding head motor 605 and cutter 606, swing angle main shaft sleeve 601 is fixed on the Z-axis slide plate 5, and swing angle main shaft 602 is installed on the swing angle In the main shaft sleeve 601, one end of the swing angle main shaft 602 is driven and connected with the swing angle servo motor 604, and the other end is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com