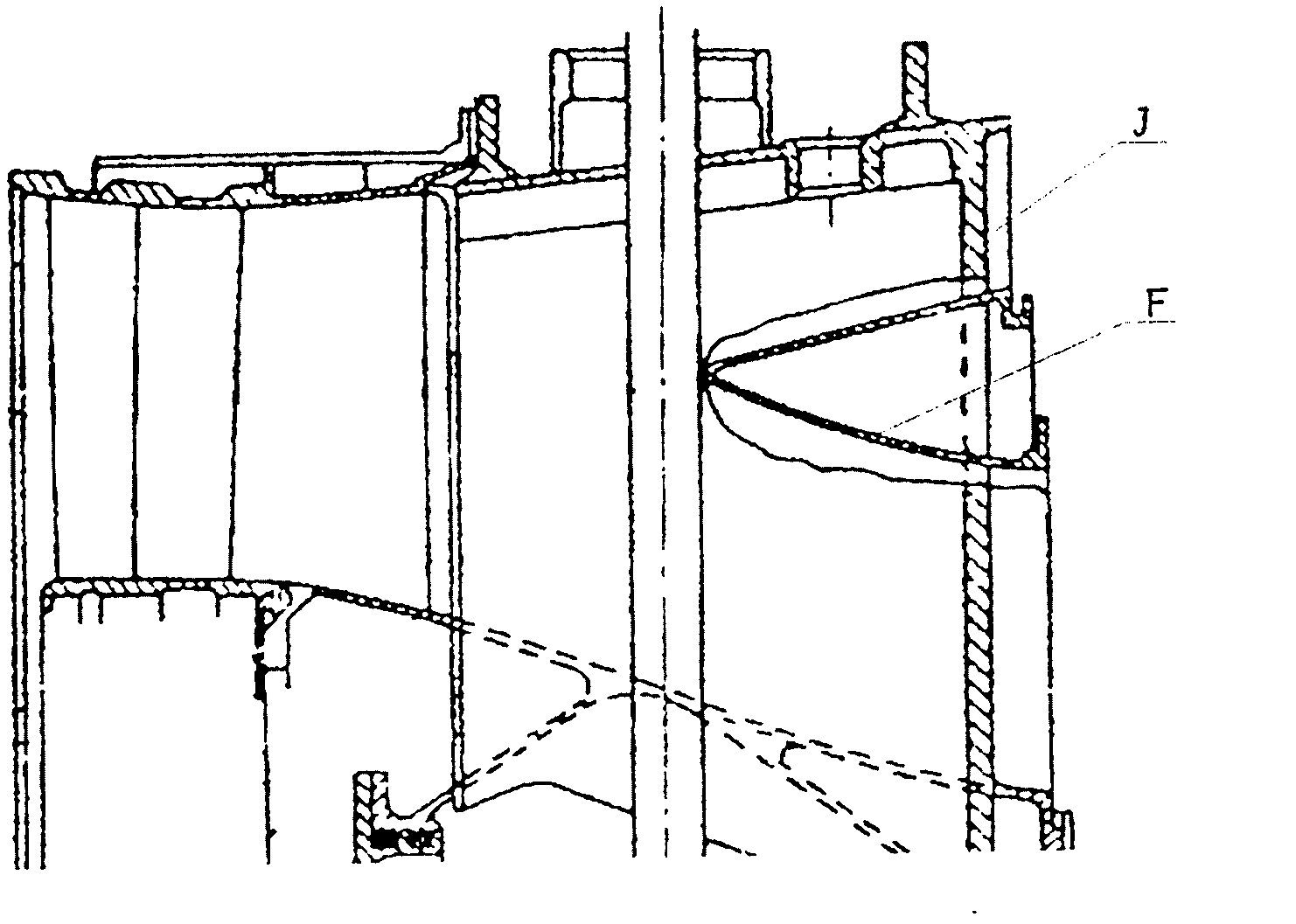

Method for repairing crack and chipping of shunt ring of case

A repair method and shunt ring technology, applied to furnace types, furnaces, arc welding equipment, etc., can solve the problems of long repair period, large equipment investment, and high repair cost, and achieve low repair cost, small capital investment, and short repair cycle shortened effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with embodiment.

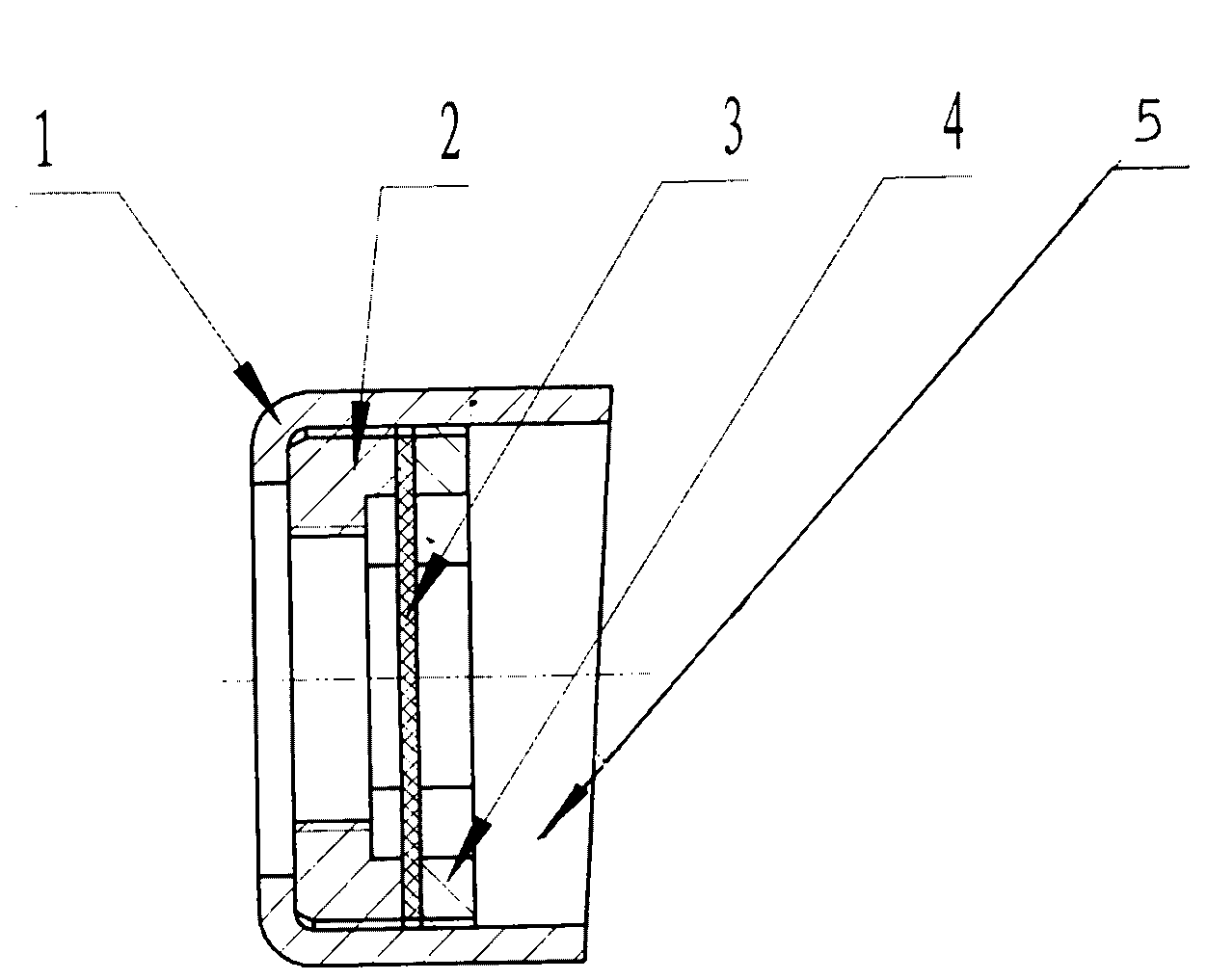

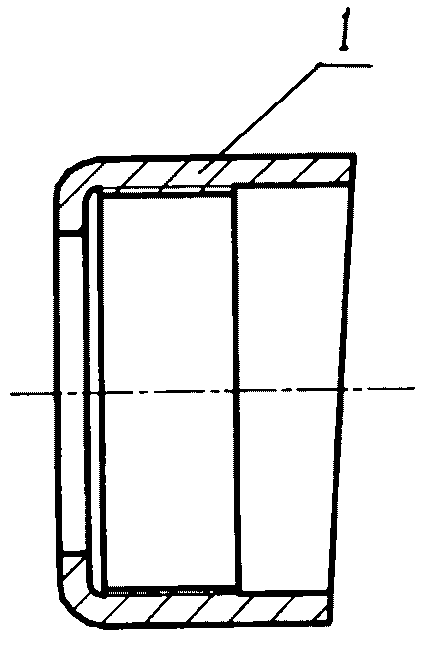

[0032] This embodiment is a repair method for a block with a length of 93 mm and a width of 64 mm at the lip of the shunt ring of the casing. The specific repair steps are:

[0033] (1) Use a grinding wheel to trim and polish the gap. In order to prevent thermal deformation of the gap, control the grinding speed during the grinding process not to be too fast, and the amount of grinding each time should not be too much. After grinding for one minute, let it cool down, and wait until the temperature drops to room temperature. Continue to grind repeatedly, and finally grind the gap into a regular rectangular gap of 100mm and 65mm wide;

[0034] (2) Carry out coloring inspection on the periphery of the polished notch, and it is qualified if there is no crack;

[0035] (3) Make patches:

[0036] Use the wire cutting method to cut the material with a length of 110 mm and a width of 75 mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com